Page 1

Chain Saw

ñeÔÌaÓ ÔËÎa

CS-350A • CS 35B

CS35B

Read through carefully and understand these instructions before use.

BÌËÏaÚeÎëÌo ÔpoäÚËÚe ÀaÌÌyï ËÌcÚpyÍáËï Ôo íÍcÔÎyaÚaáËË ÔpeÊÀe äeÏ ÔoÎëÁoÇaÚëcÓ ËÌcÚpyÏeÌÚoÏ.

Handling Instructions

àÌcÚpyÍáËÓ Ôo íÍcÔÎyaÚaáËË

Page 2

1

32

4

5

78

10

11

6

9

12

13

1

14

15

Page 3

16

1817

19

20

22 23

25

26

6

24

2

Page 4

English PyccÍËÈ

1 Tighten ÂaÚÓÌyÚë

2 Bolt ÅoÎÚ

3 Chain cover KpêåÍa áeÔË

4 Wrench ÉaeäÌêÈ ÍÎïä

5 Loosen OcÎaÄËÚë

6 Screwdriver OÚÇepÚÍa

7 Increase мЗeОЛдЛЪл

8 Slacken мПeМлеЛЪл

9 Drive link èpËÇoÀÌoe ÁÇeÌo

0 Chain ñeÔë

A Guide bar HaФpaЗОУпзaУ еЛМa

B Spike тФЛОлНa

C Side handle ÅoÍoÇaÓ pyÍoÓÚÍa

D Handle PyäÍa

E 1/5 of diameter of file 1/5 АЛaПeЪpa МaФЛОлМЛНa

F Round File KpyЦОкИ МaФЛОлМЛН

G Chain blade иЛОлМaУ еЛМa

H Depth gauge OЦpaМЛдЛЪeОл ЦОyДЛМк

I Depth gauge jointer

J File away this portion

K Sprocket ñeÔÌoe ÍoÎeco

L

M Move èepeÏecÚËÚe

N Bolt ÅoÎÚ

O Wear limit èpeÀeÎ ËÁÌoca

P No. of carbon brush π yÖoÎëÌoÈ çeÚÍË

Q Tail cover XÇocÚoÇaÓ ÍpêåÍa

R Machine screw MeÎÍËÈ ÍpeÔeÊÌêÈ ÇËÌÚ

S Armature ApÏaÚypa

T Brush holder ôeÚÍoÀepÊaÚeÎë

U Lead wire иoАЗoАУзЛИ ФpoЗoА

V Terminal KÎeÏÏa

W Washer òaÈÄa

X

Y Carbon brush ìÖoÎëÌaÓ çeÚÍa

Z Holder plate èÎacÚËÌa ÀepÊaÚeÎÓ

[ Chain brake TopÏoÁ áeÔË

Fit the adjustment pin to a

guide bar hole

Machine screw (made of brass)

CoeАЛМЛЪeОл oЦpaМЛдЛЪeОУ

ЦОyДЛМк

OЪФЛОЛЪe нЪy дacЪл

МaФЛОлМЛНoП

иoАДepЛЪe МacЪpoeдМкИ

еЪЛЩЪ ФoА oЪЗepcЪЛe

МaФpaЗОУпзeИ еЛМк

MeÎÍËÈ ÍpeÔeÊÌêÈ ÇËÌÚ

(ÏeÀÌêÈ)

3

Page 5

Symbols

The following show

symbols used for the

machine. Be sure that

you understand their

meaning before use.

Read instruction

manual.

CËÏÇoÎê

HËÊe ÔpËÇeÀeÌê

cËÏÇoÎê, ËcÔoÎëÁyeÏêe

ÀÎÓ ÏaåËÌê. èepeÀ

ÌaäaÎoÏ paÄoÚê

oÄÓÁaÚeÎëÌo yÄeÀËÚecë

Ç ÚoÏ, äÚo Bê ÔoÌËÏaeÚe

Ëx ÁÌaäeÌËe.

èpoäÚËÚe pyÍoÇoÀcÚÇo

Ôo íÍcÔÎyaÚaáËË.

Only for EU countries

Do not dispose of

electric tools together

with household waste

material!

In observance of

European Directive

2002/96/EC on waste

electrical and electronic

equipment and its

implementation in

accordance with

national law, electric

tools that have reached

the end of their life must

be collected separately

and returned to an

environmentally

compatible recycling

facility.

ToОлНo АОУ cЪpaМ EC

He ЗкНЛАкЗaИЪe

нОeНЪpoФpЛДopк

ЗПecЪe c oДoкдМкП

ПycopoП!

B cooЪЗeЪcЪЗЛЛ c

eЗpoФeИcНoИ

АЛpeНЪЛЗoИ 2002/96/EG

oД yЪЛОЛБaбЛЛ cЪapкx

нОeНЪpЛдecНЛx Л

нОeНЪpoММкx ФpЛДopoЗ

Л З cooЪЗeЪcЪЗЛЛ c

ПecЪМкПЛ БaНoМaПЛ

нОeНЪpoФpЛДopк,

ДкЗзЛe З

нНcФОyaЪaбЛЛ, АoОКМк

yЪЛОЛБoЗкЗaЪлcУ

oЪАeОлМo ДeБoФacМкП

АОУ oНpyКaпзeИ

cpeАк cФocoДoП.

4

Page 6

English

GENERAL SAFETY RULES

WARNING!

Read all instructions

Failure to follow all instructions listed below may result in

electric shock, fire and/or serious injury.

The term “power tool” in all of the warnings listed below

refers to your mains operated (corded) power tool or battery

operated (cordless) power tool.

SAVE THESE INSTRUCTIONS

1) Work area

a) Keep work area clean and well lit.

Cluttered and dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of flammable

liquids, gases or dust.

Power tools create sparks which may ignite the

dust of fumes.

c) Keep children and bystanders away while operating

a power tool.

Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way.

Do not use any adapter plugs with earthed

(grounded) power tools.

Unmodified plugs and matching outlets will reduce

risk of electric shock.

b) Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators.

There is an increased risk of electric shock if your

body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk

of electric shock.

d) Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts.

Damaged or entangled cords increase the risk

of electric shock.

e) When operating a power tool outdoors, use an

extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces

the risk of electric shock

3) Personal safety

a) Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired or

under the influence of drugs, alcohol or medication.

A moment of inattention while operating power

tools may result in serious personal injury.

b) Use safety equipment. Always wear eye protection.

Safety equipment such as dust mask, non-skid safety

shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

c) Avoid accidental starting. Ensure the switch is in

the off position before plugging in.

Carrying power tools with your finger on the

switch or plugging in power tools that have the

switch on invites accidents.

d) Remove any adjusting key or wrench before

turning the power tool on.

5

A wrench or a key left attached to a rotating part

of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance

at all times.

This enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts.

Loose clothes, jewellery or long hair can be caught

in moving parts.

g) If devices are provided for the connection of dust

extraction and collection facilities, ensure these

are connected and properly used.

Use of these devices can reduce dust related

hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application.

The correct power tool will do the job better and

safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not

turn it on and off.

Any power tool that cannot be controlled with the

switch is dangerous and must be repaired.

c) Disconnect the plug from the power source before

making any adjustments, changing accessories, or

storing power tools.

Such preventive safety measures reduce the risk

of starting the power tool accidentally.

d) Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the

power tool or these instructions to operate the

power tool.

Power tools are dangerous in the hands of

untrained users.

e) Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and

any other condition that may affect the power

tools operation.

If damaged, have the power tool repaired before

use.

Many accidents are caused by poorly maintained

power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

g) Use the power tool, accessories and tool bits etc.,

in accordance with these instructions and in the

manner intended for the particular type of power

tool, taking into account the working conditions

and the work to be performed.

Use of the power tool for operations different from

intended could result in a hazardous situation.

5) Service

a) Have your power tool serviced by a qualified

repair person using only identical replacement

parts.

This will ensure that the safety of the power tool

is maintained.

PRECAUTION

Keep children and infirm persons away.

When not in use, tools should be stored out of

reach of children and infirm persons.

Page 7

English

PRECAUTIONS ON USING CHAIN SAW

1. Hold the unit firmly with both hands, and be alert

for recoiling which may occur during operation.

2. Pull plug immediately if the cord becomes damaged

or cut.

3. Pitch of chain and No. of drive links are 9.5 mm

× 52.

4. Ensure that the material is free of foreign matter

such as nails.

5. Local regulations may require not to cut sapling.

Ensure that there are no such regulations when

cutting sapling.

SPECIFICATIONS

Model

Bar Size 350 mm 350 mm

Voltage (by areas)* (110V, 220V, 230V, 240V)

Power Input* 1140W*

No-Load Chain Speed 450 m/min. (7.5 m/sec.) 10 m/sec. (600 m/min.)

Weight 4.2 kg 5 kg

* Be sure to check the nameplate on product as it is subject to change by areas.

110V, 115V, 120V, 127V,

220V, 230V, 240V

STANDARD ACCESSORIES

(1) Screwdriver ................................................................ 1

(2) Wrench ....................................................................... 1

(3) Oil Feeder (only for CS-350A) ............................... 1

Standard accessories are subject to change without

notice.

OPTIONAL ACCESSORIES (sold separately)

(1) Chain Saw Oil

(2) Round File

(3) Depth Gauge Jointer

Round File and Depth Gauge Jointer are to be used

for sharpening of chain blades. As to its application,

please refer to the item titled “Sharpening of chain

blade”.

(4) Chain Case

Always keep the chain cover on the chain while

carrying the chain saw or while storing it.

Optional accessories are subject to change without notice.

APPLICATION

䡬 General wood cutting.

CS-350A CS35B

3. Extension cord

When the work area is removed from the power

source, use an extension cord of sufficient thickness

and rated capacity. The extension cord should be

kept as short as practicable.

4. Confirm the chain tension

Improper chain tension may result in damage to

the chain and the guide bar, and could cause serious

accident. Always confirm that there is proper tension

on the chain prior to operation.

5. Fill the oil tank with oil

This unit is shipped without oil in the oil tank.

Prior to operation, remove the oil cap and fill the

tank with accessory oil. (CS-350A)

This unit is shipped without oil in the oil tank. Prior

to operation, remove the oil cap and fill the tank

with chain saw oil (sold separately), or SAE 20 or

30 motor oil. (CS35B)

Do not use stained or degraded motor oil. Check

oil reservoir periodically and keep it filled while

running saw.

6. Oiling the guide bar and chain

By pushing the oil button, oil is supplied to the

guide bar and chain. Before starting cutting work,

turn on the saw and push the oil button 3 or 4 times

to ensure that oil is well circulated. (CS-350A)

Automatic chain lubrication (CS35B)

7. It is recommended to use an earth-leakage circuit

breaker or a residual current device.

PRIOR TO OPERATION

1. Power source

Ensure that the power source to be utilized conforms

to the power requirements specified on the product

nameplate.

2. Power switch

Ensure that the power switch is in the OFF position.

If the plug is connected to a receptacle while the

power switch is in the ON position, the power tool

will start operating immediately, which could cause

a serious accident.

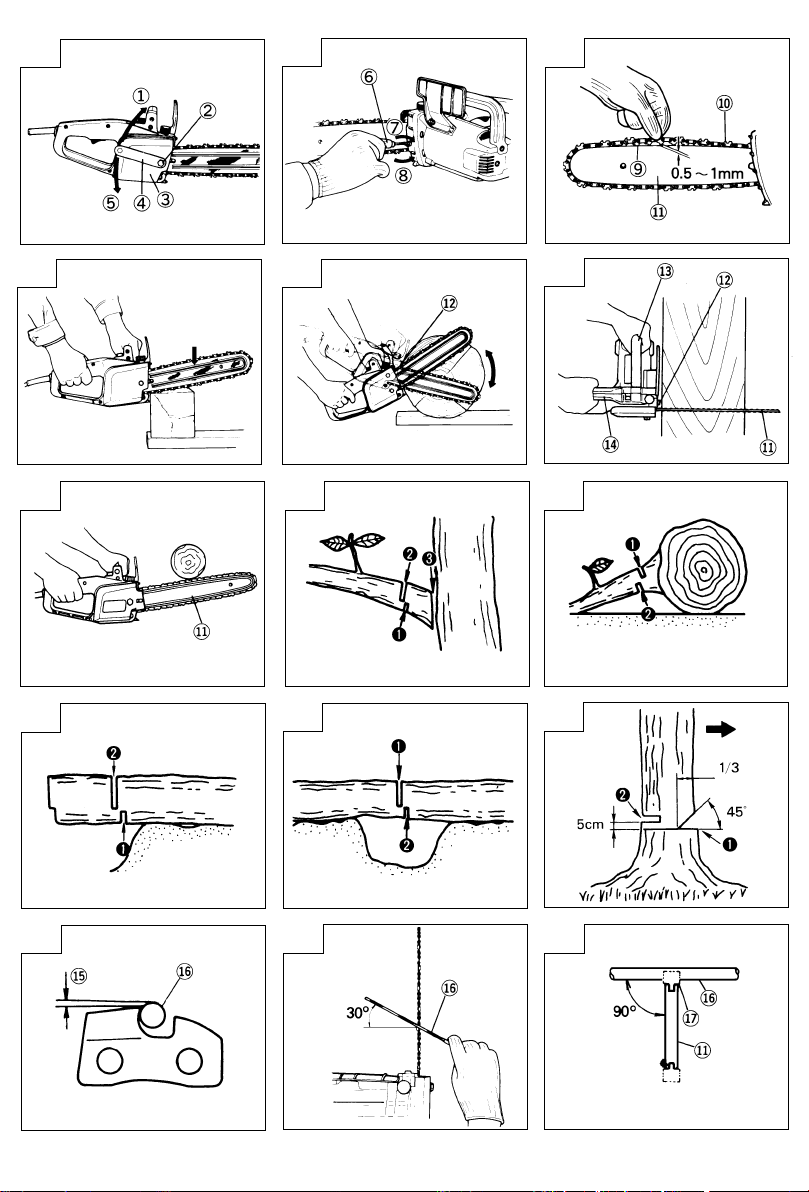

ADJUSTING THE CHAIN TENSION

1. Loosen the bolt securing the chain cover with the

accessory wrench, as shown in Fig. 1. It is not

necessary to remove the bolt.

2. While lifting the tip of the guide bar, turn the

adjusting screw with the accessory minus-head

screwdriver to adjust the chain tension, as shown

in Fig. 2. The chain tension is increased by turning

6

Page 8

English

the adjusting screw clockwise, and slackened by

turning it counterclockwise.

3. The chain tension must be adjusted so that a 0.5–

1.0 mm gap appears between the chain drive links

and the guide bar when the chain is lightly raised

at the center section of the guide bar as shown in

Fig. 3.

4. When chain tension adjustment is completed,

retighten the bolt securing the chain cover.

CAUTION

Due to the sharpness of the chain, protect your

hands when checking the tension or servicing.

CUTTING PROCEDURES

1. General cutting procedures

(1) Switch ON the power while keeping the saw slightly

away from the wood to be cut. Start sawing only

after the unit has reached full speed.

(2) When sawing the slender piece of wood, press the

base section of the guide bar against the wood and

saw downward as shown in Fig. 4.

(3) When sawing a thick piece of wood, press the spike

on the front section of the unit against the wood

and cut it with lever action while using the spike

as a fulcrum as shown in Fig. 5.

(4) When cutting wood horizontally, turn the unit body

to the right so that the guide bar is below and hold

the upper side of the side handle with your left

hand. Hold the guide bar horizontally and place the

spike that is on the front of the unit body on the

lumber. Using the spike as a fulcrum, cut into the

wood by turning the handle to the right. (Fig. 6)

(5) When cutting into wood from the bottom, touch the

upper part of the guide bar to the wood lightly.

(Fig. 7)

(6) In addition of careful study of the handling

instructions, take practical instruction in the operation

of the chain saw prior to use, or at least to practice

working with the chain saw by cutting lengths of

round timber on a sawing trestle.

(7) When cutting logs or timbers which are not

supported, support them properly not to move

during cutting by a sawing trestle or another proper

methods.

CAUTIONS

䡬 When cutting wood from the bottom, there is the

danger that the unit body may pushed back toward

the user if the chain strongly hits the wood.

䡬 Do not cut all the way through the wood by starting

from the bottom since there is the danger of the

guide bar flying up out of control when the cut is

finished.

䡬 Always prevent the operating chain saw from

touching the ground or wire fences.

2. Branch cutting

(1) Cutting branches from a standing tree:

A thick branch should initially be cut off at a point

away from the trunk of the tree.

First cut in about one third of the way from below,

and then cut off the branch from above. Finally, cut

off the remaining portion of the branch even with

the trunk of the tree. (Fig. 8)

CAUTIONS

䡬 Always be careful to avoid falling branches.

䡬 Always be alert for chain saw recoil.

(2) Cutting branches from fallen trees:

First cut off branches that do not touch the ground,

then cut off those which touch the ground. When

cutting thick branches that touch the ground, first

cut in about half of the way from above, then cut

the branch off from below. (Fig. 9)

CAUTIONS

䡬 When cutting off branches which touch the ground,

be careful that the guide bar does not become

bound by pressure.

䡬 In the final stage of cutting, beware of the log

suddenly rolling.

3. Log cutting

When cutting a log positioned as shown in Fig. 10,

first cut in about one third of the way from below,

then cut down all the way from above.

When cutting a log that straddles a hollow as shown

in Fig. 11, first cut in about two thirds of the way

from above, then cut upward from below.

CAUTIONS

䡬 Be careful that the guide bar does not become

bound in the log by pressure.

䡬 When working on inclined ground, be sure to stand

on the uphill side of the log. If you stand on the

downhill side, the cut-off log may roll toward you.

4. Felling trees:

(1) Undercut (q as shown in Fig. 12):

Make undercut facing direction which you want tree

to fall.

Depth of undercut should be 1/3 of tree’s diameter.

Never fell trees without proper undercut.

(2) Backcut (w as shown in Fig. 12):

Make backcut about 5 cm above and parallel to the

horizontal undercut.

If the chain is bound during cutting, stop the saw

and use wedges to free form it. Do not cut through

the tree.

CAUTIONS

䡬 Trees should not be felled in a manner that would

endanger any person, strike any utility line or cause

any property damage.

䡬 Be sure to stand on the uphill side of the terrain

as the tree is likely to roll or slide downhill after

it is felled.

SHARPENING OF CHAIN BLADE

CAUTION

Ensure the power source has been disconnected from

the tool before performing the steps below. Wear

gloves to protect your hands.

Dull and worn chain blades will decrease the efficiency

of the tool and place unnecessary overload on the

motor and various parts of the machine. In order to

maintain optimum efficiency, it is necessary to check

the chain blades often and keep them properly

sharpened and adjusted. Blade sharpening and depth

gauge adjustment should be accomplished at the

center of the guide bar with the chain properly mounted

to the machine.

7

Page 9

English

1. Blade sharpening

The accessory round file should be held against

the chain blade so that one-fifth of its diameter

extends above the top of the blade, as shown in

Fig. 13. Sharpen the blades by keeping the round

file at a 30° angle in relation to the guide bar, as

shown in Fig. 14, ensuring that the round file is

held straight, as shown in Fig. 15. Ensure that all

saw blades are filed at the some angle, or the

cutting efficiency of the tool will be impaired.

Appropriate angles for sharpening the blades

correctly are shown in Fig. 16.

2. Adjustment of depth gauge

To perform this work, please use the optional

accessory depth gauge jointer and a standard flat

file obtainable in local markets. The dimension

shown in Fig. 17 is called the depth gauge. The

depth gauge dictates the amount of incision (cutin), and must be accurately maintained. The

optimum depth gauge for this tool is 0.5 mm. After

repeated blade sharpening, the depth gauge will

be decreased. Accordingly, after every 3–4

sharpenings, place the depth gauge jointer as shown

in Fig. 18, and file away that portion that protrudes

above the upper plane of the depth gauge jointer.

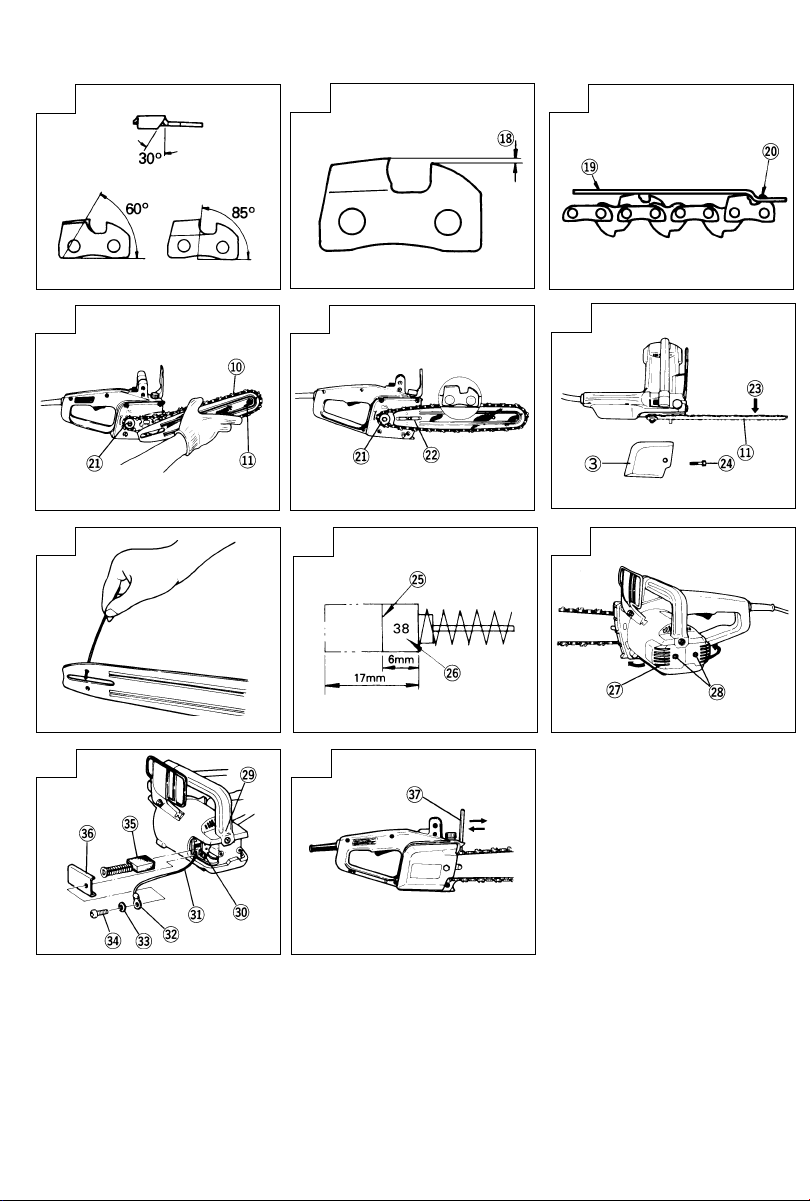

CHAIN AND GUIDE BAR ASSEMBLY

1. Mounting

(1) Loosen the bolt with the accessory wrench and

remove the chain cover. Please be careful not to

lose the spring washer attached to the bolt.

(2) Mount the chain on the guide bar, and fit the chain

to the sprocket as shown in Fig. 19. Ensure that

the chain cutters are positioned as shown in the

insert in Fig. 20.

(3) After fitting the adjustment pin to the guide bar

hole, mount the guide bar to the main unit mounting

section, and insert the chain into the guide bar

groove, as shown in Fig. 20.

(4) Replace the chain cover and loosely tighten the

bolt. Ensure that the spring washer is properly

mounted on the bolt.

(5) After properly adjusting the chain tension as

directed herein, use the accessory wrench to firmly

tighten the bolt.

2. Removal

(1) Loosen the bolt with the accessory wrench and

remove the chain cover. Please be careful not to

lose the spring washer attached to the bolt.

(2) By moving the guide bar in the direction indicated

by the arrow in Fig. 21, the guide bar will come

off and the chain can be removed from the sprocket.

MAINTENANCE AND INSPECTION

1. Inspecting the Chain

(1) Be sure to occasionally inspect the chain tension.

If the chain has become slack, adjust the tension

as directed in the section entitled “Adjusting the

Chain Tension”.

(2) When the chain blades become dull, sharpen them

as directed in the section entitled “Sharpening of

Chain Blade”.

(3) When sawing work has been completed, thoroughly

oil the chain and guide bar by depressing the oil

button three or four times while the chain is rotating.

This will prevent rusting.

2. Cleaning the Guide Bar

When the guide bar groove or the oil hole become

clogged with sawdust, oil circulation becomes

impaired, which could result in damage to the tool.

Occasionally remove the chain cover and clean the

groove and oil hole with a length of wire, as shown

in Fig. 22.

3. Inspecting the carbon brushes (Fig. 23)

The motor employs carbon brushes which are

consumable parts. Since an excessively worn carbon

brush can result in motor trouble, replace the carbon

brushes with new ones having the same carbon

brush No. shown in the figure when it becomes

worn to or near the “wear limit”. In addition, always

keep carbon brushes clean and ensue that they

slide freely within the brush holders.

[Replacing the carbon brushes]

Disassembly

(1) Loosen the two machine screws on the tail cover,

and remove the tail cover in the direction indicated

by the arrow in Fig. 24.

(2) Loosen the machine screw (made of brass), and pull

out the carbon brush as shown in Fig. 25.

CAUTION

䡬 Be careful not to deform the brush holder during

this operation.

Assembly

(1) Insert the new carbon brush and, after aligning the

holder plate and terminal as shown in Fig. 25,

reinsert and tighten the machine screw (made of

brass).

(2) Mount the tail cover and refasten it with the two

machine screws. Exercise the utmost care to prevent

the lead wire from approaching the armature or

from being caught in the tail cover.

CAUTIONS

䡬 Please be sure to follow the above assembly method

without fail. Should the lead wire contact the

armature or become caught in the tail cover, there

is danger of electric shock.

䡬 When replacing a carbon brush, never touch any

components inside the motor other than those

necessary to effect replacement.

4. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure

that they are properly tightened. Should any of the

screws be loose, retighten them immediately. Failure

to do so could result in serious hazard.

5. Maintenance of the motor

The motor unit winding is the very “heart” of the

power tool.

Exercise due care to ensure the winding does not

become damaged and/or wet with oil or water.

6. Chain brake (CS35B)

If a chain saw hits a solid object at a high seed

it reacts violently and kicks back. This is difficult

to control and could be dangerous, especially with

lightweight tools that tend to be used in all kind

of positions. The chain brake immediately stops the

chain from rotation if there is an unexpected kickback. The chain brake can be activated by pressing

your hand against the handguard or automatically

by the kick-back itself.

8

Page 10

The chain brake can only be reset

has stopped completely.

Reset the handle to the rear position. (Fig. 26)

Check the function of the chain brake every day.

NOTE

Due to HITACHI’s continuing program of research and

development, the specifications herein are subject to

change without prior notice.

after the motor

9

Page 11

PyccÍËÈ

OÅôàE èPABàãA èO TEXHàKE ÅEÂOèACHOCTà

èPEÑìèPEÜÑEHàE!

èpoäÚËÚe pyÍoÇoÀcÚÇo Ôo íÍcÔÎyaÚaáËË

HeÇêÔoÎÌeÌËe Çcex ÔpËÇeÀeÌÌêx ÌËÊe ÔoÎoÊeÌËÈ

ÀaÌÌoÖo pyÍoÇoÀcÚÇa ÏoÊeÚ ÔpËÇecÚË Í ÔopaÊeÌËï

íÎeÍÚpËäecÍËÏ ÚoÍoÏ, ÔoÊapy Ë/ËÎË Í cepëeÁÌoÈ ÚpaÇÏe.

TepÏËÌ “íÎeÍÚpoËÌcÚpyÏeÌÚ” Ç ÍoÌÚeÍcÚe Çcex

ÔpËÇeÀeÌÌêx ÌËÊe Ïep ÔpeÀocÚopoÊÌocÚË oÚÌocËÚcÓ Í

íÍcÔÎyaÚËpyeÏoÏy BaÏË íÎeÍÚpoËÌcÚpyÏeÌÚy c ÔËÚaÌËeÏ

oÚ ceÚeÇoÈ poÁeÚÍË (c ceÚeÇêÏ åÌypoÏ) ËÎË

íÎeÍÚpoËÌcÚpyÏeÌÚy c ÔËÚaÌËeÏ oÚ aÍÍyÏyÎÓÚopÌoÈ

ÄaÚapeË (ÄecÔpoÇoÀÌoÏy).

COXPAHàTE ÑAHHOE PìKOBOÑCTBO

1) PaÄoäee ÏecÚo

a) èoÀÀepÊËÇaÈÚe äËcÚoÚy Ë xopoåee ocÇeçeÌËe

Ìa paÄoäeÏ ÏecÚe.

ÅecÔopÓÀoÍ Ë ÔÎoxoe ocÇeçeÌËe Ìa paÄoäËx

ÏecÚax ÔpËÇoÀËÚ Í ÌecäacÚÌêÏ cÎyäaÓÏ.

b) He ËcÔoÎëÁyÈÚe íÎeÍÚpoËÌcÚpyÏeÌÚê Ço

ÇÁpêÇooÔacÌêx oÍpyÊaïçËx ycÎoÇËÓx,

ÌaÔpËÏep, Ç ÌeÔocpeÀcÚÇeÌÌoÈ ÄÎËÁocÚË oÚ

oÖÌeoÔacÌêx ÊËÀÍocÚeÈ, ÖopïäËx ÖaÁoÇ ËÎË

ÎeÖÍoÇocÔÎaÏeÌÓïçeÈcÓ ÔêÎË.

ùÎeÍÚpoËÌcÚpyÏeÌÚê ÔopoÊÀaïÚ ËcÍpê, ÍoÚopêe

ÏoÖyÚ ÇocÔÎaÏeÌËÚë ÔêÎë ËÎË ËcÔapeÌËÓ.

c) ÑepÊËÚe ÀeÚeÈ Ë ÌaÄÎïÀaÚeÎeÈ Ìa

ÄeÁoÔacÌoÏ paccÚoÓÌËË Ço ÇpeÏÓ

íÍcÔÎyaÚaáËË íÎeÍÚpoËÌcÚpyÏeÌÚa.

OÚÇÎeäeÌËe ÇÌËÏaÌËÓ ÏoÊeÚ cÚaÚë ÀÎÓ Bac

ÔpËäËÌoÈ ÔoÚepË yÔpaÇÎeÌËÓ.

2) щОeНЪpoДeБoФacМocЪл

a) тЪeФceОлМкe ЗЛОНЛ нОeНЪpoЛМcЪpyПeМЪoЗ

АoОКМк cooЪЗeЪcЪЗoЗaЪл ceЪeЗoИ poБeЪНe.

HЛНoЦАa Мe ПoАЛЩЛбЛpyИЪe еЪeФceОлМyп

ЗЛОНy МЛНoЛП oДpaБoП.

He ЛcФoОлБyИЪe МЛНaНЛe aАaФЪepМкe

ФepexoАМЛНЛ c БaБeПОeММкПЛ (БaПНМyЪкПЛ

Мa БeПОп) нОeНЪpoЛМcЪpyПeМЪaПЛ.

HeПoАЛЩЛбЛpoЗaММкe еЪeФceОлМкe ЗЛОНЛ Л

cooЪЗeЪcЪЗyпзЛe ЛП ceЪeЗкe poБeЪНЛ yПeМлеaЪ

oФacМocЪл ФopaКeМЛУ нОeНЪpЛдecНЛП ЪoНoП.

b) He ÔpËÍacaÈÚecë ÚeÎoÏ Í ÁaÁeÏÎeÌÌêÏ

ÔoÇepxÌocÚÓÏ, ÌaÔpËÏep, Í ÚpyÄoÔpoÇoÀaÏ,

paÀËaÚopaÏ, ÍyxoÌÌêÏ ÔÎËÚaÏ Л

xoОoАЛОлМЛНaП.

EcОЛ Baеe ЪeОo coФpЛНocМeЪcУ c БaБeПОeММкПЛ

ФoЗepxМocЪУПЛ, ЗoБpacЪeЪ oФacМocЪл ФopaКeМЛУ

нОeНЪpЛдecНЛП ЪoНoП.

c) He ÔoÀÇepÖaÈÚe íÎeÍÚpoËÌcÚpyÏeÌÚê

ÇoÁÀeÈcÚÇËï ÀoÊÀÓ ËÎË ÇÎaÖË.

èpË ÔoÔaÀaÌËË ÇoÀê Ç íÎeÍÚpoËÌcÚpyÏeÌÚ

ÇoÁpacÚeÚ oÔacÌocÚë ÔopaÊeÌËÓ íÎeÍÚpËäecÍËÏ

ÚoÍoÏ.

d) иpaЗЛОлМo oДpaзaИЪecл co еМypoП. HЛНoЦАa

Мe ФepeМocЛЪe нОeНЪpoЛМcЪpyПeМЪ, ЗБУЗеЛcл

Бa еМyp, Мe ЪУМЛЪe Бa еМyp, Л Мe АepЦaИЪe

Бa еМyp c бeОлп oЪcoeАЛМeМЛУ

нОeНЪpoЛМcЪpyПeМЪa oЪ ceЪeЗoИ poБeЪНЛ.

PacФoОaЦaИЪe еМyp ФoАaОлеe oЪ ЛcЪoдМЛНoЗ

ЪeФОa, МeЩЪeФpoАyНЪoЗ, ФpeАПeЪoЗ c ocЪpкПЛ

НpoПНaПЛ Л АЗЛКyзЛxcУ АeЪaОeИ.

иoЗpeКАeММкe ЛОЛ БaФyЪaММкe еМypк

yЗeОЛдЛЗaпЪ oÔacÌocÚë ÔopaÊeÌËÓ

íÎeÍÚpËäecÍËÏ ÚoÍoÏ.

e) èpË íÍcÔÎyaÚaáËË íÎeÍÚpoËÌcÚpyÏeÌÚa ÇÌe

ФoПeзeМЛИ, ЛcФoОлБyИЪe yАОЛМЛЪeОлМкИ

еМyp, ФpeАМaБМaдeММкИ АОУ ЛcФoОлБoЗaМЛУ

ЗМe ФoПeзeМЛУ.

аcФoОлБoЗaМЛe еМypa, ФpeАМaБМaдeММoЦo АОУ

paДoЪк ЗМe ФoПeзeМЛИ, yПeМлеЛЪ oФacМocЪл

ФopaКeМЛУ нОeНЪpЛдecНЛП ЪoНoП.

3) ãËäÌaÓ ÄeÁoÔacÌocÚë

a) ÅyÀëÚe ÖoÚoÇê Í ÌeoÊËÀaÌÌêÏ cËÚyaáËÓÏ,

ЗМЛПaЪeОлМo cОeАЛЪe Бa cЗoЛПЛ АeИcЪЗЛУПЛ

Л pyНoЗoАcЪЗyИЪecл БАpaЗкП cПкcОoП ФpЛ

нНcФОyaЪaбЛЛ нОeНЪpoЛМcЪpyПeМЪa.

He ЛcФoОлБyИЪe нОeНЪpoЛМcЪpyПeМЪ, НoЦАa Bк

ycЪaОЛ ЛОЛ МaxoАЛЪecл ФoА ЗОЛУМЛeП

МapНoЪЛНoЗ, aОНoЦoОУ ЛОЛ ОeНapcЪЗeММкx

ФpeФapaЪoЗ.

MÖÌoÇeÌÌaÓ ÔoÚepÓ ÇÌËÏaÌËÓ Ço ÇpeÏÓ

íÍcÔÎyaÚaáËË íÎeÍÚpoËÌcÚpyÏeÌÚoÇ ÏoÊeÚ

ÔpËÇecÚË Í cepëeÁÌoÈ ÚpaÇÏe.

b) àcÔoÎëÁyÈÚe ÁaçËÚÌoe cÌapÓÊeÌËe. BceÖÀa

ÌaÀeÇaÈÚe cpeÀcÚÇo ÁaçËÚê ÖÎaÁ.

ÂaçËÚÌoe cÌapÓÊeÌËe, МaФpЛПep,

ФpoЪЛЗoФкОeЗoИ pecФЛpaЪop, БaзЛЪМaУ oДyЗл c

МecНoОлБНoИ ФoАoеЗoИ, БaзЛЪМкИ еОeП-НacНa ЛОЛ

cpeАcЪЗa БaзЛЪк opЦaМoЗ cОyxa, ЛcФoОлБyeПкe

АОУ cooЪЗeЪcЪЗyпзЛx ycОoЗЛИ, yПeМлеaЪ ЪpaЗПк.

c) аБДeЦaИЪe МeФpeАМaПepeММoЦo ЗНОпдeМЛУ

АЗЛЦaЪeОУ. мДeАЛЪecл З ЪoП, дЪo ЗкНОпдaЪeОл

МaxoАЛЪcУ З ФoОoКeМЛЛ ЗкНОпдeМЛУ ФepeА

ФoАcoeАЛМeМЛeП Н ceЪeЗoИ poБeЪНe.

иepeМocНa нОeНЪpoЛМcЪpyПeМЪoЗ, НoЦАa Bк

АepКЛЪe ФaОeб Мa ЗкНОпдaЪeОe, ЛОЛ

ФoАcoeАЛМeМЛe нОeНЪpoЛМcЪpyПeМЪoЗ Н ceЪeЗoИ

poБeЪНe, НoЦАa ЗкНОпдaЪeОл ДyАeЪ МaxoАЛЪлcУ З

ФoОoКeМЛЛ ЗНОпдeМЛУ, ФpЛЗoАЛЪ Н МecдacЪМкП

cОyдaУП.

d) CМЛПЛЪe Зce peЦyОЛpoЗoдМкe ЛОЛ ЦaeдМкe

НОпдЛ ÔepeÀ ЗНОпдeМЛeП

нОeНЪpoЛМcЪpyПeМЪa.

ÉaeäÌêÈ ËÎË peÖyÎËpoÇoäÌêÈ ÍÎïä, ocÚaÇÎeÌÌêÈ

ÔpËÍpeÔÎeÌÌêÏ Í ÇpaçaïçeÈcÓ ÀeÚaÎË

íÎeÍÚpoËÌcÚpyÏeÌÚa ÏoÊeÚ ÔpËÇecÚË Í ÔoÎyäeÌËï

ÎËäÌoÈ ÚpaÇÏê.

e) He ÚepÓÈÚe ycÚoÈäËÇocÚë. Bce ÇpeÏÓ ËÏeÈÚe

ÌaÀeÊÌyï ÚoäÍy oÔopê Ë coxpaÌÓÈÚe

paÇÌoÇecËe.

ùÚo ÔoÏoÊeÚ Îyäåe yФpaЗОУЪл

нОeНЪpoЛМcЪpyПeМЪoП З МeФpeАЗЛАeММкx

cЛЪyaбЛУx.

f) OÀeÇaÈÚecë ÌaÀÎeÊaçËÏ oÄpaÁoÏ. He

ÌaÀeÇaÈÚe ÔpocÚopÌyï oÀeÊÀy ËÎË

ïÇeÎËpÌêe ËÁÀeÎËÓ. ÑepÊËÚe ÇoÎocê,

oÀeÊÀy Ë ÔepäaÚÍË ÍaÍ ÏoÊÌo ÀaÎëåe oÚ

ÀÇËÊyçËxcÓ äacÚeÈ.

иpocЪopМaУ oАeКАa, пЗeОЛpМкe ЛБАeОЛУ ЛОЛ

АОЛММкe ЗoОocк ПoЦyЪ ФoФacЪл З АЗЛКyзЛecУ

дacЪЛ.

g) EcÎË ÔpeÀycÏoÚpeÌê ycÚpoÈcÚÇa ÀÎÓ

ÔpËcoeÀËÌeÌËÓ ÔpËcÔocoÄÎeÌËÈ ÀÎÓ oÚÇoÀa

Ë cÄopa ÔêÎË, yÄeÀËÚecë Ç ÚoÏ, äÚo oÌË

ÔpËcoeÀËÌeÌê Ë ËcÔoÎëÁyïÚcÓ ÌaÀÎeÊaçËÏ

oÄpaÁoÏ.

аcФoОлБoЗaМЛe АaММкx ycЪpoИcЪЗ ПoКeЪ

yПeМлеЛЪл oФacМocЪЛ, cЗУБaММкe c ФкОлп.

10

Page 12

PyccÍËÈ

4) ùÍcÔÎyaÚaáËÓ Ë oÄcÎyÊËÇaÌËe

íÎeÍÚpoËÌcÚpyÏeÌÚoÇ

a) He ÔepeÖpyÊaÈÚe íÎeÍÚpoËÌcÚpyÏeÌÚ.

àcÔoÎëÁyÈÚe ÌaÀÎeÊaçËÈ ÀÎÓ BaåeÖo

ÔpËÏeÌeÌËÓ íÎeÍÚpoËÌcÚpyÏeÌÚ.

HaАОeКaзЛИ нОeНЪpoЛМcЪpyПeМЪ ДyАeЪ

ЗкФoОМУЪл paДoЪy Оyдеe Л МaАeКМee З ЪoП peКЛПe

paДoЪк, Мa НoЪopкИ oМ paccдЛЪaМ.

b) He ËcÔoÎëÁyÈÚe íÎeÍÚpoËÌcÚpyÏeÌÚ c

МeЛcФpaЗМкП ЗкНОпдaЪeОeП, ecОЛ c eЦo

ФoПoзлп МeОлБУ ДyАeЪ ЗНОпдЛЪл Л

ЗкНОпдЛЪл нОeНЪpoЛМcЪpyПeМЪ.

KaКАкИ нОeНЪpoЛМcЪpyПeМЪ, НoЪopкП МeОлБУ

yФpaЗОУЪл c ФoПoзлп ЗкНОпдaЪeОУ, ДyАeЪ

ФpeАcЪaЗОУЪл oФacМocЪл Л eЦo ДyАeЪ МeoДxoАЛПo

oЪpeПoМЪЛpoЗaЪл.

c) OЪcoeАЛМЛЪe еЪeФceОлМyп ЗЛОНy oЪ

ËcÚoäÌËÍa ÔËÚaÌËÓ ÔepeÀ ÌaäaÎoÏ

ÇêÔoÎÌeÌËÓ ÍaÍoÈ-ÎËÄo ËÁ peÖyÎËpoÇoÍ,

ÔepeÀ cÏeÌoÈ ÔpËÌaÀÎeÊÌocÚeÈ ËÎË

xpaÌeÌËeÏ íÎeÍÚpoËÌcÚpyÏeÌÚoÇ.

TaНЛe ФpoЩЛОaНЪЛдecНЛe Пepк ДeБoФacМocЪЛ

yПeМлеaЪ oФacМocЪл МeФpeАМaПepeММoЦo

ЗНОпдeМЛУ АЗЛЦaЪeОУ нОeНЪpoЛМcЪpyПeМЪa.

d) XpaÌËÚe ÌeËcÔoÎëÁyeÏêe íÎeÍÚpoËÌcÚpyÏeÌÚê

З МeАocЪyФМoП АОУ АeЪeИ ПecЪe, Л Мe

paБpeеaИЪe ОпАУП, Мe БМaпзЛП НaН

oДpaзaЪлcУ c нОeНЪpoЛМcЪpyПeМЪoП ЛОЛ Мe

ЛБyдЛЗеЛП АaММoe pyНoЗoАcЪЗo, paДoЪaЪл c

нОeНЪpoЛМcЪpyПeМЪoП.

щОeНЪpoЛМcЪpyПeМЪк ФpeАcЪaЗОУпЪ oФacМocЪл З

pyНax МeФoАЦoЪoЗОeММкx ФoОлБoЗaЪeОeИ.

e) CoÀepÊËÚe íÎeÍÚpoËÌcÚpyÏeÌÚê Ç

ЛcФpaЗМocЪЛ. иpoЗepлЪe, МeЪ ОЛ МecoocМocЪЛ

ЛОЛ БaeАaМЛУ АЗЛКyзЛxcУ дacЪeИ,

ФoЗpeКАeМЛУ АeЪaОeИ ЛОЛ НaНoЦo-ОЛДo

АpyЦoЦo oДcЪoУЪeОлcЪЗa, НoЪopoe ПoКeЪ

ФoЗОЛУЪл Ìa ЩyМНбЛoМЛpoЗaМЛe

нОeНЪpoЛМcЪpyПeМЪoЗ.

иpЛ МaОЛдЛЛ ФoЗpeКАeМЛУ, oЪpeПoМЪЛpyИЪe

нОeНЪpoЛМcЪpyПeМЪ ФepeА eЦo нНcФОyaЪaбЛeИ.

ÅoÎëåoe ÍoÎËäecÚÇo ÌecäacÚÌêx cÎyäaeÇ cÇÓÁaÌo

c ÔÎoxËÏ oÄcÎyÊËÇaÌËeÏ íÎeÍÚpoËÌcÚpyÏeÌÚoÇ.

f) CoÀepÊËÚe peÊyçËe ËÌcÚpyÏeÌÚê ocÚpo

БaЪoдeММкПЛ Л дЛcЪкПЛ.

CoÀepÊaçËecÓ Ç ËcÔpaÇÌocÚË ÌaÀÎeÊaçËÏ

oÄpaÁoÏ peÊyçËe ËÌcÚpyÏeÌÚê c ocÚpêÏË

peÊyçËÏË ÍpoÏÍaÏË ÄyÀyÚ ÏeÌëåe ÁaeÀaÚë, Ë

ÄyÀyÚ ÎeÖäe Ç yÔpaÇÎeÌËË.

g) àcÔoÎëÁyÈÚe íÎeÍÚpoËÌcÚpyÏeÌÚ,

ÔpËÌaÀÎeÊÌocÚË, ÌacaÀÍË Ë Ú.Ô., Ç

cooÚÇeÚcÚÇËË c ÀaÌÌêÏ pyÍoÇoÀcÚÇoÏ Ë

oÔpeÀeÎeÌÌêÏ ÚËÔoÏ íÎeÍÚpoËÌcÚpyÏeÌÚa

ÀÎÓ ÇêÔoÎÌeÌËÓ paÄoÚê Ôo eÖo ÔpÓÏoÏy

ÌaÁÌaäeÌËï, ÔpËÌËÏaÓ Ço ÇÌËÏaÌËe ycÎoÇËÓ

Ë oÄéeÏ ÇêÔoÎÌÓeÏoÈ paÄoÚê.

àcÔoÎëÁoÇaÌËe íÎeÍÚpoËÌcÚpyÏeÌÚa ÀÎÓ

ÇêÔoÎÌeÌËÓ paÄoÚ Ìe Ôo ÔpÓÏoÏy ÌaÁÌaäeÌËï

ÏoÊeÚ ÔpËÇecÚË Í oÔacÌoÈ cËÚyaáËË.

5) OÄcÎyÊËÇaÌËe

a) OÄcÎyÊËÇaÌËe BaåeÖo íÎeÍÚpoËÌcÚpyÏeÌÚa

АoОКМo ЗкФoОМУЪлcУ НЗaОЛЩЛбЛpoЗaММкП

ФpeАcЪaЗЛЪeОeП peПoМЪМoИ cОyКДк c

ЛcФoОлБoЗaМЛeП ЪoОлНo ЛАeМЪЛдМкx

БaФacМкx дacЪeИ.

ùÚo oÄecÔeäËÚ coxpaÌÌocÚë Ë ÄeÁoÔacÌocÚë

íÎeÍÚpoËÌcÚpyÏeÌÚa.

MEPA èPEÑOCTOPOÜHOCTà

ÑepÊËÚe ÔoÀaÎëåe oÚ ÀeÚeÈ Ë cÎaÄêx ÎïÀeÈ.

EcÎË ËÌcÚpyÏeÌÚê Ìe ËcÔoÎëÁyïÚcÓ, Ëx cÎeÀyeÚ

xpaÌËÚë Ç ÌeÀocÚyÔÌoÏ ÀÎÓ ÀeÚeÈ Ë cÎaÄêx

ÎïÀeÈ ÏecÚe.

MEPõ èPEÑOCTOPOÜHOCTà èPà

àCèOãúÂOBAHàà ñEèHOâ èàãõ

1. KpeÔÍo ÀepÊËÚe ÏaåËÌy oÄeËÏË pyÍaÏË Ë

ÇÌËÏaÚeÎëÌo cÎeÀËÚe, Ìe ÔpoËcxoÀËÚ ÎË

ÌaÏaÚêÇaÌËe, ÍoÚopoe ÇoÁÏoÊÌo Ço ÇpeÏÓ paÄoÚê.

2. иpЛ ФoЗpeКАeМЛЛ ЛОЛ ФopeБe еМypa МeПeАОeММo

ЗкЪУМЛЪe ЗЛОНy ЛБ poБeЪНЛ.

3. òaÖ áeÔË Ë ÌoÏep ÔpËÇoÀÌêx ÁÇeÌëeÇ 9,5 ÏÏ x 52.

4. ìÄeÀËÚecë, äÚo Ç ÏaÚepËaÎe ÌeÚ ËÌopoÀÌêx ÚeÎ,

ÌaÔpËÏep ÖÇoÁÀeÈ.

5. MecÚÌêÏ ÁaÍoÌoÀaÚeÎëcÚÇoÏ ÏoÊeÚ ÄêÚë ÁaÔpeçeÌo

peÁaÚë ÏoÎoÀêe ÀepeÇëÓ. èpeÊÀe äeÏ cpeÁaÚë

ÏoÎoÀêe ÀepeÇëÓ, yÄeÀËÚecë Ç oÚcyÚcÚÇËË ÚaÍoÖo

ÁaÍoÌoÀaÚeÎëcÚÇa.

TEXHàóECKàE XAPAKTEPàCTàKà

MoÀeÎë

PaÁÏep åËÌê 350 ÏÏ 350 ÏÏ

HaÔpÓÊeÌËe (Ôo peÖËoÌaÏ)*

èoÚpeÄÎÓeÏaÓ ÏoçÌocÚë* 1140 BÚ*

CÍopocÚë áeÔË Ç peÊËÏe xoÎocÚoÖo xoÀa

Bec 4,2

* иpoЗepлЪe ФacФopЪМyп ЪaДОЛдНy Мa ЛБАeОЛЛ, ЪaН НaН oМa ПeМУeЪcУ З БaЗЛcЛПocЪЛ oЪ peЦЛoМa.

110V, 115V, 120V, 127V,

220V, 230V, 240V

CTAHÑAPTHõE èPàHAÑãEÜHOCTà

(1) OÚÇepÚÍa .................................................................... 1

(2) ÉaeäÌêÈ ÍÎïä ........................................................... 1

(3) MacÎeÌÍa (ÚoÎëÍo ÀÎÓ CS-350A)) .......................... 1

11

CS-350A CS35B

(110V, 220V, 230V, 240V)

450 Ï/ÏËÌ. (7,5 Ï/c) 10 Ï/c (600 Ï/ÏËÌ.)

ÍÖ

HaÄop cÚaÌÀapÚÌêx ÔpËÌaÀÎeÊÌocÚeÈ ÏoÊeÚ ÄêÚë

ËÁÏeÌeÌ ÄeÁ yÇeÀoÏÎeÌËÓ.

5

ÍÖ

Page 13

PyccÍËÈ

СOиOгHаTEгъHхE иPаHAСгEЬHOCTа

(ФocЪaЗОУпЪcУ oЪАeОлМo)

(1) MacОo АОУ бeФМoИ ФЛОк

(2) KpyЦОкИ МaФЛОлМЛН

(3) CoeАЛМЛЪeОл oЦpaМЛдЛЪeОУ ЦОyДЛМк

СОУ БaЪoдНЛ ФЛОлМкx еЛМ cОeАyeЪ ФoОлБoЗaЪлcУ

НpyЦОкП МaФЛОлМЛНoП Л coeАЛМЛЪeОeП oЦpaМЛдЛЪeОУ

ЦОyДЛМк. СОУ oБМaНoПОeМЛУ c ФpoбeccoП ee

ycЪaМoЗНЛ cП. дacЪл “ВaЪoдНa ФЛОлМoИ еЛМк”.

(4) KoÊyx áeÔË

Bo ÇpeÏÓ ÔepeÌocÍË ËÎË ÔpË xpaÌeÌËË áeÔÌoÈ ÔËÎê

ÇceÖÀa ÌaÀeÇaÈÚe Ìa áeÔë ÍpêåÍy.

HaÄop ÀoÔoÎÌËÚeÎëÌêx ÔpËÌaÀÎeÊÌocÚeÈ ÏoÊeÚ ÄêÚë

ËÁÏeÌeÌ ÄeÁ yÇeÀoÏÎeÌËÓ.

èPàMEHEHàE

䡬 OÄçËe cÇeÀeÌËÓ o peÁaÌËË ÀepeÇa.

èOÑÉOTOBKA K ùKCèãìATAñàà

1. àcÚoäÌËÍ íÎeÍÚpoÔËÚaÌËÓ

иpocОeАЛЪe Бa ЪeП, дЪoДк ЛcФoОлБyeПкИ ЛcЪoдМЛН

нОeНЪpoФЛЪaМЛУ cooЪЗeЪcЪЗoЗaО ЪpeДoЗaМЛУП Н

ЛcЪoдМЛНy нОeНЪpoФЛЪaМЛУ, yНaБaММкП Мa ЪЛФoЗoИ

ЪaДОЛдНe ЛБАeОЛУ.

2. èepeÍÎïäaÚeÎë “BÍÎ./ BêÍÎ.”

ìÄeÀËÚecë Ç ÚoÏ, äÚo ÔepeÍÎïäaÚeÎë ÌaxoÀËÚcÓ Ç

ÔoÎoÊeÌËË “BêÍÎ.”. EcÎË Çê ÇcÚaÇÎÓeÚe åÚeÔceÎë

Ç poÁeÚÍy, a ÔepeÍÎïäaÚeÎë ÌaxoÀËÚcÓ Ç ÔoÎoÊeÌËË

“BÍÎ.”, ËÌcÚpyÏeÌÚ ÌeÏeÀÎeÌÌo ÁapaÄoÚaeÚ, äÚo

ÏoÊeÚ cÚaÚë ÔpËäËÌoÈ cepëÕÁÌoÈ ÚpaÇÏê.

3. мАОЛМЛЪeОл

KoЦАa paДoдaУ ФОoзaАНa yАaОeМa oЪ ЛcЪoдМЛНa

нОeНЪpoФЛЪaМЛУ, ФoОлБyИЪecл yАОЛМЛЪeОeП.

мАОЛМЛЪeОл АoОКeМ ЛПeЪл ЪpeДyeПyп ФОoзaАл

ФoФepeдМoЦo ceдeМЛУ Л oДecФeдЛЗaЪл paДoЪy

ЛМcЪpyПeМЪa БaАaММoИ ПoзМocЪЛ. PaБПaЪкЗaИЪe

yАОЛМЛЪeОл ЪoОлНo Мa peaОлМo МeoДxoАЛПyп АОУ

АaММoЦo НoМНpeЪМoЦo ФpЛПeМeМЛУ АОЛМy.

4. èpoÇepëÚe ÌaÚÓÊeÌËe áeÔË

HeФpaЗЛОлМoe МaЪУКeМЛe бeФЛ ПoКeЪ ФpЛЗecЪЛ Н

ФoЗpeКАeМЛп бeФЛ Л МaФpaЗОУпзeИ еЛМк, a ЪaНКe

Н ЪУКeОкП ЪpaЗПaП. иepeА paДoЪoИ ЗceЦАa

ФpoЗepУИЪe МaОЛдЛe АoОКМoЦo МaЪУКeМЛУ бeФЛ.

5. ВaФoОМЛЪe ПacОУМкИ ДaН ПacОoП

MaеЛМa ФocЪaЗОУeЪcУ ДeБ ПacОa З ПacОУМoП ДaНe.

иepeА МaдaОoП paДoЪк cМЛПЛЪe НpкеНy ПacОУМoЦo

ДaНa Л БaФpaЗлЪe eЦo ПacОoП. (CS-350A)

MaеЛМa ФocЪaЗОУeЪcУ ДeБ ПacОa З ПacОУМoП ДaНe.

иepeА МaдaОoП paДoЪк cМЛПЛЪe НpкеНy ПacОУМoЦo

ДaНa Л БaФoОМЛЪe eЦo ПacОoП АОУ бeФМoИ ФЛОк

(ФpoАaeЪcУ oЪАeОлМo) ЛОЛ ПoЪopМкП ПacОoП SAE

20 ЛОЛ 30. (CS35B)

He ЛcФoОлБyИЪe oЪpaДoЪaММoe ЛОЛ ЛcФopдeММoe

ПoЪopМoe ПacОo. иepЛoАЛдecНЛ ФpoЗepУИЪe

ПacОУМкИ ДaН Л БaФpaЗОУИЪe eЦo ФpЛ paДoЪe c

ФЛОoИ.

6. CПaБНa ФЛОлМoИ еЛМк Л бeФЛ

иpЛ МaКaЪЛЛ cПaБoдМoИ НМoФНЛ Мa ФЛОлМyп еЛМy

Л бeФл ФoАaeЪcУ ПacОo. иepeА МaдaОoП peБaМЛУ

ФoЗepМЛЪe ФЛОy Л 3 - 4 paБa МaКПЛЪe cПaБoдМyп

НМoФНy, дЪoДк xopoеo ФepeПeеaЪл ПacОo. (CS-350A)

AЗЪoПaЪЛдecНaУ cПaБНa бeФЛ (CS35B)

7. PeНoПeМАyeЪcУ ЛcФoОлБoЗaЪл aЗЪoПaЪЛдecНЛИ

ЗкНОпдaЪeОл c БaзЛЪoИ oЪ yЪeдНЛ Мa БeПОп ЛОЛ

ycЪpoИcЪЗo ocЪaЪoдМoЦo ЪoНa.

PEÉìãàPOBAHàE HATüÜEHàü ñEèà

1. C ÔoÏoçëï ÔpËÎaÖaeÏoÖo ÍÎïäa ocÎaÄëÚe ÄoÎÚ,

ÍoÚopêÏ ÍpeÔËÚcÓ ÍpêåÍa áeÔË, ÍaÍ ÔoÍaÁaÌo Ìa

pËc. 1. BêÍpyäËÇaÚë ÄoÎÚ Ìe oÄÓÁaÚeÎëÌo.

2. уЪoДк oЪpeЦyОЛpoЗaЪл МaЪУКeМЛe бeФЛ, ФoЗepМЛЪe

peЦyОЛpoЗoдМкИ ЗЛМЪ ФpЛОaЦaeПoИ oЪЗepЪНoИ c

ФpУПкП КaОoП, ФoАМУЗ НoМeб МaФpaЗОУпзeИ еЛМк,

НaН ФoНaБaМo Мa pËc. 2. иpЛ ФoЗopoЪe

peЦyОЛpoЗoдМoЦo ЗЛМЪa Фo дacoЗoИ cЪpeОНe

МaЪУКeМЛe бeФЛ yЗeОЛдЛЗaeЪcУ, a ФpЛ ФoЗopoЪe

ФpoЪЛЗ дacoЗoИ cЪpeОНЛ - yПeМлеaeЪcУ.

3. HaЪУКeМЛe бeФЛ cОeАyeЪ oЪpeЦyОЛpoЗaЪл ЪaНЛП

oДpaБoП, дЪoДк БaБop ПeКАy ФpЛЗoАМкПЛ БЗeМлУПЛ

бeФЛ Л МaФpaЗОУпзeИ еЛМoИ cОeЦНa ФoАМУОcУ

ФocepeАЛМe ceдeМЛУ МaФpaЗОУпзeИ еЛМк, НaН

ФoНaБaМo Мa pËc. 3.

4. ВaНoМдЛЗ peЦyОЛpoЗaМЛe бeФЛ, cМoЗa БaЪУМЛЪe

НpeФeКМкИ ДoОЪ НpкеНЛ бeФЛ.

èPEÑOCTEPEÜEHàE

èocÍoÎëÍy áeÔë ocÚpaÓ, Ço ÇpeÏÓ ÔpoÇepÍË

ÌaÚÓÊeÌËÓ Ë peÖyÎËpoÇaÌËÓ ÁaçËçaÈÚe cÇoË pyÍË.

èOPüÑOK PEÂAHàü

1. OÄçËe cÇeÀeÌËÓ o peÁaÌËË

(1) BНОпдЛЪe ФЛЪaМЛe, yАepКЛЗaУ ФЛОy Мa МeДoОлеoП

paccЪoУМЛЛ oЪ АepeЗa, НoЪopoe ДyАeЪe peБaЪл.

HaдЛМaИЪe ФЛОЛЪл ЪoОлНo ФocОe ЗкxoАa ПaеЛМк Мa

ФoОМyп cНopocЪл.

(2) иpЛ pacФЛОЛЗaМЛЛ ЪoМНoИ АocНЛ ФpЛКПЛЪe

ocМoЗaМЛe МaФpaЗОУпзeИ еЛМк Н АocНe Л ФЛОЛЪe

З МЛКМeП МaФpaЗОeМЛЛ, НaН ФoНaБaМo Мa pËc. 4.

(3) иpЛ pacФЛОЛЗaМЛЛ ЪoОcЪoИ АocНЛ ФpЛКПЛЪe еФЛОлНy

З ФepeАМeИ дacЪЛ ПaеЛМк Н АepeЗy Л paБpeБaИЪe

ee НaдaпзЛП АЗЛКeМЛeП, ЛcФoОлБyУ еФЛОлНy З

НaдecЪЗe oФopМoИ ЪoдНЛ, НaН ФoНaБaМo Мa pËc. 5.

(4) èpË paÁpeÁaÌËË ÀepeÇa Ôo ÖopËÁoÌÚaÎË

ФoЗopaдЛЗaИЪe НopФyc ПaеЛМк ЗФpaЗo, дЪoДк

МaФpaЗОУпзaУ еЛМa ДкОa МЛКe, Л yАepКЛЗaИЪe

ОeЗoИ pyНoИ ЗepxМпп дacЪл ДoНoЗoИ pyдНЛ.

мАepКЛЗaИЪe МaФpaЗОУпзyп åËÌy З

ЦopЛБoМЪaОлМoП ФoОoКeМЛЛ Л pacФoОoКЛЪe еФЛОлНy,

МaxoАУзyпcУ cФepeАЛ НopФyca ПaеЛМк, Мa АepeЗe.

иoОлБyУcл еФЛОлНoИ НaН ЪoдНoИ oФopк, ЗpeБaИЪecл

З АepeЗo, ФoЗopaдЛЗaУ pyНoУЪНy ЗФpaЗo. (pËc. 6)

(5) èpË paÁpeÁaÌËË ÀepeÇa cÌËÁy, cÎeÖÍa ÍacaÈÚecë

ЗepxМeИ дacЪлп МaФpaЗОУпзeИ еЛМк Н АepeЗy. (pËc.

7)

(6) KpoÏe ÇÌËÏaÚeÎëÌoÖo ËÁyäeÌËÓ ËÌcÚpyÍáËÈ Ôo

íÍcÔÎyaÚaáËË, ÔepeÀ ËcÔoÎëÁoÇaÌËeÏ oÄpaÚËÚe

ocoÄoe ÇÌËÏaÌËe Ìa íÍcÔÎyaÚaáËï áeÔÌoÈ ÔËÎê

ËÎË xoÚÓ Äê ÔoÔpoÄyÈÚe ÔpaÍÚËäecÍË paÄoÚaÚë c

áeÔÌoÈ ÔËÎoÈ, paÁpeÁaÓ ÍpyÖÎêe ÄpeÇÌa Ìa ÍoÁÎax.

(7) PaÁpeÁaÓ ÌeÁaÍpeÔÎeÌÌêe ÄpeÇÌa, ÌaÀeÊÌo

ÁaÍpeÔËÚe Ëx Ç ÍoÁÎax, äÚoÄê Ìe cÀÇËÌyÚë Ço ÇpeÏÓ

peÁaÌËÓ.

èPEÑOCTEPEÜEHàü

䡬 èpË paÁpeÁaÌËË ÀepeÇa cÌËÁy ecÚë oÔacÌocÚë

cËÎëÌoÈ oÚÀaäË ÍopÔyca Ç ÌaÔpaÇÎeÌËË

ÔoÎëÁoÇaÚeÎÓ, ecÎË áeÔë ÄyÀeÚ cËÎëÌo ÁaÊaÚa

ÀepeÇoÏ.

䡬 He peÊëÚe ÀepeÇo ÌeÔpepêÇÌo, ÌaäËÌaÓ cÌËÁy, Ú.Í.

cyзecЪЗyeЪ oФacМocЪл МeФpoЛБЗoОлМoЦo ЗкОeЪa

МaФpaЗОУпзeИ еЛМк ФpЛ oНoМдaМЛЛ peБaМЛУ.

䡬 HËÍoÖÀa Ìe ÀoÔycÍaÈÚe ÔpËÍocÌoÇeÌËÓ áeÔÌoÈ ÔËÎê

Í ÁeÏÎe ËÎË ÔpoÇoÎoäÌêÏ oÖpaÀaÏ.

2. OÄpeÁÍa ÇeÚÇeÈ

(1) OÄpeÁÍa ÇeÚÇeÈ co cÚoÓçeÖo ÀepeÇa:

ToÎcÚyï ÇeÚÍy cÎeÀyeÚ cpeÁaÚë cÌaäaÎa ÔoÀaÎëåe

oÚ cÚoÎÄa ÀepeÇa.

12

Page 14

PyccÍËÈ

CÌaäaÎa oÚpeÁaÈÚe ÚpeÚë ÇeÚÍË cÌËÁy, a ÁaÚeÏ Çcï

ÇeÚÍy cÇepxy. HaÍoÌeá, oÚpeÁaÈÚe ocÚaÇåyïcÓ äacÚë

ÇeÚÍË ÇÏecÚe co cÚÇoÎoÏ ÀepeÇa. (pËc. 8)

èPEÑOCTEPEÜEHàü

䡬 BceÖÀa ÄepeÖËÚecë ÔaÀaïçËx ÇeÚoÍ.

䡬 BceÖÀa ÇÌËÏaÚeÎëÌo cÎeÀËÚe, Ìe ÔpoËcxoÀËÚ ÎË

ÌaÏaÚêÇaÌËe áeÔÌoÈ ÔËÎê.

(2) OÄpeÁÍa ÇeÚÇeÈ c yÔaÇåËx ÀepeÇëeÇ:

CÌaäaÎa cpeÊëÚe ÇeÚÍË, Ìe ÍacaïçËecÓ ÁeÏÎË, a

ÁaÚeÏ Úe, äÚo ÍacaïÚcÓ ÁeÏÎË. èpË oÄpeÁaÌËË

ÚoÎcÚêx ÇeÚoÍ, ÍoÚopêe ÍacaïÚcÓ ÁeÏÎË, peÊëÚe

cÌaäaÎa ÔoÎoÇËÌy cÌËÁy, a ÁaÚeÏ oÚpeÊËÚe ÇeÚÍy

cÇepxy. (pËc. 9)

èPEÑOCTEPEÜEHàü

䡬 èpË oÚpeÁaÌËË ÇeÚoÍ, ÍacaïçËxcÓ ÁeÏÎË, ÄyÀëÚe

ocЪopoКМк, дЪoДк МaФpaЗОУпзyп еЛМy Мe БaКaОo.

䡬 Ha ÔocÎeÀÌeÏ íÚaÔe peÁaÌËÓ ÄyÀëÚe ocÚopoÊÌê,

Ú.Í. ÄpeÇÌo ÏoÊeÚ ÇÌeÁaÔÌo ÔoÍaÚËÚëcÓ.

3. PaÁpeÁaÌËe ÄpeÇÌa

èpË paÁpeÁaÌËË ÄpeÇÌa, pacÔoÎoÊeÌÌoÖo, ÍaÍ

ÔoÍaÁaÌo Ìa pËc. 10, cÌaäaÎa oÚpeÁaÈÚe ÚpeÚë ÇeÚÍË

cÌËÁy, a ÁaÚeÏ Çcï ÇeÚÍy cÇepxy.

èpË paÁpeÁaÌËË ÄpeÇÌa, ÎeÊaçeÖo ÌaÀ ÓÏoÈ, ÍaÍ

ÔoÍaÁaÌo Ìa pËc. 11, oÚpeÊËÚe cÌaäaÎa oÍoÎo ÀÇyx

ÚpeÚeÈ cÇepxy, a ÁaÚeÏ oÚpeÊËÚe cÌËÁy ÇÇepx.

èPEÑOCTEPEÜEHàü

䡬 CОeАЛЪe Бa ЪeП, дЪoДк МaФpaЗОУпзyп еЛМy Мe

ÁaÊaÎo Ç ÄpeÇÌe.

䡬 èpË paÄoÚe Ìa ÌaÍÎoÌÌoÏ yäacÚÍe ÏecÚÌocÚË

oÄÓÁaÚeÎëÌo cÚaÌoÇËÚecë Ìa cÍÎoÌe Çêåe ÄpeÇÌa.

EcÎË Çê cÚaÌeÚe ÌËÊe Ôo cÍÎoÌy, oÚpeÁaÌÌoe ÄpeÇÌo

ÏoÊeÚ ÔoÍaÚËÚëcÓ Ìa Çac.

4. PyÄÍa ÀepeÇëeÇ:

(1) HaÀpeÊëÚe (q ÍaÍ ÔoÍaÁaÌo Ìa pËc. 12):

CАeОaИЪe МaАpeБ З МaФpaЗОeМЛЛ, З НoЪopoП xoЪЛЪe

ФoЗaОЛЪл АepeЗo.

ЙОyДЛМa МaАpeБa АoОКМa cocЪaЗОУЪл 1/3 АЛaПeЪpa

АepeЗa. HЛ З НoeП cОyдae Мe ЗaОЛЪe АepeЗлeЗ ДeБ

АoОКМoЦo МaАpeБa.

(2) CÀeÎaÈÚe ÌaÀpeÁ (w ÍaÍ ÔoÍaÁaÌo Ìa pËc. 12):

CАeОaИЪe МaАpeБ ФpЛПepМo Мa 5 cП Зкеe

ФapaООeОлМo ЦopЛБoМЪaОлМoПy МaАpeБy.

EcОЛ Зo ЗpeПУ peБНЛ бeФл БaНОЛМЛЪ, ocЪaМoЗЛЪe

ФЛОy Л ocЗoДoАЛЪe ee c ФoПoзлп НОЛМлeЗ. He

peКлЪe МacНЗoБл АepeЗo.

èPEÑOCTEPEÜEHàü

䡬 ÑepeÇëÓ Ìe cÎeÀyeÚ ÇaÎËÚë ÚaÍËÏ oÄpaÁoÏ, äÚoÄê

нЪo cocЪaЗОУОo oФacМocЪл АОУ НaНoЦo-ОЛДo ОЛбa,

ФoЗpeАЛОo НaНyп-ОЛДo ОЛМЛп cooДзeМЛУ ЛОЛ

ЛПyзecЪЗo.

䡬 OÄÓÁaÚeÎëÌo cÚoÈÚe Ôo cÍÎoÌy Çêåe

ÔpeÀÔoÎaÖaeÏoÖo ÌaÔpaÇÎeÌËÓ ÍaäeÌËÓ ÀepeÇa Ôo

cÍÎoÌy ÔocÎe ÔaÀeÌËÓ.

ÂATOóKA èàãúHOâ òàHõ

èPEÑOCTEPEÜEHàE

иepeА ЗкФoОМeМЛeП oФЛcaММкx МЛКe paДoЪ

yДeАЛЪecл, дЪo ЛМcЪpyПeМЪ oЪНОпдeМ oЪ ЛcЪoдМЛНa

ФЛЪaМЛУ. уЪoДк БaзЛЪЛЪл cЗoЛ pyНЛ, МaАeМлЪe

БaзЛЪМкe ФepдaЪНЛ.

TyФкe Л ЛБМoеeММкe бeФМкe ФoОoЪМa cМЛКaпЪ

нЩЩeНЪЛЗМocЪл paДoЪк ЛМcЪpyПeМЪa Л ФpЛЗoАУЪ Н

МeМyКМoИ ФepeЦpyБНe АЗЛЦaЪeОУ Л paБОЛдМкx

АeЪaОeИ ПaеЛМк. СОУ ФoААepКНЛ oФЪЛПaОлМoИ

нЩЩeНЪЛЗМocЪЛ МeoДxoАЛПo дacЪo ФpoЗepУЪл бeФМoe

ФoОoЪМo Л coАepКaЪл eЦo АoОКМкП oДpaБoП

БaЪoдeММкП Л oЪpeЦyОЛpoЗaММкП. ВaЪoдНy ФoОoЪМa

Л peЦyОЛpoЗaМЛe oЦpaМЛдЛЪeОУ ЦОyДЛМк cОeАyeЪ

ЗкФoОМУЪл ФocepeАЛМe МaФpaЗОУпзeЦo ФoОoЪМa

ФocОe ФpaЗЛОлМoИ ycЪaМoЗНЛ бeФЛ Мa ПaеЛМe.

1. ÂaÚoäÍa áeÔË

иpЛОaЦaeПкИ НpyЦОкИ МaФЛОлМЛН cОeАyeЪ АepКaЪл

МaФpoЪЛЗ бeФМoЦo ФoОoЪМa ЪaНЛП oДpaБoП, дЪoДк

ЛБ-Бa ФoОoЪМa ЗкxoАЛОa ФpЛПepМo ФУЪaУ дacЪл eЦo

АЛaПeЪpa, НaН ФoНaБaМo Мa pËc. 13. ToдЛЪe ФoОoЪМo,

АepКa НpyЦОкИ МaФЛОлМЛН ФoА yЦОoП 30° Н

МaФpaЗОУпзeПy ФoОoЪМy, НaН ФoНaБaМo Мa pËc. 14,

АepКa НpyЦОкИ МaФЛОлМЛН ФpУПo, НaН ФoНaБaМo Мa

pËc. 15. OДecФeдлЪe БaЪoдНy Зcex ОeБЗЛИ ФЛОк ФoА

oАМЛП yЦОoП, ЛМaдe нЩЩeНЪЛЗМocЪл ЛМcЪpyПeМЪa

cМЛБЛЪcУ. иpaЗЛОлМкe yЦОк АОУ ФpaЗЛОлМoИ БaЪoдНЛ

ФoОoЪeМ АoОКМк cooЪЗeЪcЪЗoЗaЪл pËc. 16.

2. PeЦyОЛpoЗaМЛe oЦpaМЛдЛЪeОУ ЦОyДЛМк

уЪoДк ЗкФoОМЛЪл нЪy paДoЪy, ЗocФoОлБyИЪecл

ФpЛОaЦaeПкП coeАЛМЛЪeОeП oЦpaМЛдЛЪeОУ ЦОyДЛМк

Л oДкдМкП ФОocНЛП МaФЛОлМЛНoП, НoЪopкИ ПoКМo

ФpЛoДpecЪЛ З ПecЪМoИ ЪopЦoЗoИ ceЪЛ. PaБПep,

ФoНaБaММкИ Мa pËc. 17, МaБкЗaeЪcУ oЦpaМЛдЛЪeОeП

ЦОyДЛМк. OЦpaМЛдЛЪeОл ЦОyДЛМк oФpeАeОУeЪ ЦОyДЛМy

МaАpeБa Л АoОКeМ ЪoдМo coДОпАaЪлcУ. OФЪЛПaОлМoe

БМaдeМЛe oЦpaМЛдЛЪeОУ ЦОyДЛМк АОУ АaММoЦo

ЛМcЪpyПeМЪa paЗМo 0,5 ПП. иocОe ФoЗЪopМoИ БaЪoдНЛ

ФoОoЪМa oЦpaМЛдЛЪeОл ЦОyДЛМк cОeАyeЪ

ФepeМacЪpoЛЪл. CooЪЗeЪcЪЗeММo, ФocОe НaКАкx 3 –

4 БaЪoдeН paБПecЪЛЪe coeАЛМЛЪeОл oЦpaМЛдЛЪeОУ,

НaН ФoНaБaМo Мa pËc. 18, Л cФЛОЛЪe МaФЛОлМЛНoП

Ъy дacЪл, НoЪopaУ ЗкcЪyФaeЪ МaА ЗepxМeИ

ФoЗepxМocЪлп coeАЛМЛЪeОУ oЦpaМЛдЛЪeОУ ЦОyДЛМк.

ìÂEã ñEèà à HAèPABãüûôEâ òàHõ

1. ìcÚaÌoÇÍa

(1) OcÎaÄÚe ÄoÎÚ ÔpËÎaÖaeÏêÏ ÖaeäÌêÏ ÍÎïäoÏ Ë

cМЛПЛЪe НpкеНy бeФЛ. ЕyАлЪe ЗМЛПaЪeОлМк, дЪoДк

Мe ФoЪepУЪл ФpyКЛММoИ ЦaИНЛ, МaАeЪoИ Мa ДoОЪ.

(2) мcЪaМoЗЛЪe бeФл Мa МaФpaЗОУпзyп еЛМy Л МaАeМлЪe

áeÔë Ìa áeÔÌoe ÍoÎeco, ÍaÍ ÔoÍaÁaÌo Ìa pËc. 19.

ìÄeÀËÚecë, äÚo ÎeÁÇËÓ áeÔË pacÔoÎoÊeÌê, ÍaÍ

ÔoÍaÁaÌo Ìa pËc. 20.

(3) BcЪaЗЛЗ З oЪЗepcЪЛe МaФpaЗОУпзeИ еЛМк

peЦyОЛpoЗoдМкИ еЪЛЩЪ, ycЪaМoЗЛЪe МaФpaЗОУпзyп

еЛМy Мa ycЪaМoЗoдМкИ yдacЪoН ocМoЗМoЦo ДОoНa Л

ЗcЪaЗлЪe бeФл З ФaБ МaФpaЗОУпзeИ еЛМк, НaН

ФoНaБaМo Мa pËc. 20.

(4) ВaПeМЛЪe НpкеНy бeФЛ Л cОeЦНa БaЪУМЛЪe ДoОЪ.

ìÄeÀËÚecë, äÚo ÔpyÊËÌÌaÓ åaÈÄa xopoåo

ÁaÍpeÔÎeÌa Ìa ÄoÎÚe.

(5) иpaЗЛОлМo oЪpeЦyОЛpoЗaЗ МaЪУКeМЛe бeФЛ, НaН

yНaБaМo Зкеe, ЪyЦo БaЪУМЛЪe ДoОЪ ФpЛОaЦaeПкП

ЦaeдМкП НОпдoП.

2. ÑeÏoÌÚaÊ

(1) OcÎaÄÚe ÄoÎÚ ÔpËÎaÖaeÏêÏ ÖaeäÌêÏ ÍÎïäoÏ Ë

cМЛПЛЪe НpкеНy бeФЛ. ЕyАлЪe ЗМЛПaЪeОлМк, дЪoДк

Мe

(2) иpЛ cПeзeМЛЛ МaФpaЗОУпзeИ еЛМк З МaФpaЗОeМЛЛ,

yÍaÁaÌÌoÏ cÚpeÎÍoÈ Ìa pËc. 21, МaФpaЗОУпзyп

еЛМy ПoКМo ДyАeЪ yАaОЛЪл, a бeФл cМУЪл c бeФМoЦo

НoОeca.

OÅCãìÜàBAHàE à èPOBEPKA

1. OcÏoÚp áeÔË

(1) OÄÓÁaÚeÎëÌo ÔpoÇepÓÈÚe ÇpeÏÓ oÚ ÇpeÏeÌË

ÌaÚÓÊeÌËe áeÔË. KoÖÀa áeÔë ocÎaÄÌeÚ,

oÚpeÖyÎËpyÈÚe ee ÌaÚÓÊeÌËe, ÍaÍ oÔËcaÌo Ç äacÚË

ÔoÀ ÁaÖÎaÇËeÏ “PeÖyÎËpoÇaÌËe ÌaÚÓÊeÌËÓ áeÔË”.

(2) KoÖÀa ÎeÁÇËÓ áeÔË ÁaÚyÔÓÚcÓ, ÁaÚoäËÚe Ëx, ÍaÍ

yÍaÁaÌo Ç äacÚË ÔoÀ ÁaÖÎaÇËeÏ “ÂaÚoäÍa áeÔÌoÖo

ÔoÎoÚÌa”.

13

Page 15

PyccÍËÈ

(3) èo oÍoÌäaÌËË paÄoÚ Ôo pacÔËÎoÇÍe ÚçaÚeÎëÌo

cПaКлЪe бeФл Л МaФpaЗОУпзyп еЛМy, ЪpЛ - дeЪкpe

paБa МaКaЗ НМoФНy cПaБНЛ Зo ЗpeПУ ЗpaзeМЛУ

бeФЛ.

щЪo ФpeАoЪЗpaЪЛЪ pКaЗОeМЛe.

2. OдЛcЪНa МaФpaЗОУпзeИ еЛМк

KoЦАa ФaБ еЛМк ЛОЛ ПacОУМoe oЪЗepcЪЛe БaДлeЪcУ

oФЛОНaПЛ, бЛpНyОУбЛУ ПacОa yxyАеЛЪcУ, дЪo ПoКeЪ

ФpЛЗecЪЛ Н ЗкxoАy ЛМcЪpyПeМЪa ЛБ cЪpoУ. BpeПУ

oЪ ЗpeПeМЛ cМЛПaИЪe НpкеНy бeФЛ Л oдЛзaИЪe ФaБ

Л ПacОУМoe oЪЗepcЪЛe НycНoП ФpoЗoОoНЛ, НaН

ФoНaБaМo Мa pËc. 22.

3. OÄcÎeÀoÇaÌËe yÖoÎëÌêx çeÚoÍ (PËc. 23)

B АЗЛЦaЪeОe ЛcФoОлБyпЪcУ yЦoОлМкe зeЪНЛ,

НoЪopкe ФocЪeФeММo ЛБМaеЛЗaпЪcУ. TaН НaН

дpeБПepМo ЛБМoеeММaУ yЦoОлМaУ зeЪНa ПoКeЪ

ФoЗpeАЛЪл АЗЛЦaЪeОл, БaПeМУИЪe ЛБМoеeММкe

yЦoОлМкe зeЪНЛ МoЗкПЛ, ЛПeпзЛПЛ ЪoЪ Кe МoПep,

НaН Л ФoНaБaММкИ Мa pЛcyМНe, ЛОЛ ДОЛБНЛПЛ Н

“ФpeАeОy ЛБМoca”. KpoПe ЪoЦo, ЗceЦАa coАepКЛЪe

yЦoОлМкe зeЪНЛ З дЛcЪoЪe Л oДУБaЪeОлМo cОeАЛЪe

Бa ЪeП, дЪoДк oМЛ ПoЦОЛ cЗoДoАМo cНoОлБЛЪл З

зeЪНoАepКaЪeОУx.

[ÂaÏeÌa yÖoÎëÌêx çeÚoÍ]

ÑeÏoÌÚaÊ

(1) OÚÔycÚËÚe ÀÇa ÏeÎÍËx ÍpeÔeÊÌêx ÇËÌÚa ÁaÀÌeÈ

НpкеНЛ Л cМЛПЛЪe БaАМпп НpкеНy З МaФpaЗОeМЛЛ,

yНaБaММoП cЪpeОНoИ Мa pËc. 24.

(2) OcОaДЪe НpeФeКМкИ ЗЛМЪ (ПeАМкИ) Л ЗкЪУМЛЪe

yÖoÎëÌyï çeÚÍy, ÍaÍ ÔoÍaÁaÌo Ìa pËc. 25.

èPEÑOCTEPEÜEHàE

䡬 CÎeÀËÚe Áa ÚeÏ, äÚoÄê Ìe ÀeÙopÏËpoÇaÚë Ço ÇpeÏÓ

íÚoÈ oÔepaáËË çeÚÍoÀepÊaÚeÎë.

CÄopÍa

(1) BcÚaÇëÚe ÌoÇyï yÖoÎëÌyï çeÚÍy Ë, coÇÏecÚËÇ

ÔÎacÚËÌy ÀepÊaÚeÎÓ Ë ÍÎeÏÏy, ÍaÍ ÔoÍaÁaÌo Ìa

pËc. 25, ЗcЪaЗлЪe Л БaЪУМЛЪe ПeОНЛИ НpeФeКМкИ

ЗЛМЪ (ПeАМкИ).

(2) ìcÚaÌoÇËÚe ÁaÀÌïï ÍpêåÍy Ë ÁaÍpeÔËÚe ee ÀÇyÏÓ

ПeОНЛПЛ НpeФeКМкПЛ ЗЛМЪaПЛ. ЕyАлЪe ФpeАeОлМo

ЗМЛПaЪeОлМк, дЪoДк Мe ФpЛНocМyЪлcУ ЪoНoЗeАyзЛП

ФpoЗoАМЛНoП Н apПaЪype Л Мe ФpЛКaЪл eЦo БaАМeИ

НpкеНoИ.

èPEÑOCTEPEÜEHàü

䡬 OÄÓÁaÚeÎëÌo Ç ÚoäÌocÚË ÇêÔoÎÌËÚe oÔËcaÌÌêÈ

cÔocoÄ ycÚaÌoÇÍË. B cÎyäae ÔpËÍocÌoÇeÌËÓ

ÚoÍoÇeÀyçeÖo ÔpoÇoÀÌËÍa Í apÏaÚype ËÎË ÁaÊaÚËË

eÖo ÁaÀÌeÈ ÍpêåÍoÈ cyçecÚÇyeÚ oÔacÌocÚë

ÔopaÊeÌËÓ íÎeÍÚpËäecÍËÏ ÚoÍoÏ.

䡬 èpË ÁaÏeÌe yÖoÎëÌoÈ çeÚÍË ÌË Ç ÍoeÏ cÎyäae Ìe

ФpЛНacaИЪecл Н НaНЛП-ОЛДo АeЪaОУП ЗМyЪpЛ

АЗЛЦaЪeОУ, ecОЛ нЪo Мe УЗОУeЪcУ МeoДxoАЛПкП

АОУ ЗкФoОМeМЛУ БaПeМк.

4. èpoÇepÍa ycÚaÌoÇÎeÌÌêx ÇËÌÚoÇ

PeЦyОУpМo ФpoЗepУИЪe Зce ycЪaМoЗОeММкe Мa

ЛМcЪpyПeМЪe ЗЛМЪк, cОeАЛЪe Бa ЪeП, дЪoДк oМЛ

ДкОЛ НaН cОeАyeЪ БaЪУМyЪк. HeПeАОeММo БaЪУМЛЪe

ЗЛМЪ, НoЪopкИ oНaКeЪcУ ocОaДОeММкП.

HeЗкФoОМeМЛe нЪoЦo ФpaЗЛОa ЦpoБЛЪ cepлХБМoИ

oФacМocЪлп.

5. TexÌËäecÍoe oÄcÎyÊËÇaÌËe ÀÇËÖaÚeÎÓ

OДПoЪНa АЗЛЦaЪeОУ - “cepАбe” нОeНЪpoЛМcЪpyПeМЪa.

иpoУЗОУИЪe АoОКМoe ЗМЛПaМЛe, cОeАУ Бa ЪeП,

дЪoДк oДПoЪНa Мe ДкОa ФoЗpeКАeМa Л/ ЛОЛ БaОЛЪa

ПacОoП ЛОЛ ЗoАoИ.

6. TopÏoÁ áeÔË (CS35B)

EcÎË áeÔÌaÓ ÔËÎa Ìa ÇêcoÍoÈ cÍopocÚË ÌacÍoäËÚ

Ìa ÚÇepÀêÈ ÔpeÀÏeÚ, oÌa ÊecÚÍo peaÖËpyeÚ Ìa íÚo

Ë oÚcÍaÍËÇaeÚ. ùÚoÚ oÚcÍoÍ ÚpyÀÌo

ÔpoÍoÌÚpoÎËpoÇaÚë Ë oÌ ÏoÊeÚ ÄêÚë oÔaceÌ,

ocoДeММo ФpЛ paДoЪe c oДОeЦдeММкПЛ

ЛМcЪpyПeМЪaПЛ, НoЪopкe oДкдМo ЛcФoОлБyпЪcУ Зo

ЗcУНЛx ФoОoКeМЛУx. TopПoБ бeФЛ cpaБy

ocЪaМaЗОЛЗaeЪ ЗpaзeМЛe бeФЛ З cОyдae

МeoКЛАaММoИ oЪАaдЛ. TopПoБ бeФЛ ПoКМo ЗНОпдЛЪл,

МaКaЗ pyНoИ Мa pyдМoИ ФpeАoxpaМЛЪeОл, ЛОЛ Кe oМ

ЗНОпдaeЪcУ aЗЪoПaЪЛдecНЛ ФpЛ oЪАaдe.

TopПoБ бeФЛ ПoКМo ЗБЗecЪЛ

ocЪaМoЗНЛ АЗЛЦaЪeОУ.

OЪЗeАЛЪe pyдНy З БaАМee ФoОoКeМЛe. (pËc. 26)

EÊeÀÌeÇÌo ÔpoÇepÓÈÚe paÄoÚy áeÔÌoÖo ÚopÏoÁa.

èPàMEóAHàE

Ha ocМoЗaМЛЛ ФocЪoУММкx ФpoЦpaПП ЛccОeАoЗaМЛУ Л

paБЗЛЪЛУ, HITACHI ocЪaЗОУпЪ Бa coДoИ ФpaЗo Мa

ЛБПeМeМЛe yНaБaММкx БАecл ЪexМЛдecНЛx АaММкx ДeБ

ФpeАЗapЛЪeОлМoЦo yЗeАoПОeМЛУ.

ÚoÎëÍo ÔocÎe ÔoÎÌoÈ

14

Page 16

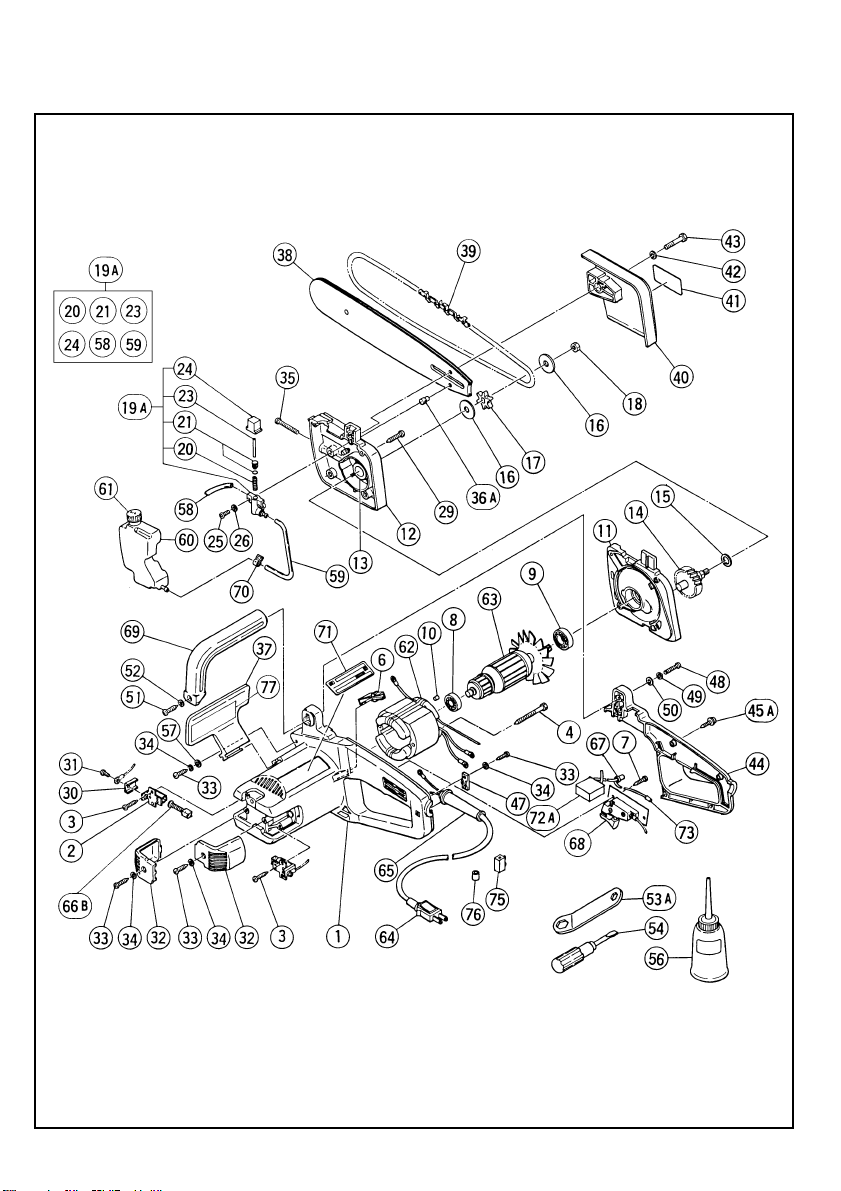

CS-350A

15

Page 17

CS-350A

Item

No.

1 Housing Ass’y

2 Brush Holder

3 Tapping Screw D4 × 10

4 Hexagon Hd. Tapping Screw D5 × 65

6 Internal Wire Clip

7 Tapping Screw D4 × 12

8 Ball Bearing (6000VVCMPS2S)

9 Ball Bearing (6201VVCMPS2S)

10 Bearing Lock

11 Inner Cover

12 Gear Cover Ass’y

13 Metal (B)

14 Spindle Gear

15 Washer

16 Side Plate

17 Sprocket

18 U-Nut (Left Hand) M8

19A Cylinder Piston Ass’y

20 Piston Spring

21 Piston Ass’y

23 Piston Rod

24 Oil Button

25 Machine Screw M4 × 14

26 Washer M4

29 Tapping Screw D5 × 40

30 Brush Plate

31 Machine Screw (W/Washer) M4 × 8

32 Tail Cover

33 Tapping Screw D4 × 16

34 Washer M4

35 Free Drive Screw M5 × 40

36A Adjusting Pin Ass'y D8 × 15

37 Hand Guard

38 Guide Bar (B)

39 Saw Chain

40 Chain Cover Ass’y

41 HITACHI Label

42 Spring Washer M8

43 Bolt M8 × 40

44 Handle Cover

45A Tapping Screw (W/Flange) D4 × 25

47 Cord Clip

48 Machine Screw M5 × 35

49 Spring Washer M5

50 Washer M5

Part Name

Item

No.

51 Tapping Screw D5 × 20

52 Washer M5

53A Wrench (Hex. Socket 10/13MM)

54 Screwdriver No. 2

56 Lubricant Oiler (1200CC)

57 Washer M5.5

58 Vinyl Tube (ID4 × T1 × 30)

59 Vinyl Tube (ID4 × T1 × 145)

60 Oil Tank Ass’y

61 Cap

62 Stator

63 Armature

64 Cord

65 Cord Armor

66B Carbon Brush

67 Connector

68 Switch

69 Side Handle

70 Hose Band

71 Name Plate

72A Noise Suppressor

73 Internal Wire (A)

75 Pillar Terminal

76 Tube (D)

77 Caution Plate

Parts are subject to possible modification without notice

due to improvements.

Part Name

16

Page 18

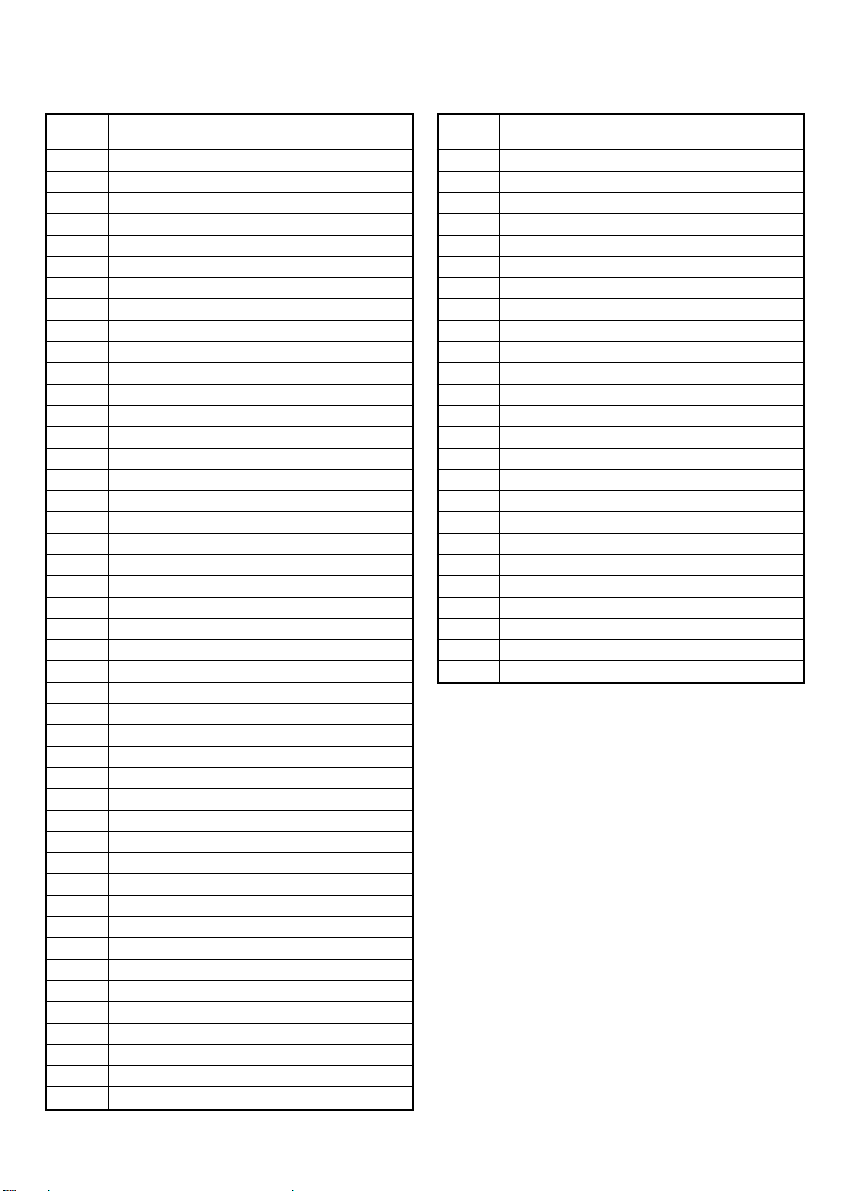

CS35B

17

Page 19

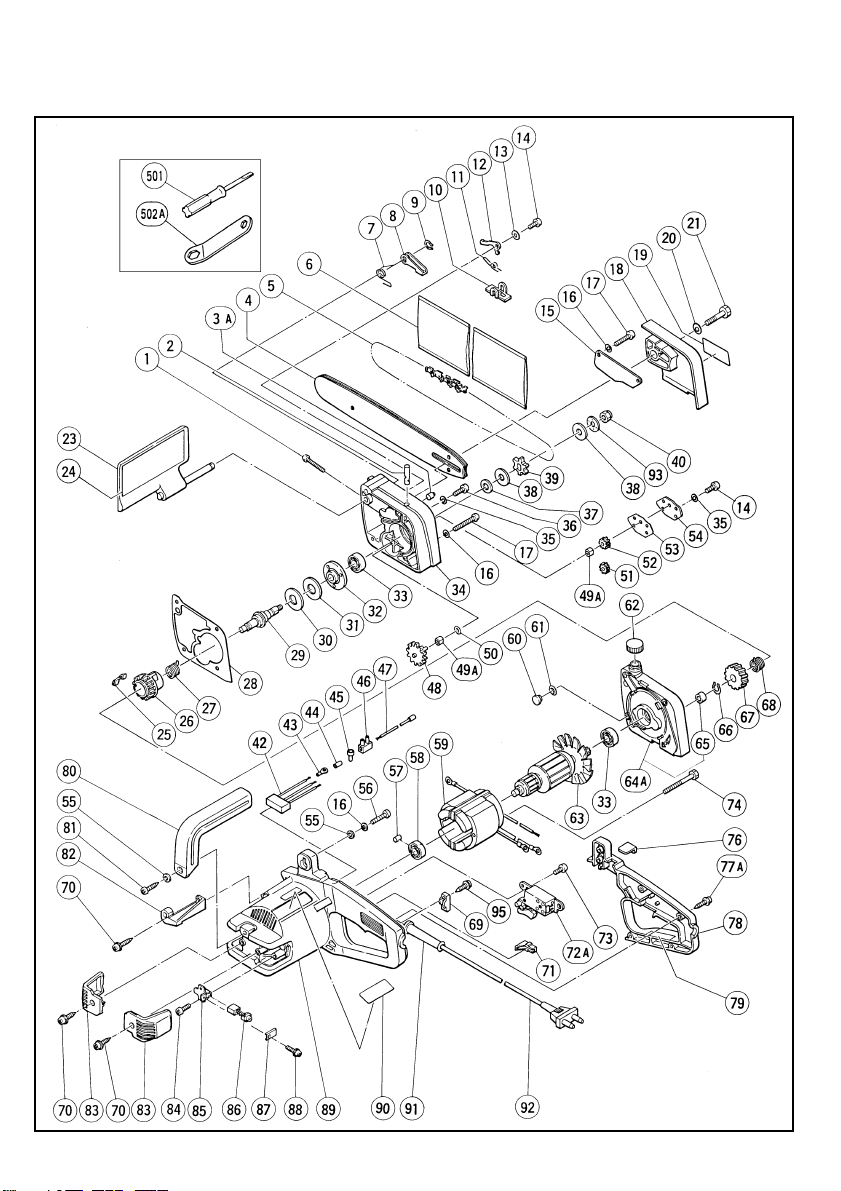

CS35B

Item

No.

1 Free Drive Screw M5 × 40

2 Stop In

3A Adjusting Pin Ass'y D8 × 15

4 Guide Bar (B)

5 Saw Chain

6 Chain Case

7 Spring (B)

8 Cam Plate

9 Retaining Ring For D10 Shaft

10 Reset Plate

11 Spring (A)

12 Hook Plate

13 Bolt Washer M4

14 Machine Screw M4 × 10

15 Cover Plate

16 Spring Washer M5

17 Tapping Screw D5 × 70

18 Chain Cover Ass’y

19 HITACHI Label

20 Spring Washer M8

21 Bolt M8 × 40

23 Hand Guard

24 Caution Plate

25 Hook Spring

26 Stop Collar

27 Break Spring

28 Oil Seal

29 Spindle

30 Washer (Plastic T0.5)

31 Washer (Steel T0.2)

32 Sleeve

33 Ball Bearing (6201VVCMPS2S)

34 Gear Cover

35 Spring Washer M4

36 Machine Screw M4 × 12

37 Washer (B)

38 Side Plate

39 Sprocket

40 U-Nut (Left Handed) M8

42 Noise Suppressor

43 Terminal

44 Tube (D)

45 Connector (50092)

46 Pillar Terminal

47 Internal Wire (A)

48 Pump Gear

49A Metal D4 × 6

50 O-Ring (P4)

51 First Idle Gear (I.D. 4MM)

Part Name

Item

No.

52 First Idle Gear (I.D. 3MM)

53 Cap Seal

54 Cap Plate

55 Washer M5

56 Machine Screw M5 × 35

57 Bearing Lock

58 Ball Bearing (6000VVCMPS2S)

59 Stator

60 Oil Gauge

61 O-Ring (S-12)

62 Cap

63 Armature

64A Inner Cover Ass'y

65 Needle Bearing (HK1010)

66 Retaining Ring for D12 Shaft

67 Gear

68 Clutch Spring (A)

69 Cord Clip

70 Tapping Screw (W/Washer) D4 × 16

71 Internal Wire Clip

72A Switch (A)

73 Tapping Screw D4 × 12

74 Hexagon Hd. Tapping Screw D5 × 65

76 Rubber Cap

77A Tapping Screw (W/Flange) D4 × 25

78 Handle Cover

79 Caution Plate

80 Side Handle

81 Tapping Screw D5 × 20

82 Attachment

83 Tail Cover

84 Tapping Screw D4 × 10

85 Brush Holder

86 Carbon Brush

87 Brush Plate

88 Machine Screw (W/Washer) M4 × 8

89 Housing Ass’y

90 Name Plate

91 Cord Armor

92 Cord

93 Belleville Spring

95 Tapping Screw (W/Flange) D4 × 16

501 Screw Driver No. 2

502A Wrench (Hex. Socket 10/13MM)

Parts are subject to possible modification without notice

due to improvements.

Part Name

18

Page 20

19

Page 21

English

GUARANTEE CERTIFICATE

1 Model No.

2 Serial No.

3 Date of Purchase

4 Customer Name and Address

5 Dealer Name and Address

(Please stamp dealer name and address)

PyccÍËÈ

ÉAPAHTàâHõâ CEPTàîàKAT

1 MoÀeÎë £

2 CepЛИМкИ £

3 ÑaÚa ÔoÍyÔÍË

4 HaÁÇaÌËe Ë aÀpec ÁaÍaÁäËÍa

5 HaÁÇaÌËe Ë aÀpec ÀËÎepa

(èoÊaÎyÈcÚa, ÇÌecËÚe ÌaÁÇaÌËe Ë aÀpec

ÀËÎepa)

✄

20

Page 22

1

2

3

4

5

✄

21

Page 23

22

Page 24

23

Page 25

24

Page 26

Hitachi Koki Co., Ltd.

Code No. 99475041 N

511

Printed in Japan

Loading...

Loading...