Page 1

C 12RSH2

Handling instructions

Page 2

12

2

3

(

4

%

e

w

!

1

Ó

&

q

™

)

*

^

^

%

t

o

i

p

z

2

r

h

8

j

f

g

s

9

$

#

a

8

f

d

7

0

6

k

104

5

u

@

3

4

1

k

4 – ø9 mm

327 mm

(12-7/8")

a

282 mm

(11-1/8")

˛

(10-1/6")

255.5 mm

5

◊

s

l

¸

2

Ç

Page 3

6

2

1

7

q

9

Â

˜

10

8

g

d

4

x

7

ı

9

Ï

1

!

@

#

;

˝

ˇ

p

8

)

11

Ï

¢

˝

⁄

∞

§

º

™

($)

)

(

)

#

3

;

Page 4

12

&

13

14

¯

!

*

¯

!

*

*

˘¿

x

™

7

&

!

4

$

!

¯

101

15

r

ª

)

¤

#

16

@

‹

4

ª

j

¤

Page 5

17

18

20

21

¤

Î

h

2

7

1

8

19

22

ⓐ

ⓐ

ⓑ

ⓑ

ⓐ

!

ÎÎ

1

ⓑ

3

;

•

£

y

c

Ô

7

5

Page 6

23

3

1

2

1

24

(

&

^

;

25

26

8

d

f

9

›

27 28

;

/

b

m

,

¡

°

‡

m

n

fi

v

b

.

v

fl

%

v

.

·

29

∞

fl

‚

⁄

°·

6

Page 7

30 31

‹

ⓐ

ⓑ

32

Ô

7

ⓑ

Ò

&

33

Ü

6

¶

Á

p

a

î

Ø

∏

¶

Å

Í

7

Page 8

34

35

Œ

e

Ú

w

„

„

w

i

!

´

17 mm

‰

6 mm

‹

102

103

103

230V 65

8

Page 9

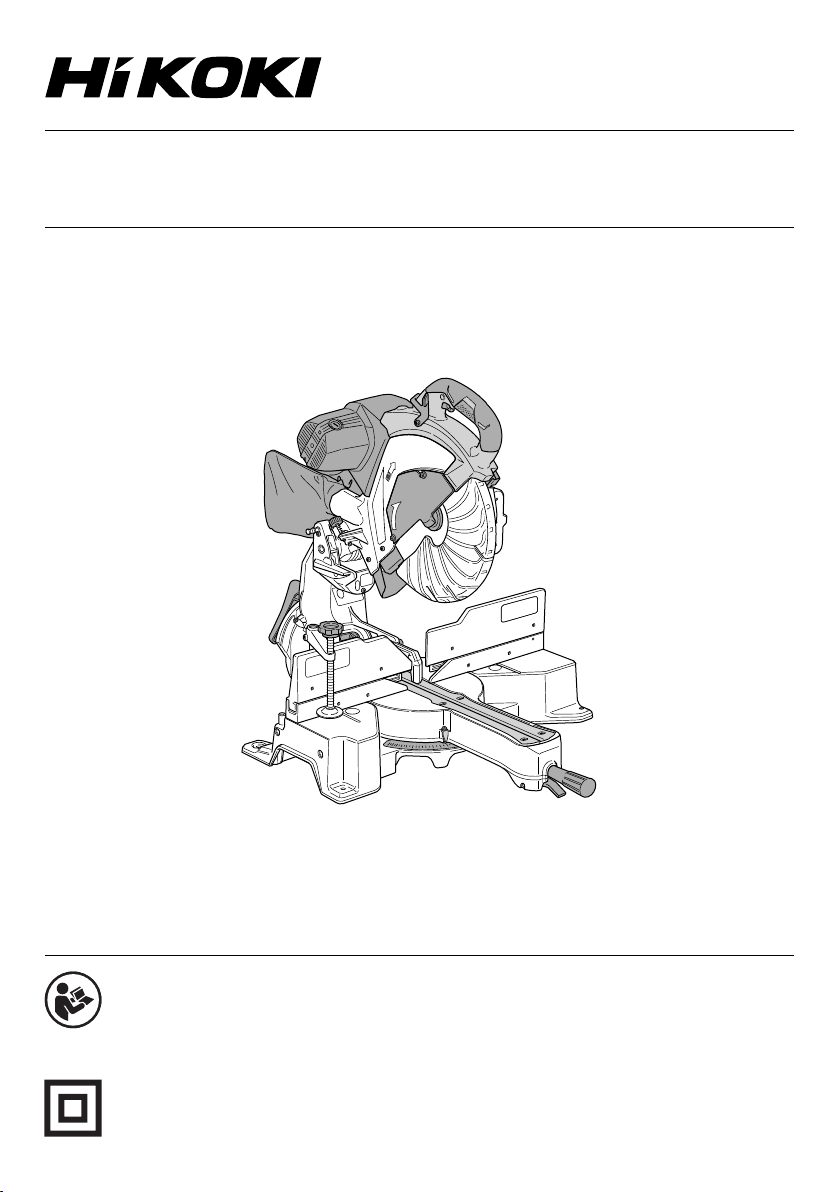

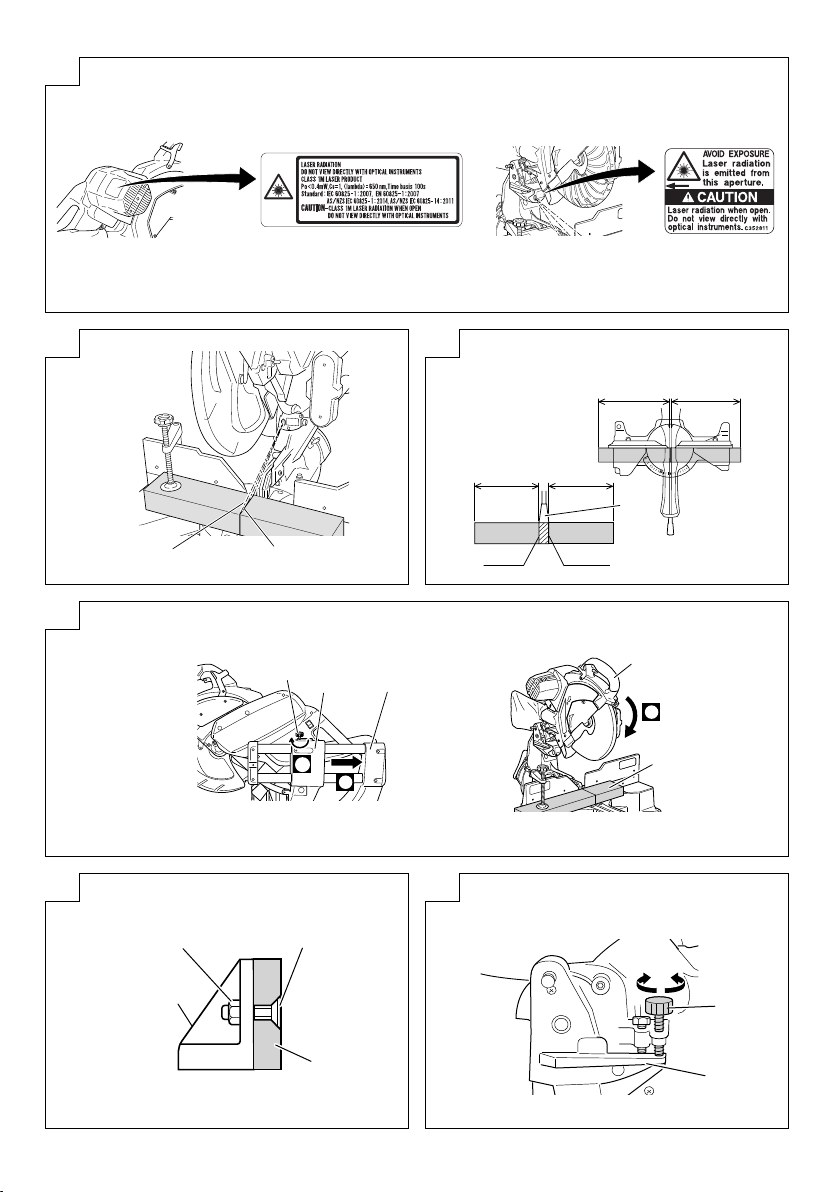

Handle

1

Lever (A)

2

Motor Head

3

Gear Case

4

Motor

5

Dust Bag

6

Hinge

7

Holder (A)

8

Indicator (For right bevel scale)

9

Laser Marker

0

Saw Blade

!

Vise Assembly

@

Fence (B)

#

Sub Fence (B)

$

Lever

%

Side Handle

^

Turntable

&

Table Insert

*

Indicator (For miter scale)

(

Fence (A)

)

Lower Guard

q

Washer (B)

w

Spindle Cover

e

Switch (For laser marker)

r

Trigger Switch

t

6 mm Flat Head Screw

y

Nameplate

u

Spindle Lock

i

Belt cover

o

Guard

p

Base

a

Holder

s

Set pin (A)

d

Clamp Lever

f

Indicator (For left bevel scale)

g

Slide Securing Knob

h

Adjuster (For laser marker)

j

Locking Pin

k

6 mm Bolt

l

Workpiece

;

Mounting hole (4 places)

z

8 mm Depth Adjustment Bolt

x

Auxiliary Board

c

6 mm Knob Bolt

v

(Optional accessory)

Holder (Optional accessory)

b

Steel Square

n

6 mm Wing Nut

m

(Optional accessory)

Height Adjustment Bolt 6 mm

,

(Optional accessory)

Base Surface

.

Stopper (Optional accessory)

/

6 mm Knob Bolt

¡

(Optional accessory)

Sub Fence (A)

™

6 mm Nut

£

Screw Holder

¢

Hex. socket set screw

∞

Vise Shaft

§

Duct

¶

Fence

•

6 mm Wing Bolt

ª

Vise Plate

º

Knob

⁄

Laser line

¤

Groove

‹

Bevel Scale

›

Miter Scale

fi

Crown molding Vise Ass’y

fl

(Optional accessory)

6 mm Wing Nut

‡

(Optional accessory)

Crown molding Stopper (L)

°

(Optional accessory)

Crown molding Stopper (R)

·

(Optional accessory)

Crown molding

‚

17 mm Box Wrench

Œ

10 mm Bolt

„

Washer (A)

´

Wear limit line

‰

6 mm Knob Bolt

ˇ

Right angle

Á

Dust extractor

¨

Hose (id 38 mm × 3 m long)

î

Adapter (Dust extractor's

Ø

standard accessory)

Joint (Optional accessory)

∏

9

Dust collection adapter

Å

(Optional accessory)

Hose band (Optional accessory)

Í

Marking (pre-marked)

Î

Line

Ï

Warning sign

˝

5 mm Machine screw

Ó

6 mm Depth adjustment bolt

Ô

Stopper holder

Bottom line of the groove

Ò

5 mm screw

Ú

Work bench

¸

8 mm Bolt

˛

8 mm Nut

Ç

25 mm thick bench

◊

8 mm Bolt (A)

ı

(Stopper for left 45° bevel angle)

8 mm Bolt (B)

˜

(Stopper for right 45° bevel angle)

8 mm Set Screw (Stopper for 0°)

Â

6 mm Machine screw

¯

Right angle cutting

˘

Left bevel angle cutting

¿

Right bevel angle cutting

101

Brush cap

102

No. of carbon brush

103

104

Guard (D)

Page 10

GENERAL OPERATIONAL

PRECAUTIONS

WARNING! When using electric tools, basic safety

precautions should always be followed to reduce the risk

of fi re, electric shock and personal injury, including the

following.

Read all these instructions before operating this product and

save these instructions.

For safe operations:

1. Keep work area clean. Cluttered areas and benches

invite injuries.

2. Consider work area environment. Do not expose power

tools to rain. Do not use power tools in damp or wet

locations. Keep work area well lit.

Do not use power tools where there is risk to cause fi re or

explosion.

3. Guard against electric shock. Avoid body contact with

earthed or grounded surfaces (e.g. pipes, radiators,

ranges, refrigerators).

4. Keep children and infi rm persons away. Do not let

visitors touch the tool or extension cord. All visitors

should be kept away from work area.

5. Store idle tools. When not in use, tools should be stored

in a dry, high or locked up place, out of reach of children

and infi rm persons.

6. Do not force the tool. It will do the job better and safer at

the rate for which it was intended.

7. Use the right tool. Do not force small tools or attachments

to do the job of a heavy duty tool. Do not use tools for

purposes not intended; for example, do not use circular

saw to cut tree limbs or logs.

8. Dress properly. Do not wear loose clothing or jewelry,

they can be caught in moving parts. Rubber gloves and

non-skid footwear are recommended when working

outdoors. Wear protecting hair covering to contain long

hair.

9. Use eye protection. Also use face or dust mask if the

cutting operation is dusty.

10. Connect dust extraction equipment.

Cutting operation by this compound miter saw may

produce considerable amount of dust from extraction

duct on fi xed guard.

(Dust material: Wood or Aluminium)

If devices are provided for the connection of dust

extraction and collection facilities ensure these are

connected and properly used.

11. Do not abuse the cord. Never carry the tool by the cord

or yank it to disconnect it from the receptacle. Keep the

cord away from heat, oil and sharp edges.

12. Secure work. Use clamps or a vise to hold the work. It

is safer than using your hand and it frees both hands to

operate tool.

13. Do not overreach. Keep proper footing and balance at all

times.

14. Maintain tools with care. Keep cutting tools sharp

and clean for better and safer performance. Follow

instructions for lubricating and changing accessories.

Inspect tool cords periodically and if damaged, have it

repaired by authorized service center. Inspect extension

cords periodically and replace, if damaged. Keep

handles dry, clean, and free from oil and grease.

15. Disconnect tools. When not in use, before servicing, and

when changing accessories such as blades, bits and

cutters.

16. Remove adjusting keys and wrenches. Form the habit

of checking to see that keys and adjusting wrenches are

removed from the tool before turning it on.

17. Avoid unintentional starting. Do not carry a plugged-in

tool with a fi nger on the switch. Ensure switch is off when

plugging in.

18. Use outdoor extension leads. When tool is used

outdoors, use only extension cords intended for outdoor

use.

19. Stay alert. Watch what you are doing. Use common

sense. Do not operate tool when you are tired.

20. Check damaged parts. Before further use of the tool, a

guard or other part that is damaged should be carefully

checked to determine that it will operate properly and

perform its intended function. Check for alignment of

moving parts, free running of moving parts, breakage of

parts, mounting and any other conditions that may aff ect

its operation. A guard or other part that is damaged

should be properly repaired or replaced by an authorized

service center unless otherwise indicated in this

handling instructions. Have defective switches replaced

by an authorized service center. Do not use the tool if the

switch does not turn it on and off .

21. Warning

The use of any accessory or attachment, other than

those recommended in this handling instructions, may

present a risk of personal injury.

22. Have your tool repaired by a qualifi ed person.

This electric tool is in accordance with the relevant safety

requirements. Repairs should only be carried out by

qualifi ed persons using original spare parts. Otherwise

this may result in considerable danger to the user.

PRECAUTIONS ON USING SLIDE

COMPOUND MITER SAW

1. Keep the fl oor area around the machine level. Well

maintained and free of loose materials e.g. chips and

cut-off s.

2. Provide adequate general or localized lighting.

3. Do not use power tools for applications other than those

specifi ed in the handling instructions.

4. Repairing must be done only by authorized service

facility. Manufacturer is not responsible for any damages

and injuries due to the repair by the unauthorized

persons as well as the mishandling of the tool.

5. To ensure the designed operational integrity of power

tools, do not remove installed covers or screws.

6. Do not touch movable parts or accessories unless the

power source has been disconnected.

7. Use your tool at lower input than specifi ed on the

nameplate; otherwise, the fi nish may be spoiled and

working effi ciency reduced due to motor overload.

8. Do not wipe plastic parts with solvent. Solvents such as

gasoline, thinner, benzine, carbon tetrachloride, alcohol,

may damage and crack plastic parts. Do not wipe them

with such solvent. Clean plastic parts with a soft cloth

lightly dampened with soapy water.

9. Use only original HiKOKI replacement parts.

10. This tool should only be disassembled for replacement

of carbon brushes.

11. The exploded assembly drawing on this handling

instructions should be used only for authorized service

facility.

12. Never cut ferrous metals or masonry.

13. Adequate general or localized lighting is provided.

Stock and fi nished workpieces are located close to the

operators normal working position.

14. Wear suitable personal protective equipment when

necessary, this could include:

Hearing protection to reduce the risk of induced hearing

loss.

Eye protection to reduce the risk of injuring an eye.

Respiratory protection to reduce the risk of inhalation of

harmful dust.

10

Page 11

Gloves for handling saw blades (saw blades shall be

carried in a holder wherever practicable) and rough

material.

15. The operator is adequately trained in the use, adjustment

and operation of the machine.

16. Refrain from removing any cut-off s or other parts of the

workpiece from the cutting area whilst the machine is

running and the saw head is not in the rest position.

17. Never use the slide compound miter saw with its lower

guard locked in the open position.

18. Ensure that the lower guard moves smoothly.

19. Do not use the saw without guards in position, in good

working order and properly maintained.

20. Use correctly sharpened saw blades. Observe the

maximum speed marked on the saw blade.

21. Do not use saw blades which are damaged or deformed.

22. Do not use saw blades manufactured from high speed

steel.

23. Use only saw blades recommended by HiKOKI.

24. The saw blades should be from 290 mm to 305 mm

external diameter ranges.

25. Select the correct saw blade for the material to be cut.

26. Never operate the slide compound miter saw with the

saw blade turned upward or to the side.

27. Ensure that the workpiece is free of foreign matter such

as nails.

28. Replace the table insert when worn.

29. Do not use the saw to cut other than aluminium, wood or

similar materials.

30. Do not use the saw to cut other materials than those

recommended by the manufacturer.

31. Blade replacement procedure, including the method for

repositioning and a warning that this must be carried out

correctly.

32. Connect the slide compound miter saw to a dust

collecting device when sawing wood.

33. Take care when slotting.

34. When transporting or carrying the tool, do not grasp the

holder. Grasp the handle instead of the holder.

35. Start cutting only after motor revolution reaches

maximum speed.

36. Promptly cut OFF the switch when abnormality observed.

37. Shut off power and wait for saw blade to stop before

servicing or adjusting tool.

38. During a miter or bevel cut the blade should not be lifted

until it has stopped rotation completely.

39. During slide cutting operation, the saw must be pushed

and slided away from the operator.

40. Take all the possibility of residual risks in cutting

operation into your consideration, such as the laser

radiation to your eyes, the inadvertent access to moving

parts on slide mechanical parts on machine and so on.

41. Ensure before each cut that the machine is stable.

Use only saw blades whose maximum permitted speed

is higher than the no-load speed of the power tool.

Do not replace the laser with a diff erent type.

42. Do not stand in a line with the saw blade In front of the

machine. Always stand aside of the saw blade. This

protects your body against possible kickback. Keep

hands, fi ngers and arms away from the rotating saw

blade.

Do not cross your arms when operating the tool arm.

43. If the saw blade should become jammed, switch the

machine off and hold the workpiece until the saw blade

comes to a complete stop. To prevent kickback, the

workpiece may not be moved until after the machine has

come to a complete stop.

Correct the cause for the jamming of the saw blade

before restarting the machine.

SYMBOLS

WARNING

The following show symbols used for the machine.

Be sure that you understand their meaning before

use.

C12RSH2: Slide Compound Miter Saw

Read all safety warnings and all instructions.

Always wear eye protection.

Always wear hearing protection.

11

Page 12

SPECIFICATIONS

Max.

sawing

dimension

Saw Blade Dimensions (oD × iD × Thickness) 305 mm × 25.4 mm × 2.3 mm

Miter Cutting Angle Right 0° – 57°, Left 0° – 45°

Bevel Cutting Angle Right 0° – 45°, Left 0° – 45°

Compound Cutting Angle

Voltage (by areas)*

Power Input* 1520 W

No-Load Speed 4000 /min

Machine Dimensions (Width × Depth × Height) 655 mm × 890 mm × 724 mm

Weight (Net) 27 kg

Laser Marker

Miter 0 0 Max. Height

Bevel Left 45° 0 Max. Height

Compound Left 45° Left 45° Max. Height

* Be sure to check the nameplate on product as it is subject to change by areas.

STANDARD ACCESSORIES

○ 305 mm TCT Saw blade (mounted on tool) ...................1

○ Dust bag .......................................................................1

○ 17 mm Box wrench .......................................................1

○ Vise Assembly ..............................................................1

○ Holder ...........................................................................1

○ Side Handle (mounted on tool) .....................................1

○ Sub Fence (mounted on tool) ........................................1

○ Washer (C) (Only For Australia) ....................................1

Standard accessories are subject to change without notice.

APPLICATION

Cutting various types of aluminium sash and wood.

PRIOR TO OPERATION

CAUTION

Make all necessary adjustments before inserting the

plug in the power source.

1. Power source

Ensure that the power source to be utilized conforms

to the power requirements specifi ed on the product

nameplate.

Do not use with direct current, or transformers such as

boosters. Doing so may result in damage or accidents.

Head Turntable Max. sawing dimension

0 Left 45°

0 Right 57° Max. Height

Right 45° 0 Max. Height

Left 45° Right 31° Max. Height

Right 45° Right 45° Max. Height

Right 45° Left 31°

Bevel (Left) 0° – 45° Miter (Left) 0° – 45°, (Right) 0° – 31°

Bevel (Right) 0° – 45° Miter (Right) 0° – 45°, (Left) 0° – 31°

Maximum output Po<0.4 mW Class 1M Laser Product

(Iambda) 650 nm

Laser medium Laser Diode

or

Right 45°

2. Power switch

Ensure that the power switch is in the OFF position. If the

plug is connected to a receptacle while the trigger switch

is in the ON position, the power tool will start operating

immediately, inviting serious accident.

3. Extention cord

When the work area is removed from the power source,

use an extension cord of suffi cient thickness and rated

capacity. The extension cord should be kept as short as

practicable.

4. Remove all packing materials attached or

connected to the tool before attempting to operate

it.

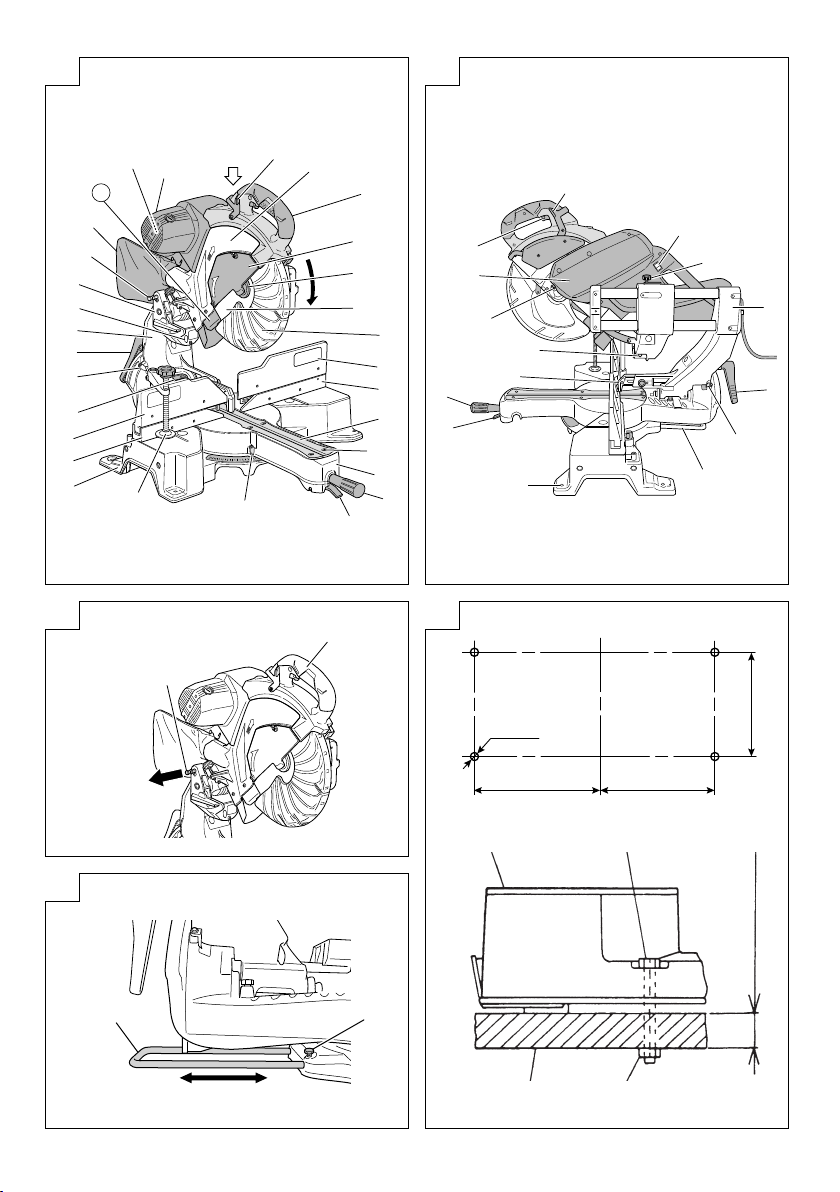

5. Releasing the locking pin (Fig. 3)

When the power tool is prepared for shipping, its main

parts are secured by a locking pin.

Move the handle slightly so that the locking pin can be

disengaged.

During transport, lock the locking pin into the gear case.

6. Attach the dust bag to the main unit (Fig. 1)

7. Installation (Fig. 4)

Ensure that the machine is always fi xed to bench.

Attach the power tool to a level, horizontal work bench.

Select 8 mm diameter bolts suitable in length for the

thickness of the work bench.

Bolt length should be at least 40 mm plus the thickness

of the work bench.

For example, use 8 mm × 65 mm bolts for a 25 mm thick

work bench.

Max. Width

Max. Height

Max. Width

Max. Width

Max. Width

Max. Width

Max. Width

Max. Width

Max. Width

Max. Height

Max. Width

230 V, 240 V

105 mm

312 mm

105 mm

220 mm

105 mm

170 mm

68 mm

312 mm

43 mm

312 mm

68 mm

220 mm

68 mm

265 mm

43 mm

220 mm

43 mm

265 mm

12

Page 13

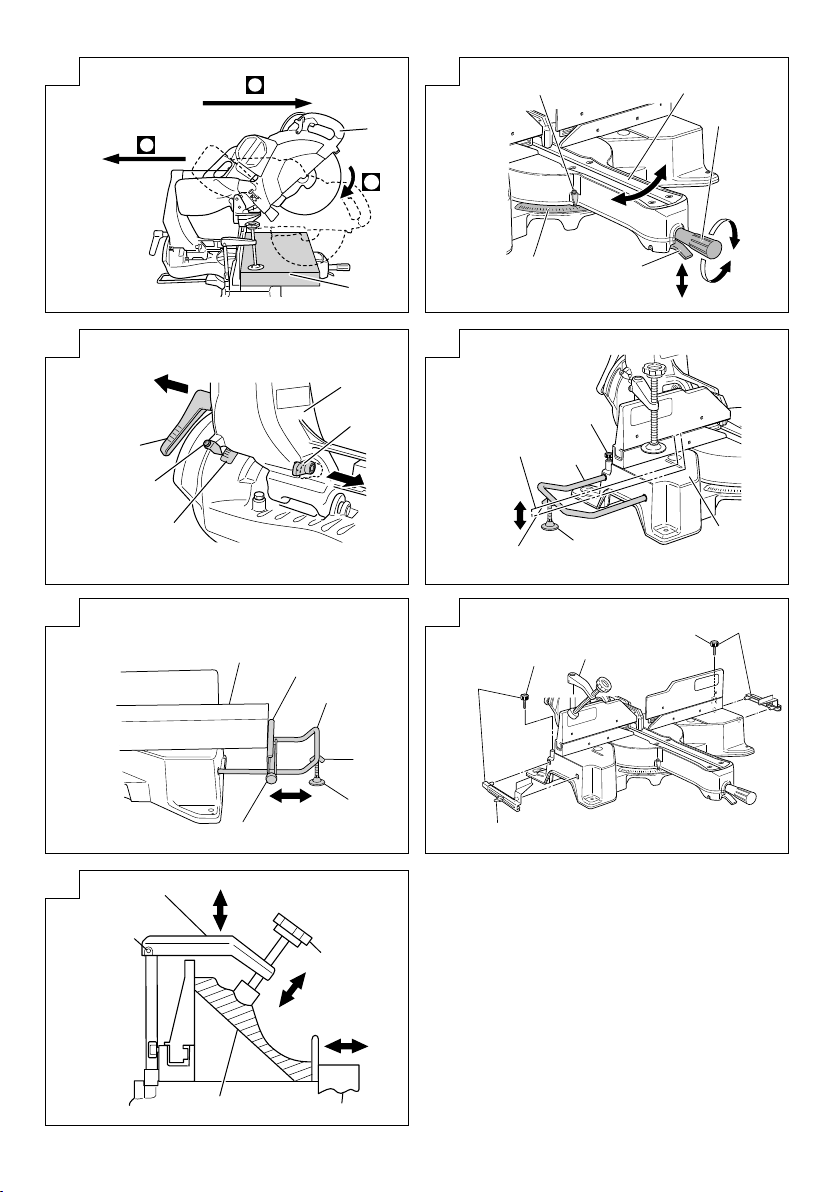

8. Base holder adjustment (Fig. 5)

Loosen the 6 mm bolt with the supplied 10 mm box

wrench. Adjust the base holder until its bottom surface

contacts the bench or the fl oor surface.

After adjustment, fi rmly tighten the 6 mm bolt.

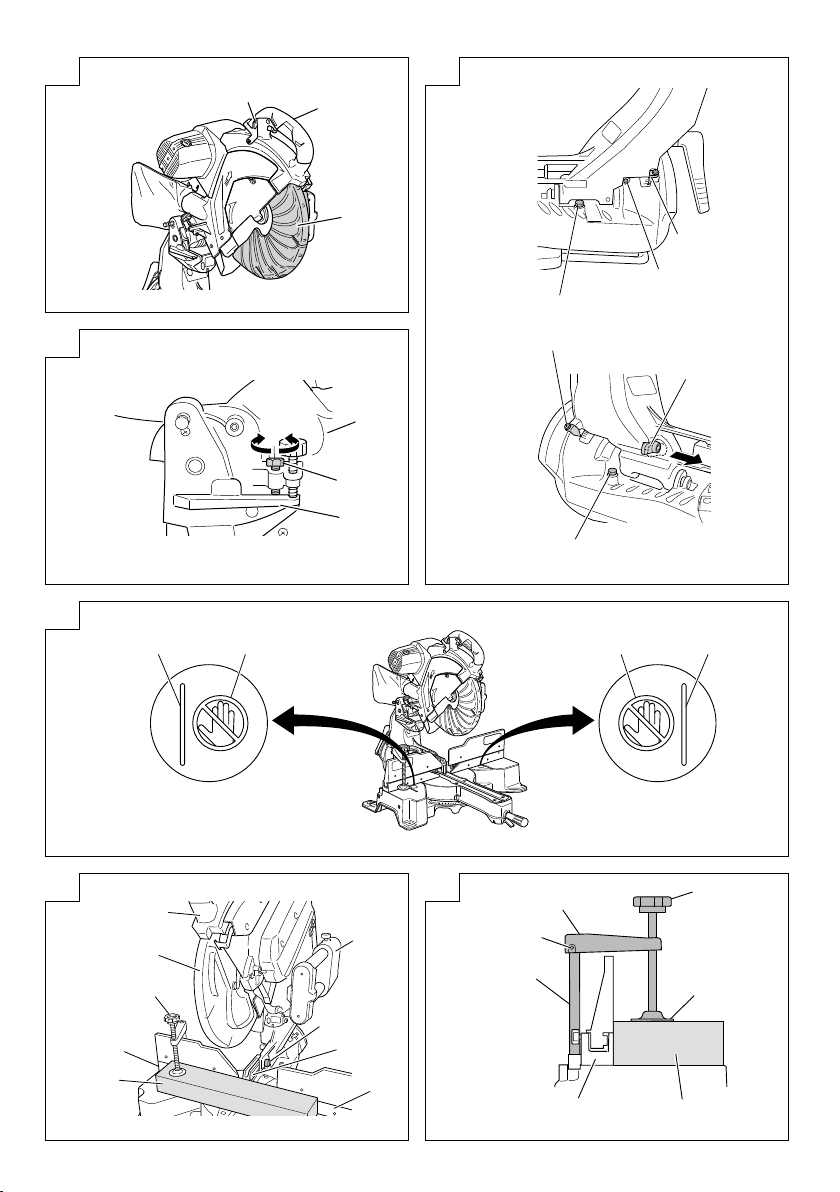

9. Check to see that the lower guard operates

smoothly

CAUTION

○ This slide compound miter saw is equipped with a saw

head lock as safety device.

○ To lower the saw head to cut, the lock must be released

by pressing the lever (A) with your thumb.

(1) When you push down the handle while pushing the

lever (A), check that the lower guard revolves smoothly

(Fig. 6).

(2) Next, check that the lower guard returns to the original

position when the handle is raised.

10. Oblique angle

Before the power tool is shipped from the factory, it is

adjusted for 0°, right angle, left 45° bevel cutting angle

and right 45° bevel cutting angle with the 8 mm set

screw, 8 mm bolt (A) and 8 mm bolt (B).

When changing the adjustment, change the height of

the 8 mm set screw, 8 mm bolt (A), or 8 mm bolt (B) by

turning them.

When changing the bevel angle to the right 45°, pull the

set pin (A) on the direction shown in Fig. 7-b and incline

the motor head to the right.

When adjusting the motor head to 0°, always return the

set pin (A) to its initial position as shown in Fig. 7-b.

11. Checking the saw blade lower limit position

Check that the saw blade can be lowered 9 mm to

10 mm below the table insert.

When you replace a saw blade with a new one, adjust

the lower limit position so that the saw blade will not cut

the turntable or complete cutting cannot be done.

To adjust the lower limit position of the saw blade, follow

the procedure (1) indicated below. (Fig. 8)

Furthermore, when changing the position of a 8 mm

depth adjustment bolt that serves as a lower limit position

stopper of the saw blade.

(1) Turn the 8 mm depth adjustment bolt, change the height

where the bolt head and the hinge contacts, and adjust

the lower limit position of the saw blade.

NOTE

Confi rm that the saw blade is adjusted so that it will not

cut into the turntable.

PRIOR TO CUTTING

1. Cutting a groove on the guard

Holder (A) has a guard (see Fig. 10) into which a groove

must be cut when using the tool for the fi rst time. Loosen

the 6 mm knob bolt to retract the guard slightly.

After placing a suitable wooden piece to sit on the

fence and the table surfaces, fi x it with the vise. Slide

the motor head backwards to the end. Then tighten the

slide securing knob. After the switch has been turned on

and the saw blade has reached maximum speed, slowly

lower the handle to cut a groove on the guard. (See

Fig. 20)

CAUTION

Do not cut the groove too quickly; otherwise the guard

might become damaged.

Do not use slide cutting for grooving tasks.

PRACTICAL APPLICATIONS

WARNING

○ To avoid personal injury, never remove or place a

workpiece on the table while the tool is being operated.

○ Never place your limbs inside of the line next to warning

sign while the tool is being operated (see Fig. 9). This

may cause hazardous conditions.

CAUTION

○ It is dangerous to remove or install the workpiece while

the saw blade is turning.

○ When sawing, clean off the shavings from the turntable.

○ If the shavings accumulate too much, the saw blade from

the cutting material will be exposed. Never subject your

hand or anything else to go near the exposed blade.

1. Switch operation

Pulling the trigger turns the switch on. Releasing the

trigger turns the switch off .

2. Using the Vise Assembly (Standard accessory)

(Fig. 11)

(1) The vise assembly can be mounted on either the left

fence {Fence (B)} or the right fence {Fence (A)}.

(2) The screw holder can be raised or lowered according to

the height of the workpiece.

(3) Turn the upper knob and securely fi x the workpiece in

position.

WARNING

Always fi rmly clamp or vise to secure the workpiece to

the fence; otherwise the workpiece might be thrust from

the table and cause bodily harm.

CAUTION

Always confi rm that the motor head does not contact the

vise assembly when it is lowered for cutting. If there is

any danger that it may do so, move the vise assembly to

a position where it will not contact the saw blade.

3. Positioning the table insert (Fig. 12)

Table inserts are installed on the turntable. When

shipping the tool from the factory, the table inserts are

so fi xed that the saw blade does not contact them. The

burr of the bottom surface of the workpiece is remarkably

reduced, if the table insert is fi xed so that the gap

between the side surface of the table insert and the saw

blade will be minimum. Before using the tool, eliminate

this gap in accordance with the following procedure.

(1) Right angle cutting

Loosen the three 5 mm machine screws, then secure

the left side table insert and temporarily tighten the 5 mm

machine screws of both ends. Then fi x a workpiece

(about 200 mm wide) with the vise assembly and cut it

off . After aligning the cutting surface with the edge of the

table insert, securely tighten the 5 mm machine screws

of both ends. Remove the workpiece and securely

tighten the 5 mm center machine screw. Adjust the right

hand table insert in the same way.

(2) Left and right bevel angle cutting

Adjust the table insert in the manner same procedure for

right angle cutting.

CAUTION

After adjusting the table insert for right angle cutting, the

table insert will be cut to some extent if it is used for bevel

angle cutting.

When bevel cutting operation is required, adjust the

table insert for bevel angle cutting.

4. Lower limit position of saw blade when cutting a

large workpiece

NOTE

When cutting a workpiece exceeding 105 mm in height

in right-angle cutting or 68 mm in left bevel angle cutting

or 43 mm in right bevel angle cutting, adjust the lower

limit position so that the base of the motor head (see

Fig. 13) will not come in contact with the workpiece.

13

Page 14

To adjust the lower limit position of the saw blade, follow

the procedure (1) shown in Fig. 13.

(1) Lower the motor head, and turn the 8 mm depth

adjustment bolt and make adjustments so that there can

be a clearance of 2 mm to 3 mm between the lower limit

position of the motor head and the top of the workpiece

at the saw blade's lower limit position where the head of

the 8 mm depth adjustment bolt contacts the hinge.

5. Confi rmation for use of sub fence (A) (Fig. 14)

WARNING

When right angle cutting, loosen the 6 mm wing bolt,

then slide the sub fence (A) outward and remove it.

Failure to do so may result in the main body or saw blade

coming into contact with the sub fence (A) and causing

injury.

This power tool is equipped with a sub fence (A).

In the case of direct angle cutting and left bevel angle

cutting, use the sub fence (A). Then, you can realize

stable cutting of the material with a wide back face.

When right angle cutting, loosen the 6 mm wing bolt,

then slide the sub fence (A) outward and remove it, as

shown in Fig. 14.

6. Confi rmation for use of sub fence (B) (Fig. 14)

WARNING

When left angle cutting, loosen the 6 mm wing bolt, then

slide the sub fence (B) outward. Failure to do so may

result in the main body or saw blade coming into contact

with the sub fence (B) and causing injury.

This power tool is equipped with a sub fence (B). In the

case of direct angle cutting and right bevel angle cutting,

use the sub fence (B). Then, you can realize stable

cutting of the material with a wide back face. When left

angle cutting, loosen the 6 mm wing bolt, then slide the

sub fence (B) outward, as shown in Fig. 14.

7. Using an ink line (Adjusting the guard)

(1) Right angle cutting

Loosen the 6 mm knob bolt and contact the tip of the

guard with the workpiece.

Aligning the ink line on the workpiece with the groove of

the guard, the workpiece is cut on the ink line.

(2) Miter cutting and compound cutting (Miter cutting +

bevel cutting)

Upon lowering the motor section, the lower guard is

raised and the saw blade appears.

Align the ink line with the saw blade.

CAUTION

In some arrangements when the turntable is rotated, the

guard projects from the fence surface. Loosen the 6 mm

knob bolt and push the guard to the retracted position.

Never lift the lower guard while the saw blade is rotating.

When cutting at an angle of 45° to the right or more,

please slide the guard to the rear.

The guard and sub-fence (A) and sub-fence (B) will not

only make contact and adversely aff ect cutting accuracy,

this could also result in damage to the guard.

8. Position adjustment of laser line

Ink lining can be easily made on this tool to the laser

marker. A switch lights up the laser marker (Fig. 15).

Depending upon your cutting choice, the laser line can

be aligned with the left side of the cutting width (saw

blade) or the ink line on the right side.

The laser line is adjusted to the width of the saw blade at

the time of factory shipment. Adjust the positions of the

saw blade and the laser line taking the following steps to

suit the use of your choice.

(1) Light up the laser marker and make a groove of about

5 mm deep on the workpiece that is about 20 mm in

height and 150 mm in width. Hold the grooved workpiece

by vise as it is and do not move it. For grooving work,

refer to “20. Groove cutting procedures”.

(2) Then, turn the adjuster and shift the laser line. (If you turn

the adjuster clockwise, the laser line will shift to the right

and if you turn it counterclockwise, the laser line will shift

to the left.) When you work with the ink line aligned with

the left side of the saw blade, align the laser line with the

left end of the groove (Fig. 16). When you align it with

the right side of the saw blade, align the laser line with

the right side of the groove.

(3) After adjusting the position of the laser line, draw a right-

angle ink line on the workpiece and align the ink line

with the laser line. When aligning the ink line, slide the

workpiece little by little and secure it by vise at a position

where the laser line overlaps with the ink line. Work on

the grooving again and check the position of the laser

line. If you wish to change the laser line’s position, make

adjustments again following the steps from (1) to (3).

WARNING

○ Make sure before plugging the power plug into the

receptacle that the main body and the laser marker are

turned off .

○ Exercise utmost caution in handling a switch trigger for

the position adjustment of the laser line, as the power

plug is plugged into the receptacle during operation.

If the switch trigger is pulled inadvertently, the saw blade

can rotate and result in unexpected accidents.

○ Do not remove the laser marker to be used for other

purposes.

CAUTION (Fig. 17)

○ Laser radiation - Do not stare into beam.

○ Laser radiation on work table. Do not stare into beam. If

your eye is exposed directly to the laser beam, it can be

hurt.

○ Do not dismantle it.

○ Do not give strong impact to the laser marker (main body

of tool); otherwise, the position of a laser line can go out

of order, resulting in the damage of the laser marker as

well as a shortened service life.

○ Keep the laser marker lit only during a cutting operation.

Prolonged lighting of the laser marker can result in a

shortened service life.

○ Use of controls or adjustments or performance of

procedures other than those specifi ed herein may result

in hazardous radiation exposure.

NOTE

○ Perform cutting by overlapping the ink line with the laser

line.

○

When the ink line and the laser line are overlapped, the

strength and weakness of light will change, resulting in a

stable cutting operation because you can easily discern the

conformity of lines. This ensures the minimum cutting errors.

○ In outdoor or near-the-window operations, it may

become diffi cult to observe the laser line due to the

sunlight. Under such circumstances, move to a place

that is not directly under the sunlight and engage in the

operation.

○ Check and make sure on a periodic basis if the position

of the laser line is in order. As regards the checking

method, draw a right-angle ink line on the workpiece with

the height of about 20 mm and the width of 150 mm, and

check that the laser line is in line with the ink line [The

deviation between the ink line and the laser line should

be less than the ink line width (0.5 mm)]. (Fig. 18)

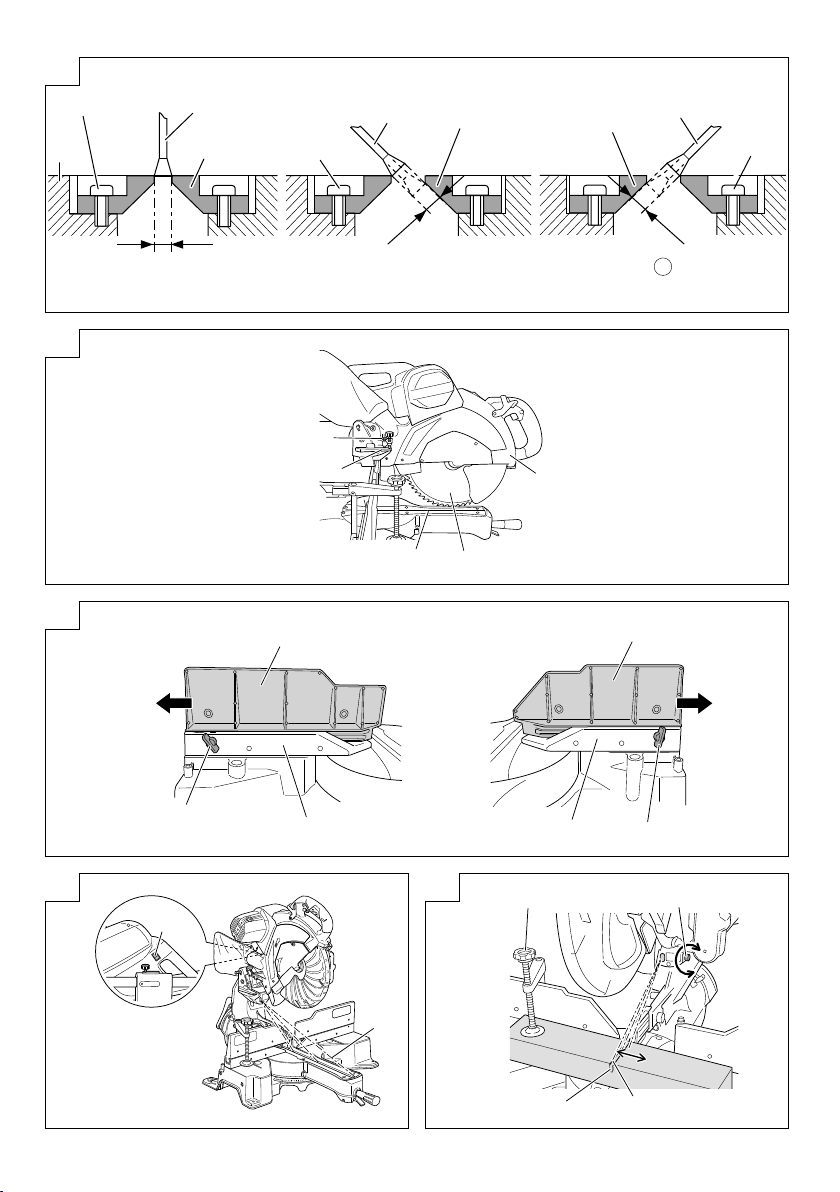

9. Cutting operation

(1) As shown in Fig. 19 the width of the saw blade is the

width of the cut. Therefore, slide the workpiece to the

right (viewed from the operator’s position) when length

is desired, or to the left when length is desired.

If a laser marker is used, align the laser line with the left

side of the saw blade, and then align the ink line with the

laser line.

14

Page 15

(2) After turning on the switch and checking that the saw

blade is rotating at maximum speed, slowly push down

the handle while holding down the lever (A) and bring the

saw blade in the vicinity of the material to be cut.

(3) Once the saw blade contacts the workpiece, push the

handle down gradually to cut into the workpiece.

(4) After cutting the workpiece to the desired depth, turn the

power tool OFF and let the saw blade stop completely

before raising the handle from the workpiece to return it

to the full retract position.

CAUTION

○ For maximum dimensions for cutting, refer to

“SPECIFICATIONS” table.

○

Increased pressure on the handle will not increase the cutting

speed. On the contrary, too much pressure may result in

overload of the motor and/or decreased cutting effi ciency.

○ Confi rm that the trigger switch is turned OFF and the

power plug has been removed from the receptacle

whenever the tool is not in use.

○ Always turn the power off and let the saw blade stop

completely before raising the handle from the workpiece.

If the handle is raised while the saw blade is still rotating,

the cut-off piece may become jammed against the saw

blade causing fragments to scatter about dangerously.

○ Every time one cutting of deep-cutting operation is

fi nished, turn the switch off , and check that the saw

blade has stopped. Then raise the handle, and return it

to the full retract position.

○ Be absolutely sure to remove the cut material from the

top of the turntable, and then proceed to the next step.

○ Continued cutting operation can result in overload of the

motor. Touch the motor and if it's hot, stop your cutting

operation once and rest for 10 minutes or so, and then

restart your cutting operation.

10. Cutting narrow workpieces (Press cutting) (Fig. 20)

Slide the hinge down to holder (A), then tighten the

slide securing knob (Fig. 2). Lower the handle to cut

the workpiece. Using the power tool this way will permit

cutting of workpieces of up to 105 mm square.

11. Cutting large workpieces (Fig. 21, 22)

There may be case when a complete cutting cannot be

done depending on the height of workpiece. In this case,

mount an auxiliary board with the 6 mm fl at head screws

and the 6 mm nuts using the 7 mm holes on the fence

surface (two holes on each side). (Fig. 21)

NOTE

When cutting a workpiece exceeding 105 mm in height

in right-angle cutting or 68 mm in left bevel angle cutting

or 42 mm in right bevel angle cutting, adjust the lower

limit position so that the base of the motor head will not

come in contact with the workpiece.

To adjust the lower limit position of the saw blade, follow the

procedure (1) shown in Fig. 22.

(1) Lower the motor head, and turn the 8 mm depth

adjustment bolt and make adjustments so that there can

be a clearance of 2 mm to 3 mm between the lower limit

position of the motor head and the top of the workpiece

at the saw blade's lower limit position where the head of

the 8 mm depth adjustment bolt contacts the hinge.

12. Cutting wide workpieces (Slide cutting) (Fig. 23)

(1) Workpieces up to 105 mm high and 312 mm wide:

Loosen the slide securing knob (A) (Fig. 2), grip the

handle and slide the saw blade forward.

Then press down on the handle and slide the saw blade

back to cut the workpiece. This facilitates cutting of

workpieces of up to 105 mm in height and 312 mm in

width.

CAUTION

○ If the handle is pressed down with excessive or lateral

force, the saw blade may vibrate during the cutting

operation and cause unwanted cutting marks on the

workpiece, thus reducing the quality of the cut.

Accordingly, press the handle down gently and carefully.

○ In slide cutting, gently push the handle back (rearwards)

in a single, smooth operation. Stopping the handle

movement during the cut will cause unwanted cutting

marks on the workpiece.

WARNING

○ For slide cutting, follow the procedures.

Forward slide cutting (toward the operator) is very

dangerous because the saw blade could kick upward

from the workpiece. Therefore, always slide the handle

away from the operator.

○ Always return the carriage to the full rear position after

each crosscut operation in order to reduce the risk of

injury.

○ Never put your hand on the side handle during the

cutting operation because the saw blade comes close to

the side handle when the motor head is lowered.

13. Miter cutting procedures

(1) Loosen the side handle and pull up the lever for angle

stoppers. Then, adjust the turntable until the indicator

aligns with desired setting on the miter scale (Fig. 24).

(2) Re-tighten the side handle to secure the turntable in the

desired position.

(3) The miter scale indicates both the cutting angle on the

angle scale and the gradient on the grade scale.

(4) The gradient, which is the ratio of the height to the base

of the triangular section to be removed, may be used

for setting the miter scale instead of the cutting angle, if

desired.

Therefore, to cut a workpiece at a grade of 2/10, set the

indicator to position.

NOTE

○ Positive stops are provided at the right and left of the 0°

center setting, at 15°, 22.5°, 30° and 45° settings.

Check that the miter scale and the tip of the indicator are

properly aligned.

○ Operation of the saw with the miter scale and indicator

out of alignment, or with the side handle not properly

tightened, will result in poor cutting precision.

14. Bevel cutting procedures (Fig. 25)

(1) Loosen the clamp lever and bevel the saw blade to the

left or to the right. When tilting the motor head to the right

pull the set pin (A) towards the rear.

The clamp lever adopts a latchet system. When

contacting the work bench and the main body, pull

the clamp lever in the direction of the arrow mark as

illustrated in Fig. 25, and change the direction of the

clamp lever.

(2) Adjust the bevel angle to the desired setting while

watching the bevel angle scale and indicator, then

secure the clamp lever.

WARNING

When the workpiece is secured on the left or right side

of the blade, the short cut-off

on the right or left side of the saw blade. Always turn the

power off and let the saw blade stop completely before

raising the handle from the workpiece.

If the handle is raised while the saw blade is still rotating,

the cut-off piece may become jammed against the saw

blade causing fragments to scatter about dangerously.

When stopping the bevel cutting operation halfway, start

cutting after pulling back the motor head to the initial

position.

Starting from halfway, without pulling back, causes the

lower guard to be caught in the cutting groove of the

workpiece and to contact the saw blade.

15. Compound cutting procedures

Compound cutting can be performed by following the

instructions in 13 and 14 above. For maximum dimensions

for compound cutting, refer to “SPECIFICATIONS” table.

15

portion will come to rest

Page 16

CAUTION

Always secure the workpiece with the right or left

hand and cut it by sliding the round portion of the saw

backwards with the left hand.

It is very dangerous to rotate the turntable to the left

during compound cutting because the saw blade may

come into contact with the hand that is securing the

workpiece.

In case of compound cutting (angle + bevel) by left

bevel, slide the sub-fence (B) outward, and engage in

the cutting operation.

In case of compound cutting (angle + bevel) by right

bevel, remove the sub-fence (A), and engage in the

cutting operation.

16. Cutting long materials

When cutting long materials, use an auxiliary platform

which is the same height as the holder (optional

accessory) and base of the special auxiliary equipment.

Capacity: wooden material (W × H × L)

17. Installing the holders … (Optional accessory)

The holders help keep longer workpieces stable and in

place during the cutting operation.

(1) As indicated in Fig. 26, use a steel square for aligning

the upper edge of the holders with the base surface.

Loosen the 6 mm wing nut. Turn a height adjustment bolt

6 mm, and adjust the height of the holder.

(2) After adjustment, fi rmly tighten the 6 mm wing nut and

fasten the holder with the 6 mm knob bolt (optional

accessory). If the length of Height Adjustment Bolt 6 mm

is insuffi cient, spread a thin plate beneath. Make sure the

end of Height Adjustment Bolt 6 mm does not protrude

from the holder.

CAUTION

○ When transporting or carrying the tool, do not grasp the

holder.

○ There is the danger of the holder slipping out of the base.

Grasp the handle instead of the holder.

18. Stopper for precision cutting … (Stopper and

holder are optional accessory)

The stopper facilitates continuous precision cutting in

lengths of 285 mm to 450 mm.

To install the stopper, attach it to the holder with the

6 mm knob bolt as shown in Fig. 27.

19. Confi rmation for use Crown molding vise, Crown

molding Stopper (L) and (R) (Optional accessory)

(1) Crown molding Stopper (L) and (R) (optional

accessories) allow easier cuts of crown molding without

tilting the saw blade. lnstall them in the base both-sides

side to be shown in Fig. 28. After inserting tighten the

6 mm knob bolts to secure the Crown molding Stoppers.

(2) The crown molding vise (B) (Optional accessory) can be

mounted on either the left fence (Fence (B)) or the right

fence (Fence (A)). lt can unite with the slope of the crown

molding and vice can be pressed down.

Then turn the upper knob, as necessary, to securely

attach the crown molding in position. To raise or lower the

vise assembly, fi rst loosen the hex. socket set screw.

After adjusting the height, fi rmly tighten the 6 mm wing

bolt; then turn the upper knob, as necessary, to securely

attach the the crown molding in position (Fig. 29).

Position crown molding with its WALL CONTACT EDGE

against the guide fence and its CEILING CONTACT

EDGE against the Crown molding Stoppers as shown in

Fig. 29. Adjust the Crown molding Stoppers according

to the size of the crown molding.

Tighten the 6 mm wing bolt to secure the Crown molding

Stoppers. Refer to the lower table for the miter angle.

Use the sub fence (A) to secure the crown molding more

fi rmly (Fig. 11).

300 mm × 43 mm × 1300 mm, or

180 mm × 25 mm × 2000 mm

WARNING

Always fi rmly clamp or vise to secure the crown molding

to the fence; otherwise the crown molding might be

thrust from the table and cause bodily harm.

Do not bevel cutting. The main body or saw blade may

contact the sub fence, resulting in an injury.

CAUTION

Always confi rm that the motor head does not contact the

crown molding vise ass’y when it is lowered for cutting.

If there is any danger that it may do so, loosen the hex.

socket set screw and move the crown molding vise ass’y

to a position where it will not contact the saw blade.

20. Groove cutting procedures

Grooves in the workpiece can be cut by adjusting the

6 mm depth adjustment bolt (Fig. 30).

(1) Turn the stopper holder on the direction shown in

Fig. 31.

Lower the motor head, and turn the 6 mm depth

adjustment bolt by hand. (Where the head of the 6 mm

depth adjustment bolt contacts the hinge.)

(2) Adjust to the desired cutting depth by setting the

distance between the saw blade and the surface of the

base (Fig. 30).

NOTE

When cutting a single groove at either end of the

workpiece, remove the unneeded portion with a chisel.

21. Using the dust bag (Standard accessory) (Fig. 32)

(1) Connect the dust bag with the duct of power tool.

(2) When the dust bag has become full of sawdust, dust will

be blown out of the dust bag when the saw blade rotates.

Check the dust bag periodically and empty it before it

becomes full.

(3) During bevel and compound cutting, attach the dust bag

at the right angle to the base surface.

22. Connecting the dust extractor (Sold separately)

(Fig. 33)

Do not inhale the harmful dusts generated in cutting

operation.

The dust can endanger the health of yourself and

bystanders.

Use of dust extractor can reduce dust related hazards.

By connecting with dust extractor through adapter,

joint and dust collection adapter, most of dust can be

collected.

Connect the dust extractor with adapter.

(1) Connect in order of hose (id 38 mm × 3 m long) and

adapter (Dust extractor’s Standard accessory) joint

(Optional accessory) and dust collection adapter

(Optional accessory) with the duct of power tool.

Connection is done by pressing in the direction of the

arrow. (Fig. 33)

The dust collection adapter (Optional accessory) is fi xed

to the duct by a hose band. (Optional accessory)

MOUNTING AND DISMOUNTING SAW

BLADE

WARNING

To prevent an accident or personal injury, always turn off

the trigger switch and disconnect the power plug from

the receptacle before removing or installing a saw blade.

1. Mounting the saw blade (Fig. 34)

(1) Use the Phillips screwdriver to loosen the 5 mm screw

fastening the spindle cover and then turn the spindle

cover.

(2) Press in spindle lock and loosen 10 mm bolt with 17 mm

wrench (standard accessory).

Since the 10 mm bolt is left-hand threaded, loosen by

turning it to the right.

16

Page 17

NOTE

If the spindle lock cannot be easily pressed in to lock

the spindle, turn the 10 mm bolt with 17 mm wrench

(standard accessory) while applying pressure on the

spindle lock.

The saw blade spindle is locked when the spindle lock is

pressed inward.

(3) Remove the bolt and washer (D)

(4) Lift the lower guard and mount the saw blade.

WARNING

When mounting the saw blade, confi rm that the rotation

indicator mark on the saw blade and the rotation direction

of the spindle cover (Fig. 1) are properly matched.

(5) Thoroughly clean washer (B) and the 10 mm bolt, and

install them onto the saw blade spindle.

(6) Press in the spindle lock and tighten the 10 mm bolt by

turning it to the left by standard accessories (17 mm

wrench).

(7) Rotate the spindle cover unitl hook in spindle cover is in

the original position. Then tighten the 6 mm bolt.

CAUTION

○ A dust guide is installed inside behind the hinge. When

removing or installing the saw blade, do not make

contact with the dust guide. Contact may break or chip

saw blade tips.

○ Tighten the 10 mm bolt so it does not come loose during

operation.

○ Confi rm the 10 mm bolt has been properly tightened

before the power tool is started.

○ Confi rm that the lower guard has closed position.

2. Dismounting the saw blade

Dismount the saw blade by reversing the mounting

procedures described in paragraph 1 above.

The saw blade can easily be removed after lifting the

lower guard.

CAUTION

Never attempt to install saw blades except

305 mm in diameter.

MAINTENANCE AND INSPECTION

WARNING

To avoid an accident or personal injury, always confi rm

the trigger switch is turned OFF and that the power

plug has been disconnected from the receptacle before

performing any maintenance or inspection of this tool.

Report to qualifi ed person as soon as possible, if you

discover the fault of machine including guards or blade

saw.

1. Inspecting the saw blade

Always replace the saw blade immediately upon the fi rst

sign of deterioration or damage.

A damaged saw blade can cause personal injury and

a worn saw blade can cause ineff ective operation and

possible overload to the motor.

CAUTION

Never use a dull saw blade. When a saw blade is dull,

its resistance to the hand pressure applied by the tool

handle tends to increase, making it unsafe to operate the

power tool.

2. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure that

they are properly tightened. Should any of the screws

be loose, re-tighten them immediately. Failure to do so

could result in serious hazard.

3. Inspecting the carbon brushes (Fig. 35)

The motor employs carbon brushes which are consumable

parts. Since an excessively worn carbon brush can result

in motor trouble, replace the carbon brushes with new

ones having the same carbon brush No. shown in the

fi gure when it becomes worn to or near the “wear limit”. In

addition, always keep carbon brushes clean and ensure

that they slide freely within the brush holders.

17

4. Replacing a carbon brushes (Fig. 35)

Disassemble the brush cap with a slotted-head

screwdriver. The carbon brushes can then be easily

removed.

5. Maintenance of the motor

The motor unit winding is the very “heart” of the power

tool. Exercise due care to ensure the winding does not

become damaged and/or wet with oil or water.

6. Inspecting the lower guard for proper operation

Before each use of the tool, test the lower guard (Fig. 6)

to assure that it is in good condition and that it moves

smoothly.

Never use the tool unless the lower guard operates

properly and it is in good mechanical condition.

7. Storage

After operation of the tool has been completed, check

that the following has been performed:

(1) Trigger switch is in OFF position,

(2) Power plug has been removed from the receptacle,

When the tool is not in use, keep it stored in a dry place

out of the reach of children.

8. Replacement of guard

After long-term use, the blade slot in the guard may

widen and require replacement. If the blade slot should

widen, replace the guard with a new one (Fig. 33). After

replacing, make a groove on it. Refer to “PRIOR TO

CUTTING 1. Cutting a groove on the guard” on page 13.

9. Lubrication

Lubricate the following sliding surfaces once a month

to keep the power tool in good operating condition for a

long time.

Use of machine oil is recommended.

Oil supply points:

* Rotary portion of hinge

* Rotary portion of holder (A)

* Rotary portion of vise assembly

10. Cleaning

Periodically remove chips and other waste material

from the surface of the power tool with a damp, soapy

cloth. To avoid a malfunction of the motor, protect it from

contact with oil or water.

If the laser line becomes invisible due to chips and the

like adhered onto the window of the laser marker's light-

emitting section, wipe and clean the window with a dry

cloth or a soft cloth moistened with soapy water, etc.

SELECTING ACCESSORIES

The accessories of this machine are listed on page 19.

CAUTION

Repair, modifi cation and inspection of HiKOKI Power

Tools must be carried out by a HiKOKI Authorized

Service Center.

Especially laser device should be maintained by the

authorized agent by laser manufacturer.

Always assign the repair of laser device to HiKOKI

Authorized Service Center.

In the operation and maintenance of power tools, the

safety regulations and standards prescribed in each

country must be observed.

NOTE

Due to HiKOKI’s continuing program of research and

development the specifi cations herein are subject to change

without prior notice.

Page 18

339652

988101

328326

324452

328520

322955

333732

998834

960017 960017

321390

301806

339730

339625

307956

307956

996722

339626

322047

304043

996722

321390

339661

965841

322283 230V: 999065

301806

339731

339662

322677

974561

949404

321549

949313

949556

322047

324412

339624

996247

339660

324464

18

Page 19

19

Page 20

Shinagawa Intercity Tower A, 15-1, Konan 2-chome,

Minato-ku, Tokyo, Japan

Code No. C99715112 F

Printed in China

806

Loading...

Loading...