Page 1

English

Model

Modèle

Modelo

C 10RB

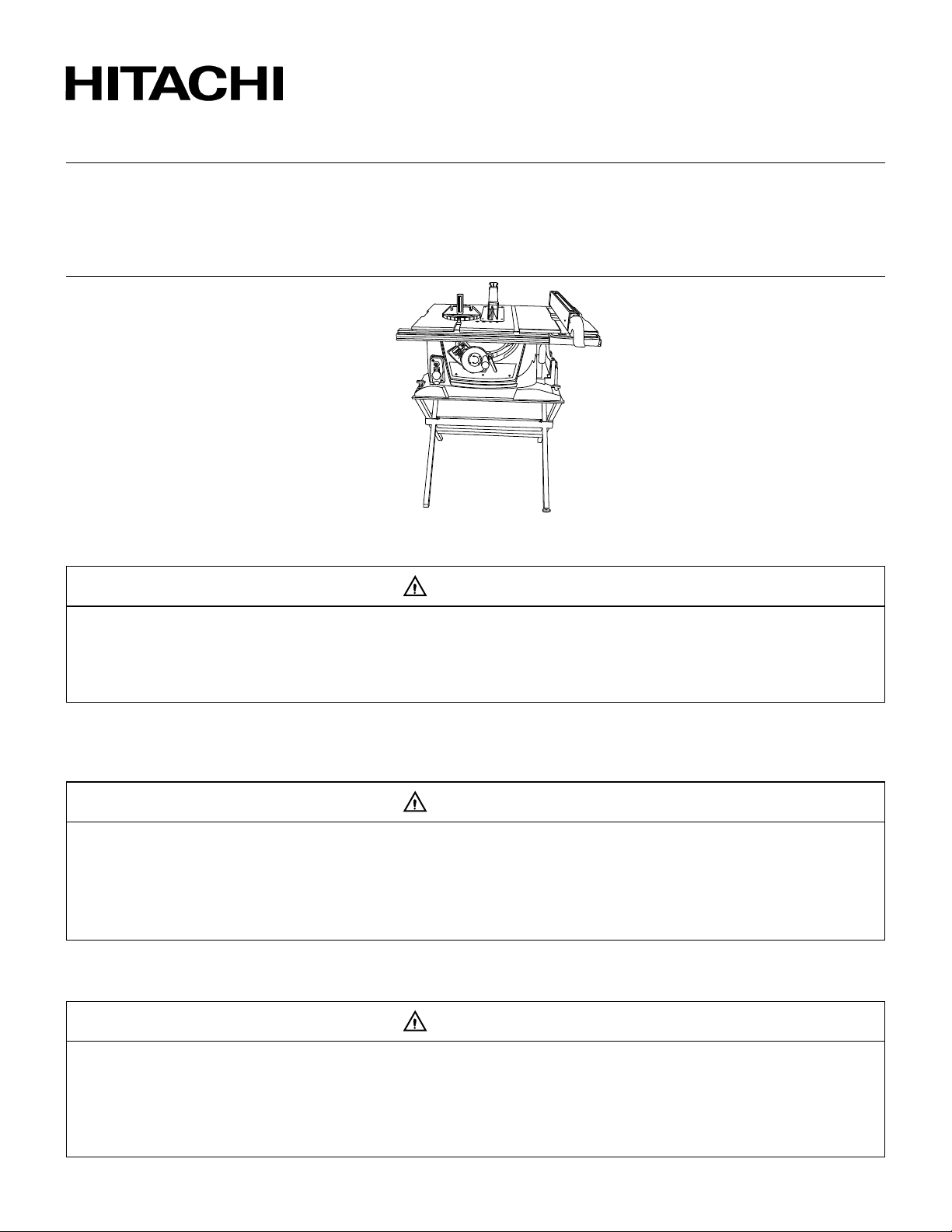

Jobsite Table Saw

Scie sur table pour chantier

Lugar de trabajo de la sierra de mesa

INSTRUCTION MANUAL AND SAFETY INSTRUCTIONS

WARNING

Improper and unsafe use of this power tool can result in death or serious bodily injury!

This manual contains important information about product safety. Please read and understand this manual

before operating the power tool. Please keep this manual available for others before they use the power

tool.

MODE D’EMPLOI ET INSTRUCTIONS DE SECURITE

AVERTISSEMENT

Une utilisation incorrecte et dangereuse de cet outil motorisé peut entraîner la mort ou de

sérieuses blessures corporelles!

Ce mode d’emploi contient d’importantes informations à propos de la sécurité de ce produit.

Priére de lire et d’assimiler ce mode d’emploi avant d’utiliser I’outil motorisé. Garder ce mode

d’emploi à la disponiblilité des autres utilisateurs avant qu’ils utilisent I’outil motorisé.

MANUAL DE INSTRUCCIONES E INSTRUCCIONES DE SEGURIDAD

ADVERTENCIA

!

La utilización inapropiada e insegura de esta herramienta eléctrica puede resultar en lesiones

serias o en la muerte!

Este manual contiene información importante sobre la seguridad del producto. Lea y comprenda

este manual antes de utilizar la herramienta eléctrica. Guarde este manual para que puedan

leerlo otras personas antes de que utilicen la herramienta eléctrica.

– 1 –

Hitachi Koki

Page 2

English

English

SECTION PAGE SECTION PAGE

Product Specifications ........................................ 3 Know Your Table Saw ........................................ 9

Power Tool Safety .............................................. 4 Glossary of Terms ............................................... 10

Table Saw Safety ................................................ 5 Assembly and Adjustments ................................. 11

Electrical Requirements and Safety .................... 6 Operation ............................................................ 18

Accessories and Attachments ............................ 7 Maintenance ....................................................... 23

Tools Needed for Assembly ................................ 7 Troubleshooting Guide ........................................ 24

Carton Contents .................................................. 7 Push Stick Pattern ............................................... 25

Parts List ............................................................. 72

HITACHI AUTHORIZED SERVICE CENTERS

Service under this warranty is available from Hitachi Koki U.S.A., Ltd. at:

CONTENTS

IN THE U.S.A.

3950 Steve Reynolds Blvd. Norcross, GA 30093

9409 Owensmouth Ave. Chatsworth, CA 91311

OR CALL: (800) 546-1666 for a service center nearest you.

Français

SECTION PAGE SECTION PAGE

Spécifications produit ......................................................... 26 Connaître votre scie sur table .................. 32

Consignes de sécurité relatives aux outile électriques ....... 27 Glossaire des termes ............................... 33

Consignes de sécurité relatives à la scie sur table ................ 28 Montage et réglages ................................ 34

Exigences électriques et sécurité ....................................... 29 Utilisation ................................................. 41

Accessoires ........................................................................ 30 Entretien ................................................... 46

Outils nécessaires pour le montage ................................... 30 Guide de dépannage ................................ 47

Contenu de l’emballage ...................................................... 30 Plan du poussoir ...................................... 48

TABLE DES MATIERES

IN CANADA

6395 Kestrel Road Mississauga, ON L5T 1Z5

OR CALL: (800) 970-2299 for a service center nearest you.

Liste des piéces ....................................... 72

CENTRES TECHNIQUES HITACHI AGREES

La réparation est réalisée dans le cadre de cette garantie par Hitachi Koki U.S.A., Ltd. :

AUX ETATS-UNIS

3950 Steve Reynolds Blvd. Norcross, GA 30093

9409 Owensmouth Ave. Chatsworth, CA 91311

OU APPELEZ LE: (800) 546-1666 pour connaître le centre

technique le plus proche de chez vous.

Español

SECCIÓN PÁGINA SECCIÓN PÁGINA

Especificaciones del producto .......................... 49 Conozca su sierra de mesa ................................ 55

Seguridad de la herramienta eléctrica .............. 50 Glosario de Términos.......................................... 56

Seguridad de la sierra de mesa ........................ 51 Montaje y ajustes ................................................ 57

Requisitos eléctricos y seguridad ..................... 52 Funcionamiento .................................................. 64

Accesorios ........................................................ 53 Mantenimiento .................................................... 69

Herramientas necesarias para el montaje ........ 53 Guía de solución de problemas .......................... 70

Contenido de la caja ......................................... 53 Patrón de empujadores ...................................... 71

ÍNDICE

AU CANADA

6395 Kestrel Road Mississauga, ON L5T 1Z5

OU APPELEZ LE: (800) 970-2299 pour connaître le centre

technique le plus proche de chez vous.

Lista de piezas .................................................... 72

CENTROS DE SERVICIO AUTORIZADOS DE HITACHI

Hitachi Koki U.S.A. Ltd. proporciona un servicio de reparaciones bajo esta garantía en:

EN EE. UU.

3950 Steve Reynolds Blvd. Norcross, GA 30093

9409 Owensmouth Ave. Chatsworth, CA 91311

O LLAME AL: (800) 546-1666 para informarse del centro de

reparaciones más cercano.

EN CANADA

6395 Kestrel Road Mississauga, ON L5T 1Z5

O LLAME AL: (800) 970-2299 para informarse del centro de

reparaciones más cercano.

– 2 –

Page 3

English

WARNING

Some dust created by power sanding, sawing, grinding, drilling and other construction activities contains

chemicals (known to the State of California) to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• Lead based paints

• Crystalline silica from bricks, cement and other masonry products

• Arsenic and chromium from chemically treated lumber

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety equipment, such

as dust masks that are specially designed to filter out microscopic particles.

PRODUCT SPECIFICATIONS

MOTOR SAW

HP (Maximum developed) ......................... 4.4 Table Size with Extensions .......... 30-3/32” x 21-3/4”

Type .......................................................... Universal Table Extension ........................... Right

Amps ......................................................... 15 Rip Capacity with Extension ......... 24-1/2”

Voltage ...................................................... 120 Blade Size .................................... 10”

Hz .............................................................. 60 Rip Scale ...................................... YES

RPM (no load) ........................................... 4000 Rip Fence ..................................... YES

Overload Protection ................................... YES Miter Gauge ................................. YES

Maximum Cut Depth @ 90º .......... 3-1/8”

Maximum Cut Depth @ 45º .......... 2-1/4”

Maximum Dado Cut Width ........... 13/16”

Net Weight ................................... 70.4 LBS

WARNING

To avoid electrical hazards, fire hazards or damage to the table saw, use proper circuit protection.

This table saw is wired at the factory for 110-120 Volt operation. It must be connected to a 110-120 Volt /

15 Ampere time delay fuse or circuit breaker. To avoid shock or fire, replace power cord immediately if it is

worn, cut or damaged in any way.

Before using your table saw, it is critical that you read and understand these safety rules. Failure to follow

these rules could result in serious injury to you or damage to the table saw.

– 3 –

Page 4

English

POWER TOOL SAFETY

WARNING

Before using your table saw, it is critical that you read and understand these safety rules. Failure to follow

these rules could result in serious injury or damage to the table saw.

Good safety practices are a combination of common

sense, staying alert and understanding how to use your

power tool. To avoid mistakes that could cause serious

injury, do not plug in your power tool until you have read

and understood the following safety rules:

1. READ and become familiar with this entire

Operator’s Manual. LEARN the tool’s applications,

limitations and possible hazards.

2.

Look for this symbol that identifies important

3. NEVER OPERATE THIS MACHINE WITHOUT

4. DO NOT USE IN A DANGEROUS ENVIRONMENT

5. DO NOT use power tools in the presence of

6. KEEP WORK AREA CLEAN. Cluttered areas and

7. KEEP CHILDREN AWAY. All visitors should be kept

8. DO NOT FORCE THE TOOL. It will do the job

9. USE THE RIGHT TOOL. Don’t force the tool or

10. WEAR PROPER APPAREL. DO NOT wear loose

Non-slip footwear is recommended. Wear protective

11. WEAR A FACE MASK OR DUST MASK. Sawing,

12. DISCONNECT TOOLS before servicing and when

13. REDUCE THE RISK OF UNINTENTIONAL

14. USE ONLY RECOMMENDED ACCESSORIES.

WARNING

safety precautions. It means BE ALERT! YOUR

SAFETY IS INVOLVED!

THE SAFETY GUARD IN PLACE FOR ALL

THROUGH–SAWING OPERATIONS.

such as damp or wet locations or in the rain. Keep

work area well lighted.

flammable liquids or gases.

benches invite accidents.

at a safe distance from the work area.

better and safer if used at the rate for which it was

designed.

attachment to do a job for which it is not designed.

clothing, gloves, neckties, rings, bracelets or other

jewelry that may get caught in moving parts.

hair covering to contain long hair.

cutting and sanding operations produce dust.

changing accessories, such as blades, cutters, etc.

STARTING. Make sure the switch is in the OFF

position before plugging tool into the power supply.

Consult the Operator’s Manual for recommended

accessories. The use of improper accessories may

cause injury to you or damage to the tool.

15. REMOVE ADJUSTING KEYS AND WRENCHES.

Form the habit of checking to see that keys and

adjusting wrenches are removed from the tool

before turning ON.

16. NEVER LEAVE TOOL RUNNING UNATTENDED.

TURN THE POWER OFF. Do not leave the tool

before the blade comes to a complete stop.

17. NEVER STAND ON TOOL. Serious injury could

occur if the tool is tipped or if the cutting tool is

unintentionally contacted.

18. DO NOT OVERREACH. Keep proper footing and

balance at all times.

19. MAINTAIN TOOLS WITH CARE. Keep tools sharp

and clean for most efficient and safest performance.

Follow instructions for lubricating and changing

accessories.

20. CHECK FOR DAMAGED OR LOOSE PARTS.

Check for alignment of moving parts, binding

of moving parts, loose mounting and any other

conditions that may affect its safe operation. A

guard or other part that is loose or damaged should

be properly adjusted, repaired or replaced.

21. MAKE WORKSHOP CHILDPROOF with padlocks,

master switches or by removing starter keys.

22. DO NOT operate the tool if you are under the

influence of any drugs, alcohol or medication that

could impair your ability to use the tool safely.

23. USE A DUST COLLECTION SYSTEM whenever

possible. Dust generated from certain materials can

be hazardous to your health and, in some cases,

a fire hazard. Always operate the power tool in a

well-ventilated area with adequate dust removal.

24. ALWAYS WEAR EYE PROTECTION. Any power

tool can throw debris into your eyes that could

cause permanent eye damage. ALWAYS wear

safety goggles (not glasses) that comply with ANSI

safety standard Z87.1. Everyday glasses have only

impact resistant lenses. They ARE NOT safety

glasses.

NOTE: Glasses or goggles not in compliance with

ANSI Z87.1 could cause serious injury when they

break.

25. DIRECTION OF FEED. Feed work into a blade or

cutter against the direction of rotation of the blade or

cutter only.

– 4 –

Page 5

TABLE SAW SAFETY

English

1. ALWAYS USE SAW BLADE GUARD, splitter and

anti-kickback pawls for every through–sawing

operation. Through–sawing operations are those

in which the blade cuts completely through the

workpiece when ripping or crosscutting. Always be

sure blade guard is tightened securely.

2. ALWAYS HOLD WORK FIRMLY against the miter

gauge or rip fence.

3. ALWAYS USE a push stick, especially when ripping

narrow stock. Refer to ripping instructions in this

Operator’s Manual where the push stick is covered

in detail. A pattern for making your own push stick is

included on page 25.

4. NEVER PERFORM ANY OPERATION

FREEHAND, which means using only your hands

to support or guide the workpiece. Always use

either the fence or the miter gauge to position

and guide the work.

WARNING: FREEHAND CUTTING IS THE

MAJOR CAUSE OF KICKBACK AND FINGER/

HAND AMPUTATIONS.

5. NEVER STAND or have any part of your body in

line with the path of the saw blade. Keep your hands

out of the saw blade path.

12. PROVIDE ADEQUATE SUPPORT to the rear

and the sides of the saw table for long or wide

workpieces.

13. AVOID KICKBACKS (work thrown back towards

you) by keeping the blade sharp, the rip fence

parallel to the saw blade and by keeping the splitter,

anti-kickback pawls and guards in place, aligned

and functioning. Do not release work before passing

it completely beyond the saw blade. Do not rip work

that is twisted, warped or does not have a straight

edge to guide it along the fence.

14. AVOID AWKWARD OPERATIONS and hand

positions where a sudden slip could cause your

hand to move into the saw blade.

15. NEVER USE SOLVENTS to clean plastic parts.

Solvents could possibly dissolve or otherwise

damage the material. Only a soft damp cloth should

be used to clean plastic parts.

16. MOUNT your table saw on a bench or stand

before performing any cutting operations. Refer to

ASSEMBLY AND ADJUSTMENTS on page 11.

17. NEVER CUT METALS or materials that may make

hazardous dust.

6. NEVER REACH behind or over the cutting tool for

any reason.

7. REMOVE the rip fence when crosscutting.

8. DO NOT USE a molding head with this saw.

9. FEED WORK INTO THE BLADE against the

direction of rotation only.

10. NEVER use the rip fence as a cut-off gauge when

crosscutting.

11. NEVER ATTEMPT TO FREE A STALLED SAW

BLADE without first turning the saw OFF. Turn

power switch OFF immediately to prevent motor

damage.

18. ALWAYS USE IN A WELL-VENTILATED AREA.

Remove sawdust frequently. Clean out sawdust

from the interior of the saw to prevent a potential

fire hazard. Attach a vacuum to the dust port for

additional sawdust removal.

19. NEVER LEAVE THE SAW RUNNING

UNATTENDED. Do not leave the saw until the blade

comes to a complete stop.

20. For proper operation follow the instructions in

this Operator’s Manual entitled ASSEMBLY AND

ADJUSTMENTS (Page 11). Failure to provide

sawdust fall-through and removal hole will allow

sawdust to build up in the motor area resulting in a

fire hazard and potential motor damage.

– 5 –

Page 6

English

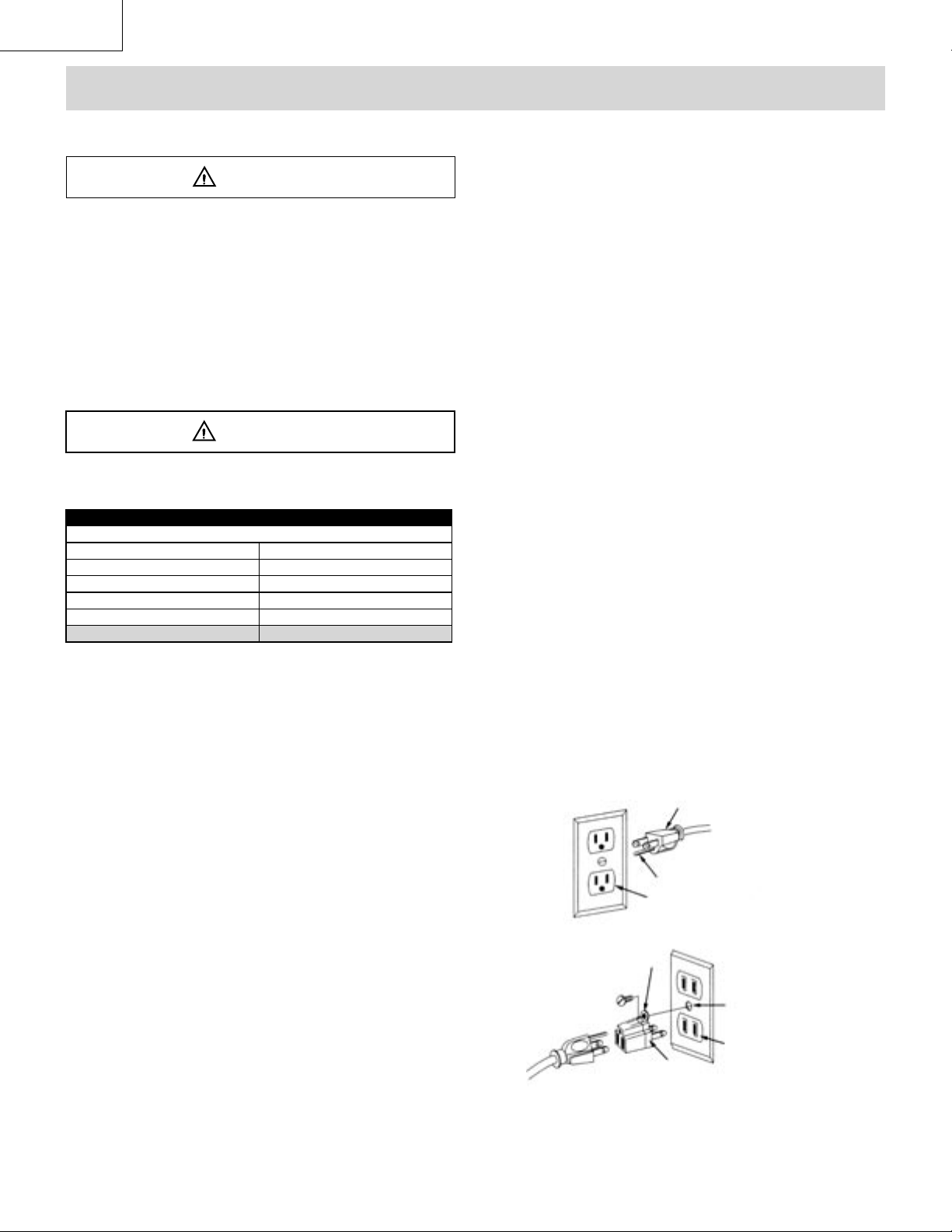

ELECTRICAL REQUIREMENTS AND SAFETY

POWER SUPPLY REQUIREMENTS

WARNING

To avoid electrical hazards, fire hazards or damage

to the table saw, use proper circuit protection.

Always use a separate electrical circuit for your

tools. This power tool is wired at the factory for

120V operation. Connect it to a 120V, 15 Amp circuit

and use a 15 Amp time delay fuse or circuit breaker.

To avoid shock or fire, replace the cord immediately

if it is worn, cut or damaged in any way.

EXTENSION CORD REQUIREMENTS

WARNING

Any extension cord must be GROUNDED for safe

operation.

MINIMUM GAUGE FOR EXTENSION CORDS (AWG)

(When using 120 volts only)

Ampere Rating Total length of Cord

More Than Not More Than 25ft. 50ft. 100ft. 150ft.

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12 Not Applicable

GUIDELINES FOR EXTENSION CORDS

GROUNDING INSTRUCTIONS

IN THE EVENT OF A MALFUNCTION OR

BREAKDOWN, grounding provides a path of least

resistance for electric current and reduces the risk of

electric shock. This saw is equipped with an electric

cord that has an equipment grounding conductor and

a grounding plug. The plug MUST be plugged into

a matching receptacle that is properly installed and

grounded in accordance with ALL local codes and

ordinances.

DO NOT MODIFY THE PLUG PROVIDED. If it will not

fit the receptacle, have the proper receptacle installed

by a qualified electrician.

IMPROPER CONNECTION of the equipment grounding

conductor can result in risk of electric shock. The

conductor (wire) with the green insulation (with or

without yellow stripes) is the equipment grounding

conductor. If repair or replacement of the electric cord

or plug is necessary, DO NOT connect the equipment

grounding conductor to a live terminal.

CHECK with a qualified electrician or service personnel

if you do not completely understand the grounding

instructions, or if you are not sure the saw is properly

grounded.

Any extension cord used for power tools MUST be

grounded (3-wire with two flat prongs and one round

ground prong).

Make sure the extension cord is in good condition.

When using an extension cord, make sure you use one

heavy enough to carry the current the tool will draw.

An undersized cord will cause a drop in line voltage

resulting in loss of power and overheating. The table

above shows the correct size to use according to

extension cord length and nameplate ampere rating. If

in doubt, use the next heavier gauge cord. The smaller

the gauge number the heavier the cord.

NOTE: The 12 to 16 amp rating is correct for this tool. It

is highlighted in the table above.

Be sure your extension cord is properly wired and in

good condition. Always replace a damaged extension

cord or have it repaired by a qualified person before

using it. Protect your extension cords from sharp

objects, excessive heat and damp or wet areas.

Before connecting the saw to the extension cord, make

sure the saw switch is turned OFF.

Use only 3-wire extension cords that have 3-prong

grounding plugs and 3-pole grounding receptacles that

accept the saw’s plug. Repair or replace damaged or

worn cords immediately.

3-Prong Plug

Grounding Prong

Properly Grounded

3-Prong Receptacle

Grounding Lug

Make sure this is

connected to a

known ground.

2-Prong

Adapter

– 6 –

Receptacle

Page 7

ACCESSORIES AND ATTACHMENTS

RECOMMENDED ACCESSORIES

English

WARNING

Visit your Hardware Department or see the Power

and Hand Tools Catalog to purchase recommended

accessories for this power tool.

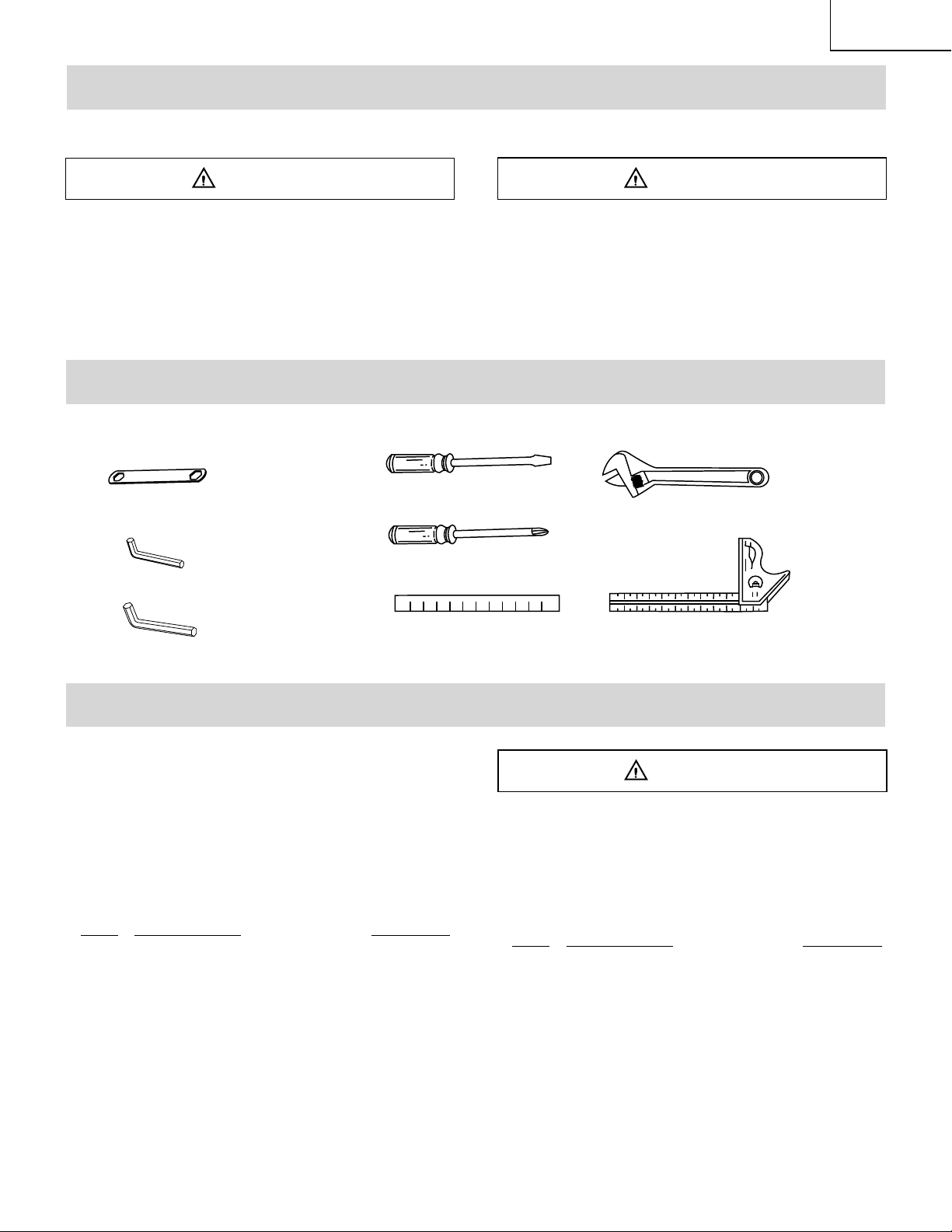

TOOLS NEEDED FOR ASSEMBLY

Supplied

13 mm Hex Wrench

4 mm Hex Wrench

5 mm Hex Wrench

Not Supplied

Medium Screwdriver

#2 Phillips screwdriver

Straight Edge

WARNING

To avoid the risk of personal injury:

• Do not use a dado with a diameter larger than 8”.

• Maximum dado width is 13/16”. DO NOT USE

WIDER COMBINATIONS.

• Do not use molding head set with this saw.

• Do not modify this power tool or use accessories

not recommended by Store.

Adjustable Wrench

Combination Square

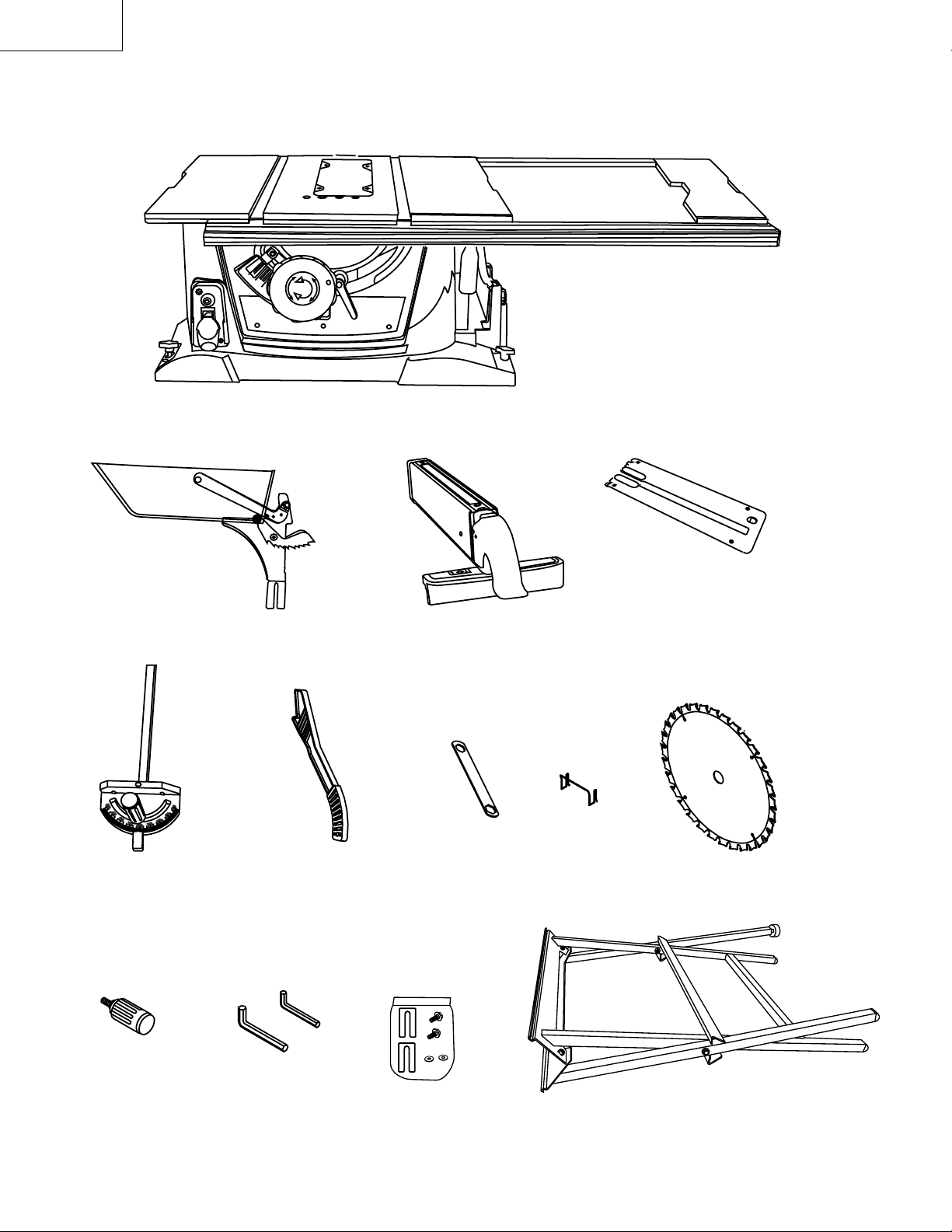

CARTON CONTENTS

UNPACKING AND CHECKING CONTENTS

Separate all parts from packing materials. Check each

part with the illustration on the next page and the “Table

of Loose Parts” to make certain all items are accounted

for, before discarding any packing material.

TABLE OF LOOSE PARTS

ITEM DESCRIPTION QUANTITY

A Table saw assembly 1

B Blade guard and splitter ass’y 1

C Rip fence 1

D Dado table insert 1

E Miter gauge 1

F Push stick 1

G Blade wrench 1

H Push stick storage 1

I Blade 1

J Handwheel handle 1

K Hex wrenchs 2

L Blade guard hardware bag ass’y 1

WARNING

If any part is missing or damaged, do not attempt

to assemble the table saw, plug in the power cord,

or turn the switch ON until the missing or damaged

part is obtained and is installed correctly.

STAND

ITEM DESCRIPTION QUANTITY

M Stand assembly 1

NOTE: To make assembly easier, keep contents of box

together. Apply a coat of automobile wax to the table.

Wipe all parts thoroughly with a clean dry cloth. This will

reduce friction when pushing the workpiece.

– 7 –

Page 8

English

UNPACKING YOUR JOBSITE TABLE SAW

A

B

C

G

E

F

H

D

I

J

K

L

– 8 –

M

Page 9

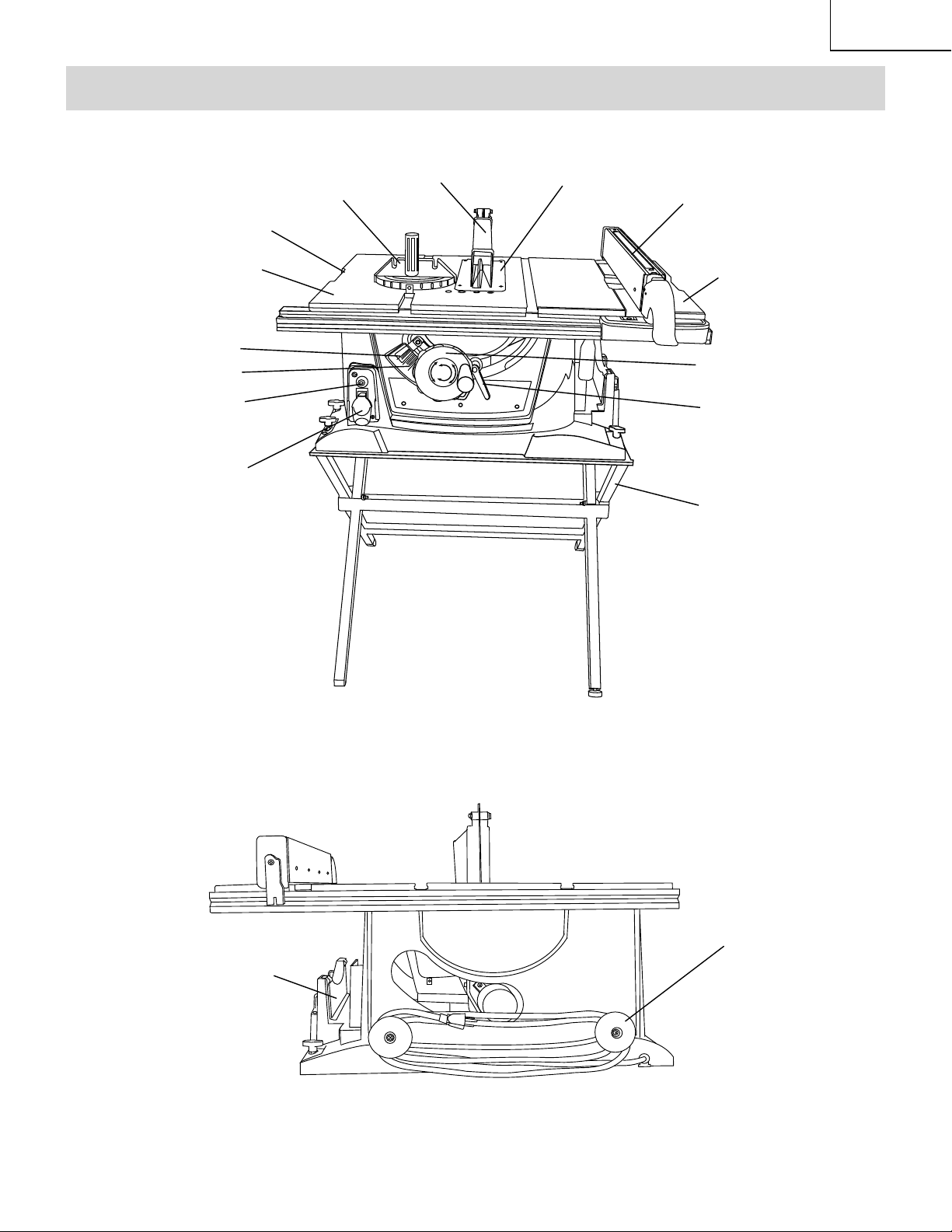

KNOW YOUR JOBSITE TABLE SAW

English

Hand hold

Tabel

Blade tilt pointer

Blade tilt scale

Overload reset switch

ON/OFF switch with key

Miter gauge

Blade guard

Table insert

Rip fence

Side table extension

Blade elevation handwheel

Blade bevel lock knob

Stand

Rip fence and miter

gauge storage

Rear Of The Table Saw

Crod wrap

– 9 –

Page 10

English

GLOSSARY OF TERMS

TABLE SAW TERMS

MITER GAUGE – A guide used for crosscutting

operations that slides in the tabletop channels located

on either side of the blade. It helps make accurate

straight or angle cuts.

RIP FENCE – A guide used for rip cutting that clamps to

the tabletop. It allows the workpiece to be straight.

TABLE INSERT – Provides access to the blade arbor

for changing blades.

OVERLOAD RESET SWITCH – Resets the

thermocouple and provides a way to restart the saw

motor if it overheats or overloads.

BLADE BEVEL SCALE – Measures the angle the blade

is tilted when set for a bevel cut.

TABLE SCALE – Measures the distance the rip fence is

set from the blade, allowing quick setups.

ANTI-KICKBACK PAWLS – Prevents the workpiece

from being kicked upward or back toward the front of the

table saw by the spinning blade.

SPLITTER – Keeps the workpiece spread apart

after being cut, to prevent binding on the blade and

workpiece.

BLADE ELEVATION HANDWHEEL – Raises and

lowers the blade.

CROSSCUT – A cut made across the width of the

workpiece.

FREEHAND – Performing a cut without using a fence

(guide), hold down or other proper device to prevent the

workpiece from twisting during the cutting operation.

GUM – A sticky sap from wood products.

HEEL – Misalignment of the blade.

KERF – The amount of material removed by a blade

cut.

MITER CUT – An angle cut made across the width of

the workpiece.

RESIN – A sticky sap that has hardened.

REVOLUTIONS PER MINUTE (RPM) – The number of

turns completed by a spinning object in one minute.

SAW BLADE PATH – The area of the workpiece or

table top directly in line with the travel of the blade or the

part of the workpiece that will be cut.

SET – The distance between two saw blade tips, bent

outward in opposite directions to each other. The further

apart the tips are, the greater the set.

WORKPIECE – The item being cut. The surfaces of a

workpiece are commonly referred to as faces, ends and

edges.

BLADE TILTING HANDWHEEL – Tilts the blade to any

angle between 0° to 45° for bevel cuts.

WOODWORKING TERMS

ARBOR – The shaft on which a blade is mounted.

BEVEL CUT – An angle cut made through the face of

the workpiece.

COMPOUND CUT – A simultaneous bevel and miter

cut.

– 10 –

Leading Edge

Kerf

Surface

Workpiece

Saw Blade Path

Trailing Edge

Page 11

ASSEMBLY AND ADJUSTMENTS

English

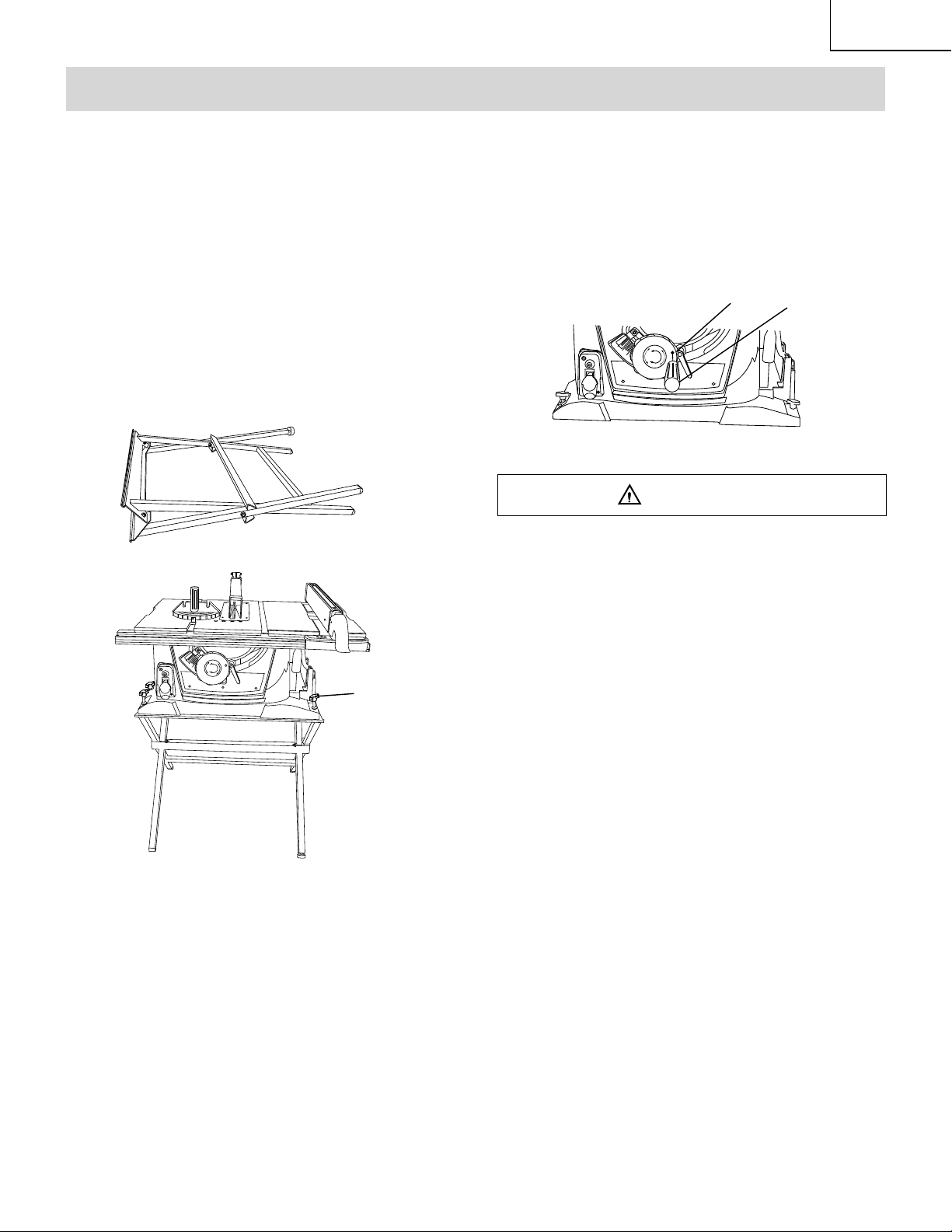

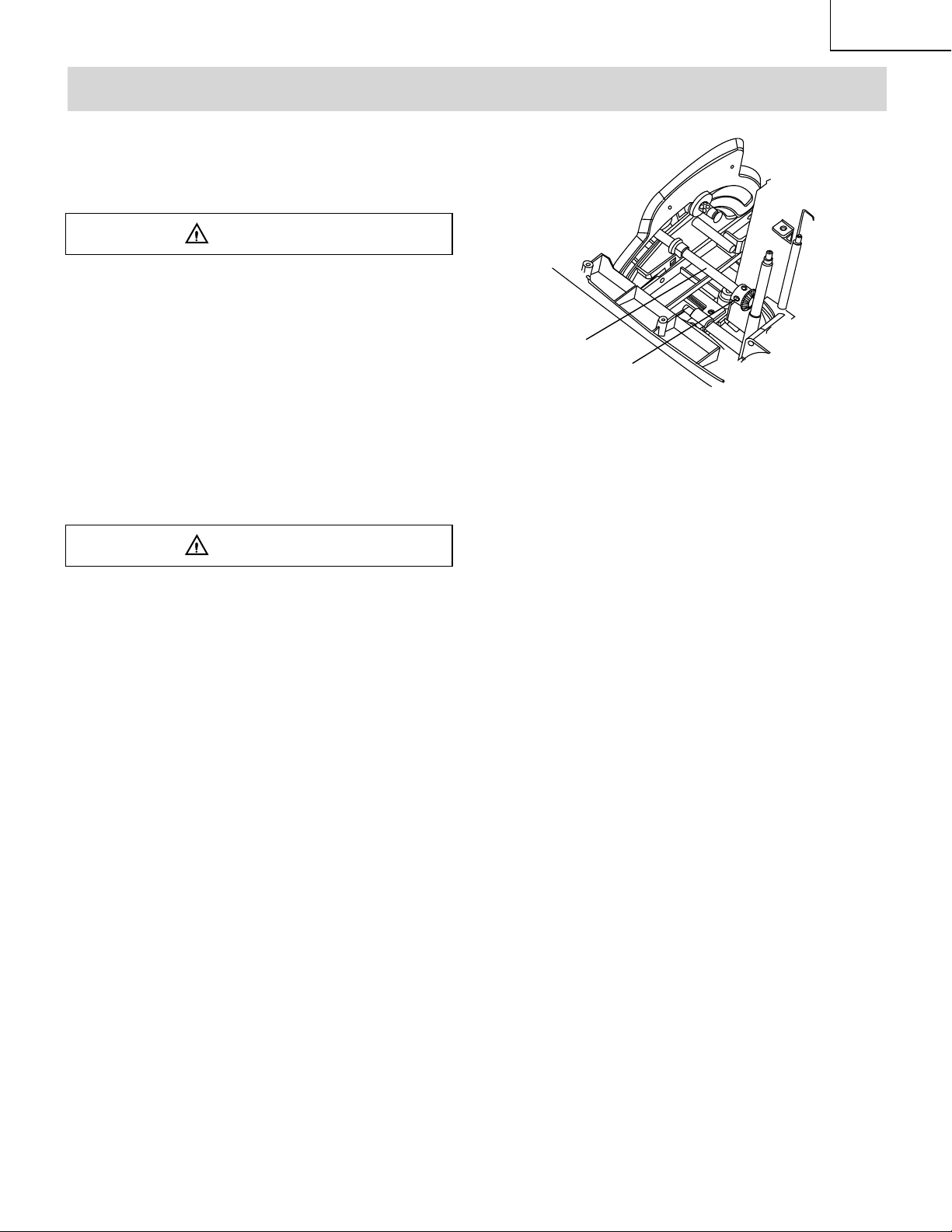

ASSEMBLE THE TABLE SAW TO THE STAND

(Fig. A)

1. Unfold the leg sets and push down in place.

2. Place the stand on a level surface and adjust the

front-right adjustable foot, so all legs are contacting

the floor and are at similar angles on the floor.

3. Match the holes of the stand to the holes on the

bottom flange of the saw base.

4. Fasten the saw to the stand using the four handle (1)

then tighten securely .

5. Position the saw on a clean, level surface.

Fig. A

1

ASSEMBLE THE HANDWHEEL HANDLE (FIG. B)

Thread the handwheel handle (1) into the handwheel

hole (2), and then tighten the nut against the handwheel

with a 10mm wrench. NOTE: If the handle bolt becomes

loose, remove the plastic end cap and this will allow you

to tighten securely.

Fig. B

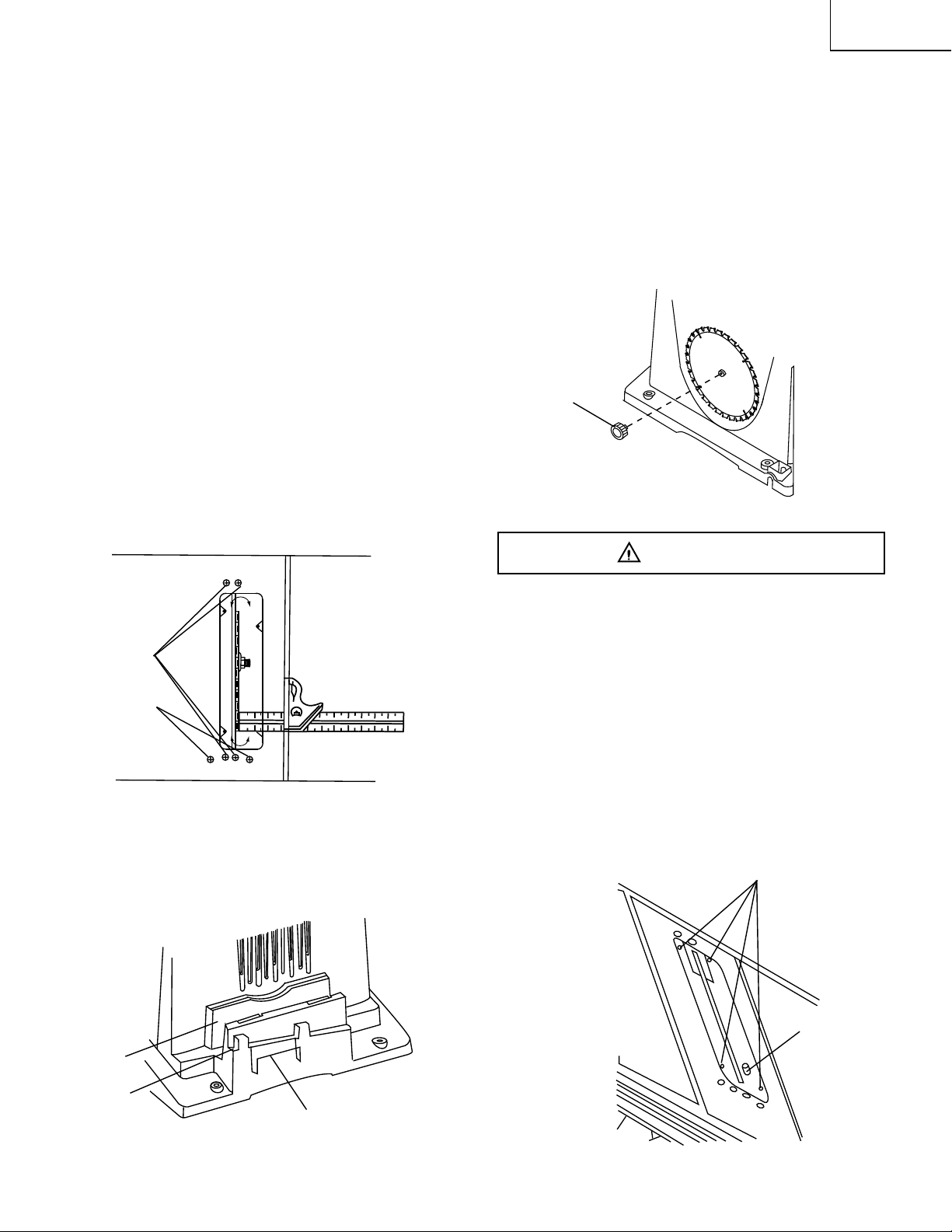

BLADE GUARD ASSEMBLY (FIG. C, D)

2

1

WARNING

To avoid injury from an accidental start, make sure

the switch is in the OFF position and the plug is

disconnected from the power source outlet.

• When installing the blade guard, cover the blade

teeth with a piece of folded cardboard to protect

yourself from possible injury.

• Never operate this machine without the safety

guard in place for all through sawing operations.

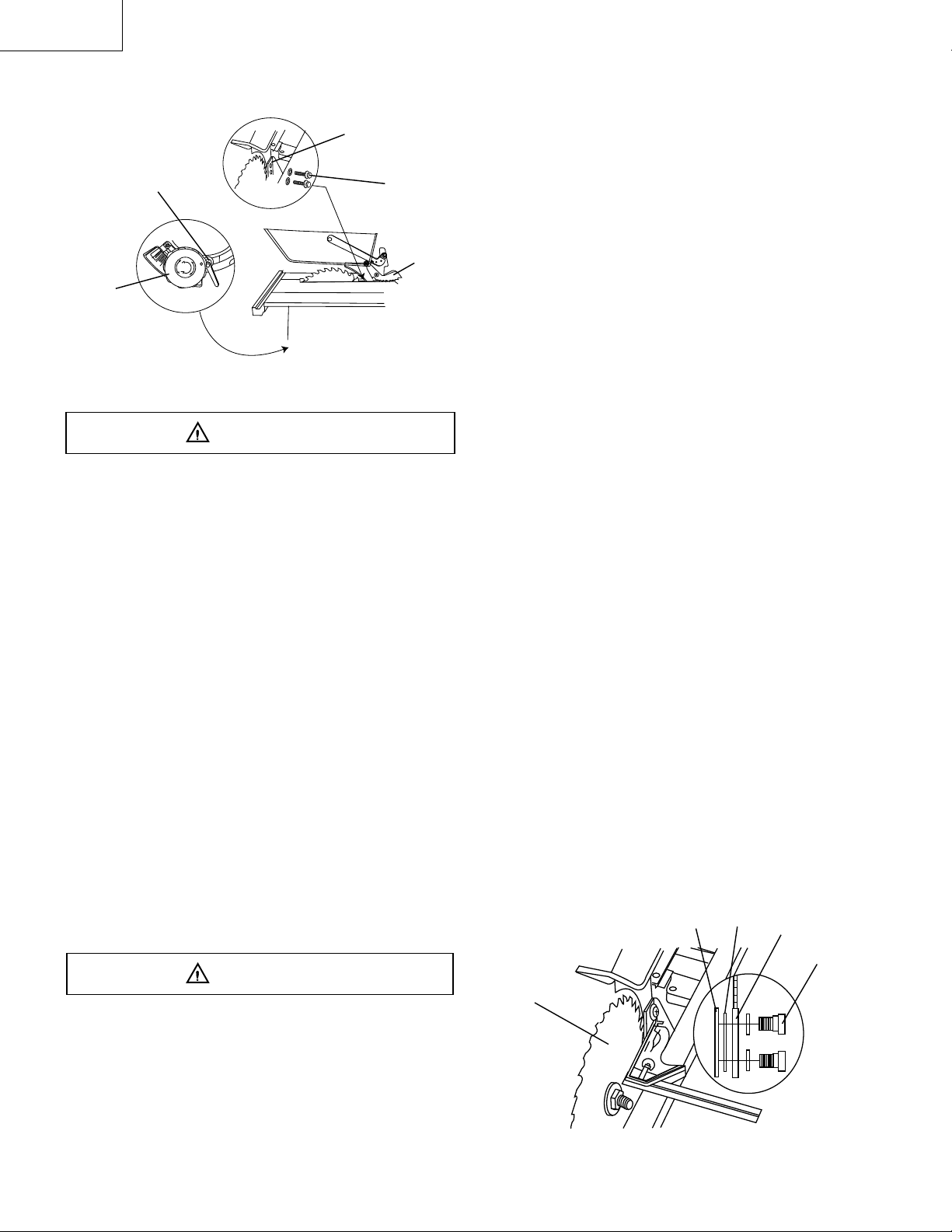

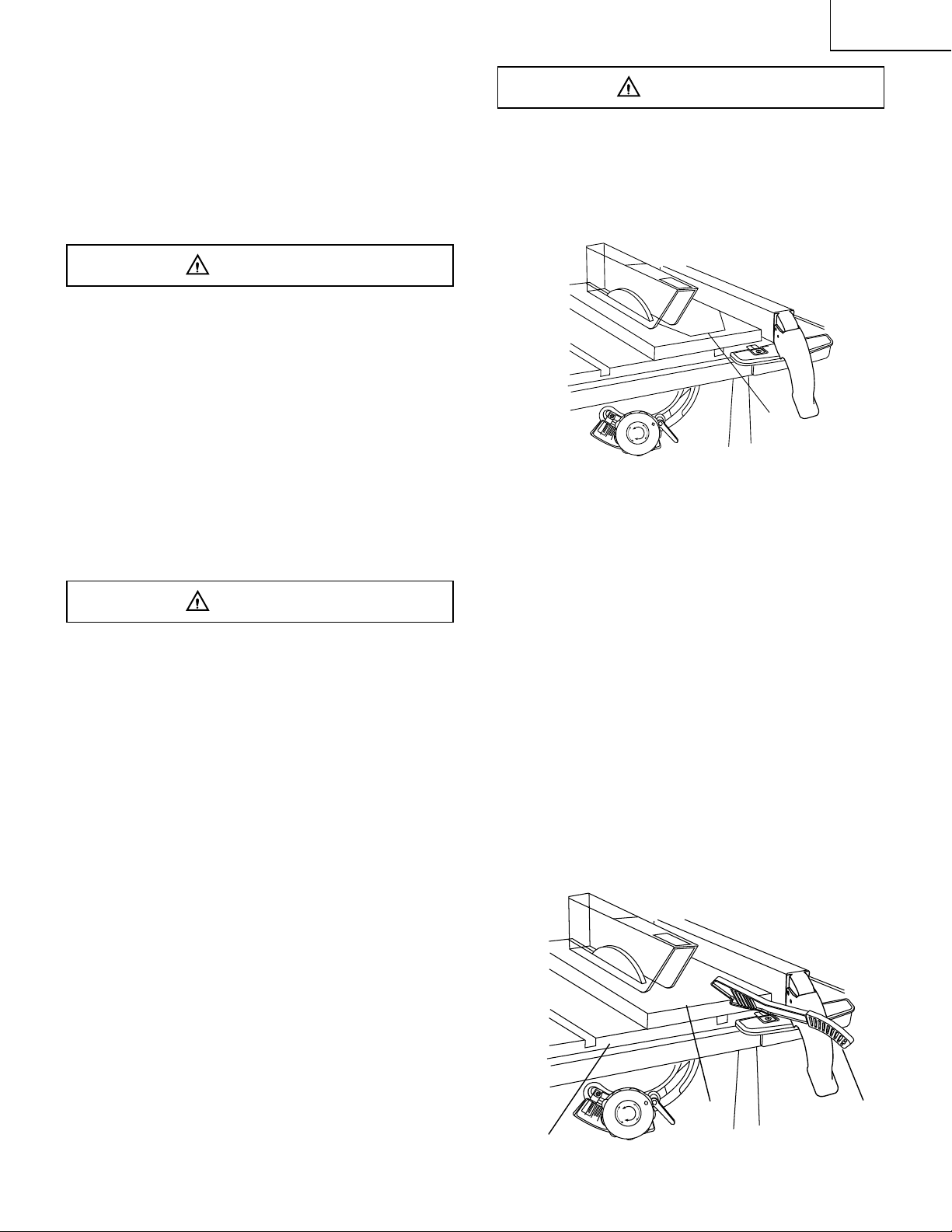

Installing the blade guard assembly (Fig. C)

1. Remove the table insert.

2. With the blade elevation handwheel (1), raise the

blade to the maximum height.

3. Loosen the blade lock handle (2) do not pull on

handle just turn and move the handwheel (1) to 45°

on the bevel scale.

4. Tighten the bevel lock handle.

5. Locate the splitter assembly mounting bracket (3) at

the rear of the blade.

6. Cover the blade teeth with a folded cardboard or

position the plastic blade guard over the blade to

protect your hands.

7. Place the two kickback pawls (4) toward the rear of

the table, and align the splitter mounting holes to the

holes in the bracket.

8. Place the flat washers onto the blade guard lock bolt

and thread the bolt (5) into the the mounting hole, then

tighten securely.

9. Return the blade to 90º and replace the table insert.

– 11 –

Page 12

English

NOTE: Make sure the “anti-kick back pawls do not get

caught between the insert and the guard, but rest on top

of the insert.

3

Fig. C

2

1

Removing the blade guard assembly (Fig. C)

5

4

WARNING

To avoid injury from an accidental start, make sure

the switch is in the OFF position and the plug is

disconnected from the power source outlet.

1. Remove the table insert.

2. With the blade elevation handwheel (1), raise the

blade to the maximum height.

3. Loosen blade lock handle (2) do not pull on handle

just turn and move the handwheel (1) to 45° on the

bevel scale.

4. Tighten the bevel lock handle.

5. Cover the blade teeth with a piece of folded

cardboard or position the plastic blade guard over the

blade to protect your hands.

6. Loosen the nut (5) and remove the blade guard

assembly, then retighten the nut.

7. Return the blade to 90° and replace the table insert.

NOTE: When took off the insert, and rise the blade, kick

back pawl will snap in the hole on the table and can not

take off. Make sure the insert is assembled before rising

the blade.

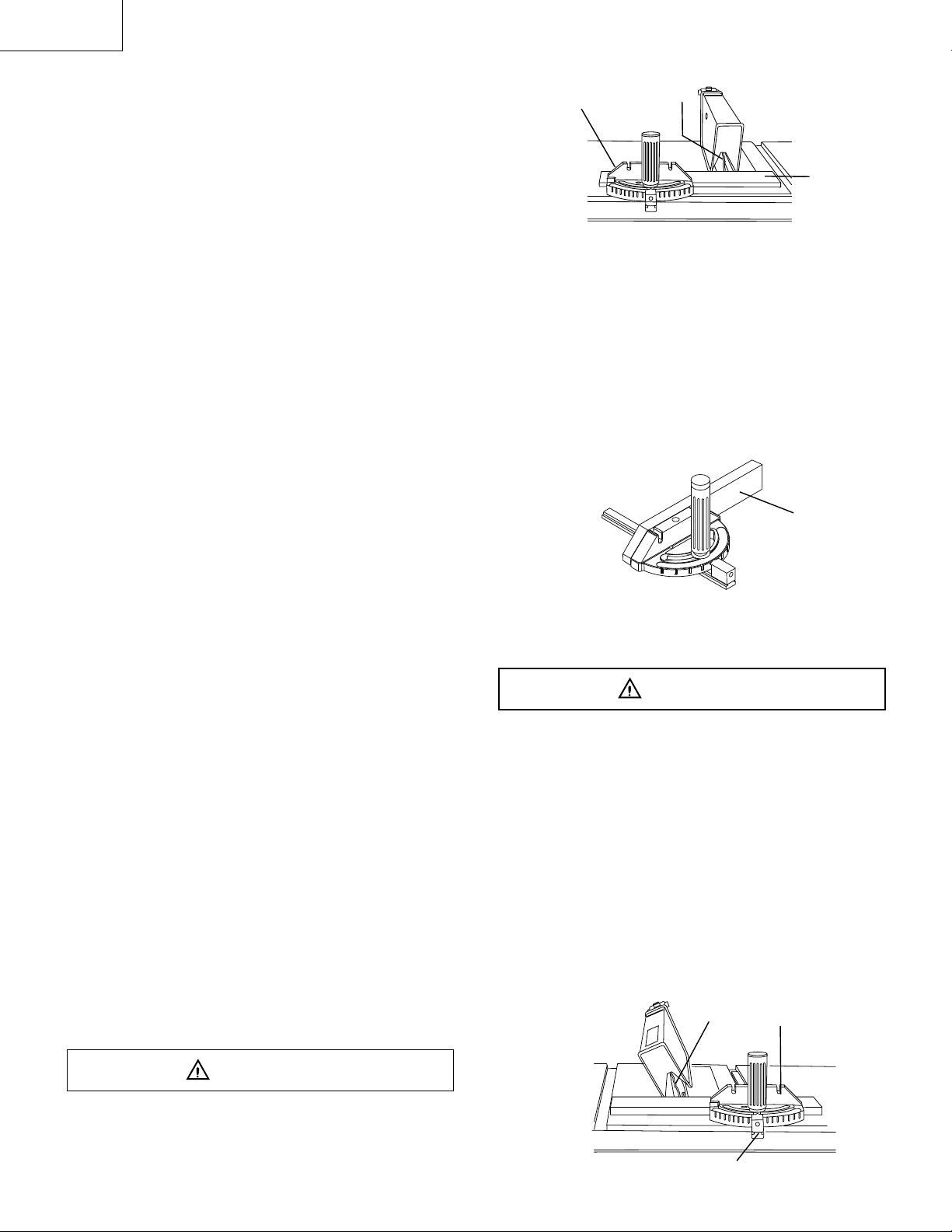

ALIGNING THE BLADE GUARD SPLITTER (FIG. D)

IMPORTANT: The splitter must always be correctly

aligned with the blade so the cut workpiece will pass on

either side without binding or twisting.

1. Remove the table insert and raise the blade to the

maximum height by turning the blade elevation

handwheel clockwise.

2. Lift the blade guard and position it toward the rear of

the table.

3. Adjust the blade to the 90° vertical position by

unlocking the blade tilting lock knob and turning the

bevel tilting handwheel counterclockwise, and then

lock into position.

4. To see if the blade (1) and splitter (2) are correctly

aligned, lay a combination square along the side of

the blade and against the splitter (making sure the

square is between the teeth of the blade).

5. Tilt the blade to the 45° position and check the

alignment again.

6. If the blade and splitter are not correctly aligned:

a. Remove the blade guard by removing the

wing bolt that locks the guard in place.

b. Loosen and remove the two bolts (3) from the

mounting bracket (5).

7. Place two spacers (4) on the guard mounting bracket

(attached to the saw). Position them over the

corresponding mounting bolt holes (refer to step 6-b)

after removing the adhesive backing affixed to the

washers.

8. Replace the two guard mounting bolts (3) and tighten

securely. Also reattach the blade guard assembly,

affixing it to the machine by its’ corresponding wing

bolt.

9. Check the splitter and blade alignment again at both

90° and 45°.

10.Add or remove the spacers until the alignment is

correct.

11.Replace the table insert.

Fig. D

4

5

2

WARNING

To avoid injury from an accidental start, make sure

the switch is in the OFF position and the plug is

disconnected from the power source outlet.

• When installing the blade guard, cover the blade

teeth with a piece of folded cardboard to protect

yourself from possible injury.

• Never operate this machine without the safety guard

in place for all through sawing operations.

3

1

– 12 –

Page 13

English

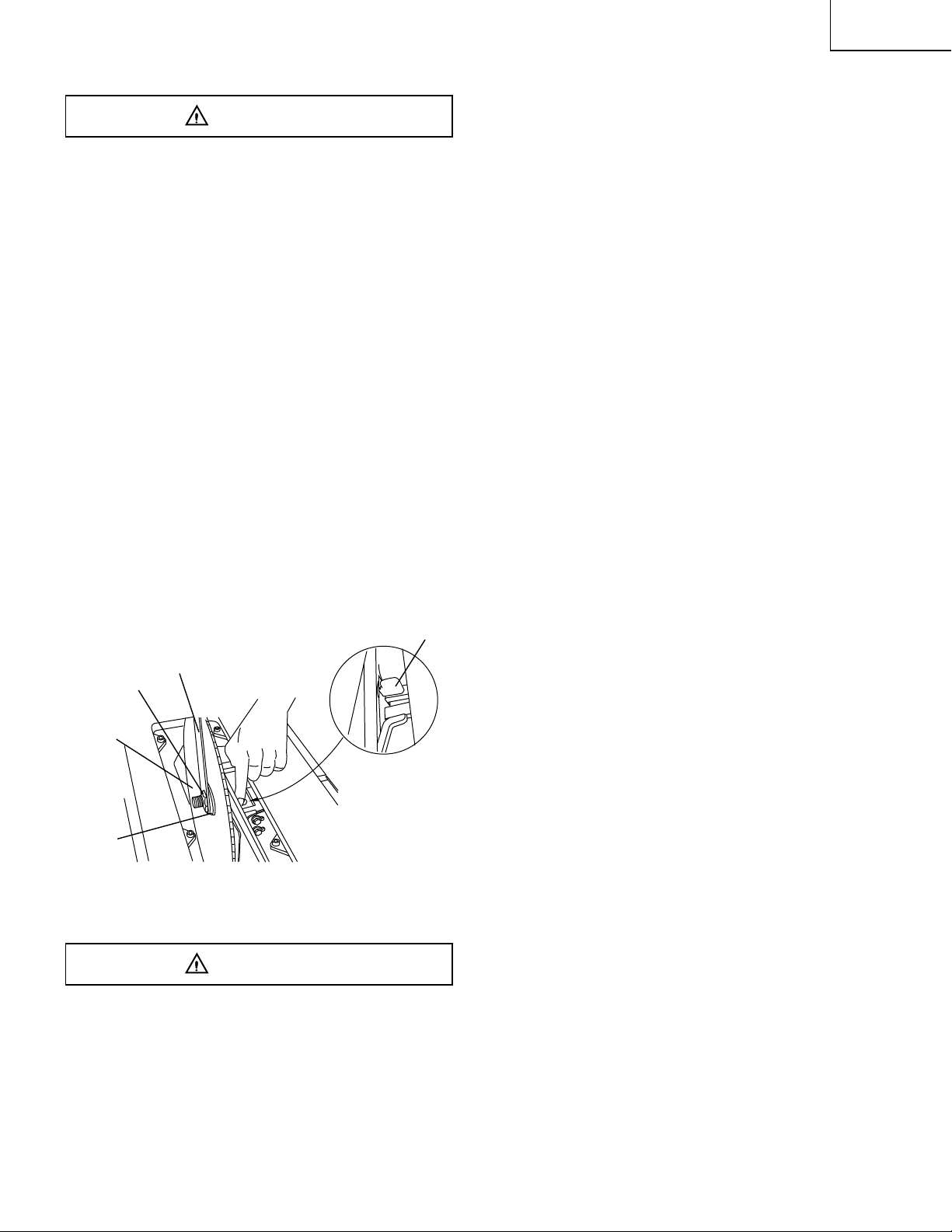

REMOVING THE BLADE (FIG. E)

WARNING

To avoid injury from an accidental start, make sure

the switch is in the OFF position and the plug is

disconnected from the power source outlet.

1. Remove the table insert and raise the blade to the

maximum height by turning the blade elevation

handwheel clockwise.

2. Lift the blade guard and position it toward the rear of

the table.

3. Adjust the blade to the 90° vertical position by

unlocking the blade tilting lock knob and turning the

bevel tilting handwheel counterclockwise, and then

lock into position.

4. Pull the motor locking lever (1) toward the front of the

machine while spinning the blade until the latch locks

into place and the blade will no longer turn.

5. Place the blade wrench (3) on the arbor nut (4).

6. Loosen and remove the arbor nut and the flange by

pulling the wrench toward the front of the

machine.

7. Then remove the blade (6). Clean but do not remove

the inner blade flange (5) before reassembling the

blade.

Fig. E

3

4

6

5

INSTALLING A BLADE (FIG. E)

1

WARNING

To avoid injury from an accidental start, make sure

the switch is in the OFF position and the plug is

disconnected from the power source outlet.

3. Clean the outer blade flange and install it onto the

arbor and against the blade.

4. Thread the arbor nut onto the arbor, making sure the

flat side of the nut is against the blade, then handtighten.

5. Pull the motor locking lever (1) toward the front of the

machine while spinning the blade until the latch locks

into place and the blade will no longer turn.

6. Place the wrench on the arbor nut and turn clockwise

(toward the rear of the saw table).

7. Replace the table insert and blade guard assembly.

Verify that the blade and blade guard splitter are

aligned. If they are not, refer to page 12, Aligning The

Blade Guard Splitter.

IMPORTANT: Do not operate this saw until the blade

and blade guard splitter are aligned and in working

order.

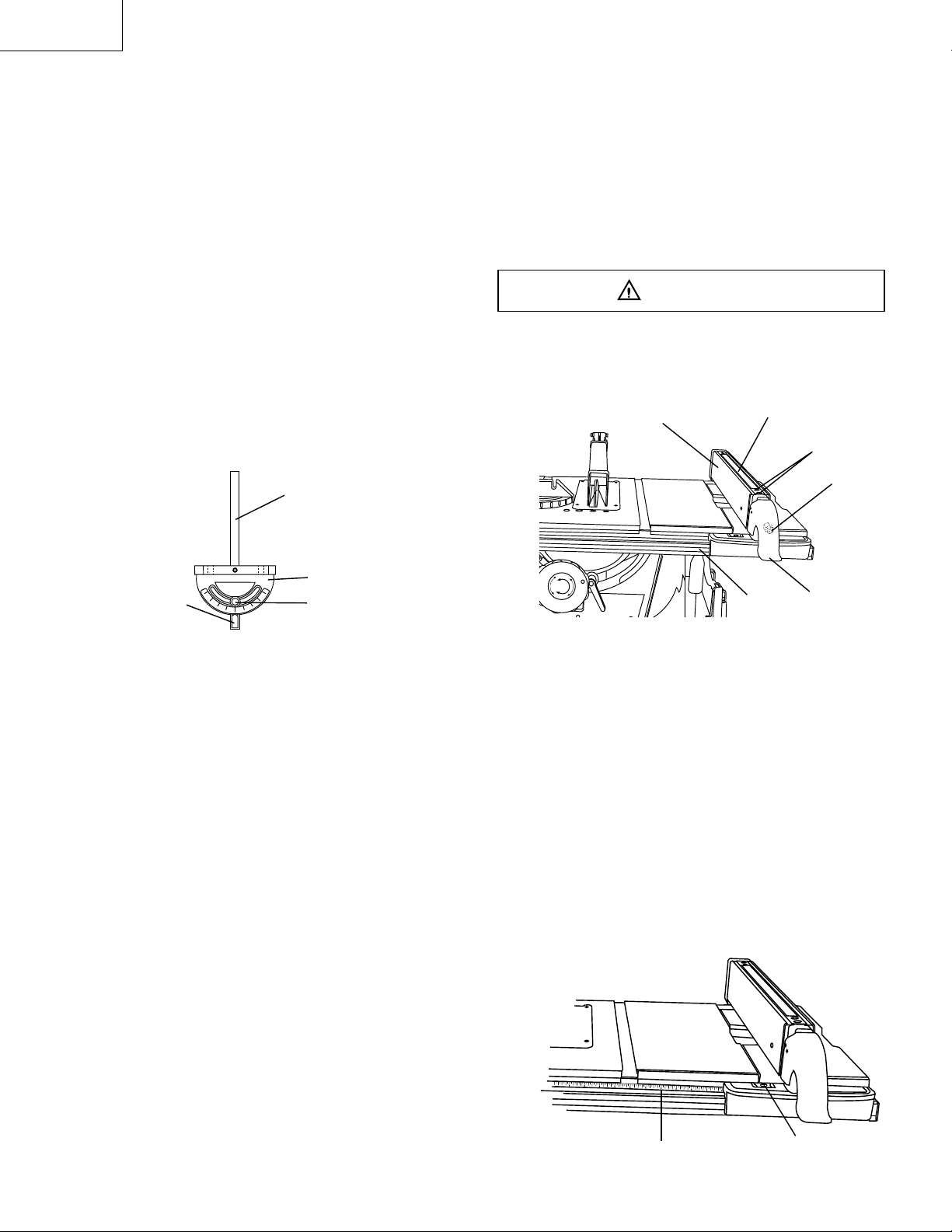

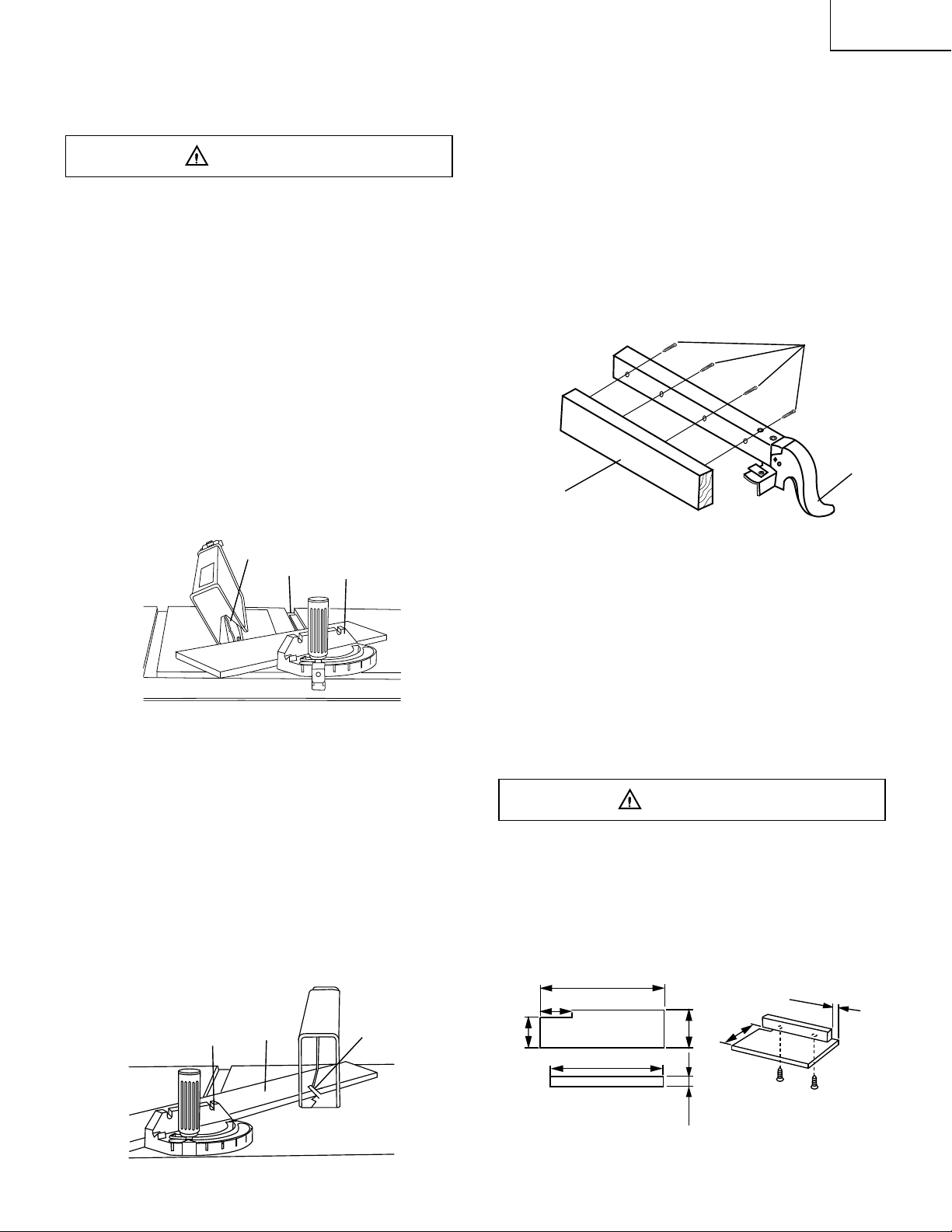

ADJUSTING THE 90° AND 45° POSITIVE STOPS

(FIG. F, G)

Your saw has positive stops that will quickly position

the saw blade at 90° and 45° to the table. Make

adjustments only if necessary.

90° Stop

1. Disconnect the saw from the power source.

2. Raise the blade to the maximum elevation.

3. Loosen the blade bevel lock handle and move the

blade to the maximum vertical position and tighten

the bevel lock handle.

4. Place a combination square on the table and against

the blade (1) to determine if the blade is 90° to the

table. (Fig. F)

5. If the blade is not 90° to the table, loosen or tighten

(depending on increasing or decreasing the degree)

the hex screw (3) with a 5 mm hex wrench until you

achieve 90°.(Fig. G)

6. The re-loosen the bevel lock handle and reset the

blade at the maximum vertical position, then tighten

the bevel lock handle.

7. Check again to see if the blade is 90° to the table. If

not, repeat step 5.

8. Lastly, check the bevel angle scale. If the pointer

does not read 90°, loosen the screw holding the

pointer and move the pointer so it is accurate at 0°

and retighten the pointer screw.

1. Place the blade onto the arbor with the blade teeth

pointing forward to the front of the saw.

2. Make sure the blade fits flush against the inner

flange.

– 13 –

Page 14

English

Fig. F

90° 45°

1

45° Stop

1. Disconnect the saw from the power source.

2. Raise the blade to the maximum elevation.

3. Loosen the blade bevel lock handle and move the

blade to the maximum bevel position (45°)and tighten

the bevel lock handle.

4. Place a combination square on the table and against

the blade (1) to determine if the blade is 45° to the

table. (Fig. F)

5. If the blade is not 45° to the table, loosen or tighten

(depending on increasing or decreasing the degree)

the hex screw (4) with a 5 mm hex wrench until you

achieve 45°. (Fig. G)

6. The, re-loosen the bevel lock handle and reset the

blade at the maximum bevel position (45°), then

tighten the bevel lock handle.

7. Check again to see if the blade is 45° to the table. If

not, repeat step 5.

Fig. G

3

4

2

BLADE PARALLEL TO THE MITER GAUGE GROOVE

(FIG. H)

WARNING

To avoid injury from an accidental start, make sure

the switch is in the OFF position and the plug is

disconnected from the power source outlet.

This adjustment was made at the factory, but it

should be rechecked and adjusted if necessary.

This adjustment must be correct or kickback could

result in a serious injury and accurate cuts cannot

be made.

1. Remove the yellow switch key and unplug the saw.

2. Raise the blade guard away from the blade.

3. Raise the blade to the maximum height and set the

belel angle at 0°

4. Select and mark with a felt tip marker, one blade

tooth with a “right set” angle and position this tooth

at the front of the saw approximately ½” above the

table.

5. Place the combination square base (1) into the right

side miter gauge groove (2) flush against the inside

of the miter gauge groove.

6. Adjust the ruler so it touches the front marked tooth

and lock ruler so it holds its position in the square

assembly.

7. Rotate the blade to the rear of the saw bringing the

marked tooth approximately ½” above the blade.

8. Carefully slide the combination square to the rear

until the ruler touches the marked tooth.

9. If the ruler touches the marked tooth at the front and

rear position, no adjustment is needed at this time. If

not, perform adjustment procedure described in next

section.

Fig. H

BLADE TILT POINTER

1. When the blade is positioned at 90°, adjust the blade

tilt pointer to read 0° on the scale.

2. Loosen the holding screw, position the pointer over

0° and tighten the screw.

NOTE: Make a trial cut on scrap wood before making

critical cuts. Measure for exactness.

1

2

– 14 –

Page 15

English

ADDITIONAL BLADE ADJUSTMENTS (Fig. I)

1. If the front and rear measurements are not the same,

remove the combination square and loosen the four

adjusting screws (1) on the top of the table about a

half turn.

2. With a folded piece of cardboard covering the blade

to protect your hands, move the blade and motor

mounting rod carefully to the left or right as much as

needed to align the blade correctly.

3. Tighten the four screws (1) and re-measure, as

described in steps 4 to 9 in the prior section.

4. If sufficient adjustment cannot be made by the

four adjusting screws (1), then also loosen the two

adjusting screws (2) and repeat all previous steps.

Loosen these screws only if necessary at they are

set for accurate 90° and 45° settings.

5. Recheck blade clearance making sure that the blade

does not hit the table insert or other parts when at the

90° and 45° settings.

6. Re-tighten all four adjusting screws (1) and reset the

90° and 45° setting as stated on page 13.

Fig. I

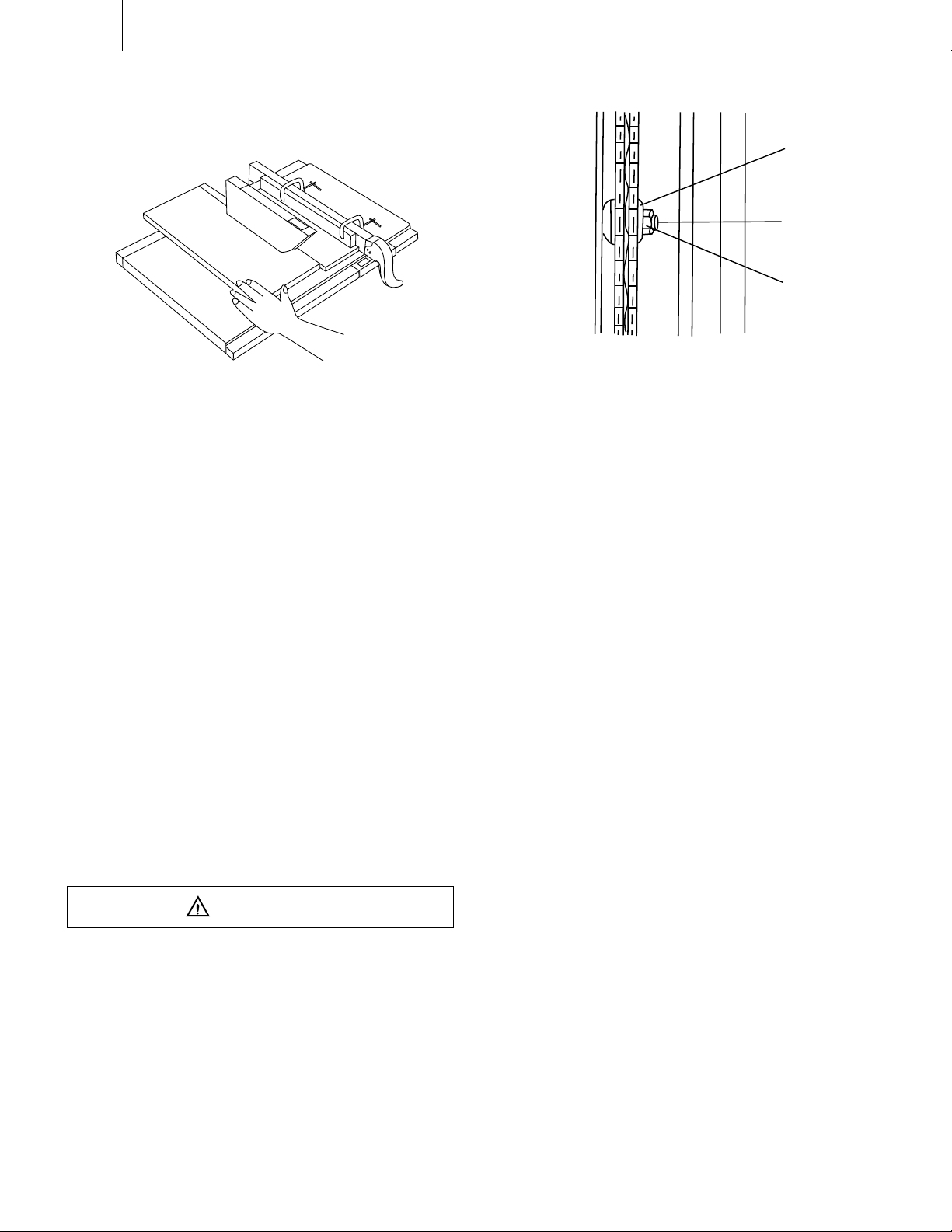

STORAGE (FIG. J, K)

Rip fence and miter gauge (Fig. J)

Storage brackets for the rip fence (3) and miter gauge

(4) are located on the right side of the saw housing.

NOTE:Adjust the miter gauge to 450~600 before putting

to the storage.

Blade (Fig. K)

1. Loosen and remove the knob (1) on the left side of

the saw housing.

2. Place extra blades onto the arbor. Replace the knob

and tighten.

Fig. K

1

INSTALLING THE TABLE INSERT (FIG. L)

1

2

INSTALLING THE PUSH-STICK STORAGE (FIG. J)

Attach the push-stick storage (1) into the right side of the

body shell.

Fig. J

WARNING

The table insert has been previously installed on

your unit. However, you must verify that the table

insert is flush with the table top surface on all four

corners of the insert.

To aviod serious injury , the table insert must be

level with the table.If the table insert is not flush

with the table, adjust the four bolts (1) with a 4

mm hex. wrench until it is parallel with the table.

NOTE: To raise the insert , turn the hex screws

counterclockwise, to lower the insert, turn the hex

screws clockwise.

1. Replace the table insert by pulling out the hold (2) of

the table insert.

1

Fig. L

2

3

4

1

– 15 –

Page 16

English

MITER GAUGE ADJUSTMENT (FIG. M)

1. Make sure that the miter gauge bar (1) will slide

freely through the table top grooves.

2. Loosen the lock knob handle (2) and turn the gauge

body (3) to set the pointer (4) at 0º on the scale.

3. Make a 90º cut in a scrap piece of wood. Check

the cut to see if it is 90º. If not, loosen the lock

knob handle (2) and move the miter gauge body

until it is square to the miter gauge bar by using a

combination square.

MITER GAUGE OPERATION (FIG. M)

The miter gauge is accurately constructed with index

stops at 0º, 15º, 30º, 45º, 60º both right and left side.

The operate the miter gauge, simply loosen the lock

handle (2) and move the body of the miter gauge to the

desired angle. The miter gauge body will stop at 0º, 15º,

30º, 45º, 60º both right and left side.

Fig. M

1

If the fence is loose when the handle is in the locked

position:

1. Move the handle upward to the unlocked position.

Turn the adjusting screw (6) clockwise until the rear

clamp is snug.

2. DO NOT turn the adjusting screw more than 1/4 turn

at a time.

3. Over-tightening the screw will cause the rip fence to

come out of alignment.

WARNING

Failure to properly align the fence can cause “

kickback” and serious injury could occur.

Fig. N

1

5

4

6

3

4

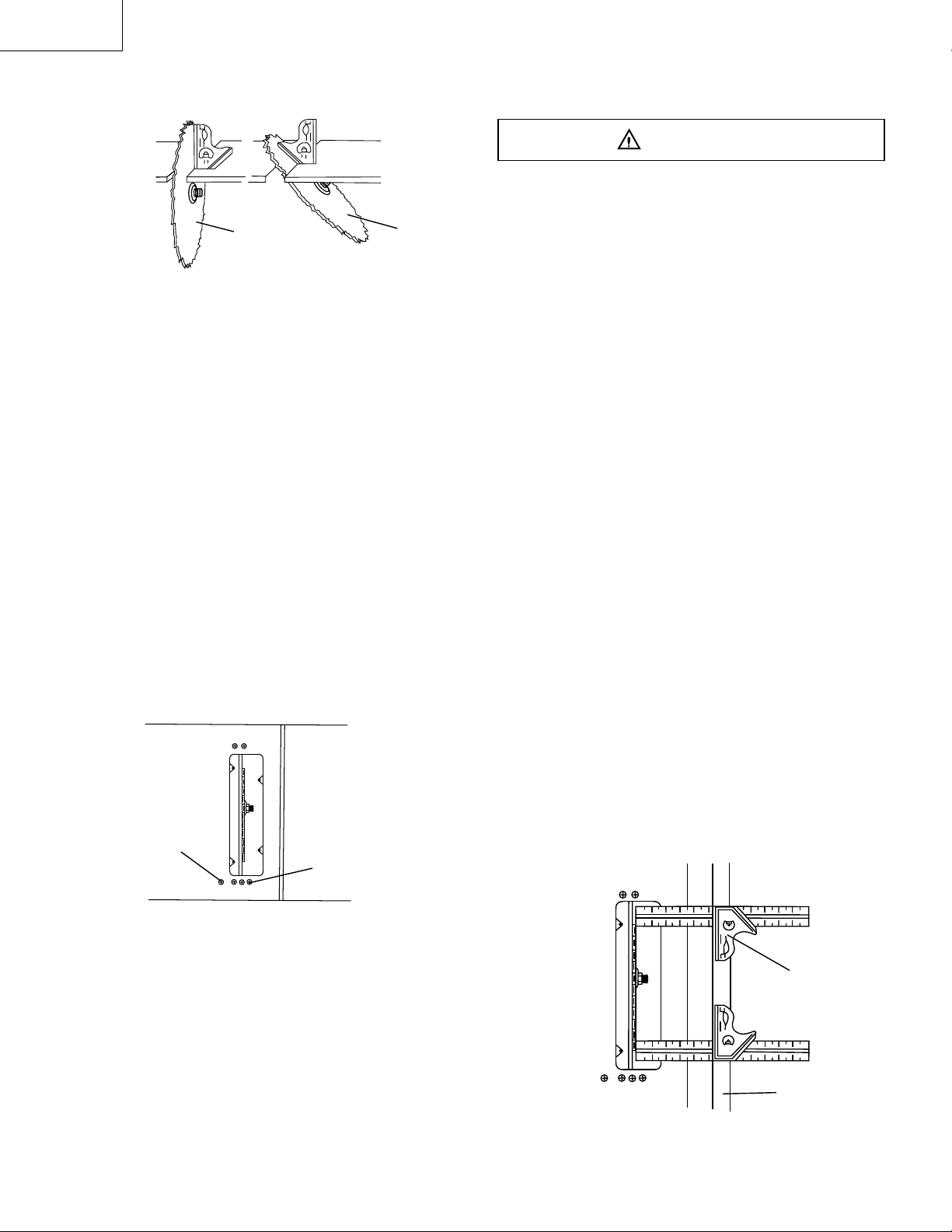

RIP FENCE ADJUSTMENT (FIG. N)

1. For adjustments, position the fence to the right of the

blade, parallel with the miter gauge groove.

2. Place the rear clamp (1) of the fence on the back rail

of the table, and lower the front end over the front

rail (2). Push the handle (3) down to lock.

3. To change the position of the fence, lift up on the

handle to unlock, and slide the fence to the desired

position, then push the handle down to lock.

4. To check the rip fence adjustment, place the fence

along one edge of the miter gauge groove, and lock

the handle. It should be parallel to the miter groove

to provide accurate cuts.

If adjustment is needed to make it parallel:

1. Loosen the two hex wrench bolts (4) on the top of

the rip fence, and lift up on the handle (3).

2. Adjust the fence (5) so it is parallel to the miter

gauge groove and lock the handle (3) into position.

3. Make sure the fence (5) is parallel to the groove and

tighten the two hex wrench bolts (4) securely.

4. Unlock the fence handle (3) and slide the fence left

and right, then reposition it against the miter gauge

groove again and lock into position to double check

its’ alignment.

2

– 16 –

2

RIP FENCE INDICATOR (FIG. O)

NOTE: The rip fence indicator points to the scale on

the front of the table saw. Measurement shown by the

indicator will provide the user with accuracy up to 1/16

of an inch. Measurement shown is the distance from the

blade to the side of the fence closest to the blade.

1. To check the accuracy, measure the actual distance

(1) to the side of the rip fence. If there is a difference

between the measurement and the indicator, adjust

the indicator as shown next.

2. Loosen the indicator screw (2). Slide the indicator to

the correct measurement position on the scale, then

retighten the screw (2).

Fig. O

13

1

3

2

Page 17

TABLE EXTENSION SCALE POINTER (FIG. P)

The table extension scale pointer (1) should be at 13

inches on the scale when the extension is in the closed

position. If not, loosen the holding screw (2), position

the pointer over 13 inches and re-tighten the screw.

Fig. P

1

13

2

English

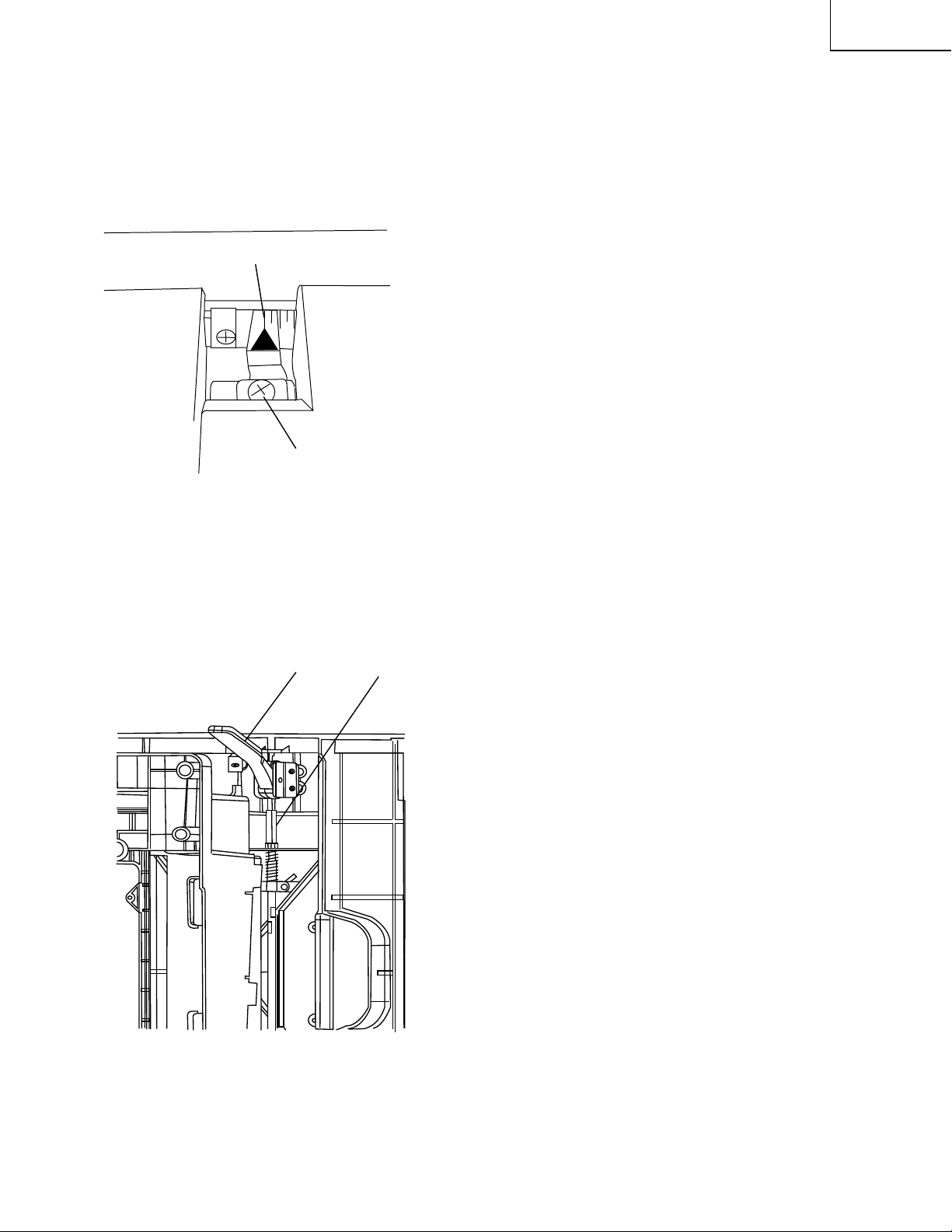

ADJUSTING CAM LOCKING LEVER (FIG. Q)

If the extension table moves when it is open and locked,

then the cam locking lever (1) may be loose and need

adjustment, therefore, adjustment to the cam locking

lever is necessary. To adjust the locking lever tension,

turn the bar (2) with a 10 mm wrench until it is tightened,

but do not over tighten.

Fig. Q

1

2

– 17 –

Page 18

English

OPERATION

BASIC SAW OPERATIONS

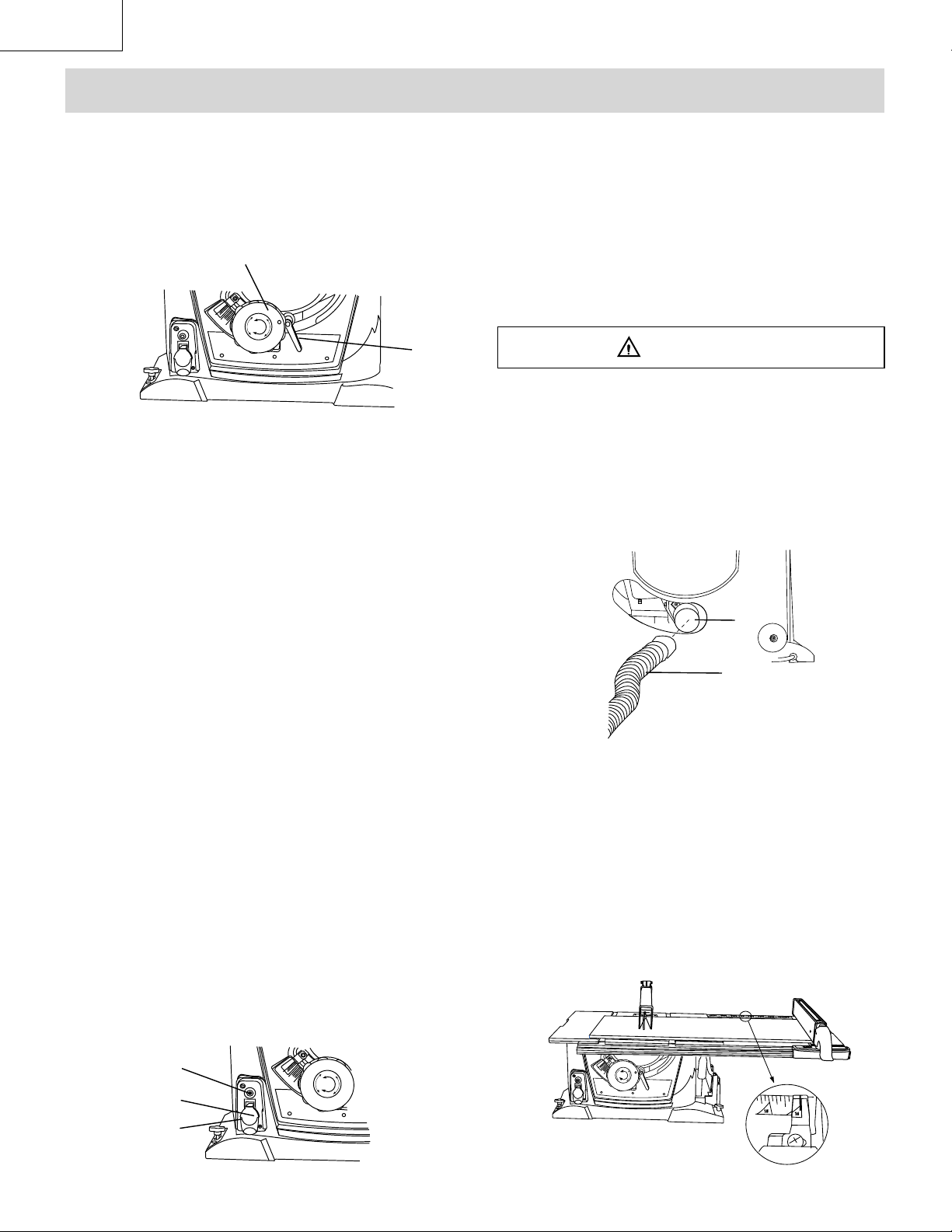

RAISE THE BLADE (FIG. R)

To raise or lower the blade, turn the blade elevation

handwheel (1) to the desired blade height, and then

tighten the bevel lock handle (2) to maintain the desired

blade angle.

Fig. R

TILTING THE BLADE

Two methods are available for tilting the saw blade.

Rapid blade tilting:

Loosen bevel lock handle (2), move the hand wheel (1)

to the desired angle then tighten the bevel lock handle.

Fine adjustment blade tilting:

Loosen the bevel lock handle (2), push in thehand

wheel (1) and at the same time turn the hand wheel

(1) to tilt the saw blade. When the saw blade is at the

desired angle, tighten the bevel lock handle (2).

1

2

OVERLOAD PROTECTION (FIG. S)

This saw has an overload relay button (3) that resets the

motor after it shuts off due to overloading or low voltage.

If the motor stops during operation, turn the ON / OFF

switch to the OFF position. Wait about five minutes for

the motor to cool, the push in on the reset button (3) and

turn the switch to the ON position.

USING THE DUST CHUTE (FIG. T)

WARNING

To prevent fire hazard, clean and remove sawdust

from under the saw frequently.

To prevent sawdust buildup inside the saw housing,

attach a vacuum hose (1) to the dust chute (2) at the

rear of the table saw. DO NOT operate the saw with

the hose in place unless the vacuum is turned on.

Fig. T

2

1

ON/OFF SWITCH (FIG. S)

The ON / OFF switch has a removal key. With the key

removed from the switch, unauthorized and hazardous

use by children and others is minimized.

1. To turn the saw ON, insert the safety switch key

(1) into the slot in the switch (2). Move the switch

upward to the ON position.

2. To turn the saw OFF, move the switch downward.

3. To lock the switch in the OFF position, grasp the end

(or yellow part) of the safety switch (1), and pull it

out.

4. With the switch key removed, the switch will not

operate.

5. If the switch key is removed while the saw is running,

it can be turned OFF but cannot be restarted without

inserting the switch key (1).

Fig. S

3

1

2

USING THE TABLE EXTENSION (FIG. U)

NOTE: Use scale on front rail for rip cuts up to 13”. For

rip cuts greater than 13” set the lock the fence on the

13” mark. Unlock the extension table, and slide the table

with the fence to the desired dimension using the scale

on rear rail.

Release cam locking lever.

1. Slide the table extension to the desired measurement

and then tighten the cam locking lever.

Fig. U

– 18 –

Page 19

CUTTING OPERATIONS

There are two basic types of cuts: ripping and

crosscutting. Ripping is cutting along the length and the

grain of the workpiece. Crosscutting is cutting either

across the width or across the grain of the workpiece.

Neither ripping nor crosscutting may be done safely

freehand. Ripping requires the use of the rip fence, and

crosscutting requires the miter gauge.

WARNING

Before using the saw each and every time, check

the following:

1. The blade is tightened to the arbor.

2. The bevel angle lock knob is tight.

3. If ripping, the fence is locked into position & is parallel

to the miter gauge groove.

4. The blade guard is in place and working properly.

5. Safety glasses are being worn.

English

WARNING

AVOID KICKBACK by pushing forward on the

section of the workpiece that passes between the

blade and the fence. Never perform any freehand

operations.

Fig. V

1

The failure to adhere to these common safety rules,

and those printed in the front of this manual, can greatly

increase the likelihood of injury.

RIPPING (FIG. V, W)

WARNING

To prevent serious injury:

• Never use a miter gauge when ripping.

• Never use more than one rip fence during a

single cut.

• Do not allow familiarity or frequent use of your

table saw to cause careless mistakes. Remember

that even a careless fraction of a second is

enough to cause a severe injury.

• Keep both hands away from the blade and clear

from the path of the blade.

• The workpiece must have a straight edge against

the fence and must not be warped, twisted, or

bowed when ripping.

1. Remove the miter gauge and store it in the “storage”

compartment in the base of the saw.

2. Secure the rip fence to the table.

3. Raise the blade so it is about 1/8” higher than the top

of the workpiece.

4. Place the workpiece flat on the table and against the

fence. Keep the workpiece away from the blade.

5. Turn the saw ON and wait for the blade to come to

full speed.

6. Slowly feed the workpiece into the blade by pushing

forward only on the workpiece section (1) that will

pass between the blade and the fence. (Fig. V)

– 19 –

NOTE: Always use a push stick. When width of the rip is

narrower than 2” the push stick cannot be used because

the guard will interfere…therefore, use the auxiliary

fence so the push stick can be used as shown on page

25.

7. Keep your thumbs off the table top. When both of

your thumbs touch the front edge of the table (2),

finish the cut with a push stick. To make an additional

push stick, use the pattern on page 25.

8. The push stick (3) should always be used. (Fig. W)

9. Continue pushing the workpiece with the push stick

(3) until it passes through the blade guard and clears

the rear of the table.

10.Never pull the piece back when the blade is turning.

Turn the switch OFF. When the blade completely

stops, you can then remove the workpiece.

Fig. W

1

2

3

Page 20

English

BEVEL RIPPING

This cut is the same as ripping except the blade bevel

angle is set to an angle other than “0º”.

RIPPING SMALL PIECES

To avoid injury from the blade contact, never make cuts

narrower than 1/2” wide.

1. It is unsafe to rip small pieces. Instead, rip a larger

piece to obtain the size of the desired piece.

2. When a small width is to be ripped and your hand

cannot safely pass between the blade and the rip

fence, use one or more push sticks to move the

workpiece. Always use a push stick during ripping

operations.

CROSSCUTTING (FIG. X)

To prevent serious injury:

• Do not allow familiarity or frequent use of your table

saw to cause careless mistakes. Remember that

even a careless fraction of a second is enough to

cause a severe injury.

• Keep both hands away from the blade and the path

of the blade.

• Never attempt to pull the workpiece backwards

during a cutting operation. This will cause kickback

and serious injury to the user can occur.

1. Remove the rip fence and place the miter gauge in a

miter gauge groove on the table.

2. Adjust the blade height so it is 1/8 in. higher than the

top of the workpiece.

3. Hold the workpiece firmly against the miter gauge

with the blade path in line with the desired cut

location. Move the workpiece to 1in. distance from

the blade.

4. Start the saw and wait for the blade (1) to come up

to full speed. Never stand directly inline of the saw

blade path, always stand to the side of the blade that

you are cutting on.

5. Keep the workpiece (2) against the face of the miter

gauge (3) and flat against the table. Then slowly

push the workpiece through the blade.

6. Do not try to pull the workpiece back with the blade

turning. Turn the switch OFF, and carefully slide the

workpiece out when the blade is completely stopped.

Fig. X

3

USING WOOD FACING ON THE MITER GAUGE

(Fig. X-1)

Slots are provided in the miter gauge for attaching an

auxiliary facing (1) to make it easier to cut very long or

short pieces. Select a suitable piece of smooth wood,

drill two holes through it and attach it to the miter gauge

with screws. Make sure the facing does not interfere

with the proper operation of the sawblade guard. When

cutting long workpieces, you can make a simple outfeed

support by clamping a piece of plywood to a sawhorse.

Fig. X-1

BEVEL CROSSCUTTING (FIG. Y)

This cutting operation is the same as crosscutting

except the blade is at bevel angle other than 0°.

1

2

1

WARNING

Always work to the right side of the blade during

this type of cut. The miter gauge (1) must be in the

right side groove (2) because the bevel angle may

cause the blade guard to interfere with the cut if

used on the left side groove.

1. Adjust the blade (3) to the desired angle, and tighten

the blade bevel lock knob.

2. Tighten miter lock handle at 90°.

3. Hold workpiece firmly against the face of the miter

gauge (1) throughout the cutting operation.

NOTE: When tilting the blade to 45°, the miter gauge

handle will hit the blade guard.

Fig. Y

3

1

WARNING

Always position the larger surface of the workpiece

on the table when crosscutting and/or bevel

crosscutting to avoid instability.

– 20 –

2

Page 21

English

COMPOUND MITER CROSSCUTTING (FIG. Z)

This sawing operation is combining a miter angle with a

bevel angle.

WARNING

Always work to the right side of the blade during this

type of cut. The miter gauge (3) must be in the right

side groove because the bevel angle may cause the

blade guard to interfere with the cut if used on the

left side groove.

When tilting the workpiece to 45° and push it toward

the blade, the blade guard may hit the blade. To

avoid injury, stop the work at that time.

1. Set the miter gauge (3) to the desired angle.

2. Place the miter gauge (3) in the right side groove (2)

of the table.

3. Set the blade (1) bevel to the desired bevel angle

and tighten the blade bevel lock knob.

4. Hold workpiece firmly against the face of the miter

gauge (3) throughout the cutting operation.

USING WOOD FACING ON THE RIP FENCE

(FIG. BB)

When performing some special cutting operations, add

a wood facing (1) to either side of the rip fence (2).

1. Use a smooth straight 3/4 in. thick wood board (1)

that is as long as the rip fence.

2. Attach the wood facing to the fence with wood

screws (3) through the holes in the fence. A wood

fence should be used when ripping material such as

thin paneling to prevent the material from catching

between the bottom of the fence and the table.

Fig. BB

3

2

1

Fig. Z

1

2

3

MITER CUTS (FIG. AA)

This sawing operation is the same as crosscutting

except the miter gauge is locked at an angle other

than 90°.

1. Set the blade (1) to 0° bevel angle and tighten the

blade bevel lock knob.

2. Set the miter gauge (3) at the desired miter angle and

lock in position by tightening the miter gauge locking

handle.

3. Hold the workpiece (2) firmly against the face of the

miter gauge throughout the cutting operation.

Fig. AA

3

2

1

AUXILIARY FENCE (FIG. CC)

Making the base:

• Start with a piece of 3/8” plywood at least 5-1/2” wide

or wider and 30” long or longer.

• Cut the piece to shape and size shown:

Making the side:

• Start with a piece of 3/4” plywood at least 2-3/8” wide

or wider and 27” long or longer

• Cut the piece to shape and size shown:

Putting it together:

• Put the pieces together, as shown:

WARNING

Make sure the screw heads do not stick out from the

bottom of the base, they must be flush or recessed.

The bottom must be flat and smooth enough to rest

on the saw table without rocking.

Fig. CC

30”

2-5/8”

3/8” Thick plywood base

3-1/2”

3/4” Thick plywood side

27”

5-1/2”

4-3/4”

1-1/4”

– 21 –

2-3/8”

Page 22

English

Attach auxiliary fence to rip fence with two “C”

clamps. (Fig. DD)

Fig. DD

DADO CUTS (FIG. EE)

1. The dado blade insert is included with this saw.

Remove the saw blade, original table inser and blade

guard. Install the dado and dado blade insert.

2. Instruction for operating the dado is packed with the

separately purchased dado set.

3. The arbor (1) on this saw restricts the maximum

width of the cut to 13/16”.

4. When making full 13/16” dado cuts, it is not

necessary to install the outside flange (2) before

screwing on the arbor nut (3). Make sure that the

arbor nut (3) is tight, and that at least one thread of

the arbor sticks out past the nut.

5. Do not exceed 8” diameter dadoes and keep the

width 13/16” or less. It will be necessary to remove

the blade guard and splitter when using a dado

blade. Always use caution when operating a dado

blade.

6. Use only the correct number of round outside blades

and inside chippers as shown in the dado set’s

instruction manual. Blade or chipper must not exceed

13/16”.

7. Check saw to ensure that the dado will not strike the

housing, insert, or motor when in operation.

Fig. EE

2

1

3

WARNING

For your own safety, always replace the blade, blade

guard assembly, and blade insert when you are

finished with the dado operation.

– 22 –

Page 23

MAINTENANCE

English

MAINTAINING YOUR TABLE SAW

GENERAL MAINTENANCE

WARNING

For your own safety, turn the switch OFF and

remove the switch key. Remove the plug from

the power source outlet before maintaining or

lubricating your saw.

1. Clean out all sawdust that has accumulated inside

the saw cabinet and the motor.

2. Polish the saw table with an automotive wax to keep

it clean and to make it easier to slide the workpiece.

3. Clean cutting blades with pitch and gum remover.

4. A worn, cut, or damaged power cord should be

replaced immediately.

WARNING

All electrical or mechanical repairs should be

attempted only by a trained repair technician.

Contact the nearest Hitachi Authorized Service

Center for service. Use only identical replacement

parts. Any other parts may create a hazard.

5. Use liquid dish washing detergent and water to clean

all plastic parts.

NOTE: Certain cleaning chemicals can damage

plastic parts.

6. Avoid use of cleaning chemicals or solvents,

ammonia and household detergents containing

ammonia.

Fig. FF

1

2

Place a small amount of dry lubricant on the bevel gear

(2). The screw rod (1) must be kept clean and free of

sawdust, gum, pitch, and other contaminants for smooth

operations.

If excessive looseness is observed in any parts of the

blade raising mechanism or tilting mechanism, contact

Hitachi Authorized Service Center immediately.

LUBRICATION

All motor bearings are permanently lubricated at the

factory and require no additional lubrication.

On all mechanical parts of your table saw where a pivot

or threaded rod are present, lubricate using graphite or

silicone. These dry lubricants will not hold sawdust as

would oil or grease.

BLADE RAISING AND TILTING MECHANISM

(FIG. FF)

After each five hours of operation, the blade raising

mechanism and tilting mechanism should be checked

for looseness, binding, or other abnormalities.

1. With the saw disconnected from the power source,

turn the saw upside down and alternately pull upward

and downward on the motor unit.

2. Observe any movement of the motor mounting

mechanism. Looseness or play in the blade raising

screw rod (1) should be limited to 1/8” or less.

3. If excessive looseness is observed in any other part

of the blade raising mechanism or tilting mechanism,

contact Hitachi Authorized Service Center

immediately.

– 23 –

Page 24

English

TROUBLESHOOTING GUIDE

WARNING

To avoid injury from an accidental start, turn the switch OFF and always remove the plug from the power

source before making any adjustments.

• Consult Hitachi Authorized Service Center if for any reason the motor will not run.

SYMPTOM POSSIBLE CAUSES CORRECTIVE ACTION

Saw will not start. 1. Saw not plugged in.

2. Fuse blown or circuit breaker tripped.

3. Cord damaged.

Does not make accurate 45°

and 90° rip cuts.

Material pinched blade when

ripping.

Material binds on splitter. 1. Splitter not aligned correctly with blade. 1. Check and align splitter with blade.

Saw makes unsatisfactory

cuts.

Material kicked back from

blade.

Blade does not raise or tilt

freely.

Blade does not

come up to

Machine vibrates excessively. 1. Saw not mounted securely to workbench.

Does not make accurate 45°

and 90° crosscuts.

speed.

1. Positive stop not adjusted correctly.

2. Tilt angle pointer not set accurately.

1. Rip fence not aligned with blade.

2. Warped wood, edge against fence is not

straight.

1. Dull blade.

2. Blade mounted backwards.

3. Gum or pitch on blade.

4. Incorrect blade for work being done.

5. Gum or pitch on blade causing erratic

feed.

1. Rip fence out of adjustment.

2. Splitter not aligned with blade.

3. Feeding stock without rip fence.

4. Splitter not in place.

5. Dull blade.

6. The operator letting go of material before

it is past saw blade.

7. Miter angle lock knob is not tight.

1. Sawdust and dirt in raising/tilting

mechanisms.

1. Extension cord too light or too long.

2. Low house voltage.

2. Bench on uneven floor.

3. Damaged saw blade.

1. Miter gauge out of adjustment. 1. Adjust miter gauge.

1. Plug in saw.

2. Replace fuse or reset circuit breaker.

3. Have cord replaced by Hitachi

Authorized Service Center.

1. Check blade with square and adjust

positive stop.

2. Check blade with square and adjust to

zero.

1. Check and adjust rip fence.

2. Select another piece of wood.

1. Replace blade.

2. Turn the blade around.

3. Remove blade and clean with

turpentine and coarse steel wool.

4. Change the blade.

5. Clean table with turpentine and steel

wool.

1. Align rip fence with miter gauge slot.

2. Align splitter with blade.

3. Install and use rip fence.

4. Install and use splitter. (with guard)

5. Replace blade.

6. Push material all the way past saw

blade before releasing work.

7. Tighten knob.

1. Brush or blow out loose dust and dirt.

1. Replace with adequate size cord.

2. Contact your electric company.

1. Tighten all mounting hardware.

2. Reposition on flat level surface. Fasten

to floor if necessary.

3. Replace blade.

– 24 –

Page 25

PUSH STICK CONSTRUCTION

●

This is a full-size drawing (actual size)

●

Use good quality plywood or solid wood

●

Use 1/2 in. or 3/4 in. material

●

Push stick MUST be thinner than the width

of material being cut

English

Drill Hole For

Hanging

Notch To Prevent

Hand From

Slipping

Cut Here To

Push 1/2 in.

Wood

– 25 –

Cut Here To

Push 3/4 in.

Wood

Page 26

Français

AVERTISSEMENT

Des études effectuées en Californie ont démontré que la poussière produite par le ponçage, le sciage, le

meulage, le perçage et les autres travaux de construction contient des produits chimiques pouvant causer le

cancer, des anomalies congénitales et autres dommages au système reproducteur. Voici des exemples de

ces produits chimiques :

• Peintures fabriquées à base de plomb

• Silice cristalline contenue dans la brique, le ciment et autres produits de maçonnerie

• Arsenic et chrome contenus dans le bois traité chimiquement

Le degré de risque relié à l’exposition à ces produits dépend de la fréquence à laquelle vous effectuez ce type

de travail. Pour réduire l’exposition à ces produits chimiques, on recommande de travailler dans une pièce

bien aérée et de porter l’équipement de sécurité approprié comme un masque antipoussières spécialement

conçu pour filtrer les particules microscopiques.

FICHE TECHNIQUE DU PRODUIT

MOTEUR SCIE

HP (Maximum d velopp)............................. 4.4 Dimensions de la table

Type …………………................................ Universel avec rallonges............................... 30-1/4 po x 21po

Intensité .................................................... 15 Rallonges...................................... Droite et arrière

Tension ...................................................... 120 Capacité, guide de rallonge ......... 24-1/2 po à droite

Hz .............................................................. 60 Dimension de la lame………......... 10 po

Tr/min (sans charge)….............................. 4000 Guide de coupe de fil ................... OUI

Protection contre surcharges.................... OUI Échelle de refente ........................ OUI

Guide de refente……………......... OUI

Prof. max. de coupe @ 90º........... 3-1/8 po

Prof. max. de coupe @ 45º........... 2-1/4 po

Largeur max. des rainures ........... 13/16 po

Poids net ...................................... 70.4 LIVRES

AVERTISSEMENT

Pour éviter les risques électriques, les risques d’incendie et l’endommagement de la scie à table, utiliser circuit

de protection approprié. Cette scie à table a été câblée à l’usine pour fonctionner sur courant de 110-120 volts.

Elle doit être branchée à un circuit de 110-120 volts avec fusible à fusion temporisée ou disjoncteur de 15

ampères. Pour éviter les risques électriques ou les incendies, remplacer immédiatement le cordon électrique s’

il est usé, coupé ou endommagé.

Avant d’utiliser la scie à table, il est important de lire et de comprendre ces consignes de sécurité. Le nonrespect de ces consignes peut entraîner des dommages à la scie ou causer de graves blessures.

– 26 –

Page 27

Français

CONSIGNES DE SÉCURITÉ SUR LES OUTILS

AVERTISSEMENT

Avant d’utiliser la scie à table, il est essentiel de lire et de comprendre les consignes de sécurité suivantes. Le

non-respect de ces consignes peut entraîner l’endommagement de la scie ou causer des blessures graves.

La sécurité est une combinaison de bon sens, de vigilance

et d’une utilisation adéquate de la scie à table. Pour éviter

toute erreur pouvant causer des blessures graves, ne pas

brancher la scie à table avant d’avoir lu et bien compris les

consignes suivantes :

1. Lire et se familiariser avec ce Guide d’utilisation.

APPRENDRE à connaître les limites d’utilisation et les

risques que présente cet outil

2.

Rechercher ce symbole qui identifie des consignes

3. NE JAMAIS UTILISER CET OUTIL SANS LE

4. NE PAS UTILISER CET OUTIL DANS UN

5. NE PAS utiliser d’outils électriques en présence de

6. GARDER LA SURFACE DE TRAVAIL PROPRE.

7. GARDER LES ENFANTS À L’ÉCART. Tous les

8. NE PAS FORCER L’OUTIL. Il a un fonctionnement

9. UTILISER LE BON OUTIL. Ne pas utiliser un outil ou un

10. PORTER DES VÊTEMENTS APPROPRIÉS. NE PAS

11. PORTER UN MASQUE PROTECTEUR OU UN

12. DÉBRANCHER LES OUTILS avant d’effectuer l’

13. LIMITER LES RISQUES DE MISE EN MARCHE

14. N’UTILISER QUE LES ACCESSOIRES

AVERTISSEMENT

de sécurité importantes. Il signifie ATTENTION!

SOYEZ VIGILANT! VOTRE SÉCURITÉ EST EN JEU!

PROTECTEUR EN PLACE POUR TOUTES LES

OPÉRATIONS DE COUPE COMPLÈTES.

ENVIRONNEMENT DANGEREUX comme des endroits

humides ou mouillés et ne pas l’exposer à la pluie.

Garder la surface de travail bien éclairée.

liquides ou de gaz inflammables.

Les surfaces de travail et les établis mal ordonnés

augmentent les risques d’accident.

visiteurs doivent être gardés à une distance sécuritaire

de l’aire de travail.

optimal et sécuritaire au régime pour lequel il a été

conçu.

accessoire pour faire un travail pour lequel il n’a pas été

conçu.

porter de vêtements amples, des gants, des cravates,

des bagues, des bracelets ou d’autres bijoux pouvant

se prendre dans les pièces mobiles. On recommande

de porter des chaussures andidérapantes. Porter un

dispositif de protection des cheveux afin de retenir les

cheveux longs.

MASQUE ANTIPOUSSIÈRES. Les opérations de

sciage, de coupe et de ponçage produisent de la

poussière.

entretien et de changer les accessoires comme les

lames, les fraises, etc.

ACCIDENTELLE. S’assurer que l’interrupteur est réglé

à OFF avant de brancher l’outil.

RECOMMANDÉS. Consulter le Guide d’utilisation pour

connaître les accessoires recommandés. L’utilisation d

– 27 –

’accessoires incorrects peut causer des blessures ou

endommager l’outil

15. RETIRER LES CLÉS ET CLÉS DE RÉGLAGE. Prendre

l’habitude de vérifier que les clés de réglage sont

retirées de l’outil avant de le mettre SOUS TENSION.

16. NE JAMAIS LAISSER UN OUTIL FONCTIONNER

SANS SURVEILLANCE. RÉGLER L’INTERRUPTEUR

À OFF. Ne pas s’éloigner de l’outil tant qu’il n’est pas

complètement arrêté.

17. NE JAMAIS S’APPUYER SUR L’OUTIL. Des blessures

graves peuvent se produire si l’outil se renverse ou si on

est accidentellement en contact avec l’outil de coupe.

18. NE PAS S’ÉTIRER POUR ATTEINDRE UN OBJET

ÉLOIGNÉ. Travailler de façon à conserver en tout

temps son équilibre.

19. ENTRETENIR LES OUTILS AVEC SOIN. Garder les

outils bien affûtés et propres pour obtenir le meilleur

rendement possible en toute sécurité. Pour le graissage

et le changement d’accessoires, suivre les directives.

20. S’ASSURER QU’IL N’Y A PAS DE PIÈCES

ENDOMMAGÉES OU DESSERRÉES. Avant d’

utiliser l’outil, vérifier attentivement les protecteurs et

pièces endommagées afin de déterminer s’ils pourront

fonctionner adéquatement et exécuter la tâche pour

laquelle ils sont conçus. S’assurer que les pièces

mobiles sont bien alignées, qu’elles ne sont pas

grippées, cassées, mal montées et qu’elles sont dans

un état propre à leur bon fonctionnement. Un protecteur

ou une pièce endommagée ou desserré doit être réglé,

réparé ou remplacé.

21. EMPÊCHER LES ENFANTS DE PÉNÉTRER DANS

L’ATELIER en posant des cadenas, ou prendre les

mesures de sécurité nécessaires en installant un

disjoncteur ou en retirant les clés de démarrage.

22. NE PAS utiliser l’outil si on est sous l’influence de

drogues, d’alcool ou de médicaments pouvant affecter

la capacité d’utiliser l’outil correctement.

23. UTILISER UN SYSTÈME D’ASPIRATION DE LA

SCIURE dans le mesure du possible. La poussière

créée par certains matériaux peut être dangereuse

pour la santé, et, dans certains cas, créer un risque d

’incendie. Toujours utiliser l’outil dans une pièce bien

aérée et prévoir un dispositif efficace d’évacuation de la

poussière.

24. TOUJOURS PORTER DES LUNETTES DE

PROTECTION. Tout outil électrique peut projeter des

corps étrangers qui risquent de causer des lésions

oculaires permanentes. TOUJOURS porter des lunettes

de sécurité (pas de simples lunettes) conformes à la

norme de sécurité ANSI Z87.1. Les lunettes ordinaires

ne résistent qu’aux chocs. Ce NE SONT PAS des

lunettes de protection.

NOTE : Les lunettes de sécurité non conformes à

la norme ANSI Z87.1 peuvent causer des blessures

graves si elles se brisent.

25. SENS DE LA ROTATION. Pousser la pièce à scier sur

la lame, contre son sens de rotation seulement.

Page 28

Français

CONSIGNES DE SÉCURITÉ SUR LA SCIE À TABLE

1. TOUJOURS UTILISER LE PROTÈGE-LAME,

le fendeur et les cliquets antirecul pour chaque

opération pour lesquelles ils doivent être utilisés, y

compris la coupe complète. Les coupes complètes

sont celles au cours desquelles la lame coupe tout

le morceau de bois, aussi bien sur le sens de la

longueur que de la largeur.

2. TOUJOURS IMMOBILISER LA PIÈCE À SCIER

contre la jauge à onglets ou le guide de refente.

3. UTILISER UN POUSSOIR si nécessaire. Toujours

utiliser un poussoir en particulier pour scier

un morceau de bois étroit. Voir les directives

concernant les opérations de refente dans le Guide

d’utilisation où on décrit en détail le poussoir. Un

modèle pour fabriquer son propre poussoir est

inclus à la page 48.

4. NE JAMAIS EFFECTUER DE COUPE « À MAIN

LIBRE », c’est-à-dire en utilisant seulement les

mains pour supporter ou guider la pièce à scier.

Toujours utiliser le guide de refente ou la jauge

à onglets pour positionner et guider la pièce.

AVERTISSEMENT : LA COUPE À MAIN LEVÉE

EST LA PRINCIPALE CAUSE DE RECUL ET D’

AMPUTATIONS DE DOIGTS ET DE MAINS.

5. NE JAMAIS SE TENIR en face de la lame de la scie

ou avoir une partie du corps en face de la lame de

la scie. Ne pas garder les mains dans l’alignement

de la lame de scie.

6. NE JAMAIS PASSER LA MAIN derrière ou audessus de l’outil de coupe.

7. RETIRER le guide de refente pour le tronçonnage.

8. NE PAS UTILISER DE porte-outil avec cette scie.

9. POUSSER LA PIÈCE À SCIER SUR LA LAME,

contre son sens de rotation seulement.

10. NE JAMAIS utiliser le guide de refente comme

jauge de coupe pour le tronçonnage.

11. NE JAMAIS ESSAYER DE LIBÉRER UNE LAME

DE SCIE COINCÉE sans d’abord mettre la scie

hors tension. Régler immédiatement l’interrupteur à

OFF pour éviter d’endommager le moteur.

13. ÉVITER LES EFFETS DE RECUL (pièces coupées

renvoyées vers l’utilisateur) en gardant la lame bien

affûtée, le guide de refente parallèle à la lame de la

scie et en laissant en place, alignés et en bon état

de fonctionnement le fendeur, les cliquets antirecul

et les protège-lames. Ne pas lâcher la pièce que l

’on scie tant qu’elle n’est pas passée derrière la

lame de la scie. Ne pas effectuer de coupe en long

si la pièce de bois est tordue, gauchie ou si son

bord n’est pas droit le long du guide.

14. ÉVITER LES OPÉRATIONS INCOMMODES

et les positions où les mains risqueraient de se

trouver dans le trajet de l’outil de coupe en cas de

mouvement brusque.

15. NE JAMAIS UTILISER DE SOLVANTS pour

nettoyer les pièces en plastique. Les solvants

pourraient éventuellement faire fondre ou

endommager le plastique. N’utiliser qu’un chiffon

doux et humide pour nettoyer les pièces en

plastique.

16. ASSEMBLER la scie à table sur un établi ou sur un

support avant de procéder aux opérations de coupe.

Voir ASSEMBLAGE ET RÉGLAGES à la page 34.

17. NE JAMAIS COUPER DES MÉTAUX ou des

matériaux pouvant produire des poussières

dangereuses.

18. TOUJOURS UTILISER LA SCIE DANS UN

ENDROIT BIEN VENTILÉ. Enlever fréquemment la

sciure, en particulier celle qui s’accumule à l’intérieur

de la scie, pour empêcher tout risque d’incendie.

Raccorder un aspirateur à l’orifice d’aspiration de la

sciure pour retirer la sciure supplémentaire.

19. NE JAMAIS LAISSER LA SCIE fonctionner sans

surveillance. Ne pas s’éloigner de la scie tant qu’elle

n’est pas complètement arrêtée.

20. Pour un bon fonctionnement, suivre les directives de

la section intitulée ASSEMBLAGE ET RÉGLAGES