Page 1

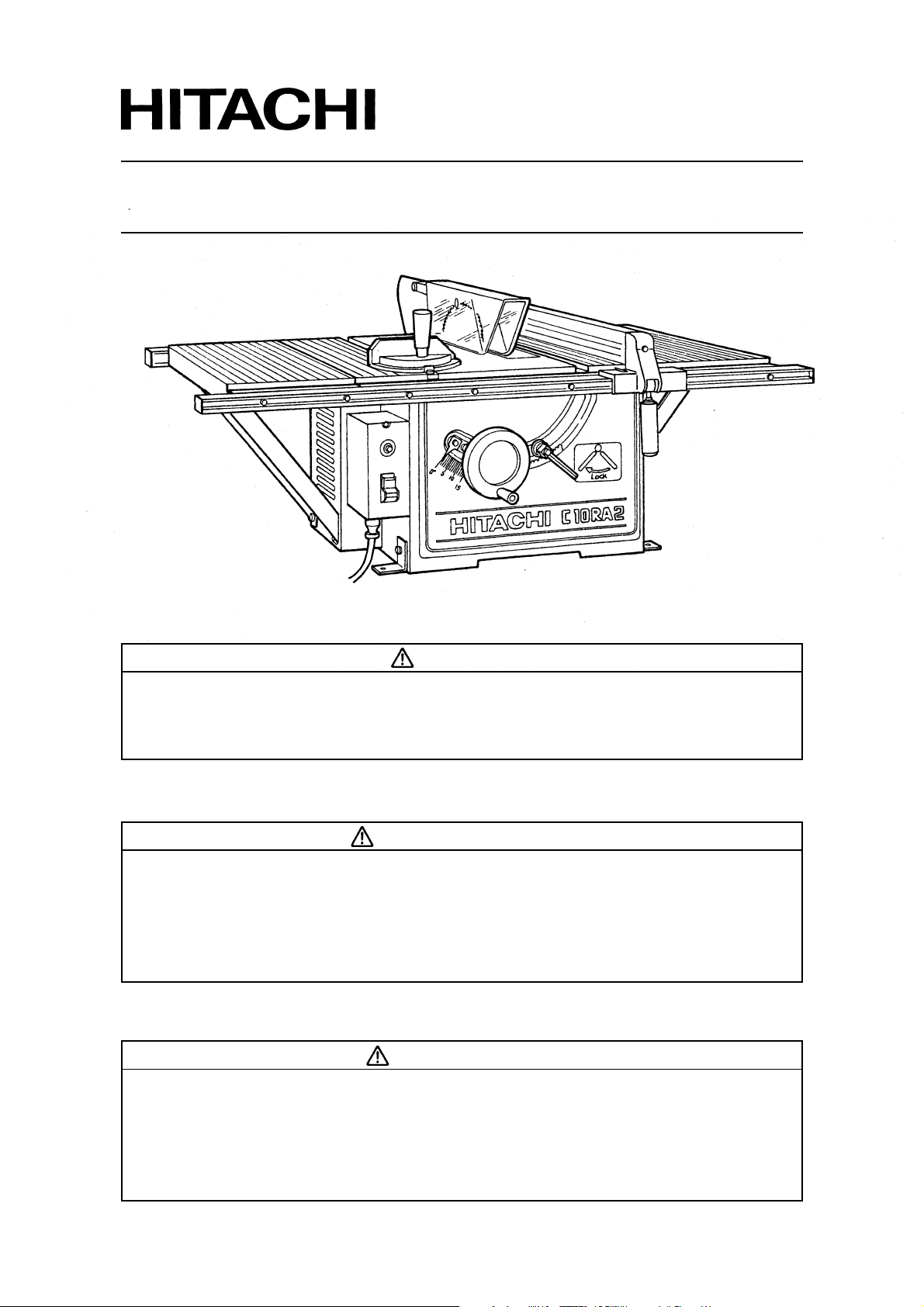

MODEL TABLE SAW

MODELE SCIE SUR TABLE

C 10RA2

MODELO SIERRA DE MESA

INSTRUCTION MANUAL AND SAFETY INSTRUCTIONS

WARNING

Improper and unsafe use of this power tool can result in death or serious bodily

injury! This manual contains important information about product safety. Please

read and understand this manual before operating the power tool. Please keep this

manual available for others before they use the power tool.

MODE D’EMPLOI ET INSTRUCTIONS DE SECURITE

AVERTISSEMENT

Une utilisation incorrecte et dangereuse de cet outil motorisé peut entraîner la mort

ou de sérieuses blessures corporelles!

Ce mode d’emploi contient d’importantes informations à propos de la sécurité de

ce produit. Prière de lire et d’assimiler ce mode d’emploi avant d’utiliser l’outil

motorisé. Garder ce mode d’emploi à la disponibilité des autres utilisateurs avant

qu’ils utilisent l’outil motorisé.

MANUAL DE INSTRUCCIONES E INSTRUCCIONES DE SEGURIDAD

ADVERTENCIA

¡La utilización inapropiada e insegura de esta herramienta eléctrica puede resultar

en lesiones serias o en la muerte!

Este manual contiene información importante sobre la seguridad del producto. Lea

y comprenda este manual antes de utilizar la herramienta eléctrica. Guarde este

manual para que puedan leerlo otras personas antes de que utilicen la herramienta

eléctrica.

Page 2

English

IMPORTANT INFORMATION .....................................3

MEANINGS OF SIGNAL WORDS ..............................3

SAFETY

IMPORTANT SAFETY INSTRUCTIONS FOR USING

ALL POWER TOOLS ................................................. 3

REPLACEMENT PARTS ...............................................6

USE PROPER EXTENSION CORD ..............................6

GROUNDING INSTRUCTIONS ................................... 7

OPERATION AND MAINTENANCE

NAME OF PARTS ......................................................... 8

SPECIFICATIONS .........................................................9

ACCESSORIES ..............................................................9

STANDARD ACCESSORIES ....................................9

OPTIONAL ACCESSORIES ....................................10

CONTENTS

Page

APPLICATIONS .......................................................... 10

UNPACKING ............................................................... 10

PREPARATION BEFORE OPERATION ..................... 11

ASSEMBLY PROCEDURES ....................................... 12

ADJUSTMENT ............................................................14

BEFORE USING...........................................................17

PRACTICAL APPLICATIONS .................................... 18

WARNINGS ON OPERATION ................................... 20

OPERATING INSTRUCTIONS ................................... 20

SAW BLADE MOUNTING AND DISMOUNTING ..25

MAINTENANCE AND INSPECTION ........................ 25

SERVICE AND REPAIRS ............................................ 27

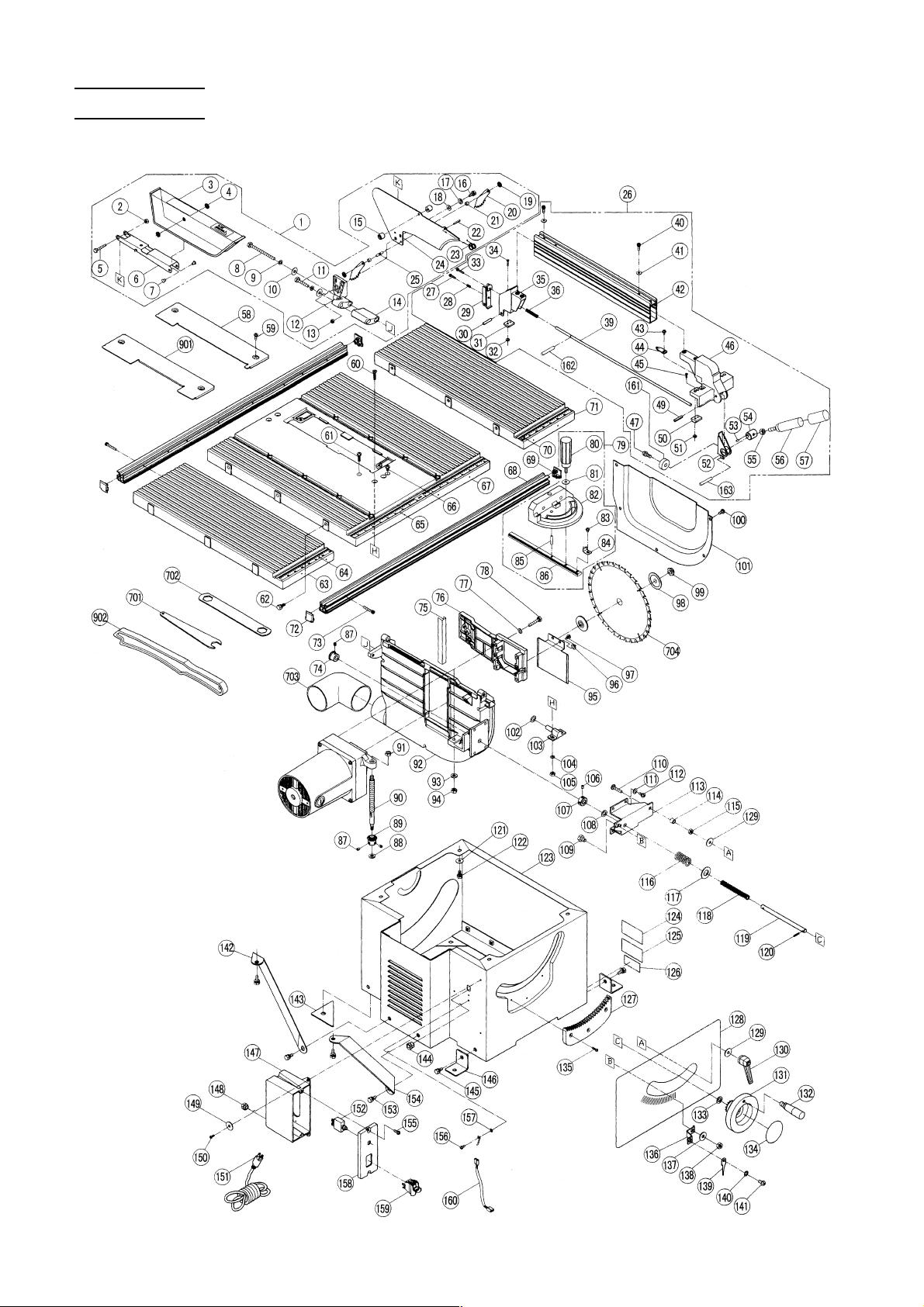

PARTS LIST .................................................................81

Page

Français

INFORMATIONS IMPORTANTES ............................28

SIGNIFICATION DES MOTS D’AVERTISSEMENT ...

SÉCURITÉ

CONSIGNES DE SÉCURITÉ RELATIVES AUX

OUTILS ÉLECTRIQUES. .........................................28

PIECES DE RECHANGE ............................................. 32

UTILISATION D'UN CORDON DE RALLONGE .......32

INSTRUCTIONS DE MISE À LA MASSE .................33

UTILISATION ET ENTRETIEN

NOM DES PIÈCES ......................................................34

SPÉCIFICATIONS .......................................................35

ACCESSOIRES ............................................................35

ACCESSOIRES STANDARD ..................................35

ACCESSOIRES EN OPTION .................................. 36

Español

INFORMACIÓN IMPORTANTE ................................54

SIGNIFICADO DE LAS PALABRAS CLAVE ............. 54

SEGURIDAD

NORMAS DE SEGURIDAD PARA LAS

HERRAMIENTAS ELÉCTRICAS ............................54

PIEZAS DE REEMPLAZO ...........................................58

UTILIZACIÓN DE UN CABLE PROLONGADOR ...... 58

AISLAMIENTO DOBLE PARA OFRECER UNA

OPERACIÓN MÁS SEGURA .................................59

OPERACIÓN Y MANTENIMIENTO

NOMENCLATURA DE PARTES ................................ 60

ESPECIFICACIONES .................................................. 61

ACCESORIOS ..............................................................61

ACCESORIOS ESTÁNDAR .................................... 61

TABLE DES MATIERES

Page

28

ÍNDICE

Página

Page

APPLICATIONS .......................................................... 36

DÉBALLAGE ................................................................36

PRÉPARATION AVANT L’UTILISATION .................37

MÉTHODES DE MONTAGE ......................................38

RÉGLAGE .....................................................................40

AVANT L’UTILISATION .............................................43

APPLICATION .............................................................44

AVERTISSEMENTS DE FONCTIONNEMENT ......... 46

INSTRUCTIONS D’UTILISATION .............................47

INSTALLATION ET RETRAIT DE LA LAME .............51

ENTRETIEN ET INSPECTION ...................................51

SERVICE APRÈS-VENTE ET RÉPARATIONS ..........53

Página

ACCESORIOS OPCIONALES................................. 62

APLICACIONES .......................................................... 62

DESEMBALAJE ..........................................................62

PREPARATIVOS PREVIOS A LA OPERACIÓN ....... 63

PROCEDIMIENTOS DE ARMADO ............................ 64

AJUSTE........................................................................66

ANTES DEL USO.........................................................70

APLICACIONES PRÁCTICAS ....................................70

ADVERTENCIAS SOBRE EL FUNCIONAMIENTO.. 72

INSTRUCCIONES DE FUNCIONAMIENTO .............73

MONTAJE Y DESMONTAJE DE LA HOJA DE SIERRA ....

MANTENIMIENTO E INSPECCIÓN .........................78

SERVICIO Y REPARACIONES ...................................80

78

Page 3

English

IMPORTANT INFORMATION

Read and understand all of the operating instructions, safety precautions and warnings in the Manual before

operating or maintaining this power tool.

Most accidents that result from tool operation and maintenance are caused by the failure to observe basic

safety rules or precautions. An accident can often be avoided by recognizing a potentially hazardous situation

before it occurs and by observing appropriate safety procedures.

Basic safety precautions are outlined in the SAFETY section of this manual and in the sections which contain

the operation and maintenance instructions.

Hazards that must be avoided to prevent bodily injury or machine damage are identified by WARNINGS on

the tool and in this Manual.

Never use this tool in a manner that has not been specifically recommended by HITACHI, unless you first

confirm that the planned use will be safe for you and others.

MEANINGS OF SIGNAL WORDS

WARNING:indicates a potentially hazardous situation which, if ignored, could result in serious personal

injury.

CAUTION: indicates a hazardous situation which, if ignored, could result in a moderate personal

injury, or could cause machine damage.

NOTE emphasizes essential information.

SAFETY

IMPORTANT SAFETY INSTRUCTIONS FOR USING ALL POWER TOOLS

READ ALL OF THE WARNINGS AND OPERATING INSTRUCTIONS IN THIS NAMUAL

BEFORE OPERATING OR MAINTAINING THIS TOOL:

WARNING:When using this electric tool, take all necessary precautions to minimize the risk of electric

shock or other personal injury.

In particular, always comply with the following safety rules:

1. ALWAYS KEEP GUARDS IN PLACE and in working order.

2. ALWAYS REMOVE ADJUSTING KEYS AND WRENCHES BEFORE STARITING TOOL.

Always confirm that all keys and adjusting wrenches have been removed from the tool before it is

turned on.

3. ALWAYS KEEP WORK AREA CLEAN. Avoid injuries by not cluttering the work areas and work

benches.

4. NEVER USE TOOL IN HAZARDOUS ENVIRONMENTS. Never use the power tool in damp or

wet places and never expose it to rain. Always keep the work area well lighted.

5. NEVER PERMIT CHILDREN OR OTHERS TO LOITER NEAR THE WORK AREA. Keep all

people (especially children) away from the work area. Always unplug unattended tools and keep the

work place tamper-proof by installing locks on the doors and on the master switches. Always remove

the safety key from the switch and store it in a secure place, when the tool is not in use.

6. NEVER FORCE THE TOOL. It will do the job better and more safely if it is operated at the rate for

which it was designed.

7. ALWAYS USE THE RIGHT TOOLS. Never force a tool or an attachment to do a job for which it

was not designed.

8. ALWAYS WEAR PROPER APPAREL WHEN WORKING WITH THE TOOL. Never wear loose

clothing, gloves, neckties, rings, bracelets or other jewelry which may get caught in the moving parts.

Always wear non-slip footwear, preferably with steel toes. Wear protective hair covering to contain

long hair.

3

Page 4

English

9. ALWAYS USE EYE PROTECTION WHEN WORKING WITH THE TOOL TO PREVENT

EYE INJURY. Ordinary eyeglasses do not provide adequate protection because they have only impact

resistant lenses, they are NOT safety glasses. Also, use a face mask for additional safety and wear a

dust mask if the cutting operation produces dust.

10. ALWAYS SECURE THE WORKPIECE TO THE FENCE OR THE TABLE. Use clamps or a vise

to hold the workpiece in place. It is safer than using your hand and it frees both hands to operate the

tool.

11. NEVER OVERREACH. Always keep proper footing and balance when working with the tool.

12. ALWAYS MAINTAIN TOOLS WITH CARE. Always keep tools sharp and clean for the best and

safest performance. Always follow instructions for lubricating the tool and for changing accessories.

13. ALWAYS DISCONNECT THE TOOL before servicing and before changing blades or other

accessories.

14. NEVER RISK UNINTENTIONAL STARTING WHEN PLUGGING IN THE TOOL. Always

confirm that the switch is in the OFF position before inserting the power plug into the receptacle.

15. ALWAYS USE RECOMMENDED ACCESSORIES ONLY WHEN OPERATING THIS TOOL.

Consult this instruction manual for descriptions of recommended accessories. To avoid personal injuries,

use only recommended accessories in conjunction with this tool.

16. NEVER STAND ON THE TOOL. Serious injury could occur if the tool is tipped or if unintentional

contact with the saw blade is made.

17. ALWAYS CHECK FOR DAMAGED PARTS BEFORE USING THE TOOL. Always check the

guard and all other components for damage before using the tool to assure that they will function

properly. Check all moving parts for proper alignment, freedom from binding and other conditions that

might affect proper operation. Always repair or replace any damaged guards or other damaged

components before using the tool.

18. ALWAYS CONFIRM THE ROTATION DIRECTION OF THE BLADE BEFORE USING THE

TOOL. Always feed work into the tool against the rotation direction of the blade in order to prevent

possible injury.

19. NEVER LEAVE THE TOOL RUNNING WHILE UNATTENDED. TURN POWER OFF. Do not

leave tool until it comes to a complete stop. Always turn the power off when the tool is not in use.

Always unplug the power cord when the tool is not in use.

20. This tool was not designed to be used for mass-production applications and should not be used in

mass-production environments.

21. When servicing this tool, use only authorized replacement parts.

22. Apply 115 volts AC only to this tool. Applying the wrong voltage or applying DC power can cause the

POWER TOOL to operate improperly and cause serious personal injury or damage to the tool.

23. PROPER GROUNDING. This tool should be grounded while in use to protect the operator from

electric shock.

Specific Safety Rules for Use of this Power Tool

WARNING:The following specific operating instructions must be observed when using this POWER

TOOL in order to avoid injury:

DO’s

ALWAYS OBSERVE THE FOLLOWING RULES TO ASSURE SAFE USE OF THIS TOOL:

1. Review this Manual and familiarize yourself with the safety rules and operating instructions for this

POWER TOOL before attempting to use it.

2. Always confirm that the POWER TOOL is clean before using it.

3. Always wear snug-fitting clothing, non-skid footwear (preferably with steel toes) and eye protection

when operating the POWER TOOL.

4. Always handle the POWER TOOL carefully. If the POWER TOOL falls or strikes against a hard object, it

might become deformed or cracked or sustain other damage.

5. Always cease operating the saw at once, if you notice any abnormality whatsoever.

4

Page 5

English

6. Always confirm that all components are mounted properly and securely before using the tool.

7. When replacing the saw blade, always confirm that the rpm rating of the new blade is correct for use on

this tool.

8. Always shut off the power and wait for the saw blade to completely stop rotating before doing any

maintenance or adjustments.

9. Always make a trial run first before attempting any new use of the saw.

10. Always handle the saw blade with care when dismounting and mounting it.

11. Always confirm that the workpiece is free of nails or other foreign objects before beginning a cut.

12. Always keep your hands out of the path of the saw blade.

13. Always confirm that the saw blade guard is in the proper place before using the saw.

14. Always confirm that the saw blade guard does not obstruct the sliding motion of the saw before

attempting cutting.

15. Inspect the tool power cords periodically.

16. Always confirm that the proper lengths and types of extension cords are being utilized, if necessary

before starting the tool.

17. Always confirm that the motor air vents are fully open before using the tool.

18. Always wait until the motor has reached full speed before starting a cut.

19. Always keep the handles dry, clean and free of oil and grease. Hold the tool firmly when in use.

20. Always use saw blade guard, spreader and anti-kickback pawls on all “through sawing” operations.

Through sawing operations are those when the blade cuts completely through the workpiece as in

ripping or cross cutting.

21. Always hold the workpiece firmly against the miter gauge or rip fence.

22. Always use a push stick for ripping narrow stock. Refer to ripping operations in instruction manual

where push stick is covered in detail.

23. Remove the rip fence when cross cutting.

24. Provide adequate support to the rear and sides of the saw table for wide or long workpiece.

25. Avoid kickbacks (work thrown back toward you).

Keeping saw blade sharp and keeping rip fence parallel to the saw blade.

Keeping spreader and anti-kickback pawls and saw blade guard in place and operating, by not releasing

work. Before it is pushed all the way past the saw blade, by not ripping work that is twisted or wraped

or does not have a straightedge to guide along the rip fence.

26. Avoid awkward operations and hand positions where a sudden slip could cause your hand to move into

the cutting tool.

27. Permanently mount your table saw before performing any cutting operations.

Refer to installation instructions.

28. Always use in a well ventilated area. Remove sawdust frequently.

Clean out sawdust from the interior of the table saw to prevent a potential fire hazard.

29. The operating instructions provided with the tool shall direct the user to secure the tool to supporting

structure if, during normal operation, there is a tendency for the tool to tip over, slide, or walk on the

supporting surface.

DON’Ts

NEVER VIOLATE THE FOLLOWING RULES TO ASSURE SAFE USE OF THIS TOOL:

1. Never operate the POWER TOOL unless you fully understand the operating instructions contained in

this Manual.

2. Never leave the POWER TOOL unattended without first unplugging the power cord.

3. Never operate the POWER TOOL when you are tired, after you have taken any medications, or have

consumed any alcoholic beverages.

4. Never use the POWER TOOL for applications not specified in the instruction manual.

5. Never operate the tool while wearing loose clothing, a necktie or jewelry, or while your hair is uncovered,

to protect against getting caught in the moving machinery.

5

Page 6

English

6. Never reach around the saw blade.

7. Never touch any moving parts, including the blade, while the saw is in use.

8. Never remove any safety devices or blade guards; use of the tool without them would be hazardous.

9. Never lock the saw blade guard; always confirm that it slides smoothly before using the tool.

10. Never damage the power cord of the tool.

11. Never attempt to move a plugged-in POWER TOOL while your finger is on the starting switch.

12. Never use the POWER TOOL if the starting switch does not turn on and off properly.

13. Never use the POWER TOOL if the plastic housing or the saw blade guard is cracked or deformed.

14. Never use the POWER TOOL near flammable liquids or gases because sparking can cause an explosion.

15. Never clean plastic components with solvents because the plastic may dissolve.

16. Never operate the table saw unless the saw blade guard is in place.

17. Never raise the saw blade guard from the workpiece until it has first come to a complete stop.

18. Never use abrasive type saw blades on this table saw.

19. Never perform any operation “freehand” which means using your hands to support or guide the

workpiece. Always use the rip fence or the miter gauge to position and the work.

20. Never stand or have any part of your body in line the path of the saw blade.

21. Never reach behind or over the cutting tool with either hand for any reason.

22. Never use the rip fence as a cut off gauge when cross cutting.

23. Never attempt to free a stalled saw blade without first turning the saw off.

24. Never cut metals or materials which may make hazardous dust.

25. Never cut ferrous metals or masonry.

WARNING

FOR YOUR OWN SAFETY READ THIS INSTRUCTION MANUAL BEFORE OPERATING

THE TABLE SAW

1. Always wear eye protection when using the table saw.

2. Always use saw blade guard and spreader for every operation for which it can be used, including all

through sawing.

3. Always keep hands out of the path of the saw blade.

4. Always use a push stick when required.

5. Pay particular attention to instructions on reducing risk of kickback.

6. Never perform any freehand operation with the table saw.

7. Never reach around or over saw blade.

REPLACEMENT PARTS

When servicing use only identical replacement parts.

Repairs should be conducted only by a Hitachi authorized service center.

USE PROPER EXTENSION CORD

Use only three-wire extension cords which have three-prong grounding-type plugs and three-pole receptacles

which accept the tool’s plug. Replace or repair damaged or worn cord immediately.

Make sure your extension cord is in good condition. When using an extension cord, be sure to use one

heavy enough to carry the current your product will draw. An undersized cord will cause a drop in line

voltage resulting in loss of power and overheating. Table shows the correct size to use depending on cord

length and nameplate ampere rating. If in doubt, use the next heavier gage. The smaller the gage number,

the heavier the cord. Check power cords and extension cords for loose or exposed wires and damaged

insulation before using. Repair or replace as needed before using the power tool.

6

Page 7

English

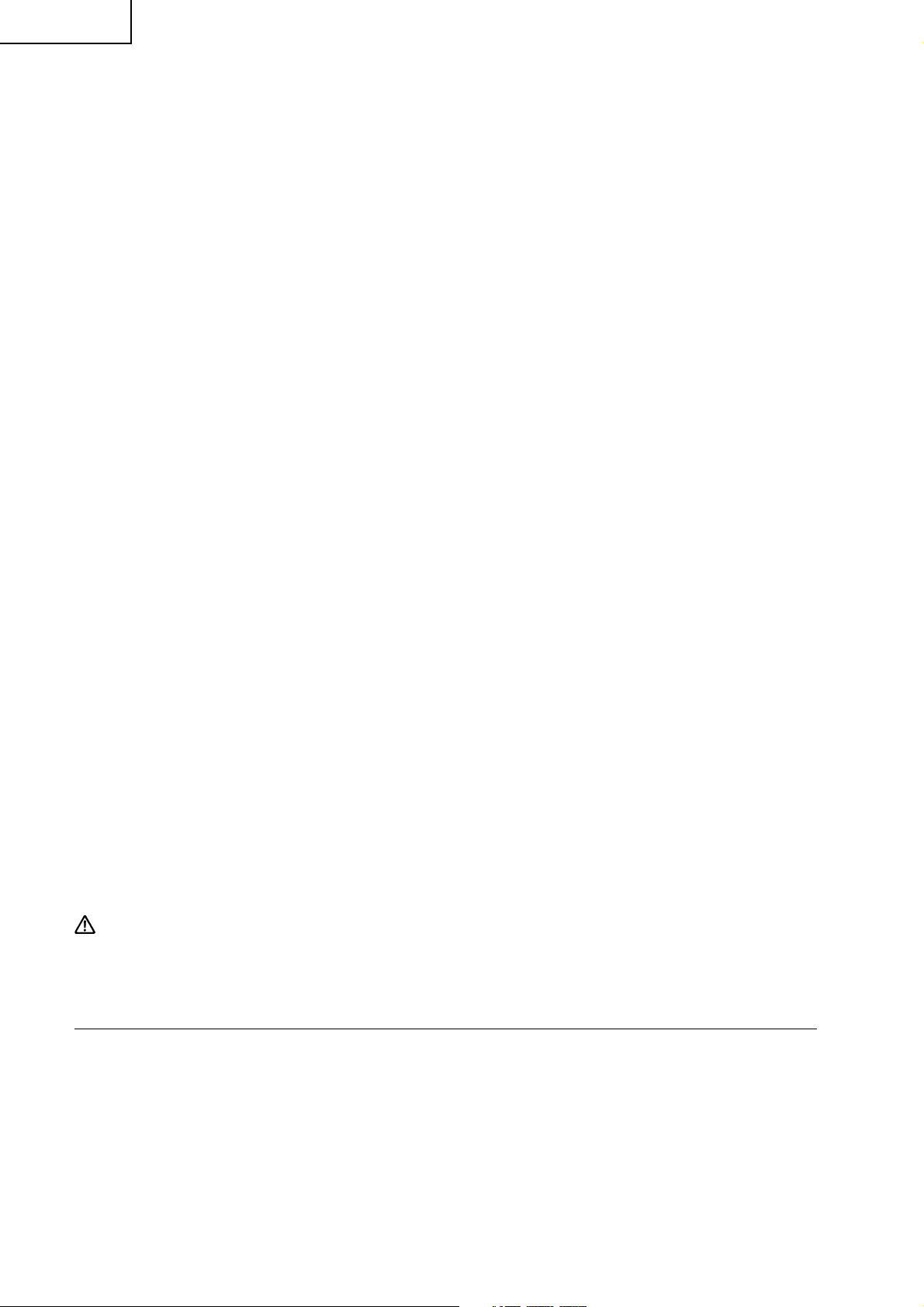

MINIMUM GAGE FOR CORD SETS

Total Length of Cord in Feet (Meter)

0 – 25 26 – 50 51 – 100 101 – 150

(0 – 7.6) (7.9 – 15.2) (15.5 – 30.5) (30.8 – 45.7)

Ampere Rating AWG

More Not More

Than Than

0 – 618161614

6 – 10 18 16 14 12

10 – 12 16 16 14 12

12 – 16 14 12 Not Recommended

WARNING:Avoid electrical shock hazard. Never use this tool with a damaged or frayed electrical cord

or extension cord.

Inspect all electrical cords regularly. Never use in or near water or in any environment

where electric shock is possible.

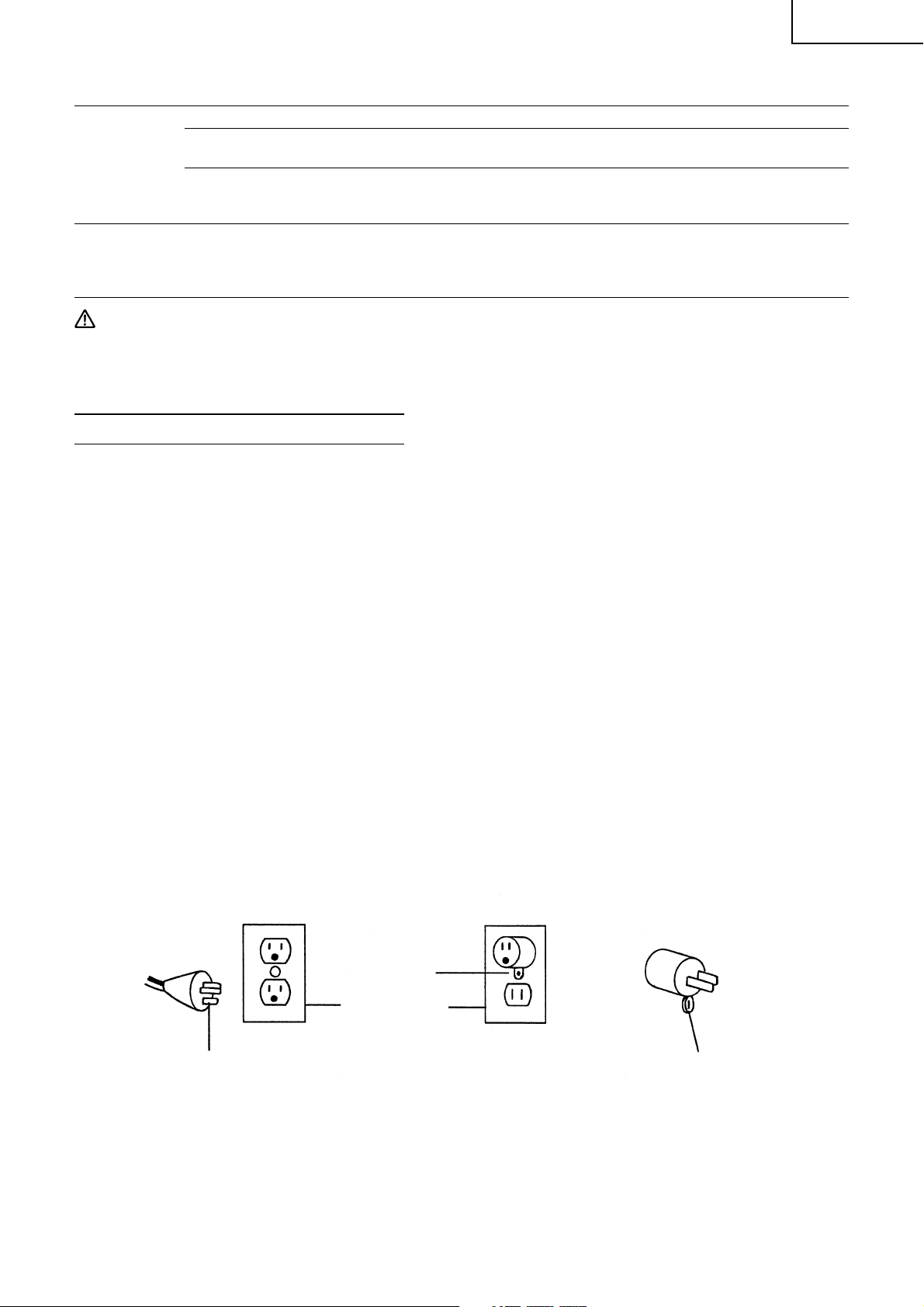

GROUNDING INSTRUCTIONS

ALL GROUNDED, CORD-CONNECTED TOOLS: In the event of a malfunction or breakdown, grounding

provides a path of least resistance for electric current to reduce the risk of electric shock. This tool is equipped

with an electric cord having an equipment-grounding conductor and a grounding plug. The plug must be

plugged into a matching outlet that is properly installed and grounded in accordance with all local codes

and ordinances. Do not modify the plug provided - if it will not fit the outlet, have the proper outlet installed

by a qualified electrician. Improper connection of the equipment - grounding conductor can result in a risk

of electric shock. The conductor with insulation having an outer surface that is green with or without yellow

stripes is the equipment grounding conductor. If repair or replacement of the electric cord or plug is necessary,

do not connect the equipment-grounding conductor to a live terminal.

Check with a qualified electrician or service personnel the grounding instructions are not completely

understood, or if it doubt as to whether the tool is properly grounded.

Use only 3-wire extension cords that have 3-prong grounding plugs and 3-pole receptacles that accept the

tool’s plug. Repair or replace damaged or worn cord immediately.

Grounded, cord -connected tools intended for use on a supply circuit having a nominal rating less than 150

volts: This tool is intended for use on a circuit that has an outlet that looks like the one illustrated in Fig. A.

The tool has a grounding plug that looks like the plug illustrated in Fig. A. A temporary adapter, which looks

like the adapter illustrated in Fig. B and C, may be used to connect this plug to a 2-pole receptacle as shown

in Fig. B if a properly grounded outlet is not available. The temporary adapter should be used only until a

properly grounded outlet can be installed by a qualified electrician. The green-colored rigid ear, lug, and the

like, extending from the adapter must be connected to a permanent ground such as a properly grounded

outlet box.

GROUNDING METHODS

Fig. A Fig. B Fig. C

Adapter

Metal Screw

Cover of Grounded

Outlet Box

Grounding Pin

Grounding Means

SAVE THESE INSTRUCTIONS

AND

MAKE THEM AVAILABLE TO

OTHER USERS OF THIS TOOL!

7

Page 8

English

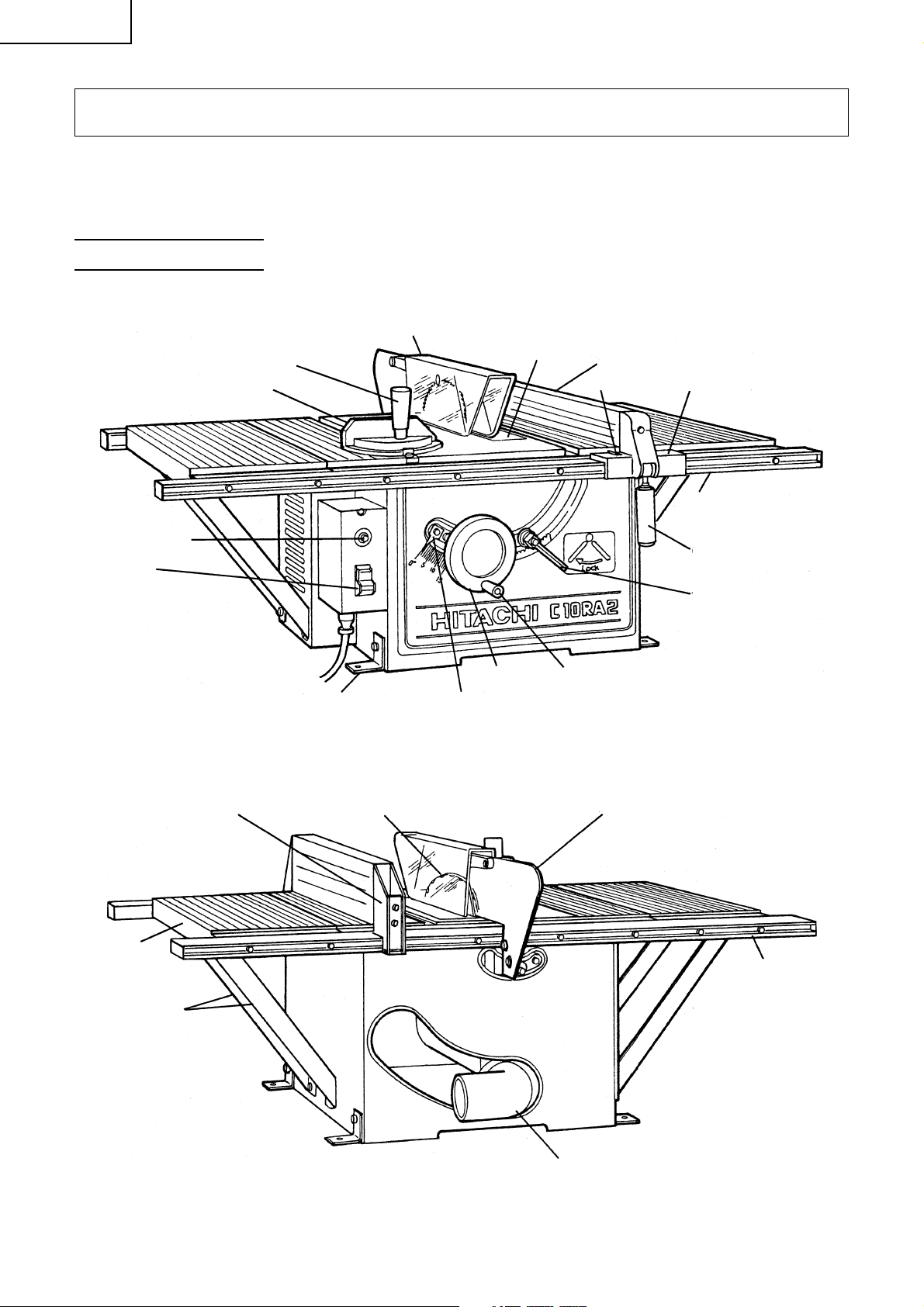

OPERATION AND MAINTENANCE

NOTE: The information contained in this Instruction Manual is designed to assist you in the safe operation

and maintenance of the power tool. Some illustrations in this Instruction Manual may show details

or attachments that differ from those on your own power tool.

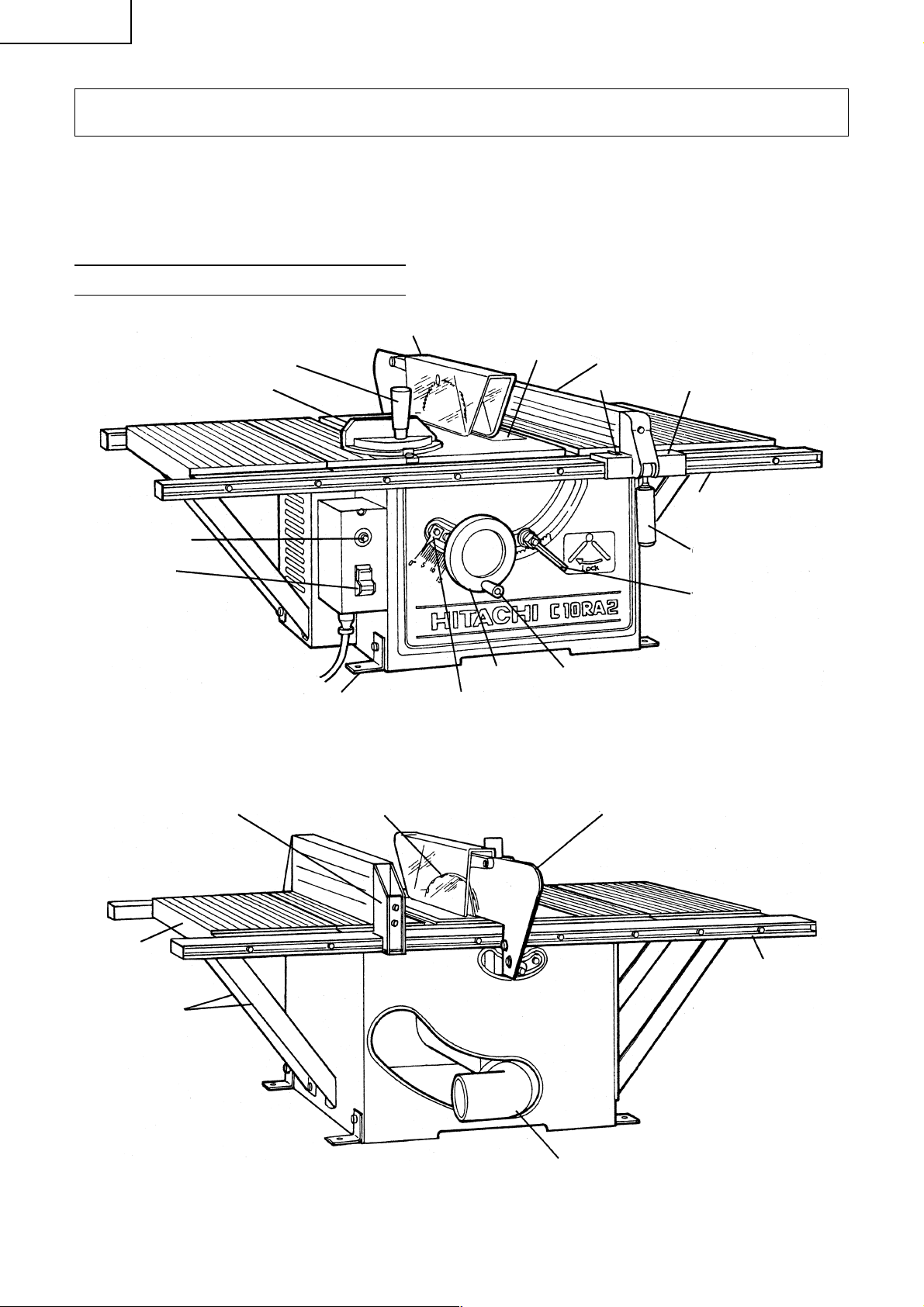

NAME OF PARTS

Saw Blade Guard Assembly

Reset Button

Switch

Clamp Handle (B)

Miter gauge

Set Plate

(Standard Accessory)

Needle Pointer

Fig. 1

Insert Rip Fence

Pointer

Handle BarWheel

Width Body

Front Rail

Grip

Tilt Lock Handle

Extension Wing

Extension Supporter

8

Support

Saw Blade

Fig. 2

Spreader

Elbow

(Standard Accessory)

Rear Rail

Page 9

SPECIFICATIONS

Item Model C10RA2

Type Series commutator motor

Motor

Applicable saw blade Outside Dia. 10" (255 mm)

No load speed 5000 rpm

Max. sawing dimension 90° Max. Height 3"

Net weight 64 lbs. (29 kg)

Cord 3 conductor type cable 6.6 ft. (2 m)

Power source Single-phase AC 60Hz

Voltage (volts) 115

Full-load current (Amp) 15

Hole Dia. 5/8" (15.9 mm)

Bevel 45° Max. Height 2 – 1/2"

English

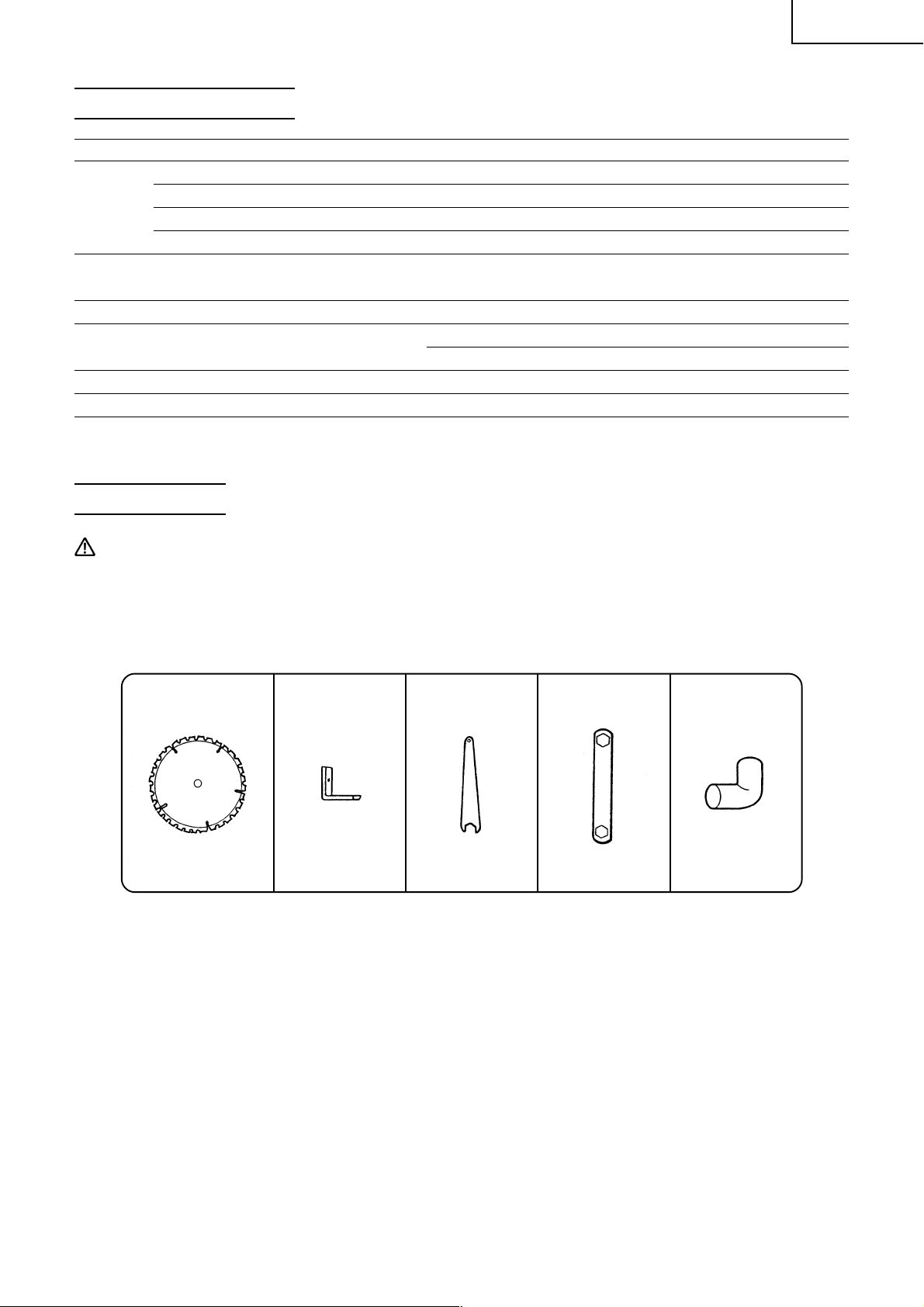

ACCESSORIES

WARNING:Accessories for this power tool are mentioned in this Instruction Manual.

The use of any other attachment or accessory can be dangerous and could cause injury or

mechanical damage.

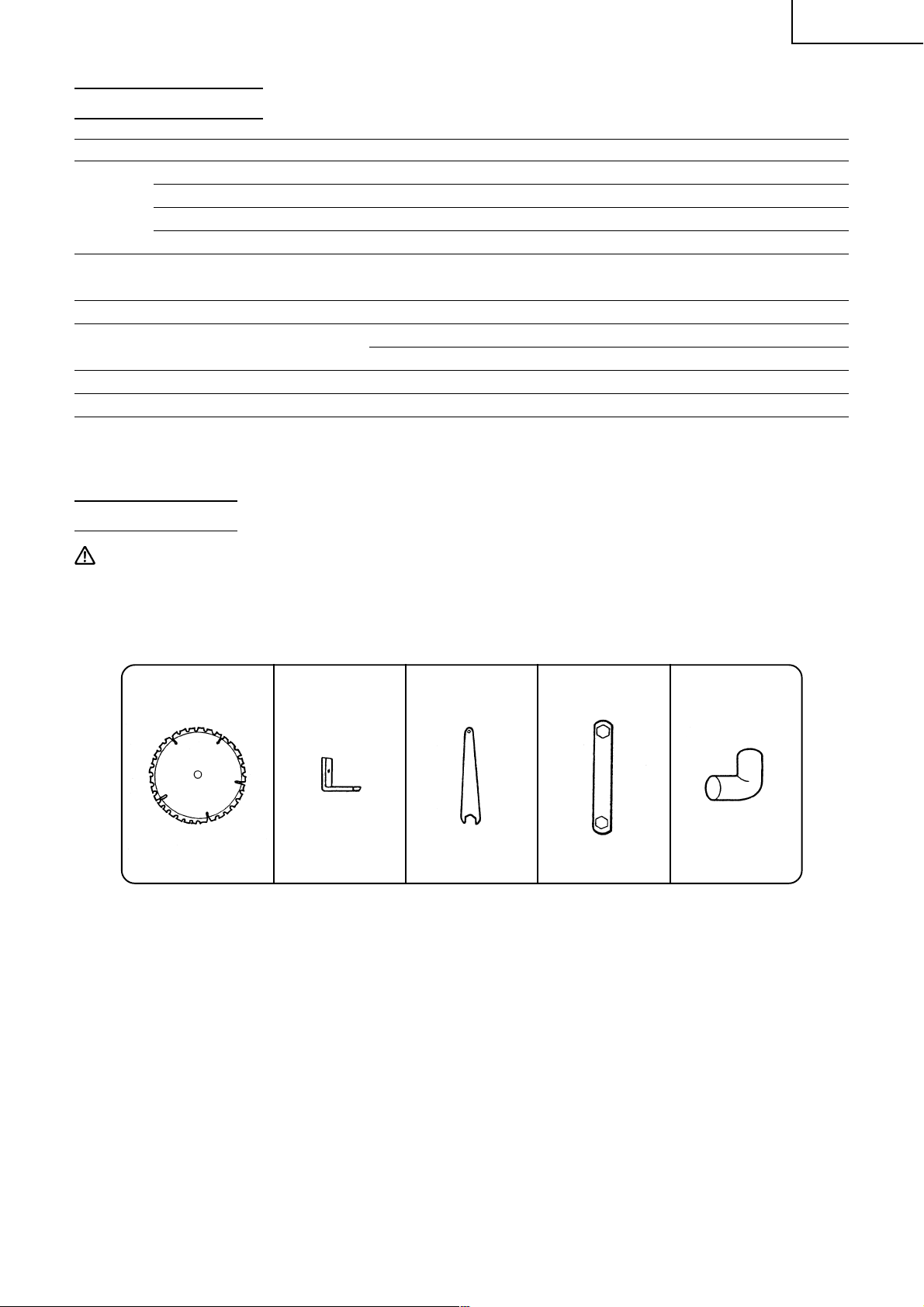

STANDARD ACCESSORIES

q 10" (255 mm) TCT w Set Plate e Wrench r Hex. Wrench t Elbow

Saw Blade (1 piece) (4 pieces) (1 Piece) (1 Piece) (1 Piece)

For how to use, For how to use,

refer to page. 11 refer to page. 14

Fig. 3

9

Page 10

English

OPTIONAL ACCESSORIES…sold separately

q Dado Insert (For dado cutter set) (Code No.314325) Convenient for dado cutting. Refer to parts list.

w Push Stick (Code No.314324) Convenient for ripping small pieces cutting. Refer to parts list.

e Table Saw Stand (Code No.314819) Convenient for setting the table saw. Refer to Fig. 12-c.

WARNING:Using attachments or accessories not recommended in this manual can be dangerous

and cause personal injury or mechanical damage to the saw.

APPLICATIONS

Wood (hard or soft woods)

UNPACKING

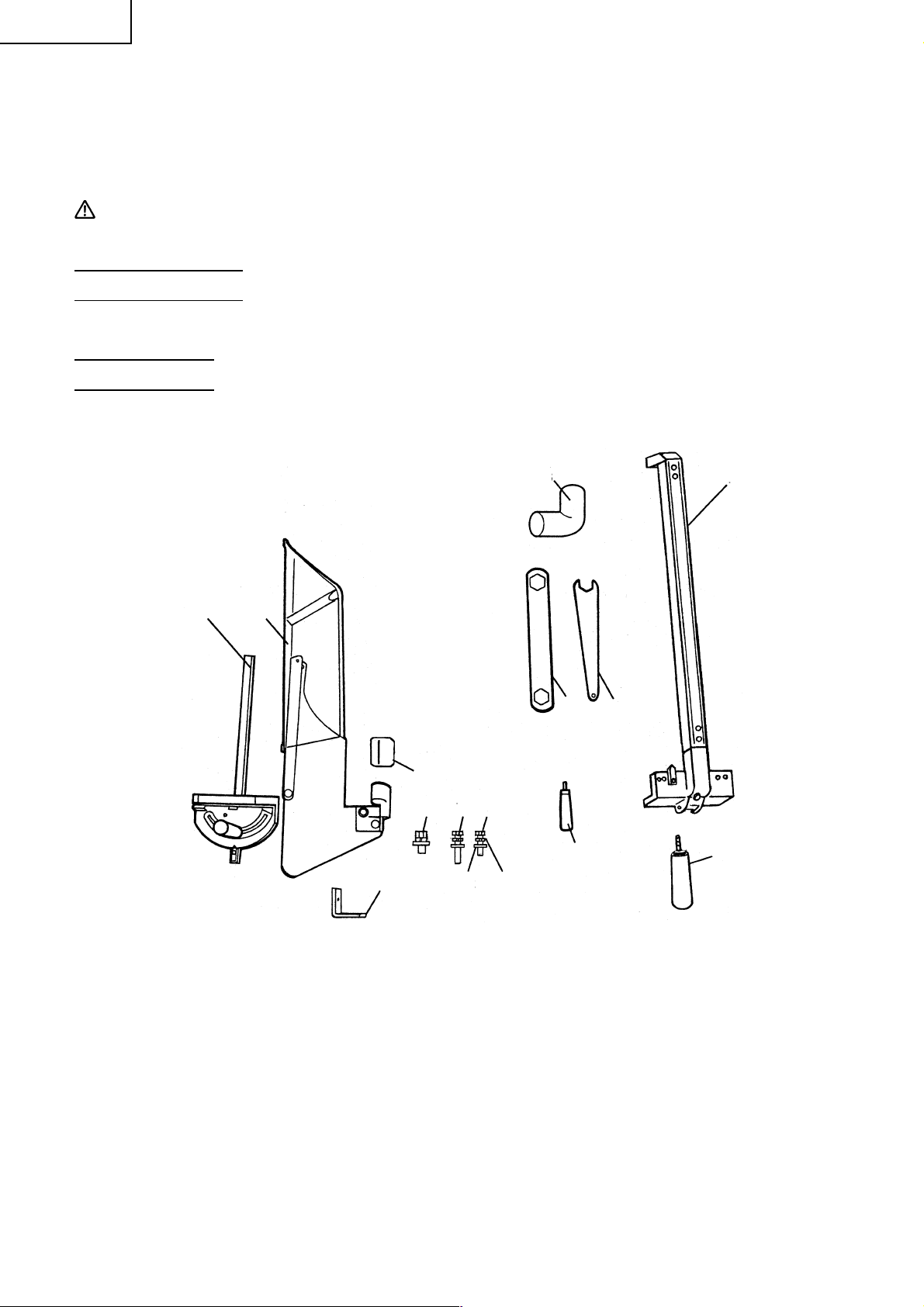

The parts illustrated in Fig. 4 described are packaged together with the tool. When unpacking, carefully

confirm that all parts are accounted for.

12

14

15

13 10 9

12 11

3

56

7

4

8

Fig. 4

1. Miter Gauge (1 piece) 8. Grip (1 piece)

2. Saw Blade Guard and Spreader Assembly (1 piece) 9. 6 × 90 mm Bolt (1 piece)

3. Elbow (1 piece) 10. 6 × 110 mm Bolt (1 piece)

4. Rip Fence (1 piece) 11. 6 mm Spring Washer (2 pieces)

5. Hex. Wrench (1 piece) 12. 6 mm Flat Washer (2 pieces)

6. Wrench (1 piece) 13. 8 × 20 mm Bolt (with / washers) (4 pieces)

7. Handle Bar (1 piece) 14. Set Plate (4 pieces)

15. Cusion (1 piece)

10

Page 11

English

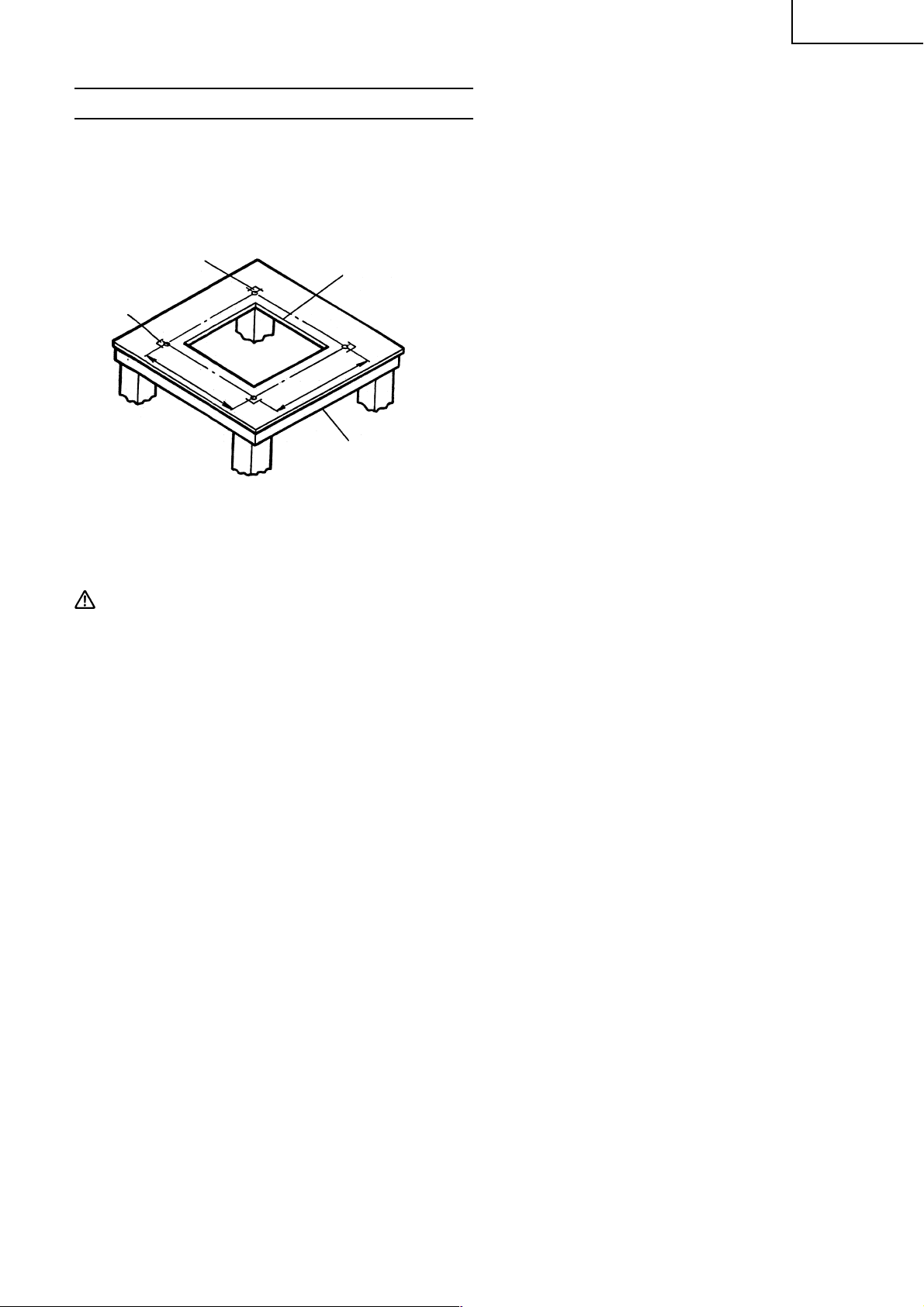

PREPARATION BEFORE OPERATION

Make the following preparations before operating the power tool:

1. Installation

The table saw must be properly secured to a sturdy workbench, stand or cabinet.

Casters (if provided) on the workbench, stand or cabinet must be locked during operation.

If there is any tendency for the table saw to move during operation, this must be corrected immediately.

5/16" (8 mm) Holes

Set Plate

Locating Marks

15-3/4" (400 mm)

Fig. 5

12" (305 mm) Square

Cut Out (center)

17-23/32" (450 mm)

Work Bench, Stand

or cabinet

(3) Remove the table saw, and locate a 11" (279 mm) or 12" (305 mm) square centered between the marks

locating the body shell. Cut out and remove the square. This opening allows sawdust to fall out of the

body shell.

(1) Place the table saw in the desired location.

Make certain that is (or will be) adequate space on all

sides of the table saw for the workpiece.

To allow maximum flexibility for sheet material and

long boards, 9 foot (2745 mm) clearance is

recommended on all sides of the table saw.

(2) Secure the four set plates to the saw base at its four

corners with four 8 × 20 mm bolts (with/washers) and

four 8 mm nuts.

Square the table saw to the workbench, stand or

cabinet. Make certain that all controls are easily

reached and there is at least 6-11/16" (170 mm) behind

the rear of the table to allow for the saw blade guard

assembly.

Temporarily mark the location of the four base corners

and set plate of the table saw.

CAUTION: Failure to provide this opening can result in insufficient cooling air to the motor causing

premature motor failure and a possible fire hazard.

(4) Replace the table saw, aligning it with the marks made above. Trace hole positions on the four set plates

on the workbench, stand or cabinet with a pencil or the like.

(5) Remove the table saw, and drill a 5/16" (8 mm) hole in each location marked. Remove all sawdust or

chips.

(6) Replace the table saw in the marked location. Check to see that the table saw does not lock on the

workbench and all four set plates are in contact with the top of the workbench, stand or cabinet.

(7) Using suitable length four 2" (50 mm) bolts, nuts, and flat washers (not provided) secure the table saw to

the workbench, cabinet or stand. Place a spring washer and flat washer on the bolt, place the bolt through

the hole in the set plate and the top of the workbench stand, or cabinet. Add another flat washer and a

nut. Do not tighten the nut yet. Repeat this operation for the other three locations.

Tighten all nuts securely.

(8) Check the sturdiness of the resulting assembly.

11

Page 12

English

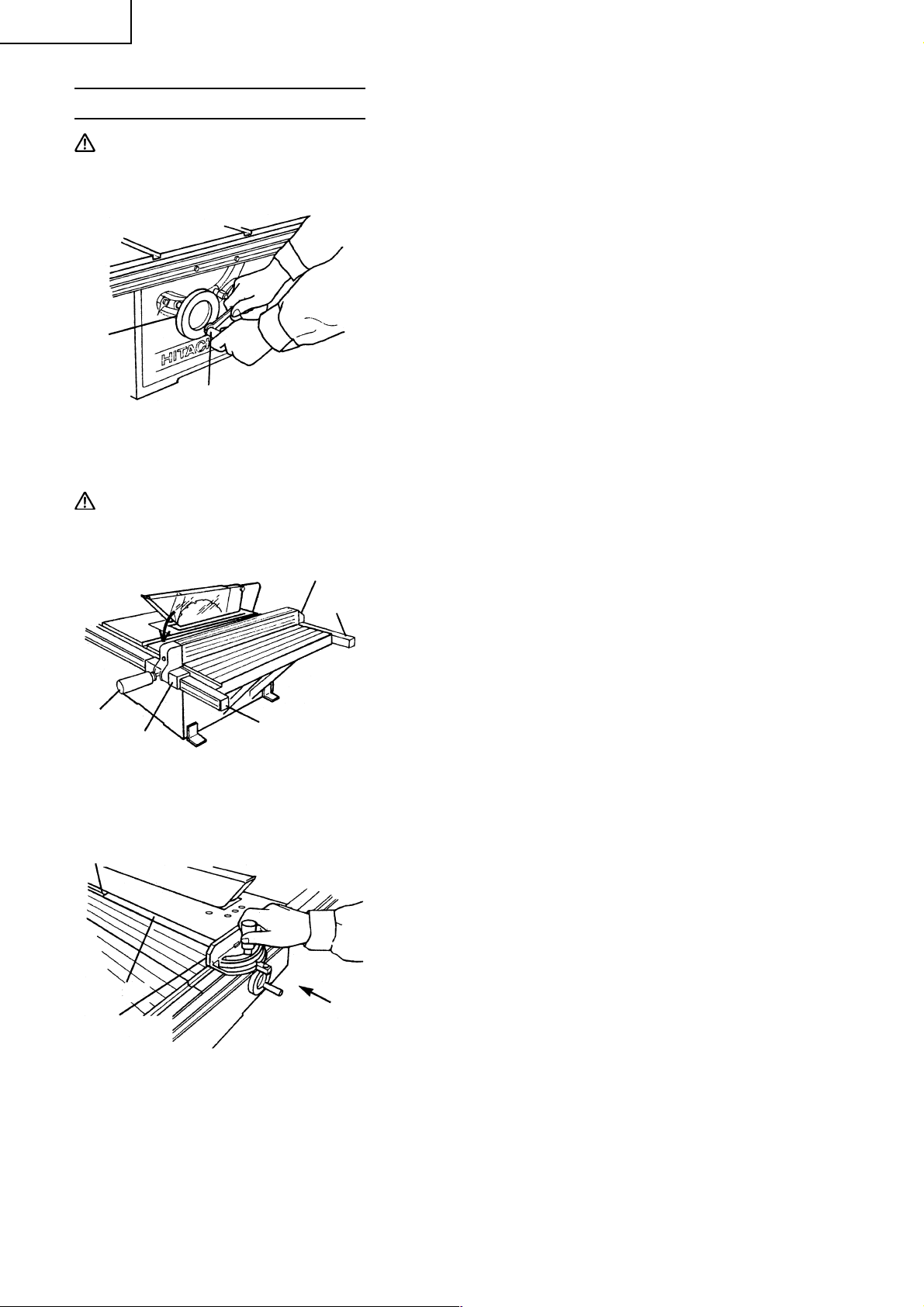

ASSEMBLY PROCEDURES

WARNING:To avoid an accident or personal injury, always confirm that the switch is turned OFF and

the power plug has been disconnected from the receptacle before assembly of this tool.

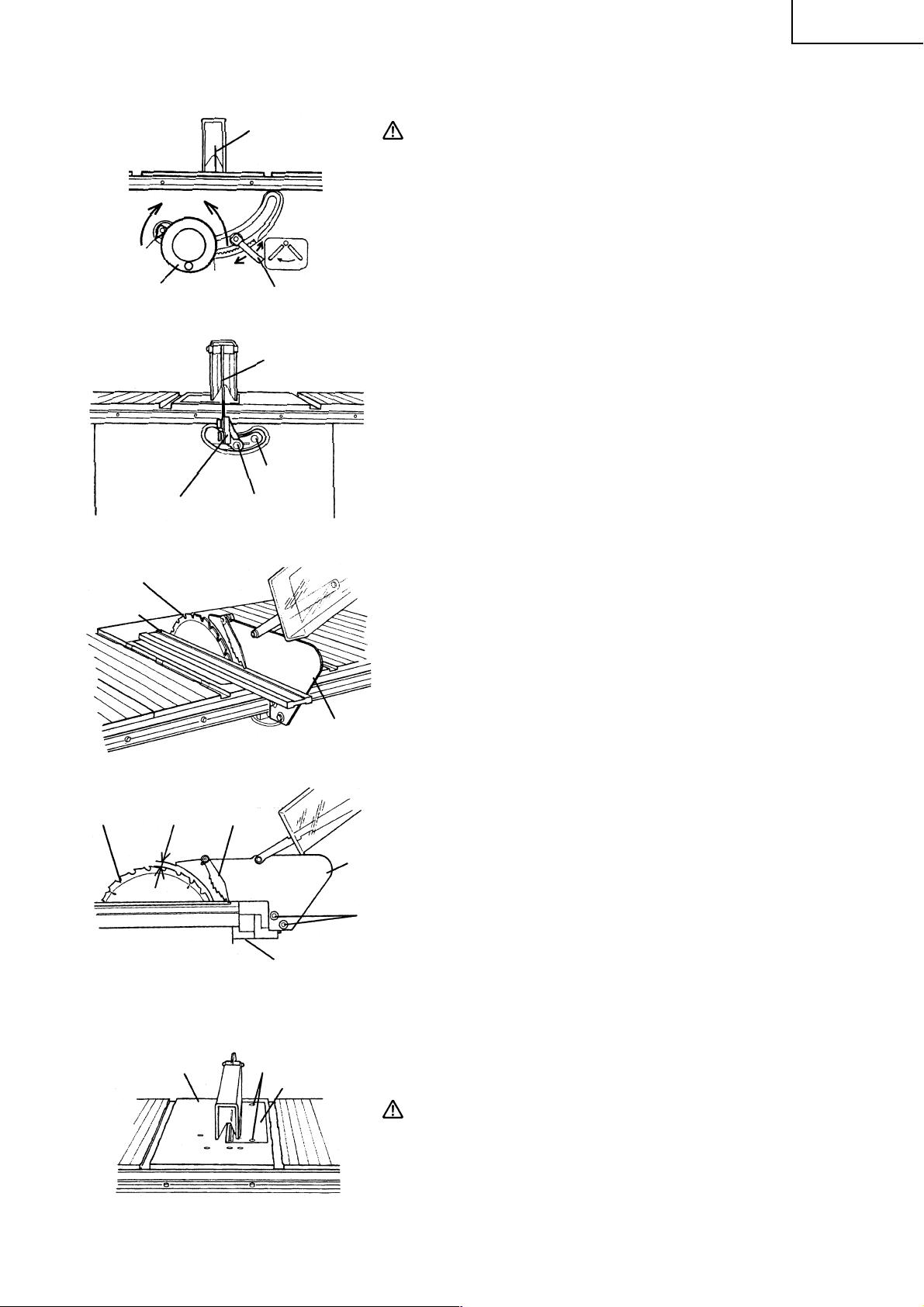

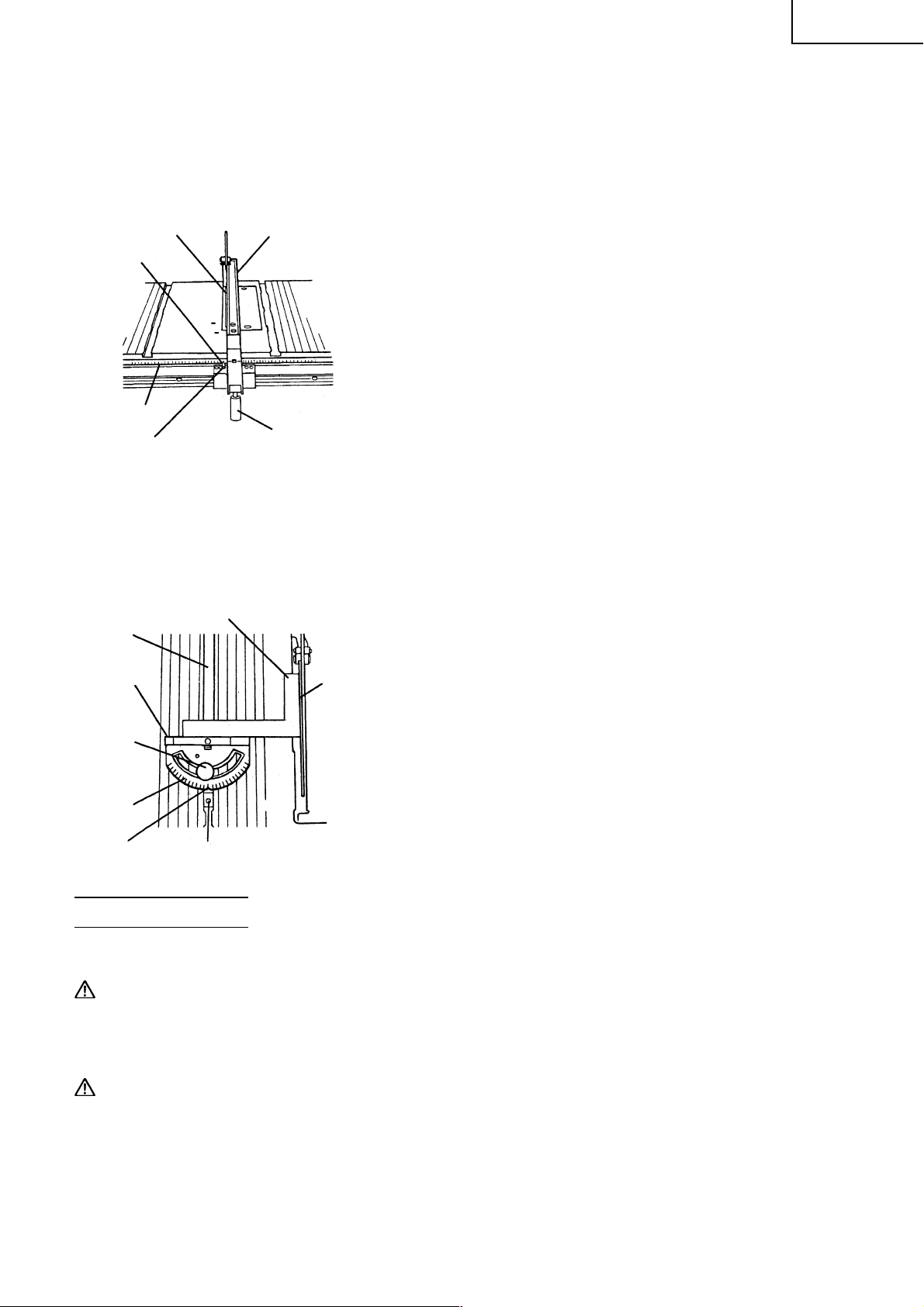

1. Assembly of Handle Bar

Wheel

Handle Bar

Fig. 6

2. Installing of Rip Fence

The handle bar allows faster turning of the wheel.

When properly assembled it with rotate freely but with only a

small amount of play,

(1) Tighten the screw of the handle bar until it hits against the

wheel.

(2) Securely tighten the handle bar nut with a wrench.

CAUTION: The rip fence must be aligned parallel to the saw blade to minimize the kickback (refer to

page 19).

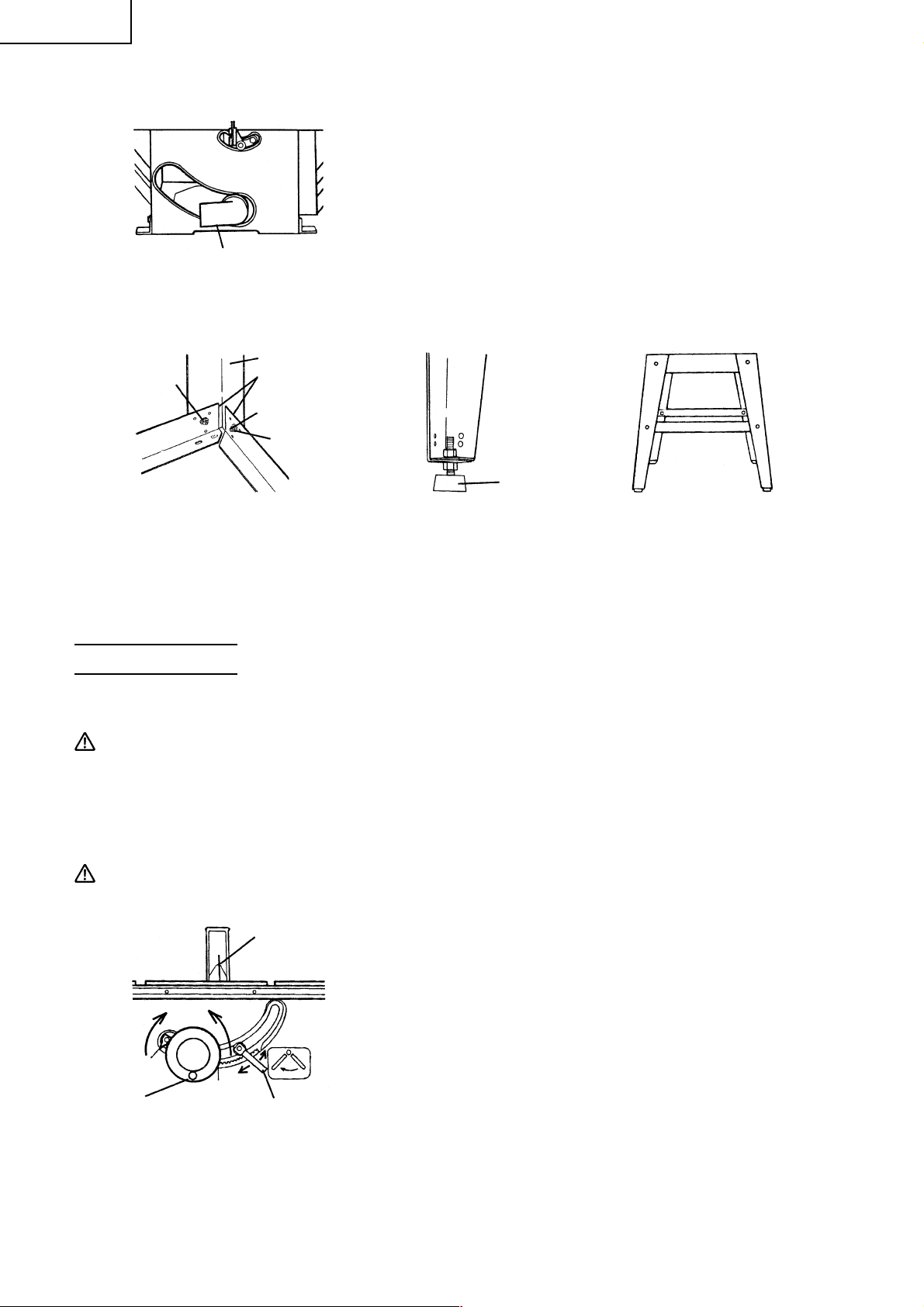

Support

The rip fence can be conveniently used to cut a workpiece into

different pieces of precise width or into parallel pieces. It can be

Rear Rail

mounted on either the right or left side of the table.

(1) Tighten the screw of the grip.

(2) Catch the hook of the support in the bottom part of the rear

rail.

(3) Lower the rip fence in the arrow direction, and fit the part of

Grip

Width Body

Front Rail

Fig. 7

the width body and support to the groove of the front and

rear rail.

(4) Confirm that the rip fence is moved right and left and it moves

smoothly.

3. Assembly of Miter Gauge

Miter Gauge Groove

The miter gauge is convenient for cutting long or angular pieces

which are difficult to work on with the rip fence. It can be mounted

on either the right or left side of the table. Align the sheet bar of

miter gauge with the miter gauge groove and slide it in the

direction indicated by the arrow through the front of the table.

Sheet Bar

Miter Gauge

12

Fig. 8

Page 13

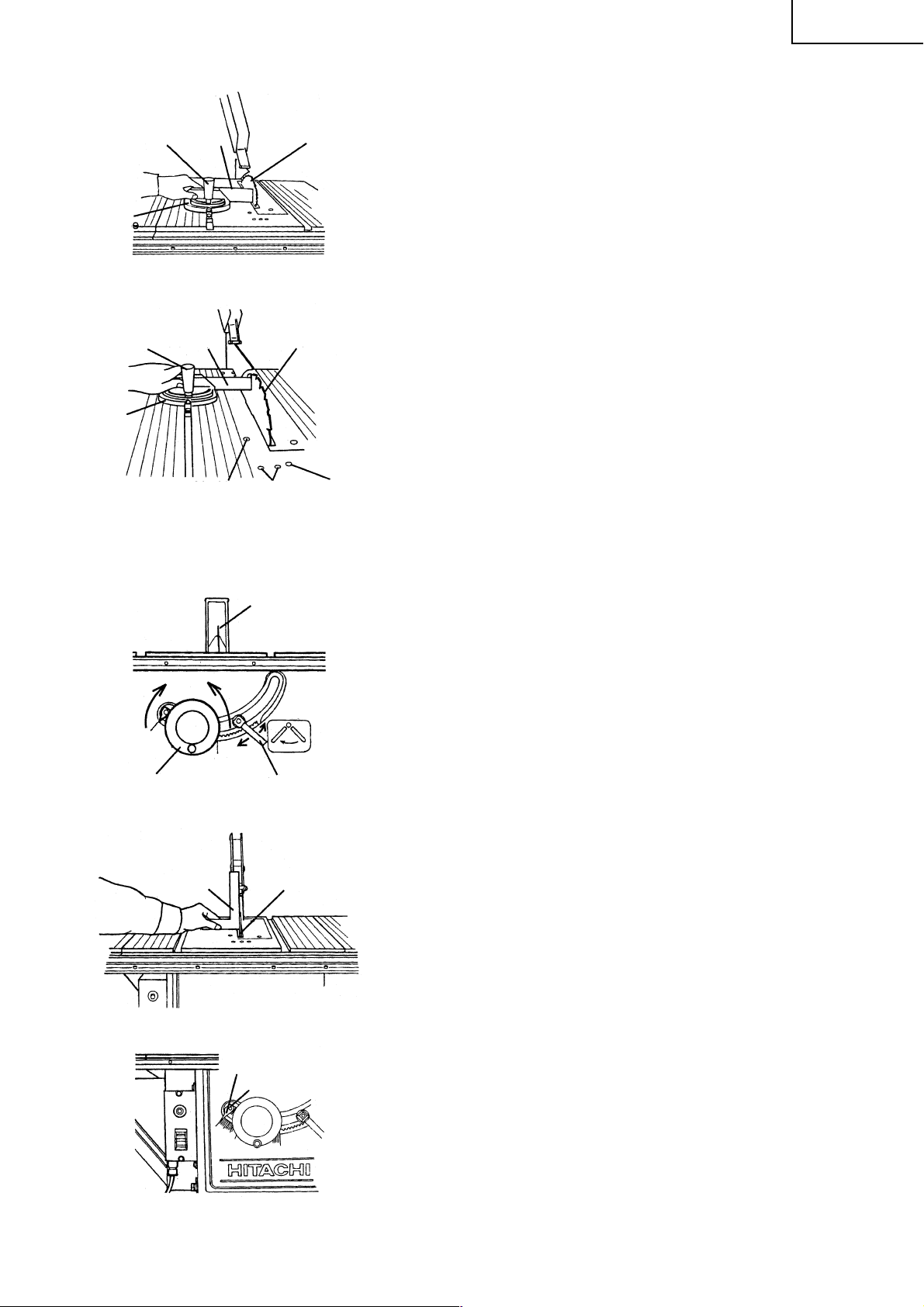

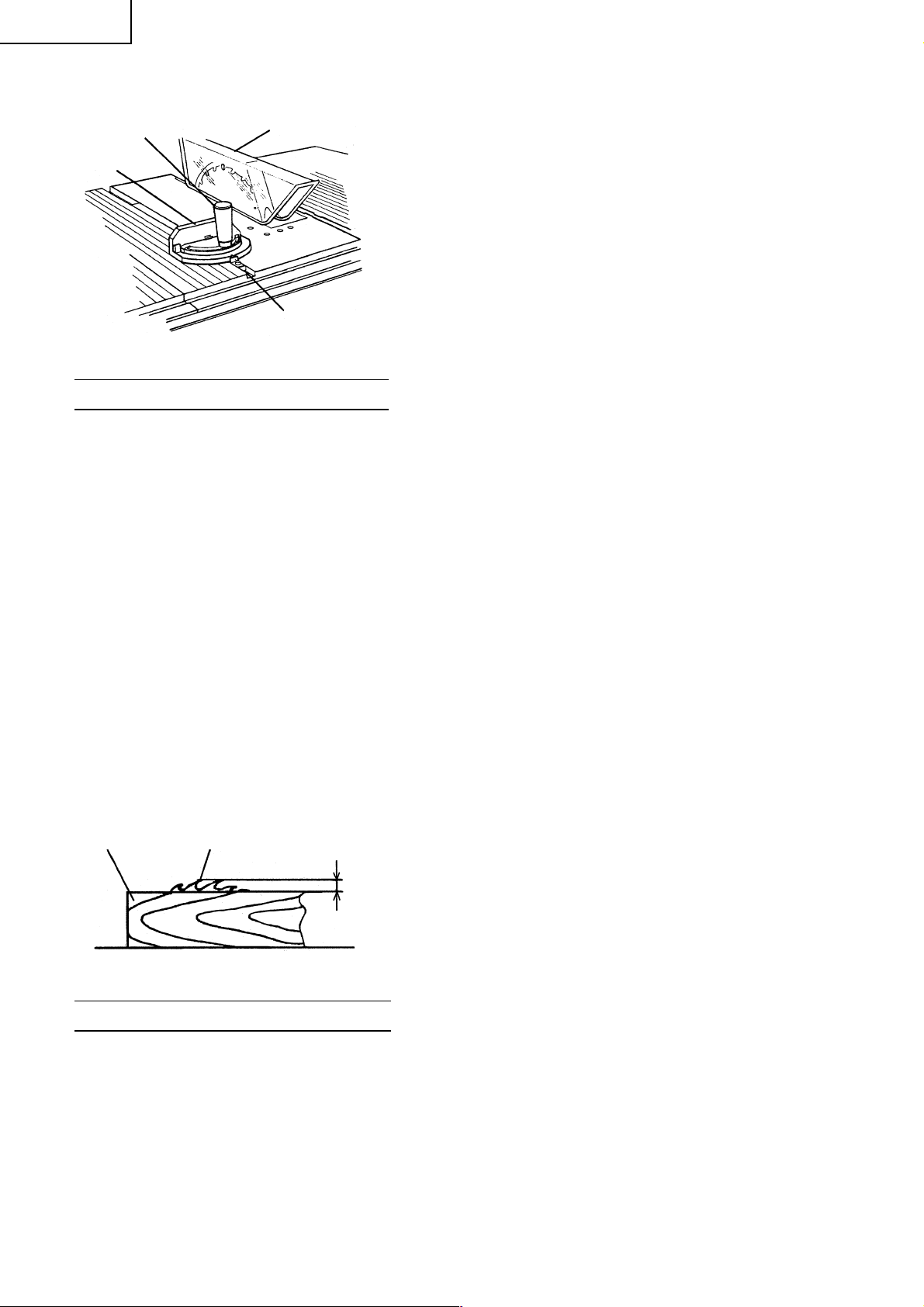

4. Mounting and adjusting Saw Blade Guard Assembly

English

Up

Wheel

Saw Blade

Straightedge

Down

Tighten

Fig. 9-a

6 × 110 mm BoltGuard Bracket

Fig. 9-b

Fig. 9-c

Saw Blade

Loosen

Tilt Lock Handle

Spreader

6 × 90 mm Bolt

Spreader

CAUTION: The saw blade guard and spreader assembly

must be aligned properly to the saw blade in

order to prevent kickback.

Mount the saw blade guard assembly, which includes the

spreader and anti-kickback pawls (see Fig. 9-d).

(1) Mounting the spreader

q Loosen the saw blade tilt lock handle, move the saw blade

tilting mechanism to the left and set the saw blade to 0° by

means of the stopper. Tighten the saw blade tilt lock handle

to lock it in position.

w Turn the wheel fully clockwise and set the saw blade to

the maximum cutting height (see Fig. 9-a).

e Put a 6 mm spring washer and a D13 flat washer on to the

6 × 90 mm and 6 × 110 mm bolts.

r Tentatively fasten the spreader on the rear section of the

body using the cusion and two 6 mm bolts mentioned

above (see Fig. 9-b and Fig. 9-d).

(The guard bracket must be attached to the spreader in

advance.)

(2) Adjusting the spreader

q Use a straightedge to align the spreader with the saw blade

(see Fig. 9-c).

Tighten the two 6 × 16 mm bolts (see Fig. 9-d) with a wrench

to lock the spreader.

w Check clearance between saw blade tip and spreader.

It should be less than 1/2" (12.7 mm) at all positions. If not,

loosen the two 6 × 16 mm bolts securing the spreader to

the guard bracket with a wrench and move the spreader

up and down. After adjustment of the spreader is complete,

firmly retighten the two 6 × 16 mm bolts with a wrench

(see Fig. 9-d).

Saw

Blade

Less than

1/2"(12.7 mm)

Anti-kickback

pawl

Cusion

Fig. 9-d

5. Mounting Table Insert

Table 5 mm Machine Screw

Fig. 10

Table Insert

Spreader

6 × 16 mm

Bolt

The table insert is mounted to the table with two 5mm machine

screws.

CAUTION: The table insert must be in place and securely

fastened at all times.

13

Page 14

English

6. Mounting Elbow (Chip Extraction Duct) (Standard Accessory)

Connect a 2 – 9/16" (65 mm) hose of dust collector to the chip

extraction duct to suck cutting chips away. Mount the chip

extraction duct on the chip discharge outlet at the body rear of

the body.

Elbow (Chip Extraction Duct)

Fig. 11

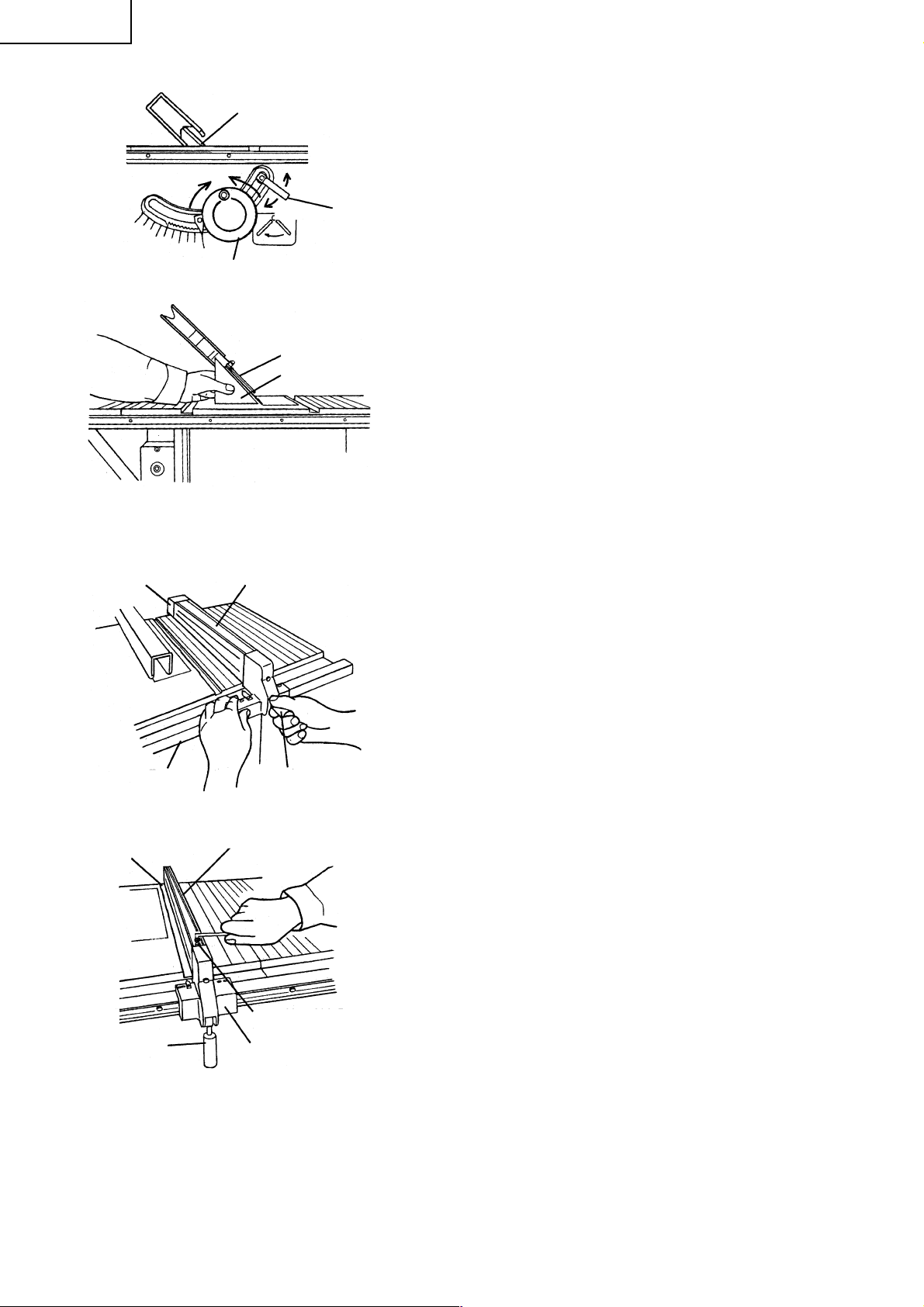

7. Assembly of Table Saw Stand (Optional Accessory)

Leg

Washer

Stay

Cap Square Neck Bolt

Nut

Rubber Cap

Fig. 12-a Fig. 12-b Fig. 12-c

Assemble it with the stay and leg(s). Set the stays below and assemble the legs outside (see Fig. 12-c).

Secure with cup square neck bolts and nuts (see Fig. 12-a).

Then attach rubber caps underneath the legs (see Fig. 12-b).

ADJUSTMENT

This tool is accurately adjusted before shipping from the factory.

Check the following accuracies and readjust them if necessary in order to obtain the best results in operation.

WARNING:To avoid an accident or personal injury, always confirm that the switch is turned off and

the power plug has been disconnected from the receptacle before adjustment of this tool.

1. Adjustment of saw blade parallel to miter gauge groove.

This is the most probably difficult of the adjustments. Before shipment from the factory this adjustment

was made but it should be rechecked and readjusted if necessary.

CAUTION: This adjustment must be correct. Kickback could result and accurate cuts cannot be made.

(1) Loosen the saw blade tilt lock handle by turning it

Up

Wheel

Saw Blade

Down

Loosen

Tighten

Tilt Lock Handle

Fig. 13-a

counterclockwise. Move the saw blade tilting mechanism to

the left and set the saw blade to 0° with the stopper.

(2) Turn the wheel fully clockwise and set the saw blade to the

maximum cutting height (see Fig. 13-a).

(3) Select a tooth on the saw blade which is bent to the right.

(4) Mark that tooth with a pencil or permanent marker.

(5) Set the miter gauge to 90° and tighten the clamp handle (B) to

lock it in that position. Place the miter gauge in the left hand

miter gauge groove in the table top (see Fig. 13-b).

14

Page 15

Clamp

Handle (B)

Miter

Gauge

Clamp

Handle (B) Bar

Miter

Gauge

Bar

Fig. 13-b

6 mm Machine

Screw (A)

Fig. 13-c

Saw Blade

Saw Blade

6 mm Flat

Screw

(6) Rotate the saw blade to bring the marked tooth in the front

(7) Place the bar of square flat against the miter gauge.

(8) Move the bar of square toward the saw blade until it just

(9) Without disturbing the bar clamped to the miter gauge, move

(10) Slide the miter gauge rearward until the clamped bar is closest

(11)If the bar just touched the tooth when the gauge was in the

(12)If the front and rear clearance are not identical,

6 mm Machine

Screw (B)

English

and about 1/2" (12.7 mm) above the table top.

touches the tip of the marked saw blade tooth.

the miter gauge to the center of the saw blade.

to the tip of the marked saw blade tooth (see Fig. 13-c).

front position, it should just touch the tooth in the rear position.

Likewise, if there was some clearance between the bar and

the tooth tip at the front, the same clearance should be at the

rear.

q Remove the miter gauge.

w Loosen four 6mm flat screws.

e Move the body and adjust it so that a bar placed on the

miter gauge is as wide as the clearance between the front

and rear of the saw blade.

r Tighten the four 6mm flat screws.

2. Adjusting 90° and 45° positive stops

This tool is equipped with positive stops for rapid and accurate

positioning of the saw blade at 90° and left bevel 45° to the table.

Check and adjust the positive stops by the following procedures.

(1) To adjust positive stop at 90°.

(2) To adjust positive stop at left bevel 45°.

Up

Wheel

Square

Saw Blade

Down

Loosen

Tighten

Tilt Lock Handle

Fig. 14-a

Saw Blade

Fig. 14-b

Needle Pointer

5 mm Machine Screw

Fig. 14-c

q Turn the wheel fully clockwise and set the saw blade to

the maximum cutting height.

w Loosen the saw blade tilt lock handle and move the saw

blade tilting mechanism to the left until it hits against the

stopper.

Then tighten the saw blade tilt lock handle (see Fig. 14-a).

e Use a square to check the saw blade is at a precise 90°

(see Fig. 14-b).

r If the saw blade is not at a precise 90°, loosen the saw

blade tilt lock handle by turning it counterclockwise. Loosen

the 6mm machine screw (A) (see Fig. 13-c) a few turns and

move the saw blade tilting mechanism until the blade is at

90° to the table (see Fig. 14-b).

t Tighten the saw blade tilt lock handle after adjustment.

y Loosen the 5mm machine screw and set the needle pointer

to 0°. On completion of adjustment, recheck the 90° of the

saw blade and table (see Fig. 14-c).

q Turn the wheel fully clockwise and set the saw blade to

the maximum cutting height.

w Loosen the saw blade tilt lock handle and move the saw

blade tilting mechanism to the right until it hits against

the stopper.

Then tighten the saw blade tilt lock handle (see Fig. 15-a).

e Use a 45° gauge to check the saw blade is at a left bevel

45° (see Fig. 15-b).

15

Page 16

English

Saw Blade

Down

Up

Tighten

Wheel

Fig. 15-a

Saw Blade

45° Gauge

Fig. 15-b

3. Adjustment of rip fence

Loosen

Tilt Lock

Handle

r If the saw blade is not at a left bevel 45°, loosen the saw

blade tilt lock handle. Loosen the 6mm machine screw (B)

(see Fig. 13-c) a few turns and move the saw blade tilting

mechanism until the blade is at left bevel 45° to the table

(see Fig. 15-b).

t After adjustment, tighten the saw blade tilt lock handle.

y On completion of adjustment, recheck the left 45° bevel of

the saw blade and table.

Support

Miter Gauge

Groove

Grip

Fig. 16-a

Parallel Bracket

Fig. 16-b

Rip Fence

GripFront Rail

6 mm Hex. Hd. Bolt

Width Body

Before shipment from the factory the saw blade is set parallel to

the miter gauge groove and the rip fence is adjusted parallel to

the miter gauge groove. Check and adjust the parallel of the rip

fence by the following procedures. In order to accurate work and

prevent kickback when ripping. Before adjustment of rip fence,

check and adjust slider (It is assembled under the width body.) to

engage with the groove on front rail.

(1) Raise the grip to the upside and release the fixation of the rip

fence (see Fig. 16-a).

(2) Position the rip fence at one edge of the miter gauge groove.

(3) Lower the grip to the bottom and fix the rip fence. The edge

of the rip fence should line up parallel with the miter gauge

groove.

(4) If the edge of the rip fence is not parallel with the miter gauge

groove.

q Loosen the four 6 mm hex. hd. bolts securing the parallel

bracket to the width body and support.

w Raise the grip to the upside and release the fixation of the

rip fence.

Align the rip fence parallel to the miter gauge groove.

Lower the grip to the bottom and fix the rip fence.

e While holding the parallel bracket to prevent movement,

tighten the four 6 mm hex. hd. bolts previously loosened

(see Fig. 16-b).

r Raise the grip to the upside and release the fixation of the

rip fence. Move and return the parallel bracket adjacent to

the miter gauge groove. Lower the grip to the bottom and

fix the rip fence. And verify that the parallel bracket is

parallel to the miter gauge groove.

t Repeat adjustment until it is parallel.

y After adjustment, tighten four 6 mm hex. hd. bolts.

u On completion of adjustment, recheck the rip fence is

parallel with the miter gauge groove.

16

Page 17

4. Adjustment of pointer

The pointer is equipped to indicate the distance the rip fence is positioned away from the saw blade.

The pointer should indicate the accurate distance from the saw blade.

Check and adjust the pointer by the following procedures.

NOTE: The pointer will need to be readjusted whenever a different thickness saw blade is installed.

English

Saw Blade

Pointer

Rip Fence

To adjust pointer 0 setting.

(1) Raise the grip to the upside and release the fixation of the rip

fence. And move the rip fence to bring it into tight contact

with the side of the saw blade.

(2) Make sure that the pointer points to 0 on the scale provided

on the table.

(3) If the pointer does not point to 0 on the scale,

q Lower the grip to the bottom and fix the rip fence.

Scale

5 mm

Machine Screw

Grip

Fig. 17

w Loosen the 5 mm machine screw holding the pointer (see

Fig. 17).

e Adjust the pointer to the 0 position and retighten the 5

mm machine screw.

r After adjustment, recheck to see that the pointer now points

to 0.

5. Adjustment of Miter Gauge

The miter gauge should be squareness to the saw blade.

Check and adjust the miter gauge the following procedures.

To adjust pointer 0 setting.

(1) Loosen the clamp handle (B) and place a square against both

the saw blade and miter gauge. The pointer should indicate

90° on the protracter scale on the miter gauge.

(2) If the pointer does not point to 0 on the miter gauge,

q Tighten clamp handle (B).

w Loosen the 5 mm machine screw on the sheet bar.

e Adjust the pointer to the 90° position and tighten the

5 mm machine screw on the sheet bar (see Fig. 18).

r After adjustment, recheck to see that the pointer now points

to 0.

Sheet Bar

Miter Gauge

Clamp

Handle (B)

Protractor

Scale

Pointer

Square

Saw Blade

5 mm Machine Screw

Fig. 18

BEFORE USING

1. Make sure the switch is turned OFF.

WARNING:If the power cord is connected to the power source with the switch turned ON the power

tool will start suddenly and can cause a serious accident.

2. Make sure the power source is appropriate for the tool.

WARNING:Never connect the power tool unless the available AC power source is of the same voltage

as that specified on the nameplate of the tool. Never connect this power tool to a DC

power source.

3. Check the saw blade for visible defects.

Confirm that the saw blade is free of cracks or other visible damage.

17

Page 18

English

4. Confirm that the saw blade is attached securely to the power tool.

Using the supplied wrench, tighten the set nut on the saw blade spindle to secure the saw blade.

For details, see Fig. 34 in the section on “SAW BLADE MOUNTING AND DISMOUNTING”.

5. Check the saw blade guard for proper operation.

Saw blade guard is designed to protect the operator from coming into contact with the saw blade during

operation of the tool.

Always check that the saw blade guard moves smoothly.

WARNING:Never operate the power tool if the saw blade guard does not function smoothly.

6. Check the Power Receptacle

To prevent overheating, accidental stopping or intermittent operation, confirm that the power cord plug

fits properly in the electrical receptacle and does not fall out after it is inserted. Repair or replace the

receptacle if it is faulty.

7. Confirm the tool’s power cord is not damaged

Repair or replace the power cord if an inspection indicates that it is damaged.

AFTER CONNECTING THE POWER PLUG TO AN APPROPRIATE AC POWER SOURCE, CHECK THE

OPERATION OF THE TOOL AS FOLLOWS:

8. Trial Run

After confirming that no one is standing behind, the power tool start and confirm that no operating

abnormalities exist before attempting a cutting operation.

9. Inspect the rotating stability of the saw blade

For precise cutting, rotate the saw blade and check for deflection to confirm that the blade is not noticeably

unstable; otherwise vibrations might occur and cause an accident.

PRACTICAL APPLICATIONS

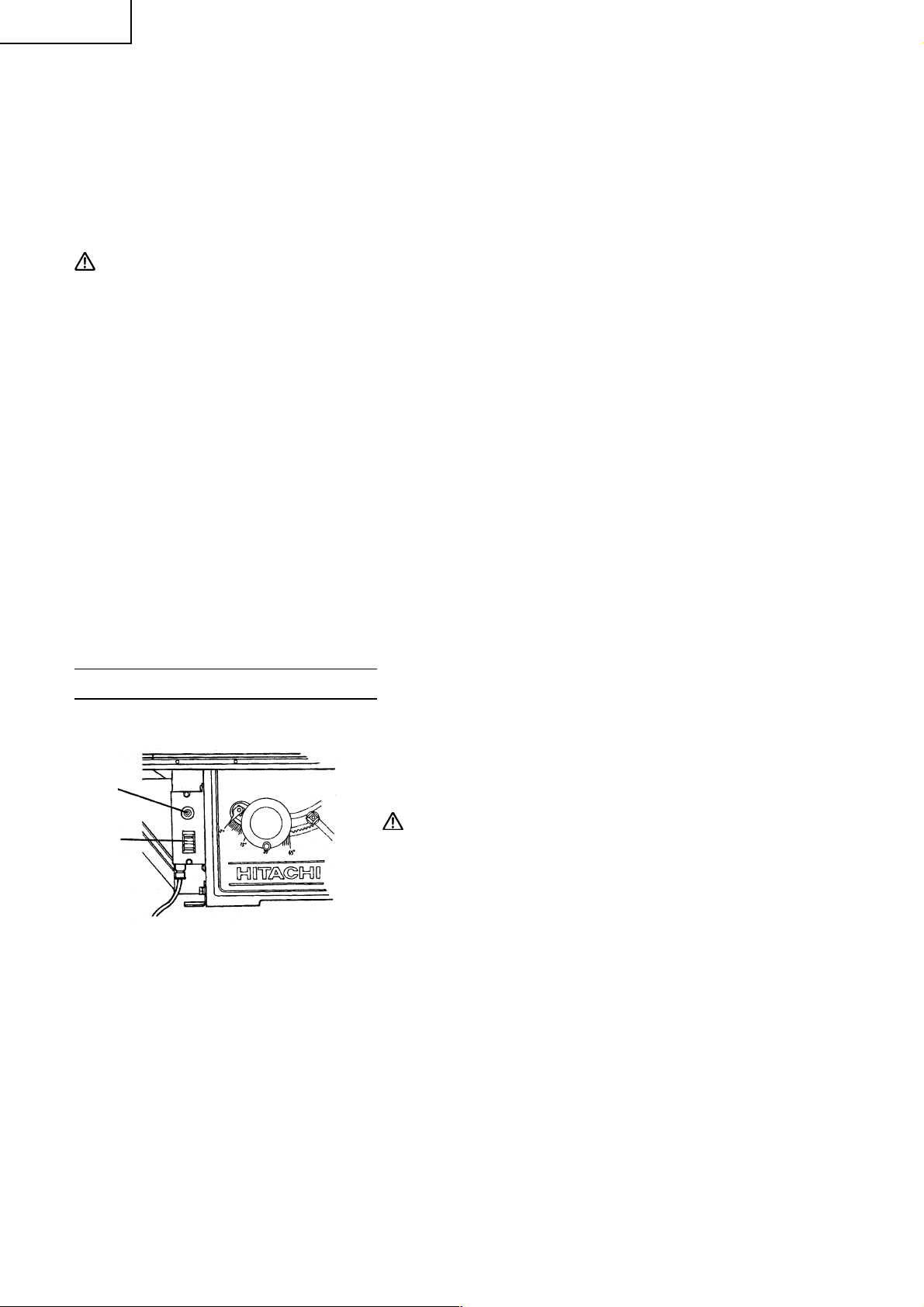

1. Switch operation

To turn the table saw on, raise the red portion of the switch. To

Reset

Button

Switch

Fig. 19

turn the table saw off, push the red portion of the switch. Try this

operation without the saw being plugged in.

WARNING:Always remove the safety key from the switch

when the table saw is not in use. This will ensure

that the table saw cannot be turned on

accidentally or by someone (especially a child)

who is not qualified to use the table saw.

If the safety key is left in the switch, serious

personal injury can result.

2. Overload protective device for motor

When the motor becomes overload, the overload protective device cuts off the current to stop the motor.

In this case, push the reset button (after few minute later).

18

Page 19

3. Raising and lowering saw blade

(1) Raising saw blade.

Saw Blade

Grasp the wheel and rotate it clockwise to raise the saw blade.

(2) Lowering saw blade.

Grasp the wheel and rotate it counterclockwise to lower the

saw blade.

CAUTION: Adjust the saw blade height so it is about 1/8"

Up

Down

Loosen

(3.2 mm) above the top of the workpiece.

Tighten

Tilt Lock HandleWheel

Fig. 20

Raising the saw blade much higher than the

workpiece does not make it cut better. It is

unsafe and provides less table surface in front

of the saw blade.

Never operate while saw blade rotating.

4. Saw Blade Tilting Operation

The saw blade tilt lock handle is spring loaded and can be repositioned by pulling out on the handle and

repositioning it on the serrated stud located underneath the handle.

WARNING:The saw tilt lock handle must be locked during

all cutting operations.

English

Saw Blade

Down

Up

Wheel

Fig. 21

5. Rip Fence Operation

Rip Fence

Loosen

Tighten

Tilt Lock

Handle

Two methods are available tilting saw blade and are as follows.

(1) Rapid saw blade tilting.

Loosen saw blade tilt lock handle, move the wheel until the

saw blade is at the desired angle and tighten saw blade tilt

lock handle.

(2) Fine adjustment saw blade tilting.

q Loosen saw blade tilt lock handle.

w Push in wheel until teeth on hub of hand wheel engauge

with segment gear.

e Turn wheel to tilt the saw blade to the desired angle and

tighten saw blade tilt lock handle.

The rip fence can be used on either side of the saw blade.

The pointer on rip fence indicates the distance between the saw

blade and rip fence.

(1) Raise the grip to the upside and release the fixation of the rip

fence.

(2) Move the rip fence right and left while pressing the width body

against the table surface and set the desired distance from

the saw blade.

(3) Lower the grip to the bottom and fix the rip fence.

Fig. 22

Grip

Width Body

WARNING:The grip must be locked during all cutting

operations.

Confirm the rip fence has been properly locked

before operation.

To prevent personal injury, never operate the

power tool if the rip fence is loose.

CAUTION: Make sure that the rip fence is always in parallel

with the miter gauge groove on the table.

19

Page 20

English

6. Miter Gauge Operation

Clamp

Handle (B)

Miter Gauge

Fig. 23

Blade Guard

Miter Gauge

Groove

The miter gauge can be used on either side of the miter gauge

grooves on the table. However, for bevel cutting (the saw blade

is tilted), use the miter gauge in the right side miter gauge groove

to prevent hands or miter gauge from interfering with the saw

blade guard. Miter gauge is accurately adjustable at 90° and 45°

right and left in relation to the saw blade.

Intentional miter cut angle can be otbained easily.

(1) Loosen clamp handle (B).

(2) Turning the miter gauge to the desired angle.

(3) Tighten clamp handle (B) to lock the miter gauge.

WARNINGS ON OPERATION

For your own safety carefully read and observe the following warnings and precautions in addition to the

[IMPORTANT INFORMATION], [SAFETY] and [WARNING]

1. The saw blade is firmly locked.

2. Never perform any operation “free hand” without using the miter gauge, rip fence, and or other auxiliary

devices. To do so could cause accidents from kickback should the saw blade become locked in the

workpiece material.

3. When miter gauge is used, remove rip fence from table.

4. When the miter gauge is used, securely tighten clamp handle (B).

5. When rip fence is used, remove miter gauge from table.

6. When the rip fence is used, securely lock the grip.

7. If blade stalls or stops, TURN SWITCH OFF before releasing blade.

8. Never remove small cut-off pieces with your fingers. Remove them by pushing them clear with a long

stick.

9. Never attempt to remove small cut-off pieces trapped inside the saw blade guard while the saw is

running. Turn the switch “OFF”, allow the saw blade to come to a complete stop, raise the saw blade

guard, and remove the cut-offs.

10. Adjust the saw blade height so it is about 1/8" (3.2 mm) above the top of the workpiece. More exposure

would be hazardous (see Fig. 24).

Workpiece

Saw Blade

Approx. 1/8"

(3.2 mm)

11. Never touch any cut-offs while saw blade is running.

12. Feed material slowly in order to make fine cut, keep accuracy,

and avoid overloading.

Fig. 24

OPERATING INSTRUCTIONS

There are two basic types of cuts. Ripping and cross cutting. In general, cutting with the grain is ripping and

across the gain is cross cutting. Neither ripping or cross cutting may be done safely freehand. Ripping

requires the use of the rip fence and cross cutting uses the miter gauge. Safety glasses are being worn.

ALWAYS USE EYE PROTECTION WHEN WORKING WITH THE TOOL TO PREVENT EYE INJURY.

Ordinary eyeglasses do not provide adequate protection since the lenses are not made of safety glass. Also,

use a face mask for additional safety and wear a dust mask if the cutting operation produces dust.

20

Page 21

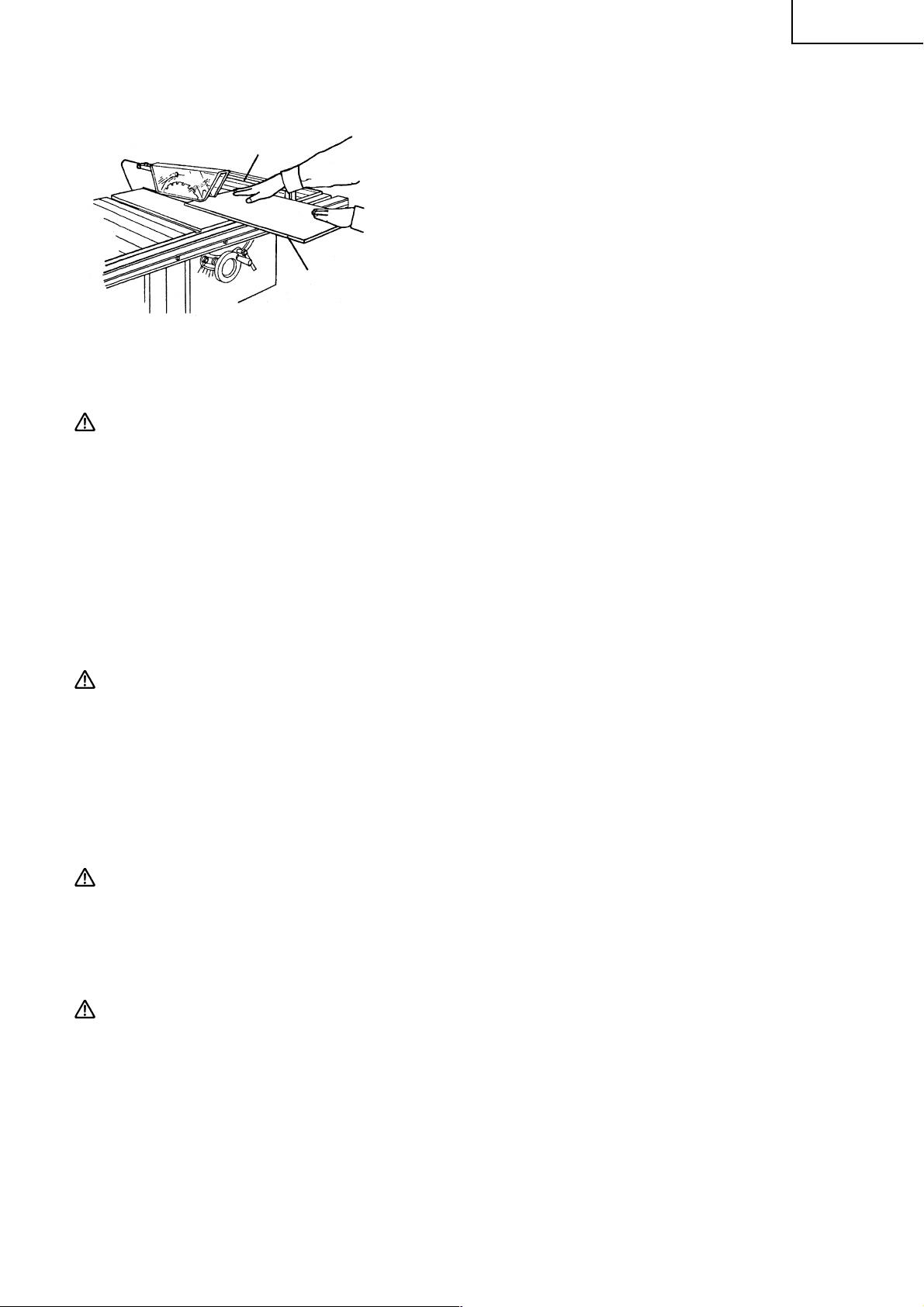

1. Ripping

Confirm the following items before ripping.

Rip Fence

Workpiece

Fig. 25

(1) Rip fence is parallel to saw blade.

(2) Rip fence is securely fixed.

(3) Remove the miter gauge.

(4) Spreader is properly aligned with saw blade.

(5) Anti-kickback pawls are functioning properly (see Fig. 9-d).

Cutting operation

q Adjust the saw blade height so it is about 1/8" (3.2 mm) above

the top of the workpiece.

w Hold the workpiece flat on the table and against the rip fence.

Keep the workpiece about 1" (25 mm) away from the saw

blade.

CAUTION: The workpiece must have a straightedge against the rip fence and must not be warped,

twisted or bowed. Keep both hands away from the saw blade and away from the path of

the saw blade.

English

e Turn on the switch on and allow the saw blade to come up to speed.

r Keeping the workpiece against the table and rip fence, slowly feed the workpiece rearward all the way

through the saw blade. Continue pushing the workpiece until it is clear of the guard and it falls off the

rear of the table.

t When ripping long boards or large panels, always use an adequate support.

A simple support can be prepared by fixing a piece of plywood to a sawhorse or the like.

y When the width of rip is more than 6" (152 mm) feed the workpiece with one or both hands continusly

until it is beyond the saw blade and anti-kickback pawls.

CAUTION: Do not push the free piece that is cut off, merely guide it.

u When the width of rip 2" (50 mm) to 6" (152 mm) wide, use a push stick to feed the workpiece. (Push stick

is optional accessory)

i When the width of rip is less than 2" (50 mm) wide, use an auxiliary guide a push block.

o When ripping thin material (such as veneer), the workpiece may slide or bind between the bottom of rip

fence and the table surface resulting in impossible ripping. Make a board which has the same height and

length of the rip fence surface by using a piece of 3/4" (19 mm) thick plywood. Fix the board to the rip

fence using four wood screws, so that the bottom of the board touches the table surface.

WARNING:Never operate to pull the workpiece back with the saw blade turning. Turn the switch off,

allow the saw blade to complete stop, raise the anti-kickback pawls (see Fig. 9-d) on each

side of the spreader if necessary and slide the workpiece out.

2. Bevel Ripping

This operation is the same as ripping except that the bevel angle is set to an angle other than 0°.

WARNING:Only work with the workpiece and rip fence on the right side of the saw blade.

21

Page 22

English

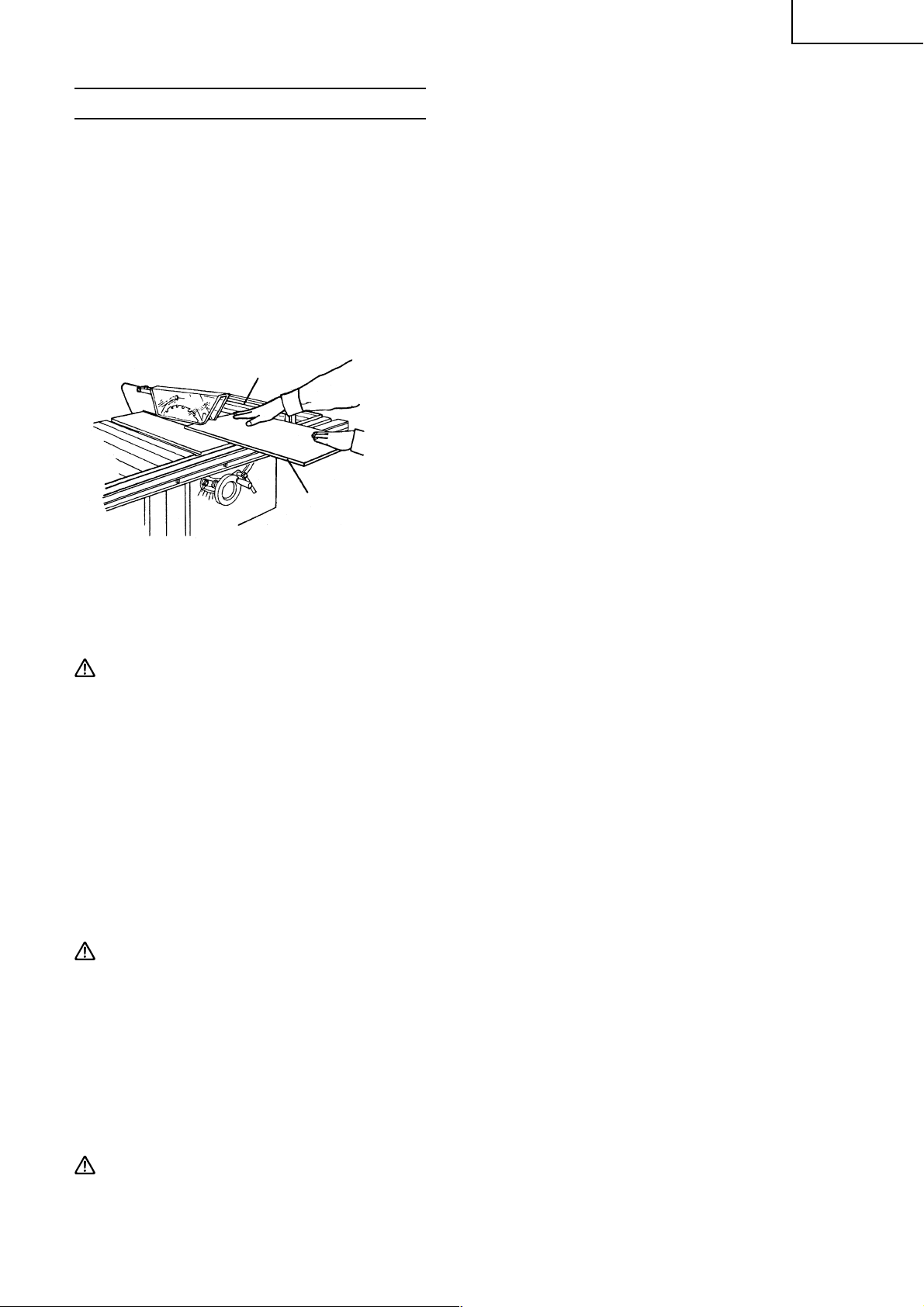

3. Ripping small pieces

WARNING:It is unsafe to rip small pieces. It is unsafe to put your hands close to the saw blade.

Workpiece Push Stick

4. Cross Cutting

When a small width is to be ripped and the hand cannot be safely

put between the saw blade and rip fence, use one or more push

sticks. Use them to hold the workpiece against the table and rip

fence and push the workpiece fully past the saw blade.

Rip Fence

Fig. 26

Miter Gauge

(1) Remove the rip fence.

(2) Spreader is properly aligned with saw blade.

(3) Anti-kickback pawls are functioning properly (see Fig. 9-d).

Cutting Operation

q Adjust the saw blade height so it is about 1/8" (3.2 mm) above

the top of the workpiece.

Confirm the following items before cross cutting.

Workpiece

Fig. 27

w Hold the workpiece firmly against the miter gauge with the

path of the saw blade in line with the desired cut distance.

Keep the workpiece about 1"(25 mm) away from the saw blade.

CAUTION: Keep both hands away from the saw blade and away from the path of the saw blade.

e Turn the switch on and allow the saw blade to come up to speed.

r While keeping the workpiece against the face of the miter gauge, and holding the workpiece flat against

the table, slowly push the workpiece through the saw blade.

CAUTION: Never operate to pull the workpiece back with the saw blade turning. Turn the switch off,

allow the saw blade to complete stop, raise the anti-kickback pawls on each side of the

spreader if necessary and slide the workpiece out.

5. Bevel Ripping

Cross Cutting

This operation is the same as cross cutting except that the bevel angle is set to an angle other than 0°.

WARNING:Only operate with the workpiece and miter gauge on the right side of the table.

6. Mitering

Miter Gauge

This operation is the same as cross cutting expect that the miter

gauge is locked at an angle other than 90°.

WARNING:Hold the workpiece firmly against the miter

gauge and feed the workpiece slowly into the

saw blade to prevent the workpiece from

moving.

Workpiece

Fig. 28

22

Page 23

7. Compound Mitering

This is compound of bevel cross cutting and mitering. It is infrequently used. Follow the instruction for

both bevel cross cutting and mitering.

8. Work Helpers

For certain operations, work helpers such as a push stick, push block, auxiliary fence, work support or

the like should be used.

These helpers can be made by yourself using this table saw.

Refer to following figures which shows typical work helpers dimensions.

English

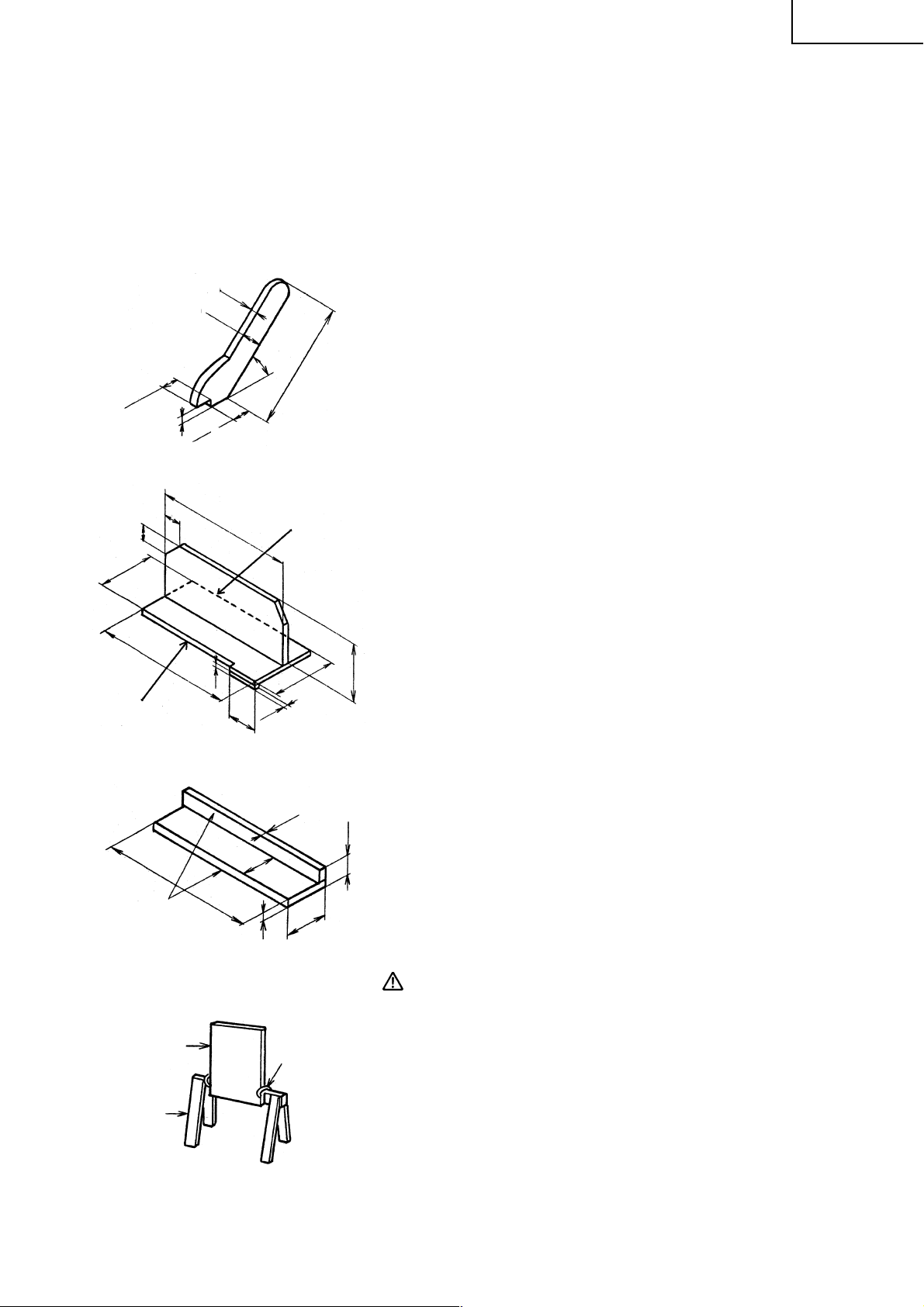

4-3/4"

1-1/4"

A

1"

12"

1/2"

1-1/4"

1"

3/4"

1-1/4"

3/8"

Fig. 29

12"

2-1/2"

45°

3/8"

5-1/8"

12"

B

(1) Push Stick

When the width of rip 2" (50 mm) to 6" (152 mm) wide, use a

push stick to feed the workpiece.

A push stick is available as an optional accessory (refer to

page 10). A push stick can be easily made from a piece of 3/4"

(19 mm) thick plywood.

(2) Push Block

When the width of rip is less than 2" (50 mm) wide, use a

push block.

q Use a piece of 3/8" (9.5 mm) and 3/4" (19 mm) thick

w Glue the small piece of wood 3/8" (9.5 mm) × 3/8" (19 mm)

e Provide a grip in the center of the plywood and fix together

5"

r A and B edges must be parallel.

plywood.

× 2-1/2" (63.5 mm).

with glue and wood screws.

This face and this

edge must be

parallel.

Plywood

Saw Horse

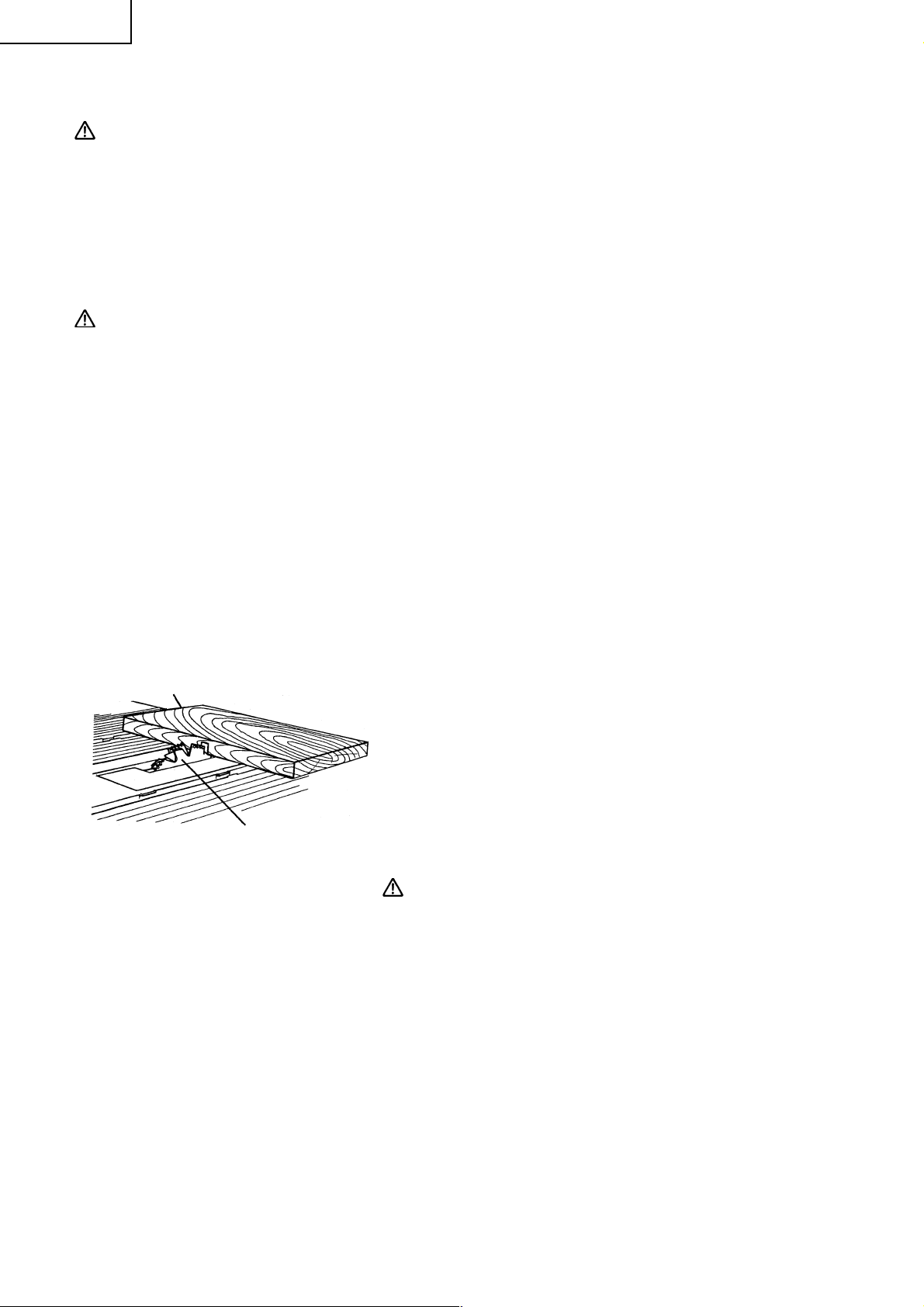

Fig. 30

20"

Fig. 31

Fig. 32

4-3/4"

3/4"

3/4"

“C” clamp

5-1/2"

(3) Auxiliary Fence

2"

When the width of rip is less than 2" (50 mm) the push stick

cannot be used because the saw blade guard (see Fig. 23) will

interfer with a push stick, use an auxiliary fence and push

stick.

q Use a piece of 3/8" (9.5 mm) and 3/4" (19 mm) thick

w Fasten both together with glue and wood screws.

CAUTION: The push block is used with the auxiliary fence.

(4) Work Support

q Clamp a piece of plywood to a sawhorse with “C” clamps.

w Adjust the height of the plywood to level it with the height

plywood.

The 4-3/4" (121 mm) dimension must be the

same on both.

of the table surface.

23

Page 24

English

9. Dado Cutting

WARNING:To prevent an accident or personal injury, always turn off the switch and disconnect the

power plug from the receptacle before mounting or dismounting the dado blade set.

Never attempt to stack dado blades thicker than 1/2" (12.7 mm) thick. Never use the dado set for cut-offs.

Never attempt bevel cuts when dadoing. Never use dado if there is vibration (flutter) or a strange noise.

Never attempt dado in other than wood. Never put hands over the dado blade.

Take every precaution to prevent kickback of the workpiece. Feed workpiece slowly, especially when cutting

deep or wide grooves. When the dado head is hidden from view while cutting, your hands should never be

on top of the workpiece. When using a dado blade, the saw blade guard assembly must be removed since

there is not cut completely through the wood which will allow the spreader to pass through the workpiece.

CAUTION: Use extreme caution when dado cutting.

Always stop the tool and wait for dado blade to come to a complete stop. Then simply

withdraw the wood. Use a push stick. Use rip fence or miter gauge. Be alert for potential

kickback conditions. Follow the dado blade set manufactures recommendations. When

using a dado blade set, the depth of cut is not indicated by the pointer. To know the depth

cut, you must measure it with a ruler. Be sure to place the saw blade guard assembly back

in its original position and check adjustments when the dado cuts are completed.

A groove cut into the workpiece is called dado. This dado does not extend completely through the workpiece.

The dado can be made in various widths and depths according to the need. A typical use for a dado is to

make the groove for a shelf. A saw blade can be used to make a dado of any width by marking multiple cuts

side by side. However, it is much easier to use a dado blade. The first has to small blades and a series of

chips to the remove scrap between the blades. The second type consists of a small thick blade which is

caused to wobble by its mounting hubs. This saw will accept dado blades of the cutter chip type to 6" (152

mm) in diameter and 1/2" (12.7 mm) in which. Most wobble type blades are too wide fit on the saw blade

spindle safely. A dado blade requires a table insert which has wider opening. This dado insert is available as

an optional accessory (refer to page 10). Purchase the dado blade set separately.

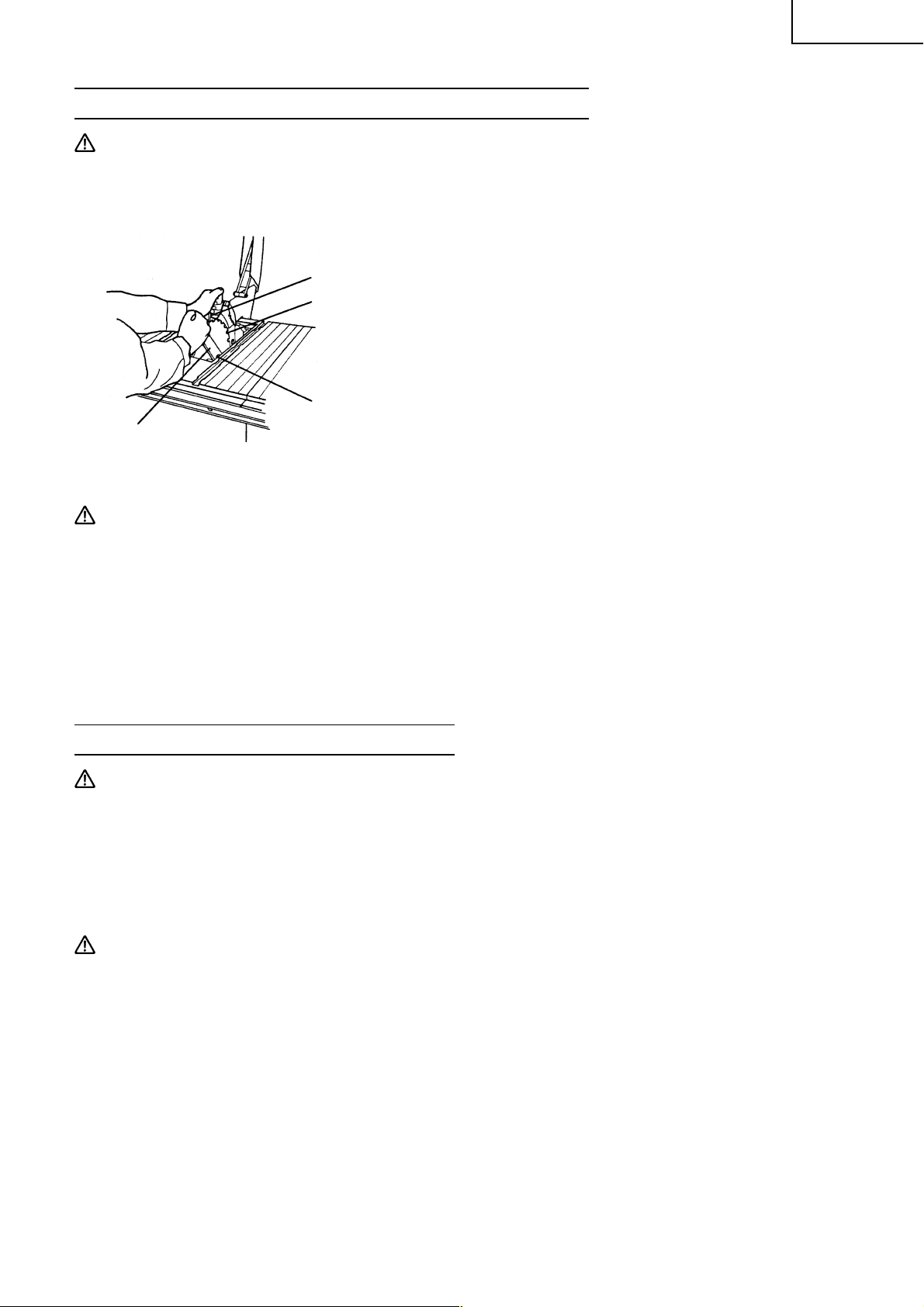

Mounting the dado blade set

Workpiece

Dado Cutter

Fig. 33

Mounting the dado blade set (see Fig. 33), procedures as follows:

q Remove the saw blade guard assembly with the spreader.

w Remove the table insert.

e Dismount the saw blade.

r Mount the dado blade with the teeth pointing down at the

front of the table (Using the instructions with the dado

blade set).

t Mount the dado table insert (optional accessory), instead

of the table insert.

CAUTION: While tightening the set nut (see Fig. 34), be

careful to maintain the even spacing between

the tips of the inside cutters. Rotate the dado

blade one turn by hand to make sure that it does

not contact anything before operation.

24

Page 25

SAW BLADE MOUNTING AND DISMOUNTING

WARNING:To prevent an accident or personal injury, always turn off the switch and disconnect the

power plug from the receptacle before mounting or dismounting a saw blade.

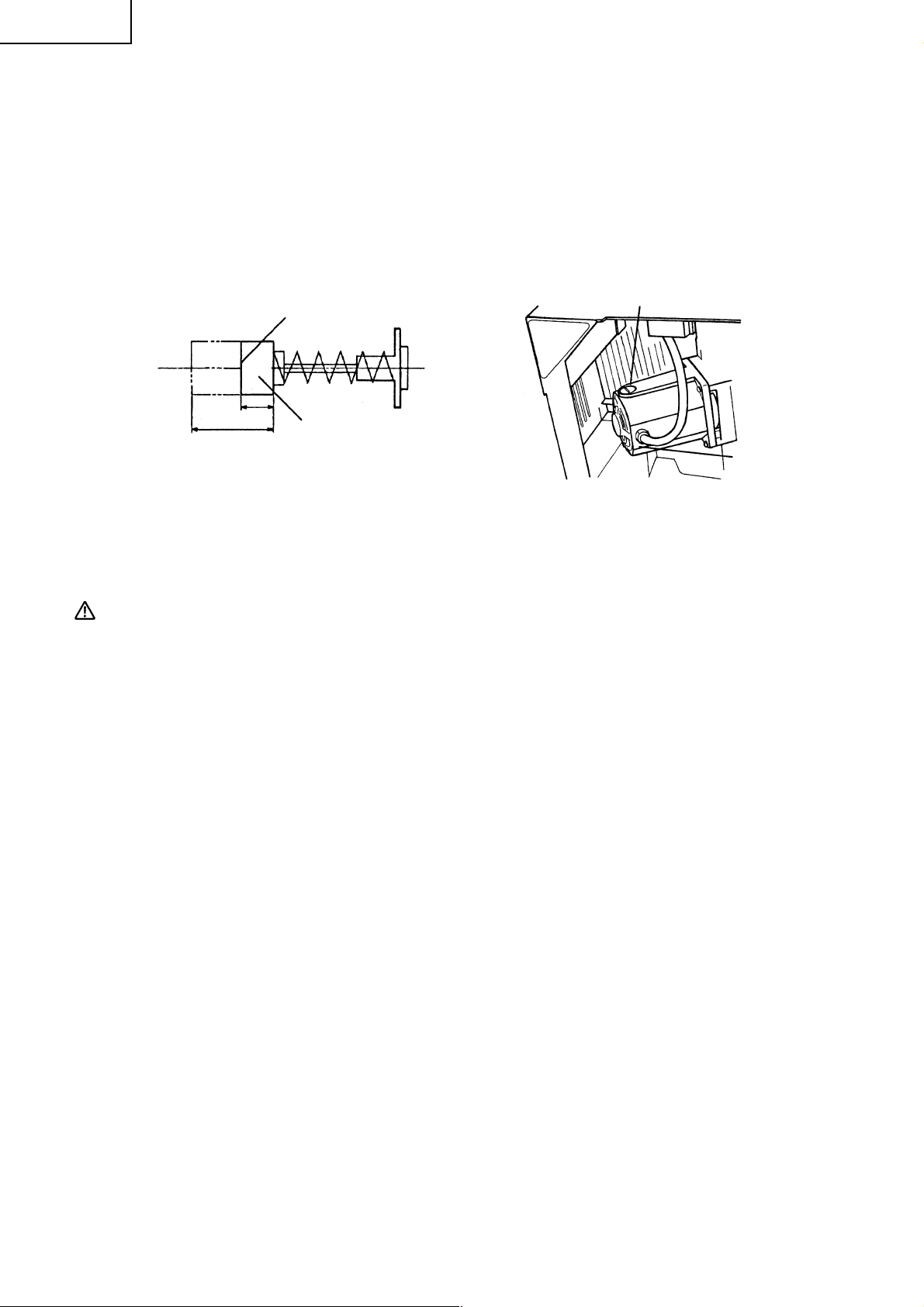

1. Mounting the saw blade

(1) Turn the wheel (see Fig. 1) fully clockwise and set the saw

blade to the maximum cutting height (see Fig. 14-a).

Wrench

Saw Blade

Set Nut

Hex. Wrench

Fig. 34

(2) Tighten the saw blade tilt lock handle and lock the saw blade

at 90°.

(3) Remove the table insert on the table.

(4) Mount the washer (A), saw blade and washer (A) in this order

on the saw blade spindle. (The saw blade with the teeth

pointing down at the front of the table.)

(5) Using the open end wrench and place the wrench on the flats

on the saw blade spindle. Hold the saw blade spindle from

turning and tighten nut using the remaining hex. wrench by

turning the set nut clockwise.

(6) Replace the table insert on the table.

English

WARNING:Be sure to grip set nut carefully with the hex. wrench. A serious injury can be sustained, if

your grip should slip, the hex. wrench come off the nut, and your hand strike the sharp

blade edges.

When mounting the saw blade, confirm that the rotation indicator mark on the sawblade

and the rotation direction of the saw are properly matched.

Tighten the set nut so it does not come loose during operation. Confirm the set nut (see

Fig. 34) has been properly tightened before the power tool is started.

2. Dismounting the saw blade

Dismount the saw blade by reversing the mounting procedures described in paragraph 1 above.

MAINTENANCE AND INSPECTION

WARNING:To avoid an accident or personal injury, always confirm that the switch is turned OFF and

that the power plug has been disconnected from the receptacle before performing any

maintenance or inspection of this tool.

1. Inspecting the saw blade

Always replace the saw blade immediately upon the first sign of deterioration or damage.

A damaged saw blade can cause personal injury and a worn saw blade can cause ineffective operation

and possible overload to the motor.

CAUTION: Never use a dull saw blade. When a saw blade is dull, its resistance to the hand pressure

applied by the tool handle tends to increase, making it unsafe to operate the power tool.

25

Page 26

English

2. Inspecting the carbon brushes (Fig. 35 and Fig. 36)

The carbon brushes in the motor are expendable parts. If the carbon brushes become excessively worn,

motor trouble might occur. Therefore, inspect the carbon brushes periodically and replace them. Check

the carbon brushes after the first 50 hours of use for a new machine or after a new set of carbon brush

have been installed. After the first check, examine them after each about 10 hours of use until such time

that replacement is necessary.

When the carbon on either brush is worn to 3/16" (5 mm) in length or if either spring or shunt wire is

burned or damaged in any way, replace both carbon brushes (see Fig. 35). If the carbon brushes are

found serviceable after removing, reinstall them in the same position as before removed. Also, keep the

carbon brushes clean so that they will slide smoothly within the brush holders. The carbon brushes can

easily be removed after removal of the brush caps (see Fig. 36) with a slotted (minus) screwdriver.

Brush Cap

Motor

Fig. 36

44

3/16"(5 mm)

43/64"(17 mm)

Wear Limit Line

No.44 indicates the last two

numbers of carbon brush code No.

Fig. 35

3. Inspecting the mounting screws

Regularly inspect each component of the power tool for looseness.

Re-tighten mounting screws on any loose part.

WARNING:To prevent personal injury, never operate the power tool if any components are loose.

4. Inspecting the saw blade guard for proper operation.

Before each use of the tool, test the saw blade guard (see Fig. 1) to assure that they are in good condition

and that they move smoothly. Never use the tool unless the saw blade guard operates properly and

unless they are in good mechanical condition. Ensure the anti-kickback pawls are always sharp so they

dig into the workpiece to help prevent kickbacks. If any damage has occurred, repair it promptly.

5. Frequently clean the saw blade guard.

Wipe off saw dust attached to the inside of the see-through saw blade guard using a soft cloth. Do not

use solvent (gasoline, thinner etc.), solvents will damage plastic parts.

6. Storage

Confirm that the switch is turned OFF, that the power plug has been removed from the receptacle and

that the safety key has been removed and has been in a secure place, after operation of the tool has been

completed. When the tool is not in use, keep it stored in a dry place out of the reach of children.

7. Lubrication

Lubricate the following moving parts and rotating parts once a month to keep the power tool in good

operating condition for a long time (see Fig. 1 and Fig. 2). Use of machine oil is recommended.

Oil supply points:

Rotary and moving portion of wheel

8. Cleaning

Periodically remove chips and other waste material from the surface of the power tool with a damp,

soapy cloth. To avoid a malfunction of the motor, protect it from contact with oil or water.

26

Page 27

English

SERVICE AND REPAIRS

All quality power tools will eventually require servicing or replacement of parts because of wear from

normal use. To assure that only authorized replacement parts will be used, all service (other than routine

maintenance) must be performed by an AUTHORIZED HITACHI POWER TOOL REPAIR CENTER ONLY.

NOTE: Specifications are subject to change without any obligation on the part of HITACHI.

27

Page 28

Français

INFORMATIONS IMPORTANTES

Lire et assimiler toutes les instructions de fonctionnement, les précautions de sécurité et les avertissements

de ce mode d’emploi avant d’utiliser ou d’entretenir cet outil électrique.

La plupart des accidents causés lors de l’utilisation ou de l’entretien de l’outil électrique proviennent d’un

non respect des règles ou précautions de sécuritéde base. Un accident peut la plupart du temps être évité si

l’on reconnaît une situation de danger potentiel avant qu’elle ne se produise, et en observant les procédures

de sécurité appropriées.

Les précautions de sécurité de base sont mises en évidence dans la section “SECURITE” de ce mode d’emploi

et dans les sections qui contiennent les instructions de fonctionnement et d’entretien.

Les dangers qui doivent être évités pour prévenir des blessures corporelles ou un dommage de l’outil sont

identifiés par AVERTISSEMENTS sur l’outil électrique et dans ce mode d’emploi.

Ne jamais utiliser cet outil électrique d’une manière qui n’est pas spécifiquement recommandée par HITACHI

sans avoir d’abord vérifié que l’utilisation prévue est sans danger pour vous et les autres.

SIGNIFICATION DES MOTS D’AVERTISSEMENT

AVERTISSEMENT: Indique des situations potentiellement dangereuses qui, si elles sont ignorées,

pourraient entraîner de graves blessures.

ATTENTION: Indique des situations dangereuses qui, si elles sont ignorées, pourrait entraîner de

légères blessures ou endommager l’outil.

REMARQUE: Met en relief des informations essentielles.

SÉCURITÉ

CONSIGNES DE SÉCURITÉ RELATIVES AUX OUTILS ÉLECTRIQUES.

LIRE TOUS LES AVERTISSEMENTS ET TOUTES LES INSTRUCTIONS D’UTILISATION DU

MANUEL AVANT DE METTRE L’OUTIL EN SERVICE OU DE L’ENTRETENIR :

AVERTISSEMENT: Lorsqu’on utilise l’outil électrique, prendre toutes les précautions nécessaires

pour éviter au maximum tout risque de choc électrique ou autre blessure

physique.

En particulier, toujours respecter les consignes de sécurité suivantes :

1. TOUJOURS LAISSER LES PROTECTIONS EN PLACE ET LES MAINTENIR EN BON

ORDRE DE MARCHE.

2. TOUJOURS RETIRER LES CLAVETTES DE RÉGLAGE ET LES CLÉS AVANT DE METTRE

L’OUTIL EN MARCHE. Toujours vérifier que les clés et les clavettes de réglage sont bien toutes

retirées de l’outil avant de le mettre en marche.

3. TOUJOURS MAINTENIR L’AIRE DE TRAVAIL PROPRE. Pour éviter tout risque de blessure, ne

pas encombrer l’aire de travail ni l’établi.

4. NE JAMAIS UTILISER L’OUTIL DANS UN ENVIRONNEMENT DANGEREUX. Ne jamais

utiliser l’outil électrique dans un endroit humide ou mouillé, et ne jamais l’exposer à la pluie. Toujours

veiller à ce que l’aire de travail soit suffisamment éclairée.

5. NE JAMAIS LAISSER LES ENFANTS NI AUCUNE AUTRE PERSONNE APPROCHER DE

L’AIRE DE TRAVAIL. Interdire l’accès de l’aire de travail à tout le monde (en particulier aux enfants).

Toujours débrancher l’outil quand on s’en éloigne et veiller à ce que personne ne puisse pénétrer dans

l’aire de travail en mettant des verrous aux portes et aux interrupteurs principaux. Quand on n’utilise

pas l’outil électrique, ne pas oublier de retirer la clé de sécurité du interrupteur et de la ranger dans un

endroit sûr.

6. NE JAMAIS FORCER L’OUTIL. Il effectuera le travail le meilleur et avec la sécurité maximale au

régime pour lequel il a été conçu.

7. TOUJOURS UTILISER LES OUTILS APPROPRIÉS. Ne jamais utiliser un outil ou un accessoire

pour un travail pour lequel il n’est pas conçu.

28

Page 29

Français

8. PORTER DES VÊTEMENTS APPROPRIÉS PENDANT LE TRAVAIL. Ne jamais porter de

vêtements lâches ni de gants, cravate, bagues, bracelets ni aucun autre bijou. Ils pourraient se coincer

dans les pièces en rotation. Toujours porter des chaussures anti-dérapantes, en particulier avec des

doigts de pied en acier. Porter un couvre-chef qui recouvre les cheveux longs.

9. TOUJOURS PORTER DES LUNETTES DE PROTECTION PENDANT LE TRAVAIL POUR

ÉVITER TOUT RISQUE DE BLESSURE DES YEUX. Les lunettes ordinaires n’assurent pas une

protection suffisante parce que leurs verres sont uniquement résistants aux chocs, ce NE sont PAS des

verres de sécurité. Par ailleurs, porter un masque sur le visage pour accroître la sécurité, et un masque

anti-poussière si le travail doit dégager de la poussière.

10. TOUJOURS FIXER LA PIÈCE À LA GARDE OU À LA TABLE. Utiliser des dispositifs de serrage

ou un étau pour tenir la pièce. Cela sera plus sûr que de tenir la pièce à la main et libérera les deux mains

pour le travail.

11. NE JAMAIS TROP SE PENCHER. Toujours garder une bonne assise et un bon équilibre pendant

le travail.

12. TOUJOURS ENTRETENIR LES OUTILS AVEC SOIN. Maintenir les outils aiguisés et propres

pour optimiser le travail et la sécurité. Toujours suivre les instructions de graissage et de remplacement

des accessoires.

13. TOUJOURS DÈBRANCHER L’OUTIL avant un entretien et lors du remplacement des lames ou de

tout autre accessoire.

14. NE JAMAIS RISQUER UNE MISE EN MARCHE INOPINÉE LORSQU’ON BRANCHE

L’OUTIL. Toujours vérifier que l’interrupteur est en position OFF avant de brancher la fiche d’alimentation

dans la prise secteur.

15. TOUJOURS UTILISER EXCLUSIVEMENT LES ACCESSOIRES RECOMMANDÈS POUR

L’OUTIL. Consulter le mode d’emploi pour la description des outils recommandés. Pour éviter tout

risque de blessure, utiliser exclusivement les accessoires recommandés pour cet outil.

16. NE JAMAIS MONTER SUR L’OUTIL. Il y a risque de blessure grave en cas de renversement de

l’outil ou en cas de contact accidentel avec la lame de scie.

17. TOUJOURS VÉRIFIER SI L’OUTIL A DES PIÈCES ENDOMMAGÉES AVANT DE

L’UTILISER. Toujours vérifier si la protection et les autres composants sont endommagés avant d’utiliser

l’outil pour s’assurer qu’ils fonctionneront correctement. Vérifier si toutes les pièces mobiles sont bien

alignées, non voilées, ou toute autre condition qui pourrait entraver leur bon fonctionnement. Toujours

réparer ou remplacer les protections ou les autres pièces endommagées avant d’utiliser l’outil.

18. TOUJOURS VÉRIFIER LE SENS DE ROTATION DE LA LAME AVANT D’UTILISER L’OUTIL.

Toujours avancer la pièce dans l’outil contre le sens de rotation de la lame pour éviter tout risque de

blessure.

19. NE JAMAIS S’ÉLOIGNER DE L’OUTIL QUAND IL FONCTIONNE. LE METTRE HORS

TENSION. Ne pas s’éloigner de l’outil tant qu’il n’est pas complètement arrêté. Toujours mettre l’outil

hors tension quand on ne s’en sert pas. Toujours débrancher le cordon d’alimentation quand on ne se

sert pas de l’outil.

20. L’outil n’est pas conçu pour des applications de fabrication en série, et il ne devra donc pas être utilisé

dans un environnement de fabrication en série.

21. Pour les réparations, utiliser exclusivement des pièces de rechange agréées.

22. Alimenter l’outil exclusivement sur un courant alternatif de 115 volts. Une tension ou une alimentation

incorrectes pourraient provoquer un mauvais fonctionnement de l’OUTIL ELECTRIQUE et provoquer

des blessures physiques ou des dommages matériels graves.

23. MISE À LA MASSE. Cet outil électrique doit être mis à la masse lors de toute utilisation afin de

protéger l’opérateur des secousses électriques.

Consignes de sécurité spéciales pour cet outil électrique

AVERTISSEMENT: Pour éviter tout risque de blessure, les consignes de sécurité spéciales suivantes

devront être respectées lors de l’utilisation de l’outil.

29

Page 30

Français

CHOSES A FAIRE

TOUJOURS OBSERVER LES CONSIGNES SUIVANTES POUR GARANTIR UNE

UTILISATION EN TOUTE SÉCURITÉ:

1. Bien lire le manuel et se familiariser avec les consignes de sécurité et les instructions d’utilisation de

l’OUTIL ELECTRIQUE avant de l’utiliser.

2. Toujours vérifier que l’OUTIL ELECTRIQUE est propre avant de l’utiliser.