Page 1

La utilización inapropiada e insegura de esta herramienta el

!

!

Page 2

–

2

–

................................

ETATS-UNIS

ître le center

technique le plus proche de chez vous.

ître le center

technique le plus proche de chez vous.

reparaciones más cercano.

reparaciones más cercano.

Page 3

–

3

–

Lead based paints

Crystalline silica from bricks, cement and other masonry products

Arsenic and chromium from chemically treated lumber

....................

Page 4

–

4

–

Look for this symbol that identifi es important

jewelry that may get caught in moving parts.

Non-slip footwear is recommended. Wear protective

Page 5

–

5

–

SAFETY

a push stick, especially when ripping

WARNING: FREEHAND CUTTING IS THE

on

Page 6

–

6

–

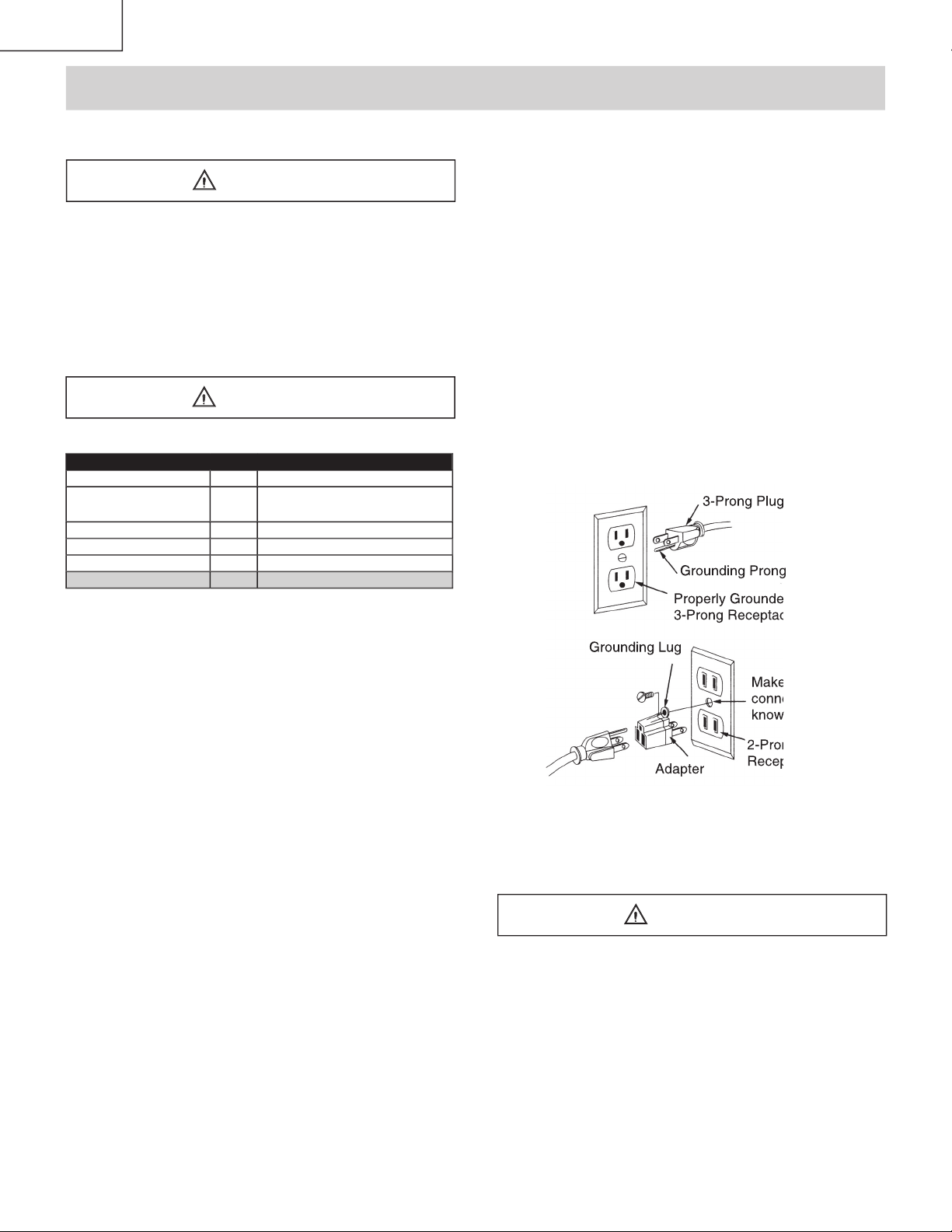

power source outlet

SAFETY

used for power tools MUST be

The 12 to 16 amp rating is correct for this tool. It

MINIMUM GAUGE FOR EXTENSION CORDS (AWG)

16 16 14

16 14 12

16 14 12

12

Page 7

–

7

–

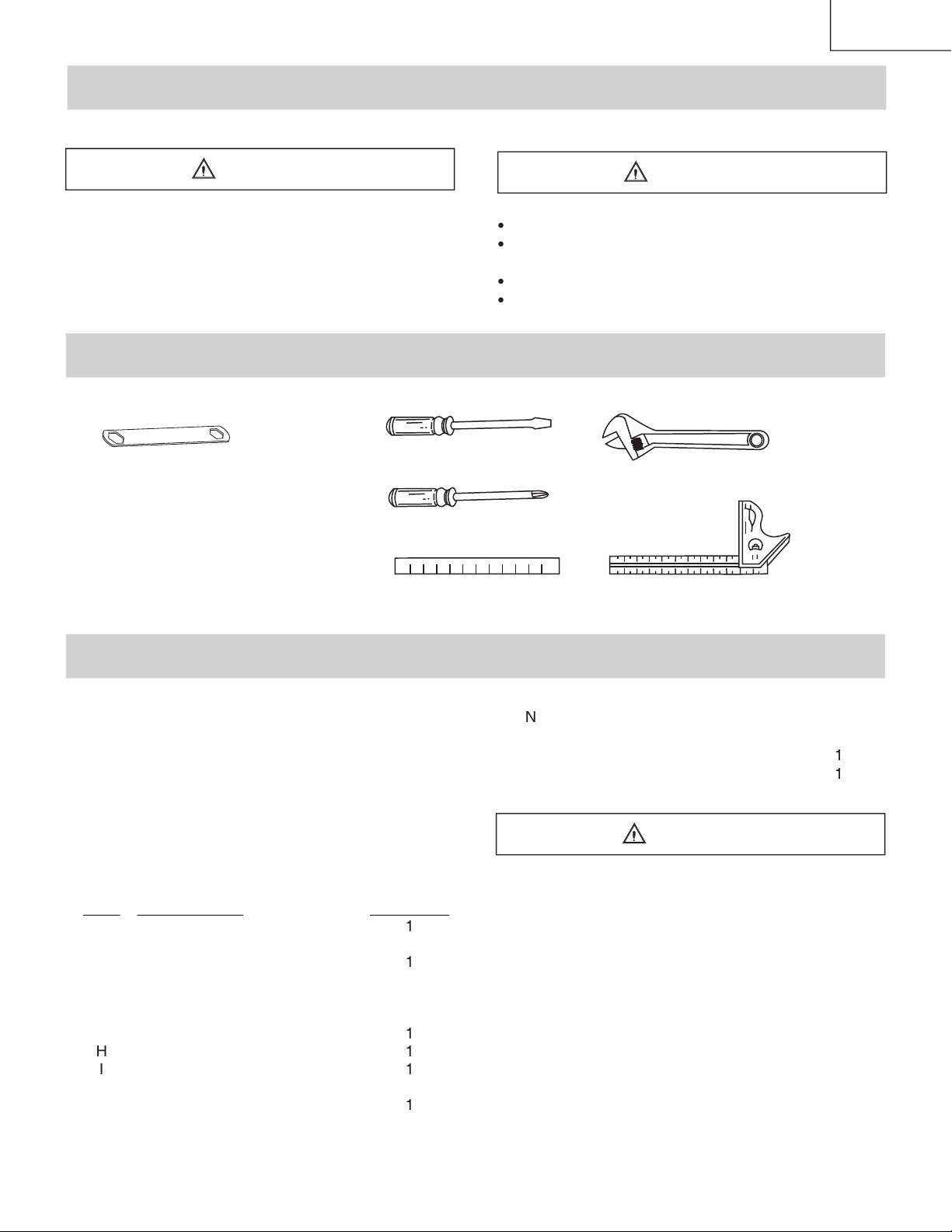

Supplied

Hex Wrench

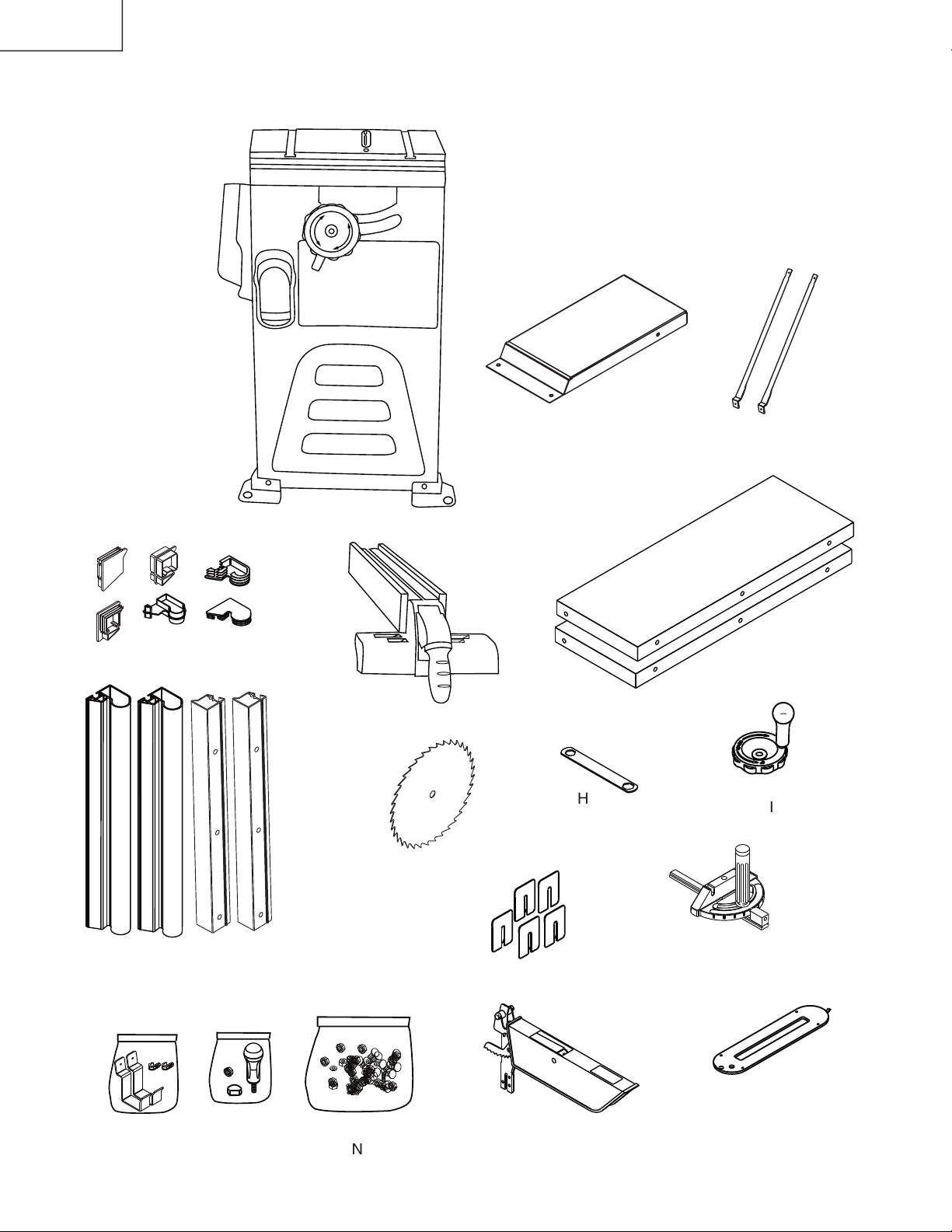

CONTENTS

1 set

1 each

1 each

Page 8

–

8

–

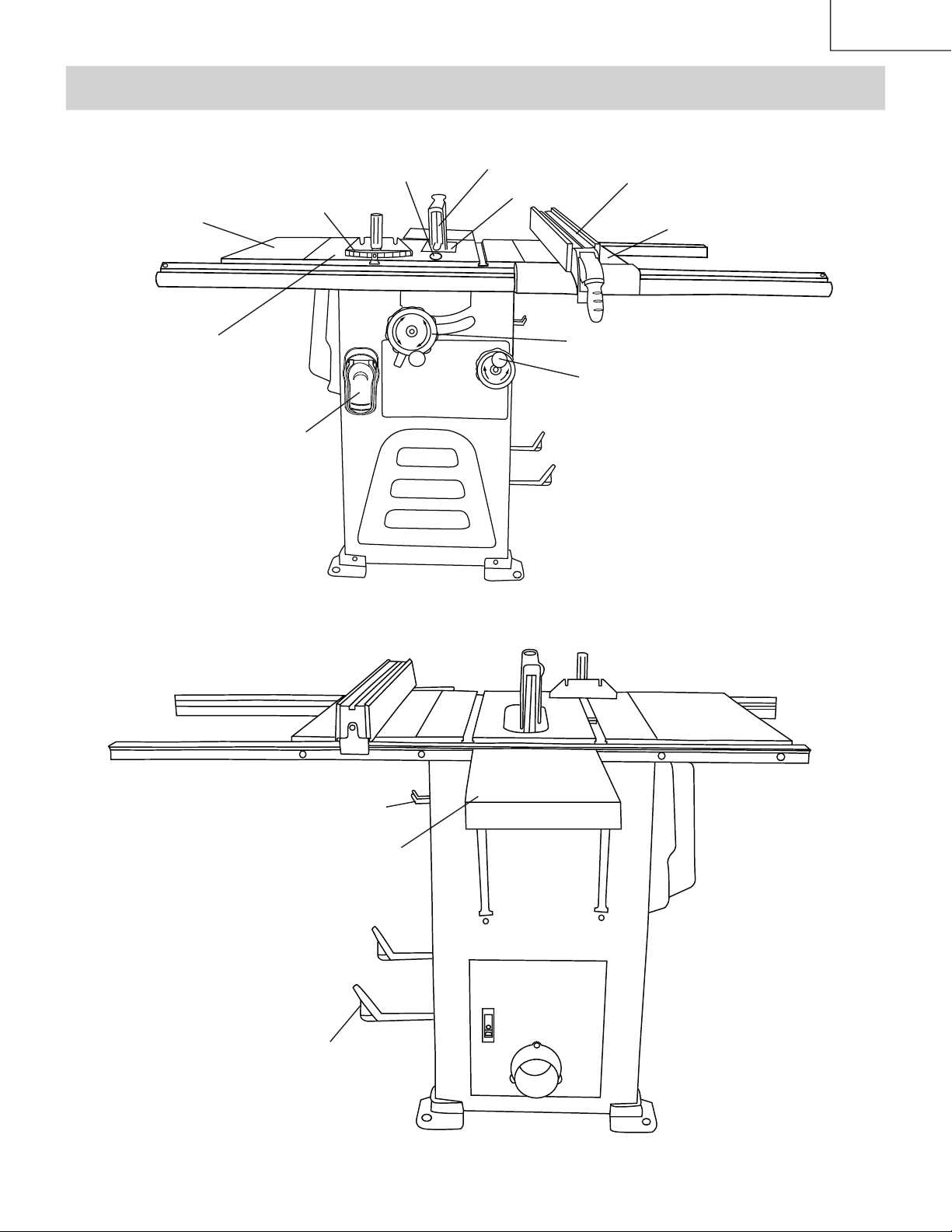

TABLE SAW

Page 9

–

9

–

Page 10

–

10

–

SAW TERMS

Prevents the workpiece

A simultaneous bevel and miter

Page 11

–

11

–

THE STYROFOAM FROM THE CABINET-

Page 12

–

12

–

Page 13

–

13

–

on the bevel scale.

and replace the table insert.

vertical position by

position and check the

a. Remove the blade guard by removing the wing

b. Loosen and remove the two bolts (3) from the

and 45

Page 14

–

14

–

vertical position by

machine.

Page 15

–

15

–

POSITIVE STOPS

and 45° to the table. Make adjustments

Stop (Fig. H, H-1)

A

B

3

4

5

6

1

2

Stop (Fig. I)

on the scale.

A

B

4

3

5

6

0

ı

5

ı

10

ı

Page 16

–

16

–

(FIG. M)

GAUGE ADJUSTMENT (FIG. N)

on the scale.

cut in a scrap piece of wood. Check

GAUGE OPERATION (FIG. N)

, 15

, 30

, 45

, 60

both right and left side.

, 45

, 60

both right and left side.

(FIG. K)

Page 17

–

17

–

1

2

5

6

7

1

12

13

20

21

22 24

4 1

Page 18

–

18

–

O

F

F

O

N

Page 19

–

19

–

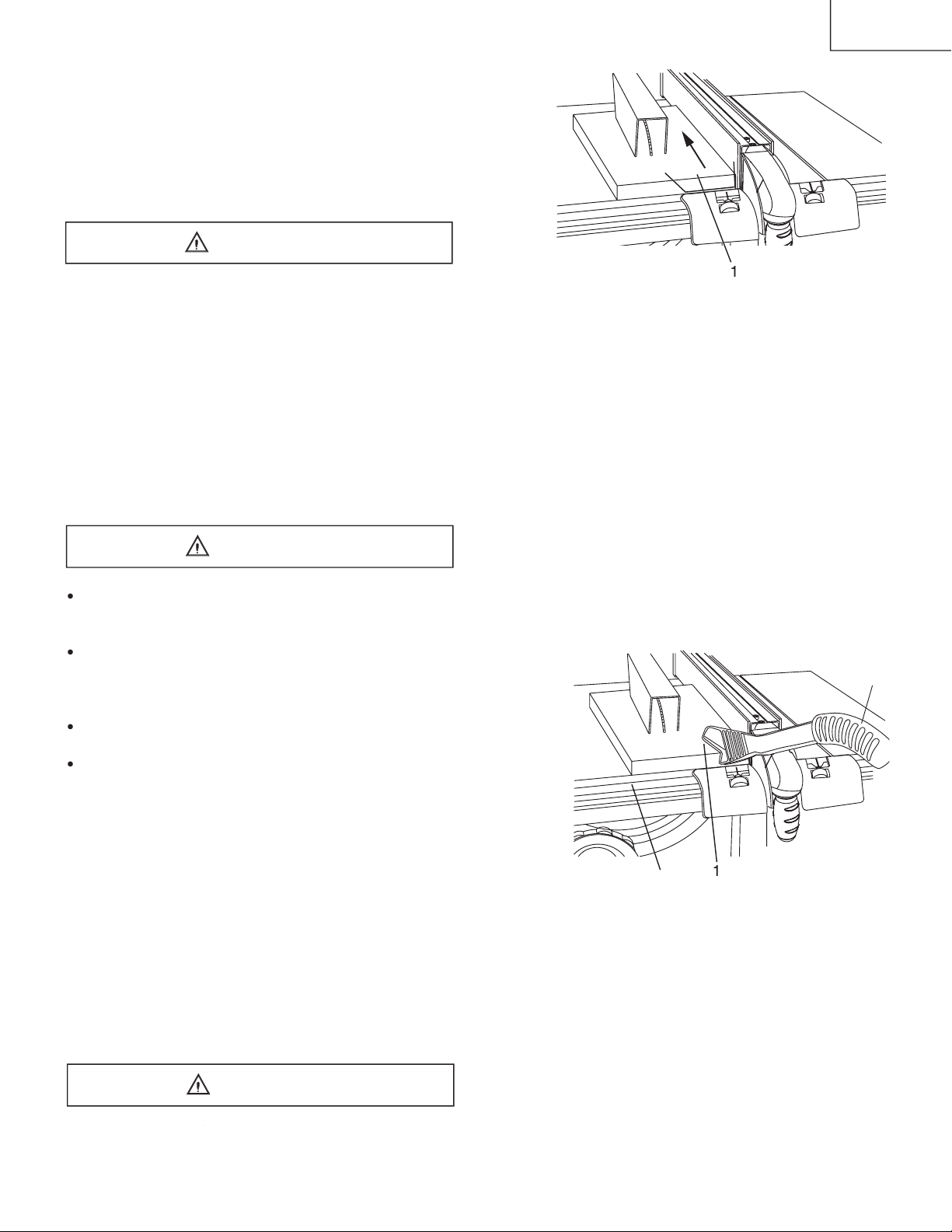

from the path of the blade.

by pushing forward on the section

3

Page 20

–

20

–

Do not allow familiarity or frequent use of your table

Keep both hands away from the blade and the path

Never attempt to pull the workpiece backwards

When tilting the blade to 45

Page 21

–

21

–

inju

at that time.

and tighten the blade bevel lock knob.

Cut the piece to shape and size shown:

4-3/4”

Page 22

–

22

–

Page 23

–

23

–

Certain cleaning chemicals can damage

Page 24

–

24

–

Service Center.

mechanisms.

Page 25

–

25

–

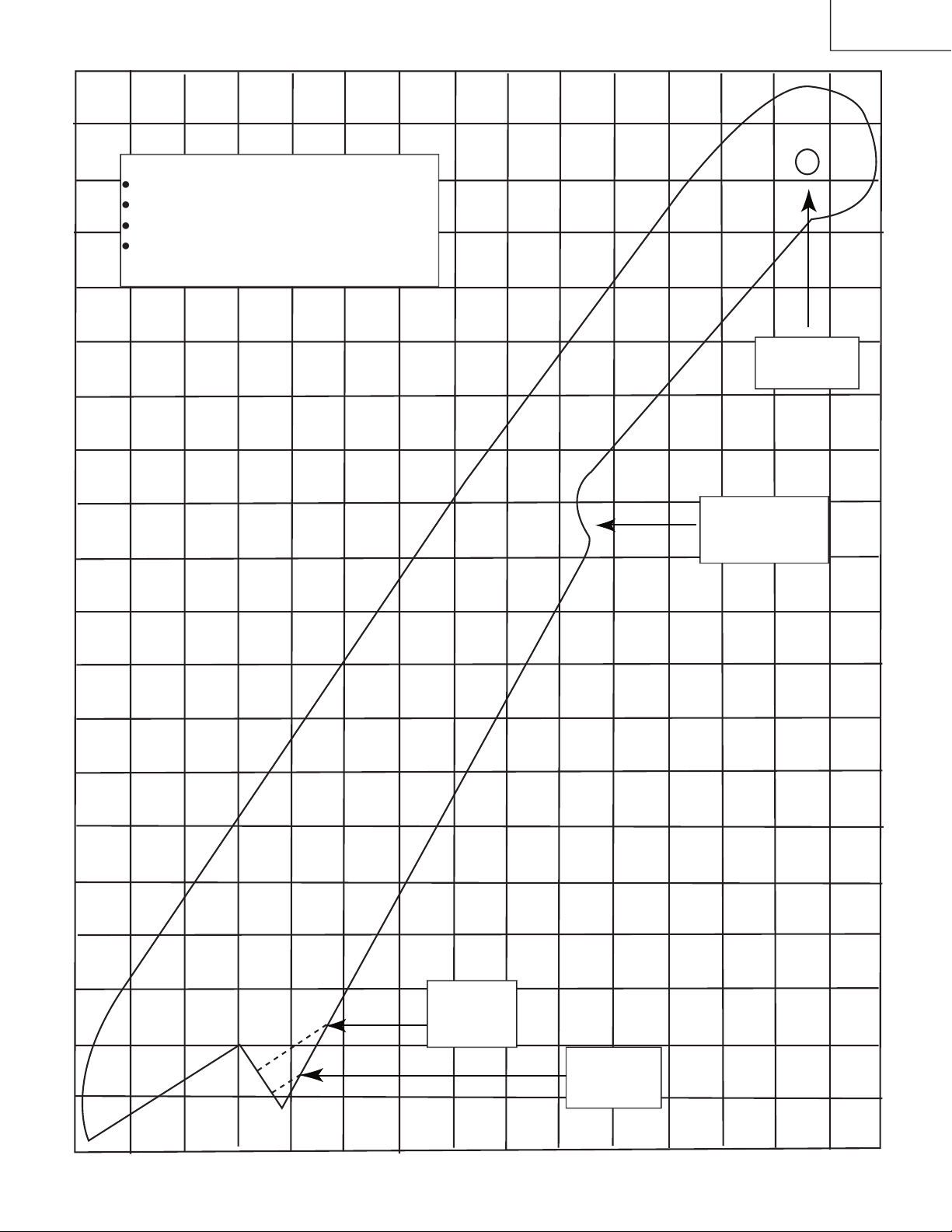

This is a full-size drawing (actual size)

Use good quality plywood or solid wood

Use 1/2 in. or 3/4 in. material

Push stick MUST be thinner than the width

Page 26

–

72

–

Size

Size

SPINDLE PULLEY

SET NUT

SIDE COVER (LEFT)

SIDE COVER (RIGHT)

SPECIAL BOLT

SCREW

T=0.2MM

SHAFT

SPRING PIN

T=3mm

SPRING PIN

SWITCH MOUNTING

SPLIT PIN

SWITCH BOX

SWITCH BOX COVER

STICKER LABEL

T=0.5MM

SLOTTED PAN HD. SCREW

TILTING SCALE

SQUARE NUT

SERRATED TOOTHED HEXAGON FLANGE NUT

SUPPORT ROD

STRAIN RELIEF

STRAIN RELIEF

SPRING PIN

SLEEVE

ASS’Y

SET PLATE

SCALE (RIGHT)

SCALE (LEFT)

SPONGE

SET PLATE

TORSION SPRING

T=3MM

Page 27

–

73

–

Page 28

–

74

–

Black

Black

120V

60HZ

Power

Rocker Switch

White

White

Blue

Black

Brown

(Terminal Block)

Black

Motor

White

White

Black

Black

Black

Black

(CIRCUIT BREAKER

SWITCH)

Black

(Rocker Switch)

240V

60HZ

Power

(Terminal Block)

White

White

Black

Blue

Black

Black

Motor

White

White

Black

Black

Black

Black

(CIRCUIT BREAKER

SWITCH)

Motor

Green

(GROUND)

(CIRCUIT BREAKER

SWITCH)

Black

White

White

Black

Black

Black

Black

Terminal Block

Rocker Switch

Blue

Black

Black

Brown

White

Power Cord

White

Black

White

Black

Green

(GROUND)

Motor

Green

(GROUND)

CIRCUIT BREAKER

SWITCH

Black

White

White

Black

Black

Black

Black

Terminal Block

Rocker Switch

Blue

Black

Black

White

Power Cord

White

Black

White

Black

Green

(GROUND)

120 V Wire Wirding

240 V Wire Wirding

Page 29

–

75

–

Issued by

Minato-ku, Tokyo 108-6020, Japan

Distributed by

Loading...

Loading...