Page 1

MITER SAW

MODEL

C 10FM

POWER TOOLS

C

TECHNICAL DATA

AND

C 10FM

SERVICE MANUAL

LIST No. E930 March 2000

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

Page 2

Notice for use

Specifications and parts are subject to change for improvement.

Refer to the Hitachi Power Tool Technical News for further information.

CONTENTS

[ Business Section ]

1. PRODUCT NAME

2. MARKETING OBJECTIVE

3. APPLICATIONS

4. SELLING POINTS

4-1. Selling Point Descriptions

5. SPECIFICATIONS

6. COMPARISONS WITH SIMILAR PRODUCTS

7. PRECAUTIONS IN SALES PROMOTION

7-1. Instruction Manual

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

8. ADJUSTMENT AND OPERATIONAL PRECAUTIONS

8-1.Confirmation of Saw Blade Lower Limit Positioning

8-2. How to Use the Vise Ass’y

8-3. Cutting Operation

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

Page

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

1

1

1

1

2

3

4

5

5

6

6

6

7

9. PACKING

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

[ Service Section ]

10. PRECAUTIONS IN DISASSEMBLY AND REASSEMBLY

10-1. Disassembly

10-2. Reassembly

10-3. Wiring Diagram

10-4. Lead Wire Precautions

10-5. No-load Current

10-6. Reassembly Requiring Adjustment

10-7. Lubrication

10-8. Product Precision

10-9. Tightening Torque

11. REPAIR GUIDE

12. STANDARD REPAIR TIME (UNIT) SCHEDULES

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••

8

9

9

15

16

16

17

17

18

18

19

20

24

[ Appendix ]

Assembly Diagram for C 10FM

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

25

Page 3

1. PRODUCT NAME

Hitachi Miter Saw, Model C 10FM

2. MARKETING OBJECTIVE

There has been persistent demand for a single-function miter saw (10" miter cutting) in the North American

markets. Responding to the market, Hitachi is pleased to introduce an inexpensive miter saw, Model C 10FM.

Accordingly, significant sales promotion and market share increases are anticipated.

3. APPLICA TIONS

Cutting various types of wood workpieces

Cutting plywood, decoration panels, soft fiberboard and hardboard

Cutting aluminum sashes

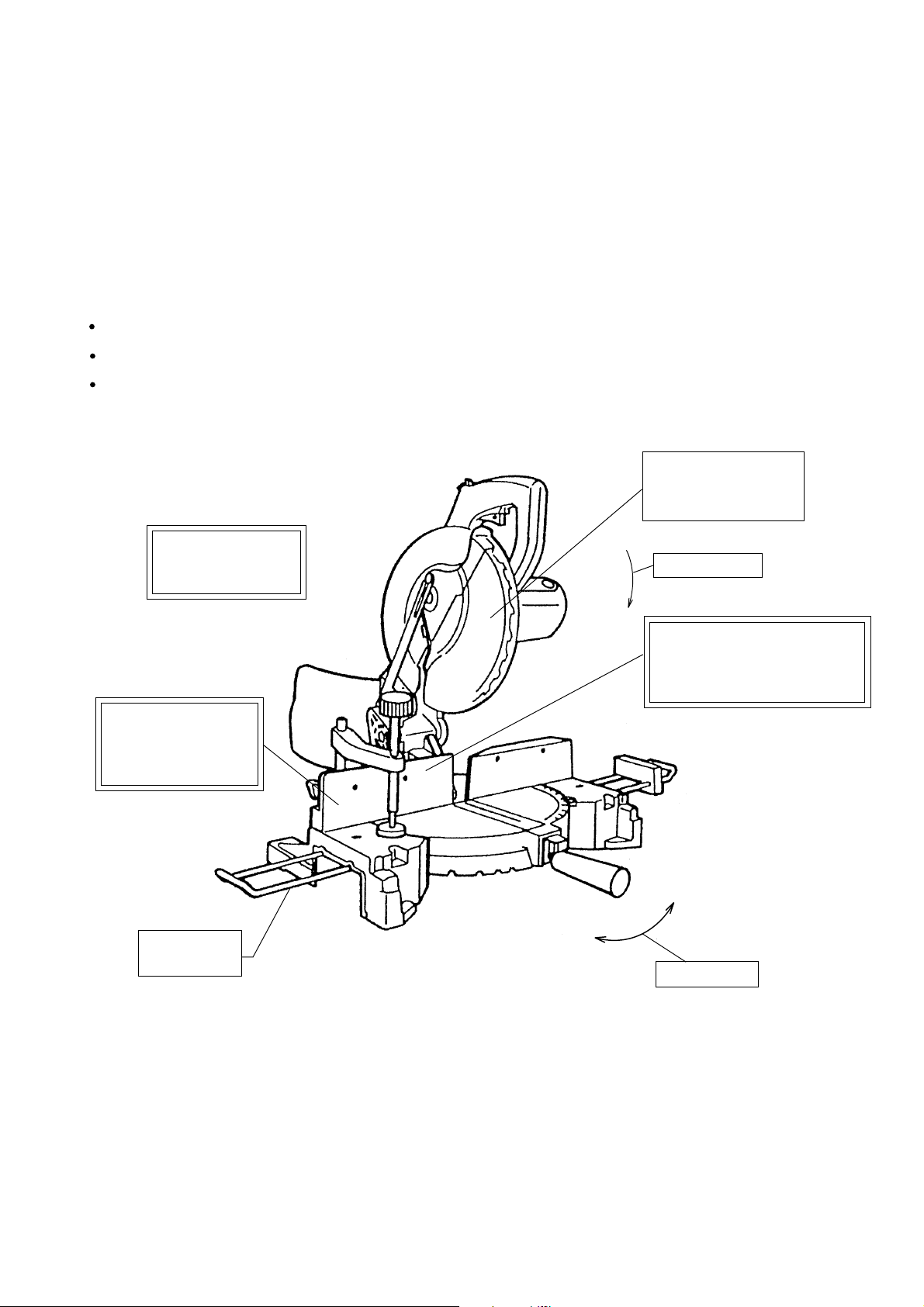

4. SELLING POINTS

24T TCT blade cuts

2 x 6 at 90˚ miter

(4)

2 x 4 at 45˚ miter

Lightweight

27.3 lbs. (12.4 kg)

for easy portability

3-1/8" extra-tall high

fence allows crown

moldings to be cut

standing vertically

Holder ass'y

optional

Left

(1)

Press cutting

(3)

Equipped with a debris

guard to restrict dispersion

of chips for enhanced safety

in operation

Right

(2)

Miter cutting

(Note) Numerals in ( ) are identical with item numbers in "4-1. Selling Point Descriptions".

--- 1 ---

Page 4

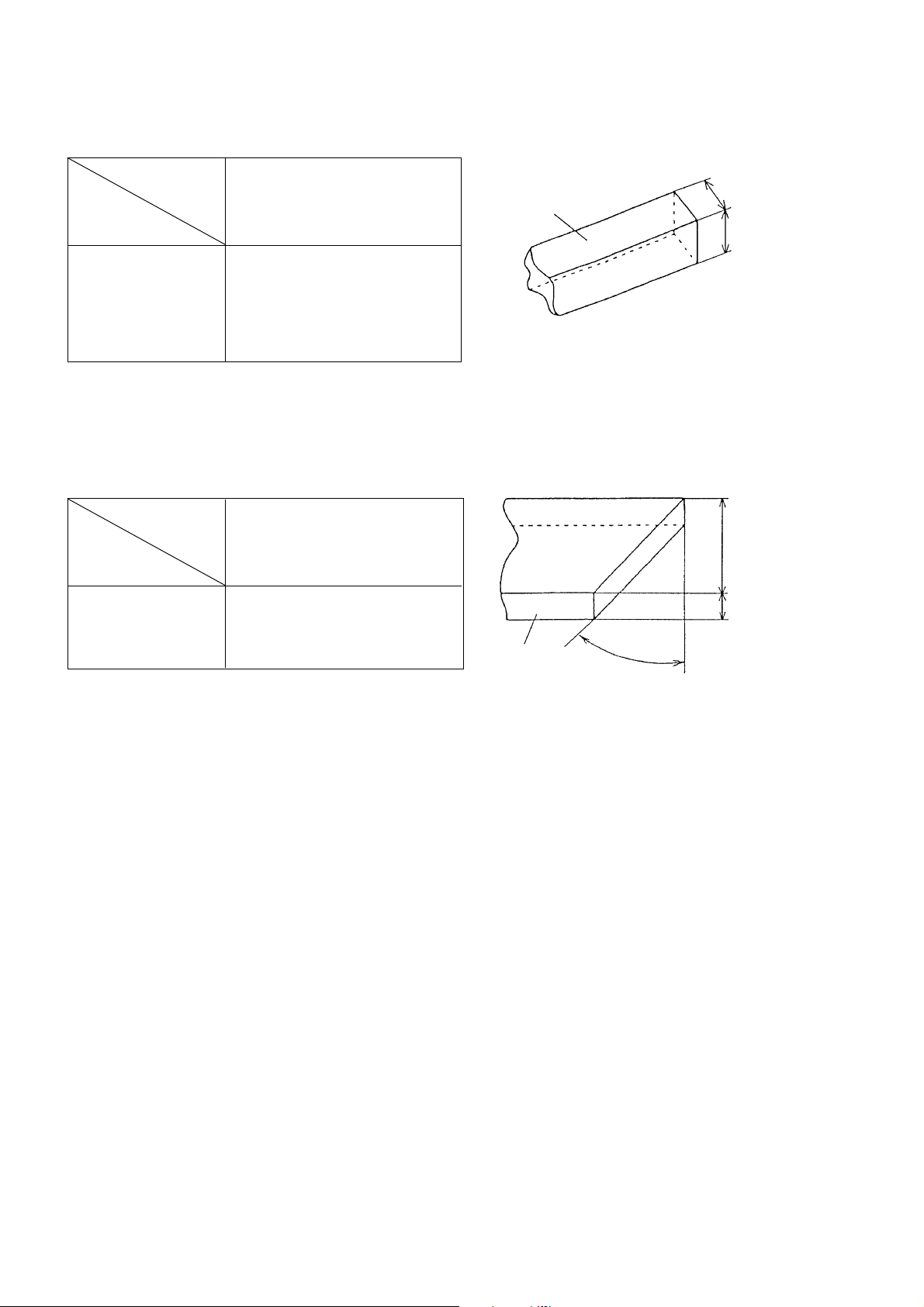

4-1. Selling Point Descriptions

(1) Press cutting

Table 1

Maker

Model

Max. cutting

dimension

66 x 144 (2-19/32" x 5-11/16")

Height x Width

(H x W)

Press cutting with the head swiveling enables cutting square workpieces as large as shown in Table 1 in a single

sawing operation. (See Fig. 1.)

(2) Miter cutting facility

Maker

Model

Max. cutting

dimension

79 x 108 (3-1/8" x 4-1/4")

90 x 90 (3-9/16" x 3-9/16")

with aux. board width

19 mm (3/4")

Table 2

HITACHI

C 10FM

HITACHI

C 10FM

(Unit: mm)

(Unit: mm)

Workpiece

Width (W)

Height (H)

Fig. 1

Width (W)

Right and left 45˚

Height x Width

(H x W)

By turning the table to the right or left as desired, the Model C 10FM is capable of miter cutting of up to 45˚ to the

right and left.

(3) Equipped with debris guard to restrict dispersion of chips for enhanced safety in operation.

A debris guard has been adopted to prevent wood chips from adhering to the saw blade at the end of the

cutting operation.

(4) Lightweight design

12.4 kg in weight, for easy transport in a workshop

68 x 98

(2-11/16" x 3-7/8")

Workpiece

45˚ right and

left

Fig. 2

Height (H)

--- 2 ---

Page 5

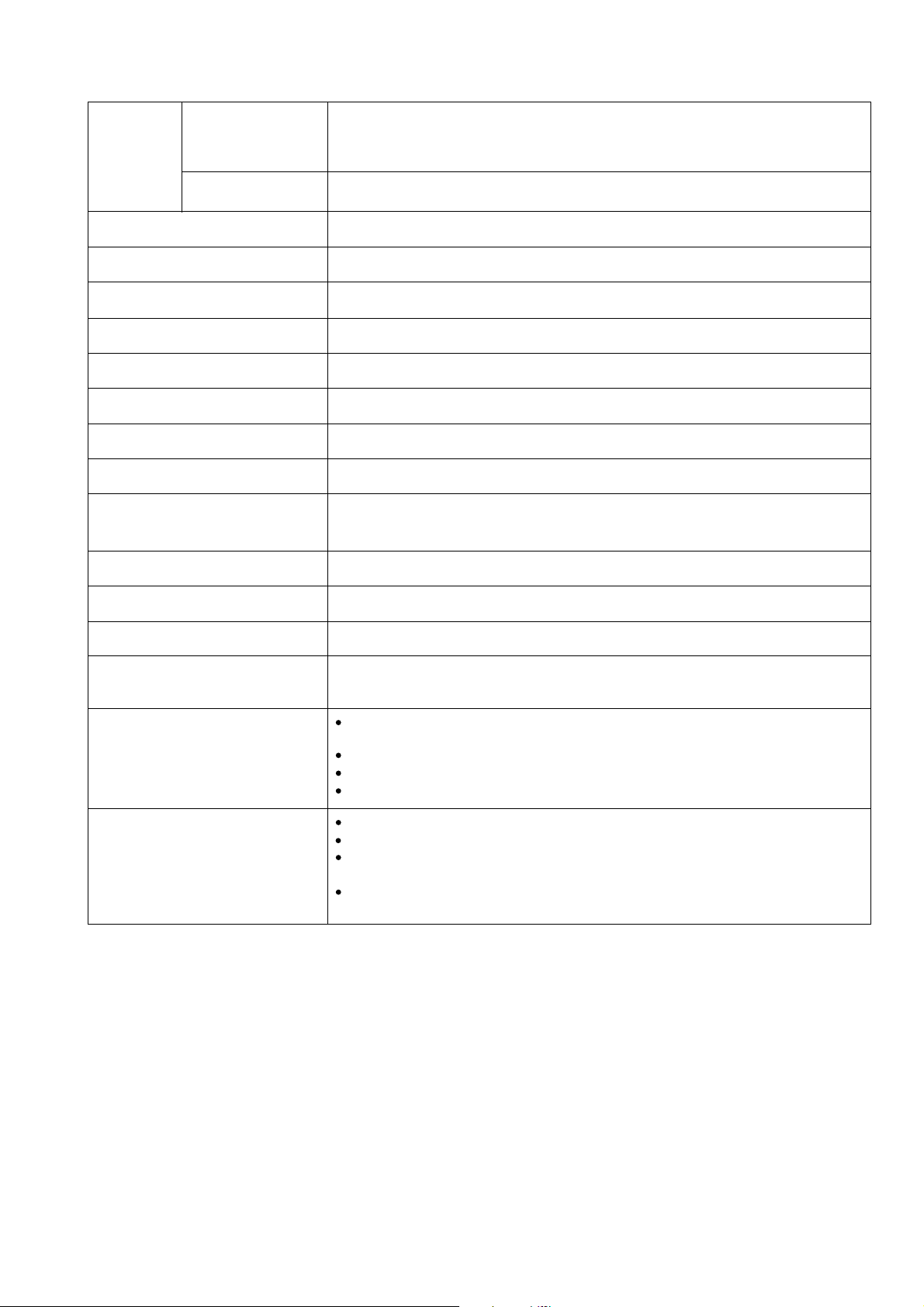

5. SPECIFICATIONS

Maximum

cutting

0˚ (Right angle)

dimentions

Height x

Width

(H x W)

Miter right/left 45˚

Miter cutting ranges

Angle stopper positions

Applicable saw blade

Power source type and voltage

Type of motor

Full-load current

No-load rotation speed

Max. output

Main body dimensions

(Width x Depth x Height)

66 mm (2-19/32") x 144 mm (5-11/16")

79 mm (3-1/8") x 108 mm (4-1/4")

90 mm (3-9/16") x 90 mm (3-9/16") [with aux. board width 19 mm (3/4")]

67 mm (2-5/8") x 98 mm (3-7/8")

Right and left 0˚ --- 45˚

Right and left 0˚, 15˚, 22.5˚, 31.6˚ and 45˚

255 mm (10") external dia. x 15.9 mm (5/8") bore

AC single phase 60 Hz, 115 V

AC single phase commutator series motor

13 A (115 V)

4,500/min.

1,600 W

510 mm x 810 mm x 575 mm

(20-3/32" x 31-29/32" x 22-21/32")

Weight

Coating

Packaging

Cord

Standard accessories

Optional accessories

12.4 kg (27.3 Ibs.), gross weight 16.5 kg (36.4 Ibs.)

Metallic silver green

Corrugated cardboard box

Type: 2-Conductor cabtire cable Nominal cross-sectional area: 16AWG (1.25 mm2)

Length: 2.2 m (7.3 ft) External dia.: 7.5 mm with mold plug

255 mm (10") TCT saw blade (24 teeth, Code No. 311128)

•••••••••••••••

for wood and aluminum cutting

Dust bag

Vise ass'y

12.7 mm wrench

Holder ass'y (Code No. 317542)

Vise ass'y (Code No. 317541)

255 mm (10") TCT saw blade (70 teeth, Code No. 976473)

•••••••••••••••

for normal cutting

255 mm (10") TCT saw blade (60 teeth, Code No. 976472)

•••••••••••••••

for fine surface cutting

--- 3 ---

Page 6

6. COMPARISONS WITH SIMILAR PRODUCTS

Maker/Model

Item

Max.

cutting

dimensions

Height

x Width

(H x W)

Miter cutting ranges

Angle stopper position

Saw blade outer diameter (mm)

Full-load current (A)

No-load revolution (/min.)

Motor

Max. output (W)

Insulation structure

Base size

Width x Depth (mm)

Debris guard

Dust bag size (mm)

Main unit dimensions

Width x Depth x Height (mm)

Product weight (kg)

Standard equipment *

Optional accessories

0˚ (Right angle)

Miter right/left 45˚

Right and left 0˚, 15˚, 22.5˚,

31.6˚ and 45˚

(20-3/32" x 31-29/32" x 22-21/32")

• 255 mm (10") TCT saw blade

(24 teeth) for wood and

aluminum cutting

• Dust bag

• Vise ass'y

• 12.7 mm (1/2") wrench

• Holder ass'y

• Vise ass'y

• 255 mm (10") TCT saw blade

(70 teeth) for normal cutting

• 255 mm (10") TCT saw blade

(60 teeth) for fine surface

cutting

HITACHI

C 10FM

66 mm x 144 mm

(2-19/32" x 5-11/16")

79 mm x 108 mm

(3-1/8" x 4-1/4")

90 mm x 90 mm

(3-9/16" x 3-9/16")

[With aux. board width

19 mm (3/4")]

67 mm x 98 mm

(2-5/8" x 3-7/8")

Right and left 0˚--- 45˚

255 (10")

13 (115 V)

4,500

1,600

Double insulation

500 x 120

(19-21/32" x 4-23/32")

Equipped

260 x 180

(10-7/32" x 7")

510 x 810 x 575

12.4 (27.3 lbs.)

*: Standard equipment may differ country to country.

ZC

63 mm x 131 mm

(2-1/2" x 5-5/32")

95 mm x 95 mm

(3-3/4" x 3-3/4")

63 mm x 91 mm

(2-1/2" x 3-19/32")

71 mm x 89 mm

(2-13/16" x 3-1/2")

Right and left 0˚--- 45˚

Right and left 0˚, 22.5˚ and 45˚

254 (10")

13 (120 V)

5,200

-----

Double insulation

450 x 105

(17-23/32" x 4-1/8")

Non

240 x 180

(9-7/16" x 7")

450 x 815 x 500

(17-23/32" x 32-3/32" x 19-21/32")

12.7 (28 lbs.)

• 255 mm (10") cross cut saw

blade (104 teeth)

• Dust bag

• Wrench

• 255 mm (10") TCT saw

blade (60 teeth)

• 255 mm (10") TCT saw

blade (80 teeth)

• Work clamp

70 mm x 119 mm

(2-3/4" x 4-11/16")

89 mm x 89 mm

(3-1/2" x 3-1/2")

70 mm x 84 mm

(2-3/4" x 3-5/16")

89 mm x 59 mm

(3-1/2" x 2-5/16")

Right 0˚--- 52˚

Left 0˚--- 45˚

Right and left 0˚, 15˚, 22.5˚, 30˚

and 45˚

255 (10")

12 (115 V)

4,600

-----

Double insulation

460 x 100

(18-3/32" x 3-15/16")

Non

190 x 205

(7-15/32" x 8-1/16")

460 x 750 x 505

(18-3/32" x 29-17/32" x 19-27/32")

12.6 (27.8 lbs.)

• 255 mm (10") cross cut saw

blade

• Dust bag

• 13 mm socket wrench

• Triangular rule

• Safety goggles

• 255 mm (10") TCT saw blade

(50 teeth) for wood

• 255 mm (10") miter saw blade

(100 teeth) for wood

• 255 mm (10") miter saw blade

(100 teeth) for aluminum

• 255 mm (10") cross cut saw

blade (50 teeth) for wood

• 255 mm (10") combination

saw blade (36 teeth) for wood

• Holder

• Vertical vise

--- 4 ---

Page 7

7. PRECAUTIONS IN SALES PROMOTION

In the interest of promoting the safest and most efficient use of the Model C 10FM Miter Saw by all of our

customers, it is very important that at the time of sale the salesperson carefully ensures that the buyer seriously

recognizes the importance of the contents of the Instruction Manual, and fully understands the meaning of the

precautions listed on the various Caution Plates attached to each machine.

7-1. Instruction Manual

Although every effort is made in each step of design, manufacture and inspection to provide protection against

safety hazards, the dangers inherent in the use of any power saw cannot be completely eliminated. Accordingly,

general precautions and suggestions for the use of electric power tools, and specific precautions and suggestions

for the use of the compound saw are listed in the Instruction Manual to enhance the safe, efficient use of the tool

by the customer. Salespersons must be thoroughly familiar with the contents of the Instruction Manual to be able

to offer appropriate guidance to the customer during sales promotion.

(1) Precautions on the Name Plate

Each Model C 10FM is furnished with a Name Plate that lists the following precautions.

Instruct the customer to thoroughly read the Instruction Manual prior to attempting to operate the machine.

(2) Warning Label (A)

The Warning Label (A) specified by the UL is affixed

on the upper righthand portion of the motor housing.

Please instruct users to strictly observe the contents

in 1 to 9 in the Warning Label (A) shown at left.

--- 5 ---

Page 8

8. ADJUSTMENT AND OPERATIONAL PRECAUTIONS

8-1. Confirmation of Saw Blade Lower Limit Positioning

The lower limit of the saw blade cutting depth is factory-adjusted

M6 x 20 mm

hex. hd. bolt

so that when the saw blade is fully lowered, its cutting edge is

28 mm to 30 mm (1-3/32" to 1-5/32") below the upper surface of

the table insert. Lower the saw blade and confirm that it stops at

the correct position.

If it is necessary to adjust the saw blade lower limit, loosen the

6 mm hex. nut on the M6 x 20 mm hex. hd. bolt, and turn the

6 mm hex. nut

M6 x 20 mm hex. hd. bolt if necessary. (See Fig. 3.)

Fig. 3

[CAUTION] Perform the adjustment carefully to ensure that the saw blade does not cut into the table. Also,

on completion of adjustment, ensure without fail that the 6 mm hex. nut is securely tightened.

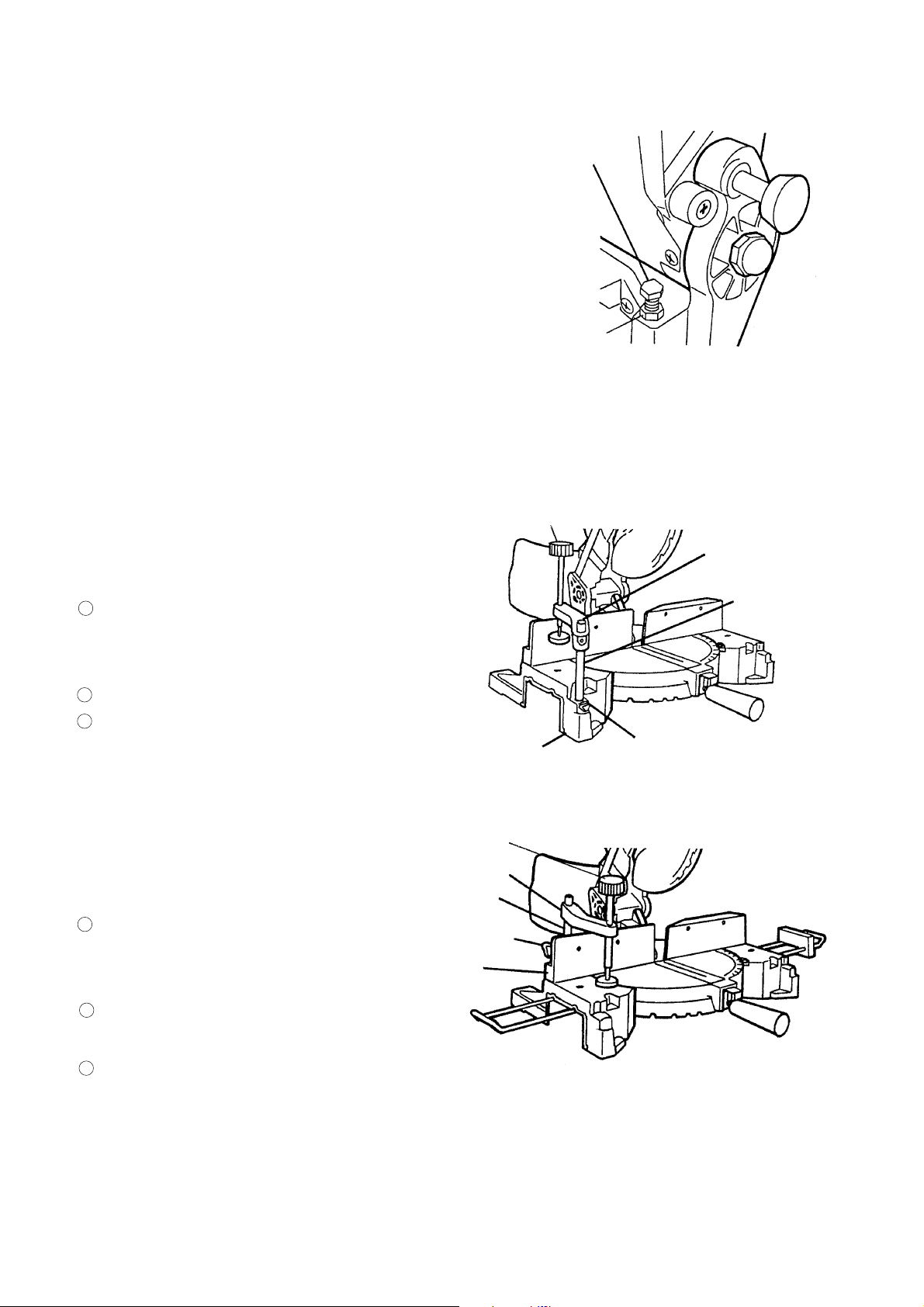

8-2. How to Use the Vise Ass'y

(1) The vise ass'y can be mounted on either the left side

base or the right side base, and can be raised or

Knob

Vise

assembly

lowered according to the height of the workpiece.

1

Insert the support of the vise ass'y into the hole

Support

located on either the left side base or the right side

base.

2

Then tighten the 5 mm clamp bolt, as shown in Fig. 4.

3

Turn the knob to thoroughly clamp the workpiece.

[NOTE] The support has two locking grooves into which

the tip of the 5 mm clamp bolt is designed to fit,

to lock the vise ass'y in the desired position.

(2) The vise ass'y can be mounted on either the left side

fence or the right side fence, and can be raised or

lowered according to the height of the workpiece.

Insert the support of the vise ass'y into the hole

1

located on either the left side fence or the right

side fence.

2

Then tighten the 5 mm clamp bolt, as shown in

Fig. 5.

3

Turn the knob to thoroughly clamp the workpiece.

Vise

assembly

Support

5 mm

clamp bolt

Fence

Base

Knob

5 mm

clamp bolt

Fig. 4

Fig. 5

[Warning] Always firmly clamp or vise to secure the workpiece to the fence; otherwise the workpiece

might be thrust from the table and cause bodily harm.

--- 6 ---

Page 9

8-3. Cutting Operation

(1) Cutting efficiency will be reduced if a dull saw blade is used, if an excessively long extension cord is used, or if

the wire gauge of the extension cord is too small. (For details on extension cords, please refer to the

Instruction Manual.) This is particularly important when cutting materials with dimensions which are at or near

the maximum capacity for the machine.

(2) The customer should be advised to thoroughly inspect the workpiece to ensure that there are no metallic

objects (nails in particular), sand, or other foreign matter in or on the workpiece. Saw blade contact with such

foreign matter will not only shorten the service life of the saw blade, but could cause serious accident. Should

the saw blade tips be broken off, the tips may fly toward the operator.

(3) Press cutting

Like Mode C 10FC2, C 10FM can be used for press cutting of workpieces up to 66 mm x 144 mm (2-19/32" x

5-11/16") in a single operation by simply pushing the saw blade section (head) downward. The customer

should be cautioned that excessive pressure on the handle will not increase the cutting speed. On the

contrary, excessive pressure may result in reduced cutting efficiency (irregular or rough cutting of the

workpiece), and could also cause overload and subsequent burnout of the motor.

On completion of the cutting operation, turn the switch OFF and wait for the saw blade to come to a complete

stop before raising the saw blade section (head) to its original position. Raising the saw blade section (head)

while the saw blade is rotating may cause unwanted cutting marks on the workpiece.

Techniques to avoid unwanted cutting marks

Uneven and unwanted cutting marks can be avoided throughout the cutting operation by gently and smoothly

pressing down on the handle, so that the entire cutting operation is accomplished in a single uninterrupted

motion.

(4) Miter cutting

Miter cutting is accomplished by turning the table. (For details, please refer to the Instruction Manual.)

--- 7 ---

Page 10

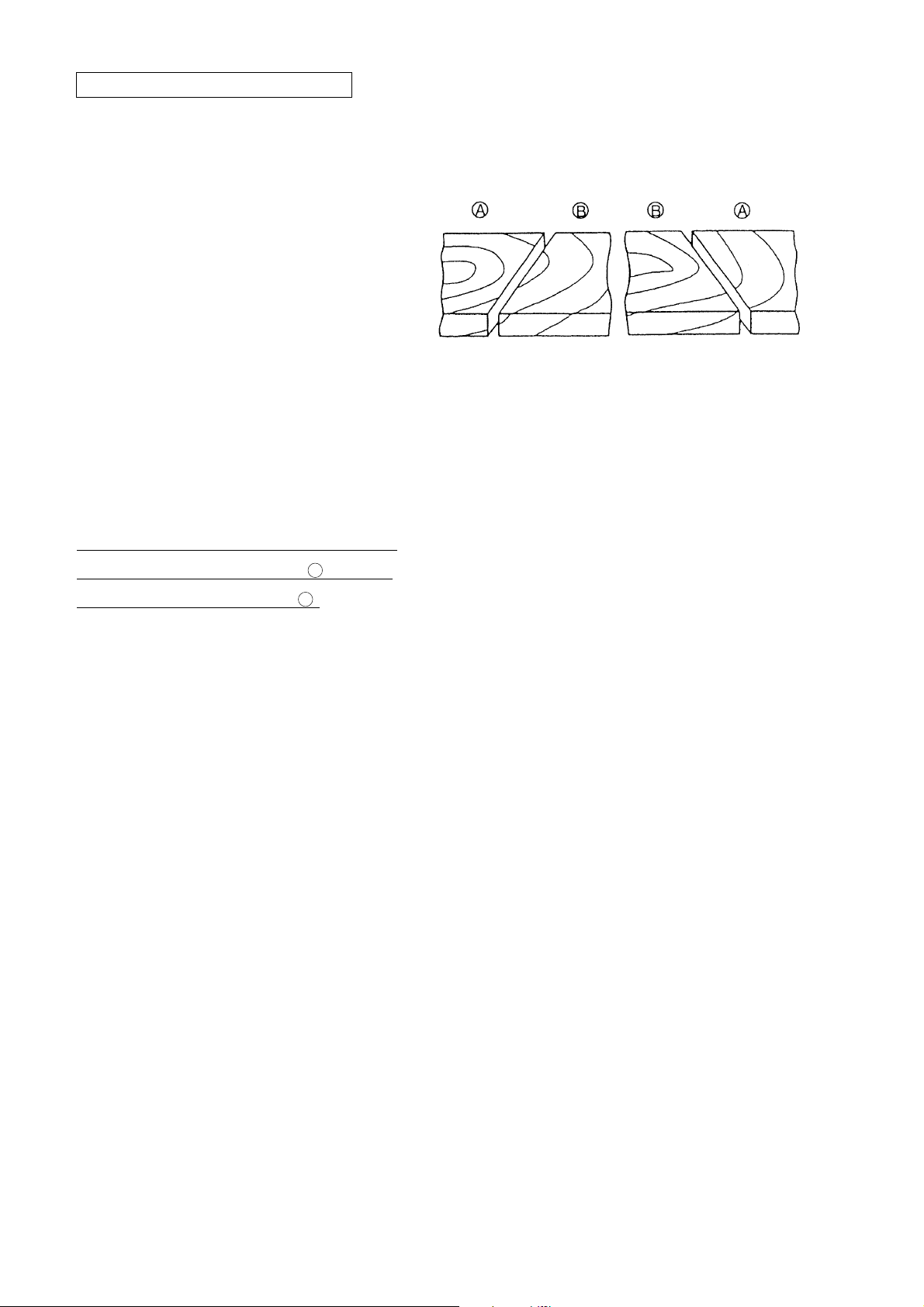

(5) Cut surface quality during miter cutting

The quality of the cut surface depends on the

type of cutting operation (miter), the type and

sharpness of the saw blade, whether the

workpiece is cut to the right or left. In miter

cutting in particular, cutting is performed across

the wood grain, so the condition of the cut

surface depends on whether the wood is cut

with or against the grain. This is the same as

when using electric portable planers.

Customers should be advised of these

phenomena so that they understand that in

cases when the cut surface may not be as

smooth as expected or hoped for, it is not

caused by the performance of the saw blade or

the Model C 10FM.

In the cutting examples illustrated in Fig. 6, the

cut surfaces on the sides marked are better

than those on the sides marked .

A

B

[Miter cutting]

Better Better

Fig. 6

9. PACKING

The main body of the Model C 10 FM is sandwiched between packing (A) and packing (B) made of styrofoam.

This system makes the packaging work easier.

(1) Preparation

Remove the vise ass'y and dust bag from the main unit.

Then swivel the table through 45˚ toward the right.

Fix the table securely with the miter handle.

Push down the head section and insert the locking pin to secure the head section at the lower position.

(2) How to install packing (A)

Put packing (A) in the carton box.

Put the main unit in packing (A).

(3) How to install packing (B)

Put packing (B) on the main unit. Put the vise ass'y and the dust bag in the groove of packing (B).

Close the lids of the carton box and bind them together.

--- 8 ---

Page 11

10. PRECAUTIONS IN DISASSEMBLY AND REASSEMBLY

Please follow the precautions below for disassembly and reassembly procedures. The circled numbers in the

following figures and the [Bold] numbers in the descriptions below correspond to the item numbers in the Parts

List and exploded assembly diagrams.

CAUTION: Prior to attempting disassembly or replacement of the saw blade, ensure that the power cord

plug is disconnected from the power source.

10-1. Disassembly

A. Disassembly of the blade guard section

Tools required:

• Phillips head screwdriver

• 12.7 mm wrench (standard accessory)

• 10 mm wrench

Fig. 7

1. Loosen the Counter Hd. Screw M5 x 12 [25] and turn the Cutter Shaft Guard [26] upward so that the Bolt (Left

Hand) W/Washer M8 x 20 [51] can be seen.

2. Put the Wrench [702] on the Bolt (Left Hand) W/Washer M8 x 20 [51] and turn the Wrench [702] until the

Bracket Stop [88] is aligned with the groove of the Arbor Shaft [76] while pushing the Bracket Stop [88].

Then loosen the Bolt (Left Hand) W/Washer M8 x 20 [51] and remove the Bolt (Left Hand) W/Washer M8 x 20

[51], outside Arbor Collar [52], TCT Saw Blade [701], inside Arbor Collar [52].

3. Put the Cutter Shaft Guard [26] back into position and tighten the Counter Hd. Screw M5 x 12 [25].

--- 9 ---

Page 12

4. Remove the Truss Hd. Step Screw M6 x 12 [14] and the Truss Hd. Step Screw M6 x 14 [15] that fix the Lever

[16]. Remove the Lever [16].

5. Secure the Special Nut Chuck M6 [27] behind the Cutter Shaft Guard [26] with a 10 mm wrench. Remove the

Counter Hd. Screw M6 x 16 [18], Collar [19], PC-Guard [20], Hex. Nut M6 [23] and Spring Guard [24].

B. Disassembly of the base section

Tools required:

• 3 mm hex. bar wrench

• Phillips head screwdriver

• 19 mm wrench

• Plastic hammer

• D10 metal bar

• 6 mm hex. bar wrench

• 10 mm wrench

• 13 mm box wrench

Fig. 8

--- 10 ---

Page 13

1. Remove the Hex. Socket Hd. Bolt M6 x 12 [33], and take out the Anchor Block [32]. As the Hex. Socket Hd.

Bolt M6 x 12 [33] acts as a stopper for the Upper Arm [86], be very careful to prevent the Upper Arm [86] from

springing up suddenly when the Hex. Socket Hd. Bolt M6 x 12 [33] is removed.

2. Remove the two Special Screws M4 x 8 [50] and the Chip Plate [49].

3. Remove the Nut Chuck [41] by turning it with a 19 mm wrench.

4. Remove the two Hex. Socket Set Screws M6 x 10 [31] behind the Upper Arm [86] with a 3 mm hex. bar

wrench.

5. Pull out the Shaft [36] by gently tapping it while holding the Upper Arm [86].

6. Removing the Shaft [36] enables you to remove the Torsion Spring [48] and the Shaft Sleeve [47].

7. Separate the Motor Ass'y [35] from the Support [39].

8. Remove the two Special Screws M5 x 16 [46] and the Chip Deflector [45] (debris guard).

9. Remove the four Special Screws M4 x 10 [65] and the Table Insert [66].

10. Remove the two Hex. Socket Hd. Bolts M8 x 45 [54] with a 6 mm hex. bar wrench. Remove the Fence [55].

11. Turn the Handle Ass'y [71] counterclockwise and remove it .

12. Then, turn the Base [59]. (Base [59] surface upside down.)

13. Remove the three Hex. Socket Hd. Bolts M8 x 25 [63] with a 6 mm hex. bar wrench. Remove the Support

[39].

14. Remove the two Hex. Bolts (W/Washer) M6 x 20 [69] with a 10 mm wrench to remove the Spring Plate [70].

15. Remove the Hex. Bolt (W/Washers) M6 x 20 [68] with a 10 mm wrench. Remove the Washer [67].

16. Then, turn the Base [59]. (Base [59] surface upside down.)

17. With a 13 mm box wrench, remove the Nut Chuck M8 [60] and the Flat Washer M8 [61] from the insert space

of the Table [64]. Extract the Center Shaft [74] which fixes the Table [64] to the Base [59] by lifting the Table

[64] upward.

--- 11 ---

Page 14

C. Disassembly of the motor section

Tools required:

• Flatblade screwdriver

• Phillips screwdriver

• Plastic hammer

• Nipper

Fig. 9

1. Remove the two Brush Caps [100] to remove two Carbon Brushes [99].

2. Remove the four Tapping Screws (W/Sp. Washer) D5 x 16 [96]. Remove the Motor Housing [95] with the

Armature Ass'y 115 V [89] and the Field [93] mounted.

--- 12 ---

Page 15

(1) Disassembly of the armature ass'y

1

Tap the Upper Arm [86] mounting surface of the Motor Housing [95] with a plastic hammer and remove the

Armature Ass'y 115 V [89].

2

Remove the Flow Guide [92].

3

Remove the six Tapping Screws D4 x 20 [9] and the Handle Cover [4].

4

Remove the Spring [7] and the Switch [8].

5

Remove the Truss Hd. Tapping Screw D4 x 12 [5] and the Switch [6].

Disconnect the three internal wires from the Switch [6].

6

7

Remove the two Truss Hd. Tapping Screws D4 x 12 [3] and the Cord Clamp [2].

(2) Disassembly of the field

1

Disconnect the Internal Wire [90] from the Brush Holder [98] and disconnect the internal wire from the Field

[93].

2

Cut the white internal wires coming from the Power Cable [13] and the Field [93] and connected with the

Terminal [12] with a nipper.

3

Remove the two Tapping Screws (W/SP. Washer) D5 x 60 [94] that fix the Field [93]. By tapping the Upper

Arm [86] mounting surface of the Motor Housing [95] with a plastic hammer, pull out the Field [93].

(3) Disassembly of the Spindle Ass'y

1

Remove the three Tapping Screws M4 x 16 [28] and the Housing [29].

2

Remove the three Machine Screws (W/Flange) M5 x 10 [78] and the Bearing Cover [79].

3

Remove the Spindle Ass'y [116] by gently tapping the Upper Arm [86] with a plastic hammer.

--- 13 ---

Page 16

D. Disassembly of the bracket stop

Tools required:

• Pliers

Fig. 10

1. Remove the Spring Pin [87] from the Bracket Stop [88].

2. Remove the Bracket Stop [88] and the Compression Spring [85] from the Upper Arm [86].

E. Disassembly of the vise ass'y

Tools required:

• 3 mm hex. bar wrench

Fig. 11

1. Remove the Hex. Socket Set Screw M6 x 10 [108] and the Support [109].

--- 14 ---

Page 17

10-2. Reassembly

Reassembly can be accomplished by following the disassembly procedures in reverse. However, special

attention should be given to following items.

(1) Prior to reassembly, measure the insulation resistance of the armature, field, switch and other electrical

components and confirm that the insulation resistance of each part is more than 7 M Ω.

(2) When assembling the Support [39] and the Upper Arm [86], apply 2 grams (2 pcs.) of Hitachi Motor Grease to

the oil groove of the Upper Arm [86].

(3) When replacing the Torsion Spring [48], apply approximately 5 grams of Hitachi Motor Grease to the inner

circumference of the new Torsion Spring [48] prior to reaasembly.

(4) When replacing the Slide Plate [75], assemble it into the unit as illustrated in Fig. 12. During reassembly,

apply 6 grams of Hitachi Motor Grease to the Slide Plate [75] against the sliding surface of the Base [59].

Ensure that the Slide Plate [75] fits into

the groove portion of the Base [59].

Fig. 12

(5) If the Center Shaft [74] at the bottom of the Base [59] is tightened excessively, the movement of the Table [64]

will become sluggish and heavy. If the bolt is loose, it will cause vibration and looseness of the Table [64]

which will reduce cutting accuracy. Adjust the Nut Chuck M8 [60] so that the Table [64] moves smoothly with

minimum play and vibration.

--- 15 ---

Page 18

10-3. Wiring Diagram

Carefully ensure that wiring is accomplished as illustrated below. As incorrect wiring will result in lack of rotation,

reverse rotation or other malfunctions, close attention is absolutely necessary.

1

Wiring diagram

Red

Switch

1a

Black

Power cable

Armature

ass'y

2

Actual wiring diagram

Switch

1

Brake coil

Field coil

Field

Power cable

Black

1

Gray

White

White

Fig. 13

1

1b

White

Terminal

Terminal

White

1b

1a

Red (Lead wire)

Gray

Field

Brush holder

Red

Fig. 14

10-4. Lead Wire Precautions

When connecting lead wires be very careful not to remove the insulation covering of each lead wire more than

needed. Exposed cores of lead wires from connectors, for example, are extremely dangerous. Also, ensure that

the lead wires are not pinched between the mating surfaces of the Motor Housing [95] and the Handle Cover [4].

--- 16 ---

Page 19

10-5. No-load Current

After no-load operation for 30 minutes, the no-load current values should be as follows.

Voltage, frequency

No-load current

115 V, 60 Hz

6.3 A max.

10-6. Reassembly Requiring Adjustment

(1) Adjustment of squareness between the saw blade (dummy disc) and the fence

After disassembly/reassembly or replacement of the Base [59], the

Table [64], the Fence [55] or the Support [39], it is necessary to

check the squareness between the saw blade (or dummy disc) and

Fence

Square

Saw blade or

dummy disc

Fig. 15

the Fence [55], and perform adjustment as necessary if they are not

at an exact right angle with relation to each other. Adjustment

procedure is as follows. First, position the saw blade (or dummy

disc) so that it is in the exact center of the groove on the Table [64]

which houses the Table Insert [66]. Next, as illustrated in Fig. 15,

place a square so that it is flush against the side surface of the saw blade (or dummy disc), and move the

Fence [55] as necessary so that it is in an exact right angle with relation to the saw blade (or dummy disc).

Finally, tighten the two Hex. Socket Hd. Bolts M8 x 45 [54] to fix the Fence [55] in position.

*Dummy disc: A dummy disc is a toothless disc with the same external diameter as a saw blade, and is used

to perform accurate inspection and adjustments.

(2) Confirmation of saw blade height

The lower limit of the saw blade cutting depth is factory-adjusted so that when the saw blade is fully lowered,

its cutting edge is 28 to 30 mm (1-3/32" to 1-5/32") below the upper surface of the Table Insert [66]. Lower the

saw blade and confirm that it stops at the correct position.

(3) Adjustment of saw blade lower limit position

When adjusting the lower limit of the saw blade, be sure to use a saw blade with an external diameter of 255

mm. Failure to properly adjust the lower limit position of the saw blade may result in the following problems.

1

Inability to obtain the maximum cutting capacities of the machine

2

There is a danger that the saw blade may come in contact with and cut into the Table [64].

The lower limit of the saw blade cutting depth is adjusted at the factory so that when the saw blade is fully

lowered, its cutting edge is 28 mm to 30 mm (1-3/32" to 1-5/32") below the upper surface of the Table Insert

[66]. If this position is lower than the specified values, confirm without fail that it does not come in contact with

the Table [64]. If it is necessary to adjust the saw blade lower limit, loosen the Hex. Nut M6 [38] on the Hex.

Bolt M6 x 20 [37] and turn the Hex. Bolt M6 x 20 [37] if necessary. By turning the Hex. Bolt M6 x 20 [37]

clockwise, the saw blade lower limit is lowered. By turning the Hex. Bolt M6 x 20 [37] counterclockwise, the

saw blade lower limit is raised. On completion of adjustment, ensure that the Hex. Nut M6 [38] is properly

tightened.

[Caution]

Perform the adjustment carefully to ensure that the saw blade does not cut into the Table [64].

--- 17 ---

Page 20

(4) Reassembly of the Table [64]

When reassembling the Table [64] and the Base [59], tighten the Nut Chuck M8 [60] so that the Table [64]

turns smoothly without excessive play or vibration.

During reassembly, liberally apply grease (Hitachi Motor Grease No. 29, Code No. 930035 is recommended.)

at the point marked A in Fig. 16.

Nut Chuck M8 [60]

Table [64]

A

A

Base [59]

Center Shaft [74]

Fig. 16

10-7. Lubrication

Advise the customer to lubricate the machine as indicated below at least once a month. Also, prior to applying

lubrication, any sawdust, dirt or other foreign matter should be thoroughly wiped away with a soft cloth.

(1) Swiveling section of the Upper Arm [86] and the Support [39]

Coat the swiveling portion of the Upper Arm [86] and the Support [39] with machine oil.

(2) Vise ass'y section

Coat the screw threads portion of the Screw Bar [110] of the Vise Ass'y [107] with machine oil.

10-8. Product Precision

On completion of reassembly, confirm precision tolerances.

(Unit: mm)

Item Tolerance

Run-out of saw blade (or dummy disc) 0.38/220 (0.015"/8-21/32")

Perpendicularity between base and fence 0.4/100 (0.016"/4")

Perpendicularity between saw blade (or dummy disc) and fence 0.4/100 (0.016"/4")

Perpendicularity between saw blade (or dummy disc) and table 0.4/100 (0.016"/4")

Surface alignment of

+ +

base and table (Use

the upper surface of

0.45 ( 0.018")

--

--

0.1 ( 0.004")

the base as a

reference).

--- 18 ---

Page 21

10-9. Tightening Torque

• D4 x 12 Truss Hd. Tapping Screw

• D4 x 20 Pan Hd. Tapping Screw

• M4 x 20 Pan Hd. Screw

••••••••••••••••••••••••••••••••••••

• D6 x 10 Pan Hd. Tapping Screw

• M6 x 14 Truss Hd. Round Neck Screw

• M6 x 16 Count Hd. Screw

• M5 x 12 Count Hd. Screw

••••••••••••••••••••••••••••••••

• D4 x 16 Pan Hd. Tapping Screw

• M6 x 10 Hex. Socket Set Screw

• M6 x 12 Hex. Socket Hd. Cap Bolt

• M6 x 20 Hex. Hd. Bolt

• M5 x 16 Pan Hd. Screw

• M4 x 8 Pan Hd. Screw

•••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••

• M8 x 20 Hex. Washer Hd. Bolt

• M8 x 45 Hex. Socket Hd. Bolt

• D4 x 8 Pan Hd. Tapping Screw

• M8 x 25 Hex. Socket Hd. Cap Bolt

• M4 x 10 Pan Hd. Screw

•••••••••••••••••••••••••••••••••••••

• M6 x 20 Hex. Hd. Bolt (W/Washers)

• M5 x 12 Pan Hd. Screw

••••••••••••••••••••••••••••••••••••

• M5 x 10 Round Hd. Washer Screw

• D5 x 60 Pan Tapping Screw & Washer

•••••••••••••••••••••

••••••••••••••••••••••

••••••••••••••••••••••••

••••••••••••••

•••••••••••••••••••••••••••••••

••••••••••••••••••••••••

••••••••••••••••••••••••

••••••••••••••••••••

•••••••••••••••••••••••••••

•••••••••••••••••••••••••

••••••••••••••••••••••••••

•••••••••••••••••••••

•••••••••••••••••

•••••••••••••••••••

••••••••••••••

• D5 x 35 Pan Hd. Tapping Screw & Washer

• M5 x 8 Hex. Socket Set Screw

•••••••••••••••••••••••••••

••••••••••

13 in-lbs. (1.5 N•m, 15 kgf•cm)

6.9 in-lbs. (0.8 N•m, 8 kgf•cm)

6.9 in-lbs. (0.8 N•m, 8 kgf•cm)

15.6 in-lbs. (1.8 N•m, 18 kgf•cm)

15.6 in-lbs. (1.8 N•m, 18 kgf•cm)

30.4 in-lbs. (3.4 N•m, 35 kgf•cm)

8.7 in-lbs. (1 N•m, 10 kgf•cm)

6.9 in-lbs. (0.8 N•m, 8 kgf•cm)

34.7 in-lbs. (3.9 N•m, 40 kgf•cm)

26 in-lbs. (2.9 N•m, 30 kgf•cm)

30.4 in-lbs. (3.4 N•m, 35 kgf•cm)

4.3 in-lbs. (0.5 N•m, 5 kgf•cm)

4.3 in-lbs. (0.5 N•m, 5 kgf•cm)

130 -- 156 in-lbs. (14.7 -- 17.6 N•m, 150 -- 180 kgf•cm)

47.7 in-lbs. (5.4 N•m, 55 kgf•cm)

15.6 in-lbs. (1.8 N•m, 18 kgf•cm)

10.4 in-lbs. (1.2 N•m, 12 kgf•cm)

8.7 in-lbs. (1 N•m, 10 kgf•cm)

52 in-lbs. (5.9 N•m, 60 kgf•cm)

8.7 in-lbs. (1 N•m, 10 kgf•cm)

34.7 in-lbs. (3.9 N•m, 40 kgf•cm)

21.7 in-lbs. (2.5 N•m, 25 kgf•cm)

22.6 in-lbs. (2.5 N•m, 26 kgf•cm)

6.9 in-lbs. (0.8 N•m, 8 kgf•cm)

--- 19 ---

Page 22

11. REPAIR GUIDE

Item Phenomenon Cause (s)

Factory

standard

Unit: mm

Inspection • Repair •

Adjustment

Inaccurate cutting

1

•••

Inaccurate

squareness of cut

surface

•••

Cut surfaces do not

fit together properly.

Fence

Table

Fig. 17

Squareness

0.4/100

(1/64"/3-15/16")

Fig. 18

Saw blade

Squareness

0.4/100

(1/64"/3-15/16")

Saw blade

Fence

a Inaccurate

squareness between

the table and the saw

blade causes the saw

blade to cut into

workpiece at an angle.

b Excessive deflection

of the saw blade

(Excessive vibration)

c Inaccurate

squareness between

the fence and the saw

blade

d Inaccurate surface

flatness of the fence

causes workpiece to

move irregularly,

causing poor

squareness of cut

surface.

0.4/100

(1/64"/3-15/16")

(Dummy disc)

(Fig. 17)

0.38/220

(0.015"/8-21/32")

(Dummy disc)

0.4/100

(1/64"/3-15/16")

(Fig. 18)

Within 0.15

(0.06")

(Fig. 19)

• Replace the Upper Arm

[86], Table [64] and/or the

Support [39]. (If deformed.)

• Replace the TCT Saw Blade

[701].

• Check for surface defects on

the Arbor Collar [52], and

repair with a file as

necessary.

• Replace the Arbor Collar

[52] as necessary.

• Loosen the Hex. Socket Hd.

Bolt M8 x 45 [54] and adjust

as necessary.

• Replace the Fence [55] as

necessary.

• Replace the Fence [55] as

necessary.

Within 0.15 (0.06") or less

Fig. 19

0.4/100

(1/64"/3-15/16")

Squareness

Fig. 20

Within 0.15 (0.06")

Fence

Fence

e Inaccurate surface

flatness of the table

f Inaccurate

squareness between

the fence and the

table and/or the base

causes the workpiece

to tilt at an angle and

prevent accurate

cutting.

Within 0.1

(0.004")

0.4/100

(1/64"/3-15/16")

(Fig. 20)

• Replace the Table [64].

• Replace the Fence [55] as

necessary.

--- 20 ---

Page 23

Item

Phenomenon

Cause (s)

Factory

standard

Inspection • Repair •

Adjustment

(Continued)

1

Base

Fig. 21

Table

g Excessive

misalignment of the

base and the table

causes the saw blade

to cut into the

workpiece at an angle.

h Loose fitting of

swiveling portion of

the upper arm and the

support or sluggish

movement. As a

result, components

may be deformed

because of unstable

upper arm or because

the operator must

apply excessive

pressure during

operation.

i Excessively fast

cutting speed causes

deflection of the saw

blade and inaccurate

cutting.

+

0.45 (0.018")

--

0.1 (0.004")

(Fig. 21)

------

------

• Replace the Base [59] and/or

Table [64] if deformed.

• Check the fitting surfaces of the

Upper Arm [86], Support [39]

and the Shaft [36] for any

foreign substance (such as

cutting dust), and remove it as

necessary.

• Reduce cutting speed.

Appropriately 10 seconds for a

square wood workpiece of

60 mm (2-3/8").

2 Rough cut surface

Parallelism A = 0.025/54

(0.001/2-1/8")

Arbor collar Arbor collar

Fig. 22

j Excessive cutting

force (pressure) is

required because of

dull saw blade.

k The workpiece moves

during cutting because

it is bent or deformed.

a Large deflection of the

saw blade. (It causes

rough cut surface.)

b Each surface

parallelism of the

arbor collar is

inaccurate due to

surface defects (such

as impact marks and

scratches).

c Inaccurate

squareness between

the table and the saw

blade, causing the

saw blade to cut at an

improper angle and

make cutting marks.

------

------

0.38/220

(0.015"/8-21/32")

(Dummy disc)

0.025/54

(0.001"/2-1/8")

(Fig. 22)

0.4/100

(1/64"/3-15/16")

(Fig. 17)

• Sharpen the TCT Saw Blade

[701] again.

• Correct bend, flex or other

deformation by planing and try

cutting.

• Same as the Item 1- b .

• Repair impact marks or

scratches at the Arbor Collar

[52] or replace it if necessary.

• Same as the Item 1- a .

--- 21 ---

Page 24

Item

Phenomenon

Cause (s)

Factory

standard

Inspection • Repair •

Adjustment

2

(Continued)

3

Saw blade is locked.

d Excessively fast

cutting speed

e Improper clamping of

workpiece

f The table is not fixed

with the handle bar.

g Loose fitting of

swiveling portion of

the upper arm and the

support, or sluggish

movement

h Cutting operation

becomes sluggish

because workpiece is

warped or bent.

i Excessive vibration

a Excessively fast

cutting speed

------

------

------

------

-----

------

------

------

• Reduce cutting speed.

• Properly clamp workpiece with

the vise Ass'y [107].

• During cutting, fix the Table [64]

in position with the Handle

Ass'y [71] without fail.

• Same as the item 1 - h .

• Correct warp or bend with

planer.

• Recheck the items a, b, c, d, f

and g.

• Reduce cutting speed.

b Core diameter of

extension cord is too

small.

c Excessive cutting force

is applied due to dull

saw blade.

d Incorrect saw blade is

used.

e The saw blade binds in

workpiece during

cutting because

workpiece is warped

or bent.

------

------

------

-----

• Use a thicker and shorter

extension cord.

Extension

cord length

25 ft. (7.5 m)

50 ft. (15 m)

100 ft. (30 m)

Wire gauge

size

2.0 mm

3.5 mm

Not

recommended

2

14 A.W.G.

2

12 A.W.G.

• Resharpen the TCT Saw

Blade [701].

• Use a suitable Hitachisupplied saw blade.

• An increased number of teeth

on the saw blade increases

the cutting resistance.

When using a saw blade with

a large number of teeth,

reduce the cutting speed.

• Correct workpiece

deformation with planer.

--- 22 ---

Page 25

Item

Phenomenon

Cause (s)

Factory

standard

Inspection • Repair •

Adjustment

4 Saw blade does not

rotate when switch is

triggered.

Saw blade runs too

5

slow.

(Not within 4050 -- 4950/min.)

a The power cord is not

connected to power

supply.

b The carbon brush

wear exceeds

allowable limit (6 mm).

c Contact failure of the

switch.

a Power supply voltage

is lower than rated

voltage.

------

------

------

------

• Check power supply voltage.

• Connect the power cord to

power supply.

• Check the Carbon Brushes [99]

for wear.

• Replace the Carbon Brushes

[99].

• Check the Switch [6] for

conductivity.

• Replace the Switch [6].

• Check for power supply

voltage.

• Check that extension cord is

appropriate. See the

Instruction Manual for

appropriate extension cords.

--- 23 ---

Page 26

12. STANDARD REPAIR TIME (UNIT) SCHEDULES

MODEL 10 20 30 40

Fixed

Variable

Work Flow

C 10FM

General Assembly

Fixed Cost

Lever

PC-Guard

Handle

Chip Deflector

Power Cable

Switch

Others

0 min.

10 min.

20 min.

Carbon Brush

Lever

PC-Guard

Chip Deflector

Fence

Table Insert

Armature Ass'y

Housing

Compression

Spring

Bracket Stop

Shaft

Torsion Spring

Handle Cover

Cord Guard

Power Cable

Spindle Ass'y

Switch

Field

Motor Housing

Base

Slide Plate

Support

50

60

Table

Spring

Plate

70 min.

Upper

Arm

--- 24 ---

Page 27

Assembly Diagram for C 10FM

--- 25 ---

Page 28

Motor Assembly

Holder Assembly

--- 26 ---

Page 29

Vise Assembly

--- 27 ---

Page 30

PARTS

ITEM

2

CODE NO. DESCRIPTION

No.

1 311-096 CORD GUARD 1

2 311-070 CORD CLAMP 1

3 311-103 TRUSS HD. TAPPING SCREW D4X12 2

4 318-850 HANDLE COVER 1

5 311-103 TRUSS HD. TAPPING SCREW D4X12 1

6 317-553 SWITCH 1

7 311-106 SPRING 1

8 318-851 SWITCH 1

9 317-377 TAPPING SCREW D4X20 6

11 317-070 MACHINE SCREW M5X12 3

12 318-852 TERMINAL 1

13 318-853 POWER CABLE 1

14 314-980 TRUSS HD. STEP SCREW M6X12 1

15 317-496 TRUSS HD. STEP SCREW M6X14 1

16 318-854 LEVER 1

17 317-505 FLAT WASHER M6 1

18 317-582 COUNTER HD. SCREW M6X16 1

19 317-583 COLLAR 1

20 318-855 PC-GUARD 1

21 311-036 RIVET 3/16"X17/32" 1

22 317-585 BUMPER 1

23 318-856 HEX. NUT M6 1

24 314-987 SPRING GUARD 1

25 317-586 COUNTER HD. SCREW M5X12 1

26 318-857 CUTTER SHAFT GUARD 1

27 314-522 SPECIAL NUT CHUCK M6 1

28 317-566 TAPPING SCREW D4X16 3

29 318-858 HOUSING 1

30 318-859 SHIM 1

31 318-860 HEX. SOCKET SET SCREW M6X10 2

32 318-861 ANCHOR BLOCK 1

33 318-862 HEX. SOCKET HD. BOLT M6X12 1

34 318-863 RUBBER PAD 1

35 318-864 MOTOR ASS'Y 1 INCLUD.76-90,92-103

36 318-884 SHAFT 1

37 318-885 HEX. BOLT M6X20 1

38 318-856 HEX. NUT M6 1

39 318-887 SUPPORT 1

40 318-888 FLAT WASHER M12 1

41 318-889 NUT CHUCK 1

42 318-890 BRACKET STOP 1

43 318-891 O-RING ROD 1

44 318-892 KNOB HANDLE 1

45 318-893 CHIP DEFLECTOR 1

46 318-894 SPECIAL SCREW M5X16 2

47 318-895 SHAFT SLEEVE 1

48 317-589 TORSION SPRING 1

49 318-896 CHIP PLATE 1

50 318-897 SPECIAL SCREW M4X8 2

51 314-348 BOLT (LEFT HAND) W/WASHER M8X20 1

52 317-360 ARBOR COLLAR 2

---

00

: ALTERNATIVE PARTS

*

NO.

USED

--- 28 ---

C 10FM

REMARKS

Page 31

PARTS

ITEM

CODE NO. DESCRIPTION

NO.

54 317-632 HEX. SOCKET HD. BOLT M8X45 2

55 318-898 FENCE 1

56 318-899 TAPPING SCREW D5X10 1

57 317-353 FOLLOWER PLATE 1

59 318-900 BASE 1

60 314-519 NUT CHUCK M8 1

61 311-047 FLAT WASHER M8 1

62 949-457 SPRING WASHER M8 (10 PCS.) 3

63 318-902 HEX. SOCKET HD. BOLT M8X25 3

64 318-903 TABLE 1

65 318-904 SPECIAL SCREW M4X10 4

66 311-046 TABLE INSERT 1

67 317-626 WASHER 1

68 318-118 HEX. BOLT (W/WASHERS) M6X20 1

69 317-628 HEX. BOLT (W/WASHER) M6X20 2

70 317-630 SPRING PLATE 1

71 317-631 HANDLE ASS'Y 1 INCLUD.115

72 317-638 ANGLE POINTER 1

73 318-905 SPECIAL SCREW M6X10 1

74 311-039 CENTER SHAFT 1

75 317-639 SLIDE PLATE 3

76 318-865 ARBOR SHAFT 1

77 318-866 PARALLEL KEY 1

78 318-867 MACHINE SCREW (W/FLANGE) M5X10 3

79 318-868 BEARING COVER 1

80 620-4VV BALL BEARING 6204VVCMPS2L 1

81 311-076 C-RING 1

82 318-869 HELIX GEAR 1

83 318-870 C-RING 1

84 314-570 NEEDLE BEARING 1

85 318-871 COMPRESSION SPRING 1

86 318-872 UPPER ARM 1

87 318-873 SPRING PIN 1

88 318-874 BRACKET STOP 1

89 318-875 ARMATURE ASS'Y 115V 1 INCLUD.91,104-106

90 318-877 INTERNAL WIRE 1

91 317-075 BEARING BUSHING 1

92 317-596 FLOW GUIDE 1

93 318-878 FIELD 1

94 318-879 TAPPING SCREW (W/SP. WASHER) D5X60 2

95 318-880 MOTOR HOUSING 1

96 318-881 TAPPING SCREW (W/SP. WASHER) D5X16 4

97 318-882 HEX. SOCKET SET SCREW M5X8 2

98 317-374 BRUSH HOLDER 2

99 311-089 CARBON BRUSH 2

100 314-583 BRUSH CAP 2

101 318-883 PLASTIC CAP 1

102 NAME PLATE 1

103 WARNING LABEL (A) 1

104 620-1DD BALL BEARING 6201DDCMPS2L 1

105 318-876 PLAIN WASHER 1

: ALTERNATIVE PARTS

*

--- 29 ---

NO.

USED

REMARKS

C 10FM

---

2

00

Page 32

PARTS

ITEM

CODE NO. DESCRIPTION

No.

106 620-0VV BALL BEARING 6200VVCMPS2L 1

107 317-642 VISE ASS'Y (FOR VERTICAL) 1 INCLUD.108-113

108 968-247 HEX. SOCKET SET SCREW M6X10 1

109 317-643 SUPPORT 1

110 317-644 SCREW BAR 1

111 317-645 VISE BEARING 1

112 317-646 FLANGE 1

113 317-647 BUSHING 1

114 HITACHI LABEL 1

115 318-819 BUSHING 1

116 319-003 SPINDLE ASS'Y 1 INCLUD.76,77,80-83

NO.

USED

REMARKS

STANDARD ACCESSORIES

ITEM

CODE NO. DESCRIPTION

No.

701 311-128

702 311-013 WRENCH 1

703 311-034 DUST BAG 1

TCT SAW BLADE 255MM-D15.88 HOLE-NT24

NO.

USED

1

REMARKS

C 10FM

OPTIONAL ACCESSORIES

ITEM

CODE NO. DESCRIPTION

No.

901 976-472

903 976-473 TCT SAW BLADE 255MM-D15.9 HOLE 1

905 317-542 HOLDER ASS'Y 1 INCLUD.906-910

906 317-654 STOCK STOP 1

907 317-375 WING BOLT 1/4"X3/4" 1

908 317-655 LOCK SUPPORT ROD 2

909 317-656 EXTENSION WING 2

910 949-271 MACHINE SCREW M8X20 (10 PCS.) 2

911 317-541 VISE ASS'Y (FOR LATERAL) 1 INCLUD.912-921

912 317-648 SCREW BAR 1

913 317-649 VISE BEARING 1

914 949-515 ROLL PIN D6X30 (10 PCS.) 1

915 317-650 CLUTCH 1

916 317-629 SET PLATE 1

917 311-126 WASHER 3/16"X1/2" 1

918 317-503 MACHINE SCREW (W/WASHER) M5X10 1

919 317-652 SUPPORT 1

920 949-518 ROLL PIN D3X18 (10 PCS.) 1

921 317-653 KNOB 1

TCT SAW BLADE CROSS-CUT 255MM-D15.9 HOLE

NO.

USED

1

REMARKS

Printed in Japan

(000210 N)

---

2

00

: ALTERNATIVE PARTS

*

--- 30 ---

Loading...

Loading...