Page 1

DG150

Bedienungsanleitung 1–10

Operating instructions 11–20

Mode d’emploi 21–30

*371747*

371747

D

GB

F

Page 2

1

Page 3

3

2

21

22

24

26

27

29

28

25

23

Page 4

11

It is essential that the operating

instructions are read before the

tool is operated for the first time.

Always keep these operating

instructions together with the tool.

Ensure that the operating instructions are with the tool when it is

given to other persons.

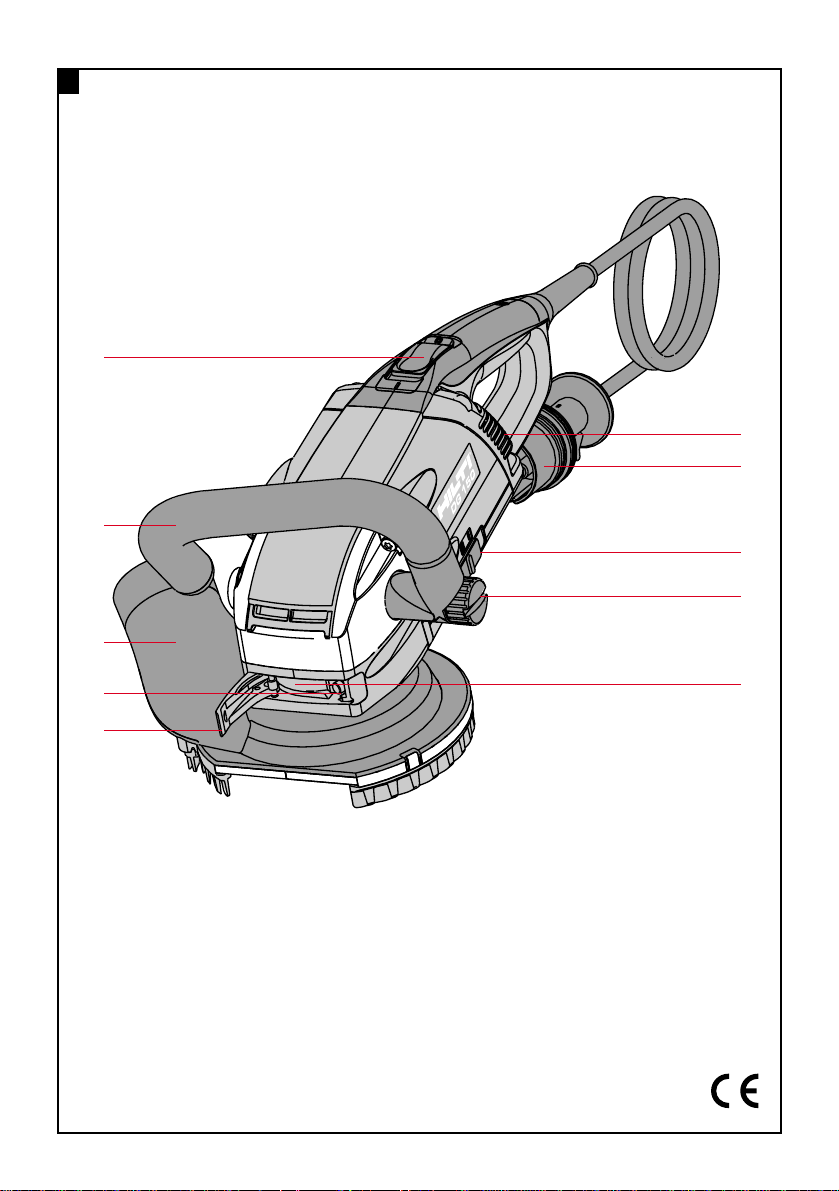

DG150 grinder with DPC20

Operating controls and

component parts of the DG150

On / off switch

Side handle

Guard assemby

Adjusting screw

Clamping lever

Indicator lamp (LED)

Supply cord plug

Speed control switch (settings 1 and 2)

Side handle fastening screw

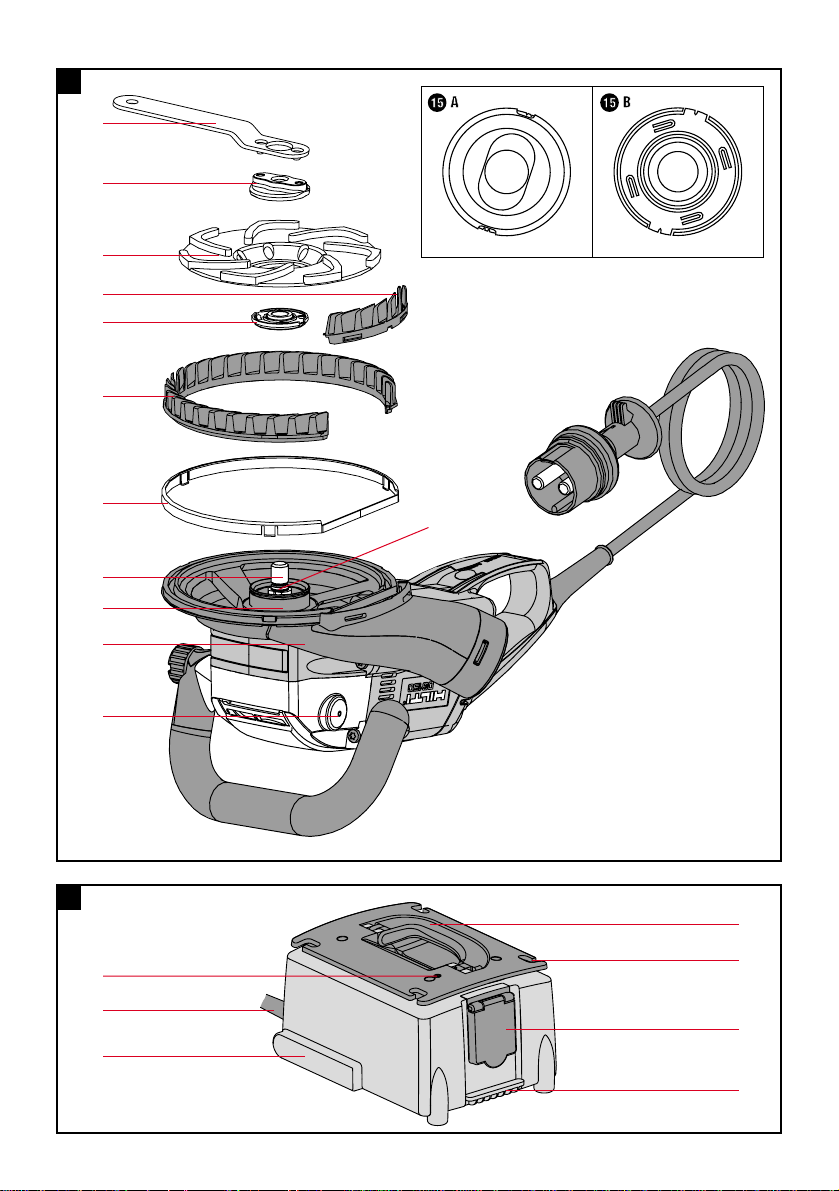

Clamping band

Wrench

Clamping nut

Diamond cup wheel

Lamellar seal, small

Clamping flange

Lamellar seal, large

Retaining ring

Spindle

Circlip

Guard lower section

21

Guard upper section with hose connector

22

Spindle lockbutton

Operating controls and component parts of the

DPC20

23

Indicator lamp (LED)

24

Supply cord

25

Guide rib

26

Carrying handle

27

Supply cord holder

28

Electric socket with cover

29

Locking lug

1. General information

These numbers refer to the tool’ s operating controls

or indicators.

These numbers refer to the corresponding illustrations. The illustrations can be found on the fold-out cover pages. Keep these pages open while studying the operating instructions.

In these operating instructions, the DG150 with the

DPC20 is referred to as «the tool».

Location of identification data on the tool

The type designation and serial number can be found

on the type plate on the tool. Make a note of this data in

your operating instructions and always refer to it when

making an enquiry to your Hilti representative or service department.

Type:

Serial no.:

Type:

Serial no.:

Contents Page

1. General information 11

2. Description 12

3. Tools and accessories 13

4. Technical data 13

5. Safety precautions 14

6. Before use 16

7. Operation 17

8. Care and maintenance 18

9. Troubleshooting 18

10. Disposal 19

11. Warranty 20

12. Declaration of confirmity See cover

Page 5

12

1.1 Indication of danger

WARNING

Used to draw attention to a potentially dangerous situation which could lead to serious personal injury or fatal accident.

CAUTION

Used to draw attention to a potentially dangerous situation which could lead to minor personal injury or damage

to the equipment or other property.

NOTICE

Used to draw attention to an instruction or other useful information. It is not used to indicate dangerous situations

or situations that could lead to damage to the equipment or other property .

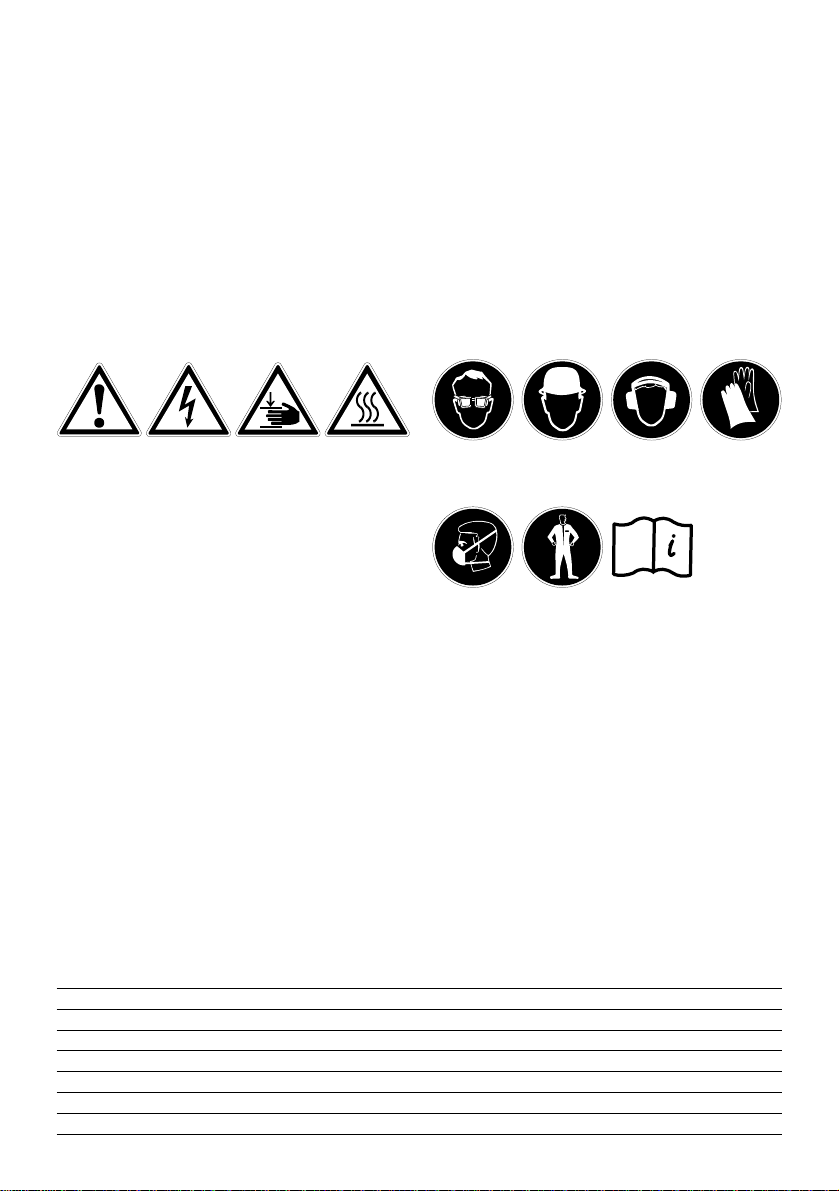

1.2 Pictograms

2. Description

The DG 150 is an electrically-powered diamond grinding tool for use by tradesmen in the construction industry for

grinding mineral materials. The DG 150 can be operated only in conjunction with the DPC 20 which, together, thus

form a system.

Items supplied

1 DG 150 grinder

1 DPC 20 power conditioner

1 Clamping flange

1 Clamping nut

1 Wrench

1 Protective goggles

1 Operating instructions

Obligation signs

Warning signs

General

warning

Warning:

electricity

Warning:

avoid hand

injuries

Warning:

hot surface

Wear eye

protection

Safety helmet

must be worn

Wear ear

protection

Wear protective

gloves

Read the

operating

instructions

before use.

Wear breathing

protection

Wear protective

clothing

Page 6

13

4. T echnical data

DG150 DPC20

Nominal voltage 100 V 110 V 120 V 220 V 230 V 240 V

Nominal current 15 A 16 A 15 A 9.6 A 9.2 A 8.8 A

Power input 1500 W 1760 W 1800 W 2100 W 2100 W 2100 W

Power output 1070 W 1260 W 1285 W 1500 W 1500 W 1500 W

Mains frequency 50/60 Hz 50/60 Hz 60 Hz 50/60 Hz 50 Hz 50 Hz

No-load speed at setting no. 1 4700 r .p.m.

No-load speed at setting no. 2 6600 r.p.m.

Weight 4.1 kg 3.8 kg 3.8 kg 3.8 kg 3.4 kg 3.4 kg 3.4 kg

Dimensions (l×w×h) 46×25×23 cm 27×22×15 cm

Electrical protection class Protection class II Z (double insulated)

Interference immunity as per EN 55014-2

Radio and television interference suppression as per EN 55014-1

Noise and vibration information (in accordance with EN 50144)

Typical A-weighted sound power level (LWA) 88 dB(A)

Typical A-weighted emission sound

pressure level (LpA) 101 dB(A)

Typical weighted vibration at the grip 4.0 m/s

2

Other significant characteristics of the appliance

Time to stop after switching off ≤ 2 sec.

Thermal overload protection

Restart safety interlock

Right of technical changes reserved

3. Diamond cup wheels and accessories

Hilti item

Diamond cup wheels Use/material

DG-CW 150/6″ A1 Grinding highly abrasive materials such as screed and similar mineral

materials

DG-CW 150/6″ B1 Grinding to remove coatings with a maximum layer thickness of 3 mm from

concrete and similar mineral materials

DG-CW 150/6″ C1 Grinding concrete and similar mineral materials of medium hardness and

medium abrasiveness

DG-CW 150/6″ C10 Grinding concrete

DG-CW 150/6″ C2 Grinding concrete and similar very hard and highly abrasive mineral materials

DG-CW 150/6″ D1 Fine finishing of concrete and similar mineral material surfaces

Lamellar seals One large lamellar seal and one small lamellar seal

Retaining ring Retaining ring for attaching the large lamellar seal to the dust hood

DG 150 toolbox Carrying case

VCD 50L Dry-type vacuum cleaner

Clamping flange for DG150 Special quick-stop compatible clamping flange to be used exclusively

for fitting Hilti DG-CW 150/6″ diamond cup wheels

Clamping nut for DG150 Special M13 clamping nut for fitting Hilti DG-CW 150/6″

diamond cup wheels

Page 7

14

5. Safety precautions

5.1 Basic safety information

In addition to the safety precautions listed in the individual sections of these operating instructions, the following points must be strictly observed at all times.

5.2 Correct use

The DG150 may be operated only in conjunction with

the DPC 20. T ogether with the Hilti VCD50L and the corresponding DG-CW 150/6" diamond cup wheels, the

DG150 forms a very advantageous electrically-powered,

hand-held grinding system that releases a minimum of

dust. In order to ensure optimum dust extraction, an

industrial vacuum cleaner in good working condition

must be used at all times. To ensure safe operation, the

DG150 may be used only together with original Hilti cup

wheels. The DG150 is designed exclusively for dry grinding on the surface of concrete or similar mineral materials and for removing thin coatings, with a maximum

thickness of 3 mm, from these materials.

The locally applicable health regulations and corresponding

safety precautions must be observed and implemented

at all times while grinding coated or uncoated mineral

materials with the DG150.

Do not, under any circumstances, use the tool in any

way other than as described in the operating instructions.

5.3 Incorrect use (misuse)

● The tool is not suitable for grinding metals, wood or

other materials not listed at paragraph 5.2.

●The tool is not suitable for use with diamond cutting

discs, abrasive cutting or grinding discs, wire brushes

or other insert tools not approved for use (see section 3).

● The tool is not suitable for wet grinding.

● Do not clamp the tool in a vice.

● Grinding materials containing asbestos is not per-

missible.

● Materials containing substances hazardous to health

may be ground only after consultation with the local

authority responsible for safety at work and in accordance with the locally applicable regulations concerning

safety at work.

●Diamond cup wheels, clamping flanges and clamping

nuts not listed in section 3 "Diamond cup wheels and

accessories" may not be used.

5.4 State of the art

●The tool is designed and manufactured according to

the state of the art.

●The tool and its ancillary equipment may present hazards when used incorrectly by untrained personnel or

not as directed.

5.5 Proper arrangement and organisation of the workplace

●Work from a safe stance and remain in balance at all

times.

●When working outdoors, the use of rubber gloves and

non-slip shoes is recommended.

●Avoid unfavourable body positions.

●Ensure that the workplace is well lit.

●Objects which could cause injury should be removed

from the working area.

●Keep other persons, children in particular , outside the

area affected (tool and supply cord) while you are working.

●Grinding off projecting objects such as nails and screws

etc. is not permissible. Such objects must be removed

carefully before beginning grinding.

●Do not wear loose clothing, loose long hair and jewellery which could become caught up in moving parts.

●Always lead the supply cord, extension cord and extraction hose away to the rear when working.

●Take care to avoid tripping over the supply cord, extension cord or extraction hose.

●Do not expose the tool to rain or snow and do not use

it in damp or wet areas or where there is a risk of fire or

explosion.

●Avoid a high dust concentration by ensuring that the

workplace is well ventilated.

●The side handle must be fitted to the tool at all times

when in use.

●Keep the grips dry , clean and free from oil and grease.

●The tool must be held by both hands when in use.

●Use clamps or a vice to secure loose workpieces.

●T ake care of the cup wheels. Y ou will work more effi-

ciently and more safely if the cup wheels are kept clean

and sharp (segments unpolished). Observe the maintenance regulations and instructions on changing cup

wheels.

●T ake care to avoid concealed electric cables, gas and

water pipes. Check the working area, e.g. using a metal

detector.

● Sparks may fly when grinding. Take care to ensure

that flying sparks do not present a hazard to other persons. Due to the risk of fire, grinding must not be carried out in the vicinity of inflammable materials (within

the area of flying sparks).

●For increased personal safety, the use of a ground fault

interrupter / residual current device (30 mA) is recommended under certain circumstances, e.g. in very damp

conditions or where large quantities of conductive dust

are produced.

Page 8

15

5.6 Information on emissions

5.6.1 Dust

CAUTION

Grinding may produce hazardous dust.

● Before starting work, find out to which dangerous

material class the grinding dust produced belongs. Use

the tool in conjunction with an industrial vacuum cleaner with an officially approved safety classification and

which complies with the local dust protection regulations.

● When grinding, the industrial vacuum cleaner used

must be equipped with a filter suitable for the application.

● Conductive dust may collect inside the tool when

grinding conductive materials. This may have a negative effect on the insulation of the tool and cause electric shocks. As a result, tools used for this application

must be checked by a technical specialist or Hilti

service department at least every six months to ensure

integrity of the insulation and to check for possible accumulation of conductive dust or other conductive substances.

5.7 General hazards presented by the tool

● Operate the tool only as directed and only when it is

in faultless condition.

● Unplug the supply cord when the tool is not in use

(e.g. during pauses between work), before cleaning or

maintenance and when changing cup wheels.

●Never leave the tool unsupervised.

●When not in use, the tool must be stored in a dry place,

locked up or out of reach of children.

●Operate the tool only together with its respective safety equipment.

●Do not overload the tool. The tool operates more efficiently and more safely within its given performance

range.

●Do not use the tool for purposes for which it was not

intended (e.g. attaching drill bits or similar, fitting saw

blades for cutting wood, etc.).

●Avoid unintentional starting. Do not keep your finger

on the on / off switch while carrying the tool when connected to the mains supply.

●Check the condition of the cup wheel before it is used.

●Use only the original accessories or items of additional

equipment listed in the operating instructions. The use

of other cup wheels or accessories may present a risk of

injury.

●Follow the instructions given by Hilti when fitting and

using cup wheels.

●T est new cup wheels by allowing them to run at maximum speed for at least 30 seconds before use.

● Damaged cup wheels of cup wheels that run out of

round (vibration) must not be used.

●Do not subject cup wheels to impacts and keep them

free from grease.

● -CAUTION- The tool continues to run for approx. 2

seconds after switching off.

● Do not attempt to brake the rotating cup wheel by

applying lateral pressure.

5.7.1 Mechanical hazards

●Do not leave wrenches etc. attached to the tool. Before

switching on, check that wrenches and adjusting tools

have been removed.

●Check whether parts have suffered damage and that

all moving parts function faultlessly without sticking. All

parts must be fitted correctly and fulfil all of the conditions necessary to ensure faultless operation of the tool.

●Use only original Hilti cup wheels.

●The mounting hole in the cup wheel must fit the cen-

tring collar of the clamping flange without play . Do not

use reducers or adaptors. Before switching on, check

that the cup wheel is fitted correctly and free to rotate.

●Always switch off the tool and unplug the supply cord

before fitting or removing the cup wheel.

● Observe the direction of rotation arrow when fitting

the cup wheel.

5.7.2 Electrical hazards

●Protect yourself from electric shocks. Avoid body contact with earthed objects, e.g. pipes and radiators.

● Check the condition of the tool including the supply

cord and extension cord as well as the plug connections.

Do not operate the tool if damage is found, if the tool is

not complete or if its controls cannot be operated faultlessly.

●Never carry the tool by the supply cord.

●Grip the plug and not the cable when pulling it out of

the socket.

● Do not expose the supply cord to heat, oil or sharp

edges.

●Do not touch the supply cord in the event of it becoming damaged while working. Disconnect the supply cord

plug from the socket.

●Disconnect the supply cord plug from the socket when

the tool is not in use, before maintenance, before changing cup wheels and before adjusting the position of the

guard or side handle.

● When working outdoors, use only extension cords

that are approved and correspondingly marked for this

application.

● Check the tool for any damage. All parts of the tool

must be checked carefully to ensure correct, faultless

functionality before further use.

●Damaged switches must be replaced at a Hilti service

centre. Do not use the tool if it cannot be switched off

and on properly.

Page 9

16

● If necessary, have the tool repaired by an electrical

specialist (Hilti service department).

●T o avoid risk of accident, use only original Hilti spare

parts.

● Insert the supply cord plug in the socket only when

the tool is switched off.

● - WARNING - Do not disconnect the plug of the DG150

from the power unit DPC20 under load.

5.7.3 Thermal hazards

●The diamond cup wheel, parts of the guard or the tool

(gearing section) may become hot during operation. To

avoid burns, do not touch these parts with the bare hands.

Wear safety gloves.

5.8 Requirements to be met by users, installation and

maintenance personnel

5.8.1 Requirements to be met by users

●The tool is intended for professional use.

●The tool may be operated, serviced and repaired only

by authorised, trained personnel. This personnel must

be informed of any special hazards that may be encountered.

●Always concentrate on the job you are doing. Proceed

carefully and do not use the tool if your full attention is

not on the job.

5.8.2 Personal protective equipment

●Always wear eye protection, a safety helmet, ear protection, safety gloves, breathing protection and protective clothing when grinding.

●Wear knee protectors when working on floors.

●Wear sturdy shoes or boots.

5.8.3 Protective equipment

●Connect the tool to the industrial vacuum cleaner .

●Unless stated otherwise in the operating instructions,

damaged protective equipment and parts must be correctly repaired or replaced at an accredited service workshop.

●For safety reasons, the tool may be operated only when

the guard and when safety gloves are worn.

● The guard may be adjusted only when the tool has

been switched off and the supply cord unplugged.

6. Before use

It is essential that the safety precautions printed in these

operating instructions are read and observed.

- WARNING -

■The guard is used in a partly open

position for working close to edges.

■The rotating cup wheel presents a

risk of serious injury.

■Work carefully when the guard is

open and close it again when you

have finished working at the edge.

6.1 Guard

–WARNING– The tool may be used only with the guard

fitted.

A damaged or incomplete guard must be replaced immediately.

6.1.1 Adjusting the guard

The extraction hose connector can be brought into the

most favourable position for working by rotating the entire

guard.

Rotating the guard

1. Switch the tool off.

2. Disconnect the supply cord plug from the socket.

3. Open the clamping lever.

4. Rotate the guard.

-NOTE- When the extraction hose connector comes

into contact with the opened lever, the guard can be

rotated further by moving it downwards.

5. Close the clamping lever.

6.1.2 Adjusting the guard to the work surface

1. Switch the tool off.

2. Disconnect the supply cord plug from the socket.

3. Lay the tool down on the cup wheel.

4. Open the clamping lever.

5. Rotate the guard and adjust it to the optimum height.

-NOTE- For optimum dust extraction while grinding,

the lamellar seal should be almost in contact with the

work surface (gap 0 ... 1 mm).

6. Close the clamping lever.

6.1.3 Adjusting the guard for working close to edges

The opening in the lower section of the guard can be

rotated until part of the cup wheel is exposed. This is of

advantage, for example, when grinding close to a wall.

- CAUTION -

■The cup wheel or parts of the guard

may become hot during use.

■These parts may burn your hands.

■ Wear safety gloves when chang-

ing the cup wheel or adjusting the

guard.

Page 10

17

-NOTE- More dust may escape from the guard when

working at edges.

Adjusting the guard

1. Switch the tool off.

2. Disconnect the supply cord plug from the socket.

3. Open the clamping lever.

4. Rotate the upper and lower sections of the guard in

opposing directions until they are in a suitable position.

5. Close the clamping lever

-NOTE-The guard engages perceptibly in the closed,

normal position.

-NOTE- If the guard is not held securely when the lever

is closed, tighten the clamping band by turning the adjusting screw in a clockwise direction.

If the guard cannot be moved when the lever is open,

release the clamping band by turning the adjusting screw

in a counter-clockwise direction.

6.2 Side handle

6.2.1 Using and adjusting the side handle

For safety reasons, the side handle must always be used.

It can be adjusted in two axes until in the most favourable

working position:

– Two angled positions for right or left-handed use

– Pivoted forwards / back in increments

1. Switch the tool off.

2. Disconnect the supply cord plug from the socket.

3. Release the side handle by turning the clamping screw

in a counter-clockwise direction.

4. Bring the side handle into the desired position.

5. Tighten the clamping screw by turning it in a clockwise direction.

6.3 Diamond cup wheel

●The tool must always be switched off and the supply

cord plug disconnected before manipulating the cup

wheel in any way.

● Press in the spindle lockbutton (only when rotation

has stopped).

● When changing the cup wheel, clean all cup wheel

mounting parts.

●Use only original Hilti diamond cup wheels, clamping

flanges and clamping nuts.

6.3.1 Fitting the diamond cup wheel

1. Place the clamping flange on the spindle, with the

O-shaped recess underneath, ensuring that it engages

securely.

A

2. Place the cup wheel on the centering collar of the clamping flange.

B

3. Screw on the clamping nut in a clockwise direction

and tighten it by hand or with the wrench against the

resistance of the motor / gearing.

6.3.2 Removing the diamond cup wheel

1. Press in the spindle lockbutton and hold it in this position.

2. Release the clamping nut by turning it with the wrench

in a counter-clockwise direction.

3. Release the spindle lockbutton.

4. Remove the diamond cup wheel.

6.3.3 Changing the speed setting

The tool provides two different speed settings.

Recommendation

Setting I: 4700 r

.p.m.

Use this setting for grinding soft mineral materials such

as paint coatings on cement rendering. At this speed setting, dust extraction performance is improved and the

tool can be guided more easily for removing coatings

from soft materials.

Setting

II:6600r.p.m.

Use this setting for grinding hard mineral materials such

as concrete, screed or rock in order to obtain full grinding performance.

7. Operation

It is essential that the safety precautions printed in these

operating instructions are read and observed.

-CAUTION-

■ Grinding may produce hazardous

dust.

■ The dust produced by grinding

may be damaging to the lungs

and eyes.

■ Use a dust extraction system,

wear a safety helmet, breathing

protection and eye protection.

-CAUTION-

■The tool and the grinding operation emit noise.

■Excessive noise may damage the

hearing.

■Wear ear protection.

7.1 Switching the tool on

1. Connect the hose between the tool and the industrial

vacuum cleaner.

2. Connect the electric cable between the DG 150 and the

DPC 20.

3. Connect the DPC 20 to the mains supply.

4. Lift the tool away from the work surface.

Page 11

18

5. Push the on / off switch forward to the ON (I) position.

The switch engages in the ON (I) position.

After a power cut, the tool can be restarted by moving

the on / off switch to the OFF (0) position and then to the

ON (I) position.

7.2 Testing new diamond cup wheels

Allow the tool to run for at least 30 seconds under no

load. The diamond cup wheel should not be used if it

vibrates. Do not subject diamond cup wheels to impacts

and keep them free from grease.

7.3 Grinding

● Never operate the tool without its protective equip-

ment.

●Use only Hilti DG-WC 150/6″ diamond cup wheels.

●Apply moderate pressure, appropriate to the materi-

al being ground. Move the tool from side to side and do

not press the diamond cup wheel into the material.

● The diamond cup wheel may overheat and suffer dam-

age when grinding particularly hard mineral materials,

e.g. concrete containing a high proportion of hard aggregates. Should this occur, the grinding operation must be

interrupted and the diamond cup wheel allowed to cool

for a short time with the tool running under no load.

●Slower progress may indicate that the diamond cup

wheel has lost cutting power (segments have become

polished). The segments can be resharpened by grinding an abrasive material (Hilti sharpening plate or abrasive sand-lime block).

7.4 Switching the tool off

1. Press the on / off switch. When released, the switch

returns to the OFF position.

2. Disconnect the supply cord from the socket.

3. If an industrial vacuum cleaner is used, disconnect the

hose between the tool and the vacuum cleaner.

8. Care and maintenance

Disconnect the supply cord plug from the socket before

manipulating the DG 150 or DPC 20 (making adjustments, cleaning, etc.). The ventilation slots in the motor

housing must be unobstructed and kept clean at all times.

If possible, use compressed air to blow dust out of the

motor at regular intervals (approx. every four weeks).

Do not use metal objects for cleaning. Under extreme

conditions, conductive dust may collect inside the tool

when grinding mineral materials. This may have a negative effect on the tool’s protective insulation.

8.1 Replacing the guard’s lamellar seal

Replace the guard's lamellar seal at least each time the

cup wheel is changed.

-NOTE- Disassembly / assembly of the seal parts can be

facilitated by rotating the parts of the guard in relation to

each other.

Disassembly

1. Always switch the tool off and unplug the supply cord

before making adjustments to the tool or changing

parts, etc.

2. Use a screwdriver to press the three lugs of the retaining ring over the edge of the guard.

3. Remove the large lamellar seal from the retaining ring.

4. Release the small lamellar seal by pressing with a

screwdriver in the two slots on the outside of the guard.

Assembly

1. Clean the locating grooves to remove large dust particles.

2. Press the small lamellar seal into the guide in the guard

until it engages.

3. Place the large lamellar seal in the groove in the retaining ring.

4. Press the retaining ring with the lamellar seal over the

edge of the guard until it engages.

8.2 Repairs

The tool requires no maintenance.

The tool has been manufactured and tested with great

care. Nevertheless, in the event of a fault developing, the

tool should be returned to a Hilti service centre for repair .

The tool may be repaired by trained electrical specialists

only.

9. T roubleshooting

9.1 DG 150 indicator lamp (LED)

Overheating of the tool is indicated by the lamp blinking

red. The lamp continues to blink for the duration of the

fault, irrespective of the switch position.

In the event of the lamp blinking red, switch the tool off

and allow it to cool until the red lamp no longer blinks.

9.2 DPC 20 indicator lamp (LED)

Indicator status:

a) Green lamp lights continuously

This indicates that the DPC 20 is ready for operation.

The DPC 20 is connected to the mains supply and indicates no malfunctions. This is the normal status.

b) Green blinking

This may occur with 100 V to 120 V versions when

under load. This indicates that the mains voltage is

too low. The DG 150 reacts by achieving significantly

lower performance.

c) Red blinking

The lamp blinks red when the DPC 20 reacts to irregularities such as too high or too low current, voltage

or temperature, etc. The indicator changes to green

when the problem has been rectified. The power output fuses should be checked if the indicator continues to blink red.

Page 12

19

No indication

The DPC 20 is receiving no power from the mains supply. This could be caused by the mains supply itself, the

supply cord or extension cable or a fault in the DPC 20.

It is not immediately possible to determine whether the

indicator itself is defective. For this reason, the DPC 20

should be checked together with the DG 150 at regular

intervals, at least every six months, by a trained specialist or at a Hilti service centre.

10.Disposal

Most of the materials from which Hilti power tools are manufactured can be recycled. The materials must be correctly separated before they can be recycled. In many countries, Hilti has already made arrangements for taking back

your old electric tools for recycling. Please ask your Hilti customer service department or Hilti sales representative

for further information.

Should you wish to return the electric tool yourself to a disposal facility for recycling, proceed as follows: Dismantle the tool as far as possible without the need for special tools. Use absorbent paper to wipe oily parts clean and

collect any oil that runs out. This paper should also be disposed of correctly. On no account should oil be allowed

to enter the waste water system or find its way into the ground.

Part / assembly Main material Recycling

Toolbox Plastic Plastics recycling

Motor housing Plastic Plastics recycling

Motor (rotor , stator) Steel, copper, plastic Scrap metal

Fan Plastic Plastics recycling

Bearing plate Magnesium alloy Scrap metal

Electronics Plastic, electronic parts Plastics recycling / electronics scrap

Gear housing Magnesium alloy Scrap metal

Flange Magnesium alloy Scrap metal

Internal gearing parts Steel Scrap metal

Side handle Plastic Plastics recycling

Guard Plastic Plastics recycling

Cup wheel mount Steel Scrap metal

Grip Plastic Plastics recycling

Electric conductors Plastic, copper Plastics recycling / scrap metal

Power conditioner housing Plastic Plastics recycling

Heat sink Aluminium Scrap metal

Page 13

20

11. Warranty

Hilti warrants that the product supplied is free of defects

in material and workmanship. This warranty is valid as

long as the tool is operated and handled correctly, cleaned

and serviced properly and in accordance with the Hilti

operating instructions, all warranty claims are made within 12 months from the date of sale (invoice date), and

the technical system is maintained. This means that only

original Hilti consumables, components and spare parts

may be used with the product.

This warranty provides the free-of-charge repair or replacement of defective parts only. Parts requiring repair or

replacement as a result of normal wear and tear are not

covered by this warranty.

Additional claims are excluded, unless stringent national rules prohibit such exclusion. In particular , Hilti is

not obligated for direct, indirect, incidental or consequential damages, losses or expenses in connection

with, or by reason of, the use of, or inability to use the

tool for any purpose. Implied warranties of merchantability

or fitness for a particular purpose are specifically excluded.

For repair or replacement, send the tool and/or related

parts immediately upon discovery of the defect to the

address of the local Hilti marketing organisation provided.

This constitutes Hilti’s entire obligation with regard to

warranty and supersedes all prior or contemporaneous

comments and oral or written agreements concerning

warranties.

Page 14

12. Konformitätserklärung

Bezeichnung: Diamantschleifgerät

Typenbezeichnung: DG150

Konstruktionsjahr: 2001

Wir erklären in alleiniger Verantwortung, dass dieses

Produkt mit den folgenden Richtlinien und Normen

übereinstimmt: 98/37 EG, 89/336/EWG, 73/23 EWG,

EN 292, EN 55014-1, EN 55014-2, EN 61000-3-2, EN

61000-3-3

Hilti Corporation

Dr. Andreas Meyer Dr. Martin Gödickemeier

Head of Diamond Systems Head of Diamond System Development

Business Unit Business Unit

July 2001 July 2001

12. EC declaration of conformity

Designation: Diamond grinder

Type designation: DG150

Year of design: 2001

We declare, on our sole responsibility , that this product

complies with the following standards or standardisation documents: 98/37 EC, 89/336/EEC, 73/23 EEC,

EN 292, EN 55014-1, EN 55014-2, EN 61000-3-2, EN

61000-3-3

12. Déclaration de conformité

Désignation: Meuleuse au diamant

Modèle: DG 150

Année de conception: 2001

Nous déclarons sous notre seule et unique responsabilité que ce produit est conforme aux directives et normes suivantes: 98/37 EC, 89/336/EEC, 73/23 EEC, EN

292, EN 55014-1, EN 55014-2, EN 61000-3-2, EN

61000-3-3.

Page 15

Hilti Corporation

FL-9494 Schaan

Tel.:+423/ 2342111

Fax: +423/234 2965

www.hilti.com

Hilti = registered trademark of Hilti Corp., Schaan W 2608 0901 00-Pos. 1 1 Printed in Liechtenstein © 2001

Right of technical and programme changes reserved S. E. & O.

371747 A

Loading...

Loading...