Henny Penny SmartCombi, ClassicComb Installation Manual

Smart Combi

Classic Combi

™

™

Planning and installation instructions

Combisteamer (electric)

Global Foodservice Solutions

306173---0AIAE-- / 14.12.2009 / TAG-MaBr

Type no.

(SmartCombi)

SizeType no.

(ClassicCombi)

615ECC61XXXXESC61XXXX

620ECC62XXXXESC62XXXX

115ECC11XXXXESC11XXXX

120ECC12XXXXESC12XXXX

215ECC21XXXXESC21XXXX

220ECC22XXXXESC22XXXX

*FM07-186B* en-US

Smart Combi

Classic Combi

™

™

Planning and installation instructions

Smart Combi

Classic Combi

™

™

Contents

5Planning ..............................................................1

5Standards and regulations ............................................1.1

5Ensure conformity with standards ............................................1.1.1

5Water ........................................................................................1.1.2

5Waste water .............................................................................1.1.3

6Electricity ..................................................................................1.1.4

6Room air ..................................................................................1.1.5

6Safety .......................................................................................1.1.6

7Food hygiene ...........................................................................1.1.7

8Relevant laws, institutions and authorities ...............................1.1.8

8Package dimensions and weights ................................1.2

9Weight ..............................................................................1.3

9Scale drawings ...............................................................1.4

9Abbreviations, installation dimensions .....................................1.4.1

10Installation dimensions .............................................................1.4.2

11Unit dimensions .......................................................................1.4.3

14Specifications, water ......................................................1.5

14Specifications, soft water .........................................................1.5.1

14Specifications, hard water ........................................................1.5.2

14Specifications, waste water ......................................................1.5.3

14Specifications, power supply ........................................1.6

15Heat loss .........................................................................1.7

16Ambient atmosphere and noise level ...........................1.8

17Transport .............................................................2

17Transporting the unit ......................................................2.1

18Installation ..........................................................3

18Installation information ..................................................3.1

19Mounting the suspension frame in the base frame .....3.2

Global Foodservice Solutions

21Installing tabletop units .................................................3.3

21Installing floor standing units .......................................3.4

21Aligning the rack trolley .................................................3.5

22Aligning the rack trolley with slide in system EasyIn ..3.6

24Electricity ............................................................4

24Power cable requirements .............................................4.1

24Opening and closing the switch cover .........................4.2

3Planning and installation instructions

Contents

Smart Combi

Classic Combi

™

™

25Description of the terminal strip ......................................4.3

26Connecting the power supply ..........................................4.4

27RS485/RS422 interface .....................................................4.5

28Connect performance optimization system (LOA) .........4.6

29Water ......................................................................5

29Water supply ......................................................................5.1

31Information about the soft water supply ......................................5.1.1

32Information about the hard water supply ....................................5.1.2

32Fitting the T-piece (accessory) ....................................................5.1.3

34Waste water connection ...................................................5.2

34Waste water connection for units with WaveClean .....................5.2.1

35Waste water connection for units without WaveClean ................5.2.2

36Air outlet connection ............................................6

36Installation under an extraction hood .............................6.1

36Connection to an air outlet duct ......................................6.2

Planning and installation instructions4

Global Foodservice Solutions

Smart Combi

Classic Combi

™

™

1 Planning

1.1 Standards and regulations

1.1.1 Ensure conformity with standards

→

Ensure that your plans conform to the standards and regulations

applying at the installation location.

NOTICE

The following overviews assist with orientation. They make no claim

to be complete.

1.1.2 Water

Planning

Drinking water supplyDIN 1988-4

Table 1: Standards/regulations relevant to water

1.1.3 Waste water

Waste water qualityDIN 1986-100

Table 2: Standards/regulations relevant to waste water

DescriptionRelates toStandard

Drinking water protection, preservation of the drinking water

quality

DescriptionRelates toStandard

Additional specifications to

DIN EN 752 and

DIN EN 12056: Drainage systems on private ground

Global Foodservice Solutions

5Planning and installation instructions

Planning

1.1.4 Electricity

DIN VDE

0100 ff.

0100-540

DIN VDE

0100-430

Table 3: Standards/regulations relevant to electricity

Requirements for electronic

components

Potential equalisationDIN VDE

Potential equalisation of the

location

Smart Combi

Classic Combi

DescriptionRelates toStandard

Provisions for the erection of

high-voltage current systems

with nominal voltages up to

1000 V

Erection of low-voltage systems

part 5-54: Selection and erection

of electrical equipment – Earthing arrangements, protective

conductors and protective potential equalisation conductors

Erection of low-voltage systems

part 4-43: Protection for safety

– Protection against overcurrent

™

™

1.1.5 Room air

VDI 2052

Table 4: Standards/regulations relevant to room air

1.1.6 Safety

BGR 111

Priority circuit room ventilation

system

Emissions and comfortASR 5

Hazards in kitchens (formerly

ZH 1/37)

DescriptionRelates toStandard

Ventilation equipment for kitchen, basis for planning the

ventilation of commercial kitchens as well as for calculating

the size and construction of

ventilation systems. It applies

in connection with the complete

reference work of DIN 1946.

General conditions for working

environments in kitchens with

regard to the planning of kitchen ventilation systems.

DescriptionRelates toStandard

Safety regulations for kitchens,

kitchen safety equipment (fire

extinguishers...)

Table 5: Standards/regulations relevant to safety

Planning and installation instructions6

Global Foodservice Solutions

Smart Combi

Classic Combi

™

™

1.1.7 Food hygiene

Regulation

(EG) Nr.

852/2004

Table 6: Standards/regulations relevant to hygiene

Planning

DescriptionRelates toStandard

Regulation about food hygieneDocumentation of heating

temperatures according to

HACCP principles

Global Foodservice Solutions

7Planning and installation instructions

Planning

Smart Combi

Classic Combi

1.1.8 Relevant laws, institutions and authorities

™

™

TAB (Technical

Connection

Conditions)

GAS (Low

Pressure Gas

Supply (NDAV))

BauO (Building

Regulations);

LBO (Regional

Building Regulations)

Commerce and

Industry regulations)

BauO (Building

Regulations);

FeuVo (Ordinance on Firing

Installations),

BISchV (Federal Emission

Control Ordinance)

AbwV (Waste

Water Ordinance)

Relates toStandard

Gas supply

Installation of the unit

Installation of the unit

Gas supply

Installation of the unit, emissions

Installation of the unit

Water/waste water connections

Name of the institute/authority

Regional gas or energy supplier (GVU) or network operator

Building inspection authoritiesGas supply

Trading standards officeInstallation of the unitGewO (Trade,

Responsible district chimney/heating inspector

Water/waste water association

or authority

ATV information sheets (Association of

Waste Water

Technicians)

TAB (Technical

Connection

Conditions)

POWER (NAV

- Ordinance on

Low-Voltage

Connections)

Table 7: Relevant laws, institutions, authorities

Installation of the unit

Mains connection

Technical connection conditions for connecting to the low

voltage mains network, requirements applying to the installation location

Mains network operators,

power suppliers

1.2 Package dimensions and weights

NOTICE

These specifications may be modified for technical reasons.

Planning and installation instructions8

Global Foodservice Solutions

Smart Combi

Classic Combi

™

™

Planning

Size

Table 8: Package dimensions and weights

1.3 Weight

NOTICE

These specifications may be modified for technical reasons.

Gross weight (lb.)Package dimensions (in.)

Depth x width x height

374.842.5 x 37.8 x 40.2615/620

429.942.5 x 37.8 x 50.4115/120

826.745.7 x 37.8 x 86.6215/220

Weight (lb.)Size

286.6615

297.6620

352.7115

396.8120

782.6215

782.6220

Table 9: Weight

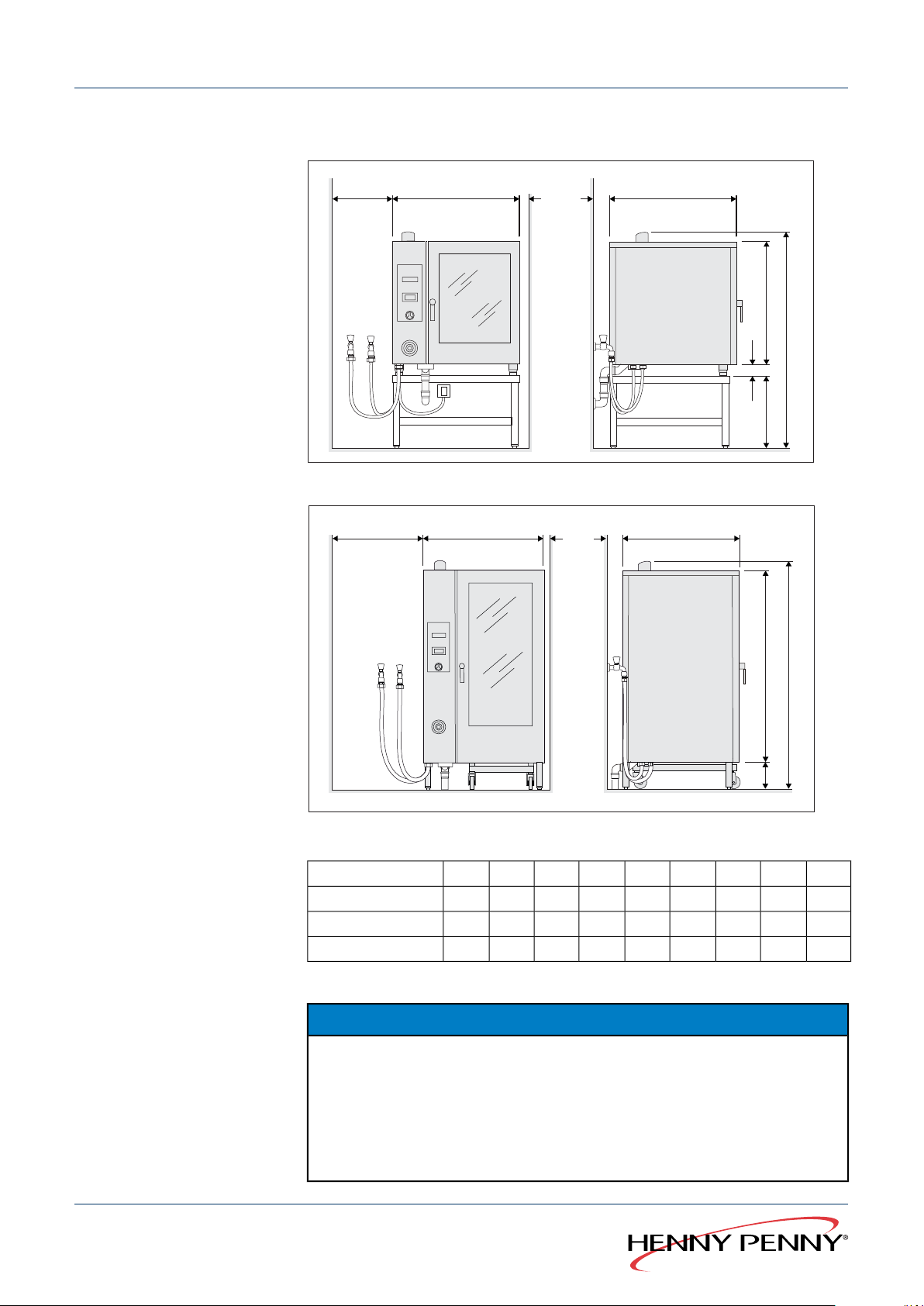

1.4 Scale drawings

1.4.1 Abbreviations, installation dimensions

MeaningAbbreviation

WidthB

Width, distance from wall to the left of the unitBL

Width, distance from wall to the right of the unitBR

HeightH

Height, distance from the ceilingHD

Height, unit feetHF

Height, overallHG

Height, tableHT

DepthT

Depth, distance to wall behind the unitTH

Table 10: Abbreviations, installation dimensions

Global Foodservice Solutions

9Planning and installation instructions

Planning

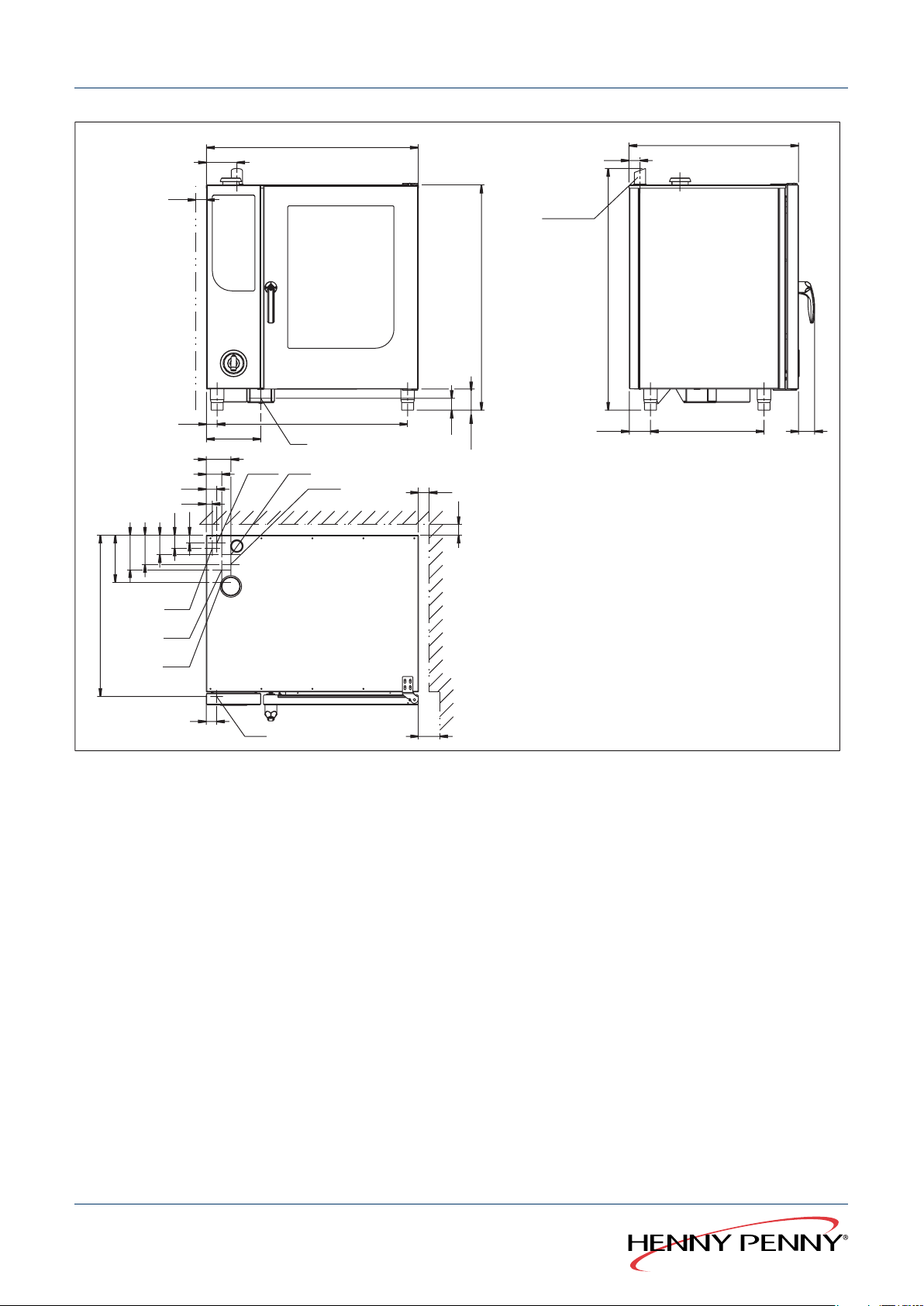

1.4.2 Installation dimensions

Smart Combi

Classic Combi

™

™

BL

B

BR

TH

T

H

HG

HF

HT

Figure 1: Installation dimensions of combisteamers 615/620 and 115/120

BL T

B

BR

TH

H

HG

HF

Figure 2: Installation dimensions, combisteamer 215/220

THTHTHGHFHBRBLBSize

5079985016401006905050997615/620

5079958016401009605050997115/120

50813 1960238172250501075215/220

Table 11: Installation dimensions in mm

NOTICE

A clearance of at least 50 mm from walls must be maintained to the

right and the left of the unit as well as behind it.

A minimum distance of 500 mm to the left is recommended for servicing.

When using rack trolleys, the distance to the left of the unit should be

at least 800 mm to allow the trolley to be positioned at the side.

Planning and installation instructions10

Global Foodservice Solutions

Smart Combi

Classic Combi

™

™

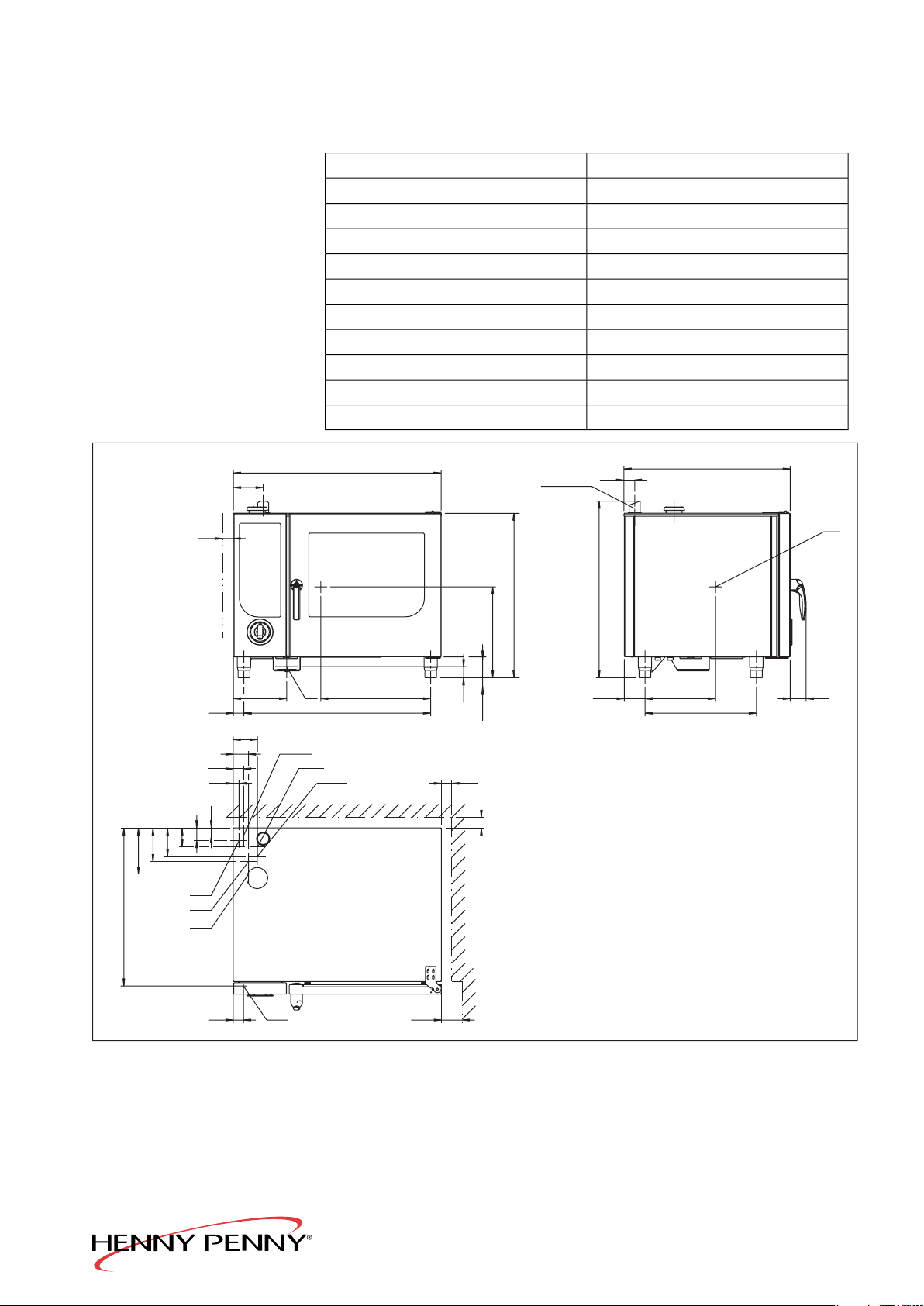

1.4.3 Unit dimensions

Planning

MeaningAbbreviation

Drain (waste water)A

Air outletAL

Electrical connectionEA

Soft water, coldEW

InterfaceKE

Cold water, hardKW

Performance optimisation systemLOA

Potential equalisation connectionPA

Centre of gravityS

Control lead, externalSTL

760

223

163

138

93

61

PA

EW

KW

50

50

50

29

38

143

117

74

255

LOA

EA

339

799

S

76

535

997

437

0

A

528

897

STL

53

50

+20

100

50

AL Ø53

790

52

849

100

49

KE

100

Figure 3: Combisteamer 615/620, unit dimensions in mm

Global Foodservice Solutions

11Planning and installation instructions

Planning

Smart Combi

Classic Combi

™

™

223

163

138

93

50

61

50

29

38

143

117

74

255

LOA

A

EA

997

89750

STL

50

56

50

+20

0

100

1060

AL Ø53

52

113 8

100

535

799

76

PA

760

EW

KW

49

KE

100

Figure 4: Combisteamer 115/120, unit dimensions in mm

Planning and installation instructions12

Global Foodservice Solutions

Loading...

Loading...