Page 1

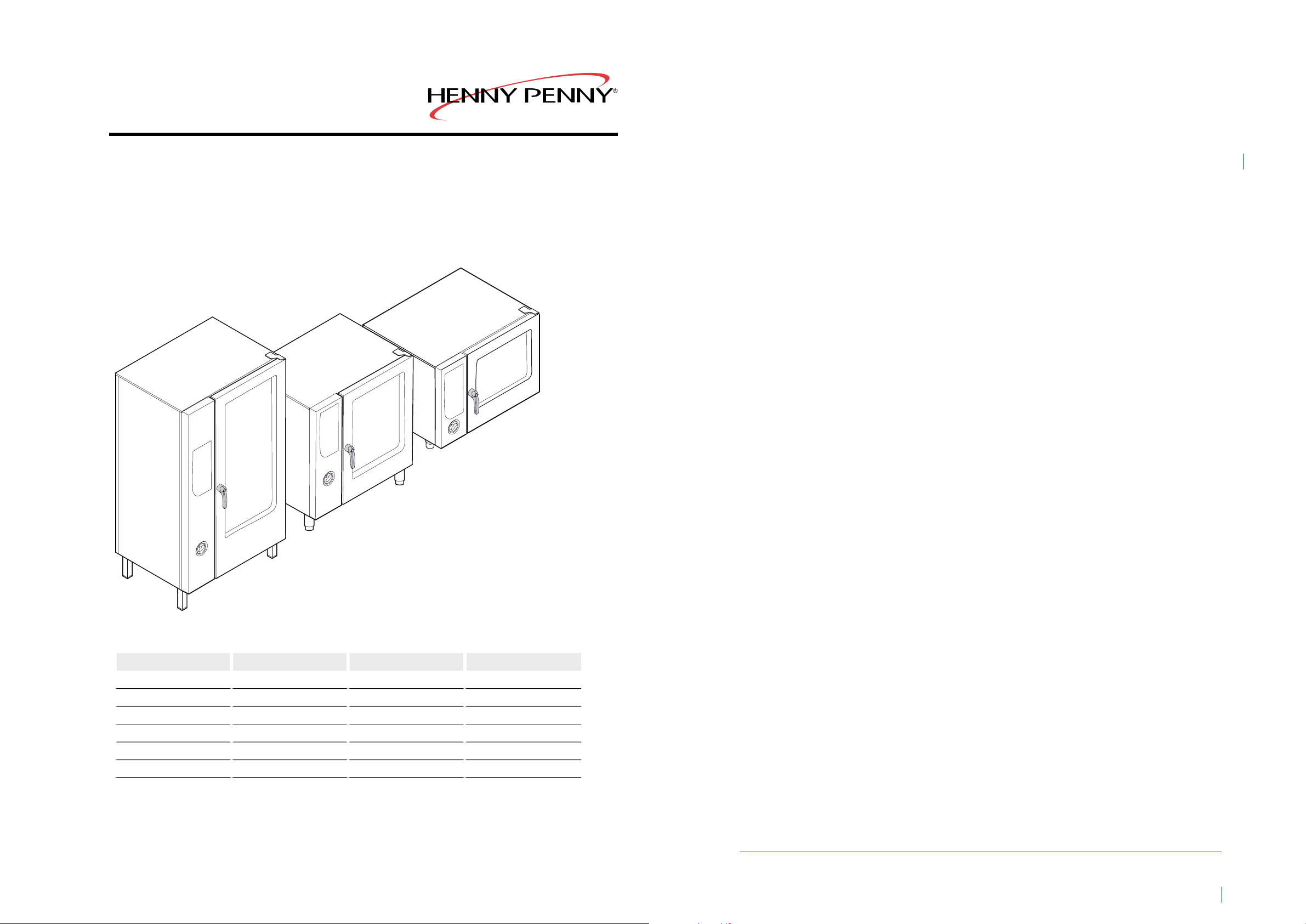

Smart Combi

Operating manual

SmartCombi

™

Global Foodservice Solutions

Open out the cover page to see the

controls.

306173----ABAE6- / 13.10.2009 / TAG-MaBr

SizeType no. (gas)Type no. (electric)Version

615GSC61XXXXESC61XXXXSmartCombi

620GSC62XXXXESC62XXXXSmartCombi

115GSC11XXXXESC11XXXXSmartCombi

120GSC12XXXXESC12XXXXSmartCombi

215GSC21XXXXESC21XXXXSmartCombi

220GSC22XXXXESC22XXXXSmartCombi

*FM05-061-A* en-US

Operating manual

Page 2

SmartCombi

™

Controls

18

17

16

Smart

with

Menu

SmartCombi

1

2

™

15

14

13

12

11

10

“Ready2Cook” button10“On/Off” button1

“Cooking time” button11“SmartMenu” button2

3

button

“Cooking temperature” button12“Combisteaming” cooking mode

Multi-function select button13Display4

“Convection” cooking mode button14“Perfection” cooking mode button5

“Steaming” cooking mode button15Multi-function select button6

Set button for the AtmosControl cli-

16“Core temperature” button7

mate control system

Set button for the AtmosControl cli-

17“Start/Stop” button8

mate control system

ClimaMonitor18“CombiDial”9

3

4

5

6

7

8

9

Operating manualOperating manual

Page 3

SmartCombi

™

Contents

7Introduction ........................................................1

7Intended use ...................................................................1.1

7About this operating manual .........................................1.2

8Warnings .........................................................................1.3

8Warranty and liability .....................................................1.4

9Signs and symbols .........................................................1.5

10Safety information ..............................................2

14Construction and function ................................3

14Description of the unit ...................................................3.1

17Description of the controls ............................................3.2

17Operating modes ............................................................3.3

18SmartMenu (automatic cooking) ...................................3.4

18Manual cooking ..............................................................3.5

18Steaming ..................................................................................3.5.1

20Combisteaming ........................................................................3.5.2

20Convection ...............................................................................3.5.3

21Perfection (climate and regeneration) ......................................3.5.4

22Delta-T cooking ........................................................................3.5.5

24Low temperature cooking .........................................................3.5.6

26Advanced cooking functions ........................................3.6

26Programmable steaming ..........................................................3.6.1

26Manual steaming ......................................................................3.6.2

26Rest period ...............................................................................3.6.3

26Preset start time .......................................................................3.6.4

27Ready2Cook (prepare for cooking) ..........................................3.6.5

27RackControl .............................................................................3.6.6

27Reduced heat output ................................................................3.6.7

28Add functions .................................................................3.7

Global Foodservice Solutions

28SES steam exhaust system .....................................................3.7.1

28Cycle fan operation ..................................................................3.7.2

28Reduced fan speed ..................................................................3.7.3

29End of step signal ....................................................................3.7.4

29AtmosControl climate control system ..........................3.8

29Core temperature measurement ...................................3.9

29HACCP log ......................................................................3.10

31WaveClean automatic cleaning system ........................3.11

3Operating manual

Page 4

Contents

SmartCombi

™

31USB interface ....................................................................3.12

32Operation ...............................................................4

4.1

4.2

Opening and closing cooking chamber door (tabletop

units) ..................................................................................

Opening and closing cooking chamber door (floor

standing units) ..................................................................

32

32Opening the cooking chamber door ............................................4.1.1

32Closing the cooking chamber door .............................................4.1.2

33

33Opening the cooking chamber door ............................................4.2.1

33Closing the cooking chamber door .............................................4.2.2

34Filling and emptying the unit (tabletop unit) ..................4.3

34Filling and emptying the unit (with loading trolley) ......................4.3.1

35Filling and emptying the unit (without loading trolley) .................4.3.2

36Filling and emptying the unit (floor standing units) ......4.4

36Switch on/switch off unit ..................................................4.5

36Switching on ...............................................................................4.5.1

36Switching off ...............................................................................4.5.2

37Working with the CombiDial ............................................4.6

37Basic functions .................................................................4.7

37Changing the language ...............................................................4.7.1

37Call up the setup menu and change parameters ........................4.7.2

38Displaying actual temperature values .........................................4.7.3

38Set the cooking temperature .......................................................4.7.4

38Setting the cooking time .............................................................4.7.5

39AtmosControl climate control system (set chamber humidity) ....4.7.6

39Measuring the core temperature .................................................4.7.7

40Connecting the USB memory stick .............................................4.7.8

40Saving the HACCP log ................................................................4.7.9

41Saving error messages ...............................................................4.7.10

41SmartMenu (automatic cooking) .....................................4.8

41Selecting the cooking program ...................................................4.8.1

42Starting the cooking program ......................................................4.8.2

43Ending the cooking program .......................................................4.8.3

43Display last program ...................................................................4.8.4

43Changing the cooking program during operation ........................4.8.5

44Save changed program ...............................................................4.8.6

44Create your own cooking programs ............................................4.8.7

45Entering a cooking program (example) .......................................4.8.8

45Copying a cooking program ........................................................4.8.9

Operating manual4

Global Foodservice Solutions

Page 5

SmartCombi

™

Contents

46Locking and releasing the SmartMenu program memory ........4.8.10

47Saving SmartMenu cooking programs .....................................4.8.11

47Loading SmartMenu cooking programs ...................................4.8.12

48Manual cooking ..............................................................4.9

48Starting the steaming process .................................................4.9.1

48Start Combisteaming ...............................................................4.9.2

49Starting the convection cooking mode .....................................4.9.3

49Starting perfection mode (climate and regeneration) ...............4.9.4

50Start Delta-T cooking ...............................................................4.9.5

50Starting low temperature cooking ............................................4.9.6

51Advanced cooking functions ........................................4.10

51Programmable steaming ..........................................................4.10.1

52Manual steaming ......................................................................4.10.2

52Setting the rest period ..............................................................4.10.3

53Setting the preset start time .....................................................4.10.4

53Starting Ready2Cook (prepare for cooking) ............................4.10.5

54Working with RackControl ........................................................4.10.6

55Reduced heat output ................................................................4.10.7

56Add functions .................................................................4.11

56Activate/deactivate add functions .............................................4.11.1

56Modify add function ..................................................................4.11.2

56Reducing the fan speed ...........................................................4.11.3

56Activating the end-of-step signal ..............................................4.11.4

57Changing standard settings ..........................................4.12

57Set service interval water volume ............................................4.12.1

58Standard settings ...........................................................4.13

62Cleaning ..............................................................5

62Automatic cleaning WaveClean .....................................5.1

62Preparing the cooking chamber ...............................................5.1.1

62Selecting the WaveClean level .................................................5.1.2

63Using the WaveClean cartridge ................................................5.1.3

64Start WaveClean ......................................................................5.1.4

64Ending WaveClean ...................................................................5.1.5

64Cancelling WaveClean .............................................................5.1.6

65WaveClean faults .....................................................................5.1.7

Global Foodservice Solutions

66System-supported manual cleaning .............................5.2

66Preparing the cooking chamber ...............................................5.2.1

66Start cleaning program .............................................................5.2.2

67Spraying cleaning solution .......................................................5.2.3

5Operating manual

Page 6

Contents

SmartCombi

™

67Let the cleaner work ...................................................................5.2.4

67Cleaning ......................................................................................5.2.5

68Rinsing out ..................................................................................5.2.6

68Cleaning the door seal ................................................................5.2.7

68Drying .........................................................................................5.2.8

69General cleaning ...............................................................5.3

69Cleaning the outside of the housing ...........................................5.3.1

69Cleaning the cooking chamber ...................................................5.3.2

69Cleaning the door seal ................................................................5.3.3

70Cleaning the cooking chamber door ...........................................5.3.4

71Cleaning the steam outlet port ....................................................5.3.5

71Descaling ....................................................................................5.3.6

72Removing the ventilation plate ........................................5.4

72Removing the ventilation plate (table top models) ......................5.4.1

72Removing the ventilation plate (floor standing units) ..................5.4.2

74Faults .....................................................................6

74Correcting faults ...............................................................6.1

74Resetting the control electronics ....................................6.2

75Cause of errors and troubleshooting ..............................6.3

77Limited Warranty ...................................................7

Operating manual6

Global Foodservice Solutions

Page 7

SmartCombi

1 Introduction

1.1 Intended use

™

Introduction

Henny Penny combisteamers are solely intended to be used for

commercial purposes, especially in commercial kitchens.

The unit may only be used for cooking food and only with the correct

racks, containers, baking sheets, rack trolleys and slide-in units.

The unit may only be used with the purest quality drinking water for

producing steam; if necessary, in combination with a water preparation

system.

It is not permitted to use the unit for the following purposes, among

others:

●

As a dishwasher

●

As a storage container

●

As a smoking oven

●

Drying towels, paper or dishes

●

Heating acids, brines or other chemicals

●

Heating closed containers (e.g. tinned food)

●

Heating inflammable liquids

●

Melting fats or salts

●

Heating rooms

●

Deep frying

●

Cleaning air filters

●

Operation without slide-in rails/trolley

1.2 About this operating manual

This operating manual is part of the equipment and contains information

required by the persons operating the unit to enable them to operate

it safely, for cleaning and looking after the unit and for handling faults.

●

The employees engaged to perform any tasks with the unit must

have read the operating manual, especially the section “Safety

information”, before beginning work.

●

Keep this operating manual stored safely during the life of the unit.

●

Make sure that this operating manual is constantly available for

the staff at the place where the unit is used.

●

Supply this operating manual to any subsequent owner or user of

the unit.

●

Include any supplements received from the manufacturer.

●

Supplement the instructions, including supervisory or notification

requirements, to take account of special operational circumstances

e.g. work organisation, workflows or deployed staff.

Global Foodservice Solutions

7Operating manual

Page 8

Introduction

SmartCombi

™

Target group

1.3 Warnings

●

This operating manual is intended for employees who are responsible

for operating, cleaning and looking after the unit as well as handling

faults.

●

Repairs to the unit may only be carried out by specially trained

technical staff.

●

Adults may not use the unit without supervision if

-

they are unable to do so due to their physical, sensory or mental

capabilities,

-

they do not have the knowledge and experience required to

operate the unit safely and in the manner intended.

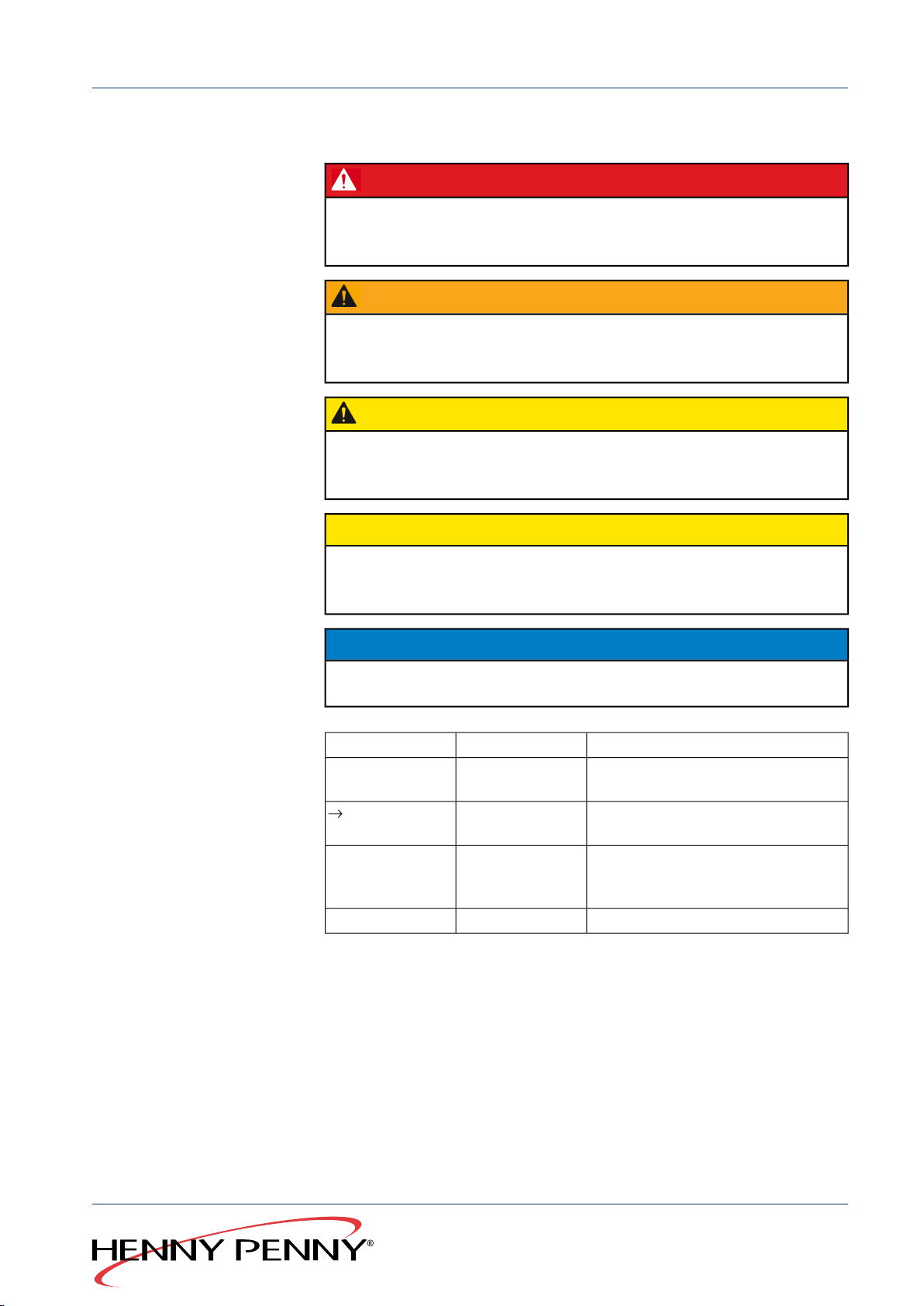

Warnings are indicated with a pictogram and a signal word.

The type and source of the risk as well as the consequences are described

together with instructions for avoiding the danger. The meanings of the

pictograms and signal words used are explained in section “Signs and

symbols” (see Chapter “Signs and symbols”, Page 9).

1.4 Warranty and liability

The unit may not be modified or technically changed.

All guarantees or warranties cease to exist if technical changes are made.

Furthermore, the safety of the unit is no longer guaranteed.

Claims for warranty or liability for damages to persons or property are

excluded if they arise from one or more of the following causes:

●

Improper use of the unit

●

Incorrect installation, commissioning, operation or servicing of the

unit

●

Technical changes to the unit without the binding agreement of the

manufacturer

●

Use of spare parts or accessories not approved by Henny Penny

●

Faults resulting from the failure to comply with these operating

instructions

Operating manual8

Global Foodservice Solutions

Page 9

SmartCombi

1.5 Signs and symbols

™

DANGER

Imminent danger

→

Non-compliance poses a threat of death or serious injury.

WARNING

Possible danger

→

Non-compliance may pose a threat of death or serious injury.

CAUTION

Dangerous situation

→

Non-compliance may result in slight injuries.

Introduction

CAUTION

Dangerous situation

→

Non-compliance may result in equipment damage.

NOTICE

Provides helpful information regarding use.

ExplanationMeaningSymbol

These must be fulfilled before you can

follow the instructions.

An action is required here.Instruction, single

Instructions must be followed in the

order given.

Emphasises the name of the controlControlOn/Off

1.

2.

RequirementsRequirements

step

Instruction, multiple steps

Global Foodservice Solutions

9Operating manual

Page 10

Safety information

Electricity Risk of electric shock

SmartCombi

2 Safety information

Henny Penny appliances comply with the relevant safety standards.

However, this does not exclude all possible dangers from arising, e.g.

due to improper use.

Therefore, when installing and operating the unit, the operating personnel

must be familiar with and observe local regulations, including BGR 111

“Working in catering kitchens”.

The following safety measures must also be observed:

WARNING

Possible danger

→

Non-compliance may pose a threat of death or serious injury.

™

●

The cover of the housing may only be opened by specially trained

technical staff.

●

Repairs to the unit and to the mains power supply may only be carried

out by specially trained technical staff.

●

Disconnect the unit from the power supply before opening the cover

of the housing.

●

Do not operate the unit when the housing cover is open.

Gas Risk of explosion due to escaping gas

●

If you smell gas:

-

Shut off the gas supply.

-

Ensure the area is adequately ventilated.

-

Do not activate any switches or use any electrical devices.

-

Do not use any open flames.

-

Notify the gas supply company and/or fire department. Use a

telephone that is outside the installation site.

●

In the event of fire

-

Shut off the gas supply.

-

Put out the fire with a fire extinguisher (class F or ABC powder)

or fire blanket, never with water.

Soiled and greasy films Risk of fire due to soiled and greasy films

●

Clean the unit after each use.

●

Observe the instructions regarding cleaning.

Operating manual10

Global Foodservice Solutions

Page 11

SmartCombi

™

Safety information

Hot surfaces, steam and

liquids

Risk of burns due to hot surfaces

●

Wear insulated protective gloves during operation.

●

Always open the door of the cooking chamber wide enough and

let it lock in place.

●

Allow surfaces to cool before cleaning.

●

Do not touch the interior of the unit or the inside of the cooking

chamber door immediately after use.

Risk of burns due to hot steam

●

Only open the door of the cooking chamber slightly at first to allow

the steam to escape. Then open the door fully.

●

Do not look into the steam outlet ports.

●

Do not hold your hand over the steam outlet ports.

Risk of burns due to hot liquids

●

Keep the door of the cooking chamber closed during the cleaning

program.

●

Do not insert containers with liquids to be cooked above eye-level.

●

When transporting food items, use a heat-resistant container with

handles and sealable lid.

●

Secure loading/rack trolleys against tipping over.

Rotating fan Risk of crushing fingers

●

Do not operate the unit without the ventilation plate.

Damaged windows Risk of injury due to glass splinters

●

Do not operate the unit if the windows are damaged.

●

Do not operate the unit if the cooking chamber lighting is defective.

●

Dispose of foods spoiled by glass splinters.

Cleaning Risk of burns caused by cleaning agents

●

Wear protective gloves and glasses when using caustic cleaning

agents.

●

Observe the information provided by the manufacturer of the

cleaning agent.

●

Store WaveClean and rinsing agent cartridges out of the reach of

children.

●

Observe the instructions for the storage of WaveClean and rinsing

agent cartridges.

Global Foodservice Solutions

11Operating manual

Page 12

Safety information

SmartCombi

CAUTION

Dangerous situation

→

Non-compliance may result in equipment damage.

™

Core temperature

Do not overheat the core temperature sensor

measurement

●

Do not heat the core temperature sensor with a lighter or similar

object.

Incorrect handling Equipment damage due to incorrect handling

●

To avoid damaging the electronics, do not operate the unit if the

controls are damaged.

●

To avoid moisture penetrating the unit, do not operate if the door

seals are damaged.

Cleaning Equipment damage due to incorrect cleaning

●

Do not cool the cooking chamber abruptly after use (e.g. with a

hand-held rinsing head).

●

Do not clean the unit with a high-pressure cleaner.

●

Do not clean the surfaces with abrasive cleaners, scouring pads or

chemically aggressive cleaners.

●

Observe the reaction times for cleaning agents.

●

Clean the unit regularly.

●

Keep the cooking chamber free of scale.

●

For “WaveClean” automatic cleaning, only use the two-in-one original

cartridges.

●

Remove all GN containers and accessories from the cooking chamber

before cleaning.

Improper use Damage to equipment due to improper use

●

Do not operate the unit at continually high temperatures.

●

Do not operate the unit at temperatures below 4 °C (39.2 °F).

●

Remove the core temperature sensor before removing the food item.

●

Replace the core temperature sensor back in its holder after use.

●

Only connect USB memory sticks based on flash memory.

Do not connect USB printers, external hard disks, WLAN, UMTS or

Bluetooth adapters or any other USB devices.

●

Do not connect PCs or notebooks.

●

Do not use force to insert USB memory sticks.

●

Insert the USB memory stick before reading/writing data and only

remove it once the data has been completely transferred.

Operating manual12

Global Foodservice Solutions

Page 13

SmartCombi

Handling foodstuffs Provisions governing foodstuffs

™

NOTICE

Provides helpful information regarding use.

●

For the function “Preset start time”, observe the provisions regarding

foodstuffs.

Safety information

Global Foodservice Solutions

13Operating manual

Page 14

Construction and function

3 Construction and

function

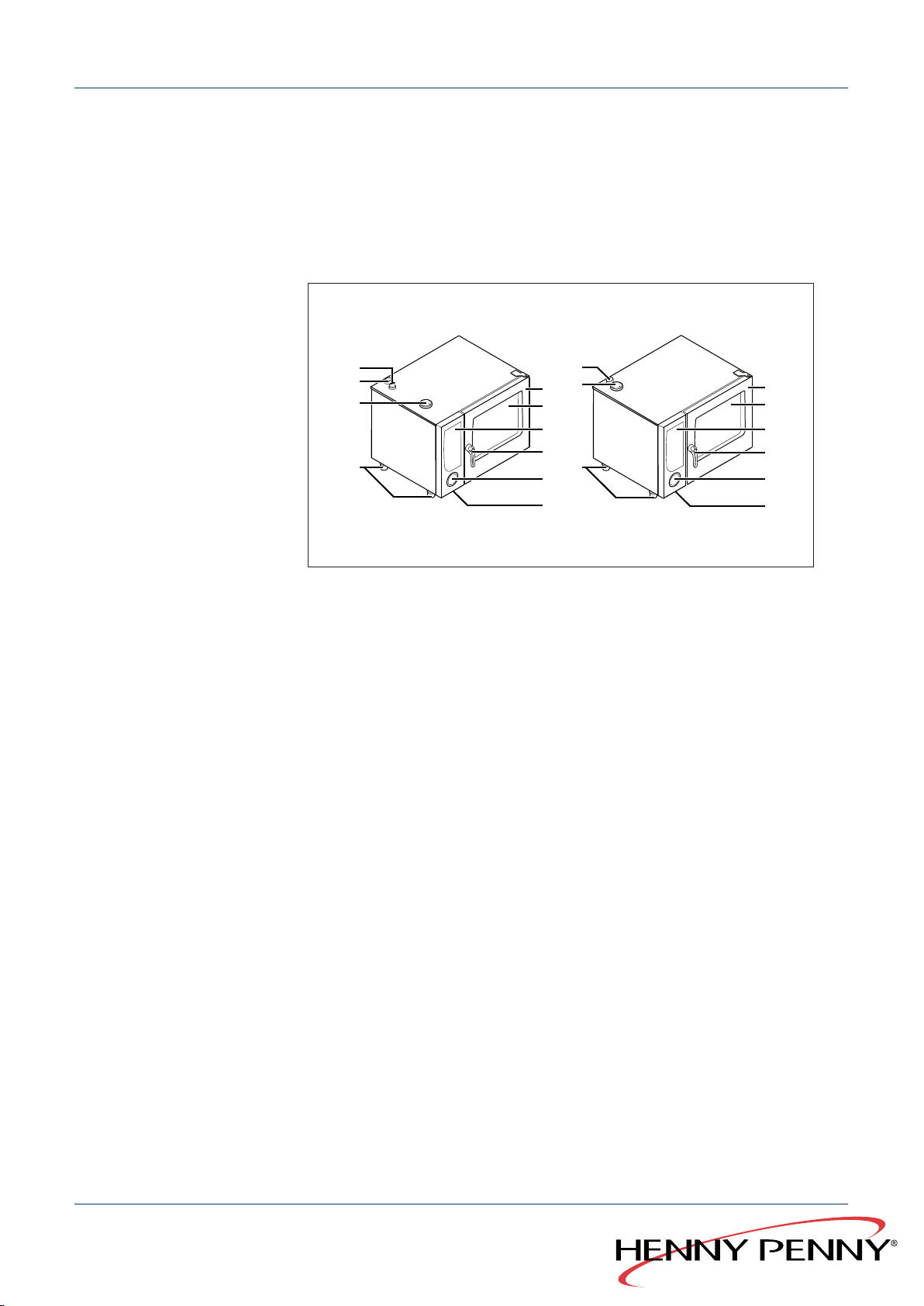

3.1 Description of the unit

SmartCombi

™

10

9

8

7

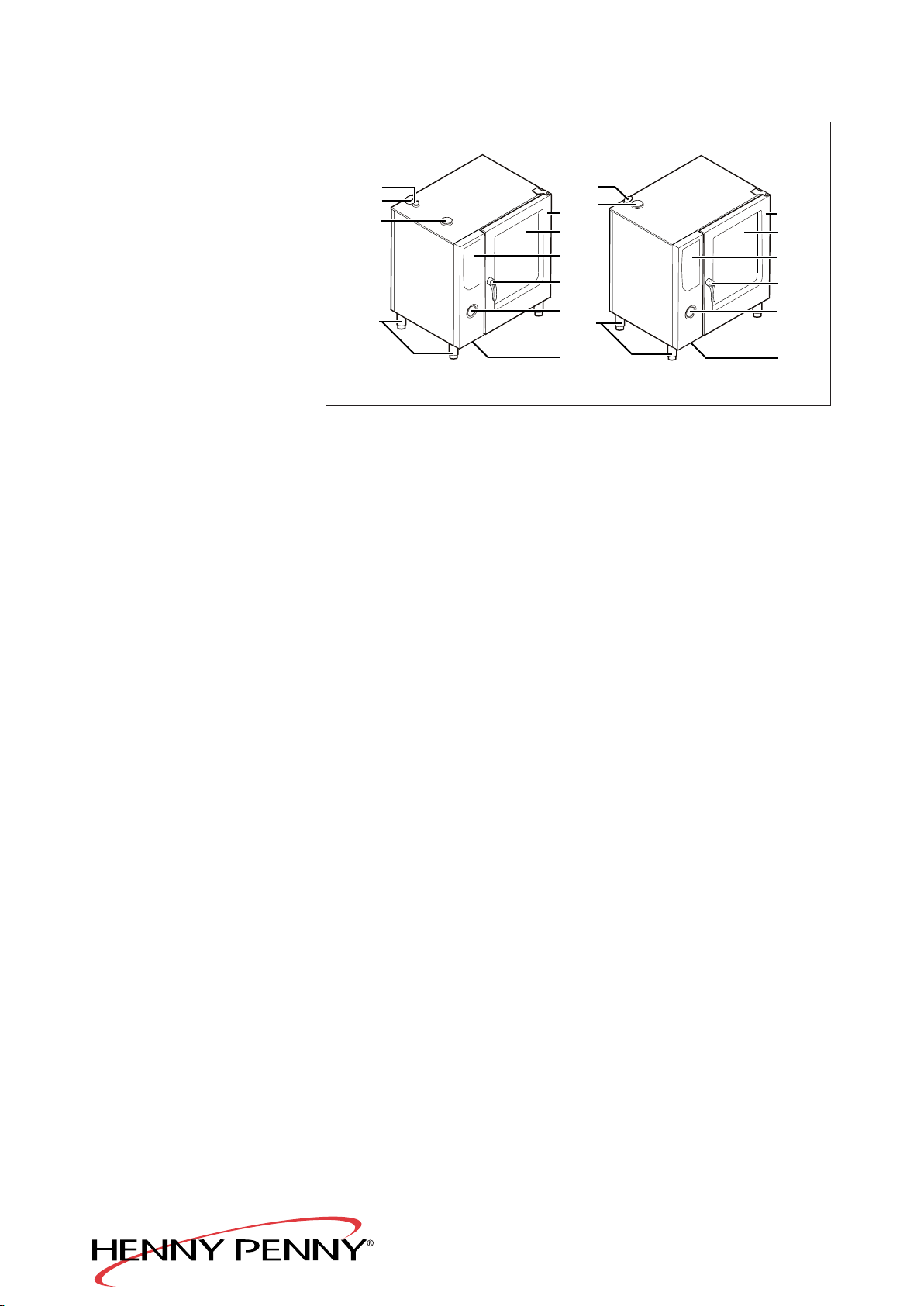

Figure 1: Sizes 615 and 620, left: gas, right: electric

9

8

1

2

3

4

7

5

6

Data interface (concealed)6Cooking chamber door1

Height-adjustable feet7Insulated window2

Air intake port for the cooking

8Controls3

chamber

Steam outlet port9Door handle4

Flue outlet10Hand-held rinsing head5

1

2

3

4

5

6

Operating manual14

Global Foodservice Solutions

Page 15

SmartCombi

™

Construction and function

10

9

8

7

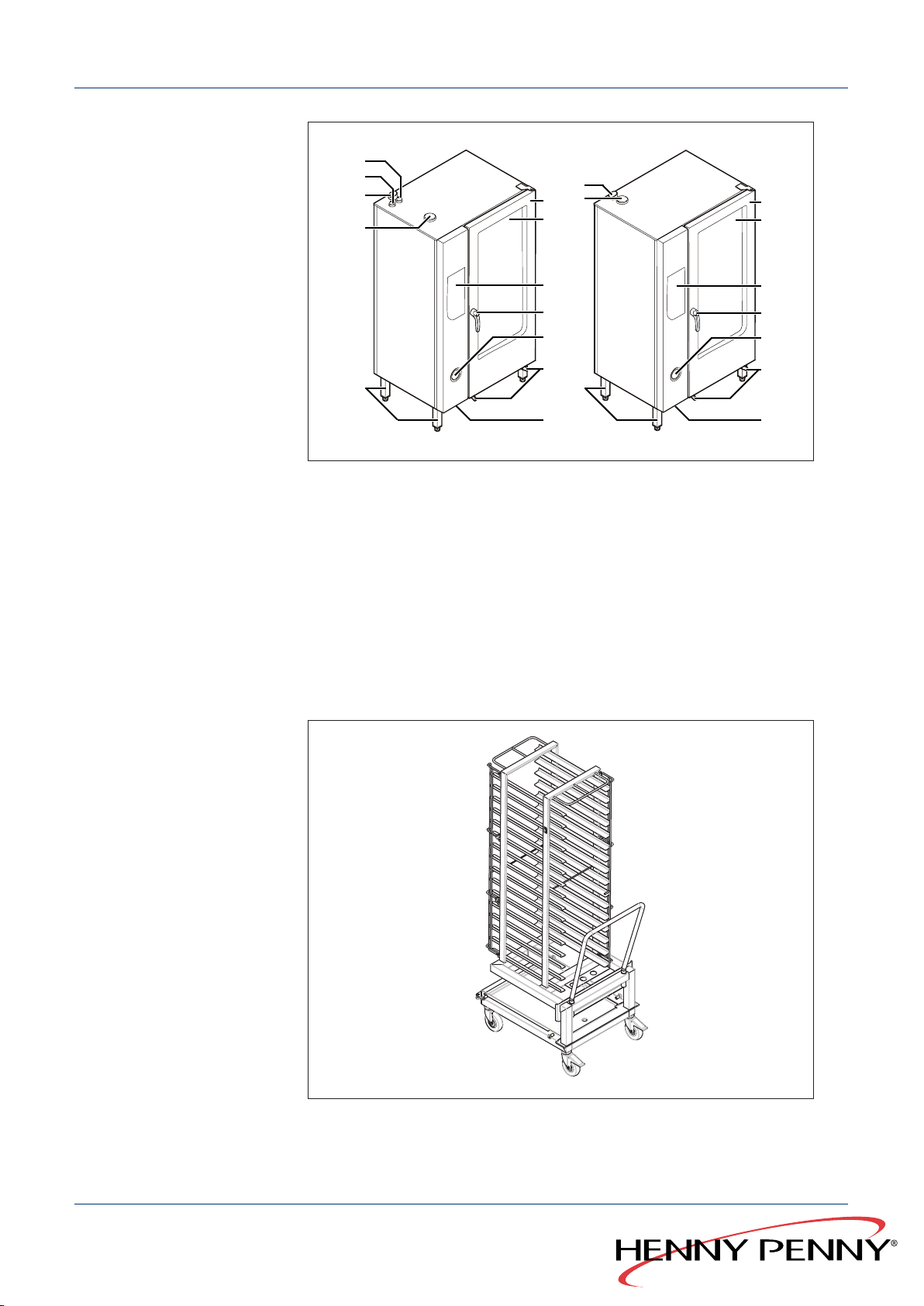

Figure 2: Sizes 115 and 120, left: gas, right: electric

9

8

1

2

3

4

5

7

6

Data interface (concealed)6Cooking chamber door1

Height-adjustable feet7Insulated window2

Air intake port for the cooking

8Controls3

chamber

Steam outlet port9Door handle4

Flue outlet10Hand-held rinsing head5

1

2

3

4

5

6

Global Foodservice Solutions

15Operating manual

Page 16

Construction and function

12

11

10

SmartCombi

10

1

9

9

2

1

2

™

3

4

5

6

8

Figure 3: Sizes 215 and 220, left: gas, right: electric

8

7

Data interface (concealed)7Cooking chamber door1

Height-adjustable feet8Insulated window2

Air intake port for the cooking

9Controls3

chamber

Steam outlet port10Door handle4

Flue outlet (lower burner)11Hand-held rinsing head5

Flue outlet (upper burner)12Rails for rack trolley6

3

4

5

6

7

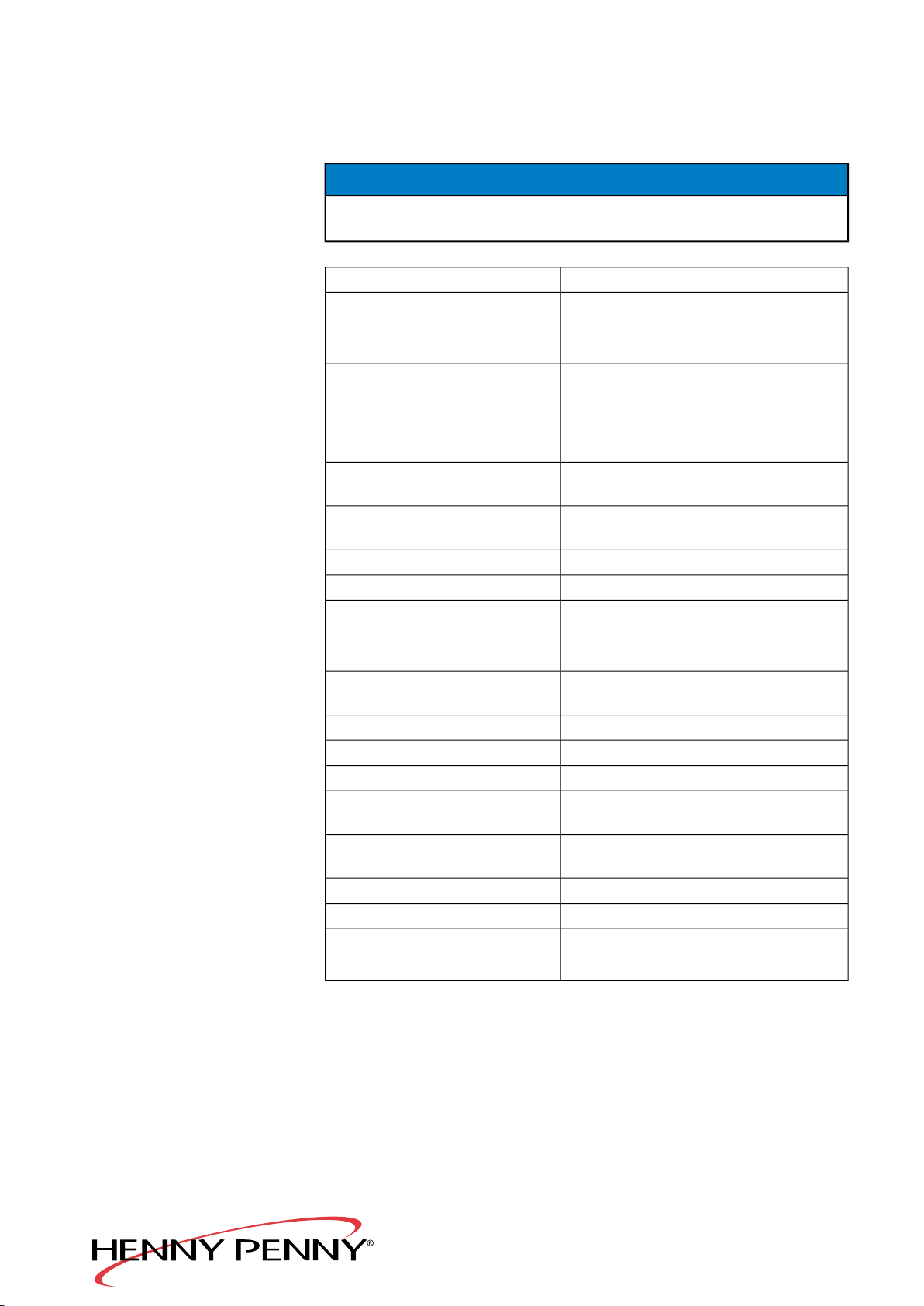

Figure 4: Rack trolley (for sizes 215 and 220)

Operating manual16

Global Foodservice Solutions

Page 17

SmartCombi

3.2 Description of the controls

™

NOTICE

Open out the front cover to see the controls.

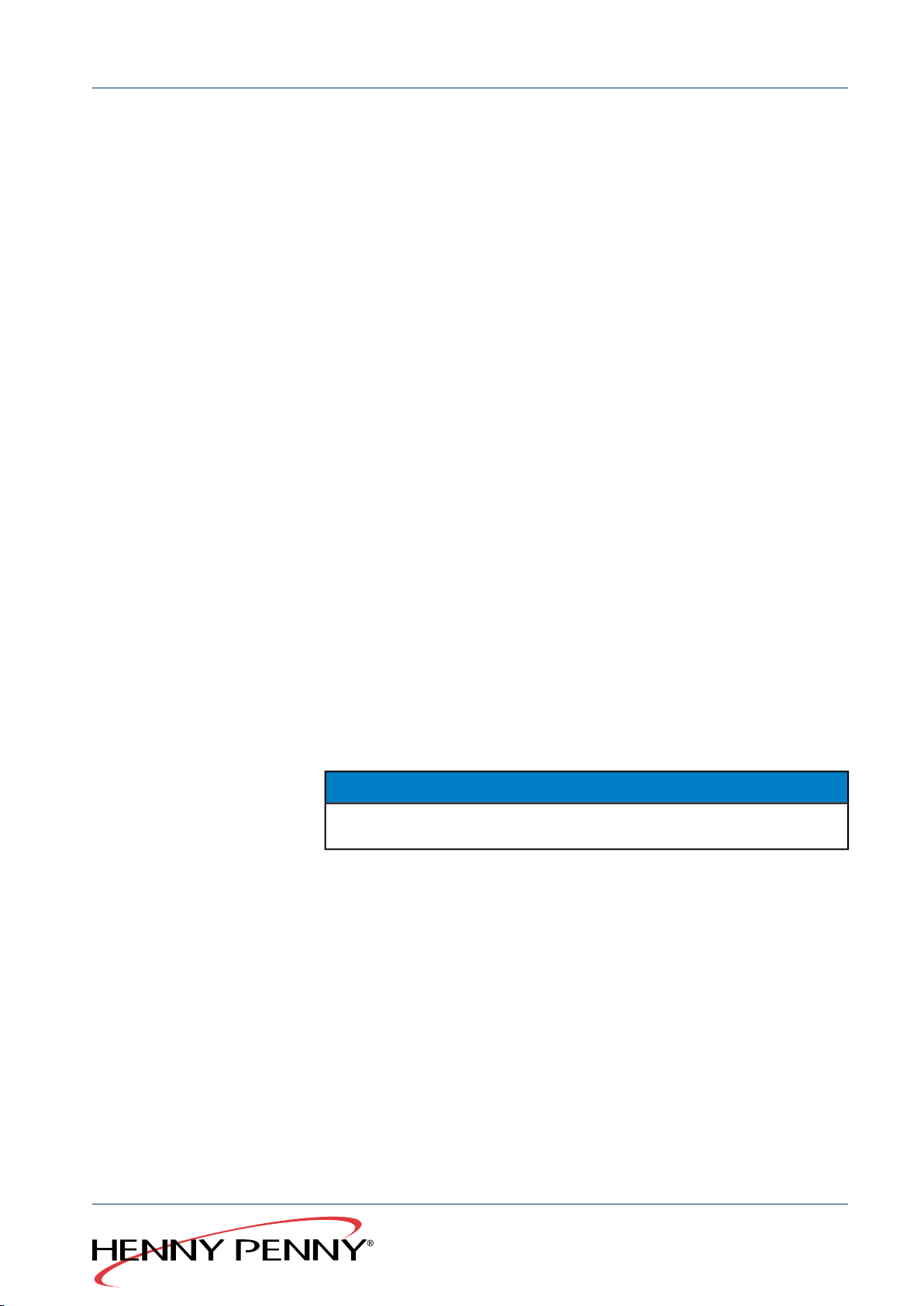

DescriptionControl

ClimaMonitor

Anzeige

isteaming”

Cooking mode button “Perfection”

Multi-function select button

Display for the SmartMenu cooking categories

Chamber humidity display

Display of temperatures and cooking times

Menu navigation display

Selection of SmartMenu cooking categories

Call up “Combisteaming” cooking modeCooking mode button “Comb-

Call up “Perfection” (climate and regeneration) cooking mode

Call up “Convection” cooking modeCooking mode button “Convection”

Call up “Steaming” cooking modeCooking mode button “Steaming”

Call up various functions

Construction and function

Set button for the AtmosControl climate control system

“Core temperature measurement”

button

“Ready2Cook” button

“CombiDial”

3.3 Operating modes

The unit has two operating modes:

The multi-function display (4) shows the

respectively assigned function

Increase or decrease cooking chamber

humidity

Switch on/off“On/Off” button

Call up SmartMenu (automatic cooking)“SmartMenu” button

Start/stop operation“Start/Stop” button

Call up the “core temperature measurement” function

Start the “Ready2Cook” function (prepare

for cooking)

Display and change cooking time“Cooking time” button

Display and change cooking temperature“Cooking temperature” button

Navigation in menus

Selection of values

Global Foodservice Solutions

●

SmartMenu (automatic cooking)

●

Manual cooking

You can use different cooking methods in both of these operating

modes.

17Operating manual

Page 18

Construction and function

Advanced cooking functions and add functions allow you to adjust the

cooking processes individually.

SmartCombi

™

Cooking modes

Advanced cooking

functions

Add functions

●

Steaming

●

Combisteaming

●

Convection

●

Perfection (climate and regeneration)

●

Delta-T cooking

●

Low temperature cooking

●

Programmable steaming

●

Manual steaming

●

Rest period

●

Preset start time

●

Ready2Cook (prepare cooking)

●

Reduced heat output

●

RackControl

●

SES steam exhaust system

●

Cycle fan operation

●

Reduced fan speed

●

End of step signal

3.4 SmartMenu (automatic cooking)

The SmartMenu operating mode is the function for automatic cooking.

The SmartMenu cooking program was developed by Henny Penny chefs,

however, it can be individually adapted.You can also create new

SmartMenu programs.

3.5 Manual cooking

3.5.1 Steaming

With the Steaming cooking mode, you can blanch, steam, steep, boil,

preserve and poach.

There are three steaming methods:

●

Soft Steaming: 30 °C (86 °F) to 99 °C (210.2 °F)

●

Steaming: 100 °C (212 °F)

●

Express Steaming: 101 °C (213.8 °F) to 130 °C (266 °F)

Benefits

●

Fast production of dishes that are firm to the bite with a good colour

and an intensive natural flavour.

●

Vitamins and minerals are retained.

●

Flavours are not transferred. The food retains its taste and aroma;

mixed loads are possible.

Operating manual18

Global Foodservice Solutions

Page 19

SmartCombi

Tips

™

Construction and function

●

Less seasoning, fats and salt needed.

●

Use perforated GN containers with a depth of 40–65 mm. These

allow for short cooking times and avoid the food underneath being

overcooked.

●

Break up lumps of ice when using frozen foodstuffs so that all the

food will be heated evenly.

●

Chill vegetables quickly after steaming, add butter and season.

●

Use stock for vegetable bundles. Steam the vegetables in

perforated GN containers and catch the stock in unperforated

containers.

●

Steam long grain rice in unperforated containers.

Use 1½ parts of cold water or cold stock to 1 part of rice.

●

Steam hard wheat pasta in unperforated containers.

Use at least 5 parts of water for 1 part of pasta.

●

Steam large and small dumplings in perforated containers lined

with baking paper.

Uncover immediately after cooking.

If necessary, keep them warm in water thickened with starch.

●

Sprinkle potatoes with fine grained salt and mix immediately before

steaming.

Alternatively, place potatoes in salt water for 15 minutes.

Benefits

Tips

Soft steaming

Steaming at temperatures between 30 °C (86 °F) and 99 °C (210.2 °F)

is called Soft steaming.

You can use soft steaming to prepare dishes especially gently, to swell

grains or to cook ham or sausages.

NOTICE

Cooking time is longer than with steaming or express steaming.

●

Less weight loss with meat and sausages.

●

Burst skin or gut is avoided when scalding or heating sausages.

●

Optimal food quality with delicate dishes such as terrines, jellies,

flans, forcemeat dumplings, creme caramel or diet meals.

●

Good when using vacuum pouches with the sous vide process.

●

Egg white sets optimally thanks to the precise cooking temperature

and doesn't run out of the food.

●

Allow yeast doughs for bread, buns or pastries to rise at a

temperature of 32 °C (89.6 °F).

●

When preparing poached trout, pour vinegar or wine over the fish.

Global Foodservice Solutions

19Operating manual

Page 20

Construction and function

Express steaming

Steaming at temperatures between 101 °C (213.8 °F) and 130 °C (266 °F)

is called Express steaming.

Express steaming is suitable for foods that are not damaged easily such

as jacket potatoes, beetroot, swede, pulses and cabbage.

Benefits The cooking time is reduced by about 10% as compared to the “Steaming”

cooking mode.

Tips

●

●

3.5.2 Combisteaming

SmartCombi

™

Set the cooking temperature between 105 °C (221 °F) and 110 °C

(230 °F) for small loads.

If the unit is fully loaded, set the temperature between 110 °C (230 °F)

and 130 °C (266 °F).

Benefits

Tips

The Combisteaming cooking mode is especially suitable for large roasting

joints, casseroles and baked foods.

●

Optimal cooking chamber climate: the food does not dry out.

●

Very fast cooking with minimum weight loss.

●

Flavours are not transferred. The food retains its taste and aroma;

mixed loads are possible.

●

Foods such as yeast-based doughs rise optimally when baking.

●

The steam closes the pores of large roasting joints immediately;

searing is not necessary.

●

Preheat unit for at least 10–15 minutes.

●

Reduce cooking temperature by 20–30 % compared to other cooking

methods.

●

Food starts to brown at a cooking temperature of 120 °C (248 °F)

and above.

The higher the set cooking temperature, the greater the food's weight

loss but the more intensive the level of browning.

●

Place roast joints on racks.The pores of the joint will be closed from

all sides, the joints do not have to be turned over.

●

Place a drip tray underneath the rack holding the joints for gravy or

drippings. Place bones, roast vegetables and seasonings in the drip

tray and pour water or stock over them.

3.5.3 Convection

The Convection cooking mode is especially suitable for products that

don't need any additional humidity.

●

Benefits

Large capacity.

●

Even cooking results thanks to auto-reverse fan.

Operating manual20

Global Foodservice Solutions

Page 21

SmartCombi

Tips

3.5.4 Perfection (climate and regeneration)

™

Construction and function

●

Up to 95 % less fat required as with other cooking modes.

●

Preheat unit for at least 10–15 minutes.

●

Food starts to brown at a cooking chamber temperature of 120 °C

(248 °F) and above.

The higher the set cooking chamber temperature, the greater the

food's weight loss but the more intensive the level of browning.

●

To produce crumbed dishes, use convenience products that are

suitable for convection or crumbed products with browning fats.

With the perfection cooking mode, food can be regenerated in perfect

quality on plates, platters or in GN containers.

Benefits

Tips

●

Production and presentation of meals in quiet, slack periods: for

banquets, you can regenerate as many plates as you wish on

demand.

●

No loss of quality due to keeping prepared meals warm.

●

Optimal cooking chamber climate: the food does not dry out.

●

No condensation or dry edges on the plates.

●

Preheat the unit then fill it quickly. In this way, the prewarmed air

remains in the cooking chamber.

●

Large thick foods such as dumplings, roulades or casseroles need

more time to regenerate: slice up thick components.

●

Individually arrange meal components evenly on the plate. Keep

overlaps to a minimum and avoid different heights when arranging.

●

Only add sauces to the plates after regeneration is completed.

●

Place fish and meat on a raised bed so that they will be regenerated

evenly and not stick to the plate.

●

Meat should be pre-cooked precisely to the minute if it is to be

served medium after regenerating.

●

Season vegetables, rice and pasta and add fat before regenerating.

●

Use thermo covers and multiple banquet trolleys if the meals are

to be transported over a long distance and for large banquets.

Warm the thermo covers before use.

Plates can only be kept warm for a maximum of 20 minutes.

Regenerate further batches during this time: in this way you can

serve the meals to your guests at the same time.

●

To reduce cooking time, use portioned GN containers with lids for

regenerating foods that are already portioned.

●

Regeneration time and regeneration temperature are dependent

on the number of plates (see table “Plate capacities” and table

“Regeneration temperatures and times”).

Global Foodservice Solutions

21Operating manual

Page 22

Construction and function

SmartCombi

™

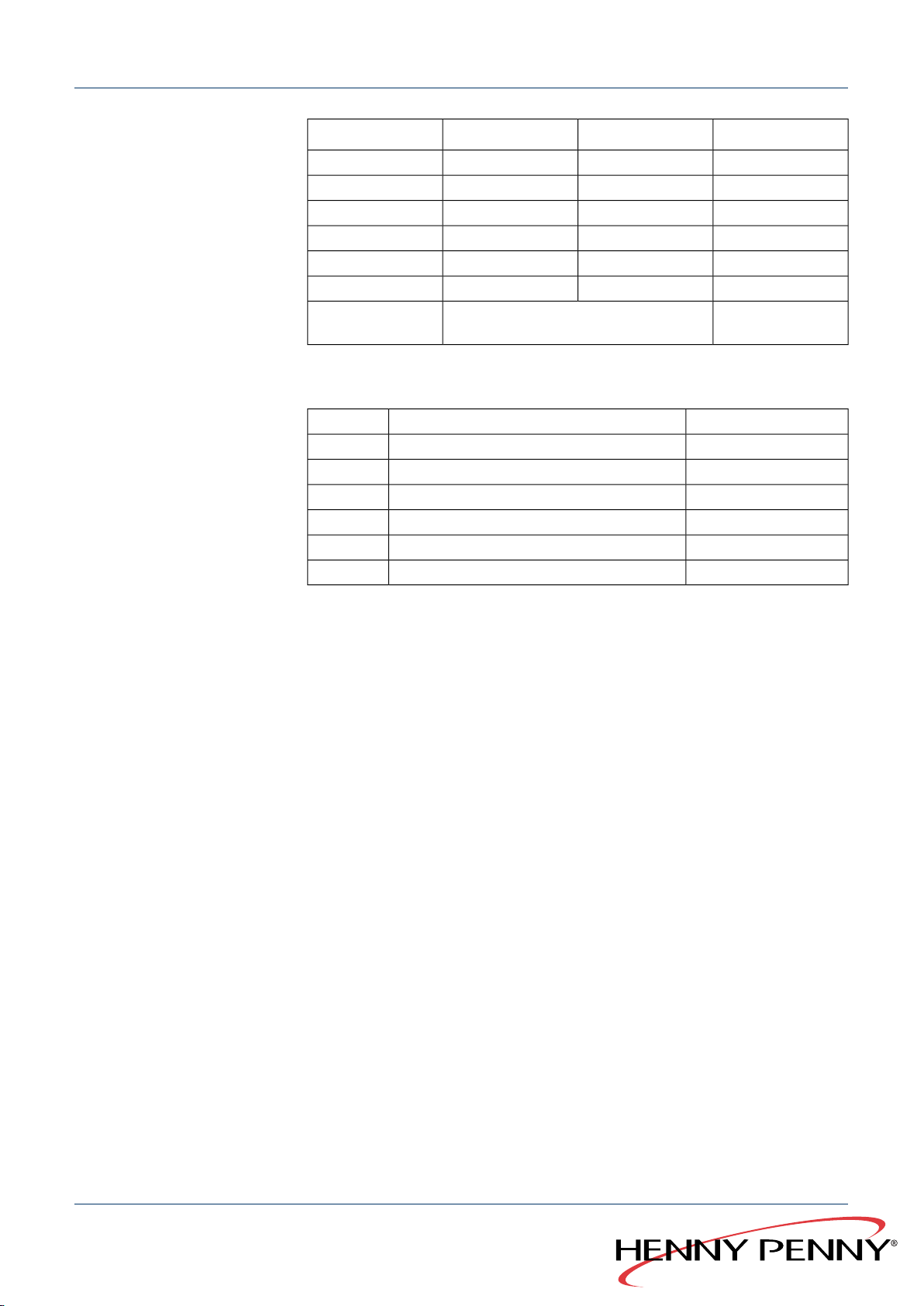

Size

On slide-in racks (1/1 unit with special

FlexiRack racks)

Table 1: Plate capacities

∅ 32 cm (12.6")∅ 28 cm (11")∅ 26 cm (10.2")

222430615

222430620

404050115

404050120

8080100215

80120120220

(plate rack frame or

rack trolley)

Regeneration timeRegeneration temperatureSize

4–8 minutes120 °C (248 °F)–130 °C (266 °F)615

4–8 minutes120 °C (248 °F)–130 °C (266 °F)620

4–8 minutes120 °C (248 °F)–130 °C (266 °F)115

4–8 minutes120 °C (248 °F)–130 °C (266 °F)120

6–10 minutes120 °C (248 °F)–130 °C (266 °F)215

6–10 minutes120 °C (248 °F)–130 °C (266 °F)220

Table 2: Regeneration temperatures and times

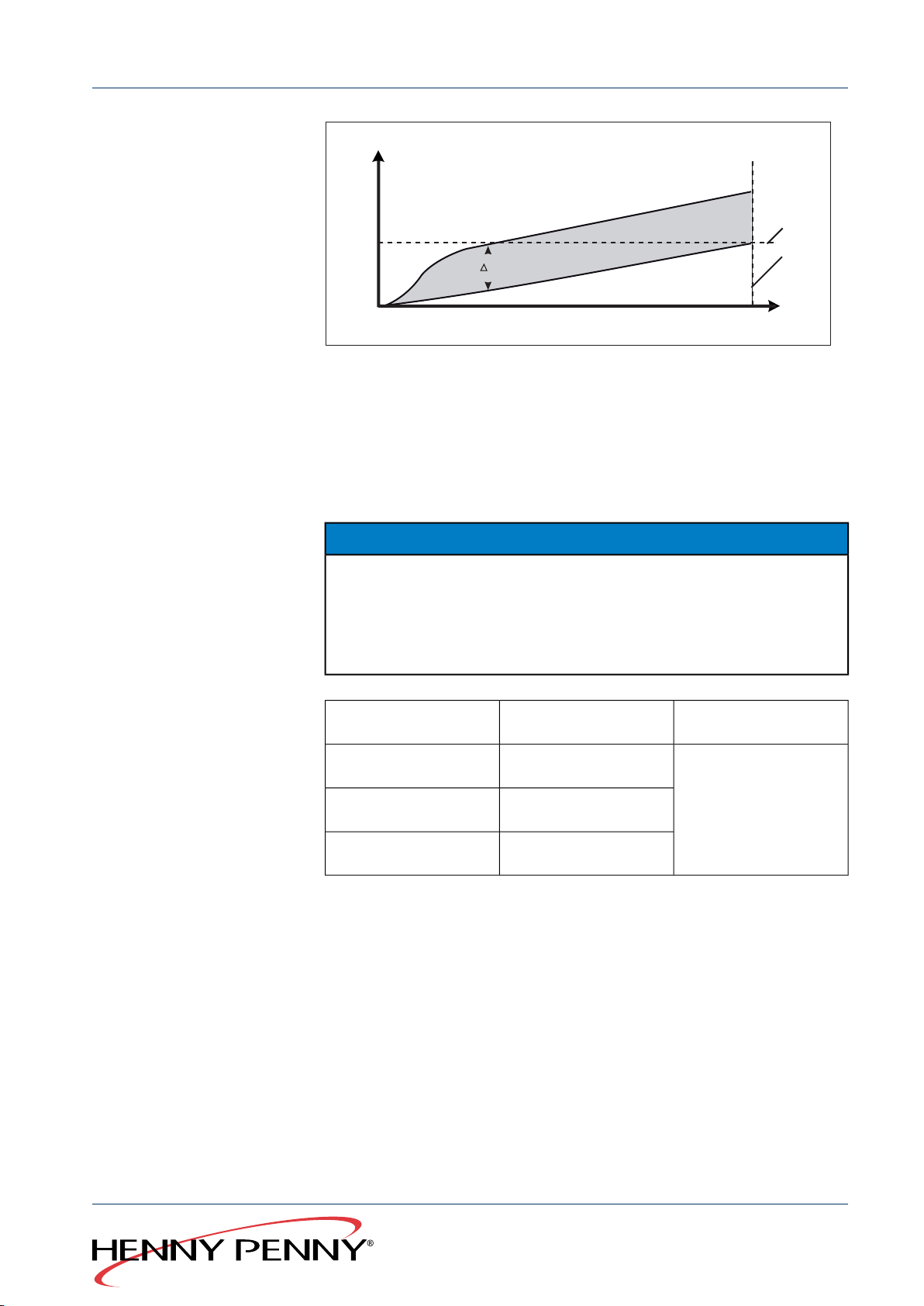

3.5.5 Delta-T cooking

With Delta-T cooking, the cooking temperature depends on the core

temperature of the food being cooked. Cooking times with Delta-T cooking

are longer than with other cooking modes.You can make good use of

slack periods by using the additional “preset start time” function.

With Delta-T cooking, the cooking temperature is always higher than the

actual core temperature of the food being cooked.This difference is a

previously set value (Delta-T value).

The formula is:

current core temperature + Delta-T value = cooking temperature

Since the core temperature of the food being cooked is needed, you must

use the core temperature sensor with Delta-T cooking.

Operating manual22

Global Foodservice Solutions

Page 23

SmartCombi

™

Construction and function

T

1

T

t

0

Timet

0

1

Delta-T value

ΔT

Target core temperature1Cooking process beginst

Target core temperature

2Cooking process endst

2

t

t

1

reached

TemperatureT

NOTICE

The higher the cooking temperature, the greater the food's weight

loss but the more intensive the level of browning.

The Delta-T value should always be at least 10 °C (50 °F) to avoid

very long cooking times.

Delta-T valueCooking mode

Steaming

Combisteaming

Convection

Table 3: Possible Delta-T values, depending on cooking mode

1 °C (33.8 °F)–31 °C

(87.8 °F)

1 °C (33.8 °F)–151 °C

(303.8 °F)

1 °C (33.8 °F)–201 °C

(393.8 °F)

Target core temperat-

21 °C (69.8 °F)–99 °C

(210.2 °F)

ure

Global Foodservice Solutions

23Operating manual

Page 24

Construction and function

Roast beef

Fillet of beef

Roast veal

Neck of pork

Boiled ham

Table 4: Recommended cooking temperatures for large roasting joints

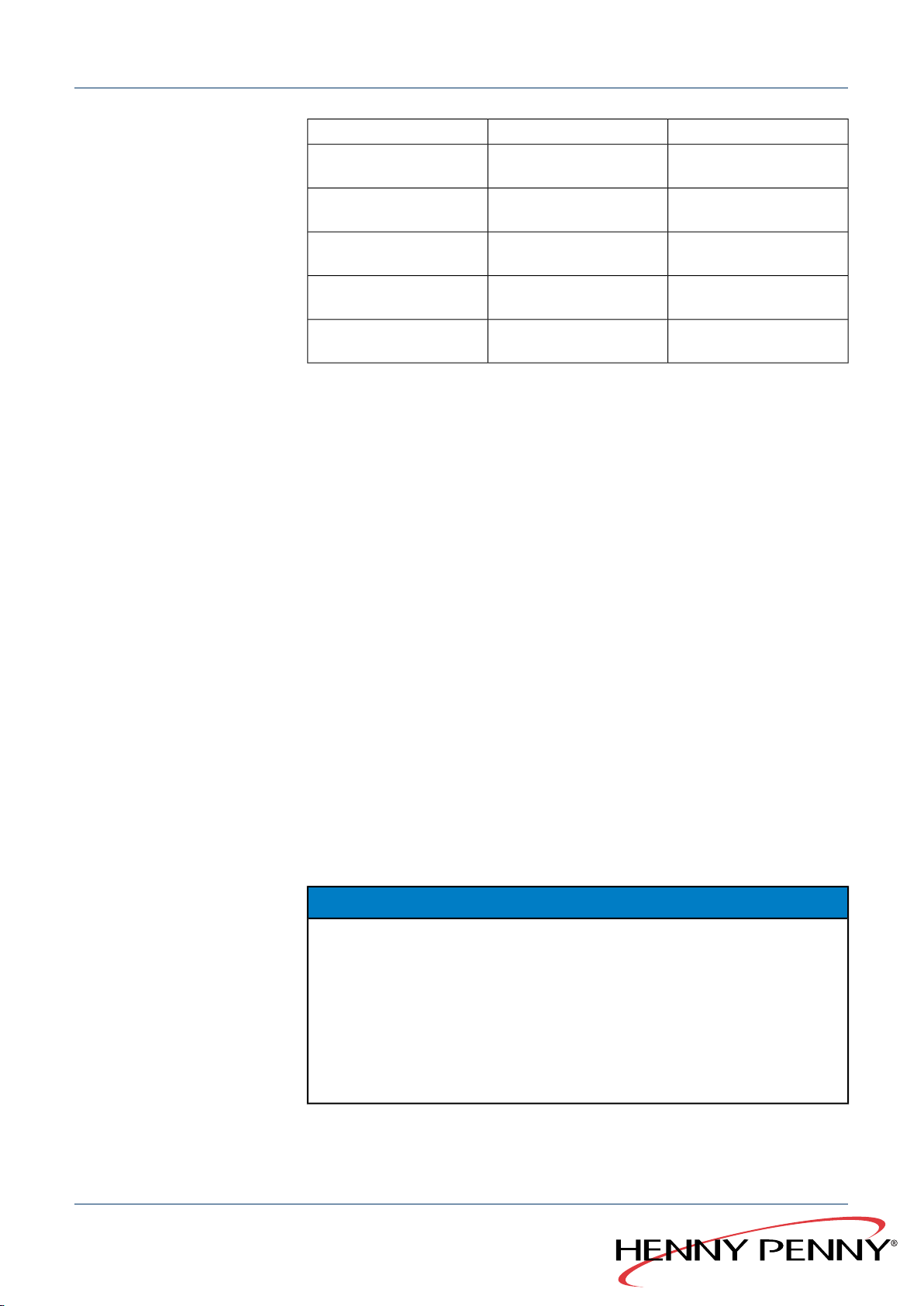

3.5.6 Low temperature cooking

The Low temperature cooking mode is especially suitable for dark

meats.

SmartCombi

50 °C (122 °F)–55 °C

(131 °F)

50 °C (122 °F)–60 °C

(140 °F)

(158 °F)

(158 °F)

(140 °F)

™

Target core temperatureDelta-T valueLarge roasting joint

48 °C (118.4 °F)–58 °C

(136.4 °F)

50 °C (122 °F)–60 °C

(140 °F)

78 °C (172.4 °F)50 °C (122 °F)–70 °C

78 °C (172.4 °F)50 °C (122 °F)–70 °C

78 °C (172.4 °F)50 °C (122 °F)–60 °C

The raw weight of large roasting joints is almost fully retained thanks to

the especially gentle cooking process (temperature range of60 °C

(140 °F)–100 °C (212 °F)); cooking losses are minimal.

To avoid crusts forming, the AtmosControl climate control system

optimises the cooking chamber climate and the fan operates in cycle

mode.

The benefits are:

●

Reduced dehydration

●

Even cooking

●

Reduced crust formation

To obtain a crisp crust, sear with higher temperatures in a previous

cooking step.

●

Food can be kept warm without the surface becoming dry.

Low temperature cooking consists of two cooking steps: searing and the

actual low-temperature cooking step.

NOTICE

The chamber temperature should be only slightly, but at least 5 °C (41

°F), above the target core temperature for the food to be cooked. If the

difference between chamber temperature and core temperature is less

than 5 °C (41 °F), it is possible that the target core temperature will not

be reached.

The higher the cooking chamber temperature, the greater the food's

cooking loss but the more intensive the level of browning.

Operating manual24

Global Foodservice Solutions

Page 25

SmartCombi

™

Construction and function

Low temperature cooking

without core temperature

measurement

Large roasting

joint

Table 5: Recommended cooking temperatures for large roasting joints

Target core tem-

perature

ature

60 °C (140 °F)55 °C (131 °F)Roast beef

80 °C (176 °F)75 °C (167 °F)Roast pork

75 °C (167 °F)70 °C (158 °F)Roast veal

80 °C (176 °F)75 °C (167 °F)Roast lamb

Cooking stepsChamber temper-

Convection or

1.

combisteaming

Low temperat-

2.

ure cooking

Low temperature cooking is possible with or without core temperature

measurement.

When using low temperature cooking without core temperature

measurement, the unit switches to low temperature cooking from the

first cooking step as soon as the set cooking temperature is reached.

T

1

2

Low temperature cooking

with core temperature

measurement

t

t

1

0

Chamber temperature1

Cooking temperature2

t

2

2

t

3

t

3

1st cooking step is endedt

2nd cooking step is ended

t

t

4

Food is ready to serve

Startt

0

Cooking chamber preheatedt

1

Maximum keep-warm periodt

4

When using low temperature cooking with core temperature

measurement, the unit switches to low temperature cooking from the

first cooking step as soon as 80 % of the target core temperature is

reached.

Global Foodservice Solutions

25Operating manual

Page 26

Construction and function

SmartCombi

T

1

2

™

t

t

1

0

Chamber temperature1

Core temperature2

t

2

2

t

3

t

3

1st cooking step is endedt

2nd cooking step is ended

Food is ready to serve

Startt

0

Cooking chamber preheatedt

1

Maximum keep-warm periodt

4

3.6 Advanced cooking functions

3.6.1 Programmable steaming

The programmable steaming advanced function, is primarily used for

baking dough that requires high levels of humidity in the cooking chamber

before the baking phase starts.

t

t

4

3.6.2 Manual steaming

The manual steaming advanced cooking function lets you increase the

humidity in the cooking chamber during operation.

Manual steaming is possible during operation with all cooking modes

apart from steaming.

3.6.3 Rest period

With the rest period advanced cooking function, you can specify a period

during which the fan is inactive.

This function is primarily used following programmed steaming to allow

the steaming process to take effect.

3.6.4 Preset start time

The delay period before a program starts can be set with the preset start

time function.

Operating manual26

Global Foodservice Solutions

Page 27

SmartCombi

3.6.5 Ready2Cook (prepare for cooking)

™

Construction and function

This lets you prepare the food, fill the unit and select the program that

you want long before the cooking process is to begin.

Bottlenecks in producing and preparing dishes can be avoided in this

way.

NOTICE

When using the preset start time feature, temperatures may occur in

the cooking chamber that encourage the growth of harmful germs on

the food to be cooked.

Observe the provisions governing foodstuffs.

The right starting conditions are important for many programs (e. g.

baking).

The advanced function Ready2Cook heats if the cooking chamber is

too cold, cools if it is too hot and prepares the cooking climate for

cooking.

NOTICE

The function can be started manually if necessary.

3.6.6 RackControl

If products with different cooking times, such as potatoes, cauliflower,

peas, carrots and meat are to be cooked in one process or if the same

meals are to be cooked at different times, the advanced function

RackControl allows you to monitor up to 5 different cooking times.

When a cooking time is reached a short signal sounds and the food

that is ready can be removed.

The cooking process is not interrupted by this (continuous operation).

“RackControl” is especially useful when regenerating plate dishes

(“perfection”). The cooking times of several plate dishes can be

monitored thanks to continuous operation.

3.6.7 Reduced heat output

Global Foodservice Solutions

The advanced cooking function Reduced heat output lowers the unit's

output and enables output peaks in the power supply to be reduced.

●

With tabletop units: A heating circuit is deactivated.

●

With floor standing units: The lower chamber is turned off.

The function is suitable for:

27Operating manual

Page 28

Construction and function

●

●

●

3.7 Add functions

With the add functions, individual cooking steps can be adjusted to suit

the food being cooked, in order to further optimise the cooking result.

The following add functions are available.

●

●

●

●

SmartCombi

™

Cooking large roasting joints

Low temperature cooking

Cooking small loads

NOTICE

The reduced heat output increases the cooking time. For this reason,

the function is not suitable for the “Perfection” (climate and regeneration)

cooking mode.

SES steam exhaust system

Cycle fan operation

Reduced fan speed

End of step signal

3.7.1 SES steam exhaust system

The unit is equipped with a safety steam extraction system. The SES

steam exhaust system extracts the steam from the cooking chamber

and condenses it at the end of the cooking time.

This avoids annoying clouds of steam escaping from the cooking chamber

when opening the door after cooking has finished. The function has no

effect on the cooking results.

The function is activated as default for all cooking programs longer than

6 minutes.

There is an add function allowing you to turn off the SES steam exhaust

system.

3.7.2 Cycle fan operation

With the add function cycle fan operation, the fan operates in interval

mode.

The function can be combined with the add function “reduced fan speed”

in order to obtain 6 different fan speeds in the cooking chamber.

3.7.3 Reduced fan speed

The add function reduced fan speed lets you reduce the air circulation

in the cooking chamber, in several stages, for dishes that are easily

Operating manual28

Global Foodservice Solutions

Page 29

SmartCombi

3.7.4 End of step signal

™

Construction and function

damaged by a strong air flow, such as soufflé. meringue, sponges,

cream puffs or flaky pastry.

With the add function end of step signal, a signal can be activated for

each step of a multi-step cooking program. It signalises that some

action is to be taken e.g. “turn the roast”.

A signal sounds for 10 seconds at the end of the cooking step (cooking

time/target core temperature reached).

The next cooking step starts immediately. The next cooking step is not

delayed because of the signal.

The end of step signal is activated as default for the last cooking step

of a program.

3.8 AtmosControl climate control system

The humidity in the cooking chamber can be set from 0−100 % in 10 %

steps with the active humidifying and dehumidifying function of the

AtmosControl climate control system.

By setting a value under 100%, you can dehumidify the cooking

chamber to achieve crisp cooking results for foods containing a lot of

water. The excess steam is extracted from the cooking chamber and

condensed.

3.9 Core temperature measurement

With core temperature measurement, the temperature in the inner

of the food being cooked is measured with a sensor.

The cooking process is ended automatically as soon as the target core

temperature is reached.

Core temperature measurement offers the following benefits:

●

Energy and water consumption is lower

●

No overcooking

●

The food loses less weight

●

High HACCP safety levels

3.10 HACCP log

Global Foodservice Solutions

Core temperature values are summarized in individual hourly blocks

for the HACCP log. This data is then printed or transferred to a PC as

a text file.

29Operating manual

Page 30

Construction and function

Serial no.: 01234567

Unit type: 6.1

Date of print: 23.06.2008

Abbrev. CM=cooking mode, S=steaming

CS=combi steaming, HC=convection

CT= core temperature

Program: Knuckle (of pork)

Cooking date:19.06.2008 8:59 End: 10:38

Cooking time: 1:39

Temp Time

No. CM Min, Max CT set act.

1 S 96, 133 - 1:00 0:49

2 CS 99, 99 75 - 0:00

3 CS 99, 161 85 - 0:11

4 CS 157, 179 90 - 0:06

5 HC 179, 199 95 - 0:27

core temp. values

8:59 45, 25, 30, 38, 45, 52 5min.

58, 62, 68, 72, 75, 78 5min.

9:58 82, 84, 89, 92, 93, 94 5min.

94, 95 5min.

Door opened.

SmartCombi

1

2

3

™

Figure 5: HACCP log (example)

1 See the following table for an explanation of the abbreviations

2 Query interval

3 Special event

ExplanationAbbreviation

Number of the cooking stepNo.

Cooking modeCM

Minimum cooking temperature during this cooking stepMin

Maximum cooking temperature during this cooking stepMax

Target core temperatureCT

Set target timeSet

Act.

Table 6: HACCP log abbreviations

Period over which the cooking temperature was maintained

Time in which the target core temperature was reached

Operating manual30

Global Foodservice Solutions

Page 31

SmartCombi

3.11 “WaveClean” automatic cleaning system

3.12 USB interface

™

Construction and function

WaveClean is an automatic cleaning system, which cleans and rinses

the cooking chamber automatically.

NOTICE

You can find notes on operating the optional PC software on the

software installation CD.

Henny Penny-combination steamers of the “SmartCombi” and

“SpaceSaver PLUS” versions are equipped with a USB 2.0 interface.

Using a USB stick enables you to copy SmartMenu cooking programs

you have made onto other devices. HACCP logs and error messages

can also be archived in this way.

File names may only be up to 8 characters long followed by an

extension. Longer file names are shortened and receive an additional

serial number, e.g.“COOKBO~1.CSP” instead of “COOKBOOK.CSP”.

File names consist of the device no. and the file name extension:

●

“HAC” for HACCP logs, e.g. “12345678.HAC”

●

“CSP” for SmartMenu cooking programs, e.g. “12345678.CSP”

●

“DIA” for error messages, e.g. “12345678.DIA”

Global Foodservice Solutions

31Operating manual

Page 32

Operation

SmartCombi

4 Operation

4.1 Opening and closing cooking chamber door (tabletop units)

4.1.1 Opening the cooking chamber door

1. Turn the door handle to the side.

The cooking chamber door will open.

2. Open the chamber door wide.

™

If you let go of the door handle, it will return to the starting position.

4.1.2 Closing the cooking chamber door

1. Turn the door handle downwards.

2. Push the door closed.

The door of the cooking chamber is closed.

Operating manual32

Global Foodservice Solutions

Page 33

SmartCombi

4.2 Opening and closing cooking chamber

4.2.1 Opening the cooking chamber door

™

Operation

door (floor standing units)

1. Turn door handle to horizontal.

The cooking chamber door will open but remain engaged.

2. Turn the door handle further upwards.

The door will disengage.

3. Let the door handle spring back to horizontal and open the chamber

door wide.

4.2.2 Closing the cooking chamber door

1. Position the door handle horizontally.

2. Close the door with the door handle horizontal.

3. Turn the door handle downwards.

The door of the cooking chamber is closed.

Global Foodservice Solutions

33Operating manual

Page 34

Operation

4.3 Filling and emptying the unit (tabletop unit)

4.3.1 Filling and emptying the unit (with loading trolley)

Requirements Suspension frame is removed

Check that food racks are correctly positioned in the suspension frames

NOTICE

This section describes the process of filling/emptying with a loading

trolley (optional accessory).

CAUTION

Risk of burns due to hot liquids

→

Only use the correct racks: The racks must lie safely on the

supporting brackets.

→

Always push the racks into the U-shaped runners.

→

Do not push in containers with liquids to be cooked above eye-level.

SmartCombi

™

Figure 6: Filling/emptying with loading trolley

1. Open the chamber door.

2. Mount the push-in frame on the bolts.

3. Rotate the lever (2).

The rack frame is secured against rolling off.

3

2

1

Operating manual34

Global Foodservice Solutions

Page 35

SmartCombi

™

Operation

4. Push the loading trolley (1) close to the unit.

5. Rotate the lever (2).

Catch of the rack frame is released.

Loading trolley is secured against rolling away.

6. Check the catch of the loading trolley by pulling lightly.

7. Push in the rack frame (3) until the wheels click into the opening

of the slide-in frame.

8. Rotate the lever (2).

The catch of the rack frame is released.

9. Push the loading trolley (1) away from the unit.

10. Close chamber door.

11. Start cooking process.

12. Open the chamber door and leave it slightly ajar until the next use.

This will increase the life of the door seal.

No moisture will build up in the chamber.

13. Empty completely after cooking is finished.

14. Remove all scraps of food from the outlet filter when emptying.

4.3.2 Filling and emptying the unit (without loading trolley)

CAUTION

Risk of burns due to hot liquids

→

Only use the correct racks.

→

Do not push in containers with liquids to be cooked above

eye-level.

1. Open the chamber door.

2. Slide racks into the suspension frame.

3. Close chamber door.

Global Foodservice Solutions

4. Start cooking process.

5. Open the chamber door and leave it slightly ajar until the next use.

This will increase the life of the door seal.

No moisture will build up in the chamber.

6. Remove racks.

7. Remove all scraps of food from the outlet filter when emptying.

35Operating manual

Page 36

Operation

SmartCombi

4.4 Filling and emptying the unit (floor standing units)

Requirements Check that food racks are correctly positioned in the trolley

CAUTION

Risk of burns due to hot liquids

→

Only use the correct racks: The racks must lie safely on the

supporting brackets.

→

Always push the racks into the U-shaped runners.

→

Do not insert containers with liquids to be cooked above eye-level.

1. Load trolley.

2. Push in trolley completely.

3. Close the chamber door.

™

4.5 Switch on/switch off unit

4.5.1 Switching on

Requirements Supply lines have been checked.

12. 08. 2008 13:32

4. Start the cooking process.

5. Open the chamber door and leave it slightly ajar until the next use.

This will increase the life of the door seal.

No moisture will build up in the cooking chamber.

6. Empty completely after cooking is finished.

7. Remove all scraps of food from the drain sieve when emptying.

→

Press On /O ff ( 1) .

On /O ff ( 1) is lit.

The multi-function display (4) shows the start screen.

Unit is switched on.

Menu RackCont.

ΔT/LTC/...

4.5.2 Switching off

Requirements Current program is completed.

→

Press On /O ff (1).

Unit is switched off.

Operating manual36

Global Foodservice Solutions

Page 37

SmartCombi

4.6 Working with the CombiDial

™

Operation

NOTICE

Open out the cover page to see the controls.

1. Turn the Co mb iD ial (9) to select menu items or values.

2. Press Co mb iD ial (9) to confirm the selection.

4.7 Basic functions

4.7.1 Changing the language

Requirements Unit is switched on

1. Press the left select button (13) to open the menu.

2. Use CombiDial (9) to select the “Settings” menu.

3. Press the right select button (6).

4. Select the desired language with Co mb iD ial (9).

5. Press the right select button (6) to save the settings.

4.7.2 Call up the setup menu and change parameters

Requirements Unit is switched on

1. Press the left select button (13) to open the menu.

2. Use CombiDial (9) to select the “Settings” menu.

Global Foodservice Solutions

37Operating manual

Page 38

Operation

SmartCombi

3. Press Co mb iD ial (9) to open the menu.

The multi-function display (4) shows “Password” and “000”.

4. Use CombiDial (9) to enter the password “111”.

5. Press St ar t /S top (8).

The multi-function display (4) shows the first parameter “Time/Date” with

the parameter number “000”.

6. Select the parameter using Co m b i D ial (9).

7. Set the parameter to the desired value with Com bi Dial (9).

8. Press the right select button (6) to save the settings.

The display changes back to the parameter list.

9. Press the left select button (13) to exit the menu.

4.7.3 Displaying actual temperature values

™

Requirements Unit is switched on

Steaming

100 C 0: 00

More

functions

Home

The current cooking temperature can be displayed during operation.

→

Hold Cooking temperature (12) pressed for about 3 seconds.

The multi-function display (4) shows the current cooking temperature for

8 seconds. The target temperature is then shown again.

4.7.4 Set the cooking temperature

1. Press the cooking mode button.

01/

01

The multi-function display (4) shows the preset cooking temperature and

the cooking time.

2. Set the cooking temperature with Co mb i D ial (9).

4.7.5 Setting the cooking time

NOTICE

Minimum: 1 minute.

Maximum: 23 hours, 59 minutes.

Operating manual38

Global Foodservice Solutions

Page 39

SmartCombi

4.7.6 AtmosControl climate control system (set chamber

™

Operation

1. Press Co mb iD ial (9) to switch to entering the cooking time.

2. Set the time with Co mb iD ial (9).

3. For continuous operation: With a time display of “0:00”, turn

CombiDial (9) to the left and hold for 3 seconds.

The time display changes to “– –”.

humidity)

The cooking chamber humidity currently set is shown in the Info monitor

(18).

NOTICE

After selecting the cooking mode, the standard settings for this cooking

mode are shown in the Info monitor (18).

120 °C

60 °C

120 °C

60 °C

40 °C

→

Set the chamber humidity with set button (16) or set button

(17)

4.7.7 Measuring the core temperature

DANGER

Risk of injury due to the sensor bursting.

The probe tip may burst if it becomes overheated.

→

Never heat sensors with a lighter or other source of heat.

NOTICE

Use core temperature measurement with all programs if possible.

The sensor measures the core temperature at four points; the coldest

point measured is used for controlling the cooking process.This means

that the tip of the sensor may be positioned somewhat away from the

core of the food to be cooked.

●

Insert the sensor into the food to be cooked at the thickest point.

●

For roasting cuts with bone (e.g. cutlets), insert the sensor close

to the bone.

●

With long roasts (e.g. sides of pork), insert the sensor crosswise

in order to avoid a hole in the middle of the slices when cutting.

●

With poultry, insert the sensor in the inner side of the thigh.

Global Foodservice Solutions

39Operating manual

Page 40

Operation

1. If possible, thaw frozen food before cooking.

2. Insert the sensor into the food to be cooked.

3. Place the food with the sensor in the middle of the cooking chamber.

4.7.8 Connecting the USB memory stick

Requirements A suitable USB memory stick is available.

NOTICE

Use an extension cable for USB memory sticks which cannot be

connected to the interface due to their size.

1. Open the black cap under the switch cover.

2. Insert the USB memory stick with the opening to the rear.

The USB memory stick is ready to use after about 5 seconds.

SmartCombi

™

The USB memory stick is connected.

4.7.9 Saving the HACCP log

Requirements The USB memory stick is connected.

The device stores up to 200 HACCP logs, depending on the number of

program steps.

HACCP logs can be saved via the USB interface with a USB memory

stick.

1. Press the left button (13) to open the menu.

2. Press Co mb iD ial (9) to select the “HACCP” menu.

3. Press Co mb iD ial (9) (9) to select the HACCP log to be saved.

4. Press the right Select button (6) briefly to save the selected HACCP

log.

or

→

Press and hold down the right Select button (6) to save all HACCP

logs from the one selected through to the latest HACCP log (daily or

weekly overview).

The HACCP log is saved on the USB memory stick.

While it is saving, the multi-function display (4) flashes “Please wait” on

the screen.

Operating manual40

Global Foodservice Solutions

Page 41

SmartCombi

4.7.10 Saving error messages

Requirements The USB memory stick is connected.

™

Operation

Once it has been saved, the multi-function display (4) flashes

“Complete” on the screen.

NOTICE

If a file of the same name is already on the USB memory stick, the

new HACCP logs will be attached.

Error messages which occurred during operation can be saved on a

USB memory stick.

Error message

01.05.2009 10:30

No water

Back

01.05.2009 10:30

finished

Back

} USB

000

1. Press the left button (13) to open the menu.

2. Press Co mb iD ial (9) to select the “Diagnosis” menu.

Multi-function display (4) shows the latest error message.

3. Press the right button (6) to save the error messages.

Error messages are saved on the USB memory stick.

While it is saving, the Multi-function display (4) flashes “Please wait”

on the screen.

Once it has been saved, the multi-function display (4) shows

“Complete” on the screen.

NOTICE

If a file of the same name is already on the USB memory stick, it will

be overwritten.

4.8 SmartMenu (automatic cooking)

4.8.1 Selecting the cooking program

Global Foodservice Solutions

1. Switch on the unit.

2. Press Sm ar t Me nu ( 2 ).

The multi-function display (4) shows the SmartMenu cooking categories.

41Operating manual

Page 42

Operation

SmartCombi

-

Meat (steak, roast pork)

-

Poultry (chicken, turkey)

-

Fish (perch fillet, trout)

-

Vegetables, side dishes (carrots, mushrooms, potatoes)

-

Bakery products (bread, croissants)

-

Overnight cooking (core temperature cooking, low temperature

cooking)

-

MyChef Special (individual programs and programs that can not be

assigned to other categories)

-

Perfection (plate dishes, banquets)

-

Cookbook (contains all cooking programs)

3. Using Co mb iD ial (9), select the SmartMenu cooking category.

™

Cauliflower, fresh

Beans, green

Fried potatoes

Prior

Programs

Delete

Program

01/

02

The list is in alphabetical order; the first program flashes.

4. Select the cooking program with Com bi Dial (9).

The multi-function display (4) shows the name of the cooking program,

the number of program steps and the respective values for temperature

and cooking time.

31

2

Fried potatoes

Combisteaming

01/

02

170 C 0: 30

More

Functions

1 Name of the program

2 Total number of program steps

3 Current program step

4 Cooking time or core temperature for the program step

5 Cooking mode for the current program step

Home

465

6 Target temperature for the current program step

4.8.2 Starting the cooking program

→

Select the cooking program with one of the following buttons:

- Start/Stop (8)

- Ready2Cook (10)

- Cooking time (11) (hold pressed)

The multi-function display (4) will show the name of the program and the

cooking mode for the first cooking step.

Operating manual42

Global Foodservice Solutions

Page 43

SmartCombi

™

1 2 43

Baked ham

53 °

01/

02

78 C 60 C

Manual

Steam

56

1 Name of the program

2 Actual core temperature

3 Total number of program steps

4 Current program step

5 Target core temperature

6 Target chamber temperature

Operation

4.8.3 Ending the cooking program

The program is ended automatically after the cooking time is over or

when the core temperature is reached.

A signal sounds and the lighting in the cooking chamber flashes.

→

Press St ar t /S top (8) or open the door of the chamber to turn off

the signal.

or

→

Press St ar t/stop (8) to end the program prematurely.

4.8.4 Display last program

1. Press Sm ar t Me nu ( 2 ).

2. Press Co mb iD ial (9).

3. Press the left select button (13) to display the last cooking

program.

The programs that were last used are shown, up to a maximum of ten.

4.8.5 Changing the cooking program during operation

Global Foodservice Solutions

You can change the cooking time, cooking temperature or target core

temperature for the individual cooking steps during operation by using

the buttons Core temperature (7), Cooking time (11), Cooking

temperature (12) and Co mb iD ial (9).

43Operating manual

Page 44

Operation

1

Baked ham*

Steaming

65 C 72 C

More

functions

Home

4.8.6 Save changed program

01/

03

SmartCombi

™

NOTICE

Changes made during operation only apply to the running program and

are not adopted as default values.

1. Press Core temperature (7), Cooking time (11) or Cooking

temperature (12).

2. Change the values with Com bi Dial (9).

An asterisk (1) alongside the program name indicates that the saved

program has been modified temporarily.

Saved

NOTICE

Always save programs that you have copied and changed under a new

name.

1. Press Sm ar t Me nu ( 2 ) longer.

The program will be saved.

The multi-function display (4) shows the SmartMenu cooking categories.

2. Use CombiDial (9) to select the SmartMenu cooking category.

01/

01

4.8.7 Create your own cooking programs

The multi-function display (4) shows “Saved” for three seconds.

Then the display returns to the stand-by mode.

The unit can store up to 350 programs.

There are two ways of creating your own programs:

●

Copy an existing cooking program, make individual adjustments and

save it under a new name in the SmartMenu program memory.

●

Create a new cooking program and save it in the SmartMenu program

memory. It makes no difference whether you save a program first

and then start it or start it first and then save it.

Operating manual44

Global Foodservice Solutions

Page 45

SmartCombi

4.8.8 Entering a cooking program (example)

™

Operation

The process of creating and storing a two-step cooking program is

described using the “Baked ham” program as an example.

01/

Steaming

01

78 C 60 C

More

functions

Baked

abcdefghijklmnopqrstu

vwxyz

a } A

1 } !

Home

01/

01

Correction

1. Press Steaming (15).

2. Set the cooking temperature.

3. Set the cooking time.

4. Set the target core temperature.

Cooking temperature: 78 °C (172.4 °F), core temperature: 60 °C

(140 °F)

5. Press Co nvection (14).

6. Set the cooking temperature.

7. Set the cooking time.

8. Set the target core temperature.

Cooking temperature: 180 °C (356 °F), core temperature: 65 °C (149 °F)

9. Hold Sm ar t Me nu ( 2 ) pressed for 4 seconds.

10. Enter a name for the new program with C om bi Dial (9).

Press the left select button (13) to switch between upper and

lower case letters or for special characters.

Press the right select button (6) to correct mistakes.

11. Press Sm ar t Me nu (2 ) longer.

The program will be saved.

The multi-function display (4) shows the SmartMenu cooking categories.

The Info monitor (18) shows in text format the respective SmartMenu

cooking category that is selected.

12. Use CombiDial (9) to select the SmartMenu cooking category.

The multi-function display (4) shows “Saved” for five seconds.

4.8.9 Copying a cooking program

Each program can be modified individually.

1. Press Sm ar t Me nu ( 2 ).

The multi-function display (4) shows the SmartMenu cooking categories.

2. Use CombiDial (9) to select the SmartMenu cooking category.

Global Foodservice Solutions

45Operating manual

Page 46

Operation

SmartCombi

3. Select the cooking program with Com bi Dial (9).

™

Bread, crusty

Convection

01/

01

175 C 0: 20

More

Functions

Bread, crusty

ABCDEFGHIJKLMNOPQRSTU

VWXYZ

a } A

1 } !

Home

01/

01

Correction

4.8.10 Locking and releasing the SmartMenu program

The multi-function display (4) shows the name of the cooking program,

the number of program steps and the respective values for temperature

and cooking time.

4. Set the values for temperature and time with C om bi Dial (9).

5. Add further program steps if needed.

An asterisk appears next to the program name as soon as a change is

made.

6. Press Sm ar t Me nu ( 2 ) longer.

The program will be copied.

The multi-function display (4) shows the original program name.

7. Enter a name for the new program with C om bi Dial (9).

Press the left select button (13) to switch between upper and

lower case letters or for special characters.

Press the right select button (6) to correct mistakes.

memory

In the “Settings menu”, you can mark the SmartMenu program memory

as fully accessible or locked.

1. Press the left select button (13) to open the menu.

2. Use CombiDial (9) to select the “Settings” menu.

3. Use CombiDial (9) to enter the password “111”.

4. Use CombiDial (9) to select the “Lock program memory” menu.

Programs in the SmartMenu program memory can no longer be created,

modified or deleted.

NOTICE

Proceed as described here to release the SmartMenu program memory.

Operating manual46

Global Foodservice Solutions

Page 47

SmartCombi

4.8.11 Saving SmartMenu cooking programs

Requirements The USB memory stick is connected.

™

Operation

CAUTION

Loss of data due to improper use

→

Only use Henny Penny software to edit SmartMenu cooking

programs

NOTICE

SmartMenu cooking programs can be saved on a USB memory stick.

Only SmartMenu cooking programs which you have made can be

saved. Saving preinstalled cooking programs is not possible.

1. Press the left button (13) to open the menu.

6 cookbook } USB

sending cookbook

6 Cookbook } USB

finished

Requirements The USB memory stick is connected.

2. Press Co mb iD ial (9) to select the “Cookbook > USB” menu.

3. Press the right button (6) to save SmartMenu cooking programs.

SmartMenucooking programs are saved on the USB memory stick.

While it is saving, the multi-function display (4) flashes “Cookb. edition

active” on the screen.

Once it has been saved, the multi-function display (4) flashes

“Complete” on the screen.

NOTICE

If a file of the same name is already on the USB memory stick, it will

be overwritten.

4.8.12 Loading SmartMenu cooking programs

Appropriate files with SmartMenu cooking programs are already on the

USB memory stick.

Global Foodservice Solutions

SmartMenu cooking programs which have been made on other Henny

Penny-combination steamers of the “SmartCombi” or “SpaceSaver

PLUS” versions or with Henny Penny software, can be loaded from a

USB memory stick.

1. Press the left button (13) to open the menu.

2. Press Co mb iD ial (9) to select the “USB > cookbook”.

3. Press the right button (6) to open SmartMenu cooking program

files.

47Operating manual

Page 48

Operation

SmartCombi

4. Press Co mb iD ial (9) to select SmartMenu cooking programs to

load.

5. Press the right button (6) to SmartMenucooking programs.

™

7 USB } cookbook

receiving 1