Henny Penny SCE-202 Installation Manual

Operator’s Manual

All SCS Models

LIMITED WARRANTY FOR HENNY PENNY APPLIANCES

Subject to the following conditions, Henny Penny Corporation makes the following limited warranties to

the original purchaser only for Henny Penny appliances and replacement parts:

NEW EQUIPMENT:

defective in material or workmanship within two (2) years from date of original installation, will be

repaired or replaced without charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor. To

validate this warranty, the registration card for the appliance must be mailed to Henny Penny w ithin ten

(10) days after installation.

REPLACEMENT PARTS:

to be defective in material or workmanship within ninety (90) days from date of original installation

will be repaired or replaced without charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized

distributor.

The warranty for new equipment and replacement parts covers only the repair or replacement of the

defective part and does not include any labor charges for the removal and installation of any parts, travel or

other expenses incidental to the repair or replacement of a part.

EXTENDED FRYPOT WARRANTY:

or workmanship issues for a period of up to seven (7) years from date of manufacture. This warranty shall not

cover any frypot that fails due to any misuse or abuse, such as heating of the frypot without shortening.

0 TO 3 YEARS:

issues will be replaced at no charge for parts, labor, or freight. Henny Penny will either install

a new frypot at no cost or provide a new or reconditioned replacement fryer at no cost.

3 TO 7 YEARS:

issues will be replaced at no charge for the frypot only. Any freight charges and labor costs to

install the new frypot as well as the cost of any other parts replaced, such as insulation,

thermal sensors, high limits, fittings, and hardware, will be the responsibility of the owner.

Any claim must be presented to either Henny Penny or the distributor from whom the appliance was

purchased. No allowance will be granted for repairs made by anyone else without Henny Penny’s written

consent. If damage occurs during shipping, notify the sender at once so that a claim may be filed.

THE ABOVE LIMITED WARRANTY SETS FORTH THE SOLE REMEDY AGAINST HENNY

PENNY FOR ANY BREACH OF WARRANTY OR OTHER TERM. BUYER AGREES T HAT NO OTHER

REMEDY (INCLUDING CLAIMS FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES) SHALL

BE AVAILABLE.

The above limited warranty does not apply (a) to damage resulting from accident, alteration, misuse, or

abuse; (b) if the equipment’s serial number is removed or defaced; or (c) for lamps and fuses. THE ABOVE

LIMITED WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING MERCHANTABILITY AND FITNESS, AND ALL OTHER WARRANTIES ARE

EXCLUDED. HENNY PENNY NEITHER ASSUMES NOR AUT HORIZES ANY PERSON TO ASSUME

FOR IT ANY OTHER OBLIGATION OR LIABILITY.

Any part of a new appliance, except lamps and fuses, which proves to be

Any appliance replacement part, except lamps and fuses, which proves

Henny Penny will replace any frypot that fails due to manufacturing

During this time, any frypot that fails due to manufacturing or workmanship

During this time, any frypot that fails due to manufacturing or workmanship

Manual

SmartCooking System

Warning:

Incorrect installation, adjustment, servicing, maintenance, cleaning, or

unauthorized modifications to the appliance can result in damage, injury

or death. Read the Operating Manual carefully before starting to use the

appliance.

For your safety:

Do not store or use any flammable gases or liquids near this appliance.

What to do in the event of danger or if you smell gas:

- Shut off the gas supply immediately

- Do not touch any electric control elements

- Make sure the area is well ventilated

- Avoid open flames or sparking

- Use an external telephone to notify the appropriate gas supplier

(if the gas supplier is unobtainable call the relevant fire station).

TM

RESET GAS

“RESET” (gas appliances only)

If the burner function is faulty, "RESET GAS" will appear on the display.

After 15 sec. you will hear an audible signal. Press the "RESET GAS" display to re-start the automatic ignition process. If the "RESET GAS" display does not light up again after approximately 15 seconds, the flame is

burning and the appliance is operational.

Please notify Customer Support if “RESET GAS” is still displayed after

repeated pressing!

- 2 -

Dear Customer

Congratulations on your new SmartCooking System

entered a new era in cooking. Thanks to a readily understandable visual control concept you and your

SmartCooking System

TM

will achieve excellent results quickly, with very little time or expense in training. Just

TM

. By purchasing a SmartCooking System

press a button to select the desired food item and how you want it cooked – that’s it! There is no longer

any need for traditional inputs such as temperature, time and humidity or complicated programming and

constant monitoring. Of course the SmartCooking System

TM

also provides the versatile capabilities of a perfect Combi-steamer. Thanks to the easy-to-understand control concept you can use Programming Mode to

create your own tailor-made cooking programs in practically no time. You’ll enjoy the peace of mind of a12

month warranty from the date of invoice. The warranty excludes glass damage, light bulbs and sealing

material as well as damage caused by improper installation, use, maintenance, repair or deliming. We recommend that you study the manual thoroughly so that you can make the best possible use of the wide

variety of applications and benefits offered by your SmartCooking System

TM

.

TM

you have

TM

And now enjoy your new SmartCooking System

.

Your Authorized Henny Penny Distributor

Call Customer Service 1-937-456-8400 for any questions or problems in operating your unit.

Henny Penny reserves the right to make technical changes in the interest of progress!

As of August 16, 2005, the Waste Electrical and Electronic Equipment directive went into

effect for the European Union. Our products have been evaluated to the WEEE directive.

We have also reviewed our products to determine if they comply with the Restriction of

Hazardous Substances directive (RoHS) and have redesigned our products as needed in

order to comply. To continue compliance with these directives, this unit must not be

disposed as unsorted municipal waste. For proper disposal, please contact your nearest

Henny Penny distributor.

- 3-

Contents

General Instructions / For Your Safety 6

Features 11

General User Instructions 12

SelfCooking ControlTMMode 14

Controls 15

Operation 16

Combi-steamer mode 24

Controls 25

Moist heat 26

Dry heat 27

Dry heat and moist heat 28

ClimaPlus Control

Time settings, continuous operation, preheating 30

Working with the temperature probe 31

Steam Injection, Fan speed control 32

Cool down 33

Programming Mode

Controls 34

Programming SmartCooking ControlTMProcesses 35

Programming in Manual Mode 36

Program start, check, change 37

Program delete, copy 38

Level Control 39

Program lock 41

Functions

®

CleanJet

CleanJet®stop 45

CleanJet®request 46

HACCP logging 47

Delta T cooking 48

Half energy, Demand-related energy supply 49

Automatic start time 50

CalcDiagnosis System®CDS 51

®

29

42

- 4 -

Contents

Service

ChefLine®/Service Info 52

Drain steam generator 53

Model and software identification 54

Settings

Real time, time format 55

Date, temperature unit, language 56

Buzzer, Display contrast, CleanJet®request 58

Manual clean 59

CleanJet®Times and Tablet Usage 61

Fault warnings 62

Help function 64

- 5 -

General Instructions – For Your Safety

Please take the time to read the following safety

and operating instructions carefully.

Keep this manual in a convenient location so that it

is available to anyone using the equipment.

This equipment must only be used to cook food in

commercial foodservice establishments. Any other

use is not intended and is therefore considered

dangerous.

Before using the unit for cooking make sure there

are no cleaner or rinse aid tablet residues in the

cooking cabinet.

Remove any cleaner and rinse aid tablet residues

and rinse thoroughly with hand shower.

Operate using hands only. Damage caused by the

use of pointed, sharp or other objects will invalidate the warranty.

The equipment must only be used by trained personnel.

It is vital that all users be given regular safety

instruction.

We recommend that the operator gives your staff

regular training to avoid the risk of accident or

damage to the unit.

Daily checks before switching on

• Lock air baffle top and bottom.

• Lock hinged racks properly in position in the

cooking cabinet.

General

• The temperature of door glass, outer casing and

add-ons may exceed 140°F (60°C)

• Avoid having heat sources (e.g. grill plates, deep

fryers etc.) near the appliance.

• If the unit is idle for prolonged periods, shut the

water supply stop valve and turn off the

appliance power supply (gas and electricity).

When setting up table-top units with the appliance

manufacturer’s original standard stand or base

cabinet the maximum top rack working height

is 63 in. (160 cm).

WARNING – If containers are filled

with liquid or contents which liquefy during

cooking, do not use rack levels higher

than those where the user can see into

the container. Warning sticker is

enclosed with equipment.

Warning!

• Caution! Hot steam (risk of scalding)!

• Caution! Containers and grids are hot!

• Make sure the mobile oven rack is

correctly locked in position!

- 6 -

General Instructions / For Your Safety

Energy saver display

To reduce unnecessary power consumption, brightness of control panel displays is reduced during

normal operation. Display readouts will dim slightly

after the first 10 minutes and once more after an

additional 10 minutes. When a display is touched

or the cooking cabinet door is opened, the display

returns to full brightness.

If the unit is switched on for longer than 20 minutes and neither a cooking mode nor CleanJet

selected, the energy saver circuit activates automatically and only the current time of day and the date

are shown on the display.

®

is

Gas appliances only

• If a gas unit is installed under a ventilation

hood, the hood must be on when the appliance

is in use.

• If a gas unit is connected to a chimney, the flue

duct must be cleaned in compliance with

specific regional regulations. Contact your

installer for this information.

• Do not put allow objects to touch the gas unit’s

exhaust stacks.

• Gas units must be operated in a stationary

condition.

Loading/removal

Open appliance door slowly.

When door is opened heating and fan shut down

automatically.

The fan wheel brake is activated. The fan keeps run-

ning for a brief period only. Do not touch the fan

wheel.

Do not insert pans or grids until the hinged rack

has been properly secured and the mobile oven

rack has been pushed up to the stop and locked in

place.

Only use commercial-grade heatproof accessories.

Units with hinged rack (061/062/101/102)

To remove rack

Slightly raise rack unit and lift out of front catch.

Swing rack to middle of cooking cabinet.

Lift up and out of slots. To replace, set into slots

and reverse the procedure.

- 7 -

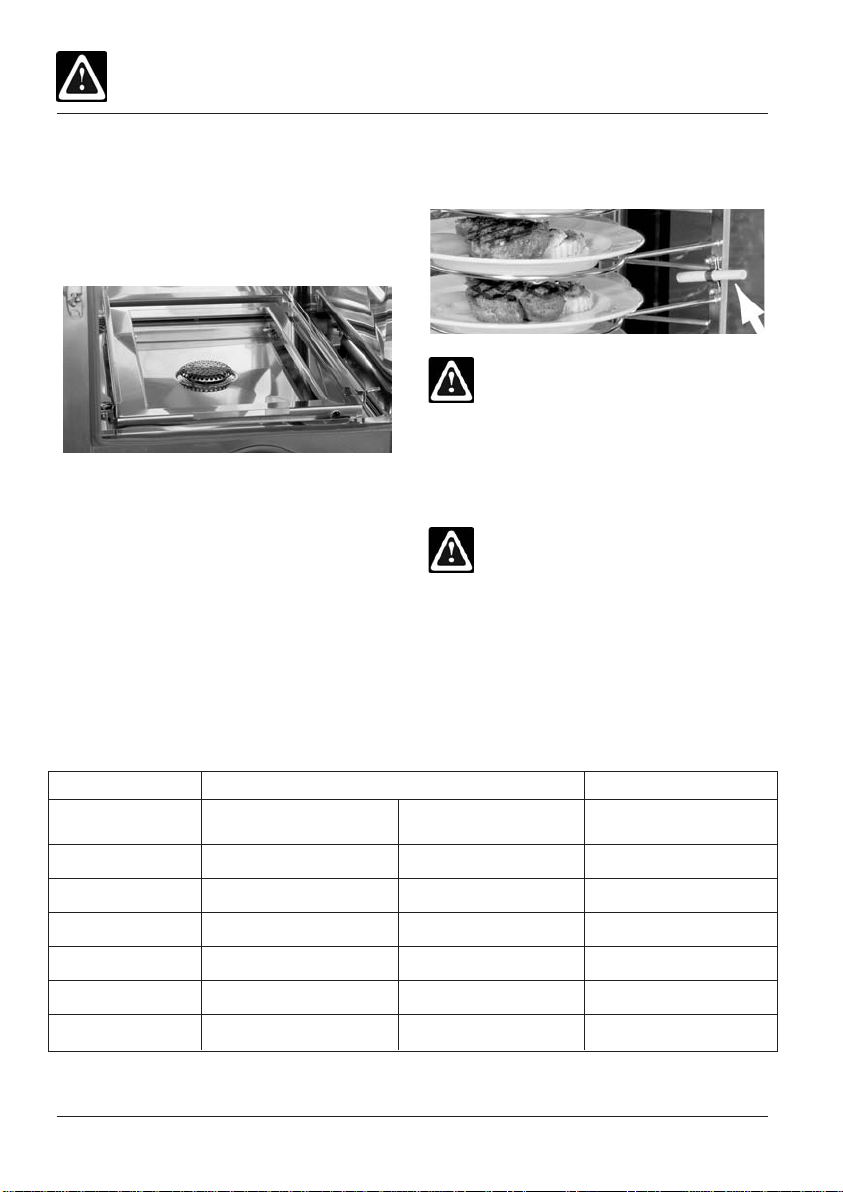

General Instructions / For Your Safety

Mobile oven rack

Working with mobile oven racks, mobile

plate racks and transport carts for

base-top units (option)

• Remove hinged rack.

• Set guide rails on cabinet floor.

• Push mobile oven rack or plate rack into cabinet

up to the stop and lock into place.

• Transport carts must be properly attached to the

unit using the holder.

• Unlock mobile oven rack or plate rack and roll

out.

• When transporting the mobile oven rack or plate

rack on the transport cart, make sure the

transport safety catch is engaged.

• Cover and secure containers with liquids to avoid

spills and the risk of scalding.

Working with mobile plate racks

When not in use make sure temperature probe is

placed in its ceramic tube holder.

Warning!

Before the mobile plate rack is removed the

temperature probe must be removed and

placed in the holding position on the run-in

rail.

Warning!

• Pans must be locked with pan locks on the

mobile oven rack!

• Mobile oven racks, mobile plate racks,

transport carts and units on casters can

tip over when being moved over an

inclined plane or threshold.

Unit size Pan capacity Max load size

Full-size steam

table pans

061 6 6x1/1 - 30 kg(15/rack)

062 12 6 6x2/1 - 60 kg(30/rack)

101 10 10x1/1 - 45 kg(15/rack)

102 20

201 20 20x1/1 - 90 kg(15/rack)

202

40

- 8 -

Full size

sheet pans

10 10x2/1 - 90 kg(30/rack)

20 20x2/1 - 180 kg(30/rack)

GN

General Instructions / For Your Safety

Low water

Low water warning may appear on the display

when you switch the unit on. It means that the

steam generator is not yet filled with water. When

filling is complete the warning display goes out

automatically.

If the display does not go out, check that the water

supply valve is open and the strainer at the water

supply (solenoid valve) is unblocked.

Ambient temperatures

If ambient temperatures drop below 35°F (5°C)

make sure the cooking cabinet has been warmed to

a temperature greater than 35°F (5°C) before

using it.

Temperature probe

• The temperature probe and temperature probe

positioning aid may be hot—use oven mitts.

• Cool temperature probe with hand shower

before use.

• Do not let temperature probe hang out of

cooking cabinet.

• Remove temperature probe before unloading

food.

Cool down

Use the "Cool Down" function to cool the cooking

cabinet .

Warning!

• During "Cool Down" the fan wheel runs

when the door is open!

• Do not switch on "Cool Down" function

unless air baffle is correctly locked.

• Do not touch the fan wheel.

• Do not attempt to cool cabinet with cold

water.

Hand shower

Pull hand shower out to use.

Press hand shower control button to select 2 jet

strengths.

Hand shower retracts automatically.

Make sure hand shower hose is fully rewound after

use.

Do not pull hand shower out beyond the end mark.

Warning!

• Hand shower and hand shower water may

be hot!

- 9 -

General Instructions / For Your Safety

Cleaning

• Hinged rack or mobile oven/plate rack must be

placed in the cooking cabinet as instructed

before starting CleanJet

TM

cleaning.

• Leave the door slightly open if the unit is going

to be idle for a prolonged period (e.g.

overnight).

• Do not clean unit with high pressure cleaner.

• Do not treat unit with acids or expose to acid

fumes —this will damage the protective layer

of stainless steel, and units may discolor.

• Follow the instructions on the cleaner pack.

• For detailed cleaning instructions, see

"CleanJet

TM

" or "Manual Cleaning” chapters.

• Only use cleaning agents available through your

authorized distributor.

Warning!

• Wear the correct protective clothing,

gloves, goggles and mask.

Deliming

• Note that the steam generator must be delimed

as required. Contact your Henny Penny

distributor.

Maintenance

• Inspection, maintenance and repair work should

only be done by trained technicians.

• The unit must be switched off during cleaning

(except CleanJet

TM

cleaning or manual/

programmed cleaning), inspections,

maintenance or repair work.

• Movement of units on casters must be

restricted so that connected power, water and

drain lines are not damaged. Before moving unit,

make sure that power, water and drainage lines

are correctly disconnected. If the unit is being

relocated or returned to its original position,

make sure that movement restriction devices,

power, water and drainage lines are properly

connected.

Servicing

• Your appliance should be serviced by an author-

ized service technician at least once a year to

ensure that it remains in perfect working order.

Warning!

• Switch the appliance off at the mains

before opening service doors or working

on live components.

- 10 -

Features

a Unit serial number

(visible only when door open)

b Exhaust diverter

(gas appliances only, optional)

c Interior lighting

d Cabinet door with double glass panel

e Door handle

Table-top units: one-handed operation with

slam function

Floor units: (One-handed operation)

f Unlocking device to open double glass

door panel

(inside)

g Integal and self-draining door drip pan

(inside)

h Drip collector connected directly to

appliance drain

i Adjustable feet

j Unit data plate

(with all important data such as power input,

gas type, voltage, phase number and frequency,

as well as model and serial number, see also

Functions/Settings/ Type)

k Control panel

l Protective cover for electrical

installation area

m Central dial

n Hand shower

(with automatic rewind)

o Run-in guide

(floor models)

p Air filter

(installation area ventilation)

b

l

k

j

m

i

p

Applies to base-top models 061, 062, 101, 102.

b

l

k

m

n

a

j

i

Applies to floor models with roll-in carts 201 and 202.

f

c

d

e

n

g

h

f

a

f

c

d

e

c

f

o

p

- 11 -

General User Instructions

SelfCooking Control

Mode

TM

Combi-Steamer Mode

200ºC

0:15

60%

Programming Mode

Clean

new

LevelControl

copy change

delete

When unit is switched on or SCC

button is touched, unit enters

SmartCooking Control

Mode. See chapter on

SmartCooking Control

TM

TM

Mode

for description.

When Moist Heat or Dry Heat

(or both simultaneously for

Combination) buttons are

touched, the unit enters

Combi-Steamer Mode. See

chapter on Combi-Steamer

Mode for description.

- 12 -

When the "Prog” button is

touched unit enters

Programming Mode. See

chapter on Programming Mode

for description.

General User Instructions

Your SmartCooking SystemTMhas a touch screen.

You can operate functions and/or enter data simply

by touching it lightly with one finger.

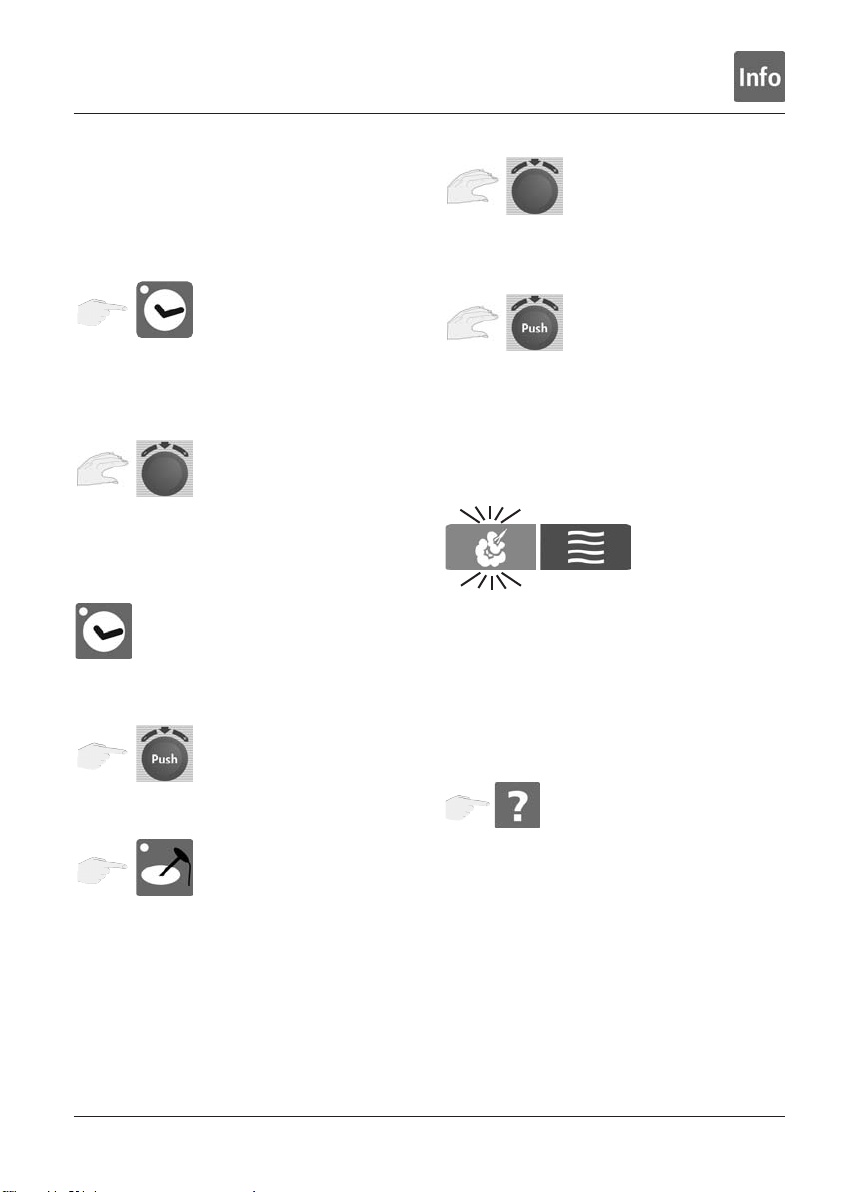

Selecting a function

Examples:

Press button

Short bleep and flashing red light confirms button

has been pressed.

Active button is surrounded by flashing red frame.

The central dial can be used to enter data while the

button is flashing.

Confirmation of data input

takes place automatically after 4 seconds.

or

Central dial

You can enter your desired values by rotating the

central dial.

Push Function

Entries can be confirmed by pressing the central

dial.

Unit too hot

If the cooking cabinet is hotter than the set temperature, the selected mode button will flash.

(See "Cool Down" chapter for cooking cabinet

cooling).

press on central dial (dial push function)

or

press any button.

Help Function

This will give you handy tips on everyday

use

(see also Help Function chapter).

- 13 -

SmartCooking ControlTMMode

The 7 SmartCooking ControlTMprocesses (large

roasts, grill/sauté, poultry, fish, bakery products,

side dishes, Finishing

product-specific requirements, the size of the food

to be cooked and the load size. Cooking time,

temperature and the ideal cooking cabinet climate

are continuously adjusted to achieve the desired

result. The remaining cooking time is displayed.

®

) automatically detect

- 14 -

?????

SmartCooking ControlTMMode – Controls

On/Off switch

7 Processes:

SmartCooking Control

Large roasts

Grill/sauté

Poultry

Fish

Bakery products

Side dishes

Finishing

TM

®

- 15 -

Function button

Programming Mode button

al dial

Centr

with Push Function

SmartCooking ControlTMMode – Operation

Following are five examples that explain the operation of SmartCooking Control

TM

mode. Or, simply

follow the User Guide on the display.

Example 1: Veal roast

1

Touch the icon illustrated by a large roast.

universal

roasting

roast with

crackling

2

soft

roasting

On the next screen will appear six preparation

options. Select one—Universal Roast, for exam-

overnight

roasting

ple—and that’s it! The unit will begin working to

give you a preset factory-tested result.

soft

cooking

overnight

cooking

You can also make changes to any of the preset

suggestions for the level of browning and cooking.

Simply select a different setting than the one highlighted. If you wish to change a setting you must

do so within 60 seconds.

When required, the unit preheats—the display

shows:

preheat

When the preheat temperature is reached the display shows:

Load

Insert core temperature probe

Please note that the temperature probe must be

inserted when required.

If the temperature probe is incorrectly inserted (see

chapter on Working with Temperature Probe) the

display will show:

Probe Position

universal

roasting

3

Or you have the option of making individual

light dark

rare

well done

changes to the level of browning and cooking.

You must then attempt to re-insert the probe properly. If the probe is not inserted, or remains improperly inserted, the mode is discontinued.

- 16 -

SmartCooking ControlTMMode – Operation

Note

The actual elapsed cooking time is displayed once

the cooking time is completed and the door has

been opened. In some SmartCooking Control

mode operations, no preheating is necessary.

Discontinuing an operation in SelfCooking

TM

Control

Mode

An operation in SmartCooking ControlTMMode may

be discontinued while the display shows the

"back" symbol. If the "back" symbol is unavailable, the only way to halt the process is to switch

off the unit.

TM

- 17 -

SmartCooking ControlTMMode – Operation

Example 2: Muffins

1

Select “Bakery Products” by touching the icon illustrated by a loaf of bread.

sweet

baking

savoury

baking

2

Select the "Sweet Baking " option—that’s it!

The unit will begin working to give you a preset

factory-tested result.

sweet

baking

light

dark

3

You can also make changes to any of the preset

suggestions for the level of browning and cooking.

Simply select a different setting than the one highlighted. If you wish to change a setting you must

do so within 60 seconds.

The unit preheats automatically—the display

shows:

preheat

When the preheat temperature is reached the display shows:

Load

Insert core temperature probe

The probe positioning aid must be used with liquid

or batter products.

Please note that the temperature probe

must be inserted when requested!

If the temperature probe is incorrectly inserted (see

chapter on Working with Temperature Probe) the

display will show:

Probe position

You must then attempt to re-insert the probe properly. If the probe is not inserted, or remains improperly inserted,

the mode is discontinued.

- 18 -

SmartCooking ControlTMMode – Operation

Note

The actual elapsed cooking time is displayed once

the cooking time is completed and the door has

been opened.

Discontinuing an operation in SmartCooking

TM

Control

An operation in SmartCooking ControlTMMode may

be discontinued while the display shows the

"back" symbol. If the "back" symbol is unavailable, the only way to halt the process is to switch

off the unit.

Mode

- 19 -

SmartCooking ControlTMMode – Operation

Example 3: "Finishing®– à la carte”

1

Select "Finishing®" mode by touching the icon

illustrated by a column of plates

plated

banquet

plates

à la carte

2

container

CT-probe

chicken

Select "à la carte" option– that’s it!

The unit will begin working to give you a preset

factory-tested result.

plates

à la carte

container

service

The unit preheats automatically—the display

shows:

preheat

If desired you can change the default settings and

store your new ones.

When the preheat temperature is reached the display shows:

Load

Level Control

Level Control automatically appears when door is

open for loading.

4

Select level (rack) you have loaded (e.g. level 3)

dry humid

3

short

long

You can also make changes to any of the preset

suggestions for the level of humidity or finishing

time. Simply select a different setting than the one

highlighted.

5

Repeat for as many levels as you load.

The time runs when the cooking cabinet door is

closed. As soon as the door is opened the time is

stopped.

- 20 -

SmartCooking ControlTMMode – Operation

”LevelControl”

With Level Control you can enter an individual time

for each of your racks and have it displayed. That

way you can always see exactly when each rack is

ready. A buzzer sounds and the indicated level

flashes as soon as the preset time for the relevant

rack is up. Once the cabinet door has been opened

and shut that level is free again and can be

reloaded.

Select the loaded level for which you want to

change the cooking time (e.g. level 3)

Turn Central Dial to input desired time and press

dial to confirm.

1

2

- 21 -

Loading...

Loading...