Page 1

TECHNICAL

MANUAL

VELOCITY SERIESTM PRESSURE FRYER

MODEL

PXE-100

REGISTER WARRANTY ONLINE AT WWW.HENNYPENNY.COM

REGISTER WARRANTY ONLINE AT WWW.HENNYPENNY.COM

Page 2

HENNY PENNY

ELECTRIC PRESSURE FRYER

SPECIFICATIONS

Pot Capacity 8 head of chicken - 24 lbs. (10.8 kg)

76 lbs. oil (34 Kg.)

Electrical 208 VAC, 3 Phase, 50/60 Hz, 17 KW, 47.2 Amps

240 VAC, 3 Phase, 50/60 Hz, 17 KW, 40.9 Amps

480 VAC, 3 Phase, 50/60 Hz, 17 KW, 20.5 Amps

Heating Two 8,500 watt electric immersion elements

A data plate, located on the back shroud behind the lid identies the fryer model, serial

number, warranty date, and other information. Also, the serial number is stamped on the

outside of the counter top. See gure below.

Serial No.

Sept. 2014

2

Page 3

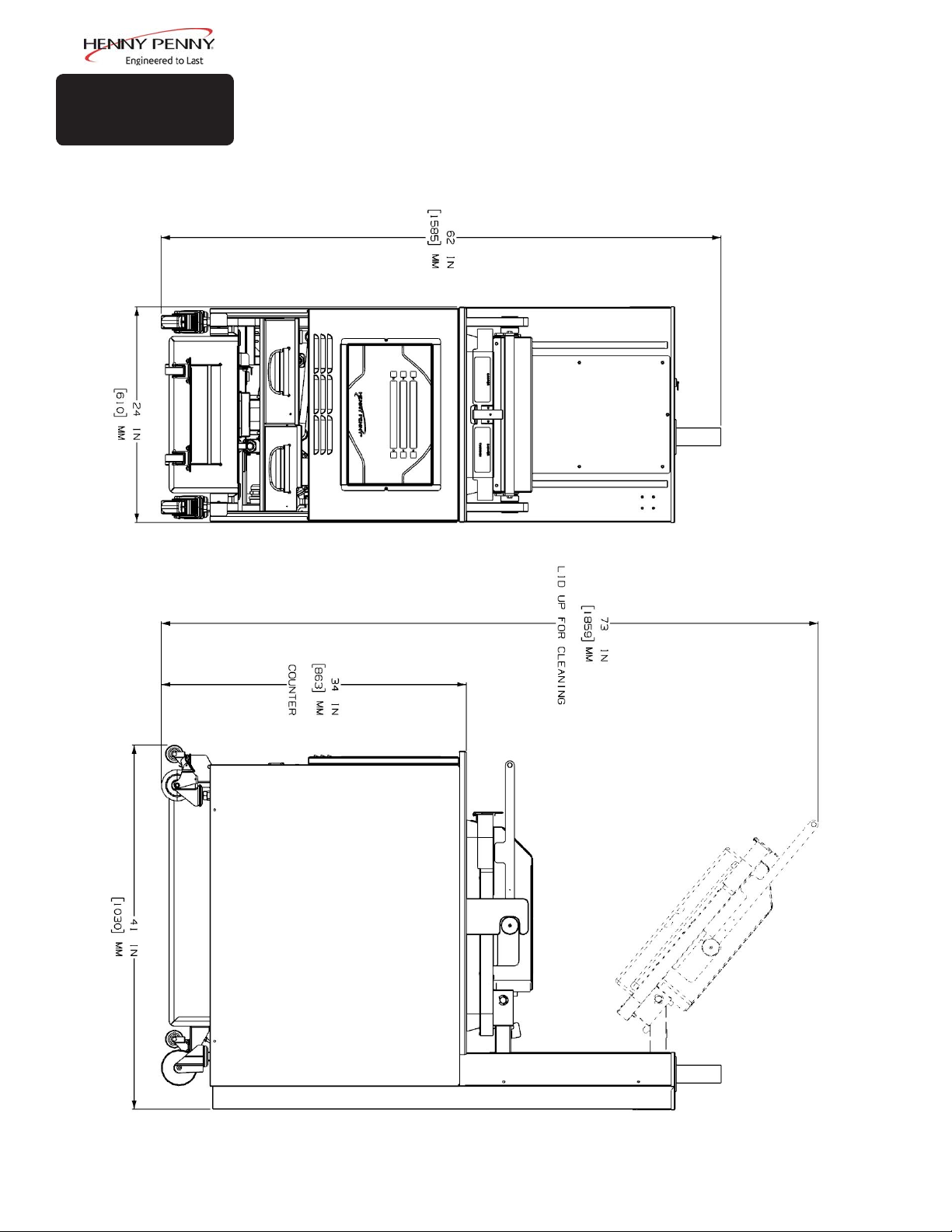

PXE-100

DIMENSIONS

Sept. 2014

3

Page 4

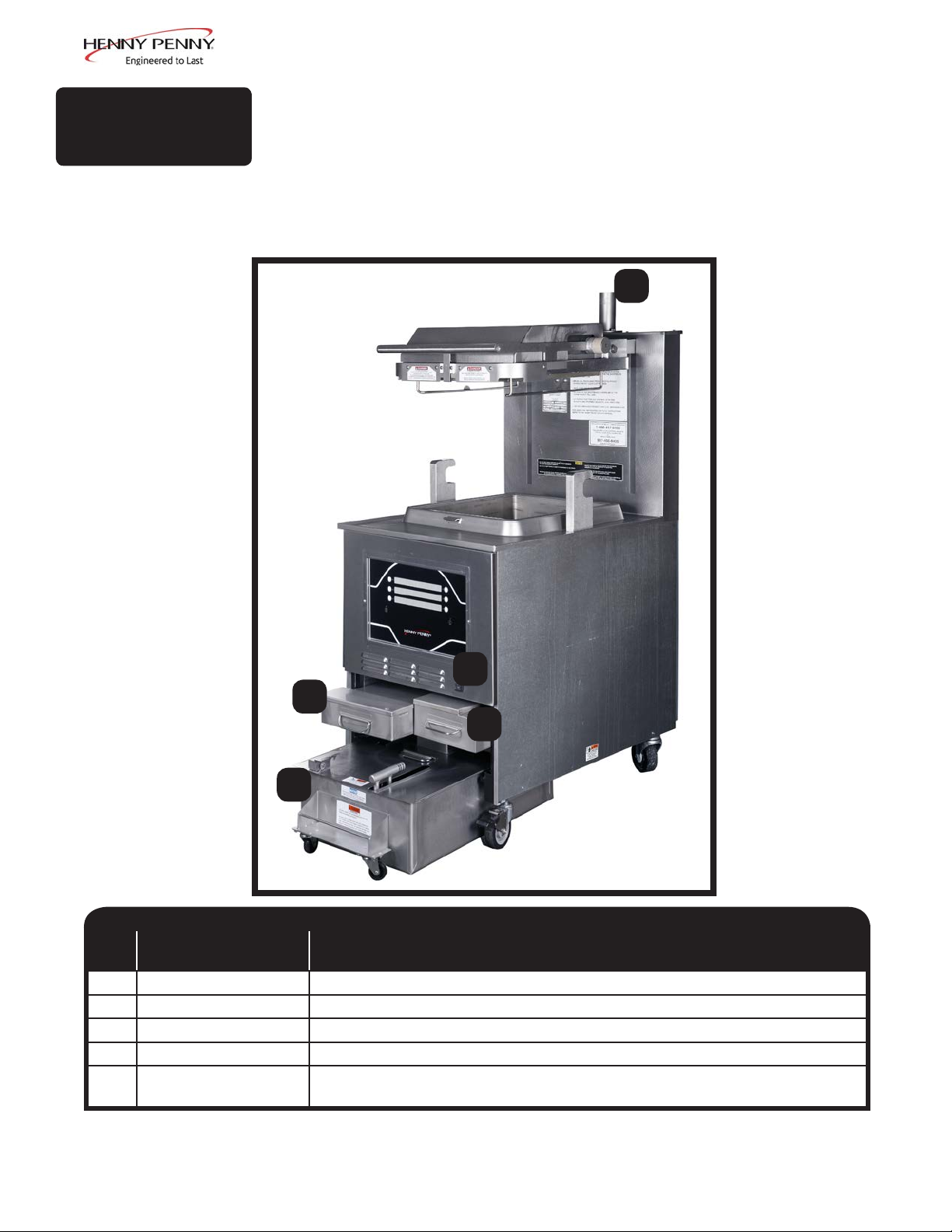

OPERATING

COMPONENTS

1

3

2

4

5

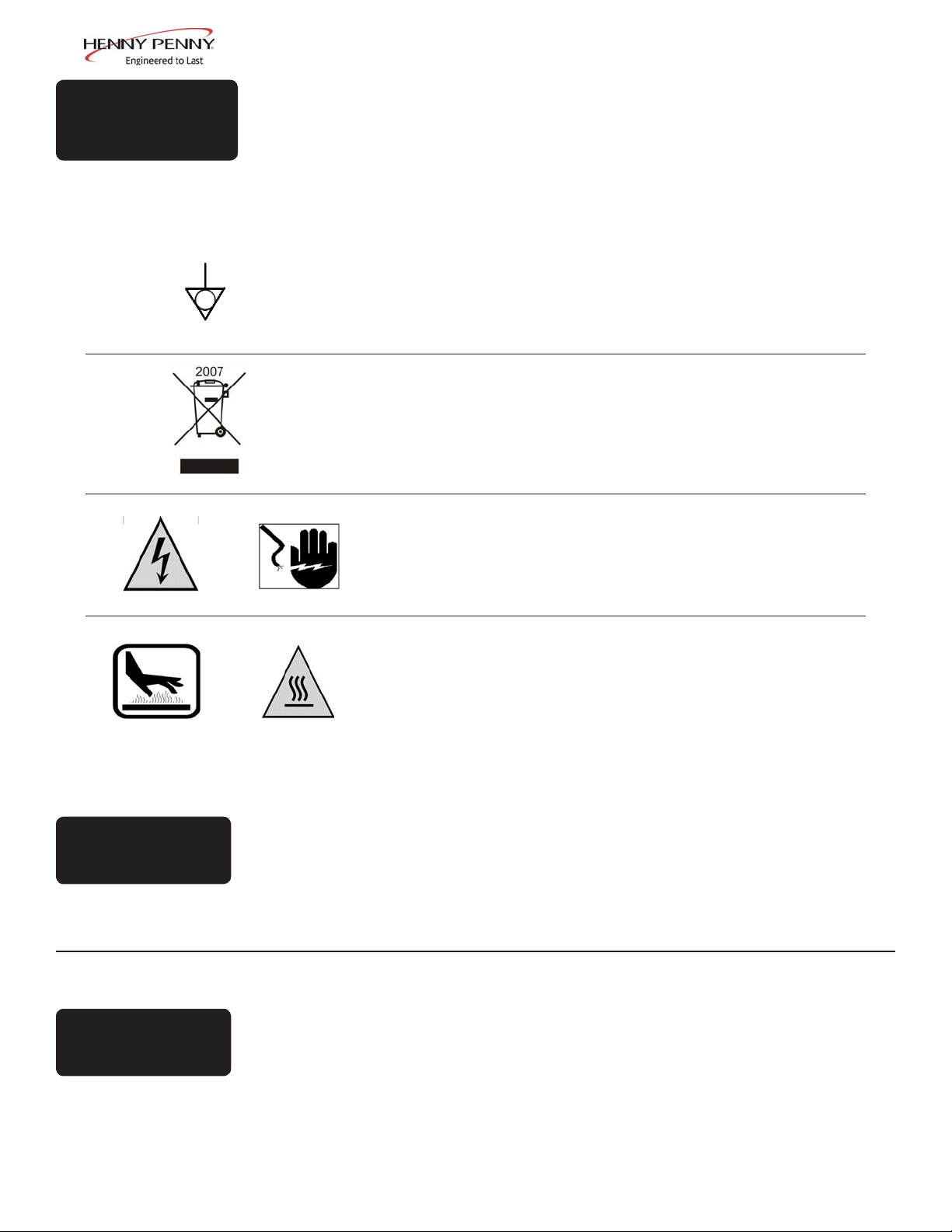

Item

No.

1 Steam-Stack Houses the dead-weight. Releases steam when pressurized

2 Fresh Oil Tank Tops the vat off with fresh oil when low

3 Power Switch Turns power to the unit ON/ OFF

4 Condensation Pan Reservoir that hold excess condensation that drains from the vat

5 Oil Drain Pan Oil is drained into this pan and then is pumped through lters to help

Description Function

prolong the use of the oil

Sept. 2014

4

Page 5

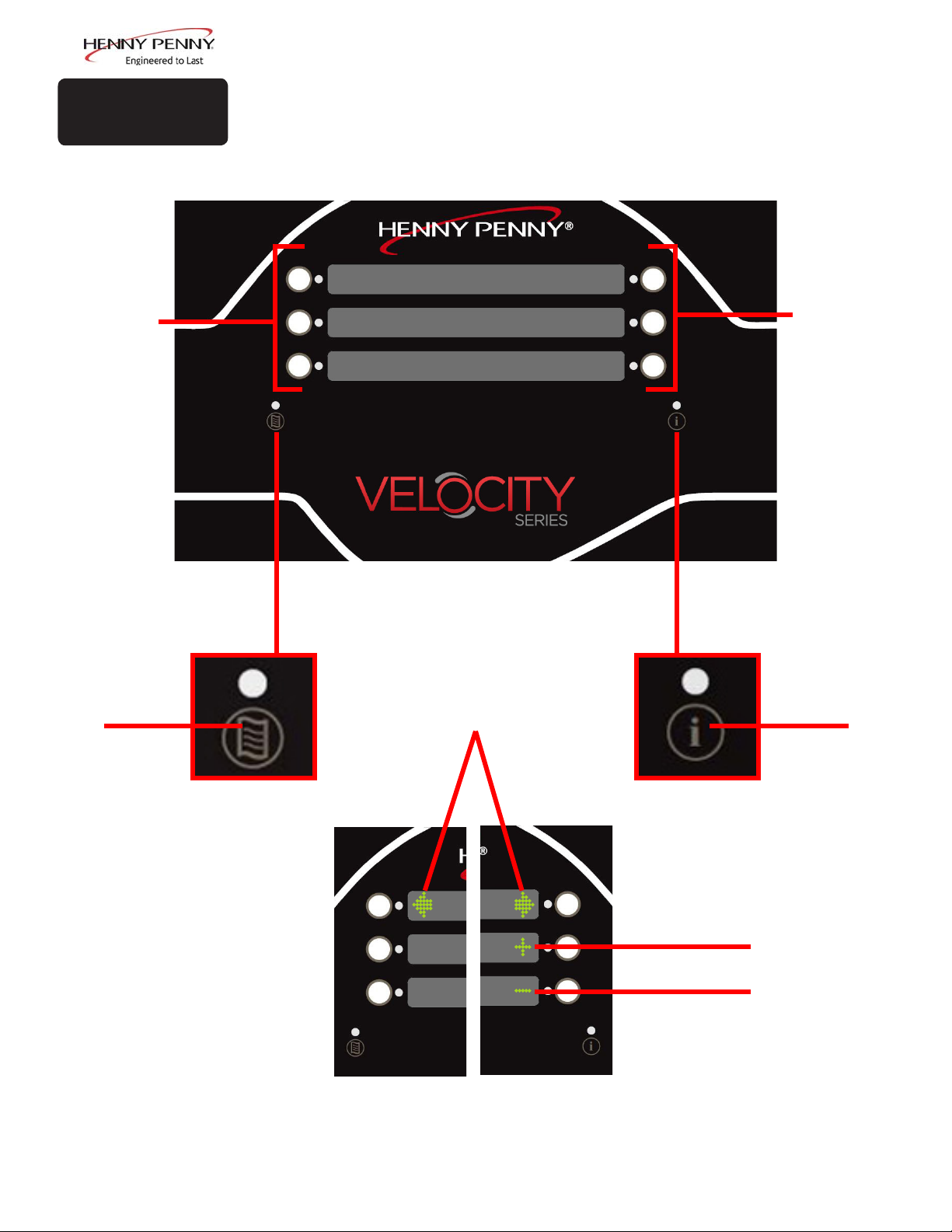

CONTROL

OVERVIEW

This section gives a control board overview and explains all the

buttons, displays and features.

1

Figure 3-1

2 3

4

1

Sept. 2014

Figure 3-2 Figure 3-3

5

6

Figure 3-4

5

Page 6

CONTROL

OVERVIEW

(CONT.)

Fig.

3-1 1 Buttons

3-2 2 Menu Button

3-3 3 Info Button

3-4 4 Arrow Displays

3-4 5 Plus Display

3-4 6 Minus Display

Item

No.

Description Function

When the light is illuminated next to the button, this indicates this button

has a product or action that can be reached by pressing.

Pressing and holding this button will access the “MAIN” menu which

includes features such as lter, info mode, and programming.

• Press this button once to display the pressure and temperature

• Press this button twice to activate the “WIPE” feature

• Press this button three times to get “LAST FILTER” information

When an arrow is displayed, this indicates there is another screen or option.

To access the next option/screen, press the button next to the desired arrow.

The plus sign is displayed when the value of the time/temp/letters can be

changed. Pressing the button next to the plus sign will increase the value.

Will be represented in the manual by: +

The minus sign is displayed when the value of the time/temp/letters can be

changed. Pressing the button next to the minus sign will decrease the value.

Sept. 2014

Will be represented in the manual by: -

6

Page 7

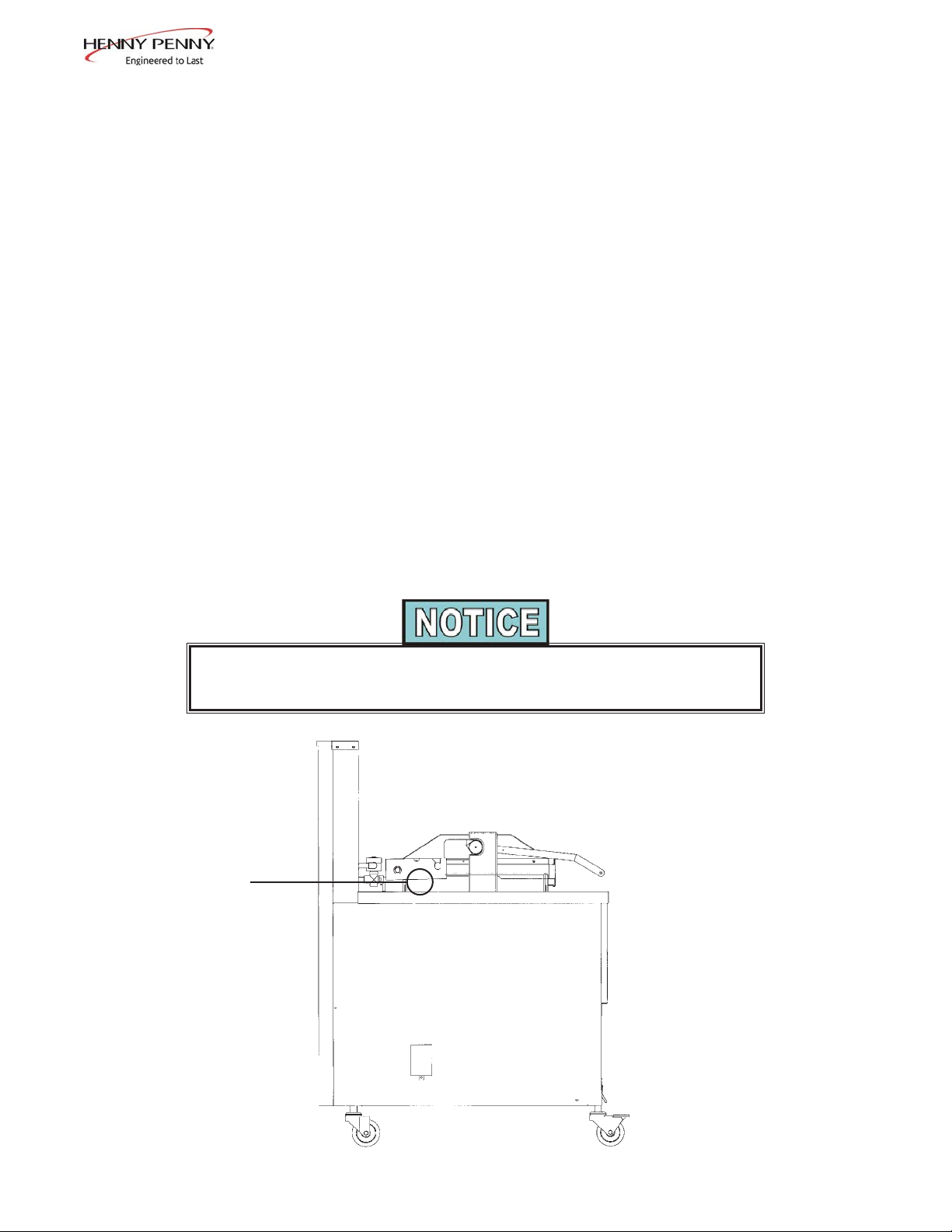

HENNY PENNY

8 HEAD ELECTRIC PRESSURE FRYER

Fryer must be installed and used in such a way to prevent water from contacting the shortening.

This appliance is not intended to be operated by means of an external timer or a separate remote control

system.

This appliance is not intended for use by persons (including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a person responsible for their safety.

Sept. 2014

7

Page 8

SECTION 1: INTRODUCTION

1-1

SAFETY

The instructions in this manual have been prepared to aid you in learning

the proper procedures for your equipment. Where information is of

particular importance or is safety related, the words NOTICE, CAUTION,

or WARNING are used. Their usage is described below.

If a problem occurs during the rst operation of a new unit, recheck the

Installation Section of the Operator’s Manual.

Before troubleshooting, always recheck the Operation

Section of the Operator’s Manual.

Where information is of particular importance or is safety related, the

words DANGER, WARNING, CAUTION, or NOTICE are used. Their

usage is described as follows:

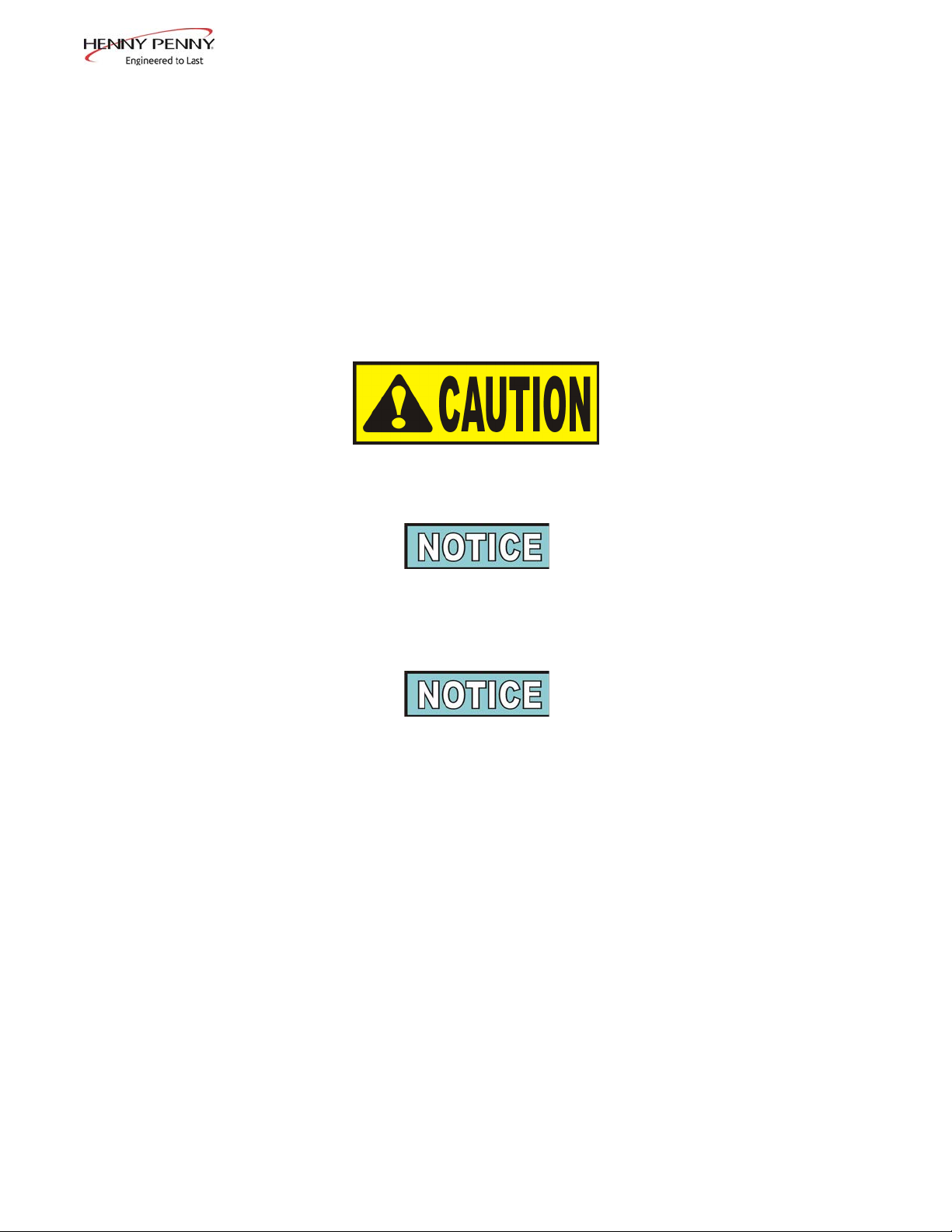

SAFETY ALERT SYMBOL is used with DANGER, WARNING

or CAUTION which indicates a personal injury type hazard.

NOTICE is used to highlight especially important information.

CAUTION used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may result

in property damage.

CAUTION used with the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, could result

in minor or moderate injury.

WARNING indicates a potentially hazardous situation which,

if not avoided, could result in death or serious injury.

DANGER INDICATES AN IMMINENTLY HAZARDOUS

SITUATION WHICH, IF NOT AVOIDED, WILL RESULT IN

DEATH OR SERIOUS INJURY.

Sept. 2014

8

Page 9

1-1.

SAFETY

(CONT.)

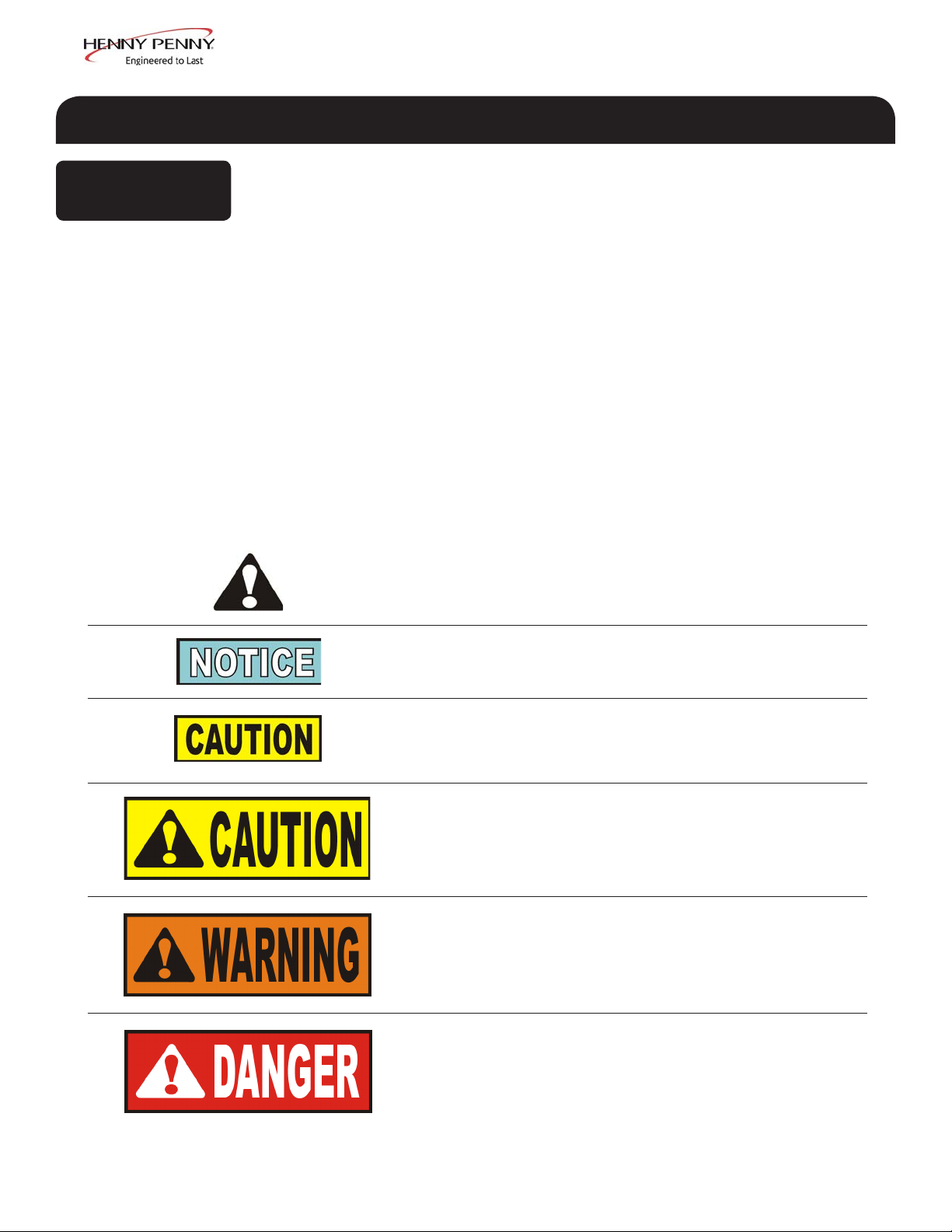

Equipotential Ground Symbol

Waste Electrical and Electronic Equipment (WEEE) Symbol

1-2.

PROPER CARE

OR

OR

Shock Hazard Symbols

Hot Surface Symbols

As in all Henny Penny equipment, the unit requires care and

maintenance. Requirements for maintenance and cleaning

are contained in this manual and must be a regular part of the

operation of the unit.

1-3.

ASSISTANCE

Sept. 2014

Should you require outside assistance, call your local distributor

in your area, or call 1-800-417-8405 or 1-937-456-8405.for

Henny Penny Technical Support.

9

Page 10

2-1.

TROUBLESHOOTING

GUIDE

PROBLEM CAUSE CORRECTION

Power switch on but fryer

completely inoperative

Pressure not exhausting at

end of Cook Cycle

SECTION 2: TROUBLESHOOTING

• Open circuit • Fryer plugged in

• Check breaker or fuse at wall

• Solenoid or exhaust line clogged • Turn off and allow fryer to cool

to release the pressure in frypot;

have all lines, solenoid and

exhaust tank cleaned

Relief valve vents

Pressure does not build

Oil not heating

Foaming or boiling over

Oil not draining

• Operating pressure too high

• Deadweight clogged

• Not enough product in frypot

• Metal shipping spacer not removed

from deadweight assy.

• Pressure not programmed

• Lid gasket leaking

• Drain valve open

• High temperature limit tripped

• See Boil-Over chart on fryer and

beginning of Operation Section in

this manual

• Drain valve clogged • Push cleaning rod through open

• Turn off and allow fryer to cool

to release the pressure in frypot;

clean deadweight; see Preventive

Maintenance Section

• Place full capacity product in

frypot when Use fresh oil.

• Remove shipping spacer; see

Unpacking Instructions Section

• Check programming

• Reverse or replace lid gasket

• Close drain valve.

• Reset high temperature limit; see

Operating Components Section

• Follow Boil-Over procedures from

chart

drain valve

Filter motor won’t run

More detailed troubleshooting information is available in the Technical Manual, available at www.

Sept. 2014

• Motor overheated • Reset motor; see Filter Pump

Motor Protector-Manual Reset

Section

hennypenny.com, or 1-800-417-8405 or 1-937-456-8405.

10

Page 11

2-2.

ERROR CODES

DISPLAY CAUSE CORRECTION

“E-4”

“CPU TOO HOT”

“E-5”

“OIL TOO HOT”

In the event of a control system failure, the digital display will show an “Error

Message”. These messages are coded: “E04”, “E05”, “E06”, “E41”. A constant

tone is heard when an error code is displayed, and to silence this tone, press any of

the product buttons.

Turn switch to OFF position, then turn switch

back to ON; if display still shows “E04”, the

Control board overheating

Oil overheating

board is getting too hot; check for signs of

overheating behind the control panel; once panel

cools down the controls should return to normal;

if “E04” persists, replace the control

Turn switch to OFF position, then back to ON;

if display shows “E05”, the heating circuits and

temperature probe should be checked; once the

unit cools down, the controls should return to

normal; if “E05” persists, replace the control.

“E-6A”

“MAIN TEMP

PROBE FAILED”

(Open Circuit)

“E-6B”

“MAIN TEMP

PROBE FAILED”

(Shorted)

“E-10”

Temperature probe failure

High limit tripped (Software prior

to version 1.60)

Turn switch to OFF position, then back to ON; if

the display shows “E06”, the temperature probe

should be checked; once the temperature probe is

repaired, or replaced, the controls should return to

normal; if “E06” persists, replace the control.

Check the error log to nd out the fry pot

temperature at the time the high limit tripped. If

this temperature was very low, this could be a sign

that the fry pot was turned on with low or no oil.

If this was the case, ll the pot with oil and reset

the high limit. If the trip temperature was several

degrees above the oil set point temperature, test

for a sticking contactor and replace if faulty. If

the high limit tripped at an oil temperature,

inspect the high limit thermocouples for carbon

build up and clean if necessary. If no carbon

found, see high limit troubleshooting.

Nov. 2016

11

Page 12

DISPLAY CAUSE CORRECTION

Check the error log to nd out the fry pot

temperature at the time the high limit tripped. If

this was several degrees above the oil set point

“E-10A”

“HIGH LIMIT

TRIPPED”

“E-10B”

“HIGH LIMIT

TRIPPED”

“E-10C”

“HIGH LIMIT

TRIPPED”

High limit tripped while vat main

probe temperature was at or above

300°F.

High limit tripped while vat main

probe temperature was below

300°F.

High limit tripped while actually

cooking (Not simply in cook mode,

but actually with cook cycle running).

temperature, test for a sticking contactor and

replace if faulty. If the trip temperature was near

the oil set point temperature, inspect the high

limit thermocouples for carbon build up and clean

if necessary. If no carbon found, see high limit

troubleshooting.

Check the error log to nd out the fry pot

temperature at the time the high limit tripped. If

this temperature was very low, this could be a sign

that the fry pot was turned on with low or no oil.

If this was the case, ll the pot with oil and reset

the high limit. If the high limit tripped at a higher

temperature, inspect the high limit thermocouples

for carbon build up and clean if necessary. If no

carbon found, see high limit troubleshooting.

Check the error log to nd out the fry pot

temperature at the time the high limit tripped. If

this was several degrees above the oil set point

temperature, test for a sticking contactor and

replace if faulty. If the trip temperature was near

the oil set point temperature, inspect the high

limit thermocouples for carbon build up and clean

if necessary. If no carbon found, see high limit

troubleshooting.

“E-10D”

“HIGH LIMIT

TRIPPED”

“E-10F”

“HIGH LIMIT

TRIPPED”

High limit tripped less than 5

minutes after fryer was performing

an AutoFilter or Quick Filter and

the control returned to cook mode

on its own after detecting that the

oil was pumped up (based on

temperature rise on level probe).

High limit tripped while ltering

(including AutoFilter, Daily Filter,

Polish, Dispose, Drain to Pan, Fill

from Pan, etc.).

Check the error log to nd out the fry pot

temperature at the time the high limit tripped. If

this was several degrees above the oil set point

temperature, test for a sticking contactor and

replace if faulty. If the trip temperature was near

the oil set point temperature, inspect the high

limit thermocouples for carbon build up and clean

if necessary. If no carbon found, see high limit

troubleshooting.

Check the error log to nd out the fry pot

temperature at the time the high limit tripped. If

this was several degrees above the oil set point

temperature, test for a sticking contactor and

replace if faulty. If the trip temperature was near

the oil set point temperature, inspect the high

limit thermocouples for carbon build up and clean

if necessary. If no carbon found, see high limit

troubleshooting.

Nov. 2016

12

Page 13

DISPLAY CAUSE CORRECTION

Check the error log to nd out the fry pot

temperature at the time the high limit tripped. If

this temperature was very low, this could be a sign

“E-10M”

“HIGH LIMIT

TRIPPED”

“E-10S”

“HIGH LIMIT

TRIPPED”

“E-10Y”

“HIGH LIMIT

TRIPPED”

High limit tripped while fryer was

in Melt Mode.

High limit tripped while vat was in

Start-up Mode (not incl. Melt mode),

but not while it was executing one of

the lter operations.

High limit tripped less than 5

minutes after user responded “YES”

to an “Is Pot Filled?” question.

that the fry pot was turned on with low or no oil.

If this was the case, ll the pot with oil and reset

the high limit. If the high limit tripped at a higher

temperature, inspect the high limit thermocouples

for carbon build up and clean if necessary. If no

carbon found, see high limit troubleshooting.

Check the error log to nd out the fry pot

temperature at the time the high limit tripped. If

this temperature was very low, this could be a sign

that the fry pot was turned on with low or no oil.

If this was the case, ll the pot with oil and reset

the high limit. If the high limit tripped at a higher

temperature, inspect the high limit thermocouples

for carbon build up and clean if necessary. If no

carbon found, see high limit troubleshooting.

Check the error log to nd out the fry pot

temperature at the time the high limit tripped. If

this temperature was very low, this could be a sign

that the fry pot was turned on with low or no oil.

If this was the case, ll the pot with oil and reset

the high limit. If the high limit tripped at a higher

temperature, inspect the high limit thermocouples

for carbon build up and clean if necessary. If no

carbon found, see high limit troubleshooting.

“E-13” Pressure transducer failed

“E-14”

“PRESSURE TOO

HIGH”

Nov. 2016

Pressure is too high within the

frypot

• Replace pressure transducer

• Check deadweight chamber for any

obstruction

• Check the steam exhaust passage for

obstruction

13

Page 14

DISPLAY CAUSE CORRECTION

Check the drain valve for obstruction. Carefully

remove any obstruction found. If no obstruction,

check to make sure both connections to the drain

valve are plugged in securely. If connections

are secure, operate the drain valve using the

drain valve test in tech mode. If no drain valve

movement, test to make sure the drain valve is

getting 24VDC from control board when testing

both directions (open and closed) from connector

P9 pins 3&4. If voltage is present and no

movement, replace drain valve motor. If no DC

voltage, replace control board

Check to make sure both connections to the drain

valve are plugged in securely. If connections

are secure, operate the drain valve using the

drain valve test in tech mode. If no drain valve

movement, test to make sure the drain valve is

getting 24VDC from control board when testing

both directions (open and closed) from connector

P9 pins 3&4. If voltage is present and no

movement, replace drain valve motor. If no DC

voltage, replace control board

“E-15C”

“DRAIN VALVE

ERROR”

“E-15P”

“DRAIN VALVE

ERROR”

The control energized the drain

valve to close it, and waited a

reasonable amount of time, but

didn’t see the expected feedback

signal that would have conrmed

that the drain valve was fully

closed.

The control energized the drain

valve to open it, and waited a

reasonable amount of time, but

didn’t see the expected feedback.

signal that would have conrmed

that the drain valve was fully open.

“E-18A”

“LEVEL SENSOR

FAILED”

(Open Circuit)

“E-18B”

“LEVEL SENSOR

FAILED”

(Shorted)

“E-41P”

“-1- LOST”

“E-41S”

“SYSTEM DATA

LOST’

The oil level probe has failed

System data lost. Both the RAM

copy and stored copy of the settings

have been lost. Settings are reset to

default

System data lost. Both the RAM

copy and stored copy of the settings

have been lost. Settings are reset to

default

• If circuit is open, check connection

• Replace probe

• Replace control board if occurs repeatedly

• Replace control board if occurs repeatedly

Nov. 2016

14

Page 15

DISPLAY CAUSE CORRECTION

“E-46C”

“INTERNAL SD

MEM ERR”

Issue with microSD chip

• Check to ensure chip is not ejected from slot

“E-46W”

“DATA SAVE

FAILED”

“E-47”

“ANALOG SYSTEM

OR 12 VOLT

FAILED”

“E-48”

“INPUT SYSTEM

ERROR”

“E-54C”

“MAIN TEMP

CIRCUIT FAILURE”

Unable to communicate and save

data to the microSD chip

Corrupt le

Problem reading the A-to-D Analog

to Digital converter inputs

Failure of the CPU board • Replace control board

• Replace control board if occurs repeatedly

• Initialize the CPU board

• Replace control board

• Initialize the CPU board

Fault on the CPU board

• Replace control board

“E-54D”

“MAIN TEMP DSC

ERROR”

“E-70A”

“FAN JUMP

MISSING”

“E-70B”

“PWR SWITCH OR

WIRES FAILED”

Nov. 2016

Fault on the CPU board

Jumper wire is loose or missing

from 15 pin connector

Short in wires/ loose connection

Power switch may be faulty

• Initialize the CPU board

• Replace control board

• Check connector for loose connection

• Check connection

• Replace power switch

15

Page 16

DISPLAY CAUSE CORRECTION

“E-70C”

“DRN JUMPER

MISSING”

“E-82”

“SELCTOR VALVE

FAILURE”

“E-84B”

“LID NOT

LOCKED”

“E-84C”

“PRESSURE

PIN DID NOT

ACTIVATE”

Loose connection on the 15 pin

connector

The selector valve failed calibration

or not responding

• Lid handle not properly locked

• Failed electric lid lock motor

• Pressure pin did not fully

engage

Check connection

• Check motor, encoder or wiring

• If unit is not equipped with a selector valve

and gives this error, check settings in T-4

(Tech Mode) to conrm settings are correct.

• Conrm handle is pushed all the way down

• Test/ replace motor

• Check to see if the pin is activating the switch

• Test switch

• If lid pin is stuck, remove lid cover and

manual free pin

“E-84D”

“PRESSURE PIN

STUCK OR NOT

CONNECTED”

“E-86B”

“PRESSURE STUCK

ON”

“E-93”

“24V DC SUPPLY”

• Cannot open lid-Pin is stuck

and has not dropped down

• Can open lid-wire may be

disconnected or monitoring

switch failed

• Sticking solenoid

• Clogged pressure exhaust port

• Faulty pressure transducer

• Disconnected from control

• Short in drain motor or selector

valve motor

• Check wire connections and reconnect loose

wires

• Replace faulty wires

• Test switch

• Replace switch if needed

• Test solenoid

• Check ports and unclog if necessary

• Test transducer

• Check plug on back of control

• Test motors

Nov. 2016

16

Page 17

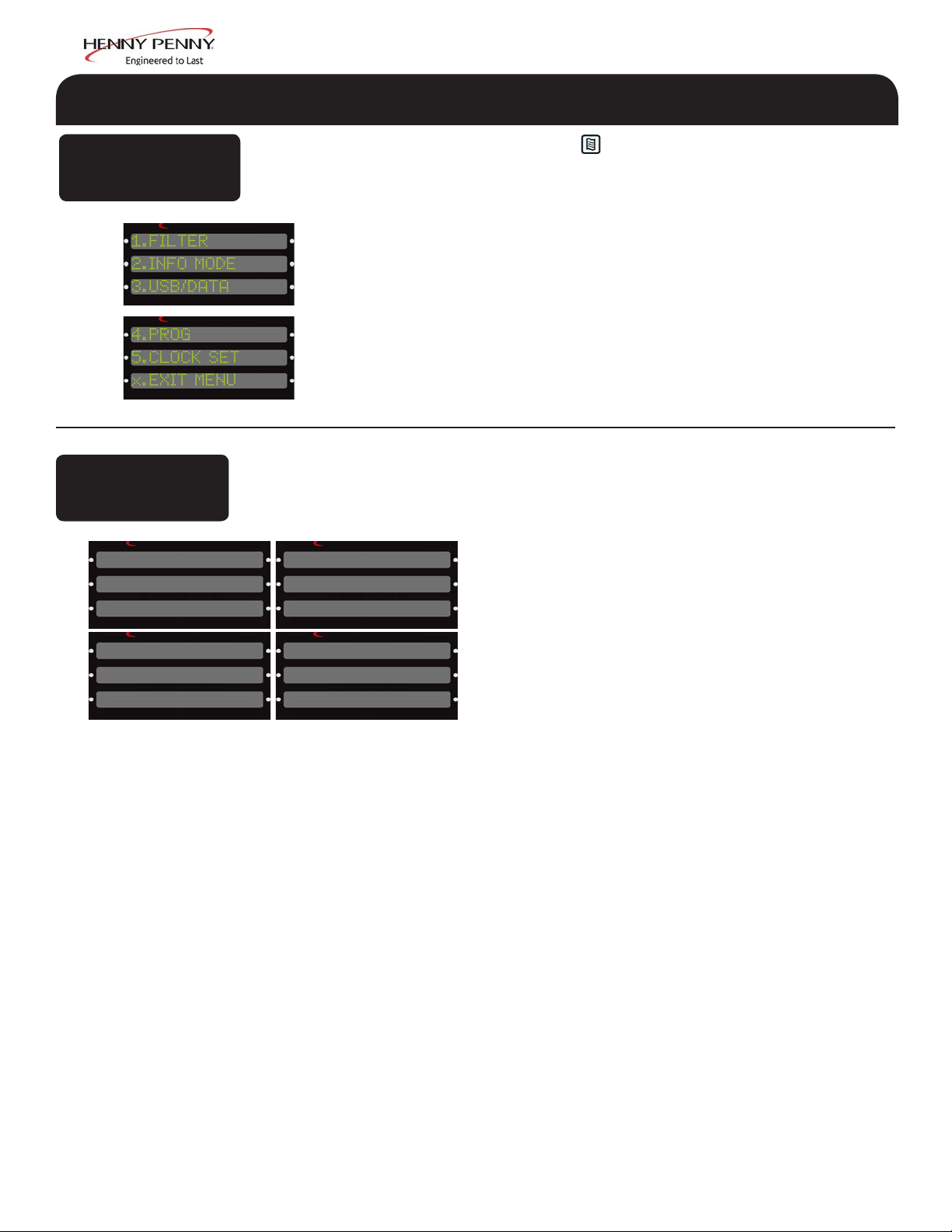

SECTION 3: PROGRAMMING

3-1.

MAIN MENU

3-2.

PROGRAMS

1.PRODUCTS

2.COOK MENUS

3.SPCL PROG

4.DATA COMM

5.HEAT CTRL

6.FLTR CTRL

7.TECH MODE

8.STATS MODE

9.LANGUAGE

x.EXIT MENU

Press and hold the button until *MAIN* shows in the display.

Once the menu activates, release the button.

The Main Menu options are displayed as follows:

1. FILTER

2. INFO MODE

3. USB/DATA

4. PROGRAM

5. CLOCK SET

x. EXIT MENU

This section shows how to access the programming

(“PROG”) menu that access the products, cook and special

program and tech mode.

1. PRODUCTS

2. COOK MENUS

3. SPECIAL PROGRAM

4. DATA COMM

5. HEAT CONTROL

6. FILTER CONTROL

7. TECH MODE

8. STATS MODE

9. LANGUAGE

x. EXIT MENU

Sept. 2014

17

Page 18

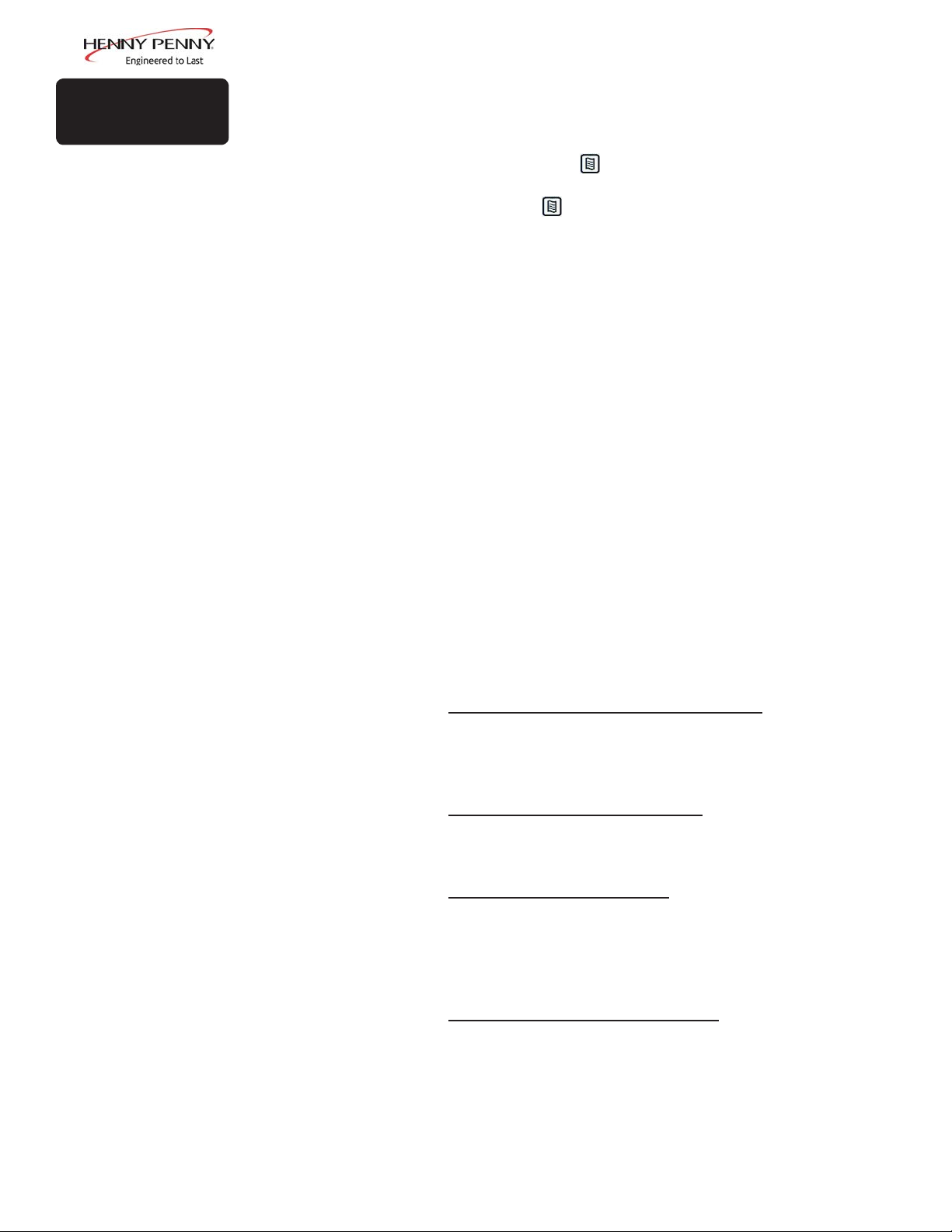

3-3.

SPECIAL

PROGRAMMING

This section shows how to access the Special Program area of

the controls in order to program cook menus, clock, and other

features.

1. Push and hold until the display reads *MAIN*.

2. Press the again to access the next set of options.

3. Press 4 to enter the “PROG” menu.

4. Press 3 to enter “SPCL PROG”.

5. Enter the code: 1, 2, 3

6. Use the left or right arrows to navigate through the options.

SP-1 • TEMP UNITS

SP-2 • LANGUAGE

SP-3 • SYSTEM INIT

SP-4 • RADIO SYSTEM ENABLED?

SP-5 • AUDIO VOL (Loudness)

SP-6 • AUDIO TONE (Frequency)

SP-7 • MELT CYCLE

SP-8 • START-UP POLISH ENABLED?

SP-9 • START-UP GO WHERE?

SP-10 • COOK MENUS OPTION

SP-11 • COOK MENU BUTTONS

SP-12 • COOK DONE GO WHERE?

SP-13 • AUTO-MENU MINUTES

SP-14 • AUTO-MENU GO WHERE?

SP-15 • COOL TEMP

SP-16 • PROD PROG T1>T2>T3)?

SP-17 • BULK DISPOSE?

SP-18 • BULK SUPPLY?

SP-19 • COOKING: SHOW PSI?

SP-20 • CHANGE MGR CODE

SP-21 • CHANGE USAGE CODE

SP-22 • CLEAN-OUT TYPE

SP-23 • CLEAN-OUT TEMP

SP-24 • CLEAN-OUT MINUTES

SP-1 • TEMPERATURE DISPLAY UNITS

1. Use the + or - to change between Fahrenheit (F°) or Celsius

(C°).

SP-2 • OPERATION LANGUAGE

1. Use the + or - buttons to scroll through the list of languages.

Sept. 2014

SP-3 • SYSTEM INITIALIZE

1. Press and hold the button next to “hold->” for three seconds.

2. System will re-initialize back to default settings.

SP-5 • AUDIO VOLUME (Loudness)

1. Use the + or - buttons will adjust the volume of the speaker

between 0-10.

2. Press the button next to “test” on the display.

18

Page 19

3-3.

SPECIAL

PROGRAMMING

(CONT.)

SP-6 • AUDIO TONE (Frequency)

1. Press the + or - to adjust the frequency setting,

2. Press the button next to “test” on the display.

SP-7 • MELT CYCLE

Specify the desired Melt Mode heating cycle.

1. Use the + or - to select wither “Solid” or “Liquid”.

SP-8 • START-UP POLISH ENABLED?

Specify whether or not an automatic polish operation should be

performed as part of the normal, morning startup process.

1. Use the + or - to select either “YES” or “NO”.

SP-9 • START-UP GO WHERE?

Specify where the control should go after exiting Melt. Choices

are “STAY PROD”, “PREV MENU”, or go specically to any of

the ten Cook Menus.

1. Use + or - to navigate through options.

SP-10 • COOK MENUS (Cook Menu Conguration)

1. Use the + or - buttons to navigate through cook menu options.

• “4+TITLE”

• “5+NEXT”

• “6 ITEMS”

See MENU OPTIONS for descriptions and examples.

SP-17 • BULK DISPOSE?

1. Use the + or - buttons to navigate through the three options:

• “NONE”

• “FRONT”

• “REAR”

2. “NONE”- Oil dispose is by draining into a disposal cart or

shuttle.

Sept. 2014

3. “FRONT”- Dispose by pumping through the front hose

connection by press and holding the illuminated button.

4. “REAR”- Dispose by pumping through the rear plumbing

connection.

19

Page 20

SP-18 • BULK OIL SUPPLY?

3-3.

SPECIAL

PROGRAMMING

(CONT.)

1. Use the + or - buttons to select either “YES” or “NO” for

whether or not a bulk oil supply is available for relling the

ATO oil tank and vat with fresh oil.

Sept. 2014

20

Page 21

3-4.

INFO MODE

Info Mode offers various diagnostic displays. To access Info

Mode, either::

1. Press and hold and until “=INFO MODE=” ashes

on the screen.

Or

1. Press and hold until “*MAIN*” ashes on the screen.

2. Press the “2. INFO” button.

Use the left or right arrow buttons to navigate through the

options:

• E-Log

• Last Load

• Daily Stat

• Review Usage

• Activity Log

• CPU Info

• Temperatures

• Digital Inputs-1

• Digital Inputs 2

• Inputs-3 (Bulk Oil Inputs)

• Pressure Inputs

• Fryer Outputs

• Drain Valve Status

• Selector Valve

• Pump Outputs

• Electric Lid Lock

• Analog Inputs

• Memory Info

• USB Drive Status

• ATO (Auto-Topoff) Level

E-Log

When E-Log is accessed, this displays the history of the previous

25 error codes starting with the most recent code rst. Each code

includes the date and time that the error occurred.

Sept. 2014

Last Load

Information about the most recent cook cycle, including total

cook time, stopped early or left beeping too long, and min/max/

avg temperatures.

Daily Statistics

Operating statistics for each of the past seven days, including

hours on, cook cycles, number of lters and etc.

21

Page 22

3-4.

INFO MODE

(CONT.)

Review Usage

Ongoing accumulation of operating statistics.

Stats accumulate until manual rest.

To reset (requires password), available by navigating all the way

to the bottom of the list.

Activity Log

History of Activity Log events:

• On/Off

• Start/Stop cook

• Filter

• Pan removed or replaced

CPU Info

Live temperature reading for the CPU (controller) temperature.

Temperatures

Live temperature readings for the Main oil temp., the Level

Probe temp., and the Bottom (bottom of vat) temperature.

The “Lvl” level probe shown here is the one actually in

use – upper or lower level probe -- as selected in Filter Ctrl

Programming mode.

Digital Inputs-1

√ = Signal present

- = No signal present

A = Power Switch

H = High Limit

D = Drain Switch Jumper

S = Power Switch Interlock

F = Fan Switch Jumper

Digital Inputs-2

√ = Signal present

- = No signal present

24dc = 24 DC Supply

Pan = Filter Drain Pan

*Lid = Lid Liner Pin

Sept. 2014

*Lid Liner Pin shows “OK” if pin is down.

Lid Liner Pin shows “PR” when pin is raised (under pressure).

22

Page 23

3-4.

INFO MODE

(CONT.)

Bulk Oil Inputs

√ = Signal present

- = No signal present

DTF = Discard Tank Full

If √ is present, tank is full and cannot dispse to it.

HDP = High Dispose Pressure (optional)

If √ is present, dispose pumping caused high pressure.

AFR = ATO Fill Request (optional)

If √ is present, switch is asking to pump Bulk Supply Oil to rell

the ATO tank.

Pressure Inputs

Shows readings from the pressure transducer:

“OK” = Safe to open lid (not under pressure)

“PR” = Lid under pressure, cannot open

Fryer Outputs

* = On

- = Off

Pri = Primary Contactor

Ht = Heat (regulating) Contactor

Pr = Pressure Solenoid

Drain Control

Par = Partially open

Stp = Forced Stop

Opn = Fully Open

Cls = Fully Closed

The current state of the drain valve is indicated with a “►”.

The below “At” indicates the drain valve position.

0 = Fully Closed

20+ = Fully Open

Selector Valve (Bulk Oil Fryers Only)

If unit is not equipped with a Bulk Oil System, “No Selector

Valve” will read in the display.

“E=001” = Encoder Position

Sept. 2014

Lower left display shows the activity of the valve.

STPD

FWD

REV

Lower right display shows the current port position.

23

Page 24

3-4.

INFO MODE

(CONT.)

Pump Outputs

* = On

- = Off

Fltr = Filter Pump

ATO = Topoff Pump

Bulk = Bulk Oil Supply

*Disp = Dispose Valve

*Dispose valve is optional

Electric Lid Lock

“R:” shows current request: Lock, Unlock

√ = request has been achieved and veried

“Mtr” = Motor

• - = Off

• “<-” = Retracting

• “->” = Extending

“R” / “X” = Retracted limit switch or Extended limit switch

currently pressed.

Analog Inputs

Analog input readings directly from the ADC chip.

Displayed as volts and as ADC counts(bits).

Use the Up and Down arrows to step through available inputs.

Memory Status (MEM INFO)

Shows the status and size of the control’s internal microSD

storage memory.

√ = Memory OK

X = Memory problem

Use the arrow buttons to scroll down to see free space, used

space and volume name.

USB Drive Status (USB INFO)

Shows the status and size of the USB ash drive, if present.

√ = Flash Drive OK

X = Flash Drive not present or drive error

Sept. 2014

Scroll down to see ash drive free space, used space and volume

name.

24

Page 25

3-4.

INFO MODE

(CONT.)

ATO-Topoff Status (ATO LEVELS)

LVL = Levels

• “FULL”

• “LOW”

• “---”

Will show when an assessment is not possible.

Delta shows the temperature difference between the main probe

and the level probe.

Cnt = Count

Count shows how many ATO pulses have been generated in the

current topoff attempt.

Sept. 2014

25

Page 26

3-5.

TECH MODE

1. Press and hold until “*MAIN*” ashes on the screen.

2. Press and release to go to the second list of menu options.

3. Press the “4.PROG” button.

4. Press the to navigate through the menu options. Select

“7.TECH MODE”.

5. Enter the code 11221122.

Use the left or right arrow buttons to navigate through the

options:

T-1 • SOFTWARE ID’S

T-2 • META DATA

T-3 • FRYER TYPE

T-4 • FRYER HAS SEL VALVE

T-5 • FRYER SERIAL NUMBER

T-6 • PUSH BUTTON TEST

T-7 • DISPLAY TEST

T-8 • AUDIO TEST

T-9 • LVL TEMP OFFSET ADJ

T-10 • MAIN TEMP OFFSET ADJ

T-11 • BOTTOM TMP OFFSET ADJ

T-12 • SPARE TMP OFFSET ADJ

T-13 • CPU° TEMP OFFSET ADJ

T-14 • INPUTS-1

T-15 • INPUTS-2

T-16 • INPUTS-3

T-17 • PRESSURE INPUTS

T-18 • OUTPUTS

T-19 • DRN VALVE

T-20 • SEL VALVE FWD/REV

T-21 • SEL VALVE PORTS

T-22 • PUMPS

T-23 • OPS SYSTEM ENABLED?

T-24 • RADIO COM

T-25 • ANALOG CHANNELS

T-26 • HEAT CTRL

T-27 • ALLOW LID OPEN

T-28 • LID LINER PIN -MUST- ACUATE

T-29 • AFTER COOK PRESSURE STUCK ON GIVES ERROR

T-30 • AUTO-CYCLE PRESSURE SOLENOID?

T-31 • BLOCKED DRAIN AUTO-REV RETRIES

T-32 • ATO DELTA -FULLT-33 • ATO DELTA -LOWT-34 • QUICK FLTR FILL TO LVL PROBE TEMP RISE

T-35 • DAILY+POL FILL TO LVL PROBE TEMP RISE

T-36 • ANY FILL, LVL PROBE MIN DETECT

T-37 • IGNOT E93 24VDC ERROR?

T-38 • CHANGE TECH CODE

T-39 • DO TOTAL INIT

T-1 SOFTWARE ID’S

Shows th active version of software in the middle display.

Jan. 2015

T-3 FRYER TYPE

Shows what type of fryer (pressure or open) in the middle

display.

To change the fryer type:

1. Press the illuminated lower-left button to change from

Pressure to Open.

The model type will change in the middle display.

26

Page 27

3-5.

TECH MODE

(CONT.)

T-4 FRYER HAS SELECTOR VALVE

• If the unit is not equipped with a selector valve, the middle

display should read “NO”.

• If the unit is equipped with a selector valve, the middle

display should read “YES”.

• If incorrectly labeled, press the illuminated buttons next to the

+ or -.

T-5 FRYER SERIAL NUMBER

This section displays the unit’s serial numbuer

T-6 BUTTON TEST

This section test all the buttons to conrm all are working

correctly. Press any of the non-illuminated buttons to enter the test

mode.

The screen will return to normal operation after 3 seconds of no

activity.

T-7 DISPLA Y TEST

This section test all of the LED and display lights. Press the

illuminated button next to the type of test listed on the display.

• Press and hold the button on the LED test to test all the lights

on the buttons

• Press and release the buttons next to the display test options to

circulate through the different sections of the display.

T -8 AUDIO TEST

• Press the button next to “Start” to start the Audio volume test.

• Press and hold the button next to “Hold” to test the current

volume.

Feb. 2015

27

Page 28

3-5.

TECH MODE

(CONT.)

T-9 LVL TEMP OFFSET ADJ

Shows the current temperature of the oil at the level probe.

1. To adjust the temperature, press and hold the button next the

“Temp”.

2. With the button held, press the + or - to adjust the temperature

3. To adjust the offset, press and hold the button next to the

“Ofst”.

4. With the button held, press the + or - to adjust the offset.

T-10 MAIN TEMP OFFSET ADJ

Shows the current main temperature of the oil.

1. To adjust the temperature, press and hold the button next the

“Temp”.

2. With the button held, press the + or - to adjust the temperature

3. To adjust the offset, press and hold the button next to the

“Ofst”.

4. With the button held, press the + or - to adjust the offset.

T-11 BOTTOM TMP OFFSET ADJ

Shows the current temperature of the oil at the bottom probe.

1. To adjust the temperature, press and hold the button next the

“Temp”.

2. With the button held, press the + or - to adjust the temperature

3. To adjust the offset, press and hold the button next to the

“Ofst”.

4. With the button held, press the + or - to adjust the offset.

T-12 SPARE TMP OFFSET ADJ

Accesses a spare temperature probe input.

Feb. 2015

28

Page 29

3-5.

TECH MODE

(CONT.)

T-13 CPU TEMP OFFSET ADJ

This dispalys the temperature of the control board. To adjust the

offset;

1. Press and hold the button next to “Ofst”.

2. Press the buttons next to the - or the + to adjust the offset

down or up.

T-14 INPUTS-1

A H D S F P M shows in the middle display.

A = Power Switch

H = High Limit

D = Drain Switch Jumper

S = Power Switch Interlock

F = Fan Switch Jumper

P = Not in use at this time

M = Not in use at this time

√ = signal present

- = signal not present

T-15 INPUTS-2

24dc = 24 DC Supply

Pan = Filter Drain Pan

Lid = Lid Liner Pin

√ = active

- = inactive

OK = lid pin is down (not under pressure)

Flashing PR = lid pin is raised (under pressure)

T-16 INPUTS-3 Bulk Oil

DTF, HDP, AFR show in the middle display

DTF = Discard Tank Full

√ = Tank is full; cannot dispose oil to tank

HDP = High Dispose Pressure

√ = Dispose pumping caused high pressure

Feb. 2015

AFR = ATO Fill Request

√ = Switch is asking to pump Bulk Supply Oil to rell the

ATO tank

29

Page 30

3-5.

TECH MODE

(CONT.)

T-17 PRESSURE INPUTS

This section shows the current psi of the lid. If “OK” is on the

display, the lid is safe to open. Otherwise, “PR” ashes showing

lid is under pressure

The bottom display reads “Lid Pin”. If “OK” is on the display, the

lid pin is down. Other wise, “PR” ashes showing the pin is raised

(under pressure).

T-18 OUTPUTS

Press the illuminated buttons next to the feature to test

Pri = Primary Contactor

Ht = Heat (regulating) Contactor

Pr = Pressure Solenoid

* = On

- = Off

T-19 DRN VALVE

NOTE: Be sure drain pan is in place before testing drain valve.

This section test the drain valve functions. A ► will show next to

the drain valves current state.

Par = Partially open

Stp = Forced stop

Opn = Fully open

NOTE: The number in the middle will display the position “At”

where the drain valve stopped from 00-20.

Cls = Fully closed

T-20 SEL VALVE FWD/REV

This section test the selector valve rotation position

Cst = Current state

Stp = Stop the selector valve rotation

Fwd = Press to rotate the selector valve forward.

Rev = Press to rotate the selector valve in reverse.

Feb. 2015

The “Enc” (encoder) will show when the encoder switch is

activated during rotation.

30

Page 31

3-5.

TECH MODE

(CONT.)

T-21 SEL VALVE PORTS

This section test the positioning of each port on the selector valve.

P0 = At pot

P1 = At dispose

P2 = At ATO rell

Enc = Encoder position

If the selector valve does not function properly, “FAIL” will show

on the middle-left display.

T-22 PUMPS

Press the illuminated button next to the function to start test.

* = On

- = Off

Fltr = Filter Pump

ATO = JIB Pump

Drn C = Drain Valve

T-23 OPS SYSTEM ENABLED?

This section allows the OPS system to be enabled for store use.

Press the + or - to either select “YES” or “NO”.

T-24 RADIO SYSTEM

Section shows if the unit is equipped with a radio system.

To change the option, pres the + or - to select “NO” or “YES”.

T -25 ANALOG CHANNELS

Displays the various analog inputs.

T-26 HEAT CTRL

Displays the performance data monitored by the heating

algorithm.

Feb. 2015

31

Page 32

3-5.

TECH MODE

(CONT.)

T-27 ALLOW LID OPEN

Displays the PSI limit value that the lid can be opened after a cook

cycle. If the PSI is above this setting, the lid will remained locked

and display “WAIT” until the PSI is at or below this value.

T-28 LID LINER PIN -MUST- ACTUATE

Displays the PSI that the monitoring switch on top of the lid liner

pressure pin must actuate.

T-29 AFTER COOK, PRESSURE STUCK ON GIVE ERROR

Displays how many seconds after pressure should be depleted

until it gives the appropriate Error Code.

T-30 AUTO-CYCLE PRESSURE SOLENOID?

This section allows the solenoid to be auto-cycled after every cook

cycle.

Pushing the up or down arrows to select either “YES” or “NO”.

T-31 BLOCKED DRAIN AUTO-REV RETRIES

AUTO-REV = Auto-Reverse

The value displayed is the number of times the drain valve tries

to close if it does not successfully close the rst time. If the drain

valve does not fully close, the unit will beep and the drain will

automatically open, allowing the user to remove any obstruction.

T-32 ATO DELTA -FULLT-33 ATO DELTA -LOW-

The temperatures displayed in each of the sections are the

threshold to determine if the oil level is full or low.

T-34 QUICK FLTR, FILL TO LVL PROBE, TEMP RISE

The temperature displayed is at what point the oil stops pumping

during the ll phase of the Quick Filter.

T-35 DAILY+POL, FILL TO LVL PROBE, TEMP RISE

Feb. 2015

The temperature displayed is at what point the oil stops pumping

during the ll phase of a Polish.

T-36 ANY FILL, LVL PROBE MIN DETECT

If the temperatures in the previous sections happen too quickly,

the controls ignore them and the oil pumps for the value displayed.

32

Page 33

3-5.

TECH MODE

(CONT.)

T-37 IGNORE E93 24VDC ERROR?

This is only for Alpha units.

T-38 CHANGE TECH CODE

Call Henny Penny Technical Support for details.

T-39 TOTAL INIT

Press and hold the button next the “hold” on the display to

institutionalize the control board.

Feb. 2015

33

Page 34

4-1.

INTRODUCTION

4-2.

MAINTENANCE

HINTS

SECTION 4: MAINTENANCE

This section provides checkout and replacement procedures, for various parts of the fryer. Before replacing any parts, refer to the Troubleshooting Section to aid you in nding the cause of the malfunction.

1. A multimeter will help you to check the electric components.

2. When the manual refers to the circuit being closed, the multime-

ter should read zero unless otherwise noted.

3. When the manual refers to the circuit being open, the multimeter

should read innity.

Do not move the fryer with hot oil in the vat or lter pan. Severe

burns can result from splashing hot oil.

Sept. 2014

34

Page 35

4-3.

CONTROL BOARD

REPLACEMENT

Disconnect the power or electrical shock will occur.

1. Use a Phillips head screwdriver to remove the two screws

securing the control board to the front shroud.

2. Press in on the bottom of the board and rotate down until it rests

on the shroud.

3. Disconnect all the connectors on the back of the control board.

4. Use a 3/8in. nut-driver or socket and remove the nut securing the

ground wire to the control board.

5. Remove old control board.

6. Place new control board onto the unit with the tab inserted into

the slot. Let the control board rest on the shroud.

7. Finish control board installation in reverse order.

Sept. 2014

35

Page 36

4-4.

POWER SWITCH

REPLACEMENT

Disconnect the power or electrical shock will occur.

1. Lower the control board (see Control Board Replacement).

2. Mark the wires and disconnect.

3. Use a at-blade screwdriver to press down on the locking tabs.

4. Pull the switch out of the shroud.

5. Place new switch in place.

6. Attach the wires to the new switch.

7. Slide new power switch into the shroud.

8. Secure the control board back in place.

9. Test operation.

Sept. 2014

36

Page 37

4-5.

USB PORT

REPLACEMENT

1. Remove the USB cap.

2. Use an adjustable wrench to remove the locking nut.

3. Remove the cap from the USB assembly.

4. Lower the control board (see Control Board Replacement).

5. Disconnect the USB plug from the receiver on the back of the

control board.

6. Pull USB port assembly out of the hole in the control board.

7. Place the new USB port assembly into the hole in the control

board.

8. Use one adjustable wrench to hold the USB port in place while

using another adjustable wrench to tighten the locking nut.

9. Plug the USB plug into the receiver on the back of the control

board.

10. Secure the control board back in place.

Sept. 2014

37

Page 38

4-6.

HIGH LIMIT

THERMOCOUPLES

Disconnect the power or electrical shock will occur.

1. Lift the lid and tilt back to lock into place.

2. Use a Phillips head screwdriver to loosen the heating element

spreaders.

3. Use a Phillips head bit to remove the screws from the left-hand

(from the front of unit) side panel.

4. Lower side panel and set aside.

5. Use a 1/2in. wrench to loosen the compression tting.

6. Pull the thermocouple from the tting.

7. Lower the control board (see Control Board Replacement).

8. Trace wires to the high limit modules on the sidewall of the

control board area.

9. Remove the wires from high limit module.

10. Use a 1/2in. wrench to remove the tting from the vat wall.

11. Locate the new thermocouple and tting.

12. Apply thread sealant to the tting and thread into the vat wall.

Tighten with 1/2in. wrench.

13. Insert the new thermocouple into the compression tting.

NOTE: Be sure the new thermocouple slides into the heating

element spreader.

14. Use a 1/2in. wrench to tighten the compression tting onto the

thermocouple.

15. Use a Phillips head screwdriver to tighten the heating element

spreader.

16. Connect the new thermocouple wires to the high limit module.

Sept. 2014

17. Place side panel back in place and secure with the screws.

18. Secure the control board back in place.

38

Page 39

4-7.

HIGH LIMIT

THERMOCOUPLES

Disconnect the power or electrical shock will occur.

1. Lower the control board (see Control Board Replacement).

2. Locate the faulty high limit module on the left-hand (from the

front) side wall.

3. Mark all the wire locations.

4. Disconnect all the wires.

5. Use a 3/8in. socket or nut-driver to remove the nuts.

6. Remove the two (2) metal lock strips.

7. Slide the high limit module off of the mounting studs.

8. Slide the new high limit module onto the mounting studs.

9. Place the two (2) metal lock strips onto the studs and secure in

place with a 3/8in. socket or nut-driver.

10. Reconnect the wires as removed.

11. Secure the control board back in place.

Sept. 2014

39

Page 40

4-8.

PRIMARY

CONTACTOR

REPLACEMENT

Disconnect the power or electrical shock will occur.

1. Lower the control board (see Control Board Replacement).

2. Mark the location of the wires.

3. Use a Phillips head screwdriver to remove the L1, L2 and L3

wires from the contactor.

4. Use a Phillips head screwdriver to remove the wires on the T1, T2

and T3 side of the contactor.

5. Disconnect the wires coming from the T1, T2 and T3 on the

contactor.

6. Disconnect the RS1 and RS2 yellow wires.

7. Use a 3/8in. socket or nut-driver to remove the nuts that secure the

contactor to the shroud.

8. Lift up on the contactor to remove it from the studs.

9. Place the new contactor onto the studs.

10. Use a 3/8in. socket or nut-driver to secure in place.

11. Replace wires as they were removed.

12. Secure the control board back in place.

13. Test operation.

Sept. 2014

40

Page 41

4-9.

HEAT CONTACTOR

REPLACEMENT

Disconnect the power or electrical shock will occur.

1. Lower the control board (see Control Board Replacement).

2. Mark the locations of the wires.

3. Use a Phillips head screwdriver to remove the blue wires in A1

and A2.

4. Use a Philips head screwdriver to remove the coming from the

1L1, 3L2 and 5L3 side on the contactor.

5. Use a Phillips head screwdriver to remove the wires from the 2T1,

4T2 and 6T3 side of the contactor.

6. Use a 3/8in. socket or nut-driver to remove the two nuts on the

mounting plate.

7. Lift up on the contactor so the mounting plate clears the studs.

8. Place new contactor on the studs as the old contactor was

removed.

9. Use a 3/8in. socket or nut-driver to secure in place.

10. Reconnect all the wires where previously removed.

11. Secure the control board back in place.

12. Test operation.

Sept. 2014

41

Page 42

4-10.

AIF MULTI-TAB

TRANSFORMER

REPLACEMENT

Disconnect the power or electrical shock will occur.

1. Lower the control board see Control Board Replacement).

2. Label the locations of the wires and disconnect.

3. Use a 3/8in. nutdriver or socket to remove the four (4) nuts.

4. Remove the transformer from the studs.

5. Place new transformer onto the studs and secure with a 3/8in.

nutdriver or socket.

6. Reconnect the wires to the correct locations.

7. Close control panel.

8. Return power back to the unit.

9. Test operations.

Sept. 2014

42

Page 43

4-12.

CONTROL

TRANSFORMER

REPLACEMENT

Disconnect the power or electrical shock will occur.

1. Lower the control board see Control Board Replacement).

2. Locate the 5-pin connector leading from the transformer.

Disconnect the connector.

3. Use a 3/8in. socket and extension, remove the two (2) nuts that

secure the transformer to the shroud.

4. Lift up on the transformer to remove it from the studs.

5. Place the new transformer onto the studs.

6. Secure the transformer in place with a 3/8in. socket and extension.

7. Connect the 5-pin connector to the 5-pin connector jumper coming

from the control board.

8. Secure the wires with tie-strips to the existing wiring harness.

9. Secure the control board back in place.

Sept. 2014

43

Page 44

4-13.

PUMP MOTOR

REPLACEMENT

1. Remove the condensation pan.

2. Remove the Fresh Oil Tank.

3. Remove the drain pan.

4. Use an adjustable wrench to remove the ex line (hard line may be

present for newer builds) and pipe connections from both ends of

the pump motor.

5. Use a Phillips head screwdriver to remove the two screws that

secure the plate onto the pump motor.

6. Mark the locations of the black wires.

7. Remove the black wires from the pump motor.

8. Use a at blade screwdriver to remove the conduit retainer ring

from the pump motor.

9. Remove the conduit retainer and conduit from the pump motor.

Jan. 2016

44

Page 45

4-13.

PUMP MOTOR

REPLACEMENT

(CONT.)

10. Use a 1/2in. wrench to remove the two nuts on the mounting plate.

11. Lift up on the pump motor then pull it off the mounting plate.

12. Place the new pump motor onto the mounting plate so the hanger

bolts rest on the top lip and slide down so the studs are in line with

the holes in the pump motor base.

13. Use a 1/2in. wrench to secure the pump motor to the mounting

plate.

14. Use an adjustable to reconnect the lines to the correct port of the

pump motor.

Jan. 2016

45

Page 46

4-14.

REMOVE THE LID

COVER

1. Use a phillips head screwdriver to remove the two (2) screws

located in the back of the lid.

2. Use a at blade screwdriver to gently pry the front of the lid

cover so that the locater pegs slide out of their holes.

3. Lift up on the back of the lid cover.

4. Set the lid cover to the side.

5. The lid components are now accessible.

6. Reverse the previous steps to reinstall the lid cover.

Jan. 2016

46

Page 47

4-16.

LOCK POSITION

SWITCHES

REPLACEMENT

1. Remove the lid cover (see Remove Lid Cover section).

2. Mark the location of each wire.

3. Disconnect the wires.

4. Use a phillips head screwdriver to remove the two (2) screws that

secure the switch to the mounting plate.

5. Place the new switch in place.

6. Secure the switch with the two (2) screws previously removed.

7. Reconnect the wires.

Jan. 2016

47

Page 48

4-17.

FLEX TUBE

REPLACEMENT

When installing new ex tubes, follow the listed guidelines to prevent

failures of the new ex tube.

1. Do not bend the ex tube within 4 nger widths of the end

ttings.

2. When bending the ex tube, the bend should not be smaller than

a golf ball in radius.

3. All ex tubes should be torque nger tight, then a ¼ turn.

4. When tightening then ex tube’s tting, hold the tting that

the nut is tightening to, while torquing, to avoid twisting of the

exible tube.

5. Discard any tube bent more than 3 times in the same area of tube.

Jan. 2016

48

Page 49

Oct. 2014

49

Page 50

Oct. 2014

50

Page 51

Oct. 2014

51

Page 52

Oct. 2014

52

Page 53

Oct.. 2014

53

Page 54

5-1

INTRODUCTION

SECTION 5: PARTS SECTION

This section lists the replaceable parts of the Henny Penny Velocity

Series Pressure Fryer.

5-2

GENUINE PARTS

5-3

WHEN ORDERING

PARTS

5-4

PRICES

Use only genuine Henny Penny parts in your fryer. Using a part of

lesser quality or substitute design may result in damage to the unit or

personal injury.

Once the parts that you want to order have been found in the parts list,

write down the following information:

Example:

Item Number 2

Part Number 60241

Description High Limit

From the data plate, list the following information:

Example:

Product Number 01100

Serial Number 0001

Voltage 208

Your distributor has a price parts list and will be glad to inform you of

the cost of your parts order.

5-5

DELIVERY

5-6

WARRANTY

5-7

RECOMMENDED

SPARE PARTS FOR

DISTRIBUTORS

Sept. 2014

Commonly replaced items are stocked by your distributor and will be

sent out when your order is received. Other parts will be ordered, by

your distributor, from Henny Penny Corporation. Normally, these will

be sent to your distributor within three working days.

All replacement parts (except lamps and fuses) are warranted for 90

days against manufacturing defects and workmanship.

If damage occurs during shipping, notify the carrier at once so that

a claim may be properly led. Refer to warranty in the front of this

manual for other rights and limitations.

Recommended replacement parts are indicated with A or B in the parts

lists: A = parts to be stocked on service vans or trucks B = parts to be

stocked at the distributor/KES location. Inventory on all other parts not

identied, should be based upon usage in the territory. Please use care

when ordering recommended parts, because all voltages and variations

a marked. Distributors should order parts based upon comm voltages

and equipment sold in their territory.

54

Page 55

9

7

1

2

4

8

3

6

5

Item No. Part No. Description Quantity

A 1 96804 ASSY-GM PXE100 CONTROL ............................................. 1

* 96613 --DECAL-PXE101 .................................................................. 1

* 26974 ASSY-SPEAKER .................................................................... 1

2 150598 FRESH OIL TANK ................................................................. 1

3 150836 CONDENSATION PAN .......................................................... 1

4 151783 ASSY-DRAIN PAN PFX ........................................................ 1

--(see next page for breakdown)

5 90227 CASTER-3.5 RIGID W/END BRAKE ................................... 2

6 35154 CASTER 4-INCH SWIVEL STEM ........................................ 2

7 89664 GASKET-V STYLE FRYPOT LID ........................................ 1

8 35227 ROLLER-LINKAGE SHAFT ................................................. 2

9 152443 ASSY-LID AND COVER ....................................................... 1

* 140440 LID ROLLER KIT .................................................................. 1

* 94123 WELD ASSY-CARRIER ........................................................ 1

* 140440 LID ROLLER KIT .................................................................. 1

* 96800 ACCSRY GM PXE100 ........................................................... 1

* = Not Shown / AR = As Required

Jan. 2016

55

Page 56

9

8

7

7

1

5

2

3

8

6

Item No. Part No. Description Quantity

1 151783 ASSY-DRAIN PAN PFX ........................................................ 1

2 156492 -WELD ASSY-FILTER DRAIN PAN ..................................... 1

3 19004 --CASTER-2 IN SWIVEL MTG PLATE ................................ 4

4 NS04-005 --SERRATED FLANGE LOCKNUT 1/4-20 .......................... 16

5 92889 -WELD ASSY-FILTER SECTION ......................................... 1

6 150739 -WELD ASSY-CARRIER CLIP ............................................. 2

7 151819 -WELD ASSY-CRUMB CATCHER ....................................... 1

A 8 86349 -O-RING -116 SUCTION LINE ............................................. 5

9 94289 -ASSY-DRAIN PAN COVER PFX ........................................ 1

B * 12102 -PHT FILTER ENVELOPES-100CT ...................................... AR

* 152204 -WELD ASSY-PNP UNIT ....................................................... 1

4

* = Not Shown / AR = As Required

Feb. 2016

56

Page 57

1

9

2

37 5 48 6

Item No. Part No. Description Quantity

A 1 154252 ASSY-2 IN RTD PROBE ........................................................ 1

B 2 89225-001 ELEMENT-HEATING 8.5 KW (208V) .................................. 2

B 2 89225-003 ELEMENT-HEATING 8.5 KW (240V) .................................. 2

B 2 89225-004 ELEMENT-HEATING 8.5 KW (480V) .................................. 2

B 2 89225-005 ELEMENT-HEATING 8.5 KW (200V) .................................. 2

B 2 89225-006 ELEMENT-HEATING 8.5 KW (230V) .................................. 2

B 2 89225-007 ELEMENT-HEATING 8.5 KW (220V) .................................. 2

3 87119 SPREADER-ANGLED ........................................................... 3

4 87120 SPREADER-TAP PLATE ....................................................... 3

5 154736 CLIP-HIGH LIMIT ................................................................. 2

6 154866 WELD ASSY-HI LIMIT CLAMP CLIP ................................. 2

7 154839 SPREADER-HI LIMIT ANGLED .......................................... 1

8 154840 SPREADER-HI LIMIT TAP PLATE ...................................... 1

* SC01-173 SCREW- #10-32 X 5/8 PH FHD SS ....................................... 8

9 90085 O RING-CRUMB SWEEP ...................................................... 2

* = Not Shown / AR = As Required

Sept. 2014

57

Page 58

1 2 3 4 5 6

Item No. Part No. Description Quantity

B 1 83581-002 CONTROL-WATLOW HIGH LIMIT (208V) ........................ 2

B 1 156985 CONTROL-WATLOW HIGH LIMIT (CE) ............................ 2

* 84987 HL SWITCH-MOMENTARY SPLASH PROOF ................... 1

B 2 51795 CONTACTOR-208/240 VAC COIL ........................................ 1

B 2 65073 CONTACTOR-SQUARE D-24V ............................................ 1

3 EF02-125 BREAKER-PUSH BUTTON RESET ..................................... 2

* EF02-104 FUSE HOLDER-20A 250V .................................................... 2

* EF02-105 FUSE 15 AMP ......................................................................... 2

B 4 29509 CONTACTOR KIT - 24VAC .................................................. 1

B 5 86087 ASSY-24V/240V 75VA TRANSFORMER ............................. 1

6 TS22-012 TRANSFORMER.................................................................... 1

* ME90-008 P&B T92 RELAY 12VDC COIL 30AMP ............................... 1

* = Not Shown / AR = As Required

July 2016

58

Page 59

1

2 3

4

Item No. Part No. Description Quantity

1 94229 INSULATION-POT LEFT SIDE ............................................ 1

A 2 154252 ASSY-2 IN RTD PROBE ........................................................ 1

3 79213 TRANSDUCER-PRESSURE 30 PSI...................................... 1

A 4 93968 THERMOCOUPLE-HI LIMIT ............................................... 2

A 4 156986 THERMOCOUPLE-HI LIMIT PROBE (CE) ........................ 2

* = Not Shown / AR = As Required

July 2016

59

Page 60

6

1

7

2

5

4

3

Item No. Part No. Description Quantity

B 1 67583 MOTOR-1/2 HP FILTER PUMP (60Hz) ................................ 1

B 1 92850 MOTOR-1/2 HP FILTER PUMP (50Hz) ................................ 1

B * 64218 ASSY-FILTER PUMP-8 GPM ................................................ 1

2 ------- FLEX LINES

(see chart below for lengths and numbers)

B 3 89780 VALVE-ACTR DRAIN W/ 4 PIN CONN .............................. 1

B 4 90506-001 VALVE-CHECK SAE 12 (max 200psi) .................................. AR

A 5 154252 ASSY-2 IN RTD PROBE ........................................................ 1

B 6 91700 ASSY-LH DRAIN PAN SW W/CONN .................................. 1

7 140444 FORM TUBE KIT ................................................................... 1

7 140446 FORM TUBE KIT (BULK OIL) ............................................. 1

Flex Line

Part Number Length

77523-002 12in.

77523-011 10in.

* = Not Shown / AR = As Required

July 2016

60

Page 61

1

3

2

5

4

Item No. Part No. Description Quantity

1 94256 SLIDE-SHROUD VERTICAL ................................................ 2

B 2 85145 VALVE-208-240V 3/4IN SOLENOID .................................... 1

3 94941 GASKET-DEAD WEIGHT HOLDER ................................... 1

* SC06-093 SCREW-10-32 X .500 KNURL PH HD ................................. 3

4 152276 ASSY-PULLEY CABLE AND LABEL ................................. 2

5 94377 HOSE-STEAM BOX CONDENSATE ................................... 1

* = Not Shown / AR = As Required

Sept. 2014

61

Page 62

1 2 3

Item No. Part No. Description Quantity

1 16903 DEAD WEIGHT-12 P.S.I. ....................................................... 1

2 152101 GASKET-STEAM BOX COVER ........................................... 2

3 16918 ORIFICE - 12 PSI ................................................................... 3

* = Not Shown / AR = As Required

Sept. 2014

62

Page 63

1 2 3 4 3 2

Item No. Part No. Description Quantity

1 59742 ASSY - SAFETY RELIEF VALVE ......................................... 1

2 94256 SLIDE-SHROUD VERTICAL ................................................ 2

3 152276 ASSY-PULLEY CABLE AND LABEL ................................. 2

4 94259 COUNTERWEIGHT BAR ..................................................... AR

* = Not Shown / AR = As Required

Sept. 2014

63

Page 64

1

Item No. Part No. Description Quantity

2

3

B 1 74583 PUMP-OIL TOP OFF 230V .................................................... 1

B 2 90506-001 VALVE-CHECK SAE 12 (max 200psi) .................................. AR

3 ------- FLEX LINES

(see chart below)

Flex Line

Part Number Length

85458-002 10in.

85458-003 25in.

* = Not Shown / AR = As Required

Sept. 2014

64

Page 65

2

8 8

1

3

6

5

4

Item No. Part No. Description Quantity

1 94825 ASSY-CABLE AND STRAIGHT SKT .................................. 1

2 49864 PAD-PRESSURE .................................................................... 2

B 3 93778 WELD ASSY-GEAR MTR 24VAC 60HZ .............................. 1

B 4 151463 SWITCH-LID LOCKING ....................................................... 2

5 151464 SWITCH-LID INTERLOCK .................................................. 1

6 94971 ASSY-COILED LID CORD.................................................... 1

7 94322 WELD ASSY-LID WIRING RACEWAY ............................... 2

8 93222 FILLER-CAM SLIDE ............................................................. 2

4

7

* = Not Shown / AR = As Required

Sept. 2014

65

Page 66

*FM06-059-B Henny Penny Corp., Eaton, Ohio 45320, Revised 10-15-16

Henny Penny Corporation

P.O.Box 60

Eaton,OH 45320

1-937-456-8400

1-937-456-8402 Fax

Toll free in USA

1-800-417-8417

1-800-417-8434 Fax

www.hennypenny.com

Loading...

Loading...