Page 1

OPERATOR’S

MANUAL

VELOCITY SERIESTM PRESSURE FRYER

MODEL

PXE-100

REGISTER WARRANTY ONLINE AT WWW.HENNYPENNY.COM

REGISTER WARRANTY ONLINE AT WWW.HENNYPENNY.COM

Read instructions before operating the applianceOriginal Instructions

Page 2

Page 3

HENNY PENNY

ELECTRIC PRESSURE FRYER

SPECIFICATIONS

Pot Capacity 8 head of chicken - 24 lbs. (10.8 kg)

76 lbs. oil (34 Kg.)

Electrical 208 VAC, 3 Phase, 50/60 Hz, 17 KW, 47.2 Amps

240 VAC, 3 Phase, 50/60 Hz, 17 KW, 40.9 Amps

480 VAC, 3 Phase, 50/60 Hz, 17 KW, 20.5 Amps

Heating Two 8,500 watt electric immersion elements

A data plate, located on the back shroud behind the lid identies the fryer model, serial

number, warranty date, and other information. Also, the serial number is stamped on the

outside of the counter top. See gure below.

Serial No.

Page 4

PXE-100

DIMENSIONS

Page 5

HENNY PENNY

8 HEAD ELECTRIC PRESSURE FRYER

Fryer must be installed and used in such a way to prevent water from contacting the shortening.

This appliance is not intended to be operated by means of an external timer or a separate remote control

system.

This appliance is not intended for use by persons (including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a person responsible for their safety.

Page 6

TABLE OF CONTENTS

Section Page

Section 1. INTRODUCTION ..................................................................................................... 1

1-1 Safety ............................................................................................................. 1

1-2 Proper Care ....................................................................................................2

1-3 Assistance ...................................................................................................... 2

Section 2. INSTALLATION .......................................................................................................3

2-1 Introduction ................................................................................................... 3

2-2 Unpacking...................................................................................................... 3

2-3 Selecting the Fryer Location ......................................................................... 7

2-4 Leveling the Fryer ......................................................................................... 7

2-5 Ventilation of Fryer........................................................................................8

2-6 Electrical Requirements .................................................................................8

2-7 International Electrical Requirements ...........................................................9

Section 3. OPERATION .............................................................................................................11

3-1 Operating Components ..................................................................................11

3-2 Control Overview ..........................................................................................12

3-3 Display Options .............................................................................................14

3-4 4+Title Option ...............................................................................................14

3-5 5+Next Option ...............................................................................................15

3-6 6 Item Option .................................................................................................15

3-7 Drain Pan Assembly ...................................................................................... 16

3-8 Product Racking Recommendations ..............................................................17

3-9 Lid Operation.................................................................................................18

3-10 Start-up .......................................................................................................... 20

3-11 Filling the Oil Tank ........................................................................................ 21

3-12 Condensation T ank ........................................................................................21

3-13 Filter Pump Motor Protector-Manual Reset .................................................. 22

3-14 Regular Maintenance Schedule ..................................................................... 22

3-15 Initial Oil Fill ................................................................................................. 23

3-16 Basic Operation ............................................................................................. 24

3-17 Care of the Oil ............................................................................................... 25

3-18 Main Menu .................................................................................................... 25

3-19 Filtering Instructions ..................................................................................... 26

3-20 Bulk Dispose ................................................................................................. 30

3-21 Changing the Filter Envelope ........................................................................ 31

3-22 Clean-Out Mode ............................................................................................ 31

3-23 Preventive Maintenance ............................................................................... 36

Section 4. PROGRAMMING ........................................................................................................39

4-1 Program Menu ............................................................................................... 39

4-2 Product Programming ....................................................................................39

4-3 Special Programming ....................................................................................41

Section 5. TROUBLE SHOOTING ...............................................................................................44

5-1 Troubleshooting Guide ..................................................................................44

5-2 Error Codes ....................................................................................................45

Sept. 2014

Page 7

SECTION 1: INTRODUCTION

1-1

SAFETY

The instructions in this manual have been prepared to aid you in learning

the proper procedures for your equipment. Where information is of

particular importance or is safety related, the words NOTICE, CAUTION,

or WARNING are used. Their usage is described below.

If a problem occurs during the rst operation of a new unit, recheck the

Installation Section of the Operator’s Manual.

Before troubleshooting, always recheck the Operation

Section of the Operator’s Manual.

Where information is of particular importance or is safety related, the

words DANGER, WARNING, CAUTION, or NOTICE are used. Their

usage is described as follows:

SAFETY ALERT SYMBOL is used with DANGER, WARNING

or CAUTION which indicates a personal injury type hazard.

NOTICE is used to highlight especially important information.

CAUTION used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may result

in property damage.

CAUTION used with the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, could result

in minor or moderate injury.

WARNING indicates a potentially hazardous situation which,

if not avoided, could result in death or serious injury.

DANGER INDICATES AN IMMINENTLY HAZARDOUS

SITUATION WHICH, IF NOT AVOIDED, WILL RESULT IN

DEATH OR SERIOUS INJURY.

March 2014

1

Page 8

1-1.

SAFETY

(CONT.)

Equipotential Ground Symbol

Waste Electrical and Electronic Equipment (WEEE) Symbol

1-2.

PROPER CARE

OR

OR

Shock Hazard Symbols

Hot Surface Symbols

As in all Henny Penny equipment, the unit requires care and

maintenance. Requirements for maintenance and cleaning are

contained in this manual and must be a regular part of the operation of the unit.

1-3.

ASSISTANCE

March 2014

Should you require outside assistance, call your local distributor in your area, or call 1-800-417-8405 or 1-937-456-8405.for

Henny Penny Technical Support.

2

Page 9

SECTION 2: UNPACKING / INSTALLATION

2-1.

INTRODUCTION

2-2.

UNPACKING

This section provides the installation and unpacking instructions.

• Any shipping damage should be noted in the

presence of the delivery agent and signed prior to

his or her departure.

• Installation of this unit should be performed only

by a qualied service technician.

• Take care when moving the fryer to

prevent personal injury. The fryer weighs

approximately 877 lbs.(398 Kg).

• Do not puncture the fryer with any objects

such as drills or screws as electrical shock or

component damage could result.

March 2014

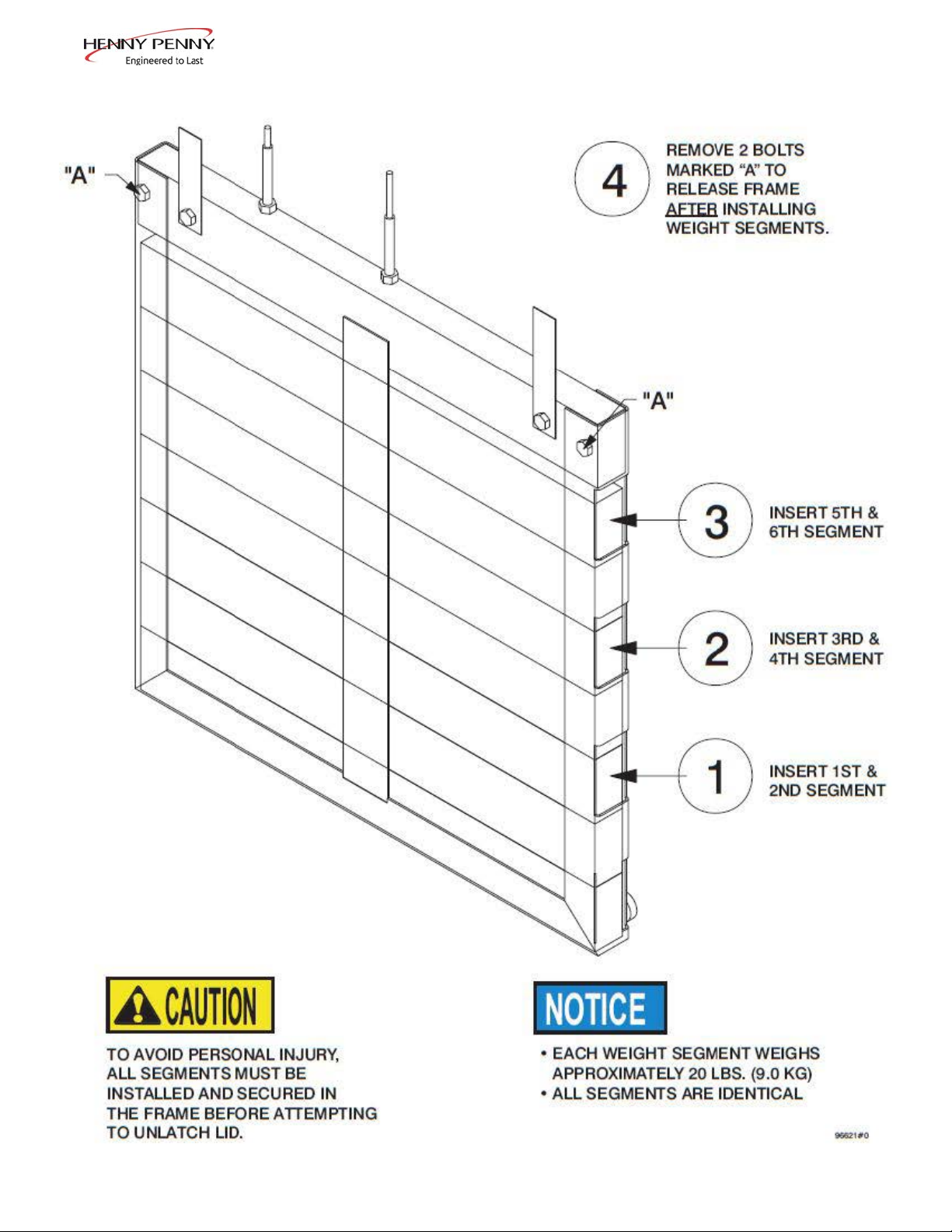

To avoid personal injury, all counter-weights must be

installed and secured before attempting to unlatch

the lid.

1. Cut and remove the plastic bands from the main box.

2. Remove the box lid and lift the main box off the fryer.

3. Remove corner packing supports (4).

4. Cut the stretch lm from around the carrier/rack box and

remove it from the top of the fryer lid.

5. Cut and remove the metal bands holding the fryer to the

pallet.

6. Remove the fryer from the pallet. See one unloading

method described on 6.

3

Page 10

2-2.

UNPACKING

(CONT.)

Do not drop counterweights , or personal injury could

result. Each counterweight weighs approximately

20 lbs. (9 kg.) each.

7. Remove the counterweights from the pallet, which are strapped

to the pallet, under the fryer.

8. Remove rear service cover.

9. Load the six weights into the counterweight assembly. See

page 7.

10. Replace rear service cover.

To avoid personal injury and assure safe

operation of unit, rear service cover must

be in place.

11. Cut warning tags from the lid assembly. The lid may now be

unlatched.

12. Remove the accessories from inside the lter drain pan.

13. Remove the protective paper from the fryer cabinet. Clean

exterior surface with a damp cloth.

March 2014

4

Page 11

Ramp Unloading

1. Front casters are xed in the forward position.

2. Pry off the rail on either side of the pallet.

3. Prop up a ramp for each caster on the selected side.

If ramp is not being used, rest the selected side’s casters onto the ground and move to step 4.

4. Tilt and roll the unit off the pallet onto the ramp (if available). The front casters will slide onto the ramp.

Pull the pallet from under the unit and set the unit onto the ground.

5. Remove the weights from the pallet.

6. Remove the rear cover. The weight segments must be installed per instructions contained therein before attempting to

unlatch the lid.

Dec. 2013

5

Page 12

Dec. 2013

6

Page 13

2-3.

SELECTING THE

LOCATION

The proper location of the fryer is very important for operation, speed,

and convenience. Choose a location which provides easy loading and

unloading without interfering with the nal assembly of food orders.

Operators nd that frying from raw to nish, and holding the product

in a warmer provides fast continuous service. Landing or dumping

tables should be provided next to the fryer. The best efciency will be

obtained by a straight line operation, i.e. raw in one side and nish out

the other side. Order assembly can be moved away with only a slight

loss of efciency.

To properly service the fryer, 24 inches (60.96 cm) of clearance is

needed on all sides of the fryer. Access for servicing by removing a

side panel.

To avoid re and ruined supplies, the area under the

fryer should not be used to store supplies.

2-4.

LEVELING THE

FRYER

To prevent severe burns from splashing hot oil, position

and install fryer to prevent tipping or movement.

Restraining ties may be used for stabilization.

For proper operation, level the fryer from side to side and front to back.

Use level on the at areas around the frypot collar.

F AILURE T O FOLLOW THESE LEVELING

INSTRUCTIONS CAN RESULT IN OIL

OVERFLOWING THE FRYPOT WHICH COULD

CAUSE SERIOUS BURNS, PERSONAL INJURY,

FIRE AND/OR PROPERTY DAMAGE.

March 2014

7

Page 14

2-5.

VENTILATION OF

FRYER

The fryer should be located with provision for venting into adequate exhaust

hood or ventilation system to permit efcient removal of steam exhaust and

frying odors. The exhaust canopy must be designed to avoid interference

with the operation of the fryer. Consult a local ventilation or heating

company to help in designing an adequate system.

Ventilation must conform to local, state,

and national codes. Consult your local re

department or building authorities.

2-6.

ELECTRICAL

REQUIREMENTS

The electric fryer requires 208, 240 or 480 volt, three phase, 50/60 Hertz

service. The power cord may be already attached to the fryer, or provided at

installation. Check the data plate to determine the correct power supply.

This fryer must be adequately and safely grounded (earthed) or

electrical shock could result. Refer to local electrical codes for

correct grounding (earthing) procedures or in absence of local codes,

with The National Electrical Code, ANSI/NFPA No. 70-(the current

edition). In Canada, all electrical connections are to be made in

accordance with CSA C22.1, Canadian Electrical Code Part 1, and/or

local codes. To avoid electrical shock, this appliance must be equipped

with an external circuit breaker which will disconnect all ungrounded

(unearthed) conductors. The main power switch on this appliance

does not disconnect all line conductors

A separate disconnect switch meeting overvoltage category III conditions

with proper capacity fuses or breakers must be installed at a convenient

location between the fryer and the power source. It should be an insulated

copper conductor rated for 600 volts and 90o C. For runs longer than 50 feet

(15.24 m), use the next larger wire size.

Aug. 2014

8

Page 15

2-7.

INTERNATIONAL

ELECTRICAL

REQUIREMENTS

Units being used outside the United States may not be shipped with the

power cord attached to the unit because of the different wiring codes.

The fryers are available from the factory wired for 200, 240, 380 and

415 volts, 3 phase, 50 Hertz service. A terminal block is mounted

inside the fryer for the cable wiring.

• CE units require a minimum wire size of 4mm to be wired to

the terminal block. If a exible power cord is used, it must be

HO7RN type.

• The supply power cords shall be oil-resistant, sheathed exible

cable, no lighter than ordinary polychloroprene or other

equivalent synthetic elastomer-sheathed cord.

• It is recommended that a 30 mA rated protective device such

as a residual current circuit breaker (RCCB), or ground fault

circuit interrupter (GFCI), be used on the fryer circuit.

(FOR EQUIPMENT WITH CE MARK ONLY!) To prevent electric

shock hazard this appliance must be bonded to other appliances or

touchable metal surfaces in close proximity to this appliance with an

equipotential bonding conductor. This appliance is equipped with an

equipotential lug for this purpose. The equipotential lug is marked

with the following symbol

March 2014

9

Page 16

BOIL-OVER PREVENTION IN HENNY PENNY FRYER

FAILURE TO FOLLOW THESE INSTRUCTIONS CAN RESULT

IN OIL OVERFLOWING THE FRYPOT WHICH COULD CAUSE SERIOUS

BURNS, PERSONAL INJURY, FIRE AND/OR PROPERTY DAMAGE.

• THE OIL MAY BE STIRRED ONLY DURING THE MORNING START UP

PROCEDURE. DO NOT STIR THE OIL AT ANY OTHER TIME.

• BRUSH ALL CRACKLINGS FROM FRYPOT SURFACES DURING THE

POT CLEAN OUT PROCESS.

• MAKE SURE THE FRYER IS LEVEL.

• BE CERTAIN THE OIL IS NEVER ABOVE THE UPPER FRYPOT “FILL”

LINE.

• BE CERTAIN THAT THE GAS CONTROL VALVE AND BURNERS ARE

PROPERLY ADJUSTED. (GAS UNITS ONLY)

• USE RECOMMENDED PRODUCT LOAD SIZE (MAXIMUM 24 LB).

FOR ASSISTANCE CALL THE HENNY PENNY SERVICE DEPARTMENT AT

1-800-417-8405.

OR

1-937-456-8405

Dec. 2013

10

Page 17

3-1.

OPERATING

COMPONENTS

SECTION 3: OPERATION

1

3

2

4

5

Item

No.

1 Steam-Stack Houses the dead-weight. Releases steam when pressurized

2 Fresh Oil Tank Tops the pot off with fresh oil when low

3 Power Switch Turns power to the unit ON/ OFF

4 Condensation Pan Reservoir that hold excess condensation that drains from the pot

5 Oil Drain Pan Oil is drained into this pan and then is pumped through lters to help

Description Function

prolong the use of the oil

Dec. 2013

11

Page 18

3-2.

CONTROL

OVERVIEW

This section gives a control board overview and explains all the

buttons, displays and features.

1

Figure 3-1

4

1

32

March 2014

Figure 3-2 Figure 3-3

5

6

Figure 3-4

12

Page 19

3-2.

CONTROL

OVERVIEW

(CONT.)

Fig.

3-1 1 Buttons

3-2 2 Menu Button

3-3 3 Info Button

3-4 4 Arrow Displays

3-4 5 Plus Display

3-4 6 Minus Display

Item

No.

Description Function

When the light is illuminated next to the button, this indicates this button

has a product or action that can be reached by pressing.

Pressing and holding this button will access the “MAIN” menu which

includes features such as lter, info mode, and programming.

• Press this button once to display the pressure and temperature

• Press this button twice to activate the “WIPE” feature

• Press this button three times to get “LAST FILTER” information

When an arrow is displayed, this indicates there is another screen or option.

To access the next option/screen, press the button next to the desired arrow.

The plus sign is displayed when the value of the time/temp/letters can be

changed. Pressing the button next to the plus sign will increase the value.

Will be represented in the manual by: +

The minus sign is displayed when the value of the time/temp/letters can be

changed. Pressing the button next to the minus sign will decrease the value.

Sept. 2014

Will be represented in the manual by: -

13

Page 20

3-3.

DISPLAY OPTIONS

3-4.

4+TITLE OPTION

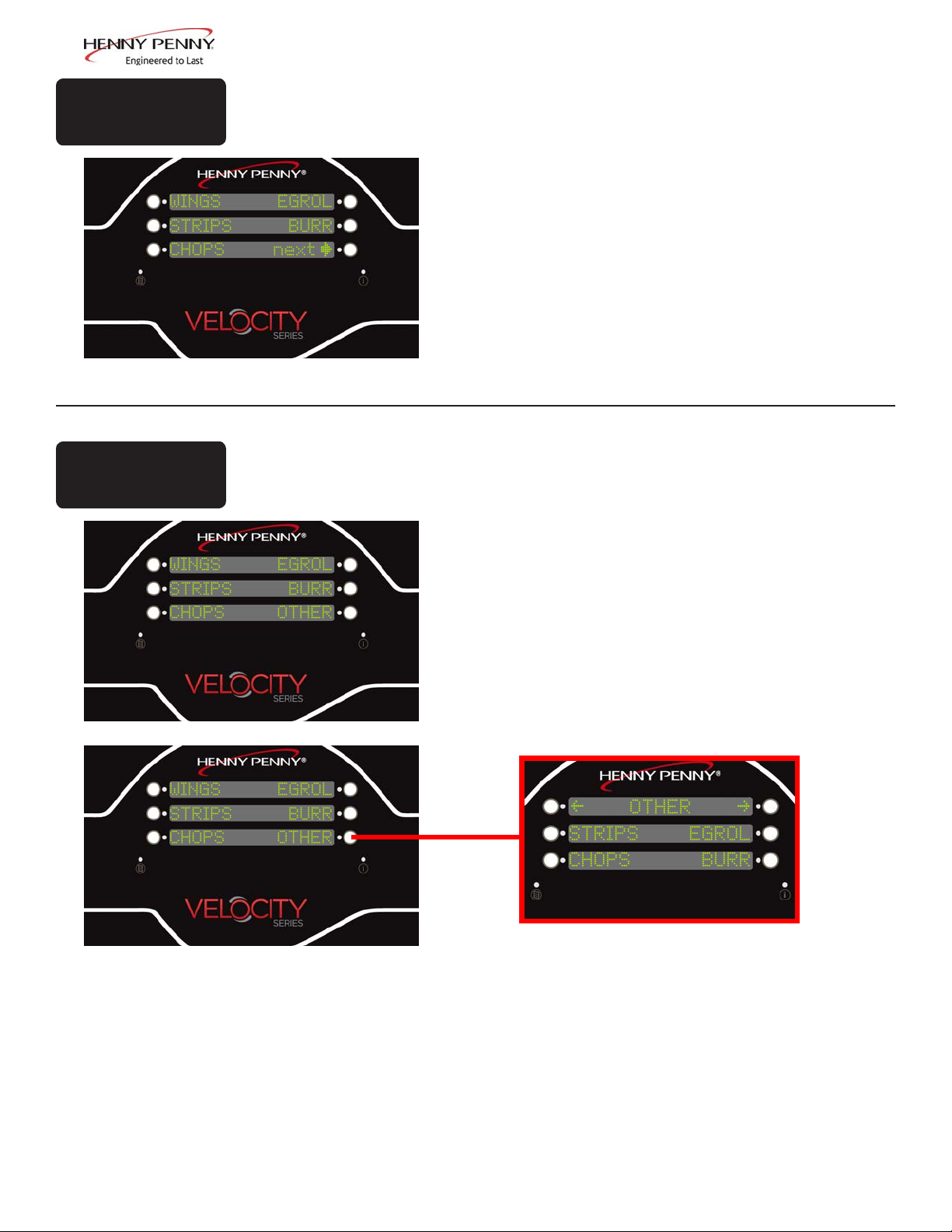

This section describes the three (3) cook display options that this

unit is equipped with. The three options are as listed below:

• 4+TITLE

• 5+NEXT

• 6 ITEMS

To change the display option, see SPECIAL PROGRAM section.

The 4+TITLE option shows up to four cook items along with the

title of the particular menu you are in.

When in a cook menu, the title of the menu will be displayed in

the top section.

Pressing the either arrow button will allow you to scroll right or

left through each menu option.

Pressing the button next to the item you want to cook starts the

heating process. ”DROP>” will be displayed when unit is ready

to cook the selected item.

March 2014

14

Page 21

3-5.

5+NEXT OPTION

3-6.

6 ITEMS OPTION

The 5+NEXT option ashows up to ve cook items, along with a

button that steps to the next cook menu.

All the cook options are displayed on the screen with the bottom-right reading “next>”. Pressing the button next to “next>”

will access the next set of cook options.

The 6 ITEM option lets the user control all six items on the cook

menu. If there is more than one cook menu, the user must program navigation links to other menus.

If there are more than 6 products that will be cooked, and this

option is selected, one of the buttons must be designated as a

link to a sub-menu, or those options will not be accessible in this

option.

See the programming section for information on setting up

menus.

March 2014

15

Page 22

3-7.

DRAIN PAN

ASSEMBLY

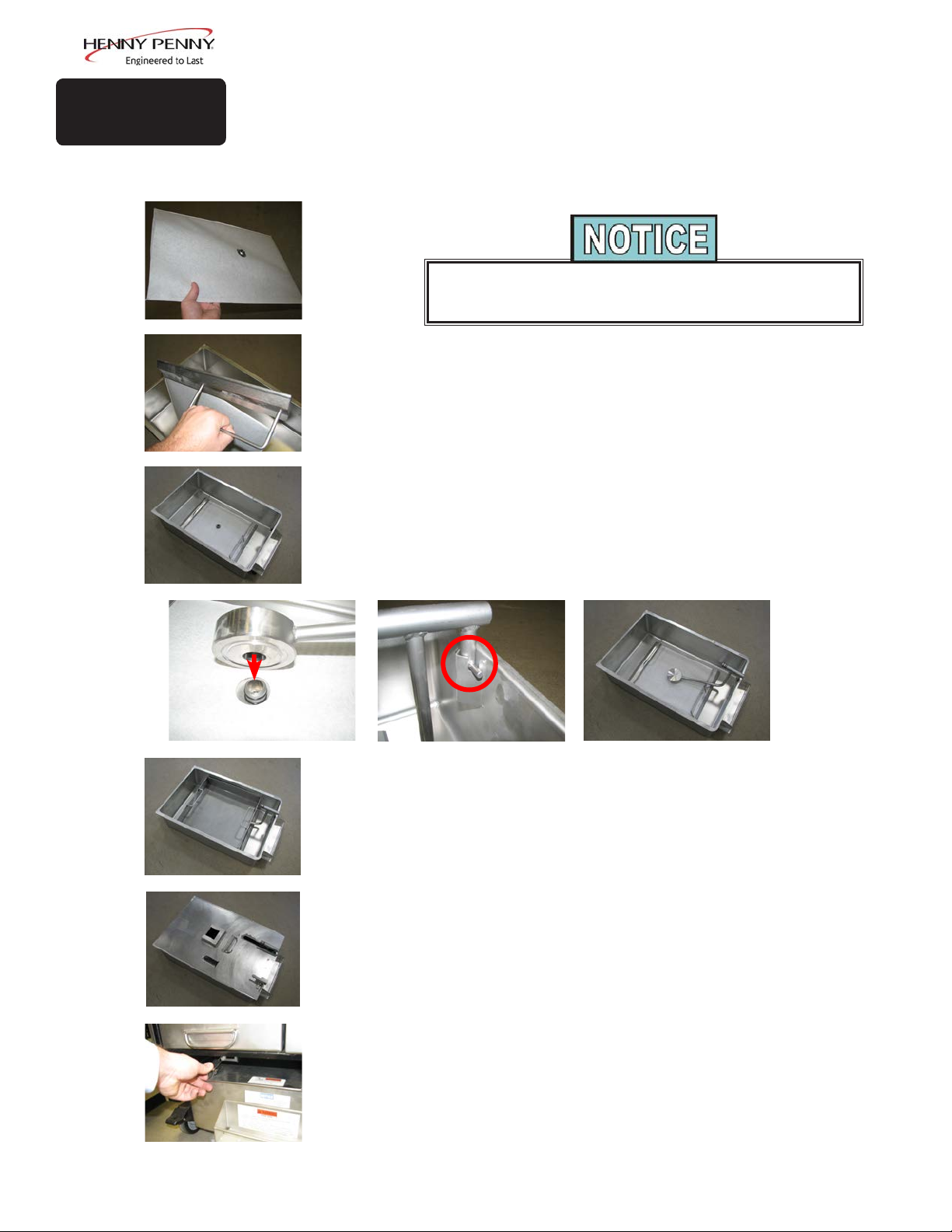

1. Slide a lter envelope onto the lter screen so the plug is protruding through the hole.

During assembly, be sure to apply oil to all O-rings to lubricate to

2. Slide the two handle clamps onto the ends of the lter screen assembly with the handles facing the same direction of the plug.

3. Place the lter screen into the bottom of the drain pan with the

plug side up.

4. Lining up the hole of the pickup tube with the plug of the lter

screen, press the tube down.

5. Position the pick up tube so that the guides slide into the notches

located on the holder in the front of the drain pan. Press down on

the pick up tube to conrm it is fully engaged on the lter screen

plug and in the holder.

help prevent tears and loss.

Dec. 2013

6. Place the crumb catcher into the drain pan so the legs straddle the

lter screen.

7. Place lid onto drain pan.

8. Push the drain pan into place and lock it into place using the locking latch.

9. To remove the drain pan for cleaning, reverse this procedure.

16

Page 23

3-8.

PRODUCT RACKING

RECOMMENDATIONS

e bottom position is to be avoided on small loads because

it is closer to the cold zone. (e oil is cooler at the bottom

of the frypot and hotter at the top.) With bigger loads,

however, there is generally enough turbulence in the oil that

the bottom rack gets sucient heat.

e top position is to be avoided on small loads because

of insucient oil coverage. With bigger loads, the top rack

has good oil coverage because the volume of product on the

lower racks raises the overall oil level.

4

3

2

1

Fully loaded with 8-head (all 4 racks used)

8-Head: Load all four racks as shown.

6-Head: Load only racks 1, 2 and 3.

4-Head: Load only racks 2 and 3.

2-Head: Load only rack 2.

March 2014

17

Page 24

3-9.

LID OPERATION

• LID MUST BE FULLY LATCHED PRIOR TO

STARTING COOK CYCLE OR PRESSURIZED

OIL AND STEAM MAY ESCAPE FRYPOT.

SEVERE BURNS WILL RESULT.

• TO AVOID SERIOUS PERSONAL INJURY, DO

NOT OPERATE WITHOUT LID COVER IN

PLACE AND ALL COMPONENTS INSTALLED.

1

To close lid:

• TO AVOID SERIOUS PERSONAL INJURY, DO

NOT TAMPER WITH ANY COMPONENT OF

LID LOCKING MECHANISM.

1. Lower the lid until lid latches into place.

2

2. Pull lid handle forward until it stops.

3

3. Lift up on the lid handle until it stops.

4

5

March 2014

4. Bring lid handle out towards you until it stops.

5. Push lid handle down, latching lid in place.

18

Page 25

3-9.

LID OPERATION

(CONT.)

DO NOT LIFT HANDLE OR FORCE LID LATCH OPEN

BEFORE THE CONTROL ALARM SOUNDS, AND IS

BLINKING “DONE” IN DISPLAY.

To open lid:

1

1. Gently raise handle until it stops.

2. Push handle back until it stops.

2

Lower the handle before attempting to raise the

lid, or damage to the lid could result.

3. Lower handle.

4. Push handle back.

3

5. Unlatch the front lid latch and raise the lid.

4

5

March 2014

If lid becomes difcult to operate, stop using the fryer and call for

service. Cables need replaced.

19

Page 26

3-10.

START-UP

If the oil is below 180o F (82o C), with the Main Power switch in

the ON position, the display will ash “START UP” “AUTO-

MELT”. The oil heats slowly to prevent scorching of the oil.

The heat cycles on and off to slowly heat the oil. When the oil

temperature reaches 215°F (102°C), Auto-Melt mode terminates

and the fryer begins heating up to the Auto-Mix temperature of

360°F (182°C).

During Start-up, the display will inform the user by displaying

a bar graph to represent the stages of the start-up process. These

stages consist of the following:

• Melt (“Mlt”)-Auto-Melt mode.

• Mix (“Mix”)-Automatic lter to ensure oil is mixed to

prevent cold pockets.

• Top Off (“Top”)- Checks to see if oil level is lled to the

proper mark. If the unit senses the oil level is low, it will run

an Auto-T op Off.

• Polish (“Pol”)-The unit will run a polish cycle.

During each stage, the bar graph will ll as each stage nears

completion. The duration of each stage depends on the

temperature of the oil at the initial start and the set-points that the

unit has in place.

Once the start-up is complete, the display will go to the main

cook menu and is ready for operations.

March 2014

20

Page 27

3-11.

FILLING THE OIL

TANK

The fresh oil tank automatically tops off the oil in the frypot

when it senses the oil level is low. User should add fresh oil to

the tank as needed. DO NOT add fresh oil directly to the frypot.

1. Pull the fresh oil tank out of the front of the fryer.

2. Open the fresh oil tank lid and locate the marks on the inside

wall of the tank.

3. Use fresh oil, ll the fresh oil tank to the marks on the inside

of the tank.

4. Shut the lid and slide back into position.

If the fresh oil tank runs low or is empty, the display will read

“FILL OIL TANK” and the left image in the middle display will

ash to represent the location of the tank on the fryer.

3-12.

CONDENSATION

TANK

This prompt will appear when the unit attempts to top off the oil

three times and is unsuccessful.

Follow the above steps to ll the tank. Once the tank is lled

press the button next to “√OK”.

Excess condensation from the pot drains into the condensation

tank. The tank is equipped with a weep hole to indicate the tank

is full and needs to be emptied.

To empty, slide the condensation tank completely out of the unit

and empty into a drain or sink.

Place back into fryer after emptying.

March 2014

21

Page 28

3-13.

FILTER PUMP

MOTOR

PROTECTOR-

MANUAL RESET

The lter pump motor is equipped with a manual reset button

located on the rear of the motor. Wait about 5 minutes before

attempting to reset this protective device to allow motor to cool.

Remove the condensation pan to reveal the reset button. It takes

some effort to reset, and a screwdriver can be used to help reset

the button.

To prevent burns caused by splashing oil, turn the unit’s

main power switch to the OFF position before resetting the

lter pump motor’s manual reset protection device.

3-14.

REGULAR

MAINTENANCE

SCHEDULE

As in all food service equipment, the Henny Penny pressure

fryer does require care and proper maintenance. The table below

provides a summary of scheduled maintenance. The following

paragraphs provide preventive maintenance procedures to be

performed by the operator.

Procedure Frequency

Changing of oil ................................... As indicated

Changing the lter envelope

Cleaning the frypot

Cleaning the Nylatrons

Lubricate Carriage Wheels.................. Annually-see Preventive Maintenance

Cleaning the deadweight assy.

Inspect Counter-Weight Cables........... Annually-see Preventive Maintenance

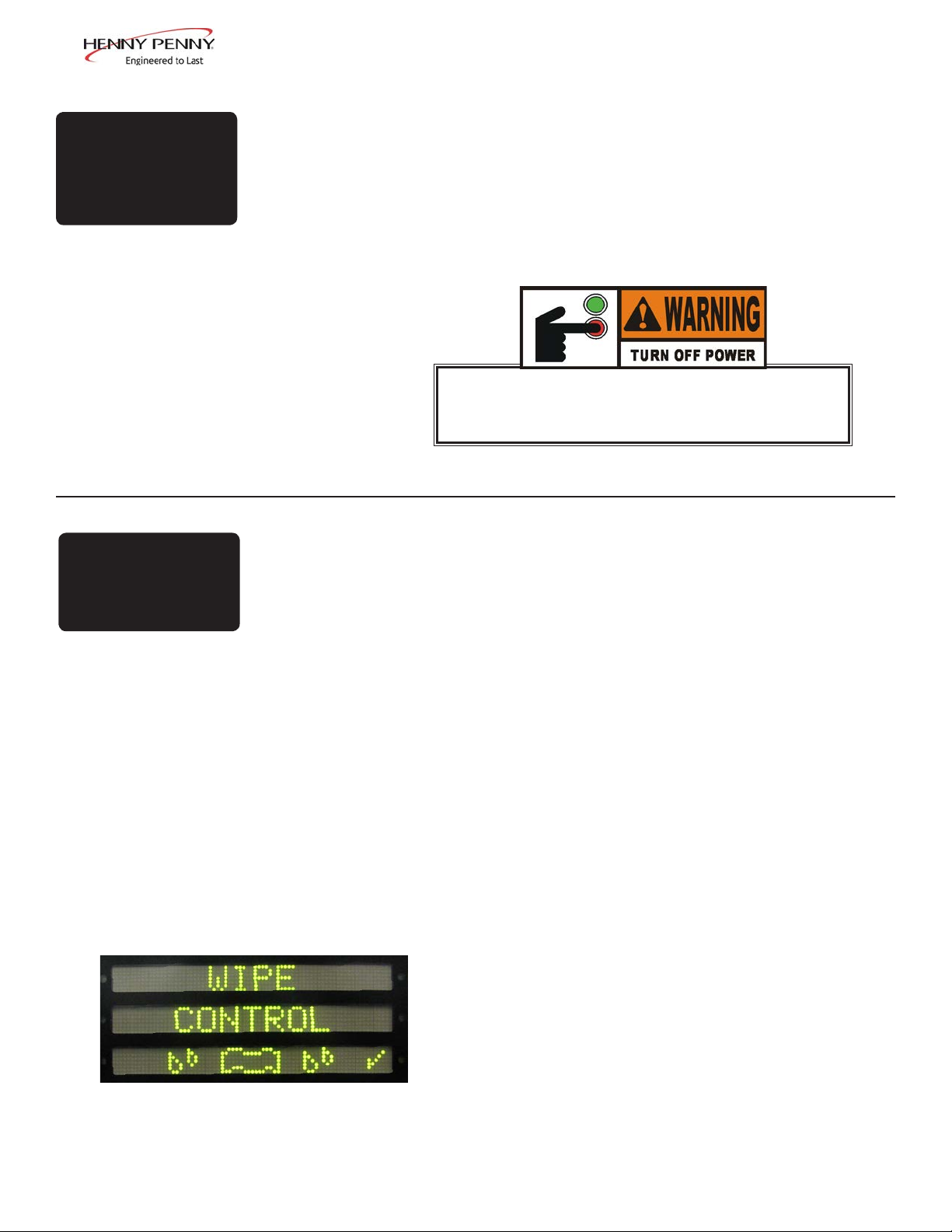

............................. Daily

This unit is equipped with a WIPE mode. This mode gives

10 seconds to wipe the control board clean of any debris

without activating the buttons.

1. Press the (i) two times.

.............. Daily

....................... Monthly-see Preventive Maintenance

........... Monthly-see Preventive Maintenance

Aug. 2014

2. Press the button next to the √ to conrm.

3. The control board will start a count down timer for 10

seconds.

4. Once the 10 seconds expires, the control will return to

the previous screen.

22

Page 29

3-15.

INITIAL OIL FILL

The oil level must always be above the heating elements when the fryer

is heating and at the frypot level indicators on the rear of the frypot

(Figure 3-3). Failure to follow these instructions could result in a re

and/or damage to the fryer.

Before lling the pot, the oil lines need purged in order to ensure

all water or dirty oil is cleared.

1. Access the “FILTER MENU” (see section 3-19 FILTER

INSTRUCTIONS).

2. Select “6. FILL FROM OIL TANK”.

3. Push and hold the “FILL” button until fresh oil enters the

pot. Release the button.

4. Use a towel to wipe the pot clean of water and dirty oil.

5. It is recommended that a high quality frying oil be used in

the pressure fryer. Some low grade oils have a high moisture

content and cause foaming and boiling over.

Figure 3-3

To avoid severe burns when pouring hot oil

into frypot, wear gloves and take care to

avoid splashing.

6. The electric model requires 76 lbs. (34.5 kg.) of oil. The

frypot has 2 level indicator lines inscribed on the rear wall

of the frypot which show when the heated oil is at the proper

level. Figure 3-3.

7. Cold oil should be lled to the lower indicator.

BE CERTAIN THE OIL IS NEVER ABOVE THE UPPER LEVEL

INDICATOR LINE. FAILURE TO FOLLOW THESE INSTRUC-

TIONS CAN RESULT IN OIL OVERFLOWING THE FRYPOT

CAUSE SERIOUS BURNS, PERSONAL INJURY, FIRE AND/OR

PROPERTY DAMAGE.

Aug. 2014

23

Page 30

3-16.

BASIC OPERATION

Follow the procedure below on the initial start-up of the fryer,

and each time the fryer is brought from a cold, or shut down

condition, back into operation. These are basic, general

instructions.

DO NOT OVERLOAD, OR PLACE PRODUCT WITH EXTREME

MOISTURE CONTENT INTO THE RACKS. 24 LBS. (10.9 KG.) IS

THE MAXIMUM AMOUNT OF PRODUCT PER FRYPOT. FAILURE

TO FOLLOW THESE INSTRUCTIONS CAN RESULT IN OIL

OVERFLOWING THE FRYPOT WHICH COULD CAUSE SERIOUS

BURNS, PERSONAL INJURY, FIRE AND/OR PROPERTY DAMAGE.

1. Make sure the frypot is lled to the proper level with oil, to

the lower level indicator.

2. Turn the POWER switch to the ON position

3. Allow fryer to heat until set point.

The heat cycles on and off approximately 10 degrees before the

setpoint temperature, to help prevent overshooting the setpoint

Push the (i) button to see set point and true

temperature of oil

temperature. (proportional control)

4. Select product button and allow the temperature to reach set

point. Once set point has been reached, the display will read

“DROP”.

5. Before loading product onto the racks, lower racks into the

hot oil to keep the product from sticking to the racks.

March 2014

6. Slide racks of breaded product into carrier on the lid,

starting with the bottom tier, to prevent damaged product.

7. Lower and lock the lid down and press the start button.

24

Page 31

3-16.

BASIC OPERATION

8. At the end of the cycle, pressure begins venting

automatically, alarm sounds, and the display shows

“DONE”. At this time, press the “DONE” button.

(CONT.)

3-17.

CARE OF THE OIL

9. Unlock and raise the lid cautiously.

10. Use the rack handles, remove the racks of product from the

carrier, starting with the top rack.

FOLLOW THE INSTRUCTIONS BELOW TO AVOID

OIL OVERFLOWING THE FRYPOT, WHICH COULD

RESULT IN SERIOUS BURNS, PERSONAL INJURY,

FIRE, AND/OR PROPERTY DAMAGE.

1. To protect the oil when the fryer is not in immediate use,

the fryer should be put into the Cool Mode by selecting a

product menu.

2. Frying breaded products requires ltering to keep the oil

clean.

3-18.

MAIN MENU

3. The proper level of cooking oil is automatically maintained.

See Filling the Oil Tank for procedures for lling the fresh

oil tank.

4. Do not overload the racks with product (24 lbs. (10.9 kgs.)

maximum), or place product with extreme moisture content

into racks.

The Main Menu is activated by pressing and holding the

Menu button (lower left corner of the control). Once the menu

actipotes, release the button.

The Main Menu options are displayed as follows:

1. FILTER

2. INFO MODE

3. USB/DATA

4. PROGRAM

5. CLOCK SET

x. EXIT MENU

March 2014

25

Page 32

3-19.

FILTERING

INSTRUCTIONS

WITH PROLONGED USE, THE FLASHPOINT OF OIL

IS REDUCED. DISCARD OIL IF IT SHOWS SIGNS OF

EXCESSIVE SMOKING OR FOAMING. SERIOUS BURNS,

PERSONAL INJURY, FIRE, AND/OR PROPERTY DAMAGE

COULD RESULT.

e Henny Penny electric 8 head fryer the fryer automatically

performs a polish during morning startup, automatically lters aer

every cook cycle, and requires a single “Daily” maintenance lter each

day; aer lunch rush and at the end of the day.

Filter oil immediately following a Cook Cycle when the oil

temperature is in the Cool Mode.

Drain the oil at 250° F (121° C) or less. Higher temperatures cause

cracklings to burn on the steel frypot surfaces after the oil has drained.

1. Push and hold until the display reads *MAIN*.

2. Press 1 to enter the “Filter” menu. Use the buttons next to the

arrows on the display to access the next set of options.

3. Push the menu button again to cycle to next set of options.

Filter Options:

1. QUICK

2. DAILY

3. POLISH

4. DRAIN TO PAN

5. FILL FROM PAN

6. FILL FROM OIL TANK

7. DISPOSE

8. CLEAN-OUT

9. FILL FROM BULK

x. EXIT MENU

Sept. 2014

26

Page 33

3-19.

FILTERING

INSTRUCTIONS

(CONT.)

Quick Filter

Option 1 allows you to perform a quick lter of the oil. After every

cook cycle, the fryer will automatically run a quick lter. You can

choose to do one at any time by selecting this option.

1. Once you have pressed 1 for “QUICK FILTER”, a “CONFIRM”

prompt will appear on display. You can cancel by pressing the

button next to the X or conrm by pressing the button next

to the √.

2. Once you have conrmed YES, the drain will open automatically

and the oil will start to drain. The display will show arrows

pointing down indicating it is draining.

During this lter cycle, the oil will not fully drain. It

maintains a constant level during lter. The display will

show the arrows pointing up and down with a sequence

of tracing light to indicate it is still ltering.

3. After a few moments, the drain will close and the oil will return

to the pot. As it is close to being lled, the display will make

a chirp sound and a timer will start counting down on the lower

left hand side. The display will show arrows pointing up to show

it is lling.

4. In some circumstances, the fryer might not detect the oil

returning to the pot, and may ask “IS Pot FILLED?”.

5. Check the oil level to conrm all oil has returned to pot. If oil

is at the correct level mark located in pot, press “YES”. If oil

is not at the level marker, press “NO” and pump will continue

pumping.

Dec. 2013

27

Page 34

3-19.

FILTERING

INSTRUCTIONS

(CONT.)

Daily Filter

Option 2 allows you to perform a daily lter of the oil. This lter

cycle will drain the pot completely enabling the user to clean the pot.

1. Once you have pressed 2 for “DAILY FILTER”, a “CONFIRM”

prompt will appear on display. You can cancel by pressing the

button next to the X or conrm by pressing the button next

to the √.

2. Once you have conrmed YES, the drain will open

automatically and the oil will start to drain. The display will

show arrows pointing down indicating it is draining.

3. As the oil is draining, a brush symbol appears to remind you to

scrub the pot. Use a brush, scrub the walls and bottom of pot. .

4. Three prompts will appear on the display. “Fill”, “Wash”,

“Drain”.

• To wash all the crumbs down the drain, select the

“WASH”option and unit will start the wash cycle. Display

will show “WASHING”. Once completed, display will show

previous display with options.

• You can stop the wash cycle any time by pressing the button

next to “STOP”.

5. Once pot is scrubbed and washed, press “FILL” to return the oil

to the pot.

6. After a few moments, the drain will close and the oil will return

to the pot. As it is close to being lled, the display will make

a chirp sound and a timer will start counting down on the lower

left hand side. The display will show arrows pointing up to show

it is lling.

7. Once the timer has counted down, the display will prompt “IS

Pot FILLED?”

8. Check the oil level to conrm all oil has returned to pot. If oil

is at the correct level mark located in pot, press “YES”. If oil

is not at the level marker, press “NO” and pump will continue

pumping.

March 2014

28

Page 35

3-19.

FILTERING

INSTRUCTIONS

(CONT.)

Polish

Option 3 allows you to polish oil.

1. Once you have pressed 3 for “POLISH”, a “CONFIRM” prompt

will appear on display. You can cancel by pressing the button

next to the X or conrm by pressing the button next to the √.

2. Once you have conrmed YES, the drain will open automatically

and the oil will start to drain. The display will show arrows

pointing down indicating it is draining.

3. A timer will start at the bottom left corner of the display for

15:00 minutes. This will cycle the oil until the timer expires.

4. Once polish is complete, the display will indicate the oil is

returning to the pot.

5. After a moment, the display will make a chirp sound and a timer

will start.

6. Once the timer has counted down, the display will prompt “IS

Pot FILLED?”

7. Check the oil level to conrm all oil has returned to pot. If oil is

at the correct level mark located in pot, press “YES”. If oil is not

at the level marker, press “NO” and pump will continue pumping.

March 2014

29

Page 36

3-20.

BULK DISPOSE

Option 7 will access “DISPOSE”. The bulk dispose option allows the oil to be discarded to an external discard tank from the

drain pan.

Conrm controls are set to the particular set up in the location.

See Special Programming for further detail on set up.

1. Display will read “DRAIN Pot?”. Press the button next to

“√” for “YES”. The display will read “DRAINING” while to

oil drains to the drain pan.

If at any point “DRAINING” needs to be canceled, pressing the “x!” button will stop draining and give the options to

either “Fill”, “RESUME”, or “QUIT”.

“FILL” - Returns what oil has drained back to the pot.

“RESUME” - Continue draining

“QUIT” - Return the “FILTER” menu

2. Next, the display will prompt to “PURGE”. This step is to

clear the lines of any old oil.

Press and hold the “PUMP” button on the display while

watching the pot. Once clean oil starts to come out of the

jets, release the button. Allow a few moments for the old oil

to fully drain in to the pan.

3. Press the “NEXT” button once all the old oil has been

purged.

4. The display reads “DISPOSE”. Press and release the

“PUMP” button. The old oil in the drain pan will now start

to dispose.

5. Once the drain pan is empty of old oil, press the “STOP”

button to shut off the pump motor.

6. Conrm all oil is cleared from the drain pan. If further

pumping is required, press “PUMP” to continue. Then press

“STOP” when completed.

7. Press “done” and the display will read “EXIT?”. Press

“√YES” when completed.

8. If the fryer’s power switch is on, the display says “TURN

OFF UNTIL FILLED”. This display continues until the fryer

is turned off.

9. Be sure to rell the fryer with new oil before turning it on

again.

March 2014

30

Page 37

3-21.

CHANGING THE

FILTER ENVELOPE

The lter envelope should be changed daily, or whenever it becomes

clogged with crumbs.

Refer back to the Drain Pan Assembly section for instructions.

Use protective cloth or glove when disconnecting the

lter union or severe burns could result. If the lter

pan is moved while full of oil, use care to prevent

splashing, or severe burns could result.

Be sure that the lter screens, crumb catcher and

lter clips are thoroughly dry before assembly of the

lter envelope or water will dissolve the lter paper.

3-22.

CLEAN-OUT MODE

Do not use steel wool, other abrasive cleaners or cleaners/sanitizer containing chlorine,

bromine, iodine or ammonia chemicals, as these will deteriorate the stainless steel material and

shorten the life of the unit.

Do not use a water jet (pressure sprayer) to clean the unit, or component damage could result.

Do not bang brushes or scrapers on the pot band. Damage to the pot band may cause gaps

around the gasket and will not build pressure properly.

Make sure the inside of the frypot, the drain

valve opening, and all parts that come in

contact with the new oil are as dry as possible.

Sept. 2014

DO NOT CLOSE LID WITH WATER AND/

OR CLEANER IN FRYPOT. WATER UNDER

PRESSURE BECOMES SUPERHEATED. WHEN

LID IS OPENED, ESCAPING WATER AND STEAM

WILL RESULT IN SEVERE BURNS.

31

Page 38

3-22.

CLEAN-OUT MODE

(CONT.)

After the initial installation of the fryer, as well as before every

change of oil, the frypot should be thoroughly cleaned as

follows:

1. Be sure the oil is disposed properly. If the unit has bulk oil,

see Bulk Dispose (Section 3-20) for instructions.

2. Turn the POWER switch to OFF position.

Moving the fryer or lter drain pan while containing hot oil is

not recommended. Hot oil can splash out and severe burns could

result. The lter drain pan must be as far back under fryer as it

will go, and the cover in place. Be sure the hole in the cover lines

up with the drain before opening the drain. Failure to follow

these instructions causes splashing of oil and could result in

personal injury.

3. Raise lid, remove the racks and carrier from lid, and tilt lid

back, so that the lid won’t interfere with cleaning.

4. Fill the pot with warm water half way between the bottom and

the oil level indicators.

5. Add 8 to 10 ounces of fryer cleaning solution.

Always wear chemical splash goggles or face shield and protec-

tive rubber gloves when cleaning the frypot as the cleaning solu-

tion is highly alkaline. Avoid splashing or other contact of the

solution with your eyes or skin. Severe burns and possible blind-

ness will result. Carefully read the instructions on the cleaner. If

solution comes in contact with your eyes, rinse thoroughly with

cool water and see a physician immediately.

6. Fill the pot with more warm water so that the water reaches

the crumb ring on the side of the pot.

7. Depending on the preferred cleaning method, see the

appropriate section below to continue the Clean-Out mode.

Options:

• Cold-Soak Clean Out

• Heated Clean-Out

Sept. 2014

Cold-Soak Clean-Out

If unit is set to Cold-Soak mode (See SP-22 in the Special

Program section), follow the following steps.

8. If the unit is not turned off, the control will prompt “TURN

FRYER OFF.”

32

Page 39

9. With the fryer off, the display will read, “-OFF-” “(soaking)”

with “done√” in the bottom right-hand display.

3-22.

CLEAN-OUT MODE

(CONT.)

10. Use a scrub brush to periodically scrub the vat walls to loosen

any crumbs or debris.

11. Once the desired time, according to the uses discretion, has

expired, press the button next to “done√”.

12. The display will show “DONE SOAKING?” “YES” “NO”.

If not done soaking, press “NO” to return to the “OFF”

“(soaking)” screen.

If completed with the soaking process, press the button next

to “YES” to continue to the CLEAN-OUT: DRAINING THE

WATER section.

Heated Clean-Out

If unit is set to Heated Clean-Out mode (See SP-22 in the Special

Program section), follow the following steps.

8. If the unit is not turned on, the control will prompt “TURN

FRYER ON.”

9. Once the unit is powered on, “==CLEAN OUT==””heating”

along with the current temperature of the water will show in

the display. The unit starts heating to the preset temperature

(see SP-23 in the Special Program section).

At any point that Clean-Out mode needs to be canceled, press the

button next to the “x!”. This will skip the heating phase and go

straight to the CLEAN-OUT: DRAINING THE WATER section.

10. Once the temperature preset is reached, “==CLEAN

OUT==””cleaning” along with the preset time (see SP-24

in the Special Program section). The time will start to count

down.

11. When the “cleaning” phase is completed, “*DONE*” ashes

in the display then prompts to “TURN FRYER OFF”.

12. Power the unit OFF and the display shows “OFF” and the

current temperature of the water.

Allow the water time to cool before proceeding to the next steps

or burns may result.

Press the button next to “next►” to proceed to draining the water.

See CLEAN-OUT: DRAINING THE WATER section.

Sept. 2014

33

Page 40

3-22.

CLEAN-OUT MODE

(CONT.)

Clean-Out: Draining the Water

The display with read “IS CART OR PAN IN PLACE?”. A

bucket, tub or the drain pan needs to be in place under the drain

before proceeding to draining.

If using the drain pan, remove all the internal parts so the pan is

empty. DO NOT put the lid onto the pan. Must remain open for

this procedure.

When placing the drain pan under the unit, DO NOT push it all

the way back. Slide it under the unit so that it is under the drain

and can still see into the pan.

13. Once a bucket, tub or drain pan is in place, press the button

next to “YES√”.

14. The display will show “▼DRAN (hold)”. Press and hold

the illuminated button. The water will start to drain into the

bucket/tub/pan.

15. Once the level of the water is at a comfortable level, release

the button and the water will stop draining.

16. Remove the bucket/tub/pan from under the fryer and dispose.

17. Repeat the following steps until the pot is empty.

18. Once the pot is empty, press the button next to “next►”.

19. The display will ask “IS POT EMPTY?”. Conrm that all the

water is cleared from the pot. Press “√YES” if so,. Otherwise,

press “NOx” and continue the draining process.

Rinse Pot with Clean Water

20. Place the bucket/tub/pan in place under the drain.

21. The screen will read “▼OPEN DRAIN”. Press the button to

fully open the drain.

22. With the drain open, use clean water to rinse the side walls

and bottom of the pot.

Be sure not to over ll the receiving container.

Sept. 2014

23. When completed with rinsing, Press the button next to

“►◄CLOSE DRN” to close the drain.

24. Remove the container from under the fryer and dispose.

34

Page 41

3-22.

CLEAN-OUT MODE

(CONT.)

25. Repeat the following steps as needed to ensure all the cleaner

is out of the pot.

26. Once the pot is rinsed clean of all chemical water, press the

button next to “next►”.

Purge Oil Lines

This step is to clear the oil lines of any remaining water that may

be left over from cleaning or rinsing.

Conrm the Fresh Oil Tank has new oil in it.

27. The display will read “=PURGE=””►PUMP”.

28. Press and hold the button next to “►PUMP” until clean, fresh

oil comes through the jets in the bottom of the pot.

29. To clear the oil from the pot, refer back to the Rinse Pot with

Clean Water section.

30. Once pat is rinsed, press the button next to “next►”.

Wipe Pot

31. The display will read “==WIPE==””▼OPEN DRAIN”.

32. Place a bucket, tub, or drain pan under the fryer.

33. Press the button next to “▼OPEN DRAIN” to open the drain.

34. Use a clean towel to wipe the sides and bottom of the pot.

Guide all the remaining water and debris down the drain.

35. Press the button next to “►◄CLOSE DRN” to close the

drain.

36. Remove the bucket/tub/pan and discard the contents.

37. Press the button next to “next►”.

Exit Conrmation

38. The displace will read “EXIT CLEAN-OUT?”.

Sept. 2014

39. If the clean-out process is completed, press the button next to

“√YES”.

40. If the drain is open, the control will automatically close the

drain.

41. The display will read “KEEP OFF UNTIL FILLED”.

35

Page 42

3-22.

CLEAN-OUT MODE

(CONT.)

3-23.

PREVENTIVE

MAINTENANCE

42. If the power switch is in the ON position, move it to the OFF

position to power off the unit.

43. Fill the pot with fresh oil to the lower indicator.

44. Once the pot is lled with fresh oil, the fryer is ready for

normal operations.

Cleaning slides (Nylatrons) - Monthly

1. Spray Henny Penny biodegradable, food safe, foaming degreaser

(part no. 12226) on Nylatrons.

2. Raise lid up and down several times to spread the degreaser.

3. Wipe Nylatrons to remove food soil, grease, and degreaser

residue.

Lubricating Carriage Wheels - Annually

The carriage wheels, in the back of the fryer, should be lubricated at

least once a year, to allow the lid easy movement.

1. Remove the back shroud of the fryer.

2. Use spindle lube, part number 12124, place a small amount of

lube on all four (4) wheels, both top and bottom wheels. Make

sure to lube both left and right rollers.

Sept. 2014

36

Page 43

3-23.

PREVENTIVE

MAINTENANCE

(CONT.)

Cleaning DeadWeight-Monthly

DO NOT REMOVE DEADWEIGHT ASSEMBLY

WHILE FRYER IS OPERATING OR SEVERE

BURNS OR OTHER INJURIES WILL RESULT.

Allow the steam stack enough time to cool before

proceeding with the following steps.

1. Loosen the 3 thumb screws that secure the steam stack to the top of

the fryer. Do NOT fully remove the screws from the steam stack.

2. Pull the steam stack out of the fryer revealing the deadweight.

3. Use a towel to wipe any build up from the dead-weight.

4. Place the gasket onto the factory location, aligning the 3 screw

holes.

5. Place the steam stack back into place and tighten the 3 thumb

screws.

Dec. 2013

37

Page 44

3-23.

PREVENTIVE

MAINTENANCE

(CONT.)

Inspect Counter-weight Cables-Annually

Henny Penny 8 head fryers use two cables in the counter-weight

mechanism that helps in the raising and lowering of the lid. Cables

should be visually inspected yearly, either as part of a planned

maintenance program or during a routine service call. Cables

more than 10 years old should be replaced regardless of inspection

results.

If lid becomes difcult to operate, stop using

the fryer and call for service. Cables need

replaced.

1. Use a 3/8” socket, remove the 6 keps nuts around exterior of

rear cover, shown in Figure 1.

2. Lift up on the rear cover and pull out at the bottom to clear

Figure 1

View of the counter-weights

with cover removed

NOT OK-REPLACE

Cracks in jacket are obvious signs

of wear

threaded studs.

3. Inspect the counter-weight cables. If cables have cracks in the

jacket, missing pieces in the jacket, or other obvious signs of

wear, call for service to have both cables replaced.

OK

No signs of wear or cracking

Dec. 2013

38

Page 45

4-1.

PROGRAM MENU

SECTION 4: PROGRAMMING

This section shows how to access the programming

(“PROG”) menu that access the products, cook and special

program.

1.PRODUCTS

2.COOK MENUS

3.SPCL PROG

4.DATA COMM

5.HEAT CTRL

6.FLTR CTRL

4-2.

PRODUCT

PROGRAMMING

1

2

3

7.TECH MODE

8.STATS MODE

9.LANGUAGE

x.EXIT MENU

1. PRODUCTS

2. COOK MENUS

3. SPECIAL PROGRAM

4. DATA COMM

5. HEAT CONTROL

This section describes how to program a new product into an

empty slot or over ride a current product.

1. Press and hold the button until *MAIN* shows in the

display.

2. Select “4. PROG”.

3. Select “1. PRODUCTS”.

4. Enter code 1,2,3 and the display will show what is the

current layout with the products.

6. FILTER CONTROL

7. TECH MODE

8. STATS MODE

9. LANGUAGE

x. EXIT MENU

5. Select an empty slot or any product that is desired to

override by pressing the button next to it. Use the buttons next to the + or - to scroll through the list of products.

6. Once the desired product or /BLANK is in the middle

display, pressing the right arrow will advance to the rst

step in programming that product.

7. Press the button next to “<-change” to proceed to changing the name. The name is what is displayed in the title

section of the display.

8. Using the buttons next to the + or - to change the letter in

the name. Once the correct letter is displayed, press the

button next the arrows to move to the next letter.

To delete any letters or numbers that may be left over

during an override or placed accidently, press the arrow

buttons unit you reach the letter or number you desire to

delete. Using the + or - buttons, advance the letters until

a blank is displayed.

March 2014

39

Page 46

4-2.

PRODUCT

PROGRAMMING

(CONT.)

9. Press the button next to the √ to conrm complete.

10. Press the right-arrow button to advance to “LINK ID”. The

Link ID is what is displayed in the cook menu. This is used as

an abbreviation or short name.

Press the button next to “<-change” to proceed with changing

the Link ID.

11. Using the buttons next to the + or - to change the letters.

Once complete, press the right-arrow button to advance to the

“COOK TIME”.

12. Using the buttons next to the left set of + or - to change the

minutes in the timer. The right set of + or - are used to change

the seconds. Once complete, press the right-arrow button to

advance to “TEMP 1”.

13. Using the buttons next to the + or - to change the numbers in

the temperature. Once complete, press the right-arrow button

to advance to “PRESSURE”.

14. Using the buttons next to the + or - to change it to either “ON”

or “OFF”. Press the right arrow to advance to the “STEP 2

AT” options.

15. “STEP 2 AT” will determine at what time the next set or

temperature and pressure settings will actipote. Use the + or

- to change the time then press the right arrow to advance to

“TEMP 2”.

16. Use the + or - to adjust the temperature then press the right arrow to advance to “PRESSURE 2” to wither “ON” or “OFF”.

17. Using the + or - buttons to select either “ON “ or “OFF”. Re-

peat these steps until complete cook cycle is set. One the nal

pressure is set, advance to the next step.

18. Once complete, enter 0:00 in the time and this will automatically be the end of the cook cycle.

March 2014

40

Page 47

4-3.

SPECIAL

PROGRAMMING

This section shows how to access the Special Program area of

the controls in order to program cook menus, clock, and other

features.

1. Push and hold until the display reads *MAIN*.

2. Enter the code: 1, 2, 3

3. Press the again to access the next set of options.

4. Press 4 to enter the “PROG” menu. Use the buttons next to

the arrows on the display to access the next set of options.

Special Programming consist of the following:

5. Use the left or right arrows to navigate through the options.

SP-1 • TEMP UNITS

SP-2 • LANGUAGE

SP-3 • SYSTEM INIT

SP-4 • RADIO SYSTEM ENABLED?

SP-5 • AUDIO VOL (Loudness)

SP-6 • AUDIO TONE (Frequency)

SP-7 • MELT CYCLE

SP-8 • START-UP POLISH ENABLED?

SP-9 • START-UP GO WHERE?

SP-10 • COOK MENUS OPTION

SP-11 • COOK MENU BUTTONS

SP-12 • COOK DONE GO WHERE?

SP-13 • AUTO-MENU MINUTES

SP-14 • AUTO-MENU GO WHERE?

SP-15 • COOL TEMP

SP-16 • PROD PROG T1>T2>T3)?

SP-17 • BULK DISPOSE?

SP-18 • BULK SUPPLY?

SP-19 • COOKING: SHOW PSI?

SP-20 • CHANGE MGR CODE

SP-21 • CHANGE USAGE CODE

SP-22 • CLEAN-OUT TYPE

SP-23 • CLEAN-OUT TEMP

SP-24 • CLEAN-OUT MINUTES

SP-1 • TEMPERATURE DISPLAY UNITS

1. Use the + or - to change between Fahrenheit (F°) or Celsius

(C°).

SP-2 • OPERATION LANGUAGE

1. Use the + or - buttons to scroll through the list of languages.

SP-3 • SYSTEM INITIALIZE

Sept. 2014

1. Press and hold the button next to “hold->” for three seconds.

2. System will re-initialize back to default settings.

SP-5 • AUDIO VOLUME (Loudness)

1. Use the + or - buttons will adjust the volume of the speaker

between 0-10.

2. Press the button next to “test” on the display.

41

Page 48

4-3.

SPECIAL

PROGRAMMING

(CONT.)

SP-6 • AUDIO TONE (Frequency)

1. Press the + or - to adjust the frequency setting,

2. Press the button next to “test” on the display.

SP-7 • MELT CYCLE

Specify the desired Melt Mode heating cycle.

1. Use the + or - to select wither “Solid” or “Liquid”.

SP-8 • START-UP POLISH ENABLED?

Specify whether or not an automatic polish operation should be

performed as part of the normal, morning startup process.

1. Use the + or - to select either “YES” or “NO”.

SP-9 • START-UP GO WHERE?

Specify where the control should go after exiting Melt. Choices

are “STAY PROD”, “PREV MENU”, or go specically to any of

the ten Cook Menus.

1. Use + or - to navigate through options.

SP-10 • COOK MENUS (Cook Menu Conguration)

1. Use the + or - buttons to navigate through cook menu

options.

• “4+TITLE”

• “5+NEXT”

• “6 ITEMS”

See MENU OPTIONS for descriptions and examples.

SP-17 • BULK DISPOSE?

1. Use the + or - buttons to navigate through the three options:

• “NONE”

• “FRONT”

• “REAR”

2. “NONE”- Oil dispose is by draining into a disposal cart or

shuttle.

Sept. 2014

3. “FRONT”- Dispose by pumping through the front hose

connection by press and holding the illuminated button.

4. “REAR”- Dispose by pumping through the rear plumbing

connection.

42

Page 49

4-3.

SPECIAL

PROGRAMMING

(CONT.)

SP-18 • BULK OIL SUPPLY?

1. Use the + or - buttons to select either “YES” or “NO” for

whether or not a bulk oil supply is available for relling the

ATO oil tank and vat with fresh oil.

SP-22 • CLEAN-OUT TYPE

This section list the two options for Clean Out Modes

• Cold-Soak

• Heater

1. Use te + or - to change the options.

SP-23 • CLEAN-OUT TEMP

NOT AVAILABLE FOR COLD-SOAK OPTION

Set the desired temperature for the water during Clean Out Mode.

1. Use the + or - to change the temperature.

SP-24 • CLEAN-OUT MINUTES

NOT AVAILABLE FOR COLD-SOAK OPTION

Set the desired time for the Clean-Out Mode.

1. Use the + or - to change the minutes.

Sept. 2014

43

Page 50

4-4.

FILTER CONTROL

Filter Control Mode allows the parameters during a lter cycle to

be modied for the best results depending on the oil type being

used.

Each parameter are grouped into sections that control a particular

settings. The section are grouped as follows. See the next page

for the full list of Filter Control programs.

• Quick Filter Settings

• Daily Filter Settings

• Polish Settings

• Auto-Top Off Settings

• Start-Up Mode Settings

• Cook Mode Auto Mix Settings

• Miscellaneous Settings

To access Filter Control:

1. Press and hold the button until *MAIN* shows in the

display.

2. Select “4. PROG”.

3. Select “6. FLTR CTRL”.

4. Enter code 1,2,3.

5. Use the left or right arrows to navigate through the options.

March 2014

44

Page 51

4-4.

FILTER CONTROL

(CONT.)

Quick Filter Settings

FC-1 “QUICK FILTER: AFTER ‘X’ COOKS”

FC-2 “QUICK FILTER: DROP OIL: TIME”

FC-3 “QUICK FILTER: DROP OIL: DRAIN OPENING”

FC-4 “QUICK FILTER: FILTER: TIME”

FC-5 “QUICK FILTER: FILTER: DRAIN OPENING”

FC-6 “QUICK FILTER: FILL: DETECT AT LEVEL PROBE, KEEP PUMPING”

FC-7 “QUICK FILTER: NORMAL FILL TIME”

FC-8 “QUICK FILTER: FILL: NO DETECT: MAX PUMP”

Daily Filter Settings

FC-9 “DAILY FILTER: DROP OIL TIME”

FC-10 “DAILY FILTER + POLISH: FILL: DETECT AT LEVEL PROBE, KEEP PUMPING”

FC-11 “DAILY FILTER: FILL: NO DETECT: MAX PUMP”

Polish Settings

FC-12 “POLISH: DROP OIL: TIME”

FC-13 “POLISH: DROP OIL: DRAIN OPENING”

FC-14 “POLISH: FILTER: TIME”

FC-15 “POLISH: FILTER: DRAIN OPENING”

FC-16 “POLISH: NORMAL FILL TIME”

FC-17 “POLISH: FILL: NO DETECT: MAX PUMP”

Auto-Top Off Settings

FC-18 “AUTO-TOPOFF: ENABLED?”

FC-19 “AUTO-TOPOFF: PUMP TIME”

FC-20 “AUTO-TOPOFF: REPEAT”

FC-21 “AUTO-TOPOFF: AFTER X ATTEMPTS, CHECK A TO”

FC-22 “COOK MODE - FORCED ATO CHECK AFTER ‘X’ COOKS”

Start-Up Mode Settings

FC-23 “START-UP: NEEDED IF TEMP < X”

FC-24 “START-UP MIX: ENABLED?”

FC-25 “START-UP MIX: PRE-HEAT MAX TEMP”

FC-26 “START-UP MIX: DROP OIL: TIME”

FC-27 “START-UP MIX: FILTER: TIME”

FC-28 “START-UP MIX: NORMAL FILL TIME”

FC-29 “START-UP MIX: FILL: NO DETECT: MAX PUMP”

FC-30 “START-UP ATO CHECK: ENABLED?”

FC-31 “START-UP ATO CHECK: PRE-HEAT MAX TEMP”

FC-32 “START-UP POLISH: ENABLED?”

FC-33 “START-UP POLISH: PRE-HEAT MAX TEMP”

Cook Mode Auto Mix Settings

FC-34 “COOK MODE AUTO-MIX: ENABLED?”

FC-35 “COOK MODE AUTO-MIX: DROP OIL: TIME”

FC-36 “COOK MODE AUTO-MIX: FILTER: TIME”

FC-37 “COOK MODE AUTO-MIX: NORMAL FILL TIME”

FC-38 “COOK MODE AUTO-MIX: FILL: NO DETECT: MAX PUMP”

FC-39 “COOK MODE AUTO-MIX: DESIRED BOTTOM TEMP”

FC-40 “COOK MODE AUTO-MIX: MIN REQUIRED OIL TEMP”

FC-41 “COOK MODE AUTO-MIX: MIN REPEAT”

FC-42 “COOK MODE TIMED AUTO-MIX, IF BAD BOTTOM PROBE”

Dispose Settings

FC-43 “DISPOSE: DROP OIL: DRAIN OPENING”

March 2014

Miscellaneous Settings

FC-44 “ALWAYS ASK ‘IS POT FILLED?’”

FC-45 “ANY FILL: NOT FILLED, EXTRA PUMP TIME”

45

Page 52

4-4.

FILTER CONTROL

(CONT.)

Quick Filter Settings

These parameters control the Quick Filter operation, which

activates automatically after a cook cycle, and may also be

initiated manually from the Filter Menu.

The Quick Filter has three basic steps:

1. DROP: Opens the drain and drops the oil level by a certain

amount. Depending on settings, could drop the oil level just a

few inches during this phase, or could drain the entire pot.

2. FILTER: Runs the lter pump with the drain partially open

for a given time, pumping the oil through the lter paper

to clean the oil. This operation typically holds a relatively

constant oil level in the pot.

3. FILL: Closes the drain fully and runs the lter pump to

rell the pot. Watches for a temperature rise on the upper

temperature probe (level probe) to indicate that the pot has

relled. Runs the pump a bit longer to get the last of the oil

out of the lter pan, then turns the pump off.

The Start-up Mix and the Cook Mode Auto-Mix operations are

specialized versions of the Quick Filter, and share some of the

Quick Filter programmable parameters. For example, both of the

Mix operations use the Quick Filter’s “Max Pump Time” setting.

FC-1 “QUICK FILTER: AFTER ‘X’ COOKS”

Controls automatic activation of the Quick Filter after the

specied number of cook cycles.

1. Enter a new value by using the product numbers.

2. Press the button next to √ to accept the new value.

3. Press the button next to X to return to default or previous

setting.

March 2014

46

Page 53

4-4.

FILTER CONTROL

(CONT.)

FC-2 “QUICK FILTER: DROP OIL: TIME”

FC-3 “QUICK FILTER: DROP OIL: DRAIN

OPENING”

For the “Drop” phase: how long to spend dropping the oil level,

and how far to open the drain valve during this step.

1. Enter a new value by using the product numbers.

2. Press the button next to √ to accept the new value.

3. Press the button next to X to return to default or previous

setting.

For very thin (low viscosity) cooking oils, drain opening setting

may need to reduce from the default value.

FC-4 QUICK FILTER: FILTER TIME

FC-5 QUICK FILTER: FILTER DRAIN POSITION

At the end of“Drop” (drop oil level) phase, the drain closes

down to a partially open position and the lter pump runs for the

specied “Filter Time”.

1. Enter a new value by using the product numbers.

2. Press the button next to √ to accept the new value.

3. Press the button next to X to return to default or previous

setting.

For very thin (low viscosity) cooking oils, you might need to

reduce the drain opening setting from the default value.

FC-6 QUICK FILTER: FILL--DETECT AT LEVEL

PROBE, KEEP PUMPING

When relling the pot, species how long to keep pumping after

the oil initially reaches or splashes on the upper probe and the

expected temperature rise is observed.

1. Enter a new value by using the product numbers.

2. Press the button next to √ to accept the new value.

March 2014

3. Press the button next to X to return to default or previous

setting.

47

Page 54

4-4.

FILTER CONTROL

(CONT.)

FC-7 QUICK FILTER: FILL--NO DETECT: MAX

PUMP

The expected time it takes to rell the vat at the end of a Quick

Filter.

1. Enter a new value by using the product numbers.

2. Press the button next to √ to accept the new value.

3. Press the button next to X to return to default or previous

setting.

FC-8 “QUICK FILTER: FILL: NO DETECT: MAX

PUMP”

If the fryer pumps for this amount of time during the Fill phase

without observing a temperature rise on the upper temperature

probe, the control turns the pump off, and asks “IS POT

FILLED?”.

1. Enter a new value by using the product numbers.

2. Press the button next to √ to accept the new value.

3. Press the button next to X to return to default or previous

setting.

For 50 Hz systems, or if the control routinely gives up before the

pot is relled, you might need to increase the “max pump” time

from the default value. 50 Hz pumps may run more slowly than

60 Hz pumps.

Daily Filter Settings

FC-9 “DAILY FILTER: DROP OIL: TIME”

Controls the time duration of the initial draining of the pot.

1. Enter a new value by using the product numbers.

2. Press the button next to √ to accept the new value.

3. Press the button next to X to return to default or previous

setting.

March 2014

48

Page 55

4-4.

FILTER CONTROL

(CONT.)

FC-10 “DAILY FILTER + POLISH: FILL: DETECT

AT LEVEL PROBE, KEEP PUMPING”

When relling the pot, species how long to keep pumping after

the oil reaches the upper probe and the expected temperature rise

is observed.

1. Enter a new value by using the product numbers.

2. Press the button next to √ to accept the new value.

3. Press the button next to X to return to default or previous

setting.

In a Daily Filter, a Fill operation can be stopped by the user at

any time.

FC-11 “DAILY FILTER: FILL: NO DETECT: MAX

PUMP”

If the fryer pumps for this amount of time during the Fill phase

without observing a temperature rise on the upper temperature

probe, the control turns the pump off, and asks “IS POT

FILLED?”. If pot is not lled completely, press “NO” and the

pump will attempt to ll further.

1. Enter a new value by using the product numbers.

2. Press the button next to √ to accept the new value.

3. Press the button next to X to return to default or previous

setting.

For 50 Hz systems, or if the control routinely gives up before the

pot is relled, you might need to increase the “max pump” time

from the default value. 50 Hz pumps run more slowly than 60 Hz

pumps.

March 2014

49

Page 56

Polish Settings

4-4.

FILTER CONTROL

(CONT.)

FC-12 “POLISH: DROP OIL: TIME”

FC-13 “POLISH: DROP OIL: DRAIN OPENING”

For the “Drop” phase: how long to spend dropping the oil level,

and how far to open the drain valve during this step.

1. Enter a new value by using the product numbers.

2. Press the button next to √ to accept the new value.

3. Press the button next to X to return to default or previous

setting.

For very thin (low viscosity) cooking oils, you might need to

reduce the drain opening setting from the default value.

FC-14 “POLISH: FILTER: TIME”

FC-15 “POLISH: FILTER: DRAIN OPENING”

At the end of the “Drop” (drop oil level) phase, the drain closes

down to a partially open position and the lter pump runs for the

specied “Filter Time”.

1. Enter a new value by using the product numbers.

2. Press the button next to √ to accept the new value.

3. Press the button next to X to return to default or previous

setting.

For very thin (low viscosity) cooking oils, you might need to

reduce the drain opening setting from the default value.

FC-16 “POLISH: NORMAL FILL TIME”

The expected time it takes to rell the vat at the end of a Polish

operation. When relling the vat, if the fryer pumps for one and

a half times this expected time, the “Slow Filling” warning is

activated, alerting that the fryer is pumping more slowly than

expected.

1. Enter a new value by using the product numbers.

2. Press the button next to √ to accept the new value.

March 2014

3. Press the button next to X to return to default or previous

setting.

50

Page 57

4-4.

FILTER CONTROL

(CONT.)

FC-17 “POLISH: FILL: NO DETECT: MAX PUMP”

If the fryer pumps for this amount of time during the Fill phase

without observing a temperature rise on the upper temperature

probe, the control turns the pump off, and asks “IS POT

FILLED?”. If pot is not lled completely, press “NO” and the

pump will attempt to ll further.

1. Enter a new value by using the product numbers.

2. Press the button next to √ to accept the new value.

3. Press the button next to X to return to default or previous

setting.

For 50 Hz systems, or if the control routinely gives up before the

pot is relled, you might need to increase the “max pump” time

from the default value. 50 Hz pumps run more slowly than 60 Hz

pumps.

Auto-Top Off Settings

FC-18 “AUTO-TOPOFF: ENABLED?”

Enables or disables all Auto-Topoff (ATO) operations.

1. Press the + or - to select either “YES” or “NO”.

Disabling the Auto-Topoff feature would normally be done only

if the topoff system itself has failed, in order to avoid the “Fill

Oil Tank” messages that occur if the fryer doesn’t detect oil at

the proper level after 3 attempts.

FC-19 “AUTO-TOPOFF: PUMP TIME”

Species how long the ATO pump runs for each individual ATO

pulse.

1. Enter a new value by using the product numbers.

2. Press the button next to √ to accept the new value.

3. Press the button next to X to return to default or previous

setting.

This setting may be manually adjusted as needed. Ideally, each

ATO pulse pumps about 1/8” to 3/16” (5 mm) of fresh oil into

the pot.

March 2014

51

Page 58

4-4.

FILTER CONTROL

(CONT.)

FC-20 “AUTO-TOPOFF: REPEAT”

Species how long the control waits before assessing the oil

level and generating a second ATO pulse if the oil level is still

low.

1. Enter a new value by using the product numbers.

2. Press the button next to √ to accept the new value.

3. Press the button next to X to return to default or previous

setting.

FC-21 “AUTO-TOPOFF: AFTER X A TTEMPTS,

CHECK A TO”

After each ATO pulse, the control monitors the level probe

temperature to see if the oil has been brought up to the proper

level. If not, a second ATO pulse is given. After a certain number

of pulses, as specied by this setting, if the oil level still has

not been brought up to the proper level, the control beeps and

displays “FILL OIL TANK”.

1. Enter a new value by using the product numbers.

2. Press the button next to √ to accept the new value.

3. Press the button next to X to return to default or previous

setting.

If “X” pulses of oil haven’t brought the level up, the control

assumes that the oil tank is empty -- that no oil is being pumped

into the pot -- and displays the “Fill Oil Tank” message.

If the fryer is congured to use a Bulk Oil Supply system, the

message displayed is “CHECK BULK OIL SUPPLY” rather

than “FILL OIL TANK”. In this case, it is possible that the

remote bulk supply tank is empty, that the bulk supply plumbing

connection is not connected to the fryer, or that the bulk supply

electrical connection is not connected.

FC-22 “COOK MODE - FORCED ATO CHECK

AFTER ‘X’ COOKS”

1. Enter a new value by using the product numbers.

March 2014

2. Press the button next to √ to accept the new value.

3. Press the button next to X to return to default or previous

setting.

52

Page 59

Start-Up Mode Settings

4-4.

FILTER CONTROL

(CONT.)

FC-23 “START-UP: NEEDED IF TEMP < X”

If the oil temperature is below 215°F when the fryer is turned

on, the fryer always executes a Melt Mode -- regardless of this

“Start-up Needed” setting. Melt Mode is important in assuring

gentle heating of the oil when it is thick and perhaps not yet

owing well.

1. Enter a new value by using the product numbers.

2. Press the button next to √ to accept the new value.

3. Press the button next to X to return to default or previous

setting.

FC-24 “START-UP MIX: ENABLED?”

Phase 2 of the morning startup procedure is to execute the Start-

up Mix operation: drop all of the oil into the drain pan, lter it