Henny Penny OFE-321 User Manual

TECHNICAL MANUAL

CFA Electric Open Fryer

Henny Penny

Model OFE-321

Model OFE-322

Model OFE-321,322

TABLE OF CONTENTS

Section Page

Section 1. TROUBLESHOOTING...................................................................................................1-1

1-1. Introduction.............................................................................................................1-1

1-2. Safety ......................................................................................................................1-1

1-3. Troubleshooting......................................................................................................1-2

1-4. Warnings and Error Messages................................................................................1-5

Section 2. MAINTENANCE.............................................................................................................2-1

2-1. Introduction.............................................................................................................2-1

2-2. Maintenance Hints..................................................................................................2-1

2-3. Complete Control Panel Replacement....................................................................2-1

2-4. Power Switch ..........................................................................................................2-2

2-5. Transformer.............................................................................................................2-2

2-6. I/O Power Supply Boards Assembly ......................................................................2-3

2-7. Drain Microswitch ..................................................................................................2-3

2-8. Filter Switch............................................................................................................2-4

2-9. Heating Elements....................................................................................................2-5

2-10. Heating Contactors .................................................................................................2-8

2-11. Speaker Assembly...................................................................................................2-10

2-12. High Temperature Limit Control............................................................................2-11

Wiring Diagrams.....................................................................................................2-13

Section 3. PARTS INFORMATION.................................................................................................3-1

3-1. Introduction.............................................................................................................3-1

3-2. Genuine Parts..........................................................................................................3-1

3-3. When Ordering Parts...............................................................................................3-1

3-4. Prices.......................................................................................................................3-1

3-5. Delivery ..................................................................................................................3-1

3-6. Warranty .................................................................................................................3-1

3-7. Recommended Spare Parts for Distributors............................................................3-1

FM06-004

Revised 4-02-09

109 i

Model OFE-321,322

SECTION 1. TROUBLESHOOTING

1-1. INTRODUCTION

an easy to read table.

If a problem occurs during the first operation of a new fryer,

recheck the Installation Section of the Operator’s Manual.

Before troubleshooting, always recheck the Operation Section of

the Operator’s Manual.

1-2. SAFETY

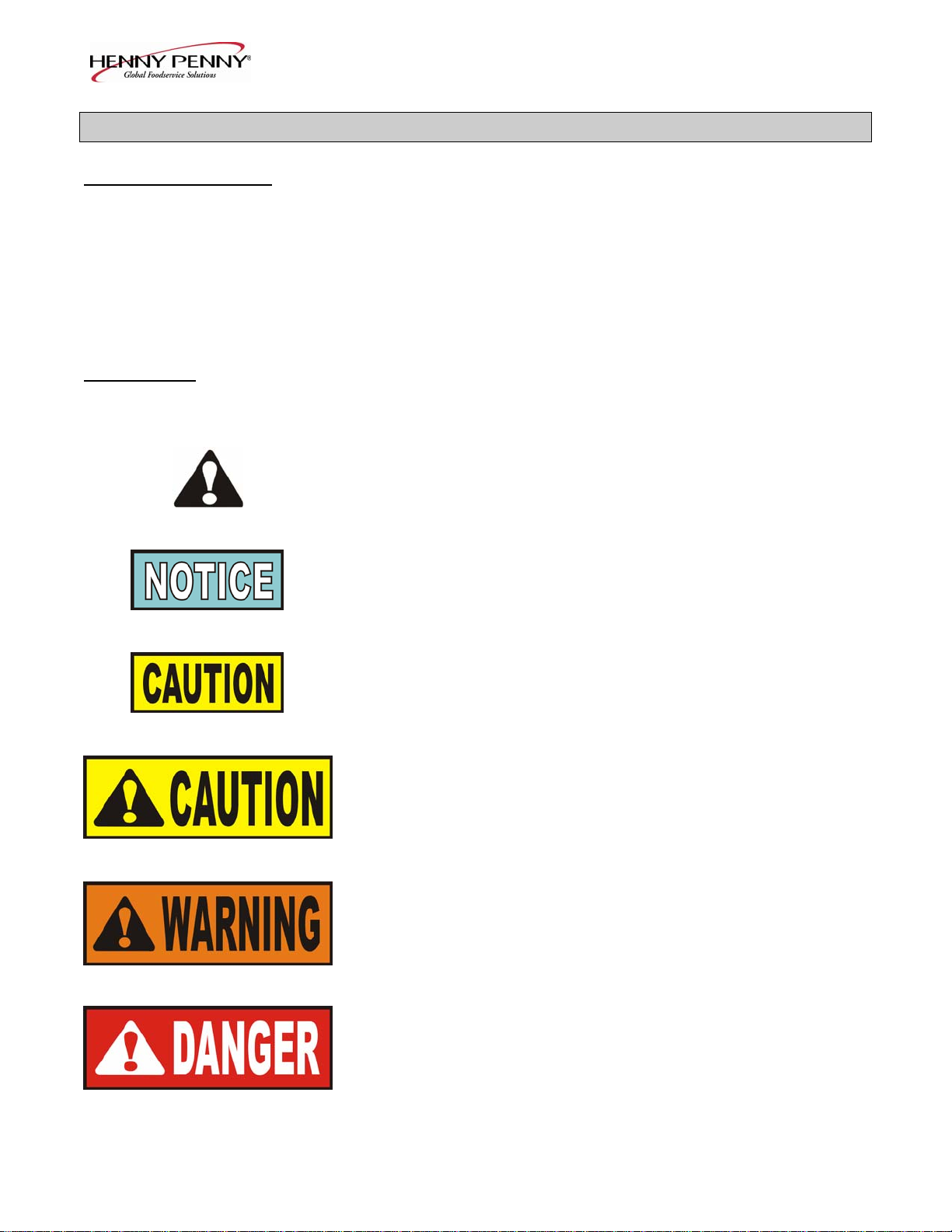

Where information is of particular importance or is safety related,

This section provides troubleshooting information in the form of

the words DANGER, WARNING, CAUTION, or NOTE are used.

Their usage is described on the next page:

SAFETY ALERT SYMBOL is used with DANGER,

WARNING or CAUTION which indicates a personal

injury type hazard.

NOTICE is used to highlight especially important

information

.

CAUTION used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may

result in property damage.

CAUTION used wih the safety alert symbol indicates a

potentially hazardous situation which, if not avoided,

could result in minor or moderate injury.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury.

DANGER INDICATES AN IMMINENTLY

HAZARDOUS SITUATION WHICH, IF NOT

AVOIDED, WILL RESULT IN DEATH OR

405 1-1

SERIOUS INJURY.

Model OFE-321,322

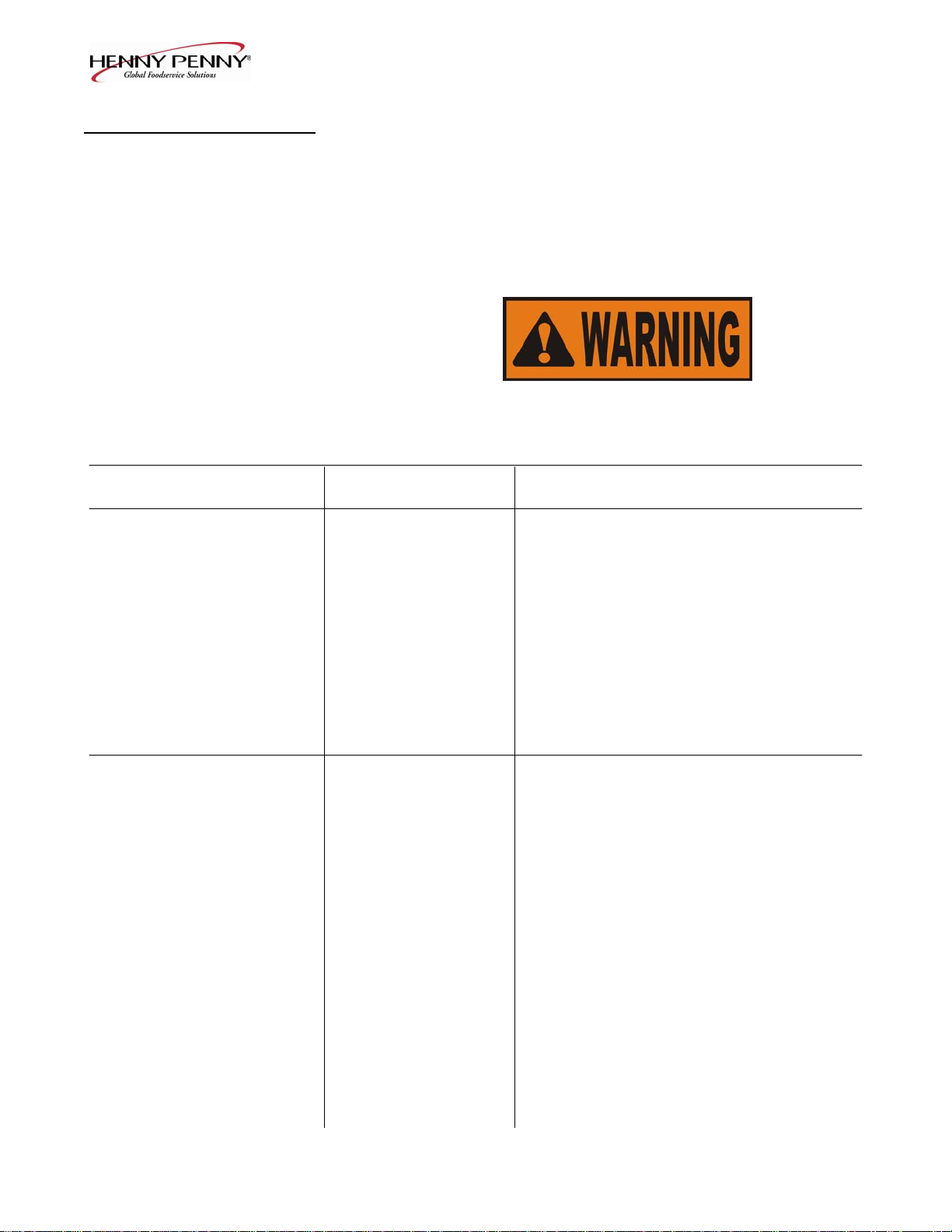

1-3. TROUBLESHOOTING To isolate a malfunction, proceed as follows:

1. Clearly define the problem, or symptom and when it

occurs.

2. Locate the problem in the troubleshooting table.

3. Review all possible causes, then one at a time, work

through the list of corrections until the problem is solved.

If maintenance procedures are not followed correctly,

injuries and/or property damage could result.

PROBLEM CAUSE CORRECTION

With the switch in • Open circuit • Check to see if unit is plugged in

the POWER position,

fryer is completely • Check breaker or fuse at supply box

inoperative

• Check POWER switch per Power Switch

Section; replace if defective

• Check voltage at wall receptacle

• Check cord and plug

Shortening will not • Faulty contactor • Check contactor per Heating Contactors

heat but lights are on (elec. model) Section

• Faulty temperature • Check temperature probe per Temperature

probe Probe Replacement Section; “E-6A or B”

• Faulty high limit • Check high limit per the appropriate High

Temperature Limit Control Section; “E-10”

• Faulty drain switch • Check drain switch per Drain Microswitch

Section; “E-15"

1-2 405

Model OFE-321,322

1-3. TROUBLESHOOTING(Continued)

PROBLEM CAUSE CORRECTION

Heating of • Low or improper • Use a meter and check the receptacle

shortening too voltage (elec. unit) voltage against the data plate

slow

• Weak or burnt out • Check heating elements per Heating

elements (elec. unit) Elements Section

• Wire(s) loose • Tighten

• Burnt or charred • Replace wire and clean connectors

wire connection

• Faulty contactor • Check contactor per Heating Contactors

Section

Shortening • Temperature probe • Calibrate temperature probe if ± 10° off;

overheating needs calibration if more than ± 10° off, replace temperature

probe

• Mercury contactor • Check mercury contactor for not opening;

stuck closed replace if necessary (elec. unit)

• Bad control board • Replace control board if heat indicator stays

on past ready temperature

Foaming or boiling • Water in shortening • At end of cook cycle, drain shortening and

over of shortening clean

• Improper or bad • Use recommended shortening

shortening

• Improper filtering • Refer to the Filtering the Shortening

Section in Operator’s Manual

• Improper rinsing • Clean and rinse the frypot; then dry

after cleaning fryer thoroughly

405 1-3

Model OFE-321,322

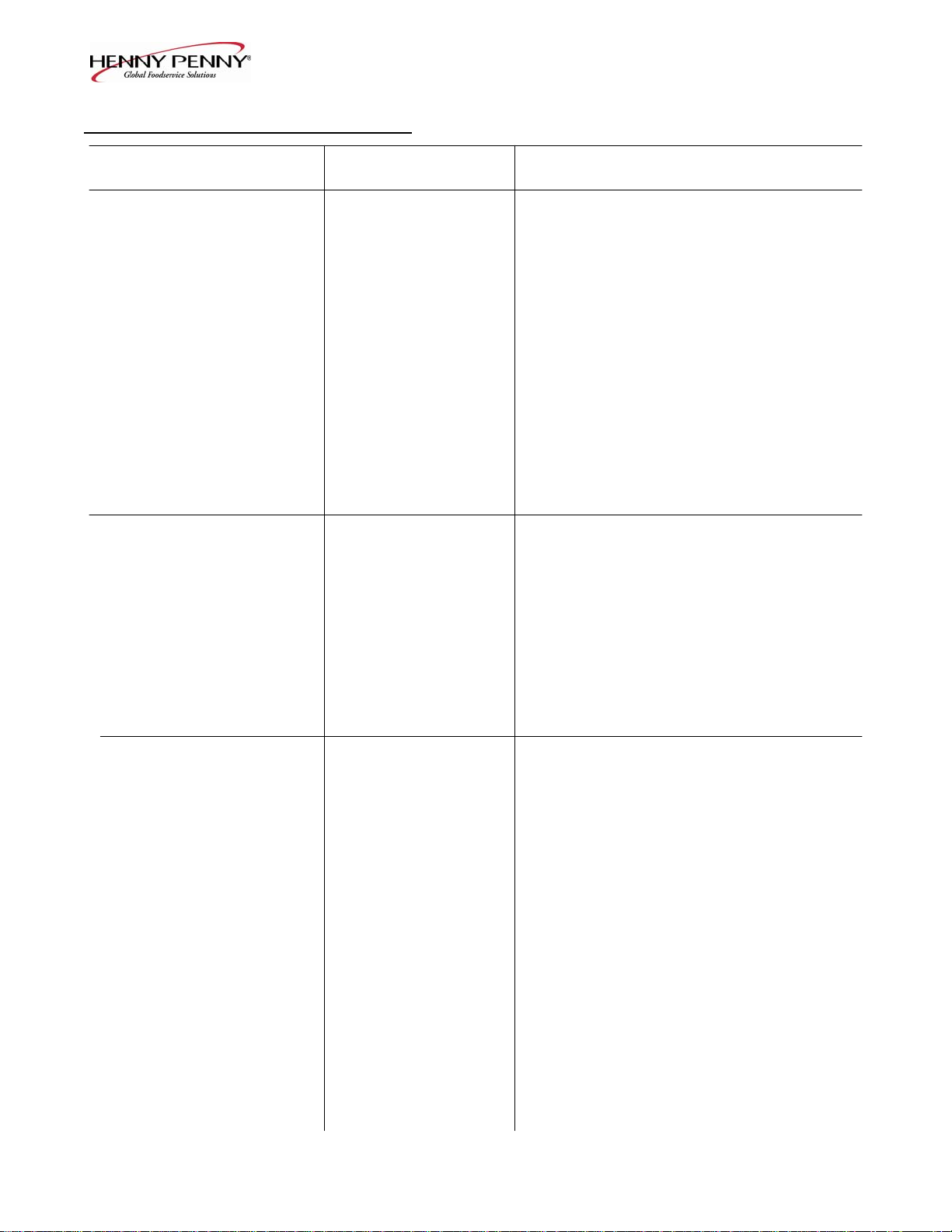

1-3. TROUBLESHOOTING

(Continued)

PROBLEM CAUSE CORRECTION

Shortening will not • Drain valve clogged • Open valve, force cleaning brush through

drain from frypot with crumbs drain

• Drain valve will not • Replace cotter pins in valve coupling

open by turning

handle

Filter motor runs • Pump clogged • Remove pump cover and clean

but pumps shortening

slowly • Filter line connection • Tighten all filter line connections

loose

• Solidified shortening • Clear all filter lines of solidified shortening

in lines

Filter switch on but • Defective switch • Check/replace switch per Filter Switch

motor does not run Section

• Defective motor • Check/replace motor

• Motor thermal • Reset thermal switch on filter motor

protector tripped

Motor hums but • Clogged lines or • Remove and clean pump and lines

will not pump pump

• Replace pump seal, rotor and rollers

1-4 405

Model OFE-321,322

1-4. WARNINGS AND The controls monitor procedure problems and system failures

ERROR MESSAGES

with warnings and error codes. The display shows the

warning or error code, and an alarm sounds.

Pressing cancels most warnings and pressing any

control button stops most error code alarms. But there are

some exceptions (see below). The display shows the error

until the situation is corrected.

WARNINGS

DISPLAY CAUSE CORRECTION

“W-1” Incoming supply voltage too low Have voltage at plug and receptacle checked

“LOW

VOLTAGE”

“W-2” Faulty components or connections Have elements, connections, and contactors

“SLOW checked

HEAT-UP”

“W-3” Product loaded into frypot Wait until shortening is at proper temperature

“WAS NOT before lights before loading product

READY”

“W-4” Too much product Do not overfill frypot

“SLOW in frypot

COOKING”

“W-5 Product loaded into frypot Wait until shortening is at proper temperature

“SLOW before lights before loading product

COOKING”

“W-6” Faulty components or connections Have elements, connections, and contactors

“SLOW checked

COOKING”

“W-7” Faulty components or connections Have elements, connections, and contactors

“LOW AMPS” checked

“W-9” Product overcooked. (may Discard product immediately

“DISCARD appear after a “SLOW COOKING”

PRODUCT” warning)

“OIL TOO Didn’t allow shortening to drop Cancel button stops this warning; once the

HOT” to current product’s setpoint shortening drops to setpoint temperature,

temperature the alarm automatically stops

405 1-5

Model OFE-321,322

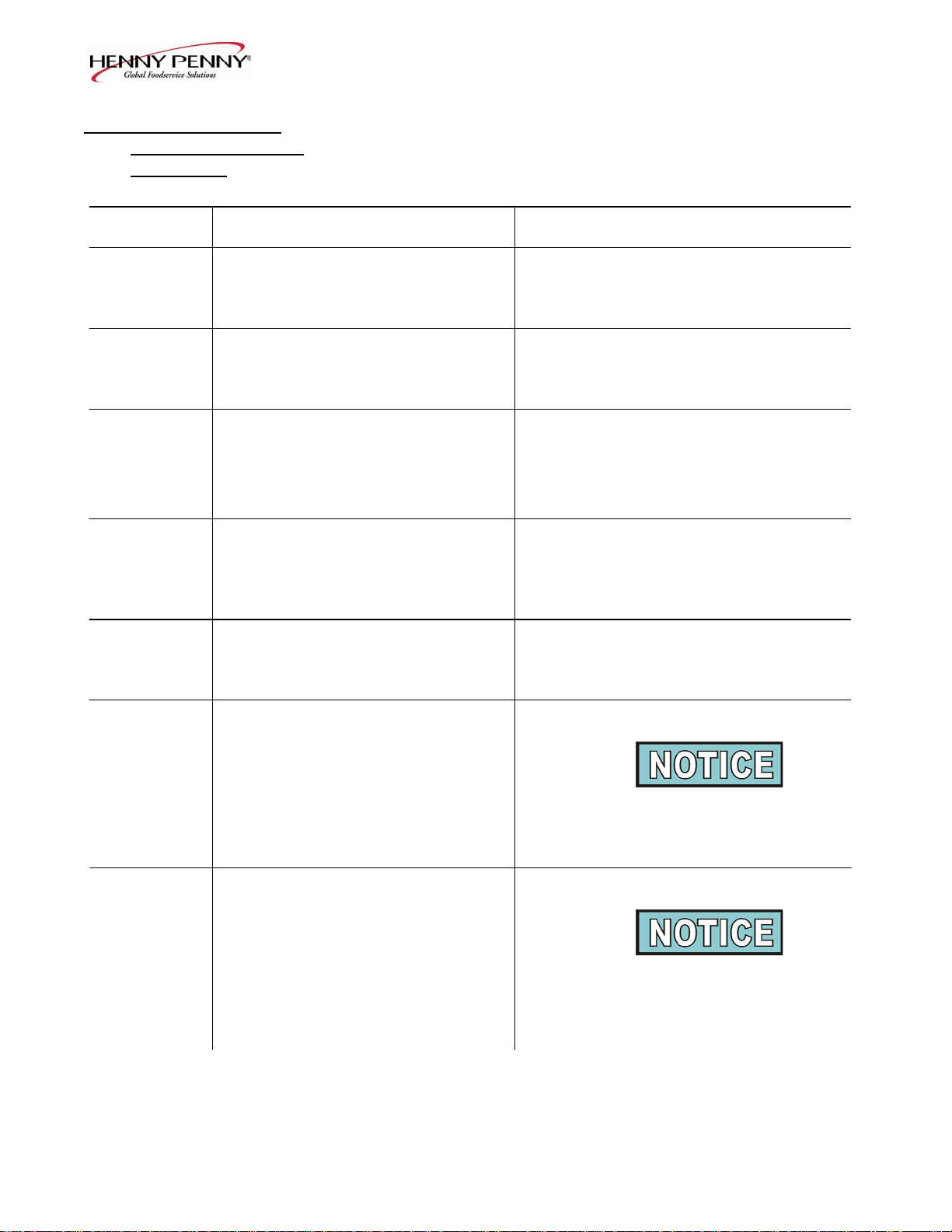

1-4. WARNINGS AND

ERROR MESSAGES

(Continued)

DISPLAY CAUSE CORRECTION

“E-4” PC board too hot Check ventilation louvers on side of fryer

“CPU TOO for obstructions; if louvers are clear,

HOT” have PC board checked

“E-5” Controls sensing 405°F Have heat components and temperature

“FRYER TOO or above probe checked

HOT”

“E-6” (A or B) Faulty temperature probe or Have temperature probe and connection

“FRYER connection checked

TEMP

SENSOR

FAILED”

“E-10” Shortening temperature too hot, Reset high limit (see Operating Components

“HIGH LIMIT drain valve opened while heat was Section); check shortening temperature for

TRIPPED” on, or faulty high limit overheating; have heat components checked

if high limit continues to trip.

“E-15” Drain is open or faulty microswitch Close drain; have drain microswitch

“DRAIN IS checked if error code persists

OPEN”

“E-25” Wrong or faulty elements or wiring Have electrical supply, wiring, and elements

“HEAT AMPS problem checked

WERE TOO

HIGH”

Because of the seriousness of this

ERROR CODES

error code, turn the POWER switch

off and back on to cancel

“E-26” Faulty contactors or PC board Have the contactors and PC board checked

“HEAT AMPS

ARE LOCKED

ON”

This error code could be displayed

even with the POWER switch turned

off. Unplug fryer or shut off the

wall circuit breaker to disconnect

electrical power to fryer.

1-6 405

Model OFE-321,322

3-5. WARNINGS AND

ERROR MESSAGES

(Continued)

ERROR CODES

DISPLAY CAUSE CORRECTION

“E-41” Memory scrambled; an individual Turn the POWER switch off and back

“SYSTEM product program may be scrambled: on; if error code persists, have the

DATA LOST” Ex: “E-41 -2- DATA LOST”; this PC board checked or re-initialized

means product #2 program is

scrambled

“E-46” Faulty eprom or PC board Turn the POWER switch OFF and back

“DATA SAVE on; if error code persists, have the

FAILED” PC board checked or re-initialized

“E-47” Failure of 12 volt DC supply Turn the COOK/PUMP switch OFF and back

“ANALOG on the I/O board to COOK; if the and DO NOT

SYSTEM

OR 12 VOLT light up when the 8888’s are displayed, have the

FAILED” I/O board replaced

Amp sensors plugged in backwards Have positions of amp sensors checked

Faulty PC board Have control panel replaced

“E-48”

INPUT on the I/O board to COOK; if the and DO NOT

SYSTEM

ERROR” light up when the 8888’s are displayed, have the

I/O board replaced

“E-70” Faulty POWER switch Have POWER switch checked, along

“PWR SW or switch wiring; faulty with its wiring; have I/O board checked

OR WIRES I/O board

FAILED”

“E-92” Blown 24 volt controller fuse, or Have the 14-pin cable connector checked or

“24 VOLT bad 14-pin cable connection have the fryer checked for a short to ground

FUSE” in components such as the drain switch,

or high limit and wiring

405 1-7

Failure of 12 volt DC supply Turn the COOK/PUMP switch OFF and back

Faulty PC board Have control panel replaced

Model OFE-321,322

SECTION 2. MAINTENANCE

2-1. INTRODUCTION

of the various parts used within the fryer. Before replacing any

parts, refer to the Troubleshooting Section. It will aid you in

determining the cause of the malfunction.

2-2. MAINTENANCE HINTS

components.

2. When the manual refers to the circuit being closed, the

multimeter should read zero unless otherwise noted.

3. When the manual refers to the circuit being open, the

multimeter will read infinity.

2-3. COMPLETE CONTROL

PANEL REPLACEMENT Should the control board become inoperative, follow these

instructions for replacing the board.

This section provides procedures for the checkout and replacement

1. You may need to use a multimeter to check the electric

1. Remove electrical power supplied to the unit.

To avoid electrical shock or property damage, move the

POWER switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove the four screws securing the control panel and lift

out.

3. Unplug the wire connectors going to the control board.

4. Install new control panel in reverse order.

When plugging connectors onto new control panel, be sure

the connectors are inserted onto all of the pins, and that the

connectors are not forced onto the pins backwards. If not

connected properly, damage to the board could result.

2-1 405

Model OFE-321,322

2-4. POWER SWITCH 1. Remove electrical power supplied to fryer.

To avoid electrical shock or property damage, move the

POWER switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove control panel.

3. Label and remove the wires from the switch. With test

instrument, check across the terminals of the switch with

the switch in the ON position, then in the OFF position.

With the switch in the ON position, the circuit should be

closed. With the switch in the OFF position, the circuit

should be open. If the switch checks defective, replace by

continuing with this procedure.

4. With control panel removed, and the wires off the switch, push

in on tabs on the switch to remove from panel.

5. Replace with new switch, and reconnect wires to switch.

6. Replace the control panel.

2-5. TRANSFORMER

The transformer reduces voltage down to accommodate those

components with low voltage.

1. Remove electrical power supplied to the unit.

To avoid electrical shock or property damage, move the

POWER switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove the control panel as discussed in Complete Control Panel

Replacement Section.

3. Squeeze on the wire connector at the I/O board assembly to

disconnect the wires from the transformer.

4. Using a Phillips head screwdriver, remove the two screws

securing the transformer to the shroud.

5. Install the new transformer in reverse order.

405 2-2

Model OFE-321,322

2-6. I/O POWER SUPPLY

BOARD ASSEMBLY

The input/output power supply board assembly distributes

voltage to the various components in the fryer. The board also

receives information from components in the fryer.

1. Remove electrical power supplied to the unit.

To avoid electrical shock or property damage, move the

POWER switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove the control panel as discussed in Complete Control

Panel Replacement Section.

3. Disconnect the wire assemblies from the board.

4. Using a nut driver or wrench, remove the four keps nuts

securing the board to the shroud.

5. Install the new I/O board assembly in reverse order.

2-7. DRAIN MICROSWITCH

Upon turning the drain handle, the drain microswitch circuit

should open, cutting off the pilot flame. This will prevent the fryer

from heating while shortening is being drained from the frypot.

1. Remove electrical power supplied to the unit.

To avoid electrical shock or property damage, move the

POWER switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2-3 405

Loading...

Loading...