559-734-7451 800-367-5480 FAX 559-734-7460

INSTALLATION INSTRUCTIONS

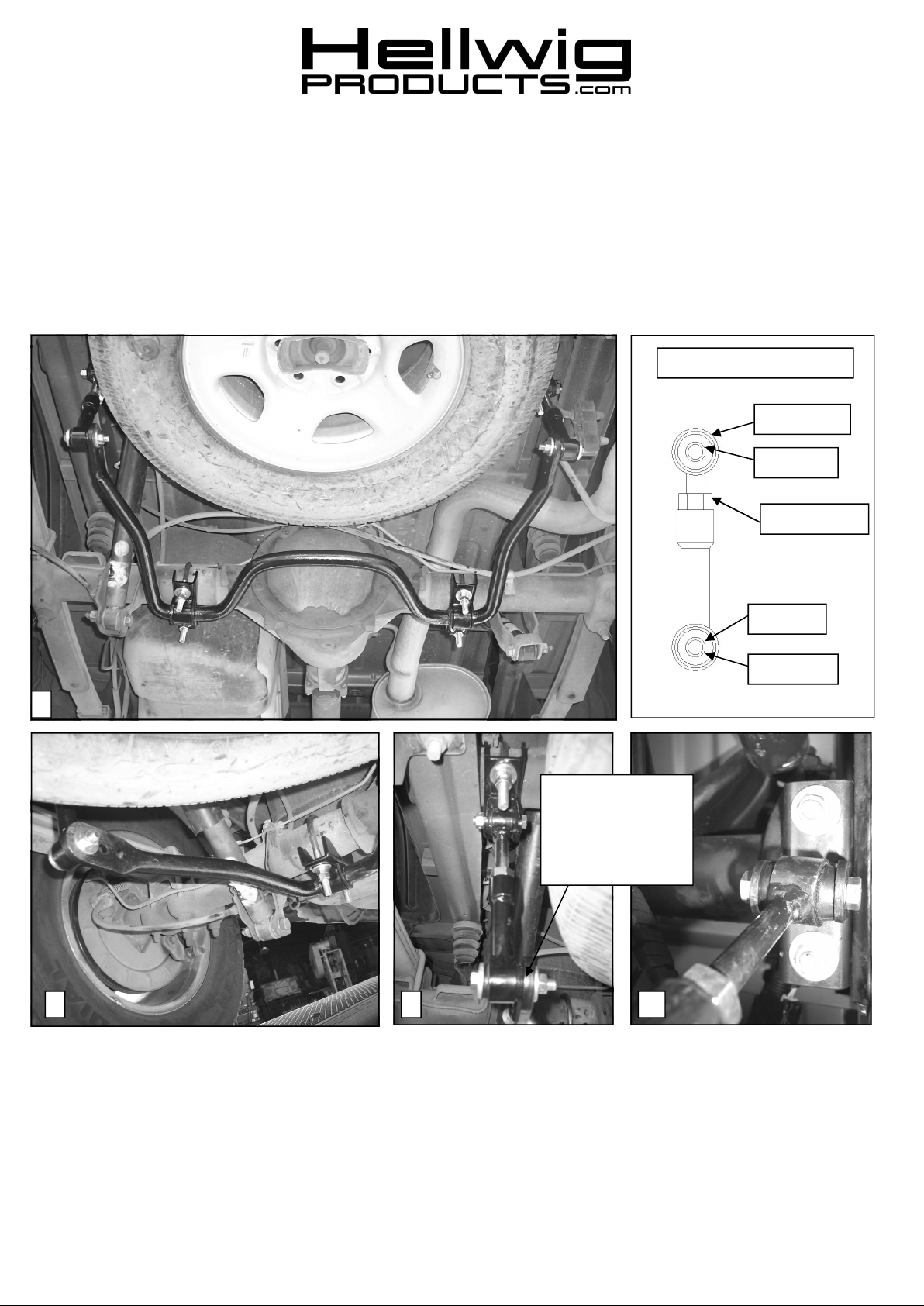

Rear Stabilizer Bar

4X2 & 4X4 1500-2500 SIERRAAND SILVERADOALSO INCLUDES

1500HD TRUCKS

Thank you for purchasing a quality Hellwig Product.

End LinkAssembly

Bushing

Sleeve

9/16-18 Nut

1

2007”+ Vehicles

1/2” spacer may be

needed between bushing and sway bar for

2007+ vehicles

2 3 4

Sleeve

Bushing

7800( R-7800) 09/09/05

559-734-7451 800-367-5480 FAX 559-734-7460

TORQUETABLE

BOLT SIZE: 3/8” = 20-30 ft. lbs. – 7/16” = 35-45 ft. lbs. – ½” = 50-70 ft. lbs. – 9/16” = 70-90 ft. lbs. –5/8”=120 ft lbs.

NOTE: THIS UNIT IS DESIGNED TO MOUNT WITH THEARMSOF THE SWAYBARTOWARDS THE REAR OF THE VECHILE.

SAFETY: BEFORE STARTING YOUR INSTALLATIONBE SURE TO SET THE EMERGENCY BRAKE AND WHEELS ARE CHOKED.

NOTE: TO EASE INSTALLATION ANDPROPERLY ADJUST THE BAR, THE WEIGHTOF THE VEHICLE MUSTBEON THE SUS

PENSION AS IF DRIVING DOWNTHE ROAD.DO NOT RAISE THE VEHICLE BY THE FRAME.

NOTE: THIS KIT INCLUDES LOCK NUTS WHICH REQUIRE TIGHTENING WITH A WRENCH AFTERBEING STARTED BY HAND.

1. 2007+ Silverado/Sierra owners read page 3 first.

2. Remove spare tire for ease of installation of sway bar.

3. Lubricate and install the D-shaped poly-bushings onto the flat areas of the bar on each side of the hump area. The hump

of the bar should tilt slightly downward. SEE PHOTO #1

4. Place the long 1/2” dia U-bolts on axle inside of the shock mounts. Make sure U-bolts are under the any brake lines,

wires, or hoses on the axle to avoid pinching or crushing when tightening. The threads should be pointing downward.

5. Place the U-plates onto the bushings mounted on the bar earlier. Place the saddle brackets onto the U-bolts on the axle

tubes and attach the U-plates using the flat washers and nuts provided.

6. Rotate the bar on the axle tubes and adjust side to side so the bar is as centered as possible and has clearance around the

differential housing.

7. Assemble the hourglass bushings and inner sleeves into the ends of the end-links. Lubricate the bushings and sleeves

with supplied lubricant before assembly. SEE DIAGRAM for assembly of end links.IMPORTANT NOTE - The end

link threads are NOT powder coated so that the end links can be threaded together. To preventcorrosion, it is

advised to lightly coat the exposed threads with black spray paint after adjusting to desired length.

8. Place the short set of 7/16” dia U-bolts around the tubular cross member above the spare tire just inside the frame rails

with the legs pointing down. Place the saddle brackets with the welded U-shaped clevis on to the cross member

mounted U-bolts. Attach saddle brackets with washers and locknuts provided. Leave loose at this time to allow for

adjustment later. Make sure U-bolts are under any lines or wires to avoid pinching or crushing when tightening.

Leave loose at this time to allow for adjustment. SEE PHOTO # 3 & 4.

9. Attach the end-links into the upper clevis brackets with the 7/16X2-1/4” bolts and locknuts provided and let hang. Leave

all mounting hardware loose at this point to allow for adjustment later. SEE PHOTO # 3 .

10. Raise the bar up so the arms are as close to level as possible and attach the lower end-links to the rear-most hole in the

sway bar using the 7/16 x 2-3/4 bolts and locknuts. 2007+ applications see note 11. SEE PHOTO # 3 Adjust the end

links so that the arms of the sway bar are as level as possible.

11. 2007+ applications—To get the end links to align vertically, it may be necessary to use the 7/16 x 3-1/4” bolts and

the 1/2” spacers between the bushing and the sway bar.

12. Rotate the U-bolts on the axle and tubular cross member to align the bar so it is as level with the frame as possible and

the end-links are straight up and down as possible. Be sure that the axle and cross member U-bolts are under any

brake lines, wires or hoses to avoid pinching or crushing when tightening.

13. With the bar properly aligned, verifythat all vehicle components have proper amount of clearance, and nothing is going

to be pinched or crushed when everything is tight. Torque U-bolts to 30-35 ft-lb and all mounting hardware to the specified rates. Double nut the axle U-bolts.

14. Replace spare tire and bounce the vehicle checking for clearance on all under carriage components – exhaust, shocks,

differential, etc. Test drive the vehicle and recheck all clearances and the installation alignment. Adjust as needed. Recheck your installation after one week of driving and periodically on a regular basis.

15. The sway bar arms have three mounting holes. Mounting the sway bar on the outer hole is the nominal position. For

firmer settings, use the inner holes. We recommend starting with the outer mounting hole as in photo ( 2 ) until you are

accustomed to the vehicles new handling characteristics. Select the mounting point that best fits your driving style.

ATTENTION INSTALLER: BE SURE CUSTOMER RECIEVES THIS INSTRUCTION SHEET, WARNING CARDS

AND THE WARRANTY FORM.

7800 ( R-7800) 09/09/05

559-734-7451 800-367-5480 FAX 559-734-7460

7800 Special instructions for 2007+ Silverado/Sierra 1500

Emergency Brake Relocation

May need to trim driver’s

side shock bracket here 1/8”

for saddle bracket to seat

1 2 3

Note Saddle bracket orientation

2007”+ Vehicles

1/2” spacer may be

needed between bushing and sway bar for

2007+ vehicles

4

BEFORE INSTALLATION OF SWAY BAR ASSEMBLY, RELOCATE EMERGENCY

BRAKE CABLE USING SUPPLIED BRACKET AND 5/16 BOLT AS SHOWN IN

PHOTO (1).

IT MAY BE NECESSARY TO TRIM THE DRIVER’S SIDE SHOCK BRACKET AS

SHOWN IN PHOTO (2) TO ALLOW SADDLE BRACKET TO SEAT ON CROSSMEMBER.

WHEN ORIENTING SWAY BAR, ROTATE SADDE BRACKETS REARWARD AS

SHOWN IN PHOTOS (3) & (4) TO ALLOW CLEARANCE TO AXLE CASTING.

FOLLOW ALL INSTRUCTIONS ON PAGE TWO WITH EXCEPTIONS LISTED

ABOVE.

7800 ( R-7800) 11/10/06

Loading...

Loading...