Hellwig 7865 User Manual

559-734-7451 800-367-5480 FAX 559-734-7460

INSTALLATION INSTRUCTIONS

Jeep Wrangler JK

7865 FRONT SWAY BAR

Thank you for purchasing a quality Hellwig Product.

PLEASE READ THIS INSTRUCTION SHEET COMPLETELY BEFORE STARTING YOUR INSTALLATION

U-Plate and D-bushing

1

SAFETY: BEFORE STARTING YOUR INSTALLATION, BE SURE TO SET PARKING BRAKE AND CHOCK

TIRES.

NOTE: TO EASE INSTALLATION AND TO PROPERLY ADJUST THE BAR, THE WEIGHT OF THE VEHICLE

MUST BE ON THE SUSPENSION, AS IF DRIVING DOWN THE ROAD. DO NOT RAISE VEHICLE BY THE

FRAME.

NOTE: THIS KIT INCLUDES LOCK NUTS WHICH REQUIRES TIGHTENING WITH A WRENCH AFTER

BEING STARTED BY HAND.

TORQUE TABLE

BOLT SIZE: 3/8” = 20-30 ft. lbs. – 7/16” = 35-45 ft. lbs. – 1/2” = 50-70 ft. lbs. – 9/16” = 70-90 ft. lbs.-5/8”=120 ft. lbs.

7865 ( R-7865 ) 08/15/2012

559-734-7451 800-367-5480 FAX 559-734-7460

3

2

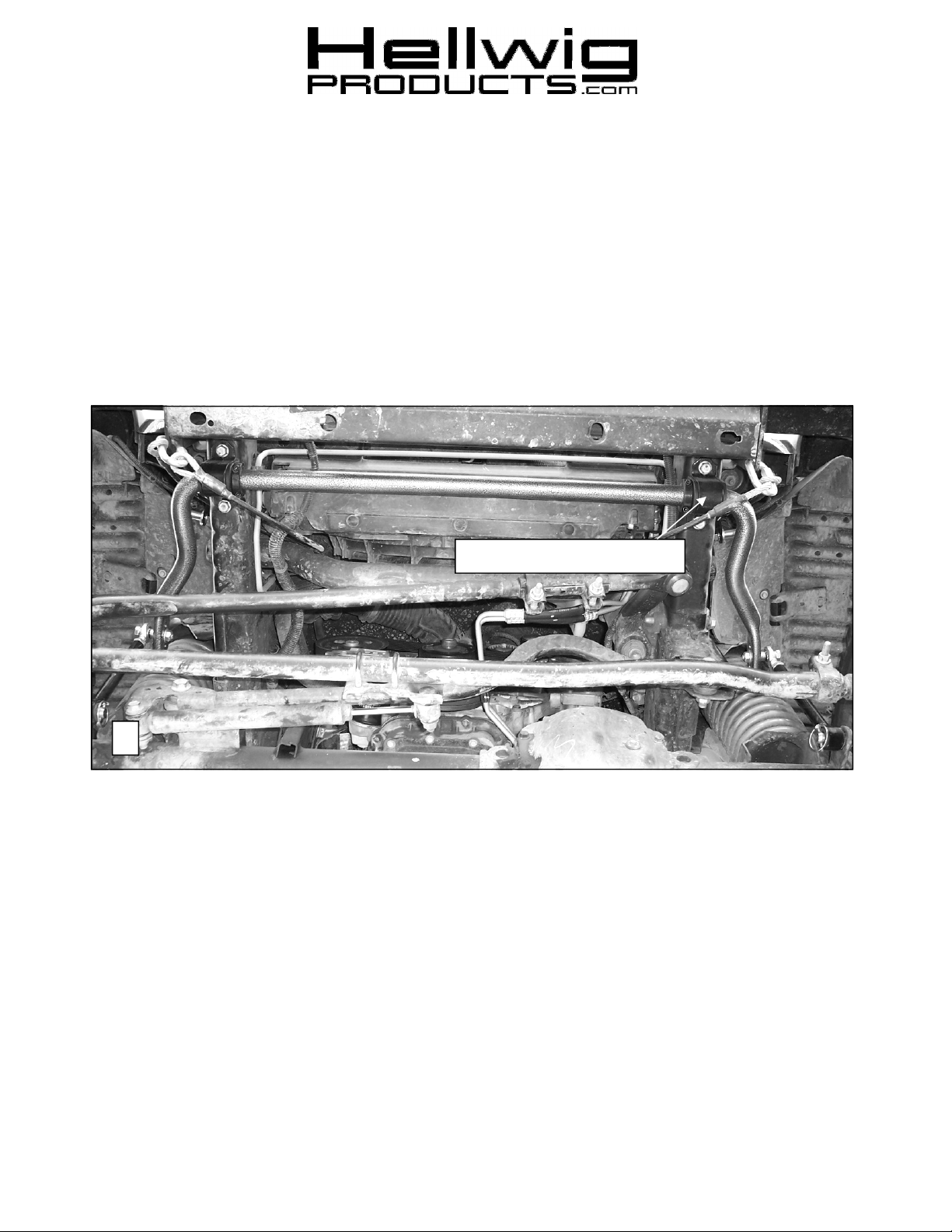

1. Entirely remove the front factory sway bar and end links. Keep the hardware as some of it will be reused in

the installation.

2. Lubricate the insides of the D-shaped polyurethane bushings and place them on the bar. Then place the Uplates over the bushings.

3. Using the factory bolts kept in Step 1, attach the sway bar to the underside of the frame in the stock location as shown in Photo 1.

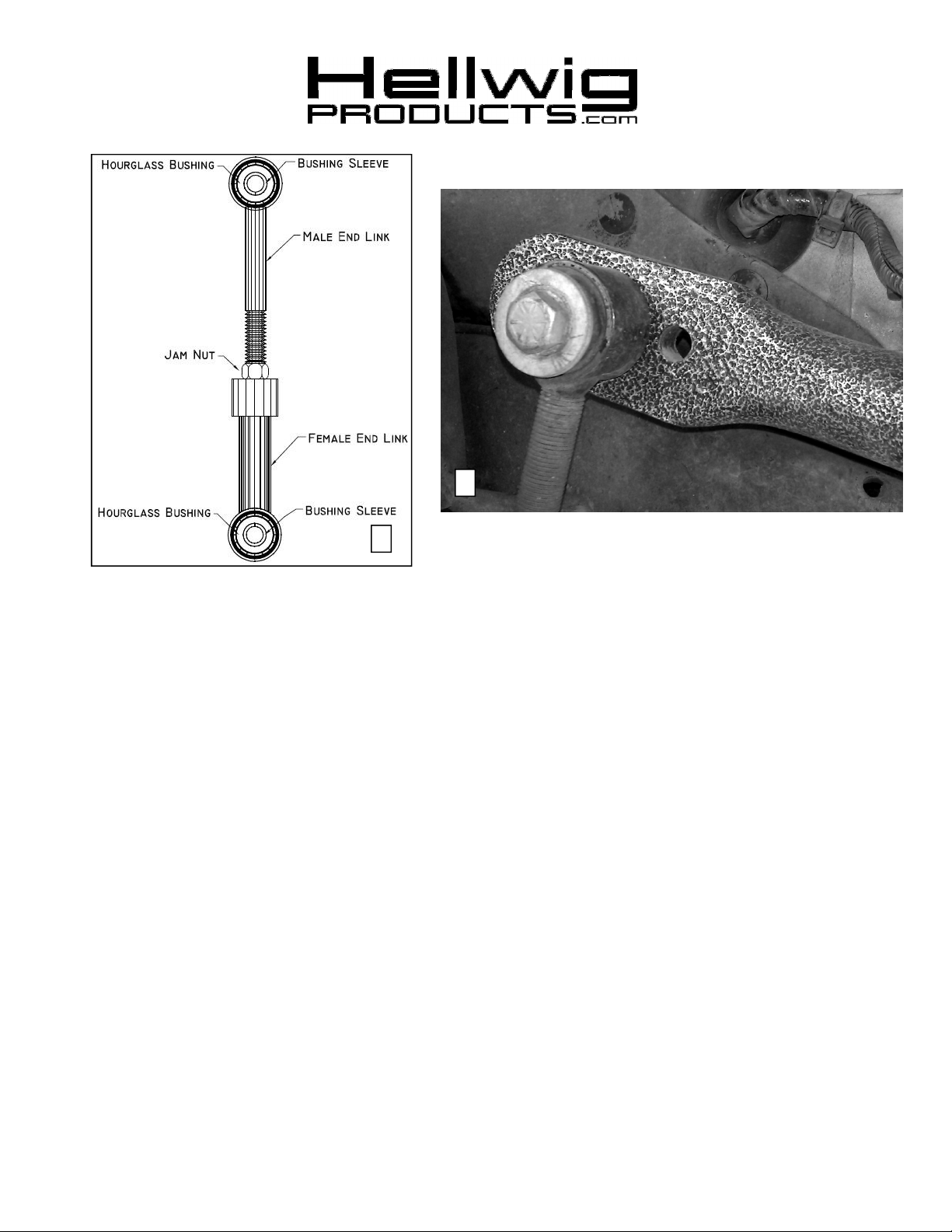

4. Assemble end links together as shown in Diagram 2 above. Lubricate the outsides of the hourglass bushing

and tap it into the hoop on the end link. Then lubricate the outside of the sleeve and press it into the bushing. Leave loose at this time for later adjustment.

6. Loosely attach the end link to the middle hole on the sway using the 7/16” bolt, washers and stover nut as

shown in Photo 3. The middle hole position is for sizing the end link only, it is recommended to start

with the end link attached to the outermost (softest) hole until the driver gets used to the change in ride

characteristic and they can then adjust the hole positioning for their driving style.

7. Adjust the length of the end link so it will allow the sway bar arms to be parallel to the ground, then tighten

the jam nut to hold it in place.

8. Attach the bottom, female part of the end link to the factory bracket using the 7/16 bolt, washers and stover

nut and then attach the top to the outermost hole using the same hardware.

9. Slide the bar so it is centered on the frame and then torque all the bolts following our torque table on the

first page.

7. Bounce the vehicle with the wheel turned full lock as well as straight checking for clearance on all under

carriage components: fuel tank, shocks, differential, brake and fuel lines, etc. Test drive the vehicle and

recheck all clearances and bolt torques. Adjust as needed. Re-check your installation after one week of

driving and periodically on a regular basis.

ATTENTION INSTALLER: BE SURE THAT THE CUSTOMER RECEIVES THIS INSTRUCTION

SHEET, ALL IMORTANT NOTE CARDS AND THE WARRANTY FORM

7865 ( R-7865 ) 08/15/2012

Loading...

Loading...