Page 1

Jade's Collection .net Archives

1

CHAPTER ONE

GENERAL INFORMATION

This detailed and comprehensive manual covers

the Harley-Davidson Dyna Glide Twin Cam 88

model from 1999-on. Procedures and specifications

unique to 2002-2005 models are covered in the

Supplement at the end of the manual. The text provides complete information on maintenance,

tune-up, repair and overhaul. Hundreds of photos

and drawings guide the reader through every job.

A shop manual is a reference tool and as in all

service manuals, the chapters are thumb tabbed for

easy reference.

end of the book. All procedures, tables and figures

are designed for the reader who may be working on

the vehicle for the first time. Frequently used specifications and capacities from individual chapters

are summarized in the Quick Reference Data at the

front of the book.

Tables 1-9 are at the end of this chapter.

Table 1 lists model designation.

Table 2 lists general vehicle dimensions.

Important items are indexed at the

Table 3 lists vehicle weight.

Table 4 lists decimal and metric equivalents.

Table 5 lists conversion tables.

Table 6 lists general torque specifications.

Table 7 lists technical abbreviations.

Table 8 lists American tap and drill sizes.

Table 9 lists special tools.

MANUAL ORGANIZATION

All dimensions and capacities are expressed in

metric and U.S. standard units of measurement.

This chapter provides general information on

shopsafety,tooluse,servicefundamentalsand shop

supplies. The tables at the end of the chapter include

general vehicle information.

Chapter Two provides methods for quick and accurate diagnosis of problems. Troubleshooting pro

cedures present typical symptoms and logical

methods to pinpoint and repair the problem.

-

Page 2

2 CHAPTER ONE

Chapter Three explains all routine maintenance

necessary to keep the vehiclerunning well.Chapter

Three also includes recommended tune-up procedures, eliminating the need to constantly consult the

chapters on the various assemblies.

Subsequent chapters describe specific systems

such as engine, transmission, clutch, drive system,

fuel and exhaust systems, suspension and brakes.

Each disassembly, repair and assembly procedure is

discussed in step-by-step form.

Some of the procedures in this manual specify

special tools. In most cases, the tool is illustrated in

use. Well-equipped mechanics may be able to substitute similar tools or fabricate a suitable replacement. However, in some cases, the specialized

equipment or expertise needed may make it impractical for the home mechanic to attempt the procedure. When necessary, such operations are

identified in the text with the recommendation to

have a dealership or specialist perform the task. It

may be less expensive to have a professional perform these jobs, especially when considering the

cost of the equipment.

WARNINGS, CAUTIONS AND NOTES

The terms, WARNING, CAUTION and NOTE

have specific meanings in this manual.

A WARNING emphasizes areas where injury or

even death could result from negligence. Mechanical damage may also occur. WARNINGS are to be

taken seriously.

ACAUTION emphasizes areas where equipment

damage could result. Disregarding a CAUTION

could cause permanent mechanical damage, though

injury is unlikely.

ANOTEprovides additional information to make

a step or procedure easier or clearer. Disregarding a

NOTE could cause inconvenience, but would not

cause equipment damage or personal injury.

SAFETY

Professional mechanics can work for years and

never sustain a serious injury or mishap. Follow

these guidelines and practice common sense to

safely service the vehicle.

1. Do not operate the vehicle in an enclosed area.

The exhaust gasses contain carbon monoxide, an

odorless, colorless, and tasteless poisonous gas.

Carbon monoxide levels build quickly in small en

closed areas and can cause unconsciousness and

death in a short time. Make sure the work area is

properly ventilated or operate the vehicle outside.

2. Never use gasoline or any extremely flammable

liquid to clean parts. Refer to Cleaning Parts and

Handling Gasoline Safely in this chapter.

3. Never smoke or use a torch in the vicinity of

flammable liquids, such as gasoline or cleaning solvent.

4. If welding or brazing on the vehicle, remove the

fuel tank, carburetor and shocks to a safe distance at

least 50 ft. (15 m) away.

5. Use the correct type and size of tools to avoid

damaging fasteners.

6. Keep tools clean andin good condition. Replace

or repair worn or damaged equipment.

7. When loosening a tight fastener, be guided by

what would happen if the tool slips.

8. When replacing fasteners, make sure the new

fasteners are of the same size and strength as the

original ones.

9. Keep the work area clean and organized.

10. Wear eye protection anytime the safety of the

eyes is in question. This includes procedures involving drilling, grinding, hammering, compressed

air and chemicals.

11. Wear the correct clothing for the job. Tie up or

cover long hair so it can not get caught in moving

equipment.

12. Do not carry sharp tools in clothing pockets.

13. Always have an approved fire extinguisher

available. Make sure it is rated for gasoline (Class

B) and electrical (Class C) fires.

14. Do not use compressed air to clean clothes, the

vehicle or the work area. Debris may be blown into

the eyes or skin. Never direct compressed air at anyone. Do not allow children to use or play with any

compressed air equipment.

15. When using compressed air to dry rotating

parts, hold the part so itcan not rotate.Do not allow

the force of the air to spin the part. The air jet is capable of rotating parts at extreme speed. The part

may be damaged or disintegrate, causing serious injury.

16. Do not inhale the dust created by brake padand

clutch wear. These particles may contain asbestos.

In addition, some types of insulating materials and

gaskets may contain asbestos. Inhaling asbestos

particles is hazardous to health.

-

Page 3

GENERAL INFORMATION 3

17. Never work on the vehicle while someone is

working under it.

18. When placing the vehicle on a stand, make sure

it is secure before walking away.

Handling Gasoline Safely

Gasoline is a volatile flammable liquidand is one

of the most dangerous items in the shop. Because

gasoline is used so often, many people forget that it

is hazardous. Only use gasoline as fuel for gasoline

internal combustion engines. Keep in mind, when

working on a vehicle, gasoline is always present in

the fuel tank, fuel line and carburetor. Toavoid a disastrous accident when working around the fuel

system, carefully observe the following precautions:

1. Never use gasoline to clean parts. See Cleaning

Parts in this chapter.

2. When working on the fuel system, work outside

or in a well-ventilated area.

3. Donot add fuel tothe fuel tank or service the fuel

system while the vehicle is near open flames, sparks

or where someone is smoking. Gasoline vapor is

heavier than air,it collects in low areas and is more

easily ignited than liquid gasoline.

4. Allow the engine to cool completely before

working on any fuel system component.

5. When draining the carburetor,catch the fuel in a

plastic container and then pour it into an approved

gasoline storage device.

6. Do notstore gasoline in glass containers. If the

glass breaks, a serious explosion or fire may occur.

7. Immediately wipe up spilled gasoline with rags.

Store the rags in a metal container with a lid until

they can be properly disposed of, or place them outside in a safe place for the fuel to evaporate.

8. Do not pour water onto a gasoline fire. Water

spreads the fire and makes it more difficult to put

out. Use a class B, BC or ABC fire extinguisher to

extinguish the fire.

9. Always turn off the engine before refueling. Do

not spill fuel onto the engine or exhaust system. Do

not overfill the fuel tank. Leave an air space at the

top of the tank to allow room for the fuel to expand

due to temperature fluctuations.

Cleaning Parts

1

Cleaning parts is one of the more tedious and difficult service jobs performed in the home garage.

There are many types of chemical cleaners and solvents available for shop use. Most are poisonous

and extremely flammable. To prevent chemical exposure, vapor buildup, fire and serious injury, observe each product warning label and note the

following:

1. Read and observe the entire product label before

using any chemical. Always know what type of

chemical is being used and whether it is poisonous

and/or flammable.

2. Do not use more than one type of cleaning solvent at a time. If mixing chemicals is called for,

measure the proper amounts according to the manufacturer.

3. Work in a well-ventilated area.

4. Wear chemical-resistant gloves.

5. Wear safety glasses.

6. Wear a vapor respirator if the instructions call

for it.

7. Wash hands and arms thoroughly after cleaning

parts.

8. Keep chemical products away from children and

pets.

9. Thoroughly clean all oil, grease and cleaner residue from any part that must be heated.

10. Use a nylon brush when cleaning parts. Metal

brushes may cause a spark.

11. When using a parts washer,only use the solvent

recommended by the manufacturer. Make sure the

parts washer is equipped with a metal lid that will

lower in case of fire.

Warning Labels

Most manufacturers attach information and

warning labels to the vehicle. These labels contain

instructions that are important to personal safety

when operating, servicing, transporting and storing

the vehicle. Refer to the owner’s manual for the description and location of labels. Order replacement

labels from the manufacturer if they are missing or

damaged.

Page 4

Jade's Collection .net Archives

4 CHAPTER ONE

SERIAL NUMBERS

Serial numbers are stamped on various locations

on the frame, engine, transmission and carburetor.

Record these numbers in the Quick Reference Data

section in the front of the book. Have these numbers

available when ordering parts.

Theframe serial number (Figure 1) is stamped on

the right side of the frame down tube.

The VIN number label (Figure 2) is located just

below the frame number on the right side frame

down tube.

Engine serial number is stamped on a pad on the

left side of the crankcase (Figure 3), as well as the

right side of the crankcase (Figure 4).

The transmission serial number (Figure 5) is

stamped on a pad on the right side of the transmission case next to the side door.

The carburetor serial number (Figure 6) is located on the side of the carburetor body next to the

accelerator pump linkage.

Table 1 lists model designation.

FASTENERS

1

2

Proper fastener selection and installation is im-

portant to ensure that the vehicle operates as de-

signedand can be serviced efficiently.The choice of

original equipment fasteners is not arrived at by

chance. Make sure that replacement fasteners meet

all the same requirements as the originals.

Threaded Fasteners

Threaded fasteners secure most of the components on the vehicle. Most are tightened by turning

them clockwise (right-hand threads). If the normal

rotation of the component being tightened would

loosen the fastener,it may haveleft-hand threads. If

a left-hand threaded fastener is used, it is noted in

the text.

Two dimensions are required to match the threads

of the fastener: the number of threads in a given distance and the outside diameter of the threads.

Two systems are currently used to specify

threaded fastener dimensions: the U.S. Standard

system and the metric system (Figure 7). Pay particular attention when working with unidentified

fasteners; mismatching thread types can damage

threads.

3

4

Page 5

GENERAL INFORMATION 5

5

8

-9.8

Grade marking

T

D

L

1

NOTE

6

To ensure that the fastener threads are

not mismatched or cross-threaded,

start all fasteners by hand. If a fastener is hard to start or turn, determine the cause before tightening with

a wrench.

The length (L, Figure 8), diameter (D) and dis-

tance between thread crests (pitch) (T) classify metric screws and bolts. A typical bolt may be

identified by the numbers, 8—1.25 × 130. This indicates the bolt has diameter of 8 mm, the distance between thread crests is 1.25 mm and the length is 130

mm. Always measure bolt length as shown in Fig-

7

ure 8 to avoid purchasing replacements of the

wrong length.

The numbers located on the top of the fastener

(Figure 8) indicate the strength of metric screws

and bolts. The higher the number, the stronger the

fastener is. Unnumbered fasteners are the weakest.

American Metric

Many screws, bolts and studs are combined with

nuts to secure particular components. To indicate

the size of a nut, manufacturers specify the internal

diameter and the thread pitch.

The measurement across two flats on a nut or bolt

indicates the wrench size.

60°

60°

WARNING

Do not install fasteners with a

strength classification lower than

what was originally installed by the

manufacturer. Doing so may cause

equipment failure and/or damage.

Torque Specifications

The materials used in the manufacture of the ve

hicle may be subjected to uneven stresses if the fas

-

-

Page 6

6 CHAPTER ONE

teners of the various subassemblies are not installed

and tightened correctly. Fasteners that are improp-

9

erly installed or work loose can cause extensive

damage. It is essential to use an accurate torque

wrench, described in this chapter, with the torque

specifications in this manual.

Specifications for torque are provided in New-

ton-meters (N•m), foot-pounds (ft.-lb.) and

inch-pounds (in.-lb.). Refer to Table 6 for general

torque specifications. To use Table 6, first deter-

Correct

installation of

cotter pin

mine the size of the fastener as described in Fasteners in this chapter. Torque specifications for

specific components are at the end of the appropriate chapters. Torque wrenches are covered in the

Basic Tools section.

Self-Locking Fasteners

Several types of bolts, screws and nuts incorporate a system that creates interference between the

two fasteners. Interference is achieved in various

ways. The most common type is the nylon insert nut

and a dry adhesive coating on the threads of a bolt.

10

Self-locking fasteners offer greater holding

strength than standard fasteners, which improves

their resistance to vibration. Most self-locking fasteners cannot be reused. The materials used to form

the lock become distorted after the initial installation and removal. It is a good practice to discard and

Internal snap ring

Plain clip

replace self-locking fasteners after their removal.

Do not replace self-locking fasteners with standard

fasteners.

Washers

There are two basic types of washers: flat washers and lockwashers. Flat washers are simple discs

with a hole to fit a screw or bolt. Lockwashers are

used to prevent a fastener from working loose.

Washers can be used as spacers and seals, or to help

distribute fastener load and to prevent the fastener

from damaging the component.

As with fasteners, when replacing washers make

sure the replacement washers are of the same design

and quality.

Cotter Pins

A cotter pin is a split metal pin inserted into a hole

or slot to prevent a fastener from loosening. In cer

External snap ring

E-ring

tain applications, such as the rear axle on an ATV or

motorcycle, the fastener must be secured in this

way. For these applications, a cotter pin and castellated (slotted) nut is used.

To use a cotter pin, first make sure the diameter is

correct for the hole in the fastener. After correctly

tightening the fastener and aligning the holes, insert

the cotter pin through the hole and bend the ends

over the fastener (Figure 9). Unless instructed to do

so, never loosen a torqued fastener to align the

holes. If the holes do not align, tighten the fastener

-

just enough to achieve alignment.

Page 7

GENERAL INFORMATION 7

11

Direction

of thrust

12

Full

support

areas

Rounded edges

Sharp edges

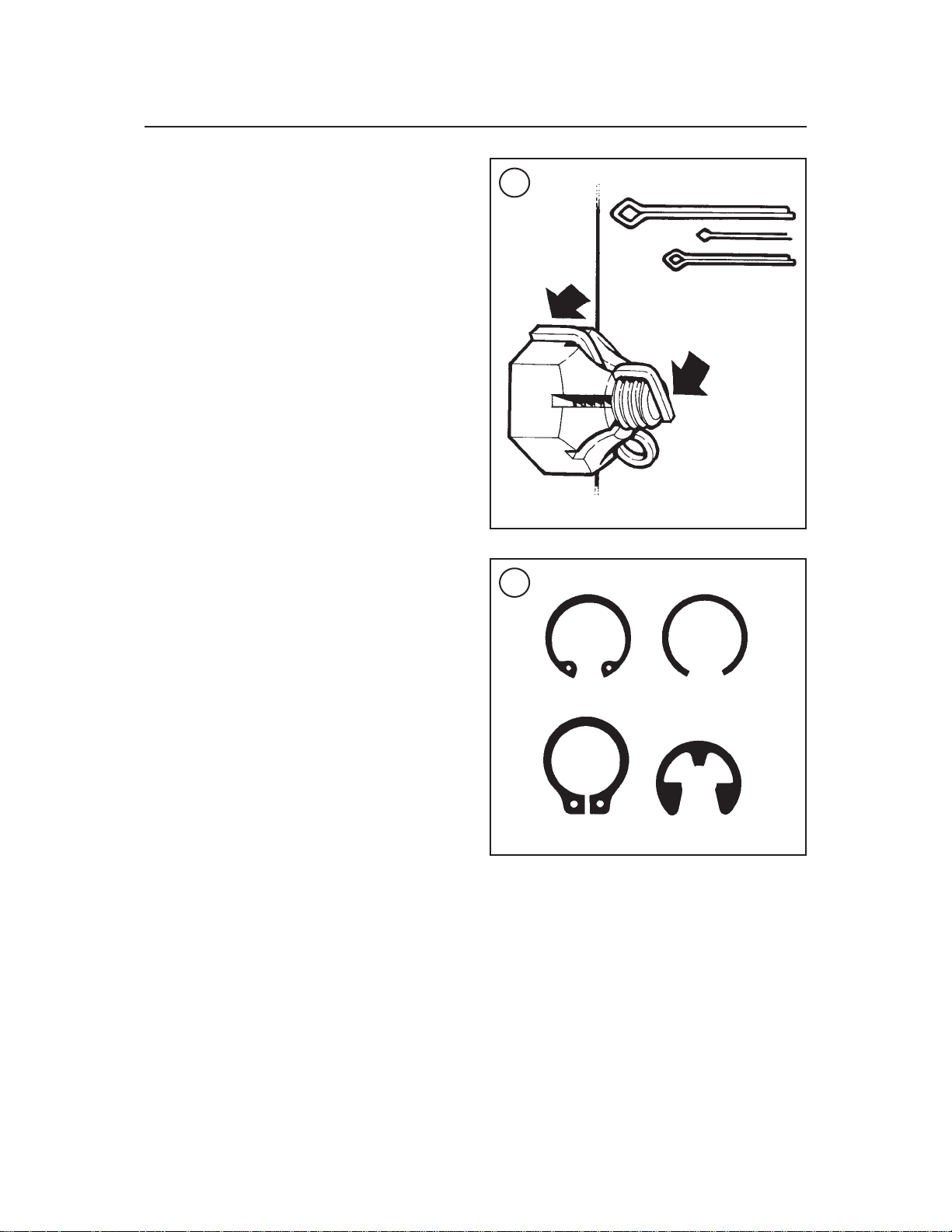

Two basic types of snap rings are used: machined

and stamped snap rings. Machined snap rings (Fig-

ure 11) can be installed in either direction, since

both faces have sharp edges. Stamped snap rings

(Figure12) are manufactured with a sharp edge and

a round edge. When installing a stamped snap ring

in a thrust application, install the sharp edge facing

away from the part producing the thrust.

E-clips and circlips are used when it is not practical to use a snap ring. Remove E-clips with a flat

blade screwdriver by prying between the shaft and

E-clip. To install an E-clip, center it over the shaft

groove and push or tap it into place.

Observe the following when installing snap rings:

1. Remove and install snap rings with snap ring pliers. See Snap Ring Pliers in this chapter.

2. In some applications, it may be necessary to replace snap rings after removing them.

3. Compress or expand snap rings only enough to

install them. If overly expanded, they lose their retaining ability.

4. After installing a snap ring, make sure it seats

completely.

5. Wear eye protection when removing and installing snap rings.

1

Direction of thrust

Cotter pins are available in various diameters and

lengths. Measure length from the bottom of the

head to the tip of the shortest pin.

Snap rings and E-clips

Snap rings (Figure 10) are circular-shaped metal

retaining clips. They are required to secure parts

and gears in place on parts such as shafts, pins or

rods. External type snap rings are used to retain

items on shafts. Internal type snap rings secure parts

within housing bores. In some applications, in addition to securing the component(s), snap rings of

varying thickness also determine endplay. These are

usually called selective snap rings.

SHOP SUPPLIES

Lubricants and Fluids

Periodic lubrication helps ensure a long service

life for any type of equipment. Using the correct

type of lubricant is as important as performing the

lubrication service, although in an emergency the

wrong type is better than none. The following section describes the types of lubricants most often required. Make sure to follow the manufacturer’s

recommendations for lubricant types.

Engine oils

Engine oil is classified by two standards: the

American Petroleum Institute (API) service classification and the Society of Automotive Engineers

(SAE) viscosity rating. This information is on the

oil container label. Two letters indicate the API service classification. The number or sequence of

numbers and letter (10W-40 for example) is the oil’s

viscosity rating. The API service classification and

Page 8

8 CHAPTER ONE

the SAE viscosity index are not indications of oil

quality.

The service classification indicates that the oil

meets specific lubrication standards. The first letter

in the classification (S) indicates that the oil is for

gasoline engines. The second letter indicates the

standard the oil satisfies. The classification started

with the letter A and is currently at the letter J.

Always use an oil with a classification recommended by the manufacturer. Using an oil with a

different classification can cause engine damage.

Viscosity is an indication of the oil’s thickness.

Thin oils have a lower number while thickoils have

a higher number. Engine oils fall into the 5- to

50-weight range for single-grade oils.

Most manufacturers recommend multigrade oil.

These oils perform efficiently across a wide range

of operating conditions. Multigrade oils are identified by a W after the first number, which indicates

the low-temperature viscosity.

Engine oils are most commonly mineral (petroleum) based; however, synthetic and semi-synthetic

types are used more frequently. When selecting engine oil, follow the manufacturer’s recommendation for type, classification and viscosity when

selecting engine oil.

Greases

Grease is lubricating oil with thickening agents

added to it. The National Lubricating Grease Institute (NLGI) grades grease. Grades range from No.

000 to No. 6, with No. 6 being the thickest. Typical

multipurpose grease is NLGI No. 2. For specific applications, manufacturers may recommend water-resistant type grease or one with an additive

such as molybdenum disulfide (MoS

).

2

Brake fluid

Brake fluid is the hydraulic fluid used to transmit

hydraulic pressure (force) to the wheel brakes.

Brake fluid is classified by the Department of

Transportation (DOT). Current designations for

brake fluid are DOT 3, DOT 4 and DOT 5. This

classification appears on the fluid container.

Each type of brake fluid has its own definite characteristics. The Harley-Davidson Dyna Glide uses

the silicone based DOT 5 brake fluid. Do not inter

mix DOT 3 or DOT 4 type brake fluid as this may

cause brake system failure since the DOT 5 brake

fluid is not compatible with other brake fluids.

When adding brake fluid, only use the fluid recommended by the manufacturer.

Brake fluid will damage any plastic, painted or

plated surface it contacts. Use extreme care when

working with brake fluid and remove any spills immediately with soap and water.

Hydraulic brake systems require clean and moisture free brake fluid. Never reuse brake fluid. Keep

containers and reservoirs properly sealed.

WARNING

Never put a mineral-based (petroleum) oil into the brake system. Mineral oil will cause rubber parts in the

system to swell and break apart, resulting in complete brake failure.

Cleaners, Degreasers and Solvents

Many chemicals are available to remove oil,

grease and other residue from the vehicle. Before

using cleaning solvents, consider how they will be

usedand disposed of, particularlyif they are not water-soluble. Local ordinances may require special

procedures for the disposal of many types of cleaning chemicals. Refer to Safety and Cleaning Parts

in this chapter for more information on their use.

Use brake parts cleaner to clean brake system

components when contact with petroleum-based

products will damage seals. Brake parts cleaner

leaves no residue. Use electrical contact cleaner to

clean electrical connections and components without leaving any residue. Carburetor cleaner is a

powerful solvent used to remove fuel deposits and

varnish from fuel system components. Use this

cleaner carefully, as it may damage finishes.

Generally, degreasers are strong cleaners used to

remove heavy accumulations of grease from engine

and frame components.

Most solvents are designed to be used in a parts

washingcabinet for individual component cleaning.

For safety, use only nonflammable or high flash

point solvents.

Gasket Sealant

Sealants are used in combination with a gasket or

seal and are occasionally alone. Follow the manu

facturer’s recommendation when using sealants.

-

Page 9

GENERAL INFORMATION 9

13

Use extreme care whenchoosing a sealant different

from the type originally recommended. Choose

sealants based on their resistance to heat, various

fluids and their sealing capabilities.

One of the most common sealants is RTV, or

room temperature vulcanizing sealant. This sealant

cures at room temperature over a specific time period. This allows the repositioning of components

without damaging gaskets.

Moisture in the air causes the RTV sealant to

cure. Always install the tube cap as soon as possible

after applying RTVsealant. RTV sealant has a limited shelf life and will not cure properly if the shelf

life has expired. Keep partial tubes sealed and discard them if they have surpassed the expiration

date.

moval process and prevent damage to the mating

surface that may be caused by using a scraping tool.

Most of these types of products are very caustic.

Follow the gasket remover manufacturer’s instructions for use.

Threadlocking Compound

A threadlocking compound is a fluid applied to

the threads of fasteners. After tightening the fastener, the fluid dries and becomes a solid filler between the threads. This makes it difficult for the

fastener to work loose from vibration, or heat expansion and contraction. Some threadlocking compounds also provide a seal against fluid leakage.

Before applying threadlocking compound, remove any old compound from both thread areas and

clean them with aerosol parts cleaner. Use the compoundsparingly.Excess fluid can run into adjoining

parts.

Threadlockingcompounds are available in different strengths. Follow the particular manufacturer’s

recommendations regarding compound selection.

Two manufacturers of threadlocking compound are

ThreeBond and Loctite. They both offer a wide

range of compounds for various strength, temperature and repair applications.

BASIC TOOLS

1

Applying RTV sealant

Clean all old gasket residue from the mating surfaces. Remove all gasket material from blind

threaded holes; it can cause inaccurate bolt torque.

Spray the mating surfaces with aerosol parts cleaner

and then wipe with a lint-free cloth. The area must

be clean for the sealant to adhere.

Apply RTV sealant in a continuous bead 2-3 mm

(0.08-0.12 in.) thick. Circle all the fastener holes

unless otherwise specified. Do not allow any sealant to enter these holes. Assemble and tighten the

fasteners to the specified torque within the time

frame recommended by the RTV sealant manufacturer.

Gasket Remover

Aerosol gasket remover can help remove stub

born gaskets. This product can speed up the re

Most of the proceduresin this manual can be carried out with simple hand tools and test equipment

familiar to the home mechanic. Always use the correct tools for the job at hand. Keep tools organized

and clean. Store them in a tool chest with related

tools organized together.

Quality tools are essential. The best are constructed of high-strength alloy steel. These tools are

light, easy to use and resistant to wear. Their working surface is devoid of sharp edges and the tool is

carefully polished. They have an easy-to-clean finish and are comfortable to use. Quality tools are a

good investment.

When purchasing tools to perform the procedures

covered in this manual, consider the tools’potential

frequency of use. If a tool kit is just now being

started, consider purchasing a basic tool set (Figure

13) from a large tool supplier. These sets are avail

able in many tool combinations and offer substan

tial savings when compared to individually

-

-

-

Page 10

10 CHAPTER ONE

purchased tools. As work experience grows and

tasks become more complicated, specialized tools

can be added.

Screwdrivers

Screwdrivers of various lengths and types are

mandatory for the simplest tool kit. The two basic

types are the slotted tip (flat blade) and the Phillips

tip. These are available in sets that often include an

assortment of tip sizes and shaft lengths.

As with all tools, use a screwdriver designed for

the job. Make sure the size of the tip conforms to the

size and shape of the fastener. Use them only for

driving screws. Never use a screwdriver for prying

or chiseling metal. Repair or replace worn or damaged screwdrivers. A worn tip may damage the fastener, making it difficult to remove.

14

15

Wrenches

Open-end, box-end and combination wrenches

(Figure14) are available in various types and sizes.

The number stamped on the wrench refers to the

distance between the work areas. This size must

match the size of the fastener head.

The box-end wrench is an excellent tool because

it grips the fastener on all sides. This reduces the

chance of the tool slipping. The box-end wrench is

designed with either a 6- or 12-point opening. For

stubborn or damaged fasteners, the 6-point provides

superior holding ability by contacting the fastener

across a wider area at all six edges. For general use,

the 12-point works well. It allows the wrench to be

removed and reinstalled without moving the handle

over such a wide arc.

An open-end wrench is fast and works best in areas with limited overhead access. It contacts the fastener at only two points, and is subject to slipping

under heavy force, or if the tool or fastener is worn.

A box-end wrench is preferred in most instances,

especially when breaking loose and applying the

final tightness to a fastener.

The combination wrench has a box end on one

end and an open end on the other. This combination

makes it a very convenient tool.

16

Adjustable Wrenches

An adjustable wrench or Crescent wrench (Fig-

ure 15) can fit nearly any nut or bolt head that has

clear access around its entire perimeter. Adjustable

wrenches are best used as a backup wrench to keep

a large nut or bolt from turning while the other end

is being loosened or tightened with a box-end or

socket wrench.

Adjustable wrenches contact the fastener at only

two points, making them more likely to slip off the

fastener. The fact that one jaw is adjustable and may

Page 11

GENERAL INFORMATION 11

17

18

19

the socket is the size of the work area and must

match the fastener head.

As with wrenches, a 6-point socket provides superior holding ability, while a 12-point socket needs

to be moved only half as far to reposition it on the

fastener.

Sockets are designated for either hand or impact

use. Impact sockets are made of thicker material for

more durability. Compare the size and wall thick-

ness of a 19-mm hand socket (A, Figure 18) and the

19-mm impact socket (B). Use impact sockets when

using an impact driver or air tools. Use hand sockets

with hand-driven attachments.

WARNING

Do not use hand sockets with air or

impact tools, as they may shatter and

cause injury. Always wear eye protection when using impact or air tools.

Various handles are available for sockets. The

speed handle is used for fast operation. Flexible

ratchet heads in varying lengths allow the socket to

be turned with varying force, and at odd angles. Extension bars allow the socket setup to reach difficult

areas. The ratchet is the most versatile. It allows the

user to install or remove the nut without removing

the socket.

Sockets combined with any number of drivers

make them undoubtedly the fastest, safest and most

convenient tool for fastener removal and installation.

1

loosen only aggravates this shortcoming. Make certain that the solid jaw is the one transmitting the

force.

Socket Wrenches, Ratchets and Handles

Sockets that attach to a ratchet handle (Figure16)

are available with 6-point (A, Figure 17) or

12-point (B) openings and different drive sizes. The

drive size indicates the size of the square hole that

accepts the ratchet handle. The number stamped on

Impact Driver

An impact driver provides extra force for removing fasteners, by converting the impact of a hammer

into a turning motion. This makes it possible to remove stubborn fasteners without damaging them.

Impact drivers and interchangeable bits (Figure 19)

are available from most tool suppliers. When using

a socket with an impact driver make sure the socket

is designed for impact use. Refer to Socket

Wrenches, Ratchets and Handles in this section.

WARNING

Do not use hand sockets with air or

impact tools as they may shatter and

cause injury. Always wear eye protec

tion when using impact or air tools.

-

Page 12

12 CHAPTER ONE

Allen Wrenches

Allen or setscrew wrenches (Figure 20) are used

on fasteners with hexagonal recesses in the fastener

head. These wrenches are available in L-shaped bar,

socket and T-handle types. A metric set is required

when working on most vehicles. Allen bolts are

sometimes called socket bolts.

Torque Wrenches

A torque wrench is used with a socket, torque

adapter or similar extension to tighten a fastener

o a measured torque. Torque wrenches come in several drive sizes (1/4, 3/8, 1/2 and 3/4) and have various methods of reading the torque value. The drive

size indicates the size of the square drive that accepts the socket, adapter or extension. Common

methods of reading the torque value are the deflecting beam, the dial indicator and the audible click

(Figure 21).

When choosing a torque wrench, consider the

torque range, drive size and accuracy. The torque

specifications in this manual provide an indication

of the range required.

A torque wrench is a precision tool that must be

properly cared for to remain accurate. Store torque

wrenches in cases or separate padded drawers

within a toolbox. Follow the manufacturer’s instructions for their care and calibration.

20

21

22

Torque Adapters

Torque adapters or extensions extend or reduce

the reach of a torque wrench. The torque adapter

shown in Figure 22 is used to tighten a fastener that

cannot be reached due to the size of the torque

wrench head, drive, and socket. If a torque adapter

changes the effective lever length (Figure 23), the

torque reading on the wrench will not equal the actual torque applied to the fastener. It is necessary to

recalibrate the torque setting on the wrench to compensate for the change of lever length. When a

torque adapter is used at a right angle to the drive

head, calibration is not required, since the effective

length has not changed.

To recalculate a torque reading when using a

torque adapter, use the following formula, and refer

to Figure 23.

TW = TA ×L

L + A = E

TW is the torque setting or dial reading on the

wrench.

TA is the torque specification and the actual

amount of torque that will be applied to the fastener.

A is the amount that the adapter increases (or in

some cases reduces) the effective lever length as

measured along the centerline of the torque wrench

(Figure 23).

L is the lever length of the wrench as measured

from the center of the drive to the center of the grip.

Page 13

GENERAL INFORMATION 13

23

HOW TO MEASURE TORQUE WRENCH EFFECTIVE LENGTH

L

L

L+A= Effective length

L

L= Effective length

L

No calculation needed

A

A

1

24

The effective length is the sum of L and A (Fig-

ure 23).

Example:

TA = 20 ft.-lb.

A = 3 in.

L = 14 in.

E = 17 in.

TW = 20×14

= 280 = 16.5 ft. Lb.

14 +3 = 17

In this example, the torque wrench would be set

to the recalculated torque value (TW = 16.5 ft.-lb.) .

25

When using a beam-type wrench, tighten the fastener until the pointer aligns with 16.5 ft.-lb. In this

example, although the torque wrench is preset to

16.5 ft.-lb., the actual torque is 20 ft.-lb.

Pliers

Pliers come in a wide range of types and sizes.

Pliers are useful for holding, cutting, bending, and

crimping. Do not use them to turn fasteners. Figure

24 and Figure 25 show several types of useful pli

-

Page 14

14 CHAPTER ONE

26

ers. Each design has a specialized function.

Slip-joint pliers are general-purpose pliers used for

gripping and bending. Diagonal cutting pliers are

needed to cut wire and can be used to remove cotter

pins. Needlenose pliers are used to hold or bend

small objects. Locking pliers (Figure 25), some-

times called Vise-grips, are used to hold objects

very tightly. They have many uses, ranging from

holding two parts together to gripping the end of a

broken stud. Use caution when using locking pliers,

as the sharp jaws will damage the objects they hold.

27

28

Snap Ring Pliers

Snap ring pliers are specialized pliers with tips

that fit into the ends of snap rings to remove and install them.

Snap ring pliers are available with a fixed action

(either internal or external) or convertible (one

tool works on both internal and external snap

rings). They may have fixed tips or interchangeable ones of various siz es and angles. For general

use, select a convertible type pliers with interchangeable tips.

WARNING

Snap rings can slip and fly off when

removing and installing them. Also,

the snap ring pliers tips may break.

Always wear eye protection when using snap ring pliers.

Hammers

Various types of hammers (Figure 26) are avail-

able to fit a number of applications. A ball-peen

hammer is used to strike another tool, such as a

punch or chisel. Soft-faced hammers are required

when a metal object must be struck without damaging it. Never use a metal-faced hammer on engine

and suspension components, as damage will occur

in most cases.

Always wear eye protection when using hammers. Make sure the hammer face is in good condition and the handle is not cracked. Select the correct

hammer for the job and make sure to strike the object squarely. Do not use the handle or the side of the

hammer to strike an object.

PRECISION MEASURING TOOLS

The ability to accurately measure components is

essential to successfully rebuild an engine. Equipment is manufactured to close tolerances, and obtaining consistently accurate measurements is

essential to determining which components require

replacement or further service.

Each type of measuring instrument is designed to

measure a dimension with a certain degree of accuracy and within a certain range. When selecting the

measuring tool, make sure it is applicable to the

task.

Page 15

GENERAL INFORMATION 15

29

Aswith all tools, measuringtools provide the best

results if cared for properly.Improper use can damage the tool and result in inaccurate results. If any

measurement is questionable, verify the measurementusing another tool. Astandardgauge is usually

provided with measuring tools to check accuracy

and calibrate the tool if necessary.

Precision measurements can vary according to

the experience of the person performing the procedure. Accurate results are only possible if the mechanic possesses a feel for using the tool.

Heavy-handed use of measuring tools will produce

less accurate results. Hold the tool gently by the fingertips so the point at which the tool contacts the

object is easily felt. This feel for the equipment will

produce more accurate measurements and reduce

therisk of damaging thetool or component. Referto

thefollowing sections for specific measuring tools.

Feeler Gauge

The feeler or thickness gauge (Figure27) is used

for measuring the distance between two surfaces.

A feeler gauge set consists of an assortment of

steel strips of graduated thickness. Each blade is

marked with its thickness. Blades can be of various

lengths and angles for different procedures.

10.00 mm

0.50 mm

10.55 mm

0.400 mm

0.013 mm

0.413 mm

Moveable scaless

Fixed scale

A common use for a feeler gauge is to measure

valve clearance. Wire (round) type gauges are used

to measure spark plug gap.

Calipers

Calipers (Figure 28) are excellent tools for obtaining inside, outside and depth measurements. Although not as precise as a micrometer, they allow

reasonable precision, typically to within 0.05 mm

(0.001 in.). Most calipers have a range up to 150

mm (6 in.).

Calipers are available in dial, vernier or digital

versions. Dial calipers have a dial readout that provides convenient reading. Vernier calipers have

marked scales that must be compared to determine

the measurement. The digital caliper uses an LCD

to show the measurement.

Properly maintain the measuring surfaces of the

caliper.There must not be any dirt or burrs between

the tool and the object being measured. Never force

thecaliper closed around an object; close the caliper

around the highest point so it can be removed with a

slight drag. Some calipers require calibration. Always refer to the manufacturer’s instructions when

using a new or unfamiliar caliper.

To read a vernier caliper refer, to Figure 29. The

fixed scale is marked in 1 mm increments.Tenindi

1

-

Page 16

16 CHAPTER ONE

30

DECIMAL PLACE VALUES*

0.1 Indicates 1/10 (one tenth of an inch

0.010 Indicates 1/100 (one one-hundreth of

0.001 Indicates 1/1,000 (one one-thousandth

*This chart represents the values of figures placed to the right of the decimal point. Use it when

reading decimals from one-tenth to one one-thousandth of an inch or millimeter. It is not a con-

version chart (for example: 0.001 in. is not equal to 0.001 mm).

or millimeter)

an inch or millimeter)

of an inch or millimeter)

vidual lines on the fixed scale equal 1 cm. The

moveable scale is marked in 0.05 mm (hundredth)

31

increments. To obtain a reading, establish the first

number by the location of the 0 line on the movable

scale in relation to the first line to the left on the

fixed scale. In this example, the number is 10 mm.

To determine the next number, note which of the

lines on the movable scale align with a mark on the

fixed scale. A number of lines will seem close, but

only one will align exactly. In this case, 0.50 mm is

the reading to add to the first number. The result of

adding 10 mm and 0.50 mm is a measurement of

10.50 mm.

Reading a Micrometer

Micrometers

Amicrometer is an instrument designed for linear

measurement using the decimal divisions of the

inch or meter (Figure 30). While there are many

types and styles of micrometers, most of the procedures in this manual call for an outside micrometer.

The outside micrometer is used to measure the outside diameter of cylindrical forms andthe thickness

of materials.

A micrometer’s size indicates the minimum and

maximum size of a part that it can measure. The

usual sizes (Figure 31) are 0-1 in. (0-25 mm), 1-2

in. (25-50 mm), 2-3 in. (50-75 mm) and 3-4 in.

(75-100 mm).

Micrometersthat cover a wider range of measurements are available. These use a large frame with

interchangeable anvils of various lengths.This type

of micrometer offers a cost savings; however, its

overall size may make it less convenient.

When reading a micrometer, numbers are taken

from different scales and added together. The following sections describe how to read the measurements of various types of outside micrometers.

For accurate results, properly maintain the measuring surfaces of the micrometer. There cannot be

any dirt or burrs between the tool and the measured

object. Never force the micrometer closed around

an object. Close the micrometer around the highest

pointso it can beremoved with a slight drag. Figure

32 shows the markings and parts of a standard inch

micrometer.Be familiar withthese terms before using a micrometer in the following sections.

Standard inch micrometer

The standard inch micrometer is accurate to

one-thousandth of an inch or 0.001. The sleeve is

marked in 0.025 in. increments. Every fourth sleeve

Page 17

GENERAL INFORMATION 17

32

33

STANDARD INCH MICROMETER

Sleeve line

Thimble marks

Sleeve

Frame

1. Largest number visible on the

sleeve line

2. Number on sleeve marks visible

between the numbered sleeve mark

and the thimble edge

3. Thimble mark that aligns with

sleeve line

Anvil

Sleeve

Spindle

Thimble

Locknut

Thimble

numbers

1

Ratchet

0.200 in.

0.025 in.

0.006 in.

mark is numbered 1, 2, 3, 4, 5, 6, 7, 8, 9. These numbers indicate 0.100, 0.200, 0.300, and so on.

The tapered end of the thimble has twenty-five

lines marked around it. Each mark equals 0.001 in.

One complete turn of the thimble will align its zero

mark with the first mark on the sleeve or 0.025 in.

When reading a standard inch micrometer, perform the following steps while referring to Figure

33.

1. Read the sleeve and find the largest number visible. Each sleeve number equals 0.100 in.

2. Count the number of lines between the numbered sleeve mark and the edge of the thimble. Each

sleeve mark equals 0.025 in.

3. Read the thimble mark that aligns with the

sleeve line. Each thimble mark equals 0.001 in.

Total reading

0.231 in.

NOTE

If a thimble mark does not align exactly with the sleeve line, estimate the

amount between the lines. For accurate readings in ten-thousandths of an

inch (0.0001 in.), use a vernier inch

micrometer.

4. Add the readings from Steps 1-3.

Vernier inch micrometer

A vernier inch micrometer is accurate to one

ten-thousandth of an inch or 0.0001 in. It has the

same marking as a standard inch micrometer with

an additional vernier scale on the sleeve (Figure

34).

Page 18

18 CHAPTER ONE

34

35

Vernier scale

1. Largest number visible on

Sleeve

Vernier scale

Sleeve

Thimble

Thimble

sleeve line

2. Number of sleeve marks visible

between the numbered sleeve mark

and the thimble edge

3. Thimble is between 0.018 and 0.019

in. on the sleeve line

4. Vernier line coinciding with

thimble line

STANDARD METRIC MICROMETER

Sleeve line

Thimble

Anvil

Locknut

Spindle

Total reading

0.100 in.

0.050 in.

0.018 in.

0.0003 in.

0.1683 in.

Sleeve marks

The vernier scale consists of 11 lines marked 1-9

with a 0 on each end. These lines run parallel to the

thimble lines and represent 0.0001 in. increments.

Whenreading a vernier inch micrometer, perform

the following steps while referring to Figure 34.

1. Read the micrometer in the same way as a standard micrometer. This is the initial reading.

2. If a thimble mark aligns exactly with the sleeve

line, reading the vernier scale is not necessary. If

they do not align, read the vernier scale in Step 3.

3. Determine which vernier scale mark aligns with

one thimble mark. The vernier scale number is the

Thimble marks

Ratchet

amount in ten-thousandths of an inch to add to the

initial reading from Step 1.

Metric micrometer

The standard metric micrometer (Figure 35) is

accurate to one one-hundredth of a millimeter

(0.01-mm). The sleeve line is graduatedin millimeter and half millimeter increments. The marks on

the upper half of thesleeve lineequal 1.00mm. Ev

ery fifth mark above the sleeve line is identified

with a number. The number sequence depends on

-

Page 19

GENERAL INFORMATION 19

36

Sleeve

Sleeve

Thimble

Thimble

the size of themicrometer. A 0-25 mm micrometer,

for example, will have sleeve marks numbered 0

through 25 in 5 mm increments. This numbering sequence continues with larger micrometers. On all

metric micrometers, each mark on the lower half of

the sleeve equals 0.50 mm.

Thetaperedendof thethimblehas 50 linesmarked

aroundit. Each mark equals0.01 mm. One complete

turnof thethimblealigns its0 mark with the first line

on the lower halfof the sleeve line or 0.50mm.

When reading a metricmicrometer, add the number of millimeters and half-millimeters on the

sleeve line to the number of one one-hundredth millimeterson the thimble. Perform the following steps

while referring to Figure 36.

1. Read the upper half of the sleeve line and count

the number of lines visible. Each upper line equals 1

mm.

2. See if the half-millimeter line is visible on the

lower sleeve line. If so, add 0.50 mm to the reading

in Step 1.

3. Read the thimble mark that aligns with the

sleeve line. Each thimble mark equals 0.01 mm.

1. Reading on upper sleeve line

2. Reading on lower sleeve line

3. Thimble line coinciding with

sleeve line

Total reading

5.00 mm

0.50 mm

0.18 mm

5.68 mm

Metric vernier micrometer

Ametric vernier micrometer (Figure 37) is accu-

rate to two-thousandths of a millimeter (0.002 mm).

It has the same markings as a standard metric micrometer with the addition of a vernier scale on the

sleeve.

The vernier scale consists of five lines marked 0,

2, 4, 6, and 8. Theselines run parallelto the thimble

lines and represent 0.002-mm increments.

When reading a metric vernier micrometer, perform the following steps and refer to Figure 37.

1. Read the micrometer in the same way as a standard metric micrometer. This is the initial reading.

2. If a thimble mark aligns exactly with the sleeve

line, reading the vernier scale is not necessary. If

they do not align, read the vernier scale in Step 3.

3. Determine which vernier scale mark aligns exactly with one thimble mark. The vernier scale

number is the amount in two-thousandths of a millimeter to add to the initial reading from Step 1.

Micrometer Adjustment

1

NOTE

If a thimble mark does not align exactly with the sleeve line, estimate the

amount between the lines. For accurate readings in two-thousandths of a

millimeter (0.002 mm), use a metric

vernier micrometer.

4. Add the readings from Steps 1-3.

Before using a micrometer, check its adjustment

as follows.

1. Clean the anvil and spindle faces.

2A. To check a 0-1 in. or 0-25 mm micrometer:

a. Turnthe thimble until the spindle contacts the

anvil. If the micrometer has a ratchet stop, use

it to ensure that the proper amount of pressure

is applied.

Page 20

20 CHAPTER ONE

37

38

Vernier scale

Sleeve

Vernier scale

Sleeve

Thimble

Thimble

1. Reading on upper sleeve line

2. Reading on lower sleeve line

3. Thimble is between 0.15 and 0.16

mm on the sleeve line

4. Vernier line coinciding with

thimble line

Total reading

39

4.0 mm

0.5 mm

0.15 mm

0.008 mm

4.658 mm

b. If the adjustment is correct, the 0 mark on the

thimble will align exactly with the 0 mark on

the sleeve line. If the marks do not align, the

micrometer is out of adjustment.

c. Follow the manufacturer’s instructions to ad-

just the micrometer.

2B. To check a micrometer larger than 1 in. or 25

mm use the standard gauge supplied by the manufacturer. A standard gauge is a steel block, disc or

rod that is machined to an exact size.

a. Place the standard gauge between the spindle

and anvil, and measure its outside diameter or

length. If the micrometer has a ratchet stop,

use it to ensure that the proper amount of

pressure is applied.

b. If the adjustment is correct, the 0 mark on the

thimble will align exactly with the 0 mark on

the sleeve line. If the marks do not align, the

micrometer is out of adjustment.

c. Follow the manufacturer’s instructions to ad-

just the micrometer.

Micrometer Care

Micrometers are precision instruments. They

must be used and maintained with great care. Note

the following:

1. Storemicrometers in protectivecases or separate

padded drawers in a toolbox.

2. When in storage, make sure the spindle and anvil

faces do not contact each other or another object. If

they do, temperature changes and corrosion may

damage the contact faces.

3. Do not clean a micrometer with compressed air.

Dirt forced into the tool will cause wear.

4. Lubricate micrometers with WD-40 to prevent

corrosion.

Page 21

GENERAL INFORMATION 21

40

41

42

themovable post in position.Remove the gauge and

measure the length of the posts. Telescoping gauges

are typically used to measure cylinder bores.

To use a small-bore gauge, select the correct size

gauge for the bore. Carefully insert the gauge into

the bore. Tighten the knurled end of the gauge to

carefully expand the gauge fingers to the limit

within the bore. Do not overtighten the gauge, as

there is no built-in release. Excessive tightening can

damage the bore surface and damage the tool. Remove the gauge and measure the outside dimension

(Figure40). Small hole gauges are typically used to

measure valve guides.

Dial Indicator

Adial indicator (Figure 41) is agauge with adial

face and needle used to measure variations in dimensions and movements. Measuring brake rotor

runout is a typical use for a dial indicator.

Dialindicators are available in various ranges and

graduations and with three basic types of mounting

bases: magnetic, clamp, or screw-in stud. When

purchasing a dial indicator, select the magnetic

stand type with a continuous dial.

1

Telescoping and

Small Bore Gauges

Use telescoping gauges (Figure 38) and small

hole gauges (Figure 39) to measure bores. Neither

gauge has a scale for direct readings. An outside micrometer must be used to determine the reading.

To use a telescoping gauge, selectthe correct size

gauge for the bore. Compress the movable post and

carefully insert the gauge into the bore. Carefully

move the gauge in the bore to make sure it is cen

tered. Tighten the knurled end of the gauge to hold

Cylinder Bore Gauge

A cylinder bore gauge is similar to a dial indica-

tor. The gauge set shown in Figure42 consists of a

dial indicator, handle, and different length adapters

(anvils) to fit the gauge to various bore sizes. The

bore gauge is used to measure bore size, taper and

out-of-round. When using a bore gauge, follow the

manufacturer’s instructions.

Compression Gauge

Acompression gauge (Figure43) measures com-

bustion chamber (cylinder) pressure, usually in psi

or kg/cm

2

. The gauge adapter is either inserted or

screwed into the spark plug hole to obtain the reading. Disable the engine so it will not start and hold

the throttle in the wide-open position when performing a compression test. An engine that does not

-

have adequate compression cannot be properly

tuned. See Chapter Three.

Page 22

22 CHAPTER ONE

43

Multimeter

A multimeter (Figure 44) is an essential tool for

electrical system diagnosis. The voltage function

indicates the voltage applied or available to various

electrical components. The ohmmeter function tests

circuits for continuity, or lack of continuity, and

measures the resistance of a circuit.

Some manufacturers’ specifications for electrical

components are based on results using a specific

test meter. Results may vary if a meter not recommend by the manufacturer is used. Such requirements are noted when applicable.

Ohmmeter (analog) calibration

44

Voltage

Voltage is the electrical potential or pressure in an

electrical circuit and is expressed in volts. The more

pressure (voltage) in a circuit, the more work that

can be performed.

Direct current (DC) voltage means the electricity

flows in one direction. All circuits powered by a

battery are DC circuits.

Alternating current (AC) means that the electricity flows in one direction momentarily then

switchesto the opposite direction. Alternator output

is an example of AC voltage. This voltage must be

changed or rectified to direct current to operate in a

battery powered system.

Each time an analog ohmmeter is used or if the

scale is changed, the ohmmeter must be calibrated.

Digital ohmmeters do not require calibration.

1. Makesure the meter battery is in goodcondition.

2. Make sure the meter probes are in good condition.

3. Touch the two probes together and observe the

needle location on the ohms scale.

The needle must align with the 0 mark to obtain

accurate measurements.

4. If necessary, rotate the meter ohms adjust knob

until the needle and 0 mark align.

ELECTRICAL SYSTEM FUNDAMENTALS

A thorough study of the many types of electrical

systems used in today’s vehicles is beyond the

scope of this manual. However, a basic understanding of electrical basics is necessary to perform sim

ple diagnostic tests.

Measuring voltage

Unless otherwise specified, perform all voltage

tests with the electrical connectors attached. When

measuringvoltage, select the meterrange that is one

scale higher than the expected voltage of the circuit

to prevent damage to the meter. To determine the

actual voltage in a circuit, use a voltmeter. To simply check if voltage is present, use a test light.

NOTE

When using a test light, either lead

can be attached to ground.

1. Attach the negative meter test lead to a good

ground (bare metal). Make sure the ground is not insulated with a rubber gasket or grommet.

2. Attach the positive meter test lead to the point

being checked for voltage (Figure 45).

3. Turnon the ignition switch. Thetest light should

-

light or the meter should display a reading. The

readingshould be within onevolt of battery voltage.

Page 23

GENERAL INFORMATION 23

45

Voltmeter

If the voltage is less, there is a problem in the circuit.

Voltage drop test

Resistancecauses voltage to drop. This resistance

can be measured in an active circuitby using avoltmeter to perform a voltage drop test. A voltage drop

test compares the difference between the voltage

available at the start of a circuit to the voltage at the

end of the circuit while the circuit is operational. If

the circuit has no resistance, there will be no voltage

drop. The greater the resistance, the greater the voltage drop will be. A voltage drop of one volt or more

indicates excessive resistance in the circuit.

1. Connect the positive meter test lead to the electrical source (where electricity is coming from).

2. Connect the negative meter test lead to the electrical load (where electricity is going). See Figure

46.

3. If necessary, activate the component(s) in the

circuit.

4. Avoltage reading of 1 volt or more indicates excessive resistance in the circuit. A reading equal to

battery voltage indicates an open circuit.

Resistance

46

Voltage drop

Battery

Resistance is measured in an inactive circuit with

an ohmmeter. The ohmmeter sends a small amount

of current into the circuit and measures how difficult it is to push the current through the circuit.

An ohmmeter, although useful, is not always a

good indicator of a circuit’s actual ability under operating conditions. This is due to the low voltage

(6-9 volts) that the meter uses to test the circuit. The

voltagein an ignition coil secondary winding can be

several thousand volts. Such high voltage can cause

the coil to malfunction, even though it tests acceptable during a resistance test.

Resistance generally increases with temperature.

Perform all testing with the component or circuit at

room temperature. Resistance tests performed at

high temperatures may indicate high resistance

readings and result in the unnecessary replacement

of a component.

Measuring resistance and continuity testing

CAUTION

Only use an ohmmeter on a circuit

that has no voltage present. The meter

will be damaged if it is connected to a

live circuit. An analog meter must be

calibrated each time it is used or the

scale is changed. See Multimeter in

this chapter.

1

Resistance is the opposition to the flow of electricity within a circuit or component and is mea

sured in ohms. Resistance causes a reduction in

available current and voltage.

A continuity test can determine if the circuit is

complete. This type of test is performed with an

ohmmeter or a self-powered test lamp.

1. Disconnect the negative battery cable.

Page 24

24 CHAPTER ONE

2. Attach one test lead (ohmmeter or test light) to

one end of the component or circuit.

3. Attach the other test lead to the opposite end of

the component or circuit (Figure 47).

4. A self-powered test light will come on if the circuit has continuity or is complete. An ohmmeter

will indicate either low or no resistance if the circuit

has continuity. An open circuit is indicated if the

meter displays infinite resistance.

Amperage

Amperage is the unit of measure for the amount

of current within a circuit. Current is the actual flow

of electricity.The higher the current, themore work

that can be performed up to a given point. If the currentflow exceeds the circuit or component capacity,

the system will be damaged.

Measuring amps

An ammeter measures the current flow or amps

ofa circuit (Figure48). Amperage measurement requires that the circuit be disconnected and the ammeter be connected in series to the circuit. Always

use an ammeter that can read higher than the anticipated current flow to prevent damage to the meter.

Connect the red test lead to the electrical source and

the black test lead to the electrical load.

SPECIAL TOOLS

Some of the procedures in this manual require

special tools (Table 9). These are described in the

appropriate chapter and are available from either

the manufacturer or a tool supplier.

In many cases, an acceptable substitute may be

found in an existing tool kit. Another alternative is

tomake the tool. Manyschools with a machineshop

curriculum welcome outside work that can be used

as practical shop applications for students.

BASIC SERVICE METHODS

Most of the procedures in this manual are

straightforward and can be performed by anyone

reasonably competent with tools. However, con

sider personal capabilities carefully before attempt

47

Ohmmeter

Component

ing any operation involving major disassembly of

the engine.

1. Front,in this manual, refersto the front of the vehicle. The front of any component is the end closest

tothe front of the vehicle. The left and right sides refer to the position of the parts as viewedby the rider

sitting on the seat facing forward.

2. Whenever servicing an engine or suspension

component, secure the vehicle in a safe manner.

3. Tag all similar parts for location and mark all

mating parts for position. Record the number and

thickness of any shims as they are removed. Identify parts by placing them in sealed and labeled

plastic sandwich bags.

4. Tag disconnected wires and connectors with

masking tape and a marking pen. Do not rely on

memory alone.

5. Protect finished surfaces from physical damage

or corrosion. Keep gasoline and other chemicalsoff

painted surfaces.

6. Use penetrating oil on frozen or tight bolts.

Avoid using heat where possible. Heat can warp,

melt or affect the temper of parts. Heat also damages the finish of paint and plastics.

7. When a part is a press fit or requires a special

tool for removal, the information or type of tool is

identified in the text. Otherwise, if a part is difficult

toremove or install, determine the cause before proceeding.

8. To prevent objects or debrisfrom falling intothe

engine, cover all openings.

-

9. Read each procedure thoroughly and compare

-

the illustrations to the actual components before

Page 25

GENERAL INFORMATION 25

48

Ammeter

Measures

current

flow

Connected

in series

starting the procedure. Perform theprocedure insequence.

10. Recommendations are occasionally made to

refer service to a dealership or specialist. In

these cases, the work can be performed more

economically by the specialist than by the home

mechanic.

11. The term replace means to discard a defective

part and replace itwith a new part. Overhaul means

to remove, disassemble, inspect, measure, repair

and/orreplace parts as required to recondition an assembly.

12. Some operations require the use of a hydraulic

press. If a press is not available, have these operations performed by ashop equipped with the necessary equipment. Do not use makeshift equipment

that may damage the vehicle.

13. Repairs are much faster and easier if the vehicle is clean before starting work. Degrease the vehicle with a commercial degreaser; follow the

directions on the container for the best results.

Clean allparts with cleaningsolventas theyareremoved.

CAUTION

Do not direct high-pressure water at

steering bearings, carburetor hoses,

wheel bearings, suspension and electrical components, or drive belt. The

water will force the grease out of the

bearings and possibly damage the

seals.

14. If special tools are required, have them available before starting the procedure. When special

tools are required, they will be described at the beginning of the procedure.

15. Make diagrams of similar-appearing parts. For

instance, crankcase bolts are often not the same

lengths. Do not rely onmemory alone. It is possible

that carefully laid out parts will become disturbed,

making it difficult to reassemble the components

correctly without a diagram.

16. Make sure all shims and washers are reinstalled

in the same location and position.

17. Whenever rotating parts contact a stationary

part, look for a shim or washer.

18. Use new gaskets if there is any doubt about the

condition of old ones.

19. If self-locking fasteners are used, replace them

with new ones. Do not install standard fasteners in

place of self-locking ones.

20. Use grease to hold small parts in place if they

tend to fall out during assembly. Do not apply

grease to electrical or brake components.

Removing Frozen Fasteners

If a fastener cannot be removed, several methods

may be used to loosen it. First, applypenetrating oil

such as Liquid Wrenchor WD-40. Apply it liberally

and let it penetrate for 10-15 minutes. Rap the fastener several times with a small hammer.Do not hit

it hard enough to cause damage. Reapply the penetrating oil if necessary.

For frozen screws, apply penetrating oil as described, then insert a screwdriver in the slot and rap

the top of the screwdriver with a hammer. This loosens the rust so the screw can be removed in the normal way. If the screw head is too damaged to use

this method, grip the head with locking pliers and

twist the screw out.

Avoid applying heat unless specifically instructed, as it may melt, warp or remove the temper

from parts.

Removing Broken Fasteners

If the head breaks off a screw or bolt, several

methods are available for removing the remaining

portion. If a large portion of the remainder projects

out, try gripping it with locking pliers. If the pro

1

-

Page 26

26 CHAPTER ONE

49

Filed

Slotted

jecting portion is too small, file it to fit a wrench or

cut a slot in it to fit a screwdriver (Figure 49).

If the head breaks off flush, use ascrew extractor.

To do this, centerpunch the exact center of the remaining portion of the screw or bolt. Drill a small

hole in the screw and tap the extractor into the hole.

Back the screw out with a wrench on the extractor

(Figure 50).

Repairing Damaged Threads

Occasionally, threads are stripped through carelessness or impact damage. Often the threads can be

repaired by running a tap (for internal threads on

nuts) or die (for external threads on bolts) through

the threads (Figure 51). To clean or repair spark

plug threads, use a spark plug tap.

If an internal thread is damaged, it may be necessaryto install a Helicoil or some other type ofthread

insert. Follow the manufacturer’s instructions when

installing their insert.

Ifit is necessary todrill and tap ahole, refer to Ta-

ble 8 for American tap and drill sizes.

50

REMOVING BROKEN

SCREWS AND BOLTS

1. Center punch broken stud 2. Drill hole in stud

3. Tap in screw extractor 4. Remove broken

stud

51

Stud Removal/Installation

A stud removal tool is available from most tool

suppliers. This tool makes theremoval andinstallation of studs easier. If one is not available, thread

two nuts onto the stud and tighten them against each

other. Remove the stud by turning the lower nut

(Figure 52).

1. Measurethe height of the stud above thesurface.

2. Thread the stud removal tool onto the stud and

tighten it, or thread two nuts onto the stud.

3. Remove the stud by turning the stud remover or

the lower nut.

4. Remove any threadlocking compound from the

threaded hole. Clean the threads with an aerosol

parts cleaner.

5. Install the stud removal tool onto the new stud or

thread two nuts onto the stud.

Page 27

GENERAL INFORMATION 27

52

53

Bearing puller

Removing Hoses

1

When removing stubborn hoses, do not exert excessive force on the hose or fitting. Remove the

hose clamp and carefully insert a small screwdriver

or pick tool between the fitting and hose. Apply a

spray lubricant under the hose and carefully twist

the hose off the fitting. Clean the fitting of any corrosion or rubber hose material with a wire brush.

Clean the inside of the hose thoroughly. Do not use

any lubricant when installing the hose (new or old).

Thelubricant may allow the hose to comeoff the fitting, even with the clamp secure.

Bearings

Bearings are used in the engine and transmission

assembly to reduce power loss, heat and noise resulting from friction. Because bearings are precision parts, they must be maintained by proper

lubrication and maintenance. If a bearing is damaged, replace it immediately.When installing a new

bearing, take care to prevent damaging it. Bearing

replacement procedures are included in the individual chapters where applicable; however,use the following sections as a guideline.

Spacer

Shaft

Bearing

6. Apply threadlocking compound to the threads of

the stud.

7. Install the stud and tighten with the stud removal

tool or the top nut.

8. Install the stud to the height noted in Step1 or its

torque specification.

9. Remove the stud removal tool or the two nuts.

NOTE

Unless otherwise specified, install

bearings with the manufacturer’s

mark or number facing outward.

Removal

While bearings are normally removed only when

damaged, there may be times when it is necessary to

remove a bearing that is in good condition. However, improper bearing removal will damage the

bearing and maybe the shaft or case half. Note the

following when removing bearings.

1. When using a puller to remove a bearing from a

shaft, take care that the shaft is not damaged. Always place a piece of metal between the end of the

shaft and the puller screw. In addition, place the

puller arms next to the inner bearing race. See Fig-

ure 53.

2. When using a hammer to remove a bearing from

a shaft, do not strike the hammer directly against the

shaft. Instead, use a brass or aluminum rodbetween

the hammer and shaft (Figure 54) and make sure to

Page 28

28 CHAPTER ONE

54

Spacer

Shaft

Bearing

Blocks

support both bearing races with wooden blocks as

shown.

3. A hydraulic press is the ideal method of bearing

removal. Note the following when using a press:

a. Always support the inner and outer bearing

races with a suitable size wooden or aluminum ring (Figure 55). If only the outer race is

supported, pressure applied against the balls

and/or the inner race will damage them.

b. Always make sure the press arm (Figure 55)

alignswith the center of the shaft. If the arm is

not centered, it may damage the bearing

and/or shaft.

c. The moment the shaftis free of the bearing, it

will drop to the floor. Secure or hold the shaft

to prevent it from falling.

Installation

1. When installing a bearing in a housing, apply

pressure to the outer bearing race (Figure 56).

When installing a bearing on a shaft,apply pressure

to the inner bearing race (Figure 57).

2. When installing a bearing as described in Step

1, sometypeof driver is required.Never strikethe

55

Press ram

Shaft

Bearing

Spacer

Press bed

56

Bearing

Bearing

Housing

bearing directly with a hammer or the bearing

will be damaged. When installing a bearing,usea

piece of pipe or a driver with a diameter that

matches the bearing race. Figure 58 shows the

correct way to use a socket and hammer to install

a bearing.

3. Step1 describes how to install a bearing in a case

half or over a shaft. However, when installing a

bearing over a shaft and into a housing at the same

time, a tight fit will be required for both outer and

inner bearing races. In this situation, install a spacer

underneaththe driver tool so that pressure is applied

evenly across both races. See Figure 59. If the outer

race is not supported as shown in Figure 59, the

balls will push against the outer bearing race and

damage it.

Page 29

GENERAL INFORMATION 29

57

Bearing

Shaft

58

Socket

Bearing

Shaft

Interference Fit

1. Follow this procedure when installing a bearing

over a shaft. When a tight fit is required, the bearing

inside diameter will be smaller than the shaft. In this

case, driving the bearing on the shaft using normal