Page 1

Instruction Manual

HI 2400

Dissolved Oxygen

Bench Meter

www.hannainst.com

1

Page 2

Dear Customer,

Thank you for choosing a Hanna Instruments product.

Please read this instruction manual carefully before using this instrument.

This manual will provide you with the necessary information for correct

use of this instrument, as well as a precise idea of its versatility.

If you need additional technical information, do not hesitate to e-mail us

at tech@hannainst.com.

WARRANTYWARRANTY

WARRANTY

WARRANTYWARRANTY

HI 2400 is guaranteed for two years against defects in workmanship and

materials when used for its intended purpose and maintained according to

instructions. Electrodes and probes are guaranteed for six months. This

warranty is limited to repair or replacement free of charge.

Damage due to accidents, misuse, tampering or lack of prescribed

maintenance is not covered.

If service is required, contact the dealer from whom you purchased the

instrument. If under warranty, report the model number, date of

purchase, serial number and the nature of the problem. If the repair is

not covered by the warranty, you will be notified of the charges incurred.

If the instrument is to be returned to Hanna Instruments, first obtain

a Returned Goods Authorization number from the Technical Service

department and then send it with shipping costs prepaid. When shipping

any instrument, make sure it is properly packed for complete protection.

TABLE OF CONTENTSTABLE OF CONTENTS

TABLE OF CONTENTS

TABLE OF CONTENTSTABLE OF CONTENTS

WARRANTY .................................................................................................... 2

PRELIMINARY EXAMINATION ............................................................................ 3

GENERAL DESCRIPTION .................................................................................... 3

PROBE FUNCTIONAL DESCRIPTION .................................................................... 4

FUNCTIONAL DESCRIPTION .............................................................................. 5

SPECIFICATIONS ............................................................................................. 6

OPERATIONAL GUIDE ....................................................................................... 7

DO CALIBRATION ............................................................................................ 10

GOOD LABORATORY PRACTICE (GLP) ................................................................. 13

SETUP .......................................................................................................... 14

LOGGING ....................................................................................................... 19

TEMPERATURE CALIBRATION (for technical personnel only) ................................. 22

PC INTERFACE ............................................................................................... 24

PROBE & MEMBRANE MAINTENANCE ............................................................... 28

TROUBLESHOOTING GUIDE .............................................................................. 29

ACCESSORIES ............................................................................................... 30

2

Page 3

PRELIMINARY EXAMINATIONPRELIMINARY EXAMINATION

PRELIMINARY EXAMINATION

PRELIMINARY EXAMINATIONPRELIMINARY EXAMINATION

Remove the instrument from the packing material and examine it

carefully to make sure that no damage has occured during shiping. If

there is any damage, notify your Dealer or the nearest Hanna Customer

Service Center.

Each instrument is supplied with:

• HI 76407/2 DO probe with 2 m (6.7') cable

• HI 76407A membrane cap (2 pcs)

• HI 7041S electrolyte solution (30 ml)

• 12 VDC power adapter

• Instruction Manual

Note: Save all packing material until you are sure that the instrument

functions correctly. All defective items must be returned in their

original packing with the supplied accessories.

GENERAL DESCRIPTIONGENERAL DESCRIPTION

GENERAL DESCRIPTION

GENERAL DESCRIPTIONGENERAL DESCRIPTION

HI2400 is a logging microprocessor-based DO/Temperature bench meter.

It can store up to 100 lots in memory, with up to 8000 readings. These

readings can be transferred to a computer for further analysis or permanent

storage.

Dissolved Oxygen is indicated in ppm (parts per million) or in %.

All measurements are automatically compensated for temperature.

Salinity compensation in water allows direct determination of Dissolved

Oxygen in saline waters and altitude compensation readjusts for the

altitude variance.

The Dissolved Oxygen probe has a membrane covering the polarographic

sensors and a built-in thermistor for temperature measurements and

compensation.

This permeable PTFE membrane isolates the sensor elements from the

testing solution, but allows Oxygen to pass through. When a voltage

is applied across the sensor, oxygen that has passed through the

membrane reacts causing a current flow, and hence determining a

reading.

3

Page 4

7

8

10

9

3

4

1

2

4

5

6

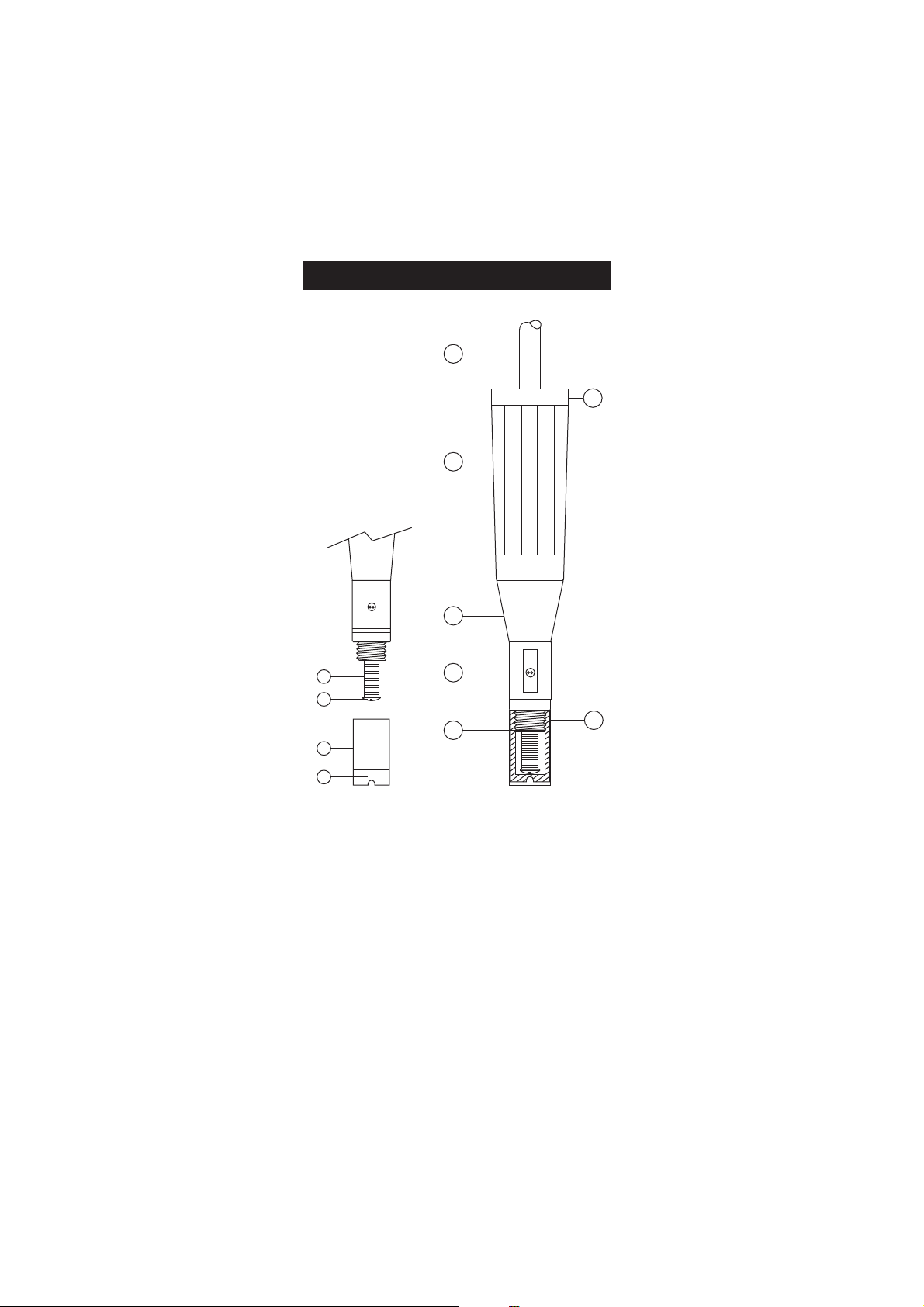

PROBE FUNCTIONAL DESCRIPTIONPROBE FUNCTIONAL DESCRIPTION

PROBE FUNCTIONAL DESCRIPTION

PROBE FUNCTIONAL DESCRIPTIONPROBE FUNCTIONAL DESCRIPTION

1. DO Probe

2. Protective Cap

3. Watertight Shielded Cable

4. Polypropylene Probe Body

5. Temperature Sensor

6. O-Ring Seal

7. Silver Chloride Anode

8. Platinum Cathode (sensor)

9. Oxygen Permeable PTFE Membrane

10. Membrane Cap

4

Page 5

FUNCTIONAL DESCRIPTIONFUNCTIONAL DESCRIPTION

FUNCTIONAL DESCRIPTION

FUNCTIONAL DESCRIPTIONFUNCTIONAL DESCRIPTION

Front Panel

Rear Panel

1) Liquid Crystal Display (LCD).

2) CAL key, to enter and exit calibration mode.

3) CFM/GLP key, to confirm calibration selection, different setup values

or to display Good Laboratory Practice information.

4) ºC key, to manually increase temperature value or other parameters.

5) ºC key, to manually decrease temperature value or other parameters.

6) SETUP key, to enter/exit SETUP mode.

7) RANGE key, to select measurement range (% or ppm), switch to

focused data in SETUP or toggle between standard value and

temperature during calibration.

8) LOG/CLR key, to store a value into memory, or to select to delete log

records.

9) RCL key, to enter and exit view memory mode.

10) ON/OFF switch.

11) Power supply socket.

12) USB connector.

13) DO probe connector.

5

Page 6

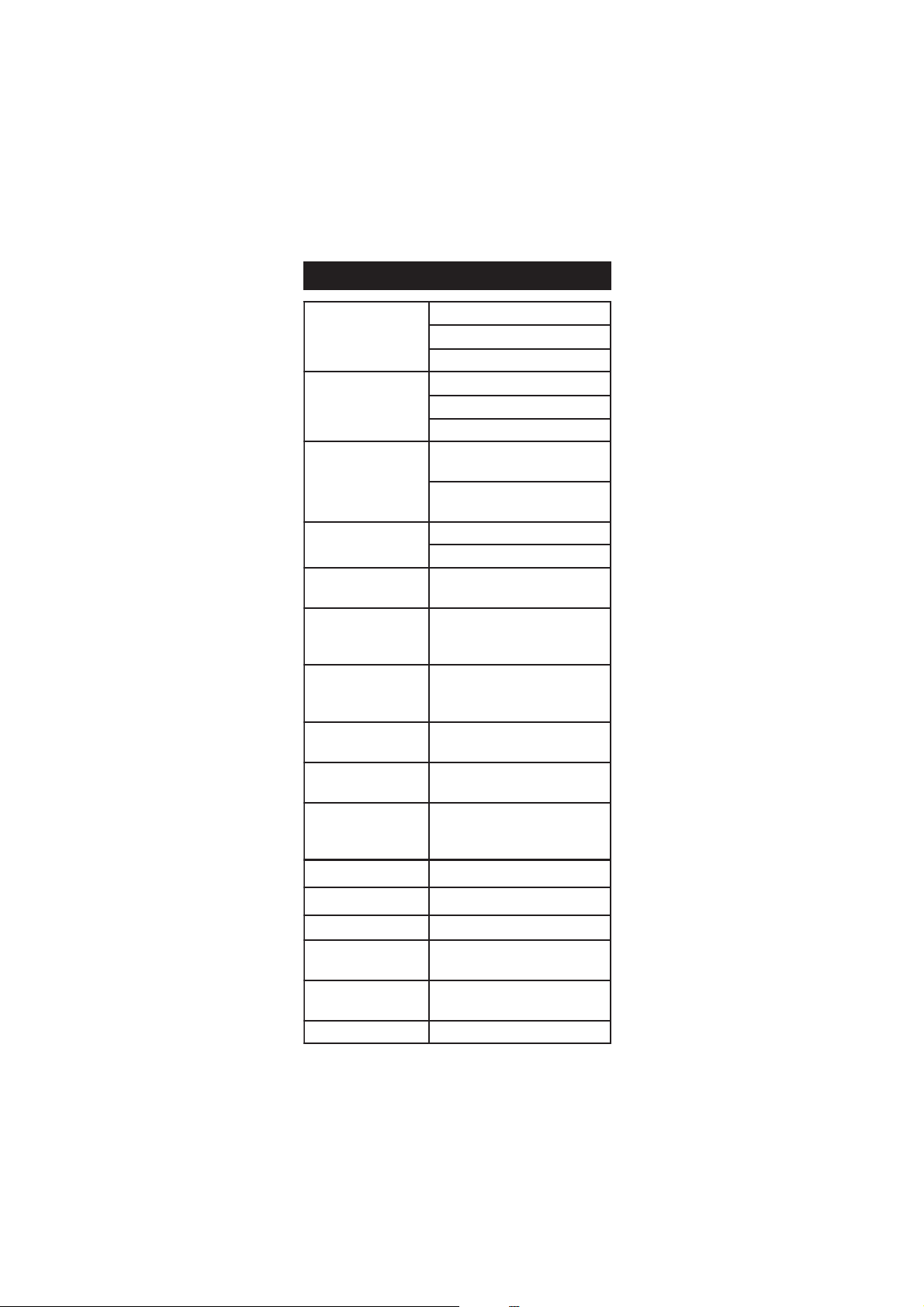

SPECIFICATIONSSPECIFICATIONS

EGNAR

mpp00.54ot00.0

%0.003ot0.0

)F°221ot0.23(Cº0.05ot0.0

NOITULOSER

mpp10.0

%1.0

C°1.0

YCARUCCA

F°86/C°02@

,tigid1±roelacslluffo%5.1±

retaergsirevehcihw

)rorreeborpgnidulcxe(Cº2.0±

noitaiveDCMElacipyT

elacslluffo%5.1±

Cº5.0±

noitarbilaCOD

%0tatniopelbuodroelgniS

( 0407IH )riani(%001dna)

edutitlA

noitasnepmoC

noituloseR

)'021,31(m000,4ot0

)'823(m001

ytinilaS

noitasnepmoC

noituloseR

l/g04ot0

l/g1

noitasnepmoCerutarepmeT

Cº0.05ot0.0

)Fº221ot0.23(

eborP

2/70467IH htiw

elbac)'6.6(m2

lavretnigniggoL

sdnoces03,01,5

,021,06,03,51,01,5,2,1ro

setunim081

noitacinummocCP BSUdetalosiotpO

ylppusrewoP retpadaCDV21

snoisnemiD )”3.4x7.8x2.9(mm901x222x532

thgieW

)bl9.2(gK3.1

)bl6.4(gK1.2redlohhtiwtik

tnemnorivnE

)Fº221-23(Cº05–0

gnisnednocnonHR%59.xam

ytnarraW sraey2

SPECIFICATIONS

SPECIFICATIONSSPECIFICATIONS

6

Page 7

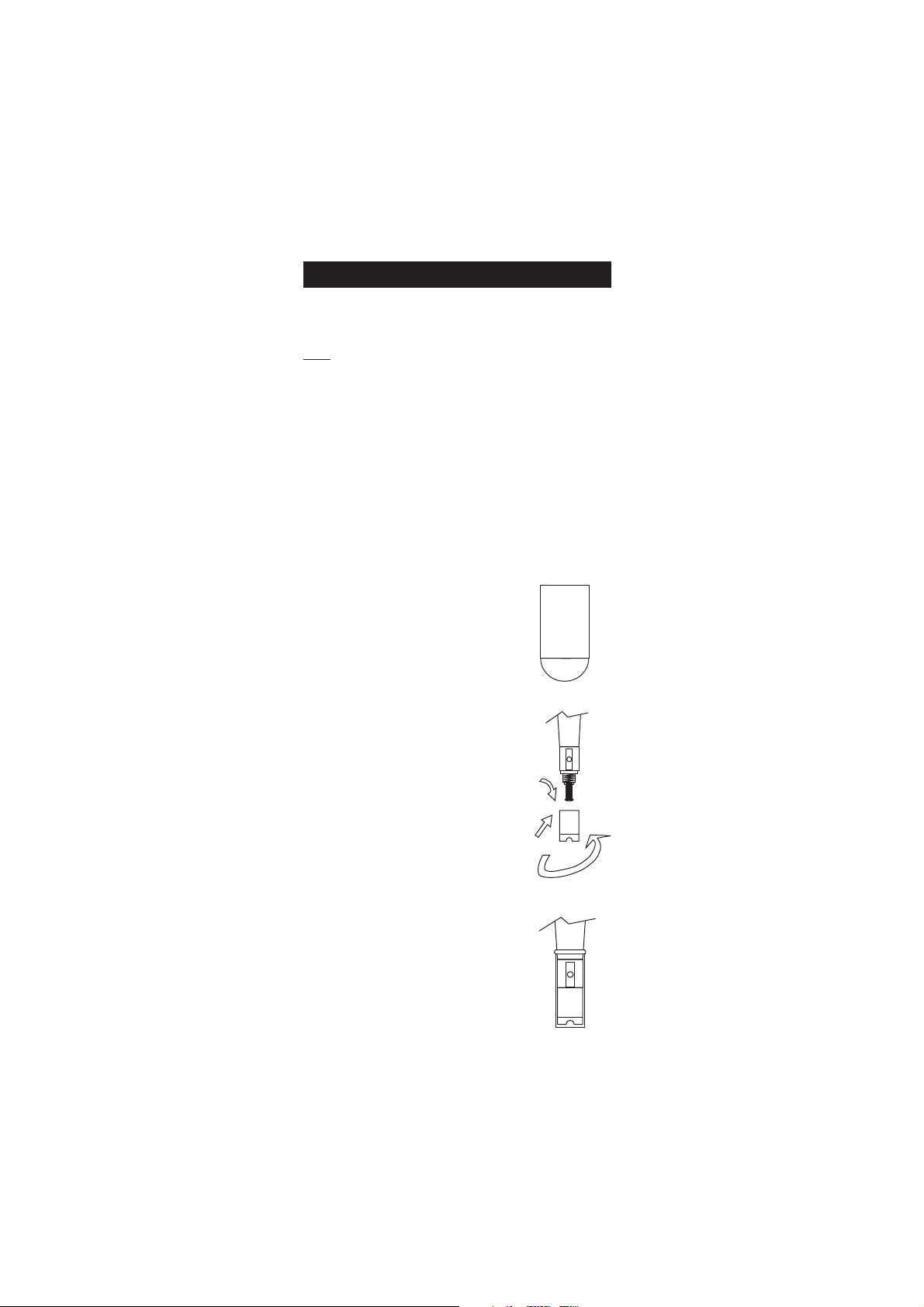

Shipping

cap

black

red

FILLFIRST

THENTAP

THENSCREW

BACKON

OPERATIONAL GUIDEOPERATIONAL GUIDE

OPERATIONAL GUIDE

OPERATIONAL GUIDEOPERATIONAL GUIDE

POWER CONNECTION

Plug the 12 VDC adapter into the power supply socket.

Notes: • This instrument use non volatile memory to retain the

calibration parameters and all the other settings even when

unplugged.

• Make sure a fuse protects the main line.

PROBE CONNECTION AND PREPARATION

To take measurements, connect the DO probe to the meter securely by

aligning the pins with the socket located on the back of the meter,

pushing the plug in and tightening the threaded ring.

Probes shipped from Hanna Instruments are dry. To hydrate the probe

and prepare it for use, connect it to the

meter and proceed as follows:

1. Remove the red and black plastic

cap. This cap is for shipping purposes

and can be thrown away.

2. Wet the sensor by soaking the bottom

2½ cm (1") of the probe in electrolyte

(HI 7041S) for 5 minutes.

3. Rinse the membrane cap (HI 76407A

supplied in the kit with the meter)

with electrolyte solution while shaking

it gently. Refill with clean electrolyte

solution.

4. Tap gently the sides of the membrane

cap with your finger tip to ensure

that no air bubbles are trapped. To

avoid damaging the membrane, do

not tap it directly on the bottom.

5. Make sure that the rubber O-ring

sits properly inside the membrane

cap.

6. With the sensor facing down,

slowly screw the cap clockwise.

Some electrolyte will overflow.

When not in use and during polarization

(see page 8), use the protective transparent

cap supplied in the kit with the meter.

7

Page 8

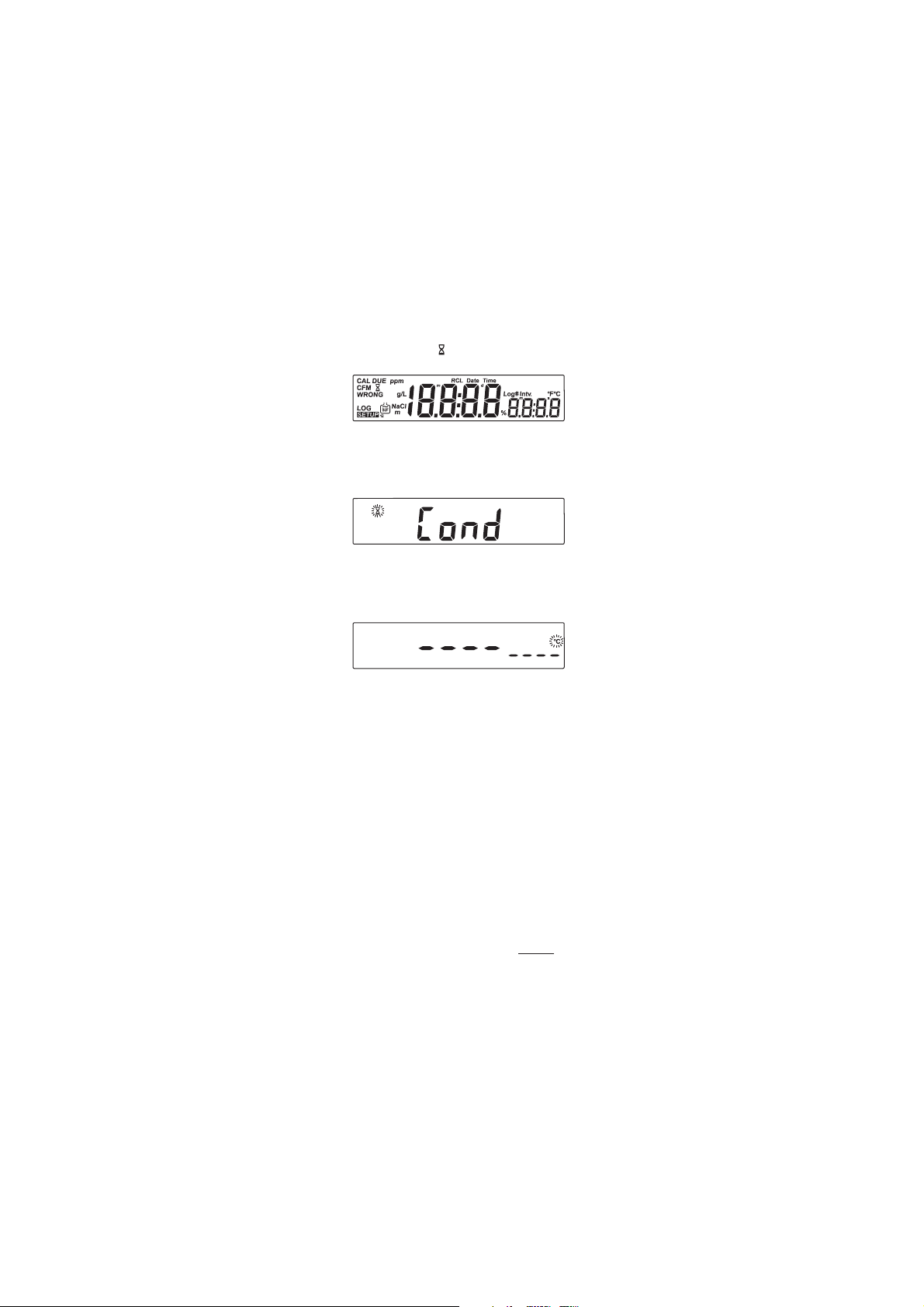

INSTRUMENT START-UP

• Turn the instrument on by pressing the ON/OFF switch.

• All LCD tags are displayed and a beep is generated while the

instrument performs a self test.

• The instrument will display “ ” blinking until initialization is complete.

• After a few seconds “Cond” message appears on the LCD to inform

the user that the probe is in auto-conditioning (automatic polarization)

mode.

• When this message disappears, the probe is polarized and the

instrument can be calibrated.

• If the probe is disconnected, the meter will display “----”.

PROBE POLARIZATION

The probe is under polarization with a fixed voltage of approximately

800 mV.

Probe polarization is essential for stable measurements with the same

recurring degree of accuracy.

With the probe properly polarized, oxygen is continually consumed when

it passes through the sensitive diaphragm and dissolves in the electrolyte

solution contained in the probe.

If polarization is interrupted, the electrolyte solution continues to be

enriched with oxygen until it reaches an equilibrium with the surrounding

solution.

Whenever measurements are taken with a non-polarized probe, the

oxygen level revealed is both that of the tested solution, as well as that

present in the electrolyte solution. This reading is incorrect.

The calibration of this instrument is very simple.

Before proceeding with the calibration, make sure the probe is ready for

measurements (see page 7), i.e. the membrane cap is filled with electrolyte

and the probe is connected to the meter and properly polarized.

8

Page 9

For an accurate calibration, it is recommended to wait at least 15 minutes

to ensure precise conditioning of the probe.

Keep the protective cap on during polarization time and remove it for

calibration and measurements. Follow the calibration procedure (see

page 10).

SALINITY AND ALTITUDE COMPENSATION

If the sample contains significant concentration of salinity or if you are

performing measurements at an altitude different from sea level, the

read out values must be corrected, taking into account the lower degree

of oxygen solubility in these situations (see pages 15-16).

Remember to set the altitude and/or the salinity before taking any DO

measurements. The meter will automatically compensate for these factors.

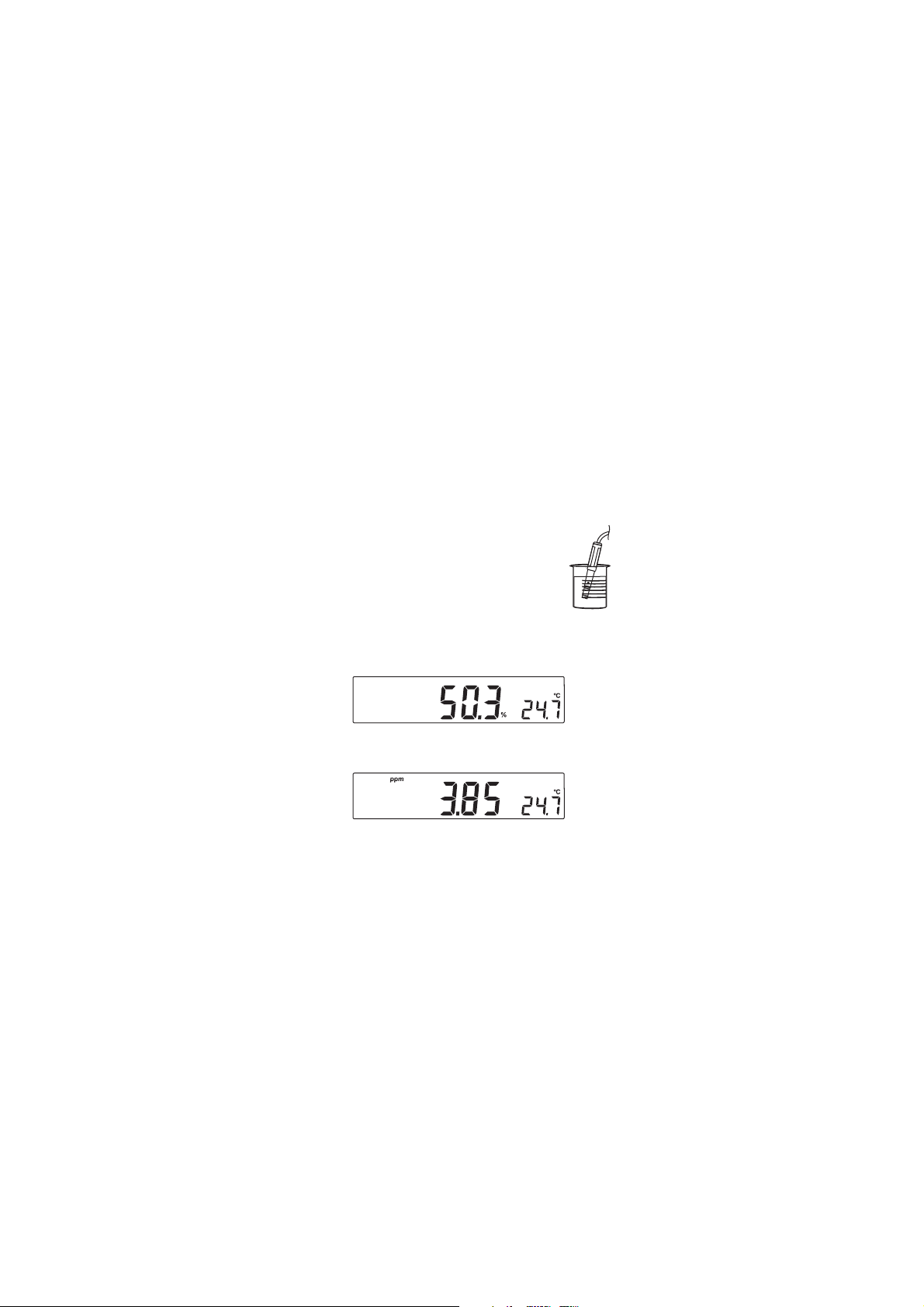

DO MEASUREMENTS

Make sure that the instrument has been calibrated and

the protective cap has been removed.

• Submerse the tip of the probe in the sample to be

tested. Allow approximately one minute for the reading

to stabilize.

• The Dissolved Oxygen value (in %) is displayed on the primary LCD

and the temperature on the secondary LCD.

• Press RANGE to change the reading from % to ppm and vice-versa.

For accurate Dissolved Oxygen measurements, a water movement of

0.3 m/s is required. This is to ensure that the oxygen-depleted

membrane surface is constantly replenished. A moving stream will

provide adequate circulation.

The use of a magnetic stirrer to ensure a certain fluid velocity is

recommended.

9

Page 10

TEMPERATURE MEASUREMENTS

HI 7040

HI 7040

The probe has a built-in temperature sensor.

The measured temperature is indicated on the secondary LCD as shown

above.

Allow the probe to reach thermal equilibrium before taking any measurement.

This can take several minutes. The greater the difference between the

temperature at which the probe was stored and the temperature of the

sample, the longer the time will be.

Note: If “----” is displayed, the DO probe is not properly connected. This

also indicates the posibility of a broken probe cable. If temperature

displayed blinking, the temperature is out of range.

DO CALIBRATIONDO CALIBRATION

DO CALIBRATION

DO CALIBRATIONDO CALIBRATION

Calibrate the instrument frequently, especially if high accuracy is

required.

The instrument can be calibrated in maximum 2 points: 0.0% (zero

calibration) and 100.0% (slope calibration).

The zero calibration of the HI 2400 is very stable, therefore this procedure

needs to be performed only whenever the probe or the membrane is

replaced.

However, because the slope calibration is more critical, it is recommended

to perform this procedure every week.

INITIAL PREPARATION

• Pour small quantities of HI 7040 Zero Oxygen

solution into a beaker. If possible, use a plastic

beaker to minimize any EMC interferences.

• Make sure the probe is ready for measurements

(see probe preparation on page 7), i.e. the

membrane is filled with electrolyte and the probe

is connected to the meter.

• Switch the meter on by pressing the ON/OFF

switch.

• For an accurate calibration, it is recommended

to wait for at least 15 minutes to ensure precise

conditioning of the probe.

• Remove the protective cap from the DO probe.

• Set the appropriate altitude factor (see page 15). Make sure the

salinity factor is set to zero (see page 16).

10

Page 11

ZERO CALIBRATION

OR

zero oxygen

• Submerse the probe into HI 7040

solution and stir gently for 2-3 minutes.

• Press CAL. The “~” and “ ” tags will blink on the

LCD until the reading is stable.

• When the reading is stable, “CFM” starts blinking.

Press CFM to confirm the “0.0%” DO calibration.

• If the reading is within the limits (±15% f.s.), the

meter stores the value (and adjusts the slope point).

• Press CAL. The instrument will return to measurement

mode and will memorize the zero calibration data.

For a two-point calibration do not press CAL and

follow the procedure below.

SLOPE CALIBRATION

It is suggested to perform the slope calibration in air.

• Rinse the probe in clean water to remove any residual

zero oxygen solution.

Note: If you did not perform the zero calibration procedure, press CAL

and then the ARROW keys to select the 100% DO calibration

point.

• Dry the probe tip and allow a few seconds for the LCD reading to

stabilize. The “

stable.

• When the reading is stable, “CFM” tag starts blinking. Press CFM to

confirm the “100.0%” DO calibration.

• If the reading is within the limits (±15% f.s.), the

meter stores the value (and adjusts the slope point).

~~

~” and “ ” tags will blink until the reading is

~~

11

Page 12

• The instrument stores the slope calibration data and returns to

measurement mode.

Notes: • If the reading is not close to the selected value, “WRONG“

tag will blink.

• If the temperature goes out of range during calibration the

“WRONG”, temperature unit tag and both measurements

will blink.

• HI 2400 has automatic buffer recognition function. If the

ARROW keys are pressed to select the desired calibration

value, the automatic buffer recognition function is disabled.

12

Page 13

GOOD LABORATORY PRACTICE (GLP)GOOD LABORATORY PRACTICE (GLP)

GOOD LABORATORY PRACTICE (GLP)

GOOD LABORATORY PRACTICE (GLP)GOOD LABORATORY PRACTICE (GLP)

GLP is a set of functions that allows storage and retrieval of data

regarding the maintenance and status of the system.

All data regarding DO calibration is stored for the user to review when

necessary.

LAST DO CALIBRATION DATA

The last DO calibration data is stored automatically after a successful

calibration. To view the DO calibration data, press GLP when the

instrument is in measurement mode.

The instrument will display the time (hh:mm) of the last calibration.

Press the ARROW keys to view the next calibration parameter.

Pressing the key:

• The date of the calibration.

• The calibration standards.

• Press SETUP to view the temperature of the calibration.

• The altitude value.

• The salinity value.

13

Page 14

• The instrument ID.

SETUPSETUP

SETUP

SETUPSETUP

Setup mode allows viewing and modifying the following parameters:

• Salinity Factor

• Altitude Factor

• Log Interval

• Current Time (hour & minute)

• Current Date (month, day & year)

• Beep Status

• Instrument ID

• Temperature Unit

To enter the Setup mode press SETUP while the instrument is in

measurement mode. Press SETUP again to exit SETUP mode.

Select a parameter with the ARROW keys.

Press CAL if you want to change a parameter value. The selected

parameter will blink.

Press RANGE to toggle between displayed parameters.

Press the ARROW keys to increase or decrease the displayed value.

Press CFM to save the modified value or CAL to escape.

Press the ARROW keys to select the next/previous parameter.

SALINITY FACTOR

Press CAL when the salinity factor is displayed. The salinity factor (“0” to

“40” g/l) and the “CFM” tag will start blinking.

Press ARROW

Press CFM to save the modified value or press CAL to escape without

saving.

The salinity affects the DO concentration, decreasing its value. The next

table shows the maximum oxygen solubility at various temperatures and

salinity levels.

keys to change the salinity factor value.

14

Page 15

Cº

leveLaeSta)l/g(ytinilaS

Fº

l/g0 l/g01 l/g02 l/g03 l/g53

0 06.41 46.31 47.21 09.11 05.11 0.23

2 18.31 19.21 70.21 92.11 19.01 6.53

4 90.31 52.21 74.11 37.01 83.01 2.93

6 44.21 56.11 19.01 22.01 98.9 8.24

8 38.11 90.11 04.01 57.9 44.9 4.64

01 82.11 85.01 39.9 23.9 30.9 0.05

21 77.01 11.01 05.9 29.8 56.8 6.35

41 92.01 86.9 01.9 55.8 03.8 2.75

61 68.9 82.9 37.8 12.8 79.7 8.06

81 54.9 09.8 93.8 09.7 66.7 4.46

02 80.9 65.8 70.8 06.7 83.7 0.86

22 37.8 32.8 77.7 33.7 21.7 6.17

42 04.8 39.7 94.7 70.7 78.6 2.57

52 42.8 97.7 63.7 59.6 57.6 0.77

62 90.8 56.7 32.7 38.6 46.6 8.87

82 18.7 83.7 89.6 16.6 24.6 4.28

03 45.7 41.7 57.6 93.6 22.6 0.68

23 92.7 09.6 45.6 91.6 30.6 6.98

43 50.7 86.6 33.6 10.6 58.5 2.39

63 28.6 74.6 41.6 38.5 86.5 8.69

83 16.6 82.6 69.5 66.5 15.5 4.001

04 14.6 90.6 97.5 05.5 63.5 0.401

24 22.6 39.5 36.5 53.5 22.5 6.701

44 40.6 77.5 84.5 12.5 90.5 2.111

64 78.5 16.5 33.5 70.5 79.4 8.411

84 07.5 74.5 02.5 59.4 58.4 4.811

05 45.5 33.5 70.5 38.4 57.4 0.221

Note: The relationship between salinity and chlorinity for sea water is

given by the equation below:

Salinity (g/l) = 1.80655 Chlorinity (g/l)

ALTITUDE FACTOR

Press CAL when the altitude factor is displayed. The altitude factor

(“0” to “4000” m, in steps of 100 m; 1 meter = 3.28 feet) and the

“CFM” tag will start blinking.

Press the ARROW

keys to change the altitude factor value.

Press CFM to save the modified value or press CAL to escape without saving.

15

Page 16

Cº

leveLaeSevobasreteM,edutitlA

Fº

m0

003m006m009m0021m0051m0081m0012m0042m0072m0003m0033m0063m0093m0004

m

0 6.41 1.41 6.31 1.31 6.21 1.21 7.11 2.11 8.01 4.01 0.01 7.9 3.9 0.9 9.8 0.23

2 8.31 3.31 8.21 4.21 9.11 5.11 0.11 6.01 2.01 9.9 5.9 2.9 8.8 5.8 4.8 6.53

4 1.31 6.21 2.21 7.11 3.11 9.01 5.01 1.01 7.9 3.9 0.9 7.8 4.8 0.8 9.7 2.93

6 4.21 0.21 5.11 1.11 7.01 3.01 9.9 6.9 2.9 9.8 6.8 2.8 9.7 6.7 5.7 8.24

8 8.11 4.11 0.11 6.01 2.01 8.9 5.9 1.9 8.8 4.8 1.8 8.7 5.7 3.7 2.7 4.64

01 3.11 9.01 5.01 1.01 7.9 4.9 0.9 7.8 4.8 1.8 8.7 5.7 2.7 9.6 8.6 0.05

21 8.01 4.01 0.01 6.9 3.9 9.8 6.8 3.8 0.8 7.7 4.7 1.7 9.6 6.6 5.6 6.35

41 3.01 9.9 6.9 2.9 9.8 5.8 2.8 9.7 6.7 4.7 1.7 8.6 6.6 3.6 2.6 2.75

61 9.9 5.9 2.9 8.8 5.8 2.8 9.7 6.7 3.7 0.7 8.6 5.6 3.6 1.6 0.6 8.06

81 5.9 1.9 8.8 5.8 1.8 8.7 6.7 3.7 0.7 8.6 5.6 3.6 0.6 8.5 7.5 4.46

02 1.9 8.8 4.8 1.8 8.7 5.7 3.7 0.7 7.6 5.6 2.6 0.6 8.5 6.5 5.5 0.86

22 7.8 4.8 1.8 8.7 5.7 2.7 0.7 7.6 5.6 2.6 0.6 8.5 6.5 4.5 3.5 6.17

42 4.8 1.8 8.7 5.7 2.7 0.7 7.6 5.6 2.6 0.6 8.5 6.5 4.5 2.5 1.5 2.57

52 3.8 0.8 7.7 4.7 1.7 8.6 6.6 4.6 1.6 9.5 7.5 5.5 3.5 1.5 0.5 0.77

62 1.8 8.7 5.7 2.7 0.7 7.6 5.6 2.6 0.6 8.5 6.5 4.5 2.5 0.5 9.4 8.87

82 8.7 5.7 3.7 0.7 7.6 5.6 2.6 0.6 8.5 6.5 4.5 2.5 0.5 8.4 7.4 4.28

03 6.7 3.7 0.7 8.6 5.6 3.6 0.6 8.5 6.5 4.5 2.5 0.5 8.4 6.4 6.4 0.68

23 3.7 0.7 8.6 5.6 3.6 1.6 8.5 6.5 4.5 2.5 0.5 8.4 7.4 5.4 4.4 6.98

43 1.7 8.6 6.6 3.6 1.6 9.5 6.5 4.5 2.5 0.5 9.4 7.4 5.4 3.4 3.4 2.39

63 8.6 6.6 3.6 1.6 9.5 7.5 5.5 3.5 1.5 9.4 7.4 5.4 4.4 2.4 1.4 8.69

83 6.6 4.6 1.6 9.5 7.5 5.5 3.5 1.5 9.4 7.4 5.4 4.4 2.4 1.4 0.4 4.001

04 4.6 2.6 9.5 7.5 5.5 3.5 1.5 9.4 7.4 6.4 4.4 2.4 1.4 9.3 9.3 4.401

24 2.6 0.6 8.5 6.5 3.5 2.5 0.5 8.4 6.4 4.4 3.4 1.4 0.4 8.3 8.3 6.701

44 0.6 8.5 6.5 4.5 2.5 0.5 8.4 6.4 5.4 3.4 1.4 0.4 8.3 7.3 7.3 2.111

64 8.5 6.5 4.5 2.5 0.5 8.4 7.4 5.4 3.4 2.4 0.4 9.3 7.3 6.3 5.3 8.411

84 7.5 5.5 3.5 1.5 9.4 7.4 5.4 4.4 2.4 0.4 9.3 7.3 6.3 5.3 4.3 4.811

05 5.5 3.5 1.5 9.4 7.4 6.4 4.4 2.4 1.4 9.3 8.3 6.3 5.3 4.3 3.3 0.221

16

Page 17

LOG INTERVAL

Press CAL when log interval is displayed. The log interval and “CFM”

tag is displayed blinking.

Press the ARROW keys to change the custom buffer value.

Press CFM to confirm the selection.

Press CAL to escape without saving.

CURRENT TIME

Press CAL when the current time is displayed. The hour and “CFM” tag will

start blinking.

Press the ARROW

Press RANGE. The minutes will start blinking.

Press the ARROW keys to change the minutes.

Press CFM to save the modified value.

Press CAL to escape without saving.

CURRENT DATE

Press CAL when the current date is displayed. The month and “CFM” tag

will start blinking.

Press the ARROW

Press RANGE. The day and “CFM” tag will start blinking.

Press the ARROW

Press RANGE. The year and “CFM” tag will start blinking.

keys to change the hour.

keys to change the month.

keys to change the day.

Press the ARROW keys to change the year.

17

Page 18

Press CFM to save the modified value.

Press CAL to escape without saving.

BEEP STATUS

Press CAL when the beep status is displayed. The beep status (“ON” or

“OFF”) and “CFM” tag will start blinking.

Press the ARROW

Press CFM to save the modified value or press CAL to escape without

saving.

INSTRUMENT ID

Press CAL when “InId” is displayed. The instrument ID (“0000“ to

“9999“) and “CFM” tag will start blinking.

Press the ARROW

Press CFM to save the modified instrument ID value.

Press CAL to escape without saving.

Note: The instrument ID is downloaded to a PC as part of a logged

data, set to identify its origin.

TEMPERATURE UNIT

Press CAL when “Unit“ is displayed. The temperature unit and “CFM”

tag will start blinking.

keys to change the beep status.

keys to change the instrument ID value.

Press the ARROW keys to change the option.

Press CFM to save the modified temperature unit.

Press CAL to escape without saving.

18

Page 19

LOGGINGLOGGING

LOGGING

LOGGINGLOGGING

This function allows the user to log DO (in ppm or %) together with

temperature automatically, for long periods of time. All logged data can

be stored into a PC through the USB port.

The memory used for storing the logged data is divided in 32 pages. The

capacity of each page is 250 samples. The lot number goes from 1 to

100. The maximum capacity of the log memory is 8000 samples. Each

time a new lot starts, it automatically starts from a new page. When the

samples collected for a single lot reach the limit (8000 samples) or all

memory pages are occupied, the meter stops logging automatically.

The appropriate logging interval can be set between 5, 10, 30 seconds

or 1, 2, 5, 10, 15, 30, 60, 120, 180 minutes (see SETUP section for

details).

LOGGING THE CURRENT DATA

To start the Auto LOG mode press LOG while in measurement

mode.

When the selected interval is reached the instrument will display the

current lot number on the primary LCD line, the record number on the

secondary LCD line and the LOG tag ( see example below: Lot 15 record 22)

followed by the number of free records on the corresponding memory

space.

If there are less than 6 memory locations remaining, the record number

and “Lo” message will be displayed to alert the user.

To stop the Auto LOG mode press LOG again. The “LOG” tag will be

cleared.

19

Page 20

If the log space is full, the “FULL LOG” message will be displayed and

no more data will be saved.

Note: When pressing any key that is not active, while lot logging is

running, the following message is displayed for a few seconds.

VIEW LOGGED DATA

Press the RCL

key while in measurement mode to retrieve the stored

information.

If no lots are memorized, the next messages will be displayed:

Otherwise, the instrument will display “L” and the lot number on the

primary LCD and the number of records on the secondary LCD, “RCL” tag

and “CFM” blinking.

Press ARROW keys to select different lot.

Press CFM to view record information. Then the record information will

appear. To view the record number at any time just press the SETUP

key.

Use the ARROW keys to scroll through the records.

To view additional information press RANGE:

• The time on the primary LCD, along with “TIME” tag and the

seconds on the secondary LCD.

20

Page 21

• The date on the primary LCD, along with “DATE”, month and day

tags.

• The salinity on the primary LCD and “SAL” message on the secondary

LCD.

• The altitude on the primary LCD and “ALt” message on the

secondary LCD.

• The interval for lot logging.

TO DELETE LOTS

To delete a lot, use the ARROW keys to select the desired lot. Press CLR key.

The “dEL” message is displayed on the primary LCD and the selected lot on

the secondary LCD, along with ”RCL” tag.

• The ARROW keys can be used to change the lot number.

• Press SETUP to select delete all lots feature. The display will show

“dEL” in the primary LCD and “ALL” in the secondary LCD.

• Press CFM to confirm delete.

• Press CAL, CLR or RCL to escape and return to the RCL screen.

• If “dEL ALL” option was selected, all the lots are deleted. The “no rEc”

message will appear.

• Press RCL exit record information and enter lot information.

• Press RCL again to return to measurement mode.

21

Page 22

TEMPERATURE CALIBRATIONTEMPERATURE CALIBRATION

TEMPERATURE CALIBRATION

TEMPERATURE CALIBRATIONTEMPERATURE CALIBRATION

((

for technical personnel onlyfor technical personnel only

(

for technical personnel only

((

for technical personnel onlyfor technical personnel only

Each meter has been factory calibrated for temperature with the supplied

DO probe and is ready for measurements.

The DO probes are interchangeable and no temperature calibration is

needed.

If the temperature measurements are not accurate, temperature

recalibration should be performed.

For an accurate recalibration, contact your dealer or the nearest Hanna

Customer Service Center, or follow the procedure below.

• Prepare a vessel containing ice and water and another one containing

hot water (at a temperature of around 50 °C). Place insulation

material around the vessels to minimize temperature changes.

• Use a calibrated thermometer with a resolution of 0.1 °C as a

reference thermometer. Connect the HI 76407/2 DO probe to the

appropriate socket.

• With the instrument off, press and hold down CFM&SETUP, then

power on the instrument. The “CAL” tag will appear and the

secondary LCD will show “0.0 °C”.

))

)

))

• Submerse the DO probe in the vessel with ice

and water as near as possible to the reference

thermometer. Allow a few seconds for the probe

to stabilize.

• Use the ARROW keys to set the reading on

the secondary LCD to that of ice and water,

measured by reference thermometer. When

the reading is stable, the “CFM” tag starts blinking.

• Press CFM to confirm. The secondary LCD will show “50.0 °C”.

22

Page 23

• Submerse the DO probe in the second vessel

as near as possible to the reference thermometer. Allow a few seconds for the probe to

stabilize.

• Use the ARROW keys to set the reading on

the secondary LCD to that of the hot water.

• When the reading is stable, the “CFM” tag starts

blinking.

• Press CFM to confirm. The instrument returns to

measurement mode.

Note: If the reading is not close to the selected calibration point,

“WRONG” tag will blink. In this case, check if the value set on the

secondary LCD and the temperature measured with reference

thermometer are close. Change the DO probe or restart calibration

if necessary.

23

Page 24

PC INTERFACEPC INTERFACE

PC INTERFACE

PC INTERFACEPC INTERFACE

Data transmission from the instrument to the PC can be done with the

HI 92000 Windows® compatible software (optional). HI 92000 also

offers graphing and an on-line help feature.

Data can be exported to the most popular spreadsheet programs for

further analysis.

To connect your instrument to a PC, use a standard USB cable. Make

sure that your instrument is switched off and plug one connector to the

instrument’s USB socket and the other to the USB port of your PC.

Note: If you are not using Hanna Instruments HI 92000 software,

please see the following instructions.

SENDING COMMANDS FROM PC

It is also possible to remotely control the instrument with any terminal

program. Use a standard USB cable to connect the instrument to a PC,

start the terminal program and set the communication options as follows:

8, N, 1, no flow control, baud rate 9600.

COMMAND TYPES

To send a command to the instrument follow the next scheme:

<command prefix> <command> <CR>

where: <command prefix> is a selectable ASCII character

between 0 and 47 (default 16).

<command> is the command code.

Note: Either small or capital letters can be used.

SIMPLE COMMANDS

RNG Is equivalent to pressing RANGE

CAL Is equivalent to pressing CAL

CFM Is equivalent to pressing CFM

UPC Is equivalent to pressing the UP arrow key

DWC Is equivalent to pressing the DOWN arrow key

LOG Is equivalent to pressing LOG

RCL Is equivalent to pressing RCL

SET Is equivalent to pressing SETUP

24

Page 25

CHR xx Change the instrument range according with the parameter

value (xx):

• xx=06 % range

• xx=07 ppm range

The instrument will answer for these commands with:

<STX> <answer> <ETX>

where: <STX> is 02 ASCII code character (start of text)

<ETX> is 03 ASCII code character (end of text)

<answer>:

<ACK> is 06 ASCII code character (recognized command)

<NAK> is 21 ASCII code character (unrecognized command)

<CAN> is 24 ASCII code character (corrupted command)

COMMANDS REQUIRING AN ANSWER

The instrument will answer for these commands with:

<STX> <answer> <checksum> <ETX>

where the checksum is the bytes sum of the answer string sent as 2 ASCII

characters.

All the answer messages are with ASCII characters.

RAS Causes the instrument to send a complete set of readings.

The answer string contains:

• Meter mode (2 chars):

• 06 - % range

• 07 - ppm range

• Meter status (2 chars of status byte): represents a 8

bit hexadecimal encoding.

• 0x10 - temperature probe is connected

• 0x01 - new GLP data available

• 0x02 - new SETUP parameter

• Reading status (1 char): R - in range, O - over

range, U - under range.

• The reading (corresponding to the selected range) 7 ASCII chars, including sign and decimal point.

• Temperature reading - 7 ASCII chars, with sign and

two decimal points, always in ºC.

25

Page 26

MDR Requests the instrument model name and firmware code

(16 ASCII chars).

GLP Requests the calibration data record.

The answer string contains:

• GLP status (1 char): represents a 4 bit hexadecimal

encoding.

• 0x04 - DO calibration available

• DO calibration data (if available), which contains:

• the number of calibrated satandards (1 char)

• the calibration time, yymmddhhmmss (12 chars)

• standards information

• standard value, with sign and decimal point

(7 chars).

• the standard temperature, with sign and decimal

point (7 chars)

• the salinity value (4 chars)

• the altitude value (4 chars)

PAR Requests the setup parameters setting.

The answer string contains:

• Instrument ID (4 chars)

• SETUP information (2 chars): 8 bit hexadecimal

encoding.

• 0x01 - beep ON (else OFF)

• 0x04 - degrees Celsius (else degrees Fahrenheit)

• Log type - 01 to 12 - the coresponding interval for

lot log (5 s to 180 min)

• Salinity value (4 chars)

• Altitude value (4 chars)

LLsxff: requests information about all lots and it sends the information in

frames of 10 lots each (a frame contains information about 10 lots)

Command Parameters:

x = D - request DO data

ff - requested frame number - first frame is labeled 01

26

Page 27

GLDxxxfff:Requests the records of the “xxx” lot number. The records are

sent in frames of 10 records; “fff” is the frame number (01 first

frame). (Example: Lot 13 has 53 records. The records will be

sent in 6 frame, 5 with10 records and 1 with 3 records.)

Command Parameters:

xxx - Lot number (eq: for lot number 1 xxx = 001)

fff - requested frame number - first frame is labeled 01

Notes: • “Err3” is sent if the Log on demand is empty.

• “Err4” is sent if the requested set parameter is not available.

• “Err5” is sent if the command argument is wrong.

• “Err6” is sent if the requested range is not available.

• “Err7” is sent if the instrument is logging.

• “Err8” is sent if the instrument is not in measurement mode.

• Invalid commands will be ignored.

27

Page 28

PROBE & MEMBRANE MAINTENANCEPROBE & MEMBRANE MAINTENANCE

TWIST

AND

PULL

UNSCREW

fig.1

fig.2

PROBE & MEMBRANE MAINTENANCE

PROBE & MEMBRANE MAINTENANCEPROBE & MEMBRANE MAINTENANCE

The oxygen probe body is made of reinforced plastic for maximum

durability.

A thermistor temperature sensor provides temperature measurements of

the sample. Use the protective probe cap when not in use.

To replace the membrane or refill with electrolyte, proceed as follows:

• Remove the protective cap by gently

twisting and pulling it off the body of

the probe (see fig. 1).

• Unscrew the membrane cap by turning

it counterclockwise (see fig. 2).

• Wet the sensor by soaking the bottom

2½ cm (1") of the probe in electrolyte

(HI 7041S) for 5 minutes.

• Rinse the new membrane cap

(HI 76407A), supplied with the meter

with electrolyte solution while shaking

it gently. Refill with clean electrolyte

solution.

• Gently tap the sides of the membrane

cap with your finger tip to ensure that

no air bubbles remain trapped. Do not

tap directly the bottom with your finger,

as this will damage the membrane.

• Make sure that the rubber O-ring sits

properly inside the membrane cap.

• With the sensor facing down, slowly

screw the membrane cap clockwise.

Some electrolyte will overflow.

The Platinum cathode (#8 in the Functional

Description page 4) should always be bright

and untarnished. If it is tarnished or

stained, the cathode should be cleaned.

You can use a clean lint-free cardboard or

cloth. Rub the cathode very gently side to side 4-5 times. This will be

enough to polish and remove any stains without damaging the platinum

tip. Afterwards, rinse the probe with deionized or distilled water and

install a new membrane cap using fresh electrolyte and follow the steps

above. Recalibrate the instrument.

28

Page 29

SMOTPMYS MELBORP NOITULOS

puetautculfsgnidaeR

.)esion(nwoddna

toneveelseborpOD

.detresniylreporp

.eveelsehtresnI

ODswohsyalpsidehT

.gniknilbgnidaer

ODniegnarfotuO

.elacs

.retemehtetarbilaceR

noitulosehterusekaM

.egnardeificepsnisi

tonseodretemehT

ehterusaem

.erutarepmet

.eborpnekorB .eborpehtecalpeR

otsliafretemehT

sevigroetarbilac

.sgnidaerytluaf

.eborpnekorB .eborpehtecalpeR

retemehtputratstA

sgatDCLllasyalpsid

.yltnenamrep

sisyekehtfoenO

.dekcolb

rodraobyekehtkcehC

.rodnevehttcatnoc

" xxrrE egassemrorre"

.deyalpsid

.rorrelanretnI dnaretemehtfforewoP

ehtfI.notirewopneht

ehttcatnoc,stsisreprorre

.rodnev

LAC " dorP egassem"

.putratsta

yrotcaftontnemurtsnI

.detarbilac

lacinhceTannaHtcatnoC

yrotcafroftroppuS

.noitarbilac

Important

In order to have accurate and stable measurements, it is important that

the membrane surface is in perfect condition. This semipermeable

membrane isolates the sensor elements from the environment but allows

oxygen to enter. If any dirt is observed on the membrane, rinse carefully

with distilled or deionized water. If any imperfections still exist, or any

damage is evident (such as wrinkles or tears-holes), the membrane

should be replaced.

Make sure that the O-Ring sits properly in the membrane cap.

TROUBLESHOOTING GUIDETROUBLESHOOTING GUIDE

TROUBLESHOOTING GUIDE

TROUBLESHOOTING GUIDETROUBLESHOOTING GUIDE

29

Page 30

ACCESSORIESACCESSORIES

ACCESSORIES

ACCESSORIESACCESSORIES

HI 7040M Zero Oxygen Solution, 230 ml

HI 7040L Zero Oxygen Solution, 500 ml

HI 7041S Refilling Electrolyte Solution, 30 ml

HI 710005 115VAC to 12VDC converter

HI 710006 230VAC to 12VDC converter

HI 76407/2 Spare probe with 2 meters (6.7') cable

HI 76407/10 Spare probe with 10 meters (33') cable

HI 76407/20 Spare probe with 20 meters (67') cable

HI 76407A/P 5 spare membranes

HI 76404N Electrode holder

OTHER ACCESSORIES

HI 710005 Voltage adapter from 115 VAC to 12 VDC (USA plug)

HI 710006 Voltage adapter from 230 VAC to 12 VDC (European

plug)

HI 710012 Voltage adapter from 240 VAC to 12 VDC (UK plug)

HI 710013 Voltage adapter from 230 VAC to 12 VDC (South Africa

plug)

HI 710014 Voltage adapter from 230 VAC to 12 VDC (Australia

plug)

ChecktempC Pocket-size thermometer (range –50.0 to 150.0 ºC)

HI 76310 Platinum 4-ring conductivity/TDS probe with temperature

sensor and 1 m (3.3') cable

HI 92000 Windows® compatible software.

Windows® is registered Trademark of "Microsoft Co."

30

Page 31

RECOMMENDATIONS FOR USERS

Before using this product, make sure that it is entirely suitable for the

environment in which it is used.

Operation of this instrument in residential areas could cause unacceptable

interferences to radio and TV equipment, requiring the operator to follow

all necessary steps to correct interferences.

During operation, ESD wrist straps should be worn to avoid possible

damage to the electrode by electrostatic discharges.

Any variation introduced by the user to the supplied equipment may

degrade the instrument’s EMC performance.

To avoid electrical shock, do not use this instrument when voltages at the

measurement surface exceed 24 VAC or 60 VDC.

To avoid damage or burns, do not perform any measurement in

microwave ovens.

Hanna Instruments reserves the right to modify the design,

construction and appearance of its products without advance notice.

31

Page 32

Hanna Instruments Inc.

Highland Industrial Park

584 Park East Drive

Woonsocket, RI 02895 USA

Technical Support for Customers

Tel. (800) 426 6287

Fax (401) 765 7575

E-mail tech@hannainst.com

www.hannainst.com

Local Sales and Customer Service Office

Printed in EUROPE

(ROMANIA) MAN2400Y 07/10

32

Loading...

Loading...