Page 1

HANNA LITERATURE

Instruction Manual

Hanna publishes a wide range of catalogs and handbooks for an

equally wide range of applications. The reference literature currently covers areas such as:

• Water Treatment

• Process

• Agriculture

• Food

• Laboratory

• Thermometry

and many others. New reference material is constantly being

added to the library.

For these and others catalogs, handbooks and leaflets, contact

your dealer or the Hanna Customer Service Center nearest to you.

To find the Hanna Office in your vicinity, check our home page at

www.hannainst.com

HI 2400

Microprocessor

Dissolved Oxygen

Bench Meter

MANHI2400

06/03

www.hannainst.com

This instrument is in compliance with the CE directives

WWW.HANNAINST.COM

Page 2

Dear Customer,

Thank you for choosing a Hanna Instruments product.

Please read this instruction manual carefully before using the instrument.

This manual will provide you with all the necessary information for the correct

use of the instrument, as well as a precise idea of its versatility in a wide range

of applications.

This instrument is in compliance with directives.

TABLE OF CONTENTS

PRELIMINARY EXAMINATION ............................................................................................3

GENERAL DESCRIPTION ....................................................................................................3

FUNCTIONAL DESCRIPTION PROBE ..................................................................................4

FUNCTIONAL DESCRIPTION OF HI 2400 ..........................................................................5

SPECIFICATIONS OF HI 2400 ............................................................................................7

LCD FUNCTIONAL DESCRIPTION .......................................................................................8

OPERATIONAL GUIDE ........................................................................................................8

D.O. CALI BRATION ..........................................................................................................12

TEMPERATURE CALIBRATION.........................................................................................16

SETUP .............................................................................................................................17

TEMPERATURE COMPENSATION ....................................................................................26

LOGGING FUNCTION ......................................................................................................26

INTERFACE WITH PC ......................................................................................................29

PROBE & MEMBRANE MAINTENANCE ...........................................................................30

ADDITIONAL INFORMATION ...........................................................................................32

ACCESSORIES .................................................................................................................37

WARRANTY ....................................................................................................................38

CE DECLARATION OF CONFORMITY ..............................................................................39

CE DECLARATION OF CONFORMITY

All rights are reserved. Reproduction in whole or in part is prohibited

without the written consent of the copyright owner, Hanna Instruments

Inc., 584 Park East Drive, Woonsocket, Rhode Island, 02895 , USA.

Visit our Internet Home Page:

www.hannainst.com

2

Recommendations for Users

Before using this product, make sure that it is entirely suitable for the environment in which it is used.

Operation of this instrument in residential area could cause unacceptable interference to radio and TV equipment,

requiring the operator to take all necessary steps to correct interference.

The metal bands of the probe are sensitive to electrostatic discharges. Avoid touching these metal bands at all times.

To maintain the EMC performance of this equipment the recommended cables must be used.

Any variation introduced by the user to the supplied equipment may degrade the instruments EMC performance.

To avoid electrical shock, do not use this instrument when voltage at the measurement surface exceeds 24VAC or

60 VDC.

To avoid damages or burns, do not perform any measurement in microwave ovens.

39

Page 3

WARRANTY

PRELIMINARY EXAMINATION

All Hanna Instruments meters are warranted for two years against defects in

workmanship and materials when used for their intended purpose and maintained according to instructions. The electrodes and the probes are warranted

for a period of six months. This warranty is limited to repair or replacement free

of charge.

Damages due to accident, misuse, tampering or lack of prescribed maintenance are not covered.

If service is required, contact the dealer from whom you purchased the

instrument. If under warranty, report the model number, date of purchase,

serial number and the nature of the problem. If the repair is not covered by

the warranty, you will be notified of the charges to be incurred. If the

instrument is to be returned to Hanna Instruments, first obtain a Returned

Goods Authorization number from the Technical Service department and then

send it with shipping costs prepaid. When shipping any instrument, make

sure it is properly packaged for complete protection.

To validate your warranty, fill out and return the enclosed warranty card

within 14 days from the date of purchase.

Hanna Instruments reserves the right to modify the design, construction and appearance of its products without advance notice.

Remove the instrument from the packing material and examine it to make

sure that no damage has occurred during shipping. If there is any damage,

notify your Dealer.

Each HI2400 bench D.O. meter comes supplied complete with:

• HI 76407/2 D.O. probe with 2 m (6.7') cable

• HI 76407A membrane cap (2 pcs)

• HI 7041S electrolyte solution (30 ml)

• 12 VDC power adapter (HI 710005 or HI 710006)

Note: Save all packing material until you are sure that the instrument

functions correctly. All defective items must be returned in the original

packing with the supplied accessories.

GENERAL DESCRIPTION

HI 2400 is a microprocessor-based, logging bench meter for

Dissolved Oxygen measurements.

It can store in memory up to 99 lots with up to 8000 readings. These readings

can be transferred to a computer system for elaboration or permanent storage.

Dissolved Oxygen is indicated in ppm (parts per million) or in %.

Temperature is compensated for by the meter’s ATC circuitry. Salinity compen-

sation in water allows direct determination of Dissolved Oxygen in saline

waters and the altitude compensation readjusts for the altitude variance.

The Dissolved Oxygen probe has a membrane covering the polarographic

sensors and a built-in thermistor for temperature measurements and compensation.

This permeable Teflon®membrane isolates the sensor elements from the testing solution, but allows Oxygen to pass through. When a voltage is applied

across the sensor, oxygen that has passed through the membrane reacts

causing a current flow, and hence determining a reading.

Teflon®is registered Trademark of “Du Pont de Nemours & Co.”

38

3

Page 4

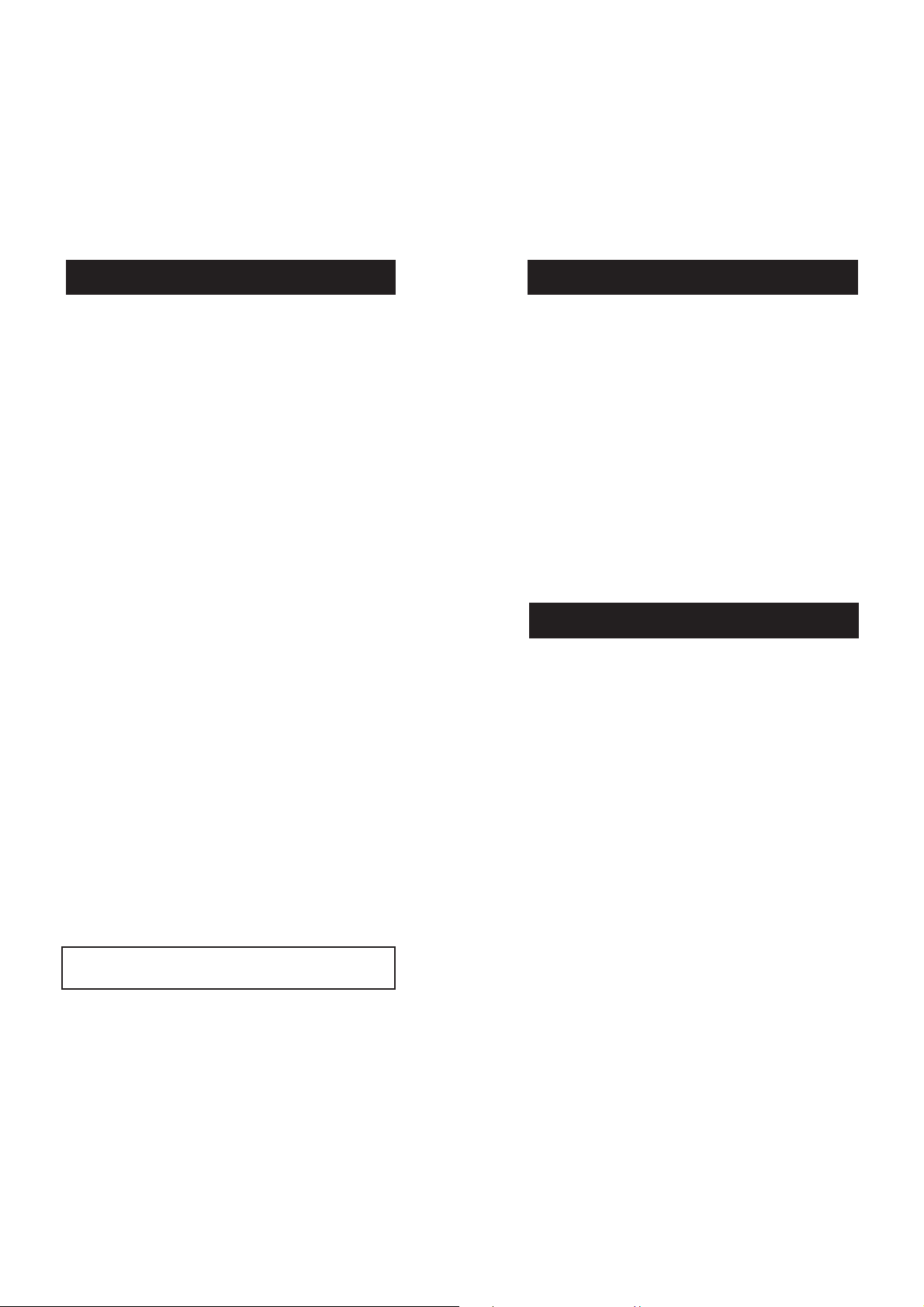

FUNCTIONAL DESCRIPTION PROBE

3

4

4

7

8

10

5

6

ACCESSORIES

ChecktempC Electronic thermometer (range: -50.0 to 150.0°C)

ChecktempF Electronic thermometer (range: -58.0 to 302°F)

HI 7040M Zero Oxygen Solution, 230ml

1

2

HI 7040L Zero Oxygen Solution, 460ml

HI 7041S Refilling Electrolyte Solution, 30ml

HI 710005 115VAC to 12VDC converter

HI 710006 230VAC to 12VDC converter

HI 76407/2 Spare probe with 2 meters (6.7') cable

HI 76407/10 Spare probe with 10 meters (33') cable

HI 76407/20 Spare probe with 20 meters (67') cable

HI 76407A/P 5 spare membranes

HI 92000/16 Windows® 3.11 compatible application software

HI 92000/32 Windows® 95 compatible application software

HI 920010 25-pin PC connection cable

HI 920010/9 9-pin PC connection cable

MANHI2400 Instruction manual

9

1. D.O. Probe

2. Protective Cap

3. Watertight Shielded Cable

4. Polypropylene Probe Body

5. Temperature Sensor

6. O-Ring Seal

7. Silver Chloride Anode

8. Platinum Cathode (sensor)

9. Oxygen Permeable Teflon® Membrane

10. Membrane Cap

Teflon is registered Trademark of “Du Pont de Nemours & Co.”

4

Windows is registered Trademark of “Microsoft Co.”

37

Page 5

sample no. 1

—— send ppm data if ppm is log selected

—— send % data if % is log selected

—— send temperature data if temperature is log selected

sample no. 2 ...

until the last sample

sample “XXX” is signed hex format.

15) last sample time, min. E.g. “59” for 59 minute

16) last sample time, hour. E.g. “12” for 12 hour

17) last sample time, day. E.g. “09” for 9th day

18) last sample time, month. E.g. “09” for September

19) last sample time, year. E.g. “96” for year 1996

20) etx end

The meter will send “Err6” if in a different measurement range.

Commands setting parameters:

/ML To select the data lot for data transfer.

E.g. send “/ML05” to select lot no. 5.

If the lot no. is valid, the meter will send <ACK>, otherwise it

will send <CAN>.

/BR To set the RS232C baud rate.

E.g. send “/BR0” to set the meter to baud rate of 150

send “/BR1” to set the meter to baud rate of 300

send “/BR2” to set the meter to baud rate of 600

send “/BR3” to set the meter to baud rate of 1200

send “/BR4” to set the meter to baud rate of 2400

send “/BR5” to set the meter to baud rate of 4800

send “/BR6” to set the meter to baud rate of 9600

/PF To set the RS232C command prefix.

E.g. send “/PF05” to set the command prefix to 05.

Note: <ACK> will be sent by the meter if the command received is ac-

cepted, otherwise it will send <CAN>.

<ACK> equals to ASCII code 06 and <CAN> equals to

ASCII code 24.

If sample data is out of range “07FFFH” is sent.

These commands may be sent with either capital or small letters. Invalid

commands will be ignored. The characters sent by the pH meter are always

capital letters.

36

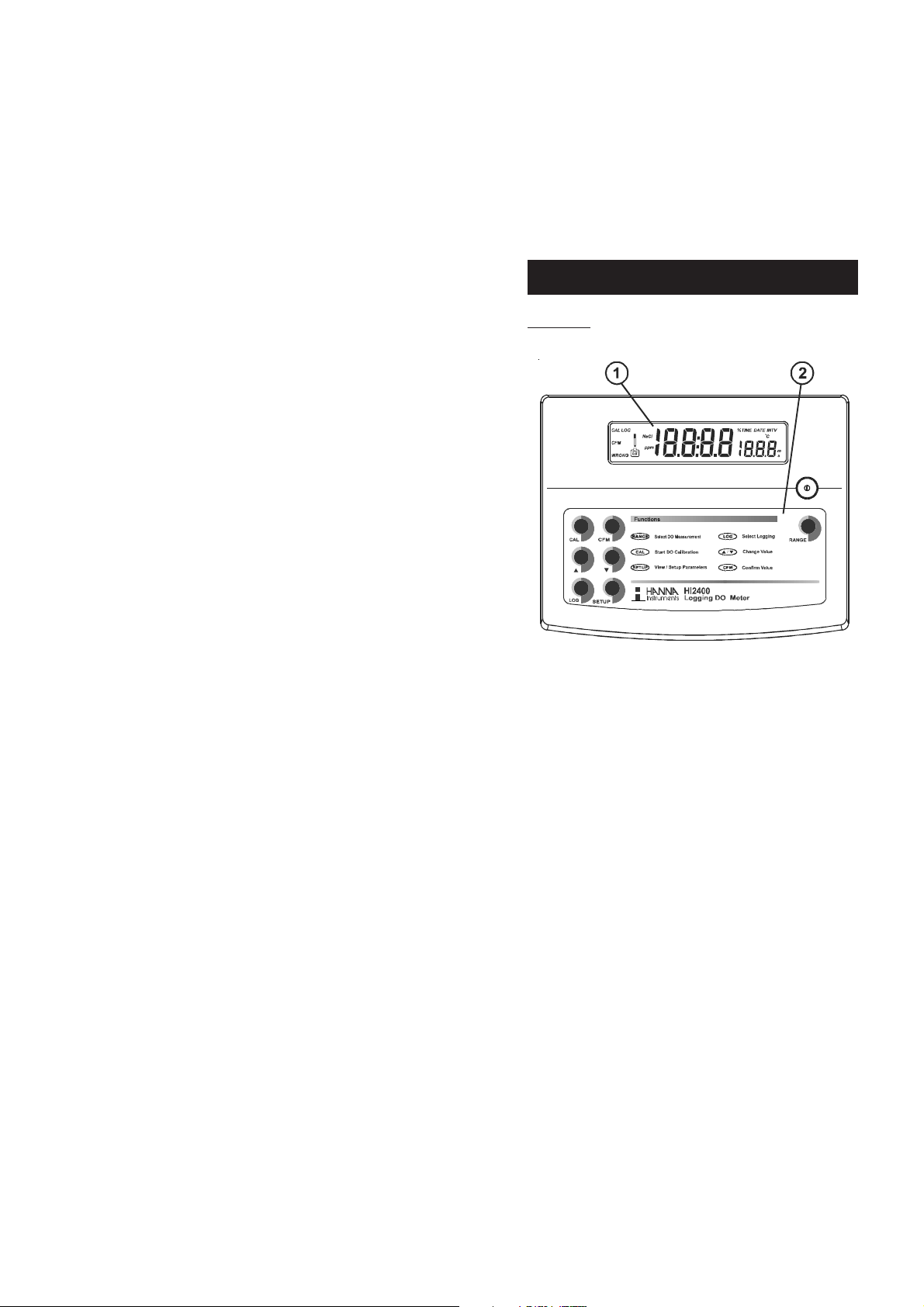

FUNCTIONAL DESCRIPTION OF HI 2400

Front Panel

1. Liquid Crystal Display

2. Keyboard:

CAL keyto enter or exit the calibration mode; to enter or exit setup

(change setting); to start or exit the D.O. logging mode

CFM key to confirm the calibration values and the set values

UP key to select the calibration value; to change menus in setup (view

settings) and to increase the setting values in setup (change setting)

DOWN key to select the calibration value; to change menus in setup (view

settings) and to decrease the setting values in setup (change setting)

LOG key to display the lot number on the primary LCD and the page

number on the secondary one

SETUP key to enter/exit the setup (view settings)

ON/OFF switch to turn the meter on or off

RANGE key to select dissolved oxygen measurement mode in ppm or in %.

5

Page 6

Rear Panel

1. Socket for D.O. Probe

2. Reset Button

3. RS 232C Connector

4. DC Power Socket (for HI 710005 or HI 710006)

19) etx end

?DM Requests the meter to send the selected lot data memory. The

data is sent in the following order:

1) stx

2) Lot number E.g. “01” for lot No. 1

3) Channel #1 status

E.g. “1” for ppm logging selected in this lot

“0” for ppm logging not selected in this lot

4) Channel #2 status

E.g. “1” for % logging selected in this lot

“0” for % logging not selected in this lot

5) Channel #3 status

E.g. “1” for not used “0” for not used

6) Channel #4 status

E.g. “1” for temperature logging selected in this lot

“0” for temperature logging not selected in this lot

7) begin sample time, min. E.g. “59” for 59 minute

8) begin sample time, hour E.g. “12” for 12 hour

9) begin sample time, day E.g. “09” for 9th day

10) begin sample time, month E.g. “09” for September

11) begin sample time, year

E.g. “96” for year 1996

12) logging interval

E.g.“0” for 1 second

“1” for 15 seconds

“2” for 30 seconds

“3” for 1 minu

“4” for 5 minutes

“5” for 30 minutes

“6” for 60 minutes

“7” for 120 minutes

“8” for 180 minutes

13) Total number of samples per lot

E.g. “1234” for total no. of samples: 1234.

14) Logged data in signed integer, repeat sending in logged

channel sequence

6

35

Page 7

8) ... Repeat from 2 to 7 for the next available lot No.

9) etx

?VM Requests the meter to send the selected lot status. The data is

sent in the following order:

1) stx

2) Lot number E.g. “01” for lot No. 1

3) Total number of samples per lot

E.g. “1234” for total no. of samples: 1234.

4) Channel #1 status

E.g. “1” for ppm logging selected in this lot

“0” for ppm logging not selected in this lot

5) Channel #2 status

E.g. “1” for % logging selected in this lot

“0” for % logging not selected in this lot

6) Channel #3 status

E.g. “1” for not used “0” for not used

7) Channel #4 status

E.g. “1” for temperature logging selected in this lot

“0” for temperature logging not selected in this lot

8) Begin sample time, min. E.g. “59” for 59 minutes

9) Begin sample time, hour. E.g. “12” for 12 hours

10) Begin sample time, day. E.g. “09” for the 9th day

11) Begin sample time, month. E.g. “09” for September

12) Begin sample time, year. E.g. “96” for year 1996

13) Logging interval. E.g. “0” for 1 second

“1” for 15 seconds

“2” for 30 seconds

“3” for 1 minute

“4” for 5 minutes

“5” for 30 minutes

“6” for 60 minutes

“7” for 120 minutes

“8” for 180 minutes

14) last sample time, min. E.g. “59” for 59 minute

15) last sample time, hour. E.g. “12” for 12 hour

16) last sample time, day. E.g. “09” for 9th day

17) last sample time, month. E.g. “09” for September

18) last sample time, year. E.g. “96” for year 1996

SPECIFICATIONS OF HI 2400

Ran ge D.O. ppm

D.O. %

Temp. ºC

Resolution D.O. ppm

D.O. %

Temp. ºC

Accuracy D.O.

Temp. ºC

Typical EMC Deviation D.O.

Temp. ºC

Calibration D.O.

Temp. ºC

Altitude Compensation

Resolution

Salinity Compensation

Resolution

Temperature Compensation

Probe

single or double point at 0%

(HI 7040) and 100% (in air)

0.00 to 45.00

0.0 to 300.0

0.0 to 50.0

0.01

0.1

0.1

±1.5% of full scale

±0 . 5

±1.5% of full scale

±0 . 5

single point or double point

at 0.0ºC and/or 50.0ºC

0 to 4,000 m (13,120')

100 m (328')

0 to 40 g/l

1 g/l

0.0 to 50.0ºC

(32 to 122ºF)

HI 76407/2 with

2 meters (6.7") cable

1, 15, 30 seconds

34

7

Page 8

Commands requiring an answer:

Environment 0 to 50ºC (32 to 122ºF);

95% RH

Dimensions 240x182x74 mm

(9.4x7. 1x2. 9")

Wei ght 1.2 kg (2.7 lb.)

Response time The response time is approximately 20 seconds for a

95% reading at a constant temperature of 25ºC.

The response time for low oxygen readings or at low temperature is

approximately 40 seconds. Allow more time to obtain more accurate

readi ngs.l

LCD FUNCTIONAL DESCRIPTION

PRIMARY DISPLAY

SECONDARY DISPLAY

OPERATIONAL GUIDE

POWER CONNECTION

Plug the 12 VDC adapter into the meter.

HI 2400 uses an EEPROM to retain the D.O. calibration and temperature

calibration as well as the serial communication setting. The instrument will

store the respective data after a calibration or serial communication setting,

even when it is not pluggedin.

DO? Causes the meter to send the D.O. (% or ppm will depend on the

meter setting). If the reading is out of range “Err 1” is sent.

TM? Causes the meter to send the temperature value. If the reading

is out of range “Err 3” is sent.

DA? Requests the meter to send the date

E.g. “022896” for 28th Feb. 96

TI? Requests the meter to send the time.

E.g.

“233001” for 23:30 hr, 1 sec. as interval

“233002” for 23:30 hr, 15 sec. as interval

“233003” for 23:30 hr, 30 sec. as interval

“233004” for 23:30 hr, 1 min. as interval

“233005” for 23:30 hr, 5 min. as interval

“233006” for 23:30 hr, 30 min. as interval

“233007” for 23:30 hr, 60 min. as interval

“233008” for 23:30 hr, 120 min. as interval

“233009” for 23:30 hr, 180 min. as interval

?ML Requests the meter to send the available lot number collected in

memory. The transmission begins with <STX> and terminates

with <ETX>. The data are sent in the following order:

1) stx

2) Lot number

E.g. “01” for lot No. 1

3) Total number of samples per lot

E.g. “1234” for total no. of samples: 1234.

4) Channel #1 status

E.g. “1” for ppm logging selected in this lot

“0” for ppm logging not selected in this lot

5) Channel #2 status

E.g. “1” for % logging selected in this lot

“0” for % logging not selected in this lot

6) Channel #3 status

E.g. “1” for not used “0” for not used

7) Channel #4 status

E.g. “1” for temperature logging selected in this lot

“0” for temperature logging not selected in this lot

8

33

Page 9

Shipping

F

ADDITIONAL INFORMATION

If you are not using Hanna Instruments HI 92000 application software,

please find below some additional information to help your connection to the

PC.

SENDING COMMANDS FROM PC

With terminal programs such as Telix® and Windows Terminal®, it is possible

to remotely control your HI 2400. Use HI 920010 cable to connect the meter

to the PC, start the terminal program and set the communication options as

follows: 8, N, 1, no flow control.

Command Types

To send a command to the D.O. meter the scheme is:

<DLE> <command> <CR>

This line makes the computer send a Data Link Escape character, the command expressed as a number or a 3-character sequence and a CR character.

Note: Windows Terminal® and all the other terminal programs that support

the ANSI escape sequence, represent the DLE character by the string

‘^P’ and the CR character by the string ‘^M’. E.g. the line

‘^PPPM^M’ sets the range to ppm.

Commands not requiring an answer from the meter:

PPM sets the range to ppm D.O.

PER sets the range to % D.O.

PROBE CONNECTION & PREPARATION

To prepare the instrument for use, connect the D.O. probe to the meter

securely by aligning the pins with the socket located on the back of the meter,

pushing the plug in and tightening the threaded ring.

Probes shipped from Hanna Instruments are dry. To hydrate the probe and

prepare it for use, connect it to the meter and proceed as follows:

1. Remove the red and black plastic cap. This cap is

for shipping purposes and can be thrown away.

cap

2. Wet the sensor by soaking the bottom 2½ cm (1")

of the probe in electrolyte (HI 7041S) for 5 minutes.

black

3. Rinse the membrane cap (HI 76407A supplied in

the kit with the meter) with electrolyte solution

red

while shaking it gently. Refill with clean electrolyte

solution.

4. Gently tap the sides of the membrane cap

with your finger tip to ensure that no air

bubbles remain trapped. To avoid damaging the membrane, do not tap the mem-

ILL FIRST

brane directly on the bottom.

5. Make sure that the rubber O-ring sits prop-

THEN TAP

erly inside the membrane cap.

6. With the sensor facing down, slowly screw

the cap clockwise. Some electrolyte will overflow.

THEN SCREW

BACK ON

When not in use and during polarization (see page 10),

use the protective transparent cap supplied in the kit with

the meter.

TELIX® is registered Trademark of “Deltacomm”

Windows Terminal® are registered Trademark of “Microsoft Co.”

32

9

Page 10

TURNING THE METER ON

To switch the meter on, press the ON/OFF switch key

and leave the probe in the auto-conditioning (polarization) mode before proceeding. After approximately

5 minutes, the instrument can be calibrated (see

page 12).

If the probe is disconnected, the meter will display “----”.

This also indicates the possibility of a broken probe cable.

PROBE POLARIZATION

The probe is under polarization with a fixed voltage of approximately 800 mV.

Probe polarization is essential for stable measurements with the same recur-

ring degree of accuracy.

With the probe properly polarized, oxygen is continually “consumed” when it

passes through the sensitive diaphragm and dissolves in the electrolyte solution contained in the probe.

If polarization is interrupted, the electrolyte solution continues to be enriched

with oxygen until it reaches an equilibrium with the surrounding solution.

Whenever measurements are taken with a non-polarized probe, the oxygen

level revealed is both that of the tested solution as well as that present in the

electrolyte solution. This reading is incorrect.

The calibration of this instrument is very simple.

Before proceeding with the calibration, make sure the probe is ready for

measurements (see page 9), i.e. the membrane cap is filled with electrolyte

and the probe is connected to the meter and properly polarized.

For an accurate calibration, it is recommended to wait at least 15 minutes to

ensure precise conditioning of the probe.

Keep the protective cap on during the polarization time and remove it for the

calibration and the measurements.

Follow the calibration procedure on page 12.

The Platinum cathode (#8 in the Functional Descripti on page 4)

should always be bright and untarnished. If it is tarnished or stained,

the cathode should be cleaned. You can use a clean lint-free cardboard

or cloth. Rub the cathode very gently side to side 4-5 times. This will

be enough to polish and remove any stains without damaging the

platinum tip. Afterwards, rinse the probe with deionized or distilled

water and install a new membrane cap using fresh electrolyte and

follow the steps above. Re-calibrate the instrument.

Important

In order to have accurate and stable measurements, it is important

that the surface of the membrane is in perfect condition. This semipermeable membrane isolates the sensor elements from the environment

but allows oxygen to enter. If any dirt is observed on the membrane,

rinse carefully with distilled or deionized water. If any imperfections still

exist, or any damage is evident (such as wrinkles or tears-holes), the

membrane should be replaced.

Make sure that the O-Ring sits properly in the membrane cap.

10

31

Page 11

PROBE & MEMBRANE MAINTENANCE

The oxygen probe body is made of reinforced plastic for maximum durability.

A thermistor temperature sensor provides temperature measurements of the

sample. Use the protective probe cap when not in use.

To replace the membrane or refill with electrolyte, proceed as follows:

• Remove the protective cap by gently twisting

and pulling it off the body of the probe (see

fig. 1).

• Unscrew the membrane cap by turning it counterclockwise (see fig.2).

• Wet the sensor by soaking the bottom 2½

cm (1") of the probe in electrolyte (HI 7041S)

for 5 minutes.

• Rinse the new membrane cap (HI 76407A)

supplied with the meter with electrolyte solution while shaking it gently. Refill with clean

electrolyte solution.

• Gently tap the sides of the membrane cap

with your finger tip to ensure that no air

bubbles remain trapped. Do not directly tap

the bottom with your finger as this will damage the membrane.

• Make sure that the rubber O-ringsits properly inside the membrane cap.

• With the sensor facing down, slowly screw the

membrane cap clockwise. Some electrolyte will

overflow.

TWIST

AND

PULL

fig. 1

D.O. MEASUREMENTS (in ppm or %)

Make sure the meter has been calibrated (see page 12) and the protective cap

has been removed.

Salinity and Altitude compensation

If the sample contains significant concentration of salinity or if you are performing measurements at an altitude different from sea level, the readout values

must be corrected, taking into account the lower degree of oxygen solubility in

these situations as explained on pages 18-20.

Remember to set the altitude and/or the salinity before taking any D.O.

measurements. The meter will automatically compensate for these factors.

Taking measurements

Immerse the tip of the probe in the sample to be

tested. Make sure the temperature sensor is also

immersed.

Press the RANGE key to display D.O. measurements. Allow approximately one minute for the

meter to stabilize and read the ppm value of

Dissolved Oxygen on the display.

Press the RANGE key to change the reading from ppm to % and vice-versa.

UNSCREW

fig. 2

For accurate Dissolved Oxygen measurements, a water movement of 0.3 m/sec

is required at a minimum. This is to ensure that the oxygen-depleted membrane surface is constantly replenished. A moving stream will provide adequate circulation.

30

11

Page 12

The use of a magnetic stirrer to ensure a certain velocity of the fluid is

recommended.

Always allow a few minutes for thermal equilibrium to occur

between the probe and the measurement sample.

TAKING TEMPERATURE MEASUREMENTS

The probe has a built-in temperature sensor.

The measured temperature is indicated on the secondary display.

Allow the probe to reach thermal equilibrium before taking any measurement.

Reaching thermal equilibrium can take several minutes. The greater the

difference between the temperature at which the probe was stored and the

temperature of the sample, the longer the time will be.

If “----” is displayed, it indicates that the D.O. probe is not properly connected

or the temperature is out of range. This also indicates the possibility of a

broken probe cable.

D.O. CALIBRATION

For greatest accuracy, it is recommended that the instrument is calibrated

frequently.

The standard calibration program of the meter is prepared for 2 (maximum)

values: 0.0% (zero calibration) and 100.0% (slope calibration).

The next logging will start from page 16.

INTERFACE WITH PC

Data transmission from the instrument to a PC is now much easier with the

new HI 92000 Windows® compatible software (optional).

User friendly, HI 92000 offers a variety of features and has on line help to

support you throughout all situations.

HI 92000 allows you to use the powerful means of the most popular spread

sheet programs (e.g. Excel©, Lotus 1-2-3©). Simply run your favorite spread

sheet and open the file downloaded by HI 92000. It is then possible to make

any elaboration available with your software (e.g. graphics, statistical analysis).

To install HI 92000 you need a 3.5" drive and few minutes to follow the

instructions conveniently printed on the disk’s label.

To connect your HI 2400 to a PC, use HI9 20010, available through your

Hanna Dealer. Make sure that your meter is switched off and plug the

connectors, one into the meter RS232C connector, the other into the serial port

of your PC.

Note: Cables different from the HI 920010 may use a different configuration.

In such case any communication between the meter and the PC is not

possible.

Windows® and Windows Terminal

Excel© Copyright of “Microsoft Co.”

Lotus 1-2-3© Copyright of “Lotus Co.”

12

®

are registered Trademark of “Microsoft Co.”

29

Page 13

Note: If the ON/OFF switch is pressed while

logging, the meter will stop the logging

first and then will turn off.

MEMORY ORGANIZATION

The meter is equipped with a stability indicator and the user will be guided

step by step with symbols on the display during the D.O. calibration. This will

make the calibration a simple and error-free procedure.

The zero calibration of the HI 2400 is very stable, therefore this procedure

needs only to be performed whenever the probe or the membrane is

replaced.

However, because the slope calibration is more critical, it is recommended

to perform this procedure every week.

The memory used for storing the logged data is divided into 16 pages. The

capacity of each page is 500 samples. It starts to log from page 16 downwards

until 1 and then 16 again, overwriting the previous data. However, when

this happens the LCD will show page “0”, indicating overwriting has occurred.

Each time a new logging period starts, it automatically starts from a new

page.

When the samples collected for a single lot are more than the limit (8000

samples) the meter will stop logging automatically.

TO CLEAR LOGGED DATA

The entire logged data can be cleared by pressing the ON/OFF switch and the

LOG key simultaneously.

INITIAL PREPARATION

• Pour small quantities of HI 7040 Zero Oxygen

solution into a beaker. If possible, use a plastic

beaker to minimize any EMC interferences.

• Make sure the probe is ready for measurements

(see initial preparation at page 9), i.e. the membrane is filled with electrolyte and the probe is

connected to the meter.

• Switch the meter on by pressing the ON/OFF switch.

• For an accurate calibration, it is recommended to

wait for at least 15 minutes to ensure precise conditioning of the probe.

• Remove the protective cap from the D.O. probe.

• Set the appropriate altitude factor (see page 19).

Make sure the salinity factor is set to zero (see page

18).

ZERO CALIBRATION

• Dip the probe into HI 7040 zero oxygen solution

and stir gently for 2-3 minutes.

HI 7040

HI 7040

The choice has to be confirmed by pressing the CFM key.

28

13

Page 14

• Press the CAL key and the “~” indicator will blink until the reading is

stable.

• As soon as the reading is stable, the “CFM” indicator will start blinking.

Press the CFM key to confirm the “0.0%” D.O. reading.

• If the reading is not close to the selected value,“WRONG “ and

“WRONG ” will blink alternatively.

• If the reading is within the margins (±15%), the meter stores the value

(and adjusts the offset point). The meter will then proceed with the next

calibration point.

• Press the CAL key and the calibration process

is ended with only the zero of the calibrated

meter. For a two-point calibration do not press

the CAL key and follow the procedure below.

During logging, you can check some information about the logged data.

Press the LOG key to display the current sample number (the number of

readings that have been stored in the current lot).

Press the RANGE key to display the measurement reading during the logging

mode.

Press the LOG key again and the primary LCD will show the current lot

number and the secondary LCD will display the current page number.

TO STOP LOGGING

To stop logging press the LOG and then CAL key.

SLOPE CALIBRATION

It is suggested to perform the slope calibration in air.

• Rinse the probe in clean water to remove any residual zero oxygen

solution.

Note: If you did not perform the zero calibration procedure, press the CAL key

and then the UP key to select the 100% calibration value.

14

The display will show the next lot number.

27

Page 15

TEMPERATURE COMPENSATION

The D.O. probe has a built-in sensor for temperature so that the D.O.

readings are automatically compensated for temperature effects.

LOGGING FUNCTION

This function allows the user to log D.O. (in ppm or %) together with the

temperature automatically for long periods of time. All logged data can be

stored into a PC through the RS232C port.

The lot number goes from 1 to 99 and then back to #1. The maximum

capacity per lot is 8000 samples.

Set the appropriate logging interval (see page12). Select between 1, 15, 30

seconds or 1, 5, 30, 60, 120, 180 minutes.

Press the RANGE key first (to select D.O. readings in ppm or in %), then press the LOG and

then CAL key to enter the logging mode.

• Dry the probe tip and allow a few minutes for the LCD readout to stabilize.

The “~” indicator will blink until the reading is stable.

As soon as the reading is stable, the “CFM” indicator will start blinking. Press

the CFM key to confirm the “100.0%” D.O. reading.

• If the reading is not close to the selected value,“WRONG “ and

“WRONG ” will blink alternatively.

Once in the logging mode, the interval cannot be changed.

Exit the logging mode first (by pressing the LOG and then CAL key) before

setting a new interval.

• If the reading is within the margins (±15%), the meter stores the value

(and adjusts the slope point). The calibration is ended and the meter will

then revert to the normal measurement mode.

Note: HI 2400 has automatic buffer recognition function. Press the UP or

DOWN arrow keys to select the desired calibration value, but if these

keys are pressed, the automatic buffer recognition function is disabled.

1526

Page 16

Press the CAL key at any time to exit the calibration

mode.

TEMPERATURE CALIBRATION

Each meter has been factory calibrated for the temperature with the D.O.

probe supplied and is ready for measurements.

The D.O. probes are interchangeable and no temperature calibration is

needed.

If the temperature measurements are not accurate, the temperature recalibration should be carried out.

For an accurate re-calibration, contact your nearest Hanna Service Center or

follow the procedure below (for technical personnel only).

INITIAL PREPARATION

• Prepare a beaker containing ice(at 0.0°C/32°F) and water and another

one containing hot water (at a temperature of 50.0°C/122°F). Place insulation

material around the container to minimize temperature changes.

• Use a ChecktempC or a calibrated thermometer with a resolution of 0.1°C as a

reference thermometer.

Setting the Buzzer Status

In the View Settings Mode, press the UP or DOWN arrow keys to display the

buzzer status; ON is the factory setting.

Press the CAL key to enter the change setting mode, the buzzer status will

start blinking.

Select the buzzer status (ON or CLR) by pressing the UP or DOWN arrow keys.

PROCEDURE

• Switch the meter on while pressing the CAL key. The “CAL” indicator will

be lit. The secondary LCD section will show “0.0°C”.

16 25

Press the CFM key to confirm the buzzer status.

RESET BUTTON

The RESET button is used when the instrument displays erroneous messages

due to strong electrical interference or when the instrument’s power supply

was disconnected before the meter was switched off.

It is necessary to press the RESET button and restart the entire operation.

Calibration points should remain memorized. It is recommended to verify

calibration before proceeding.

Page 17

The following baud rate can be selected through the UP or DOWN arrow keys:

150, 300, 600, 1200 (factory setting), 2400, 4800 and 9600.

Press the CFM key to confirm the baud rate setting.

Setting the Command Prefix

In the View Settings Mode, press the UP or DOWN arrow keys to display the

command prefix; 16 is the factory setting.

Press the CAL key to enter the change setting mode, the command prefix will

start blinking.

Select a different command prefix (between 0 to 47 decimal) by pressing the

UP or DOWN arrow keys.

• Immerse the D.O. probe in the vessel

with the ice and water.

• Wait for about 30 seconds until the

“CFM” indicator starts blinking. Press

the CFM key. The secondary LCD section will show “50.0°C”.

• Immerse the D.O. probe in the vessel with

hot water.

• Wait for about 30 seconds until the “CFM”

indicator starts blinking. Press the CFM key.

• The temperature calibration procedure is

now completed.

SETUP

Press the CFM key to confirm the command prefix

setting.

Note: The Command Prefix does not have to be changed using HI 92000

Hanna software.

Setup is used to view or change the instrument parameters. To enter in View

Settings press the SETUP key when the meter is in measurement mode.

View Setttings

By pressing the UP or DOWN arrow keys you can view the setting values for

the following parameters:

1724

Page 18

• Salinity Compensation

• Altitude Compensation

• Log Interval

• Time

• Date

• Baud Rate

• Command Prefix

• Buzzer Status

If you press the SETUP key anytime in theView Settings Mode the device will

enter the measurement mode.

CHANGE SETTINGS

Press the CFM key, the day starts blinking.

Use the UP or DOWN arrow keys to select the day.

To modify a parameter from the setup menu press the CAL key. You will enter

the Change Settings Mode.

If you don’t want to change the parameter press the CAL key. The setting

value will revert to the previously memorized value and the device will return

to the View Settings.

Setting the Salinity Compensation

In the View Settings Mode, press the UP or DOWN arrow keys to display the

salinity factor.

Press CAL to enter the change setting mode, the salinity factor will start

blinking.

Use the UP and DOWN arrow keys to set the

salinity between 0 and 40 g/l.

Press the CFM key to confirm the salinity factor.

Press the CFM key and the year on the secondary LCD will blink.

Use the UP or DOWN arrow keys to select the year.

Press the CFM key to confirm the date setting.

Setting the Baud Rate

In the View Settings Mode, press the UP or DOWN arrow keys to display the

baud rate.

The transmission speed (baud rate) of your HI2400 and of the external device

must be the same.

Press the CAL key to enter the change setting mode, the baud rate will start

blinking.

18 23

Page 19

4

0

6

2

8

4

0

Use the UP and DOWN arrow keys to set the hour.

Press the CFM key and the minutes will start blinking.

Use the UP or DOWN arrow keys to select the minutes.

Press the CFM key to confirm the time setting.

Setting the Date

In the View Settings Mode, press the UP or DOWN arrow keys to display the

date. The month and the day will be displayed on the primary LCD, the year

on the secondary one.

Press the CAL key to enter the change setting mode, the month will start

blinking.

The salinity affects the D.O. concentration, decreasing its value. Below is a

table showing the maximum solubility of oxygen at various temperatures and

salinity levels.

S alinity (g/l) at Sea L eve l

ºC

0 g/l 10 g/l 20 g/l 30 g/l 35 g/l

0 14.6 13.6 12.7 11.9 11.5 32.0

2 13.8 12.9 12.1 11.3 10.9 36.5

4 13.1 12.3 11.5 10.7 10.4 39.2

6 12.4 11.7 10.9 10.2 9.9 42.8

8 11.8 11.1 10.4 9.8 9.4 46.4

10 11.3 10.6 9.9 9.3 9.0 50.0

12 10.8 10.1 9.5 8.9 8.6 53.6

14 10.3 9.7 9.1 8.6 8.3 57.2

16 9.9 9.3 8.7 8.2 8.0 60.8

18 9.5 8.9 8.4 7.9 7.6 64.4

20 9.1 8.5 8.0 7.6 7.4 68.0

22 8.7 8.2 7.8 7.3 7.1 71.6

24 8.4 7.9 7.5 7.1 6.9 75.2

26 8.1 7.6 7.2 6.8 6.6 78.8

28 7.8 7.4 7.0 6.6 6.4 82.4

30 7.5 7.1 6.8 6.4 6.2 86.0

32 7.3 6.9 6.5 6.2 6.0 89.6

34 7.1 6.7 6.3 6.0 5.9 93.2

36 6.8 6.5 6.1 5.8 5.7 96.8

38 6.6 6.3 6.0 5.7 5.5 100.

40 6.4 6.1 5.8 5.5 5.4 104.

42 6.2 5.9 5.6 5.3 5.2 107.

44 6.0 5.8 5.5 5.2 5.1 111.

46 5.9 5.6 5.3 5.1 5.0 114.

48 5.7 5.5 5.2 4.9 4.9 118.

50 5.5 5.3 5.1 4.8 4.7 122.

ºF

Setting the Altitude Compensation

In the View Settings Mode, press the UP or DOWN arrow keys to display the

altitude factor.

Press the CAL key to enter the change setting mode, the altitude factor will

start blinking.

Use the UP or DOWN arrow keys to select the month.

Use the UP and the DOWN arrow keys to set the altitude between 0 and

4000 m, in steps of 100 m (1 meter = 3.28 feet).

1922

Page 20

ºC

300m600m900m1200m1500m1800m2100m2400m2700m3000m3300m3600m4000

0 m

0 14 .6 14.1 13.6 13. 2 1 2.7 12. 3 11 .8 10. 9 10.2 9.4 8 .7 8. 1 7.6 6.6 32.0

2 13.8 13.3 12.9 12.4 12.0 11.6 11.2 10.3 9.6 8.9 8.2 7.7 7.1 6.3 35.6

4 13.1 12.7 12.2 11.9 11.4 11.0 10.6 9.8 9.1 8.5 7.8 7.3 6.7 6.0 39.2

6 12 .4 12.0 11.6 11. 2 1 0.8 10. 4 10.1 9.3 8.6 8.0 7.4 6.9 6.4 5.7 42.8

8 11 .8 11.4 11.0 10. 6 1 0.3 9.9 9 .6 8.8 8.2 7.6 7.1 6.5 6.1 5.4 46.4

Altitude, Meters above S ea L evel

m

Press the CFM key to confirm the altitude factor.

ºF

The altitude affects D.O. concentration decreasing its value. The table on the

previous page reports the maximum oxygen solubility at various temperatures

and altitudes.

Setting the Logging Interval

10 11.3 10. 9 10.5 10.2 9.8 9 .5 9.2 8.4 7.8 7.3 6.8 6.3 5. 8 5. 1 5 0.0

12 10.8 10.4 10.1 9.7 9.4 9.1 8.8 8.1 7.5 7.0 6.4 6.0 5.6 4.9 53.6

14 10.3 9.9 9.6 9. 3 9. 0 8.7 8.3 7.7 7. 2 6.6 6.2 5.7 5.3 4.7 57.2

16 9.9 9.7 9.2 8.9 8.6 8.3 8.0 7.4 6.9 6.4 5.9 5.5 5.1 4.5 60.8

18 9.5 9.2 8.7 8.6 8.3 8.0 7.7 7.1 6.6 6.1 5.7 5.3 4.9 4.3 64.4

20 9.1 8.8 8.5 8.2 7.9 7.7 7.4 6. 8 6.3 5.9 5.5 5.1 4.7 4.1 68.0

22 8.7 8.4 8. 1 7.8 7.7 7.3 7. 1 6.5 6.0 5.6 5.3 4.9 4.5 4.0 71.6

24 8.4 8.1 7.8 7.5 7.3 7.1 6.8 6.3 5.8 5.5 5.1 4.7 4.4 3.8 75.2

26 8.1 7.8 7.5 7.3 7.0 6.8 6.6 6. 0 5.7 5.2 4.8 4. 5 4. 2 3.7 7 8.8

28 7.8 7.5 7.3 7.0 6.8 6.6 6.3 5.9 5.4 5.0 4.7 4.3 4.0 3.6 82.4

30 7 .5 7.2 7.0 6.8 6.5 6.3 6. 1 5. 7 5.2 4.9 4.6 4.2 3. 9 3.5 86. 0

32 7.3 7.1 6.8 6.6 6.4 6.1 5.9 5.5 5.1 4.7 4.4 4.1 3.8 3.3 89.6

34 7.1 6.9 6.6 6.4 6.2 6.0 5.8 5. 3 4.9 4.6 4.2 3.9 3. 7 3.2 93. 2

36 6.8 6.6 6.3 6.1 5.9 5.7 5.5 5.1 4.8 4.5 4.1 3.8 3.5 3.1 96.8

38 6.6 6.4 6.2 5.9 5.7 5.6 5.4 5. 0 4.6 4.3 4.0 3.7 3.5 3.0 100.4

In the View Settings Mode, press the UP or DOWN arrow keys to display the

logging interval.

Press the CAL key to enter the change setting mode, the logging interval will

start blinking.

Use the UP and the DOWN arrow keys to set the logging interval between 1,

15, 30 seconds, or 1, 2, 5, 15, 30, 60, 120, 180

minutes.

Press the CFM key to confirm the setting.

Setting the Time

In the View Settings Mode, press the UP or DOWN arrow keys to display the

time.

Press the CAL key to enter the change setting mode, the hour will start

blinking.

20 21

Loading...

Loading...