Page 1

Instruction Manual

HI 222

pH/mV/ºC

Bench Meter

with Calibration Check

P

O

O

R

G

O

O

D

S

L

O

W

FA

S

T

C

A

L

C

C

L

O

G

R

C

L

CFM

GLP

SET

/CLR

CFM

/GLP

F

u

n

ctio

n

s

RANGE

S

e

lec

t

pH

LOG

/O

S

to

re

L

og

RCL

In

form

R

e

ca

ll

Lo

g

In

S

e

fo

tIn

rm

C

stru

a

le

tio

ar

m

L

e

og

n

t

/C

P

a

a

ram

lIn

S

h

o

fo

eters

w

rm

G

atio

L

P

Info

rm

ation

HI 222 Calibration Check

M

icroprocessor

R

P

p

H

C

a

CAL

tio

n

S

/

n

S

elec

CFM

C

n

o

n

firm

/

S

elec

n

d

t

2

CFM

B

u

C

on

firm

n

d

2

B

uffer

pH

M

eter

p

H

AT

C

C

a

lib

ratio

n

tart

C

a

lib

ration

s

t

t1

B

uffer

s

R

t

A

1

N

B

G

uffer

E

ffer

SET

CLR

Manufacturer since 1978

www.hannainst.com

1

Page 2

Dear Customer,

Thank you for choosing a Hanna Instruments product.

Please read this instruction manual carefully before using the instrument.

This manual will provide you with the necessary information for correct use of

the instrument, as well as a precise idea of its versatility.

For additional technical information, do not hesitate to e-mail us at

tech@hannainst.com or refer to back cover for our worldwide contact list.

This instrument is in compliance with the directives.

WARRANTY

HI 222 is guaranteed for two years against defects in workmanship and

materials when used for their intended purpose and maintained according to

instructions. Electrodes and probes are guaranteed for a period of six months.

This warranty is limited to repair or replacement free of charge.

Damage due to accidents, misuse, tampering or lack of prescribed maintenance are not covered.

If service is required, contact the dealer from whom you purchased the

instrument. If under warranty, report the model number, date of purchase,

serial number and the nature of the problem. If the repair is not covered by

the warranty, you will be notified of the charges incurred. If the instrument is

to be returned to Hanna Instruments, first obtain a Returned Goods Authorization number from the Technical Service department and then send it with

shipping costs prepaid. When shipping any instrument, make sure it is

properly packaged for complete protection.

TABLE OF CONTENTS

PRELIMINARY EXAMINATION ........................................................................................... 3

GENERAL DESCRIPTION.................................................................................................... 3

FUNCTIONAL DESCRIPTION ............................................................................................. 4

HI 222 SPECIFICATIONS .................................................................................................. 5

OPERATIONAL GUIDE ....................................................................................................... 6

pH CALIBRATION ................................................................................................................ 8

ENHANCED CALIBRATION MESSAGES ....................................................................11

ELECTRODE CONDITION AND RESPONSE TIME ............................................................13

GOOD LABORATORY PRACTICE (GLP) .........................................................................14

LOGGING .........................................................................................................................17

SETUP ............................................................................................................................ 21

TEMPERATURE CALIBRATION (for technical personnel only) .............................. 25

mV CALIBRATION (for technical personnel only) .................................................. 27

PC INTERFACE ............................................................................................................... 28

pH VALUES AT DIFFERENT TEMPERATURES .................................................................... 30

ELECTRODE CONDITIONING & MAINTENANCE .............................................................. 31

TROUBLESHOOTING GUIDE .......................................................................................... 33

TEMPERATURE CORRELATION FOR pH SENSITIVE GLASS ............................................35

ACCESSORIES ................................................................................................................ 36

2

Page 3

PRELIMINARY EXAMINATION

Remove the instrument from the packing material and examine it carefully to

make sure that no damage has occurred during shipping. If there is any

damage, notify your Dealer or the nearest Hanna Customer Service Center.

Each instrument is supplied complete with:

• HI 1048P Glass-body pH Electrode with 1 m (3.3 “) cable

• HI 7669/2W Temperature Probe

• HI 76404 Electrode Holder

• HI 50003 & HI 70007 pH Calibration Solutions (20 mL each)

• HI 700635 Cleaning Solution for wine deposits (2x20 mL)

• HI 700636 Cleaning Solution for wine stains (2x20 mL)

• HI 7082 Electrode Refilling Solution (30 mL) & 5 mL Syringe

• 12 VDC Power Adapter

• Instruction Manual

Note: Save all packing material until you are sure that the instrument

functions correctly. All defective items must be returned in the original

packing with the supplied accessories.

GENERAL DESCRIPTION

HI 222 is a logging microprocessor-based pH/ORP/temperature bench meter

with Calibration Check.

Calibration Check performs a set of diagnostic tests during calibration using the

history of electrode slope and offset to detect problems that can cause loss of

accuracy.

Calibration Check Features are listed below:

• Enhanced Calibration Messages

During calibration the user is warned if one or more parameters are not suitable

to perform an accurate calibration.

• Electrode Condition on LCD Display

Determined from the electrode offset and slope.

• Electrode response time on LCD Display

Determined from electrode performance during calibration.

• Calibration Alarm Time Out

Can be programmed from 1 to 7 days or can be disabled.

Other features include 1 or 2-point pH calibration with seven memorized

buffers (1.68, 3.00, 6.86, 7.01, 9.18, 10.01 and 12.45 pH), logging up to

100 samples, last calibration date and data (GLP), pH reading with manual

or automatic temperature compensation and PC interface software.

The pH 3.00 memorized buffer makes the instrument useful for wine pH

measurements.

3

Page 4

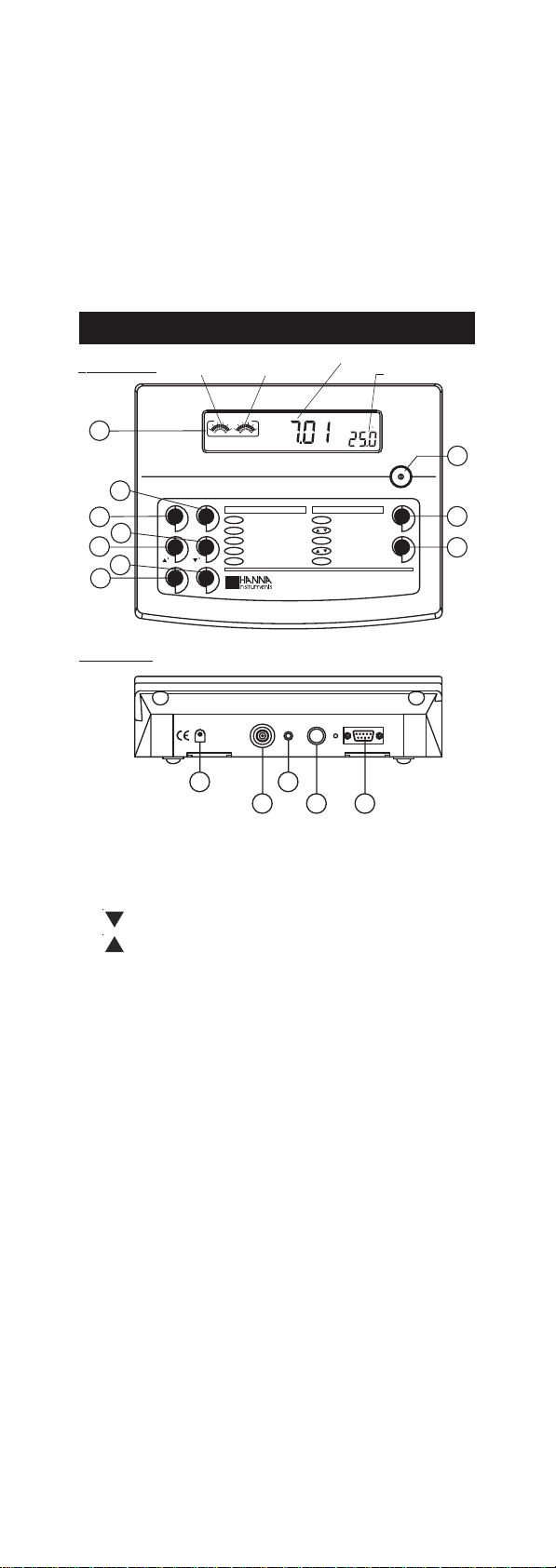

Front Panel

1

FUNCTIONAL DESCRIPTION

POOR GOOD

Electrode

Response

SLOW

FAST

Primary LCD

pH

Secondary LCD

ATC

C

Electrode

Condition

10

2

Functions pH Calibration

Select pH/ORP

3

5

7

CAL

4

6

LOG

RANGE

CFM

LOG

Store Log Information

GLP

RCL

Recall Log Information

Set Instrument Parameters

SET/CLR

Clear Log/Cal Information

CC

CFM/GLP

Show GLP Information

RCL

CAL

Start Calibration

st

/

Select 1 Buffer

st

CFM

Confirm 1 Buffer

nd

/

Select 2 Buffer

nd

CFM

Confirm 2 Buffer

HI 222 Calibration Check

Microprocessor pH Meter

RANGE

SET

CLR

8

9

Rear Panel

POWER

12VDC

11

1) Liquid Crystal Display (LCD)

2) CFM / GLP key, to confirm different values or to display Good Laboratory

Practice information

3) CAL key, to enter and exit/escape the calibration mode

4) / ºC key, to manually decrease temperature, or other parameters

5) / ºC key, to manually increase temperature, or other parameters

6) RCL key, to enter or exit the recall mode

7) LOG key, to store measured data

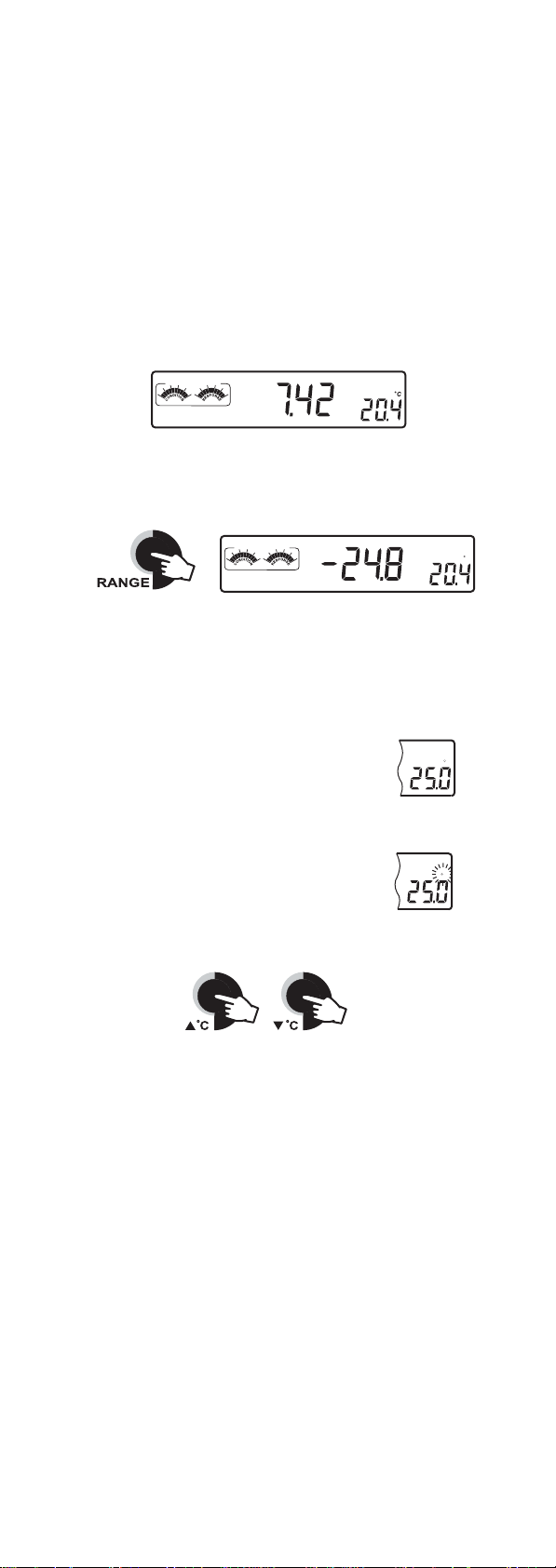

8) RANGE key, to select the measurement range or switch the focused data

9) SET / CLR key, to enter the Setup mode or clear calibration history

10) ON / OFF switch

11) Power supply socket

12) BNC connector for electrode

13) Pin input socket

14) Temperature probe socket

15) RS232 serial communication port

Note: Pin input socket can not be used as reference input for separate

electrode reference.

INPUT TEMP

13

12

RS232

14

15

4

Page 5

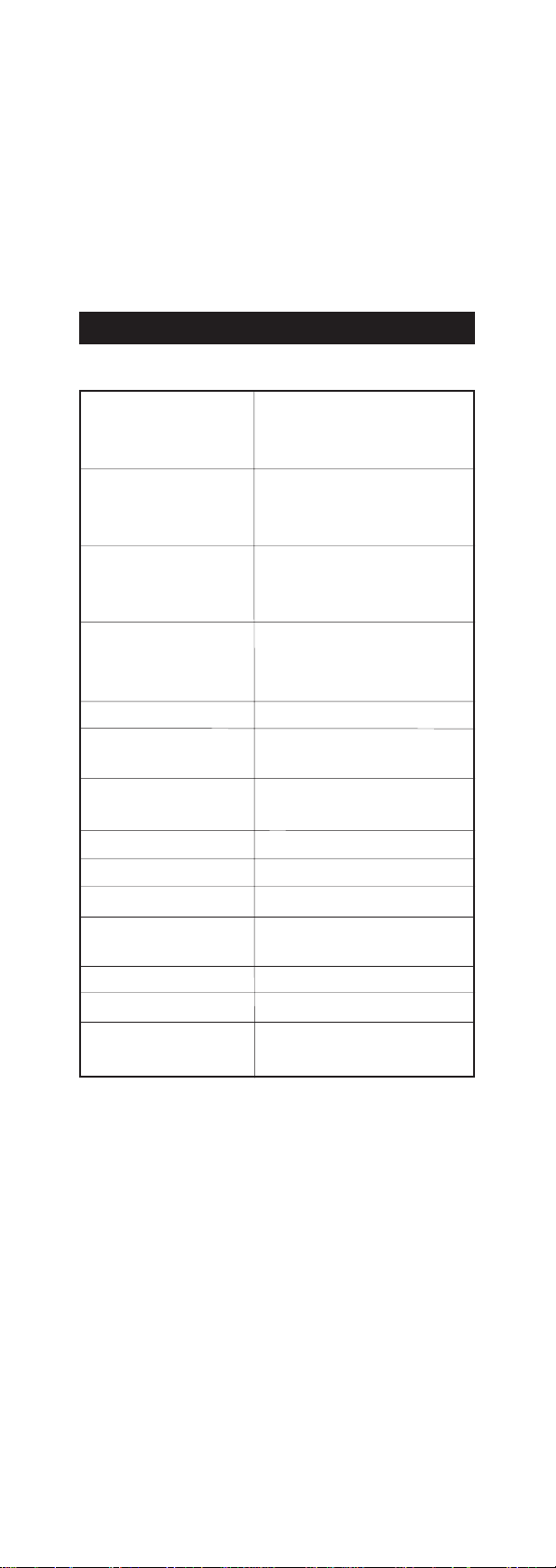

HI222 SPECIFICATIONS

Range -2.00 to 16.00 pH

±699.9 mV / ±2000 mV

-20.0 to 120.0 °C

Resolution 0.01 pH

0.1 mV / 1 mV

0.1 °C

Accuracy ±0.01 pH

(@20°C/68°F) ±0.2 mV / ±1 mV

±0.5 °C

pH Calibration 1 or 2-point, automatic,

with 7 memorized pH buffer values

(1.68, 3.00, 6.86, 7.01, 9.18, 10.01, 12.45)

Temperature Compensation Automatic or manual, from -20 to 120°C

pH Electrode HI 1048P glass-body, single junction,

(included) refillable, BNC + pin

Temperature probe HI 7669/2W stainless steel probe

(included)

Input impedance 10

Computer Interface RS232, optoisolated

Logging 100 points

Environment 0 to 50°C (32 to 122°F)

Power supply 12 VDC adapter (included)

Dimensions 240x182x74 mm (9.4x7.1x2.9")

Weight 1.1 kg (2.5 lb.);

12

Ω

max. 95% RH non-condensing

kit with holder: 2.5 kg (5.5 lb.)

5

Page 6

OPERATIONAL GUIDE

POWER CONNECTION

Plug the 12 VDC adapter into the power supply socket.

Note: These instruments use non volatile memory to retain the pH, mV,

temperature calibrations and all other settings, even when unplugged.

Note: Make sure a fuse protects the mains line.

ELECTRODE AND PROBE CONNECTIONS

For HANNA P Type pH or ORP electrodes (with internal reference) connect the

electrode’s BNC to the socket on the back of the instrument and the pin to the

appropriate socket.

Note: Electrode condition and response information is displayed on the bar

graph gauges. During the day the calibration is performed only if

HANNA P type (PIN) electrodes are used.

If the electrode is not recognized as a HANNA P type electrode, the bar

graph gauges will blink (25 seconds OFF, 4 seconds ON, full bar graph).

For temperature measurement and automatic temperature compensation

connect the temperature probe to the appropriate socket.

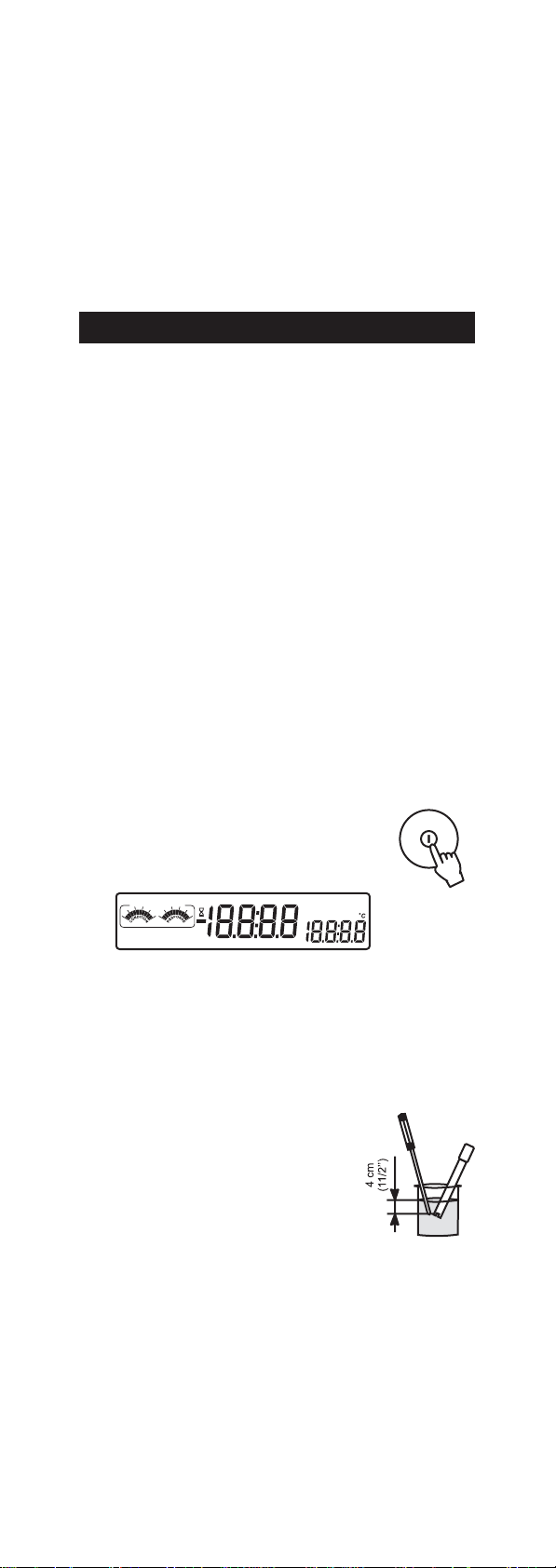

INSTRUMENT START-UP

• Turn the instrument on by pressing the ON/OFF switch.

• All LCD tags are displayed and a beep is sounded

while the instrument performs a self test.

CFM

CAL

DUE

POOR GOOD

CHECK

WRONG

CONTAMINATED

ELECTRODE

CLEAN

SLOW

BUFFER

BUFFER

Unscrew electrode refilling cap

FAST

CLEAR CAL if new electrode

mV

pH

SETUP

LOG

BUFFER 12

ATC

MTC

RCL

DEL

• The “Unscrew electrode refilling cap” message reminds the user to loosen

or remove the electrode refilling cap to improve the electrode’s response

time.

• The instrument automatically defaults to pH measurement mode unless a

HANNA P type ORP electrode is detected.

pH MEASUREMENT

Make sure the instrument has been calibrated before

taking pH measurements.

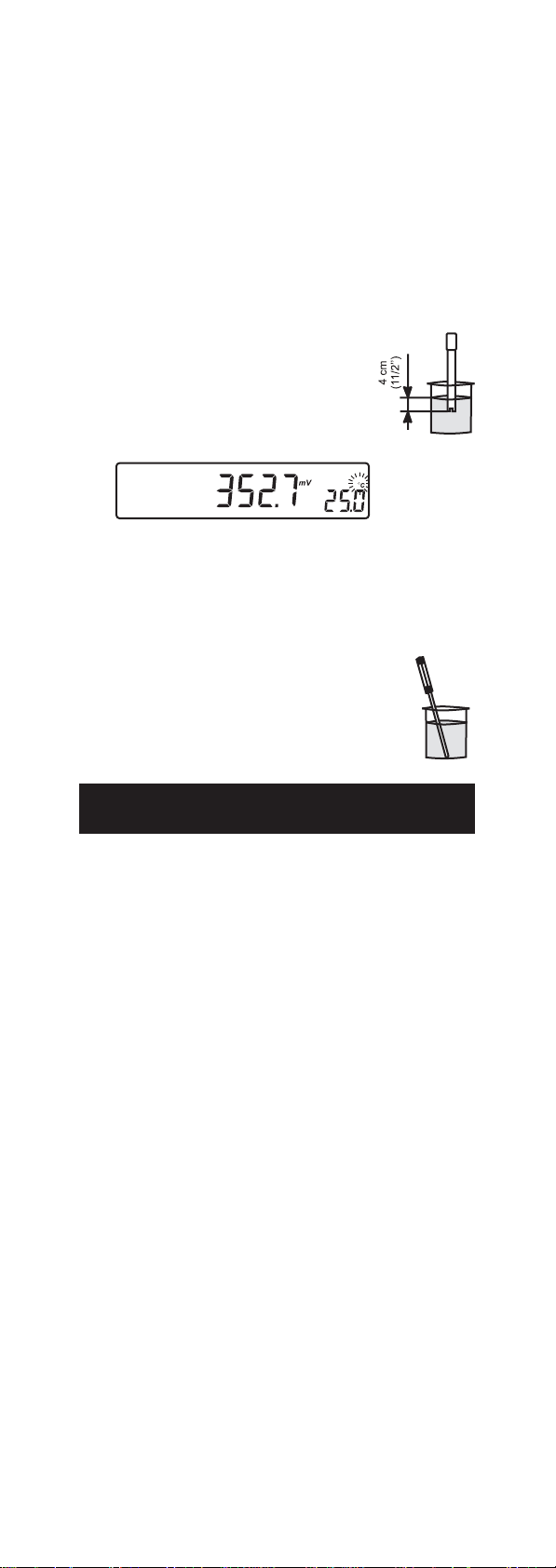

• Submerge the tip (4 cm/1½”) of a properly condi-

tioned electrode (see page 31) and the temperature probe into the sample to be tested. Allow time

for the electrode to stabilize.

6

Page 7

• The pH is displayed on the primary LCD and the temperature on the

secondary LCD.

ATC

POOR GOOD

SLOW

FAST

pH

• The pH reading is out of range, the closest full-scale value will be displayed

blinking on the primary LCD.

• It is also possible to view the mV reading by pressing the RANGE key.

POOR GOOD

SLOW

FAST

mV

If measurements are taken successively in different samples, it is recommended

to rinse the electrode thoroughly with deionized water or tap water and then

with some of the next sample to prevent cross-contamination.

The pH reading is affected by temperature. In order to measure the pH

accurately, this temperature effect must be compensated for. To use the

Automatic Temperature Compensation feature, connect

and submerge the HI 7669/2W temperature probe into

ATC

C

the sample as close to the electrode as possible and wait

for a few minutes.

If the temperature of the sample is known, manual compensation can be

performed by disconnecting the temperature probe.

The display will then show the default temperature of 25 °C

MTC

C

or the last recorded temperature reading with the “°C”

symbol blinking.

The temperature can now be adjusted with the ARROW keys (from -20.0 ºC

to 120.0 ºC).

ORP MEASUREMENTS

An optional ORP electrode must be used to perform ORP measurements (see

Accessories).

Oxidation-Reduction Potential (REDOX) measurements provide the quantification of the oxidizing or reducing power of the tested sample.

To correctly perform a REDOX measurement, the surface of the ORP electrode

must be clean and smooth. Pretreatment solutions are available to condition

the electrode and speed up the response time.

C

7

Page 8

• The instrument automatically defaults to the ORP

measurement mode if HANNA P type ORP electrode

is detected.

• Submerge the ORP electrode tip (4 cm/1½”) into the

sample. Allow a few minutes for the reading to stabilize.

• The instrument displays the mV reading on the primary LCD.

• If the reading is out of range, the closest full-scale value will be displayed

blinking on the primary LCD.

TAKING TEMPERATURE MEASUREMENTS

Connect the HI 7669/2W temperature probe and turn the

instrument on. Dip the temperature probe into the sample and

allow the reading on the secondary LCD to stabilize.

pH CALIBRATION

Calibrate the instrument frequently, especially if high accuracy is required. For

best results and constant display of electrode condition and electrode response

on the bar graph gauges we suggest at least a daily calibration.

The instrument should be re-calibrated:

• Whenever the pH electrode is replaced.

• At least once a day.

• After testing aggressive chemicals.

• If high accuracy is required.

• If CAL DUE message is displayed during measurement.

Every time you calibrate the instrument use fresh buffers and perform an

electrode cleaning procedure (see page 31).

PREPARATION

Pour small quantities of the buffer solutions into clean beakers. If possible, use

plastic or glass beakers to minimize any EMC interferences.

For accurate calibration and to minimize cross-contamination, use two beakers

for each buffer solution. One for rinsing the electrode and one for calibration.

8

Page 9

PROCEDURE

The user has a choice of 7 memorized buffers: pH 1.68, 3.00, 6.86, 7.01,

9.18, 10.01 and 12.45.

It is always recommended to perform a two-point calibration. The instrument

however allows a one-point calibration, as described on page 10.

TWO-POINT CALIBRATION

For most applications it is recommended that pH 7.01 or 6.86 buffers to be

used as the first calibration point and pH 3.00 (for acidic samples) or pH

9.18/10.01 (for alkaline samples) as the second calibration point.

Note: The pH 12.45 buffer is not for general measurement; use only if the

sample is very alkaline to avoid sodium error.

• Immerse the pH electrode and the temperature probe approximately

4 cm (1½”) into the buffer solution of your choice (pH 1.68, 3.00,

6.86, 7.01, 9.18, 10.01 or 12.45) and stir gently. The temperature

probe should be close to the pH electrode.

• Press the CAL key. “CAL” and “pH” tags will be on, and the “CLEAR

CAL if new electrode” tag will blink.

CAL

CLEAR CAL if new electrode

pH

• Press the CLR key if you are using a new electrode or want to clear the

calibration history. The instrument will display the “donE” message for

a few seconds.

It is very important to clear the calibration history when a new electrode is

used because all error and warning messages that appear during calibration

depend on the calibration history.

• Press the CAL key or wait a few seconds to continue.

Note: The above behavior appears only if calibration history is not empty.

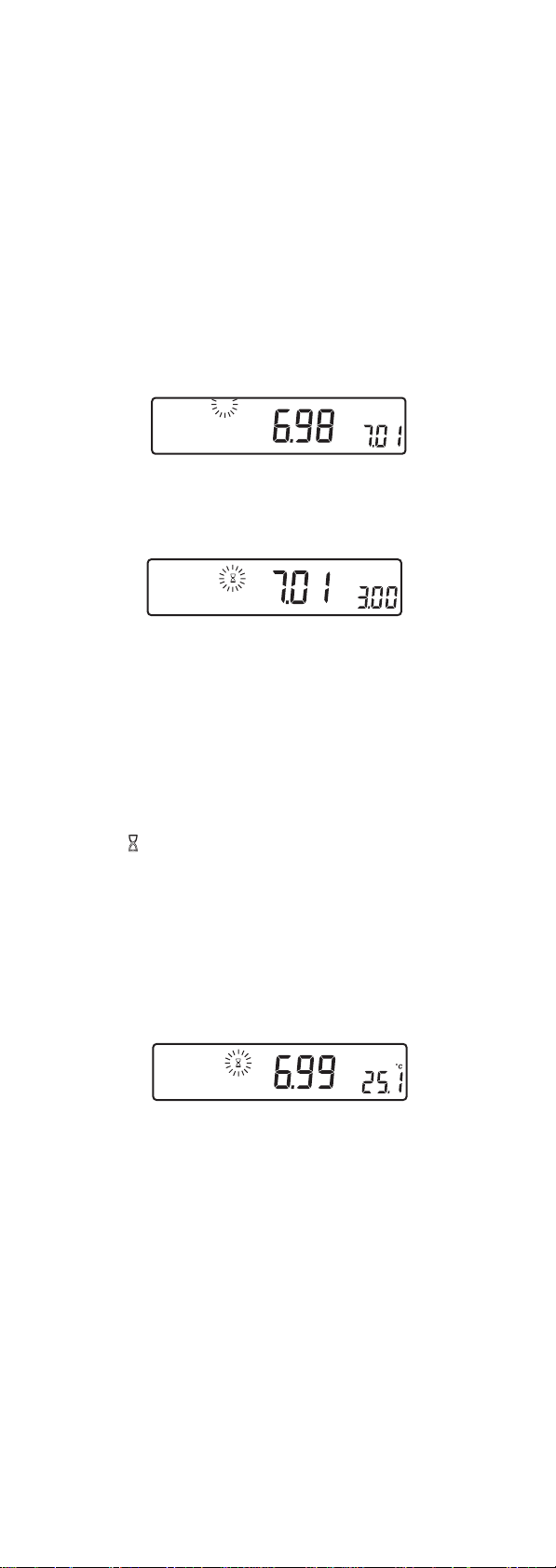

• The instrument will display the measured pH on the primary LCD, and

the most common buffer (“7.01”) on the secondary LCD, along with

“CAL”, “pH” and “BUFFER 1” tags.

• The “ ” tag will blink until the reading has stabilized.

CAL

9

pH

ATC

BUFFER 1

Page 10

• Press the ARROW keys to select a different buffer value, if necessary.

• When the reading is stable and close to the selected buffer, the “CFM”

tag will blink and if enabled, an audible signal will sound.

CFM

CAL

pH

ATC

BUFFER 1

• Press the CFM key to confirm calibration. The instrument will ask for a

second calibration buffer and will display the measured pH on the first LCD

and the second calibration buffer on the second LCD.

CAL

pH

ATC

BUFFER 2

• If necessary, press the ARROW keys to select a different buffer value.

Note: The instrument will automatically skip the buffer used for the first point.

It also skips 6.86 if 7.01 was used, and vice versa. Likewise, it will skip

9.18 if 10.01 has been used, and vice versa.

• Rinse the electrode in one of the beakers of the second buffer solution, then

immerse the pH electrode and the temperature probe approximately 4 cm

(1½”) into the second buffer solution and stir gently. The temperature

probe should be close to the pH electrode.

• The “ ” indication will blink on LCD until the reading has stabilized.

• When the reading is stable and close to the selected buffer, the

“CFM” tag will blink.

• Press the CFM key to confirm the calibration.

The instrument will return to normal operational mode and will memorize the

calibration data.

Note: Press the RANGE key any time during calibration to display the

temperature reading.

CAL

ATC

pH

ONE-POINT CALIBRATION

• Proceed as described in “two-point calibration” section.

• Press the CAL key after the first calibration point has been confirmed.

The instrument will return to normal operational mode and will memorize the

one-point calibration data.

10

Page 11

ENHANCED CALIBRATION MESSAGES

The stored calibration history to used issue error and warning messages during

calibration to help ensure the highest accuracy.

As electrode aging is normally a slow process, substantial changes from

previous calibrations are likely due to a temporary problem with the electrode

or buffers. Calibrating under these conditions will give measurement errors.

ERROR MESSAGES

Error messages appear if one or all of the calibration parameters are out of

accepted windows. When these messages are displayed calibration cannot be

confirmed.

WRONG BUFFER

This message appears when the difference between the pH reading and the

value of the selected buffer is too big. If this error message is displayed, check

if you have selected the proper calibration buffer.

CAL

WRONG

BUFFER

CLEAN ELECTRODE

This error message indicates a bad electrode condition (offset out of accepted

window, or slope under the accepted lower limit).

Clean the electrode according to the Cleaning Procedure on page 31 to

improve its condition and repeat the calibration. This ensures the removal of

film, dirt or deposits on the glass bulb and reference junction.

pH

ATC

BUFFER 1

CAL

ELECTRODECLEAN

pH

ATC

BUFFER 1

CHECK ELECTRODE alternating with CHECK BUFFER

This error message appears when electrode slope exceeds the highest accepted

slope limit. You should check your electrode and use fresh buffer.

CHECK

CAL

ELECTRODE

BUFFER

11

pH

ATC

BUFFER 1

Page 12

ELECTRODE

This message appears if the cleaning procedure performed as a result of the

above two messages is found by the instrument to be unsuccessful. Replace the

electrode.

CAL

ELECTRODE

pH

ATC

BUFFER 1

WRONG BUFFER TEMPERATURE

This message appears if the temperature of the buffer is outside the defined

buffer temperature range.

CAL

WRONG

BUFFER

ATC

pH

WARNING MESSAGES

During calibration, the Calibration Check feature analyzes the electrode calibration

history and warns the user when problems have been detected. It is possible to

over ride the warning messages and confirm the calibration but it is not

recommended.

CLEAR CAL IF NEW ELECTRODE

This warning is displayed any time the new calibration parameters are better

than the previous parameters. You can clear the calibration history by pressing the CLR key, or continue by pressing the CAL key.

CAL

CLEAR CAL if new electrode

pH

ATC

BUFFER 1

CLEAN ELECTRODE

This warning appears during Calibration Check for the second calibration

buffer when the instrument has detected a small variation of offset or both

offset and slope parameters. This variation may result from dirt on the

electrode. Refer to the electrode cleaning procedure. This ensures the removal

of film, dirt or deposits on the glass bulb and reference junction.

CFM

CAL

ELECTRODECLEAN

pH

ATC

BUFFER 1

CLEAN ELECTRODE alternating with CHECK BUFFER

This warning appears during Calibration Check in the first calibration buffer as

12

Page 13

a result of unacceptable offset variation or in the second calibration buffer as

a result of unacceptable slope variation. This variation may result from dirt on

the electrode or contaminated buffer. Refer to the electrode cleaning procedure

or use fresh buffer.

CFM

CHECK

CAL

BUFFER

ELECTRODECLEAN

pH

ATC

BUFFER 1

CONTAMINATED BUFFER

This warning message appears in order to alert that the buffer could be

contaminated. Refresh your buffer and continue the calibration procedure.

CFM

CAL

CONTAMINATED

BUFFER

pH

ATC

BUFFER 1

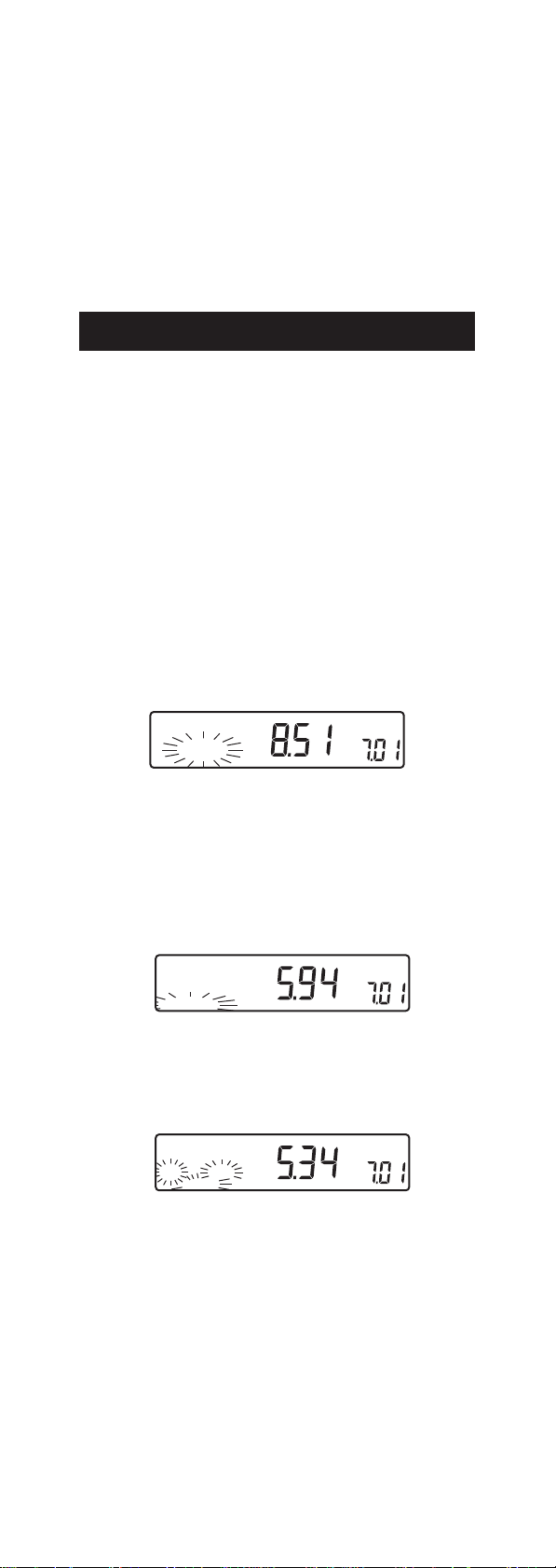

ELECTRODE CONDITION &

ELECTRODE RESPONSE TIME

When using HI 1048P electrode, HI 222 will assess electrode condition and

response time during each calibration and will display the calibration status

for the rest of the day.

POOR GOOD

SLOW

FAST

The digital gauge for electrode condition is a representation of the offset and

slope performance of the electrode. The response gauge is a function of the

stabilization time between the first and second calibration buffers. These

gauges reflect electrode performance and should be expected to slowly decrease over the life of the electrode.

The condition and response gauges show the electrode’s condition at the time

of calibration only and are displayed for the rest of the day the calibration is

performed. For a continuous display of electrode condition at the time of

calibration, daily calibration is necessary. The condition and response are also

visible when viewing GLP data.

If the instrument is not calibrated, it has been calibrated only at one point,

the two-point calibration was not performed using pH 7.01 and pH 3.00

buffers, or if the calibration history was deleted, the electrode condition and

response gauges will be empty.

13

SLOW

FAST

POOR GOOD

Page 14

Also, when the instrument cannot evaluate the electrode response or pH 1.68 or

pH 12.45 buffer were used as calibration buffer, the response gauge will be empty.

If the electrode is in a very poor condition the first condition segment will blink.

If electrode response is very slow the first response segment will blink.

GOOD LABORATORY PRACTICE (GLP)

GLP is a set of functions that allows the storage and retrieval of data regarding

the maintenance and status of the electrode.

All data regarding the last calibration (one or two points) is stored for the user

to review when necessary. This data includes the following: calibration time

stamp, offset (in mV), slope (in mV/pH), electrode condition and response

gauges, calibration buffers and the amount of time until a new calibration is

required.

CALIBRATION ALARM TIME-OUT

HI 222 allows the user to set the number of days before the next required pH

calibration. This value can be set from 1 to 7 days. The default value is OFF

(disabled).

The instrument checks if the time-out time has expired. If the time has

elapsed, the CAL DUE will blink as a reminder.

Note: If the instrument was not calibrated, or if the calibration history was

deleted, the CAL DUE message will be displayed even if this feature is

disabled in the SETUP menu.

If the instrument was calibrated using an electrode with pin and the

electrode is changed with an electrode without pin or vice-versa CAL

DUE will blink. This feature helps ensure use of a calibrated instrument.

LAST CALIBRATION DATA

Last calibration data is stored automatically after a successful calibration.

To view the pH calibration data, press the GLP key when the instrument is in

pH measuring mode.

The instrument will display the time of the last calibration.

Press the ARROW keys to view the following logged calibration parameters

(pressing the / ºC key):

• The time (hh:mm).

14

Page 15

• The date (mm.dd).

• The year (yyyy).

• The pH calibration offset.

• The pH calibration slope in mV/pH normalized to 25 °C.

Note: If you calibrate using electrodes with pin the electrode condition and re-

sponse gauges appear while the offset and slope are displayed.

• The first pH calibration buffer along with any warning messages issued

while calibrating at this point.

• The second pH calibration buffer along with any warning messages issued

while calibrating at this point.

CAL

pH

BUFFER 2

RCL

Note: If the last calibration was a single point calibration, the message for

the second buffer will be: “no bUFF”.

15

Page 16

• The calibration Alarm Time-Out status:

if disabled

or the number of days until the calibration alarm will be displayed

or if expired (7 days ago)

Press the GLP key at any time and the instrument will return to measuring mode.

If calibration has not been performed, the instrument displays “no CAL”

blinking.

16

Page 17

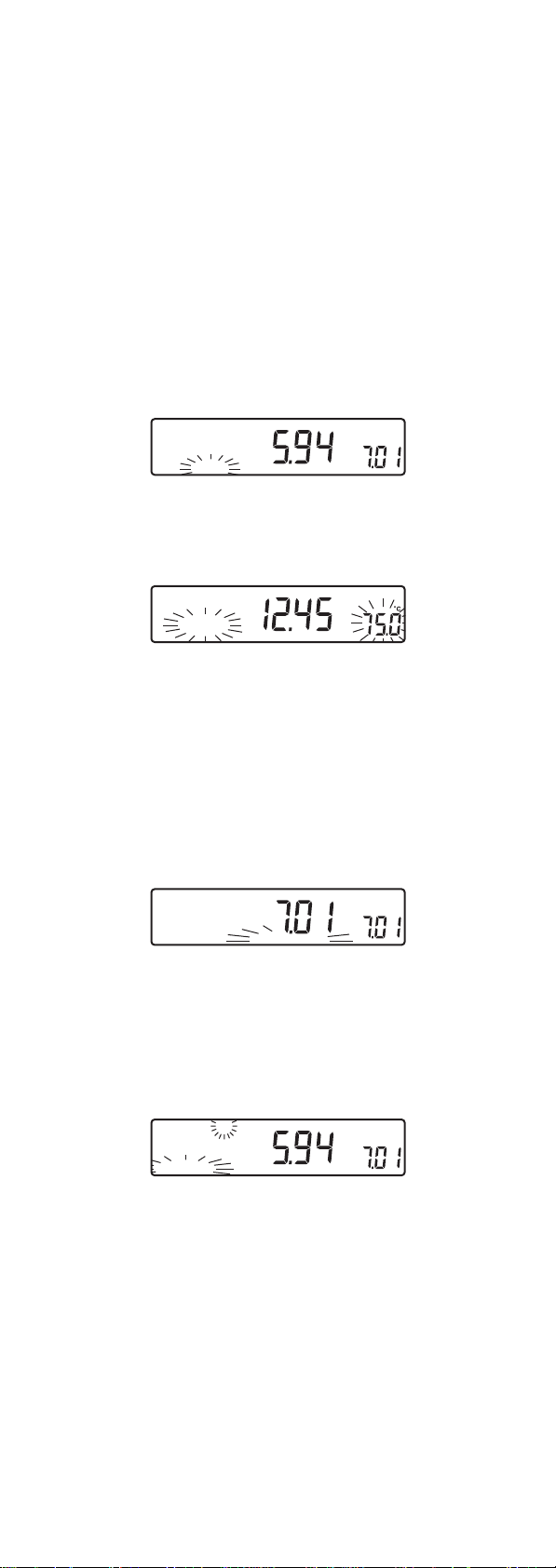

LOGGING

Up to 100 LOG samples can be stored in memory.

LOGGING THE CURRENT DATA

To store the current reading into memory press the LOG key while in measuring mode.

The instrument will display the current date (mm.dd) on the primary LCD, the

record number on the secondary LCD and the “LOG” tag will blink for a few

seconds (see example below: record No. 27 dated July 14):

If there are less than 6 memory locations remaining, the record number and

the “Lo” message will blink to alert the user.

LOG

If the log space is full, the “FULL LOC” message will be displayed and no more

data will be saved.

When the LOG key is pressed, a complete set of information is stored. The

parameters of a record are date, time, pH, mV, temperature, and pH

calibration data. If a HANNA P Type ORP electrode is used pH information is

not stored.

VIEW LOGGED DATA

Press the RCL key to retrieve the information stored while in measuring mode.

If no data were logged the instrument displays:

17

Page 18

Otherwise the instrument will display log data on the primary LCD and the

last stored record number on the secondary LCD, along with the “LOG” and

the “RCL” tags.

Note: The “LOG” and “RCL” tags remain on LCD while instrument is in the

viewing logged data mode.

LOGpHRCL

Press the RCL key at any time to return to measuring mode.

Press the ARROW keys to scroll between same parameter for different records,

while pH, mV, temperature, “Hour”, “Year”, “oFFS”, “SLoP” or “dEL

record” is displayed:

pH

LOG

RCL

or to scroll between different dates while “dAtE” or “dEL date” is displayed.

LOG

RCL

Press the RANGE key and the instrument will display the next logged

parameter, as follows:

•The mV value on the primary LCD and the record number on the secondary

LCD.

•The temperature value on the primary LCD and the record number on the

secondary LCD.

•The time on the primary LCD and the “Hour” message on the secondary

LCD.

18

Page 19

•The date on the primary LCD and the “dAtE” message on the secondary

LCD.

•The year on the primary LCD and the “YEAr” message on the secondary

LCD.

•The calibration offset on the primary LCD and the “oFFS” message on the

secondary LCD.

•The calibration slope on the primary LCD and the “SLoP” message on the

secondary LCD.

Note: Before displaying the “Hour”, “Year”, “oFFS” or “SLoP” messages,

the record number is displayed for about one second.

The RANGE key has no effect if “nuLL” record message is displayed on

the first LCD line.

LOG

RCL

or if “nuLL” date message is displayed.

LOG

RCL

You can skip this message by selecting an undeleted record (date)

using the ARROW keys.

19

Page 20

•The “dEL” message on the primary LCD and the selected record or date on

the secondary LCD. The “CFM” and the ”DEL” tags will blink:

Press SET key to select the current record, the records from the selected date or

all records to be deleted.

the date.

or “ALL” records.

Press the ARROW keys to change the record or the date.

Press the CFM key to confirm the deleting of the selected record, all the records

for the selected date, or all the records and the instrument will display on the

secondary LCD the “nuLL” message.

LOG

RCL

Note:• Pressing RANGE key the instrument skips to the pH information on

the next undeleted record.

• The instrument optimizes the usage of the memory when it returns to

measurement mode after a deleting operation is performed. This will

change the record numbers of logged data.

• If all the records are deleted the instrument returns to the measuring

mode.

• After the LOG key is pressed or “dEL” is confirmed the instrument will

display the amount of free log space for about one second (example:

25 records free).

LOG

20

Page 21

SETUP

Setup mode allows viewing and modification of the following parameters:

• Calibration Alarm Time Out

• Instrument ID

• Current Time (hour & minute)

• Current Date (month & day)

• Current Year

• Beep Status

• Baud Rate (serial communication)

• Command Prefix (serial communication)

To enter the Setup mode press the SET/CLR key while the instrument is in

measuring mode. Press SET/CLR key to exit SETUP mode.

Select a parameter with the ARROW keys.

Press the CAL key to change a parameter value. The selected parameter will

start to blink.

Press the RANGE key to toggle between the displayed parameters.

Press the ARROW keys to increase or decrease the displayed value.

Press the CFM key to save the modified value or the CAL key to cancel.

Press the ARROW keys to select the next/previous parameter.

CALIBRATION ALARM TIME OUT CHANGE

Press the CAL key when the calibration time out is displayed. Calibration time

out (OFF=disabled or 1 to 7 days) will begin blinking.

Press the ARROW keys to change the calibration time out value.

Press the CFM key to save the modified calibration time out value or press the

CAL key to cancel without saving the calibration time out.

INSTRUMENT ID PARAMETER CHANGE

Press the CAL key when the instrument ID is displayed. The instrument ID

(0000 to 9999) will begin blinking.

21

Page 22

Press the ARROW keys to change the instrument ID value.

Press the CFM key to save the modified instrument ID value or press the CAL

key to cancel without saving the instrument ID.

Note: The instrument ID is downloaded to a PC as part of a logged data set

to identify it’s origin.

CURRENT TIME SET

Press the CAL key when the current time is displayed. The hour will begin

blinking.

Press the ARROW keys to change the hour.

Press the RANGE key. The minutes will begin blinking.

Press the ARROW keys to change the displayed value.

Press the CFM key to save the modified value or press the CAL key

to cancel without saving the time.

CURRENT DATE SET

Press the CAL key when the current date is displayed. The month will begin

blinking.

Press the ARROW keys to change the month.

Press the RANGE key. The day will begin blinking.

Press the ARROW keys to change the displayed value.

Press the CFM key to save the modified value or press the CAL key to cancel

without saving the date.

22

Page 23

CURRENT YEAR SET

Press the CAL key when the current year is displayed. The year will begin

blinking.

Press the ARROW keys to change the year.

Press the CFM key to save the modified value or press the CAL key to cancel

without saving the year.

BEEP STATUS SET

Press the CAL key when the beep status is displayed. The beep status (On or

OFF) will begin to blink.

Press the ARROW keys to change the beep status (On or OFF).

Press the CFM key to save the modified beep status or press the CAL key to

cancel without saving the beep status.

Note: If enabled, an audible signal will follow each key press. Inactive keys

have a longer beep. A longer beep is also sounded when the limits of

the range of a parameter are reached.

An audible signal will also sound when the reading becomes stable

during calibration.

23

Page 24

SERIAL COMMUNICATION BAUD RATE SET

Press the CAL key when the baud rate is displayed. The baud rate (600,

1200, 2400, 4800 or 9600) will begin to blink.

Press the ARROW keys to change the baud rate.

Press the CFM key to save the modified baud rate or press the CAL key to

cancel without saving the baud rate.

SERIAL COMMUNICATION COMMAND PREFIX SET

Press the CAL key when the command prefix is displayed. The command prefix

(0 to 47) will begin to blink.

Press the ARROW keys to change the command prefix.

Press the CFM key to save the modified command prefix value or press the CAL

key to cancel without saving the command prefix.

Note: See the PC Interface section on page 28 for a complete explanation. The

command prefix must be 16 if the HI 92000 PC software is used.

24

Page 25

TEMPERATURE CALIBRATION

(for technical personnel only)

The instruments are factory calibrated for temperature.

Hanna’s temperature probes are interchangeable and temperature calibra-

tion is not necessary when replaced.

If the temperature measurements are not accurate, temperature recalibration

should be performed.

For an accurate recalibration, contact your dealer or the nearest Hanna

Customer Service Center, or follow the instructions below.

• Switch off the instrument.

• Prepare a vessel containing ice and water and another one containing hot

water (around 50 °C). Place insulation material around the vessels to

minimize temperature changes during calibration.

• Use a ChecktempC or a calibrated thermometer with a resolution of 0.1 °C

as a reference thermometer.

• Immerse the temperature probe and the ChecktempC into the vessel

containing ice and water. Wait a few minutes for the probe to stabilize.

• Press the CAL and LOG keys simultaneously and then switch the instrument on. After a few seconds, the instrument enters the temperature

calibration mode. The “CAL” tag will come on. The primary LCD will

display the measured temperature or the ”- - - -” message if the

measured temperature is out of range. The secondary LCD will display 0.0 °C

(First calibration point). The “ ”tag will blink until the reading has

stabilized.

• Use the ARROW keys to set the reading on the secondary LCD to that of

ice and water measured by ChecktempC (for example, -0.1 °C).

CAL

C

-0.1°C

• When the reading is stable and close to the selected calibration point, the

“CFM” tag will blink.

• Press the CFM key to confirm the calibration or the CAL key to leave the

calibration mode.

• The secondary LCD will display 50.0 °C (Second calibration point).

• Immerse the temperature probe and the ChecktempC into the second

vessel.

• Allow a few minutes for the probe to stabilize.

25

Page 26

• The “ ” tag will blink until the reading has stabilized.

• Use the ARROW keys to set the reading on the secondary LCD to that of

the hot water bath.

• When the reading is stable and close to the selected calibration point, the

“CFM” tag will blink.

CFM

CAL

C

• Press the CFM key to confirm the calibration or the CAL key to leave the

calibration mode.

Note: If the measured value is not close enough to the displayed value on

secondary LCD, the “WRONG “ tag will blink. In this case, check if the

value set on secondary LCD and the temperature measured with

ChecktempC are close. Change the temperature probe and restart

calibration if necessary.

26

Page 27

mV CALIBRATION

(for technical personnel only)

All instruments are factory calibrated for mV.

Hanna’s pH and ORP electrodes are interchangeable and mV calibration is

not needed when replaced.

If mV measurements are not accurate, mV recalibration should be carried out.

For an accurate recalibration, contact your dealer or the nearest Hanna

Customer Service Center or follow the instructions below.

A two or three point calibration can be performed at 0 mV, +600 mV and

+1800 mV.

• Switch off the instrument.

• Attach a mV simulator with an accuracy of at least ±0.1 mV to the BNC

connector.

• Press the RCL and CFM/GLP keys simultaneously and switch the instrument on. After a few seconds, the instrument enters the mV calibration

mode.

• The primary LCD will show the “CAL” and “mV” tags along with measured mV and the secondary LCD will display 0.0 calibration point.

• Set 0.0 mV on the simulator.

• The “ ” tag will blink on LCD until the reading has stabilized.

• When the reading is stable, the “CFM” tag will blink.

• Press the CFM key to confirm the calibration.

• The instrument will prompt for a second calibration point and will display

600 on the secondary LCD line.

• Set the simulator to +600.0 mV.

• The “ ” tag will blink on the LCD until the reading has stabilized.

• When the reading is stable, the “CFM” tag will start to blink.

• Press the CFM key to confirm the calibration.

• The instrument will prompt for a third calibration point and will display

1800 on the secondary LCD line.

• The two-point mV calibration is now complete.

• Set +1800.0 mV on the simulator.

• The “ ” tag will blink on the LCD until the reading has stabilized.

• When the reading is stable, the “CFM” tag will start to blink.

• Press the CFM key to confirm the calibration.

• The instrument will memorize the calibration and return to measuring

mode.

27

Page 28

Note: Press the CAL key to leave the calibration mode at any time.

If the measured value is not close to the calibration point, the “WRONG“

tag will start to blink. In this case, check if the value set on the

simulator is the same as the calibration value on the instrument. Set

the proper value on the simulator.

PC INTERFACE

Data transmission from the instrument to the PC can be done with HI 92000

Windows® compatible software (optional). The HI 92000 also offers graphing

and on-line help.

Data can also be exported to the most popular spreadsheet programs for

further analysis.

To connect your instrument to a PC, use the optional Hanna HI 920010 cable.

Make sure that your instrument is switched off and plug one end into the

instrument’s RS232 socket and the other end into the serial port of your PC.

Note: Cables other than HI 920010 may use a different configuration, in

which case communication between the instrument and the PC may

not be possible.

If you are not using optional Hanna HI 92000 software, please see the

following instructions.

The Command Prefix must be 16 when using HI 92000 software.

SENDING COMMANDS FROM PC

It is also possible to remotely control the instrument with any terminal program. Use the optional Hanna HI 920010 cable to connect the instrument to

a PC, start the terminal program and set the communication options as

follows: 8, N, 1, no flow control.

COMMAND TYPES

To send a command to the pH meter the scheme is:

<command prefix> <command> <CR>

where: <command prefix> is a selectable ASCII character

between 0 and 47 (default 16).

<command> is the command code (3 characters).

Note: Either small or capital letters can be used.

28

Page 29

SIMPLE COMMANDS

RNG Is equivalent to pressing the RANGE key

CAL Is equivalent to pressing the CAL key

CFM Is equivalent to pressing the CFM/GLP key

UPC Is equivalent to pressing the UP arrow key

DWC Is equivalent to pressing the DOWN arrow key

SET Is equivalent to pressing the SET/CLR key

COMMANDS REQUIRING AN ANSWER

pH? Causes the instrument to send the pH reading (“Err 1” is sent if

out of range). If the range is set to mV, “Err 6” is received.

MV? Causes the instrument to send the mV reading (“Err 2” is sent if

out of range). If the range is set to pH, “Err 6” is received.

TM? Causes the instrument to send the temperature reading

(“Err 3” is sent if out of range).

MDR Requests the instrument model name and firmware code.

PAR Requests the setup parameters (instrument ID, calibration alarm

time-out, pH range, beep status).

NSL Requests the number of logged samples.

GLP Requests the calibration data record.

LOD xxx Requests the xxxth record logged data.

LOD ALL Requests all logged data.

Invalid commands will be ignored. The characters sent by the instrument are

always capital letters. When the instrument receives an unknown or a corrupted command, it will send a character CAN (ASCII Code 24).

29

Page 30

pH VALUES AT DIFFERENT

TEMPERATURES

Temperature has an effect on pH. The calibration buffer solutions are affected

by temperature changes to a lesser degree than normal solutions. During

calibration the instrument will automatically calibrate to the pH value corresponding to the measured or set temperature.

TEMP pH VALU

ºC ºF 1.68 4.01 6.86 7.01

0321.67 4.01 6.98 7.13

5411.67 4.00 6.95 7.10

10 50 1.67 4.00 6.92 7.07

15 59 1.67 4.00 6.90 7.04

20 68 1.68 4.00 6.88 7.03

25 77 1.68 4.01 6.86 7.01

30 86 1.68 4.02 6.85 7.00

35 95 1.69 4.03 6.84 6.99

40 104 1.69 4.04 6.84 6.98

45 113 1.70 4.05 6.83 6.98

50 122 1.71 4.06 6.83 6.98

55 131 1.72 4.07 6.84 6.98

60 140 1.72 4.09 6.84 6.98

65 149 1.73 4.11 6.85 6.99

70 158 1.74 4.12 6.85 6.99

During calibration the instrument will display the buffer value at 25 °C.

30

Page 31

ELECTRODE CONDITIONING

& MAINTENANCE

PREPARATION

Remove the protective cap.

DO NOT BE ALARMED IF SALT DEPOSITS ARE PRESENT. This is normal with

electrodes. They will disappear when rinsed with water.

During transport, tiny bubbles of air may form inside the glass bulb affecting

proper functioning of the electrode. These bubbles can be removed by “shaking down” the electrode as you would do with a glass thermometer.

If the bulb and/or junction is dry condition the electrode by soaking it in

HI 70300 or HI 80300 storage solution for at least one hour.

31

Page 32

For Refillable Electrodes:

If the filling solution (electrolyte) is more than 2½ cm (1") below the fill hole,

add HI 7082 or HI 8082 3.5M KCl Electrolyte Solution for double junction or

HI 7071 or HI 8071 3.5M KCl+AgCl Electrolyte Solution for single junction

electrodes using a plastic refilling pipette (HI 740157).

As recommended by the LCD message on instrument on start-up, remove or

loosen the fill hole screw on the electrode for better performance.

STORAGE

To minimize clogging and assure a quick response time, the glass bulb and

the junction should be kept moist and not allowed to dry out.

Replace the solution in the protective cap with a few drops of HI 70300 or

HI 80300 Storage Solution or, in its absence, Filling Solution (HI 7071 or

HI 8071 for single junction or HI 7082 or HI 8082 for double junction

electrodes). Follow the Preparation Procedure on page 31 before taking

measurements.

Note: NEVER STORE THE ELECTRODE IN DISTILLED OR DEIONIZED WATER.

PERIODIC MAINTENANCE

Inspect the electrode and the cable. The cable used for connection to the

instrument must be intact and there must be no points of broken insulation on

the cable or cracks on the electrode stem or bulb. Connectors must be perfectly

clean and dry. If any scratches or cracks are present, replace the electrode.

Rinse off any salt deposits with water.

For Refillable Electrodes:

Refill the reference chamber with fresh electrolyte (HI 7071 or HI 8071 for

single junction or HI 7082 or HI 8082 for double junction electrodes) using a

plastic refilling pipette (HI 740157). Allow the electrode to stand upright for

1 hour.

Follow the Storage Procedure above.

CLEANING PROCEDURES

• General Soak in HI 7061 (or HI 8061) General Cleaning Solution

for approximately 30 minutes.

• Protein Soak in HI 7073 (or HI 8073) Protein Cleaning Solution

for 15 minutes.

• Inorganic Soak in HI 7074 (or HI 8074) Inorganic Cleaning

Solution for 15 minutes.

• Oil/grease Rinse with HI 7077 (or HI 8077) Oil and Fat Cleaning

Solution for approx. 30 seconds.

32

Page 33

IMPORTANT:

After performing any of the cleaning procedures, rinse the electrode thoroughly

with distilled water, refill the reference chamber with fresh electrolyte (not

necessary for gel-filled electrodes) and soak the electrode in HI 70300 or HI

80300 Storage Solution for at least 1 hour before taking measurements.

TROUBLESHOOTING GUIDE

Symptoms Problem Solution

Slow response / excessive drift.

The reading drifts.

Low electrode condition.

Readings fluctuate up

and down (noise).

The display shows

blinking dashes during

pH measurements.

The display shows

blinking dashes during

mV measurements.

Out of range mV scale.

The meter does not

work with temperature

probe.

Dirty pH electrode.

Bad or dirty pH electrode.

Clogged or dirty junction.

Low electrolyte level (for

refillable electrodes

only).

Out of range pH scale.

Out of range mV scale.

Dry membrane/junction.

Broken temperature

probe.

Soak the electrode tip in

HI7061 solution for about 30

minutes, then clean the electrode.

Soak the electrode tip in

warm (approx. 50-60°C)

HI7082 solution. Refill with

fresh electrolyte solution (for

refillable electrodes only).

Replace the electrode.

Clean the electrode.

Refill with fresh electrolyte solution (for refillable electrodes only).

a) Recalibrate.

b) Make sure the pH sample

is in the specified range.

c) Check the electrolyte level

and the general state of

the pH electrode.

Electrode not connected.

Soak in HI 70300 Storage solution for at least one hour.

Replace the temperature

probe.

33

Page 34

Symptoms Problem Solution

AmpHel electrodes do

not respond to pH

changes.

The meter fails to calibrate or gives faulty

readings.

At start-up the LCD display all segments permanently.

Explicit warnings are

displayed during pH

calibration.

The electrode condition and response

gauges are not displayed after calibration.

The electrode condition and response

gauges are empty.

The meter displays

empty Electrode response scale.

“Err xx” message displayed.

The battery is run down.

Broken pH electrode.

One of the keys is

blocked.

Dirty pH electrode or contaminated buffers.

a) The meter has not

been calibrated on

the current day.

b) Only 1-point calibra-

tion has been preformed.

c) Calibration not per-

formed with pH 7.01

and pH 3.00 buffers.

Not enough data available to evaluate response time.

Internal error.

Replace the electrode.

Replace the pH electrode.

Check the keyboard or contact your dealer.

Follow displayed instructions.

Use Hanna HI1048P electrode and check the pin connection.

Perform a 2-point calibration

procedure.

Calibrate using pH 7.01 and

pH 3.00 buffers.

Repeat calibration more

carefully.

Power the meter OFF and then

ON again. If the error persists,

contact your dealer.

34

Page 35

TEMPERATURE CORRELATION

FOR pH SENSITIVE GLASS

The resistance of glass electrodes partially depends on the temperature. The

lower the temperature, the higher the resistance. It takes more time for the

reading to stabilize if the resistance is higher. In addition, the response time

will suffer to a greater degree at temperatures below 25 °C.

Since the resistance of the pH electrode is in the range of 50-200 Mohm

depending on the composition of the glass, the current across the membrane

is in the pico-Ampere range. Large currents can disturb the calibration of the

electrode for many hours. For these reasons high humidity environments, short

circuits and static discharges are detrimental to a stable pH reading.

The pH electrode’s life also depends on the temperature. If constantly used at

high temperatures, the electrode life is drastically reduced.

Typical Electrode Life: Ambient Temperature 1- 3 years

90 °C Less than 4 months

120 °C Less than 1 month

Alkaline Error:

High concentrations of sodium ions interfere with readings in alkaline solutions. The pH at which the interference starts to be significant depends upon

the composition of the glass. This interference is called alkaline error and causes

the pH to be underestimated. Hanna’s glass formulations have the indicated

characteristics.

Sodium Ion Correction for the Glass at 20-25 °C

Concentration pH Error

0.1 Mol L-1 Na

1.0 Mol L-1 Na

+

+

13.00

13.50

14.00

12.50

13.00

13.50

14.00

0.10

0.14

0.20

0.10

0.18

0.29

0.40

35

Page 36

ACCESSORIES

pH CALIBRATION SOLUTIONS

HI 50003P pH 3.00 Buffer Solution, 20 mL sachet, 25 pcs

HI 70004P pH 4.01 Buffer Solution, 20 mL sachet, 25 pcs

HI 70007P pH 7.01 Buffer Solution, 20 mL sachet, 25 pcs

HI 70010P pH 10.01 Buffer Solution, 20 mL sachet, 25 pcs

HI 7001M pH 1.68 Buffer Solution, 230 mL bottle

HI 5003 pH 3.00 Buffer Solution, 500 mL bottle

HI 7004L pH 4.01 Buffer Solution, 500 mL bottle

HI 7006L pH 6.86 Buffer Solution, 500 mL bottle

HI 7007L pH 7.01 Buffer Solution, 500 mL bottle

HI 7009L pH 9.18 Buffer Solution, 500 mL bottle

HI 7010L pH 10.01 Buffer Solution, 500 mL bottle

HI 7001L pH 1.68 Buffer Solution in FDA approved bottle, 500 mL

HI 8004L pH 4.01 Buffer Solution in FDA approved bottle, 500 mL

HI 8006L pH 6.86 Buffer Solution in FDA approved bottle, 500 mL

HI 8007L pH 7.01 Buffer Solution in FDA approved bottle, 500 mL

HI 8009L pH 9.18 Buffer Solution in FDA approved bottle, 500 mL

HI 8010L pH 10.01 Buffer Solution in FDA approved bottle, 500 mL

ELECTRODE STORAGE SOLUTION

HI 70300L Storage Solution, 460 mL bottle

HI 80300L Storage Solution in FDA approved bottle, 460 mL

ELECTRODE CLEANING SOLUTIONS

HI 70000P Electrode Rinse Solution, 20 mL sachet, 25 pcs

HI 700635P Cleaning Solution for wine deposits, 20 mL sachet, 25 pcs

HI 700636P Cleaning Solution for wine stains, 20 mL sachet, 25 pcs

HI 70635L Cleaning Solution for wine deposits, 460 mL bottle

HI 70636L Cleaning Solution for wine stains, 460 mL bottle

HI 7061L General Cleaning Solution, 460 mL bottle

HI 7073L Protein Cleaning Solution, 460 mL bottle

HI 7074L Inorganic Cleaning Solution, 460 mL bottle

HI 7077L Oil & Fat Cleaning Solution, 460 mL bottle

HI 8061L General Cleaning Solution in FDA approved bottle, 460 mL

HI 8073L Protein Cleaning Solution in FDA approved bottle, 460 mL

HI 8077L Oil & Fat Cleaning Solution in FDA approved bottle, 460 mL

36

Page 37

REFILLING ELECTROLYTE SOLUTIONS

HI 7071 3.5M KCl + AgCl Electrolyte, 4x30 mL, for single junction electrodes

HI 7072 1M KNO3 Electrolyte, 4x30 mL

HI 7082 3.5M KCl Electrolyte, 4x30 mL, for double junction electrodes

HI 8071 3.5M KCl + AgCl Electrolyte in FDA approved bottle, 4x30 mL,

for single junction electrodes

HI 8072 1M KNO3 Electrolyte in FDA approved bottle, 4x30 mL

HI 8082 3.5M KCl Electrolyte in FDA approved bottle, 4x30 mL, for

double junction electrodes

ORP PRETREATMENT SOLUTIONS

HI 7091L Reducing Pretreatment Solution, 460 mL bottle

HI 7092L Oxidizing Pretreatment Solution, 460 mL bottle

pH ELECTRODES

All electrodes with code ending with P are supplied with BNC & pin connector

and 1 m (3.3') cable, as shown below.

HI 1043P; Use: strong acid/alkali.

Glass-body, double junction, refillable, combination pH electrode.

12 mm

0.5"

HI 1043

"S" VERSION

9.5mm DIA

120 mm

4.7"

0.37"

HI 1053P; Use: emulsions.

Glass-body, triple ceramic, conic shape, refillable, combination pH electrode.

12 mm

0.5"

HI 1053

37

120 mm

4.7"

"S" VERSION

Page 38

HI 1131P; Use: general purpose.

Glass-body, single junction, refillable, combination pH electrode.

12 mm

0.5"

HI 1131

"S" VERSION

9.5mm DIA

120 mm

4.7"

0.37"

HI 1083P; Use: biotechnology, micro titration.

Glass-body, micro, Viscolene, nonrefillable, combination pH electrode

HI 1083

12 mm

0.5"

5 mm

0.2"

120 mm

3 mm

0.12"

"

3.0 mm DIA

0.12"

HI 1048P; Use: wine measurements.

Glass-body, refillable pH electrode with open junction, Teflon® collar

HI 1048

ORP ELECTRODES

HI 3131P; Use: titration.

Glass-body, refillable, combination platinum ORP electrode

12 mm

0.5"

HI 3131

150 mm

"S" VERSION

5.9"

Consult the Hanna General Catalog for more electrodes with BNC and pin

connectors.

OTHER ACCESSORIES

HI 710005 Voltage adapter from 115 VAC to 12 VDC (USA plug)

HI 710006 Voltage adapter from 230 VAC to 12 VDC (European plug)

HI 710012 Voltage adapter from 240 VAC to 12 VDC (UK plug)

HI 710013 Voltage adapter from 230 VAC to 12 VDC (South African plug)

HI 710014 Voltage adapter from 230 VAC to 12 VDC (Australian plug)

ChecktempC Pocket-size thermometer (range -50.0 to 120.0 ºC)

Ultem® is registered Trademark of “General Electrics Co.”

Kynar® is registered Trademark of “Pennwalt Corp.”

Windows® is registered Trademark of “Microsoft Co.”

38

Page 39

HI 76405Electrode holder

HI 8427 pH and ORP electrode simulator with 1 m (3.3') coaxial

cable ending in female BNC connectors

HI 931001 pH and ORP electrode simulator with LCD and 1 m (3.3')

coaxial cable ending in female BNC connectors

HI 7669/2W Temperature probe with 1 m (3.3') cable

HI 740157 Plastic electrode refilling pipet (20 pcs)

HI 92000 Windows® compatible software

HI 920010 9 to 9-pin RS232 connection cable

Recommendations for users

Before using this product, make sure that it is entirely suitable for the environment in which

it is used. Operation of this instrument in residential areas could cause unacceptable interferences to radio and TV equipment, requiring the operator to take all necessary steps to correct

interferences.

The glass bulb at the end of the pH electrode is sensitive to electrostatic discharges. Avoid

touching this glass bulb at all times.

During operation, ESD wrist straps should be worn to avoid possible damage to the electrode

by electrostatic discharges.

Any variation introduced by the user to the supplied equipment may degrade the instrument's

EMC performance.

To avoid electrical shock, do not use this instrument when voltages at the measurement surface

exceed 24 VAC or 60 VDC.

To avoid damage or burns, do not perform any measurement in microwave ovens.

Hanna Instruments reserves the right to modify the design, construction

and appearance of its products without advance notice.

39

Page 40

HANNA SALES AND TECHNICAL SERVICE

Australia:

Tel. (03) 9769.0666 • Fax (03) 9769.0699

China:

Tel. (10) 88570068 • Fax (10) 88570060

Egypt:

Tel. & Fax (02) 2758.683

Germany:

Tel. (07851) 9129-0 • Fax (07851) 9129-99

Greece:

Tel. (210) 823.5192 • Fax (210) 884.0210

Indonesia:

Tel. (21) 4584.2941 • Fax (21) 4584.2942

Japan:

Tel. (03) 3258.9565 • Fax (03) 3258.9567

Korea:

Tel. (02) 2278.5147 • Fax (02) 2264.1729

Malaysia:

Tel. (603) 5638.9940 • Fax (603) 5638.9829

Singapore:

Tel. 6296.7118 • Fax 6291.6906

South Africa:

Tel. (011) 615.6076 • Fax (011) 615.8582

Taiwan:

Tel. 886.2.2739.3014 • Fax 886.2.2739.2983

Thailand:

Tel. (2) 619.0285 • Fax (2) 619.0284

United Kingdom:

Tel. (01525) 850.855 • Fax (01525) 853.668

USA:

Tel. (401) 765.7500 • Fax (401) 765.7575

For e-mail contacts and a complete list of Sales and

Technical offices, please see www.hannainst.com.

40

05/04 R3

MAN222

Loading...

Loading...