Page 1

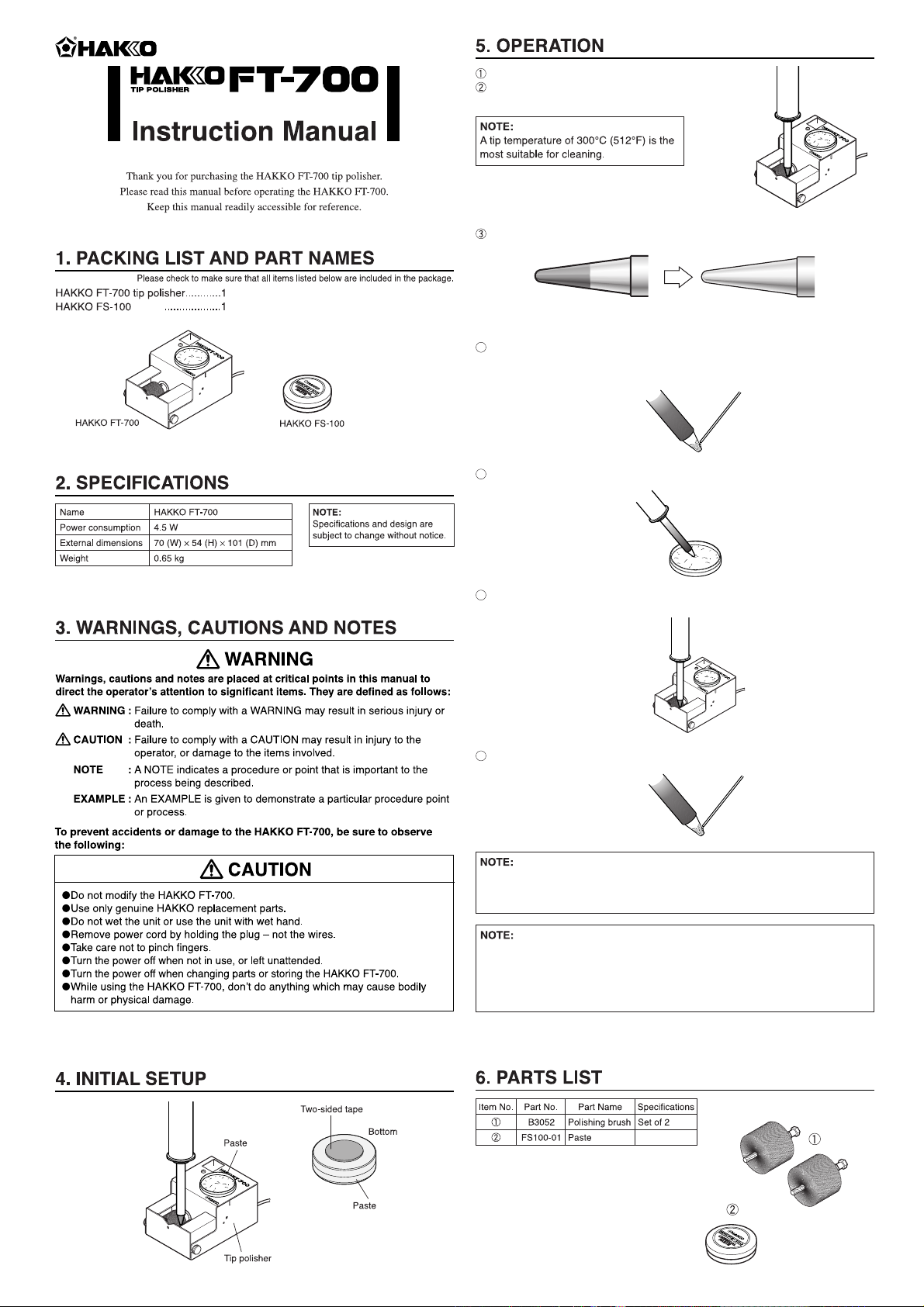

Turn on the power switch.

Touch the blackened tip to the polishing

brushes to remove the oxide film.

Inspect the tip to see that the oxide film has been removed by the HAKKO FT-700.

paste

Polished tipBlackened oxidized tip

4

If all of the oxide film has been removed by the HAKKO FT-700, promptly re-tin

the tip with the solder wire currently being used. If there is any oxide film

remaining, proceed to the next step.

5

If all of the oxide film could not be remvoed, touch the tip to the HAKKO FS-100

paste.

6

Touch the tip to the polishing burshes again to remove any remaining oxide film

and any paste residue.

7

Promptly re-tin the tip with the solder wire currently being used.

Even after being cleaned by the HAKKO FT-700, a tip temperature of 400°C

(752°F) or higher will blacken and oxidize the tip quickly unless it is re-tinned

promptly after cleaning.

The HAKKO FS-100 has more flux than typical flux cored solder. To prevent

flux residue from coming into contact with the P.W.B. after the HAKKO FS-100

is used, touch the tip to the polishing brushes of the HAKKO FT-700 to remove

any remaining residue on the tip and re-tin the tip using the solder wire

currently being used.

Page 2

HEAD OFFICE

4-5, SHIOKUSA 2-CHOME, NANIWA-KU, OSAKA, 556-0024 JAPAN

TEL:+81-6-6561-3225 FAX:+81-6-6561-8466

http://www.hakko.com/ E-mail:sales@hakko.com

AMERICAN HAKKO PRODUCTS, INC.

28920 N. AVENUE WILLIAMS VALENCIA CA 91355, U.S.A.

TEL: (661) 294-0090 FAX: (661) 294-0096

Toll Free (800)88-HAKKO http://www.hakkousa.com

4 2 5 5 6

Copyright © 2005 HAKKO Corporation. All Rights Reserved.

MA01358JZ050606

2005.6

Page 3

IMPORTANT SAFETY INSTRUCTIONS

WARNING−When using electric appliances, basic precautions should always

be followed, including the following.

Read all the instructions before using the appliance.

a) To reduce the risk of injury, close supervision is necessary when an

appliance is used near children.

b) Do not contact moving parts.

c) Only use attachments recommended or sold by the manufacture.

d) Do not use outdoors.

e) For a cord-connected appliance.

−Do not unplug by pulling on cord. To unplug, grasp the plug, not the

cord.

−Unplug from outlet when not in use and before servicing or cleaning.

−Do not operate any appliance with a damaged cord or plug ,or after

the appliance malfunctions or is dropped or damaged in any

manner. Return appliance to the nearest authorized service facility

for examination, repair, or electrical or mechanical adjustment.

f) To reduce the risk of electrical shock, do not put FT-700 in water or other

liquid. Do not place or store appliance where it can fall or be pulled into a

tub or sink.

g) Connect to a properly grounded outlet only. See Grounding Instructions.

SAVE THESE INSTRUCTIONS

INSTALLATION INSTRUCTIONS

GROUNDING INSTRUCTIONS

This appliance must be grounded. In the event of malfunction or breakdown,

grounding provides a path of least resistance for electric current to reduce the risk of

electric shock. This appliance is equipped with a cord having an equipment-

grounding conductor and a grounding plug. The plug must be plugged into an

appropriate outlet that is properly installed and grounded in accordance with all local

codes and ordinances.

Page 4

DANGER − Improper connection of the equipment-grounding conductor can

result in a risk of electric shock. The conductor with insulation having an outer

surface that is green with or without yellow stripes is the equipment-grounding

conductor. If repair or replacement of the cord or plug is necessary, do not connect

the equipment-grounding conductor to a live terminal. Check with a qualified

electrician or serviceman if the grounding instructions are not completely

understood, or if in doubt as to whether the appliance is properly grounded. Do not

modify the plug provided with the appliance−if it will not fit the outlet, have a proper

outlet installed by a qualified electrician.

For grounded, cord-connected appliances rated less than 15 A and intended for use

on a nominal 120 V supply circuit:

This appliance is for use on a nominal 120 V circuit, and has a grounding plug that

looks like the plug illustrated below. A temporary adaptor, which looks like the

adaptor illustrated in sketches B and C, may be used to connect this plug to a 2-pole

receptacle as shown in sketch B if a properly grounded outlet is not available. The

temporary adaptor should be used only unit a properly grounded outlet can be

installed by a qualified electrician. The green colored rigid ear, lug, and the like,

extending from the adaptor must be connected to a permanent ground such as a

properly grounded outlet box cover. Whenever the adaptor is used, it must be held in

place by the metal screw.

A qualified electrician should be consulted if there is any doubt as to whether an

outlet box is properly grounded.

2005.6

MA01428XZ050606

Loading...

Loading...