Page 1

Declaration of Conformity

GOM-802 DC MILLI-OHM METER

USER MANUAL

We

GOOD WILL INSTRUMENT CO., LTD.

No. 95-11, Pao-Chung Rd., Hsin-Tien City, Taipei Hsien, Taiwan

GOOD WILL INSTRUMENT (SUZHOU) CO., LTD.

No.69 Lushan Road, Suzhou New District Jiangsu , China .

declare that the below mentioned product

GOM-802

is herewith confirmed to comply with the requirements set out in the Council Directive on

the Approximation of the Law of Member States relating to Electromagnetic Compatibility

(89/336/EEC, 92/31/EEC, 93/68/EEC) and Low Voltage Equipment Directive

(73/23/EEC).

For the evaluation regarding the Electromagnetic Compatibility and Low Voltage

Equipment Directive, the following standards were applied:

◎ EMC

EN 61326-1: Electrical equipment for measurement, control and laboratory use –– EMC

requirements (1997+A1: 1998)

Conducted and Radiated Emission

EN 55011: 1998 class B

Current Harmonic

IEC 61000-3-2: 2000

Voltage Fluctuation

IEC 61000-3-3: 1995

-------------------------

-------------------------

-------------------------

-------------------------

Electrostatic Discharge

IEC 61000-4-2: 1995+A1: 1998

Radiated Immunity

IEC 61000-4-3: 1996+A1: 1998

Electrical Fast Transients

IEC 61000-4-4: 1995

Surge Immunity

IEC 61000-4-5: 1995

Conducted Susceptibility

IEC 61000-4-6: 1996

Power Frequency Magnetic Field

IEC 61000-4-8: 1993

Voltage Dips/ Interrupts

IEC 61000-4-11: 1994

◎ Safety

Low Voltage Equipment Directive 73/23/EEC & amended by 93/68/EEC

IEC / EN 61010-1: 2001

CONTENTS PAGE

1. PRODUCT INTRODUCTION............................ ........ ...........… …

1-1. Description…………………………………………………………..

1-2. Key Feature……………………………………………..…………..

1

2

2. SPECIFICATIONS………………...…………………………… 4

3. PRECAUTIONS BEFORE OPERATION…….………….…...

3-1. Unpacking the Instrument...…………….………….……………....

3-2. Checking the Line Voltage………………..………………………...

4. PANEL INTRODUCTION……………………..………….…...

4-1. Front Panel……………………………………………………….…

4-2. Rear Panel……………………………………….…………………..

5. OPERATION INTRODUCTION...……………………...……..

5-1. The [SHIFT] key and function keys………………..….…………...

5-2. Warm up…………………..………………………………………..

5-3. Over-range indicator…..……………………………………………

5-4. TRIG standby indication…………………………………………...

5-5. Input overload protection.….…………………………..…………..

5-6. Interface Operation…….…………………………………………..

5-7. Installation and Operation………………………………………….

6. MEASUREMENT INSTRUCTION……………………………

6-1. Resistance measurement……………………………………………

6-2. Temperature measurement………………………………………...

6-3. Temperature Compensation Measurement………………………..

6-4. General Function……………………………………………………

7. MEASUREMENT TECHNIQUES…………….………………

7-1. 4-wire measurement………………………………………………..

7-2. Temperature measurement………………………………………...

8. MAINTENANCE………………………………………….…….

8-1. Line fuse replacement……………………………….……………...

8-2. Line voltage conversion…..…………………………..…………….

8-3. Cleaning……………………………………………………………..

7

7

8

10

10

11

11

11

11

11

11

12

12

13

13

17

18

19

26

26

28

31

31

31

32

1

7

i

⎯ ⎯

Page 2

GOM-802 DC MILLI-OHM METER

USER MANUAL

GOM-802 DC MILLI-OHM METER

USER MANUAL

SAFETY TERMS AND SYMBOLS

These terms may appear in this manual or on the product:

WARNING. Warning statements identify condition or

practices that could result in injury or loss of life.

CAUTION. Caution statements identify conditions or

practices that could result in damage to this product or

other property.

WARNING: This equipment is not for measurements

performed for CAT II, III and IV.

The following symbols may appear in this manual or on the product:

FOR UNITED KINGDOM ONLY

NOTE: This lead/appliance must only be wired by competent persons

WARNING: THIS APPLIANCE MUST BE EARTHED

IMPORTANT: The wires in this lead are colored in accordance with

the following code:

Green/ Yellow: Earth

Blue: Neutral

Brown: Live (Phase)

As the colors of the wires in main leads may not correspond with the

colors marking identified in your plug/appliance, proceed as follows:

The wire which is colored Green & Yellow must be connected to the

Earth terminal marked with the letter E or by the earth symbol

DANGER ATTENTION Protective Earth(ground)

High Voltage refer to Manual Conductor Terminal

Terminal

ii

⎯ ⎯

or colored Green or Green & Yellow.

The wire which is colored Blue must be connected to the terminal

which is marked with the letter N or colored Blue or Black.

The wire which is colored Brown must be connected to the terminal

marked with the letter L or P or colored Brown or Red.

If in doubt, consult the instructions provided with the equipment or

contact the supplier.

iii

⎯ ⎯

Page 3

GOM-802 DC MILLI-OHM METER

USER MANUAL

GOM-802 DC MILLI-OHM METER

USER MANUAL

This cable/appliance should be protected by a suitably rated and

approved HBC mains fuse: refer to the rating information on the

equipment and/or user instructions for details. As a guide, cable of

0.75mm

2

should be protected by a 3A or 5A fuse. Larger conductors

would normally require 13A types, depending on the connection

method used.

Any mounded mains connector that requires removal /replacement

must be destroyed by removal of any fuse & fuse carrier and disposed

of immediately, as a plug with bared wires is hazardous if a engaged

in live socket. Any re-wiring must be carried out in accordance with

the information detailed on this label.

1. PRODUCT INTRODUCTION

1-1. Description

GOM-802 is a high precision programmable DC Milli-ohm meter suitable

for the low resistance measurements of switches, relays, connectors, PCB

tracks and variety of other devices. With the easy-to-use features, superior

performance, and automatic test interfaces described as below, GOM-802 is

obviously a reliable and handy instrument for the low resistance

measurements.

Easy-to-use features:

Utilizing the arrow key for setting the percentage of upper and lower limit based on

the normal value can make it easier to execute the HI-LO-GO comparator function.

Besides, through the Alarm Buzzer setting can indicate the PASS/FAIL status, and

all kinds of output status can be indicated through Handler Interface output.

The RELATIVE feature that enables GOM-802 to remove the stray resistance easily,

and the 20 sets of Normal/Hi/Lo setting memories can satisfy with different kind of

test condition. Also, the last setting will be recalled every time when the GOM-802

is turned on.

Superior Performance:

There are nine measurement ranges from 30mΩ to 3MΩ selected automatically or

manually with the constant current between 1μA and 1A, 0.05% high accuracy,

1μΩ resolution and four terminals Kelvin connection to make a reliable and

consistent test result.

The flexible choice for a high measurement accuracy at speed of 7 sampling/sec

(full scale at 30000) or a less measurement accuracy at speed of 30 sampling/sec

(full scale at 3000) can match with the speed requirement of test.

iv

⎯ ⎯

1

⎯ ⎯

Page 4

GOM-802 DC MILLI-OHM METER

USER MANUAL

GOM-802 DC MILLI-OHM METER

USER MANUAL

Temperature Compensation (Option):

The optional temperature probe PT-100 can control the measuring resistance to meet

the required temperature. When the temperature coefficient and required

temperature is keyed in under TC mode, GOM-802 will display the measuring

resistance corresponding to the required temperature.

Automatic Test:

For automatic system applications, the GOM-802 provides a handler interface that

can indicate the output status on PASS, FAIL, HI, LO, READY, or EOT, and

control signal of measurement trigger. An optional RS-232 GPIB is also available

for the computer control application.

Application:

z Production testing for contact resistance of switches, relays, connectors,

cables and printed circuit boards and other low resistance devices.

z Component testing of resistors, motors, fuses, heating elements.

z Incoming inspection and quality assurance testing.

z Conductivity evaluation for product design.

1-2. Key Feature:

z Four-wire measurement method.

z Auto-recall last setting on re-power on.

z Diode test.

z Alarm setting for PASS/FAIL test result.

z Sampling rate: 7 or 30 sampling/sec.

z Standard interface: Scan, Handler, optional interface: RS-232 GPIB.

z 30,000 counts.

z Measurement Range:

30mΩ~3MΩ.

z 0.05 high accuracy.

z Hi/Lo comparator and limit percentage setting with 20 memory sets.

z Measurement of REL, Actual and % value.

z Manual or Auto-ranging.

z Continuous or Trigger measurement mode.

z Temperature compensation and measurement.

2

⎯ ⎯

3

⎯ ⎯

Page 5

GOM-802 DC MILLI-OHM METER

h

USER MANUAL

GOM-802 DC MILLI-OHM METER

USER MANUAL

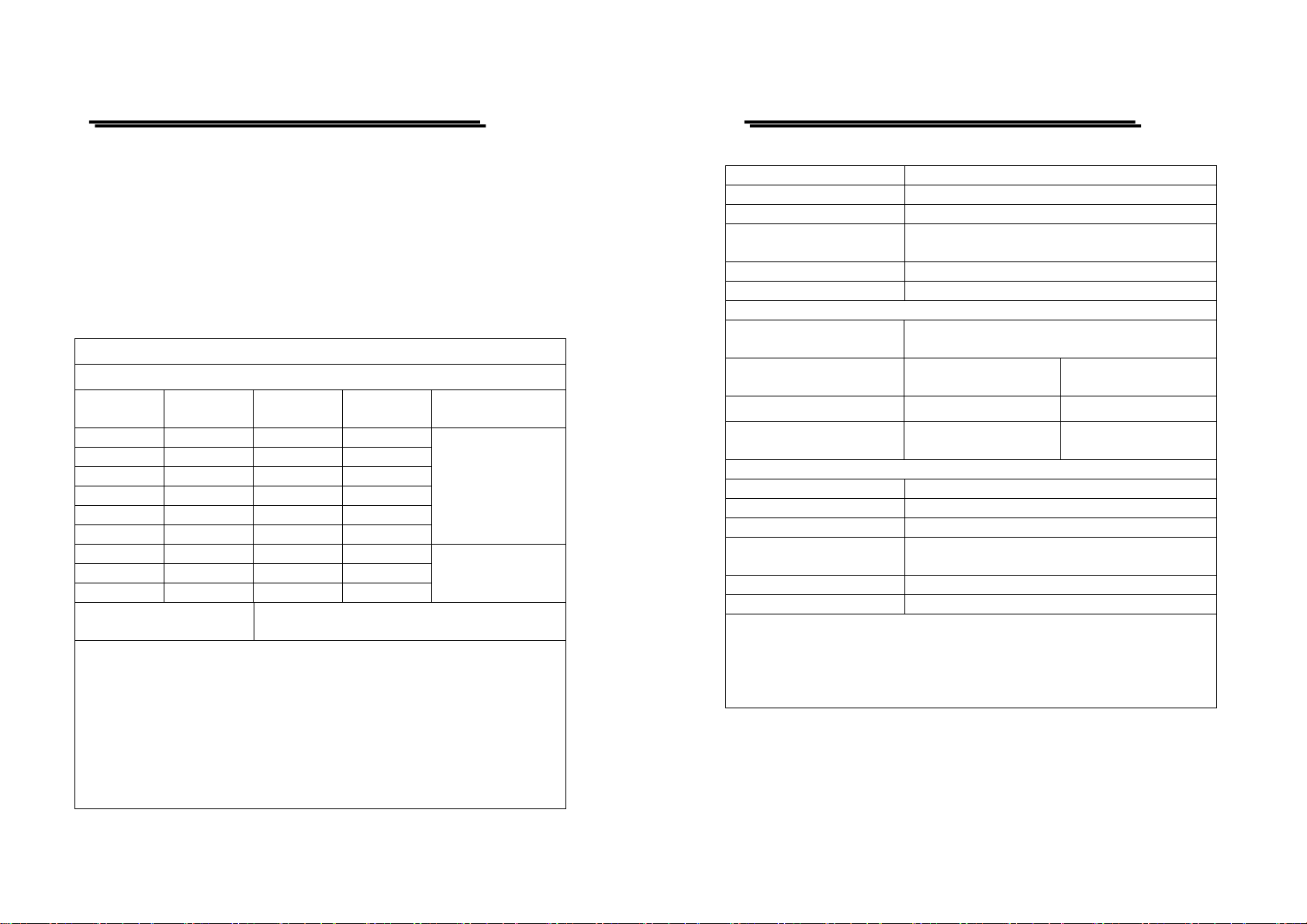

2. SPECIFICATIONS

The specifications are operated under the essen tial conditions as follows:

z A 1-year calibration cycle.

z An operating temperature of 18 to 28℃ (64.4 to 82.4℉).

z Relative humidity not exceeding 80%.

z Accuracy is expressed as ±(percentage of reading + digits).

z The instrument requires 30 minutes warm-up time to achieve rated

accuracy.

1. Resistance Measurement

30000 counts (speed : 7 times/second)

Range Resolution

Measuring

Current

Accuracy

30m 1μ 1A approx. 0.1%+6*

300m 10μ 100mA 0.05%+6*

3 100μ 100mA 0.05%+3

30 1m 10mA 0.05%+2

300 10m 1mA 0.05%+2

3k 100m 100μA0.05%+2

30k 1 100μA0.05%+2

300k 10 10μA0.05%+2

3Meg 100 1μA0.05%+2

3000 counts Accuracy

(speed: 30 times/second)

*When the instrument is set to 30mΩ or 300mΩ range, the resistance value will

be changed while connecting or disconnecting the test lead to the panel due to the

different temperature between internal and external of the instrument. Therefore,

it must wait 1 minute in order to obtain an accurate value after the test lead is

connected or disconnected.

* When use Kelvin clip to resume testing after long time ending, it needs more

time to wait for a stable value.

** In high speed mode, first assure that the instrument has been grounded throug

power cord.

±5 counts **

Open-terminal

Voltage

3V

4.8V

Measurement Four-terminal method.

Auto-ranging Provided.

Over input range“OL” indication

Maximum Applied voltage

Comparator 20 sets of comparator status can be selected.

Buzzer mode switchable NON, PASS, FAIL

2.Temperature Measurement

Temperature sensor (option)

Range

-9.9℃ ~ 39.9℃ 0.3%+0.5℃ 0.3%+2℃

-50.0℃ ~ -10.0℃

40℃ ~ 100℃

3. Temperature Correction Function

Temperature correction range 0.0℃~40.0℃

Reference temperature range 0℃~99.9℃

Thermal coefficient range ±9999 ppm

Temperature range

0℃~39.9℃ 0.3%+resistance measurement accuracy.

40℃~100℃ 0.6%+resistance measurement accuracy.

* The temperature coefficiency for the other setting must be calculated individually

according to different conditions.

* If the temperature coefficiency or the difference between the environmental

temperature and the require temperature exceeds normal operation, after

compensation calculation, the variation of the reading value will be tremendous.

30m~3Ω range: 30VpDC

Other range: 100VpDC

Platinum resistor.

Lead length: 1.5m approx.

Accuracy

Speed: 7 times/second

0.3%+1.0℃ 0.3%+3℃

Accuracy of temperature compensation for

3930 ppm/Cu wire, speed: 7 times/second.*

Accuracy

Speed: 30 times/second

4

⎯ ⎯

5

⎯ ⎯

Page 6

GOM-802 DC MILLI-OHM METER

USER MANUAL

GOM-802 DC MILLI-OHM METER

USER MANUAL

4. Interface

Signal: START TTL input

Signal: LOW, HIGH, FAIL, PASS, EOT, READY

Handler interface

Scanner

RS-232 GPIB (option) IEEE488.1-1987, IEEE488.2-1992 and SCPI-1994

5. ENVIRONMENTAL

Operation

Environment

Storage temperature

6. GENERAL

Power source

Accessories

Dimension 251(W)×91(H)×291(D) m/m

Weigh

total 6 TTL outputs.

(This function is valid only under the resistance

measurement mode and the compare mode is

enabled.)

Signal: READY, PASS, LOW, HIGH, CLOCK,

STRB total 6 TTL outputs.

(This function is valid only under the resistance

measurement mode and the compare mode is

enabled.)

Indoor use, altitude up to 2000m.

Ambient Temperature 0℃ to 40℃.

Relative Humidity 80% (Maximum).

Installation category II

Pollution Degree 2

-10℃ to 70℃.

AC 100V/120V/220V/230V±10%, 50/60Hz, 27VA,

22W.

Test Lead × 1, Instruction manual × 1,

Programmable manual × 1 (option),

Temperature sensor (option) × 1

Approx. 3 kg

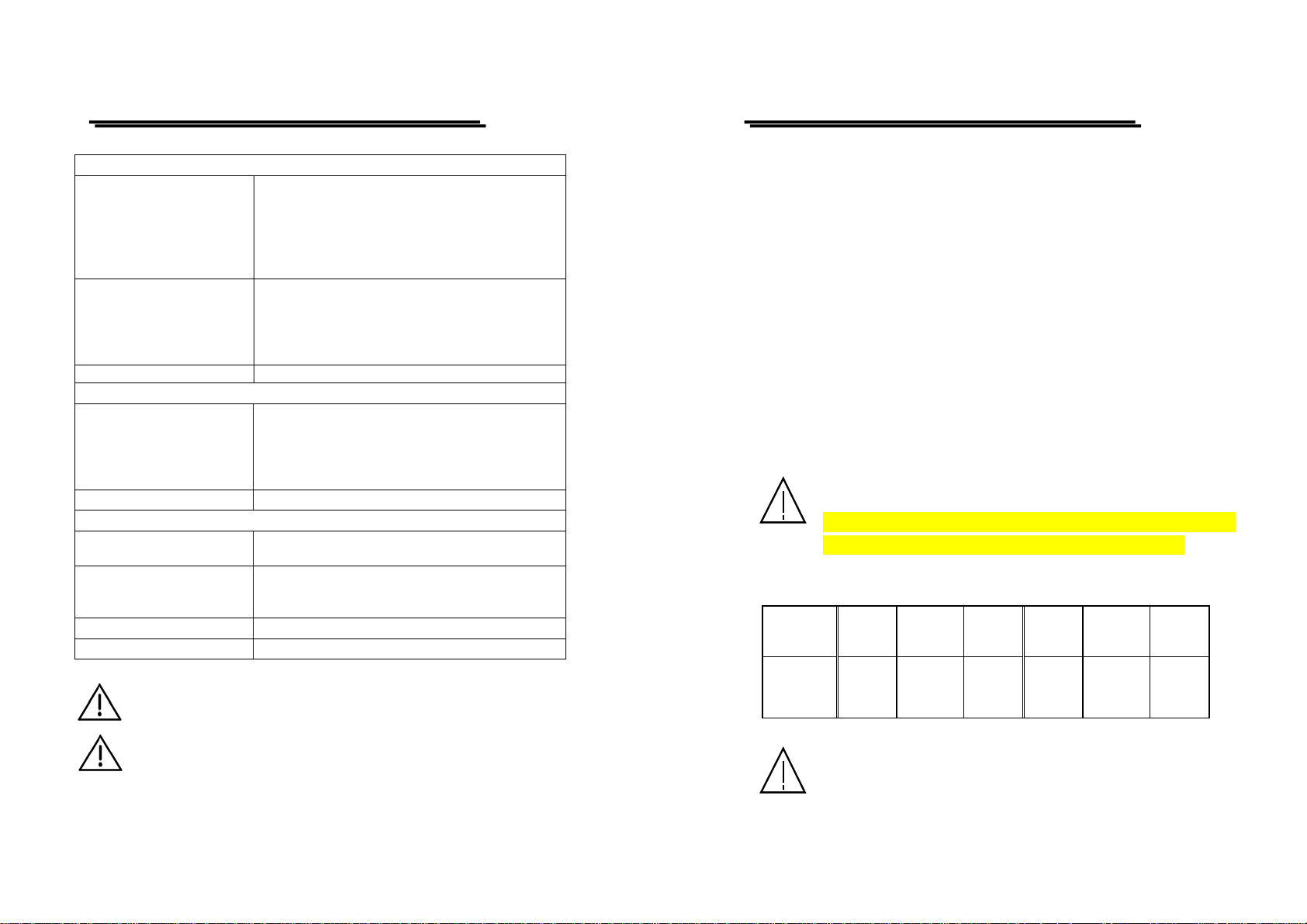

3. PRECAUTIONS BEFORE OPERATION

3-1.Unpacking the Instrument

The product has been fully inspected and tested before shipping from the factory.

Upon receiving the instrument, please unpack and inspect it to check if there is

any damage caused during transportation. If any sign of damage is found, notify

the bearer and/or the dealer immediately.

3-2.Checking the Line Voltage

The product can be applied by any ki nd of line vo ltage s sho wn in the table b elo w.

Before connecting the power plug to an AC line outlet, make sure the voltage

selector of the rear panel is set to the correct position corresponding to the line

voltage. It might be damaged the instrument by connecting to the wrong AC line

voltage.

WARNING. To avoid electrical shock the power cord protective

grounding conductor must be connected to ground.

AVERISS: Pour éviter les chocs électriques, le fil de terre du

cordon secteur doit impérativement être relié à la terre.

When line voltages are changed, replace the required fuses shown as below:

Model

Line

voltage

Range Fuse

Line

voltage

Range Fuse

WARNING: To avoid electrical shock, the power cord

protective grounding conductor must b e connect ed to grou nd.

CAUTION:To avoid damaging th e instrument , do not use it

in a place where ambient temperature exceeds 4

6

⎯ ⎯

0℃.

GOM-802

100V

120V

WARNING. To avoid personal injury, disconnect the power cord

before removing the fuse holder.

90-110V

108-132V

⎯ ⎯

TT0.3A

250V

7

220V

230V

198-242V

216-250V

T0.25A

250V

Page 7

GOM-802 DC MILLI-OHM METER

USER MANUAL

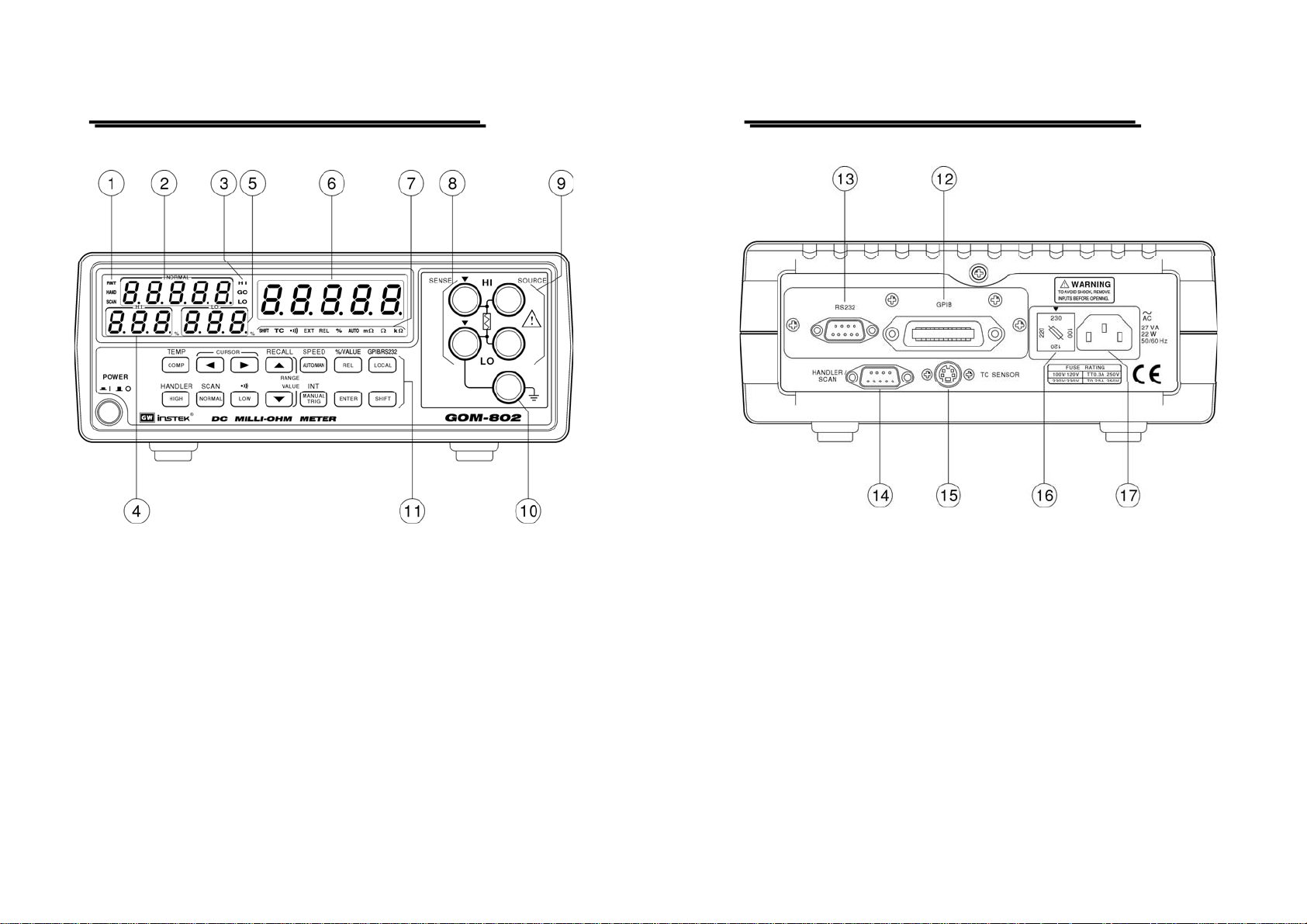

4. PANEL INTRODUCTION

GOM-802 DC MILLI-OHM METER

USER MANUAL

Figure 4-1. Front Panel

8

⎯ ⎯

Figure 4-2. Rear Panel

9

⎯ ⎯

Page 8

GOM-802 DC MILLI-OHM METER

USER MANUAL

GOM-802 DC MILLI-OHM METER

USER MANUAL

5. OPERATION INTRODUCTION

4-1. Front Panel

1. Interface Indicator

2. Normal value displayed area.

3. Comparator indicator.

4. Upper limit percentage display area.

5. Low limit percentage display area.

6. Measurement value displayed area.

7. Functions control indicator.

8. Measurement terminal: Sense HI, Sense LO

9. Current source terminal: Source HI, Source LO.

10. The negative measurement terminal has the same potential as the

circuit earth terminal, but can not be replaced by it.

11. Function Control knob.

WARNING: This equipment is not for measurements

performed for CAT II, III and IV.

4-2. Rear Panel

12. GPIB Interface terminal.

13. RS232 Interface terminal.

14. Handler and SCAN interface terminal.

15. Temperature compensation probe terminal (TC SENSOR).

16. Line voltage selector and input fuse holder.

17. AC Power-line connector.

5-1. The [SHIFT] key and function keys

The [SHIFT] button is used to enable the secondary function of certain

function keys that with blue symbols printed above. The SHI FT LED will

be on after pressed the [SHIFT] button. At this time, only the buttons with

blue symbols are workable. To release SHIFT function, press [SHIFT]

again.

5-2. Warm up

The instrument requires half-an-hour warm up to achieve rated accuracy.

5-3. Over-range indication

If the input exceeds the full scale of the selected range, the instrument will

indicate over-range input by lighting the “OL” message on the display.

5-4. TRIG standby indication

Under the TRIG mode, change the range or power on the instrument, the

“————” message will be displayed on the measurement displayed area,

now the instrument is in the TRIG standby status. The decimal is

represented the range. When proceeding the TRIG measurement, the

measurement displayed area will display the present measuring value.

5-5. Input overload protection

The maximum allowable input is shown as table 5-1. Please proceed the

measurement accordingly.

Table 5-1:

RANGE MAXIMUN INPUT

30mΩ, 300mΩ,3Ω 30Vp DC

Other ranges 100Vp DC

10

⎯ ⎯

WARNING: To avoid shock hazard and/or instrument

damage, do not apply input potentials that exceed the input

overload limits shown in table 5-1.

11

⎯ ⎯

Page 9

GOM-802 DC MILLI-OHM METER

USER MANUAL

GOM-802 DC MILLI-OHM METER

USER MANUAL

5-6. Interface Operation

This instrument equips RS-232 as standard device with a D-SUB 9 PIN

SHELL on the rear panel. Besides, the instrument also provides a GPIB

option device with a 24 PIN SHELL in blue. The configuration is

compliance with IEE488.

For further detailed operation, please refer to the Interface manual.

5-7. Installation and Operation

Operate the GOM-802 in a location with a suitable environment free from

dust, direct exposition of sunlight, and strong effect of magnetic fields.

If you have no idea about the resistor value b efore testing, start from the

high resistor value range to the low until the right value can be read out.

6. MEASUREMENT INSTRUCTION

6-1. Resistance measurement

(1) Resistance measurement function

1) Get into resistance measurement function by pressing [SHIFT] and

[TEMP] in sequence to select main function mode.

2) Press [▲]or[ ▼ ] can switch over the function, and 3 kinds of

measurements “ohm”, “℃” and “TC” will be displayed on the panel.

3) Press “ohm” and [ENTER] to get into resistance measurement

mode.

4) Use [▲]or[▼] to switch to adequate range or press [AUT/MAN] for

Auto range measurement.

(2) Compare function

Compare function:

1) Enable or disable the Compare function by pressing [COMP]

button.

2) Make HI, GO, LO judgment shown on the panel indicator according

to the setting of the upper and low normal value percentage.

3) When the Compare function is relieved, the setting for % and REL

will be relieved too.

Example:

Normal value: 100.00

up limit: 10.0% = up limit value: 110.00

down limit: 20.0% = down limit value: 80.00

The indicators of GO, HI, and LO will be lighted up according to

the resistance value of DUT:

109.00 GO indicator lights up

12

⎯ ⎯

120.00 HI indicator lights up

70.00 LO indicator lights up

Normal value setting:

13

⎯ ⎯

Page 10

GOM-802 DC MILLI-OHM METER

USER MANUAL

GOM-802 DC MILLI-OHM METER

USER MANUAL

1) Under Compare function, press [NORMAL] button to turn on/off

the function of normal value setting.

2) When the normal value setting is enabled, the maximum number

displayed on the normal value area will be flashing, adjust the value

by using

[ ], then press [ENTER] to confirm the correct value. The maximum

normal value is set at 33000 while the minimum normal value is set at

00000.

[▲]and [▼], and move the flashing number by using [ ] or

3) After setting, the HI, LO, GO judgment is according to the new

setting value.

4) If the setting is not saved, once jump out the setting function and re-

power on, the setting will be cleared.

High limit percentage setting:

1) Under the compare function, press [HIGH] to turn on/off the up

limit percentage setting function, and press [SHIFT] to clear the

setting.

2) After setting, the maximum number displayed on the up limit

percentage area will be flashing, adjust the value by using

[▼], and move the flashing number by using [ ] or [ ], then press

[ENTER] to confirm the correct value. The maximum up limit percentage

value is set at 999 while the minimum up limit percentage value is set at

000.

[▲]and

3) After setting, the HI, LO, GO judgment is according to the new

setting value.

4) If the setting is not saved, once leave the setting function and re-

power on, the setting will be cleared.

Low limit percentage setting:

1) Under the comp are function, press [LOW] to turn on/off the down

limit percentage setting function, and press [SHIFT] to clear the

setting.

2) After setting, the maximum number displayed on the up/down limit

percentage area will be flashing, adjust the value by using

[▼], and move the flashing number by using [ ] or [ ], then press

[ENTER] to confirm the correct value. The maximum down limit

percentage value is set at 999 while the mi nimum down limit percentage

value is set at 000.

[▲]and

3) After setting, the HI, LO, GO judgment is according to the new

setting value.

4) If the setting is not saved, once leave the setting function and re-

power on, the setting will be cleared.

The save function for the compare setting:

1) Under Compare function, set the high and low limit percentage of

normal value according to the setting procedure of Normal value,

High limit percentage and low limit percentage.

2) Press [SHIFT] and [RECALL]

in sequence getting into save and

recall function of Compare setting.

3) Switch to save function by pressing

message will be displayed on the panel, press [ENTER] to confirm the

setting, or press [SHIFT] to clear the setting.

[▲] or [▼], and the “SAVE”

4) Among the message “S MXX” displayed on the panel, XX means the

number of the storage group from 00 to 19. Use [▲] or [▼], [ ] or

[ ] to adjust the save location, then press [ENTER] to replace the

previous save location, or press [SHIFT] to clear the setting.

14

⎯ ⎯

15

⎯ ⎯

Page 11

GOM-802 DC MILLI-OHM METER

USER MANUAL

GOM-802 DC MILLI-OHM METER

USER MANUAL

The recall function for the c omp are s ett ing:

1) Under Compare function, set the high and low limit percentage o f

normal value according to the setting procedure of Normal value,

High limit percentage and low limit percentage.

2) Press [SHIFT] and [RECALL]

in sequence getting into save and

recall function of Compare setting.

3) Switch to recall function by pressing

message will be displayed on the panel, press [ENTER] to confirm the

setting, or press [SHIFT] to clear the setting.

[▲] or [▼], and the “CALL”

4) Among the message “C MXX” displayed on the panel, XX means the

number of the recall group from 00 to 19. Use [▲] or [▼], [ ] or [ ]

to adjust the recall location, the panel will display the normal value and

the up/down limit percentage of normal value.

5) After recall setting, the HI, LO, GO judgment is according to the

new setting value.

The Buzzer function setting:

1) Under the Compare mode, press [SHIFT] and [ ]

in sequence

getting into buzzer setting. The panel will display the present

setting status, the message “NON” means no action, “bP” means the

buzzer is activated when the test is pass, and “bF” means the buzzer

is activated when the test is failed.

2) Use

[▲] or [▼] to select “NON”, “bP” or “bF”, then [ENTER] to confirm

the setting, or press [SHIFT] to clear the setting.

3) The buzzer will be disabled once leave the Compare mode.

Display measurement value percentage:

1) Under the Compare mode, press [SHIFT] and [%/VALUE]

sequence

to select resistance value which is based on actual value or

normal value to calculate the percentage, and displays it on the

panel.

Normal value: 20.000

Actual value: 10.000

Percentage: 050.00%

2) Enable the measurement value percentage calculation, and the auto

range function will be annulled.

(3) REL FUNCTION

1) Use this function to do zero adjustment when the test lead or the

resistance of the DUT needs to be adjusted.

2) Pre-set a refe ren ce v alu e, th en eve ry v alu e mu st minu s th e re fer ence

value before displaying on the panel for the compare judgmen t.

3) Under the compare mode, enable REL function, the auto-range

function will be annulled.

4) After calculation, if the value is negative, the minus symbol and the

number will be displayed alternately on the position of MSD (most

significant digit) under low converted speed mod e (7 ti mes/second),

while only the minus symbol will be displayed on the position of

MSD under high converted speed mode.

6-2. Temperature measurement

(1) Temperature measurement

1) Connect an optional temperature probe to the rear panel.

2) Press [SHIFT] and [TEMP]

in sequence getting into main function

selection mode.

in

3) Press

[▲] or [▼] can switch over 3 kinds of functions of “ohm”, “℃”, and

“TC” on the panel.

4) Select “ ℃ ”and press [ENTER] getting into temperature

measurement mode. The measuring value will be displayed on the

normal value displayed area.

16

⎯ ⎯

17

⎯ ⎯

Page 12

GOM-802 DC MILLI-OHM METER

USER MANUAL

GOM-802 DC MILLI-OHM METER

USER MANUAL

(2) REL function

Pre-set a reference value, then every value must minus the reference

value before displaying on the panel for the compare judgment.

(3) Single range

There is only a single range for the temp eratu re me asure ment.

6-3. Temperature Compensation Measurement

(1) Temperature compensation measurement mode

1) The adequate resistance value of the DUT can be calculated through

the environment temperature, the setting coefficient of temperature

of the DUT, and the requ ire ob serv ation temp era tur e.

2) Press [SHIFT] and [TEMP]

in sequence getting into main function

selection mode.

3) Press

[▲] or [▼] can switch over 3 kinds of functions of “ohm”, “℃”, and

“TC” on the panel.

4) Select “TC” and press [ENTER] getting into temperature compensation

measurement mode.

5) The up limit percentage area display the observation temperature and the

setting coefficient of temperature will be displayed on the normal value

displayed area.

6) Use [▲] or [▼], [ ] or [ ] to set the require observation temperature

and the coefficient of temperature, then press [ENTER] to confirm the

setting or press [SHIFT] to clear the setting.

(3) REL function

Pre-set a reference value, then every value must minus the reference

value before displaying on the panel for the compare judgmen t.

6-4. General Function

(1) Converted speed selection

1) Press [SHIFT] and [SPEED]

in sequence to switch over the

converted speed.

2) Low converted speed: 7 times/second, full scales: 30000.

3) High converted speed: 30 times/second, full scale: 3000.

4) The converted speed function can be app lied on the measurement of

resistance, temperature, and temperature compensation.

(2) Auto range function

1) Press [AUTO/MAN] to switch over auto range or manual range.

2) Under the Compare mode, switch over the range will annulled the

previous setting of % or REL function.

3) The temperature measurement only has a single range.

4) Under external trigger mode, Auto range function is disabled.

(3) Trigger function

1) Press [MANUAL TRIG] getting into external trigg er mode.

2) Each time when the [MANUAL TRIG] bu tton is pressed, the EXT

LED will be flashing once and the panel value will be updated again.

Press [SHIFT] and [INT]

in sequence to leave Trig mode.

(2) Range selection

[▲] or [▼] to switch over the range or set [AUTO/MAN] to auto range

Use

mode.

18

⎯ ⎯

19

⎯ ⎯

Page 13

GOM-802 DC MILLI-OHM METER

K

USER MANUAL

GOM-802 DC MILLI-OHM METER

USER MANUAL

3) Under the TRIG mode, change the range or power on the instrument, the

“————” message will be displayed on the measurement displayed area,

now the instrument is in the TRIG standby status. The decimal is

represented the range. When proceeding the TRIG measurement, the

measurement-displayed area will display the present measuring value.

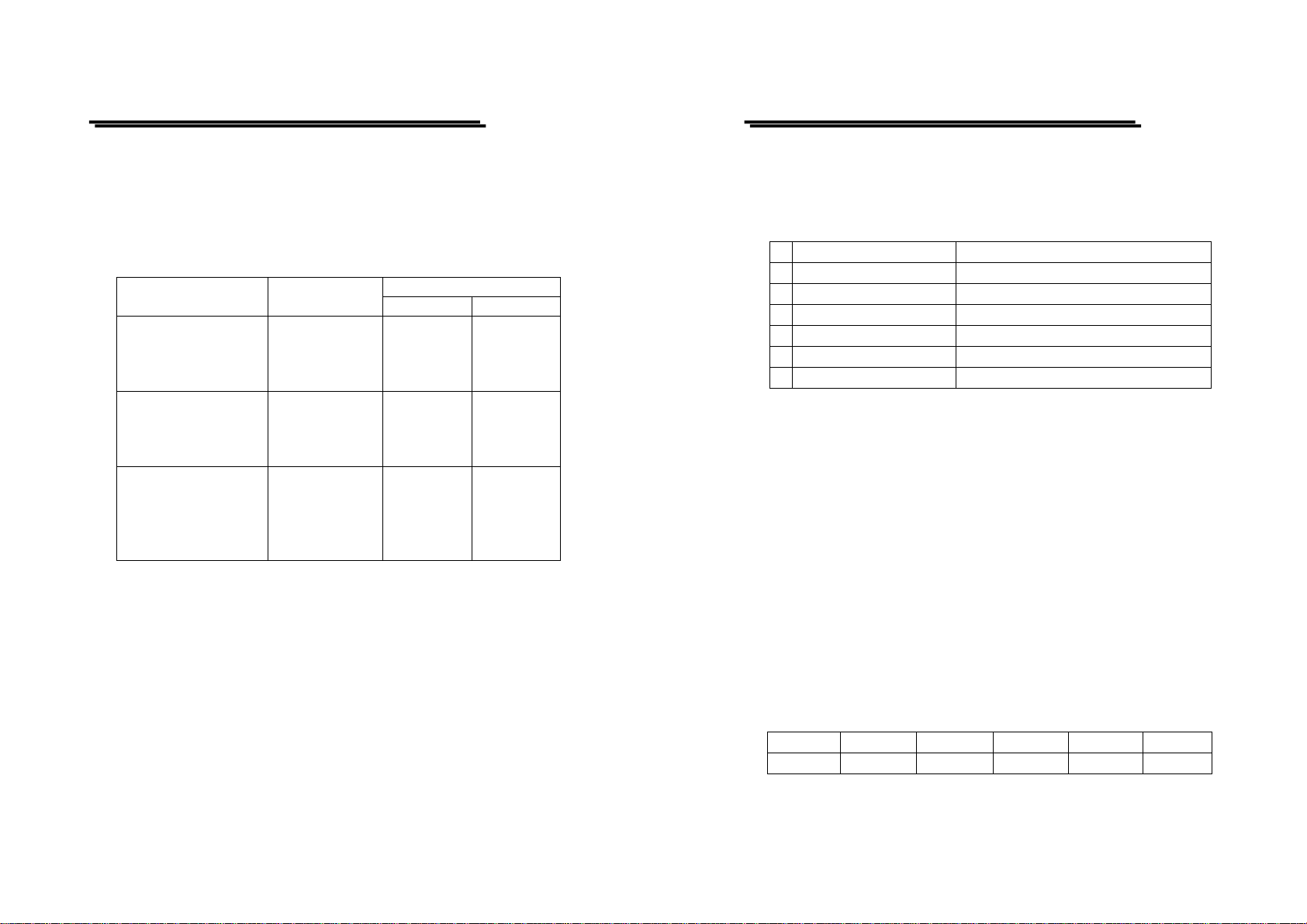

(4) Handler interface

The handler interface provides a TTL input (START), 6 TTL outpu ts,

including LOW, HIGH, FAIL, PASS, EOT and READY (

valid only under the resistance measurement mode and the compare mode is

enabled).

9-PIN D-SHELL (FEMALE)

READY

EOT

LOW

HIGH

START

GND

+5V

PASS

FAIL

This function is

START: Start trigger and proceed one time measurement, negative edge

trigger.

READY: Output “1” to GND, means the measurement is co mpleted and

can proceed next trigger.

FAIL: Output “1” to GND, means the judgment of the compare

function is High or low.

PASS: Output “1” to GND, means the judgment of the compare

function is GO.

The output current from all output collector and +5V

terminal can not exceed 60mA.

(5) Interface setting

Please refer to the programmable manual.

(6) SCAN interface

1) The scan interface provides 6 TTL outputs, including READY,

PASS, LOW, HIGH, FAIL, CLOCK, and STRB.

9-PIN D-SHELL (FEMALE)

RELAY

PASS

STRB

CLOC

RELAY: Control the relay signal, and series signal output.

PASS: Indicate PASS sign al, and series signal output.

GND

+5V

LOW

HIGH

EOT: Output “1” to GND, means the AD convert procedure is

completed, can change the DUT.

LOW: Output “1” to GND, means the judgment of the compare

function is low.

HIGH: Output “1” to GND, means the judgment of the compare

function is high.

20

⎯ ⎯

LOW: Indicate LOW signal, and series signal output.

HIGH: Indicate HIGH signal, and series signal output.

CLOCK: When every group of output signal (including READY,

PASS, LOW, HIGH) is ready, a CLOCK signal will be sent

out. There are 100 groups of output signals totally.

STRB: After all 100 groups of output signals have been ready, a

STRB signal will be sent out.

21

⎯ ⎯

Page 14

GOM-802 DC MILLI-OHM METER

USER MANUAL

GOM-802 DC MILLI-OHM METER

USER MANUAL

2) SCAN Operation

{ Set to SCAN mode from the resistance measurement mode, first

enable the compare func tion and ch ange the r ange manual ly, th en

press [SHIFT] and [SCAN] in sequence.

| Set sweep count by adjusting

maximum count can be up to number 100. Press [ENTER] to confirm

the setting or press [SHIFT] to cancel the setting.

[▲] or [▼], [ ] or [ ], the

} Set one count sweep delay time up to 30000 unit maximum or 30 unit

minimum (unit: 16.2ms) by adjusting [▲] o r [▼], [ ] or [ ], then

press [ENTER] to confirm the setting or press [SHIFT] to cancel the

setting.

~ When the setting is completed, the message of “READY” will be

displayed on the measurement value displayed area. Now the setting of

range and up/down limit of the compare function can not be changed.

Proceed sweep function by press [MANUAL TRIG], and the result will

be output through SCAN interface.

Press [SHIFT] and [SCAN] in sequence to leav e S CAN mo de.

After sweep, the measurement results can be observed by

adjusting

[▲] or [▼].

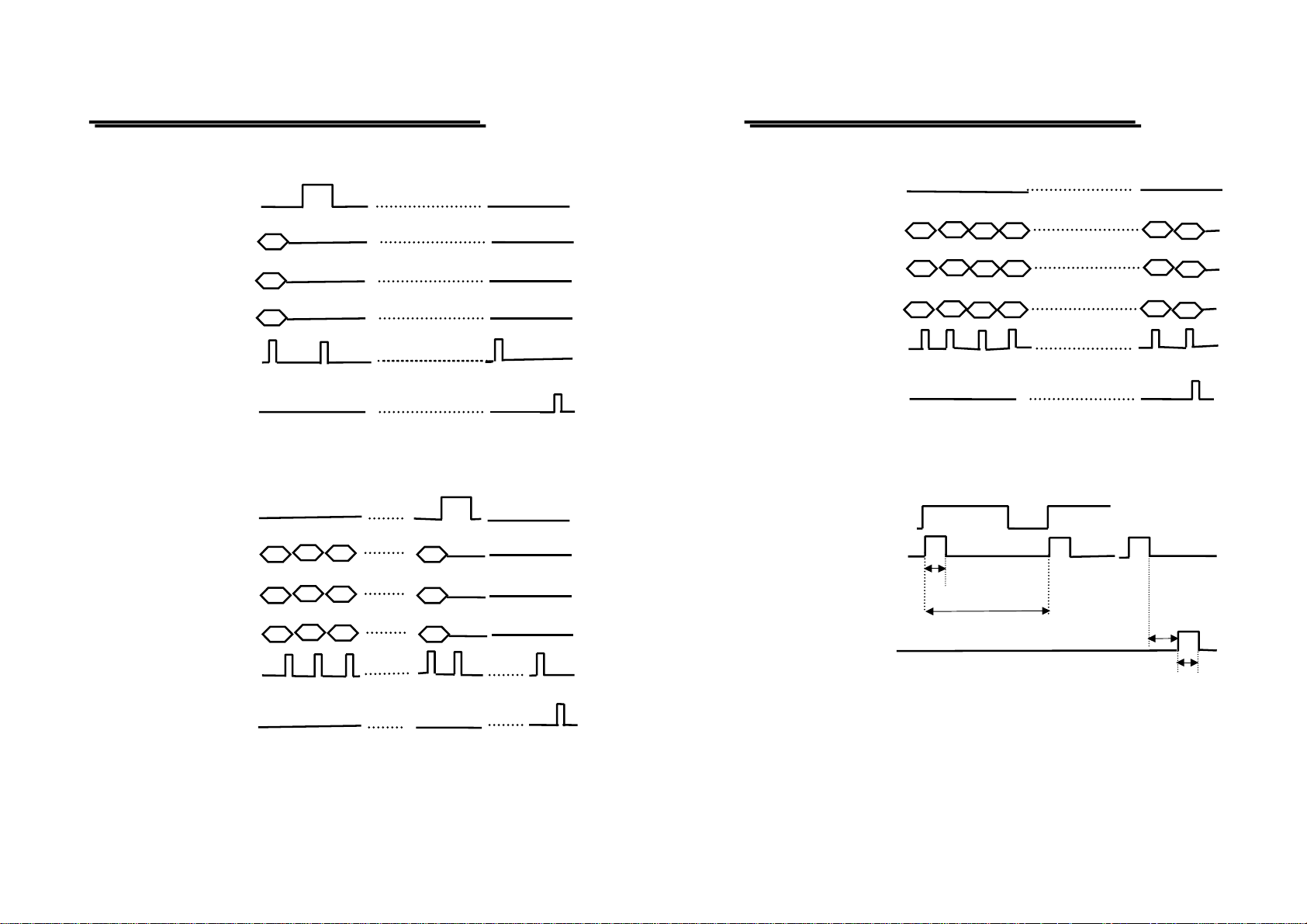

Please refer to the procedure of SCAN interface output as follows:

Step 1. After the SCAN setting, the message of “READY” will be

displayed on the panel, SCAN interface starts output:

RELAY:

PASS:

LOW:

HIGH:

CLOCK:

∬∬

1 2 3 4 99 100

STRB:

Step 2. Press [MANUAL TRIG] to start scan:

RELAY:

∬∬

PASS: ∬∬

LOW: ∬∬

HIGH: ∬∬

CLOCK: ∬∬

1 2 99 100

22

⎯ ⎯

STRB: ∬∬

23

⎯ ⎯

Page 15

GOM-802 DC MILLI-OHM METER

2μs

μ

s

μ

s

USER MANUAL

GOM-802 DC MILLI-OHM METER

USER MANUAL

Step 3: Scan channel on e, the swe ep d elay ti me is up:

RELAY:

∬∬

PASS: ∬∬

LOW: ∬∬

HIGH: ∬∬

CLOCK: ∬∬

1 2

100

STRB: ∬∬

Step 4: Scan channel n, the sweep delay time is up:

RELAY:

∬∬ ∬

PASS: ∬∬ ∬

LOW: ∬∬ ∬

Step 5: Scan channel 100, the sweep delay time is up:

RELAY:

∬∬

PASS: ∬∬

LOW: ∬∬

HIGH: ∬∬

CLOCK: ∬∬

99 1001 2 3 4

STRB: ∬∬

The account of output time for SCAN interface:

Data:

∬

Clock: ∬

20

HIGH: ∬∬ ∬

128μs

3

STRB: ∬

CLOCK: ∬∬ ∬∬

1 2 3

n n+1

100

20

STRB ∬∬ ∬∬

24

⎯ ⎯

25

⎯ ⎯

Page 16

GOM-802 DC MILLI-OHM METER

I

I

USER MANUAL

7. MEASUREMENT TECHNIQUES

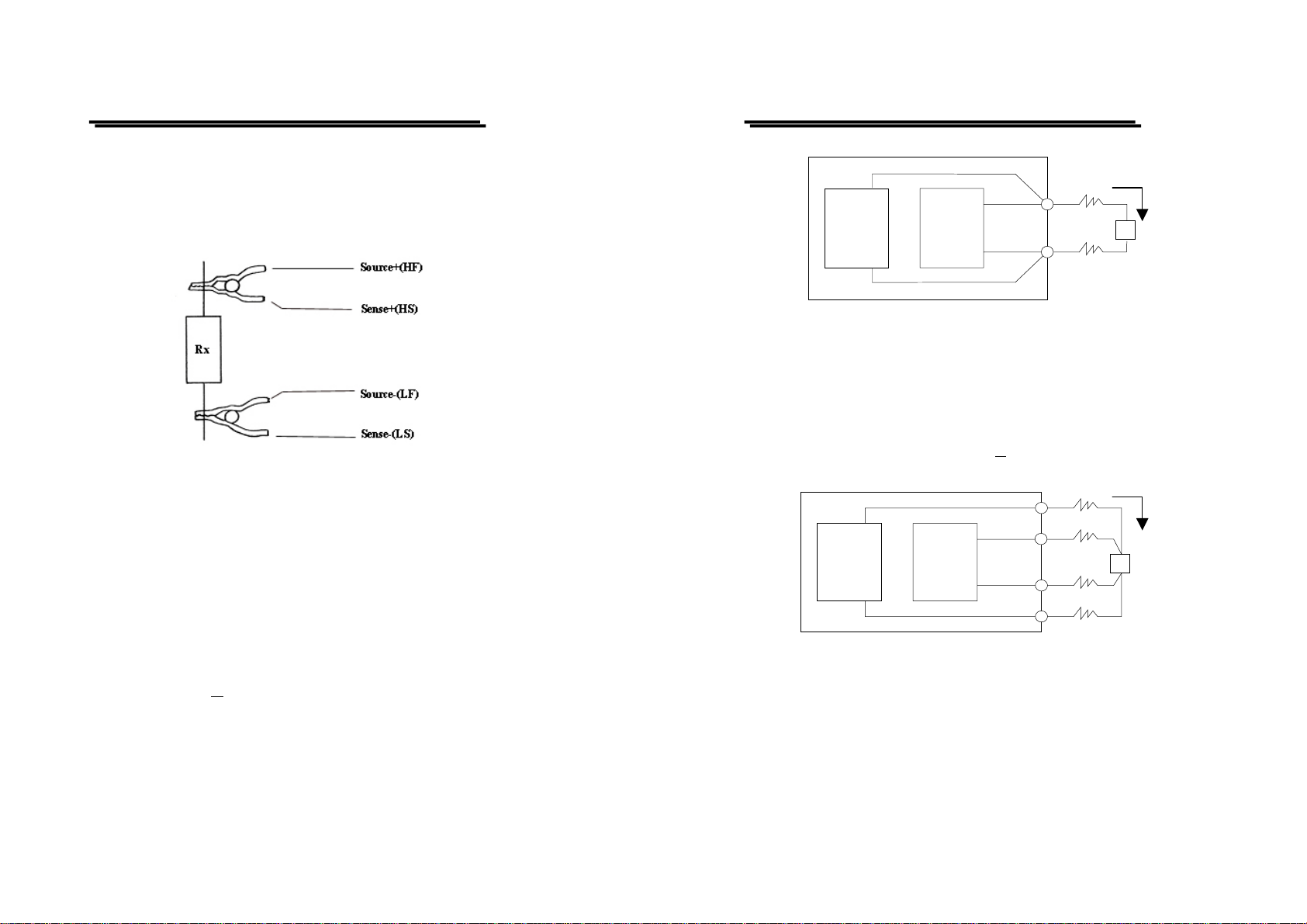

7-1. 4-wire measurement

(1) The 4-wire measurement can eliminate wire resistance and get accurate

resistance. Please refer to the wiring method as Figure 7-1.

Figure 7-1

Note: 1. Before testing, make sure that the KELVIN clip is well

connected with the DUT.

2. The terminals of HF (Source HI), LF (Source LO), HS (Sense

HI) and LS (Sense LO) must be connected to front panel

terminals properly.

(2) Pr incip le

1) The traditional 2-wire measurement result combines the test lead

resistance. Please refer to Figure 7-2 for the measurement result:

V

++=

21 rRr

GOM-802 DC MILLI-OHM METER

USER MANUAL

r1

CONSTANT

CURRENT

SOURCE

VOLTMETER

Ohm Meter

+

V

_

R

r2

Figure 7-2

2) 4-wire measurement.

The 4-wire measurement takes advantage of the high input

resistance characteristic of the voltmeter that there is no voltagedrop on r3 and r4 as no current getting through these resistances.

Therefore, the voltmeter can measure the voltage precisely on the

resistance.

The measuring result is:

CONSTANT

CURRENT

SOURCE

VOLTMETER

Ohm Meter

R =

V

r1

r3

+

R

V

_

r4

r2

Figure 7-3

(3) Zeroing

The clip of test lead includes Source+ (HF), Source- (LF), Sense+

(HS), Sense- (LS) terminals. Before zeroing test, make sure that the

clip of Sense+ is next to Sense- for accurate zeroing test. When the

quality of the wire and material can not be guaranteed, use REL

function for zeroing adjustment.

I

I

26

⎯ ⎯

27

⎯ ⎯

Page 17

GOM-802 DC MILLI-OHM METER

USER MANUAL

GOM-802 DC MILLI-OHM METER

USER MANUAL

7-2. Temperature measurement

(1) Reference temperature

The international Temperature Scale (ITS) is based on the following

table 7-1 which was revised in 1990 with seventeen fixed points and

corresponding temperatures.

Table 7-1:

Element Type

(H2)

(Ne)

(O

(Ar)

(Hg)

(H

(Ga)

(In)

(Sn)

(Zn)

(Al)

(Ag)

(Au)

)

2

O)

2

Hydrogen

Neon

Oxygen

Argon

Mercury

Water

Gallium

Indium

Tin

Zinc

Aluminum

Silver

Gold

Tripple point

Tripple point

Tripple point

Melting point

Freezing point

Freezing point

Temperature

K ℃

13.8033

24.5561

54.3584

83.8058

234.325

273.16

302.9146

429.7485

505.078

692.677

933.473

1234.93

1337.33

Note: 1. Temperature unit:

Thermodynamic temperature: T

Kelvin: K

2. Temperature scale:

Celsius scale: ℃

Rankinescale:

°R

Kelvin: ℉

℃ =5/9 (℉-32)

K = ℃+273.15

°R= ℉+459.67

-259.3467

-248.5939

-218.7916

-189.3442

-38.8344

+0.01

29.7646

156.5985

231.928

419.527

660.323

961.78

1064.18

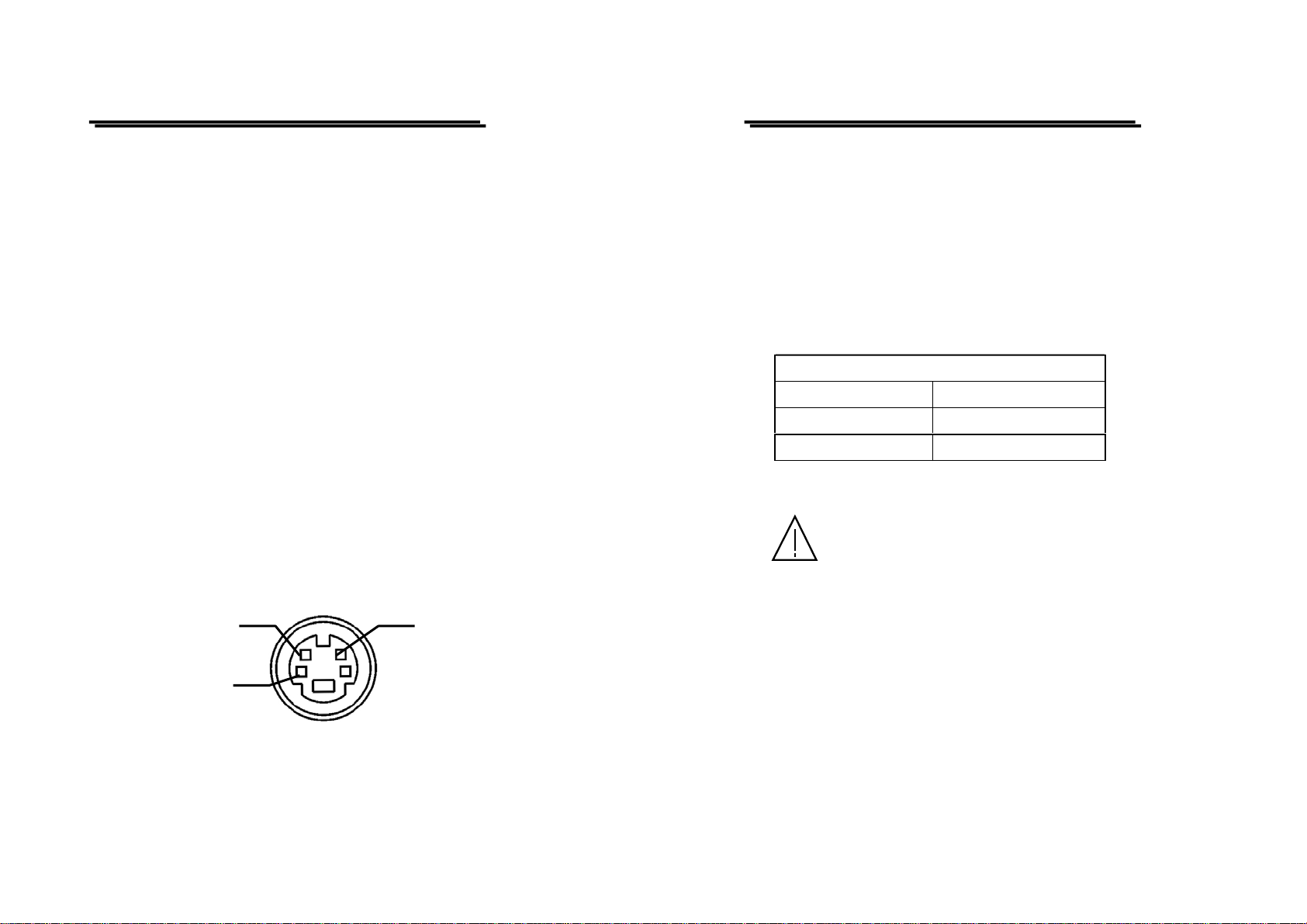

(2) Temperature measurement sensor

The common usage for the resistance temperature detectors, RTD, is to

convert temperature into electro signal. Please refer to following tab le

7-2 of its feature:

Table 7-2

Feature Description

1. Accuracy Higher accuracy

2. Resolution 0.1~1.0℃ higher resolution

3. Speed of response Slower

4. Self-heating yes

5. Long term stability Good

6. Output characteristic Approx. 0.4 ohm/℃, near linear.

(3) Optional Platinum resistance sensor

This kind of temperature probe meets the specification of German

DIN43760: 1968, 3-wire measurement.

The relation between temperature and resistance can refer to the

description of the Gallendarvan Dusen Equation as follows:

R

RTD=R0

Where: R

[1+AT+BT2+CT3(T-100)]

is the calculated resistance of the RTD.

RTD

R

is the known RTD resistance at 0℃.

0

T is the temperature in ℃.

A=alpha [I+(delta/100)]

B=-I(alpha)(delta)(Ie-4)

C=-I(alpha)(beta)(Ie-8)

The alpha, beta, and delta values are listed in Table 7-3.

Table 7-3

Type Standard Alpha Beta Delta Ωat 0℃

PT-100 ITS90 0.003850 0.10863 1.49990 100Ω

28

⎯ ⎯

29

⎯ ⎯

Page 18

GOM-802 DC MILLI-OHM METER

USER MANUAL

GOM-802 DC MILLI-OHM METER

USER MANUAL

Example—Calculate the resistance of a PT-100 RTD at 100℃(T). The

following R

(Ωat 0℃), alpha, beta, and delta values are used for the

0

PT-100 RTD:

T=100℃

R

(Ωat 0℃)=100Ω

0

Alpha=0.003850

Beta=0.10863

Delta=1.49990

A, B, and C are calculated according to above value as follows:

A=0.00391

B=5.77e-7

C=4.18e-12

The resistance of the RTD at 100℃ (R100) is then calculated as

follows:

R

[1+AT=BT2+CT3(T-100)

100=R0

=100{1+[(0.00391)(100)]+[(-5.77e-7)(100

3

(100

)(100-100)]]

2

)+[(-4.18E-12)

=100[1+0.391+(-0.006)+0]

=100(1.385)

=138.5Ω

(4) Temperature Sensor Terminals

8. MAINTENANCE

Qualified personnel execute the following instructions only. To avoid

electrical shock, do not perform any servicing other than the operating

instructions unless you are qualified to do so.

8-1. Line fuse replacement

If the fuse blows, the meter would not work. Try to determine and correct

the cause of the blown fuse, then replace the fuse with correct rating and

type shown as below:

FUSE RATING AND TYPE

100/120V TT0.3A 250V

220/230V T0.25A 250V

F101 on PCB T6.3A 250V

WARNING: For continued fire pr otect ion, rep lace o nly

with 250V fuse of the specified type and rating, and

disconnect the power cord before proceeding fuse

replacement.

Source+ Sense-

Source-

Sense+

30

⎯ ⎯

8-2. Line voltage conversion

The primary winding of the power transformer is tapped to permit

operation from 100/120V, or 220/230V AC 50/60Hz line voltage.

Conversion from one line voltage to another is done by changing the line

voltage selector switch as shown in Figure 4-2. The rear panel identifies

the line voltage to which the unit was factory set. To convert to a

different line voltage, perform the following procedure:

31

⎯ ⎯

Page 19

GOM-802 DC MILLI-OHM METER

USER MANUAL

1) Make sure the power cord is unplugged.

2) Adjust the line voltage selector switch to the desired line voltage

position.

3) A change in line voltage may also require a corresponding change

of fuse value. Install the correct fuse value as listed on rear panel.

8-3. Cleaning

To keep the instrument clean, wipe the case with a damp cloth and

detergent. Do not use abrasives or solven ts.

32

⎯ ⎯

Loading...

Loading...