Page 1

Service Document

Exchange Set

RRCD 1300

Service

Manual

Sicherheit

Safety

Materialnr./Part No.

720108000001

Dieses Service Dokument ist nur in Datenform verfügbar

This Service Document is only available as data

Änderungen vorbehalten/Subject to alteration

Made by GRUNDIG in Germany • HS-41 0305

http://www.grundig.com

Es gelten die Vorschriften und Sicherheitshinweise

gemäß dem Service Manual "Sicherheit", Material-

S

nummer 720108000001, sowie zusätzlich die eventuell abweichenden, landesspezifischen Vorschriften!

The regulations and safety instructions shall be

valid as provided by the "Safety" Service Manual,

S

part number 720108000001, as well as the

respective national deviations.

ǵ

Page 2

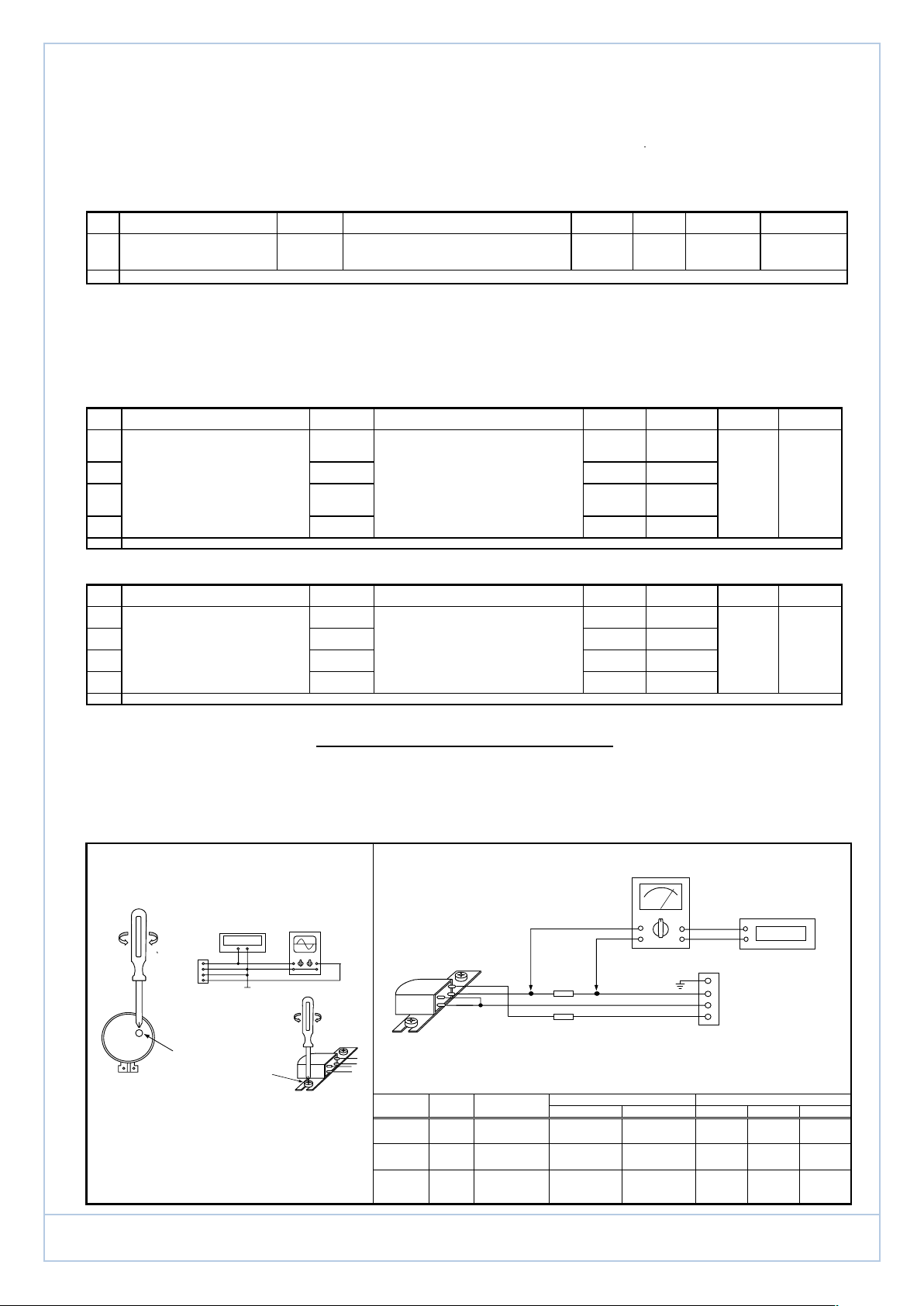

A L I G N M E N T P R O C E D U R E

y

y

(

INSTRUMENTS REQUIRED GENERAL PREPARATION

1. Signal Generator 1. Check source voltage, DC or AC according to specificaions

2. FM Signal Generator 2. Set function switch to band being aligned

3. FM/AM IF Sweep Generator (10.7 MHz for FM) 3. Signal input should be kept as low as possible to avoid AGC and AFC function

4. VTVM 4. Standard modulation :

5. Oscilloscope

6. Frequency counter

7. Regulated DC power supply

AM IF ALIGNMENT

SIGNAL SOURCE (AM RF Gen.)

STEP

1 loop

2 Repeat step 1 for max. output

CONNECT TO

A standard radiation

SET SIGNALTOALIGNMENT INDICATOR (Oscilloscope, VTVM)

465KHz Detector output terminal

and ground

CONNECT TO

TP5

FM IF ALIGNMENT

This model requires no FM IF alignment as the IF is fixed by ceramic filter and discriminator CF503 & CF504. Please take note that correct type and same color dot of ceramic filter is used

in servicing, diff color dot of ceramic filter may cause worse IF 'S' curve characteristic and distortion.

Connect IF genescope output terminal to TP3 & TP4 (GND) in series with a 1000Pf capacitor, connect scope input terminal to TP5 & TP4 (GND), then the IF characteristic curve can be

observed.

FM RF ALIGNMENT

STEP

SIGNAL SOURCE (FM Signal Gen.)

1

2

3

4

5

Repeat steps 3 and 4 as necessary to minimize tracking error and also steps 1 and 2 if necessar

CONNECT TO

TP1 & TP2 108.25 MHz Terminals VC 501A Volume

through matching network (modulated) across speaker (Highest end) (Osc. trimmer) Maximum control at

if necessary voice coil L503 (RF coil) max. position

SET SIGNALTOALIGNMENT INDICATOR (Oscilloscope, VTVM)

87.35 MHz (Lowest end) stretch or

(modulated) squeeze

88 MHz 88 MHz stretch or

(modulated) squeeze

106 MHz VC 501B

(modulated) 106 MHz (RF trimmer)

CONNECT TO

AM 1 KHz 30% mod

FM 1 KHz 22.5 KHz dev

SET RADIO

DIAL TO

Quiet Volume control at

Point

SET RADIO

ADJUST ADJUST FOR REMARKS

T501 Maximum

DIAL TO

ADJUST ADJUST FOR REMARKS

L502 (Osc. coil)

min. position

AM RF ALIGNMENT

STEP

SIGNAL SOURCE (AM Signal Gen.)

1

2

3

4

5

Repeat steps 3 and 4 as necessary to minimize tracking error and also steps 1 and 2 if necessar

CONNECT TO

A standard radiation (modulated) Across speaker (Highest end) (Osc. trimmer) Maximum control at

loop ant. 600 KHz voice coil L 504 max. position

SET SIGNALTOALIGNMENT INDICATOR (Oscilloscope, VTVM)

515 KHz T 502

(modulated) (Lowest end) (Osc. coil)

1635 KHz VC 501C Volume

(modulated) 600 KHz (ant. coil)

1400 KHz VC 501D

(modulated) 1400 KHz (ant. trimmer)

CONNECT TO

SET RADIO

DIAL TO

ADJUST ADJUST FOR REMARKS

ALIGNMENT PROCEDURE FOR CD SECTION

Applicable unit :

1 This model is using CD drive unit No. SANYO DA11B3V

2 The alignment for CD section is fully automatic and no adjustment is reguired

GENERAL PREPARATION -

A ) MEASURING INSTRUMENTS REQUIRED FOR TAPE B ) EQUIPMENTS REQUESTED FOR AC BIAS FREQUENCY / CURRENT ADJUSTMENT :

SPEED AND HEAD AZIMUTH ADJUSTMENT.

( 1 ) TAPE SPEED ADJUST

MTT-211NA (3150 Hz) TEST

SPEAKER

TERMINALS

MOTOR

( 2 ) HEAD AZIMUTH ADJUSTMENT . Test Point Adjust Frequency Frequency Observe at Observe

2.1 - Connect the equipments as shown in the Fig. 1. at Beat 0 Beat 1 Beat 2 Beat 0 Beat 1 Beat 2

TAPE IS REQUIRED

(The Both Speakers loading Are Required) Resistor

2.2 - Insert a test tape

2.3 - Press PLAY and set VOLUME at reference output.

2.4 - Adjust the azimuth adjustment screw for the max.

& balance ch. output on both ch. of oscilloscope.

2.5 - Secure above screw with glue after adj. completed.

1 ) Check source voltage, DC or AC according to specifications . 2 ) Set function switch to Tape being aligned .

°

FREQUENCY

COUNTER

3150 Hz

AZIMUTH ADJ. SCREW

CH. 1

R/P HEAD

OSCILLOSCOPE

FIG.1

10 KHz : MTT-114 ) into deck.

CH. 2

FIG.2

R/P HEAD

AC BIAS FREQUENCY ALIGNMENT :

Note :The test unit should be keep in recording mode and added two resistors Ra & Rb as shown in the

Ra

10 ohm

Rb

10 ohm

Fig. 2 before alignment. be sure to delete the both resistors Ra & Rb after alignment completed.

Ra or Rb L401 60 KHz ± 0.3K

INPUT

VTVM

OUTPUT

4

1

SO457

FREQUENCY

COUNTER

62KHz

==> TO CASS PCB

CN207

ǵ

RRCD 1300

Page 3

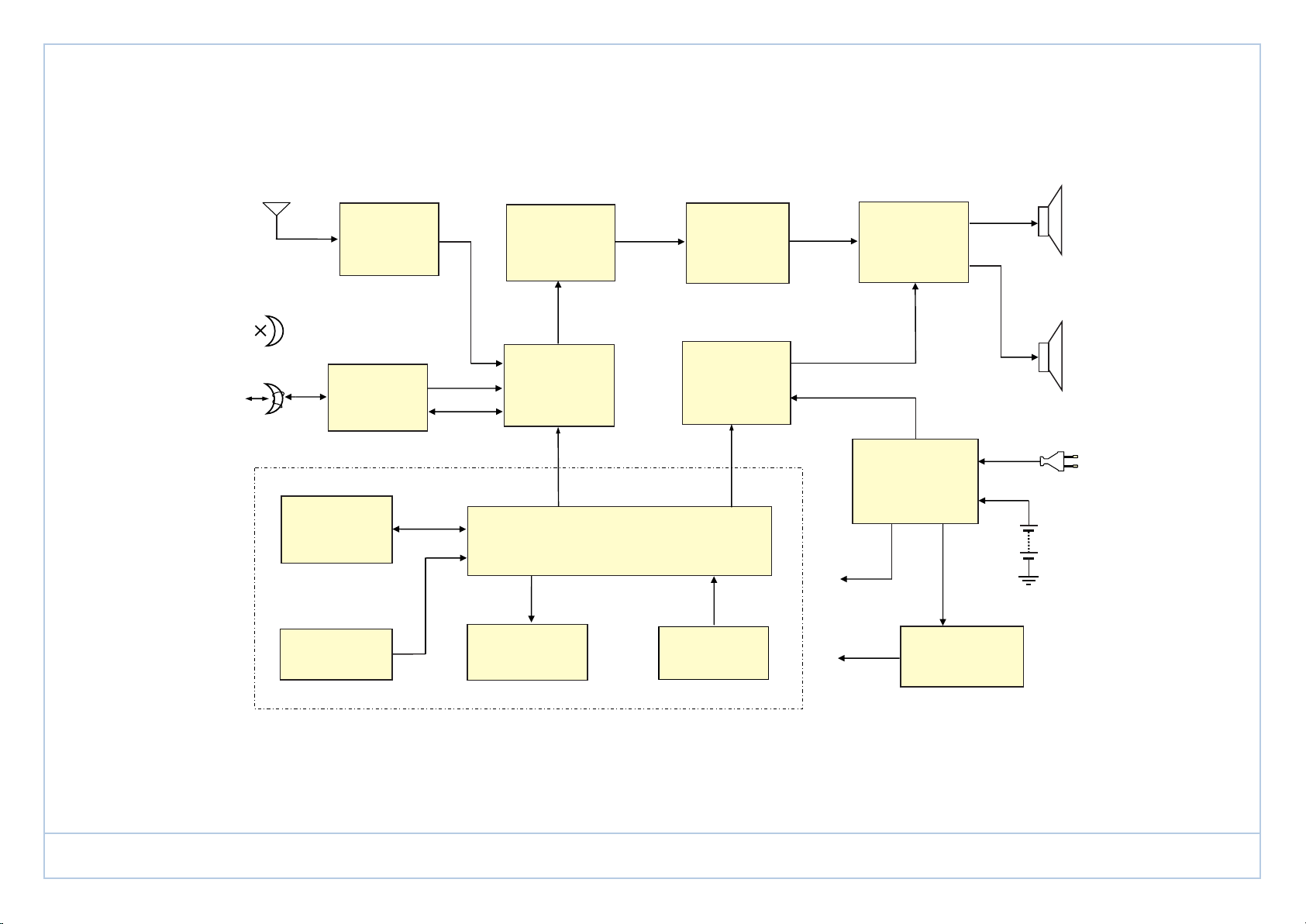

R

FM ANTENNA

E. HEAD

TUNER

IC 501

U.B.S.

Q206 Q207

AUDIO

CONTROL

VR351

POWER

AMPLIFIER

IC201

-CH SP

L-CH SP

R/P HEAD

CD

MECHANISM

KEY BOARD

TAPE R/P

IC 401

DA11 B3N

FUNCTION

SELECTOR

REC

SW 201

CD SERVO SYSTEM

U701 U702

CD DISPLAY

MUTING

CIRCUIT

Q204 Q205

IR RECEIVER

9V MAIN SUPPLY

D301 D302

D303 D304

DC 9V

DC 6V

Q201 Q202 Q203

AC IN

BATT.

12V

6V REG

ǵ

RRCD 1300

Page 4

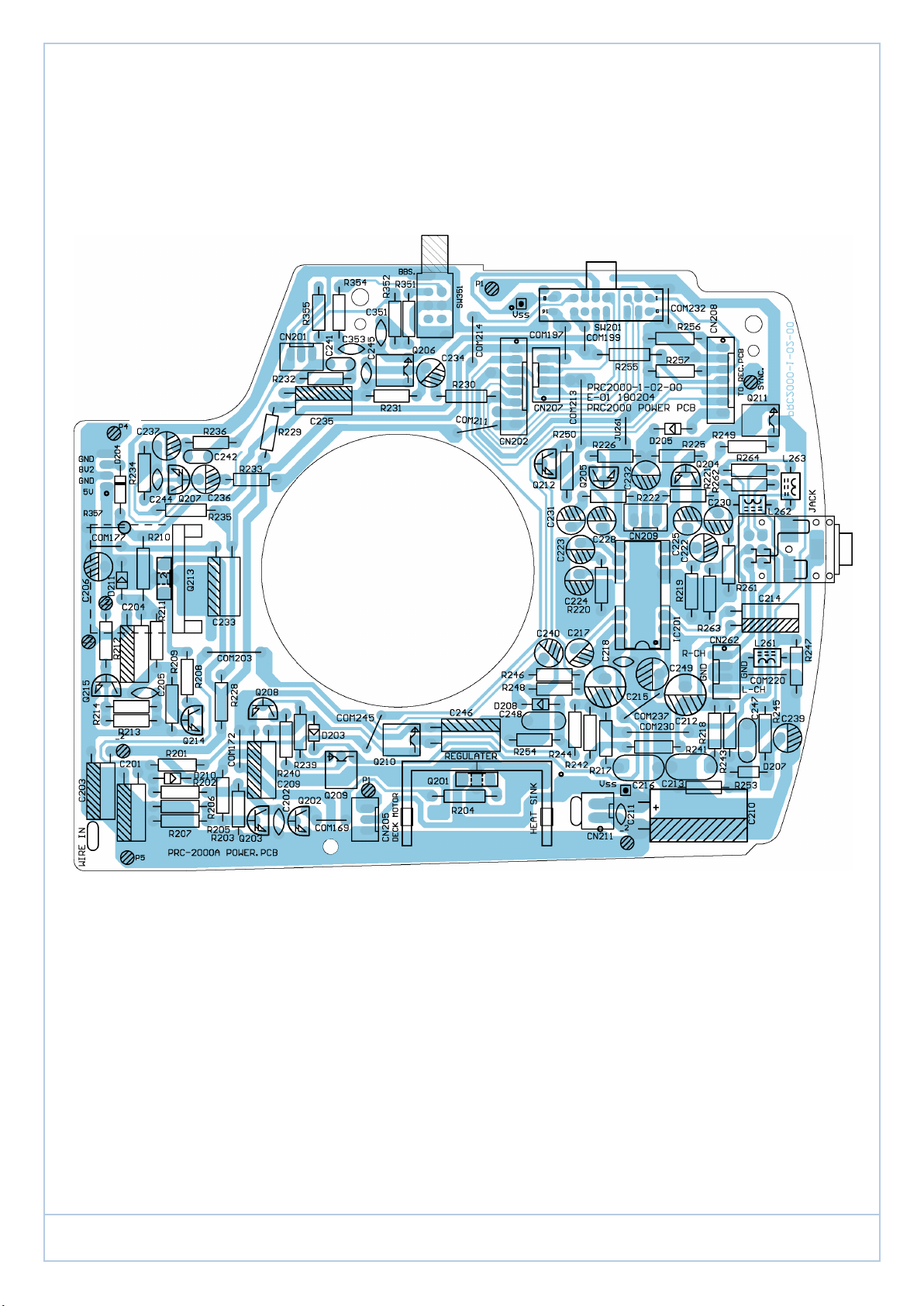

ǵ

RRCD 1300

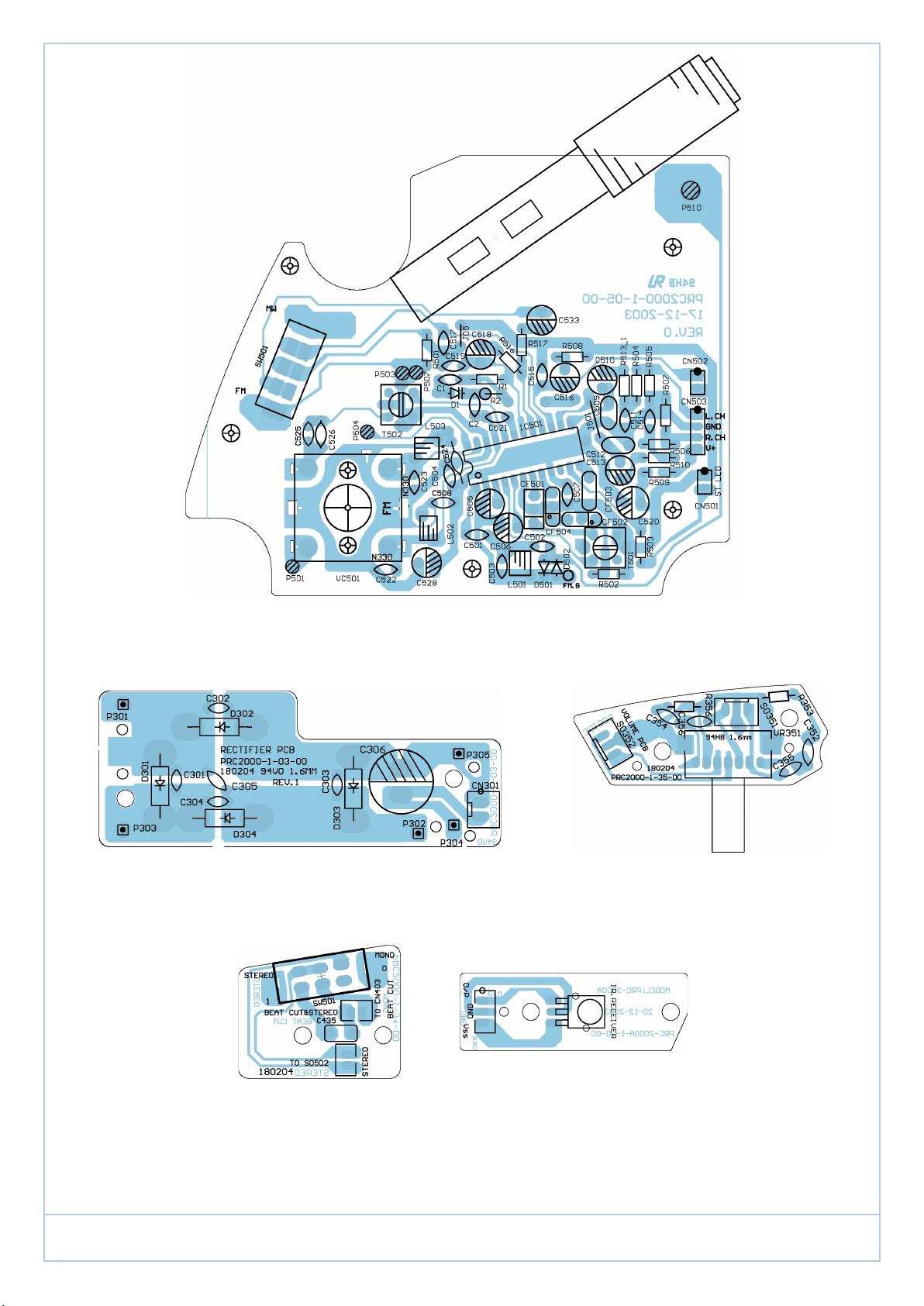

Page 5

ǵ

RRCD 1300

Page 6

C526

140P(NPO)

TO CD POWER

CN206

2PINS

CD 7V

1

PW GND

2

TO RADI O PCB

L CH

1

GND

2

R CH

3

RA 7V

4

CN207

4PINS

SW201D

SK43D06-GB7

RA

TA

CD

1

2

3

4

5

6

7

CN208

7PINS

TO CD SECTION

VC501D

PVC126

54

L504

MW ANT

1

P501

MW

P502

1

MB

VC501C

PVC126

16

15

14

13

R CH

A GND

L CH

SYNC

OP. LED.

3V3 PROTECT

MUT E

RADI O PCB

PRC200-1-05-00

VC501B

C524

5n

1

C523

22P(N330)

P503

MR

1

P504

MG

5 3

MW/ LW OSC

3

2

1 6

T502

RED

7

9330

SW201C

SK43D06-GB7

12

11

10

9

R257

5K6

4.5X3T5

PVC126

52

4

R233

56K

SW201A

SK43D06-GB7

RA

TA

CD

D205

1N4148

L503

12

FM ANT

P510

TP1

D501

1N4148

C528

10u

C236

u47

4

3

2

1

R256

5K6

C522

22P(N330)

+

+

L502

5x2T5

C502

C503

D502

1N4148

TP2

R234

C244

68P(NPO)

VC501A

12

PVC126

51

20P

C501

30P

30P

C504

10n

680K

R230

+

SW501

SS22F16-G6

FM

C533

MW

+

1u

R517

4K7

7P

C521

20

21

22

23

24

IC501

1234567

+

+

u47

4u7

CF501

C506

L501

56K

C234

1 2

C237

9014C

u47

u47

Q207

R255

4.5X3T5

+

330

C505

R511

330K

R501

Q206

9014C

SYNC REC

TP3

1 6

2

3

T501

2492

AM IF YELLOW

10

R236

27K

C242

1n8(M)

R231

680K

CN202

8PINS

R-REC

GND

L-REC

R-CH

GND

L-CH

7V

TO TAPE PCB

7

+

8

7

6

5

4

3

2

1

465KHz

R235

3K3

C235

u47

68P(NPO)

C519

C518

19

4

R232

27K

C241

1n8(M)

C245

R352

SW351A

2P2TD

C517

100n

1n

u47

+

18

( SP2111 )

R512

R229

3K3

8K2

R516

8 17

330

1

2

3

1K

10.7MS3

R351

16

91011 14

CF504

R502

40n(Y5P)

560

R508

3K3

+

C516

1u

15

TP4

R503

470

470

PRC2000-1-65-00

40n(Y5P)

C353

4

5

6

SW351B

2P2TD

R-CH

1

GND

2

L-CH

3

CN201

3PINS

C351

C515

100n

C509

10n

12 13

CF503

10.7 MG77

LED PCB

R355

8K2

R354

560

SO351

3PINS

C507

100n

CN501

2PINS

1

2

3

R-CH

GND

L-CH

2

1

R510

C513

+

4u7

C512

10n

+

C510

4u7

TP6

C511

1n2(M)

C520

470u

2

1

CN651

2PINS

VOLUM E PCB

C356

1n

8

C354

120n(M)

R356

2K7

C355

3

1n

4

120n(M)

1

C352

R353

2K7

PRC2000-1-35-00

AUDI O POWER PCB

PRC200-1-02-00

12K

R513

12K

R504

18K

R505

12K

+

R509

LED651

3MM GREEN

7

50KB

VR351B

6

5

R-CH

GND

L-CH

SO352

3PINS

2

VR351A

50KB

220

1

2

3

TP5

C514

1n2(M)

R506

R507

RA 6V

18K

12K

L-CH

GND

R-CH

CN503

4PINS

1

2

3

4

CN502

2PINS

CN209

1

2

R225

1

2

3

3PINS

10K

Q204

R-CH

GND

L-CH

R226

C232

9014C

10K

+

CN552

2PINS

PRC2000-1-55-00

R221

5K6

R222

5K6

1u

SW551A

1

2

SKE22F03

SWITCH PCB

R207

33K

R228

1K5

+

C233

470u

+

1u

C230

+

C231

Q205

1N4148

1u

9014C

D210

R205

47K

R206

5K6

9014C

Q208

1N4148

123

D203

220

Q203

9014C

R219

SW551B

SKE22F03

R202

33K

7V REG.

C225

C224

C228

+

1u

+

100u

1

+

( 7V )

+

C452

1n

C203

100u

Q202

R203

9014C

220K

R201

39K

Q201

2SB772Q

CN551

2PINS

R204

2

1K

UNIT : RESISTOR IN OHM

CAPACITOR I N F

INDUCTOR I N H

UNLESS OTHER SPECIFY

8

RA

7

6

TA

5

CD

SW201B

SK43D06-GB7

MOTOR

CN205

3PINS

B+IN

B+OUT

GND

123

+-

TAPE SWITCH

POWER SUPPLY SECTION

IN4001

D301

C301

20n

20n

C302

D302

IN4001

C303

20n

C304

20n

1000u 16V

C306

+

D303

IN4001

D304

IN4001

P301

20n

C305

P302

P303

DC OUT

1

AC1

1

AC2

1

TRANSFORMER

T503

X'FRM

AC SOCKET

AC

DC IN

P304

115

T H E R M A L

F U S E

1

L505

DC

C

9V

1

P30 5

GND

456

C202

20n

1u

C201

DECK MECH.

+12V

C210

47K

47K

GND

R242

C246

220u

+

F1510100D

LF302

R-CH

GND

L-CH L-CH

+

C211

3

2

4

11

108

100n(M)

C218

100n

C216

C214

C217

100u

+

+

100u

100n

R217

1.5

C212

1000u

Q210

+

R218

C213

100n(M)

+

C215

1000u

2200u 16V

9014C

R241

1.5

R239

390K

R240

15K

C249

220u 16V

1u

C222

100u

+

+

+

C223

100u

R220

220

+

6

5

9

7

DV3287B

IC201

Q209

8550C

1

C209

10u

12

GND

2

2

1

1

CN301

CN211

2PINS

2PINS

R-CH

GND

CN262

4PINS

+

5ohm7 5ohm7

POWER SUPPLY PCB

1006-1-03-00

PHONE SECTION

C253

2n

C254

2n

L262

3T5

R261

150

R262

150

4

4

L261

3T5

STJ 5P/2P2T

J261A

5

4

3

2

1

L263

3T5

R263

150

150

R264

123

123

R-CHL-CH

+

-

ǵ

RRCD 1300

Page 7

ǵ

RRCD 1300

Page 8

DA11T3CN

CN701

VC

VDD

GND

LD

VR

MD

F(+)

T(-)

T(+)

F(-)

CN703

2PINS

1

2

Q709

9014C

E

D

A

B

C

F

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

CD 6V

PW GND

L703

3T5

R773

D701

1N4148

22K

R774

220K

C739

470u

GND

R701

91

MGND

L702

3T5

220u

100n

SGND

MVDD

R705

Q701

4.7

R702

2SA933AS

C702

10n

100u

CD SERVO PCB

PRC2000-1-07-00

DA11

CN702

SPIND+

SPINDSLED+

SLED-

INNER

GND

C740

VCC(6V)

100n

Q703

2SB1237

C741

C742

VDD

TP714

SGND

C703

3V3

4.7

TP713

VDD

R750

R749

47K

C701

1

2

3

4

5

6

0

100u

R704

R703

10K

100K

1K

R752

R751

R713

TP706

RFRPRFM

C721

150P

TP705

TZCRFM

C722

2n2

TP704

C747

18K

R715

TE

75K

C723

R722

100P

C724

6n8

1u

63

60

61

64

62

RFI

TEN

EQO

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

6K8

R716

CAGC

AVDD1

AC

BD

VBIAS

E

F

AGND1

FEN

FEO

PKC

BTC

PD

LD

ASY

AVDD2

PCO

FCO17AGND218FDOUT19JUMPO20TDOUT21SDIN22SDOUT23CLVOUT24ADC0/G AIN_SEL25ADC1/KEY26CLK8827LON28SEGa/CO M029SEGb/CO M130SEGc/CO M231SEGd/CO M3

390K

R717

33K

4K7

100n

R719

C718

C717

10u

R718

R723

9K1

TP715

SP

TP716

SD

R725

8K2

TP717

FD

R724

4K7

TP718

TD

R726

0

100u

AVDD

C704

OPEN

C706

OPEN

100n

100u

150K

100n

3u3

0.22u

Q702

DTC114TSA

R768

TP707

TDOUT

28

27

26

25

24

23

22

21

20

19

18

17

16

15

C705

100n

47K

OPEN

TP703

RF

C711

470P

C712

100n

C713

100n

R714

470

TP708

JUMPO

C744

47u

C750

220u

C745

100n

C746

4u7

AGND

TP701

VC

0

1

2

3

4

5

6

7

8

9

10

11

12

13

10K

14

R767

C707

OPEN

C708

C709

TP702

C710 120P

FE

R712

C714

C715

C716

IC702

BA5826FP

VO1(-)

POW GND

VO1(+)

VIN1

VO4(+)

RESET

REG B

REGOUT

MUTE

REGGND

IN2'

IN2

VO2(+)

VO3(+)

VO2(-)

POW GND

OPIN(-)

OPOUT

R753 10K

C743

R706 47K

R707 47K

R708

R709 47K

R710 56K

R711 56K

VO4(-)

IN4

IN4'

BIAS

VCC

VCC

IN3'

VIN3

VO3(-)

RSTT

OPEN

27K

R721

57

59

58

SC

TEO

TZCRFM

IC701

BU24530-9A

C719 100n

55

56

AGND3

RDACO

RFRPRFM

TP709

TP710

R746 10K

R747 10K

SEGa/COM0

SEGb/COM1

SEGc/COM2

SEGd/COM3

SEGe/SEG0

SEGf/SEG1

SEGg/SEG2

SEG./SEG3

COM0/SEG4

COM1/SEG5

R762

4K7

Q707

R763

22K

2SA933AS

R729 2K2

R728

2K2

C726

100n

C725

51

52

54

DGND

AVDD3

LDACO53VCDAC

PWC/W _REMO TE

P03/PRO _LED

P02/MM UTE

SEG6/AM UTE

COM1/SEG 5

COM0/SEG 4

SEGa/COM0

SEGb/COM1

C720 100n

R748

R754 100

R755 100

R756 100

R757 100

R758

R759 100

R760 100

R761 100

C734

100n

C727

R727

220

R720 1M

50

49

XI

XO

DVDD

RESET B

P11/SYNC

P10/PLAY

P01/LID

P00/INNER

SEG./3

SEGg/2

SEGf/1

SEGe/0

R739 OPEN

32

R740 470K

R741 OPEN

R742 OPEN

R743 OPEN

R744 470K

R745 470K

SEGc/COM2

SEGd/COM3

7K5

R764

4K7

R765

22K

C733

560P

AFVCC

100u

100

Q7082SA933AS

R731 2K2

R730

2K2

560P

C728

15P(A)

X701

16.9344MHz

C729

15P(A)

100n

48

47

46

45

44

43

42

41

40

39

COM1/SEG5

38

COM0/SEG4

37

SEG./SEG3

36

SEGg/SEG2

35

SEGf/SEG1

34

SEGe/SEG0

33

C735

C736

560P

DGND

X101:TDK FCR16.93M2G

DVDD

C730

C731

100u

R734

1K

1

2

3

4

5

6

7

8

9

10

11

12

13

14

CN705

14PINS

C737 4u7

C738 4u7

560P

L701

100uH

COM1/SEG5

COM0/SEG4

SEG./SEG3

SEGg/SEG2

SEGf/SEG1

SEGe/SEG0

SEGd/COM3

SEGc/COM2

SEGb/COM1

SEGa/COM0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

CN805

14PINS

C732

PROGRAM

R732

100n

D802

100K

R733

R736

10K

R735

100K

TP720

TP721

TP722

TP723

TP724

TP725

TP726

TP727

TP728

TP729

TP730

TP731

TP732

TP733

R737

100K

D803

10K

>/II

DTA124ESA

Q704

R766

330

D804

REPEAT

R771

82K

R772

82K

AFGND

TP719

123

123

1K8

R851

2K7

R852

3K3

R853

4K7

R854

R855

10K

789

10

12345 6

R775

22K

R769

4K7

CN706

3PINS

CN856

3PINS

K850

PLAY

STOP

REPEAT

K851

K852

K854

K853

K855

PROG

FF

FR

L704

OP. LED.

DIS801

2D-LED

3T5

OPEN

2

CLOSE

1

CN707

CD DOOR

KEY CONTROL PCB

PRC2000-1-85-00

Pin30

Pullup

Pulldow n

Pin31

Pullup

Pulldow n

Pin32

Pullup

Pulldow n -12db

Tracking

0db

0db

+3db

+3db +3db

+6db +3db

GAIN SELECT OPTION

D801

PRC2000-1-08-00

DISPLAY PCB

R.CH

A.GND

L.CH

SYNC.

OP.LED.

3V3 PRODECT

MUTE

DISP.

LED

LCD

CDM

TCP-11TK2X

DA11T3CN

SEARCH_MUTE

NO SOUND

R748Focus

0db OPEN

+3db

22K

12K

0db

7K5

4K7

+6db+3db

1K8

SHORT

+6db+6db

R748

CN704

1

2

3

4

5

6

7

7PINS

ǵ

RRCD 1300

Page 9

L.CH OUT

L-CH

R-CH

GND

COMMAN

R.CH OUT

7V

Q401

9014C

1

2

3

4

CN401

4PINS

16

17

18

SW401F

PS-82D06

19

20

21

SW401G

PS-82D06

7

8

9

SW401C

PS-82D06

3

2

1

4

6

7

L401

9170

10

11

12

SW401D

PS-82D06

22

23

24

SW401H

PS-82D06

D401

1N4148

13

14

15

SW401E

PS-82D06

C402

10n

+

C404

47u

C405

10n

D402

1N4148

4

5

6

SW401B

PS-82D06

+

C401

1000u

C406

1n8(m)

R450

3K9

R453

120K

R454

1K

R455

820K

R456

100

R401

120

R405

1M

+

C403

47u

R402

470

R410

10K

R411

47K

+

C410

1u

R412

680K

Q402

9014C

R414

4K7

+

C411

1u

R413

470

R420

470

R421

10K

R423

680K

Q403

9014C

R422

47K

R424

4K7

+

C420

1u

R441

10K

R431

10K

Q404

9014C

Q405

9014C

R404

10K

R403

10K

R442

6K8

R432

6K8

C413

18n(m)

C424

18n(m)

+

C414

47u

+

C423

47u

R444

82K

R434

82K

+

C422

1u

+

C412

1u

R445

10K

R435

10K

C425

1n5(M)

C415

1n5(M)

C416

2n7(M)

C426

2n7(M)

+

C421

1u

+

C407

22u

R415

180K

R425

180K

R436

10K

R446

10K

R452

150

R430

12K

R440

12K

1

2

3

4

5

6

7

8

9

IC401

LS22241

C427

1n5

C417

1n5

R443

68

R433

68

R426

5K6

R416

5K6

SYNC

L-OUT

GND

R-OUT

L-REC

R-REC

GND

REC. 6V5

REC GND

1

2

CN403

2PINS

C409

180P

C408

180P

C418

1n

C419

1n

TO R/P HEAD

TO MAIN PCB

1

2

3

4

5

6

7

8

CN402

8PINS

NF(R)

IN(R)

OUT(R)

GND

ALC

Vcc

OUT(L)

IN(L)

NF(L)

PLAY HEAD NO. 4211

ǵ

RRCD 1300

Page 10

1

2

3

4

5

6

7

8

9

12

13

14

15

16

17

18

19

20

10

11

IC601

PT2221-001/UPC6121-001

K10

K11

K12

K13

REM

VDD

SEL

OSCO

OSCI

VSS

CCS

KI /O0

KI /O1

KI /O2

KI /O3

KI /O4

KI /O5

KI /O6

KI /O7

LM P

K602

STOP

K604

SKIP+

K606

REPEAT

K601

PLAY

K603

SKIP-

Q601

2SC1740

CF601

455KHz

D

IR_LED

R601

1

+

C603

10u/10V

C601

100P

C602

100P

+3V

GND

ǵ

RRCD 1300

Page 11

ǵ

RRCD 1300

Page 12

ǵ

RRCD 1300

Page 13

ǵ

RRCD 1300

Page 14

ǵ

Ersatzteilliste

Spare Parts List

3 / 2005

POS. NR. ABB. MATERIAL-NR. ANZ. BEZEICHNUNG DESCRIPTION

POS. NO. FIG. PART NUMBER QTY.

757123445000 RRCD 1300 CHROME/VERO RRCD 1300 CHROME/VERO

0001.000 759551128900 TUER CASSETTE CASSETTE DOOR

0002.000 759551129300 LINSE TUER CASSETTE CASSETTE DOOR LENS

0003.000 759551129500 EINSATZ CASSETTE EMPLOYMENT CASSETTE

0004.000 759551128600 FEDER TUER CASSETTE SPRING CASSETTE DOOR

0015.000 759551129400 TASTENSATZ CASSETTE TASTE SET CASSETTE

0025.000 759551128500 LAUFWERK CASS. CS-21V-1006-C CASS. MECHANISM CS-21V-1006-C

0035.000 759551129600 ABDECKUNG SPEICHERBATTERIE DOOR BATTERIE MEMORY

0036.000 759551129100 BATTERIEFACHABDECKUNG DOOR BATTERY

0061.000 759551129200 TRAGEGRIFF HANDLE

0063.000 759551129000 TUER CD CD DOOR

0064.000 759550615400 FEDER TUER CD 1,2MM SPRING TUER CD 1,2MM

0065.000 759551128700 TELESKOPANTENNE TELESKOPANTENNE

0070.000 S 759550615100 LAUFWERK CD DA11-T3CN CD MECHANISM DA11-T3CN

0150.000 S 759551128800 NETZANSCHLUSSKABEL AC POWER CORD

720114052000 BEDIENUNGSNLEITUNG INSTRUCTION MANUAL

NUR FÜR INTERNEN GEBRAUCH

FOR INTERNAL USE ONLY

AUDIO

RRCD 1300

MATERIAL-NR. / PART NO.: 757123445000

BESTELL-NR. / ORDER NO.: GDP5600 CHROME/VERO

d©

TAUSCHGERAET EXCHANGE SET

D/GB/F/I/P/E/NL/PL/DK/S/FIN D/GB/F/I/P/E/NL/PL/DK/S/FIN

ǵ

Es gelten die Vorschriften und Sicherheitshinweise

gemäß dem Service Manual "Sicherheit", Mat.-Nummer 720108000001, sowie zusätzlich die eventuell abweichenden, landesspezifischen Vorschriften!

The regulations and safety instructions shall be valid

!

as provided by the "Safety" Service Manual, part

number 720108000001, as well as the respective

( ! )

national deviations.

ÄNDERUNGEN VORBEHALTEN / SUBJECT TO ALTERATION

RRCD 1300

Loading...

Loading...