Page 1

IMPORTANT INFORMATION

IMPORTANT INFORMATION KEEP FOR OPERATOR

IMPORTANT INFORMATION IMPORTANT INFORMATION

KEEP FOR OPERATOR IMPORTANT INFORMATION

KEEP FOR OPERATOR KEEP FOR OPERATOR

IMPORTANT INFORMATION

IMPORTANT INFORMATION IMPORTANT INFORMATION

E-CC-MOLAUNAM ROTAREPO

Part Number 121015 Rev. A DOMESTIC

MODEL: CC-E

CONVECTION COMBO™

Combination Steamer-Oven

CC10-E

CC20-EF

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE. READ,

UNDERSTAND AND FOLLOW THE INSTRUCTIONS AND WARNINGS

CONTAINED IN THIS MANUAL.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND

LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE

.

Information contained in this document is

known to be current and accurate at the time

of printing/creation. Unified Brands recommends referencing our product line websites,

unifiedbrands.net, for the most updated

product information and specifications.

Page 2

OM-CC-E

IMPORTANT — READ FIRST — IMPORTANT

WARNING:

CAUT ION: SHIPPING ST RAPS ARE UNDER T ENSION AND CAN SNAP BACK WHEN CUT .

CAUT ION:

CAUT ION:

WARNING: TO AVOID DAMAGE OR INJURY, FOLL OW T HE WIRING DIAGRAM EXACT LY WHEN

CAUT ION:

WARNING:

WARNING:

IM PORTANT:

IM PORTANT:

WARNING:

THE UNIT MUST BE INST ALLED BY PERSONNEL QUALIFIED TO WORK WITH ELECTRICITY

AND PLUM BING. IM PROPER INST ALLAT ION CAN CAUSE INJURY T O PERSONNEL AND/OR

DAMAGE TO THE EQUIPMENT. THE UNIT MUST BE INSTALLED IN ACCORDANCE WITH

APPLICABLE CODES.

DO NOT INSTAL L T HE UNIT IN ANY WAY WHICH WILL BLOCK T HE RIGHT SIDE VENT S,

OR WITHIN 12 INCHES OF A HEAT SOURCE SUCH AS A BRAISING PAN, DEEP FRYER,

CHAR BROILER OR KET T LE.

LEVEL THE UNIT FRONT TO BACK, OR PITCH IT SLIGHTLY TO THE REAR, TO AVOID

DRAINAGE PROBLEM S.

CONNECTING A UNIT .

DO NOT USE PLAST IC PIPE. DRAIN MUST BE RATED FOR BOILING WAT ER.

DO NOT CONNECT T HE DRAIN DIRECTLY T O A BUILDING DRAIN.

BLOCKING THE DRAIN IS HAZARDOUS.

Improper drain connection will void warranty.

Do not allow any water traps in the line. A trap can cause pressure to build up inside the

cavity during steaming, which will make the door gasket leak.

WHEN YOU OPEN THE DOOR, STAY AWAY FROM STEAM COMING OUT OF THE UNIT.

ST EAM CAN CAUSE BURNS.

WARNING: BEFORE CL EANING THE OUTSIDE OF THE ST EAMER, DISCONNECT THE ELECTRIC POWER

SUPPLY. KEEP WATER AND CLEANING SOLUTIONS OUT OF CONTROLS AND ELECTRICAL

COMPONENTS. NEVER HOSE OR STEAM CLEAN ANY PART OF THE UNIT.

WARNING:

WARNING:

WARNING:

WARNING: DO NOT PUT HANDS OR T OOLS INT O T HE COOKING CHAM BER UNTIL T HE FAN HAS

WARNING:

NOT ICE:

NOT ICE:

WARNING:

ALLOW COOKING CHAMBER T O COOL BEFORE CLEANING.

CAREFULLY READ T HE WARNINGS AND FOLLOW T HE DIRECTIONS ON THE LABEL OF EACH

CLEANING AGENT.

DELIM ING AGENT M ANUFACT URER.

DO NOT MIX DE-LIMING AGENT S (ACID) AND DE-GRE ASERS (ALKALI).

STOPPED TURNING.

DO NOT OPERATE THE UNIT UNLESS THE REMOVABLE RIGHT SIDE PANEL HAS BEEN

RET URNED T O IT S PROPER L OCATION.

DO NOT USE A CLEANING OR DE -LIMING AGENT THAT CONT AINS ANY SUL FAM IC ACID

OR ANY CHLORIDE, INCLUDING HYDROCHLORIC ACID. IF THE CHLORIDE CONT ENT OF

ANY PRODUCT IS UNCLEAR, CONSULT T HE MANUFACT URER.

DO NOT USE ANY DE-GREASE R THAT CONT AINS POTASSIUM HYDROXIDE OR SODIUM

HYDROXIDE OR THAT IS ALKALINE.

USE OF ANY REP LACEM ENT PARTS OT HER THAN T HOSE SUPPLIE D BY GROEN OR THEIR

AUTHORIZED DIST RIBUTOR VOIDS ALL WARRANTIES AND CAN RESULT IN BODILY INJURY

TO T HE OPERATOR AND DAMAGE T HE EQUIPMENT . SERVICE BY OTHER T HAN FACTORYAUTHORIZED PERSONNEL WILL VOID ALL WARRANTIES .

USE SAFETY GLASSES AND RUBBER GLOVES AS RECOMMENDED BY

WARNING:

HIGH VOLTAGE EXIS TS INSIDE CONTROL COMPART MENT S. DISCONNECT FROM BRANCH

BEFORE SERVICING. FAILURE TO DO SO CAN RESULT IN SERIOUS INJURY OR DEATH.

2

Page 3

Table of Contents

OM-CC-E

OPERATOR WARNINGS

REFERENCES ..........................................................3

EQUIPMENT DESCRIPTION

INSPECTION AND UNPACKING

WATER CONDITIONING/REQUIREMENTS .....................................6

INSTALLATION AND START-UP INSTRUCTIONS

OPERATING INSTRUCTIONS

CLEANING ............................................................21

MAINTENANCE

TROUBLESHOOTING

SERVICE LOG..........................................................30

........................................................

...................................................

................................................

.............................................

................................

..............................................

....................................................

2

4

5

7

13

24

25

WARRANTY PROTECTION

UNDERWRITERS LABORATORIES, INC.

333 Pfingsten Road

Northbrook, Illinois 60062

KLENZADE SALES CENTER

ECOLAB, Inc.

370 Wabasha

St. Paul, Minnesota 55102

800 328-3663 or 612 293-2233

................................................

31

References

NATIONAL FIRE PROTECTION

ASSOCIATION

60 Battery March Park

Quincy, Massachusetts 02269

NFPA/70 The National Electrical Code

NATIONAL SANITATION FOUNDATION

3475 Plymouth Road

Ann Arbor, Michigan 48106

3

Page 4

OM-CC-E

Equipment Description

Your Groen Convection Combo™ has a stainless

steel cooking chamber, an air heating compartment

with electric heating elements and fan, a steam

generator with electric heating elements, and a

control compartment which houses other electrical

components.

All major components of the Convection Combo™

are encased in a 16 gauge stainless steel cabinet.

Glass fiber insulation, lines the cabinet at a thickness

of 1½ to 2 inches (4 to 5 cm). A removable drip tray

is located beneath the door.

Door hinges are reversible so that doors may open

from the left or right side. Operator controls are

located on the right side of the front panel.

Standard controls let you to operate the Convection

Combo in any one of three cooking modes:

1. As a convection oven

2. As a self-contained, pressureless steamer

3. As a c ombination oven-steamer

Models CC10-E and CC20-E differ in cooking

chamber size and capacity:

CC10-E: 4 steam table pans (12x20x2½”), or

7 half-size (13x18") US baking pans

CC20-E: 10 steam table pans (12x20x2½”), or

9 full-size (18x26") US baking pans

The smaller Convection Combo™ is available as a

table-top unit (the single CC10-E). These units are

also supplied on a stainless steel stand as models

CC10-EF and (2)CC10-EF. The larger Convection

Combo™ is always supplied with a stand as the

single CC20-EF or the double-stacked (2)CC20-EF.

The Convection Combo™ Family: 1. Model (2)CC20-EF (Full-sized double-stacked unit on rigid stand),

2. Model CC-20-EF (Full-sized single unit on a convenient stand), 3. Model (2)CC10-EF (Double-stacked,

stand-mounted, half-pan Combo, 4. Model CC10-EL single four inch leg-mounted. (Also available in

tabletop (CC10-E) and stand-mounted (CC10-EF) versions.

4

Page 5

Inspection and Unpacking

OM-CC-E

Your Convection Combo™ will be completely

assembled in a heavy shipping carton or wooden

crate, and attached to a skid. On receipt, inspect

the carton or crate carefully for exterior damage.

CAUT ION

SHIPPING ST RAPS ARE UNDER T ENSION AND

CAN SNAP BACK WHEN CUT.

Carefully cut the straps around the carton and detach

the sides of the carton from the skid. Pull the carton

up off the unit. Be careful to avoid personal injury or

equipment damage from staples which might be left in

the carton walls.

Water Conditioning

It is essential to supply the steam generator with

water that will not form scale. Even though the

steam generator is engineered to minimize scale

formation, scale development depends on the

hardness of your water and the number of hours you

operate the equipment.

In some areas, water is low enough in mineral

content to avoid scale formation. But most water

supplies are full of minerals which form scale. It is

this scale which could lead to an early component

failure.

Your water utility can tell you about the minerals in

your water. The water going to the steam generator

should have between 30 and 40 parts per million

(ppm) total dissolved solids (TDS) and should have a

pH (acidity rating) of 7.0 to 9.0. Please follow these

simple precautions:

Do not rely on unproven water treatments

1.

which are sold for scale prevention or scale

removal. They don’t always work. The best

way to prevent scale is to supply the purest

possible water (30 -40 ppm TDS).

Write down the model number, serial number and

installation date and keep this information for future

reference. Space for these entries is provided at the

top of the Service Log in the back of this manual.

CAUT ION

THIS UNIT IS VERY HEAVY. YOU SHOULD GET

HELP AS NEEDED TO LIFT T HIS WEIGHT

SAFELY.

When starting installation, lift the unit straight up off

the skid. Check packing materials to make sure

loose parts are not discarded with the material.

softener will provide longer generator life, higher

steam capacity, and reduce maintenance

requirements.

If you notice a slowdown in steam production,

3.

have the unit checked for scale build-up. Heavy

scale reduces the unit’s ability to boil water, and

can even cause heating elements in the steam

generator to overheat and burn out.

MINIMIZE SCALE PROBLEM S, BY USING AND

MAINTAINING A SOFT ENER, AND BY CLEANING

THE STEAM GENERATOR REGULARL Y.

Groen Convection Combo™ ovens are also available

with an option for two separate water connections —

one for the steam generator (soft water), the other

for the spray condenser (untreated water). The

steam generator only uses 14 to 31% of a

combination oven’s water.

Since softener systems are typically sized by total

GPH (gallons per hour), the second connection could

reduce treatment requirements by up to 80%,

resulting in significant savings.

2. If your water contains scale-forming minerals, as

most water does, use a well-maintained water

softener. Whether an exchangeable softener

cartridge or a regenerating system is chosen, a

regular exchange schedule is essential.

Installing a water meter between the softener and

the steamer will provide an accurate gauge of water

use, and will help determine when to exchange

cartridges or regenerate the softener. Using a water

5

Page 6

OM-CC-E

Installation and Start-Up

WARNING

THE UNIT MUST BE INST ALLED BY PERS ONNEL WHO ARE QUALIFIED T O WORK WIT H ELECTRICITY AND

PLUM BING. IMPROPER INSTALLATION CAN CAUSE INJURY TO PERSONNEL AND/OR DAMAGE TO THE

EQUIPMENT. THE UNIT MUST BE INSTALLED IN ACCORDANCE WITH APPLICABLE CODES.

CAUT ION

DO NOT INSTALL THE UNIT WITH THE RIGHT SIDE VENTS BLOCKED OR WITHIN 12 INCHES OF A HEAT

SOURCE (SUCH AS A BRAISING PAN, DEEP FRYER, CHAR BROILER OR KET TLE). DO NOT INSTAL L T O

THE LEFT OF ANY OPEN-FLAME EQUIPMENT.

TO AVOID DRAINAGE PROBLEMS, LEVEL THE UNIT FRONT TO BACK.

A.MODEL CC10-E

Terminal block

1. Mounting

d.

If you wish to install a Convection Combo™ on

top of another, you should obtain a double

stacked unit from the factory.

If the unit does not have a factory-installed stand,

the installer must provide a table, stand or

counter which is strong enough to support the

unit. Use of casters is not recommended.

To avoid drainage problems, level the unit front

to rear, or provide a slight pitch to the rear.

Bolt the unit to the table, stand or counter top,

using the mounting holes in its base.

2. Electrical Supply Connections

Panel Removal

a.

The right side panel must be removed to gain

access to the wiring and control

compartment. Remove the two screws at

the bottom of the panel. Slide the panel

toward the front of the unit, lift it and set it

aside.

Supply Voltage

b.

The CC10-E must operate at the rated

nameplate voltage, plus or minus 10%.

Phase Select Plug (Units manufactured

c.

before 1996)

Locate the phase select plug assembly on

the wiring harness from the relay board.

This assembly is black, blue and red. Refer

to the labels located below the motor and

above the distribution block for the correct

phase connection.

The terminal block for incoming power is

located at the back of the control

compartment.

WARNING

WHEN CONNE CT ING FOR SINGLE PHASE

OPERAT ION, DO NOT CONNECT ANY WIRE TO

LINE 3 (T HE TERMINAL FART HEST LEFT ). T HIS

WILL CAUSE A SHORT CIRCUIT .

The ground terminal is found on the relay

bracket below the terminal block. The

Convection Combo™ must have a separate

ground wire for safe operation. The ground

wire must be at least 10 AWG (2.6 mm).

e. Supply Wire

The type of wire needed is determined by

finding the operating voltage and phase from

the unit’s back data plate and (on pre-1996

models) phase select connector. Refer to

the “Electrical Supply Connection” label on

the back of the unit for correct wire size and

insulation temperature rating.

The specified wire must be used to comply

with Underwriters Laboratories and National

Electric Code requirements.

The knockout hole is sized for a ¾ inch (19

mm) conduit fitting.

6

Page 7

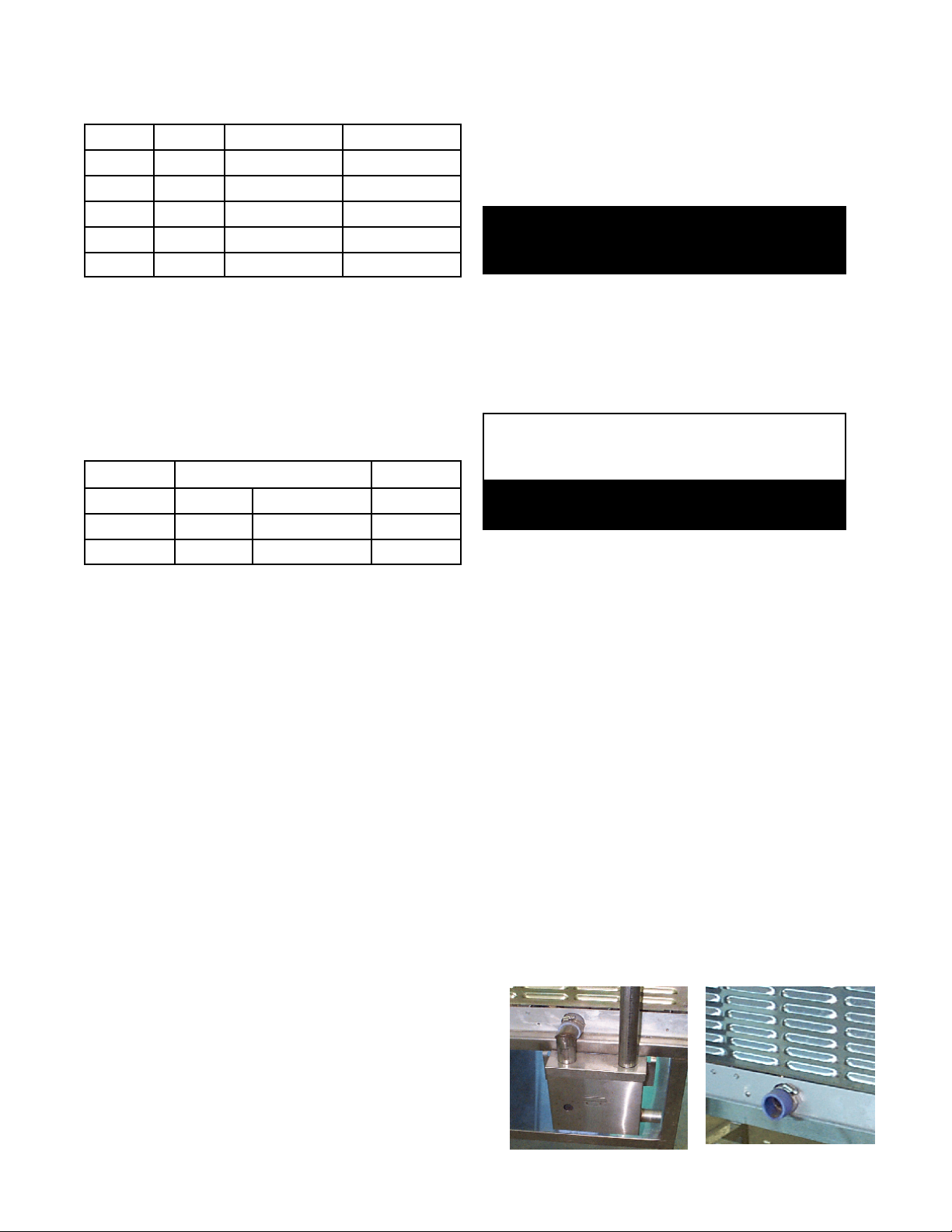

CC10-E ELECTRICAL SUPPLY CONNECTION

(All wires copper only.

Reference: National Electrical Code)

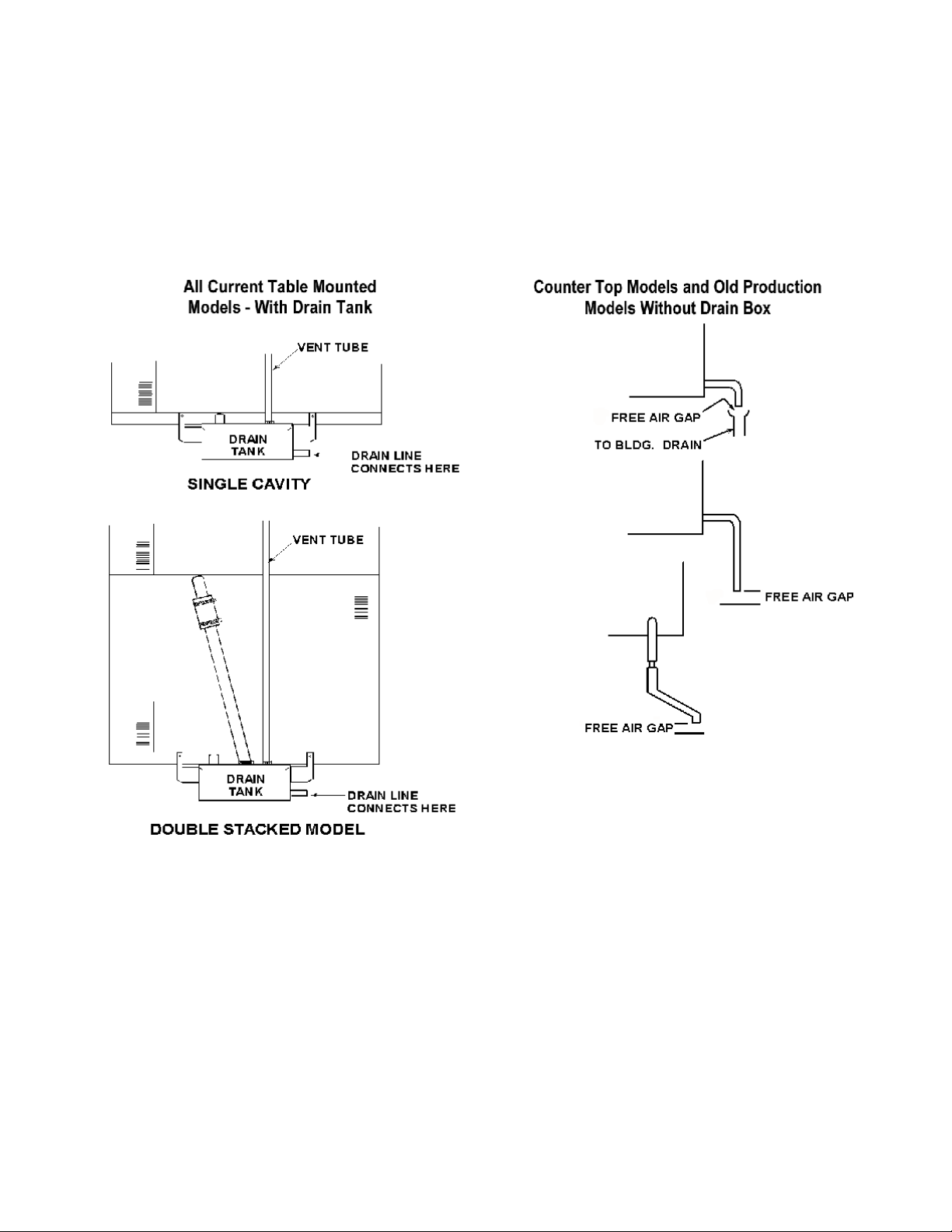

4. Drain Connection

CC10-E Without Drain Tank (tabletop model)

a.

OM-CC-E

Voltage Phase Wire Size Insulation

208 1 6AWG (4.1mm) 75oC

208 1 8AWG (3.3mm) 90oC

208 3 8AWG (3.3mm) 75oC

240 1 8AWG (3.3mm) 75oC

240 3 8AWG (3.3mm) 75oC

Branch Circuit Protection

f.

Groen strongly recommends that each

Convection Combo™ have its own branch

circuit protection. A double stacked unit should

have separate protection for the upper and

lower steamer-ovens.

CURRENT DEM AND

Voltage Current Power

1 Phase 3 Ph., per Line

208 44.7 A 27.5 A 9.3 KW

240 38.8 A 24.1 A 9.3 KW

Each current-carrying conductor must have

overcurrent protection. Refer to the label on

the back of the unit for proper wire size and

type. Watertight connections are required.

3. Water Supply Connection

A check valve (back siphonage device) must be

installed in the incoming cold water line in keeping

with local plumbing codes. Water line pressure

should be between 30 and 60 PSI (210 and 410

kPa). A pressure regulator is required above 60

PSI (410 kPa).

A ¾ inch (19 mm) NH (garden hose type)

connector is required to connect the water supply

to the water inlet valve. The water feed line

diameter may not be less that ½ inch (13 mm).

Use a washer (or if necessary, two washers) in the

hose connection. Do not allow the co nnection to

have any le ak, no matter how small.

A 1½ inch (4 cm) hose may be attached to the

provided drain elbow with a clamp. Do not use

plastic pipe. The drain must withstand boiling

water.

WARNING:

DO NOT CONNECT T HE DRAIN DIRECTLY T O A

BUILDING DRAIN.

There must be a free air gap between the end

of the hose and the building drain. The free air

gap should be as close as possible to the unit’s

drain. There must also be no other elbows or

othe r res trictions between the unit drain and the

two inch free air gap.

CAUT ION

DO NOT USE PLASTIC PIPE. DRAIN MUST BE

RATED FOR B OIL ING WAT ER.

WARNING

BLOCKING THE DRAIN IS HAZARDOUS.

Ins tall the drain line with a constant downward

pitch.

IMPORTANT: Do not allow any water traps in the

line. A trap can cause pressure to build up inside

the cavity during steaming, which will make the

door gasket leak.

NOT E: Improper drain connection will void the warranty.

b. CC10-E With Drain Tank

A 1½ inch (4 cm) ID hose may be attached to

the supplied drain elbow with a clamp. The

hose may be connected directly to a building

drain since the drain tank has an air vent, which

eliminates the need for a free air gap at the

building drain. Do not block the air vent in any

way. Do not attach anything to the vent tube or

reduce its size.

Do NOT use plastic pipe in the drain line,

because the drain must withstand boiling water.

If your CC10-E is equipped with the optional split

water supply, the supply for each steam generator

must be able to fill the generator with 1½ gallons

(5.7 liters) or water in 1½ minutes. The make-up

water rate is 0.06 gallons per minute (0.2 liters per

minute). Condensate spray water rate is 0.34

gallons per minute (1.3 liters per minute) at 30 PSI

(210 kPa).

7

Drain Tank

Tabletop Model

Page 8

OM-CC-E

Proper Drain Line Connections

8

Page 9

B.MODEL CC20-E

Mounting

1.

If you wish to install one Convection Combo™

above another, obtain a double-stacked unit from

the factory.

CAUT ION

DO NOT INSTAL L A CC20-E IN ANY LO CATION

WHERE RIGHT SIDE VENTS ARE BLOCKED, OR

WIT HIN 12 INC HE S OF A HEAT SOURCE SUCH

AS A BRAISING PAN, DEEP FRYER, CHAR

BROILER OR KETT LE.

DO NOT INSTALL THE UNIT TO THE LEFT OF

ANY OPEN FLAME EQUIPMENT.

OM-CC-E

breaker or 10 AWG (2.6 mm) for a 40 to 60

amp breaker.

d. Supply Wire

The type of wire needed is determined by

finding the operating voltage and phase from

the unit’s back data plate and phase select

connector. Refer to the “Electrical Supply

Connection” label on the back of the unit for

correct wire size and insulation temperature

rating.

The specified wire must be used to comply

with Underwriters Laboratories and National

Electric Code requirements.

To avoid drainage problems, level the unit frontto-rear, or provide a slight pitch to the rear.

WARNING

THE UNIT MUST BE INSTALLED BY

PERSONNEL QUALIFIED TO WORK WITH

ELECTRICITY AND PLUMBING. IMPROPER

INSTAL LATION CAN CAUSE INJURY TO

PERSONNEL AND/OR DAMAGE TO

EQUIPMENT.

CAUT ION

INSTALLAT ION MUST BE IN ACCORDANCE

WITH ALL APPLICABLE CODES.

Electrical Supply Connections

2.

a. Panel Removal

The right side panel must be removed to gain

access to the wiring and control

compartment. Remove the screw at the

back of the panel. Slide the panel toward

the front of the unit, lift it and set it aside.

b. Supply Voltage

The CC20-E must operate at the rated

nameplate voltage, plus or minus 10%.

c. Terminal block

The terminal block for incoming power is

located at the back of the control

compartment.

The knockout hole is sized for a one inch

(25.4 mm) conduit fitting.

CC20-E ELECTRICAL SUPPLY CONNECTION

(All wires copper only.

Reference: National Electrical Code)

o

Voltage

208 4 AWG (5.2 mm) 6 AWG (4.1 mm)

240 4 AWG (5.2 mm) 6 AWG (4.1 mm)

480 8 AWG (3.3 mm) 8 AWG (3.3 mm)

e. Branch Circuit Protection

Voltage

Size for 75

(T HWN)

Groen strongly recommends that each

Convection Combo™ have its own branch

circuit protection. A double stacked unit

should have separate protection for the

upper and lower steamer-ovens.

CURRENT DEM AND

208 65.4 A 21 KW

240 56.7 A 21 KW

480 28.3 A 21 KW

Each current-carrying conductor must have

overcurrent protection. Refer to the label on

the back of the unit for proper wire size and

type. Watertight connections are required.

C

Current per line

(Three Phase)

Size for 90oC (THHN)

Power

The ground terminal is found below the

terminal block. The Convection Combo™

must have a separate ground wire for safe

operation. The ground wire must be at least

8 AWG (3.3 mm) for a 100 amp circuit

Water Supply Connection

3.

A check valve (back siphonage device) must be

installed in the incoming cold water line in

keeping with local plumbing codes. Water line

pressure should be between 30 and 60 PSI (210

9

Page 10

OM-CC-E

and 410 kPa). A pressure regulator is required

above 60 PSI (410 kPa).

A ¾ inch (19 mm) NH (garden hose type)

connector is required to connect the water supply

to the water inlet valve. The water feed line

diameter may not be less that ½ inch (13 mm).

Use a washer (or if necessary, two washers) in

the ho se connection. Do not allow the

connection to have any leak, no matter how

small.

Drain Connection

4.

CAUT ION

DO NOT USE PLAST IC PIPE. DRAIN MUST BE

RATED FOR B OIL ING WAT ER.

WARNING

BLOCKING THE DRAIN IS HAZARDOUS.

IMPORTANT: Do not allow any water traps in the

line. A trap can cause pressure to build up

inside the cavity during steaming, which will

make the door gasket leak.

NOT E: Improper drain connection will void the

warranty.

CC20-E With Drain Tank

A two inch (51 cm) ID hose may be attached to

the supplied drain elbow with a clamp. The hose

may be connected directly to a building drain

since the drain tank has an air vent, which

eliminates the need for a free air gap at the

building drain.

Do not block the air vent in any way. Do not

attach anything to the vent or reduce its size.

Do NOT use plastic pipe in the drain line,

because the drain must withstand boiling water.

10

Page 11

OM-CC-E

Initial Start-Up

WARNING

ANY POT ENT IAL USER OF THE EQUIPM ENT SHOULD BE TRAINE D IN SAFE AND CORRECT OPERATING

PROCEDURES.

After the Convection Combo™ has been installed,

test it to ensure that it is operating correctly.

Remove all literature and packing materials from

1.

the interior and exterior of the unit.

2. Check that the cold water supply line is open and

that none of the f ittings are leaking.

Turn on electrical service to the unit.

3.

High Altitude Operation. At altitudes above

4.

5,000 feet (1524m), the unit will not operate in

the Steamer or Combo Modes unless the altitude

is set. You can program the altitude as follows:

a. If the unit is on, turn it off by pressing the ON

touc h pad.

b. Press and hold the STEAM touch pad while

turning the unit on by pressing the ON touch

pad. The Timer Display will show the letters

AL and a number representing the altitude in

thousands of feet. If the altitude has not

been set for your unit, the display will be 0.

c. Enter an altitude value between 0 and 15,

using the numbered touch pads. For

example, if the unit will be operating at 7,000

feet, enter 7.

For CC20-E only: Check Fan

5.

Rotation — IMPORT ANT ! As

seen from inside the oven cavity,

the fan should be turning in a

counterclockwise direction. If the

fan is running backwards

(clockwise), have a qualified

electrician turn off the main power and switch

any two incoming power leads on the distribution

block. An incorrectly turning fan will eventually

shut the oven down.

Select Farenheit or

6.

Celsius

Temperatures. The

Convection Combo™

is delivered with the

Farenheit scale as

default. To c hange

the current

temperature scale,

holding the 5 key in,

press ON. The Timer

Display will either

show dEG°F or

dEG°C. Press the 5

key again to change

from one to the other. Press START to accept

the change.

d. Press the START touch pad.

Altitude Metric Conversion

Altitude

Feet Meters

5000 1524 5

6000 1830 6

7000 2133 7

8000 2438 8

9000 2745 9

10000 3048 10

11000 3353 11

12000 3658 12

13000 3962 13

14000 4267 14

15000 4572 15

Setting

11

To Test Steamer Mode Operation, turn on the

7.

unit. (For details of operating procedure, see the

Operation section of this manual.) Clear time

from the time display. Press the STEAM touch

pad. (If the HOT light is on, see the Fast Cool

instructions in the Operation section.)

The WAIT light will stay on while the steam

generator fills with and heats the water. The

WAIT light should turn off within three minutes,

and the READY light should come on. This

indicates that the water is at its standby

temperature. The timer only controls operations

in the Steamer Mode. Enter a time and press

ST ART. (“Time” is set in minutes and hours

only. Seconds are not displayed).

Examples: 2 minutes = 00:02

(Just press 2).

1 hour and 30 minutes = 01:30

(Press 1, 3, and 0, or press 9,0

the timer will change to 1:30)

Page 12

OM-CC-E

The colon [:] between the numbers on the time

display will blink and the generator will begin to

produce steam. The time will not count down

unless the READY light is lit.

NOT E: You cannot chang e modes if the timer is

running.

8. To Test Combo Mode Operation, turn on the

power and clear any time from the timer display.

Press the COMBO touch pad. Set the COOK

temperature to 300

will come on. It will remain on while (1) the

steam generator fills with water and heats it to

its standby temperature and (2) the air heater

raises the air temperature to 300

actions should be completed in about five

minutes, starting with a cold unit. When the set

temperature is attained, the WAIT light will go

off, and the READY light will come on.

NOT E: The timer does not control the oven in

either the Combo or Oven Modes.

o

F (150oC). The WAIT light

o

F. Both

To Test Oven Mode Operation, turn on the

9.

power and clear the timer display. Press the

OVEN touch pad. Set the cook temperature to

o

F (175oC). The WAIT light will come on.

350

Within six minutes from a cold start, the WAIT

light should go out and the READY light should

come on. When that happens, turn the COOK

temperature setting down to 320oF (160oC). The

HOT light will come on.The heat-up times

provided above may vary slightly as a result of

voltage or water pressure differences.

To shut down the unit, first clear the timer. Next,

10.

press the mode pad for the mode in which the

unit is operating. Finally, switch off the power.

11. If your Convection Combo™ behaves as

described, the unit is functioning correctly, and is

ready for use.

12

Page 13

OM-CC-E

Operation

WARNING

ANY POT ENT IAL USER OF THE EQUIPM ENT SHOULD BE TRAINE D IN SAFE AND CORRECT OPERATING

PROCEDURES.

Controls and Indicators

A.

Operator controls features are on the right front side

of the unit. Their use is described below:

1. Time Section

In Oven and Combo Modes, the timer

func tions only as a “cooking time minute

minder” and does not turn the unit on or off.

In the Steamer Mode, however, it controls

the steaming function.

a. Display Window — Shows operating

time remaining in the Steamer, Oven or

Combo Mode. The timer counts down.

If the unit is equipped with, and operating

in the optional Hold Mode, the timer will

count up, and will show the total

accumulated time that the product has

been holding. The window shows

operating time in “hours:minutes” format.

For example, entering 9 and 0 will result

in a display of 01:30. (On some older

units numbers higher than 59 will not be

accepted - in these cases, convert the

time to hours and minutes. 90 minutes

would be entered 1,3, 0.

beeper will sound and the SERVICE light

will be on when you switch on the power.

The unit may continue to operate,

depending on the type of problem.

Refer to the Troubleshooting section to

determine the nature of the problem.

b. Time touch pads — used to enter time

values .

c. CLEAR — Pressing this touch pad once

stops the beeper and resets the timer to

the time that was last set. Pressing

twice clears it to 00:00. At the end of a

cooking period, opening the door is the

same as pressing CLEAR once.

d. ST ART — Press this touch pad to start

the timer. If the unit is in Steamer Mode,

it will also cause steaming to begin.

2. Status Lights

a. HOT — Indicates chamber temperature

is more than 15

temperature. (See Paragraph 5 in this

section)

b. SERVICE — Indicates that there is a

problem which might require a service

call. If there is such a problem the

o

F (8oC) over the set

13

Page 14

OM-CC-E

c. WAIT — Indicates the unit is either

d. READY — Indicates the unit is ready for

Cooking Mode Selection

3.

a. STEAM — Selects steamer operation

b. COMBO — Selects superheated steam

c. OVEN — Selects convection oven

4. Power

The ON touch pad turns the unit on or off.

When power is on, the ON light just above

the touch pad is lit. Use of this pad does not

reset the controls. The unit will always come

on in the same mode it was in when shut

down.

heating or cooling toward the set

temperature. The HOT and WAIT lights

will both be on if the chamber is more

than 15

o

F (8oC) above the set point.

use.

only.

and convection oven operation.

operation only.

5. Temperature (TEMP) Section

a. The Temperature Display Window shows

the selected temperature in either Oven

or Combo Mode. It is blank in the

Steamer Mode or when the optional Hold

Mode is operational.

b. Turning the Temperature Control Knob

selects the cooking temperatures in 5

increments. The control ranges are:

Oven Mode 200-575oF (95-300oC)

Combo Mode 220-575oF (105-300oC)

Optional HOLD Section

6.

This optional feature permits low

temperature holding or (on models built

before November 1996) proofing with

controlled humidity, when the unit has

already been set in the Oven or Combo

Mode. Whether Oven or Combo Mode has

been selected has no effect on this optional

feature’s operation. Hold Mode controls are

located at the bottom of the control panel.

o

F

a. The upper window shows the selected

holding temperature. This display is

blank when the Hold Mode has been

turned off.

14

Page 15

b. Turning the Hold Control Knob clockwise

activates the Hold Mode and sets

temperatures in 5oF increments within a

range of 90oF to 200oF (30 to 95oC).

The OVEN or COMBO mode light must

be on before Hold Mode can operate.

c. On units with the Hold Option which

were manufactured before November

1996, there is a lower window which

displays the selected humidity. If the

Hold Mode is turned off, it will be blank.

d. Pressing the humidity set touch pad on

these units selects the relative humidity

Available choices for humidity settings

are LO; 45, 50, 55, 60, 65, 70, or 80%;

and HI.

Operating Instructions

B.

1. Steamer Mode

a. If the unit is off, switch on the electric

power by pressing the ON touch pad. (If

the SERVICE light comes on when you

turn on the power, see the

Troubleshooting section).

OM-CC-E

WARNING

WHEN YOU OPEN THE DOOR STAY AWAY

FROM ANY STEAM COMING OUT OF T HE

UNIT. STEAM CAN CAUS E BURNS.

e. The WAIT light will be on until the water

reac hes 200oF (93oC). It will then turn

off and the READY light will come on.

You are now ready to steam foods in

your Convection Combo™.

f. Load the food into pans in an even,

b. If the power is already on, and there is a

number in the time display window,

press the CLEAR touch pad one or more

times to reset the time to zero.

NOT E: You cannot change operating

modes while the timer is running

c. The unit will power up in the mode of

operation in which it was last used.

Because of this, the indicator light for

that mode will be lit. If the unit is not

already in the Steamer Mode, press the

STEAM touch pad. The STEAM light

will come on and the Temperature

Window will go blank.

d. If the unit was recently used in Oven or

Combo Mode, the HOT light may come

on, indicating that the cooking chamber

is too hot for use as a steamer. The unit

can be cooled quickly to the steaming

temperature range by leaving the door

open or following the Fast Cool

procedure described near the end of this

section (Paragraph 5). With the door

open the generator can fill and heat the

water to 200

steam.

o

F, but it cannot produce

uniform layer.

g. Carefully open the door and slide the

pan or pans onto the pan racks in the

cooking chamber. If you are only using

one pan, place it in the middle position.

Close the door.

h. Press the numbered touch pads to set

the cooking time. The time will appear in

the Time Display Window. If you enter

the wrong number, press the CLEAR

touch pad to erase the time from the

display, and enter the time again.

i. When the correct cooking time has been

entered, press the ST ART pad. The

colon in the display will blink and the time

will count down the cooking time. (The

unit must be READY before the timer

can count down.

j. If you open the door during the cooking

period, steaming and the timer will stop

(but will not reset). When you close the

door, steaming and timing will continue.

15

Page 16

OM-CC-E

WARNING

WHEN YOU OPEN THE DOOR STAY AWAY

FROM ANY ST EAM COMING OUT OF T HE UNIT.

ST EAM CAN CAUSE BURNS.

number keys when you first use set that

time.

n. After the display has counted down to

zero you can reset the time to zero by

either (1) opening the door and pressing

CLEAR or pressing CLEAR twice. A

new cooking time may then be set by

using the number keys.

2. Oven Mode

a. To use the Convection Combo™ as a

convection oven, first switch on the

electric power by pushing the ON touch

pad. (If the SERVICE light comes on

when you turn on the power, see the

Troubleshooting section). If the door is

closed and the cooking temperature is

above 200

o

F (93oC) the fan will begin to

operate.

b. If the power is already on, and there is a

number in the time display window,

press the CLEAR touch pad one or more

times to reset the time to zero.

When the timer reaches zero, it stops steam

k.

generation and sounds a beeper alarm. Water in

the steam generator stays at its standby

temperature (200

o

F - 93oC). On some older

models, the beeper will continue to sound until

the door is opened or the CLEAR pad is

pressed.

l. Carefully open the door. If the food is

cooked, remove the pans using hot pads

or oven mitts to protect your hands from

the ho t pans.

m. After the display has counted down to

zero opening the door or pressing

CLEAR once

will reset the display to the

time that was last used. Pressing

ST ART will repeat the cook cycle. If the

NOT E: You cannot change operating

modes while the timer is running

c. The unit will power up in the mode of

operation in which it was last used.

Because of this, the indicator light for

that mode will be lit. If the unit is not

already in the Oven Mode, press the

OVEN touch pad. The OVEN light will

come on and the oven fan will operate.

d. Use the Temperature Control Knob to

set the desired cooking temperature,

which will appear in the temperature

display window. Unless the cooking

chamber is already at or above the

selected temperature, the unit will begin

heating and the WAIT light will come on.

same cooking time will be used

repeatedly, you only need to press the

16

Page 17

e. If the unit was recently used at a

temperature more than 15oF (8oC) higher

than the temperature selected, the HOT

and WAIT lights will turn on. The unit can

be cooled quickly to the desired cooking

temperature by leaving the door open or

following the Fast Cool procedure

described near the end of this section

(Paragraph 5).

f. The READY light will indicate when the

oven is at the desired temperature.

OM-CC-E

k.

To stop cooking, take the pans out of the

oven using hot pads or oven mitts to

protect your hands from the hot pans.

The unit will continue heating to keep the

chamber at the set temperature until the

temperature control is reset, or the power

is shut of f.

g. Load the food into the pan or pans in a

uniform layer.

h. The Convection Combo™ will operate in

Oven Mode with the timer either on or off.

If you want to time the cooking, press the

numbered pads in the TIME portion of the

control panel to set the cooking time. The

time will appear in the Time Display

Window. If you enter the wrong number,

press the CLEAR touch pad to erase the

time from the display, and enter the time

again. Remember that the timer does not

control the unit in the Oven Mode.

i. Open the door and slide the pan or pans

onto the pan racks in the cooking chamber.

If you are only using one pan, place it in

the middle position. Close the door.

j. If the correct time has been set on the

timer, press the ST ART pad. The colon [:]

between the numbers in the display will

blink and the time will count down the

cooking time. W hen the timer has counted

down to zero, it will sound a beeper. This

sound will continue until the door is opened

or the CLEAR pad is pressed.

WARNING

PANS AND INT ERNAL PARTS OF THE OVEN

WILL BE VERY HOT . AV OID C ONT ACT WITH

HOT SURFACE S.

l. Opening the door during operation shuts

of f power to the heaters and fan and

stops the timer, but it has no other affect

on the controls. When the door is closed,

operation continues. Note that cooking

time will be extended by the period the

door was open.

3. Combo Mode

a. If the unit is off, switch on the electric

power by pressing the ON touch pad. (If

the SERVICE light comes on when you

turn on the power, see the

Troubleshooting section). If the door is

closed and the cooking temperature is

above 200

o

F (93oC) the fan will begin to

operate.

b. If the power is already on, and there is a

number in the time display window, press

the CLEAR touch pad one or more times

to reset the time to zero.

17

NOT E: You cannot change operating

modes while the timer is running

c. The unit will power up in the mode of

operation in which it was last used.

Because of this, the indicator light for that

mode will be lit. If the unit is not already

in the Combo Mode, press the COMBO

touch pad. The COMBO light will come

on and if the steam generator is not

already full, water will flow into it and

begin heating.

d. Use the Temperature Control Knob to set

the desired oven temperature between

220 and 575

o

F (105 to 300oC). The

temperature will appear in the

temperature display window.

Page 18

OM-CC-E

e. If the unit was recently used at a

temperature more than 15oF (-8oC) higher

than the temperature selected, the HOT

and WAIT lights will turn on. The unit can

be cooled quickly by leaving the door open

or following the Fast Cool procedure

described near the end of this section

(Paragraph 5).

WARNING

WHEN YOU OPEN T HE DOOR STAY AWAY

FROM ANY ST EAM COMING OUT OF T HE UNIT.

ST EAM CAN CAUSE BURNS.

f. The WAIT light will be on until the water in

the steam generator reaches the boiling

point and the air in the cooking chamber

reaches the set temperature. It will then

turn off and the READY light will come on

indicating that the oven is at the desired

temperature.

i. Open the door and slide the pan or pans

onto the pan racks in the cooking

chamber. If you are only using one pan,

place it in the middle position. Close the

door.

j. If the timer has been set, press the

ST ART pad. The colon [:] between the

numbers in the display will blink and the

time will count down the cooking time.

When the timer has counted down to

zero, it will sound a beeper. This beeping

will continue until the door is opened or

the CLEAR pad is pressed.

k. To stop cooking, take the pans out of the

oven using hot pads or oven mitts to

protect your hands from the hot pans.

The unit will continue steaming and

heating the oven at the set temperature

until the temperature control is re set, or

the power is shut off.

Hold Mode (Cook-n-Hold Option) - (Cook-n-

4.

Hold/Proofing Option on Models Manu-

g. The unit will operate in Combo Mode with

the timer either on or off. If you want to

time the cooking, press the numbered

pads in the TIME portion of the control

panel to set the cooking time. The time

will appear in the Time Display Window. If

you enter the wrong number, press the

CLEAR touch pad to erase the time from

the display, and enter the time again. The

timer does not control the unit in Combo

Mode.

h. Load the food into the pan or pans in a

uniform layer.

WARNING

WHEN YOU OPEN THE DOOR ST AY AWAY FROM

ANY ST EAM COMING OUT OF THE UNIT. STEAM

CAN CAUSE BURNS.

factured Before November 1996) Items

identified by an asterisk (*) and/or in italics pertain

to Humidity Control features on some models

manufactured prior to November 1996.

18

Page 19

a. If these optional features are included in

your Convection Combo,™ the controls are

located near the bottom of the Control

Panel. Hold Mode may be activated when

the oven is either in Combo or Oven Mode,

and works the same in both.

b. If you want your Convection Combo™ to

switch to Hold Mode automatically when it

finishes cooking, use the following

procedure:

1) Set the unit for Combo or Oven Mode.

2) Set COOK temperature.

OM-CC-E

NOT E: Food will continue to be cooked

by the excess heat as the unit

slows to the set HOLD

temperature. The amount of

additional cooking depends on

the food product and the initial

COOK temperature.

The oven will operate at the set HOLD

temperature (and humidity)* until it is

changed or turned off. If desired, you

may check the time on hold by pressing

ST ART. The unit will count up and

display the time elapsed since it has been

holding. The maximum that the timer is

able to display is 19 hours and 59

minutes. After that the display will flash

19:59, but the unit will continue to

maintain the HOLD settings.

c. To end manual operation of the Hold

Mode, first remove the food from the unit.

Then take either of the following steps:

1) If the timer is not running, turn the

COOK temperature set knob

clockwise until a number appears in

the COOK temperature display. (The

unit will heat to the COOK setting).

2) If the timer is running, press and hold

in the CLEAR touch pad for at least

two seconds.

3) Set the cooking time.

4) Turn the HOLD temperature set knob

until the desired hold temperature

appears in the HOLD temperature

display.

5) (Press HUM IDIT Y set touch pad until

the desired setting appears in the

HUM IDITY display).*

6) After the READY light comes on to

indicate the oven is at the set

temperature, open the door, load food

into the unit and close the door.

7) Press the ST ART touch pad.

When the set cook time is ended, the unit

will automatically switch to the Hold Mode.

The beeper will NOT sound. The timer

will now count UP. The COOK

temperature display will be blank and the

temperature of the unit will slowly drop to

the HOLD temperature setting.

19

Page 20

OM-CC-E

5. Fast Cool

Shutting Down

6.

a. When the HOT indicator is lit and the

timer is cleared, the unit can be cooled

quickly by opening the door and

pressing ST ART . The fan will

operate, and the TIME window will

display the word “COOL.” This is the

only time the fan operates with the

door open.

WARNING

DO NOT PUT HAND S OR OT HER OBJECT S

INTO T HE COOKING CHAMBER DURING THE

FAST COOL OPERATION. T HE ROTATING FAN

CAN BE HAZARDOUS.

b. To stop the Fast Cool operation, press

any touch pad or close the door.

a. Press the touch pad for the mode in which

the unit is operating.

b. Switch off the power by pressing the ON

touc h pad.

Leave the door at least partially open, if local

sanitation regulations permit.

20

Page 21

OM-CC-E

Cleaning

To keep your Convection Combo™ in proper operating condition and to make the cleaning process easier, cleaning

should be a daily activity.

Suggested Tools and Cleaners

A.

1. Mild detergent

2. Stainless steel exterior cleaner such as

Zepper®

3. Steam generator de-liming agent, such as

Groen Delimer Descaler, Lime-Away®

or an equivalent. A liquid de-liming agent

will be easier to use than crystals or

powders. See the warning about chlorides

below.

4. De-greaser, s uch as EncompasS®, Malone

34®, Puritan Puribrute®, or Con-Lie®

5. Cloth or sponge

Plastic wool or a brush with soft bristles

6.

Spray bottle

7.

8. Measuring cup

9. Nylon pad

10. Towels

Plastic disposable gloves

11.

Procedure

B.

1. Exterior Cleaning

a. Prepare a warm solution of the mild

detergent as instructed by the supplier. Wet

a cloth with this solution and wring it out.

Use the moist cloth to clean the outside of

the unit. Do not allow freely running liquid to

touc h the contro ls, the control panel, any

electrical part, or any open louver.

To remove material which may be stuck to

b.

the unit, use plastic wool, a fiber brush, or

a plastic or rubber scraper with a

detergent solution.

Stainless steel surfaces may be polished

c.

with a recognized stainless steel cleaner

such as Zepper®.

DISCONNECT THE POWER SUPPLY

BEFORE CL EANING THE OUTSIDE OF

THE UNIT.

KEEP WATER AND CLEANING

SOLUT IONS OUT OF CONTROLS AND

ELECTRICAL COMPONENTS. NEVER

HOSE OR STEAM CL EAN ANY PART

OF THE UNIT.

DON’T MIX DE-LIMING AGENTS (ACID)

WITH DE-GREASERS (ALKALI)

ANYWHERE IN THE UNIT

AVOID CONT ACT WIT H ANY

CLEANERS, DE-LIMING AGENT OR DEGREASER AS RECOMMENDED BY THE

SUPPLIER. M ANY ARE HARMFUL.

READ THE WARNINGS AND FOLLOW

THE DIRECTIONS!

EVEN WHEN THE UNIT HAS BEEN

SHUT OFF, DON’T PUT HANDS OR

TOOLS INTO THE COOKING

CHAM BER UNTIL T HE FAN HAS

STOPPED TURNING.

DON’T USE ANY CL EANING OR DELIMING AGENT THAT CONT AINS ANY

SULFAM IC AGENT OR ANY CHLORIDE,

INCLUDING HYDROCHLORIC ACID

(HCl). TO CHECK FOR CHLORIDE

CONTENT SEE ANY MATERIAL

SAFETY DATA SHEETS PROVIDED BY

THE CLEANING AGE NT

MANUFACTURER.

UNIT MAY BE HOT. TAKE

PRECAUTIONS TO PREVENT

CONTACT WITH HOT SURF ACES.

PRECAUT IONS

WARNING

IM PORTANT

DO NOT USE ANY M ET AL MATERIAL (SUCH AS METAL SPONGES) OR METAL IMPLEMENTS (SUCH AS

A SPOON, SCRAPER OR WIRE BRUSH) THAT MIGHT SCRATCH THE SURFACE. SCRATCHES MAKE THE

SURFACE HARD TO CLEAN AND PROVIDE PLACES FOR BACTERIA TO GROW. DO NOT USE STEEL

WOOL, WHICH MAY LEAVE PARTICLES IMBEDDED IN THE SURFACE WHICH COULD EVENTUALLY

CAUSE CORROSION AND PITTING.

21

Page 22

OM-CC-E

Interior Cleaning

2.

To exit the Clean Cycle at any time, press and

hold the CLEAR touch pad. Be sure to wash

out all chemical residues thoroughly before

using the unit.

WARNING

UNIT MAY BE HOT . DO NOT T OUCH HOT

SURFACES.

DO NOT PUT HAND S OR OT HER OBJECT S

INTO COOKING CHAMBER WHILE CONVECTION

COMBO™ IS OPERATING. T HE ROT ATING FAN

CAN BE HAZARDOUS.

a. Turn off all operating modes by stopping the

timer, and pressing the mode touch pad(s).

b. Enter 99 on the timer. The display should

show “00:99.”

c. If the HOT light is on, use the Fast Cool

method to reduce the temperature

(Paragraph 5, Operation, Page 18). If the

HOT light is off, “CI” will be displayed in the

timer window, and you may proceed to the

next step.

Remove all pan racks and clean them in a

d.

sink. To remove the right side rack, lift it up

and to the left.

Remove the right side of the cooking

e.

chamber.

Prepare oven degreaser as directed on the

f.

product label. Thoroughly coat all inside

surfaces of the cooking chamber and both

sides of the right side panel with the

degreaser.

It may cause the unit to display false service

messages.

Replace the generator cover and right side

i.

panel in their normal positions.

Close the door and press START . The timer

j.

will display “CL:50,” with the colon [:]

between the numbers flashing. The timer will

count down to “CL:26.”

k. When the buzzer sounds and the timer

displays “C2,” open the door.

WARNING

THE UNIT WILL BE HOT ENOUGH TO CAUSE A

BURN. DO NOT TOUCH ANY HOT SURFACE.

l. Remove the right side panel and steam

generator cover and rinse them in the sink.

l. Rinse and wipe down the cooking chamber

with a cloth and plenty of clean water. Rinse

the cloth often.

n. Add de-liming agent to the steam generator

as specified by the de-liming agent label.

o. Put the generator cover and right side panel

back in place.

p. Close the door. The timer will display

“CL:26" and count down automatically to

“CL:00.”

q. Press the ON switch to turn off the unit. Let

the unit cool.

Remove the steam generator cover.

g.

NOT E:

h. If there are grease deposits in the generator,

Add degreaser to the steam generator

only if you see grease deposits.

add ¼ to ½ cup (60 to 125 ml) of full

strength degreaser to the generator, or

lightly coat the generator with spray

degreaser. Do not use too much degreaser.

22

WARNING

UNIT MAY BE HOT . DO NOT T OUCH HOT

SURFACES.

Remove the right side panel and steam

r.

generator cover and rinse them thoroughly in

a sink.

Page 23

Rinse and wipe down the cooking chamber

s.

with a cloth and plenty of clean water. Rinse

the cloth often.

3. De-liming Only

If you only want to clean hard, white deposits out of

the steam generator, it is not necessary to degrease

the unit.

a. Turn off all operating modes by stopping the

timer, and pressing the mode touch pad(s).

Enter 99 on the timer. The display should

b.

show “00:99.”

c. If the HOT light is on, use the Fast Cool

method to reduce the temperature

(Paragraph 5, Operation, Page 18). If the

HOT light is off, “CI” will be displayed in the

timer window, and you may proceed to the

next step.

OM-CC-E

Press the ON switch to turn off the unit. Let

k.

the unit cool.

WARNING

UNIT MAY BE HOT . DO NOT T O UCH HOT

SURFACES.

l. Remove the right side panel and steam

generator cover and rinse them thoroughly in

a sink.

m. Rinse and wipe down the cooking chamber

with a cloth and plenty of clean water. Rinse

the cloth often.

n. Re-install the pan racks.

d. Remove all pan racks and clean them in a

sink. To remove the right side rack, lift it up

and to the left.

Pour one pint (two pints for CC-20E) de-

e.

liming agent into the steam generator.

Close the door and press START . The timer

f.

will display “CL:50,” with the colon [:]

between the numbers flashing. The timer will

count down to “CL:26.”

WARNING

THE UNIT WILL BE HOT ENOUGH TO CAUSE A

BURN. DO NOT TOUCH ANY HOT SURFACE.

g. When the buzzer sounds and the timer

displays “C2,” open the door AND CHECK

THE STEAM GENERATOR.

NOT E: If the timer stops and the SERVICE light

comes on, it means that there have been

errors that prevent the unit from completing

its Clean Cycle. Take the following steps:

1) Perform a reset. W ith the unit turned of f,

press and hold the COMBO touch pad.

Then press the ON touch pad to display any

error codes.

If the error numbers displayed are 1 and 3,

2)

or 2 and 3, press CLEAR, and restart the

Clean Cycle by entering “99" (00:99) on the

timer. Add one cup of full strength

degreaser and continue the Clean Cycle by

pressing ST ART .

3) If the error numbers are 1 and 2, or 6, call

your authorized Groen Service Agency for

immediate service.

If the error number displayed is 1 or 2, but

4)

not both, the unit may need more cleaning.

If there are other errors, refer to this manual’s

Troubleshooting Section (Page 24)

h. If the generator is free of hard deposits, go

to the next step. If hard, white deposits are

still visible, add de-liming agent again before

proceeding.

i. Put the generator cover and right side panel

back in place.

j. Close the door. The timer will display

“CL:26" and count down automatically to

“CL:00.”

Clean Cycle Counter

The Convection Combo™ keeps track of

completed Clean Cycles. To see this total, turn

of f the unit. Press and hold the 0 touch pad while

turning on the unit. The total will show in the

timer windo w. It cannot be reset.

3. Manual Cleaning

This procedure may be necessary if regular cleaning

was not performed.

23

Page 24

OM-CC-E

NOT E:

DO NOT PUT HANDS OR OTHER OBJECT S

INTO THE COOKING CHAMBER WHILE THE FAN

IS TURNING.

It is strongly recommended that the unit be

run through a Clean Cycle after manual

cleaning. Repeat as necessary.

WARNING

1. If the unit has been operating in the Oven or

Combo Mode, allow it to cool or use the

Fast Cool procedure described in the

Operations Section (Page 18).

Maintenance

When the unit has cooled enough to be

2.

cleaned, switch it off by pressing the ON

touc h pad.

3. Remove the right side panel from the cooking

chamber.

®

Using Easy-Off

4.

comparable product, thoroughly coat all

inside surfaces of the chamber, including the

right side panel. Follow the manuf acturer’s

instructions on the cleaning agent label.

5. Install the right side panel.

Rinse and wipe down the cooking chamber

6.

with a cloth and plenty of clean water. Rinse

the cloth often.

Oven Cleaner or a

The Groen Convection Combo™ is designed for

minimum maintenance. Certain parts may need

replacement after prolonged use. If there is a need

for service, only Groen personnel or authorized

Groen representatives should perform the work.

Always supply water with a low mineral count that

meets the standards outlined in the Water

Conditioning section of this manual.

If steam or condensate is seen leaking from around

the door, take the following steps:

Check the door gasket. Replace if it is cracked

1.

or split. Inspect the cooking chamber drain to be

sure it is not blocked.

Troubleshooting

Resetting the Solid State Controls

A.

(If problems persist call an authorized Groen

Service Agency)

If the controls stop responding to normal

operations, or the unit is behaving oddly, reset

the controls using the following procedure:

1. Switch off the power by pressing the ON

touc h pad.

2. While pressing the COMBO touch pad,

switch the power back on. If no errors are

present the unit will beep and show four

zeroes in the display. If there are errors, the

unit will not beep, but will display Service

Codes, in the timer and cook temperature

displays. Note the Service Codes. Press

CLEAR to exit Service Mode and refer to the

fo llowing exp lanation of service messages.

Adjust the latch pin as follows:

2.

a. Loosen the lock nut at the base of the latch

pin, and turn the latch pin ¼ turn clockwise.

Re-tighten the lock nut.

b. After adjustment, run the unit to test for

further steam leaks.

c. If there is still leakage, repeat the

adjustment.

d. Continue adjusting the pin clockwise until the

door fits tightly enough to prevent leaks.

Service Messages

B.

There are two types of service message:

1. Non-critical error: signaled by three quick

beeps. The SERVICE light comes on for 15

seconds and then goes out.

Critical error: signaled by a continuous five

2.

second beep. The SERVICE comes on and

stays on.

If there is a non-critical error you may continue to

operate the unit. When possible, inspect the Service

Code. Turn off the unit by pressing the ON touch

pad. While pressing the COMBO touch pad, switch

the power back on. Note the numbers and refer to

the Troubleshooting Guide which follows. Press

CLEAR to exit the Service Mode. If there is a critical

error, the unit will not operate in its current mode, but

may operate in another. Inspect the Service Code

as described above, and call your authorized Groen

Service Agency.

24

Page 25

OM-CC-E

Troubleshooting Guide

If a problem persists after taking the actions suggested below, call your authorized Groen service representative.

CODE INDICATES SUGGESTED ACTION

Try cleaning steam generator to remove contamination from the probes.

1 Low water level probe

2 High water level probe

Maximum generator fill

3

time (90 seconds) has

been exceeded.

4 Faulty air probe

5*

7*

7A*

*Service Code 5 is not used on units manufactured af ter March 1, 1997. Service Code 7 indicates Out of

Calibration for units made before March 1, 1997. Thereafter it indicates Time Between Fills, described in 7A,

above. These changes were made on units after Serial Number C7439MS.

Faulty drain probe

(Units Before 3/97 Only)

6 Faulty generator probe

Out of Calibration

(Units Before 3/97 Only)

Time Between Fills

(Units After 3/97 Only)

Maximum generator drain

8

time (five minutes) has

been exceeded.

If either code continues call your Groen Service Agency.

•

If both codes are displayed the unit will only operate in the Oven Mode.

•

If only one code is displayed the unit will operate in all modes, but water

•

may overflow from the generator into the cooking chamber during

operations in either the Steam or Combo Modes.

Make sure the water supply is fully turned on and that hoses are not kinked

or pinched.

If the code is still displayed the unit will operate in the Oven Mode only.

•

Call your Groen Service Agency

•

• The unit will operate in Steamer and Clean Cycle Modes only.

• Call your Groen Service Agency

The unit will operate in all modes.

•

Call your Groen Service Agency

•

• The unit will operate in Oven Mode only.

• Call your Groen Service Agency

The unit will operate in all modes.

•

Call your Groen Service Agency

•

Check for a leaky fill valve.

The unit will operate in Oven Mode only.

•

Call your Groen Service Agency

•

Ins pect the drain line and re move any blockage. Make certain that the

drain is free-vented as detailed in the Installation Section of this Manual.

(Paragraph 4, Page 6)

Mode Operation — After a Service Code Occurs

Mode

12345* 5A 6 7* 7A 8 1 & 2

Steam Yes Yes No Yes Yes NA No Yes No No No

Combo YesYesNoNoYesNANoYesNoNoNo

Oven Yes Yes Yes No Yes NA Yes Yes Yes Yes Yes

Clean Yes Yes No Yes Yes NA No Yes No No No

*Service Code 5 is not used on units manufactured af ter March 1, 1997. Service Code 7 indicates Out of

Calibration for units made before March 1, 1997. Thereafter it indicates Time Between Fills. These changes

were made on units after Serial Number C7439MS.

Service Code

25

Page 26

OM-CC-E

Diagrams & Schematics

CC10-E Control Schematic

CC10-E Heater Schematic

26

Page 27

Diagrams & Schematics, Continued

OM-CC-E

CC20-E Control Schematic, 208/240 Volts

CC20-E Control Schematic 480 Volts

27

Page 28

OM-CC-E

Diagrams & Schematics, Continued

CC20-E Heater Schematic, 208/240 Volts

CC20-E Heater Schematic, 480 Volts

28

Page 29

Diagrams & Schematics, Continued

OM-CC-E

CC20-E Heater Schematic 208/240 Volts

(Units That Meet Canadian Standards Association Requirements)

29

Page 30

OM-CC-E

Service Log

Model No.

Serial No.

Date Purchased

Purchase Order No.

Date Maintenance Performed Performed by

Purchased From

Location

Date Installed

For Service Call

30

Page 31

OM-CC-E

LIMITED WARRANT Y T O

COMMERCIAL PURCHASERS*

(Continental U.S., Hawaii and Canadian Sales Only)

Groen Foodservice Equipment (“Groen Equipment”) has been skillfully manufactured, carefully inspected, and

packaged to meet rigid standards of excellence. Groen warrants its Equipment to be free from defects in material

and workmanship for (12) twelve months with the following conditions an subject to the following limitations.

I. This parts and labor warranty is limited to Groen Equipment sold to the original commercial

purc haser/users (but not original equipment manufacturers {O.E.M.}), at its original place of installation in

the c ontinental United States, Hawaii and Canada.

II. Damage during shipment is to be reported to the carrier, is not covered under this warranty, and is the sole

responsibility of the purchaser/user.

III. Groen,, or an authorized service representative, will repair or replace, at Groen’s sole election, any Groen

equipment, including but not limited to, draw-off valves, safety valves, gas and electric components, found

to be defective during the warranty period. As to warranty service in the territory described above, Groen

will absorb labor and portal to portal transportation costs (time and mileage) for the first twelve (12)

months from date of installation or fifteen (15) months from date of shipment from Groen.

IV. This warranty does not cover boiler maintenance, c alibration, perio dic adjustments as spe cif ied in

operating instructions or manuals, and consumab le parts s uch as scraper blades, gaskets, p acking , etc.,

or labor costs incurred for removal of adjacent equipment or objects to gain access to Groen Equipment.

This warranty does not cover defects caused by improper installation, abuse, careless operation, or

improper maintenance of equipment. This warranty does not cover damage caused by poor water quality

or improper boiler maintenance.

V. T HIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OT HER WARRANTIE S, EXPRESS OR

IM PLIED, INCLUDING ANY IMPLIED WARRANT Y OF M ERCHANTABILITY OR FIT NESS FOR A

PART ICULAR PURPOSE, EACH OF WHICH IS HEREBY EXPRESSLY DISCLAIMED. THE REMEDIES

DESCRIBED ABOVE ARE EXCLUSIVE AND IN NO EVENT SHALL GROEN BE LIABLE FOR SPECIAL,

CONSEQUENT IAL OR INCIDENTAL DAMAGES FOR T HE BREACH OR DELAY IN PERFORMANCE

OF THIS WARRANT Y.

VI. Groen Equipment is for commercial use only. If sold as a compo nent of another (O.E.M.) Manuf acturer’s

equipment, or if used as a consumer product, such Equipment is sold AS IS and without any warranty.

*(Covers all Foodservice Equipment Ordered after October 1, 1995)

31

Page 32

1055 Mendell Davis Drive OM-CC-E (Revised 7/00)

Jackson, MS 39212 Part Number 121015 Rev. A

Telephone 601 372-3903

Fax 601 373-9587

Loading...

Loading...