Page 1

Installation and Operation

Profile

PLS 200 Library

Printed in USA or United Kingdom

Tektronix, Inc.

PO Box 1000

Wilsonville, OR 97070-1000 USA

1-800-547-8949 (USA and Canada)

1-503-682-7300

http://www.tek.com

Page 2

Copyright Copyright 1996 Tektronix, Inc. Wilsonville, Oregon.

Printed in the United States of America or the United Kingdom. All rights

reserved. This document may not be copied in whole or in part, or otherwise

reproduced except as specifically permitted under U.S. copyright law, without

the prior written consent of Tektronix, Inc., P.O. Box 1000, Wilsonville, Oregon

97070-1000.

Some portions are reprinted with permission:

Copyright 1994 – 1996 Exabyte Corporation. All rights reserved.

Disclaimer Tektronix, Inc., makes no representation or warranties with respect to the

contents of this document and specifically disclaims any implied warranties of

merchantability or fitness for any particular purpose. Further, Tektronix, Inc.

reserves the right to revise this publication without obligation of Tektronix, Inc.

to notify any person or organization of such revision or changes.

Trademark Notices TEKTRONIX and TEK are registered trademarks of Tektronix, Inc. Profile is

a trademark of Tektronix, Inc.

EXABYTE, EXAPAK, EXB, FileSECURE, LANCourier, and NetSECURE

are registered trademarks of Exabyte Corporation. Eagle, EXA, EXAFacts,

EXAsoft, EXATAPE, and SCIMON are trademarks of Exabyte Corporation.

Other trade names used in this document are trademarks or registered

trademarks of the manufacturers or vendors of the associated products.

Revision Status

Rev Date Description

December 1996 Original Issue; Manual Part Number 070-9619-00

ii PLS200 Library Installation and Operation

Page 3

Contents

Welcome

About this Manual......................................................................................xvi

Related Documentation.............................................................................xvi

Conventions Used in this Manual......................................................... xvi

Tektronix Product Support........................................................................ xvii

United States and Canada .................................................................. xvii

Europe................................................................................................. xvii

Asia and South America...................................................................... xvii

World Wide.......................................................................................... xvii

About the PLS200....................................................................................xviii

Library Elements .......................................................................................xxi

Chapter 1 Installing the Hardware

Preparing for Installation ..............................................................................1

Unpack the Library ..................................................................................1

Check the Accessories............................................................................2

Protect the Library Against ESD..............................................................2

Prepare the Library..................................................................................3

Verify Your Profile Software Version.......................................................3

Installing the SCSI Adapter Into the VDR.....................................................3

Installing the Library Hardware.....................................................................7

Install the Library Into a Rack..................................................................8

Unlatch and Open the Door...................................................................14

Remove the Packing Foam...................................................................15

Move the CHM Out of the Way..............................................................16

Prepare and Install Cartridges...............................................................17

Install Cartridge Magazines...................................................................20

Install a Cleaning Cartridge...................................................................22

Close the Library Door...........................................................................23

Connect the SCSI Cables......................................................................23

Connect the Power Cord.......................................................................28

Power-on the Library.............................................................................28

SCSI Adapter Board Software Update..................................................30

PLS200 Library Installation and Operation iii

Page 4

Contents

Chapter 2 Configuring the Library

Main Screen...............................................................................................32

Displaying the Configuration Menu ............................................................32

Setting the SCSI IDs ..................................................................................34

Setting Other Configuration Options ..........................................................36

Setting Parity Checking.........................................................................36

Adjusting the Contrast...........................................................................37

Setting the Back Light............................................................................38

Setting the Library Date.........................................................................38

Setting the Library Time ........................................................................39

Checking the Serial Number..................................................................39

Checking the Tape Drive Model............................................................41

Chapter 3 Operating the Library

Using the Operator Panel...........................................................................43

Main Screen ..........................................................................................43

Error Codes...........................................................................................44

Main Menu.............................................................................................44

Operator Keys .......................................................................................46

Operating in Different Control Modes.........................................................46

SCSI Interface Mode.............................................................................47

LCD Interface Mode ..............................................................................47

25/9 Pin Serial Port Mode......................................................................47

Changing the Control Mode...................................................................48

Replacing Data Cartridge Magazines.........................................................49

Resetting the Library..................................................................................51

Reset Key..............................................................................................52

Power-on Reset.....................................................................................52

Chapter 4 Operating the Tape Drives

Monitoring the Tape Drive LEDs................................................................53

Displaying Information About Tape Drives.................................................54

Fields on Drive Status Screen...............................................................55

Additional Fields on Mammoth Drive Status Screen.............................56

Ejecting a Cartridge Manually ....................................................................57

Chapter 5 Maintaining the Library

Replacing Tape Drives or Drive Blanks......................................................59

Using Drive Blanks................................................................................59

Replacing Tape Drives..........................................................................60

Replacing the Fuse ....................................................................................63

Replacing the Air Filter...............................................................................65

Cleaning the Front Window........................................................................67

iv PLS200 Library Installation and Operation

Page 5

Chapter 6 Packing and Shipping the Library

Returning the Library for Service............................................................... 69

Shipping the Library...................................................................................69

Preparing the Library for Shipping........................................................70

Inserting the Packing Foam in the Library ............................................71

Removing the Library From the Rack...................................................73

Packing the Library in the Shipping Containers.................................... 77

Chapter 7 Performing Diagnostics

Using the LCD Diagnostics Menu..............................................................83

Summary of Diagnostic Tests............................................................... 84

Accessing the Diagnostics Menu.......................................................... 85

Specifying Element Indexes..................................................................85

Stopping Diagnostic Tests....................................................................85

Self Test................................................................................................86

Position to Element............................................................................... 86

Park.......................................................................................................87

Move Cartridge ..................................................................................... 87

Scan......................................................................................................88

Scan with Range...................................................................................89

Home Gripper ....................................................................................... 89

Home CHM...........................................................................................90

Cycle Pick/Place...................................................................................90

Cycle Gripper........................................................................................ 91

Cycle S Axis..........................................................................................92

Cycle L Axis..........................................................................................92

Cycle Drum...........................................................................................93

Cycle Solenoid...................................................................................... 93

Cycle E/E..............................................................................................94

Configuring the Serial Ports for Diagnostics.............................................. 95

Chapter 8 Using the Library Info Menu

Accessing the Library Info Menu ............................................................... 97

Using the SCSI Menu................................................................................98

SCSI Mode Parameters........................................................................ 98

SCSI Reservations..............................................................................100

SCSI Sense Data................................................................................102

Viewing Statistics.....................................................................................104

Viewing System Sensors......................................................................... 106

Viewing Command History ......................................................................108

Using the Inventory Menu........................................................................110

Bar Code Label Information................................................................ 110

Element Occupied Information............................................................112

Element Position Information.............................................................. 113

Contents

PLS200 Library Installation and Operation v

Page 6

Contents

Chapter 9 Troubleshooting

Problems With Installation........................................................................115

Problems With Tape Drive Operation.......................................................116

Problems With Library Operation.............................................................117

If You Cannot Resolve the Problem.........................................................117

Appendix A Specifications

Storage Capacity......................................................................................119

Operating Environment ............................................................................119

Power.......................................................................................................120

Power Cord Requirements.......................................................................120

SCSI Terminator Specifications ...............................................................120

SCSI Cable Specifications .......................................................................121

Appendix B LCD Error Codes

Appendix C Bar Code Label Specification

Materials for the Label..............................................................................131

Dimensions of the Label...........................................................................132

Bar Code Characters................................................................................133

Checksum Character...........................................................................134

Bar Code Element Widths...................................................................135

Quality......................................................................................................136

Spots and Voids ..................................................................................136

Edge Quality........................................................................................136

Reflectance and Contrast....................................................................136

Label Degradation after Exposure to Light..........................................137

Optional Features.....................................................................................137

Alphanumeric Characters....................................................................137

Background Color................................................................................138

Testing the Bar Code Labels....................................................................138

Index

vi PLS200 Library Installation and Operation

Page 7

Figures

Contents

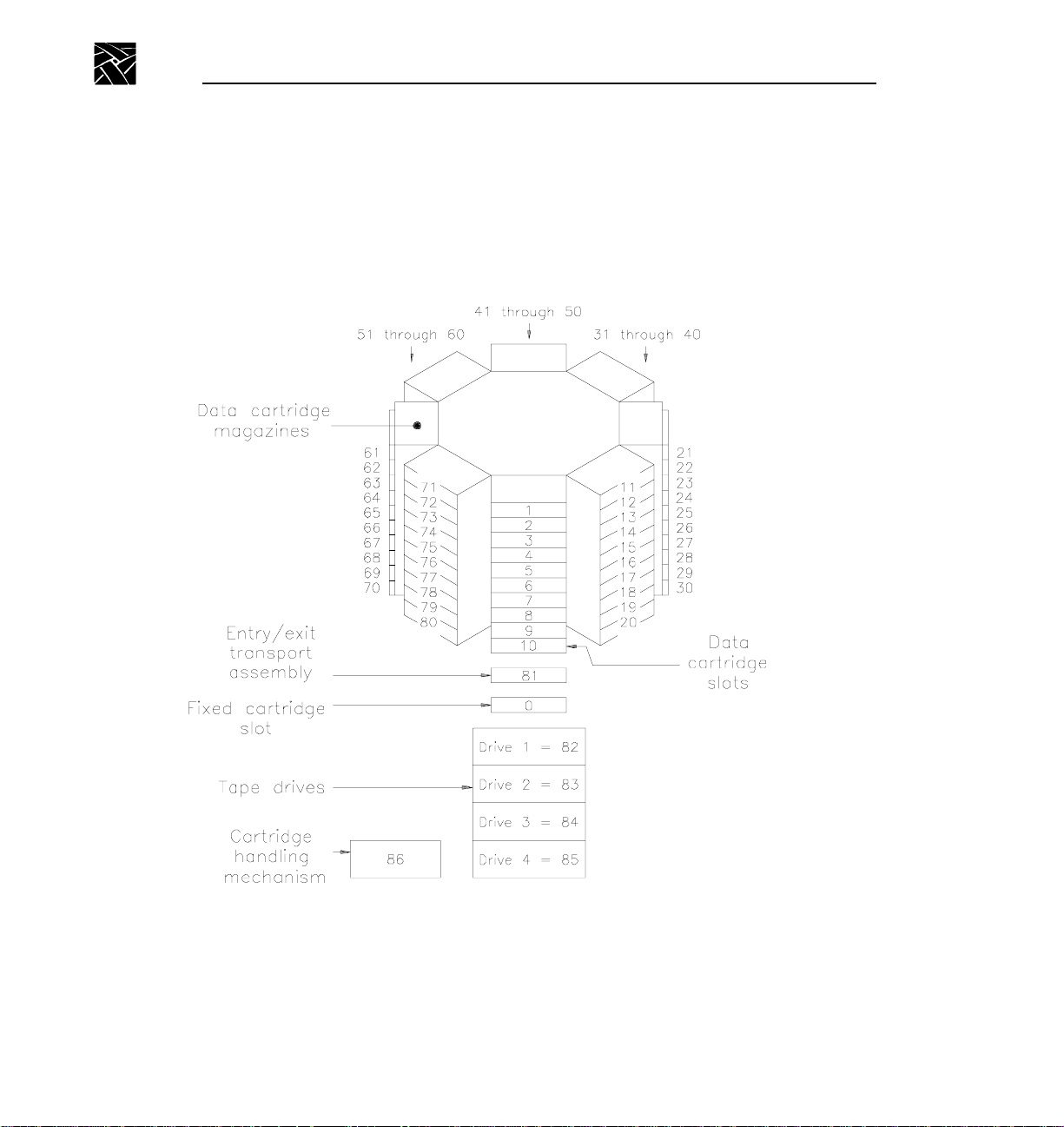

Element indexes for PLS200...................................................................xxiii

1-1 Removing the top covers............................................................................. 4

1-2 Removing the circuit board hold-downs.......................................................5

1-3 Screw locations for board mounting bracket................................................6

1-4 Attaching the slide rails................................................................................9

1-5 Adjusting the distance between the front mounting brackets ....................10

1-6 Installing the library in a rack.....................................................................11

1-7 Attaching the screws to the sides of the library .........................................12

1-8 Securing the library in the rack..................................................................13

1-9 Opening the door....................................................................................... 14

1-10 Removing the packing foam from the library.............................................15

1-11 Moving the CHM to the bottom of the long axis.........................................16

1-12 Positioning a bar code label on a data cartridge........................................17

1-13 Setting the write-protect switch on a data cartridge...................................18

1-14 Installing data cartridges in the magazine .................................................19

1-15 Installing a cartridge magazine in the library .............................................21

1-16 Installing a cartridge in the fixed cartridge slot...........................................22

1-17 Installing the terminators and SCSI jumpers .............................................24

1-18 SCSI connections from the VDR to the PLS200 ....................................... 25

1-19 SCSI connections through the PDX103 to the PLS200............................26

1-20 SCSI connections through the PRS200 to the PLS200............................27

2-1 Operator panel...........................................................................................31

3-1 Library menu structure...............................................................................45

3-2 Opening the library door............................................................................49

3-3 Replacing a cartridge magazine................................................................50

4-1 Eject button................................................................................................57

5-1 Removing and installing a tape drive.........................................................61

5-2 Replacing the fuse..................................................................................... 63

5-3 Replacing the air filters..............................................................................65

5-4 Replacing the air filter inside the air filter grille..........................................66

PLS200 Library Installation and Operation vii

Page 8

Contents

6-1 Installing the packing foam in the library....................................................71

6-2 Adjusting the packing foam........................................................................72

6-3 Removing the screws from the front of the rack.........................................74

6-4 Removing the screws from the sides of the library.....................................75

6-5 Lifting the library from the rack...................................................................76

6-6 Placing the antistatic bag over the library...................................................77

6-7 Placing the cushioned packaging around the library..................................78

6-8 Placing the accessory box and top on the library.......................................79

6-9 Placing the carton over the library..............................................................80

6-10 Securing the banding material....................................................................81

C-1 Dimensions of the bar code label.............................................................132

C-2 Area for printing bar code characters.......................................................133

C-3 Element dimensions; spots and voids......................................................135

C-4 Area for printing alphanumeric characters ...............................................137

viii PLS200 Library Installation and Operation

Page 9

General Safety Summary

!

!

WARNING: The instructions in this manual are for use by

qualified service personnel only. To avoid personal injury,

do not perform any servicing unless you are qualified to do

so. Refer to all safety summaries before performing service.

Review the following safety precautions to avoid injury and

prevent damage to this product or any products connected to it.

While using this product, you may need to access other parts of

the system. Read the General Safety summary in other system

manuals for warnings and cautions related to operating the

system.

Injury Precautions

Use Proper Power

Cord

Ground the Product This product is grounded through the grounding conductor of the

Do Not Operate

Without Covers

To avoid fire hazard, use only the power cord specified for this

product.

power cord. To avoid electric shock, the grounding conductor

must be connected to earth ground. Before making connections

to the input or output terminals of the product, ensure that the

product is properly grounded.

To avoid electric shock or fire hazard, do not operate this product

with covers or panels removed.

Use Proper Fuse To avoid fire hazard, use only the fuse type and rating specified

for this product.

Do Not operate in

Wet/Damp

Conditions

Do Not Operate in an

Explosive

Atmosphere

To avoid electric shock, do not operate this product in wet or

damp conditions.

To avoid injury or fire hazard, do not operate this product in an

explosive atmosphere.

PLS200 Library Installation and Operation ix

Page 10

General Safety Summary

Avoid Exposed

Circuitry

To avoid injury, remove jewelry such as rings, watches, and

other metallic objects. Do not touch exposed connections and

components when power is present.

Product Damage Precautions

Use Proper Power

Source

Provide Proper

Ventilation

Do Not Operate With

Suspected Failures

Do not operate this product from a power source that applies

more than the voltage specified.

To prevent product overheating, provide proper ventilation.

If you suspect there is damage to this product, have it inspected

by qualified service personnel.

Safety Terms and Symbols

Terms in This

Manual

!

!

!

!

These terms may appear in this manual:

WARNING:Warning statements identify conditions or practices

that can result in personal injury or loss of life.

CAUTION: Caution statements identify conditions or practices

that can result in damage to the equipment or other property.

Terms on the

Product

x PLS200 Library Installation and Operation

These terms may appear on the product:

DANGER indicates a personal injury hazard immediately

accessible as one reads the marking.

WARNING indicates a personal injury hazard not immediately

accessible as you read the marking.

CAUTION indicates a hazard to property including the product.

Page 11

Safety Terms and Symbols

Symbols on the

Product

!

!

The following symbols may appear on the product:

DANGER high voltage

Protective ground (earth) terminal

ATTENTION – refer to manual

PLS200 Library Installation and Operation xi

Page 12

Service Safety Summary

!

!

Do Not Service

Alone

Disconnect Power To avoid electric shock, disconnect the main power by means

Use Care When

Servicing With

Power On

WARNING: These instructions are for use by qualified

service personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to do so.

Refer to all safety summaries before performing service.

Do not perform internal service or adjustment of this product

unless another person capable of rendering first aid and

resuscitation is present.

of the power cord or, if provided, the power switch.

Dangerous voltages or currents may exist in this product.

Disconnect power and remove battery (if applicable) before

removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections

xii PLS200 Library Installation and Operation

Page 13

Regulatory Information

EC Declaration of Conformity

Tektronix, Inc.

Video Networking Division

14180 SW Karl Braun Drive

P.O. Box 500

Beaverton, Oregon 97077-0001 U.S.A.

Tektronix, Inc., Video Networking Division, declares on 27 September, 1996, under our sole

responsibility, that the PLS200 Video video Archive system to which this declaration relates,

is in conformity with the following standard(s) or other normative document(s):

EMC Directive 89/336/EEC

EC EN55022 Limits and methods of measurement of radio interference

characteristics of Information Technology Equipment

EC 50082-1

1992

Electromagnetic compatibility generic immunity standard Part 1:

Residential, commercial, and light industry.

Environmental Phenomena Test Specification Basic Standard

Radio-Frequency

Electromagnetic Field

Electrostatic Discharge 8kV (charge Voltage) IEC801-2

Fast Transients common

mode on Signal lines

AC mains ports 1.0kV (peak)

Low Voltage Directive 73/23/EEC

EN60950 Safety of Information Technology Equipment including

Electrical Business Equipment (includes Appendix ZB)

27-500 MHz

3V/m (unmodulated)

0.5kV (peak)

5/50 Tr/Th ns

5kHz Rep. Frequency

5/50 Tr/Th ns

5kHz Rep. Frequency

IEC801-3

IEC801-4

xiii

Page 14

Regulatory Information

Certifications and Compliances

Canadian Certified

Power Cords

FCC Emission

Control

Canadian EMC

Notice of

Compliance

Canadian approval includes the products and power cords

appropriate for use in the North America power network. All

other power cords supplied are approved for the country of use.

This equipment has been tested and found to comply with the

limits for a Class A digital device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and

can radiate radio frequency energy and, if not installed and used

in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the

interference at his own expense. Changes or modifications not

expressly approved by Tektronix can affect emission compliance

and could void the user’s authority to operate this equipment.

This digital apparatus does not exceed the Class A limits for

radio noise emissions from digital apparatus set out in the Radio

Interference Regulations of the Canadian Department of

Communications.

Le présent appareil numérique n’emet pas de bruits

radioélectriques dépassant les limites applicables aux appareils

numeriques de la classe A préscrites dans le Règlement sur le

brouillage radioélectrique édicte par le ministère des

Communications du Canada.

xiv

EN55022 Class A

Warning

For products that comply with Class A. In a domestic

environment this product may cause radio interference in which

case the user may be required to take adequate measures.

Page 15

Welcome

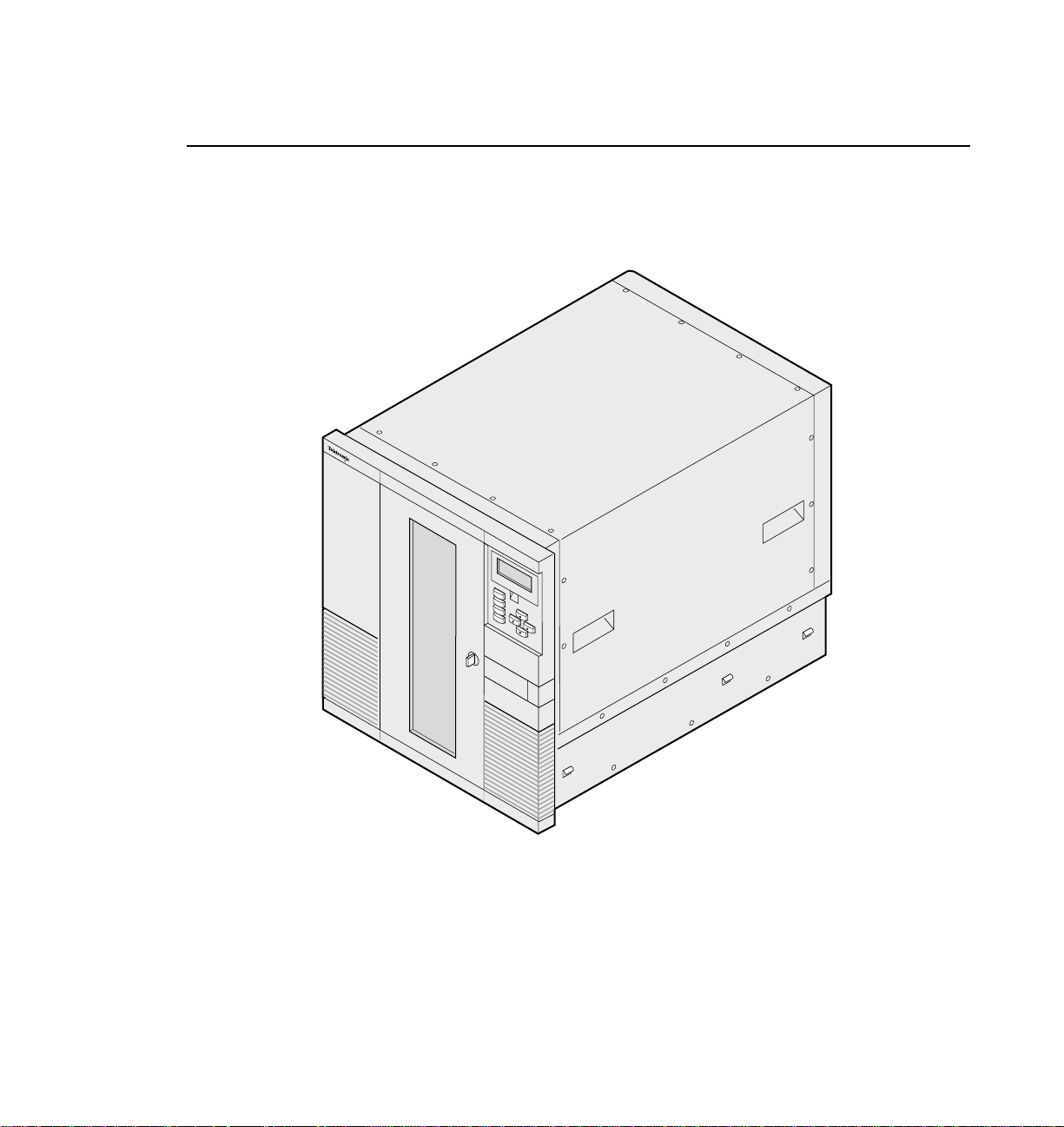

Congratulations on selecting the Tektronix PLS200 Library. Your new library

provides automated data storage, archiving, backup, and retrieval for Tektronix

Profile Video Disk Recorders (VDRs).

PLS 200

Profile

Help

Escape

Enter

Reset

9619-6

The library's robotic cartridge handling mechanism (CHM) responds to

commands from the VDR to move 8mm data cartridges between tape drives and

storage slots, while the tape drives read and write data. You can insert and

remove cartridges through the entry/exit port without opening the library door.

The PLS200 includes 80 data cartridge slots and four tape drives. The library is

connected to the VDR by three wide, differential SCSI buses.

PLS200 Library Installation and Operation xv

Page 16

Welcome

About this Manual

This manual provides the information you need to install, configure, operate,

maintain, and diagnose problems with the PLS200 Library and its enclosed

8mm tape drives. The operator information in this manual covers only the

operation of the library from the library’s operator panel. Information about the

operation of the library from the Profile Video Disk Recorder and its software

is available in the Profile System User Manual.

Related Documentation

The following documents are available from Tektronix:

• Profile System User Manual

• PLS200 Service Manual

• Profile Software Developer’s Kit

Conventions Used in this Manual

Enter

NOTE: Notes provide hints or suggestions about the topic or procedure being

xvi PLS200 Library Installation and Operation

Boxed characters indicate keys on the library's keypad.

discussed.

➤ Important Information next to the word “Important” will help you

complete a procedure or avoid extra steps.

The “attention” symbol and the word “CAUTION” precede information you

!

must know to avoid damaging the library or tape drives or losing data.

The “attention” symbol and the word “WARNING!” precede information

!

you must know to avoid personal injury.

Page 17

Tektronix Product Support

You can get technical assistance, check on the status of problems, or report new

problems by contacting our Product Support Group.

United States and Canada

Monday–Friday 5:30AM–5:00PM Pacific Time — (800) 547-8949

Europe

Monday–Friday 9:00AM–5:30PM

Austria 222-799-3535 Netherlands 010-495-4255

Belgium 02-714-3401 Norway 22-83-85-69

Denmark 3543-5259 Spain 91-564-4692

Finland 161-691-98559 Sweden 08-679-8419

Germany 069-935-25001 Switzerland 041-210-6009

Italy 44-1908-681-706 United Kingdom 01908-681-703

Luxembourg 400-848 Other 44-1908-681-703

Tektronix Product Support

Email: EuroProfile@tek.com

Asia and South America

Australia 61-2-888-7066 Korea 82-2-528-5299

Brazil 55-11-543-1911 Mexico 52-5-666-6333

Hong Kong 852-2585-6688 Singapore 65-356-3900

Japan 81-3-3448-3111 Taiwan 886-2-765-6362

World Wide

24-hour Emergency Hotline: (503) 685-2345

(Contract and warranty customers)

World Wide Web:http://www.tek.com/Profile/Support

FTP Site: ftp.tek.com (IP address: 134.62.48.21)

Email: ProfileSupport@tek.com

Users Group: profile-users@tek.com

PDR 100 1.4 Release Notes xvii

Page 18

Welcome

Reset

Enter

Escape

Help

About the PLS200

The following illustrations and descriptions summarize the important library

features.

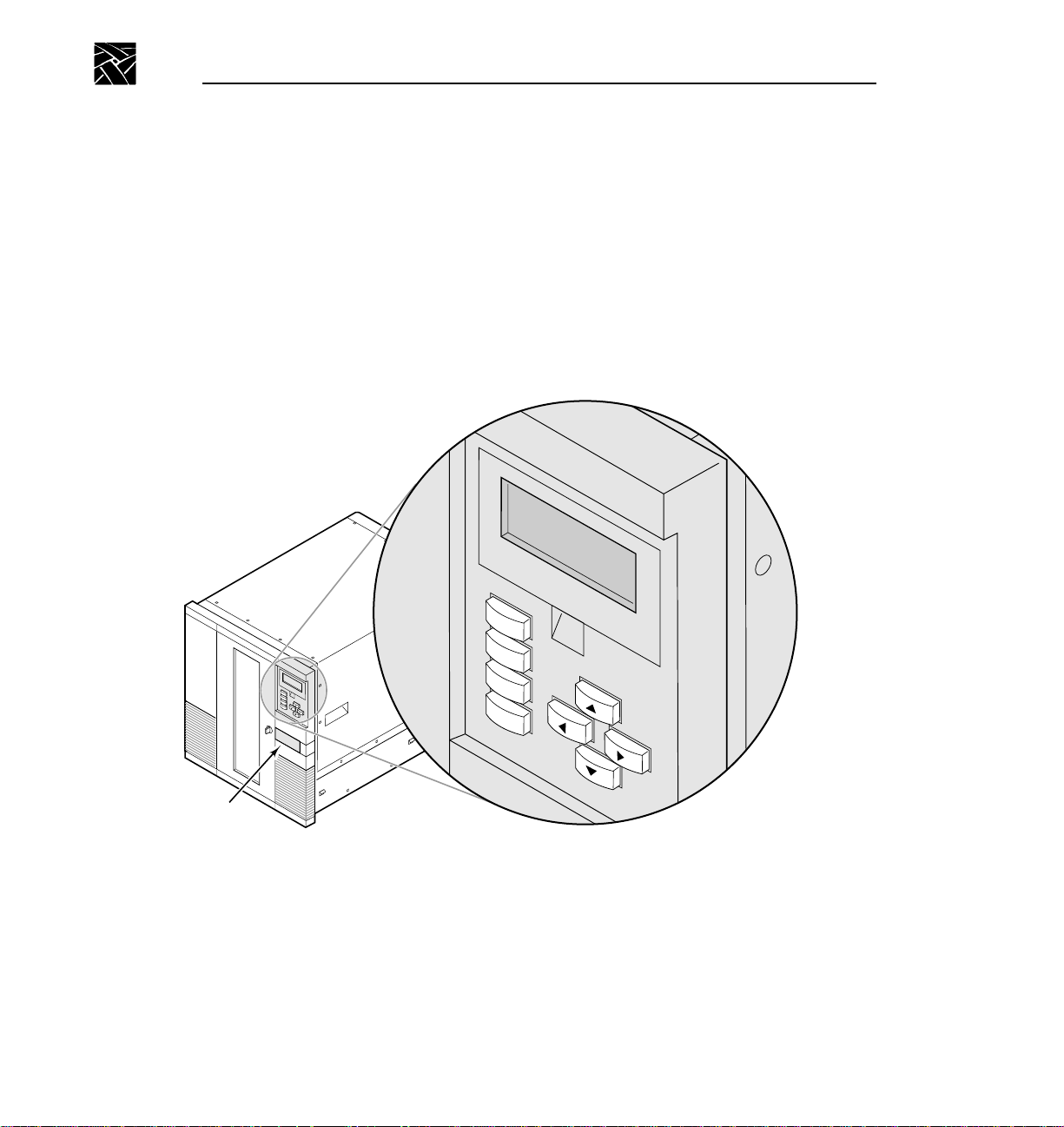

Operator Panel

The operator panel includes a four-line liquid crystal display (LCD) and a

keypad. You use the operator panel to configure the library and monitor

operations. If necessary, you can tilt the LCD for easier viewing.

Help

Escape

Enter

Reset

Entry/exit

port

xviii PDR 100 1.4 Release Notes

9619-7

Page 19

About the PLS200

Entry/Exit Port and Transport Assembly

The entry/exit port allows you to insert or remove individual cartridges from the

library without opening the door. The entry/exit transport assembly moves the

transport arm to and from the entry/exit port to pick up cartridges.

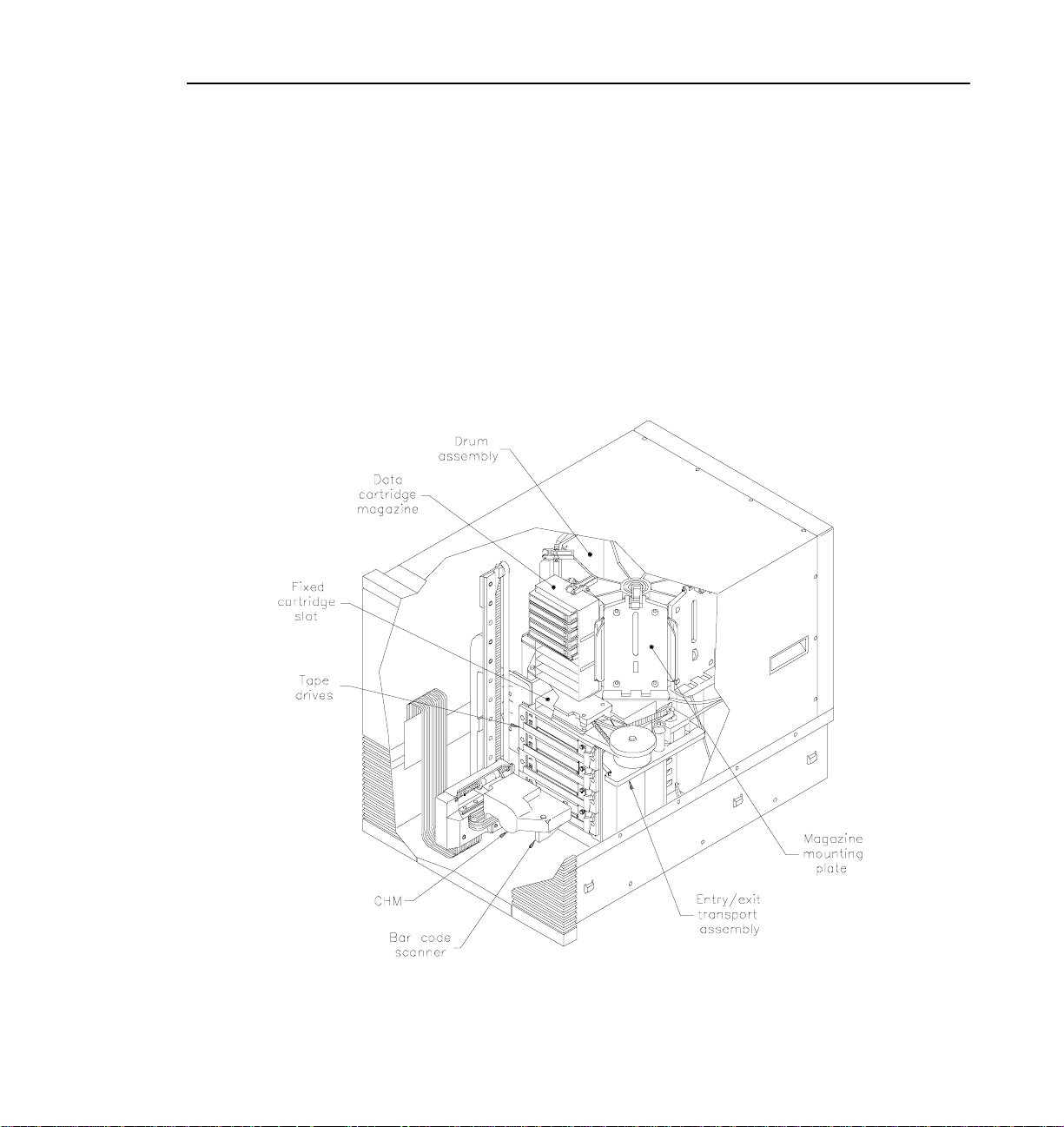

Drum assembly

The drum assembly holds the data cartridge magazines and rotates 180 degrees

in either direction to position the magazines in front of the cartridge handling

mechanism (CHM).

PDR 100 1.4 Release Notes xix

Page 20

Welcome

Data cartridge magazines

Data cartridge magazines are the removable carriers for the 8mm data

cartridges. The magazines snap onto mounting plates on the library's rotating

drum assembly and allow easy removal and replacement of cartridges. Each

magazine has individual cartridge slots for 10 cartridges. The PLS200 contains

up to eight cartridge magazines.

Fixed cartridge slot

The fixed cartridge slot, located directly above the tape drives, provides a

storage location for a single cartridge. This slot is normally used to store an

8mm cleaning cartridge.

Tape drives

The PLS200 uses four Exabyte Mammoth 8mm half-height tape drives with a

wide, differential SCSI configuration.

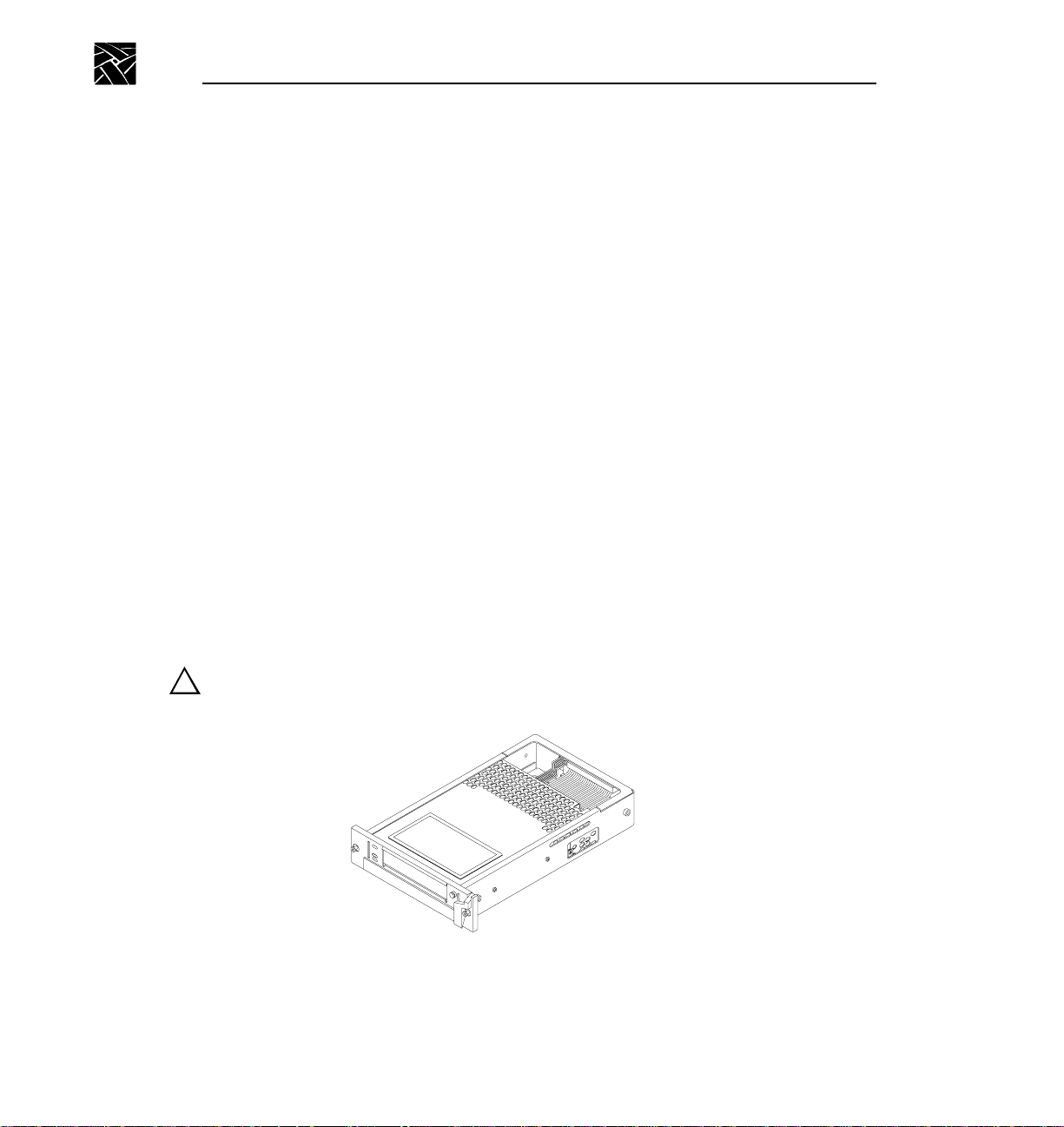

Drive carrier

When you purchase the library, each tape drive in the library is fitted inside a

drive carrier. The drive carrier allows you to slide the drive in and out of the

library if the tape drive needs repair.

CAUTION: To avoid possible damage to the tape drive, do not remove it from

!

the drive carrier.

xx PDR 100 1.4 Release Notes

Page 21

Library Elements

Drive blank (not shown)

Drive blanks are “empty” drive carriers with solid faceplates. If you plan to

operate the library with fewer than four tape drives, you must install drive

blanks in the empty drive positions. The drive blanks ensure correct air flow

through the library for cooling, compliance with EMI regulations, and in some

configurations, correct SCSI connection.

Cartridge handling mechanism (CHM)

The cartridge handling mechanism (CHM) moves cartridges between cartridge

slots, tape drives, and the entry/exit port.

Bar code scanner

The high-speed bar code scanner, mounted on the CHM, reads bar code labels

affixed to the cartridges to track individual cartridges. Cartridge label

information becomes part of the library's cartridge inventory stored in

nonvolatile RAM.

Serial ports (not shown)

Two serial ports (25-pin and 9-pin) at the back of the library allow an external

computer to communicate with the tape drives and the library across a serial

cable. By running a special diagnostic program, service personnel can perform

diagnostics, upgrade firmware, and test CHM motion.

SCSI connectors (not shown)

The library has ten SCSI connectors, accessible through the cabling bay on the

back.

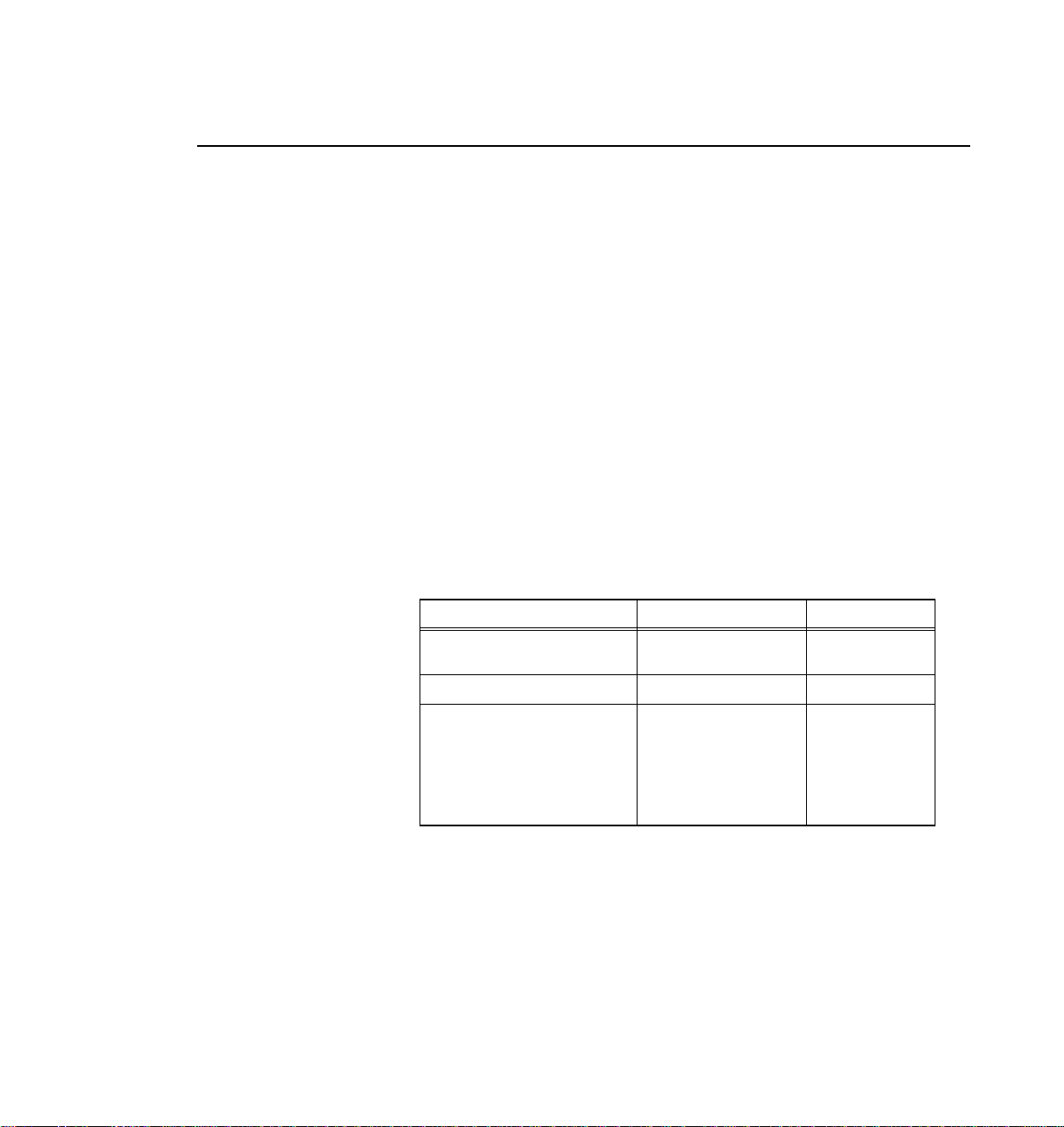

Library Elements

The library contains four types of elements:

• The CHM is the medium transport element.

• The entry/exit port is the import/export element.

• The cartridge slots are the storage elements.

• The tape drives are the data transfer elements.

PDR 100 1.4 Release Notes xxi

Page 22

Welcome

Each element has an element index, which is the number you must specify

when you use the entry/exit port. Element indexes must be the same as the

default element addresses used in SCSI commands.

The following figure shows the element indexes for the PLS200.

xxii PDR 100 1.4 Release Notes

Element indexes for PLS200

Page 23

Chapter

1

Installing the Hardware

This chapter describes how to install and set up the library hardware.

Preparing for Installation

Before installing the library, complete the preliminary steps listed in the table

below. Each step is described on the following pages.

✔

Step Description

1 Unpack the library.

2 Check the accessories.

3 Protect the library against ESD.

4 Obtain a fork lift or at least four people.

5 Verify your Profile software version.

Unpack the Library

Complete the unpacking steps printed on the box. Save the packing materials in

case you need to ship the library later.

PLS200 Library Installation and Operation 1

Page 24

Chapter 1 Installing the Hardware

Check the Accessories

Make certain you received the following accessories packed with the PLS200:

• Slide rails and mounting hardware

• Four power cords (North America, United Kingdom, Europe, Australia)

• BusLogic BT-757CD SCSI bus adapter board

• Three SCSI cables

• One SCSI terminator

• Four SCSI jumpers

• Eight Data Cartridge Magazines with covers

• Eighty data cartridges

• Two cleaning cartridges

• One spare drive blank (in addition to those installed)

• Bar code labels for the data cartridges (three sheets)

• PLS200 Operation and Installation Manual

• PLS200 Order Information Technical Data Sheet

Protect the Library Against ESD

If you remove the cover from the library, its internal components are

susceptible to damage from electrostatic discharge (ESD). To ensure that the

work area is as free from ESD as possible, place a grounded, static protection

mat on the work surface, and wear a static protection wrist band. If a mat and

wristband are unavailable, discharge static electricity from your body before

touching the inside of the library or the tape drives. (Touch a known grounded

surface, such as your computer's metal chassis.)

2 PLS200 Library Installation and Operation

Page 25

Prepare the Library

Prepare the Library

The slide rails and mounting hardware for rack-mounting the library are

shipped in the box with the library. The library weighs 152 pounds (69 kg) with

four tape drives installed. Before installing the library, make sure that your rack

has extension support legs and that you have at least four people or two people

and a small fork lift.

Verify Your Profile Software Version

The PLS200 requires Profile Software version 2.0 or higher, and WindowsNT

3.51 or higher.

Installing the SCSI Adapter Into the VDR

Before you install the PLS200 hardware, install the SCSI adapter board into the

Profile video disk recorder. The SCSI adapter board provides an EISA-to-SCSI

interface that allows the Media Manager or similar software on the VDR to

control the library’s cartridge handling mechanism. The procedures that follow

take you step-by-step through the recommended sequence for installation of the

SCSI adapter board.

WARNING: The VDR is too heavy for one person to remove from an

!

!

equipment rack. To avoid possible injury, get help when removing the VDR

from its rack.

WARNING: Before performing any installation or maintenance procedures,

!

be sure that:

• the rear-panel power switch is in the off position

• the power cord is disconnected from the video disk recorder and the outlet

PLS200 Library Installation and Operation 3

Page 26

Chapter 1 Installing the Hardware

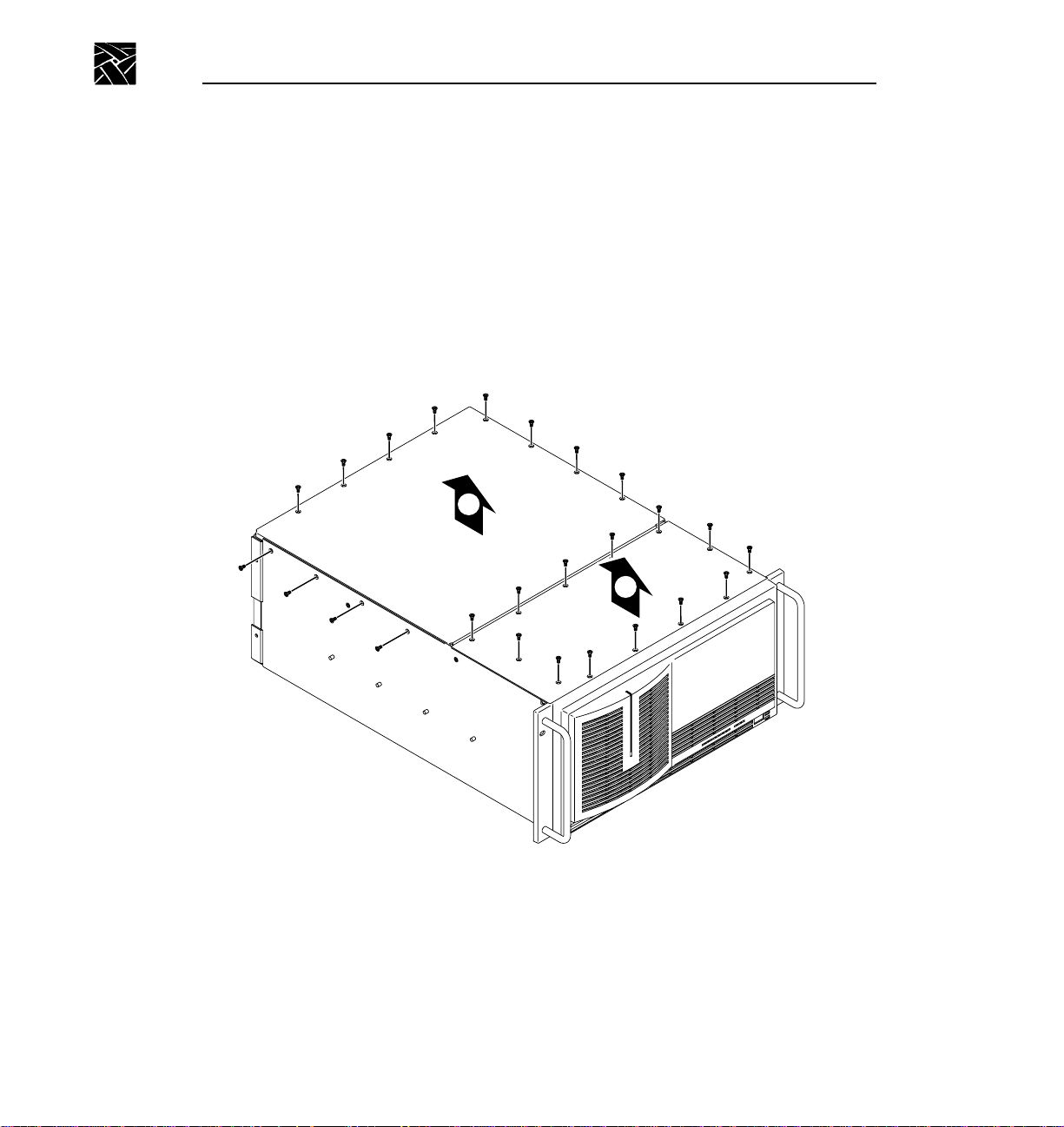

1. Loosen the front panel retaining screws and pull the cabinet out until all three

slide sections latch.

2. Remove the top covers in the order shown in Figure 1-1. The front cover

must be removed first since it overlaps the rear cover. Use a T-10 TORX

driver to remove the screws.

NOTE: Take care not to lose these cabinet screws. They are required to meet the EMI

specifications for the VDR.

2

1

Figure 1-1 Removing the top covers

4 PLS200 Library Installation and Operation

Page 27

Installing the SCSI Adapter Into the VDR

3. Remove the two circuit board hold-downs as shown in Figure 1-2. Both

hold-downs are held in place by T-10 TORX head screws, and must be

removed in order to install the SCSI adapter board.

➤ Important Be sure to remove the jumper as described in the following step.

If the jumper is left in place, the VDR will display an error when initializing

the SCSI adapter board.

4. Unpack the SCSI adapter board and remove the jumper from W1 on the

board. Refer to the manual packed with the board to locate the jumper.

Figure 1-2 Removing the circuit board hold-downs

PLS200 Library Installation and Operation 5

Page 28

Chapter 1 Installing the Hardware

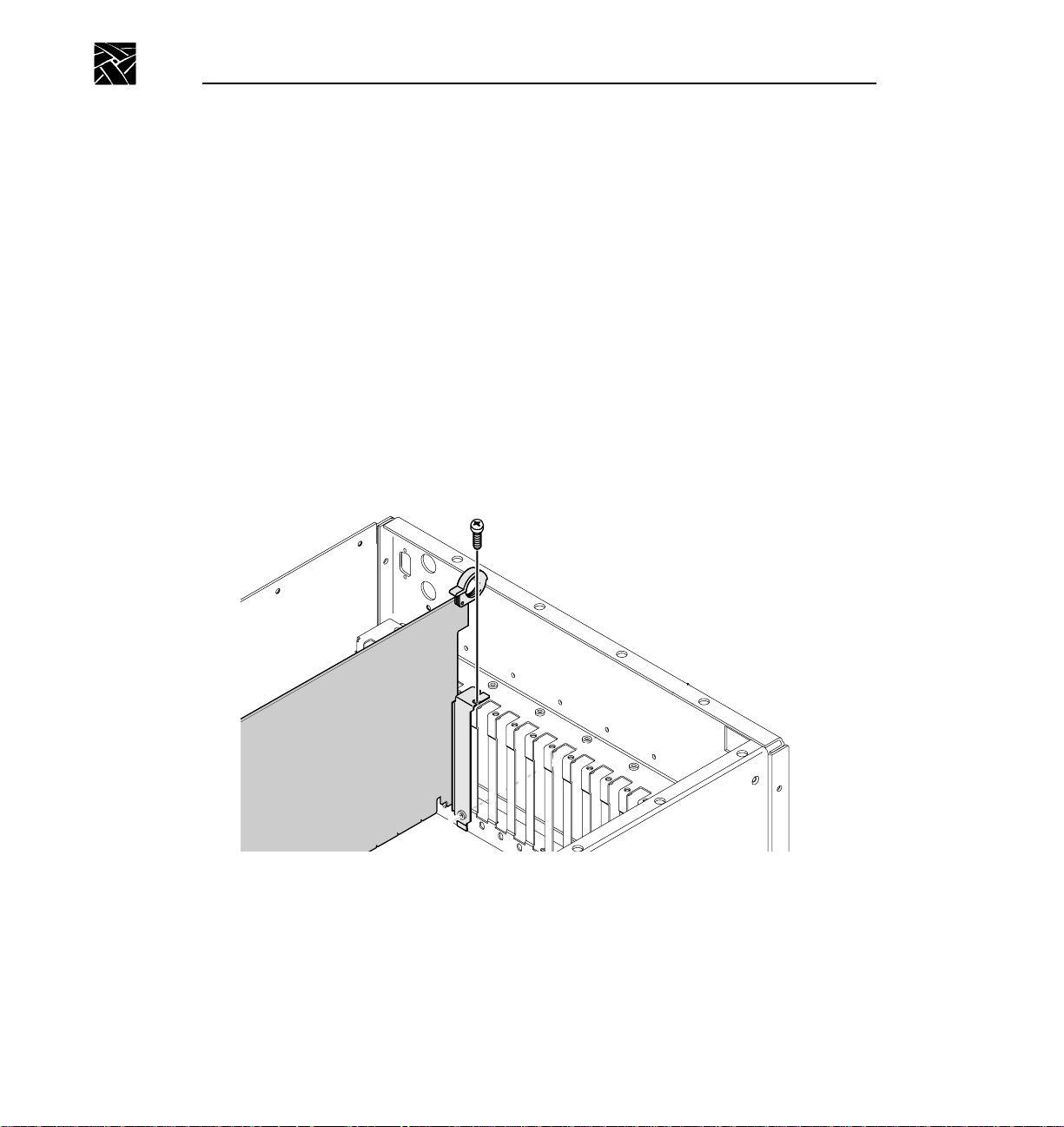

5. Remove the blank cover plate from the J4 slot in the VDR rear panel.

6. Plug the SCSI adapter board into the J4 socket and press down till the board

is fully plugged into the socket.

7. Install the mounting screw in the top of the bracket inside the cabinet (as

shown in Figure 1-3).

8. Re-install the hold-downs. Align each hold-down over the circuit boards and

replace the mounting screws.

9. Re-install the cabinet covers. Do not tighten any of the screws until all the

screws are started.

10. Install the VDR power cord, but do not turn on the VDR.

1

Figure 1-3 Screw locations for board mounting bracket

6 PLS200 Library Installation and Operation

2

Page 29

Installing the Library Hardware

Use the following table as a checklist for installing the library.

Installing the Library Hardware

✔

WARNING: Before performing any installation or maintenance procedures,

!

be sure that the library power switch is in the off position and that the power

Step Description

1 Install the library into a rack

2 Unlatch and open the door

3 Remove the packing foam

4 Move the CHM

5 Prepare and install cartridges in magazines

6 Install the magazines in the library

7 Install a cleaning cartridge

8 Close the library door

9 Connect the SCSI cables

10 Connect the power cord

11 Power on the library

12 Complete the SCSI adapter board software update

cord is disconnected from the library and the outlet.

PLS200 Library Installation and Operation 7

Page 30

Chapter 1 Installing the Hardware

Install the Library Into a Rack

Follow these instructions to install the library into a standard EIA 19-inch rack.

WARNING: The library weighs 137 – 167 pounds (62 – 76 kg). You need at

!

least 4 people, or 2 people and a small fork lift, to lift it.

Make sure you install the library in the lowest possible location in the rack

and that the rack is equipped with extension support legs.

Make sure you extend the support legs before installing the library in the rack

or when sliding it out of the rack.

Tools required

You need the following tools to install the library into a rack

• T-15 TORX screwdriver

• T-25 TORX screwdriver

8 PLS200 Library Installation and Operation

Page 31

Install the Library Into a Rack

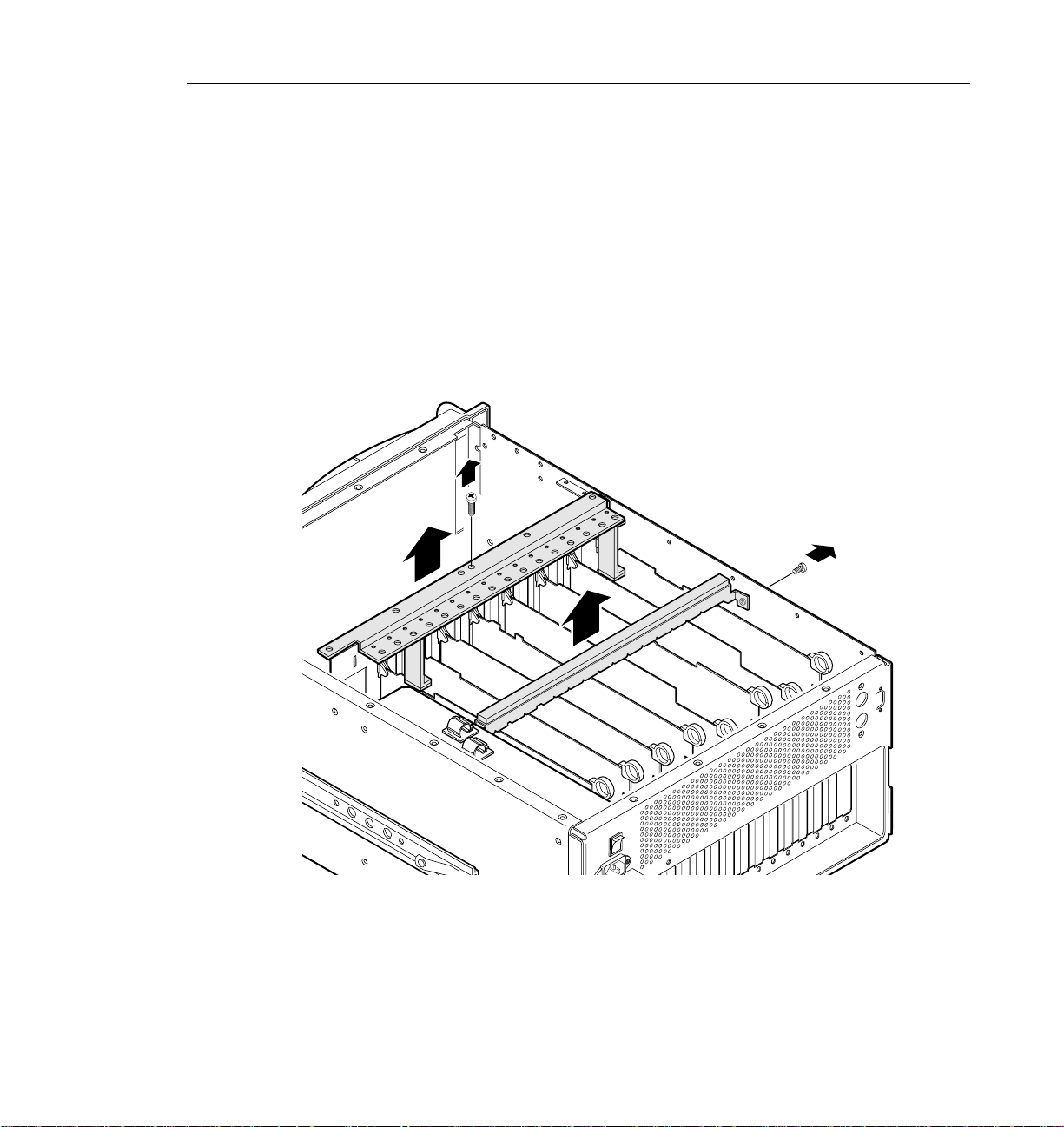

Installing the Slide Rails

1. Identify the holes on the rack where you want to install the library. The

library will extend 1 to 2 inches (3 to 4 cm) below the slide rails.

2. If the rack does not have threaded holes, attach the eight clip nuts over the

holes (see Figure 1-4).

3. Using a T-25 TORX driver and eight 10-32 × 0.5 screws, attach, but do not

tighten, the slide rails to the rack (see Figure 1-4).

Figure 1-4 Attaching the slide rails

PLS200 Library Installation and Operation 9

Page 32

Chapter 1 Installing the Hardware

4. As shown in Figure 1-5, adjust the distance between the front mounting

brackets to 17 inches (44.8 cm).

5

-- 8

Figure 1-5 Adjusting the distance between the front mounting brackets

5. Tighten the screws.

6. Repeat steps 4 and 5 for the rear mounting brackets.

10 PLS200 Library Installation and Operation

Page 33

Install the Library Into a Rack

Installing the Library

1. Extend the extension support legs on the rack.

2. Slide the inside rails as far out of the rack as they will go (see Figure 1-6).

Figure 1-6 Installing the library in a rack

3. Remove the air filter grilles from the front of the library by lifting the outside

edges and pulling the grilles away from the library (see Figure 1-6).

4. Using four people, or two people and a fork lift, lift the library by the handles

and lower it onto the slide rails so the mounting tabs on each side of the

library fit into the slots in the rails (see Figure 1-6). Make sure all six

mounting tabs are fitted securely into the slots.

PLS200 Library Installation and Operation 11

Page 34

Chapter 1 Installing the Hardware

5. Press the spring clips and slide the library most of the way into the rack.

6. Install one 8-32 × button head screw into the screw hole on each rail, as

7

----- 16

shown in Figure 1-7.

Figure 1-7 Attaching the screws to the sides of the library

12 PLS200 Library Installation and Operation

Page 35

Install the Library Into a Rack

7. If the holes in the rack are not threaded, install a clip nut on each side of the

rack, as shown in Figure 1-8.

Figure 1-8 Securing the library in the rack

8. Slide the library completely into the rack. Use a T-25 TORX driver to insert

the two 10-32 × 1.0 pan head screws on the front panel, as shown in

Figure 1-8. These screws prevent the library from sliding out of the rack.

9. Replace the air filter grilles on each side of the front panel.

PLS200 Library Installation and Operation 13

Page 36

Chapter 1 Installing the Hardware

Reset

Enter

Escape

Unlatch and Open the Door

To open the door, turn the door latch handle one quarter turn to the right, as

shown in Figure 1-9. Pull open the door.

Help

Escape

Enter

Reset

Figure 1-9 Opening the door

14 PLS200 Library Installation and Operation

9619-8

Page 37

Remove the Packing Foam

Remove the packing foam from the library as shown in Figure 1-10.

1. Take out the center cross piece shown at arrow 1.

2. Move the vertical piece to the right as shown by arrow 2 to disengage it from

the CHM.

3. Bend the top of the vertical piece to the left and remove the top cross piece.

4. Pull the top of the vertical piece out of the door enough to allow removal of

the bottom cross piece, then take out the vertical piece.

Remove the Packing Foam

➌

➍

➊

Figure 1-10 Removing the packing foam from the library

➋

PLS200 Library Installation and Operation 15

Page 38

Chapter 1 Installing the Hardware

Move the CHM Out of the Way

Move the cartridge handling mechanism (CHM) so it is not blocking the

magazine mounting plates on the drum. To move the CHM, reach in through

the door and push against the base of the CHM, sliding it firmly to the bottom

of the long axis until it stops. See Figure 1-11.

➤ Important Do not touch the lens on the bar code scanner; smudges on the

lens can cause scanning errors.

Figure 1-11 Moving the CHM to the bottom of the long axis

16 PLS200 Library Installation and Operation

Page 39

Prepare and Install Cartridges

Prepare and Install Cartridges

Before installing data cartridges in the library, attach the bar code labels and set

the write-protect switches.

➤ Important Two types of EXATAPE™ 8mm Data Cartridges are available:

advanced metal evaporated (AME) and metal particle (MP). Use only the

AME tape cartridges in the PLS200. The tape drives in PLS200 cannot write

or read to the MP tape cartridges.

Attach Bar Code Labels

Position the label as shown in Figure 1-12, using the recessed area on the

cartridge for guidance. Make sure you orient the label correctly. For

information on how to prepare bar code labels, refer to Appendix C, Bar Code

Label Specification.

NOTE: Be sure to attach a bar code label to the cleaning cartridge as well as the data

cartridges.

➤ Important If you create your own bar code labels, be sure to follow the

specification precisely.

Figure 1-12 Positioning a bar code label on a data cartridge

CAUTION: If you remove a bar code label from a data cartridge without

!

replacing it, make sure to clean the label area thoroughly. Bar code labels

can leave adhesive on the label area, which may cause the data cartridge to

stick to the CHM.

PLS200 Library Installation and Operation 17

Page 40

Chapter 1 Installing the Hardware

Set the Write-protect Switches

Make sure the write-protect switch on each data cartridge is set appropriately

(see Figure 1-13). You can use a ball-point pen or similar instrument to move

the write-protect switch. If the write-protect switch window is red, the cartridge

is write-protected.

Figure 1-13 Setting the write-protect switch on a data cartridge

18 PLS200 Library Installation and Operation

Page 41

Prepare and Install Cartridges

Install Data Cartridges in the Magazines

The empty magazines are packed in the box of accessories shipped with the

PLS200.

1. Place the magazine on its feet with the single mounting guide toward the

right, as shown in Figure 1-14.

2. Position each cartridge so that the bar code label is on top and the

write-protect switch is toward the front (see Figure 1-14).

3. Insert the cartridge into the magazine slot.

NOTE: Very little force is needed to install a data cartridge. If it does not snap into

place easily or if it protrudes further than the magazine’s center rib, check

the orientation of the cartridge.

Figure 1-14 Installing data cartridges in the magazine

PLS200 Library Installation and Operation 19

Page 42

Chapter 1 Installing the Hardware

Install Cartridge Magazines

➤ Important Use only magazines designed for half-height Exabyte 8mm

libraries. Do not use Exabyte Data Cartridge Holders designed for

full-height Exabyte 8mm libraries.

The following instructions describe how to install cartridge magazines onto the

mounting plates on the drum.

CAUTION: Make sure the CHM and its cabling are safely out of the way

!

before installing cartridge magazines.

1. If necessary, manually rotate the drum to access the mounting plate where

you want to install the magazine.

2. On the magazine mounting plate, locate the roller on the top end of the plate.

3. Position the magazine over the mounting plate with the single mounting

guide toward the top, as shown in Figure 1-15.

4. Insert the bottom end of the magazine first, then snap the magazine into place

by pressing against the top.

20 PLS200 Library Installation and Operation

Page 43

Install Cartridge Magazines

Figure 1-15 Installing a cartridge magazine in the library

PLS200 Library Installation and Operation 21

Page 44

Chapter 1 Installing the Hardware

Install a Cleaning Cartridge

The following procedure describes how to manually install a cleaning cartridge

in the fixed cartridge slot. To replace this cartridge later, use the Export

Cartridge and Import Cartridge functions of the Media Manager in the Profile

Tool Box. Refer to the discussion of the Media Manager in the Profile System

User Manual.

CAUTION: Use Tektronix-approved cleaning cartridges only. Using cloth

!

swabs, cotton swabs, cleaning agents, or cleaning cartridges not approved by

Tektronix will void the tape drive warranty.

To install a cleaning cartridge in the fixed cartridge slot:

1. Position the cartridge so that the window showing the tape reels is toward the

top (see Figure 1-14).

➤ Important The cleaning cartridge must have a bar code label.

2. Insert the cartridge into the fixed cartridge slot until it snaps into place.

Figure 1-16 Installing a cartridge in the fixed cartridge slot

22 PLS200 Library Installation and Operation

Page 45

Close the Library Door

Close the library door and turn the door latch handle a quarter turn to the left.

Connect the SCSI Cables

The library is connected to the Profile system with three SCSI cables. One cable

controls the library and attaches to the SCSI adapter board. The other two

cables transfer data to and from the tape drives. These cables connect to the

SCSI A and SCSI B busses at the VDR Disk Recorder boards, the PDX103, or

PRS200 as shown in Figures 1-18, 1-19, and 1-20. All cables are fast wide,

differential with screw fasteners on both ends.

The SCSI connectors for the library and tape drives are accessible through the

cabling bay at the back of the library.

1. Remove the terminator plugs from the Master and Slave Disk Recorder

boards (or from the loop-through connectors on the PDX103 or PRS200).

Retain these plugs for use in the next step.

2. Install the SCSI jumpers and terminators on the PLS200 as shown in

Figure 1-17.

Close the Library Door

3. Connect the SCSI cables included with the PLS200. Refer to Figures 1-18,

1-19, and 1-20 as appropriate for your installation.

CAUTION: To avoid damaging the tape drives, make sure the power is off in

!

all devices connected to the SCSI bus when you connect the tape drives to the

SCSI bus.

PLS200 Library Installation and Operation 23

Page 46

Chapter 1 Installing the Hardware

PLS200

Library

Terminator

SCSI Jumper

Terminator

SCSI Jumper

Terminator

Drive 1

Drive 2

Drive 3

Drive 4

9619-4

Figure 1-17 Installing the terminators and SCSI jumpers

24 PLS200 Library Installation and Operation

Page 47

Connect the SCSI Cables

J15 J14 J4

PDR100

PLS200

SCSI Cable

Terminator

SCSI Jumper

9619-5

Figure 1-18 SCSI connections from the VDR to the PLS200

PLS200 Library Installation and Operation 25

Page 48

Chapter 1 Installing the Hardware

J15 J14 J4

PDR100

PDX103

PLS200

SCSI Cable

Terminator

Figure 1-19 SCSI connections through the PDX103 to the PLS200

26 PLS200 Library Installation and Operation

SCSI Jumper

9619-2

Page 49

Connect the SCSI Cables

PDR100

PRS200

PLS200

J15 J14

J4

Additional

PRS200

SCSI Cable

Terminator

SCSI Jumper

Figure 1-20 SCSI connections through the PRS200 to the PLS200

PLS200 Library Installation and Operation 27

9619-3

Page 50

Chapter 1 Installing the Hardware

Connect the Power Cord

➤ Important Tektronix ships the PLS200 with four power cords, each for use

in a different location. If none of the power cords are appropriate for your

location, you must supply a power cord with the proper plug that meets the

specifications listed in Appendix A, Specifications.

1. Make sure that the power switch on the back of the library is off (the 0 is

pressed).

2. Connect the female end of the power cord to the power connector on the back

of the library.

3. Plug the male end of the power cord into the power source.

NOTE: The library has autoranging voltage selection, so you do not need to change

the voltage setting.

Power-on the Library

1. Make certain the library's door is closed and latched.

2. Push the power switch on the back of the library to the on (I) position.

3. Turn on the PDX103 or PRS200 if one of them is attached to the SCSI bus.

4. Turn on the Profile video disk recorder.

NOTE: When you turn on the VDR, a warning will appear that slot 2 needs to be

configured. This is normal and is addressed when you complete the SCSI

adapter board software update at the end of this chapter.

5. Wait while the library performs its power-on self-test. During this time, the

following activities occur:

- The cooling fan begins to rotate.

- The LCD illuminates and displays the Main Screen.

- The tape drives perform their power-on self-tests.

- The library performs its power-on self-test.

28 PLS200 Library Installation and Operation

Page 51

Power-on the Library

Tape Drive Power-on Self-test

During its power-on self-test, each tape drive checks its operating conditions

and sends status information to the library.

Library Power-on Self-test

During its power-on self-test, the library:

• Engages the locking solenoid in the door.

• Moves the CHM to the home positions on the short and long axes.

• Moves the drum to the home position.

• Retracts the entry/exit port transport arm.

• Verifies the CHM's full range of motion by moving it to the top of the

long axis.

• Touches each cartridge to update the cartridge inventory.

• Moves to the home position on the long axis.

If Problems Occur...

If the library does not complete its power-on self-test and nothing is displayed

on the LCD, check the following:

• Is the power switch on? (Is the I pressed?)

• Is the power cord inserted correctly?

• Is the library door closed?

• Is the video disk recorder on?

If the library does not complete its power-on self-test and the LCD displays an

error code, see Appendix B, LCD Error Codes.

For more detailed troubleshooting information, see Chapter 9,

Troubleshooting.

PLS200 Library Installation and Operation 29

Page 52

Chapter 1 Installing the Hardware

SCSI Adapter Board Software Update

When you applied power to the Profile VDR (in the step on page 28), a warning

appeared that Slot 2 needed to be configured. The following procedure updates

software on the VDR and enables communication between the VDR and the

PLS200.

1. Double click the “Load DTI CMOS” icon to rewrite a new image into

CMOS. The console window indicates that the software has found the

BT-757CD (the SCSI adapter board) and has used the correct .cmo file.

2. Restart the VDR, and verify that the card in EISA slot two initializes

correctly. At this point the Buslogic BT-757CD SCSI card will be initialized

but can not be used by the PLS200 software until you install the driver for

the SCSI adapter board.

3. Install the driver for the SCSI adapter board.

a. Double click the “Windows NT Setup” icon in the Main group.

b. Pull down the “Options” menu and select “Add/Remove SCSI

Adapters...”, then click the “Add...” button.

c. Select the “Buslogic Standard SCSI Host Adaptor” driver from the list

and click the “Install” button. In the box that requests the location, type

“c:\i386” and click the “Continue” button.

d. Restart the Profile VDR, and log in as administrator (hold down the shift

key when the blue screen appears — factory-loaded password is triton).

4. Verify that Windows NT on the Profile VDR found the SCSI robot device.

a. Double click the “Windows NT Diagnostics” icon in the “Administrative

Tools” group.

b. Select “Registry Editor” found under the “Tools” menu.

c. In the “HKEY_LOCAL_MACHINE on Local Machine” window expand

the “HARDWARE,” then the “DEVICEMAP,” and then the “Scsi”

selections. Look for “SCSI” There should be a selection under “Scsi0” for

“ScsiPort0” that can be expanded to the “ScsiBus0” selection with

selections for the Initiator and each SCSI device on the bus. The PLS200

device will display as an EXABYTE EXB-480 under the “LogicalUnit0”

selection of the “Target” selection.

30 PLS200 Library Installation and Operation

Page 53

Chapter

2

Configuring the Library

After installing the library hardware, you need to set or check the library's

configuration options. Configuration steps include:

• Displaying the Configuration Menu

• Setting the SCSI IDs

• Setting or checking other configuration options as required

To change options, you will use the operator panel (LCD and keypad) on the

front of the library, as shown in Figure 2-1.

Figure 2-1 Operator panel

PLS200 Library Installation and Operation 31

Page 54

Chapter 2 Configuring the Library

Main Screen

The Main Screen appears when you apply power to the library. The first and

second lines on the Main Screen display the product name, version, and the

current time. The third and fourth lines display status information about the

library and tape drives.

P L S 2 0 0

V E R

S t a t u s : M o v e 1 - D

P i c k i n g F r o m S l o t 1

n . n n . n n h h : m m : s s

NOTE: The exact wording on your Main Screen may be different, and the

information that appears at power-up is overwritten as the PLS200 software

executes.

Displaying the Configuration Menu

To display the Configuration Menu:.

1. Access the Main Menu by pressing on the keypad. The Main Menu

is displayed:

M a i n S c r e e n

→

E x t e n d / R e t r a c t E / E

I n t e r f a c e M e n u

C o n f i g u r a t i o n M e n u

Escape

↓

32 PLS200 Library Installation and Operation

Page 55

Displaying the Configuration Menu

2. Press to scroll down to Configuration Menu. Press . The

Enter

Configuration Menu is displayed:

S e t S C S I I D s

→

S C S I P a r i t y O N

A d j u s t C o n t r a s t

B a c k L i g h t O N

↓

During library configuration, use the operator keys for the following functions:

Scrolls the screen arrow (→) up or down. The screen arrow points to

the current selection.

In some screens, moves the screen arrow left or right. On some menu

selections, toggles an option on or off.

Enter

Escape

Help

Selects the item next to the screen arrow or accepts a change.

Returns to the previous menu or screen, or cancels an operation

without saving changes.

Displays the Help screen. To exit Help, press .

Escape

PLS200 Library Installation and Operation 33

Page 56

Chapter 2 Configuring the Library

Setting the SCSI IDs

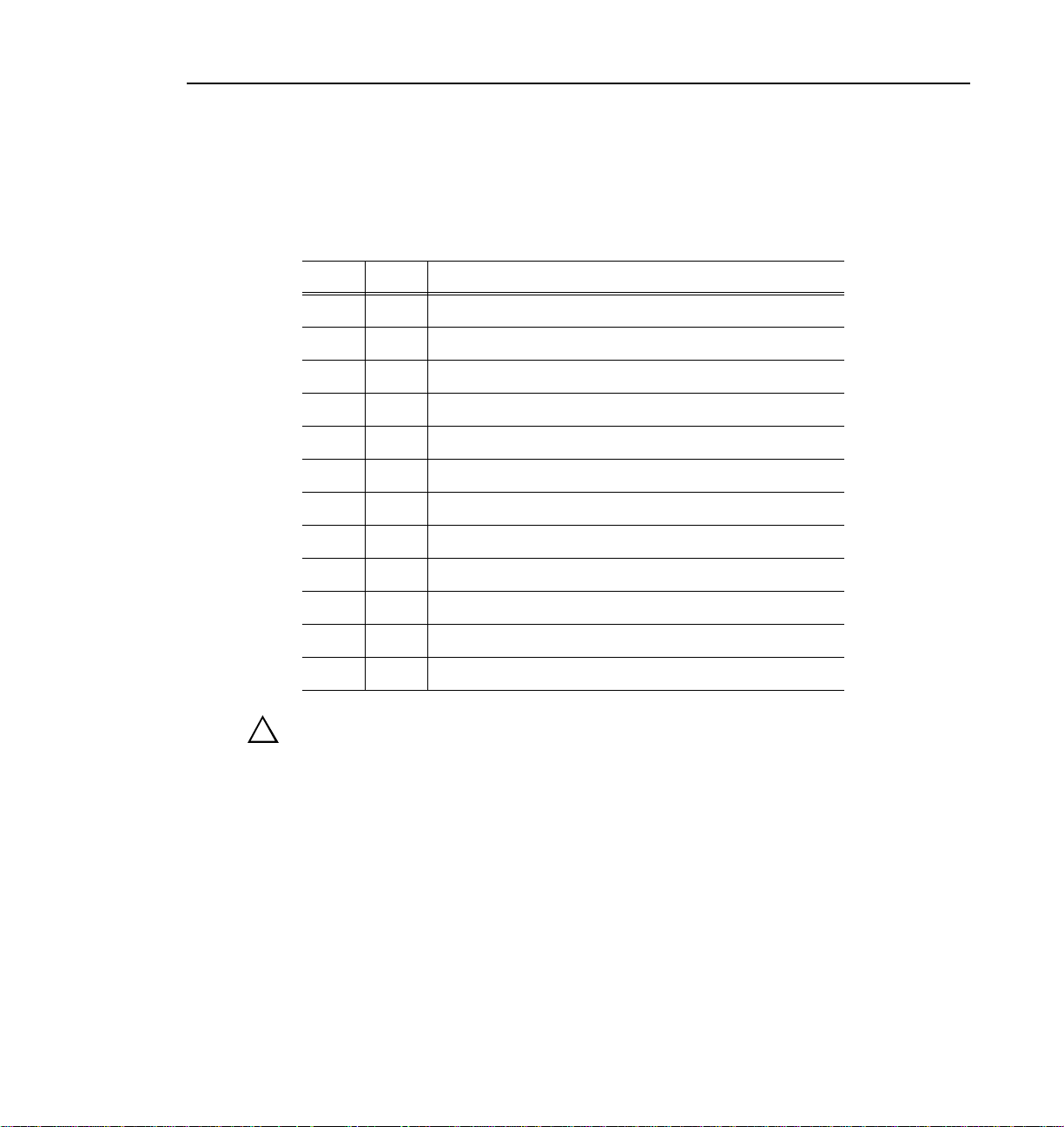

NOTE: The SCSI IDs shown are factory default settings. The default settings are the

correct IDs for use with the Profile system. Unless the SCSI IDs in the Profile

system have been altered, you should not need to change the library’s SCSI

ID settings. If one of the drive carrier slots contains a drive blank, the library

displays a B (for blank) instead of a SCSI ID.

Default SCSI IDs are assigned at the factory for the library and each tape drive.

Drive blanks are assigned B (for blank). This section describes how to view the

default settings and change them if necessary.

➤ Important The library and tape drives must each have a unique SCSI ID

within each SCSI bus. Because you have multiple SCSI buses, the library

does not check for duplicate SCSI IDs. It is your responsibility to make sure

you do not assign duplicate SCSI IDs within a SCSI bus.

To view or change SCSI IDs:

1. From the Configuration Menu, make sure the screen arrow is pointing to Set

SCSI IDs and press . The following screen appears, where Dn

indicates a tape drive and LIB indicates the library:

Enter

S C S I D 4 D 3 D 2 D 1 L I B

I D s : 0 2 0 1 0 2 0 1 0 5

↑

↓ →

2. To set the SCSI ID for the bottom tape drive (D4), press or until the

screen displays the SCSI ID you want. SCSI IDs for wide SCSI

configurations range from 0 to 15.

34 PLS200 Library Installation and Operation

Page 57

Setting the SCSI IDs

3. Press to move the up and down screen arrows to D3, as shown. Press

or until the screen displays the SCSI ID you want.

S C S I D 4 D 3 D 2 D 1 L I B

I D s : 0 2 0 1 0 2 0 1 0 5

↑

← ↓ →

NOTE: If any drive carrier slot contains a drive blank, the cursor will skip over the

SCSI ID field for that slot.

4. Continue this process until you have set the SCSI IDs for all tape drives and

the library.

5. When the SCSI IDs for all tape drives and the library are correct, press

Enter

to accept your choices. If you have changed one or more of the tape

drive IDs, the library displays the following screen:

P r e s s E N T E R t o r e s e t

t h e d r i v e ( s ) o r E S C

t o c a n c e l t h e S C S I

I D c h a n g e s .

6. Press . The library resets the tape drives that have changed IDs and

Enter

redisplays the Configuration Menu.

PLS200 Library Installation and Operation 35

Page 58

Chapter 2 Configuring the Library

Setting Other Configuration Options

After setting the SCSI IDs, you may need to set or check the following

configuration options before putting your library into operation:

• SCSI parity checking for the library

• LCD contrast

• LCD back light

• Library date

• Library time

• Library serial number

• Tape drive model

Setting Parity Checking

NOTE: The BusLogic BT-757CD SCSI adapter board used to connect the PLS200 to

the video disk recorder does not support parity checking for the library. As a

result, it makes no difference whether the setting for the library is ON or

OFF.

The SCSI Parity option allows you to enable parity checking for the library if

the SCSI adapter card connected to the library supports it. When the parity

option is enabled, the library checks all data coming across the SCSI bus for

parity. The setting you specify remains in effect across power cycles.

NOTE: Parity checking can also be enabled and disabled by application software

using a SCSI MODE SELECT command. The method last used to set parity

checking (LCD or SCSI command) has precedence.

36 PLS200 Library Installation and Operation

Page 59

Adjusting the Contrast

To change parity checking:

1. From the Configuration Menu, press to select SCSI Parity.

S e t S C S I I D s

→ S C S I P a r i t y O N

A d j u s t C o n t r a s t

B a c k L i g h t O N

2. Use and to toggle parity checking on and off.

Adjusting the Contrast

The Adjust Contrast option controls the brightness of the lettering on your

LCD. To adjust the contrast:

1. From the Configuration Menu, press to select Adjust Contrast and press

Enter

. The library displays the following screen:

L C D C o n t r a s t

L o w H i g h →

←

M i n . . . . . . . | . . . . . . M a x

2. Press and to change the contrast. Press to save your changes

and exit the Adjust Contrast screen.

←

↓

Enter

PLS200 Library Installation and Operation 37

Page 60

Chapter 2 Configuring the Library

Setting the Back Light

The Back Light option turns the LCD background on or off.

To change the back light:

1. From the Configuration Menu, press or to select Back Light.

S e t S C S I I D s

S e t P a r i t y O N

A d j u s t C o n t r a s t

B a c k L i g h t O N

→

2. Press and to toggle back lighting on and off.

Setting the Library Date

The Set Date option allows you to set the date for the library. The date appears

on the Command History screen (see page 108) and on diagnostic listings.

↓

To set the date:

1. From the Configuration Menu, press or to select Set Date and press

Enter

.

S e t M o n t h D a y Y e a r

D a t e : J a n 0 3 1 9 9 6

2. Press and to cycle through the selections under Month, Day, and

Year. Use and to move between the columns.

3. Press to save your changes and exit the Set Date screen.

38 PLS200 Library Installation and Operation

Enter

↑ →

Page 61

Setting the Library Time

Setting the Library Time

The Set Time option allows you to set the time that is shown on the library's

Main Screen and Command History screen (see page 108).

NOTE: The clock in the library is independent of outside clocks. It is not locked to

any external synchronization, and cannot be set or accessed by the Media

Manager on the Profile video disk recorder.

To set the time:

1. From the Configuration Menu, press to select Set Time and press

Enter

.

2. Use and to toggle through the selections under HH (hours), MM

(minutes), and SS (seconds). Use and to toggle between the columns.

S e t H H : M M : S S

T i m e : 2 0 : 2 2 : 0 9

↑ →

↓

3. Press to save your changes and exit the Set Time screen.

Enter

Checking the Serial Number

The serial number is entered into the library firmware at the factory. You can

read the serial number label on the back of the library or use the Set Serial

Number option. The serial number displayed on this screen appears on

diagnostic listings.

NOTE: If the serial number has never been entered, the number stored in memory is

99999999.

PLS200 Library Installation and Operation 39

Page 62

Chapter 2 Configuring the Library

To check the serial number:

1. From the Configuration Menu, press or to select Set Serial Number

and press .

2. If necessary, enter the serial number by pressing and to change each

digit. Press and to move from column to column.

Enter

S e t S e r i a l

N u m b e r : 9 9 9 9 9 9 9 9

↓ →

3. Press . The library displays the following screen:

4. Press to save your changes or press to cancel changes.

Enter

T h e s e r i a l n u m b e r i s

n n n n n n n n

E N T E R t o a c c e p t o r

E S C t o c a n c e l .

Enter

. P r e s s

Escape

40 PLS200 Library Installation and Operation

Page 63

Checking the Tape Drive Model

The tape drive model is entered into the library firmware at the factory. The

PLS200 uses only the Mammoth drives, and normally displays “ON” for the

Use Mammoth option.

To view the tape drive model:

1. From the Configuration Menu, press or to select Use Mammoth.

Checking the Tape Drive Model

S e t T i m e

S e t S e c u r i t y O N

S e t S e r i a l N u m b e r

U s e M a m m o t h O N

→

2. Press to return to the Configuration Menu.

Escape

↑

PLS200 Library Installation and Operation 41

Page 64

Chapter 2 Configuring the Library

42 PLS200 Library Installation and Operation

Page 65

Chapter

3

Operating the Library

This chapter describes library operations that you may occasionally need to

perform:

• Using the operator panel

• Operating the library in different control modes

• Resetting the library

Using the Operator Panel

The library includes a four-line LCD and keypad, called theoperator panel, that

allows you to control library operations. Using the operator panel, you can set

library options, check operating statistics, and diagnose errors. If desired, you

can tilt the LCD for easier viewing.

Main Screen

The Main Screen appears when you apply power to the library. The first and

second lines on the Main Screen display the product name, version, and the

current time. The third and fourth lines display status information about the

library and tape drives.

P L S 2 0 0

V E R

S t a t u s : M o v e 1 - D

P i c k i n g F r o m S l o t 1

NOTE: The exact wording on your Main Screen may be different, and the

information that appears at power-up is overwritten as the PLS200 software

executes.

n . n n . n n h h : m m : s s

PLS200 Library Installation and Operation 43

Page 66

Chapter 3 Operating the Library

Error Codes

If a library hardware error occurs, an error code appears on the third and fourth

lines of the Main Screen. The third line provides the error's numerical code; the

fourth line provides a brief explanation of the error. You must correct the error

before operation can continue; refer to Appendix B for a list of error codes and

corrective actions.

P L S 2 0 0

Main Menu

Use the Main Menu (shown below) to access LCD options and functions. To

access the Main Menu, press from the Main Screen.

• Select Main Screen to return to the Main Screen.

• Select Interface Menu to change the control mode (see page 48) and

configure the serial ports (see page 95).

•

Extend/Retract E/E can be used to control the entry/exit port. Not

recommended for adding tapes because it upsets the tape inventory database.

V E R

S t a t u s : E r r o r 1 1

S O U R C E E M P T Y

M a i n S c r e e n

→

E x t e n d / R e t r a c t E / E

I n t e r f a c e M e n u

C o n f i g u r a t i o n M e n u

n . n n . n n h h : m m : s s

Escape

↓

• Select Configuration Menu to set or change the library's configuration

options (see Chapter 2).

• Select Maintenance Menu to run demos (see page 95), or perform

diagnostic tests (see page 85).

44 PLS200 Library Installation and Operation

Page 67

Main Menu

• Select Library Info Menu to learn about library operations (see page 97)

and tape drive operations (see page 54).

The library menu structure is shown in Figure 3-1.

Main Menu Main Screen

Extend/Retract

E/E

Interface

Menu

Control Mode

Menu

LCD Interface

SCSI Interface

25/9 Pin Port

Config 25/9

Pin Menu*

Connect Drive 1

Connect Drive 2

Connect Drive 3

Connect Drive 4

Diag Console

Baud Rate 1200

Baud Rate 2400

Baud Rate 4800

Baud Rate 9600

Baud Rate 19200

*Your LCD may show

two entries: Config 25-Pin

Port and Config 9-Pin

Port.

Configuration

Menu

Set SCSI IDs

SCSI Parity

Adjust Contrast

Back Light

Set Date

Set Time

Set Security

Set Serial Number

Use Mammoth

Maintenance

Menu

Insert Cartridge

Remove Cartridge

Clean Drives

Menu

Clean Drive 1

Clean Drive 2

Clean Drive 3

Clean Drive 4

Demo Menu

Slot Demo

Drive Demo

Diagnostics

Menu

Self Test

Position to Element

Park

Move Cartridge

Scan

Scan w/Range

Home Gripper

Home CHM

Cycle Pick/Place

Cycle Gripper

Cycle S Axis

Cycle L Axis

Cycle Drum

Cycle Solenoid

Cycle E/E

Library

Info Menu

SCSI Menu

SCSI Mode Params

SCSI Reservations

SCSI Sense Data

Statistics

System Sensors

Command History

Drive Info Menu

Drive 1 Status

Drive 2 Status

Drive 3 Status

Drive 4 Status

Inventory Menu

Label Information

Occupied Info

Position Info

Figure 3-1 Library menu structure

PLS200 Library Installation and Operation 45

Page 68

Chapter 3 Operating the Library

Operator Keys

The keys on the operator panel perform the following functions:

Scrolls the screen arrow (→) up or down. The screen arrow points to

the current selection.

In some screens, moves the screen arrow left or right. On some menu

selections, toggles an option on or off.

Enter

Escape

Reset

Help

Selects the item next to the screen arrow or accepts a change.

Returns to the previous menu or screen, or cancels an operation

without saving changes.

Displays the Reset screen, which allows you to reset the library and the

tape drives.

Displays the Help screen. To exit Help, press .

Escape

Operating in Different Control Modes

The library's control mode determines which interface controls CHM motion.

In this control mode... The CHM is controlled by... Purpose

SCSI Interface Media Manager (or other similar

application software)

LCD Interface A user at the operator panel Diagnostics

25/9 Pin A user operating a console interface

to access library firmware across the

25- or 9-pin port