Page 1

Installation Manual

Profile Family

PLS20 Data Tape Drive

Tektronix, Inc.

P.O. Box 1000

Wilsonville, OR 97070-1000 USA

1-800-547-8949 (USA and Canada)

1-503-682-7300

http://www.tek.com

N 60

Page 2

Copyright Copyright © 1998 Tektronix, Inc. Wilsonville, Oregon.

Printed in the United States of America or the United Kingdom. All rights reserved. This

document may not be copied, in whole or in part, or otherwise reproduced, except as

specifically permitted under U.S. copyright law, without the prior written consent of

Tektronix, Inc., P.O. Box 1000, Wilsonville, Oregon 97070-1000.

Some portions are reprinted with permission:

Copyright 1996 Exabyte Corporation. All rights reserved.

Disclaimer Tektronix, Inc., makes no representation or warranties with respect to the contents of

this document and specifically disclaims any implied warranties of merchantability or

fitness for any particular purpose. Further, Tektronix, Inc. reserves the right to revise

this publication without obligation of Tektronix, Inc. to notify any person or organization

of such revision or changes.

Trademark Notices TEKTRONIX, TEK, and Profile are registered trademarks of Tektronix, Inc.

EXABYTE, EXAPAK, EXB, FileSECURE, LANCourier, and NetSECURE are registered

trademarks of Exabyte Corporation. Eagle, EXA, EXAFacts, EXAsoft, EXATAPE, and

SCIMON are trademarks of Exabyte Corporation.

Other trade names used in this document are trademarks or registered trademarks of

the manufacturers or vendors of the associated products.

Revision Status

Rev Date

May 1998 Original issue. Manual Part Number 071-0183-00.

Description

Page 3

Contents

Welcome...................................................................................................................... 1

Installing the PLS20..................................................................................................... 2

Location of components....................................................................................... 2

Set the SCSI ID.................................................................................................... 2

Install the Orientation Pads.................................................................................. 3

Connect the Drive to the SCSI Bus...................................................................... 4

Connect Power..................................................................................................... 6

Operating the Tape Drive............................................................................................. 7

Monitoring the Status LEDs.................................................................................. 7

Monitoring the LCD .............................................................................................. 9

Selecting Appropriate Data Cartridges................................................................. 12

Loading Data Cartridges ...................................................................................... 12

Unloading Data Cartridges................................................................................... 13

Resetting the Tape Drive...................................................................................... 14

Cleaning the Tape Drive....................................................................................... 14

Packing the Tape Drive................................................................................................ 15

Specifications............................................................................................................... 16

Figures

19 The PLS20 Profile Data Tape Drive.........................................................................1

210 Component locations................................................................................................2

311 Installing the orientation pads...................................................................................3

412 SCSI Bus Connections.............................................................................................5

513 PLS20 Front Panel Components.............................................................................7

614 A PLS20 170m tape cartridge..................................................................................12

715 Setting the Write Protection switch...........................................................................12

816 Inserting the tape cartridge.......................................................................................13

Tables

11 LED status................................................................................................................8

22 LCD Message Descriptions......................................................................................9

33 Tape capacity...........................................................................................................16

44 Date rate...................................................................................................................16

55 Environmental specifications....................................................................................16

66 Input voltages...........................................................................................................17

77 SCSI cable specifications.........................................................................................17

88 Terminator specifications..........................................................................................17

Profile PLS20 Data Tape Drive iii

Page 4

iv Profile PLS20 Data Tape Drive

Page 5

Safety Summary

Review the following safety precautions to avoid injury and

prevent damage to this product or any products connected to

it.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts

of the system. Read the General Safety summary in other

system manuals for warnings and cautions related to operating

the system.

Injury Precautions

Use Proper Power

Cord

Ground the Product This product is grounded through the grounding conductor of

Do Not operate in

Wet/Damp

Conditions

Do Not Operate in an

Explosive

Atmosphere

To avoid fire hazard, use only the power cord specified for this

product.

the power cord. To avoid electric shock, the grounding

conductor must be connected to earth ground.

To avoid electric shock, do not operate this product in wet or

damp conditions.

To avoid injury or fire hazard, do not operate this product in

an explosive atmosphere.

Product Damage Precautions

Use Proper Power

Source

Provide Proper

Ventilation

Do Not Operate With

Suspected Failures

Do not operate this product from a power source that applies

more than the voltage specified.

To prevent product overheating, provide proper ventilation.

If you suspect there is damage to this product, have it

inspected by qualified service personnel.

Profile PLS20 Data Tape Drive v

Page 6

Safety Summary

Safety Terms and Symbols

Terms in This

Manual

!

!

!

!

Terms on the

Product

Symbols on the

Product

These terms may appear in this manual:

WARNING: Warning statements identify conditions or

practices that can result in personal injury or loss of life.

CAUTION: Caution statements identify conditions or

practices that can result in damage to the equipment or other

property.

These terms may appear on the product:

DANGER indicates a personal injury hazard immediately

accessible as one reads the marking.

WARNING indicates a personal injury hazard not

immediately accessible as you read the marking.

CAUTION indicates a hazard to property including the

product.

The following symbols may appear on the product:

DANGER high voltage

Protective ground (earth) terminal

!

!

vi Profile PLS20 Data Tape Drive

ATTENTION – refer to manual

Page 7

Tektronix Product Support

You can get technical assistance, check on the status of problems, or report

new problems by contacting our Product Support Group.

United States and Canada

(800) 547-8949

Monday–Friday 6:00AM–5:00PM Pacific Time

Europe

Monday–Friday 9:00AM–5:30PM

Austria 222-799-3535 Netherlands 010-495-4255

Belgium 02-714-3401 Norway 22-83-85-69

Denmark 3543-5259 Spain 91-564-4692

Finland 161-691-98559 Sweden 08-679-8419

Germany 069-935-25001 Switzerland 041-210-6009

Italy 44-1908-681-706 United Kingdom 01908-681-703

Luxembourg 400-848 Other 44-1908-681-703

Tektronix Product Support

E-mail: EuroProfile@tek.com

Asia and South America

Australia 61-2-888-7066 Korea 82-2-528-5299

Brazil 55-11-543-1911 Mexico 52-5-666-6333

Hong Kong 852-2585-6688 Singapore 65-356-3900

Japan 81-3-3448-3111 Taiwan 886-2-765-6362

World Wide

(503) 685-2345 24-hour Emergency Hotline

(Contract and warranty customers)

World Wide Web http://www.tek.com/VND/

FTP Site ftp.tek.com

E-mail ProfileSupport@tek.com

Profile PLS20 Data Tape Drive vii

Page 8

Safety Summary

Certifications and Compliances

Canadian Certified

Power Cords

FCC Emission

Control

Canadian EMC

Notice of

Compliance

Canadian approval includes the products and power cords

appropriate for use in the North America power network. All

other power cords supplied are approved for the country of use.

This equipment has been tested and found to comply with the

limits for a Class A digital device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and

can radiate radio frequency energy and, if not installed and used

in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the

interference at his own expense. Changes or modifications not

expressly approved by Tektronix can affect emission compliance

and could void the user’s authority to operate this equipment.

This digital apparatus does not exceed the Class A limits for

radio noise emissions from digital apparatus set out in the Radio

Interference Regulations of the Canadian Department of

Communications.

Le présent appareil numérique n’émet pas de bruits

radioélectriques dépassant les limites applicables aux appareils

numériques de la classe A préscrites dans le Règlement sur le

brouillage radioélectrique édicté par le ministère des

Communications du Canada.

Canadian Certified

AC Adapter

EN55022 Class A

Warning

viii Profile PLS20 Data Tape Drive

Canadian approval includes the AC adapters appropriate for

use in the North America power network. All other AC

adapters supplied are approved for the country of use.

For products that comply with Class A. In a domestic

environment this product may cause radio interference in

which case the user may be required to take adequate

measures.

Page 9

Certification

Category Standard

Safety Designed/tested for compliance with:

UL1950 -Safety of Information Technology Equipment, including Electrical Business

Equipment (First Edition)

CAN/CSA C22.2, No. 950-M89 - Safety of Information Technology Equipment,

including Electrical Business Equipment

EN60950:1992 +A1 +A2:1993- Safety of Information Technology Equipment,

including Electrical Business Equipment

Certification

Profile PLS20 Data Tape Drive ix

Page 10

Safety Summary

x Profile PLS20 Data Tape Drive

Page 11

Welcome

Congratulations on selecting the PLS20 Profile Data Tape Drive. The PLS20

lets you quickly (up to 3 megabytes per second) and economically store your

audio and video material from your Profile Professional Disk Recorder on

durable data tape cartridges for archive purposes, or to move material to remote

locations without video networking.

The PLS20 Profile Data Tape Drive tape drive is a tabletop model housed in its

own enclosure (shown in Figure 9).

Welcome

.

0183-2

Figure 9. The PLS20 Profile Data Tape Drive

Profile PLS20 Data Tape Drive 1

Page 12

Installing the PLS20

The following sections explain how to install a Profile Data Tape Drive and

connect it to a PDR100 or PDR200 Professional Disk Recorder.

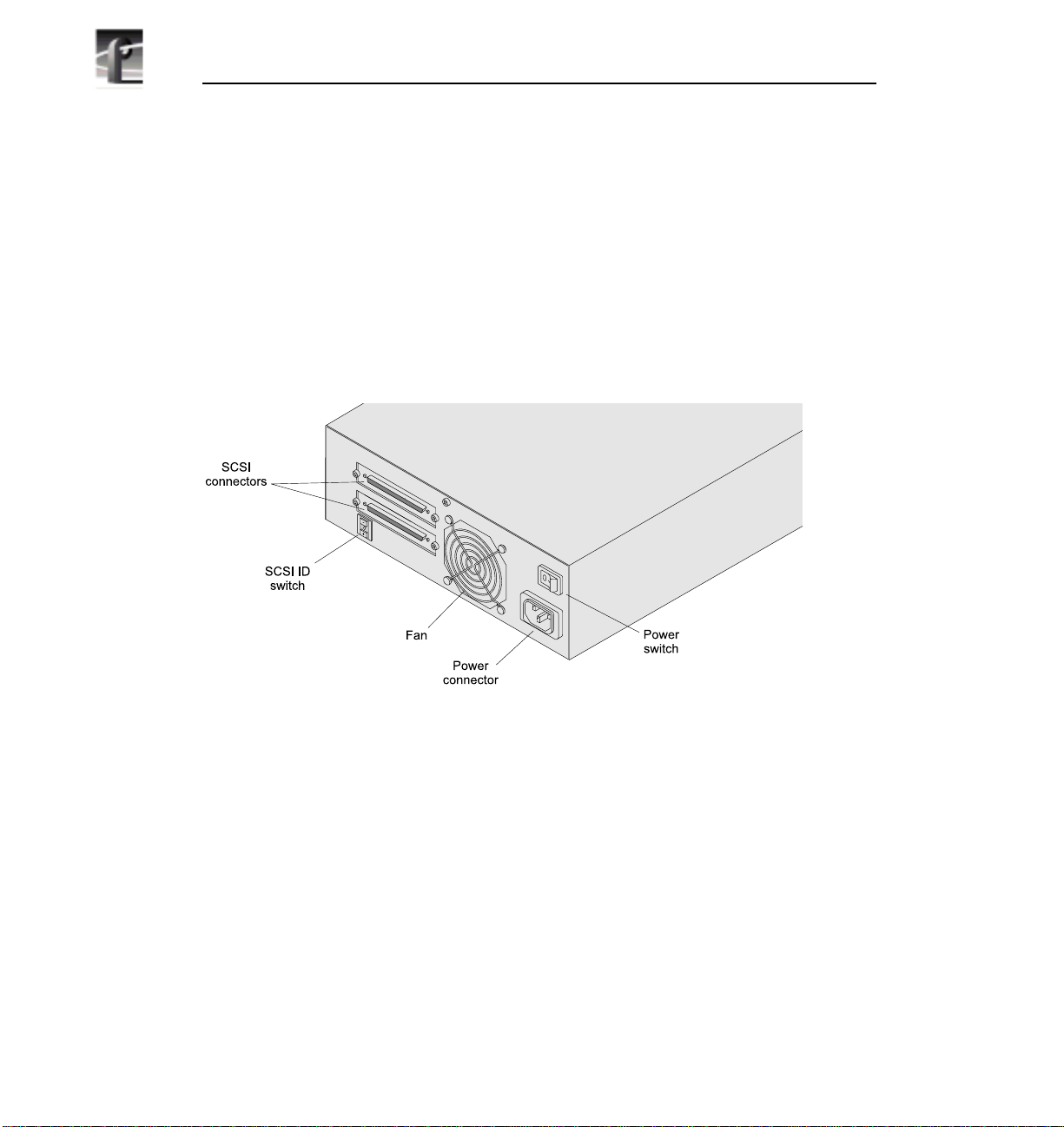

Location of components

When installing the PLS20, refer to Figure 10 for the location of components

on the rear panel.

0183-9

Figure 10. Component locations

Set the SCSI ID

To set the SCSI ID for the tape drive, use a pen or other fine-tipped instrument

to press the SCSI ID switch. Set the SCSI ID to 1 or 2., and ensure that no other

SCSI device on the bus is using the same ID.

NOTE: Changes in the SCSI ID setting take effect after a normal

power-on or SCSI bus reset.

2 Profile PLS20 Data Tape Drive

Page 13

Install the Orientation Pads

The tabletop model includes adhesive pads that you must apply to either the

base or the right side, depending on how you plan to position the tape drive.

These pads protect the tape drive’s surface and allow air to flow through the

vents when the tape drive is positioned on its side.

To install the pads:

1. Remove the backing from four pads. (Five pads are shipped with the tape

drive.)

2. Affix the pads to each corner, approximately -inch (1.3 cm) from the sides.

For a horizontal orientation, place the pads on the bottom. For a vertical

orientation, place the pads on the right side (the side with the external vents).

Install the Orientation Pads

0183-8

Figure 11. Installing the orientation pads

>>> If you want to position the tape drive on its side, you must place the pads on

the right side. Otherwise, the air flow vents will be blocked and the enclosed

tape drive will overheat.

Profile PLS20 Data Tape Drive 3

Page 14

Connect the Drive to the SCSI Bus

The PLS20 receives both data and commands through a single SCSI connector.

Figure 12 shows examples of how to connect your tape drive to a Profile

system.

CAUTION: To avoid damaging the tape drive and the Profile Professional

!

Disk Recorder, make sure that both devices are powered off when you

connect the cables on the back.

1. Connect the tape drive to one of the SCSI ports on the Profile rear panel with

the provided cable.

a. On a PDR100, connect to the SCSI A or SCSI B connector, or to another

device in the chain connected to that bus.

b. On a PDR200, connect to the SCSI B or SCSI D connector, or to another

device in the chain connected to that bus.

2. If the tape drive is the last device on the SCSI bus, install a terminator on the

other connector. If it is not the last device, connect another SCSI cable. Do

not install more than four Profile Data Tape Drives to a single Profile system.

NOTE: You may not connect a PLS200 Profile Library System and

a PLS20 Profile Data Tape Drive to the same Profile system.

However, you may connect up to four Profile Data Tape Drives to the

same Profile system, provided you do not exceed two PLS20s per

SCSI bus.

See Appendix A for cable and terminator requirements.

4 Profile PLS20 Data Tape Drive

Page 15

Connect the Drive to the SCSI Bus

SCSI A

SCSI B

PLS20

PLS20

PDR100

PDR200

SCSI Cable

Terminator

Figure 12. SCSI Bus Connections

Profile PLS20 Data Tape Drive 5

0183-1

Page 16

Connect Power

To connect power to the tape drive:

1. Connect the power cord to the back.

2. Press the power switch to the on (l) position.

Be sure to power on the PLS20 before starting the Profile system to

ensure that the Profile Data Tape Drive is recognized as a SCSI

device.

The tape drive performs its power-on self-test in about 30 seconds. When the

tape drive is ready to accept a cartridge, the LEDs turn off.

➤ Important: Do not insert a cartridge into the tape drive during the

power-on self-test. The tape drive will eject the cartridge.

6 Profile PLS20 Data Tape Drive

Page 17

Operating the Tape Drive

This section describes how to operate your PLS20 Profile Data Tape Drive.

Figure 13 below shows the front-panel components used for tape drive

operation.

Power LED

Status LEDs

LCD display

Door

Unload button

Operating the Tape Drive

0183-4

Figure 13. PLS20 Front Panel Components

Monitoring the Status LEDs

The status LEDs have the following, general meanings:

• Top LED (amber). When this LED is flashing, an error has occurred. When

this LED is on solid, the tape drive needs to be cleaned (see page 14).

• Middle LED (green). When this LED is on, tape is loaded and the tape drive

is ready to begin operations.

• Bottom LED (green). When this LED is flashing, tape motion is occurring.

Profile PLS20 Data Tape Drive 7

Page 18

Table 1 describes the LED combinations that occur during normal tape drive

operation.

Table 1. LED status

Tape Drive State

a

POST

or reset

Top LED

(Error/Cl

ean)

Middle

LED

(Tape

Ready)

Bottom

LED

(Tape

Motion)

a. POST = power-on self-test.

●

●❍❍●●●n/a ●

●❍❍❍

Error

or

failed

POST

❊

Ready

(no tape

loaded)

Ready

(tape

loaded)

Normal

tape

motion

High

speed

motion

Time to

clean

Clean in

progress

n/a n/a n/a n/a ●●

❊

❊

fast

n/a

Legend: ❍ = off ● = on ❊ = flash n/a = not applicable (may be any state)

❊

8 Profile PLS20 Data Tape Drive

Page 19

Monitoring the LCD

If the tape drive includes an LCD, refer to the following table for a detailed list

of messages that may appear.

Table 2. LCD Message Descriptions

Reset messages.

(When the tape drive is reset, the LCD cycles through the following messages.)

Monitoring the LCD

RESET

MODEL:

SUBMOD:

SN:

CODE:

LAST CLN:nn hrs

COMPRESS: ON

COMPRESS: OFF

SINGLE-ENDED

DIFFERENTIAL

WIDEor NARROW

SCSI ID:

LANGUAGE

nn

or

:

or

The first message in the power-on sequence.

The model number of the tape drive.

The submodel number of the tape drive.

The serial number of the tape drive.

The level of the tape drive’s firmware.

The number of hours since the tape drive has last been cleaned.

Compression is turned on or on. Must be off for operation with

a Profile Professional Disk Recorder.

The tape drive has a single-ended or differential SCSI

configuration. Must be Differential.

The tape drive has a wide or narrow SCSI configuration. Must

be wide.

The SCSI ID of the tape drive.

The available foreign languages for the LCD appear when you

perform the following steps:

1. Press and hold the unload button during the reset

sequence. After the SCSI ID message appears, the

LCD cycles through the languages.

2. When the desired language displays, release the

button and the messages appear in that language.

Profile PLS20 Data Tape Drive 9

Page 20

Table 2. LCD Message Descriptions

Tape drive status messages

READY–NOTAPE

LOADING . . . .

READY–TAPE

EJECT ■■■===

EJECT PREVNT

ILLEGAL TAPE

Tape motion messages

READ +■■■===

WRITE+■■■===

PROTECTED

The tape drive is ready to accept a cartridge.

The tape drive is loading the tape.

The tape drive has successfully loaded the tape and is ready for

read/write operations.

The unload button was pressed. The tape drive will eject the

cartridge as soon as it has finished its current operation. The

icon to the left of the Eject message indicates the current suboperation (write, erase, etc.).

The software has disabled the eject function with the

PREVENT/ALLOW MEDIA REMOVAL command. The

tape drive will rewind and unload the tape, but will not eject

the cartridge.

The tape drive detected an incompatible cartridge and ejected

it.

The tape drive is reading or writing data.

The + sign appears when the data is compressed. The boxes

show the amount of tape used.

The tape drive cannot write data because the data cartridge is

write-protected.

ILLEGAL WRT

The tape drive cannot write to the type of data cartridge

inserted. This message remains until an appropriate tape is

inserted or a tape motion command is issued.

>>

<<

<<

SEARCH ■■====

SEARCH ■■====

REWIND ■■====

ERASE ■■====

High-speed search is in progress. The arrows indicate either a

forward or backward search.

Rewind is in progress.

The tape drive is erasing data on the tape.

10 Profile PLS20 Data Tape Drive

Page 21

Table 2. LCD Message Descriptions

Monitoring the LCD

FORMAT ■■■■■■

The drive is repartitioning the tape to the requested format. The

icon to the left of the message displays the current suboperation (write, erase, search, etc.).

Cleaning messages

CLEAN SOON

MUST CLEAN

The tape drive should be cleaned at the next convenient time.

The tape drive must be cleaned after a metal particle tape has

been used in the drive. If you attempt to insert an AME data

cartridge before cleaning the tape drive, the cartridge will be

ejected.

CLEANING . . .

DEPLETED

Cleaning is in progress.

The cleaning tape in the cartridge is depleted and the tape drive

will eject it. Use a new cleaning cartridge.

Error conditions

(When a hardware error occurs, the LCD cycles through the current error code and the

previous three error codes.)

ERR 1:

ERR 2:

ERR 3:

xx yy zz

xx yy zz

xx yy zz

In the error display, xx indicates the fault symptom code, and

yy and zzindicate secondary errors (if any). If an error appears,

contact Exabyte Technical Support.

Profile PLS20 Data Tape Drive 11

Page 22

Selecting Appropriate Data Cartridges

For writing data, use only Profile 170m advanced metal evaporated (AME) data

cartridges, as shown in Figure 14. You must use Profile Media Manager to

format these cartridges before using them in a PLS20 connected to a Profile

Professional Disk Recorder. See the Profile Family User Manual for

information on running Profile Media Manager.

Data cartridges are completely interchangeable between a PLS20 Profile Data

Tape Drive and a PLS200 Profile Library System.

0183-7

Figure 14. A PLS20 170m tape cartridge

Loading Data Cartridges

To load a cartridge:

1. Make sure the tape drive is ready to accept a cartridge (all LEDs are off). Do

not insert a cartridge if the tape drive is still performing its power-on selftest.

2. Set the write-protect switch for the desired operation as shown in Figure 15.

Figure 15. Setting the Write Protection switch

12 Profile PLS20 Data Tape Drive

0183-6

Page 23

3. Insert the cartridge as shown in the Figure 16.

Figure 16. Inserting the tape cartridge

The tape drive loads the tape in approximately 20 seconds. When the middle

LED is on, the tape drive is ready for read and write operations.

Unloading Data Cartridges

Unloading Data Cartridges

0183-5

In normal operation, you should use the appropriate command in Media

Manager (or any other Profile application that supports Profile Library

Systems) to eject or export a data tape from the PLS20. See the Profile Family

User Manual for information on running Profile Media Manager.

In some cases, such as when the PLS20 is not connected to a Profile system,

you may have to manually unload a data tape from the PLS20.

To unload a cartridge, press the unload button. Do not press and hold the

unload button for more than 10 seconds; this can cause a reset under

certain conditions. If the tape drive is free of errors, it performs the following

actions in about one minute:

• Completes any command in process

• Writes any buffered information to tape

• Rewinds the tape to the beginning

• Unloads the tape and ejects the cartridge

Profile PLS20 Data Tape Drive 13

Page 24

NOTE: If an error occurs before or during the unload procedure, the

tape drive suspends the unload sequence. To clear the error, press the

unload button again. The tape drive reattempts the unload sequence,

but does not write data in the buffer.

Resetting the Tape Drive

To reset the tape drive, press and hold the unload button for at least 10 seconds,

or power the drive off and back on again.

If you reset the tape drive while a cartridge is loaded, it rewinds the

tape to the beginning after the reset is complete. The reset may take

as long as two minutes if the tape is positioned near the end.

Cleaning the Tape Drive

When the tape drive requires cleaning, the top (amber) LED turns on. You

should clean the tape drive as soon as possible after this LED turns on. The tape

drive’s cleaning requirements depend on the number of tape motion hours

To clean the tape drive, insert an Profile 8mm Cleaning Cartridge (or a cleaning

cartridge approved by Tektronix for use with the PLS20). When finished, the

tape drive turns off the top LED and ejects the cleaning cartridge.

Cleaning cartridges generally have a useful life of about 12 cycles. Be sure to

change your cleaning cartridges often to ensure the best results.

14 Profile PLS20 Data Tape Drive

Page 25

Packing the Tape Drive

If you are shipping the tape drive to another location or returning it for repair,

pack the tape drive in its original shipping container and packing materials.

CAUTON: To avoid damaging the tape drive and voiding your warranty, use

!

the original shipping materials (or replacement materials from your dealer).

➤ Important: If you are returning the tape drive for service, remove and

keep all cartridges, cables, and terminators.

If you are returning the tape drive to Tektronix, contact Tektronix Product

Support at a number listed at the front of this manual to obtain an RMA number.

Packing the Tape Drive

Profile PLS20 Data Tape Drive 15

Page 26

Specifications

The following tables provide specifications for the PLS20 Profile Data Tape

Drive when used with a Profile Professional Disk Recorder.

Table 3. Tape capacity

Tape Length Data

a

170m

a. PLS20 and PLS200 do not support 22m tapes

Table 4. Date rate

Maximum Data Capacity

20 gigabytes

Maximum Data Transfer Rates

Compressed video

a

data

a. Tape drive compression is not used on compressed video data.

Table 5. Environmental specifications

3 MB/sec.

Operating Environment Specifications

Tape Path Temperature

Range

+5° C to + 45° C

(+41° F to +104° F)

Relative Humidity 20% to 80%; non-condensing

Wet Bulb 26°C (79°F) max

Altitude –304.8 m to +3,048 m

(–1,000 ft to +10,000 ft)

16 Profile PLS20 Data Tape Drive

Page 27

Table 6. Input voltages

Specifications

Input Voltages

Automatic input

Accepts 120 or 240 VAC at 50 to 60 Hz.

voltage selection.

Table 7. SCSI cable specifications

SCSI Cable Specifications

Type Fast Wide Differential

Connector type Wide

68-pin male, high-density, shielded,

AMP 750752-1

Length (maximum)

a

Differential

25 meters (82 feet)

a. Each PLS20 tape drive attached to the SCSI bus uses 0.4 meters (1.31 feet) of cable

length internally. To determine the total length, add 0.4 meters (1.31 feet) to the length

of cable used on the bus for each tabletop tape drive.

Table 8. Terminator specifications

Terminator Specifications

Wide Differential Tektronix Part Number 011-0166-00

Profile PLS20 Data Tape Drive 17

Page 28

Index

Index

A

altitude specifications 16

AME tape 12, 14

Asia and South America, Tektronix Product

Support vii

Asia, Tektronix Product Support vii

B

back panel 2

C

Canada, Tektronix Product Support vii

Canadian Certified AC Adapter viii

Canadian Certified Power Cords viii

Canadian EMC Notice of Compliance viii

cartridges

data capacity 16

loading 12

types to use 12

unloading 13

Certification ix

cleaning

LED indicator 7–8

procedure 14

code level of tape drive 9

compression mode 9

D

data capacity 16

data transfer rate 16

E

EN55022 Class A Warning viii

environmental specifications 16

error conditions

displayed on LCD 11

displayed on LEDs 8

Europe, Tektronix Product Support vii

Exabyte Service 15

F

FCC Emission Control viii

front panel components 7

H

humidity specifications 16

I

input voltages 17

installation 2–6

L

language on LCD 9

LCD

changing the displayed language 9

status messages 9–11

LEDs

status messages 7–8

O

orientation pads for tabletop model 3

P

packing the tape drive 15

performance specifications 16

power

connecting for tabletop model 6

18

Page 29

Index

R

resetting the tape drive 14

returning the tape drive 15

S

SCSI bus

connecting 4

SCSI cable

specifications 17

SCSI ID

displayed on LCD 9

setting 2

serial number of tape drive 9

service 15

shipping the tape drive 15

South America, Tektronix Product Support

vii

T

tape motion LED 7–8

tape ready LED 7–8

Tektronix Product Support vii

temperature specifications 16

termination 4, 17

transfer rate 16

W

World Wide Tektronix Product Support vii

U

United States and Canada, Tektronix Prod-

uct Support vii

unload button

location 7

used for resetting tape drive 14

used for unloading cartridges 13

V

voltages 17

19

Page 30

Index

20

Loading...

Loading...