Page 1

PFR600/E

FIBRE CHANNEL RAID STORAGE SYSTEM

Instruction Manual

071-8266-00

FEBRUARY 2004

the most watched worldwide

Page 2

Copyright Copyright 2004 Grass Valley Group. Grass Valley, California.

Portions copyright Ciprico, Inc. Reprinted with permission.

Printed in th e United States of A m eri ca. All rights reserved. This document may not be copied

in whole or in part, or otherwise reproduced except as specifically permitted under U.S.

copyright law, without the prior written consent of Grass Valley Group Inc., P.O. Box 1114,

Grass Valley, C alifornia 95945 USA .

Trademarks Grass Valley, Profile, and Profile XP are either registered trademarks or trademarks of

Thomson Broadcast and Media Solutions, Inc. in the United States and/or other countries.

Other trademarks used in this document are either registered trademarks or tr ademark s of the

manufacturers or vendors of the associated products. Thomson Broadcast and Media

Solutions, Inc. products are covered by U.S. and foreign patents, issued and pending.

Additional information regarding Thomson Broadcast and Media Solutions, Inc. trademarks

and other proprietary rights may be found at www.thomsongrassval ley.com.

Disclaimer Product options and specifications subject to change without notice. The information in this

manual is furn i shed for informational use only, is subject to chang e without notice, and should

not be construed as a commitment by Thomson Broa dcast and Media Solu tions, I nc. Thomso n

Broadcast and Media Solutions, Inc. assumes no responsibility or liability for any errors or

inaccuracie s that may appear in this publi cation.

U.S. Government

Restricted Rights

Legend

Use, duplicat ion, o r disclos ure by t he Unite d States Governme nt is su bject to restric tions as s et

forth in subparagraph (c)(1)(ii) of the Rights in Technical Data and Computer Software clause

at DFARS 252.277-7013 or in subparagraph c(1) and (2) of the Commercial Computer

Software Re st ri cted Rights c l ause at FAR 5 2.227-19, as applicable. Manufacturer is Thomson

Broadcast and Media Solutions, Inc., P.O. Box 59900, Nevada City, California 95959-7900

U.S.A.

Revision Status

Rev Date Description

20 February 2004 First releas e. 071-8266-00

2 PFR 600/E Instruction Manual 20 February 2004

Page 3

Contents

Safety Summaries

Preface

About this manual.................................................................................................................9

Using the Profile XP documentation Set .........................................................................9

Manual descriptions.......................................................................................................10

How this manual is organized........................................................................................11

Getting more information....................................................................................................12

On-line manuals ................ ......... ........ ......... ........ ........ ........................................... .......12

Chapter 1 About the PFR600 Series

PFR6 00 Series features.....................................................................................................15

PFR600 features...........................................................................................................16

Capacity and redundancy..............................................................................................16

PFR6 00 Series components..............................................................................................17

Chassis..........................................................................................................................19

Midplane........................................................................................................................19

Disk modules.................................................................................................................20

PFR600/E circuit board modules...................................................................................21

PFR 600 RAID Storage Chassis circuit board modules............................................21

PFR600E RAID Expansion Chassis circuit board modules......................................24

Power supplies..............................................................................................................25

Fan modules..................................................................................................................25

Configurations....................................................................................................................26

Chapter 2 PFR600 Series Installation Information

Installation requirements................. ........ ......... ........ ........ ......... ........ ......... ........................27

Site requirements..........................................................................................................27

Power........................................................................................................................27

Cooling......................................................................................................................27

Chassis address setting requirement............................................................................28

Cabling requirements ....................................................................................................29

Binding disk modules into groups..................................................................................30

Installing a PFR600/E in an equipment rack......................................................................31

Unpacking the chassis...................................................................................................31

Installing the rack mounts..............................................................................................32

Inserting the PFR600/E chassis in the rack..................................................................34

Installing the chassis with drive the support bracket.................................................34

Installing chassis without the drive support bracket..................................................34

PFR6 00/E power-up and initialization................................................................................36

Connecting electrical cables..........................................................................................36

Powering-up the PFR600/E system..............................................................................37

PFR6 00/E power-down......................................................................................................38

Battery Backup recharge....................................................................................................38

Chapter 3 Servicing the PFR600 Series RAID

Maintenance procedures using GVG Disk Utility ...............................................................40

Monitoring PFR600 Series RAID status using NetCentral.................................................40

Interpreting disk module LEDs ...........................................................................................41

Interpreting rear panel status LEDs....................................................................................42

LBB 7-segment display codes............................................................................................43

Removing and installing disk modules ...............................................................................44

20 February 2004 PFR600/E Instruction Manual 3

Page 4

Contents

Moving disk modules.....................................................................................................44

Removing a disk module...............................................................................................45

Installing disk module....................................................................................................46

Replacing the Loop Bypass Board (LBB) or

RAID Controller.............................................................................................................47

Removing the LBB or RAID Controller..........................................................................47

Installing the LBB or RAID Controller............................................................................48

Replacing data ports..........................................................................................................49

Replacing a power supply..................................................................................................50

Replacing the fan module..................................................................................................51

Appendix A Technical Specifications and

Operating Limits

AC power requirements.....................................................................................................53

Size and weight..................................................................................................................53

Cable lengths.............................. ......... ........ ......... ........ ........ .............................................53

Environmental limits...........................................................................................................54

Index.................................................................................................................................55

4 PFR 600/E Instruction Manual 20 February 2004

Page 5

Safety Summaries

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage

to this product or any products connected to it.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of the system.

Read the General Safety summary in other system manuals f or warnings an d

cautions related to operating the system.

Injury P r e caution s

Use Correct Power

Cord

Ground the Product This product is grounded through the grounding conductor of the power

Do Not Operate Without Covers

Do Not operate in

Wet/Damp

Conditions

Do Not Operate in an

Explosive

Atmosphere

Avoid Exposed

Circuitry

Power cords for this equipment, if provided, meet all North American

electrical codes. Operation of this equipment at voltages exceeding 130

VAC requir es power supply cords which comply with NEMA

configurations. International power cords, if provided, have the approval

of the count ry of use.

cord. To avoid electric shock, the grounding conductor must be connected

to earth ground. Before making connections to the input or output terminals

of the product, ensure t hat the product is prope rl y grounded .

To avoid electric shock or fire hazard, do not operate this product with

covers or pa nels removed.

To avoid electric shock, do not operate this product in wet or damp

conditions.

To avoid injury or fire hazard, do not operate this product in an explosive

atmosphere.

To avoid injury, remove jewelry such as rings, watches, and other metallic

objects. D o not to uc h exp os e d con ne cti o ns and c ompon e nts wh en po we r is

present.

Product Dam age P recautions

Use Proper Power

Source

Provide Proper

Ventilation

Do Not Operate With

Suspected Failures

20 February 20 04 PFR600 /E Ins tru c t ion Manual 5

Do not operate this product from a power source that applies more than the

voltage specified.

To prevent product overheating, provide proper ventilation.

If you suspect there is damage to this product, have it inspected by qualified

service personnel.

Page 6

Safety Terms and Symbols

Terms in This

Manual

!

!

Terms on the

Product

Symbols on the

Product

These terms may appear in this manual:

WARNING: Warning statements identify conditions or practices that can

result in personal injury or loss of life.

CAUTION: Caution statements identify conditions or practices that may

result in damage to equ ipment or oth er property, or which may cause

equipment crucial to your business environment to become temporarily

non-operational.

These terms may appear on the product:

DANGER indicates a personal injury hazard immediately accessible as one

reads the marking.

WARNING indicates a personal injury hazard not immediately accessible

as you read the marking.

CAUTION indicates a hazard to property including the product.

The following symbols may appear on the product:

DANGER high voltage

!

ATTENTION – refer to manual

Service Safety Summary

Do Not Service

Alone

Disconnect Power To avoid electric shock, disconnect the main power by means of the power

Use Care When

Servicing With

Power On

Do not perform internal service or adjustment of this product unless another

person capable of rendering first aid and resuscitation is present.

cord or, if provided, the power switch.

Dangerous voltages or currents may exist in this product. Disconnect power

and remove battery (if applicable) before removing protective panels,

soldering, or replacing components.

To avoid electric shock, do not touch exposed connections

6 PFR600/E Instruction Manual 20 Februa ry 2004

Page 7

Certifications and Compli ances

Canadian Certified

Power Cords

FCC Emission

Control

Canadian EMC

Notice of

Compliance

Canadian approval includes the products and power cords appropriate for

use in the North America power network. All other power cords supplied

are approved for the country of use.

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at his own expense. Changes

or modifications not expressly approved by Grass Valley Group can affect

emission compliance and could void the user’s authority to operate this

equipment.

This digital apparatus does not exceed the Class A limits for radio noise

emissions from digital apparatus set out in the Radio Interference

Regulations of the Canadian Department of Communications.

Le présent appareil numérique n ’émet pas de br uits radioélectriques

dépassant les limites applicables aux appareils numériques de la classe A

préscrites dans le Règlement sur le brouillage radioélectrique édicté par le

ministère des Communications du Canada.

EN55022 & EN55024

Class A Warning

FCC Emission

Limits

This product has been evaluated for Electromagnetic Compatibility under

the EN 55022 a nd 550 24 sta nd ard s fo r Emis si ons a nd Im mu nit y an d mee ts

the requirements for E4 environment.

This product complies with Class A (E4 environment). In a domestic

environment this product may cause radio interference in which case the

user may be required to take adequate measures .

This device complies with Part 15 of the FCC rules. Operation is s ubject

to the following two conditions: (1) this device may not cause harmful

interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

20 February 20 04 PFR600 /E Ins tru c t ion Manual 7

Page 8

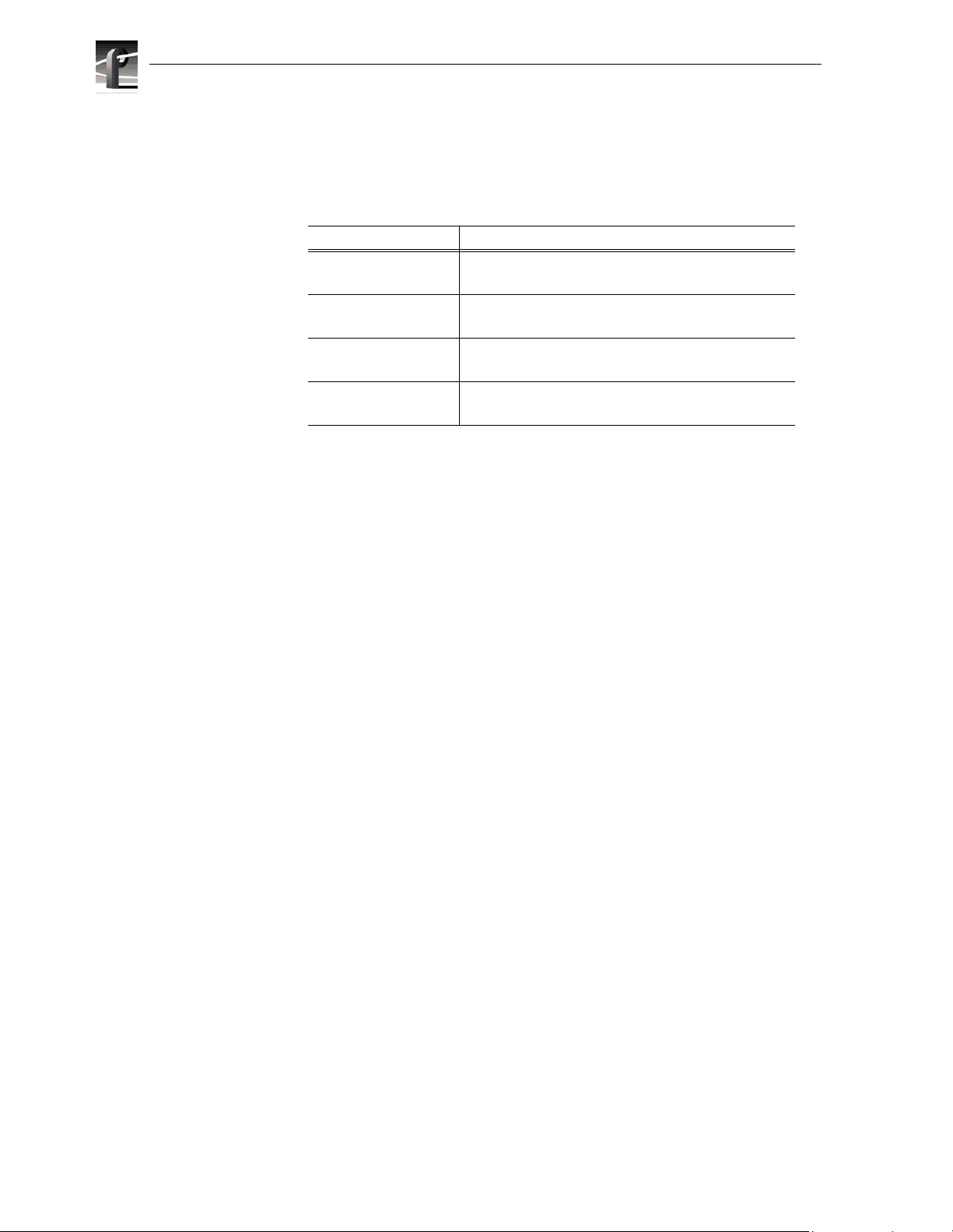

Safety Certification

This product has been evaluated and meets the following Safety

Certification Standards:

Standard Designed/teste d for compliance with:

UL1950 Safety of Information Technology Equipment, including

IEC 950 Safety of Information Technology Equipment, including

Electrical Business Equipment (Third edition).

Electrical Business Equipment (Second edition, 1991).

CAN/CSA C22.2,

No. 950-95

EN60950 Safety of Information Technology Equipment, including

Safety of Information Technology Equipment, including

Electrical Business Equipment.

Electrical Business Equipment 1992.

ATTENTION This product has been designed and certified to comply with certain

regulatory requirements pertaining to Information Technology

Equipment. This pr oduct has not been designed for us e as a medical

device. Without limitation of the foregoing, this product is not intended

and has not been certified for use in a hospital or clinical environment to

diagnose, treat, or monitor patients under medical supervision, and is not

intended and has not been certified to make physical or electrical contact

with patients, nor to transfer energy to or from patients and/or to detect

such energy transfer to or from patients.

8 PFR600/E Instruction Manual 20 Februa ry 2004

Page 9

Preface

About this manual

The PFR600/E Fibre Channel RAID Storag e Chassis prov ides RAID protected

storage for Profile XP Media Platforms and Grass Valley Open SANs. If you are

responsible for installing and servicing the PFR600/E in one of these systems, you

should read this manual.

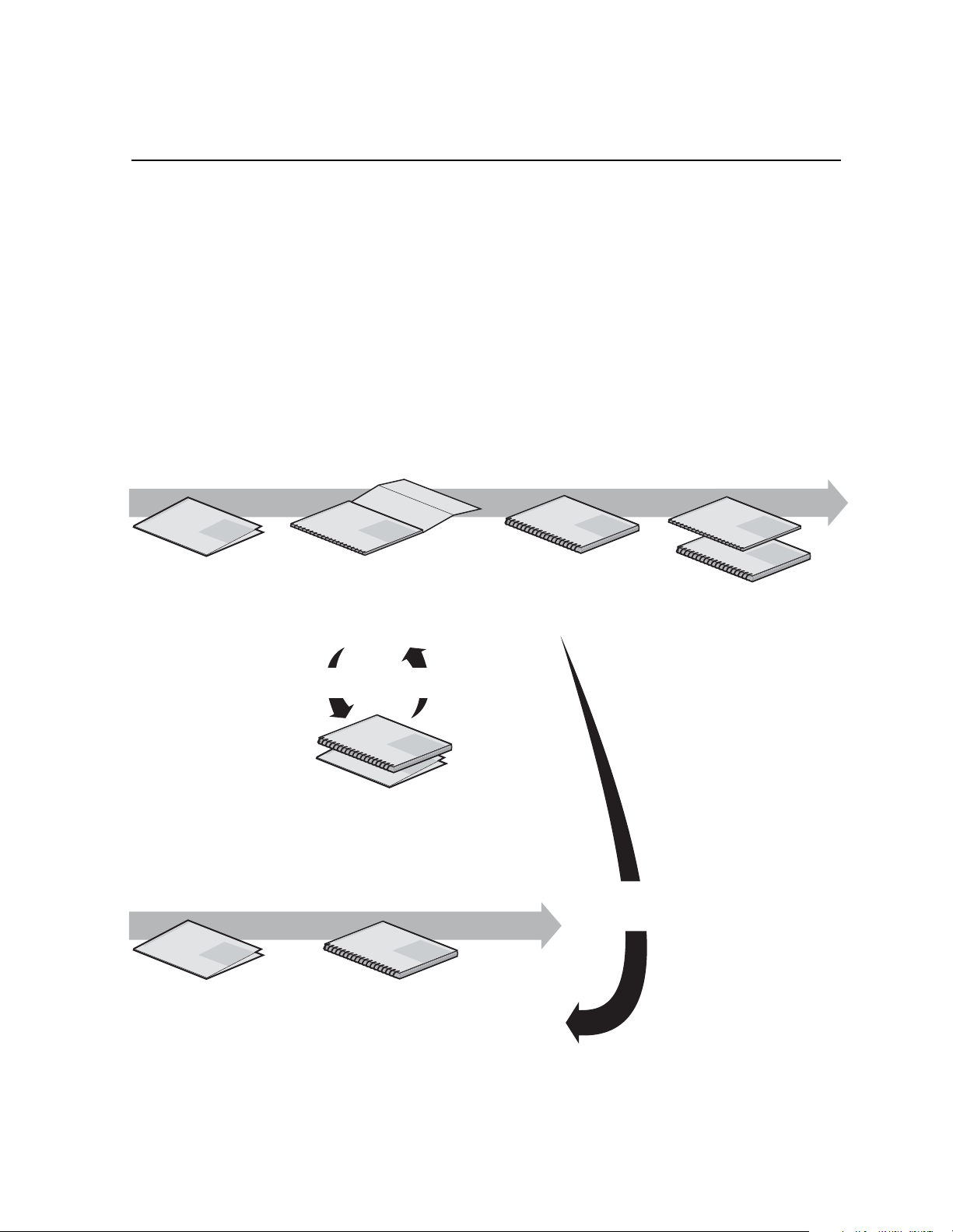

Using the Prof ile XP documentat ion Set

This manual is part of a full set of support documentation for the Profile XP Media

Platform. The following figure illustrates how to use the Profile XP documentation

depending on the task you are performing. For instructions on connecting and

configuring the PFR600 Series Fibre Channel RAID Storage Chassis, consult the

Profile XP Installation Guide (local storage) or Open SAN Instruction Manual

depending on the system you are installing.

Path for the Installer

s

ie

r

e

S

Profile XP

P

X

f

o

y

il

m

Manual

a

F

Grass Valley Group

Release Notes

Contains the latest

information about Profile XP

hardware and software

shipped with your system.

Grass Vall

ey Group

Profile XP

Manual

s

e

i

r

e

S

P

X

f

o

y

l

i

m

a

F

Installation Guide

Contains essential steps for

installing your Profile XP

system with local storage,

using factory default settings.

Use alternate procedures

for shared storage option.

System Guide

Contains the product description

and step-by-step instructions for

modifying system settings.

Grass Valley Group

Profile XP

s

e

i

r

e

S

P

X

f

o

y

l

i

Manual

m

a

F

Grass Valley Group

Grass Valley Group

Profile XP

s

e

i

r

e

S

P

X

f

o

y

l

i

Manual

m

a

F

s

e

i

r

e

S

P

X

f

o

Profile XP

y

l

i

Manual

m

a

F

Other Manuals

These manuals include:

- PFC500 Instruction Manual

- PFR500 Instruction Manual

- PFR600 Instruction Manual

- Profile XP Service Manual

Path for the Operator

up

s

e

i

r

e

S

Profile XP

P

X

f

o

ly

i

m

Manual

a

F

Grass Valley Gro

Release Notes

Contains the latest

information about Profile XP

hardware and software

shipped with your system.

ey Group

Grass Vall

Grass Valley Group

Profile XP

Profile XP

Manual

s

e

i

r

e

S

P

X

f

o

y

l

i

Manual

m

a

F

s

ie

r

e

S

P

X

f

o

ly

i

m

a

F

Open SAN

Instruction Manual and Release Notes

Contains instructions for installing storage

that is shared by multiple Profile XP systems.

s

e

i

r

e

Profile XP

S

P

X

f

o

y

l

i

Manual

m

a

F

Grass Valley Group

User Manuals

Contains complete instructions for using

Profile applications. These manuals include:

- Profile XP User Manual

- Other user manuals you received with

optional Profile applications.

Installers consult

the User Manuals

as needed.

20 February 2004 PFR 600/E Instruction Manual 9

Page 10

Manual descripti on s

• Installation Guide (for each Profile XP Model) This guide provides step-by-step

instructions for installing the Profile XP Media Platform using factory default

settings for all record/play channels. Factory default settings are indicated within

the guide. After installing the Profile XP system using this installation guide, you

can refer to this Profile XP System Guide to customize system settings for your

installation.

Profile XP System Guide This guide provides all the information you need to go

•

beyond factory default settings and customize your system’ s configuration to meet

your site-specific needs. This guide also provides an overview of your Profile XP

system, and provides all the specifications you need to integrate the Profile XP

Media Pla tform into your ope rat ion.

Profile XP User Manual Contains complete instructions for using Profile

•

applications to operate the Profile XP Media Platform.

Profile XP Service Manual Contains information for servicing the Profile XP

•

Media Platform, and includes procedures for the following tasks:

- Problem analysis using symptom, problem, solution tables.

- Runnin g di ag nostics loca l ly and remotel y

- Set up and operation of NetCentral monitoring software.

- Replacing field replaceable units.

Profile XP Release Notes Contains the latest information about the Profile

•

hardware and the software release shipped on your system. This information

includes software specifications and requirements, feature changes from the

previous releases, helpful system administrative information, and any known

problems.

PFR Series Instruction Manual Contains information for servicing the PFR600

•

Series Fibre Channel RAID Storage Chassis including step-by-step procedures for

replacing field replaceable units.

10 PFR600/E Instruction Manual 20 February 2004

Page 11

How this manual is organized

The PFR Series Instruction Manual is organized around t he tasks you’l l be

performing to install and service your Fibre Channel RAID Storage System. You can

see this reflected in the chapter titles chosen for this manual. The following identifies

and describes the chapters included in this manual:

Chapter 1 - About the PFR600 Series

Introduces the PFR600 Series Fibre Channel RAID Storage Chassis (PFR600) and

the RAID Expansion Chassis (PFR600E). You can read this chapter to get familiar

with the RAID Storage Chassis key features and components.

Chapter 2 - PFR 600 Series Installation Information

Describes how to install a RAID Storage Chassis and RAID Expansion Chassis,

including rack mounting. Refer to the Profile XP System Guide for connection and

configuration information.

Chapter 3 - Servicing the PFR600 Series RAID

Describes how to rep lace CRUs , such as dis k module s, and a dd disk m odules an d

redundant CRUs.

Appendix A - Technical Specifications and Operating Limits

This appendix consists of electrical and environmental specifications.

How this manual is organized

Glossary

The Glossary explains terms used throughout this manual.

20 February 2004 PFR 600/E Instruction Manual 11

Page 12

Getting more information

In addition to printed documents, Profile XP product information is available in

on-line manuals. Use these as additional sources for information.

On-line manuals

Electronic versions of the following manuals are located on the system drive of your

Profile XP Media Platform and on the Profile XP software CD-ROM.

• Installation Guide (for your model)

• Profile XP System Guide

• Profile XP User Manual

• Profile XP Service Manual

• PFR Series Instruction Manual

• Profile XP Release Notes

You can view these manuals using Adobe Acrobat Reader which is also pre-installed

on your Profile XP system .

12 PFR600/E Instruction Manual 20 February 2004

Page 13

Grass Valley Product Support

To get technical assistance, check on the status of problems, or report new problems,

contact Grass Valley Product Support via e-mail, the Web, or by phone or fax.

Web Technical Support

To access support information on the Web, visit the product support Web page on the

Grass Valley Web site. You can download software or find solutions to p roblems by

searching our Frequently Asked Questions (FAQ) database.

World Wide Web: http://www.thomsongrassvalley.com/support/

Technical Support E-mail Address: gvgtechsupport@thomson.net.

Phone Support

Use the following information to contact product support by phone during business

hours. Afterhours phone support is available for warranty and contract customers.

United States (800) 547-8949 (Toll Free) France +33 (1) 34 20 77 77

Latin America (800) 547-8949 (Toll Free) Germany +49 6155 870 606

On-line manuals

Eastern Europe +49 6155 870 606 Greece +33 (1) 34 20 77 77

Southern Europe +33 (1) 34 20 77 77 Hong Kong +852 2531 3058

Middle East +33 (1) 34 20 77 77 Italy +39 06 8720351

Australia +61 3 9721 3737 Netherlands +31 35 6238421

Belgium +32 2 3349031 Poland +49 6155 870 606

Brazil +55 11 5509 3440 Russia +49 6155 870 606

Canada (800) 547-8949 (Toll Free) Singapore +656379 1390

China +86 106615 9450 Spain + 34 91 512 03 50

Denmark +45 45968800 Sweden +46 87680705

Dubai + 971 4 299 64 40 Switzerland +41 (1) 487 80 02

Finland +35 9 68284600 UK +44 870 903 2022

Authorized Support Representative

A local authorized support representative may be available in your country. To locate

the support representative for your country, visit the product support Web page on the

Grass Valley Web site.

Profile Users Group

You can connect with other Profile XP Media Platform users to ask questions or share

advice, tips, and hints. Send e-mail to profil e-users@ thoms on.net to join the community

and benef it from the experience of others.

20 February 2004 PFR 600/E Instruction Manual 13

Page 14

14 PFR600/E Instruction Manual 20 February 2004

Page 15

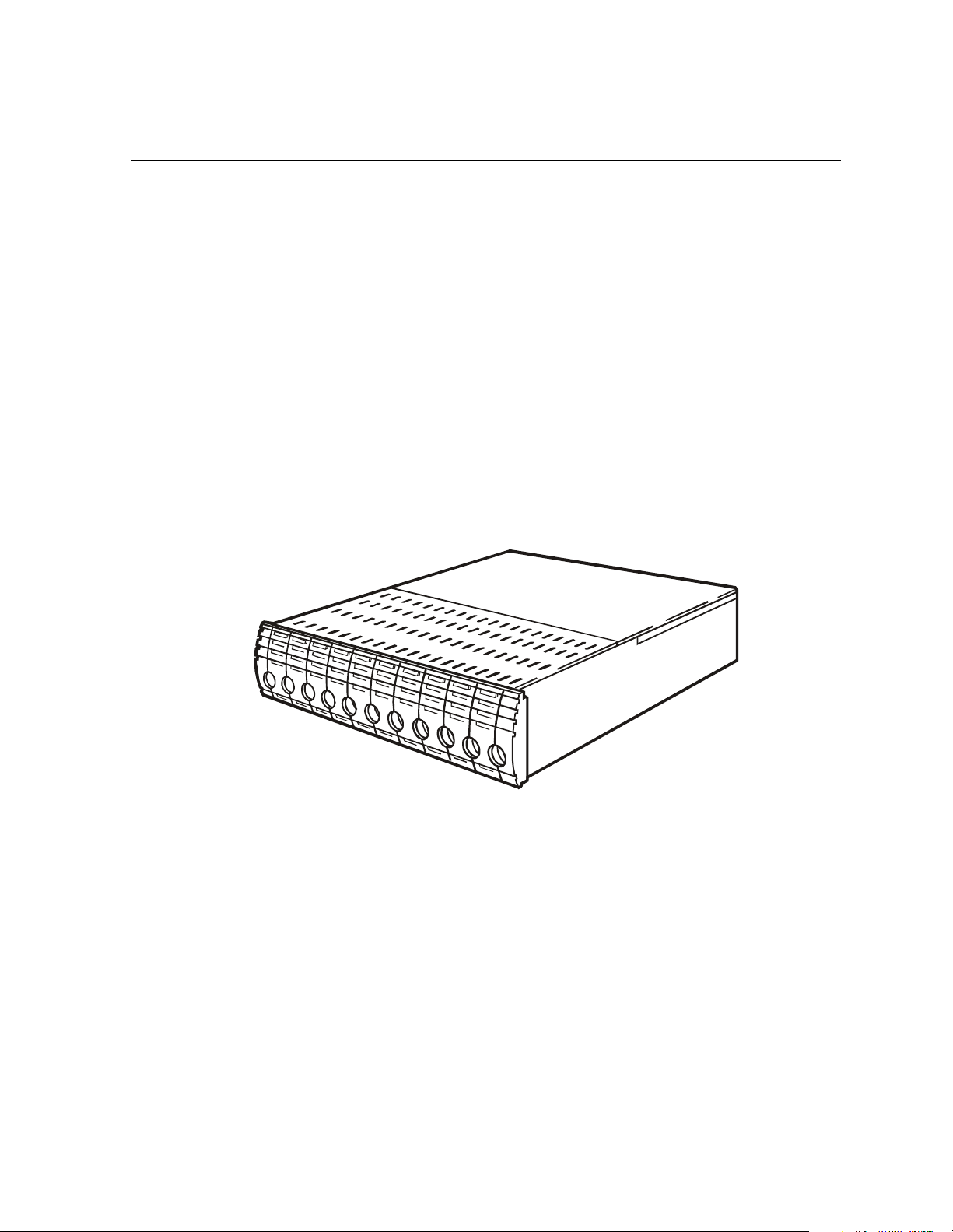

Chapter

1

About the PFR600 Series

This chapter introduces the PFR600 Series Fibre Channel RAID Storage Chassis.

Topics include:

• PFR600 Seri es fea ture s

• PFR600 Se rie s comp on e nts

• Configurations

PFR600 Series features

The PFR600 Series Fibre Channel RAID Storage Chassis is a high performance, high

availability mass storage system. High-bandwidth storage is made possible using

Fibre Channel Arbitrated Loop (FC-AL) technology. The PFR600 Series’s modular,

scalable design provides additional disk storage as your needs increase.

2359

Feature highlights:

• Ten drives in a 3U vertical rack space

• No single point of failure

• Many active components are hot-serviceable

• Scalable expansion using RAID Expansion Chassis

• Optional dual RAID controllers provide Fibre Channel failover

• Copper or Optical Fibre Channel Small Form-Factor Pluggable interface (SFP)

The PFR600 Series utilizes dual FC-AL technology, allowing two loop

configurations within a single chassis. Port-Bypass Circuits have been added to

maintain loop integrity during failures without user intervention. Each loop and

associated Port Bypass Circuits along with all other active components are on

20 February 2004 PFR600/E Instruction Manual 15

Page 16

Chapter 1 About the PFR600 Series

redundant modules. This improves serviceability and increases fault tolerance by

eliminating any single point of failure. With two RAID Controllers, the two loops

within a single standard chassis are configured as a single loop with a backup loop in

standby mode.

PFR600 features

The PFR600 controllers provide enhanced performance of up to 2 Gb/s transfer rates

using SCSI protocol. Interchangeable SFPs (Small Form-factor Pluggable) adapters

allow you to configure your PFR600 for operation in a copper or fiber-optic (optical)

cabling environment. Generally, use optical SFPs and cables, which are rated at

2Gb/s, wherever possible, such as to connect a PFR600 to a Profile XP Media

Platform equipped with a Fibre Channel Disk II card, or to a Fibre Channel switch in

an Open SAN installation. Use copper SFPs and cables, which are rated at 1 Gb/s, to

connect a PFR600 directly to an older Profile XP Media Platform that does not

contain a Fibre Channel Disk II card.

The PFR600 su pp orts up to four PFR6 00E RAID Expansio n Ch as s is. It doe s not

support connection to PFR500E RAID Expansion Chassis. Always use optical SFPs

and cables to connect the PFR600 to PFR600E RAID Expansion Chassis to ensure

optimal performance of your RAID storage system.

Capacity and redundan cy

The PFR600 Series contains five or ten half-height 3.5" Fibre Channel Arbitrated

Loop (FC-AL) disk drives. The chas sis also support s one or two hardware RAID

Controllers in one 3U high rack-mountable chassis. The PFR600 Series currently uses

36GB, 73GB or 146GB drive capacities. With ten drives, one chassis holds up to

360GB, 730GB or 1.46TB depending on the disk drive option.

The RAID Expansion Chassis provides additional storage capacity. It is an identical

chassis with two Loop Bypass Board installed. Up to four RAID Expansion Chassis

can be connected to a single PFR600 Series comprising a single disk-array storage

system with a total of 60 driv es and 2. 16TB, 4.38TB or 8.88TB of stora ge de pending

on the disk drive option. The built-in chassis daisy-chaining capabilities provide for

cost effective storage expansion as requirements grow.

16 PFR600/E Instruction Manual 20 February 2004

Page 17

PFR600 Series components

The PFR600 Series components are:

• The chassis with passive midplan e board

• One or two RAID controllers (not present i n expansion units)

• One or t wo Loop Bypass B oards

• As many as ten Fibre Channel disk drives per chassis

• Two power supplies

• Two fa n modules

The disk drives, power supplies, and fan modules are hot-swappable field replaceable

units (FRUs), which means you can add or replace them while the PFR600 Series is

powered up.

IMPORTANT: You must not hot swap operational devices such as disk drives

without first disabling the target component using the Grass Valley Disk Utility.

An optional second RAID Controller Module in the PFR600 Series, allows for

continued access to the PFR600 Series if the primary RAID Controller fails. Adding

a second RAID Controller to the same chassis is not intended to increase performance,

but rather to add re dundanc y

for detailed connection and configuration instructions.

. Refer to your Profile XP PVS Series Installation Guide

PFR600 Series components

NOTE: Hot swapping disk drives may occasionally cause a slight interruption in

record or play operations.

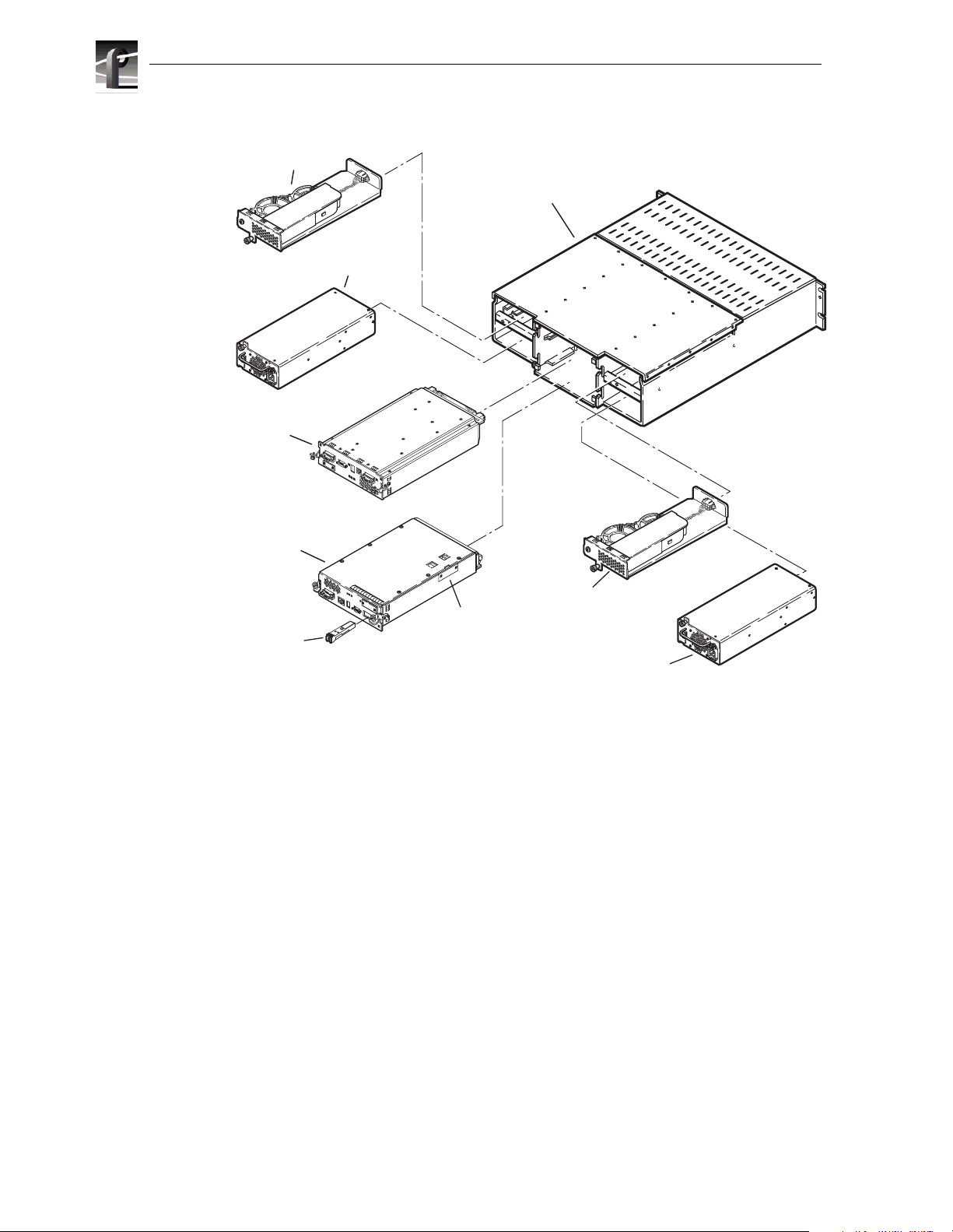

The following figure shows the RAID Storage Chassis components. Details on each

component follow the figure.

20 February 2004 PFR600/E Instruction Manual 17

Page 18

Chapter 1 About the PFR600 Series

Fan Module A

Power Supply A

LBB B

Chassis

LBB A

Fan Module B

Battery Backup

SFP

Unit (BBU)

Power Supply B

NOTE: Every PFR600 Series RAID controller includes a backup battery so that if

electrical power is lost, data stored in cache memory will be saved. Data store cache

is not used in the PFR600 Series, so the Battery Backup module is not used, even

though it ships as part of the LBB module.

18 PFR600/E Instruction Manual 20 February 2004

Page 19

Chassis

Chassis

The chassis is a sheet-metal housing which contains a passive midplane and chassis

slots for the RAID Controllers, or Loop Bypass Boards, disk drives, power supplies,

and the fan modules.

Each chassis includes a chassis add ress switch on t he midpl ane boar d that mus t be set

to a unique address 0 thro ugh 9 during installation. Refer to your PVS Series

Installation Guide or the Open SAN Installation Manual for information on setting the

chassis address switch depending how the PFR600 Series RAID is used. See also,

“Chassis address setting requirement” on page 28.

The following diagram shows how disk modules are identified based on the chassis

address and physical location. The chassis with an address set to 0 contains drives

from 1 to 10; the chassis with an address set to 1 contains drives from 11 to 20; and

so forth.

Midplane

The midplane distributes power and signals to all the chassis components. All FRUs

plug directly into midplane connectors. The midplane includes a chassis address

switch that must be set during installation. Refer to “Chassis address setting

requirement” on page 28 for information on setting the chassis address.

12345

Disk Modules

678910

20 February 2004 PFR600/E Instruction Manual 19

Page 20

Chapter 1 About the PFR600 Series

Disk modules

Each disk module consists of a Fibre Channel disk drive in a carrier assembly. If a

disk drive fails, and needs replacing, you can do so while the RAID Storage Chassis

is powered up. Replacement disk drives take 3-4 minutes to begin rebuild after being

installed. (See “Removing and installing disk modules” on page 44.)

The disk drives are 3.5-inch FC-AL drives that conform to the Fibre Channel

Arbitrated Loop (FC-AL) standards and support dual-port FC-AL interconnects

through the two RAID controllers and their cabling.

CAUTION: Once the PFR600 Series RAID is installed and configured, the disk

!

modules become slot dependent. Moving disk modules between physical slots will

result in loss of data and the need to reconfigure the system.

2299

1

2

20 PFR600/E Instruction Manual 20 February 2004

Page 21

PFR600/E circuit board modules

There are two circuit board modules used: the Loop Bypass Board module (LBB) and

the RAID Controller module. The LBB module contains one Loop Bypass Board

which provides an internal Fibre Channel loop for the disk modules installed in the

chassis. The RAID Controller module also contains a Loop Bypass Board plus a

RAID Controller board used to manage the disk drives and provide a Fibre Channel

interface to the Profile system.

PFR600 RAID Storage Chassis circuit board modules

The PFR600 includes one or two RAID Controller modules. Two RAID Controller

modules are installed when the redundant Fibre Channel option is installed. This

provides redundant Fiber Channel interface ports t o t he Profile sy st em or Fibre

Channel switch fabric.

The following figure shows a PFR600 RAID Storage Chassis with the two RAID

Controller Modules installed. RAID controllers can be installed in either position, top

or bottom. The one in the bottom position is identified as Controller A, the one in the

top position is identified as Controller B.

7 Segment LED

(displays chassis address)

Host Fibre

Channel Port

Serial

Port

Ethernet

Port

PFR600 /E ci rcuit board modules

Fibre

Channel

Loop Port

PFR600

Fibre

Channel

Loop Port

Ethernet

Port

7 Segment LED

(displays chassis address)

Serial

Port

RAID Controller B

RAID Controller A

Host Fibre

Channel Port

20 February 2004 PFR600/E Instruction Manual 21

Page 22

Chapter 1 About the PFR600 Series

Each RAID Controller module includes a Loop Bypass Board (LBB). These boards

provides internal Fibre Channel loops for the disk modules. In the event of an LBB

module failure, the faulty loop is bypassed and all disk drives failover to the

remaining LBB module.

The LBB in the PFR600 RAID Controller module has two Fibre Channel ports: the

Fibre Channel Host Port and the Fibre Channel Loop Port. Copper or optical SFP

(Small Form-factor Pluggable) modules are used in the Host Fibre Channel ports to

connect Fibre Channel cabling to a Profile XP Media Platform or to a Fibre Channel

switch in an Open SAN fabric, respectively. Optical SFP modules are used in the

Fibre Channel Loop ports to connect to a PFR600E. This extends the Fibre Channel

loop of the corresponding PFR600 chassis. There is a port status LED for each Fibre

Channel port. Refer to “Interpreting rear panel status LEDs” on page 42.

Tab

Optical SFP adapter

Remove

white cap

Remove

white cap

22 PFR600/E Instruction Manual 20 February 2004

Page 23

PFR600 /E ci rcuit board modules

When the redundant Fiber Channel option is not installed in the PFR600 RAID

Storage Chassis, only one RAID Controller is installed along with one LBB module

as shown in the following figure. The LBB module and the LBB contained in the

RAID Controller module provide the two LBBs required in the PFR600 Series Fibre

Channel RAID Storage Chassis. The LBB and RAID Controller modules are clearly

labeled on the rear panel of each canister.

7 Segment LED

(displays chassis address)

Serial

Port

Ethernet

Port

Fibre

Channel

Loop Port

Loop Bypass Board B

RAID Controller A

PFR600

Fibre

Channel

Loop Port

Ethernet

Port

7 Segment LED

(displays chassis address)

Serial

Port

Host Fibre

Channel Port

An RJ-type connector is provided for Ethernet network connection, which is used for

SNMP monitoring and firmware downloads. A DB-9 serial port is provided for serial

communications with a console program to configure the RAID Controller’s IP

address, subnet mask, SNMP domain, and other network settings. These settings are

required to use the NetCentral monitoring software. Refer to your PVS Ser i es

Installation Guide or the Open SAN Instruction Manual for information how these

connectors are used.

20 February 2004 PFR600/E Instruction Manual 23

Page 24

Chapter 1 About the PFR600 Series

PFR600E RAID Expansion Chassis circuit board modules

The PFR600E RAID Expansion Chassis always has two LBB modules installed as

shown in the following figure. The LBBs are identical, and can be used in either the

top or the bottom position.

7 Segment LED

Left

Fibre Channel

Loop Port

(displays chassis address)

Serial

Port

Ethernet

Port

Right

Fibre Channel

Loop Port

Loop Bypass Board B

Loop Bypass Board A

PFR600E

Left

Fibre Channel

Loop Port

Ethernet

Port

7 Segment LED

(displays chassis address)

Serial

Port

Right

Fibre Channel

Loop Port

The LBB in the PFR600E has two Fibre Channel ports: the Left and Right Fibre

Channel Loop Ports. 2Gb/s optical SFPs are used in these ports to connect Fibre

Channel cabling to a PFR600 or PFR600E. This extends the Fibre Channel loop of

the corresponding PFR600 chassis. There is a port status LED for each Fibre Channel

port. Refer to “Interpreting rear panel status LEDs” on page 42.

A DB-9 serial port is provided for serial communications with the PFR600 through

the supplied cable. Refer to your PV S Series Installation Guide or the Open SAN

Instructi on Manual for connection info rm at ion .

NOTE: The PFR600E Expansion chassis and P FR600 Controller chassis must be

powered on and off in the proper sequence. Refer to proper power procedures in

Chapter 2, “PFR600 Series Installation Information”.

24 PFR600/E Instruction Manual 20 February 2004

Page 25

Power supplies

There are two auto-ranging power supplies, each with its own power cord and standby

switch. Each supply supports a fully configured PFR600 Series RAID and shares load

currents with the other supply, if it is present. The power supplies are designed so as

to protect the disk drives if you install them while the PFR600 Series RAID is

powered up. A disk with power-related faults will not adversely affect the operation

of any other disk.

Each power supply has status LEDs visible from the rear panel. The status LEDs are

described in the “Interpreting rear panel status LEDs” on page 42.

A retaining screw secures the power supply in place. You can add or remove one

power supply in the RAID Storage Chassis while the RAID Storage Chassis is

powered up.

Fan modules

There are two fan modules used to cool the components installed in the PFR600

Series RAID chassis. The fan modules connect to the midplane board for power.

One status LED on the rear panel of the fan module indicates status. The status LED

is described in the “Interpreting rear panel status LEDs” on page 42.

Power supplies

A retaining screw on the fan module holds the module in place.

NOTE: If power is connected, fans run at low speed even with the power supply

switches in standby position.

20 February 2004 PFR600/E Instruction Manual 25

Page 26

Chapter 1 About the PFR600 Series

Configurations

The RAID Storage Chassis minimum and maximum configurations are as follows.

PFR600

Configuration

minimum 1 1 2 5

maximum 2 0 2 10

RAID Controller

Module

(Includes one LBB)

Loop Bypass

Board Module

Power Supplies/Fan

modules

Disk Modules

The maximum configuration provides the most redundancy, and therefore the highest

degree of system availability.

The PFR600E RAID Expansion Chassis minimum and maximum configurations are

as follows.

PFR600/E

Configuration

minimum 2 2 5

maximum 2 2 10

Loop Bypass

Board Module

Power Supplies/Fan

modules

Disk Modules

IMPORTANT : Gr ass Valley does not support mi xing disk dri ves of differing

capacities in any RAID chassis. All disk drives in any RAID chassis must be of the

same capacity. For example, if a PFR600 and a PFR600E are connected, all the

disk drives in both the PFR600 and the PFR600E must be of the same capacity.

26 PFR600/E Instruction Manual 20 February 2004

Page 27

Chapter

2

PFR600 Series Installation Information

This chapter describes information you’ll need to install the PFR600 Series Fibre

Channel RAID Storage Chassis (PFR600/E). Major topics are:

• Installation requirements

• Installing a PFR600/E in an equipment rack

• PFR 6 00/E power-up and initialization

• PFR600/E power-down

Installation requirements

This section describes the following requirements:

• “Site requirements” on page 27

• “Chassis address setting requirement” on page 28

• “Cabling requirements” on page 29

• “Binding disk modules into groups” on page 30

Site requirements

For proper PFR600/E operation, the installation site must conform to certain

environmental specifications. These are detailed below and in Appendix A, “Technical

Specifications and Operating Limits”.

Power

Refer to “AC power requirements” on page 53 for AC power requirements. The values

indicate either the values for the power cord of a PFR600/E with a single power supply,

or the total values shared by the line cords of two power supplies in the same PFR600/

E, with the division between the power cords and supplies at the current sharing ratio. If

one of the two power supplies fails, the remaining supply and cord must support the full

load. You must use a rack mount cabinet with ac power distribution, and have main

branch ac distribution that can handle these values for the number of PFR600s and

PFR600Es that you will interconnect.

Cooling

Make sure your site has air conditioning of the correct size and placement to maintain

the specified ambient temperature range. The air conditioning must be able to handle the

requirements of the PFR600s and any connected PFR600Es as indicated under

“Environmental limits” on page 54.

20 February 2004 PFR600/E Instruction Manual 27

Page 28

Chapter 2 PFR600 Seri es Inst al la tion Information

Chassis address setting requi re m ent

Each PFR600/E storage chassis has a chassis address switch that must be set to a unique

chassis address. Valid chassis addresses are 0-9 with 0 being reserved for the PFR600

RAID Chassis. All chassis are shipped with the chassis address set to 0.

The chassis address switch is located inside the chassis on the midplane board. The

following figures show how to gain access to the switch by removing the board canisters.

CAUTION: Refer to the PVS Series Installation Guide

you received with your Profile XP

storage syst em or the Open SA N Instructi on Manual for step-by-step instructions for

setting the chassis address.

Enclosure

LBB goes

in the top slot (B)

LBB goes

in the bottom slot (A)

2930

28 PFR600/E Instruction Manual 20 February 2004

Page 29

Cabling requirements

The midplane is at the back of the slot that held the LBB can isters. On the midplane is a

small, white rotary switch.

.

After the chassis addresses have been set and the chassis powered-up, the chassis address

is displayed on the 7-segment display LED as shown.

7-Segment Display LED

Cabling re quirements

You should use the Fibre Channel cables shipped with your PFR600/E when making

connections.

Optical cables must meet the appropriate 2-Gbit FC-AL loop standards. You must use

this type of cable to connect PFR600E expansion chassis to the PFR600 controller.

Any copper cables you use must meet the appropriate standards for 1-Gbit FC-AL loops.

Such cables are fully shielded, twin-axial, full-duplex cables with DB-9 connectors.

Cables greater than 10 meters must be equalized; cables equal to or less than 10 meters

do not need to be equalized. Do not use copper cables longer than 15 meters for any Fibre

Channel connection in a Profile system.

2796

2915a

PFR600 and PFR600E inter connec tio ns shoul d mai ntain LBB co nsist ency. T hat is , one

FC loop sh ould conn ect the PFR600’s RAID Contro ller A and each P FR600E’s LBB A.

The other FC loop should connect the PFR600E’s RAID Controller B and each

PFR600E’s LBB B.

Do not leave an unused (that is, dangling) cable connected to a Fibre Channel port

because it may cause excess noise on the loop.

20 February 2004 PFR600/E Instruction Manual 29

Page 30

Chapter 2 PFR600 Seri es Inst al la tion Information

Binding disk modules into groups

After cabl ing a PFR600 and any PFR600Es, you must bind di sk modules int o LUNs

using a GVG Disk Utility provided by Grass Valley. Refer to the appropriate manual for

information on using the GVG Disk Utility to bind drives.

Type of PFR500/E installation Manual to use for binding procedures

Part of an Open SAN Open SAN Instruction Manual

Connected directly to a Profile XP Media

Platform as local storage

PVS Installation Guide (for your Pr ofile XP model) or

the Profile XP System Guide

30 PFR600/E Instruction Manual 20 February 2004

Page 31

Installing a PFR600/E in an equipment rack

Installing a PFR600/E in an equipment rack

Use the information in this section to unpack the PFR600/E chassis and mount in an

equipment rack.

Procedures include:

• Unpacking the chassis

• Installing the rack mounts

• Installing the chassis with drive the support bracket

• Installing chassis without the drive support bracket

Unpacking the chassis

Unpack the PFR600/E chassis, cables, and installation kit.

WARNING: A PFR600/E chassis is heavy. Two people should lift and

!

move it.

Box containing cables

and manuals

Packaging

Chassis with

shipping bar

8136-4

CAUTION: Save the chassis packaging. Use only PFR600 approved packaging to ship.

20 February 2004 PFR600/E Instruction Manual 31

Page 32

Chapter 2 PFR600 Seri es Inst al la tion Information

You can either remove the drive support bracket, as shown in the following figure so that

you can hot-swap drives, or you can leave the bracket in place for greater drive stability.

In either case, keep the bracket and retaining screws in case you have to ship the chassis

in the future.

2781

Installing the rack mounts

To install the PFR600/E rack mounts:

1. Loosely fasten the left stationary chassis mount to th e left chassis slide rail with the

locking nuts.

2. Adjust the length of the outside edges of the chassis mount assembly to fit between

the front and back channel mounts. Secure these two pieces together. Pull chassis

mount assembly away from channel mounts.

3. Place cage nuts around the top and bottom two holes on the front of the chassis

mount assembly, such that the nuts are inside the front and the back of the chassis

mount assembly.

4. Place one cage nut on the bottom hole, and one cage nut on the second hole from

the top on the back, such that the nuts are inside the front and the back of the chassis

mount assembly.

5. Slide the chassis mount assembly between the left front and back channel mounts.

Secure the screws through the channel mounts into the cage nuts.

32 PFR600/E Instruction Manual 20 February 2004

Page 33

Cage Nuts

(2 per side)

Back Channel

Mount

Locking Nits

(3 per side)

Left Chassis

Slide Rail

Installing the rack mounts

Left Stationary

Chassis Mount

Front

Channel

Mount

Cage Nuts

(4 per side)

0626-15

6. Repeat steps 1 through 5 for the right side.

20 February 2004 PFR600/E Instruction Manual 33

Page 34

Chapter 2 PFR600 Seri es Inst al la tion Information

Inserting the PFR600/E chassis in the rack

Every PFR600/E chassis ships with drive support brackets. The support bracket provides

additional disk module support. If the ch assis will operate in a high-vibration area, leave

the brackets on. This adds time when hot-swapping drives, but provides additional

stability.

Installing the chassis with drive the support bracket

To install a chassis with the drive support bracket:

1. Rest the chassis on the support angles shown. Slide the chassis back and into place.

2. Add the drive support bracket and secure the chassis to the rack with the mounting

screws that shipped with the chassis.

Drive Support

Brackets

3006

Mounting Screws

Drive Support Bracket

3. Repeat steps 1-2 to insert each PFR600/E chassis in the rack.

The drive support brackets preclude edge covers.

Installing chassis without the drive support bracket

To install a chassis without the drive support bracket:

1. Rest the chassis on the rack mounts as shown. Slide the chassis back and into place.

2. Secure the chassis to the rack with the mounting screws included in the installation

kit.

34 PFR600/E Instruction Manual 20 February 2004

Page 35

Inserting the PFR600/E chassis in the rack

3. Apply the edge covers that are packaged with the PFR600/E.

4. Repeat steps 1-3 to install each PFR600/E chassis in the rack.

20 February 2004 PFR600/E Instruction Manual 35

Page 36

Chapter 2 PFR600 Seri es Inst al la tion Information

PFR6 00/E power-up and initialization

This section gives information about connecting power and powering-on the

PFR600/E system.

Connecting electrical cables

For each chassis, there are two electrical cables which should be connected to separate

outside power sources, as shown.

On/Off standby switches

To power

source

WARNING: Make sure the power cords meet local safety and elec t rical

!

standards.

CAUTION: The PFR600/E system must be electrically grounded.

!

Operating t he syste m without proper gr oundin g can dama ge disk d rives. If

To power

source

2924a

the outlet you use is not grounded, make sure that a licensed electrician

replaces it and installs a grounding conductor.

To prevent the plug from inadvertently being unplugged, secure the electrical cable into

the outlet by doing the following:

1. Insert the pl u g.

2. Press the small tabs together.

3. Slide the lock past the plug until the tabs snap into the plug housing.

Snap to here

Press small tabs

together

2798

36 PFR600/E Instruction Manual 20 February 2004

Page 37

Powering-up the PFR600/E system

1. Power-up the PFR600E Expansion chassis prior to, or at the same time as the

PFR60 0 Co nt roller chas s i s .

NOTE: You must al ways po wer-up the PFR600E Expansion ch assis pri or to, or at

the same time as the PFR600 RAID Controller chassis. Failure to do so may

prevent some LUNs in the expansion chassis from being recognized.

2. Wait for RAID storage initialization, as follows:

- Rear panel 7-segment LED displays the chassis address — approximately two

minutes.

7-Segment Display LED

Powering-up the PFR600/E syst em

2915a

- Wait until all disk access LEDs are steady green— approximately 3 minutes.

- Refer to sections in Chapter 3, “Servicing the PFR600 Series RAID” for

information on interpreting status LED behavior.

NOTE: Refer to the Profile XP System Guide or Open SAN Instruction Manual for

complete system power-up procedures.

20 February 2004 PFR600/E Instruction Manual 37

Page 38

Chapter 2 PFR600 Seri es Inst al la tion Information

PFR6 00/E power-down

IMPORTANT: If your PFR600/E system is part of an Open SAN, refer to the Open

SAN Instruction Manual for instructions on shutting down the Open SAN before

powering down a PFR600/E.

To power-down the PFR600/E correctly:

1. Stop all read/write activity to the PFR600/E storage system.

2. Power-down the RAID storage system by powering-down the PFR600 Controller

chassis prior to, or at the same time as with the PFR600E Expansion chassis.

>>> CAUTION: You must always power down the PFR600 RAID Controller chassis

prior to, or at the same time as the PFR600E Expansion Chassis.

To turn on power, refer to “PFR600/E power-up and initialization” on page 36.

Battery Backup recharge

Every PFR600/E RAID controller includes a backup battery so that if electrical power

is lost, data stored in cache memory will be saved.

Data store cache is not used in Profile storage systems, so the Battery Backup module is

not used, even though it ships as part of the LBB module.

38 PFR600/E Instruction Manual 20 February 2004

Page 39

Chapter

3

Servicing the PFR600 Series RAID

This chapter describes how to monitor PFR600 Series RAID status and replace Field

Replaceable Units (FRU).

Topics include:

• “Maintenance procedures using GVG Disk Utility” on page 40

• “Monitoring PFR600 Series RAID status using NetCentral” on page 40

• “Interpr eting disk module LEDs” on page 41

• “Interpreting rear panel status LEDs” on page 42

• “LBB 7-segme nt display codes” on page 43

• “Removing and installing disk modules” on page 44

• “Replacing the Loop Bypass Board (LBB) or RAID Contro l ler” on page 47

• “Replacing data ports” on page 49

• “Replacing a power supply” on page 50

• “Replacing the fan module” on page 51

20 February 2004 PFR600/E Instruction Manual 39

Page 40

Chapter 3 Servicing the PFR600 Series RAID

Maintenance procedures using GVG Disk Utility

Several maintenance procedures can be performed using the GVG Disk Utility

installed on the Profile XP Platform for standalone storage, or on the FSM in Open

SAN systems.

To perform the following tasks, refer to Chapter 3 of the Profile XP System Guide:

• Verifying and loading RAID controller microcode

• Downloading disk drive fi rmware

• Forcing a replacement drive to rebuild

• Disabling operational components for removal

Monitoring PFR600 Series RAID status using

NetCentral

You can moni t or PFR600 Series RAID Stora ge systems usin g Grass Valley’s

NetCentral monitoring software. Enabled by SNMP, NetCentral can continuously

monitor the storage system and send notifications if there is a problem. The SNMP

agent software required for NetCentral monitoring runs on the PFR600 Series RAID

Controller module. As a result, the PFR600 Series RAID appears in NetCentral as a

standalone device rather than a subsystem of the Profile XP Media Platform.

Communication with NetCentral takes place over the RAID Controller Ethernet port.

To monit or the PFR600 Series RAID , you must co nnect network cabling, power on

the system, then configure network and SNMP settings as described in the PVS Series

Installation Guide.

Refer to the Profile XP Service Manual for information on monitoring the PFR600

Series RAID with NetCentral.

40 PFR600/E Instruction Manual 20 February 2004

Page 41

Interpreting disk module LEDs

The disk module LEDs and the 7-segment display on the back of the RAID

Controllers are used to indicate system status. The following table describes how to

interpret the dis k modu le LED behav ior and rear panel 7 -segme nt disp lay f or var ious

conditions.

a

LEDs

7-Segment

Display

Interpreting disk module LEDs

Meaning

All drives are green,

non-blinking

All drives are green, rapid

blinking

One drive is blue chassis address Drive has been identified using the GVG Disk

One drive is alternating blue/

green, rapid blinking

One drive is green/red (orange) Drive itself has determined it is bad, or the

One drive is blue/red (purple) Drive itself has determined it is bad and the drive

All drives are blue/red (purple),

slow blink

One drive is white (red, green,

and blue LEDs active)

chassis address Drives are behaving normally— no disk access

in progress

chassis address Disk I/O in progress

Utility.

F Drive is failed.

chassis address Disk I/O in progress and the drive has been

identified using the GVG Disk Utility.

midplane has failed.

has been identified using the GVG Disk Utility.

A failure affecting drives or midplane has

occurred. Consult NetCentral for failure

information.

The drive is off the Fibre Channel loop, possibly

due to a drive or midplane failure, and the drive

has been identified using the GVG Disk Utility,

or the RAID array has gone critical.

b

a.

If the disk access LED is unlit at any point, it indicates one of the colored LEDs has failed. The access

LED should display some color at all times.

b.

A RAID LUN may fail without providing blue LED indication, however, NetCentral alerts can provide

this information.

20 February 2004 PFR 600/E Instruction Manual 41

Page 42

Chapter 3 Servicing the PFR600 Series RAID

Interpreting rear panel status LEDs

Refer to the following illustration to interpret rear panel LEDs.

FC loop status

lit - loop is down

off - loop is valid

Power supply - on

Fan light

red - fault

Reset button for LBB

(Use only when

advised by

Ciprico personnel)

FC loop status

lit - loop is down

off - loop is valid

Fan light

red - fault

FAULT

FAULT

OUTPUT

GOOD

Power supply

standby

Power supply status:

amber - fault

green - good

FC loop status:

lit - loop is down

off - loop is valid

Ethernet transmit

Ethernet receive

HOST B

LOOP

PORT

LOOP

SERIAL

LOOP

HOST A

TX

ETHERNET

LOOP

PORT

ID

RX

RX

ID

SERIAL

LOOP

ETHERNET

TX

HOST A

LOOP

LOOP

PORT

LOOP

PORT

HOST B

FAULT

FAULT

OUTPUT

GOOD

Power supply status:

amber - fault

green - good

FC loop status

lit - loop is down

off - loop is valid

Reset button for LBB

(Use only when advised

by Ciprico personnel)

Flashing decimal point

heartbeat for ESI processor

Drive enclosure number

and event code display

2948d

42 PFR600/E Instruction Manual 20 February 2004

Page 43

LBB 7-segment display codes

The following table shows event codes for the rear panel 7-segment display on each

LBB.

Code Type Blink Rate Meaning

LBB 7-segment display co des

0 thru 9 Informational Steady or

alternating with

other code.

A Warning Alternating with

chassis address

C Power-up Steady during

power-up

C Critical Steady >30

seconds from

power-up

F Critical Alternating with

chassis address

. Informational Blinking

throughout

operation

. Critical Blinking halted The LBB has critically failed (steady for greater

H Informational Alternating with

the chassis

address

Chassi s ad dress. R efer to “Chassis address setting

requirement” on page 28.

Fibre Channel speed has changed. Power cycle of

all connected RAID chassis is required.

Initially displayed during cold boot, will switch to

chassis address within 30 seconds

If C remains longer than 30 seconds after power up,

the LBB has failed. Board may not be fully seated

or may have suffered a critical error during a

firmware upgrade.

An error or event has occurred that requires human

intervention. Check disk LEDs and rear panel

LEDs. Also, check system status using NetCentral.

Indicates the LBB is functioning properly.

than 30 seconds)

A firmware update is in progress

H Warning Steady for short

duration with no

alternating

H Identify Alternating with

the chassis

address

Ethernet link has been detected

LBB has been sent an identify command by GVG

Disk Utility

20 February 2004 PFR 600/E Instruction Manual 43

Page 44

Chapter 3 Servicing the PFR600 Series RAID

Removing and installing disk modules

Use the following instructions to replace a faulty disk module. It should be replaced

while the array is running (hot-swapped).

NOTE: Grass Valley does not support mixing disk drives of differing capacities

within a RAID chassis connected to a Profile XP Media Platform or Open SAN. All

disk drives in any RAID chassis must be of the same capacity. For example, if a

PFR600 and a PFR600E are used, all the disk drives in both the PFR600 and the

PFR600E mus t be of the same capacity.

Moving disk modules

CAUTION: You can destroy the media file system beyond recovery if you move a

!

disk module to a different slot. The service person can move a disk module when you

don’t care about losing the media in the media file system and under the following

cautions:

• The disk module must be unbound.

• Moving a drive module that is part of a LUN to another slo t makes all information

on the LUN inaccessible.

• You must remove and install the disk m odule while the s torage system is p owered

up.

A disk module must be inserted all the way or removed entirely. Do not leave a disk

module partially removed except for periods when you are allowing it to spin down.

When replacing multiple disks, observe the following:

• After removing a disk module, wait for the activity LEDs on the other disk modules

to resume a steady flicker before removing the next module.

• After inserting a disk module, wait for the activity LEDs on the other drives to

resume a steady flicker before inserting the next module.

CAUTION: Handle a disk module gently and use an ESD wristband. Do not remove

!

a faulty disk module until you have a replacement module (with the same part

number) or a filler module available.

44 PFR600/E Instruction Manual 20 February 2004

Page 45

Removing a disk module

NOTE: If a disk module has been bound into a LUN, do not move it to another slot

unless you do not care about the data on the LUN. Each module has LUN

identifying information written when it is bound. Moving it to another slot can

make information on the original LUN inaccessible.

Generally, you should not remove a disk module unless it is faulty. Refer to

“Interpreting disk module LEDs” on page 41 and “Monitoring PFR600 Series RAID

status using NetCentra l” on page 40.

NOTE: If you wish to remove an operational disk module, use the Grass Valley

Disk Utility to disable the disk before removing it.

To remove the dis k mo du l e:

1. Confirm the drive location by ensuring that the disk module LED is blue or red.

NetCentral messages may report disk faults by disk module number. To locate a

disk modul e by nu mber, lo ok at th e 7-seg ment LED d isplay o n the r ear pan el of th e

RAID Controller or Loop Bypass Boards. It displays a single digit (0 through 9).

This indicates the chassis address of the chassis. The chassis displaying chassis

address 0 contains drives from 1 to 10; the chassis displaying chassis address 1

contains drives from 11 to 20; and so forth.

Removing a disk m odule

NOTE: Use the Identify Disks command in the GVG Disk Utility to flash the LED

on the drive to be removed.

2. Remove the drive support bracket, if installed (refer to “Installing the chassis with

drive the support bracke t” on page 34.)

3. Grasp the relea se lever wit h your thumb a nd index finge r and pull out ward to open the

door.

2

2905

4. Carefully slide the disk module out until it is free and out of its bay.

20 February 2004 PFR 600/E Instruction Manual 45

1

Page 46

Chapter 3 Servicing the PFR600 Series RAID

Installing disk module

To install a disk module:

1. Wait at least three minutes after removing the previous disk module.

2. I nsert the replacement disk module into the empty bay.

1

2299

3. Press the release lever down and into place, as shown.

4. T he disk spins up automatically.

5. Disk module rebuild begins in approximately 3-4 minutes. If not, refer to Chapter 3

of the Profile XP System Guide for instructio ns on fo rci ng disk mo du le reb uil d us i ng

GVG Disk Utility. Also refer to “Inter preti ng rear pa nel stat us LEDs” on page 42 fo r

disk module LED status during rebuild. Afterward, check disk module status using

NetCentral or GVG Disk Utility.

6. Replace the drive support bracket, if used (refer to “Installing the chassis with drive

the support bracket” on page 34.)

2

46 PFR600/E Instruction Manual 20 February 2004

Page 47

Replacing the Loo p Bypass Board (LBB) or RAID Controller

Replacing the Loop Bypass Board (LBB) or

RAID Controller

Use the following instructions to replace an LBB or RAID Controller module. It

should be replaced while the chassis is powered up.

NOTE: A PFR600 Series RAID must have at le ast one RAID Controller installed

while it is powered up. Do not remove both RAID Controllers while the PFR600

Series RAID is powered up.

Removing the LBB or RAID Controller

To remove the LBB or RAID Controller:

1. Identify the module to be replaced using NetCentral or rear panel LED indicators. If

you are removing an operational LBB or RAID controller, use the GVG Disk Utility

to disable the desired module.

2. Remove the cables connected to the module. Note where the cables connect to the

module.

3. Loosen captive screws as shown in the figure below.

1

2

3

4. Unseat the mod ule by pushing down on the two ejector le vers.

5. Pull the module out of the chassis.

2920

20 February 2004 PFR 600/E Instruction Manual 47

Page 48

Chapter 3 Servicing the PFR600 Series RAID

Installing the LBB or RAID Controller

To install the LBB or RAID Controller:

1. Insert the replacement module into the empty bay. Make sure the module is seated.

1

3

2

2921

2. Pu sh up the two ejector levers to seat the module.

3. Tighten the captive screws.

4. Reconnect cabling.

5. Verify module initialization using rear panel status LEDs. Refer to “Interpreting rear

panel status LEDs” on page 42.

6. Ensure that the replacement drive firmware matches that of the other controller. Refer

to Chapter 3, “Working with Storage Using GVG Disk Utility”, in the Profile XP

System Guide for information on checking and loading controller firmware.

7. If installing a RAID controller, configure the network and SNMP settings as

described in th e P VS Installation Guide.

8. Check module status using NetCentral or GVG Disk Utility. If required, update the

firmware to match the version on the other RAID controller using GVG Disk Utility.

48 PFR600/E Instruction Manual 20 February 2004

Page 49

Replacing data ports

The PFR600/E uses either 1Gb/s copper SFPs or 2GB/s optical SFPs as the Host Fibre

Channel data ports, and 2Gb/s SFPs as the Fibre Channel Loop data ports.

To replace the data ports:

1. Remove cabling and remove t he data port as shown.

2. Insert the replacement data port into the module as shown, then reconnect cabling.

3. Verify the Fibre Channel connection using the port Loop LED. Refer to “Interpreting

rear panel status LEDs” on page 42.

Tab

Replacing data ports

Optical SFP adapter

Remove

white cap

Remove

white cap

20 February 2004 PFR 600/E Instruction Manual 49

Page 50

Chapter 3 Servicing the PFR600 Series RAID

Replacing a power supply

CAUTION: Turn off the power supply before unplugging the power cord from the

!

supply or removing the supply f rom the chassis.

To replace the power supply:

1. Turn the standby switch to Standby (0), as shown.

On/Standby

switch

2750

2. Remove the electrical cable from the power supply.

3. Loosen the captive screw on the power supply.

4. Pull the module out of the enclosure, as shown.

Captive

screw

2918a

5. Insert the replacement power supply into the empty bay.

6. Tighten t he ca pti v e screw on the po w er supply.

7. Plu g the electrical cable into the power supply.

50 PFR600/E Instruction Manual 20 February 2004

Page 51

Replacing the fan module

8. Turn on the power supply. Turn the standby switch to ON (1).

9. Monitor the status of the power supply using rear panel status LEDs and NetCentral.

Replacing the fan module

CAUTION: Do not remove a faulty fan module until you have a replacement fan module

available. You can remove the drive fan module while the PFR600/E is powered up.

To replace a fan module:

1. Loosen the captive screw on the fan module.

2. Pull the module out of the enclosure.

3. Insert the replacement fan module into the empty bay.

4. Tighten the captive screw on the module.

Captive

screw

2919a

5. As soon as the module is reinstalled, the fans start spinning and the system fault

indicators are cleared if no other FRUs are faulty.

20 February 2004 PFR 600/E Instruction Manual 51

Page 52

Chapter 3 Servicing the PFR600 Series RAID

52 PFR600/E Instruction Manual 20 February 2004

Page 53

Appendix

A

Technical Specifications and Operating Limits

AC power requirements

Power Input

100-120 VAC, 50/60Hz, 6amps

200-240 VAC, 50/60Hz, 3 amps

If one of the two power supplies fails, the remaining supply and cord must support the

full load. Your rackmount cabinet must include ac power distribution that can handle

these values.

Size and weight

Item Measurement

Height 13.34 cm (5.25 in) (3 rack units)

Width 44.83 cm (17.65 in)

Depth 55.88 cm (22 in)

Weight 34.0 kg (75.0 lbs)

Cable lengths

You should use the Fibre Channel cables shipped with your PFR600/E when making

connections.

Any copper cables you use must meet the appropriate standards for 1-Gbit FC-AL loops.

Such cables are fully shielded, twin-axial, full-duplex cables with DB-9 or connectors.

Cables greater than 10 meters must be equalized; cables equal to or less than 10 meters

do not need to be equalized. Do not use copper cables longer than 15 meters for any Fibre

Channel connection in a Profile system.

Any optical cables you use must meet the appropriate standards for 2-Gb/s FC-AL loops.

Such cables are duplex LC cables with lengths up to 300m on 50/125

150m on 62.5/125

µm MMF, or up to

µm MMF

20 February 2004 PFR600/E Instruction Manual 53

Page 54

Appendix A

Environmental limits

Requirements Description

Temperature (Operating) 5 to 35 degrees C (41 to 95 degrees F)

Temperature (Non-operating -40 to 65 degrees C (-40 to 149 degrees F)

Relative Humidity (Operating) 5 to 75%, non-condensing

Relative Humidity (Non-operating 5 to 95%, non-condensing

The system includes two temperature level sensors used to issue auto-warning and

auto-shutdown incase the over temperature limit is reached.

54 PFR600/E Instruction Manual 20 February 2004

Page 55

Index

A

AC power

current draw 53

overview 27

address switch, chassis 28

B

Battery Backup Unit 18, 38

binding disk modules 30

blinking disk module LEDs 41

C

cabling

max lengths 29, 53

requirements 29

cabling requirements 29, 53

Canadi an Certifi ed Power Co r ds 7

Canadian EMC Notice of Compliance 7

capacity 1 6

chassis address switch 28

chassis description 19

chassis dimensions 53

chassis weight 53

colors, disk module LEDs 41

components 17

See FRUs (fi eld replaceable units )

configurations 26

console progra m 23

D

depth, chassis 53

disk module

descrip t io n 20

disk module LED colors 41