Page 1

Instruction Manual

071-8136-01

SEPTEMBER 2 002

PROFILE XP PFR500/E

FIBRE CHANNEL RAID STORAGE SYSTEM

Page 2

Copyright Copyright 2002 Grass Valley Group Inc. Grass Valley, California.

Portions copyright

Printed in the United States of America. All rights reserved. This document may not be copied in

whole o r in part, or ot herw ise r eprod uced excep t as s peci ficall y per mit ted und er U. S. cop yri ght l aw,

without the prior written consent of Grass Valley Group Inc., P.O. Box 1114, Crass Valley,

Califor n ia 95 94 5 U S A.

Ciprico, Inc. Reprinted w ith permission.

Trademarks Grass Va lley , GRA SS VAL L EY GR OUP, Prof ile an d Pro file XP are ei the r reg ister ed tr adem ar ks

or trad emarks of Gr ass Va lley G roup in the Uni ted State s and/ or oth er coun tries . Oth er tra dema rks

used in this doc ument are e ither r egistered tradem arks or t rademar ks of the m anufactu rers or

vendors of t he ass oc ia te d p rod uct s. G ra ss Va ll ey Gr ou p pro du cts a r e co ver ed by U. S. an d for e ig n

patents, issued and pending. Additional information regarding Grass Valley Group’s trademarks

and other proprietary rights may be found at www.grassvalleygroup.com.

Windows NT is a registered trademark of Microsoft.

Disclaimer Produc t opti ons an d spe cifi cation s sub ject to ch ange wi thout not ice. Th e inf ormat ion i n this m anua l

is furnis hed for inform ational use on ly, is subjec t to change with out notice, and should not be

const rued as a commit ment by Grass V all ey Group . Gr ass Val ley Gr oup assu mes no respon sibi lity

or liability for any errors or inaccuracies that may appear in this publication.

U.S. Government

Restricted Rights

Legend

Revision Status

Notice

Use, du pli cati on, or di sclo su re by th e Unit ed Sta tes G ove rnme nt i s su bjec t to rest ric tions a s se t

forth in subparagraph (c)(1)(ii) of the Rights in Technical Data and Computer Software clause at

DFARS 252.277-7013 or in subparagraph c(1) and (2) of the Commercial Computer Software

Restricted Rights clause at FAR 52.227-19, as applicable. Manufacturer is Grass Valley Group

Inc., P.O . Bo x 59 90 0, N ev a da City, Cal ifo r ni a 95959-7 90 0 U .S.A.

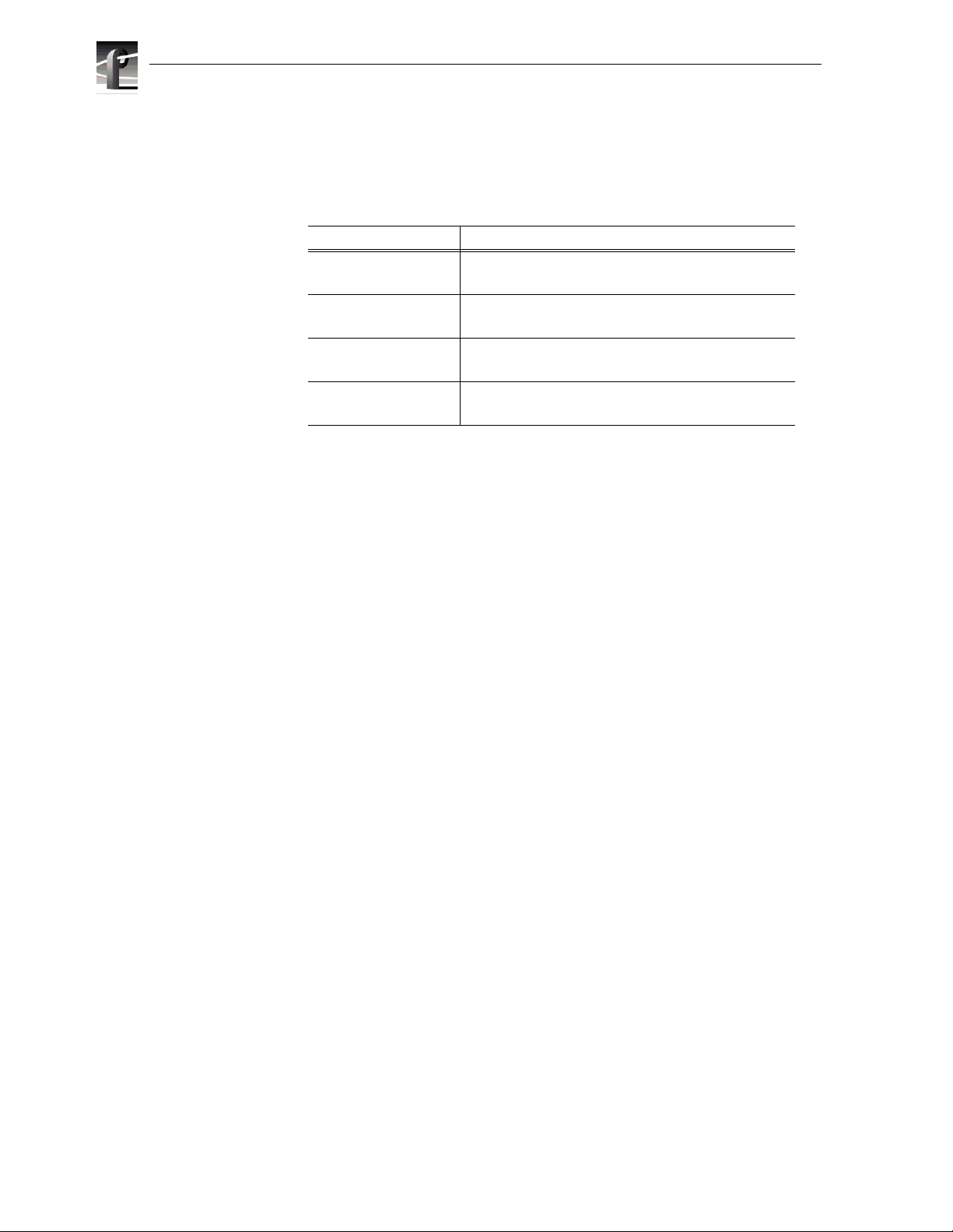

Rev Date Description

October 16, 2001 Initial release of th e PFR500/E Fibre Channel RAID Storage

Chassis Instruction Manual. 071-8136-00

September 20, 2002 Revised service and int roduction chapters. 071-8136-01

THIS DOCUMENT HAS BEEN PREPARED FOR USE BY GRASS VALLEY GROUP INC.

PERSONNEL, CUSTOMERS, AND PROSPECTIVE CUSTOMERS. THE INFORMATION

CONTAINED HEREIN SHALL NOT BE REPRODUCED IN WHOLE OR IN PART WITHOUT

PRIOR WRITTEN APPRO VA L.

The right to make chan ges in speci fications a nd other info rmation conta ined in this document

without prior notice is reserved, and the reader should in all cases consult GRASS VALLEY

GROUP INC. to determine whether any such changes have bee n made.

NO REPRESENTATION OR OTHER AFFIRMATION OF FACT CONTAINED IN THIS

DOCUMENT INCLUDING BUT NOT LIMITED TO STATEMENTS REGARDING CAPACITY,

RESPONSE-TIME PERFORMANCE, SUITABILITY FOR USE OR PERFORMANCE OF

PRODUCTS DESCRIBED HEREIN SHALL BE DEEMED TO BE A WARRANTY FOR ANY

PURPOSE, OR GIVE RISE TO ANY LIABILITY OF DGC WHATSOEVER.

IN NO EVENT SHALL LIABILITY FOR ANY INCIDENTAL, INDIRECT, SPECIAL OR

CONSEQUENTIAL DAMAGES WHATSOEVER (INCLUDING BUT NOT LIMITED TO LOST

PROFITS) ARISE OUT OF THIS DOCUMENT OR THE INFORMATION CONTAINED IN IT,

EVEN IF THE POSSIBILITY OF SUCH DAMAGES WAS KNOWN OR SHOULD HAVE BE EN

KNOWN.

Page 3

Contents

Safety Summaries

Preface

About this manual.................................................................................................................9

Using the Profile XP documentation set ..........................................................................9

Manual descript ions....................... .......... .......... .......... .......... ..................... .......... .........10

How this manual is organized.................. .. ...................... .................................. ............11

Getting more information....................................................................................................12

Grass Valley Group Web site .......................... .......... ..................... .......... .......... .......... .12

Other on-line documentation .........................................................................................12

Grass Valley Group Pr oduct Support.............. .. .................... .. .................... .. .................... .13

Chapter 1 About the PFR 500/ E

PFR500/E features.............................................................................................................15

Capacity and redundancy................... .................... .......... .. .......... .......... .. .......... .. .........16

PFR500/E components ......................................................................................................16

Chassis..........................................................................................................................18

Midplane........................................................................................................................18

Disk modules................ .................... .. .................... .. .................... .. .................... .. .........19

Circuit board modules................ ...................... ............ ...................... ............ ................20

PFR 500E RAID Expansion Chassis circuit board modules......................................20

PFR 500 RAID Storage Chassis circuit board modules............................................22

Power supplies ..............................................................................................................23

Fan mod ul e s........... .......... .......... ................. .......... ................. ......... .......... ................. ...24

Configurations ....................................................................................................................24

Chapter 2 PFR 500/ E Installation Informati on

Installation requirements ....................................................................................................25

Site requirements ..........................................................................................................25

Power........................................................................................................................25

Cooling......................................................................................................................25

Chassis address setting requireme nt.............. .. .......... .......... ........... .......... .......... .. .......26

Cabling requirements ....................................................................................................27

Binding disk modul es into groups................. .. .......... .......... .. .......... .. .......... .......... .. .......27

Installing a PFR500/E in an equipment rack........ .. .. .......... .. .......... ............ .......... .. ............28

Unpacking the Chassis..................................................................................................28

Install in g the ra c k mo u nt s.................. ................. .......... ................. .......... ................. .....2 9

Inserting the PFR500/E chassis in the rack...... .......... .. .......... .. .......... .......... .. .......... .. ..31

Installing the chassis with drive the support bracket.................................................31

Installing chassis without the drive support bracket............................. .......... .......... .31

PFR50 0/ E pow e r- up and in itializa tio n....... .. .. .......... ................. .......... .......... ................. .....3 3

Connec ting elect ri ca l c ab l es......... .......... .......... ................. .......... ................. ......... ........33

Powering-up the PFR500/E system ..............................................................................33

PFR500/E power-down ......................................................................................................34

Battery Backup recharge....................................................................................................34

Chapter 3 Servicing the PFR500/E

Maintenance procedures using GVG Disk Util it y............................................... .. .......... .. ..36

Monitoring PFR500/E status using NetCentral.... ....................................................... .......36

Interp re ti ng d is k m o d ul e LED s ............. ................. .......... ................. ......... ................. ........3 7

Interp re ti ng re a r p an e l st a tu s LED s. .. .......... ................. .......... ................. .......... ................. 3 8

LBB 7-segment displ ay codes.................... .. .......... .. .......... .. .......... .................... .......... .. ....39

20 September 2002 PFR500/E Instruction Manual 3

Page 4

Contents

Removi n g a nd in st a lling disk m o d ul e s ... ... ......... .................. ......... .......... ................. ..........4 0

Moving disk modules.....................................................................................................40

Removing a disk module......... ..................... .. .......... .......... .. .......... .......... .. .......... .. .......41

Installing disk module............. .......... .. .................. .......... ........... .......... .. .................. ......42

Replacing the Loop Bypass Board (LBB) or

RAID Co nt ro ll er ..................... ................. .......... ................. .......... ................. ......... ........4 3

Removing the LBB or RAID Controller ..........................................................................43

Installing the LBB or RAID Controller ............................................................................44

Repla ci ng G B IC data ports ............... ................. .......... ................. .......... .......... .................4 5

Replacing a power supply ..................................................................................................46

Repla ci ng th e fan m o dule ............... ................. .......... ................. .......... ................. ......... ...47

Appendix A Technical Specifications and

Operating Li m i ts

AC power requirements..................... ...................... .................................. ...................... ..49

Size and weight..................................................................................................................49

Copper cable lengths.............. .. .................... .. .......... .. .......... .. .......... .. .................... .. .........49

Enviro n me n ta l lim its......... .......... .......... ................. .......... ......... ................. .......... ...............50

Index.................................................................................................................................51

4 PFR500/E Instruct ion Manual 20 September 2002

Page 5

Safety Summaries

General Safety Summary

Review the following sa fety precautions to a void injury and prevent damage

to this product or any products conne ct ed to it.

Only qualified personne l should perform service procedures.

While using this product, you may need to acces s other parts of the system.

Read the General Safety summary in other system manuals for warning s and

cautions related to operating the system.

Injury Precautions

Use Cor r ect Power

Cord

Ground the Product This product is grounded through the grounding conductor of the power

Do Not Operate Without Covers

Do Not operate in

Wet/Damp

Conditions

Do Not Opera te i n an

Explosive

Atmosphere

Avoid Exposed

Circuitry

Power cords for this equipment , if provided, meet all North American

electrical code s. Ope ration of this equipment at voltages exceeding 130

VAC requires power supply cords which comply with NEMA

configuration s. I nternati onal po wer cor ds, i f provided, have the appro val

of the country of use.

cord. To avoid electric shock, the grounding conductor must be connected

to earth gr ound. B efore makin g c onnections to the in put o r output ter minal s

of the product, ensure that the product is properly grounded.

To avoid electric shock or fir e hazar d, do not ope rate this product with

covers or panels removed.

To avoid electric shock, do not operate this product in wet or damp

conditions.

To avoid injury or fire hazard, do not opera te this product in an ex plosive

atmosphere.

To avoid injury, remove jewelry such as rings, watches, and other metallic

objects. Do not touch exposed connections and components when power is

present.

Product Damage Precautions

Use Proper Power

Source

Provide Proper

Ventilation

Do Not Operate With

Suspec ted Failures

20 September 2002 PFR500/E Instruction Manual 5

Do not operate this product from a power source that applies mo re than the

voltage specifie d.

To prevent product overheating, provide proper ventilation.

If you suspect there is dama ge to this product, have it inspected by qualifi ed

service personnel.

Page 6

Safety Summaries

Safety Terms and Symbols

Terms in This

Manual

!

!

Terms on the

Product

Symbols on the

Product

These terms may appear in this manual:

WARNING: War ning statements identi fy conditions or pr actices that can

result in personal injur y or loss of life.

CAUTION: Cautio n s tatements ide ntify conditi ons or pr actic es t hat m ay

result in damage to equipment or other property, or which may cause

equipment crucial to your business environment to become temporarily

non-operational.

These terms may appear on the product:

DANGER indicates a person al inj ury ha zard i mmediately acc essible as one

reads the marking.

WARNING indicates a personal injury hazard not immediately accessible

as you read the marking.

CAUTION indicates a hazard to property inc luding the product.

The following symbols may appear on the produc t:

DANGER high voltage

!

ATTENTION – refer to manual

Service Safety Summary

Do Not Service

Alone

Disconnect Power To avoid electric shock, disconnect the main power by means of the power

Use Care When

Servicing With

Power On

Do not perform interna l service or adjus tment of this pr oduct unless another

person capable of rendering first aid and resuscitation is present.

cord or, if provided, the power switch.

Dangerous voltages or currents may exi st in this produc t. Disconnect power

and remove battery (if applicable) before removing protecti ve panels,

soldering, or replacing components.

To avoid electric shock, do not touch exposed connections

6 PFR500/E Instruction Manual 20 September 2002

Page 7

Certifications and Compliances

Certifications and Compliances

Canadian Certified

Power Cords

FCC Emission

Control

Canadian EMC

Notice of

Compliance

Canadian approval incl udes the products and power cords appropriat e for

use in the North America power network. All other power cord s supplied

are approved for the country of use.

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause

harmful inter ference t o rad io communic ations . Opera tion of thi s equipmen t

in a reside ntial area is like ly to cause harmful int erfere nce in whic h case the

user will be r equired t o correct t he interfer ence at his own expense . Changes

or modifications not expressly approved by Grass Valley Group can affect

emission compliance and could void the user’s authority to operate this

equipment.

This digital apparatus doe s not exceed the Class A limits for radio noise

emissions from digital apparatus set out in the Radio Interference

Regulations of the Canadian Department of Communications.

Le présent appareil num érique n’émet pas de bruit s radioélectriques

dépassant les limites applicables aux appareils numériques de la classe A

préscrites dans le Règlement sur le brouillage radioélectrique édicté par le

ministère des Communications du Canada.

EN55022 & EN55024

Class A W ar n i n g

FCC Emission

Limits

This product has been evaluat ed for Elec tromagnetic Compatibility under

the EN 55022 and 55024 standards for Emissions and Immunity and meets

the requirements for E4 environment.

This product complies with Class A (E4 environment). In a domestic

environment this product may cause radio interference in which case the

user may be required to take adequate measures.

This device complies wit h Part 15 of the FCC rules. Operation is sub ject

to the following two conditions: (1) this device may not cause harmful

interferen ce, and (2) thi s devi ce mu st acc ep t any int erf erence receive d,

including interf erence that may cause undesired operati on.

20 September 2002 PFR500/E Instruction Manual 7

Page 8

Safety Summaries

Safety Certification

This product has been evaluated and meets the following Safety

Certification Standards:

Stand a rd Designed/tested for compliance wi th:

UL1950 Safety of In for mat ion Tec hnol og y Equipme nt, incl udi ng

IEC 950 Safety of In form atio n Tec hnolog y Equi pme nt, in cl uding

Electrical Business Equipment (Third editio n).

Electrical Business Equipment (Second edition , 1991).

CAN/CSA C22.2,

No. 950-95

EN60950 Safet y of In for mat ion Tec hnol og y Equipme nt, incl udi ng

Safety of In for mat ion Tec hnol og y Equipm ent, incl udi ng

Electrical Business Equipment.

Electrical Business Equi pm ent 1992.

ATTENTION This product has been designed and certified to comply with certain

regulatory requi rements pertaining to Information Te chnology

Equipment. This product has not been designed for use as a medical

device. Without limitation of the foregoing, this product is not intended

and has not been certified for use in a hospi tal or clini cal envir onment to

diagnose, trea t, or monito r pat ients under medical su pervi sion, and i s no t

intended and ha s not be en certif ied t o make physi cal or el ectrica l conta ct

with patients, nor to transfer energy to or from patients and/or to detect

such energy transfer to or from patients.

8 PFR500/E Instruction Manual 20 September 2002

Page 9

Preface

About this manual

The PFR 500/E Fibre Channel RAID Storage Chassis provides RAID protected

storage for Profile XP Media Platf orms and Grass Valley Group Media Area

Networks. If you are responsible for installing and servic ing the PFR500/E in one of

these systems, you should read this manual.

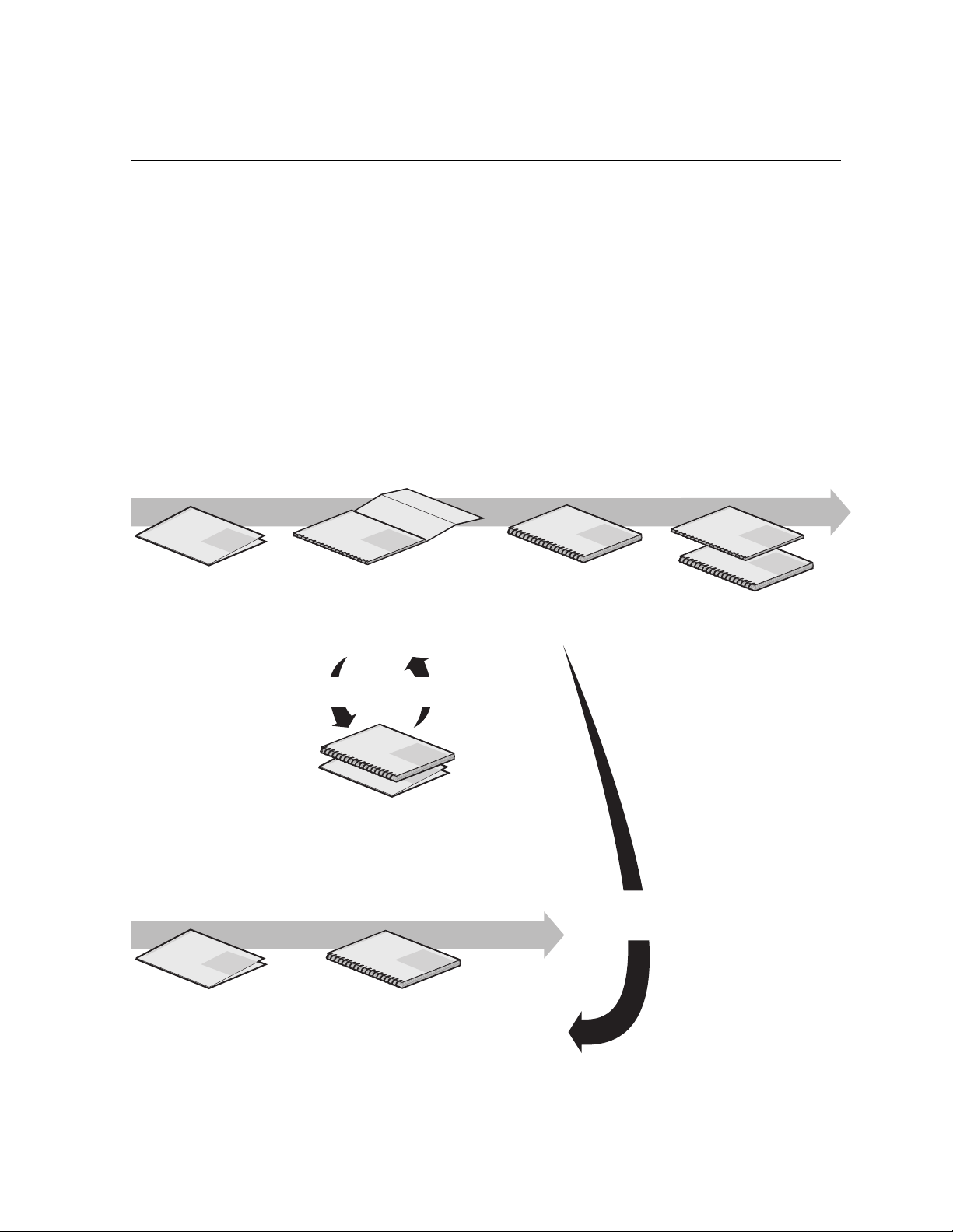

Using the Profile XP documentation set

This manual is part of a full set of support documentation for the Profile XP Media

Platform. The following figure illustrates how to use the Profile XP documentation

depending on the task you are performi ng. F or instructions on connecting and

configuring the PFR500 Fibre Channel RAID Stor age Chassis, consult the Profile XP

Installation Guide (local storage) or Media Area Network Instruc tion Manual

depending on the system you are installing.

Path for the Installer

Profile XP

Manual

Family of XP S

eries

Grass Valley Group

Release Notes

Contains the latest

information about Profile XP

hardware and software

shipped with your system.

Path for the Operator

alley Group

V

Grass

Profile XP

Manual

Family of XP Series

rass Valley Group

alley Group

Grass V

Profile XP

Manual

Family of XP Series

Installation Guide

Contains essential steps for

installing your Profile XP

system with local storage,

G

System Guide

Contains the product description

and step-by-step instructions for

modifying system settings.

using factory default settings.

Use alternate procedures

for shared storage option.

alley Group

Grass V

Profile XP

Manual

p

Family of XP Series

alley Grou

V

rass

G

Profile XP

Manual

Family of XP Series

Media Area Network

Instruction Manual and Release Notes

Contains instructions for installing storage

that is shared by multiple Profile XP systems.

p

Grass Valley Grou

Profile XP

Manual

Family of XP Series

Profile XP

Manual

Family of XP Series

Installers consult

the User Manuals

as needed.

rass Valley Group

G

Profile XP

Manual

Family of XP Series

Grass Valley Group

Profile XP

Manual

Family of XP Series

Other Manuals

These manuals include:

- PFC500 Instruction Manual

- PFR500 Instruction Manual

- Profile XP Service Manual

Release Notes

Contains the latest

information about Profile XP

hardware and software

shipped with your system.

User Manuals

Contains complete instructions for using

Profile applications. These manuals include:

- Profile XP User Manual

- ContentShare Explorer User Manual

- Other user manuals you received with

8118-10

optional Profile applications.

20 September 2002 PFR500/E Instruction Manual 9

Page 10

Preface

Manual descriptions

• Installation Guide (for each Profile XP Model) This guide provides step-by-step

instructions for installing the Profile XP Media Platform usi ng factory default

settings for all recor d/play channels. Factory default settings are indicated wit hin

the guide. After installing the Profile XP system using this installation guide , you

can refer to this Profile XP System Guide to customize system settings for your

installation.

•

Profile XP System Guide This guide provides all the information you need to go

beyond factory default settings and customize your syst em’s configuration to meet

your site-specif ic needs. This guide also provides an overview of your Profile XP

system, and provides all the specifications you need to integra te the Profile XP

Media Platform into your operation.

•

Profile XP User Manual Contains complete instructions for using Profile

applications to operate the Profile XP Media Platform.

Profile XP Service Manual C ontains information for servicing the Profile XP

•

Media Platform, and includes proc edures for the fol lowing tasks:

- Problem analysis using symptom, pr oblem, solution tables.

- Running diagnostics locally and remotely

- Set up and operate NetCentral Lite monitoring software.

- Replacing field replaceable units.

Profile XP Release Notes Contains the latest information about the Profile

•

hardware and the software release shipped on your system. This information

includes software specifications and requirements, feature changes from the

previous releases, helpful system administrative information, and any known

problems.

•

PFC500/E Instruction Manua l Contains information for servicing the PFC500

Fibre Channel RAID Storage Chassis (PFC500/E) including step-by-step

procedures for replacing field replaceable units.

10 PFR500/E Instruc tion Manual 20 September 2002

Page 11

How this manual i s organized

The following identif ies and describes the chapters include d in this manual:

Chapter 1 - About the PFR500/E

Introduces the PFR500 Fibre Channel RAID Storage Chassis and the PFR500E

RAID Expansion Chassis. You can read this c hapter to get famili ar with key fe atures

and components.

Chapter 2 - PFR500/E Installation Information

Contains informati on needed for installation of a RAID Storage Chassis and RAID

Expansion Chassis, including rack mounting information.

Chapter 3 - Servicing the PFR500/E

Contains service infor mation, such as FRU replacement procedures.

Appendix A - Technical Specification s and Operati ng Li mit s

This appendix consists of electrical and environmental specifications.

How this manual is organized

20 September 2002 PFR500/E Instruction Manual 11

Page 12

Preface

Getting more information

In addition to printed documents, Profile XP product information is av ailable in

electronic form. Use these as additional sources for information.

Grass Valley Group Web site

Current versions of this manua l and other Profile product documentation may be

downloaded via the Product Document ation link on the Grass Valley Group home

page.

Other on-line documentation

Electronic ver sions of the following manuals are lo cated on the system drive of your

Profile XP Media Platform and on the Profil e XP software CD-ROM.

• Installat ion Guide (for your model )

• Profile XP System Guide

• Profile XP User Manual

• Profile XP Service

• PFR500/E Instruction Manual

• Profile XP Release Notes

You can view these m anuals using Adobe Acrobat Reade r which is al so pre-in stalled

on your Profile XP system.

12 PFR500/E Instruc tion Manual 20 September 2002

Page 13

Grass Valley Group Product Support

Grass Valley Group Product Support

To get technical assist ance, check on the status of problems, or report new problems,

contact Grass Valley Produc t Support via e-mail, the Web, or by phone or fax.

Web technical support

To access support information on the Web, visit the product support Web page on the

Grass Valley Group Web site. You can download soft ware or find solutions to proble ms

by searching our Frequently Aske d Questions (FAQ) database.

Worl d Wide Web: http://www.grassvalleygroup.com/support/

Technical Support E-mail Address: gvgtechsupport@grassvalleygroup.com.

Phone support

Use the following information to contact product support by phone during business

hours. Afterhours phone support is available for warranty and contract customers.

USA and Americas (includes Latin America and Canada)

Telephone (800) 547-8949 (Toll Free)

(530) 478-4148 (Direct Dial Toll Call)

Fax (530) 478-3181

Europe and UK

UK Regional

Service

Location

France Tel +33 145 297 300

Tel +44 1753 218 777

Fax +44 1753 218 757

Fax +33 145 297 302

Asia Pacific

Australia Tel (612) 8877 6800

Fax (612) 8877 6825

China Tel (86) 10 6235 1185

Fax (86)10 6235 1190

Hong Kong Tel (852)-2531-3000

Fax (852)-2802-2996

Autho rized support representative

A local authorized supp ort representative may be avail able in your country. To locate the

support represe ntative for your country, visit t he product suppor t Web page on the Gra ss

Valley Group Web site.

Profile Users Group

Italy Tel +39 72 901 428

Fax +39 72 905 371

Germany Tel +49 221 1791 234

Fax +49 221 1791 235

India Tel (91) 11 373 0544

Fax (91) 11 373 0543

Japan Tel (813) 548 4 6869

Fax (813) 5484 3775

South East

Asia

Tel (65) 6 7328 729

Fax (65) 6 7327 649

You can connect with other Profil e XP Media Platform users to ask questions or share

advice, tips, and hints. Send e-mail to profile-users@grassvalleygroup.com to join the

community and benefit from the exper ience of others.

20 September 2002 PFR500/E Instruction Manual 13

Page 14

Preface

14 PFR500/E Instruc tion Manual 20 September 2002

Page 15

Chapter

1

About the PFR500/E

This chapter introduces the PFR500 Fibre Channel RAID Storage Chassis. Topics

include:

• PFR 500/E features

• PFR 500/E components

• Configurations

PFR500/E features

The PFR 500 Fibre Channel RAID Storage Chassis is a high performance, high

availability mass stor age system. High-bandwidth storage is made possible using

Fibre Channel Arbitrated Loop (FC-AL) technology. The PFR500’s modular,

scalable design provides additional disk storage as your needs increase.

2359

Feature highlights:

• Ten drives in a 3U vertica l rac k sp ace

• No single point of failure

• All active components are hot- se rviceable

• Scalable expansion using P FR500E RAID Expansion Chassis

• Optional dual RAID controllers provide Fibre Channel failover

• Copper Fibre Channel interf ace (GBIC)

The PFR500 utilizes dual FC-AL technology, allowing two loop configurations

within a single chassis. Port-Bypass Circuits have been added to maintain loop

integrity during failures without user intervention. Each loop and associated Port

Bypass Circuits a long with al l other act ive components a re on redundant , separate h ot

20 September 2002 PFR500/E Instruction Manual 15

Page 16

Chapter 1 About the PFR500/E

swappable modules. This improves serviceability and incre ases fault tolerance by

eliminating any singl e point of failure. With two RAID Controllers, the two loops

within a single standa rd chassis are configur ed as a singl e loop with a backup loop in

standby mode.

Capacity and redundancy

The PFR500 contains five or ten half-height 3.5" Fibre Channel Arbitrate d Loop

(FC-AL) disk drives. The chassis also supports one or two hardware RAID

Controllers in one 3U high r ack-mountable chassis. The PFR500 currently uses 73GB

or 180GB drive capacities. With ten drives, one c ha ssis holds up to 730GB or 1.8TB

depending on the disk drive option.

The PFR500E RAID Expansion Chassis provides additi onal storage capacity. It is an

identical chassis with two Loop Byp ass Board installed. Up to nine PFR500E RAID

Expansion Chassis can be connected to a single PFR500 comprising a single

disk-array storage system with a total of 100 drives and 7.3TB or 18TB of storage

depending on the disk drive option. The built-in chassis daisy-chaining capabilities

provide for cost effective storage expansion as requiremen ts grow.

Throughout this m anual, the term PFR500/E is used to refer to either the PFR500 or

the PFR500E interchangeably.

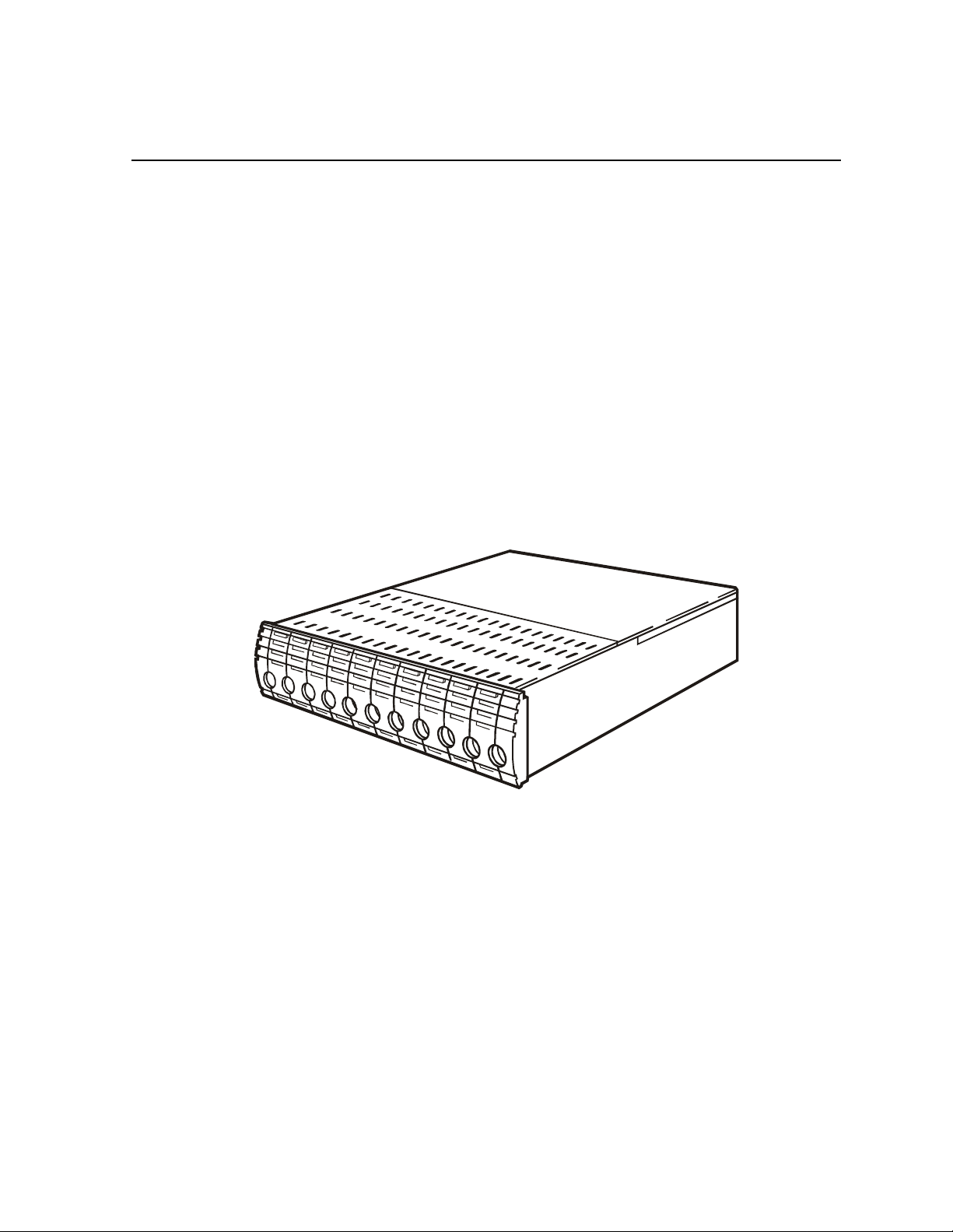

PFR500/E com ponents

The PFR500/E components are:

• The chassis with passive midpl ane board

• One or two RAID controllers (PFR500 only)

• One or two Loop Bypass Boards

• As many as ten Fibre Channel disk drives per chass is

• Two power supplies

• Two fan modules

The RAID Controllers, Loop Bypass Boards, disk drives, power supplies, and fan

modules are hot -swappable field r eplacea ble uni ts (F RUs), which means you can add

or replace them while the PFR500/E is powered up.

An optional second RAID Controller Modul e in the PFR500, allows for continued

access to the PFR500 if the primary RAID Controller fai ls. Adding a second RAID

Controller to the same chassi s is not intended to increase performance, but r ather to

add redundancy

connection and configuration instructions.

NOTE: Hotswapping the RAID Controlle r or LBB modules (removing or inserting )

causes approximately a 10 second loss of video (record/play). This happens

regardless of whether you exchang e the primary controller or the secondary

controller.

. Refer to your Profile XP PVS Series I nstall ation Guid e for detaile d

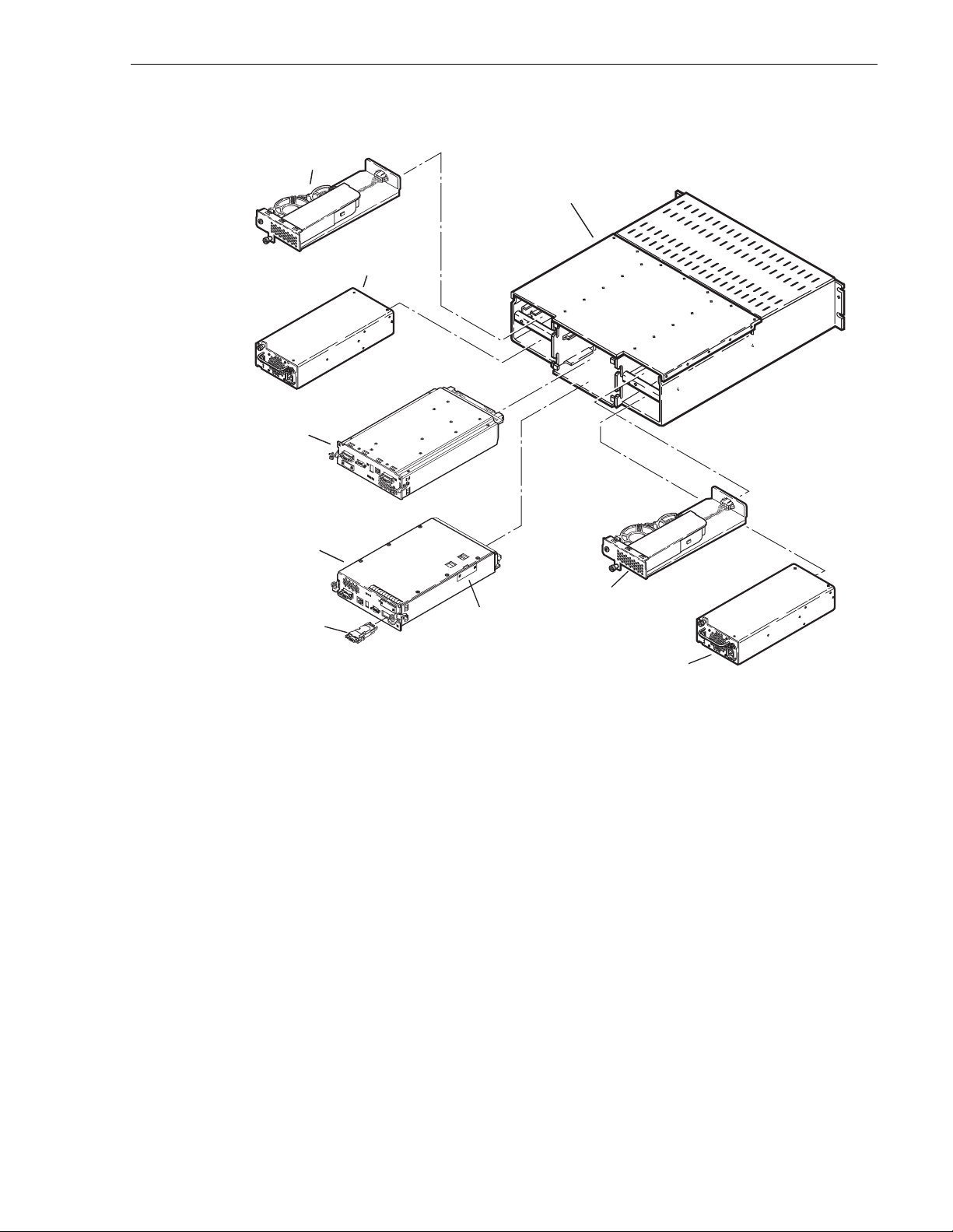

The following figure shows the PFR500/E components. Details on each component

follow the figure.

16 PFR500/E Instruc tion Manual 20 September 2002

Page 17

Fan Module A

Power Supply A

LBB B

PFR500/E components

Chassis

8136-5

LBB A

Fan Module B

GBIC

Battery Backup

Unit (BBU)

Power Supply B

NOTE: Every PFR500/E RAID controller includes a backup battery so that if

electrical power is lost, data store d in cache memory will be saved. Data store cache

is not used in the PFR500/E, so the Batte r y Back up mo d u le is not used , ev en

though it ships as part of the LBB module.

20 September 2002 PFR500/E Instruction Manual 17

Page 18

Chapter 1 About the PFR500/E

Chassis

The chassis is a sheet-metal housing which contains a passive midplane and chassis

slots for the RAID Con trollers, or Loop Bypass B oards, disk drives, power supplies,

and the fan modules.

Each chassis includes a chassis addre ss switch on the midplane board t hat must be set

to a unique address 0 through 9 during installation. Refer to your PVS Series

Installation Guide or t he Medi a Area Netw ork Installati on Manual for informat ion on

setting the chassis address switch depending how the PFR500 is used. See also,

“Chassis address setti ng requirement” on page 26.

The following diagram shows how disk modules are identified based on the chassis

address and physical loca tion. The chassis with an address set to 0 contains drives

from 0 to 9; the chassis with an address set to 1 contains drives from 10 to 19; and so

forth.

PFR500 Front Panel

Midplane

The midplane distributes power and signals t o all the chassis components. All FRUs

plug directly into midplane connectors. The midplane includes a chassis address

switch that must be set during inst allation. Refer to “Chassis address se tting

requirement” on page 26 for information on setting the chassis address.

n0 n1 n2 n3 n4

Disk Modules

n5 n6 n7 n8 n9

Chassis

Address

8136-3

Disk

ID

18 PFR500/E Instruc tion Manual 20 September 2002

Page 19

Disk modules

Each disk module consists of a Fibre Channel disk drive in a carrier assembly. If a

disk drive fails, and needs replacing, you can do so while the PFR500/E is powered

up. Replacement disk drives take 3-4 minutes to begin rebuild after being installed.

(See “Removing and installing disk modules” on page 40.)

The disk drives are 3.5-inch FC-AL drives that conform to the Fibre Channel

Arbitrated Loop (FC-AL) sta ndards and support dual-port FC-AL interco nnects

through the two RAID controller s and their cabling.

CAUTION: Once the PFR500/E is installed and configured, the disk modules

!

become slot dependent. Moving disk modules betwee n ph ysi cal slots will result in

loss of data and the need to reconfigure the system.

Disk modules

2299

1

2

20 September 2002 PFR500/E Instruction Manual 19

Page 20

Chapter 1 About the PFR500/E

Circuit board modules

There are two cir cuit board modules used: the Loop Bypa ss Board module (LBB) and

the RAID Controller module. The LBB module contains one Loop Bypass Board

which provides an internal Fi bre Channel loop for the disk modules installed in the

chassis. The RAID Controller module also contains a Loop Bypass Board plus a

RAID Controller board used to manage the disk drives and provide a Fibre Channel

interface to the Profile system.

PFR500E RAID Expansion Chassis circuit board modules

PFR500E RAID Expansion Chassis alway s has two LBB modules insta lled as shown

in the following figure. This provides two internal Fibre Channel loops for the disk

modules. At powe r-up, odd num bered disk drives are supported b y the LBB in the ‘A’

slot, while even numbered d isk drives ar e supporte d by the LBB i n the ‘B’ slot. In the

event of an LBB module failure, the faulty loop is bypassed and all disk drives

failover to the remaining LBB module. The LBBs are clearly labeled “A” or “B” on

the rear panel of the canister.

7 Segment LED

Left

Fibre Channel

Loop Port

(displays chassis address)

Serial

Port

Ethernet

Port

Fibre Channel

Right

Loop Port

Loop Bypass Board B

Loop Bypass Board A

PFR500E

Left

Fibre Channel

Loop Port

Ethernet

Port

7 Segment LED

(displays chassis address)

Serial

Port

Right

Fibre Channel

Loop Port

8136-2

The LBB in the PFR500E has two Fibre Channel ports: the Left and Right Fibre

Channel Loop Ports. Copper GBICs (Gigabit Interface Converter) are used in these

ports to connect Fibre Channel cabling to a PFR500 or PFR500E. This extends the

Fibre Channel loop of the corresponding PFR500/E chassis. There is a port status

LED for each Fibre Channel port. Refer to “Interpreting rear panel status LEDs” on

page 38.

20 PFR500/E Instruc tion Manual 20 September 2002

Page 21

Circuit board modules

Installing a GBIC

(Gigabit Interface Converter)

B

A

A

8136-7

An RJ-type connector is provid ed for Ethernet network connection. A DB-9 serial

communications connect or is provided for serial communicati ons with a console

program. Th es e con nect o rs are u se d when N etCe ntral monitori ng so ftw are i s used .

Refer to your PVS Series Installation Guide or the Media Area Network Instructi on

Manual for information how these connectors are used.

NOTE: The PFR500E Expansion chass is and PF R500 Controller chassis must be

powered on and off in the proper sequence. Refer to proper power procedures in

Chapter 2, “PFR500/E Installation Information”.

20 September 2002 PFR500/E Instruction Manual 21

Page 22

Chapter 1 About the PFR500/E

PFR500 RAID Storage Chassis circuit board modules

A PFR 500 includes one or two RAID Controller modules. Two RAID Controller

modules are installed when the redund ant Fibre Channel option is installed. This

provides redundant Fib er Channel interface ports to the Profile system or Fibre

Channel switch fabric. The following figure shows a PFR500 Fibre Channel RAID

Storage Chassis with the two RAID Controlle r Modules installed. The RAID

Controlle rs are cl ear ly la b eled “A” or “B” on the rear panel of the canister. The “A”

and “B” RAID Controllers must be installed in the chassis a s shown, the y cannot be

swapped.

7 Segment LED

(displays chassis address)

Serial

Port

Ethernet

Port

Host Fibre

Channel Port

Fibre

Channel

Loop Port

RAID Controller B

RAID Controller A

PFR500

Fibre

Channel

Loop Port

Ethernet

Port

7 Segment LED

(displays chassis address)

Serial

Port

Host Fibre

Channel Port

8136-1

When the redundant Fiber Channel opti on is not in stalled, only one RAID Control ler

is installed along with one LBB module as shown in the following figure. The LBB

module and the LBB contained in t he RAID Controlle r module provide the two LBBs

required in the PFR500 Fibre Channel RAID Storage Chassis. The LBB and RAID

Controller modules are cl early labeled on the rear panel of each canist er.

22 PFR500/E Instruc tion Manual 20 September 2002

Page 23

Left

Fibre Channel

Loop Port

7 Segment LED

(displays chassis address)

Serial

Port

Ethernet

Port

Power supplies

Loop Bypass Board B

RAID Controller A

PFR500

The RAID Controller is equipped with a passive 9-pin copper GBIC installed as the

Fibre Channel host port. The RAID Controller also has a Fibre Channel loop

expansion port which extend s the internal Fibre Channel Loop to the correspon ding

Loop Bypass Board in a PFR500E Expansion Chassis.

An RJ-type connector is provid ed for Ethernet network connection. A DB-9 serial

communications connect or is provided for serial communicati ons with a console

program. Th es e con nect o rs are u se d when N etCe ntral monitori ng so ftw are i s used .

Refer to your PVS Series Installation Guide or the Media Area Network Instructi on

Manual for information how these connectors are used.

The RAID Controller includes rear panel Fibre Channel loop port status LEDs and

other status LEDs. Refer to “Interpre ting rear panel status LEDs” on page 38.

NOTE: The PFR500E Expansion chass is and PF R500 Controller chassis must be

powered on and off in the proper sequence. Refer to proper power procedures in

Chapter 2, “PFR500/E Installation Information”.

Power supplies

Fibre

Channel

Loop Port

Ethernet

Port

7 Segment LED

(displays chassis address)

Serial

Port

8136-6

Host Fibre

Channel Port

There are two auto-rangi ng power supplies, each with its own power cord and standby

switch. Each suppl y supports a fully c onfigured PFR500 and shares load currents with

the other supply, if it is present. The power supplies are d esigned so as to protect the

disk drives if you install them while the PFR500/E is powered up. A disk with

power-related faults will not adversely affect the operation of any other disk.

Each power supply has status LEDs visible from the rear pane l. The status LEDs a re

described in the “Interpreting rear panel status LEDs” on page 38.

A retaining screw secures the power suppl y in place. You can add or remove one

power supply in the PFR500/E while the PFR500/E is powered up.

20 September 2002 PFR500/E Instruction Manual 23

Page 24

Chapter 1 About the PFR500/E

Fan mod ules

There are two fan modules used to cool the components insta lled in the PFR500/E

chassis. The fan modules connect to the midplane board for power.

One status LED on the r ear panel of the fan module indicates status. The status LED

is described in the “Interpre ting rear panel status LEDs” on page 38.

A retaining screw on the fan module holds the module in place .

NOTE: If power is connected, fans run at low speed even with the power supply

switches in standby position.

Configurations

The PFR 500 RAID Storage Chassis minimum and maximum configurations are as

follows.

PFR500

Configuration

minimum 1 1 2 5

maximum 2 0 2 10

RAID Controller

Module

(Includes one LBB)

Loop Bypass

Board Module

Power Supplies/Fan

modules

Disk Modules

The maximum configuratio n provides the mos t redundancy, an d therefore the h ighest

degree of system availabi lity.

The PFR500E RAID Expansion Chassis minimum and maxim um configur ations ar e

as follows.

PFR500E

Configuration

minimum 2 2 5

maximum 2 2 10

Loop Bypass

Boa rd Module

Power Supplies/Fan

modules

Disk Modules

IMPORTANT: Grass Valle y Group does not support mixing dis k drives of differing

capacities in any RAID chassis. A ll disk drives in any RAID chassis must be of the

same capacity. For example, if a PFR500 and a PFR500E are connected, all the

disk drives in both the PFR500 and the PFR500E must be of the same capacity.

24 PFR500/E Instruc tion Manual 20 September 2002

Page 25

Chapter

2

PFR500/E Installation Information

This chapter describes information you’ll need to install the PFR500 Fibre Channel

RAID Storage Chassis (PFR500/E). Major topics are:

• Installation r equirements

• Installing a PFR500/E in an equipment rack

• PFR 500/E power-up and initialization

• PFR 500/E power-down

Installation requirements

This section describes the following requirements:

• “Site requirements” on page 25

• “Chassis address setti ng requirement” on page 26

• “Cabling requirements” on page 27

• “Binding disk modules into groups” on page 27

Site requirements

For proper PFR500/E operation, the installation site must conform to certain

environmental spe cifications. These are detailed below and in Appendix A, “Technical

Specificat ions an d Operating Limi ts”.

Power

Refer to “AC power requirements” on page 49 for AC power requirements. The values

indicate eith er the value s for the power cor d of a PFR500/E with a single power supply,

or the total values shared by the line cords of two power supplies in the same PFR500/

E, with the divi sion betwe en the powe r co rds and suppl ies at the c urrent s harin g ratio. If

one of the two power sup plies f ails, the r emaining s upply and cor d must suppo rt the full

load. You must use a rack mount cabinet with ac power distribution, and have main

branch ac distributi on that can handle these values for the number of PFR500s and

PFR500Es that you will interconnect.

Cooling

Make sure your site has air conditioning of the correct size and placement to maintain

the specified a mbient temperature range. The air c onditioning must b e able to handle th e

requirements of the PFR500s and any connected PFR500Es as indicated under

“Environmental limits” on page 50.

20 September 2002 PFR500/E Instruction Manual 25

Page 26

Chapter 2 PFR500/E Installation Information

Chassis ad dr es s set tin g re qu ir em e nt

Each PFR500/E storage chassis has a c hassis address swit ch tha t must be set to a unique

chassis address. Valid chassis addresses are 0-9 with 0 being reserved for the PFR500

RAID Chassis. All chassis are shipped with the chassis address set to 0.

The chassis address switch is located inside the chassis on the midplane board. The

following figure s show how to gain access to the switch by removing the board canisters.

CAUTION: Refer to the PVS Serie s Instal lati on Guide

you received with your Profile XP

storage system or the Media Area Network Instruction Manual for step-by-step

instructions for setting the chassis address.

LBB B goes

in the top slot

LBB A goes

in the bottom slot

The midplane is at the back of the slot that held the LBB canisters. On the midplane is a

small, white rotary switch.

3001

.

26 PFR500/E Instruc tion Manual 20 September 2002

2796

Page 27

After the chassi s addresses have been set and the chassis powered-up, the chassi s address

is displayed on the 7-segment display LED as shown.

7-Segment Displ ay LED

Cabling requirements

It is recommended that you use the copper Fibr e Channel c ables shipped with your

PFR 500 when making connections.

Any copper cable s you use must meet the a ppropriate st andards fo r 1-Gbit FC-AL l oops.

Such cables are fully shielded, twin-axial, full-duplex cables with DB-9 connectors.

Cables greater th an 10 meters must be equalized; cab les equal to or less than 10 meters

do not need to be equalized. Do not use copp er cables longer than 15 meters for any Fibr e

Channel connection in a Profil e system.

Cabling requirements

2792

PFR500 and PFR500E interconne ctions shoul d maintai n LBB consi stency . That is, one

FC loop should conne ct the PFR500’s RAID Controller A and each PFR500E’s LBB A.

The other FC loop should connect the PFR500/E’s RAID Controller B and each

PFR500E’s LBB B.

Do not leave an unused (that is, dangling) cable connected to a Fibre Channel port

because it may cause excess noise on the loop.

Binding disk modules into gr oups

After cabling a PFR500 and any PFR500Es, you must bind disk modules into LUNs

using a GVG Disk Utility provided by Grass Valley Gro up. Ref er to the appropriate

manual for information on using the GVG Disk Utility to bind drives.

Type of PFR500/E installation Manual to use for binding procedures

Part of a Media Area Network Media Area Net w ork Instruction Manual

Connected directly t o a Profile XP Media

Platfo rm as local storage

PVS In stalla tio n Gui de ( for your Prof ile XP mo del) or

the Profile XP System Guide

20 September 2002 PFR500/E Instruction Manual 27

Page 28

Chapter 2 PFR500/E Installation Information

Installing a PFR500/E in an equipment rack

Use the information in this sect ion to unpack the PFR500/E chassis and mount in an

equipment rack.

Procedures include:

• Unpacking the Chassis

• Installing the rack mounts

• Installing the chassis with drive the support bracket

• Installing chass is without the drive support bracket

Unpacking the Chassis

Unpack the PFR500/E chassis, cables, and installation kit.

WARNING: A PFR500/E chassis is heavy. Two people should lift and

!

move it.

Box containing cables

and manuals

Packaging

Chassis with

shipping bar

8136-4

CAUTION: Save the chassis packaging. Use only PFR500 approved packaging to ship.

28 PFR500/E Instruc tion Manual 20 September 2002

Page 29

Installing the rack mounts

You can eithe r remove th e drive supp ort bracket, as shown in the f ollowing fi gure so t hat

you can hot-swa p dri ves, or you can l eave t he br acket i n pl ace for gre ater d rive sta bil ity.

In either case, keep the bra cket and retaini ng sc rews in case you have to shi p the chassis

in the future.

2781

Installing the rack mounts

To install the PFR500/E rack mounts:

1. Loosely fasten the left st ationar y chassis mount to the left chassis sl ide rail wit h the

locking nuts.

2. Adjust the length of the outside edges of the chassis mo unt assembly to fit be tween

the front and back channel mounts. S ecure these two pieces together. Pull chassis

mount assembly away from channel mounts.

3. Place cage nuts around the top and bottom two holes on the front of the chassis

mount assembly, such that the nuts are inside the front and the back of the chassis

mount assembly.

4. Place one cage nut on the bottom hole, and one cage nut on the second hole from

the top on the back, such that the nuts are inside the front and the back of the chassis

mount assembly.

5. Slide the chassis mount assembly betwe en the left front and back channe l mounts.

Secure the screws through the channel mounts into the cage nuts.

20 September 2002 PFR500/E Instruction Manual 29

Page 30

Chapter 2 PFR500/E Installation Information

Back Channel

Mount

Cage Nuts

(2 per side)

Locking Nits

(3 per side)

Left Chassis

Slide Rail

Left Stationary

Chassis Mount

Cage Nuts

(4 per side)

Front

Channel

Mount

0626-15

6. Repeat steps 1 through 5 for the right side.

30 PFR500/E Instruc tion Manual 20 September 2002

Page 31

Inserting the PFR500/E chassis in the rack

Drive Support

Inserting the PFR500/E chassis in the rack

Every PFR500/E chassis ships with drive suppor t brackets. The support bracket provide s

additional disk module support. If the chassi s will operate in a high- vibration area, le ave

the brackets on. This adds time when hot-swapping drives, but provides additional

stability.

Installing the chassis with drive the support bracket

To install a chassis with the dri ve support bracket:

1. Rest the chassis on the s upport angles shown. S lide the c hassis back and int o pl ace.

2. Add the drive support br acket and se cure the ch assis t o the r ack with t he mounti ng

screws that shipped with the chassis.

Mounting Screws

Brackets

3006

Drive Support Bracket

3. Repeat steps 1-2 to insert each PFR500/E chassis in the rack.

The drive support brackets preclude edge covers.

Installing chassis without the drive support bracket

To install a chassis without the drive support bracket:

1. Rest the chassis on the rack mounts as shown. Slide the chassis back and into pl ace.

2. Secure the chassis to the rack with the mounti ng screws included in the inst allation

kit.

20 September 2002 PFR500/E Instruction Manual 31

Page 32

Chapter 2 PFR500/E Installation Information

3. Apply the edge covers that are packaged with the PFR500/E.

4. Repeat steps 1-3 to inst al l each PFR500/E chassis in t he rack .

32 PFR500/E Instruc tion Manual 20 September 2002

Page 33

PFR500/E power-up and initialization

To power

PFR500/E power-up and initialization

This section gives information about connecting power and powering-on the

PFR 500/E system.

Connectin g ele ct ric al cab le s

For each chassis, there are two ele ctrical cables which should be connecte d to separate

outside power sources, as shown.

Off/Standby switches

To power

source

source

2783

WARNING: Make sure the power cords meet local safety and electrical

!

standards.

CAUTION: The PFR500/E system must be electrically grounded.

!

Operating the system wi thout proper groundi ng can damage disk driv es. If

the outlet you use is not grounded, make sure that a licensed electrician

replaces it and installs a grounding conductor.

Powering-up the PFR500/E system

1. Power-up the PFR500E Expansion chassis prior to, or at the same time as the

PFR500 Controller chassis.

NOTE: You must always power-up th e PFR500E Expansion chassis prior to, or at

the same time as the PFR500 RAID Controller chassis. Failure to do so may

prevent some LUNs in the expansion chassis from bein g recognized.

2. Wait for RAID storage initialization, as follows:

- Rear panel 7-segment LED displa ys t he chassis address, and Host RDY LED is

ON— approximately 2 minutes.

- Wait until al l disk access LEDs are stea d y green — approximately 3 minutes.

- Refer to sections in Chapter 3, “Servicing the PFR500/E” for inform at ion on

interpreting status LED behavior.

NOTE: Refer to the Profile XP System Guide or Media Area Network Instruction

Manual for complete system power-up procedures.

20 September 2002 PFR500/E Instruction Manual 33

Page 34

Chapter 2 PFR500/E Installation Information

PFR5 00/E power-down

IMPORTANT: If your PFR500/E system is part of a Media Area Network, re fer to

the Media Area Network Instruction Manual for instructions on shutting down the

Media Area Network before powering down a PFR500/E.

To power-down the PFR500/E correctly:

1. Stop all read/write activity to the PFR500/E storage system.

2. Power-down the RAID stora ge system by power ing-down the PFR500 Controller

chassis prior to, or at the same time as with the PFR 500E Expansion chassis.

>>> CAUTION: You must always power down the PFR500 RAID Controller chassis

prior to, or at the same time as the PFR500E Expansion Chassis. Failure to do so

may force some LUNs offline. This will cause loss of access to the media file system

when the system is powered up again. Refer to “Forcing LUNs online: Recovery

from improper power- sequence” in Chapter 3 of the Profile XP System Guide.

To turn on power, refer to “PFR500/E power-up and initialization” on page 33.

Battery Backup recharge

Every PFR500/E RAID controller includes a backu p battery so that if electrical power

is lost, data stored in cache memory will be saved.

Data store cache is not use d in Pr ofile stor age syste ms, so t he Batte ry Backup mod ule is

not used, even though it ships as part of the LBB module.

34 PFR500/E Instruc tion Manual 20 September 2002

Page 35

Chapter

3

Servicing the PFR500/E

This chapter describes how to monitor PFR500/E status and replace Field

Replacea ble Un i ts (FR U ).

Topics include:

• “Maintenance procedures using GVG Disk Utility” on page 36

• “Monitoring PFR500/E status using NetCentral” on page 36

• “Interpreting disk modul e LEDs” on page 37

• “Interpreting rear panel status LEDs” on page 38

• “LBB 7-segment display codes” on page 39

• “Removing and installing disk modules” on page 40

• “Replacing the Loop Bypass Board (LBB) or RAID Controller” on page 43

• “Replacing GBIC data ports” on page 45

• “Replacing a power supply” on page 46

• “Replacing the fan module” on page 47

20 September 2002 PFR500/E Instruction Manual 35

Page 36

Chapter 3 Servicing the PFR500/E

Maintenance procedures using GVG Disk Utility

Several maintenance pr ocedur es can be performed using the GVG Disk Utility

installed on the Profil e XP Platform for standalone storage, or on the FSM in Media

Area Network systems.

To perform the following tasks , refer to Chapter 3 of the Profile XP System Guide:

• Verifying and loading RAID controller microcode

• Downloading PFR 500 disk drive firmware

• Forcing LUNs online: Recovery from improper power-off sequence

• Forcing a replacement drive to rebuild

• Checking and restoring defa ult PFR 500 RAID Controller settings

• Checking and restoring disk se ttings

Monitoring PFR500/E status using NetCentral

You can monitor PFR500/E RAID Storage systems using Grass Valley Group’s

NetCentral monitoring sof tware. Enabled by SNMP, NetCentral can continuously

monitor the storage syst em and send notifications if there is a problem. The SNMP

agent software require d for NetCentral monitoring runs on the PFR500 RAID

Controller module. As a result, the PFR500 appears in NetCentral as a standalone

device rather than a subsystem of the Profile XP platform.

Communication with NetCentra l takes place over the RAID Controller Ethe rnet port.

To monitor the PFR500, you must connect network cablin g, powe r on the syste m,

then configure network a nd SNMP settings as described in the PVS Series Ins tallation

Guide.

Refer to the Profile XP Service Manual for information on monitoring the PFR500

with NetCentral.

36 PFR500/E Instruction Manual 20 September 2002

Page 37

Interpreting disk module LEDs

The disk module LEDs and the 7-segment display on the back of the RAID

Controllers are used to indicate system status. The following table describes how to

interpret the the disk module LED behavior and rear panel 7-segment display for

various conditions.

a

LEDs

7-Segment

Display

Interpreting disk module LEDs

Meaning

All drives are green,

non-blinking

All drives are green, r apid

blinking

One drive is blue Drive has been identified using the GVG Disk

One drive is red Drive itself has determined it is bad.

All drives are alt e rnating blue/

green at two second intervals

RAID only: All drives are blue

for 5 minutes, then green for 30

seconds

RAID only: All drives are blue System-wide failure has occurred. Do not

One drive is green while all other

drives are blinking blue.

a.

If the dis k access LED is un lit at any po int, it indicates one of the colored LEDs has failed. The access

LED should display some color at all times.

b.

A RAID LUN may fail without providing blue LED in dication, ho wever, NetCentral alerts can provide

this information.

chassi s address Drives are behaving nor m ally— no disk access

in progress

chassi s address Disk I/O in progress

Utility.

F Drive is failed.

F and ch as sis

address

(alternating)

Chassis ID LUN is rebuil ding. D o not power dow n the arra y

Something ( such as a power su pply, blower, etc.)

in the array failed.

Failed drive in the array needs to be replaced.

remove a drive. Call Grass V alley Group

Support as described in page 13.

until the rebuild fin ishes.

b

20 September 2002 PFR500/E Instruction Manu al 37

Page 38

Chapter 3 Servicing the PFR500/E

Interpreting rear panel status LEDs

Refer to the following tabl e to inter pret rear panel LEDs on FRUs.

Module LED Name Meaning

Loop Bypass Board Loop LED is ON when the Fib er Channel port does not

detect a valid Fibre Channel signal on t he G B IC.

LED is OFF when sign al is valid.

7-segment LED Chassis number and event code display. R efer to

“LBB 7-segment display codes” on page 39.

Flashing decimal point indicates he artbeat for

communicat ion between LBB modules. Solid

indicates LBB has critically failed (steady for more

than 30 seconds).

RAID Controller Host Loop LED is ON when the Fiber Channel port does not

detect a valid Fibre Channel signal on t he G B IC.

LED is OFF when sign al is valid.

Host RDY LED is ON when the hos t p ort is initialized and

ready for com m unication. LED OFF indic ates the

RAID Con t ro ller is not fully initia liz e d.

Disk ACT LED is ON when there is disk activity, i.e. data

packets on the disk loops.

Host ACT The host acti vity LED is ON when there i s host por t

activity, i.e. data packets on th e host loop.

Tx and Rx LEDs indicate Ethernet port transmit and receive

status.

Power Supply Output Good LED is ON (green) when power supply output is

good.

Fault LED is ON (amber) when there is a fault in the

power supply.

Fan Module Fault LED is ON (red) when there is a fan failure

38 PFR500/E Instruction Manual 20 September 2002

Page 39

LBB 7-segment display codes

The following table shows event codes for the rear panel 7-segment display on each

LBB.

Code Type Blink Rate Meaning

LBB 7-segment display codes

0 thru 9 Informational Steady or

alternating with

other code.

C Power-up Steady during

power-up

C C r iti cal Stead y > 30

seconds fr om

power-up

F Critical Alternating with

chas si s ad dress

. Informational Blinking

throughout

operation

. Critica l B l in k ing halte d T he LBB has crit ic ally faile d (st ea d y fo r gr eater

H Informational Alternating with

the chassis

address

H Warning Steady for short

duration wi th n o

alternating

Chassis addre ss. Refer to “Chassis address set ting

requirement” on page 26.

Initial ly displaye d during cold boot, will switch to

chassi s address within 30 seconds

If C remai ns l onger t han 3 0 seconds aft er pow er up,

the LBB has failed. Board may n ot be fully seated

or may have suffered a cri tical err or during a

firmwa re upgra d e.

An error or ev ent has oc curred that requi res human

interve n tion. Chec k di sk LE D s an d re ar pa ne l

LEDs. Also, check s yst em st atus usi ng Net Cen tral .

Indicates the LBB is functioning prope rly.

than 30 seconds)

A firmwa re update is in progress

Ethernet li nk has been detected

H Identif y Alternati ng wi th

the chassis

address

LBB has been sent an identify command by GVG

Disk Utility

20 September 2002 PFR500/E Instruction Manu al 39

Page 40

Chapter 3 Servicing the PFR500/E

Removing and installing disk modules

Use the following instructions to replace a faulty disk module. It should be replaced

while the array is running (hot-swapped).

NOTE: Grass Valley Group does not support mixing disk drives of differing

capacities within a RAID chassis connected to a Profile XP Media Platform or

Media Area Network. All disk drives in any RAID chassis must be of the same

capacity. For e xample , if a PFR500 and a PFR500E are used, all the di sk dr ives in

both the PFR500 and the PFR500E must be of the same capacity.

Moving disk modules

CAUTIO N: Y o u can d es troy the media file syst em be yond re covery if you move a

!

disk module to a diffe rent slot. The se rvice person can move a dis k module when you

don’t care about losing the media in the media file system and under the following

cautions:

• The disk module must be unbound.

• Moving a drive module that is part of a LUN to anoth er slot makes all information

on the LUN inaccessible.

• You must remove and install t he disk modul e while the storage syst em is powe red

up.

A disk module must be inserted a ll the way or removed entirely. Do not leave a disk

module partially r emoved except for periods when you are all owing it to spin down.

When replacing multiple disks, observe the following:

• After removing a disk modul e, wait for the activit y LEDs on the other disk modules

to resume a steady flicker before removing the next module.

• After inserting a disk module , wai t for the activity LEDs on the other drives to

resume a steady flicker before inserting the next module.

CAUTION: Handle a disk module gently and use an ESD wristban d. Do not remove

!

a faulty disk module until you have a replacement module (wit h the same part

number) or a filler module available.

40 PFR500/E Instruction Manual 20 September 2002

Page 41

Removi ng a disk module

NOTE: If a disk module has be en bound i nto a LUN, do not m ove it to an other s lot

unless you do not care about the data on the LUN. Each module has LUN

identifying inform ation written when it is bound. Moving it to another slot can

make information on the original LUN inaccessible.

Generally, you should not remove a disk module unless it is faulty. Refer to

“Interpreting disk module LEDs” on page 37 and “Monitoring PFR500/E status using

NetCentral” on page 36.

To remove the disk module:

1. Confirm the drive location by ensuring that the dis k module LED is blue or red.

NetCentral messages may repor t disk faults by disk module number. To locate a

disk module by nu mber, look at th e 7-segment LED di splay on the rear panel of the

RAID Controller or Loop Bypass Boards. It displays a single digit (0 through 9).

This indicates the ch assis address of t he chassis. The chassis displayin g chass is

address 0 contains drives from 0 to 9; the chassis displaying chassis address 1

contains drives from 10 to 19; and so forth.

2. Remove the drive support bracket, if insta lled (r efer to “Installing the chassis with

drive the support bracke t” on page 31.)

Removing a disk module

3. Grasp the release leve r with your th umb and index f ing er and pull outward to ope n

the door.

2

2905

4. Carefully slide the disk module out until it is free and out of its bay.

1

20 September 2002 PFR500/E Instruction Manu al 41

Page 42

Chapter 3 Servicing the PFR500/E

2

Installing dis k module

To install a disk module:

1. Insert the replacement disk module into the empty bay.

1

2299

2. Press the release lever down and into place, as shown.

3. The disk spins up automatically.

4. Disk module rebuild begins i n approximately 3-4 minut es. If not, refer to Chapter

3 of the Profile XP System Guide for instructions on forcing disk module rebuild

using GVG Disk Utility. Also refer to “Interpr eting rear panel status LEDs” on

page 38 for di sk module LED s ta tus duri ng re build. Af terward, check di sk module

status using NetCentra l or GVG Disk Utility.

5. Replace the drive support bracket, if used (refer to “Installing the chassis with drive

the support bracket” on page 31.)

42 PFR500/E Instruction Manual 20 September 2002

Page 43

Replacing the Loop Bypass Board (LBB) or RAID Controller

Replacing the Loop Bypass Board (LBB) or

RAID Controller

Use the following instructions to replace an LBB or RAID Controller module. It

should be replaced while the chas sis is powered up (hot-swapped).

NOTE: Ensure that the RAID Controller or LBB you are installing has the same

microcode version as the module being replaced. Otherwise, the replacement

module will not initialize. Refer to the Profile XP System Guide for information on

checking co ntr o ller fi rmware versions .

NOTE: A PFR500 must have at least one RAID Controller installed while it is

powered up. Do not remove both RAID Controlle r while the PFR500 is powered up.

Removing the LBB or RAID Controller

NOTE: Removing or insertin g the RAID Controller or LB B causes approximately

a 10 second loss of video (record/play ). This happens regardles s of whether you are

exchanging the primary controlle r or the secondary controller.

To remove the LBB or RAID Controller:

1. Identify the module to be replaced using NetCentral or rear panel LED indicators.

2. Remove the cables connected to the module. Note where the cables connec t to the

module.

3. Loosen captive screws as shown in the figure below.

1

2

3

20 September 2002 PFR500/E Instruction Manu al 43

2909

Page 44

Chapter 3 Servicing the PFR500/E

4. Unseat the module by pushing down on the two ejector levers.

5. Pull the module out of the chassis.

Installing the LBB or RAID Controller

Before instal ling the rep lacement RAID Co nt ro ller or LBB , ens u re it has the sam e

microcode version as th e module bei ng re placed. Oth erwise , the repla cement module

will not initializ e.

NOTE: Removing or insertin g the RAID Controller or LB B causes approximately

a 10 second loss of video (record/play ). This happens regardles s of whether you are

exchanging the primary controlle r or the secondary controller.

To install the LBB or RAID Controller:

1. Insert the replacement module in to the empty bay . Make sure the module is sea ted.

2. Push up the two ejector levers to seat the module.

3. Tighten the captive screws.

4. Reconnect cabling.

5. Verify module initialization using rear panel status LEDs. Refer to “Interpreting

rear panel status LEDs” on page 38. If the repl acement module fail s to initia lize, it

may have the wrong microcode version installed. Refer to Chapter 3, “Working

with Storage Using GVG Disk Utility”, in the Profile XP System Guide for

information on checking and loading controller firmware.

6. Check module status using NetCentral or GVG Disk Utility.

44 PFR500/E Instruction Manual 20 September 2002

Page 45

Replacing GBIC data ports

The PFR500/E ships with passive copper data ports installed in t he RAID Controller

and Loop Bypass Board (LBB) modules.

To replace the GBIC:

1. Remove cabling and remove the GBIC as shown.

2. Insert the replacement GBIC into the module as shown, then reconnect cabling.

3. Verify the Fibre Channel connection using the port Loop LED. Refer to

“Interpreting rear panel status LEDs” on page 38.

Replacing GBIC data ports

2904

20 September 2002 PFR500/E Instruction Manu al 45

Page 46

Chapter 3 Servicing the PFR500/E

Replacing a power supply

CAUTION: Turn off the power supply before unplugging the power cord from the

!

supply or removing the supply from the chassis.

To replace the power supply:

1. Turn the standby switch to Standby (0), as shown.

2750

Off/Standby

switch

2. Remove the electrical cable from the power supply.

3. Loosen the captive screw on the power supply.

4. Pull the module out of the enclosure, as shown.

2908

5. Insert the replacement power supply into the empty bay.

6. Tighten the captive screw on the power supply.

46 PFR500/E Instruction Manual 20 September 2002

Page 47

Replacing the fan module

7. Pl ug the el ectri ca l cabl e i nto the p ow er s uppl y .

8. Turn on the power supply. Turn the standby switch to ON (1).

9. Monitor the status of the power supply using rear panel status LEDs and

NetCentral.

Replacing the fan module

CAUTION: Do not remove a faulty fan module until you have a replacement fan module

available. You can remove the drive fan module while the PFR 500/E is powered up.

To replace a fan module:

1. Loosen the captive screw on the fan module.

2. Pull the module out of the enclosure.

3. Insert the replacement fan module into the empty bay.

4. Tighten the captive screw on the module.

2907

5. As soon as the module is reinstalled, the fans start spinning and the system fault

indicators are cle are d if no other FRUs are faulty.

20 September 2002 PFR500/E Instruction Manu al 47

Page 48

Chapter 3 Servicing the PFR500/E

48 PFR500/E Instruction Manual 20 September 2002

Page 49

Appendix

A

Technical Specifications and Operating Limits

AC power requirements

Power Input

100-120 VAC, 50/60Hz, 6amps

200-240 VAC, 50/60Hz, 3 amps

If one of the two po wer supplies f ails, the r emaining supply and c ord must su pport the

full load. Your ra ckmount cabinet must i nclude ac power distribu tion t hat can handle

these values.

Size and weight

Item Measurement

Height 13.34 cm (5.25 in) (3 rack units )

Widt h 44.83 cm (1 7.65 in)

Dept h 5 5. 88 cm (22 in )

Weight 34.0 kg (75.0 l b s)

Copper cable lengths

It is recommended that you use the copper Fibr e Channel c ables shipped with your

PFR 500 when making connections.

Any copper cable s you use must meet the a ppropriate st andards fo r 1-Gbit FC-AL l oops.

Such cables are fully shielded, twin-axial, full-duplex cables with DB-9 connectors.

Cables greater th an 10 meters must be equalized; cab les equal to or less than 10 meters

do not need to be equalized. Do not use copp er cables longer than 15 meters for any Fibr e

Channel connection in a Profil e system.

20 September 2002 PFR500/E Instruction Manual 49

Page 50

Appendix A

Environmental limits

Requirements Description

Temperat ure (Operating) 5 to 35 degrees C (41 to 95 degrees F)

Temperat ure (Non-op erating -40 to 65 de grees C (-40 to 149 degrees F)

Relative Humidity (Oper ating) 5 to 75%, non-conde nsing

Relative Humidity (Non-operating 5 to 95%, non-condensing

The system includes two temperat ure level sensors used to issue auto-warning and

auto-shutdown incas e the over te mperature limit is reached.

50 PFR500/E Instruc tion Manual 20 September 2002

Page 51

Index

Numerics

9-pin cable 23

A

AC power

current draw 49

overview 25

address switch, chassis 26

Authorized support representative 13

B

Battery Backup Unit 17, 34

binding disk modules 27

blinking disk module LEDs 37

blue drive LED, blinking 37

C

cabling

max lengths 27, 49

requirements 27

cabling requirements 27, 49

Canadian Certified Power Cords 7

Canadian EMC Notice of Compliance 7

capacity 16

chassis address switch 26

chassis description 18

chassis dimensions 49

chassis weight 49

colors, disk module LEDs 37

components 16

See FRUs (field replaceable units)

configurations 24

console program 21, 23

D

depth, chassis 49

disk module

description 19

disk module LED colors 37

identification 18

installing 42

removing 41

replacing 40

disk module LED displays, interpreting 37

disk utilities 27

documentation set 9

documentation, online 12

drive support bracket 31

E

ejector lever 44

Emission Control, compliance 7

EN55022 Class A Warning 7

error codes 39

Ethernet connector 21, 23

F