Page 1

Instruction Manual

071-0683-03

NOVEMBER 2000

PROFILE XP PFC500/E

FIBRE CHANNEL RAID STORAGE SYSTEM

Page 2

Copyright Copyright 2000 Grass Valley Group Inc. Grass Valley, California.

Portions copyright

Printed in the United States of America. All rights reserved. This document may not be copied in

whole or in part, or otherwise reproduced except as specifically permitted under U.S. copyright law,

without the prior written consent of Grass Valley Group Inc., P.O. Box 1114, Crass Valley,

California 95945 USA.

CLARiiON Storage Systems, Inc. Reprinted with permission.

Trademarks Grass Valley, GRASS VALLEY GROU P, Profile and Pro file XP are either registered trad emarks

or trademarks of Grass Valley Group in the United States and/or other countries. Other trademarks

used in this document are either registered trademarks or trademarks of the manufacturers or

vendors of the associated products. Grass Valley Group products are covered by U.S. and foreign

patents, issued and pending. Additional information regarding Grass Valley Group’s trademarks

and other proprietary rights may be found at www.grassvalleygroup.com.

Windows NT is a registered trademark of Microsoft.

Disclaimer Product options and specifications subject to change without notice. The information in this manual

is furnished for informational use only, is subject to change without notice, and should not be

construed as a commitment by Grass Valley Group. Grass Valley Group assumes no responsibility

or liability for any errors or inaccuracies that may appear in this publication.

U.S. Government

Restricted Rights

Legend

Revision Status

Use, duplication, or disclosure by the United States Government is subject to restr ictions as set

forth in subparagraph (c)(1)(ii) of the Rights in Technical Data and Computer Software clause at

DFARS 252.277-7013 or in subparagraph c(1) and (2) of the Commercial Computer Sof tware

Restricted Rights clause at FAR 52.227-19, as applicable. Manufacturer is Grass Valley Group

Inc., P.O. Box 59900, Nevada City, California 95959-7900 U.S.A.

Rev Date Description

November 8, 1999 Initial release of the PFC500/E RAID Storage Instruction Manual

071-0683-00A

December 2, 1999 Revised to include Customer Replaceable Parts list.

071-0683-01

July 21, 2000 Corrected instructions for setting FC-AL IDs in installation chapter.

071-0683-02

November 17, 2000 Added procedure for wholesale drive replacement. 071-0683-03.

2 PFC500/E Instruction Manual November 17, 2000

Page 3

Notice

THIS DOCUMENT HAS BEEN PREPARED FOR USE BY GRASS VALLEY GROUP INC.

PERSONNEL, CUSTOMERS, AND PROSPECTIVE CUSTOMERS. THE INFORMATION

CONTAINED HEREIN SHALL NOT BE REPRODUCED IN WHOLE OR IN PART WITHOUT

PRIOR WRITTEN APPROVAL.

The right to make changes in specifications and other information contained in this document

without prior notice is reserved, and the reader should in all cases consult GRASS VALLEY

GROUP INC. to determine whether any such changes have been made.

NO REPRESENTATION OR OTHER AFFIRMATION OF FACT CONTAINED IN THIS

DOCUMENT INCLUDING BUT NOT LIMITED TO STATEMENTS REGARDING CAPACITY,

RESPONSE-TIME PERFORMANCE, SUITABILITY FOR USE OR PERFORMANCE OF

PRODUCTS DESCRIBED HEREIN SHALL BE DEEMED TO BE A WARRANTY FOR ANY

PURPOSE, OR GIVE R I SE T O AN Y LIA BI L IT Y O F D G C WH A TSOEVER.

IN NO EVENT SHALL LIABILITY FOR ANY INCIDENTAL, INDIRECT, SPECIAL OR

CONSEQUENTIAL DAMAGES WHATSOEVER (INCLUDING BUT NOT LIMITED TO LOST

PROFITS) ARISE OUT OF THIS DOCUMENT OR THE INFORMATION CONTAINED IN IT,

EVEN IF THE POSSIBILITY OF SUCH DAMAGES WAS KNOWN OR SHOULD HAVE BEEN

KNOWN.

LICENSED INTERNAL

CODE

Items of hardware (called "Machines") as described herein which are supplied to Buyer by GRASS

VALLEY GROUP INC. use licensed internal code ("LIC"). CLARiiON Storage Systems, Inc. owns

copyrights in the LIC and any updates or replacements and any utility software supplied with or for

a Machine (all "CODE") and all copies of the Code. All Code is subject to the following license

terms and conditions:

(a) License. Code is licensed for use only by Buyer, only for the specific Machine, designated by

serial number or other unique identifier, for which the Code is provided, and only while Buyer

is the rightful possessor of the Machine. Under this license, Buyer, and Buyer is authorized,

and Buyer agrees, to do only the following:

1. Execute the Code only on the Machine, as necessary to operate or maintain the Machine

according to its specifications except that utility software, designated as such, may be

executed on a host connected to the Machine but only for use with the Machine; and

2. make a backup or archival copy of t he Code, which Buyer may use only when necessary

to replace the original, provided Buyer reproduces the copyright notice and any other

legend on the copy.

(b) Duration of License. Buyer’s license terminates when Buyer no longer rightfully pos sesses

the Machine. Buyer may transfer possession of the Code to another party only with the transfer

of the Machine. If Buyer does so, Buyer shall (i) either give the other party, or destroy, all

Buyer’s copies of the Code, and (ii) give the other party a copy of these license terms together

with the serial number or other unique identifier for the Machine. The other party shall be

licensed only when the other party accepts these terms by initial use of the Code.

(c) Actions Buyer May Not Take. Buyer agrees to use the Code only as authorized above. Buyer

may not do, for example, any of the following:

1. otherwise copy, display, transfer, adapt, modify, distribute or transfer the Code, in whole

or in part,electronically or otherwise;

2. reverse assemble, reverse compile, or otherwise translate the Code; or

3. sublicense, assign or otherwise transfer Buyer’s license for the Code.

November 17, 2000 PFC500/E Instruction Manual 3

Page 4

4 PFC500/E Instruction Manual November 17, 2000

Page 5

Contents

Safety Summaries

General Safety Summary.....................................................................................................7

Safety Terms and Symbols..................................................................................................8

Service Safety Summary.......................................................... .................................. ..... .....8

Certifications and Compliances........................................... ..... ...... ..... ...... ...........................9

Preface

About this manual...............................................................................................................11

Using the Profile XP Documentation Set.......................................................................11

Manual Descriptions...................................... ................................. ...... ...... ..... ..............12

How this manual is organized........................................................................................13

Getting more information....................................................................................................14

On-line manuals............................................................................................................14

Grass Valley Group Product Support.................................................................................15

Chapter 1 About the PFC500/E

PFC 5 00/E components......................................................................................................18

Chassis...............................................................................................................................18

Midplane........................................................................................................................20

Front door......................................................................................................................21

RAID Controllers (RCs).................................................................................................21

Disk modules................................................. ..... .................................. ...... ..... ...... ..... ...22

Disk drives..................................................... ..... ...... .................................. ..... ...... ..... .. .22

Drive carrier...................................................................................................................22

Power supplies (PSs).........................................................................................................23

Drive fan pack ....................................................................................................................24

Configurations....................................................................................................................25

What next?.........................................................................................................................25

Chapter 2 Installing a PFC500/E

Requirements.....................................................................................................................27

Site requirements ..........................................................................................................27

Power........................................................................................................................27

Cooling......................................................................................................................27

Cabling requirements....................................................................................................28

Addressing requirements.................... ..... ...... ..... ...... .................................. ..... ...... ..... ...28

FC-AL address ID.....................................................................................................28

Chassis address (CA)...............................................................................................28

Installing a PFC500/E in a cabinet.......... ..... ...... ................................. ...... ...... ...................29

Determining the rail mounting positions........................................................................29

Attaching the mounting rails..........................................................................................31

Sliding PFC500/E onto rails ..........................................................................................32

Setting addresses and connecting cables.....................................................................35

PFC 5 00/E powerup and initialization.................................................................................40

PFC500/E powerdown.......................................................................................................40

Binding disk modules into groups.......................................................................................40

November 17, 2000 PFC500/E Instruction Manual 5

Page 6

Contents

Chapter 3 Servicing and upgrading a PFC500/E

Hot swapping components.................................................................................................41

Monitoring PFC500/E status..............................................................................................42

Handling CRUs ..................................................................................................................44

Power issues and CRUs ...............................................................................................44

Avoiding electrostatic discharge (ESD) damage...........................................................44

Emergency procedures (without an ESD kit)............................................................45

Precautions when removing, installing, or storing CRUs...............................................45

Replacing or adding a disk module.................................................................................... 46

Replacing all disk modules in a PFC500/E........................................................................51

Removing an RC or an RC filler module............................................................................52

Installing or removing the RC memory module..................................................................54

Installing an RC or an RC filler module..............................................................................57

Replacing the drive fan pack..............................................................................................60

Replacing or adding a power supply module.....................................................................62

Appendix A Technical specifications and operating limits

Technical specifications.....................................................................................................71

ac power requirements..................................................................................................71

Size and weight.............................................................................................................72

Drive type......................... ...... ..... .................................. ...... ..... ...... ..... ...... ....................72

Disk module address................................................................................................72

RC FC-AL interface.......................................................................................................72

Copper cabling..............................................................................................................73

Standards certification and compliance.........................................................................73

Safety standards.......................................................................................................73

EMI standards ..........................................................................................................73

Fibre Channel related standards..............................................................................73

Operating limits..................................................................................................................74

Shipping and storage requirements...................................................................................74

Glossary..........................................................................................................................75

Index.................................................................................................................................79

6 PFC500/E Instruction Manual November 17, 2000

Page 7

Safety Summaries

General Safety Summary

Review the following saf ety precautions to avoid injury and prevent damage

to this product or any products connected to it.

Only qualified personnel should perform service procedures.

While using this pr oduc t, you may need t o acce ss oth er par ts o f the syste m.

Read the General Safety summary in other system manuals for warnings and

cautions related to operating the system.

Injury Precautions

Use Proper Power

Cord

Ground the Product This product is grounded through the grounding conductor of the power

Do Not Operate Without Covers

Do Not operate in

Wet/Damp

Conditions

Do Not Operate in an

Explosive

Atmosphere

Avoid Exposed

Circuitry

To avoid fire hazard, use only the power cord specified for this product.

cord. To avoid electric shock, the grounding conductor must be connected

to earth ground. Before maki ng connections to the input or outpu t terminals

of the product, ensure that the product is properly grounded.

To avoid electric shock or fire hazard, do not operate this product with

covers or panels removed.

To avoid electric shock, do not operate this product in wet or damp

conditions.

To avoid injury or fire hazar d, do not operate this pr oduct in an explosive

atmosphere.

To avoid injury, remove jewelr y such as ring s, wa tc hes , and othe r meta ll ic

objects. Do not touch ex posed conn ectio ns and compone nts when power is

present.

Product Damage Precautions

Use Proper Power

Source

Provide Proper

Ventilation

Do Not Operate With

Suspected Failures

November 17, 2000 PFC500/E Instruction Manual 7

Do not operate this product f rom a power sour ce that applie s more than the

voltage specified.

To prevent product overheating, provide proper ventilation.

If you suspect t here is da mage to th is product, have it in spected by qu alified

service personnel.

Page 8

Safety Summaries

Safety Terms and Symbols

Terms in This

Manual

!

!

Terms on the

Product

Symbols on the

Product

These terms may appear in this manual:

WARNING: Warning statemen ts identify conditi ons or practices that can

result in personal injury or loss of life.

CAUTION: Caution statement s i dent if y conditions or practi ces tha t can

result in damage to the equipment or other property.

These terms may appear on the product:

DANGER indicates a personal injury hazard immediately acce ssible as one

reads the marking.

WARNING indicates a personal injury hazard not immediately accessible

as you read the marking.

CAUTION indicates a hazard to property including the product.

The following symbols may appear on the product:

DANGER high voltage

Protective ground (earth) terminal

!

ATTENTION – refer to manual

Service Safety Summary

Do Not Service

Alone

Disconnect Power To avoid electric shock, disconnect the main power by means of the power

Use Care When

Servicing With

Power On

Do not perform interna l service or adj ustment of this pro duct unless anothe r

person capable of rendering first aid and resuscitation is present.

cord or, if provided, the power switch.

Dangerous voltages or currents may exist in t his product. Discon nect power

and remove battery (if applicable) before removing protective panels,

soldering, or replacing components.

To avoid electric shock, do not touch exposed connections

8 PFC500/E Instruction Manual November 17, 2000

Page 9

Certifications and Compliances

Canadian Certified

Power Cords

FCC Emission

Control

Canadian EMC

Notice of

Compliance

Canadian approval includes the products and power cords appropriate for

use in the North America power network. All other power co rds supplied are

approved for the country of use.

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if

not installed and use d in accordance with th e instruction ma nual, may cause

harmful interfere nce to radio communication s. Operation of this equipment

in a residential area is likely to cause harmful interference in which case the

user will be required to cor rect the interference at his own expense. Changes

or modifications not expressly approved by Tektronix can affect emission

compliance and could void the user’s authority to operate this equipment.

This digital apparatus does not exceed the Class A limits for radio noise

emissions from digital apparatus set out in the Radio Interference

Regulations of the Canadian Department of Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques

dépassant les limites applicables aux appareils numériques de la classe A

préscrites dan s le Règlement sur le brouillage radioélectrique édicté par le

ministère des Communications du Canada.

Canadian Certified

AC Adapter

EN55022 Class A

Warning

FCC Emission

Limits

Canadian approval includes the AC adapters appropriate for use in the

North America power network. All other AC adapters supplied are

approved for the country of use.

For products that comply with Class A. In a domestic environment this

product may cause radio interference in which case the user may be

required to take adequate measures.

This device complies with Part 15 of th e FCC rules. Operation is subject

to the following two conditions:

(1) this device may not cause harmful interference, and (2) this device

must accept any interference received, including interference that may

cause undesired operation. Testing was done with shielded cables.

Therefore, in order to comply with the FCC regulations, you must use

shielded cables with your installation.

November 17, 2000 PFC500/E Instruction Manual 9

Page 10

Safety Summaries

Manufacturer’s

Declaration of

Conformity

This equipment has been tested and found to comply with the

requirements of European Community Council Directives 89/336/EEC

and 73/23/EEC relating to electromagnetic compatibility and product

safety respectively.

ATTENTION This product has been designed and certified to comply with certain

regulatory requirements pertaining to Information Technology

Equipment. This product has not been designed for use as a medical

device. Without limitation of the foregoing, this product is not intended

and has not been ce rtif ied f or use i n a hosp ital or cl inica l envi ro nment t o

diagnose, treat, or monitor patients un der medical super vision, and is not

intended and has not been certif ied to make phys ical or electr ical co ntact

with patients, nor to transfer energy to or from patients and/or to detect

such energy transfer to or from patients .

10 PFC500/E Instruction Manual November 17, 2000

Page 11

Preface

About this manual

This manual explains how to install t he Profile XP Fibre Channel RAID Storage

Chassis and RAID Expansion Chassis (PFC500/E), and how to replace and add

customer-replaceable units (CRUs).

If you are a technical service person who will install and service the PFC500/E, you

should read this manual. After reading it, you will be able to install a PFC500/E,

replace any CRUs tha t may fail, and u pgrade a PFC500/E by adding disk modules and

redundant CRUs.

You must consult the Profile XP System Guide for information on connecting and

configuring your PFC500/E to a Profile XP Media Platform.

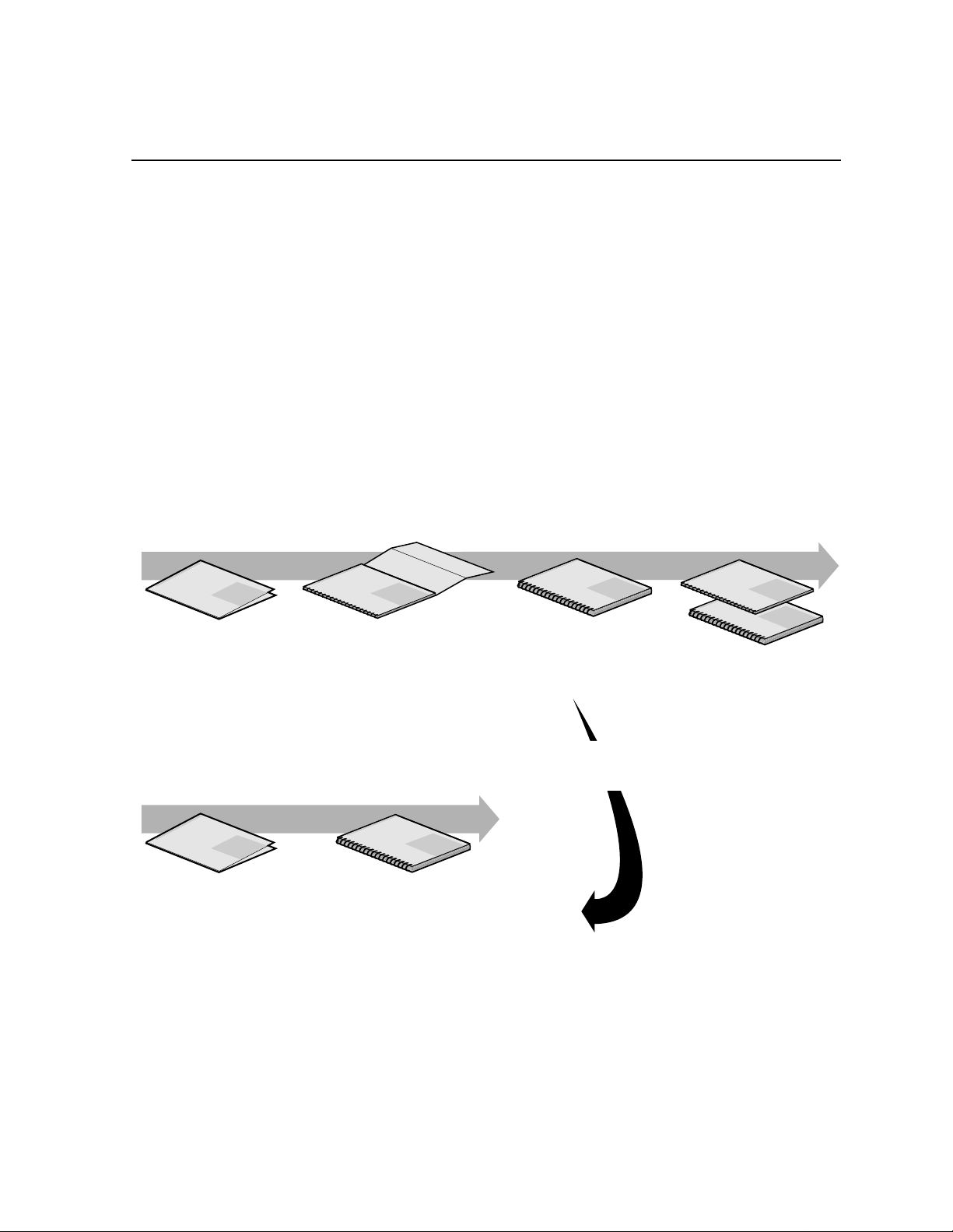

Using the Profile XP Documentation Set

This manual is part of a full set of support documentation for the Profile XP Media

Platform. The following illustrates how to use the Profile XP documentation

depending on the task you are performing.

Path for the Installer

Grass Valley Group

Profile XP

Manual

Family of XP Series

Release Notes

Contains the latest

information about Profile XP

hardware and software

shipped with your system.

Path for the Operator

Grass Valley Group

Profile XP

Manual

Family of XP Series

Release Notes

Contains the latest

information about Profile XP

hardware and software

shipped with your system.

Grass Valley Group

Profile XP

Manual

Family of XP Series

Installation Guide

Contains essential steps for

installing your Profile XP

system using factory

Grass Valley Group

System Guide

Contains the product description

and step-by-step instructions for

modifying system settings.

default settings.

Grass Valley Group

Profile XP

Manual

Family of XP Series

User Manuals

Contains complete instructions for using

Profile applications. These manuals include:

- Profile XP User Manual

- ContentShare Explorer User Manual

- Other user manuals you received with

Profile XP

Manual

Family of XP Series

Installers consult

the User Manuals

as needed.

Grass Valley Group

Profile XP

Manual

Family of XP Series

Grass Valley Group

Profile XP

Manual

Family of XP Series

Other Manuals

These manuals include:

- PFC500 Instruction Manu

- Profile XP Service Manua

with NetCentral.

0624-39

November 17, 2000 PFC500/E Instruction Manual 11

Page 12

Preface

Manual Descriptions

• Inst all atio n Guide (for your Profile XP Model) This guide provides step-by-step

instructio ns for installing the Profile XP Media Platform using factory default

settings fo r all record/play channels. Factory de fault settings are indicated within

the guide. After installing the Profile XP system using this installation guide, you

can refer to this Profile XP System Guide to customize system settings for your

installation.

•

Profile XP System Guide This guide provides al l t he inf or ma ti on yo u nee d to go

beyond factory defa ult settings an d customize your sys tem’s comfiguration to meet

your site-specific needs. This guide also provides an overview of your Profile XP

system, and provides all the spscifications you need to integrate the Profile XP

Media Platform into your operation.

•

Profile XP User Manual Contains complete instructions for using Profile

applications to operate the Profile XP Media Platform.

•

Profile XP Service with NetCentral Manual Contains information for servicing

the Profile XP Media Platform, and includes procedures for the following tasks:

- Problem analysis using symptom, problem, solution tables.

- Running diagnostics locally and remotely

- Set up and operation of Portals remote monitoring software.

- Replacing field replaceable units.

•

Profile XP Release Notes Contain s the latest inf ormation about the Profil e

hardware and the software release shipped on your system. This information

includes software specifications and requirements, feature changes from the

previous releases, helpful system administrative information, and any known

problems.

• PFC500/E Instruction Manual

Contains information f or servicing the Profile X P

Fibre Channel RAID Storage Chassis (PFC500/E) including step-by-step

procedures for replacing field replaceable units.

12 PFC500/E Instruction Manual November 17, 2000

Page 13

How this manual is organized

The PFC500/E Instruction Manual is organized around the tasks you’ll be

performing to install and service your Fibre Chann el RAID Storage Sys tem. You can

see this refl ected in the chap ter tit les chos en for t his man ual. The f ollowing i dentifi es

and describes the chapters included in this manual:

Chapter 1 - About the PFC500/E

Introduces the Profile XP Fibre Channel RAID Storage Chassis (PFC500) and the

RAID Expansion Chassis (PFC500E). You can read this chapter to get familiar with

the RAID Storage Chassis key features and components.

Chapter 2 - Installing a PFC500/E

Describes how to install a RAID Storage Chassis and RAID Expansion Chassis,

including rack mounting. Refer to the Profile XP System Guide for connection and

configuration information.

Chapter 3 - Servicing and upgrading a PFC500/E

Describes how to replace CRUs, such as disk modules , and add disk modules and

redundant CRUs.

Appendix A - Technical specifications and operating limits

This appendix consists of electrical and environmental specifications.

How this manual is organized

Glossary

The Glossary explains terms used throughout this manual.

November 17, 2000 PFC500/E Instruction Manual 13

Page 14

Preface

Getting more information

In addition to printed do cuments, Pro file XP product information is availabl e in

on-line manuals. Use these as additional sources for information.

On-line manuals

Electronic versions of the following manuals are located on the syst em dr i ve o f your

Profile XP Media Platform and on the Profile XP software CD-ROM.

• Installation Guide (for your model)

• Profile XP System Guide

• Profile XP User Manual

• Profile XP Service with NetCentral Manual

• PFC500/E Instruction Manual

• Profile XP Release Notes

You can view these manu als usin g Adobe Acroba t Reader whi ch is al so pre-in stalled

on your Profile XP system.

14 PFC500/E Instruction Manual November 17, 2000

Page 15

On-line manuals

Grass Valley Group Product Support

You can get technical assistanc e, c hec k on the status of pr obl ems, or report new problems b y

contacting our Product Support Group.

United States and Canada

Monday–Friday 5:30AM–5:00PM Pacific Time

(800) 547-8949

Europe

Monday–Friday 9:00AM–5:30PM

France 01 69 86 83 47 United Kingdom 01628 40583 0

Germany 0221 9477 446 Other +44 1628 405840

Italy 02 25086606

Asia and South America

Australia

- from overseas

Beijing 86-10-62351230

Brazil 55-11-3741-8422 Taiwan 886-2-27571571

Hong Kong 852-25856655

02-9888 0100

61-2-9888 0100

ext. 711

Japan 81-3-3448-3111

Korea 82-2-528-5299

Mexico 52-5-666-6333

Singapore 65-356-3900

World Wide

24-hour Emergency Hotline (530) 478-4148 (C ontr act and warranty customers)

World Wide Web http://www.grassvalleygroup.com

FTP Site ftp.grassvalleygroup.com

Users Group profile-users@grassvalleygroup.com

November 17, 2000 PFC500/E Instruction Manual 15

Page 16

Preface

16 PFC500/E Instruction Manual November 17, 2000

Page 17

Chapter

1

About the PFC500/E

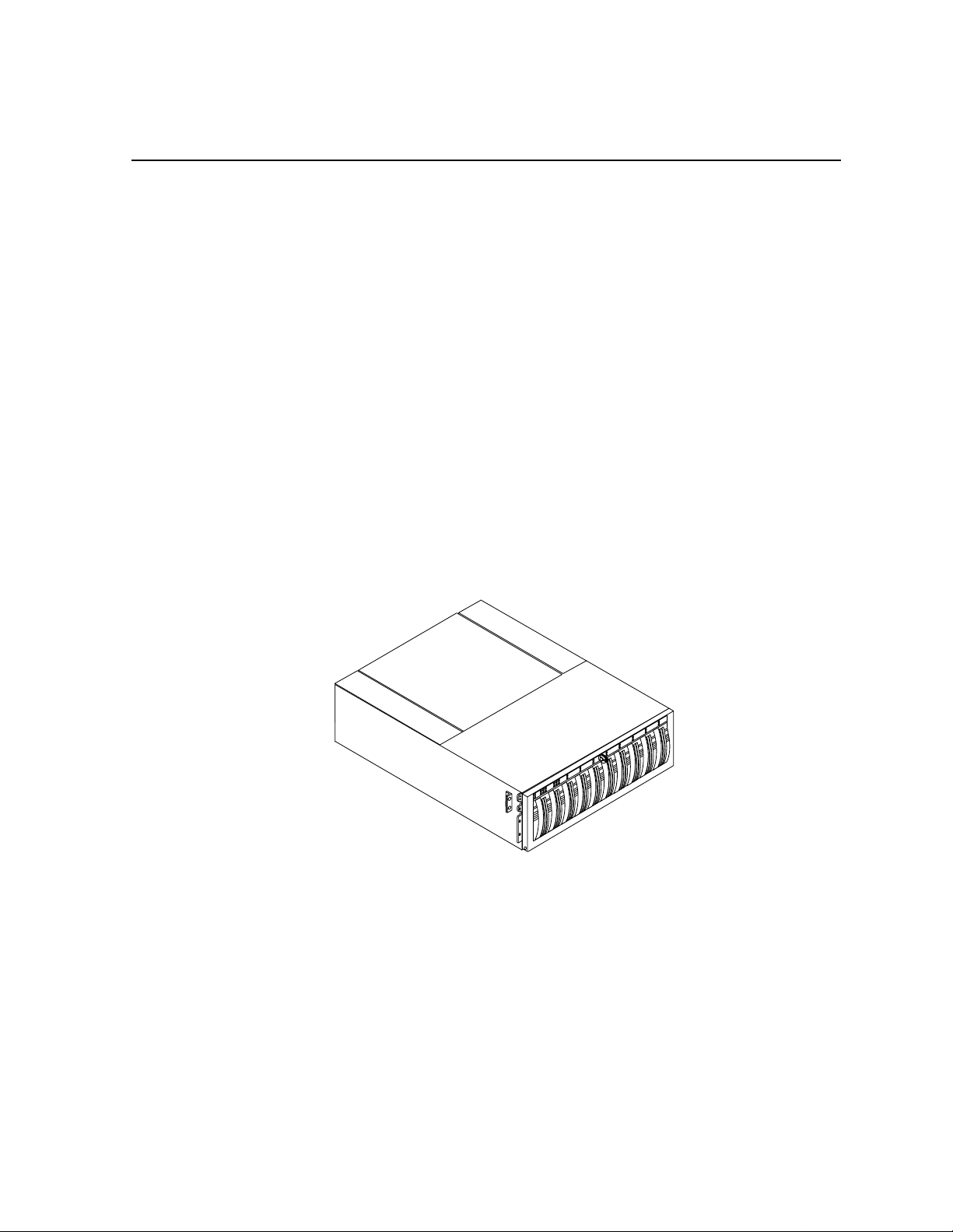

This chapter introduce s the Pro file XP Fibr e Channel RAID Storage Chassis . Topics

are :

• PFC500/E components

• Enclosure

• RAID Controllers (RCs)

• Disk modules

• Power supplies

• Drive fan pack

• Configurations

The PFC500 is an intelligent, highly available, high performance, high capacity

storage system that uses a Fibre Channel Arbit rated Loop (FC-AL) as it s interconnect

interface. Its modula r, s calab le desi gn prov ides ad dit ional disk s torage as your needs

increase.

Using its FC-AL interface , with si mple FC-AL se rial cablin g, a PFC500 can support

up to two PFC500E RAID Expansion Chassis. A PFC500E is a basic chass is without

a RAID controller (RC). The PFC500 and two PFC500Es support up to 30 disk

modules in a single disk-array storage system. You can place the PFC500Es in the

same cabinet as the PFC500, in a separate cabinet, or in two separate cabinets.

A PFC500 connects to a Profile XP Media Platform using the server’s Fibre Channel

Disk adapter (FC adapter ).

Throughout this manual , t he term PFC500/E is used to refer to either the PFC500 or

the PFC 500E interchangeably.

November 17, 2000 PFC500/E Instruction Manual 17

Page 18

Chapter 1 About the PFC500/E

PFC500/E components

The PFC500/E components are:

• A sheet-metal chassis with a midplane and front door

• One or two RAID controllers (PFC500 only)

• One or two Link Control cards (PFC500E only)

• As many as ten Fibre Channel disk modules

• One or two power supplies

• One drive fan pack

Any unoccupied slot (RAID controller, disk module, or power supply) has a filler

module to maintain ai r flow and complian ce with electroma gnetic interfe rence (EMI)

standards.

The RCs, disk modules, power supplies, fan packs, and filler modules are

customer-replaceabl e units (CRUs), which you can add or replace without tools whi le

the PFC500/E is powered up.

The optional high availability features for a PFC 500/E are

• second RC (PFC500 only)

• second power supply

A second RC provides cont inued access to the PFC500 and any connected PFC500Es

if the first RC fails. Adding a second RC to the same chassis is not in tended to increase

performance, but ra ther to add re dundancy

detailed connection, configuration, and performance information.

The disk drives are FC-AL compliant and support dual-port FC-AL interconnects

through the two RCs and their cabling.

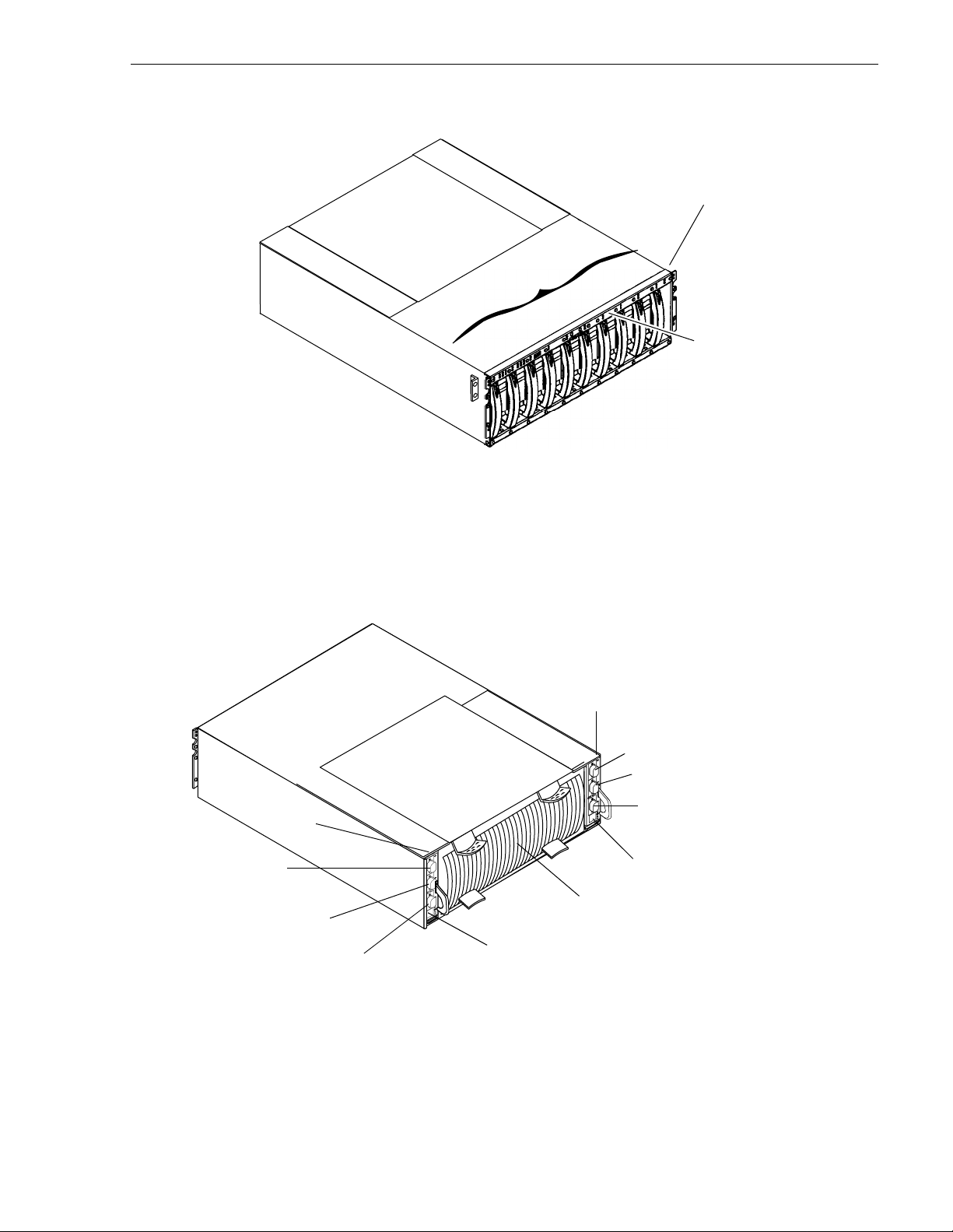

Chassis

The chassis is a sheet-metal housing with a front panel, a midplane, front door, and

slots for the RCs, disk modules, power supplies, and the fan pack.

The following figures show the PFC500/E components. Details on each component

follow the figures. If the chassis provides slots for two identical components, the

component in slot A is called component-name A. If there is a second component, it

is in slot B and is called component-nameB, as follows.

. Refer to the Profile XP System Guide for

Component Name in slot A Name in slot B

RAID Controller RC A RC B

Power supply PS A PS B

If you have one power supply, it can be in either slot A or slot B. If you have one

RAID controller, it can be in either slot A or B.

18 PFC500/E Instruction Manual November 17, 2000

Page 19

Front panel with door

removed for clarity.

*

s

e

l

u

d

o

m

k

s

i

D

n2

n1

n0

n3

n4

n5

n6

n7

n8

n9

* n is the chassis address (CA) set on the front panel at

installation. It must be set to 0 for a

values are invalid for a

PFC500. The disk module ID is the

PFC500. All other CA

chassis address and the module ID (0-9) within the chassis. In

PFC500, the ID for the right most disk module is 09.

a

Chassis

Front panel

Expansion (EXP) port

RC B

Port B

Port A

RC A

Expansion (EXP) port

E

X

P

Port B

A

B

Port A

E

X

P

A

B

Serial port

Drive fan pack

Serial port

November 17, 2000 PFC500/E Instruction Manual 19

Page 20

Chapter 1 About the PFC500/E

Power supply

in slot A

Power supply

E

X

P

in slot B

A

B

E

X

P

A

B

Power cord

connectors

Chassis

address lights

0

10

12345

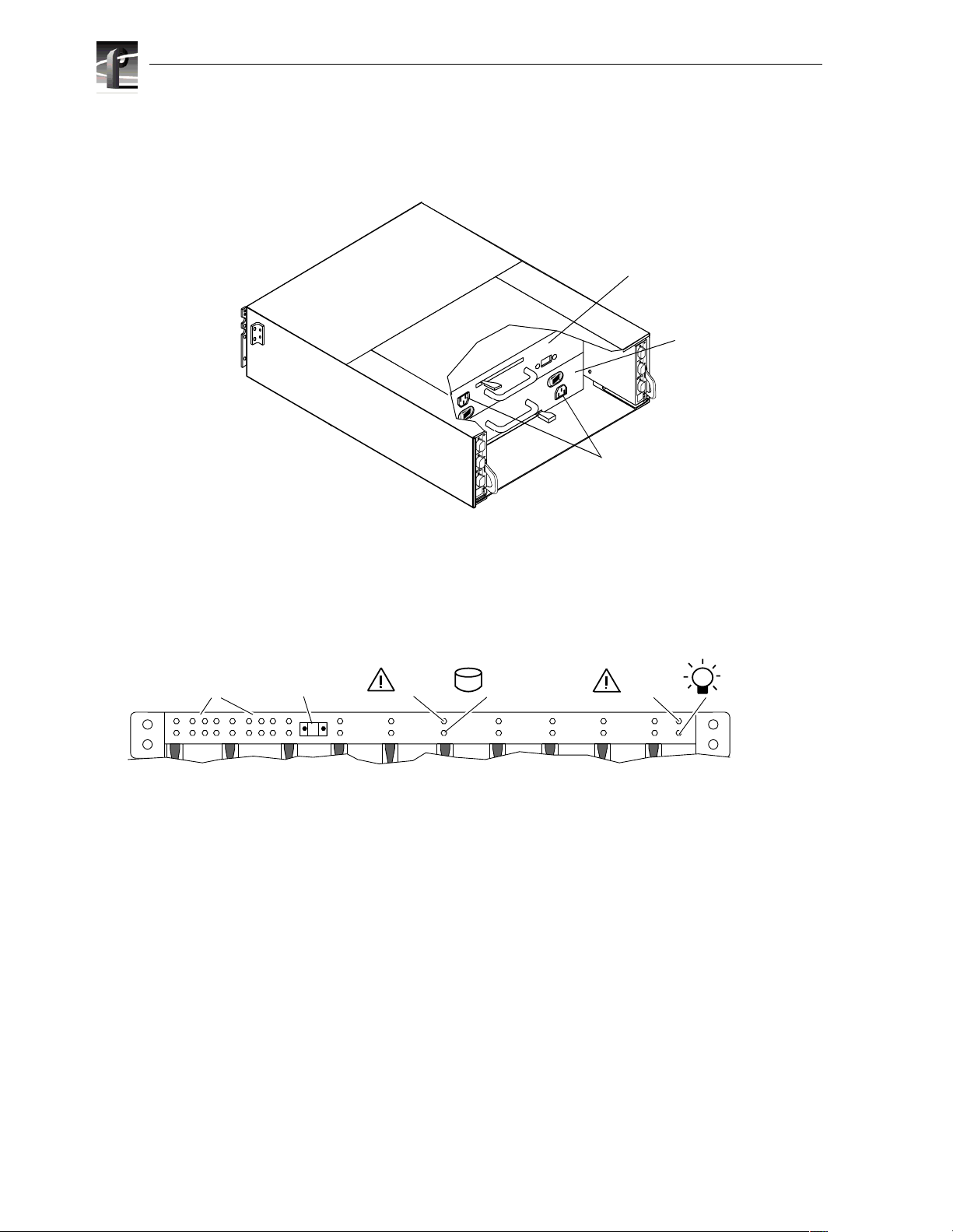

The front panel contains t he chassis address (CA) light, two status ligh ts for each disk

module slot, and two status lights. All lights are visible with the front door closed.

The chassis address light displays the chassis address setting for the PFC500. The

PFC500 must have a CA of 0. You must set that CA using the chassis address

switches, as explained in Chapter 2.

The status lights are described in the “Monitoring PFC500/E status” on page 42.

Midplane

The midplane distri but es power and signals t o a ll t he chassis components. All CRUs

except the fan packs plug directly into midplane connectors.

Disk module status lights

Chassis

address switch

(not visible with

door closed)

678910

0

2 3 4 5 6 7 8 9

11

(two per module)

Disk

check

Disk

Active

PFC 500/E status lights

System

Check

Power

20 PFC500/E Instruction Manual November 17, 2000

Page 21

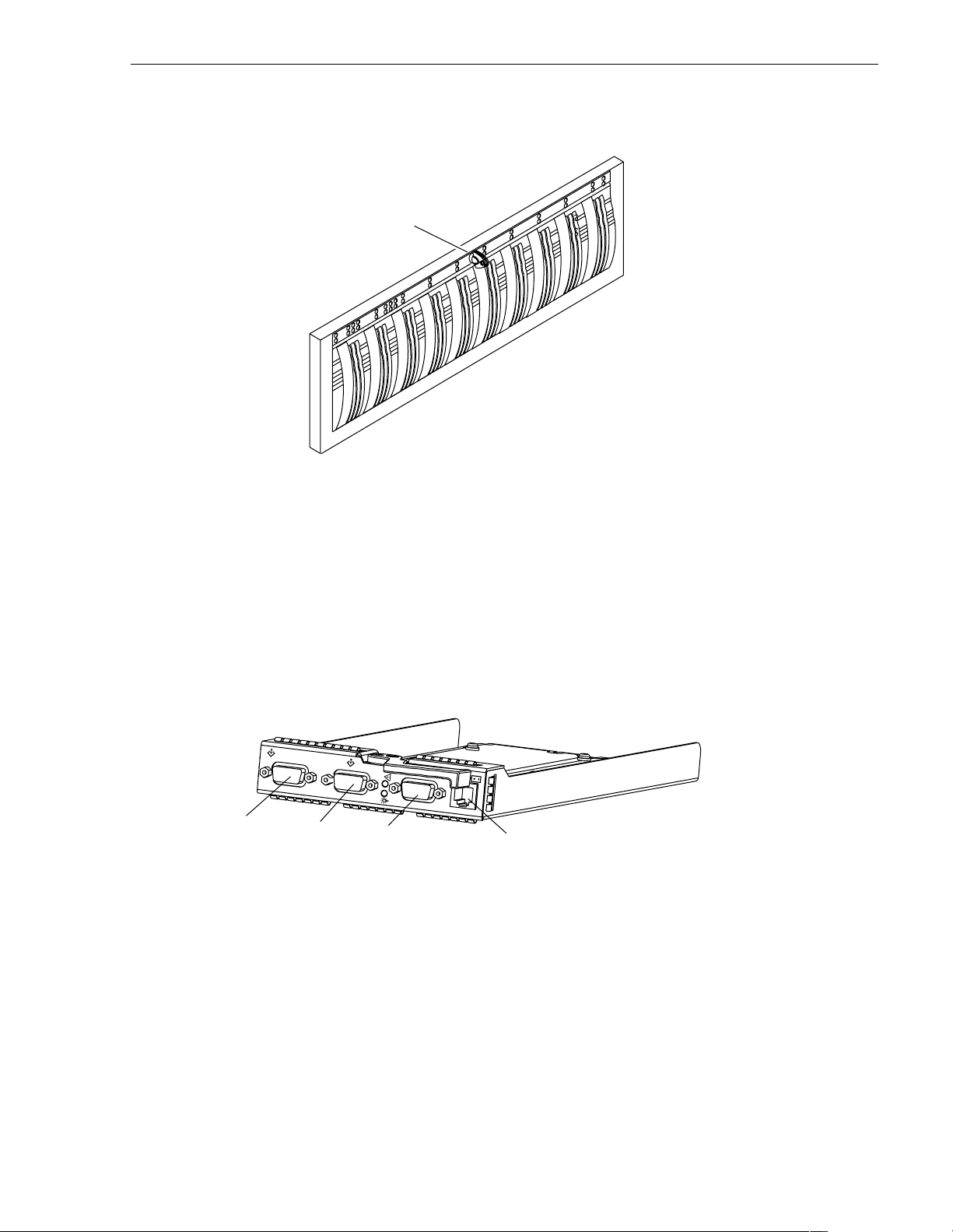

Front door

The front door has a loc king l atch a nd an EMI shiel d. The l atch i s a push button with

a removable locking key that you can use i n any PFC500 or PFC500E. When the door

is open, you can remove or install disk modules.

Front door

Locking latch

with key

IMPORTANT: The front door must be closed for the PFC500/E to be EMI

compliant. Opening the door to access the disk modules is a service procedure.

RAID Controllers (RCs)

The RC is the PFC500’s intelligent component. It defines the PFC500 and

differentiate s the

with one dual in-line memory module (DIMM), a bezel with status lights, and

securing latches.

E

X

P

expansion (EXP) port

The RC has three Fibre Channel ports. Port A and Port B are for connecting to a

Profile XP Media Platform. The expansion connector (EXP) is for connecting to a

PFC500E. The port interface is ca lled the RC front end. It can connect to a Profile XP

Media Platform’s Fibre Channel storage board. You set an RC’s FC-AL address ID

using rotary switches.

The RC connects to disk modules in the same chassis via an internal FC-AL. The

expansion port extends the internal FC-AL to the corresponding link control card

(LCC) in the PFC500E chassis. This FC-AL is referred to as the RC back end.

port B

PFC500 from a PFC500E. An RC is a printed-circuit board

B

port A

serial connection

An RC also has an RJ-type connector for serial communications with a console.

Each RC has two status light s visible from the rear of the PFC500/E. For the meaning

of these lights, see “Monitoring PFC500/E status” on page 42.

November 17, 2000 PFC500/E Instruction Manual 21

Page 22

Chapter 1 About the PFC500/E

Storage-system read caching requires one RC, and mirrored storage-system write

caching requires two RCs. If a PFC500 has one RC, you can install a second on e while

the PFC500 is running. When both RCs are ins talled, you can r eplace either RC whi le

the PFC 500 is running. You should never attempt to replace any of the RC’s

components, except the memory modules.

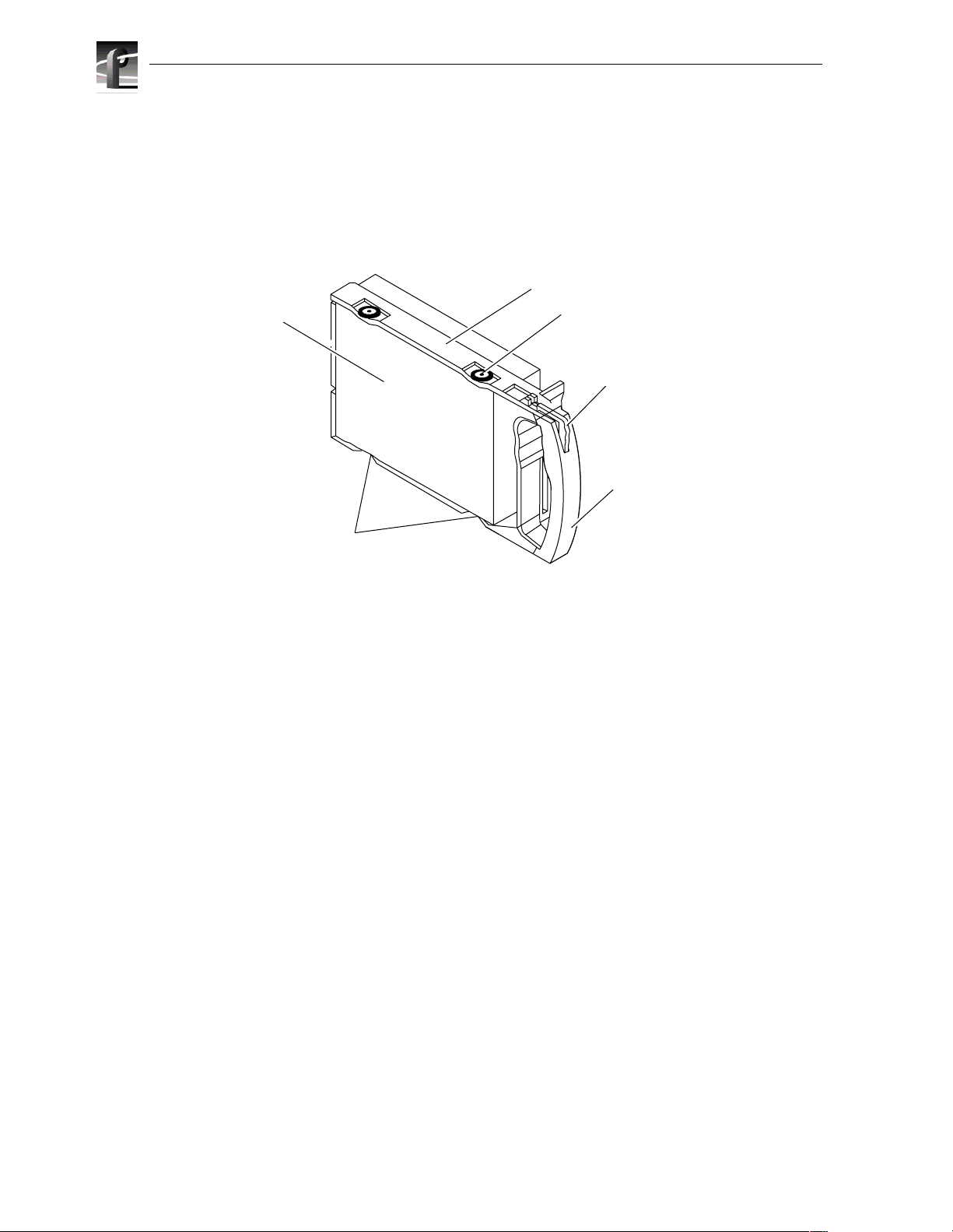

Disk modules

Disk drive

Carrier

Shock mount (4)

Latch

Handle

Each disk module consists of a Fibre Channel disk drive in a carrier assembly. You

can add or remove a disk module while the PFC500/E is powered up.

Disk drives

The disk drives are 3.5-inch FC-AL drives that conform to the following standards:

• SFF-8045

• Fibre Channel Arbitrated Loop (FC-AL)

• FC-AL Private Loop Direct Attach (PLDA) profile

The disk module slots in the chassis accommodate drives with heights of either

1.0 inch (2.54 cm) or 1.6 inches (4.06 cm). You can combine approved dr ives of either

height, and from different manufacturers, within the same PFC500/E, subject to the

restrictions imposed by the Licensed Internal Code (LIC) running in the PFC500’s

RCs.

Drive carrier

The disk-drive carr ier is a pl astic as sembly that s lides int o the chassi s slot gui des and

midplane connectors. It has a handle with a latch and electrostatic discharge (ESD)

clips, which connect to the drive’s head-disk assembly. The latch holds the disk

module in place to ensure proper connection with the midplane.

ESD clip (2)

22 PFC500/E Instruction Manual November 17, 2000

Page 23

Power supplies (PSs)

The power supplies are located behind the drive fan pack. With two power supplies,

the top supply is installed inverted with respect to the bottom supply.

Each power supply is an auto-ran ging, power -factor-c orrected , multi-outp ut, off-li ne

converter with its own line cord and on/off switch. Each supply supports a fully

configured PFC500 and shares load currents with the other supply, if it is present. The

drive voltage lines have individual soft-start switches that protect the disk drives if

you install them whil e the PFC500/E is powered up. A disk with power-rela ted faults

will not adversely affect the operation of any other disk.

On/Off switch and

circuit breaker

Check light

!

(amber)

Cooling Check

light (amber)

Power supplies (PSs)

Ac line cord

connector

Latch

Active light

(green)

Each power supply has status lights. These status lights are partially visible through

the drive fan pack, and fully visible wi th the drive fan pack removed. The s tatus lights

are described in the “Monitoring PFC500/E status” on page 42.

A latch on the power supply locks it into place to ensure proper connection to the

midplane. You can add or remove on e power supp ly in a hig hly avai lable PFC500/E

while the PFC500/E is powered up.

November 17, 2000 PFC500/E Instruction Manual 23

Page 24

Chapter 1 About the PFC500/E

Drive fan pack

The drive fan pack cool s the disk modules and RCs in the PFC500. The drive fan pac k

contains three fans tha t draw ambient room air throug h the front door, across th e drive

modules, and through t he midpl ane and p ower supp lies. The dr ive f an pack c onnect s

directly to both power supplies, and ei the r s uppl y c an power it. The fans ope rat e a t a

lower voltage and speed durin g normal ope ration to min imize acoust ic noise. If a fan

fails, the voltag e and speed of the remaining fans increase to c ompensate, resul ting in

higher acoustic noise.

Check light

(amber)

!

Latches

Latches

One status light on th e dri ve fan pack i ndica te s sta tus. The stat us li ght i s desc ribed in

the “Monitoring PFC500 status” section of Chapter 3.

Latches on the drive fan pack hold the pack in place.

IMPORTANT: You can remove the drive fan pack while the PFC500 is powered

up. While the pack is removed, the Cooling Check light on each power supply

flashes. If the pack is removed for more than approximately two minutes, the disk

modules power down and the RCs go into standby mode. When you re-install the

drive fan pack, the disk modules power up and the RCs go into active mode.

24 PFC500/E Instruction Manual November 17, 2000

Page 25

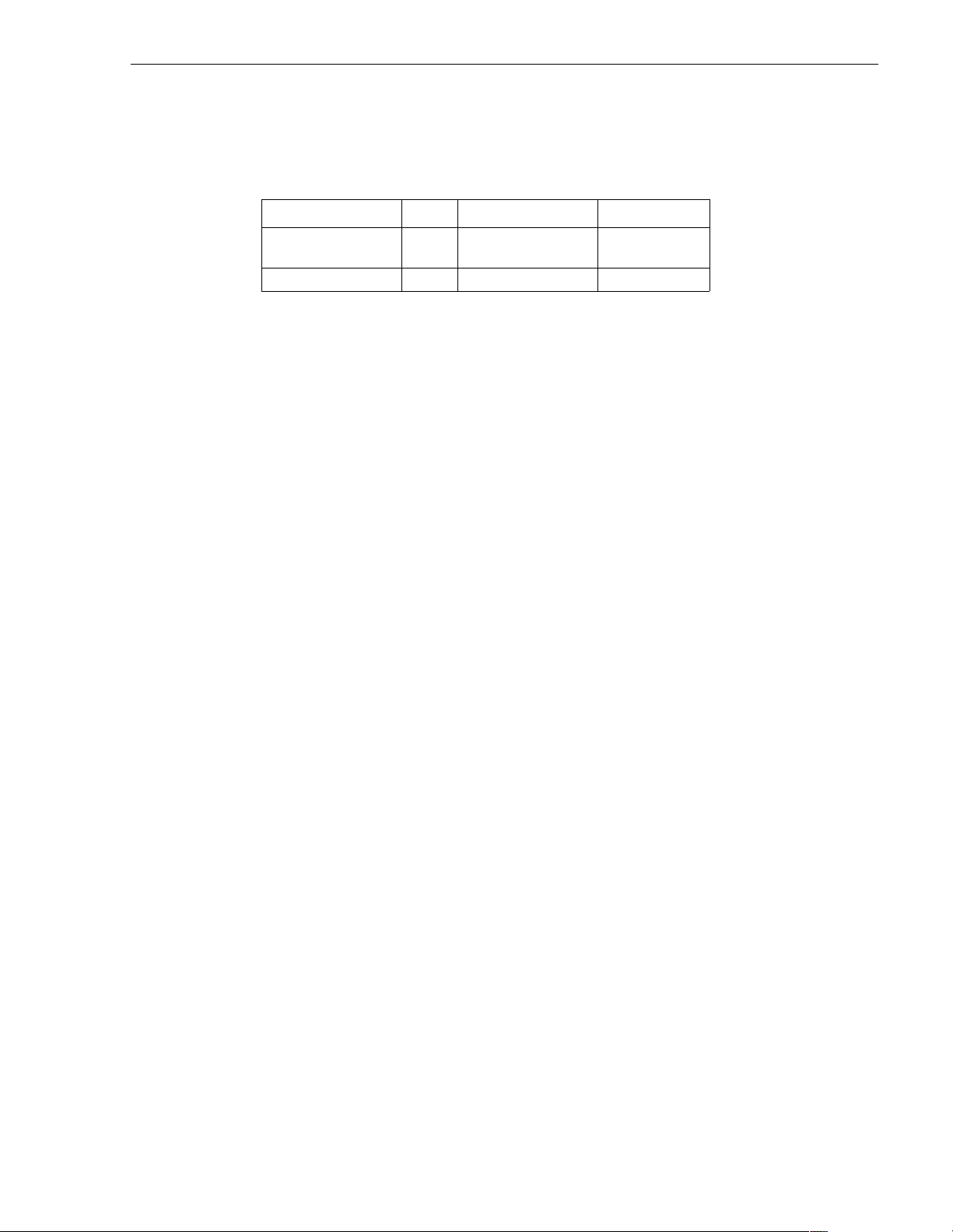

Configurations

The PFC500 minimum and maximum configurations are as follows.

Configuration RCs Power Supplies Disk Modules

minimum 1

maximum 2 2 10

The maximum configurati on provides the most redundancy, and theref ore the highest

degree of system availability. The fan pack provides redundant cooling for any

configuration.

IMPORTANT: Grass Valley Group does not supp ort mixing disk drives of differing

capacities in any RAID c hassis connected to a Pr ofi le XP medi a platform. All disk

drives in any RAID chassis connect ed to a Profile XP media platform must be of the

same capacity. For example, if a PFC500 and a PFC500E are connected to a

Profile XP system, all the disk drives in both the PFC500 and the PFC500E must

be of the same capacity.

What next?

Configurations

1

2

1

5

5

Continue to the next chapter, which te lls how to install a PFC500/E.

November 17, 2000 PFC500/E Instruction Manual 25

Page 26

Chapter 1 About the PFC500/E

26 PFC500/E Instruction Manual November 17, 2000

Page 27

Chapter

2

Installing a PFC500/E

This chapter describes t he Profile XP Fibre Channel RAID Storage Chassis (PFC500/E)

installation requirements and procedures. Major topics are:

• Requirements

• Rack mounting a PFC500/E

• PFC500/E powerup and initialization

• PFC500/E powerdown

• Binding disk modules into groups

Requirements

This section explains site, cabling, and addressing requirements.

Site requirements

For proper PFC500/E operation, the installation site must conform to certain

environmental specifications. These are detailed below and in Appendix A.

Power

Cooling

To determine a PFC500/E’s power requirements, use the power rating on the chassis

label. This rating is the maximum power required for a fully loaded chassis. The input

current, power (VA), and dissipation for the PFC500/E are based on the maximum

capability of the power supplies and cooling system to provide internally regulated

power. Typical values will be less depending on the number and manufacturer of disk

drives and activity level. These values represent either the values for the power cord of

a PFC500/E with a single power supply, or the total values shared by the line cords of

two power supplies in the same PFC 500/E, with the division between the power cords

and supplies at the current sharing ratio. If one of the two power supplies fails, the

remaining supply and cord suppo rt the full load. You must use a rack mou nt cabinet with

ac power distribut ion, and have mai n branch ac dist ributio n that c an handle these values

for the number of PFC500s and PFC500Es that you will interconnect.

The ambient temperature spe cificat ion is measured at the front door in let. The site must

have air condit ioning of the correct siz e and placement to maintain the specified ambient

temperature range. The air conditioning mus t be able to handle the BTU requirements o f

the PFC 500s and any connected PFC500Es.

November 17, 2000 PFC500/E Instruction Manual 27

Page 28

Chapter 2 Installing a PFC500/E

Cabling requirements

You mst use copper cables for the FC-AL connections between the RCs and the server

adapters or hubs. You should use a common ground distribution grid for all

interconnected devices.

IMPORTANT: You must use a copper cable on ly (not an o pti cal cable) to connect

a PFC500 to a PFC500E.

Any copper cables you use must meet the appropriate standards for 1-Gbaud FC-AL

loops. Such cables are fully shielded, twin-axial, full-duplex cables with DB-9

connectors. Cables gr eater than 10 meters must be equalized; ca bles equal to or les s than

10 meters do not need to be equalized.

PFC500 and PFC500E interconnections should maint ain LCC consistency. That is, one

FC loop should conne ct the PFC500’s RC A and each PFC500E’s LCC A. The other FC

loop should connect the PFC500/E’s RC B and each PFC500E’s LCC B.

Do not leave an unused ( that is , dangling) cable conn ected to a n RC port beca use it may

cause excess noise on the loop.

Addressing requirements

There are two addresses for the PFC500: the Fibre Channel Arbitrated Loop add ress ID

(FC-AL address ID) and the chassis address.

FC-AL address ID

Each node (such as an RC) on the Fibre Channel front-end loop must have a unique

FC-AL address ID. The FC-AL protocol translates the FC-AL address ID into an 8-bit

arbitrated loop physical address (ALPA). You set the RC FC-AL address ID using

switches, as expla ined later in t his chapter . If your PFC500 has a second, redundant RC,

it should be set to a different FC-AL address ID than the primary FC.

Chassis address (CA)

Each PFC500 and PFC500E on a back-end loop needs a unique chassis address (CA)

that identifies the chassis and determines disk module addresses . The PFC500 must have

a CA of 0. You must set that CA using the chassis address switches, as explained later

in this chapter. If you cable any PFC500Es to the PFC500, you might want to set the

nearest PFC500E’s CA to 1, and the next to 2. The chassis a ddress is displayed in light s

visible behind the front door.

28 PFC500/E Instruction Manual November 17, 2000

Page 29

Installing a PFC500/E in a cabinet

Installing a PFC500/E in a cabinet

The cabinet in which you will insta ll the PFC500/E(s) must have a full earth ground to

provide reliable grounding. Also, the cabinet should have its own switchable power

distribution. If any PFC500/E you will install has two power supplies, we suggest that

you use a cabinet that has dual power distribution units, one on each side.

>>> WARNING: The rack mount PFC500/E is heavy and should be installed into a

rack by two people. To avoid personal injury and/or damage to the equipment, do

not attempt to lift an d ins ta ll the PFC500/E into a rack without help from ano the r

person.

We recommend that you use cabinet anti-tip devices, especially if you are installing or

removing a PFC500/E in the upper half of the cabinet when the lower half is empty.

You install each PFC500/E on two L-shaped mounting rails connected to the cabinet’s

vertical channels. The PFC500/E mounting rails attach to the cabinet only, and do not

have components which attach to the RAID chassis.

Rack-mounting the PFC500/E chassis consists of:

1. Determining the rail mounting positions in the cabinet.

2. Attaching the mounting rails to the cabinet.

3. Sliding the PFC500/E chassis onto the mounting rails.

4. Setting addresses and connecting cables.

The following sections describe these operations.

Determining the rail mounting positions

The following table lists the heights of the PFC500 and the PFC500E. Use these

measurements to determine the position of your RAID devices in your cabinet.

Device Height

PFC 500 RAID Storage

Chassis

PFC 500E RAID Expansion

Chassis

NOTE: Because the RAID storage units are eac h 3.5 U high, a 0.5 U open space is

created if you install one of these units immediately below your Profile XP Media

Platform. You can fill this gap with a 1/2 U filler, which attaches to the chassis, not

to the cabine t channels.

3.5. U, 6-1/8 in,

15.6 cm

3.5. U, 6-1/8 in,

15.6 cm

Number of cabinet

channel holes,

starting U-aligned

10

10

November 17, 2000 PFC500/E Instruction Manual 29

Page 30

Chapter 2 Installing a PFC500/E

The following illustration shows the baselines of different devices in a cabinet.

6.5U

6U

5U

4U

3.5U

3U

2U

1U

1/2in

5/8in

5/8in

1/2in

5/8in

5/8in

1/2in

5/8in

5/8in

1/2in

5/8in

5/8in

1/2in

5/8in

5/8in

1/2in

5/8in

5/8in

1/2in

5/8in

5/8in

1/2in

Pre drilled holes for

rail installation

3.5U device

1U device

Baseline of next device

Baseline of next device

6.5U device

Baseline of next device

Baseline of device at a

U-aligned position, between

two holes 1/2in apart.

Review your plan to make sure all devices will fit in the cabinet and also review any

requirements for filler panels.

30 PFC500/E Instruction Manual November 17, 2000

Page 31

Attaching the mounting rails

Once you have determined the positions for the mounting rails, you can attach them to

the cabinet. Each rail has threaded nuts on its front flange. You can install any rail in a

U-aligned or U-nonaligned position.

1. For each device, attach the rails to the front channels as follows.

Attaching the mounting rails

DPE rails

Baseline

A. Align the base of the left rail with the

baseline and use two screws to

attach the front of the left rail loosely

to the cabinet’s front channel.

Baseline

B. Align the base of the right rail with

the baseline and use two screws to

attach the front of the right rail

loosely to the cabinet’s front channel.

November 17, 2000 PFC500/E Instruction Manual 31

Page 32

Chapter 2 Installing a PFC500/E

2. Attach the rails to the middle channel, as shown next.

A.

Push the rail away from the middle channel and slide clip nuts onto the

channel, into the channel holes that align with the rail holes. The

surface of the channel you use depends on the type of rail.

B.

Use two screws to fasten the back of the rail to the clip nuts.

Middle channel,

view from front

of cabinet

C.

Tighten all screws that fasten the rails to the channels.

If you want to use one or more filler panels for esthetic purposes, attach them after

installing the devices in the cabinet.

Sliding PFC500/E onto rails

To install PFC500/Es on the mounting rails in the cabinet

1. Attach th e clip of the ESD wristband (strap) to bare metal on the cabinet, and put

the wristband around your wrist with the metal button against your skin.

2. Lift the PFC500/E, and from the front of the cabin et, sl ide the PFC500/E onto the

lowest rail s. Brackets on the rear of the rails fit into cutouts on the PFC500/E.

Middle channel,

view from front

of cabinet

32 PFC500/E Instruction Manual November 17, 2000

Page 33

3. Open the PFC500/E front door as shown here.

CAUTION: Do not force the door open.

If the door snaps off the hinges, re-install it by positioning it at a

o

angle to the chassis and snapping it into the hinge openings.

45

Latch

Key

Latch

Sliding PFC500/E onto rails

If the door is locked

• Insert the key in the door’s latch.

• Turn the key 180

• Remove the key, if desired. (If you

do not remove the key, it may fall

to the floor after you open the

door.)

• Press the door latch.

• Lower the door until it is perpendi cular

to the font of the chassis.

o

clockwise.

4. Secure the PFC500/E to the vertical channels of the cabinet as shown here.

Fasten the front of the enclosure to

the front mounting holes in the cabinet

using two screws (one per side)

NOTE: Only one hole in the chassis bracket aligns with

a mounting hole on the cabinet. The mounting hole you

use depends on where the rails are mounted in the cabinet.

November 17, 2000 PFC500/E Instruction Manual 33

Page 34

Chapter 2 Installing a PFC500/E

5. Close the PFC500/E front door, as shown here.

IMPORTANT: The door must be closed for EMI compliance. Open the door only

to service the PFC500/E.

A. Raise the door until it

latches into place.

B. If desired, lock the door as follows:

• Insert the key into the door latch.

• Turn the key 180

• Remove the key, if desired.

o

counterclockwise.

Latch

Latch

Key

34 PFC500/E Instruction Manual November 17, 2000

Page 35

Setting addresses and connecting cables

Setting addresses and connecting cables

You must now set FC-AL address ID on the RAID controllers, set the chassis ID,

connect Fibre Channel cables, and connect power cables. Refer to the Profile XP System

Guide for the settings required for your installation.

1. At the back of the PFC500 chassis, remove each RC f rom its slot as s hown below.

Latch up

P

X

E

A

B

A. Pull up the latch on the RC.

EXP

A

B

B. Grasp the RC and gently

pull it out of the slot

2. For each RC, set the FC-AL address ID using the FC-AL ID switches on the RC

printed circuit board.

Each node (such as an RC) on a Fi bre Channel front-end loop mu st have a unique

FC-AL address ID. The FC-AL protocol translates the FC-AL address ID into an

8-bit arbitrated loop physical address (ALPA).

IMPORTANT: Each RC’s FC-AL ID must be unique from all other FC devices on

that same FC-AL loop.

When using redundant RCs, set the FC-AL ID on the RCs for all PFC500s

connected as indicated in the following table.

Number of

PFC500s

1First 0 1

2First

PFC500

chassis

Second

Primary RC’s

FC-AL ID

0

1

Redundant

RC’s FC-AL ID

2

3

3First

Second|

Third

0

1

2

3

4

5

November 17, 2000 PFC500/E Instruction Manual 35

Page 36

Chapter 2 Installing a PFC500/E

The valid FC-AL address ID range is a number 0 through 125 decimal, whi ch is 0

through 7D hexadecimal. The following figures and table locate the switches and

show how to select ID numbers using them.

E

X

P

RC FC-AL address ID switches

B

For address ID Set top switch to Set bottom switch to

00 0

10 1

.

.

.

15 0 F

16 1 0

.

.

.

29 1 D

Location of switches

.

.

.

.

.

.

.

.

.

.

.

.

3. Set the PFC500’s chassis address (CA) switch to 0 using t he tip of a pen or a paper

clip as shown in the following illustration.

To access the CA switch, you must open the PFC500/E’s front door. The chassis

address, referred to as the back-end address, identifies the PFC500/E and

determines disk module addresses. The PFC500 chassis address must be set to 0.

00

1

2

3

4

5

123

6

7

8

9

10

11

0

Chassis

address lights

Decrement button

Push to decrease address.

Increment button

Push to increase address.

Address

switch

0

NOTE: The address

switch has 16 positions, 12 are marked

0 through 11 and the

remaining 4 are

marked with a dash

(-). A dash position

is equivalent to the 0

position.

36 PFC500/E Instruction Manual November 17, 2000

Page 37

4. Reinstall each RC in its slot as shown below.

A. Pull up the latch on the RC.

B. Align the RC with the guide on the slot.

C. Gently slide the RC into the slot.

EXP

A

B

EXP

Setting addresses and connecting cables

Latch up

A

B

5. Remove the drive fan pack as shown below.

E

X

P

A

B

A. Grasp the latches on the drive fan pack.

B. Squeeze the latch es to get her an d p ul l the

fan pack from the chassis.

D. Push dow n the latch until

the RC is fully seated in

the slot.

Latch down

November 17, 2000 PFC500/E Instruction Manual 37

Page 38

Chapter 2 Installing a PFC500/E

6. From the ba ck of the cabin et, plug the ac line cord in to each power su pply and tur n

on the supply’s power, as shown next.

ac inlet

Bottom power supply

E

X

P

A

B

ac inlet

Power switch and

circuit breaker

Top power supply

E

X

P

A

B

Channel

B

A

P

X

E

Channel

ac power cord

B

A

P

X

E

(right-angle plug)

ac power cord

(right-angle plug)

Power switch and

circuit breaker

For each power supply:

A. Insert the right-angle plug on the ac line cord into the supply’s ac inlet

B. Route the cord along the power supply to the side of the chassis.

IMPORTANT: The cord must not occupy the drive fan pack space.

C. Bend the cord into a U shape and slide the U into the channel so the end of

the cable comes out of the channel at the back of the chassis.

D. Plug the end of the cord into one of the cabinet’s power outlets.

E. Set the supply’s power switch to the on (1) position.

7. Re-install the drive fan pack in the back of the PFC500/E.

You can install the drive fan pack in either horizontal position. However, for a

consistent image with a ll PFC500/Es, we recommend you install it with the status

light in the upper right corner as shown below.

A. Grasp the latches on the

drive fan pack.

B. Squeeze the latches

together and gently push

the fan pack into the

E

X

P

A

B

chassis until it clicks in

place.

38 PFC500/E Instruction Manual November 17, 2000

Page 39

Setting addresses and connecting cables

8. Attach the Fibre Chann el cable from t he Profile XP Media Plat form Fibre Chan nel

Disk board to the RC’s A port. Use a copper cable as shown here

IMPORTANT: Do not leave an unused (that is, dangling) c able connected to an RC

port because it may cause excess noise on the loop.

EXP

A. Plug the copper cable from the

Profile XP Media Platform Fibre

Channel Disk board into po rt A on the

EXP

A

B

EXP

A

B

Port B

A

Port A

B

RC.

B. Tighten the two screws on each

cable connector.

RJ-style connector for

serial connection to an

RCS or a console

To server, hub, or other FC device

9. To expand this PFC500, cable its EXP connector to the correspond ing PFC500E’s

PRI (primary) connector as shown here.

IMPORTANT: Do not connect a cable between

an RC in slot A and any L CC in slot B or between

an RC in slot B and any LCC in slot A.

A. Plug one end of the copper cable

onto the expansion (EXP)

EXP

A

B

PRI

EXP port

connector on the RC in the

PFC 500/E.

B. Tighten the two screws on the

cable’s connector.

EXP

C. Plug the other end of the copper

cable into the primary (PRI)

connector on the LCC in the

A

PFC500E.

D. Tighten the two screws on the

cable’s connector.

10.If the PFC500 has another RC and PFC500Es , connect the PFC500’s other RC and

the PFC 500E’s other LCCs as above.

November 17, 2000 PFC500/E Instruction Manual 39

Page 40

Chapter 2 Installing a PFC500/E

11.To connect additional PFC500Es, attach a copper cable between the PFC500E’s

LCC EXP connector and the next PFC500E’s PRI (primary) connector. If this

PFC500E and the next PFC500E have a second LCC, repeat this step for the

second LCC.

12.Make sure all the slo ts in the PFC500 and each PFC500E contain either CRUs or

filler modules. At least three disk modules (in slots 0, 1and 2) are required in the

PFC500.

13.In the cabinet, set the main circuit breaker switches to the on position.

The PFC500 and any PFC500Es in the cabinet will power up.

PFC500/E powerup and initialization

The only power switches on a PFC 500/E are those on the power supply, which are

normally covered by the drive fan pack. As a result, a PFC500/E is always active.

When ac power is initially applied to a PFC500/E, the disk drives power up according

to their specifications, and spin up in a specified sequence. The slot spin-up delays are

multiples of 12 seconds. The maximum delay is 84 seconds. The same delays are used

when you insert a drive while a PFC500/E is powered up.

NOTE: Upon powerup, all LUNs are controlled by RAID Controller A if it is

operational. RC B controls LUNs onl y if RC A fails, and continue s to control LUNs

until the next powerup.

PFC500/E powerdown

To turn off power correctly

1. Stop any I/O activity to the PFC500/E.

2. Shut off power to the ac distribution strips that supply the PFC500/E.

The power in the distribution strips ma y be co ntr o l le d by a circuit breaker l oca ted

inside the cabinet (if the cabinet has such breakers) or may be controlled by a

circuit breaker located externally to the cabinet.

To turn on power, reverse the steps to powerup the PFC 500/E.

Binding disk modules into groups

After cabling a PFC500/E and any PFC500Es, you must bind disk modules into LUNs

and create a file system using the Profile XP Disk Utility. Refer to the Profile XP System

Guide for more information on configuring your storage system.

40 PFC500/E Instruction Manual November 17, 2000

Page 41

Chapter

3

Servicing and upgrading a PFC500/E

This chapter describes how to monitor PFC500/E status, handle CRUs, and replace

or add a CRU. Topics are

• Hot swapping components

• Monitoring PFC500/E status

• Handling CRUs

• Replacing or adding a disk module

• Replacing all disk modules in a PFC500/E

• Removing an RC or an RC filler module

• Installing or removing the RC memory module

• Installing an RC or RC filler module

• Replacing the drive fan pac k

• Replacing or adding a power supply

Hot swapping comp onents

The PFC500/E is designed for co ntinuous operation, and it should always be p owered

up. You can replace any disk module, redundant RC, or fan pack while the PFC500/

E is running.

During normal PFC500/E operation, all compartments s hould contain either a modul e

or filler, and t he front door s hould be closed. Th is ensures EMI complia nce and proper

air flow (cooling) within the unit.

The following CRUs are available from Grass Valley Group.

Description Part Number

18GB replacement drive PFC18G

36GB replacement drive PFC36G

RAID Controller (RC) 039-0084-XX

Link Controller Card (LCC) 116-0942-XX

Power supply 119-6314-XX

Fan module 119-6315-XX

Rackmount kit 016-1863-00

Fibre Optic Cable, PFC500 to PFC500E 174-4409-00

November 17, 2000 PFC500/E Instruction Manual 41

Page 42

Chapter 3 Servicing and upgrading a PFC500/E

Monitoring PFC500/E status

Status lights on the PFC500/E and its CRUs indicate error conditions. Thes e lights are

visible outsid e the PFC500/E. Some lights are visibl e from th e front, and ot hers fr om

the back. The following figure and table describes the status lights.

IMPORTANT: The PFC500 chassis address must be set to 0 (zero)

Disk module status lights

(two per module)

Disk

check

Disk

Active

Chassis

address lights

0

10

12345

Chassis

address switch

(not visible with

door closed)

678910

0

2 3 4 5 6 7 8 9

11

.

PFC 500/E status lights

System

Check

Power

Light Quantity Color Meaning

PFC500/E Power

PFC500/E System

1Green

On when the PFC500/E is powered up.

1 Amber On when any fault condition exists.

Check

Disk Active 1 per disk

module slot

Green Off when the disk module slot is empty or

contains a filler module.

Flashing (mostly off) when the drive is

powered up but not spinning; this is a

normal part of the spin

-up sequence,

occurring during the spin -up delay of a slot.

Flashing (at a const ant rate) when the disk

drive is spinning up or spinning down

normally.

On when the drive is spinning but not

handling any I/O activity (the ready state).

Flashing (mostly on ) when the disk drive is

spinning and handling I/O activity.

Disk Check 1 per disk

module slot

Amber On when the disk module is faulty, or as an

indication to remove the drive.

Chassis Address 12 Green The chassis ad dress for the PFC500 must

be set to 0 (zero), the only chassis

address that is valid for the PFC500.

42 PFC500/E Instruction Manual November 17, 2000

Page 43

Monitoring PFC500/E status

Status lights visible at the back of the PFC500/E

Light Quantity Color Meaning

Active 1 per RC Green On when the RC is powered up.

RC Check 1 per RC Amber On when either the RC or a Fibre Channel

connection is faulty.

Power Supply Active 1 per supply Green On when the power supply is operating.

Power Supply Check 1 per supply Amber On when the power supply is faulty or is

not receiving ac line voltage.

Cooling Check 1 per supply Amber Flashing when either multiple fans in the

drive fan pack are faulty or the drive fan

pack is removed. The RC powers down

the disk drives and goes into standby

mode when the fault persists for more

than about two minutes.

Drive Fan Pack Check 1 on drive

fan pack

If the RC Check light is on, you should look at the other Check lights to determine

which CRU is faulty. If a check light on a CRU remains on, you should replace that

CRU as soon as possible.

Yellow On when a fan in the drive fan pack is

faulty.

If a non-redundant CRU fails in a PFC500, the system may be inoperable while you

replace the CRU. If a redundant CRU fails, high availability will be compromised

until you replace the faulty CRU.

November 17, 2000 PFC500/E Instruction Manual 43

Page 44

Chapter 3 Servicing and upgrading a PFC500/E

Handling CRUs

This section describes the pre cauti ons that you must tak e and the genera l procedu res

you must follow when removing, installing, and storing CRUs.

Power issues and CRUs

The PFC500/E is designed for continuous operation and to be hot repairable . It should

always be powered up. You should replace any disk module, redundant RC,

redundant power supply, or the fan pack while the PFC500/E is running.

Its front door sh ould be clos ed and each o f its compar tments shoul d contain a CRU or

filler panel to ensure EMI compliance and proper air flow over the CRUs.

While the PFC500/E is powered up, you can service or replace any CRU. You should

not remove a faulty CRU until you have a replacement available.

IMPORTANT: You can remove the drive fan pack while the PFC500/E is powered

up. While the pack is removed, the Cooli ng check light on the power supply flashes.

If the pack is removed f or mor e t han 2 minut es, the disk modules power do wn and

the each RC goes into standby mode . When you reinstall the drive f an pack, the disk

modules power up and each RC goes into active mode.

Since you can replace or add any CRU without sliding the PFC500/E out of the

cabinet, you do not have to use cabinet anti-t ip de vi ces wh en yo u upgr ad e or service

a PFC500/E.

If you need to power down a PFC500/E, refer to “PFC500/E powerdown” on page 40.

Avoiding electrostatic discharge (ESD) damage

When you replace or install CRUs, you can inadvertently damage the sensitive

electronic circui ts in the equipment by si mply touching them. Electr ostatic charge that

has accumulated on your body discharges through the circuits. If the air in the work

area is very dry, running a humidifier in the work area will help decrease the risk of

ESD damage. You must follow the procedures below to prevent damage to the

equipment.

IMPORTANT: Read and understand the following instructions.

• Provide enough room to work on the equipment. Clear the work site of any

unnecessary materi als or materials th at naturally buil d up electrostati c charge, such

as foam packaging, foam cups, cellophane wrappers, and similar items.

• Do not remove replacement or upgrade CRUs from their anti static packagin g until

you are ready to install them.

• Gather together the ESD kit and all other materials you will need before you

service a PFC500/E. Once servicing begins, you should avoid moving away fr om

the work site; otherwise, you may build up an electrostatic charge.

• Use the ESD kit when handling any CRU. If an emergency arises and the ESD kit

is not available, follow the procedures in the “Emergency procedures (without an

ESD kit)” section.

44 PFC500/E Instruction Manual November 17, 2000

Page 45

Precautions when removing, installing, or storing

• To use an ESD wristband, attach the clip of the ESD wristband (str ap) to any bare

(unpainted) metal on the PFC500/E chassis; then put the wristband around your

wrist with the metal button against your skin.

Emergency procedures (without an ESD kit)

In an emergency when an ESD kit is not available, use the following procedures to

reduce the possibi lity of an ele ctrostatic di scharge by e nsuring that your body and the

subassembly are at the same electrostatic potential.

IMPORTANT: These procedures are not a substitute for the use of an ESD kit.

Follow them only in the event of an emergency.

• Before touching any CRU, touch a bare (unpainted ) metal surface of the cabinet o r

chassis.

• Before removing any CRU from its anti stat ic ba g, pla ce one hand firml y o n a ba re

metal surface of the chassi s, and at the sa me time, pi ck up the CRU while i t is s till

sealed in the antistat ic bag. Once you have done this, do not move around the room

or contact other furnishings, personnel, or surfaces until you have installed the

CRU.

• When you remove a CRU from the antistatic bag, avoid touching any electronic

components and circuits on it.

• If you must move around the room or touch o ther surfaces before instal ling a CRU,

first place the CRU back i n the antistatic bag. When you are ready again to i nst al l

the CRU, repeat these procedures.

Precautions when rem ov in g , inst a ll ing , or st or ing CRUs

Use the precautions listed below when you remove, handle, or store CRUs.

• Do not remove a faulty CRU until you have a replacement available.

• Handle a CRU only when using an ESD wristband as follows: attach the clip of the

ESD wristband to the ESD bracket or bare metal on the PFC500/E chassis, and put

the wristband around your wrist with the metal button against your skin.

• Handle CRUs gently. A sudden jar, drop, or vibration can permanently damage a

CRU.

• Never use excessive force to remove or install a CRU.

• Store a CRU in the antistatic bag and specially designed shipping container in

which you received it. Use tha t container if yo u need to return the CRU for repair.

• Maintain the location where you store CRUs within the limits specified in

Appendix A.

November 17, 2000 PFC500/E Instruction Manual 45

Page 46

Chapter 3 Servicing and upgrading a PFC500/E

Replacing or adding a disk module

IMPORTANT: Grass Valley Group does not support mixing disk drives of differing

capacities in any RAID c h ass is co nnect ed to a Profile XP media pla tf orm. Al l disk

drives in any RAID chassis conn ected to a Profile XP media platfo rm must be of the

same capacity. For example, if a PFC500 and a PFC500E are connected to a

Profile XP system, all the disk drives in both the PFC500 and the PFC500E must

be of the same capacity.

>>> CAUTION: You can destroy a storage system beyond recovery if you move the

wrong drive. The system operator or service person can move a disk module with

the followin g cautions:

• The disk module must be unbound.

• Moving a module that is part of a LUN to another slot makes all information on the

LUN inaccessible.

• You must remove and install the disk module while the storage system is powered

up.

A disk module must be inserted all the way or removed entirely. Do not leave a disk

module partially removed except for periods when you are allowing it to spin down.

A disk module being inserted or removed may be damaged by a partially removed

adjacent module.

When replacing multiple disks, observe the following:

• After removing a disk module, wait for the act ivity lights on the o ther disk modules

to resume a steady flicker before removing the next module. The activity lights

show that the LIC (licensed internal code) has rediscovered the FC loop.

• After inserting a disk module, wait for the activity lights on the other drives to

resume a steady flicker bef ore inserting the next module. As with module removal,

the activity lights show that the LIC has rediscovered the FC loop.

>>> CAUTION: Handle a disk module gently and use an ESD wristband. Do not remove

a faulty disk module until you have a replacement module (with the same part

number) or a filler module avai lable. The part number appears on t he top or bottom

of the module. A replacement or add-on disk module should have the same format

(520- or 512-byte sec tors) and the sa me capacity as the other modules in the chassis.

IMPORTANT: You must open the PFC500/E’s front door to access the disk

modules. The door must be closed for EMI compliance when the PFC500/E is

powered up. Open it only to replace or add a disk module.

46 PFC500/E Instruction Manual November 17, 2000

Page 47

Latch

3. To unlock and open the front door

CAUTION: Do not force the door open.

If the door snaps off the hinges, re-install it by positioning it at a

o