Page 1

Instruction Manual

TP3461-01

FIRST PRINTING: SEPTEMBER 1994

PERFORMER

DIGITAL 10X1 ROUTING SWITCHER

Page 2

Contacting Grass Valley Group

Region Voice Fax Address Web Site

North America (800) 547-8949

530-478-4148

Pacific Operations +852-2585-6688

Support: 852-2585-6579

U.K., Europe, Asia, Middle East +44 1753 218 777 +44 1753 218 757

France +33 1 45 29 73 00

Germany +49 221 1791 234 +49 221 1791 235

Copyright © Grass Valley Group. All rights reserved.

This document may not be copied, in whole or in part, or otherwise reproduced, except as specifically

permitted under U.S. copyright law, without the prior written consent of Grass Valley Group, P.O. Box

599000, Nevada City, CA 95959-7900 USA. GRASS VALLEY GROUP is a registered trademark and

Grass Valley is a trademark of Grass Valley Group. All registered trademarks and trademarks are property of their respective holders. Grass Valley Group products are covered by U.S. and foreign patents,

issued and pending. Product options and specifications subject to change without notice. The information in this manual is furnished for informational use only, is subject to change without notice, and

should not be construed as a commitment by Grass Valley Group. Grass Valley Group assumes no responsibility or liability for any errors or inaccuracies that may appear in this publication.

(530) 478-3347 Grass Valley Group

+852-2802-2996

P.O. Box 599000

Nevada City, CA 95959-7900

USA

www.grassvalleygroup.com

Page 3

Contents

Important Safeguards and Regulatory Notices

Symbols and Their Meaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xii

North American Power Supply Cords . . . . . . . . . . . . . . . . . xiii

International Power Supply Cords . . . . . . . . . . . . . . . . . . . . xiii

EMC Regulatory Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

Federal Communications Commission

(FCC) Part 15 Information . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

Germany – FTZ. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

iii

Preface

About the Performer™ Manual. . . . . . . . . . . . . . . . . . . . . . . . . . xiiv

Glossary of Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

Section 1 — Product Description

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Product Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Page 4

Contents

Section 2 — Installation

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Rear Motherboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

VAA Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Front Panel Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Power Supply Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Tally Board (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Installation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Uncrating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Button Labeling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Switcher Power-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Common Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Performer Setup Switch Location . . . . . . . . . . . . . . . . . . . . 2-10

Performer Remote to Performer . . . . . . . . . . . . . . . . . . . . . 2-11

PC (Performer ASCII) to Performer . . . . . . . . . . . . . . . . . . 2-12

PC (Performer ASCII) to Performer (cont.) . . . . . . . . . . . . 2-13

PC (Performer ASCII) to Modem to Performer . . . . . . . . . 2-14

PC (Performer ASCII) to Modem to Performer (cont.) . . 2-15

PC (TEN-XL ASCII) to Performer (cont.) . . . . . . . . . . . . . 2-17

PC (TEN-XL ASCII) to Modem to Performer . . . . . . . . . . 2-18

PC (TEN-XL ASCII) to Modem to Performer (cont.) . . . . 2-19

TEN-XL SCP (XY-mode) to Performer . . . . . . . . . . . . . . . . 2-20

TEN-XL SCP (XY-mode) to Modem to Performer . . . . . . 2-21

TEN-XL Remote Panels to Performer . . . . . . . . . . . . . . . . . 2-22

TNX-AFV19 to Performer . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

20-TEN XYCP to Performer . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Model 100/110 to Performer (Always Follow mode) . . . 2-25

Model 100/110 to Performer (Conditional mode) . . . . . . 2-26

Model 200 to Performer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

Model 300 to Performer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

Installation Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-29

Frame Top Removal and Replacement . . . . . . . . . . . . . . . . 2-30

iv

Page 5

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

Removing/Replacing Terminating Resistors . . . . . . . . . . 2-32

Remote Connector Cabling . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

OPTION Connector Cabling . . . . . . . . . . . . . . . . . . . . . . . . 2-35

Tally Board Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

Tally Board Option Installation . . . . . . . . . . . . . . . . . . . . . . 2-36

Looping Cable Option Installation . . . . . . . . . . . . . . . . . . . 2-39

Vertical Interval Strobe Selection . . . . . . . . . . . . . . . . . . . . 2-40

Switch Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

Switcher Polling Address . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-43

Polling Address,

Non GVG TEN-XL ASCII Protocols. . . . . . . . . . . . . . . 2-44

Polling Address, GVG TEN-XL ASCII Protocol . . . . 2-44

Serial Communications Protocol Selection. . . . . . . . . . . . . 2-45

General Selection Instructions . . . . . . . . . . . . . . . . . . . 2-45

Control Panel Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-47

Performer Serial Remote Control Panel . . . . . . . . . . . . . . . 2-48

Performer Protocol Selection . . . . . . . . . . . . . . . . . . . . 2-48

General Rules for Performer/TEN-20,

20-TEN Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-50

Performer S1 Switch Settings . . . . . . . . . . . . . . . . . . . . 2-50

Remote Panel Switch Settings . . . . . . . . . . . . . . . . . . . 2-54

TEN–XL SCP Switch Configuration . . . . . . . . . . . . . . . . . . 2-59

Controlling More Than One Performer . . . . . . . . . . . 2-59

SCP Power Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-68

TEN–20/20–TEN Panels and Serial Interface . . . . . . . . . . 2-69

Panel Protocol Selection . . . . . . . . . . . . . . . . . . . . . . . . 2-69

General Rules for TEN-20, 20-TEN Protocol . . . . . . . 2-71

Performer S1 Switch Settings. . . . . . . . . . . . . . . . . . . . . 2-71

TEN–20 Panel Switch Settings . . . . . . . . . . . . . . . . . . . 2-75

Serial Interface Switch Settings . . . . . . . . . . . . . . . . . . 2-79

20–TEN Panel Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . 2-83

DC Power Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-85

Contents

Section 3 — Operation & Service

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Performer Front & Remote Panel Operation . . . . . . . . . . . . . . . 3-2

v

Page 6

Contents

Audio Follow Video . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Breakaway . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Video Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Audio 1 Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Audio 2 Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Protect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Joystick Override Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

TEN-XL Control Panels Operation . . . . . . . . . . . . . . . . . . . . . . . 3-10

TNX–RCP, TNX–TCP Remote Control . . . . . . . . . . . . . . . . 3-10

Audio Follow Video Source Selection . . . . . . . . . . . . . 3-10

Breakaway Source Selection . . . . . . . . . . . . . . . . . . . . . 3-11

TEN–XL Audio Follow Video Control Panels . . . . . . . . . . 3-12

Audio Follow Video Source Selection . . . . . . . . . . . . . 3-12

19 x 1 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

TNX–SCP Serial Remote Control Panel . . . . . . . . . . . . . . . 3-14

Dual Mode Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

X–Y Mode Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Error Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Power Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

TEN–20, 20–TEN Control Panels Operation . . . . . . . . . . . . . . . 3-19

10 BPS Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Source Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Placing Protects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Error Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

MBCP Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Selecting Destinations . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Presetting and Taking a Source . . . . . . . . . . . . . . . . . . 3-23

Clearing Entry Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Placing Protects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Displaying Destinations . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

XYCP Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

Presetting Destinations . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

Presetting Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

Performing a Take . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Using the Last Function . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Using the Protect Function . . . . . . . . . . . . . . . . . . . . . . 3-29

Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

Serial Protocol Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

vi

Page 7

Performer ASCII Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

Command Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

Command Strings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-33

Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-35

Performer Remote, TEN–20/20-TEN

Compatible Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

TEN–20/20–TEN Serial Interface Protocol . . . . . . . . . . . . 3-38

Take Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-39

Enable Protect Message . . . . . . . . . . . . . . . . . . . . . . . . . 3-40

Release Protect Message . . . . . . . . . . . . . . . . . . . . . . . . 3-40

Status Request Message . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

Response Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-42

TEN–XL ASCII Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-43

TEN–XL SMPTE Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-45

Model 100/110 Compatible Protocol. . . . . . . . . . . . . . . . . . 3-48

Model 200 Compatible Protocol. . . . . . . . . . . . . . . . . . . . . . 3-49

Model 300 Compatible Protocol. . . . . . . . . . . . . . . . . . . . . . 3-51

SMPTE 3245-E Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-52

Notes About SMPTE Message Processing . . . . . . . . . 3-55

Performer Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . 3-58

Exchange Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-58

In Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-58

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-59

Contents

vii

Index

Page 8

Contents

viii

Page 9

Important Safeguards and

Regulatory Notices

Information on the following pages provides important safety

guidelines for both Operator and Service Personnel. Specific

warnings and cautions will be found throughout the manual

where they apply, but may not appear here. Please read and

follow the important safety information, noting especially those

instructions related to risk of fire, electric shock, or injury to

persons.

WARNING

Any instructions in this manual that require opening the

equipment cover or enclosure are for use b y qualified service

personnel only. To reduce the risk of electric shock, do not

perform any servicing other than that contained in the

operating instructions unless you are qualified to do so.

vii

Page 10

Safeguards and Notices

Symbols and Their Meaning

The lightning flash with arrowhead symbol, within an equilateral

triangle, alerts the user to the presence of “dangerous voltage”

within the product’s enclosure that may be of sufficient

magnitude to constitute a risk of electric shock to persons.

The exclamation point within an equilateral triangle alerts the

user to the presence of important operating and maintenance

(servicing) instructions in the literature accompanying the

appliance.

The fuse symbol indicates that the fuse referenced in text must be

replaced with one having the ratings indicated.

This symbol represents a protective grounding terminal. Such a

terminal must be connected to earth ground prior to making any

other connections to the equipment.

viii

CAUTION

This equipment contains static sensitive components. Use antistatic grounding equipment when handling or servicing modules

and components. When circuit modules are removed from the

frame, place them on a flat, static-controlled surface. Failure to

follow this precaution can result in component damage due to

electrostatic discharge.

Page 11

Warnings

Safeguards and Notices

Heed all warnings on the unit and in the operating

■

instructions.

■

Do not use this product in or near water.

■

Disconnect ac power before installing any options.

This product is grounded through the grounding conductor

■

of the power cord. To avoid electrical shock, plug the power

cord into a properly wired receptacle before connecting the

product inputs or outputs.

■

Route power cords and other cables so that they are not likely

to be damaged.

Disconnect power before cleaning. Do not use liquid or

■

aerosol cleaners; use only a damp cloth.

■

Dangerous voltages exist at several points in this product. To

avoid personal injury, do not touch exposed connections and

components while power is on.

■

Do not wear hand jewelry or watches when troubleshooting

high current circuits, such as the power supplies.

■

During installation, do not use the door handles or front

panels to lift the equipment as they may open abruptly and

injure you.

■

To avoid fire hazard, use only the specified correct type,

voltage and current rating as referenced in the appropriate

parts list for this product. Always refer fuse replacement to

qualified service personnel.

■

To avoid explosion, do not operate this product in an

explosive atmosphere unless it has been specifically certified

for such operation.

■

Have qualified personnel perform safety checks after any

completed service.

■

If equipped with redundant power, this unit has two power

cords. To reduce the risk of electric shock disconnect both

power supply cords before servicing.

ix

Page 12

Safeguards and Notices

Cautions

To prevent damage to equipment when replacing fuses, locate

■

and correct the trouble that caused the fuse to blow before

applying power.

Verify that all power supply lights are off before removing

■

power supply or servicing equipment.

■

Use only specified replacement parts.

■

Follow static precautions at all times when handling this

equipment.

■

Leave the back of the frame clear for air exhaust cooling and

to allow room for cabling. Slots and openings in the cabinet

are provided for ventilation. Do not block them.

■

Front door is part of fire enclosure and should be kept closed

during normal operation.

■

This product should be powered only as described in the

manual. To prevent equipment damage select the proper line

voltage at the ac input connector as described in the

Installation documentation.

■

To reduce the risk of electric shock, ensure that the two power

supply cords are each plugged into a separate branch circuit.

■

Circuit boards in this product may be populated with surface

mount and ASIC components. Special tools and techniques

are required to safely and effectively troubleshoot and repair

modules that use SMT or ASIC components. For this reason,

service and repair of GVG products incorporating surface

mount technology are supported only on a module exchange

basis. Customers should not attempt to troubleshoot or repair

modules that contain SMT components. GVG assumes no

liability for damage caused by unauthorized repairs. This

applies to both in- and out-of-warranty products.

x

Page 13

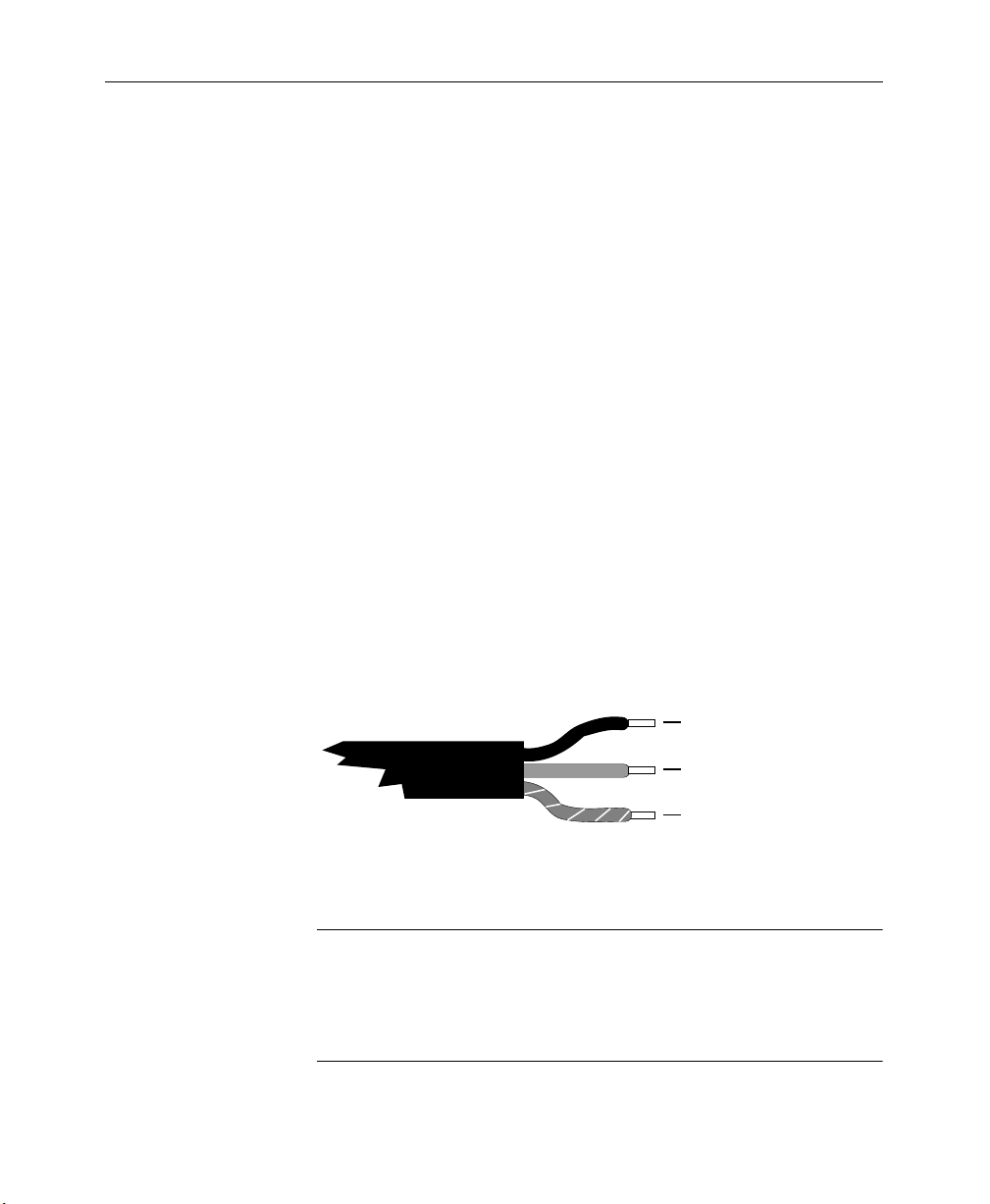

North American Power Supply Cords

This cord is supplied with a molded grounding plug (NEMA 5-

15P) at one end and a molded grounding connector (IEC 320-C13)

at the other. Conductors are CEE color coded, light blue (neutral),

brown (line), and green/yellow (ground). See the illustration.

Operation of this equipment at voltages exceeding 130 VAC will

require power supply cords which comply with additional

NEMA guidelines.

International Power Supply Cords

This cord is supplied with a molded grounding connector (IEC

320-C13) at one end and stripped conductors (50/5 mm) at the

other. Conductors are CEE color coded, light blue (neutral),

brown (line), and green/yellow (ground). Other IEC 320 C-13

type power supply cords can be used if they comply with the

safety regulations of the country in which they are installed. See

the illustration.

Safeguards and Notices

Brown

Line

NOTE:

Blue

Green with

Yellow stripe

When used in the United States, this cord is for 100 - 130VAC

Neutral

Ground

(Earth)

use only.

When used internationally, this cord is for 100 - 130VAC or

200 - 240VAC (one line, one neutral, one earth).

xi

Page 14

Safeguards and Notices

EMC Regulatory Notices

Federal Communications Commission (FCC) Part 15 Information

This equipment has been tested and found to comply with the

limits for a Class A digital device pursuant to Part 15 of FCC

Rules.

These limits are designed to provide reasonable protection

against harmful interference in a commercial environment. This

equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio

communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user

will be required to correct the interference at his own expense.

xii

Page 15

Germany – FTZ

Safeguards and Notices

Hiermit wird bescheingt, dieses Gerät in Übereinstimmung mit

den Bestimmungen der Amtsblatt-Verfügung Vfg. 243/46 (1992)

funk-entstört ist. Der Deutschen Bundespost wurde das

inverkehrbringen dieses Gerätes angezeigt und die

Berechtingung zur Überprüfung der Serie auf Einhalten der

Bestimmungen eingeräumt.

We hereby certify that this equipment complies with the RFI

suppression requirements of Vfg. 243/46 (1992). The German

postal service was notified that the equipment is being marketed.

The German Postal Service has the right to re-test the equipment

and verify compliance.

Grass Valley Group, Inc.

P.O. Box 1114

Grass Valley, CA 95945

U.S.A.

HINWEIS FÜR DEN BENUTZER/BETREIBER: Die Vom

Betreiber zusammengestellte Anlage, innerhalb dieses Gerätes

eingesetzt wird, muß ebenfalls den Voraussetzungen Vfg. 243/46

(1992) genügen.

The German Postal Service requires that systems assembled by

the operator/user of this instrument must also comply with Postal

Regulation Vfg. 243/46 (1992).

HINWEIS FÜR DEN BENUTZER/BETREIBER: Dieses Gerät darf

in Meßaufbauten nur betrieben werden, wenn die

Voraussetzungen Vfg. 243/46 (1992) eingehalten werden.

The German Postal Service requires that this equipment, when

used in a test setup, may only be operated if the requirements of

Postal Regulation Vfg. 243/46 (1992) are complied with.

xiii

Page 16

Safeguards and Notices

xiv

Page 17

2

About the Performer

Preface

™

Manual

The manual contains installation, operation, and service

instructions for Performer and its optional accessories and

control panels.

The manual contains the following sections.

■

Product Description—An overview of Performer,

including a functional description and a table of

specifications.

■

Installation—A comprehensive guide to uncrating,

installing, configuring, and cabling your Performer

system and its options.

■

Operation and Service—A guide to using your Performer

system and information regarding service.

■

Index—An alphanumeric locator of subjects in this

manual.

In addition, a glossary of terms begins on the next page.

xv

Page 18

Preface

Glossary of Terms

The terms defined below are used in this manual. We have listed

them here for your convenience.

AC coupled

address An identification tag for separate devices sharing a common

ASCII (American Standard Code for Information Interchange) – A

ASCII string

audio follow video An operational mode in which audio and video channels are

baud rate In terms of bits, the number of bits per second transmitted in

binary A base-2 numbering system using the two digits 0 and 1, as

BPS

breakaway The source number of at least one level (video, audio 1, or au-

bus A signal path to which a number of devices (control panels,

channel In routing switchers, a complete and independent signal path.

controlled destinations Outputs that are assigned to a specific control panel.

destination offset The addresses of the destinations controlled by a control pan-

destination The point to which a source signal is routed.

A method of connecting one circuit to another so as to transmit the varying AC characteristics of the signal while blocking

the static (DC) characteristics.

communications bus.

standard system used extensively in data transmissions, in

which 128 letters, numerals, symbols, and special codes are

each represented by a binary number.

A group of letters, numerals, and/or symbols represented by

ASCII code equivalents.

tied together so that when the operator selects the video

source, the audio simultaneously and automatically switches

with the video.

a digital signal.

opposed to the ten digits, 0 through 9, in the decimal system.

(Button Per Source) A router control panel that has a designat-

ed button for every controlled source.

dio 2) is different from the source number of one or both of the

other levels.

routers, etc.) are connected.

el which have been incremented to a higher set of numbers.

xvi

Page 19

Glossary of Terms

level offset The addresses of a level controlled by a control panel which

have been incremented to a higher set of numbers.

level(s) An independently controllable stratum of signals within a

routing switcher. Typically, a routing switcher will have a level of video and one or more audio levels.

MBCP

offset Where a set of numbers such as 1 through 10 are incremented

parity A method of verifying the accuracy of transmitted or record-

polling address A unique device designation that allows a controller to make

protect The current selection is locked and prevented from accidental

protocol A set of conventions governing the format and timing of mes-

RS232, RS422, RS485 Electrical/mechanical standards for serial communications.

serial bit rate The speed at which bits are transmitted in a serial digital sig-

SERIM (SERial Interface Module) Translates RS232 and RS422 com-

slave mode A condition in which a piece of equipment does not act inde-

source offset

source The origin of a video &/or audio signal—i.e., video tape re-

stop bit The indicator in the serial digital communications protocol

tally The acknowledgement returned to a control panel or terminal

(MultiBus Control Panel) A router control panel capable of

controlling multiple destinations. The destinations are selectable on the front panel.

to another range of values such as 11 through 20.

ed data.

regular status checks of a number of devices on a common

communications bus.

change.

sage exchanges to control data movements and detect errors.

nal.

mands into RS485 format.

pendently, but only under the control of another piece of

equipment.

The addresses of the sources controlled by a control panel

which have been incremented to a higher set of numbers.

corder, video camera, production switcher, etc..

that the transfer of one byte is complete.

that an operation has been executed.

xvii

Page 20

Preface

vertical interval strobe (VI) In relation to video switching applications, a signal sent

to indicate the beginning of the vertical interval.

video clamped Re-establishment of a fixed DC reference level for the video

signal.

X-Y mode A switching matrix which places inputs (sources) on an X axis

and outputs (destinations) on a Y axis. Routing connections

are made by specifying an X value to be connected to a Y value. Any available source can be connected to any available

destination.

xviii

Page 21

1

Introduction

Product Features

Product Description

This section provides a general description of the serial digital

version of the Performer™ 10 x 1 Routing Switcher. Included are

Product features

■

Functional description

■

■

Specifications

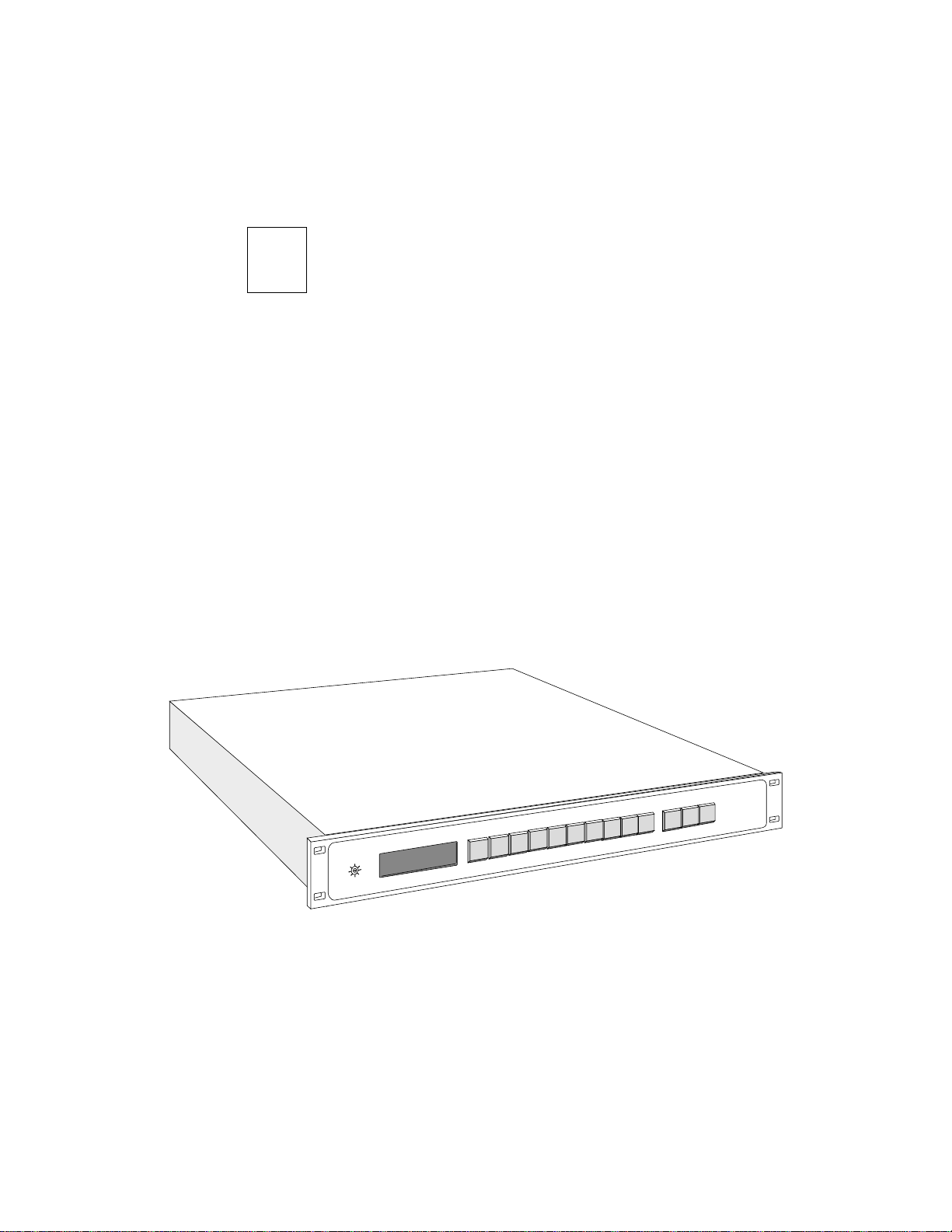

Performer is a serial digital, 10-input by 1-output, video with dual

(AES/EBU) audio routing system from Grass Valley Group.

8

7

6

5

4

3

2

1

/4

3

h

C

2

A

/2

1

h

C

1

A

V

b

M

0

6

3

O

T

U

A

b

M

0

7

2

T

C

E

IR

D

b

M

7

7

1

b

M

3

4

1

STATUS DISPLAY

INPUT SELECTION

PERFORMER–SD

VAA

GRASS VALLEY GROUP

0

1

9

1-1

Page 22

Section 1 —

Product Description

Performer standard features include:

Automatic television standards compatibility

■

■

AFV or full breakaway operation

■

Protect function

Front panel control

■

■

TEN–XL and TEN–20/20–TEN compatibility

■

Source display for Video, A1, & A2 assignments

RS232, RS422, or RS485 control port

■

ASCII, SMPTE, & production switcher compatibility

■

■

External or internal Vertical Interval strobe select

■

BNC video connectors

■

BNC or D type AES/EBU connectors

■

Dual video and audio outputs

Compact, 1 rack unit construction

■

■

90 to 250-volt operation

■

Relegendable pushbutton caps

Performer options include:

Tally relays for 10 inputs & Joystick Override control

■

■

Remote control panel

Performer circuitry resides in a sealed, 1 rack unit frame. The

standard unit contains just four printed circuit boards. These are:

Rear Motherboard (two versions available)

■

■

VAA board

■

Front Panel board

Power Supply board

■

■

Optional tally relays and GPI inputs can add one more

board, the Tally board, to the system.

1-2

Page 23

Functional Description

System

Functional Description

See descriptions and the block diagram on the following pages.

The PERFORMER Serial Digital Video and AES/EBU Digital

Audio10X1 routing switcher. It is available in four (4) basic

models (configured with either BNC or D type audio connectors

and supplied with either local or remote control panel) as

described below. A bit-rate mode select switch is located on the

front of the local control panel.

D type audio I/O connectors (local or remote control):

Model PFR-SD 10X1 Serial Digital Video & AES/EBU Audio

(female D type connector ), Local Control Version.

Model PFR-SDRC 10X1 Serial Digital Video & AES/EBU Audio

(female D type connector ), Remote Control Version.

BNC type audio I/O connectors (local or remote control):

Model PFR-SDB 10X1 Serial Digital Video & AES/EBU Audio

(75Ω BNC type connector ), Local Control Version.

Model PFR-SDBRC 10X1 Serial Digital Video & AES/EBU Audio

(75Ω BNC type connector ), Remote Control Version.

NOTE:

The two AES/EBU audio channels can be: switched

together with video, switched together separately, or switched

individually. If audio is not synchronous with video, some

disturbances may occur during switching.

Tally and Cable Kit options

The tally option is a module providing contact closures for each

video input. As a video crosspoint is selected, the appropriate

relay closes. This closure can be used to light an external lamp for

tally, or can be used for a bi-directional route for an intercom.

The cable kit option is installed in the frame to permit use of an

additional control panel.

1-3

Page 24

Section 1 —

Product Description

Front panel bit-rate mode switch:

The bit-rate switch on the local control panel allows you to choose

between FORCED, AUTO, or DIRECT modes of matching input/

output bit rates.

• Forced modes include: 143 Mb/s for D2/NTSC; 177 Mb/s for

D2/PAL; 270 Mb/s for D1 both 625 and 525; and 360 Mb/s for

future HDTV use. NOTE: Care must be taken when using the

forced modes of operation; the bit rate selected via the front panel

switch must match the input rate(s).

• AUTO mode: provides automatic bit rate selection when input

rates are different. The PERFORMER automatically detects the

input bit rate and switches to the correct rate, i.e. with D1 at Input

1 and D2 at Input 2 user switches from Input 1 to Input 2. The

switcher will automatically switch to the new rate. NOTE: The

input sources must be locked together and timed).

• DIRECT mode: like the AUTO mode it automatically selects the

input rate and the non-reclocked mode (signal goes directly from

the input to the output without going through the deserializer or

the regenerator circuitry).

1-4

Video

Ten by one (10X1) video switcher. Provides 10 inputs and 1 output

serial digital video switching.

An equalizer is located on each video input path to equalize up to

225m of 8281 cable. The serial data stream output of the equalizers

enter a 10X1 crosspoint.

Audio

Ten by one (10X1) audio switcher. Provides two (2) “stereo” AES/

EBU channels of 10 by 1 serial digital audio switching.

Page 25

Rear Motherboard

All inputs and outputs are through connectors on the Rear

Motherboard. This board has only mechanical functions and

mounts no active circuitry.

There are two different types of rear connector panels available

(unbalanced BNC type audio connectors and balanced D type

audio connctors). Both types accomodate 10 video inputs, 1 pair

of video outputs, 2X10 audio inputs, and 2X2 audio outputs.

Unbalanced BNC type audio connectors

Ten (10) BNC connectors for ten (10) video inputs

Two (2) BNC connectors for the video output pair

Twenty (20) BNC connectors (10 for AES1 and 10 for AES2)

Four (4) BNC connectors (2 for AES1 out and 2 for AES2 out

An IEC connector for the mains power supply

One (1) 25-pin female D type connector for serial communication

and a slot for an optional 25-pin female D type connector

Functional Description

Balanced D type audio connector

Ten (10) BNC connectors for ten (10) video inputs

Two (2) BNC connectors for the video output pair

Two (2) 37-pin D type connectors (one each for AES1 and AES2 in)

An IEC connector for the mains power supply

Twenty-five (25) pin female D type connector for serial

communication and a slot for an optional twenty-five (25) pin

female D type connector

1-5

Page 26

Section 1 — Product Description

VAA Board

The VAA board contains:

■ Video processing circuitry

■ Audio processing circuitry

■ Control circuitry

■ Parameter-determining switches

■ Vertical Interval Strobe generating circuitry

Performer video processing circuitry consists of: ASIC cable

equalizers, an ASIC serial crosspoint, and an ECL line driver.

Serial bit stream at inputs is converted to parallel, and processed

in parallel digital domain, to extract line ID information and to

generate the vertical interval switching strobe.

The Performer supports two independent audio AES/EBU

channels (AUDIO 1/2 and AUDIO 3/4). Inputs can be either

balanced or unbalanced. Audio is received and converted to TTL

signals by RS485 line receiver circuitry. A pair of 8X1 multiplexers

form a 10X1 multiplexer to select one of the ten input signals of

AES Ch 1/2 to the output. AES Ch 3/4 uses identical circuitry.

Control circuitry is based on an 68HC711 CPU running at

4.9152MHz, supported by a 27C256 PROM and a DS1225AD

RAM. The CPU contains a programmable, full-duplex, serial

channel to handle serial data to and from the RS232, RS422, and

RS485 driver and receiver circuits. Three 8-segment switches

allow users to determine serial baud rate, communications

protocol, external or internal VI strobe, and other functions. The

internal VI strobe is stripped from digital video by a TRS ID Data

Separator. An external VI strobe may be used if desired.

1-6

Front Panel Board

The Front Panel board mounts a row of 13 buttons and three, twocharacter, seven-segment displays. The buttons are sequentially

scanned by the VAA board microcomputer (Switch Write); a

pressed button is detected by one of the two Switch Read lines and

the appropriate source taken to the output of the switcher. The

take may be Audio Follow Video or breakaway depending upon

Page 27

the state of the three “breakaway” buttons (V, AES1, and AES2).

The Performer is capable of full breakaway operation, meaning

that video may be separately switched from audio and even the

two audio channels may be separately switched one from the

other.

The microcomputer writes to the displays over an 8-bit parallel

bus. The appropriate display is enabled by a driver output from

the VAA board to accept the source number data.

Power Supply Board

The automatic switchmode Power Supply board delivers +5VDC

to the VAA main board. A step-up converter provides +15VDC

necessary for remote operation and for lighting the front panel

LEDs. Input power may be 100 to 240 volts. The AC line cord is

hardwired to the frame and is UL or TUV selectable at time of

original order.

The AC input is fused but is not user serviceable. This fuse is

soldered onto the power supply circuit board and is accessible to

a qualified service person only by removing the top cover.

Functional Description

Tally Board (option)

The optional Tally board mounts 10 relays and 13 opto-isolated

inputs. The 10 relays are slaved to the video selections made by

the switcher operator. When a video source is selected, the

corresponding relay closes (only a dry contact relay closure is

provided). The opto-isolated inputs provide a connection point

for a Joystick Override or other remote control device.

1-7

Page 28

Section 1 — Product Description

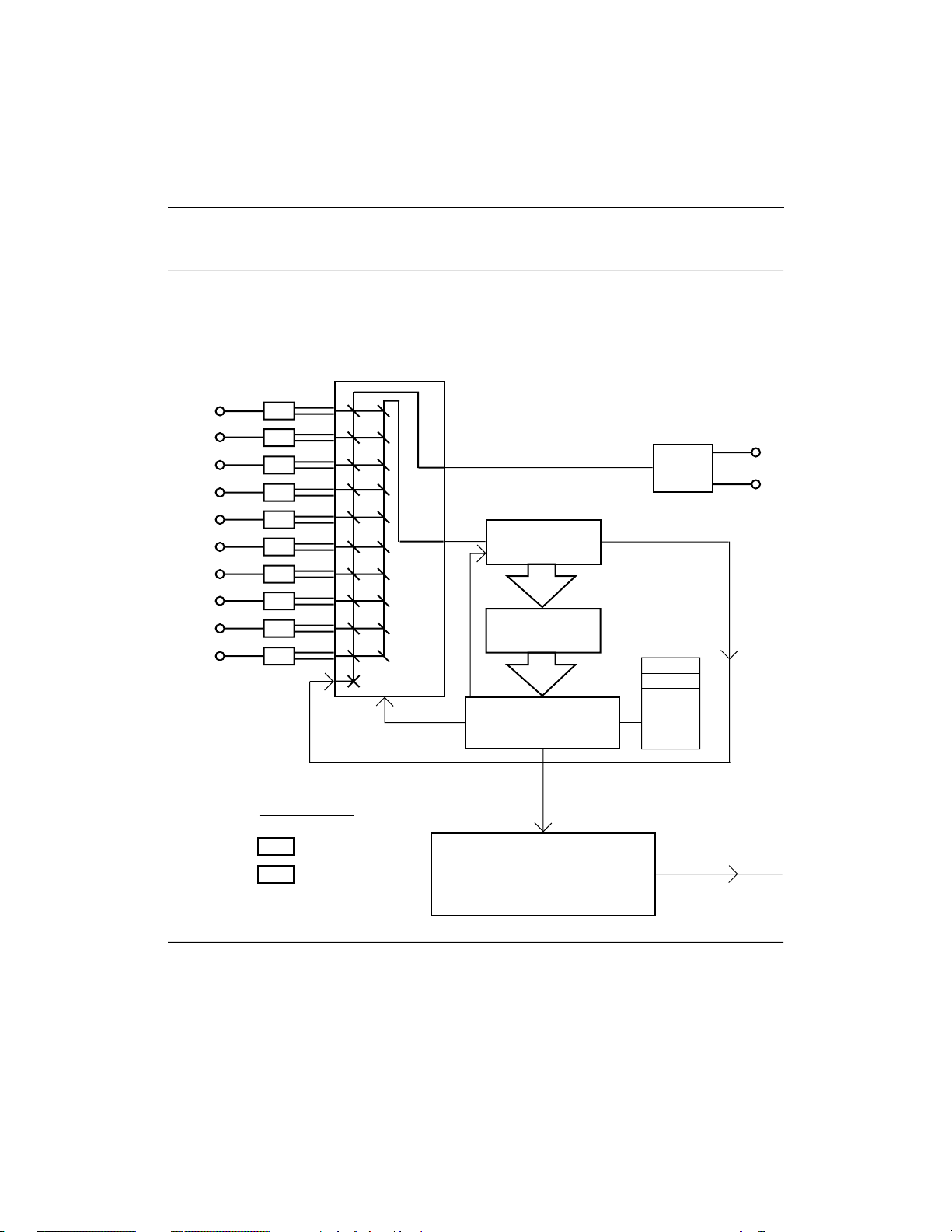

VIDEO/MICROPROCESSOR CONTROLLER

FUNCTIONAL BLOCK DIAGRAM

EQUALIZERS

VIDEO

INPUTS

(1 - 10)

Front Panel

Read/Write

LED Control

GPI/Tally

Options

Serial

Communications

AUTOMATIC

1

2

3

4

5

6

7

8

9

10

11th input

RS422

RS232

16X8 VIDEO

CROSSPOINT

Serial Control

Data Stream

Direct Mode

DESERIALIZER

COPROCESSOR

Indirect Mode

Bit Rate Switch

FIELD PROGRAMMABLE

GATE ARRAY

(Rate Detector)

Vertical

Interval

MICRO-PROCESSOR CONTROLLER

• Front panel control & communication

• RS422/232 communication control

• GPI and Tally control

SERIAL

LINE

DRIVER

(front panel)

Direct

Auto

143Mb/s

177Mb/s

270Mb/s

360Mb/s

To Audio Multiplexer

VIDEO

OUTPUTS

1-8

Page 29

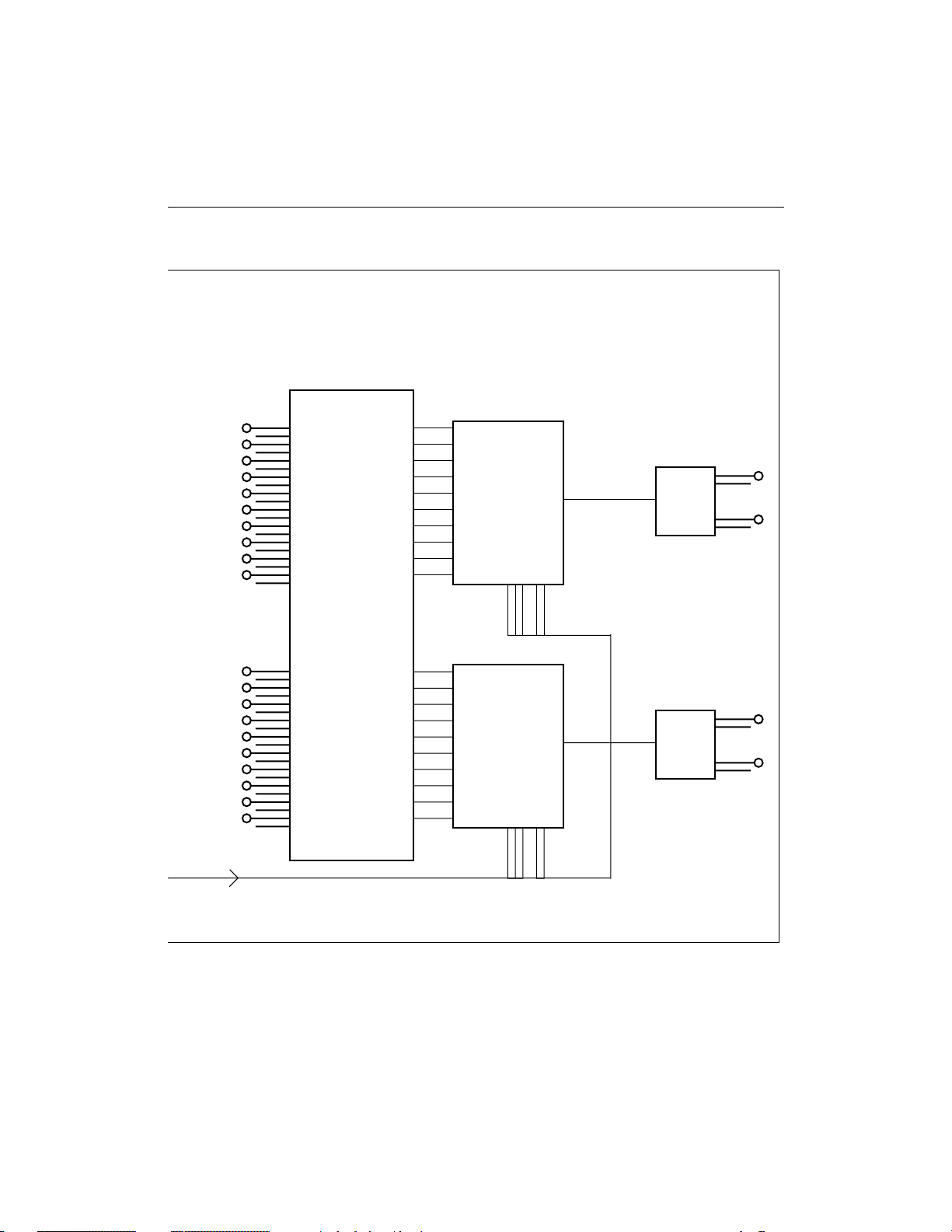

AUDIO

FUNCTIONAL BLOCK DIAGRAM

Functional Description

AES/EBU

AUDIO

INPUTS

(Ch 1)

AES/EBU

AUDIO

INPUTS

(Ch 2)

From Controller

LINE

RECEIVERS

Channel 1

10 X 1

AUDIO

MULTIPLEXER

Channel 2

10 X 1

AUDIO

MULTIPLEXER

RS485

LINE

DRIVER

RS485

LINE

DRIVER

CH 1

OUTPUTS

CH 2

OUTPUTS

1-9

Page 30

Section 1 — Product Description

Performer Specifications

Table 1-1. Performer Specifications

Parameter Performanace

Serial Digital Video Inputs

Video Data Type Serial Digital conforms to SMPTE 259M (D1, D2N, D2P)

Number of inputs Ten (10)

Data Format Selection Internal Selector Switch

Input Impedance 75Ω nominal, self terminating

Input Return Loss >15dB (1MHz to 270MHz)

Connector Type 75Ω BNC (compatible with 50Ω cable ends)

Cable Equalization Automatic for <225m of Belden 8281 up to 270MHz

For direct mode, depends on serial standard and

receiving equipment.

AES/EBU Digital Audio Inputs

Number of Audio Matrices Two (2) 10X1 AES/EBU matrices

Audio Data Type Serial Digital conforms to standard AES3-1992 (ANSI

S4.40-1985)

Number of Inputs Ten per each audio matrix (20 total)

Input Level 400mV <signal level <7Vp-p balanced

Input Connector Type Either balanced female “D” connector or unbalanced

75ΩBNC connector

Input Impedance 110Ω, ±5%, 100KHz to 6MHz (D connector input only)

75Ω, ±5%, 100KHz to 6MHz (BNC connector input only)

Common Mode Voltage +7V, –7V Maximum (D connector input only)

Serial Digital Video Outputs

Video Data Type Serial Digital conforms to SMPTE 259M standard

Number of Outputs Two (2)

Output Impedance 75Ω nominal

Output Return Loss >15dB (1MHz to 360MHz)

Signal Amplitude 800mV ±10% when terminated into 75Ω

D.C. Offset ±0.5V

Rise and Fall Times ≤1.5 nS when terminated into 75Ω

Connector Type 75Ω BNC

1-10

Page 31

Functional Description

Table 1-1. Performer Specifications (continued)

Parameter Performanace

AES/EBU Digital Audio Outputs

Audio Data Type Serial Digital conforms to AES3-1991 (ANSI S4.40-1985)

Number of Outputs Two per audio matrix (4 ea. total)

Output Connector Balanced female “D” or unbalanced 75Ω BNC

Output Level 1.0Vp-p, ±10%, into 75Ω BNC connector.

5Vp-p ±20% into 110Ω balanced Output D connector

(both ±5% and 100KHz to 6MHz)

Operating Modes and Electrical Length

Mode Length

143Mb 38.3 ns

177Mb 37.6 ns

270Mb 36.6 ns

360Mb 35.6 ns

Auto See Above

Direct 26.0 ns (non-reclocked)

Mechanical & Power

Size H-1 Rack Unit, 1.75" (4.45cm); D-10" (25.4cm);

W-EIA standard, 19" (48.3cm)

Weight <15 Lbs (6.75kg)

Temperature Range 0 to 50° C (operational)

Humidity Range 0 to 95% non-condensing (operational)

Operational Range 0-250V AC, 50/60Hz, <45 Watts

Miscellaneous

Vertical Interval

Switching Line 10/525 line standards; Line 6/625 line standards

Control Interfaces RS422 or RS232 25-pin female "D" connector

1-11

Page 32

Section 1 — Product Description

1-12

Page 33

Introduction

2

Installation

Installation Overview

This section provides installation information for Performer

10 x 1 Routing Switcher. Included here are:

■ Installation Overview

■ Common Configurations

■ Installation Reference

This section provides step-by-step installation instructions for the

Performer™ in the following order:

■ Uncrating Unpacking and inspecting the

equipment.

■ Button Labeling Installing supplied source names

under front panel button caps.

■ Rack Mounting Installing frame in an equipment rack.

■ Bit-Rate Selection Selecting correct in/out bit-rates via

front panel bit-rate mode switch.

■ Cabling Making cable connections to frame.

■ Power-Up Applying AC power and running a

brief switcher operating check.

TM

NOTE: Factory default settings allow a single system (frame

including local control panel) and a single remote panel to be

connected and used without following all the procedures

necessary for more complicated installations.

2-1

Page 34

Section 2 — Installation

Uncrating

When you opened the box in which your Performer arrived, you

found this guide. If there was more than one box, they were each

assigned a number. In the box labeled number 1, there was a

System Packing List. Use the packing list to check your order’s

completeness; use the guide to direct you through installation and

operation.

While checking off each item, make sure that no damage was

incurred during shipping. If you find shipping damage, contact

the shipping agency immediately.

Save the shipping containers. You can reuse them any time you

transport the equipment.

Safety Information

WARNING

High voltage. Do not apply AC power with cover removed.

Disconnect AC power before cover is removed.

2-2

Page 35

Button Labeling

Film chips imprinted with standard source names and clear

button caps are included with Performer. Select names which suit

your requirements and install the chips and caps as illustrated.

b

M

0

6

3

A

b

M

0

7

2

b

M

7

7

1

b

M

3

4

1

NOTE: Tally Board and Looping Cable Option .If you order the

Performer and the Tally Board or Looping Cable Option at the same time,

the board is installed at the factory. If you order the Tally Board or

Looping Cable Option later, see the Installation Reference section and

install it as described.

O

T

U

T

C

E

IR

D

A1 CH1/2

V

STATUS DISPLAY

Film Chip

A2 CH1/2

INPUT SELECTION

VTR

27

Installation Overview

Install caps so that the

“fingernail” slots are at top

and bottom.

If the factory settings meet your requirements and you are not installing

a Tally Board or Looping Cable Option, go to Rack-Mounting the

Performer in this section to begin frame installation. If you wish to

make changes in the factory configuration or learn more about potential

settings, go to the Installation Reference section.

2-3

Page 36

Section 2 — Installation

Rack-Mounting the Performer

Performer is designed to mount in a 19-inch equipment rack. The

frame occupies 1 RU (Rack Unit, 1.75 inches/4.45 cm) of vertical

space. The illustration below shows you how to mount the frame

in the rack. The rear rack mounting bracket is supplied with the

frame as shipped. You should consider it if you have a lot of

unsupported cable weight on the back of Performer.

P

U

O

R

G

Y

E

L

L

VA

S

S

A

R

G

D

S

–

R

E

10

9

8

7

6

5

4

3

2

1

2

A

1

A

V

b

M

0

6

3

O

T

U

A

b

M

0

7

2

T

C

E

R

I

D

b

M

7

7

1

b

M

3

4

1

STATUS DISPLAY

INPUT SELECTION

M

R

O

F

R

E

P

VAA

2-4

There are many different rack manufacturers. The size and thread

pitch of mounting screws varies. Thus, these screws must be

supplied by the rack manufacturer or purchased locally.

Page 37

Installation Overview

Front Panel Bit-Rate Mode Switch

The bit-rate switch on the local control panel allows you to choose

between “forced”, AUTO, or DIRECT modes of matching input/

output bit rates. The electrical length of each operating mode is

listed in the specifications section of Section 1 - Product

Description. The modes are described below.

V

b

360M

AUTO

b

270M

177M

b

143M

DIRECT

b

STATUS

• “forced” modes include: 143 Mb/s for D2/NTSC; 177 Mb/s for

D2/PAL; 270 Mb/s for D1 (625 and 525); and 360 Mb/s for future

HDTV use. NOTE: Care must be taken when using any of these

modes of operation, the bit rate selected via the front panel switch

must match the input rate(s).

• AUTO mode: provides automatic bit rate selection when input

rates are different. The PERFORMER automatically detects the

input bit rate and switches to the correct rate (i.e. with D1 at Input

1 and D2 at Input 2 user switches from Input 1 to Input 2. The

switcher will automatically switch to the new rate.) NOTE: The

input sources must be locked together and timed.

• DIRECT mode: like the AUTO mode it automatically selects the

input rate and the non-reclocked mode (signal goes directly from

the input to the output without going through the deserializer or

the regenerator circuitry).

2-5

Page 38

Section 2 — Installation

V

Cabling

Performer cabling is straightforward. Refer to the illustration.

Input 1,

(+) (–) (s)

(s) (+) (–)

Input 2

AC IN

Input 3,

(+) (–) (s)

(s) (+) (–)

Input 4

1

Input 5,

(+) (–) (s)

(s) (+) (–)

9

Input 6

7

Input 7,

(+) (–) (s)

(s) (+) (–)

Input 8

35

Input 9,

(+) (–) (s)

(s) (+) (–)

Input 10

1

Output

(+) (–) (s)

19181716151413121110987654321

373635343332313029282726252423222120

37-Pin, D

Audio Connectors

9

1

7

1

35

AC IN

The Performer power

supply automatically

accepts 120V or 240VAC

input power. No special

settings are necessary.

The frame is shipped with

either TUV or UL AC line

cords as requested in the

original system order.

AUDIO NOTE:

The frame is shipped with

either AES/EBU “D” or

BNC audio connectors.

The BNC frame and the

pinout of the D audio

connectors are shown

above.

8

AUDIO 2 IN

8

AUDIO 1 IN

2

46

A1 OUT

2

46

10

2

A2 OUT

2

10

A1, A2

A1 and A2 audio connectors may be used as left and right channels

for stereo applications, or as two independent audio channels.

AUDIO 1 & 2 (BNC) IN

1. Using 50-ohm coaxial cable,

connect the left or right channel

of your number 1 audio source

to AUDIO 1 IN BNC #1.

2. Connect the remaining

number1 audio source chan-

AUDIO 1 & 2 (BNC) OUT

Two points of connection are

provided for the single output of

each audio channel. Typically,

one is used as a monitor output;

the other as the primary destination.

nels to AUDIO 1 IN BNCs #2 -

10.

3. Connect your second audio

source left or right channel to

AUDIO 2 IN BNC #1.

4. Connect the remaining number

2 audio source channels to AUDIO 2 IN BNCs #2 - 10.

AUDIO 1 & 2 AES/EBU I/O

37-pin D connectors provide left

and right channel inputs and

outputs. Each D connector supports 10 audio inputs and 1 audio output. See above for pinout

information.

2-6

Page 39

tput

–) (s)

Installation Overview

1

7

8

35

AUDIO 1 IN

46

1

V OUT

2

2

Video IN (1-10)

1. Using 75-ohm coaxial cable,

connect your number 1 video

source to Video IN 1 BNC.

2. Connect additional video

sources to V2 through V10

just as you did for V1.

3. Unused inputs must be

terminated with a 75-ohm

load for proper operation.

NOTE

Video sources should be

1V p-p optimum, and must

not exceed 2V p-p. For

AUTO mode, inputs will be

automatically equalized to

270MHz for up to 225m of

BELDEN 8281 cable. For

DIRECT mode, cable length

is dependent on serial

standard and receiving

equipment.

9

7

VIDEO IN

8

10

1

35

2

46

Video Out (V OUT 1 and 2)

Single video output has two

points of connection.

1. Using 75-ohm coaxial cable,

connect the V OUT 1 or

V OUT 2 BNC to the equipment you are feeding.

2. Connect the unused V OUT

BNC in step 1 to additional

equipment or to a video

monitor as necessary.

3.The output cable must be

terminated with a 75-0hm

load for proper operation.

OPTION and REMOTE

Information is located in the

Common Configurations and

Installation Reference subsections of this Installation

section.

OPTION

REMOTE

2-7

Page 40

Section 2 — Installation

Switcher Power-Up

Once you have completed setup, mounting, and cabling you can

apply power to the system and perform an operational check.

To power up and perform an operational check:

At this point, Performer does a self-test.

NOTE: Displays may be accelerated by pressing any of buttons 1

through 8 on the Performer front panel or skipped entirely by

pressing any other button.

Status information is displayed in the following order:

1. Connect the AC line cord from switcher to an AC main.1

Start-up

Display

88 88 88 LED test

rE SE t Warm reset

10 20 TEN-20 compatible

7 68 00 Baud rate

PA r n8 No parity / 8 data bits

SO 1- 10 No source offset

DE St 01 No destination offset

LV L1 23 No level offset

SL AV E0 Master mode

NT SC NTSC video source*

*Performer automatically adjusts itself to NTSC or PAL video

signals.

1. Due to the variation in styles, you must provide and install the

AC plug end for export units (PFR-240).

Protocol or Test

2-8

Page 41

Common Configurations

After setup switch locations are described, this section provides

illustrated switch and cabling information for the most common

configurations.

Common Configurations

■ Performer Remote to Performer

■ PC (Performer ASCII) to Performer

■ PC (TEN-XL ASCII) to Performer

■ PC (Performer ASCII) to Modem to Performer

■ PC (TEN-XL ASCII) to Modem to Performer

■ TEN-XL SCP (XY-mode) to Performer

■ TEN-XL SCP (XY-mode) to Modem to Performer

■ TEN-XL Remote Panels to Performer

■ TNX-AFV19 to Performer

■ 20-TEN XYCP to Performer

■ 100/110 to Performer

■ 200 to Performer

■ 300 to Performer

2-9

Page 42

Section 2 — Installation

Performer Setup Switch Location

While setting up your Performer, you may need to change the

settings of switches S1, S2, and S3 located within the frame. You

won’t have to remove the top cover to access these switches

because a small “slide” cover is located on the frame’s top cover

directly above the switches. See the illustration below.

2-10

S3

OPEN

12345678

12345678

OPEN

OPEN

12345678

S2

1. Remove screw from side of "slide" cover.

S1

2. Hold "slide" cover tightly against side of

frame and remove top screw.

3. Slide cover to the left to open.

Page 43

Performer Remote to Performer

Common Configurations

Performer Remote Control Panel

12345678910

VA1A2

Dot indicates

switch down

on that side

12345678ON12345678

AUDIO

VIDEO

Grass Valley Group

AUDIO

PERFORMER–SD

1

2

REMOTE

1234

These are default settings; unless you

have changed the settings, proceed to

cabling.

12345678

12345678

OPEN

1

1234

OPEN

Performer

12345678910

V A1 CH1/2 A2 CH3/4

360Mb

270Mb

AUTO

177Mb

DIRECT

143Mb

S3

OPEN

12345678

OPEN

S2

OPEN

Grass Valley Group

A1

A2

VIDEO

PERFORMER–SD

CH1/2

CH3/4

VAA

S1

12345678

Dot indicates

switch down

on that side

12345678

These are default settings; unless you

have changed the settings, proceed to

cabling.

35

7

AUDIO 2 IN

8

46

Performer–SD

AES/EBU IN/OUT 1AES/EBU IN/OUT 2

Performer–SDB

1

9

1

7

AUDIO 1 IN

A1 OUT V OUT

2

8

10

2

AC IN

9

1

AC IN

A2 OUT

10

2

9

1

V OUT

2

1

1

35

2

2

46

1

35

7

VIDEO IN

8

10

2

46

9

1

35

7

VIDEO IN

8

10

2

46

14

1

OPTION

REMOTE

OPTION

REMOTE

25

13

Performer

9 pin

Female

RS485 (+) 3

RS485 (-) 8

GND (S) 9

Cable (max 2000'/610m)

User fabricated

Performer

25 pin

Male

1 RS485 (+)

2 RS485 (-)

18 GND (S)

2-11

Page 44

Section 2 — Installation

PC (Performer ASCII) to Performer

PC (Performer ASCII)

Baud 9600

Data Bit 7

Parity Odd

Stop 1

25

Performer

12345678910

V A1 CH1/2 A2 CH3/4

360Mb

270Mb

AUTO

177Mb

DIRECT

143Mb

S3

OPEN

12345678

OPEN

S2

OPEN

12345678

35

7

AUDIO 2 IN

8

46

Performer–SD

AES/EBU IN/OUT 1AES/EBU IN/OUT 2

Performer–SDB

1

9

1

A1 OUT V OUT

2

2

35

7

AUDIO 1 IN

8

10

46

1

2

AC IN

9

1

AC IN

A2 OUT

10

2

1

S1

V OUT

1

2

1

2

VIDEO

12345678

9

10

9

10

Grass Valley Group

A1

A2

CH1/2

CH3/4

Dot indicates

switch down

on that side

7

VIDEO IN

8

7

VIDEO IN

8

14

1

PERFORMER–SD

VAA

1

35

2

46

1

35

2

46

OPTION

REMOTE

OPTION

REMOTE

25

13

2-12

PC

25 pin

Female

TXD 2

RXD 3

GND 7

Cable (max 50'/15.25m)

TNX-IRS (056857)

Performer

25 pin

Male

16 RXD

3 TXD

18 GND

Page 45

Common Configurations

PC (Performer ASCII) to Performer (cont.)

The following is an example of a Performer ASCII string used to

control a Performer via a PC. The command string will switch

video input number 5 on all levels of the Performer (video, audio

1, and audio 2).

Performer ASCII command strings:

■ Preset string – ^M0007D000501

■ Take string – ^M0003T01

Table 2-1.

ASCI

I

Description

Preset String

Byte 1 ^M carriage return

Byte 2 00 Performer address

Byte 3 07 number of data string characters

CMD D data preset, source to destination

Byte 4 00 level, 00 = all levels

Byte 5 05 input selection

Byte 6 01 output selection

Take Strings

Byte 1 ^M carriage return

Byte 2 00 Performer address

Byte 3 03 number of data string characters

CMD T take the specified destination

Byte 4 01 output selection

2-13

Page 46

Section 2 — Installation

PC (Performer ASCII) to Modem to Performer

PC (Performer ASCII)

Baud 1200

Data Bit 7

Parity Odd

Stop 1

1

25

Modem*

V A1 CH1/2 A2 CH3/4

360Mb

270Mb

AUTO

177Mb

DIRECT

143Mb

Performer

12345678910

S3

OPEN

S2

OPEN

S1

12345678

OPEN

VIDEO

12345678

CH1/2

Grass Valley Group

A1

A2

PERFORMER–SD

CH3/4

Dot indicates

switch down

on that side

VAA

12345678

7

AUDIO 2 IN

8

Performer–SD

AES/EBU IN/OUT 1AES/EBU IN/OUT 2

Performer–SDB

1

9

35

1

7

A1 OUT V OUT

2

8

10

46

2

AUDIO 1 IN

AC IN

9

1

AC IN

A2 OUT

10

2

1

25

25

1

9

1

V OUT

2

1

1

35

2

2

46

1

OPTION

35

7

VIDEO IN

8

10

9

7

8

10

REMOTE

2

46

1

35

OPTION

VIDEO IN

2

46

REMOTE

14

1

25

13

SCP

25 pin

Female

TXD 2

RXD 3

GND 7

Cable (max 50'/15.25m)

TNX-CTM (056862)

Modem

25 pin

Male

2 RXC

3 TXD

7 GND

Modem

25 pin

Male

TXD 2

RXD 3

GND 7

Cable (max 50'/15.25m)

TNX-MIC (056861)

Performer

25 pin

Male

16 RXD

3 TXD

18 GND

*Disable or turn off modem response codes to terminal, or select the mode which sends them

as numbers; disable or turn off command character echo.

2-14

Page 47

Common Configurations

PC (Performer ASCII) to Modem to Performer (cont.)

The following is an example of a Performer ASCII string used to

control a Performer via a PC. The command string will switch

video input number 5 on all levels of the Performer (video, audio

1, and audio 2).

Performer ASCII command strings:

■ Preset string – ^M0007D000501

■ Take string – ^M0003T01

Table 1-2.

ASCI

I

Description

Preset String

^M carriage return

00 Performer address

07 number of data string characters

D CMD = data preset, source to destination

00 level, 00 = all levels

05 input selection

01 output selection

Take String

^M carriage return

00 Performer address

03 number of data string characters

T CMD = take the specified destination

01 output selection

2-15

Page 48

Section 2 — Installation

PC (TEN-XL ASCII) to Performer

PC (TEN-XL ASCII)

Baud 9600

Data Bit 7

Parity Odd

Stop 1

25

Performer

12345678910

V A1 CH1/2 A2 CH3/4

360Mb

270Mb

AUTO

177Mb

DIRECT

143Mb

S3

OPEN

12345678

OPEN

S2

OPEN

12345678

35

7

AUDIO 2 IN

8

46

Performer–SD

AES/EBU IN/OUT 1AES/EBU IN/OUT 2

Performer–SDB

1

9

1

A1 OUT V OUT

2

2

35

7

AUDIO 1 IN

8

10

46

AC IN

9

1

AC IN

A2 OUT

10

2

1

Grass Valley Group

A1

A2

VIDEO

PERFORMER–SD

CH1/2

CH3/4

VAA

S1

12345678

Dot indicates

switch down

on that side

9

1

V OUT

10

2

9

1

1

10

2

2

1

OPTION

35

7

VIDEO IN

8

7

8

REMOTE

2

46

1

35

OPTION

VIDEO IN

2

46

REMOTE

14

1

25

13

2-16

PC

25 pin

Female

TXD 2

RXD 3

GND 7

Cable (max 50'/15.25m)

TNX-IRS (056857)

Performer

25 pin

Male

16 RXD

3 TXD

18 GND

Page 49

PC (TEN-XL ASCII) to Performer (cont.)

The following is an example of a TEN-XL ASCII string used to

control a Performer via a PC. The command string will switch

video input number 4 and both audio channels to input number 6.

TEN-XL ASCII protocol does not allow left and right audio

channel breakaway.

TEN-XL ASCII command string: ^B0035

Table 2-2.

ASCII Description

Byte 1 ^B start of transmission

Byte 2 00 Performer address

Byte 3 35 video crosspoint 4*

audio crosspoint 6*

Common Configurations

*The video and audio crosspoints are numbered 0 through 9.

2-17

Page 50

Section 2 — Installation

PC (TEN-XL ASCII) to Modem to Performer

PC (Performer ASCII)

Baud 1200

Data Bit 7

Parity Odd

Stop 1

1

25

Modem*

V A1 CH1/2 A2 CH3/4

360Mb

270Mb

AUTO

177Mb

DIRECT

143Mb

Performer

12345678910

S3

OPEN

S2

OPEN

S1

12345678

OPEN

VIDEO

CH1/2

12345678

Grass Valley Group

A1

A2

PERFORMER–SD

CH3/4

Dot indicates

switch down

on that side

VAA

12345678

35

7

AUDIO 2 IN

8

46

Performer–SD

AES/EBU IN/OUT 1AES/EBU IN/OUT 2

Performer–SDB

1

9

1

7

AUDIO 1 IN

A1 OUT V OUT

2

8

10

2

AC IN

9

1

AC IN

A2 OUT

10

2

1

25

25

1

9

1

V OUT

10

2

1

1

35

2

2

46

1

OPTION

35

7

VIDEO IN

8

9

7

8

10

REMOTE

2

46

1

35

OPTION

VIDEO IN

2

46

REMOTE

14

1

25

13

SCP

25 pin

Female

TXD 2

RXD 3

GND 7

Cable (max 50'/15.25m)

TNX-CTM (056862)

Modem

25 pin

Male

2 RXC

3 TXD

7 GND

Modem

25 pin

Male

TXD 2

RXD 3

GND 7

Cable (max 50'/15.25m)

TNX-MIC (056861)

Performer

25 pin

Male

16 RXD

3 TXD

18 GND

*Disable or turn off modem response codes to terminal, or select the mode which sends them

as numbers; disable or turn off command character echo.

2-18

Page 51

PC (TEN-XL ASCII) to Modem to Performer (cont.)

The following is an example of a TEN-XL ASCII string used to

control a Performer via a PC. The command string will switch

video input number 4 and both audio channels to input number 6.

TEN-XL ASCII protocol does not allow left and right audio

channel breakaway.

TEN-XL ASCII command string: ^B0035

ASCII Description

^B start of transmission

00 Performer address

35 video crosspoint 4*

Common Configurations

Table 2-3.

audio crosspoint 6*

*The video and audio crosspoints are numbered 0 through 9.

2-19

Page 52

Section 2 — Installation

TEN X L

TEN-XL SCP (XY-mode) to Performer

TEN-XL SCP

12345678910 12345678910

Grass Valley Group

OPEN

12345678

S1

SERIAL CONTROL PANEL

Performer

12345678910

V A1 CH1/2 A2 CH3/4

360Mb

270Mb

AUTO

177Mb

DIRECT

143Mb

S3

OPEN

12345678

OPEN

OPEN

12345678

S2

35

7

AUDIO 2 IN

8

46

Performer–SD

AES/EBU IN/OUT 1AES/EBU IN/OUT 2

Performer–SDB

1

9

1

A1 OUT V OUT

2

2

35

7

AUDIO 1 IN

8

10

46

1

2

AC IN

9

1

AC IN

A2 OUT

10

2

1

25

Grass Valley Group

A1

A2

VIDEO

PERFORMER–SD

CH1/2

CH3/4

VAA

12345678

S1

Dot indicates

switch down

on that side

9

1

V OUT

10

2

9

1

10

2

1

OPTION

35

7

VIDEO IN

8

7

8

1

REMOTE

2

46

1

35

OPTION

VIDEO IN

2

46

REMOTE

14

25

13

TEN-XL

25 pin

Female

TXD 2

RXD 3

GND 7

Cable (max 50'/15.25m)

Performer

25 pin

Male

16 RXD

3 TXD

18 GND

TNX-IRS (056857)

To control more than one Performer, see additional information in Installation Reference section.

2-20

Page 53

Common Configurations

TEN X L

TEN-XL SCP (XY-mode) to Modem to Performer

TEN-XL SCP

12345678910 1 2345678910

Grass Valley Group

OPEN

12345678

S1

25

SERIAL CONTROL PANEL

1

Modem*

A1 CH1/2 A2 CH3/4

V

360Mb

270Mb

AUTO

177Mb

DIRECT

143Mb

Performer

12345678910

S3

OPEN

12345678

OPEN

OPEN

VIDEO

12345678

A1

CH1/2

Grass Valley Group

A2

PERFORMER–SD

CH3/4

S1

Dot indicates

switch down

on that side

VAA

12345678

S2

35

7

AUDIO 2 IN

8

46

Performer–SD

AES/EBU IN/OUT 1AES/EBU IN/OUT 2

Performer–SDB

1

9

1

7

AUDIO 1 IN

A1 OUT

2

8

10

2

AC IN

9

1

AC IN

A2 OUT

10

2

1

25

25

1

9

1

7

V OUT

8

10

2

9

1

1

35

46

7

V OUT

8

10

2

2

OPTION

1

35

VIDEO IN

REMOTE

2

46

OPTION

1

35

VIDEO IN

REMOTE

2

46

13

25

1

14

TEN-XL

25 pin

Female

TXD 2

RXD 3

GND 7

Cable (max 50'/15.25m)

TNX-CTM (056862)

Modem

25 pin

Male

RXC 2

TXD 3

GND 7

Modem

25 pin

Male

TXD 2

RXD 3

GND 7

Cable (max 50'/15.25m)

TNX-MIC (056861)

Performer

25 pin

Male

16 RXD

3 TXD

18 GND

*Disable or turn off modem response codes to terminal, or select the mode which sends them as

numbers; disable or turn off command character echo.

To control more than one Performer, see additional information in Installation Reference section.

2-21

Page 54

Section 2 — Installation

TEN X L

TEN-XL Remote Panels to Performer

TEN-XL Remote Panels

Grass Valley Group

TEN-XL Remote panels include:

TNX-RCP, TNX-AFV, TNX-TCP,

TNX-SMP, TNX-2AFV

25

Performer

12345678910

V

A1 CH1/2 A2 CH3/4

360Mb

270Mb

AUTO

177Mb

DIRECT

143Mb

S3

OPEN

12345678

OPEN

OPEN

12345678

S2

35

7

AUDIO 2 IN

8

46

Performer–SD

AES/EBU IN/OUT 1AES/EBU IN/OUT 2

Performer–SDB

1

9

1

35

7

AUDIO 1 IN

A1 OUT

2

8

10

2

46

AC IN

9

1

AC IN

A2 OUT

10

2

1

Grass Valley Group

A1

A2

VIDEO

PERFORMER–SD

CH1/2

CH3/4

VAA

12345678

S1

Dot indicates

switch down

on that side

9

1

7

V OUT

8

10

2

9

1

1

7

V OUT

8

10

2

2

OPTION

1

35

VIDEO IN

REMOTE

2

46

OPTION

1

35

VIDEO IN

REMOTE

2

46

1

25

TNX

25 pin

Male

1

25

Cable (max 1000'/305m)

Performer

25 pin

Male

1

25

TNX-RCC (056851)

Pins are one to one

To control more than one Performer, see additional information in Installation Reference section.

2-22

Page 55

TNX-AFV19 to Performer

TEN X L

Common Configurations

TEN-AFV19

Grass Valley Group

Performer (Primary and Secondary)

Note: Switch settings for S2 are different

for primary and secondary, see below.

12345678910

V

A1 CH1/2 A2 CH3/4

360Mb

270Mb

AUTO

177Mb

DIRECT

143Mb

S3

OPEN

12345678

OPEN

VIDEO

12345678

OPEN

Grass Valley Group

A1

A2

PERFORMER–SD

CH1/2

CH3/4

S1

Dot indicates

switch down

on that side

VAA

12345678

S2

Primary Performer

(increments 1 to 10)

Secondary Performer

(increments 2 to 10)

S3

OPEN

12345678

OPEN

OPEN

12345678

S1

Dot indicates

switch down

on that side

12345678

S2

35

7

AUDIO 2 IN

8

46

Performer–SD

AES/EBU IN/OUT 1AES/EBU IN/OUT 2

Performer–SDB

1

9

1

7

AUDIO 1 IN

A1 OUT

2

8

10

2

J1S

1

25

J1P

1

25

AC IN

9

1

AC IN

A2 OUT

10

2

9

1

7

V OUT

8

10

2

9

1

1

35

7

V OUT

8

10

2

2

46

OPTION

1

35

VIDEO IN

REMOTE

2

46

OPTION

1

35

VIDEO IN

REMOTE

2

46

13

1

TNX

25 pin

Male

TNX

25 pin

Male

1

25

Cable (max 1000'/305m)

TNX-RCC (056851)

Pins are one to one

Requires two cables

(Primary & Secondary)

Performer 25 pin

Male

1

Note: Wiring is identical

for both primary and

secondary Performers.

25

25

14

2-23

Page 56

Section 2 — Installation

20-TEN XYCP to Performer

TEN-20 XYCP

LEVEL 1 LEVEL 2 LEVEL 3 LEVEL 4 DESTINATION

1

2

3

OPEN

LEVELS

4

5

6

7

8

OPEN

PANEL

NUMBER

12345678

12345678

12345678

OPEN

OPEN

OPEN

Performer

0123 4

PROTECT

CLEAR

LAST

TAKE

5678 9

Grass Valley Group

1

2

3

4

5

6

7

8

OPEN

1

2

3

4

5

6

7

8

360Mb

270Mb

AUTO

177Mb

DIRECT

143Mb

DEST

AC IN

AC IN

A2 OUT

12345678910

V

A1 CH1/2 A2 CH3/4

S3

S2

9

1

35

7

AUDIO 2 IN

8

10

2

46

OPEN

12345678

OPEN

12345678

Performer–SD

AES/EBU IN/OUT 1AES/EBU IN/OUT 2

Performer–SDB

1

9

1

35

7

AUDIO 1 IN

A1 OUT

2

8

10

2

46

OPEN

1

2

Grass Valley Group

A1

A2

VIDEO

PERFORMER–SD

CH1/2

CH3/4

VAA

12345678

S1

Dot indicates

switch down

on that side

9

1

7

V OUT

8

10

2

9