Page 1

PDR200, PDR300, & PDR400

Installation Manual

071-8005-00

MARCH 23, 2 000

PROFILE FAMILY

VIDEO FILE SERVERS

Page 2

Copyright Copyright © 2000 Grass Valley Group Inc. All rights reserved. Printed in the United States of

America.

This document may not be copied in whole or in part, or otherwise reproduced except as

speci fical ly pe rmit ted u nder U.S . cop yri ght la w, wit ho ut the p rio r writ ten cons ent of Gr ass Va lley

Group Inc., P.O. Box 59900, Nev ad a City, C alifo rni a 95 959-7 90 0

Trademarks Grass Va lley , GRA SS VAL L EY GR OUP, Prof ile an d Pro file XP are ei the r reg ister ed tr adem ar ks

or trad emarks of Gr ass Va lley G roup in the Uni ted State s and/ or oth er coun tries . Oth er tra dema rks

used in this doc ument are e ither r egistered tradem arks or t rademar ks of the m anufactu rers or

vendors of t he ass oc ia te d p rod uct s. G ra ss Va ll ey Gr ou p pro du cts a r e co ver ed by U. S. an d for e ig n

patents, issued and pending. A dditional information regarding

Grass Valley Group's trademarks and other proprietary rights may be found at

www.grassvalleygroup.com.

Disclaimer Produc t opti ons an d spe cifi cation s sub ject to ch ange wi thout not ice. Th e inf ormat ion i n this m anua l

is furnis hed for inform ational use on ly, is subjec t to change with out notice, and should not be

const rued as a commit ment by Grass V all ey Group . Gr ass Val ley Gr oup assu mes no respon sibi lity

or liability for any errors or inaccuracies that may appear in this publication.

U.S. Government

Restricted Rights

Legend

Use, du pli cati on, or di sclo su re by th e Unit ed Sta tes G ove rnme nt i s su bjec t to rest ric tions a s se t

forth in subparagraph (c)(1)(ii) of the Rights in Technical Data and Computer Software clause at

DFARS 252.277-7013 or in subparagraph c(1) and (2) of the Commercial Computer Software

Restricted Rights clause at FAR 52.227-19, as applicable. Manufacturer is Grass Valley Group

Inc., P.O . Bo x 59 90 0, N ev a da City, Cal ifo r ni a 95 959-790 0 U. S. A .

Revision Status

REV DATE DESCRIPTION

April, 1997 Initial release of In stallation Manual 070-9676-00

May, 1997 Procedure change, roll Part Nu mber to 070-9676-01

September, 1997 Add Analog Composite I/O and Monitor Boards, remove Fibre Channel

January, 1998 Change slot positions for systems above S/N B030000, roll P/N to

June, 1998 Added PDR300 with MPEG, PDR200 slot positions change for systems

user information, roll P/N to 070-9676-02

070-9676-03

above S/N B040000, roll P/N to 070-9676-04.

October, 1998 Added support for PDR200 Option DV and PDR304. Roll P/N to

070-9676-05.

November, 1998 Modif ied sections to sup port cha nges to the CPU board for PDR200

system s above S/N B050000 an d PDR300 systems above S/ N B020000.

Roll P/N to 070-9676-06.

December , 1998 Modified se ction s to sup port 1 8GByte d riv es, for PDR200 systems abo ve

S/N B060000 and P DR300 systems above S/N B030000.

Roll P/N to 070-9676-07.

April, 1999 Modified manual title and added support for the PDR400 with DVCPRO.

Roll P/N to 070-9676-08

October, 1999 Added six-channel DVCPRO support. Roll P/N to 070-9 676-09.

March 23, 2000 Added DVCPRO 50 support. New P/N to 071-8005-00.

Page 3

Grass Valley Group Product Support

You ca n get technical assistance, check on the status of problems, or r eport new proble ms by

contacting our Product Sup port Group.

United States and Canada

Monday–Friday 5:30AM–5:00PM Pa cific Time

(800) 547-8949

Europe

Monday–Friday 9:00AM–5:30PM

France 01 69 86 83 47 United Ki ngdom 01628 405830

Germany 0221 9477 446 Other +44 1628 405840

Italy 02 25086606

Asia and South America

Australia

- from overseas

Beijing 86-10-62351230

Brazil 55-11-3741-8422 Taiwan 886-2-27571571

Hong Kong 852-25856655

02-9888 0100

61-2-9888 0100

ext. 711

Japan 81-3-3448-3111

Korea 82-2-528-5299

Mexico 52-5-666-6333

Singapore 65-356-3900

World Wide

24-hour Emergency Hotline (530) 478-4148 (Contract and warranty customers)

W orld Wide Web http://www.grassvalleygroup.com/support/

FTP Site ftp.grassvalleygroup.com

Users Group profile-users@grassvalleygroup.com

Profile Video File Server Installation iii

Page 4

Grass Valley Group Product Support

iv Profile Video File Server Instal lation

Page 5

Contents

Grass Valley Group Pr oduct Support ................................... .. .............................. .. ...............iii

Chapter 1 Introducti on

Scope..................................................................................................................................... 1-1

Related Documentation ......................................................................................................... 1-2

Organization of the Manual....................................................................................................1-2

Product Descri pti on...................................... .. .............................. .. .......................................1-3

Product Feature s.......... .. .......................................... ........................................... ............ .1-4

Front Pan e l C o n tro l s a nd In d ic at o rs ...... ... .......... ......... ... .......... ......... .......... .......... ......... .. 1-5

Accessories ...........................................................................................................................1-6

Standard Accessor ies............................. ......................................................................... .1-6

Optiona l Acc e s so r ie s ............ .......... .......... .......... .. .......... .......... ......... .......... .......... ......... .. 1-7

Configurations........................................................................................................................1-8

Configuration Labels..............................................................................................................1-14

Maximu m V id eo D a ta Rate s .. .. .......... ......... .......... .......... .......... ......... ... .......... ......... .......... .... 1-15

Storage Capacit y Esti m ates ............................. .......... .. .............................. .. .........................1-16

DVCPR O Sy s te m T imin g C on s id e ra t io n s... ... .......... ......... .......... .......... .......... .. .......... ......... .. 1-17

Chapter 2 Mechanical Installation

Rack Mo unting........ .......... ......... ... .......... ......... .......... .......... .......... ......... ... ......... .......... .........2-1

Mounting the Slide Tracks in the Rack .............. ............................... .. .......... .. ..................2-2

Mounting the Profil e Video File Server .............. .. .. ............ ............ ...................... ............ .2-5

Making Rack Slide Adjustments ....................................................................................... 2-6

Mounting Panels and Audi o Chassis ............ ......................................... .. .................... .. ...2-6

Making Re a r P ane l C o nn e c tio n s ............ .. .......... ......... ... .......... ......... .......... .......... .......... ...... 2-7

Connecting the Mouse and Keyboard........... .. .. .......... .. .......... ............ .......... .. .......... ........2-8

Connec ting the Mon it o r......... ... .......... ......... .......... .......... .......... ......... ... ......... .......... ......... 2-8

Connecting the Reference Genlock .................................................................................. 2-9

Connec ting Video.... .. .......... .......... ......... .......... .......... .......... .. .......... .......... ......... .......... .... 2-10

Connec ting Serial D ig ital Video............ .. .......... .......... .......... ......... .......... .. .......... ......... 2-10

Connecting Analog Composite Video I/O.....................................................................2-11

Connec ting Analog C o mp os ite Monit or..... ......... .......... .......... .......... .. .......... .......... ...... 2-1 2

Connecting Analog Composite Video Out....................................................................2-13

Connecting Component Analog Video.........................................................................2-14

Connec ting Audio.... .. .......... .......... ......... .......... .......... .......... .. .......... .......... ......... .......... .... 2-15

Connecting 16 Channels AES/EBU Digital Audio (XLR216 or BNC 216) ....................2-16

Connecting 32 Channels AES/EBU Digital Audio (XLR216 or BNC 216) ....................2-18

Connecting 8 Analog and 8 Digital Channels (PAC208)..............................................2-20

Connecting 16 Analog/Digital Channels (PAC216) ......................................................2-22

Connecting 32 Analog/Digital Channels (PAC216) ......................................................2-24

Connec ting SCSI D ev ic e s.......... .......... .......... ......... .......... ... ......... .......... .......... .......... ...... 2-26

Connecting RS-422 Devices.............................................................................................2-32

Connec ting Netwo rk De v ic e s................. .......... .......... .......... ......... ... .......... ......... .......... .... 2-33

Connecting Fibre Channel...........................................................................................2-33

Connec ting to Ether n et ....... .......... ......... ... ......... .......... .......... .......... ......... .......... ......... 2 -3 3

Making Power Connecti ons................ ........................................... ...................... ............ .2-34

Power Source............................................................................................................... 2-34

Source Power Frequency and Voltage Ranges............... ...................... ......................2-34

Profile Video File Server Installation v

Page 6

Contents

Chapter 3 Starting Your Profile System

Power On/Off ......................................................................................................................... 3-1

Logging On ....................................................................................................................... 3-1

Automa tic Logon ...................... .. .......... .......... ......... .......... .......... .......... .. .......... ......... .. 3-1

Logon as Administr ator ........................................ .. .......... .. .................... .. .......... .. ........3-2

Logon as Profile....... ........................................... .........................................................3-2

Turning Power On.............................................................................................................3-2

Turning Power Off............................................................................................................. 3-4

System Set-up .......................................................................................................................3-5

Configu ring Your Prof ile S ys t em........ ......... .......... .......... .......... .. .......... ......... .......... ......... 3-6

Updating an Emergency Repair Disk................................................................................3-6

Installation Verification...........................................................................................................3-7

Initial P owe r On Check s ........ .. .......... .. .......... .......... ......... .......... ... ......... .......... .......... ......... .. 3-7

System Board Diagnostics..................................................................................................... 3-9

Chapter 4 Networking Your Profile System

Network C on f ig u ra ti on s ...... ... ......... .......... .......... ......... .......... .......... .. .......... .......... .......... ...... 4-1

Network M o dels . ... ......... .......... .......... ......... .......... .......... .. .......... .......... .......... ......... .......... .... 4-1

Networking Several Profile Systems................................................................................. 4-2

Cascading Several Hubs .................................................................................................. 4-2

Point to Point Network Connection ................................................................................... 4-3

Connec ting Ethern e t .... .......... .. .......... ......... .......... .......... .......... ......... .......... ... ......... .......... .... 4-4

Etherne t In te rface Co n fig u ration........ ......... .......... .......... .......... .. .......... ......... .......... ......... 4-4

Configu ring Ethe rn e t fo r T CP /IP ... .. .......... .......... .. .......... .......... ......... .......... .......... ......... .. 4-5

Testing Your Ethernet Connection................ .. .. .............................. .. .. .................... .. ........4-5

Connecting Fibre Channel.....................................................................................................4-6

Appendix A S pecifications

General Information ............................................................................................................... A-1

Test Equipment......................................................................................................................A-1

Electrical Specifications......................................................................................................... A-2

Enviro n me n ta l C rit e ria . .......... .. .......... ......... .......... .......... .. .......... .......... .......... ......... .......... .. .. A-10

Mechan ic a l S pe c if ic at io n s ....... .. .......... .......... .......... ......... ... .......... ......... .......... .......... ......... .. A-11

PAC 208/216 Power Requiremen ts................ ............ .. ................................. .. ............ .. ........A-11

Appendix B Conne ct or Pin-outs

S-VGA C o nne c to r . .. .......... ......... .......... .......... .......... ......... .......... ... ......... .......... .......... ......... .. B-1

Etherne t C o nn e c to r. .. .......... .......... .. .......... .......... ......... .......... .......... .......... .. .......... .......... ......B-2

Parallel Port Conne ctor..................................... ............ ...................... ...................... .............B-3

RS-232 Connectors.................. .. ...................... ............ ...................... ...................... .............B-4

SCSI Connector..................................................................................................................... B-5

Fibre Channel Connec tor.................................................................... ...................................B-7

Fibre Channel Cable Specifications................ .. ............ ...................... ............ ..................B-7

Reference Genlock D-Connector............. .. ............ ............ .................................. ..................B-8

Audio Signal Processing Board Connector.......... ............ ............ ............ ...................... ........B-9

vi Profile Video File Server Insta llation

Page 7

Figures

1-1 The Profile Video File Server ......... ........... .. .. .. ........... .. .......................... .............................. 1-1

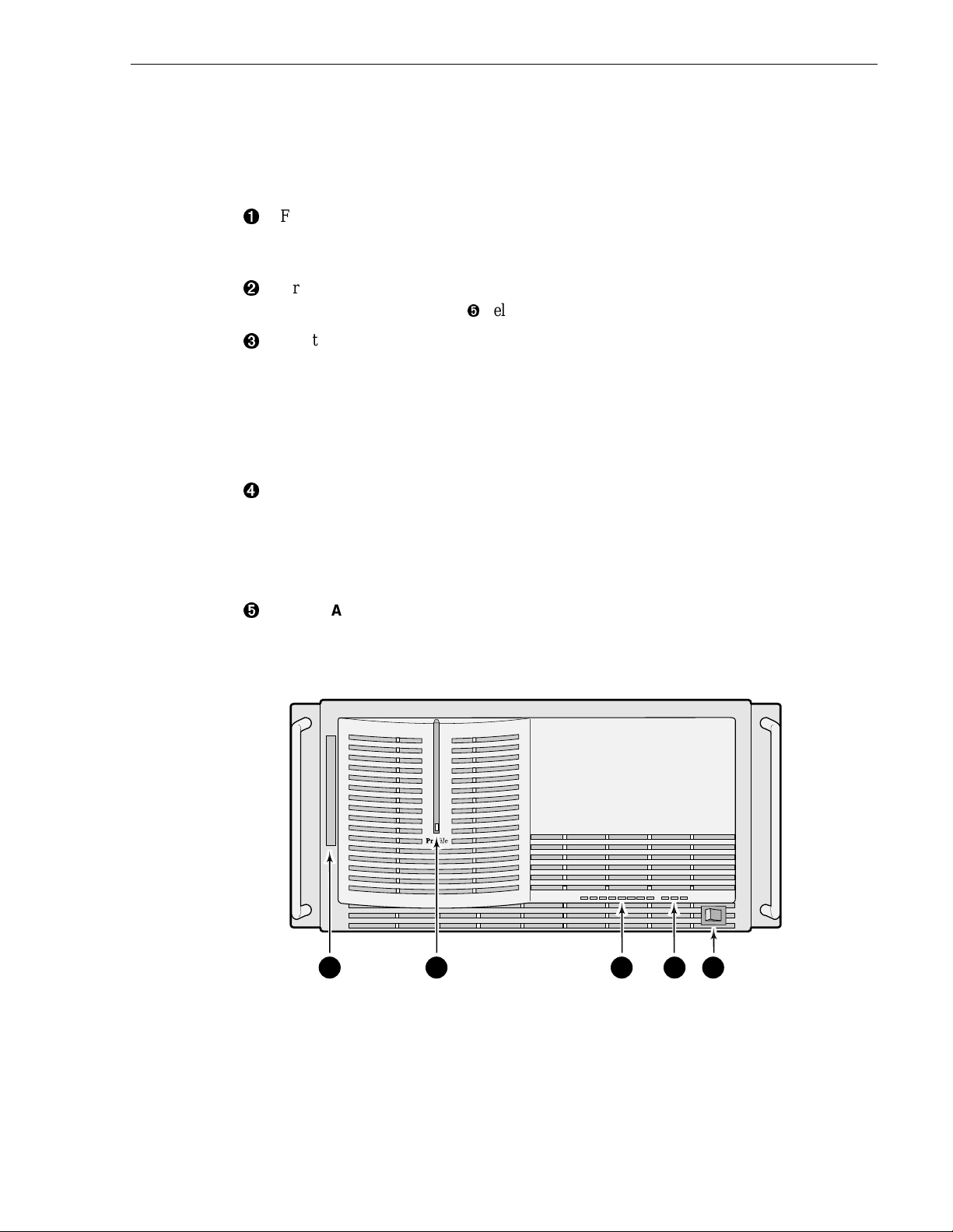

1-2 Profile Video File Server Front Panel.......................................................... ......................... 1-5

1-3 Configuration Labels Locations..................... .. .......... .......... .. .......... .......... .. .......... .......... .. ... 1-14

2-1 Rack Slide Set for Right Side of Profile Chassis and Rack.................................................. 2-2

2-2 Spacing Specification for Mounting Holes in a Rack............................................................ 2-3

2-3 Front Rail Mounting Detail.................... ............ ............ ............ ............ ............ .................... 2-4

2-4 Rear Rail M o u nt in g Deta il ...... ... ......... .......... .......... ......... ... .......... ......... .......... .......... .......... . 2-4

2-5 Rack Slide Stop Latch.......................................................................................................... 2-5

2-6 BNC Conne ction Wit h EM I G a s ke t... .. ... ......... .......... .......... .......... .. .......... .......... ......... ......... 2-7

2-7 Mouse, Keyboard, and S-VGA Monitor Connections ........................................................... 2-8

2-8 Reference Genlock Cable Connections................ .. .......... .. .......... .. .......... .. .......... .. .......... ... 2-9

2-9 Breako u t Cab l e.... .. .......... .......... ......... .......... .. .......... .......... .......... ......... .......... .......... ......... .. 2-9

2-10 Serial Digital I/O Cable Connections........... .. .. ...................... .................................. ............. 2-10

2-11 Analog Composite I/O Cable Connections....................................... ....................... ............. 2-11

2-12 Analog Composite Monitor Cable Connections......... ........................................................... 2-12

2-13 Analog Composite Out Cable Connections.......................................................................... 2-13

2-14 Analog Component Video In Cable Connections................................. ...................... .......... 2-14

2-15 ASPB Connections for 16 Channels of AES/EBU Digital Audio........... .. ........... ................... 2-17

2-16 ASPB Connections for 32 Channels of AES/EBU Digital Audio........... .. ........... ................... 2-19

2-17 ASPB Connecti ons for 8 Analog and 8 Digital Audio Channels........... ............ ............ ........ 2-21

2-18 ASPB Connections for 16 Analog and 16 Digital Audio Channels............................... ........ 2-23

2-19 ASPB Connections for 32 Analog and 32 Digital Audio Channels............................... ........ 2-25

2-20 SCSI Cable Connections......... ........................ ........... ............ .. .. ............ ........... .. ............ .. ... 2-26

2-21 Example 1: Connecting a PDX218 Disk Expansion Chassis............... .................... .. .......... 2-27

2-22 Example 2: Connecting two PDX218 Disk Expansion Chassis ............. .......... ............ ........ 2-28

2-23 Example 3: Profile Video File Server to PLS 200 Connections............................................ 2-29

2-24 Example 4: Profile Video File Server to PDX 218 and PLS 200 Connect ions.......... .. .......... 2-30

2-25 Example 5: Profile Video File Server to Multiple RAIDs and PLS 200 Connections............ 2-31

2-26 Profile Video File Server and RS-422 Connector Panel Cabl e Connection......................... 2-32

2-27 Power Cord Connector......................................................................................................... 2-35

3-1 Rear Panel Main Power Switch............................................................................................ 3-3

3-2 Front Panel Power Switch........................................................ ............................................ 3-3

3-3 Profile VdrPanel ................................................................................................................... 3-5

4-1 Basic Hub Connections......................................................... ...................... ............ ............. 4-2

4-2 Cascading Severa l Hubs........ .......... .......... ......... .......... .......... .. .......... .......... ......... .......... .... 4-3

4-3 Point-to-Point Network Connection....................................... ............................................... 4-3

4-4 System Ethernet Connector................................................................................................. 4-4

4-5 Example of Profile System and Fibre Channel Connec ti ons...................................... .......... 4-6

4-6 Fibre Channel Board and Hub Connection ........................... ............................................... 4-7

B-1 S-VGA Moni tor Co nnector.................................................................. .................................. B-1

B-2 Ethernet RJ-45 Connector...................... ............ .. ............ .................................................... B-2

B-3 Parallel Port Connector ........................................................................................................ B-3

B-4 RS-232 Connector Pin-outs ................................................................................................. B-4

B-5 68 Pin SC S I C o nne c to r ............. .. .......... ......... .......... .......... .......... ......... ... .......... ......... ......... B-5

B-6 Fibre Channel Connector ..................................................................................................... B-7

B-7 Reference Genlock 25-pin Connector.................................................................................. B-8

B-8 ASPB Connector .................................................................................................................. B-9

Contents

Profile Video File Server Installation vii

Page 8

Contents

Tables

1-1 Profile Video File Server Model Descriptions ....... .. ..................................................... ....1-8

1-2 PDR202 and PDR204 Factory Standard Configurations with Installable Options ..........1-9

1-3 PDR304 and PDR308 Factory Standard Configurati ons wit h Installable Options ..........1-10

1-4 PDR312 and PDR316 Factory Standard Configurati ons wit h Installable Options ..........1-11

1-5 PDR324 Factory Standard Configurations with Installable Options ...............................1-12

1-6 PDR404 Factory Standard Configurations wit h Installable Options ................ ............ ....1-13

1-7 Maximum Video Data Rates Per Channel With Non-RAID Storage ............ .. .. ............ ....1-15

1-8 Maximum Video Data Rates Per Channel With PRS255 RAID Storage Chassis ...........1-15

1-9 Maximum Video Data Rates Per Channel With PRS255M RAID Storage Chassis ........1- 15

1-10 Profile Video File Server Stora ge Capacity Estimates ......... ...................... ............ .........1-16

2-1 Audio Interface Chassis Summary ..................................................................................2-15

2-2 RS-422 Interface Board Connector ....... ...................... ...................... ...................... ........2-32

2-3 Power Cords for the Profile Video File Server and PAC 208 ..........................................2-35

3-1 Rear Panel Board Indicators ............ .. .................... .. .............................. .. .......................3-8

A-1 Serial Digital Video Input/Output .....................................................................................A-2

A-2 Analog Composite Video Output ............................... .. ........................ .. ........... .. .. ...........A-3

A-3 Analog Composite Video I/O ............... .. .. ................................... .. ...................................A-4

A-4 Component Analog Video Input .......................................................................................A-5

A-5 Component Analog Video Performance . .........................................................................A-5

A-6 Format Voltage Level Def initions for CAVmtrxN Colorbar Matrix Test Clip ............. ........A-6

A-7 Format Voltage Level Def initions for CAVmtrxP Colorbar Matrix Test Clip .....................A-7

A-8 Program Input Genlock ....................................................................................................A-8

A-9 Reference Genlock ..........................................................................................................A-8

A-10 Time Code .................... ........... .. ............ .. ......................................................... .. .............A-8

A-11 Analo g Au di o . .. ... ......... .......... .......... .......... .. .......... ......... .......... .......... .......... ......... ... .......A-9

A-12 Digital Audio ....................................................................................................................A-9

A-13 Profile Video File Server Power Source ..........................................................................A-9

A-14 Profile Video File Server Power Supply Specifications (from Man ufacturer) .......... .........A-10

A-15 Environmental Criteria .....................................................................................................A-10

A-16 Profile Video File Server Mechanical Specifications .......................................................A-11

A-17 PAC208/216 Power Requirements ...... .. ............ .. ............ ........... ............ .. ............ .. .........A-11

viii Profile Vide o File Server Installation

Page 9

Safety Summaries

General Safety Summary

Review the following sa fety precautions to a void injury and prevent damage

to this product or any products conne ct ed to it.

Only qualified personne l should perform service procedures.

While using this product, you may need to acces s other parts of the system.

Read the General Safety summary in other system manuals for warnings and

cautions related to operating the system.

Injury Precautions

Use Proper Power

Cord

Ground the Product This produ ct is grounded through the grounding conductor of the power

Do Not Operate

Without Covers

Do Not operate in

Wet/Damp

Conditions

Do Not Opera te i n an

Explosive

Atmosphere

Avoid Exposed

Circuitry

To avoid fire hazard, use only the power cord spe cified for this product.

cord. To avoid electric shock, the grounding conductor must be connected

to earth gr ound. B efore makin g c onnections to the in put o r output ter minal s

of the product, ensure that the product is properly grounded.

To avoid electric shock or fir e hazar d, do not ope rate this product with

covers or panels removed.

To avoid electric shock, do not operate this product in wet or damp

conditions.

To avoid injury or fire hazard, do not opera te this product in an ex plosive

atmosphere.

To avoid injury, remove jewelry such as rings, watches, and other metallic

objects. Do not touch exposed connections and components when power i s

present.

Product Damage Precautions

Use Proper Power

Source

Provide Proper

Ventilation

Do Not Operate With

Suspec ted Failures

Do not operate this product from a power source that applies more than the

voltage specifie d.

To prevent product overheating, provide proper ventilation.

If you suspect there is dama ge to this product, have it inspected by qualifi ed

service personnel.

Profile Video File Server Installation ix

Page 10

Safety Summaries

Safety Terms and Symbols

Terms in This

Manual

!

!

Terms on the

Product

Symbols on the

Product

These terms may appear in this manual:

WARNING: Warning statements identify conditio ns or practices t hat can

result in personal injur y or loss of life.

CAUTION: Caution statements identify conditions or practic es that can

result in damage to the equipment or other property.

These terms may appear on the product:

DANGER indicates a person al inj ury ha zard i mmediately acc essible as one

reads the marking.

WARNING indicates a personal injury hazard not immediately accessible

as you read the marking.

CAUTION indicates a hazard to property inc luding the product.

The following symbols may appear on the produc t:

DANGER high voltage

Protective ground (ear th) terminal

!

ATTENTION – refer to manual

Service Safety Summary

Do Not Service

Alone

Disconnect Power To avoid ele ctric shock, disc onnect the main power b y means of the power

Use Care When

Servicing With

Power On

Do not perform interna l service or adjus tment of this pr oduct unless another

person capable of rendering first aid and resuscitation is present.

cord or, if provided, the power switch.

Dangerous voltages or currents may exi st in this produc t. Disconnect power

and remove battery (if applicable) before removing protecti ve panels,

soldering, or replacing components.

To avoid electric shock, do not touch exposed connections

x Profile Video File Server Installation

Page 11

Certifications and Compliances

Certifications and Compliances

Canadian Certified

Power Cords

FCC Emission

Control

Canadian EMC

Notice of

Compliance

Canadian approval incl udes the products and power cords appropriat e for

use in the North Ameri ca power network. All other power cords supplied are

approved for the country of use.

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmf ul interference

when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause

harmful inter ference t o rad io communic ations . Opera tion of thi s equipmen t

in a reside ntial area is like ly to cause harmful int erfere nce in whic h case the

user will be r equired t o correct t he interfer ence at his own expense . Changes

or modifications not expressly approved by Grass Valley Group can affect

emission compliance and could void the user’s authority to operate this

equipment.

This digital apparatus does not exceed the Class A limits for radio noise

emissions from digital apparatus set out in the Radio Interference

Regulations of the Canadian Department of Communications.

Le présent appareil num érique n’émet pas de bruit s radioélectriques

dépassant les limites applicables aux appareils numériques de la classe A

préscrites dans le Règlement sur le brouillage radioélectrique édicté par le

ministère des Communications du Canada.

Canadian Certified

AC Adapter

EN55022 Class A

Warning

Laser C om p liance

Laser Safety

Requirements

Canadian approval incl udes the AC adapters appropriate for use in the

North America power network. All other AC adapters supplied are

approved for the country of use.

For products that comply with Class A. In a domestic environment this

product may cause radio interf erence in which case the user may be

required to take adequate measures.

The device used in this product is a Class 1 certified laser product.

Operating this product outside specifications or altering its original design

may result in hazardous radi ation exposure, and may be considered an act

of modifying or new manufacturing of a laser product under U.S.

regulations cont ained in 21CFR Chapter 1, subchapter J or CENELEC

regulations in HD 482 S1. People performing such an act are required by

law to recer tify and reidenti fy this pr oduct i n accor danc e with p rovision s of

21CFR subchapter J for distribution within the U.S.A., and in accordance

with CENELEC HD 482 S1 for distribution within countries using the IEC

825 standard.

Profile Video File Server Installation xi

Page 12

Safety Summaries

Laser Safety Laser safety in the United States is regul ated by the Center for Devi ces and

Radiological Hea lth (CDRH). The laser safe ty r egulations are published in

the “Laser Product Performance Standard,” Code of Federal Regulation

(CFR), Title 21, Subchapter J.

The International Electrotechnical Commission (IEC) Standard 825,

“Radiation of Laser Produc ts, Equi pment Clas sific ation, Requirements a nd

User’s Guide,” governs laser products outside th e United States. Europe and

member nations of the European Free Trade Association fall under the

jurisdiction of the Comité Européen de Normalization Electrotechnique

(CENELEC).

For the CDRH: The radiant power is detected through a 7 mm apertur e at a

distance of 200 mm from the source focused through a lens with a focal

length of 100 mm.

For IEC compli ance: The radia nt power is detect ed through a 7 mm apertur e

at a distanc e of 100 mm f rom the so urce f ocused thr ough a lens with a foc al

length of 100 mm.

FCC Emission

Limits

Certification

Category Standard

Safety Designed/tested for compliance with:

This device c omplies with Part 1 5 of the FCC R ules. Operati on i s subje ct t o

the following two conditions: (1) This device may not cause harmful

interferen ce, and (2) thi s devi ce mu st acc ep t any int erf erence received ,

including interf erence that may cause undesirable operation. This device

has been tested and found to c omply with FCC Part 15 Class B limits for a

digital device when test ed with a representative laser-based fiber optical

system that complies with ANSI X3T11 Fiber Channe l Standard.

UL1950 - Sa fe ty of Inf or mation Techn olo gy Equipme nt, incl udi ng Elect ri cal Bus in ess

Equipment (Third Edition, 1995)

IEC 950 - Sa fe ty o f Info rma tion Te chn ol ogy Eq uipment , inclu di ng Elec tr ical Busines s

Equipment (Second edition, 1991)

CAN/CSA C22.2, No. 950-95 - Safety of Information Technology Equipment,

including Electrical Business Equipment

EN60950 - Sa fety of Inf ormation Technol ogy Eq uipment, includi ng El ectric al Busin ess

Equipment

xii Profile Video File Server Installation

Page 13

Chapter

1

Introduction

Scope

This is the Installation manual for the Grass Valley Group Profile Family of Video

File Servers. The Profile family of products includes the PDR200 JPEG Video File

Server, the PDR300 MPEG Video File Server, and the PDR400 DVCPRO Video File

Server. This Insta llation manual provides a n overview of the Prof ile Video File Server

(shown in Figure 1-1) and descriptions of the tasks listed below:

• Installing the vide o file server into an equipment rack.

• Connecting Video and Audio I/O.

• Connecting SCSI devices.

• Connecting Fibre Channel and Ether net.

• Configuring Ethernet IP Address.

• Power On/Off procedures.

9675-10

Figure 1-1. The Profile Video File Server

Profile Video File Server Installation 1-1

Page 14

Chapter 1 Introduction

Related Documentation

Profile Family User Manual

PDR200 Service Manua l

Profile Syst em Sof twa re Re le as e No te s

PDX218 Disk Expansion Chassis Instruction Manual

Windows NT Instruction Manual

Organization of the Manual

The Installation manual is divided into the chapters identif ied and described below.

Chapter 1 - Introduction: This chapter describes the contents of the manual and

provides a brief overview of the Profile Video File Server. It includes configuration

and board location information.

Chapter 2 - Mechanical Installati on: This c hapter describes the physical

installation of the system up to initial power-on.

Chapter 3 - Starting Your Profile System: This chapter consists of procedures to

turn system powe r On and Off, to set up the system, and to verify correct installation

of the Profile Video File Server.

Chapter 4 - Networking Your Profile System: This chapter describes the Ethernet

and Fibre Channel networking use d in the Profile Video File Server, including

connections.

Appendix A - Sp ecificatio ns: This appendi x consists of physical and electrica l

specifications a nd environmental criteria.

Appendix B - Connector P in-outs: This appendix identifies certain connectors and

the signals present and the pins of those connectors.

1-2 Profile Video File Server Installation

Page 15

Product Description

The Profile Video File Server is a disk-based video file server with enhanced record

and playback quality, and rapid storage/retrieval c apabilities. In addition to the

advantage of not having to load tape as with VTRs, the Profile Video File Server

occupies less rack space and is fully computer controlled.

The PDR200 provides up to four Motion-JPEG encoders/decoders (CODECs) in a

flexible system which star ts with four base configurations: two are for 2- channel

Profile systems and t wo are for 4- channel Pr ofile syste ms. These base configur ations

can be ordered with analog or digital inputs and outputs. Each configuration is then

tailored, through factory installed options, to meet your site-specific needs . Many

options may be e asily added to your PDR 200 as your needs change and expand. For

information on adding options, contact your Grass Valley Group represe ntative.

A two-channel system (PDR202) is equipped with a single Master Enhanced Disk

Recorder board, which provid es two JPEG codecs, and two SCSI buss es, SCSI A and

SCSI B, although SCSI B may not be a vailable on all models. A four- channel sy stem

(PDR204) adds a Slave Enhanced Disk Recorder, which pr ovides two additional

JPEG codecs and two more SCSI busses (SCSI C and SCSI D).

The PDR300 adds factory-installed MPEG encoders and decoders to the Profile

Video File Server, while retaining all the capabiliti es and optional configurations of

the PDR200. Two MPEG boards, one with one encoder and two decoders, the other

with four decoders, provide many combinations of capabiliti es to meet your needs.

The JPEG codecs on the Master and Slave Enhanced Disk Recorder boards remain

available as resources f or record/p lay channel s or for transcoding cli ps betwee n JPEG

and MPEG.

Product Description

The PDR400 adds factory-inst alled DVCPRO boards to the Profile Video File S erver,

while retaini ng the same capabili ties and optiona l configura tions of the PDR200. The

DVCPRO boards includes up to six DVCPRO 2 5 codecs arra nged in pair s. Ea ch pair

of DVCPRO 25 codecs may be used a s a single DVCPRO 50 codec. Bec au se of this

paired codec arc h itec tur e, s ome s y stem tim ing rest ri ction s ap ply . These res tri ct ions

are discussed in “DVC PRO System Timing Consider ations” on page 1-17. The JPEG

codecs on the Master and Slave Enhanced Disk Recorder boards remain available as

resources for record/play channels or for transcoding clips between JPEG and

DVCPRO. In some configurations, the operation of one of the JPEG codecs may be

restricted as described in “C onfigurations” on page 1-8.

The Profile Vide o File Server is mounted o n rack slides for installation in a st andard

electronic equip ment rack. All connections to the Profi le Video File Server are on the

rear panel (see Chapter 2, “Mechanical In sta llat io n ”). Also see Appendix A,

“Specifications”, for physic al and electrical spe cifications and environmental crite ria.

Profile Video File Server Installation 1-3

Page 16

Chapter 1 Introduction

Product Features

Record/playback and storage/retrieval applications for the Profile Video File Server

run in the Windows NT

loaded on the dedi cated system hard disk, which is also used for application storage .

Control is via an internal Pentium-based CPU board.

Other features incl ude:

• Super-VGA monitor output

• Auto switching 10/100BASE-T Ether net network support

• Control interfaces:

- RS-232 (two rear panel ports)

- RS-422 (eight ports through breakout panel)

- Keyboard and mouse

- Parallel port

• Front panel controls and indic ators.

TM

environment. The Windows NT operating software is

1-4 Profile Video File Server Installation

Page 17

Front Panel Controls and Indicators

The Profile Video File Server front panel, shown in Figure 1-2, consists of the

controls and indicator s keyed to Figure 1-2 and briefly described below.

Floppy Disk Drive access for loading operating system software or specific

Ê

application soft ware. The drive accepts standard 3-1/2-inch double density

(720KB) or high density (1.44MB) floppy diskettes.

Green LED indic ator light ed when bot h the p ower s witch on the r ear pane l and the

Ë

one on the front panel (see Î below) are On.

Eight green LED indicators, labeled DISK ACCESS, show disk activity. They are

Ì

mapped right to left to the physical loc a tion of each hard disk drive in the chassis

and flash on when activity occurs on the associated disk. A LED should flash on

for every disk ins tal led in the unit . If a LED fai l s to flash on for each disk in the

unit or if a LED remains lit, there may be a problem with the one of the disks. If

you do not have any internal disk storage, which is an option, these LEDs remain

off.

Í

Three red Trouble LED indicators. When lighted they provide warnings of

(from the left):

Front Panel Controls and Indicators

SYS FAULT (not used)

FAN FAULT (failure of one or more fans)

OVER TEMP (power supply over temperature)

The STANDBY/ON switch provides system On/Off control (the same as pressing

Î

the rear pan el On/Off switch). Both must be On for o peration of the Profile Video

File Server.

9676-2

1 2 3 4 5

Figure 1-2. Profile Video File Server Front Panel

Profile Video File Server Installation 1-5

Page 18

Chapter 1 Introduction

Accessories

There are two types of accessories for the Profile Video File Server: Standard and

Optional. Standard Accessories are those items required to install and operate the

Profile Video File Server. They are shipped with your Profile system. Optional

accessories expand P rof ile Vi deo File Server capabili tie s, si mplif y i nstallati on, or aid

in servicing. Optional accessories are available through Grass Valley Group.

Standar d Acc ess or ie s

A Profile Video File Server shipmen t includes the following items:

• 1 Manual, Profile Family User

• 1 Manual, Installation

• Profile Syst em Sof twa re R elease Notes

• Soft ware Pa ckage which includ es the l atest versi on of Pro fil e Syste m Softwa re an d

an Emergency Repair diskette.

• Windows NT software package

• 1 Keyboard (Grass Valley Group part number 119-4899-XX)

• 1 Mouse (Grass Valley Group part number 119-433 0-XX)

• EMI Suppression Gaskets f or BNC Connectors (Grass Val ley Group part number

016-1448-XX)

• Cable Assemblies, Power (161-0123-00 for US and Japan; 161-0066-09 for

Europe; 161-0066-10 for the United Kingdom; or 161-0066-11 for Australia)

• 1 RS-422 Connector Panel and cable

• 1 Set of rack-mounting slides

• Ethernet cable

1-6 Profile Video File Server Installation

Page 19

Optional Accessories

If ordered, Grass Valley Group provide s the optional accessories listed below.

Contact your nearest fie ld office or distributor for more inform ation.

• Ethernet Hub (for Ethernet connections)

• Fibre Channel Hub (for Fibre Channel networking)

• Optical Media Interfa ce Adapter (copper-to-fibe r) for fibre channel networking.

• S-VGA Monitor

• PAC208/216 Analog/Digita l Profile Audio Chassis

• XLR216 or BNC216 Digital Audio Breakout Panel

• PDX218 Disk Drive Expansion Chassis

• 1 SCSI Terminator (011-0166-0 0)

• Eight-connecto r DB25-XLR breakout cable for longitudinal ti me code I/O, 6 ft.

(Grass Valley Group part number 174-3249-XX)

• Eight-connecto r breakout c able, with DB25 conne ctor, 24 ft. (Grass Valley Gr oup

part number 174-3481-XX)

Optional Accessories

• External CD ROM drive (Grass Valley Group part number PDRFCD)

• Service Manual (070-9675-XX)

Profile Video File Server Installation 1-7

Page 20

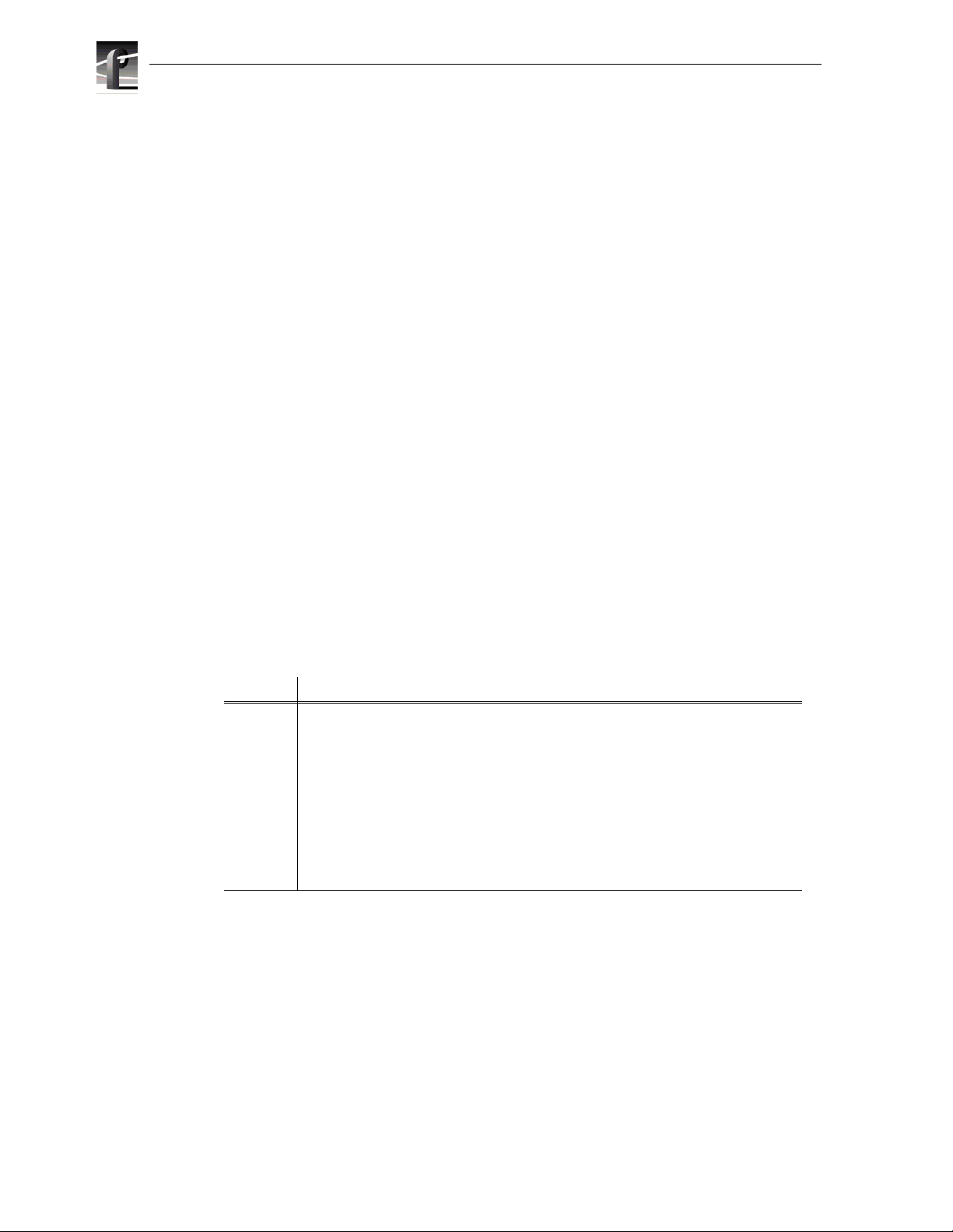

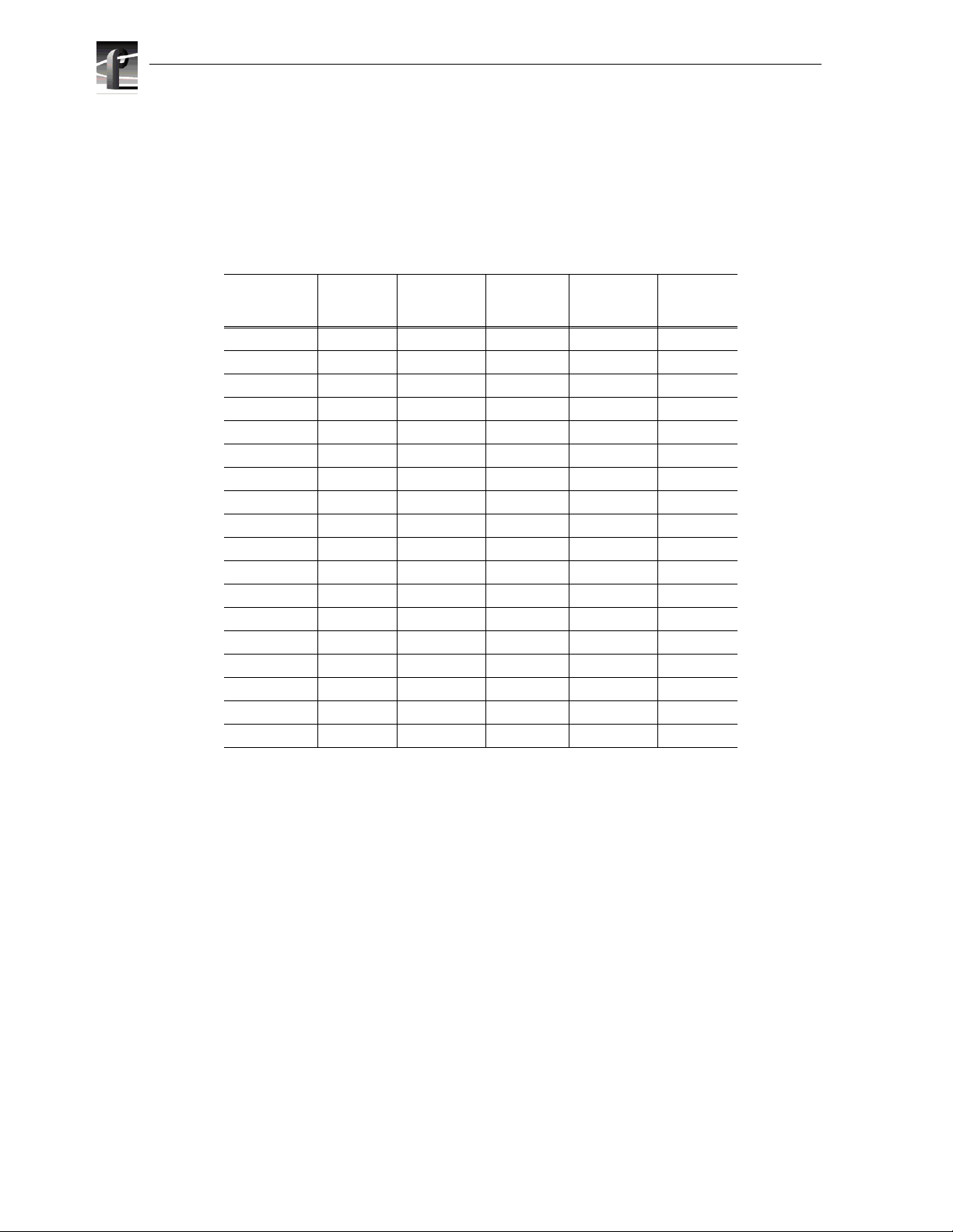

Chapter 1 Introduction

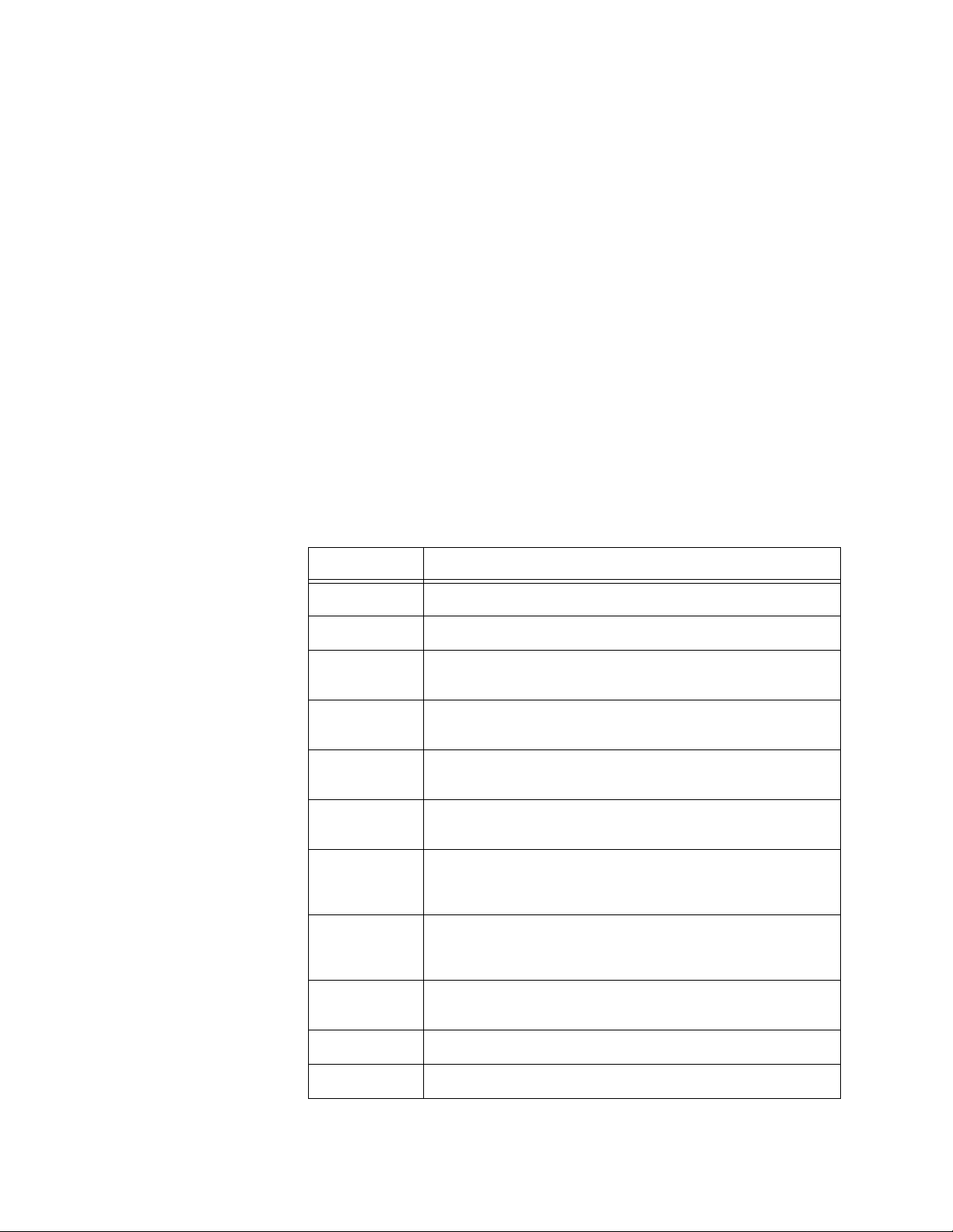

Configurations

The Profile Vide o File Server is ava ilable in several factory instal led configurations.

Table 1-1 lists the available JPEG codecs, MPEG encoders, MPEG decoders and

DVCPRO2 5 co d ecs t hat are available on each mod el .

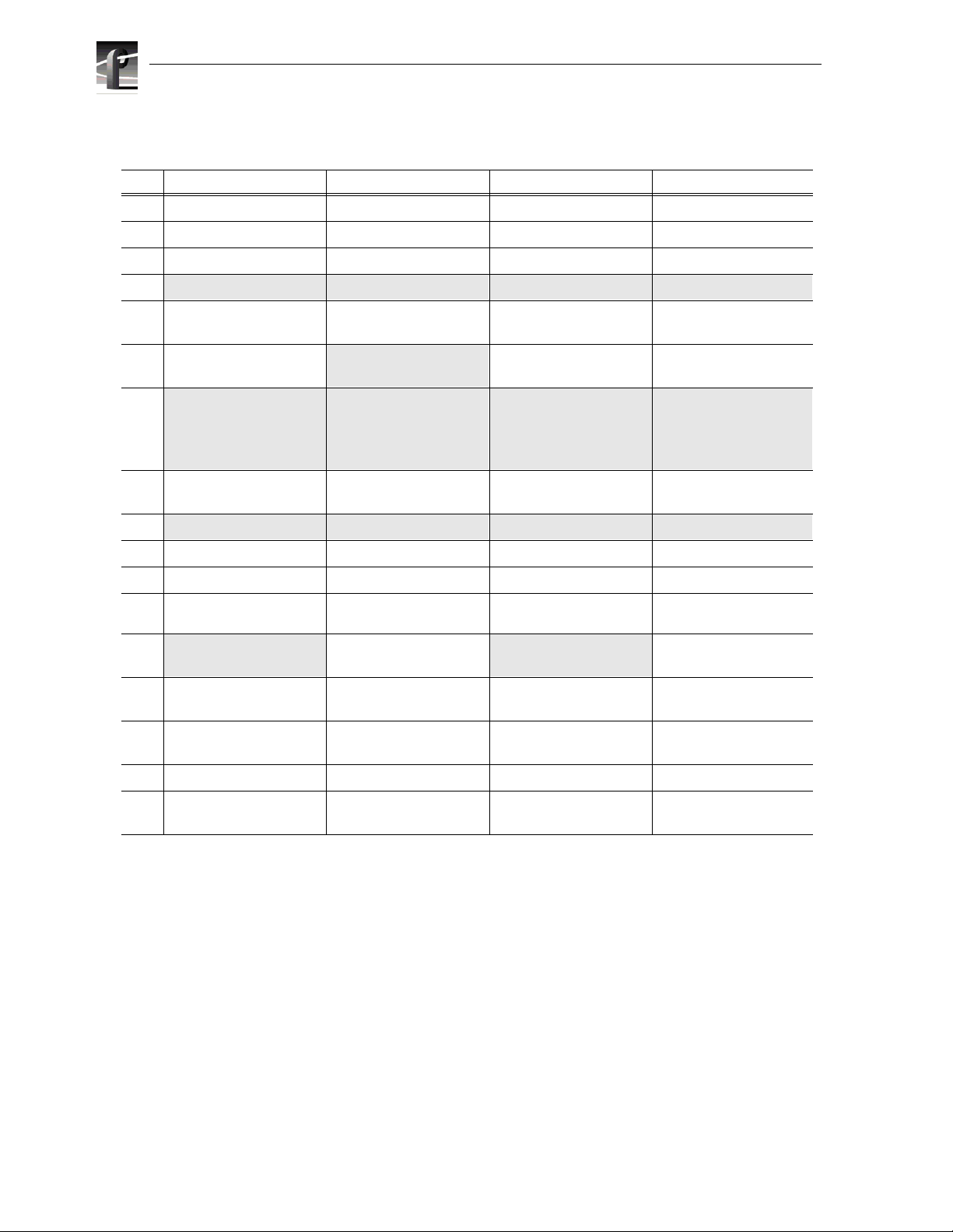

Table 1-1. Profile Video File Server Model Descriptions

Model

Number

PDR202A 2 0 0 0 Analog

PDR204A 4 0 0 0 Analog

PDR202D 2 0 0 0 Digital

PDR204D 4 0 0 0 Digital

PDR304A 2 0 4 0 Analog

PDR304D 2 0 4 0 Digital

PDR308A 2 0 8 0 Analog

PDR308D 2 0 8 0 Digital

PDR312A 2

PDR312D 2

PDR316A 2

PDR316D 2

PDR324A 4 2 4 0 Analog

PDR324D 4 2 4 0 Digital

PDR404A 4

PDR404D 4

PDR406A 4

PDR406D 4

a.

4 if Slave Di sk Recorder is installed

b.

If JPEG #2 and DVCPRO25 #4 are used, t hey must both be connected to the same video

input via the internal video crosspoint router, otherwis e, the wrong video input may be

record ed. To avoi d this res tricti on, use on e of the other thr ee JPEG c odecs avai labl e in the

system.

Number

of JPEG

CODECs

a

a

a

a

b

b

b

b

Number of

MPEG

Encoders

120Analog

120Digital

160Analog

160Digital

004Analog

004Digital

006Analog

006Digital

Number of

MPEG

Decoders

Number of

DVCPRO25

CODECs

Video I/O

Type

Tables 1-2 through 1-6, on pages 1-9 through 1-13, list the various video I/O

configurations, as well as the locations of all the boards in the system. In the tables,

note that factory inst allable option boards are shaded.

1-8 Profile Video File Server Installation

Page 21

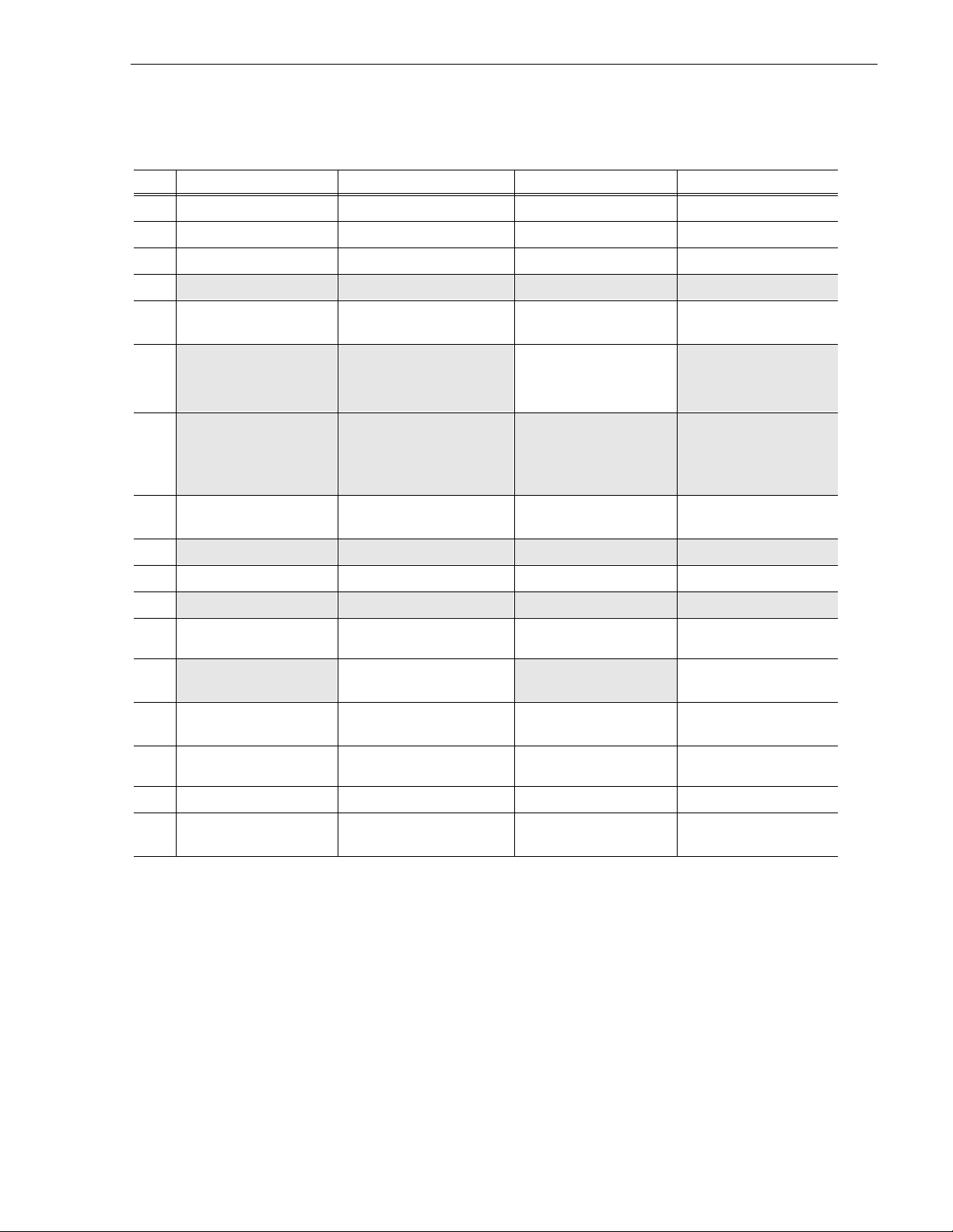

Table 1-2. PDR202 and PDR204 Factory Standard Configurations with Instal lable Options

Slot PDR202A PDR202D PDR204A PDR204D

J1 System CPU System CPU System CPU System CPU

J2 Parallel Port Parallel Port Parallel Port Parallel Port

J3

Configurations

J4

J5 Audi o I/O

J6

J7

J8

J9

J10 Disk Recor der Master Disk Recorder Master Disk Recorder Master Disk Recorder Master

J11 Disk Recorder Slave Disk Recorder Slave

J12

J13

J14 Video I/O

J15 Video I/O

J16 Reference / Tim ecode Reference / Timecode Reference / Timecode Reference / Timecode

System SCSI System SCSI System SCSI System SCSI

Audio I/O

Digita l A E S/ E BU

Video Mixer Video Mixer Video M ixer Video Mixer

Audio I/O

Digita l A E S/ E BU

Video I/O

Serial D igital Compone nt

Fibre Channel Fibre Channel Fibre Channel Fibre Channel

Video Out

Picture M onitor (Analog)

or

Video Out

Analog Composite

Video In

Analog Component

Analog Composite

Digital AES/ E B U

Audio I/O

Digital AES/ E B U

Video I/O

Analog Composite

Video Out

Picture Monitor (Analog)

or

Video Out

Analog Composite

Video In

Analog Compo nent

Video I/O

Serial Digi tal Compon ent

Audio I/O

Digital AES/ E B U

Audio I/O

Digital AES/ E B U

Video I/O

Serial Di gi ta l C ompo nent

Video Out

Picture M onitor ( A nalog)

or

Video Out

Analog Composi te

Video In

Analog Component

Video I/O

Analog Composi te

Analog Composi te

Digital AES/ E B U

Digital AES/ E B U

Analog Composi te

Picture Mo nitor (Analog )

Analog Composi te

Analog Component

Serial Digital Component

Serial Digital Component

Audio I/O

Audio I/O

Video I/O

Video Out

or

Video Out

Video In

Video I/O

Video I/O

J17 Remote I/O

RS422

Remote I/O

RS422

Remote I/O

RS422

Remote I/O

RS422

Profile Video File Server Installation 1-9

Page 22

Chapter 1 Introduction

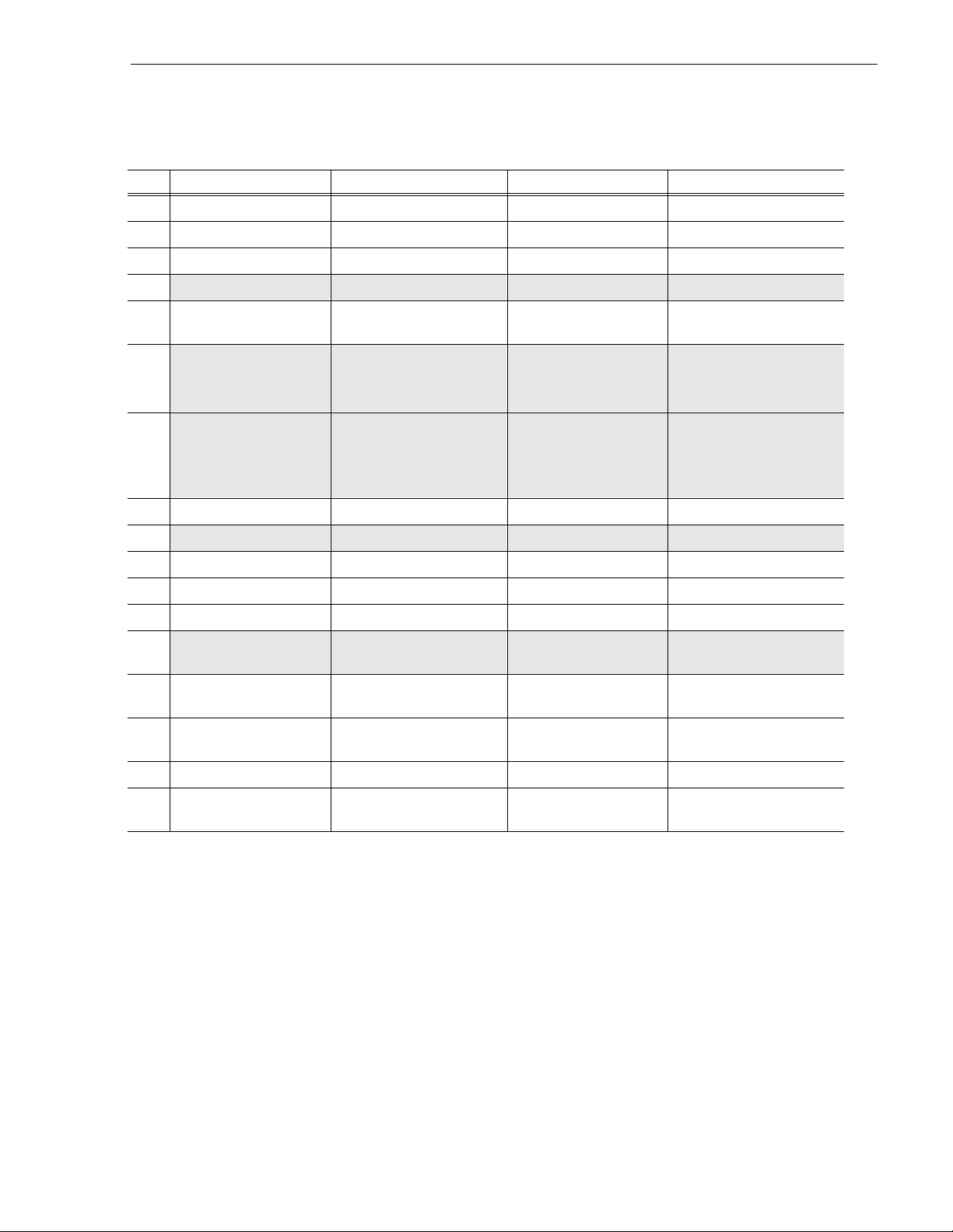

Table 1-3. PDR304 and PDR308 Factory Standard Configurations with Installable Options

Slot PDR304A PDR304D PDR 308A PDR308D

J1 System CPU System CPU System CPU System CPU

J2 Parallel Port Parallel Port Parallel Port Parallel Port

J3

J4

J5 A udio I/O

J6 Video Out

J7

J8 MPEG Video

J9

J10 Disk Recorder Master Disk Recorde r Ma ster Disk Recorder Master Disk Recorder Master

J11

J12 MPEG Video

J13

J14 Video I/O

J15 Video I/O

System SCSI System SCSI System SCSI System SCSI

Audio I/O

Digital AES/EBU

Analog Compos ite

Audio I/O

Digital AES/EBU

or

Video Out

Picture Monitor (Analog)

Decoder

Fibre Channel Fibre Channel Fibre Channel Fibre Channel

Video I/O

Serial Digit al Component

Digita l A E S/ E BU

Video Out

Picture Monitor (Analog)

Audio I/O

Digita l A E S/ E BU

or

Video Out

Picture Monitor (Analog)

MPEG Video

Decoder

Serial Digital Component

Serial Digital Component

Audio I/O

Digita l A E S /E BU

Video Out

Analog Composite

Audio I/O

Digita l A E S /E BU

or

Video Out

Picture Mo nitor (Analog)

MPEG Video

Decoder

Decoder

Video I/O

Serial Digital Component

Video I/O

Analog Composite

Video I/O

Analog Composite

Digital AES/EBU

Serial Digit al Component

Digital AES/EBU

Picture M onitor (Analog)

MPEG Video

MPEG Video

Serial Digit al Component

Serial Digit al Component

Serial Digit al Component

Audio I/O

Video I/O

Audio I/O

or

Video Out

Decoder

Decoder

Video I/O

Video I/O

Video I/O

J16 Reference / Timecode Reference / Timecode Reference / Timecode Reference / Timecode

J17 Remote I/ O

RS422

1-10 Profile Video File Se rver Installation

Remote I/O

RS422

Remote I/O

RS422

Remote I/O

RS422

Page 23

Table 1-4. PDR312 and PDR316 Factory Standard Configurations wit h Inst allable Options

Slot PDR312A PDR312D PDR316A PDR316D

J1 System CPU System CPU System CPU System CPU

J2 Parallel Port Parallel Port Parallel Port Parallel Port

J3

Configurations

J4

J5 Audio I/O

J6

J7

J8 MPEG Video

J9

J10 Disk Recorder Master Disk Recorder Master Disk Recorder Master Disk Recorder Master

J11

J12 MPEG Video

J13

J14 Video I/O

System SCSI System SCSI System SCSI System SCSI

Audi o I/ O

Digital AES/ E B U

Video Mixer

or

Video Out

Picture Mo nitor (Analog )

Audio I/O

Digital AES/ E B U

or

Video Out

Picture Mo nitor (Analog )

Encoder/Decoder

Fibre Chan nel Fibr e Channel Fibre Channel Fibre Channel

Disk Recorder Slave Disk Recorder Slave Disk Recorder Slave Disk Recorder Slave

Video I/O

Serial Digital Component

Analog Composi te

Digital AES/ E B U

Video Mixer

or

Video Out

Picture Mo nitor (Analog)

Audi o I/ O

Digital AES/ E B U

or

Video Out

Picture Mo nitor (Analog)

MPEG Video

Encoder/Decoder

Video I/O

Serial Digital Component

Audio I/O

Digital AES/EBU

Video Out

Analog Compos ite

Audio I/O

Digital AES/EBU

or

Video Out

Picture Monitor (Analog)

MPEG Video

Encoder/Decoder

Decoder

Video I/O

Serial Digital Component

Video I/O

Analog Compos ite

Audio I/O

Digital AES/ E B U

Video Mixer

or

Video Out

Picture Mo nitor (Ana log)

Audio I/O

Digital AES/ E B U

or

Video Out

Picture Mo nitor (Ana log)

MPEG Video

Encoder/Decoder

MPEG Video

Decoder

Video I/O

Serial Di gi ta l C ompo nen t

Video I/O

Serial Di gi ta l C ompo nen t

J15 Video I/O

J16 Reference / Timecode Reference / Timecode Reference / Timecode Reference / Timecode

J17 Remote I/O

RS422

Remote I/O

RS422

Remote I/O

RS422

Serial Di gi ta l C ompo nen t

Remote I/O

RS422

Profile Video File Server Installation 1-11

Page 24

Chapter 1 Introduction

Table 1-5. PDR324 Factory Standard Configurations with Instal lable Options

Slot PDR324A PDR324D

J1 System CPU System CPU

J2 Parallel Port Parallel Port

J3

J4

J5 Audio I/O

J6

J7

J8 MPEG Video

J9

J10 Disk Recorder Master Disk Recorder Master

J11

J12 MPEG Video

J13

J14 Video I/O

System SCSI System SCSI

Audio I/O

Digita l A E S/ E BU

Video Mixer

or

Video Out

Picture Monitor (Analog)

Audio I/O

Digita l A E S/ E BU

or

Video Out

Picture Monitor (Analog)

Encoder/Decoder

Fibre Channel Fibre Channel

Disk Recorder Slave Disk Recorder Slave

Encoder/Decoder

Video I/ O

Serial Dig ital Com ponent

Analog Composite

Digital AES/EBU

Video Mixer

or

Video Out

Picture Monitor (Analog)

Audio I/O

Digital AES/EBU

or

Video Out

Picture Monitor (Analog)

MPEG Video

Encoder/Decoder

MPEG Video

Encoder/Decoder

Video I/O

Serial Digital Component

J15 Video I/O

J16 R eferenc e / Timeco d e Referenc e / Ti m ec ode

J17 Remote I/O

Analog Composite

1-12 Profile Video File Se rver Installation

RS422

Video I/O

Serial Digital Component

Remote I/O

RS422

Page 25

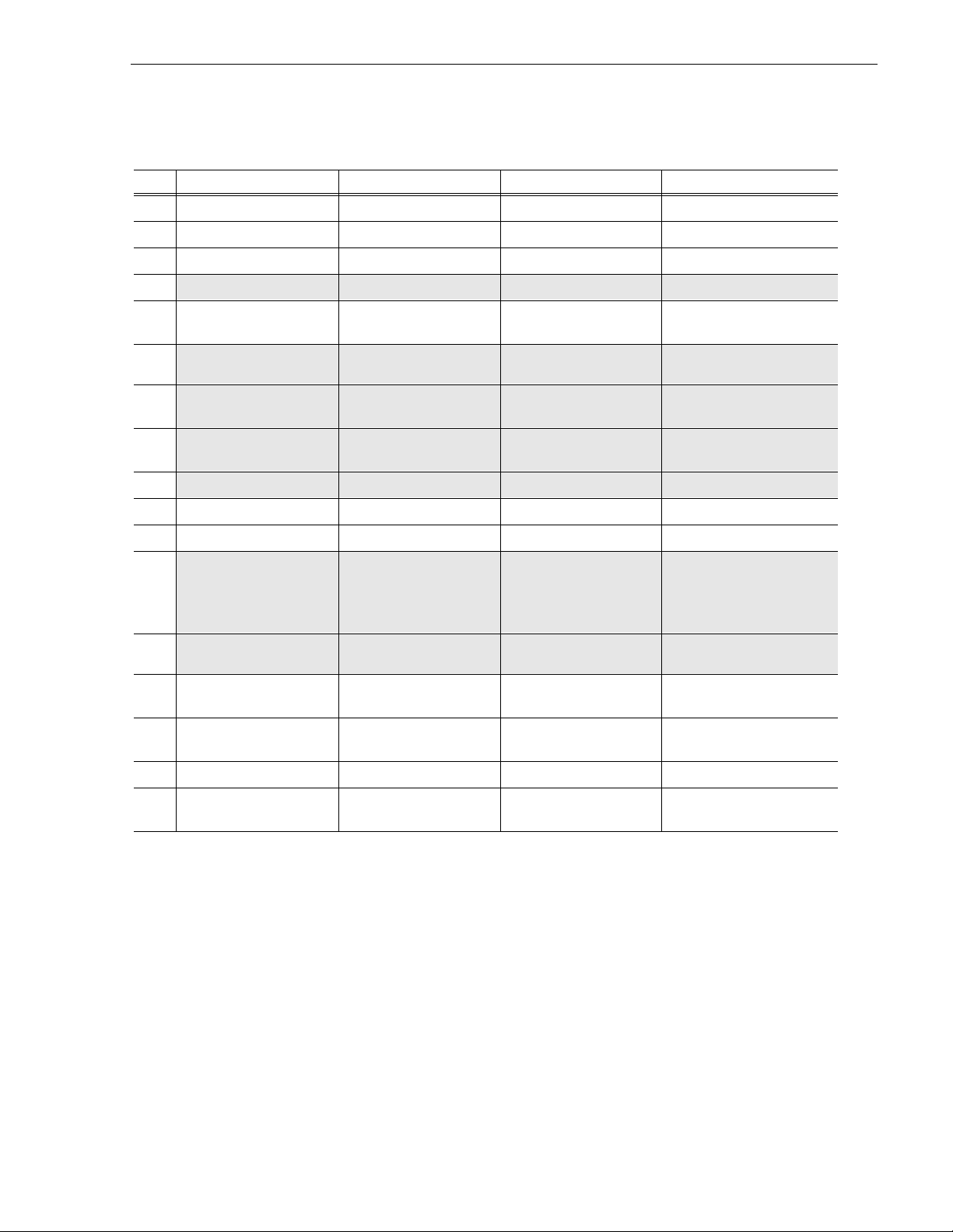

Table 1-6. PDR404 Factory Standard Configurations with Installable Options

Slot PDR404A PDR404D PDR406A PDR406D

J1 System CPU System CPU Syst em CPU System CPU

J2 Parallel Port Parallel Port Parallel Port Parallel Port

J3

Configurations

J4

J5 Audio I/O

J6

J7

J8 Disk Recorder Slave Disk Recorder Slave Disk Recorder Sla v e Disk Recorder Slave

J9

J10 Disk Recorder Master Disk Recorder Master Disk Recorder Master Disk Recorder Master

J11 DVCPRO Four-codec DVCPRO Four-codec DVCPRO Four-codec DVCPRO Four-codec

J12 DVCPRO Two-codec DVCPRO Two-codec DVCPRO Two-codec DVCPRO Two-codec

J13

J14 Video I/O

J15 Video I/O

J16 Reference / Timecode Reference / Timecode Reference / Timecode Reference / Timecode

System SCSI System SCSI System SCSI System SCSI

Audio I/O

Digita l A E S/ E BU

Video Mixer

or

Video Out

Picture M onito r (Ana lo g)

Audio I/O

Digita l A E S/ E BU

or

Video Out

Picture M onito r (Ana lo g)

Fibr e C h annel Fi bre Channel Fibre Channel Fibre Channel

Video I/O

Analog Composite

Analog Composite

Analog Composite

Digita l A E S/ E BU

Video Mixer

or

Video Out

Picture Monitor (Analog)

Audio I/O

Digita l A E S/ E BU

or

Video Out

Picture Monitor (Analog)

Video I/ O

Serial Digital Component

Video I/ O

Serial Digital Component

Video I/ O

Serial Digital Component

Audio I/O

Digita l A ES/EBU

Video Mixer

or

Video Out

Picture M onitor (Analog)

Audio I/O

Digita l A ES/EBU

or

Video Out

Picture M onitor (Analog)

Video I/O

Analog Composite

Video I/O

Analog Composite

Video I/O

Analog Composite

Digital AES/EBU

Video Mixer

Picture Monitor (Analog)

Digital AES/EBU

Picture Monitor (Analog)

Serial Digital Component

Serial Digital Component

Serial Digital Component

Audio I/O

or

Video Out

Audio I/O

or

Video Out

Video I/O

Video I/O

Video I/O

J17 Remote I/O

RS422

Remote I/O

RS422

Remote I/O

RS422

Remote I/O

RS422

Profile Video File Server Installation 1-13

Page 26

Chapter 1 Introduction

Configuration Labels

You may check/identify your conf iguration, including factory installed options, by

looking at the bottom panel just bel ow the rear panel board connectors. A

configuration label, whic h identifie s the board installe d in the sl ot above t he label, ha s

been attached to assist you in making connections to your Profile system. F igure 1-3

shows the location of the configur ation label.

9676-26

Labels

Figure 1-3. Configuration Labels Locations

1-14 Profile Video File Se rver Installation

Page 27

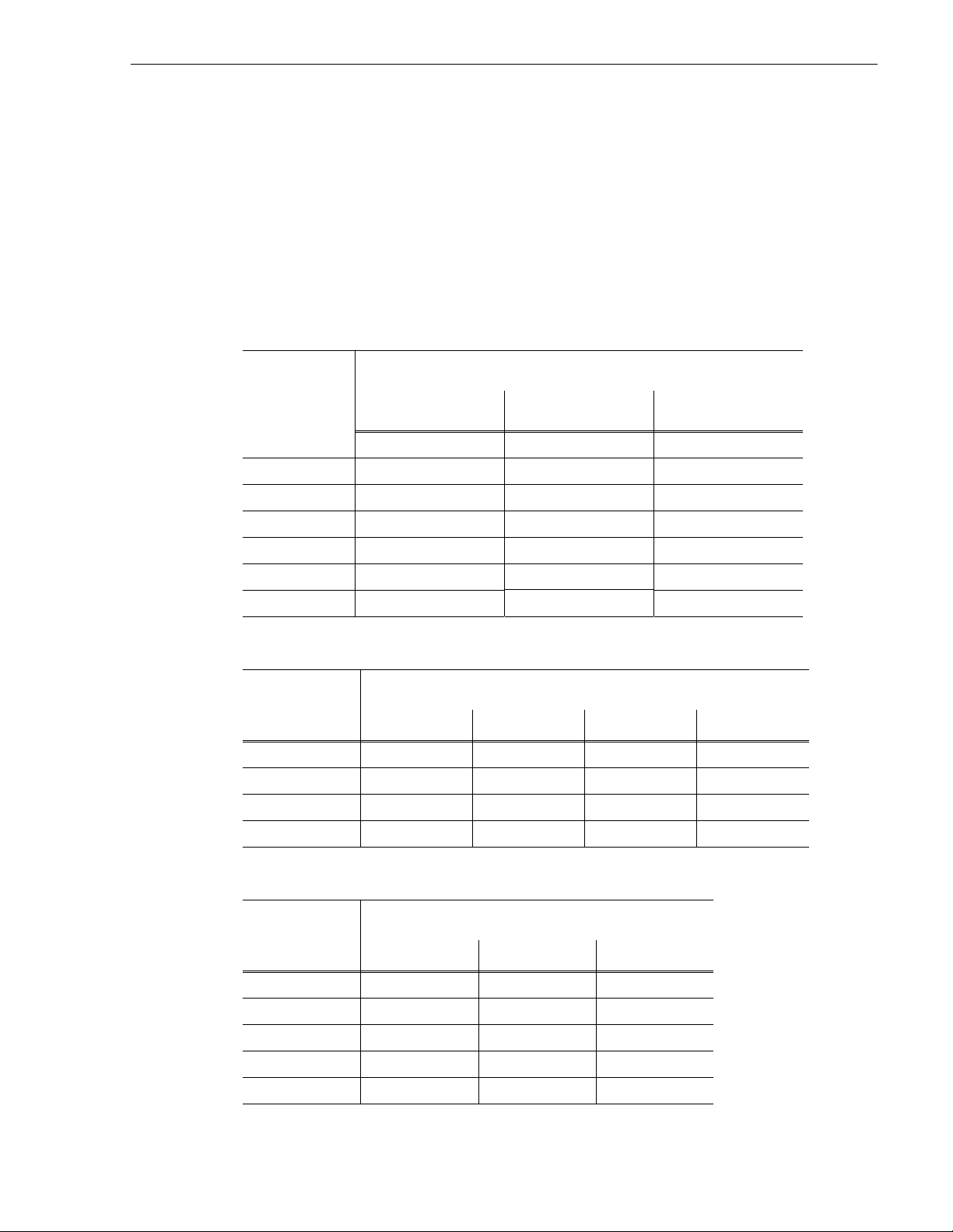

Maximum Video Data Rates

This section describes the maximum video data rate available per channel on the

Profile Video Fi le Server whe n all c hannels are in use. The maximum video da ta r ate

per channel depends on the Profile model, the type of storage, and the number of

storage disk drives in the system. The Profile Video File Server can be configured

with either RAID or non-RAID s torage. Refer t o Table 1-7, Table 1-8, and Table 1-9

to determine the maximum video data rates for various Profile models and storage

options.

Table 1-7. Maximum Video Data Rates Per Channel With Non-RAID Storage

Maximum Video Data Rates

Profile Models

with Non-RAID

Storage

PDR202 48Mb/s 48Mb/s 48Mb/s

PDR204 not available 48Mb/s 48Mb/s

PDR312 24Mb/s 50Mb/s 50Mb/s

PDR304 24Mb/s 50Mb/s 50Mb/s

PDR324 not available 24Mb/s 24Mb/s

PDR 316 not available 24Mb/s 24Mb/s

PDR308 not available 18Mb/s 24Mb/s

Table 1-8. Maximum Video Data Rates Per Channel With PRS255 RAID Storage Chassis

Profile Models

with the

PRS255 RAID

Storage Chassis

PDR202 24Mb/s 48Mb/s 48Mb/s 48Mb/s

PDR204 not allowed 36Mb/s 36Mb/s 48Mb/s

PDR312 24Mb/s 24Mb/s 24Mb/s 50Mb/s

PDR304 24Mb/s 24Mb/s 24Mb/s 24Mb/s

3 Internal Drives 5 Internal Drives 8 Drives

5 Drives 10 Drives 15 Drives 20 Drives

Maximum Video Data Rat e Per Chan nel

(When All Channe ls Are In Use )

(Internal or PDX218 )

Maximum Video Data Rat e Per Chan nel

(When All Channe ls Are In Use )

Table 1-9. Maximum Video Data Rates Per Channel With PRS255M RAID Storage Chassis

Profile Models

with the

PRS255M RAID

Storage Chassis

PDR312 50Mb/s 50Mb/s 50Mb/s

PDR304 24Mb/s 50Mb/s 50Mb/s

PDR324 24Mb/s 24Mb/s 24Mb/s

PDR 316 not allowed 24Mb/s 24Mb/s

PDR308 not allowed 18Mb/s 24Mb/s

10 Drives 15 Drives 20 Drives

Maximum Video Data Rate Per Channel

(When All Channels Are In Use)

Profile Video File Server Installation 1-15

Page 28

Chapter 1 Introduction

You can select the video data rate the Profile system uses to record the video signal,

unless you are using DVCPRO25 codecs which operate at a fixed 25Mb/s. When

selecting video data rates, be sure not to exceed the total Profile system bandwidth.

Fibre channel trans fers, archive opera tions, and high bandwidth recor ding or playout

may require that you reduce the data rate on other channels or operate fewer channels

at one time. Although playout and recording take priority over other operations,

exceeding your P rofile syst em bandwidth may result in r ecord or pla yback pr oblems.

For information on setting the video data rate in Profile applications software, ref er to

the appropriate sections o f the Profile Family User Manual

Storage Capacity Estimates

The Profile Video File Server stor a ge capacity is determined by the number of disk

drives in the system and the video data rate selected to record the video signal. The

Profile Video File Server can be configured with three, five, or eight int ernal 18GB

disk drives. You c an r efer to Tabl e 1-10 for storage esti mates ba sed on t he number of

disk drives installed and the video data rate. All Profile applications allow you to

select the video data rate used to record the video signal, unless you are using

DVCPRO 25 compression which operates at a fixed 25Mb/s data rate, or

DVCPRO 50 compression which operates at a fixed 50Mb/s data rate. For more

information about set ting the video data rate, refer the appropr iate sections of the

Profile Family User Manual.

Table 1-10. Profil e Video Fi le Ser ver Storage Capacity Estimates

Number of

Internal

Drives

3 disks 2 hrs 4 hrs 4 hrs 6.1 hrs 10.2 hrs

5 disks 3.5 hrs 6.5 hrs 6.5 hrs 10.2 hrs 17 hrs not available

8 disks 5.5 hrs 10.5 hrs 10.5 hrs 16.3 hrs 27.2 hrs 9

JPEG Factory Preset

Data Rate Targets

48Mb/s 24Mb/s 24Mb/s 15Mb/s 8Mb/s 25Mb/s

100KB/fld 50KB/fld 102KB/frm 66KB/frm 37KB/frm 120KB/frm 525/60

120KB/fld 60KB/fld 123KB/frm 78KB/frm 41KB/frm 144KB/frm 625/50

MPEG-2 Factory Preset

Data Rate Targets

DVCPRO 25

Data Rate

not available

Video storage times are estimates (within 10%) and include 2 audio channels and 1 timecode channel.

Adding 2 more channels of audio adds approximately 1.5 Mb/s to the total data rate .

The Profile Video File Server stor age space can be expanded by adding one or two

PDX 218 Disk Expansion Chassis containing eight 18GB disk drives each. You can

refer to entrie s for eight drive systems in Table 1-10 to determine the storage capacity

of a PDX218 at various video data rates.

NOTE: Storage capacity estimate s for the PRS255 RAID Storage Chassis are

located in the PRS255 RAID Storage Instruction Manual.

1-16 Profile Video File Se rver Installation

Page 29

DVCPRO System Timing Considerations

DVCPRO System Timing Considerations

The DVCPRO codecs used in Profile systems are actually pairs of codecs. Because of this

paired codec arc h itec ture, some restrict io ns ap pl y to the DVCPRO codec s whic h require the

follow ing sy stem ti ming li mita ti o ns:

1. Y ou must supply a Reference In signal to the Profile system.

2. All video signals that you want to record with a D VCPR O codec must be synchronous with

the Reference In signal.

3. If you want to use the DVCPRO codecs as independent codecs, all of your video inputs

must be auto-timed to the Reference input. In Configuration Manager, select Enable

Auto-Tim ing for each input. You must ensure that each input actually auto-times by

checking that th e Auto-Tim ed indicator in the V ideo Input dia log box is li t. Refer to “Using

the Profile Configuration Manager ” in the Profile Family User Manual for more

information on Auto-Timing.

4. If you are unable to auto-time an input, or if you wish to use the DVCPRO 25 codecs for

BVW Insert/Edit operations, you may only use one of the codecs from each pair,

DVCPRO25 #1, DVCPRO25 #3, and D VCPRO25 #5. Note that the second DVCPRO 25

codec from each pair must not be used.

Profile Video File Server Installation 1-17

Page 30

Chapter 1 Introduction

1-18 Profile Video File Se rver Installation

Page 31

Chapter

2

Mechanical Installation

This chapter describes the mechanical installation of your Profile Video File Server

into an equipment rack and the connection of cables to the rear panel. The chapter

includes examples of connections to peripheral equipment such as the PDX218

storage expansion chassis, the PRS255 RAID Storage chassis. See the appropria te

manuals for ins tal l ation inst ru cti o ns for pe rip he ral eq u ipm en t. T he info rm at io n here

covers:

• Mounting the Profile Video Fil e Server in the rack.

• Mounting the RS-422 Connector Panel.

• Mounting the audio interfac e cha ssis (XLR216, BNC216, or PAC208/216).

• Making Profile Video File Server rear panel cable connections.

• Making other system connections.

Rack Mounting

The equipment for the P rofile Vi deo File S erver syste m installs in a st andard 19-inc h

equipment rac k. Rack slide tracks shipped with the Profile Video File Se rver and the

Profile Audio Chass is allow them to slide in and out without having to remove the m

from the rack. However, if the rack does not already have rack slides installed , or if

the slides are not correctly positioned, you will have to use those shipp ed with the

Profile Video File Server.

When determining the location of the Profile Video File Server in the rack, bear in

mind that the chassis with a full complement of disk drives we ighs appr oximately 70

pounds. Observe the following warnings:

!

!

WARNING: To prevent injury, t wo people are requi red to lift the Prof ile Video File

Server. The Profile Video File Server is too heavy for one person to install in the

rack.

WARNING: To prevent serious i njury , in sure that the rack i s anc hored to t he f loor

so that it cannot tip over when the Profile Video File Server is extended out of the

rack.

Profile Video File Server Installation 2-1

Page 32

Chapter 2 Mechanical Installation

Mounting the Slide Tracks in the Rack

Figure 2-1 shows the components of a right-hand rack slide set. Note that the chassis

sections are already att ached to the Profile Video File Server and PAC208/216. When

mounting rack slides in the equipment rack, bear the following in mind:

• The Profile Video File Server occupies 5 rack units (RUs).

• The PAC208/216 occupies 2 RUs

Automatic

Profile Chassis Section

Stationary

Rack

Section

Flat Nut Bar

10-32 PHS

Stop Latch

Intermediate

Figure 2-1. Rack Slide Set for Right Side of Profile Chassis and Rack

NOTE: Right-hand and left-hand stationary section is designated by the

RH and the LH marked on the rails. Stop latch holes should be towards

Rear

10-32 PHS

Flat

Nut

2-2 Profile Video File Server Installation

Page 33

Mounting the Slide Tracks in the Rack

From Figure 2-2, choose the proper set of rail mounting holes on the rack. Notice that

the hole spacing can vary with the rack type. When mounting the slides in r acks with

EIA spacing, make sure that the slides are attached to the 0.5-inch spaced holes.

MIL STD 189

1.250 in

0.625 in

1.250 in

Figure 2-2. Spacing Specif ication for Mounting Holes in a Rack

“UNIVERSAL” SPACING

1.250 in

0.500 in

0.625 in

Profile Video File Server Installation 2-3

Page 34

Chapter 2 Mechanical Installation

Figure 2-3 and Figure 2-4 show front and rear rail mounting details for both deep and

shallow racks. Mount the rails using the enclosed hardware. Make sure the stationary

sections are horizontally aligned and are level, as well as parallel to each other.

BAR NUT

(Use if the front rail is not tapped)

Figure 2-3. Front Rail Mounting Detail

BAR NUT

PNH

REAR RACK RAIL

Figure 2-4. Rear Rail Mounting Detail

2-4 Profile Video File Server Installation

Page 35

Mounting the Profile Video File Server

In addition t o room to make cab le connecti ons, the Profil e Video File Serve r require s

six inches (15.25 cm) of clearance behind the rear panel for connectors and cable

bends. Insure adequate air flow around the chassis to provide suffic ient cooling.

(Operating ambient temperature will affect the amount of air circulation required to

keep the Profile Video File Serve r with in its temperature limitations.)

1. Pull the slide-out track section to the fully extended position. See Figure 2-5.

Mounting the Profile Video File Server

!

!

WARNING: To prevent injury, t wo people are requi red to lift the Prof ile Video File

Server. It is too heavy for one person to install in the rack.

WARNING: To prevent serious i njury , in sure that the rack i s anc hored to t he f loor

so that it cannot tip over when the Profile Video File Server is extended out of the

rack.

2. Insert the ends of the chassis sections into the slide-out se ctions.

3. Push the chassis toward the rack unti l the chassis s ections lock into the int ermediate

sections.

4. Press the stop latches in the intermediate sections an d push the chassis toward the

rack until the latches sna p into their holes.

Stop Latch

5. Again, press the stop latches and push the cabinet fully into the rack.

6. Insert and tighten the front panel retaining screws.

Figure 2-5. Rack Slide Stop Latc h

Profile Video File Server Installation 2-5

Page 36

Chapter 2 Mechanical Installation

Maki ng Rack Slide Adjustments

After install ation, binding may occu r if the slide tracks are not properly adjusted. To

adjust the tracks:

1. Slide the chassis out approximately 10 inches.

2. Slightly loosen the mounting screws holding the tr acks to the f ront of the rail s and

allow the tracks to seek an unbound posit ion.

3. Tighten the mounting screws and check the tra cks for sm ooth operat ion by sli ding

the chassis in and out of the rack several times.

4. Tighten the front panel retaining scr ews once the cabinet is in place within th e rack

to complete the installation.

Mounting Panels and Audio Chassi s

Refer to the information that f ollows when mounting panels and audio chassis:

• The RS-422 Connector Panel is 1 RU high with the mounting holes space d 1.250

inches (3.17 5 cm ) apart .

• The XLR 216 is 2 RUs high with holes spaced 3.000 inches (7.62 cm) apart.

• The BNC216 is 1 RU high with holes spaced 3.000 inches (7.62 cm) apart.

• The PAC208 and PAC216 Audio Breakout panels are 2 RUs high with holes

spaced 3.000 inches (7.62 cm) apart.

The RS-422, XLR216 and BNC216 panels mount at the back of the rack with four

pan head screws. Ensure that there is ro om to make cable connections and mount in

any order which allows connection to the PRO Series Video Disk Recorder.

2-6 Profile Video File Server Installation

Page 37

Making Rear Panel Connections

Because of the flexible c onfigurations of the Profile Video File Server, not all of the

rear panel connections de scribed here may apply to your Profile system. The

connections are described as though all factory installable options were in fact

installed. As yo u go thr ough these instr uctions, simply ignor e a board you do not have

installed. Note that any rear panel sl ot which does not h ave a board insta lled will have

a blank cover over the rear panel slot.

NOTE: Insure that power switches of all equipmen t to be installed are in the

Off (O) positions.

To insure complianc e with EMI st andards, all B NC cable connec tions requi re tha t an

EMI suppression gasket be attac hed as shown in Figure 2-6. Your Profile system

shipment included a set of gaskets.

Making Rear Panel Connections

9040-1

Figure 2-6. BNC Connection With EMI Gasket

Profile Video File Server Installation 2-7

Page 38

Chapter 2 Mechanical Installation

Connecting the Mouse and Keyboard

The Profile system mouse and keyboard con nector s are located on the rear panel as

shown in Figure 2-7.

Connect the mouse and keyboard as shown in Figure 2-7.

J11 J9

J13

J12

J10

J14 J6J7

J8

J5

J4 J3 J2

J1

9676-68

Mouse

Monitor

Keyboard

Figure 2-7. Mouse, Keyboard, and S- VGA Monitor Connections

Connecting the Monitor

The S-VGA monitor c onnector is locate d on the Syste m CPU boa rd lo cated i n sl ot J 1.

Connect the S-VGA Monitor cable to the 15-pin conn ector as shown in Figure 2-7.

Parallel

Port

System

CPU

2-8 Profile Video File Server Installation

Page 39

Connecting the Referen ce Genlock

The Profile Video File Server pro vides a Reference Genlock board, standard on all

configuration s, with two BNC connec tors and a 25-pin DIN connector. The BNC

connectors form a bridging, high impedance loop-th rough for the analog black burst

house reference si gnal. Thi s sig nal is used to sync hronize t he syste m video clock a nd

provide frame referenc e. The 25-pin DIN provides Longitudinal Time Code

interfaces, four in and four out. See Figure 2-8.

Connecting the Reference Genlock

J17 J13J16

J15 J14 J6J7J4J5

75Ω Terminator

House Reference

LTC Breakout Cable

Reference Analog Video

Figure 2-8. Reference Genlock Cable Connections

To make cable connections to the Reference Genlock board, refer to Figure 2-8 and:

1. Attach the optional Longitudinal Time Code breakout cable (Figure 2-9) to the

25-pin DIN connector.

J12

J11 J9

J10

J8

9676-9

9040-5

Figure 2-9. Break out Cable

2. Place EMI gaskets on the BNC connectors as shown in Figure 2-6, page 2-7.

3. Attach the House Reference (Black Burst) BNC cable to the lower BNC connector.

4. Attach a 75Ω End-line Terminator to the upper BNC connector.

Profile Video File Server Installation 2-9

Page 40

Chapter 2 Mechanical Installation

Connecting V ide o

The Profile Video File Server supports S erial Digita l I/O, Analog Composite I/O, and

Analog Component Inputs . The v ideo conne ctions yo u make depen ds o n your Pro file

Video File Server configuration.

Connecting Serial Digital Video

The Profile Video File Server allows Serial Digital Video I/O board installati ons for

two channels of serial digital input and output per board. Figure 2-10 shows serial

digital cable connect ions for a typ ical loc ation, slot J14. Refer to the rear panel la bels

or Tables 1- 2 through 1-6 in Chapter 1, pages 1- 9 through 1-13, to determine the slot

location of this board in your system.

1. Place EMI gaskets on the four BNC connectors as shown in Figure 2-6, page 2-7.

2. Attach two BNC cables from seria l digit al sources to t he IN A a nd IN B connect ors.

3. Attach two BNC cables to serial digital sources to the OUT A and OUT B

connectors.

J17 J13J16

J15 J14 J6J7

Video I/O Serial Digital Component

Figure 2-10. Serial Dig ital I/O Cable Connections

J12

J11 J9

J10

In A

In B

Out A

Out B

J8

J5

J4 J3 J2

J1

9676-56

2-10 Profile Video File Se rver Installation

Page 41

Connecting Analog Composite Video I/O

The Profile Vide o File Server may include one or more an Analog Composite Video

In/Output boards. Figur e 2-11 shows analog composite video cable conne ctions for a

typical locatio n, slot J14. Refer to the rear panel labels or Tables 1-2 through 1-6 in

Chapter 1, pages 1-9 through 1-13, to determine the slot location of thi s board in your

system.

The Analog Composite I/O board accepts two composite analog video inputs, and

provides two composite analog vide o outputs. The board is also equipped with an

S-Video connector, which allows video input to the Profile system directly from a

source such as a vi deo cassette re corder. However, the S-Video devi ce takes the plac e

of one of the input s (eithe r In A or I n B). The board pr ovides ti me base cor rectio n for