Page 1

QuickStart Guide

NV920 Control System

and Accessories

Product Summary

Your shipment from Grass Valley contains an NV920 frame

containing one or two NV920 system controllers and power

supplies, power cords, and this Quick Start guide. Depending

on your order options, the shipment might also include

cables and peripheral devices. See Figure 1.

An NV920 system controller allows you to configure and

operate routers, control panels, and other connected equipment. A complete NV920 control system includes several

parts that work together:

• NV920 system controller(s).

• NV9000-SE Utilities configuration software.

• PCs running configuration or control software.

• Routers.

• Control panels (physical or virtual).

• Optionally, master control components.

• Optionally, automation, UMD, monitor walls, and other

subsystems.

Control Systems

The NV920 is a member of Grass Valley’s NV9000 family of

system controllers. In order of price and performance, the

series includes these control systems:

• NV960

Each NV960 system controller is 2RU, has 2 disk drives,

and 3 PCI expansion slots. Two of the expansion slots typically provide Ethernet connections. The remaining expansion slot can be used for other purposes such as

connecting serial devices.

Several models of the NV960 are available.

• NV920

Each NV920 is 1RU and houses two system controllers.

Each system controller has 2 disk drives, 3 Ethernet ports,

and no expansion slots. However each NV920 does have

an RS-485 port that supports one serial device.

Several models of the NV920 are available. as listed on this

page.

• NV915

Each NV915 system controller is 1RU, has one disk drive, 2

Ethernet ports, and no expansion ports. One of the Ethernet port is available to support routers and control panels.

(Older NV915s had compact flash and no disk drive.)

The NV960, NV920, and the NV915 run the same software.

The NV920 is priced between the NV960 and the NV915.

A system controller is a device that (1) receives commands

from control panel operators or from third-party systems, (2)

Figure 1. Package Contents

NV920

Power cords

Software and

Documentation CD

QuickStart Guide

(this document)

dispatches instructions to routers, and (3) returns status

information to the control panels or to automation.

The NV920 product line includes these items:

• NV920D. NV920 frame with dual controllers.

• NV920S. NV920 frame with a single controller.

• NV920-PRI. A primary NV920 system controller.

• NV920-SEC. A secondary NV920 system controller.

• NV920-FME. An NV920 frame only.

• NV920-FRU. A “field replacement unit,” that is, a spare

system controller.

The NV920

The NV920 frame is a 1RU frame which contains a power supply having two removable power supply modules, and one or

two removable NV920 system controllers. See Figure 2.

One controller is labeled ‘Primary’ and the other ‘Secondary’.

These terms distinguish one from the other, but otherwise

have no specific meaning.

The NV920 frame has two power supply modules for redundancy. In normal operation, both supplies operate in tandem, sharing the load. If one power supply module fails, the

other immediately absorbs the full load.

If the NV920 frame has two system controllers, it is for redundancy. One of the system controllers is active; the other is

stand-by. If the active system controller fails, the stand-by

system controller takes over.

Product Number: QG0014-03 Revision: A0; Date: 11/26/14 1

Page 2

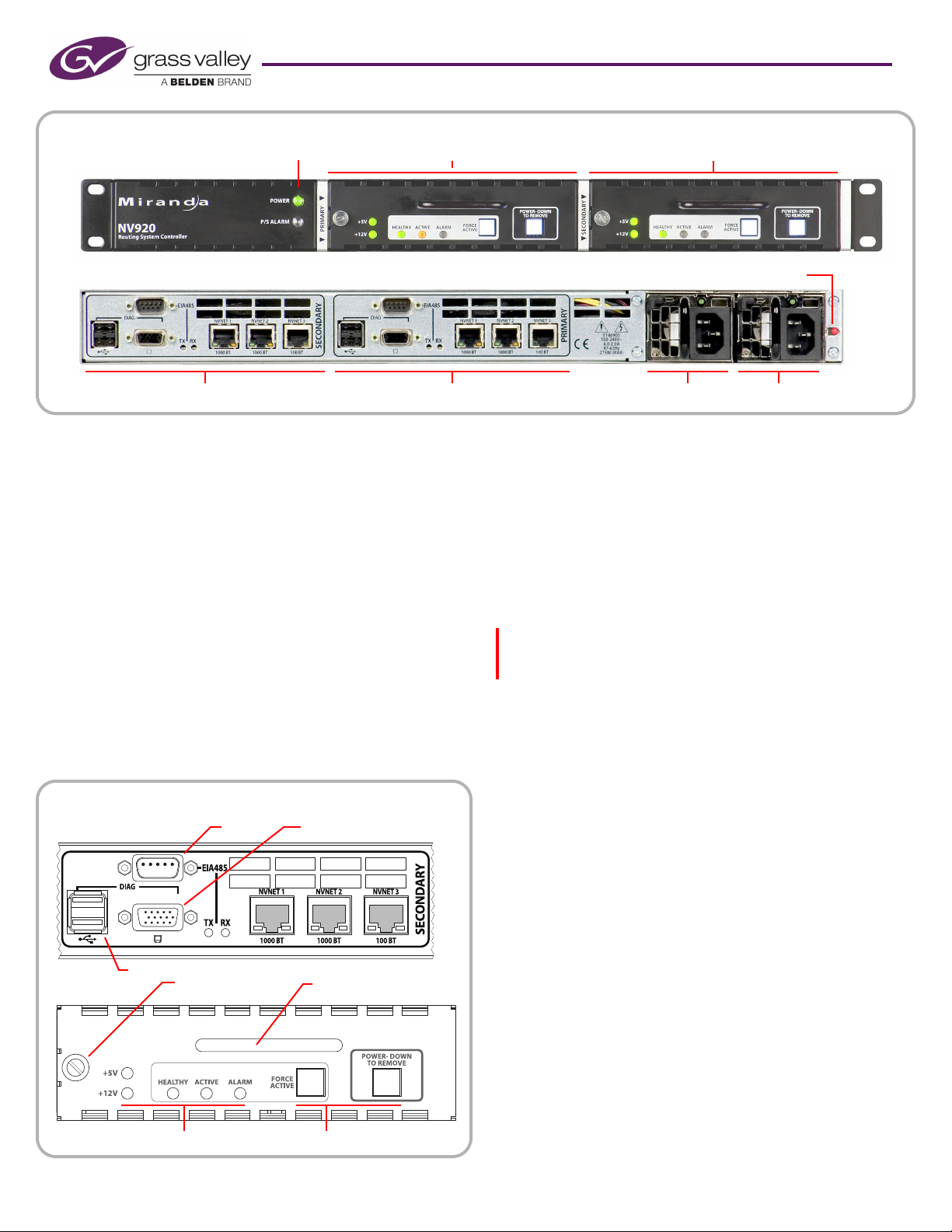

Figure 2. NV920

Front View

Power LEDs

NV920 Control System

Primary System Controller Secondary System Controller

Rear View

Connectors for Secondary System Controller Connectors for Primary System Controller

The power supplies are removable (replaceable) from the rear

of the frame. The system controllers are removable (replaceable) from the front of the frame.

If you have an NV920S (single controller) the empty secondary bay will have a blank front plate.

The System Controller

At the rear of the NV920 frame are two identical sets of connectors, one for each system controller. See Figure 3.

Among these are 3 Ethernet (RJ-45) connectors. Two support

1G Ethernet. The third supports 100M Ethernet. The Ethernet ports are otherwise identical. At least one must be used

for a panel and router network. One must be connected to

your “house network” for configuration and monitoring.

Two USB ports and a VGA port allow you to connect a keyboard, mouse, and monitor to the system controller. (The system controller runs Windows XP embedded, so you can

Figure 3. System Controller

Latch

COM2 VGA

Handle

Rear (Panel) View

USB

Front View

LEDs Buttons

Power Failure Alarm Mute Button

PS 2 PS 1

perform diagnostic and maintenance tasks using XP’s normal

Windows desktop.) You can also use the USB ports to update

the system controller’s software.

The “EIA-485” connector (DE9) supports the control of one

serial device. The port’s pinout is the same as that of a Moxa

CP-118U. You can use a WC0137 “Y” cable to connect the two

system controllers of an NV920 to the device you are controlling. The “Y” cable forms a redundant connection.

There are Tx and Rx status LEDs for the serial port that illuminate when the port is transmitting and receiving, respectively. (Internally, the port is COM2. This designation might

be important, for example, when you are using NV9000-SE

Utilities to configure routers that have serial connections.)

There are also cooling fans at the rear of each system controller. The rear of the NV920 frame has grill openings that vent

the exhaust from the fans.

Each system controller is removable. At the left side at the

front of the system controller is a latch. Turn the latch a quarter turn to lock the system controller in place. Turn the latch

in the other direction to remove the system controller.

Use the handle of the system controller to pull it out of its bay

(or to carry it).

The large button (backlit, white) at the right is labeled “Power

Down to Remove.” It is important to power the system controller off before removing it. When the system controller is

powered up, the 2 green LEDs (labeled +5V and +12V), the 3

status LEDs, and the 2 white buttons illuminate. When the

system controller’s software finishes initializing, the alarm

LED goes out.

There are 3 status LEDs in the middle of the front of the system controller:

• Healthy. This LED is green (on) when the system control-

ler is running properly. If the NV920 frame has two system

controllers, the health LED is normally on for both.

• Active. This LED is amber (yellow) when the system con-

troller is the active controller. When the NV920 frame has

2 Product Number: QG0014-03 Revision: A0; Date: 11/26/14

Page 3

NV920 Control System

two system controllers, the LED is on only for the one controller that is active.

• Alarm. This LED is normally off, but turns red when an

alarm condition is present in the controller. It is possible

for each controller in a dual-controller frame to show an

alarm.

The ‘Force Active’ button (backlit, white) allows you to cause

the stand-by system controller (in a dual-controller frame) to

become the active controller. When the controller becomes

active, its active LED turns on and the active LED of the other

controller turns off.

Power Supplies

Both of the frame’s power supply modules accept from 100 to

240 VAC, 47–63 Hz, automatically sensing the line voltage

and frequency.

The NV920 frame has two power LEDs. One LED, labeled

‘Power’ at the front of the frame, indicates the presence of

power. The other power LED (‘PS Alarm’) is off under normal

circumstances, but turns red and blinks when one of the

power supplies is missing or faulty.

When one of the power supplies is removed (or fails), the

frame emits an audible alarm (a continuous tone). The frame

has a red button (at the rear) near the power supplies that

turns off the alarm.

This QuickStart Guide

The purpose of this document is to guide you through the

physical installation of the NV920 frame, the installation of

configuration software, and the initial setup of the software

so that you can build configurations and read from and write

to your system controller(s).

NV9000-SE Utilities is the primary tool for configuration.

NV9000-SE Utilities

NV9000-SE Utilities is software that is required for the configuration and management of the NV920 control system. It is

available on the SB0033 CD in this shipment.

After you have obtained NV9000-SE Utilities, you can install

it on any PC.

Control Panels

Control panels allow operators to setup and execute “takes”

(routes) between source devices and destination devices.

Physical control panels are separate hardware units that connect to the system controller. Virtual control panels are software applications that emulate physical control panels and

run on any PC (or Mac) connected, through Ethernet, to the

system controller.

For more information on control panels, obtain the appropriate control panel user’s guide from the Grass Valley website.

Contact Grass Valley customer service for assistance.

Master Control

Master Control is a name given to an optional subsystem that

allows operators to transition program output from one

source to another with real-time effects such as cross-fades,

keyer and logo overlays, squeezeback, and audio overs.

For more information, either visit the Grass Valley website or

contact Grass Valley customer service.

System Controller Redundancy

A redundant system includes 2 system controllers. If one system controller fails, the control system immediately switches

to the other controller.

The two system controllers of a dual-controller NV920 communicate with each other through an internal Ethernet link.

The stand-by system controller queries the active system controller frequently through the internal link. If the query and

response mechanism fails, the stand-by controller presumes

that the active controller is no longer functioning properly

and takes over the role of active controller.

Installation

Setting up the NV920 system controller requires several steps:

Part 1 Mount the NV920 in a rack, insert its power sup-

plies, system controllers, and connect power.

Part 2 Make physical network and I/O connections.

Part 3 Install NV9000-SE Utilities software on your config-

uration PC(s).

Part 4 Perform initial setup in NV9000-SE Utilities.

Networks require an Ethernet switch and CAT5 Ethernet

cable. (Grass Valley’s EC9415

suitable.)

Part 1: Mount the Controller and Connect Power

The 1RU NV920 frame fits in a standard 19″ (482.6 mm) rack.

When placing the NV920 frame in your facility, keep in mind

that the NV920 needs a minimum of 6″ (15

stricted air flow at the front and rear for cooling and needs an

adequate amount of space at the sides for air intake.

The NV920 frame (with power supplies and system controllers installed) extends 19.9″ toward the rear of the rack and

projects about 1.2″ in front of the rack.

The removable power supply modules are about 10.5″ deep.

So you will need about 12″ clearance at the rear to remove and

insert power supply modules.

The NV920 frame is heavy and requires mounting hardware

at the rear of the frame. See Figure 4.

— a 24-port Ethernet switch — is

cm) of unre-

Product Number: QG0014-03 Revision: A0; Date: 11/26/14 3

Page 4

Follow these steps to mount the NV920:

NVNET 1

NVNET 2

House Net

NV9000

GUIs

NVNET 2

Tally

Config.

PCs,

GUIs

NV Router

NV920

Controller 1

Tally

Router

NVNET 1

Router

Prim. Ctrl.

Sec. Ctrl.

Panel

Panel

Tally

Tally

Router

RouterPanel

Panel

NVNET 3

NVNET 3

NV920

Controller 2

Panel

and

Router

Networks

1) Locate the mounting hardware attached to the side of the

NV920 frame. There are two metal parts for each side of

the frame. Unscrew the metal parts from the frame.

2) Referring to Figure 4, attach the two small parts (with the

slot) to the posts at the rear of the frame at the height at

which you will install the frame.

3) Reattach the two long parts to the frame so that they will

extend into the slots of the small parts at the rear of the

frame. Again, refer to Figure 4.

4) Now move the frame into position, with its support extensions sliding into the slots of the supports at the rear of the

frame.

Attach the front of the frame to the front posts of the

frame using appropriately sized screws.

5) Insert power supply module(s) and system controller(s).

6) Use the supplied power cords to connect power. The controller’s power supplies accept 100–240VAC, 47–63 Hz).

UL caution: to reduce the risk of electric shock, plug each power

supply cord into separate branch circuits employing separate

service grounds. Redundant power connections, of course, provides additional protection against failure.

If the NV920 frame emits an alarm tone, press the red button

next to the power supplies at the rear of the frame.

Caution: If you disconnect power without first shutting down

the system controllers, you risk corrupting system data. Before

disconnecting power, press the ‘Power Down to Remove’ button

of each system controller of the frame. Wait for the system controllers’ LEDs to turn off. Then disconnect power.

Part 2: Make Connections to the System Controller

The additional units that compose the NV9000 control system

— PCs, control panels, routers — communicate through

the active system controller. The system controller uses

Ethernet to communicate

NV920 Control System

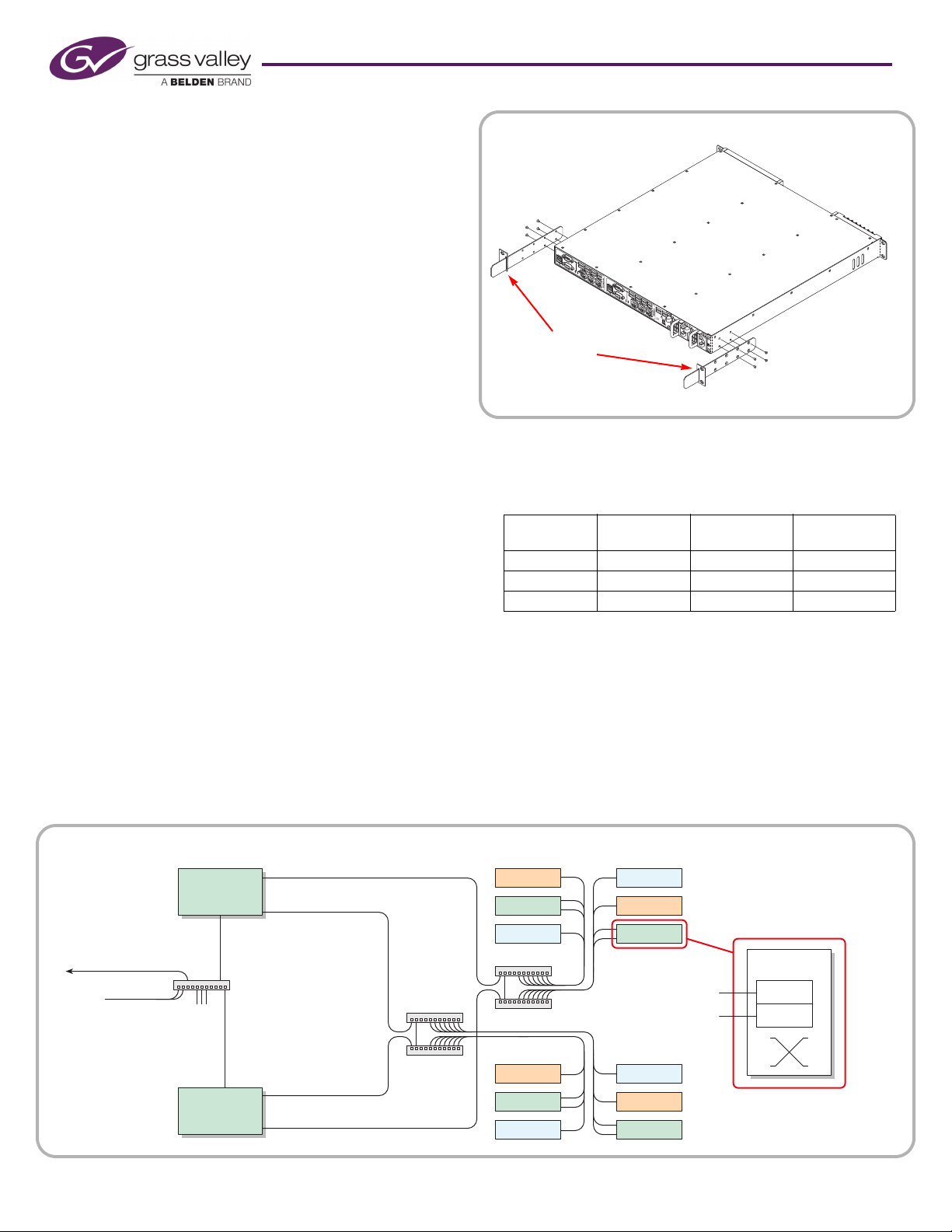

Figure 4. Frame Support

(front of unit)

Attach to rear

rack posts.

with system components.

Each of the NV920’s ports has a unique IP address, fixed internally. The IP addresses depend on whether the system controller is stand-alone or redundant:

Port

NVNET1 192.168.1.1 192.168.1.1 192.168.1.2

NVNET2 192.168.2.1 192.168.2.1 192.168.2.2

NVNET3 192.168.3.1 192.168.3.1 192.168.3.2

You may change any of these addresses to match your facility’s

networks.

Single

Controller

Example: Two Networks for Panels and Routers

Figure 5, below, diagrams a redundant system that uses two

Ethernet ports for panels and routers and the third port for

configuration and monitoring. (If your system has a single

system controller, please disregard controller 2 in the diagram and any connections to it.)

Redundant

Controller 1

Redundant

Controller 2

Figure 5. Connections for a Redundant NV920 — Two Panel and Router Networks

4 Product Number: QG0014-03 Revision: A0; Date: 11/26/14

Page 5

NV920 Control System

NVNET 1

NVNET 2

NVNET 2

House Net

NV9000

GUIs

NVNET 1

M.C. Panels,

Config. PCs,

GUIs

Master

Control

NV5100MC

Tally

Config.

PCs,

GUIs

MCE 1

NV Router

Tally

Router

Router

Prim. Ctrl.

Sec. Ctrl.

Panel

Panel

NVNET 3

NVNET 3

MCE n

NV920

Controller 1

NV920

Controller 2

Panels and

Routers

Referring to Figure 5, follow these steps to make system controller connections:

1) Connect routers to the system controller.

Connect an Ethernet switch to either or both of the panel

and router network ports on system controller 1. (In Figure

5, those are NVNET 1 and NVNET 2.) Do the same for system controller 2 if you have one.

A router might have both a primary and secondary control

card for redundancy. Either or both may connect to a

panel and router network.

Note that the Ethernet switches are cross-connected in a

redundant system:

The cross-connection allows either controller to communicate with any panel or router. In a non-redundant system, the cross-connection is not necessary.

2) Connect physical control panels to the system controller

using the same Ethernet switches. (Software control panels are treated separately and differently.)

The NV9000 system uses DHCP to assign a panel’s IP

address whereas the IP addresses of router control cards are

fixed.

Each physical control panel must have a unique panel ID.

You must set the panel IDs. The method is different for

each physical panel. Refer to panel documentation or call

Grass Valley customer support. (Note that a panel ID is not

an IP address.)

Virtual control panels (a separately purchased option) can

be installed on your PCs. Each virtual panel also has a

panel ID. The installation method is the same for all virtual panel types. Refer to the virtual panel documentation.

Panel IDs are important in the configuration software.

A Panel/Router Network and a Master Control Network

Figure 6, below, diagrams a redundant system that uses

• NVNET 1 for a network of panels and routers

• NVNET 2 for a master control network

• NVNET 3 for configuration and monitoring. (If your sys-

tem has a single system controller, please disregard controller 2 in the diagram and any connections to it.)

This guide does not address master control planning and setup.

Consult Grass Valley customer support or obtain master control

documentation from the Grass Valley website if you need a master

control system.

Referring to Figure 6, follow these steps to make system controller connections:

1) Connect routers to the system controller.

Connect an Ethernet switch to the panel and router network on system controller 1. (In Figure 6, that is NVNET 1.)

Do the same for system controller 2 if you have one.

Note again that the Ethernet switches are cross-connected

in a redundant system:

The cross-connection allows either controller to communicate with any panel or router. In a non-redundant system, the cross-connection is not necessary.

2) Connect physical control panels to the system controller

using the same Ethernet switches. (Software control panels are treated separately.)

3) Connect master control devices to the system controller.

Master control devices include MCEs, MCPMs, Imagestore

750s, and control panels (such as the iMC-Panel-100).

Connect an Ethernet switch to NVNET 2 (for master control) on system controller 1. Do the same for system controller 2 if you have one.

Figure 6. Connections for a Redundant NV920 — a Panel and Router Network and a Master Control Network

Product Number: QG0014-03 Revision: A0; Date: 11/26/14 5

Page 6

NV920 Control System

(Each MCE in the NV5100MC frame connects to the master control Ethernet switch. The NV5100MC itself connects to the NV920 through the NV920’s router network.)

Configuration PCs

Connect any PCs you want connected to the system controller to a switch on the Ethernet port for configuration and

monitoring. Set the PC’s IP address to a fixed, unique value

on that network.

Each user at your facility might wish to have a set of virtual

panels, or to use the EC9700 or EC9710 GUIs. These software

control panels allow remote or distributed control of the

NV9000 system. In addition, one or more persons will use

NV9000-SE Utilities to configure the system.

Install and use NV9000-SE Utilities on one or more PCs connected to the system controller.

Part 3: Install NV9000-SE Utilities

NV9000-SE Utilities is a software application to create complete NV9000 system configurations. It allows you also to

configure routers and control panels, and to perform system

maintenance.

(A configuration must be uploaded to the system controller

and the system controller must be restarted for the configuration to take effect.)

NV9000-SE Utilities can run on any PC connected over Ethernet to the system controller.

NV9000-SE Utilities can also be used “offline” to create configurations that you can transport and use at different locations.

Note that NV960, NV920, and NV915 configurations are inter-

changeable.

The system controllers in a redundant system must be configured

identically (except for their IP addresses, of course).

Installation Steps

To install NV9000-SE Utilities on a PC, follow these steps:

1) Load the SB0033 CD in your PC’s CD ROM drive. The CD

will auto-play and you will see the following screen:

Click ‘Configuration Software’. The next page appears:

Installing NV9000-SE Utilities on a PC

The PC on which NV9000-SE Utilities is installed must have

the following:

• Windows XP Professional, Vista, or Windows 7.

• Late-model Pentium-class processor.

• 256MB (or more) RAM.

• At least one 10/100baseT Ethernet port

Ensure that the PC’s network connection has a fixed IP

address on the system controller’s house network. You do not

need the network connection to install the software, or even

to run the software, but you will need it to write configurations to the system controller.

Click ‘Install NV9000-SE Utilities’ to launch the installer.

2) You can also copy the installer from the CD to your system’s hard drive or a USB memory device and launch it

from there. We recommend that you do this.

Double-click the copied installer to launch it.

6 Product Number: QG0014-03 Revision: A0; Date: 11/26/14

Page 7

NV920 Control System

3) When you launch the installer, the ‘Welcome’ screen

appears after several seconds:

4) Click ‘Next’. The ‘Folder Location’ screen appears:

6) Click ‘Install’. The installation then begins. It takes less

than a minute.

NV9000-SE Utilities provides online help, which provides

some orientation for new users and detailed information

for experienced users.

An NV9000-SE Utilities user’s guide (PDF) is available

through Grass Valley customer support.

Part 4: Perform initial setup of NV9000-SE Utilities

You must set up NV9000-SE Utilities so it can write configurations to the system controller(s).

We invite you to copy the sample configuration from the installa-

tion CD. It is instructive. You can also use the sample configuration as a starting point and modify it to represent the routers,

control panels, and devices in your system.

After the initial configuration, you will be able to create panel

configurations, define levels, identify device categories, and

so on.

How to Set Up NV9000-SE Utilities

This discussion assumes that the configuration and monitoring network you set up is working satisfactorily and that the

system controllers are running. (It is not necessary to have

routers and panels connected at this time.)

1) Launch NV9000-SE Utilities, either on your PC or on the

system controller.

2) Click ‘Add Control System’ in the ‘System’ menu.

5) Click ‘Next’ to accept the default location.

Or

Click ‘Choose’ to open the ‘Browse for Folder’ window to

browse to the folder you want. When you have selected a

folder, click ‘OK’ to close the browse window, and then

click ‘Next’.

Or

Click ‘Restore Default Folder’ if you want to restore the

default location, and then click ‘Next’.

The ‘Install’ screen appears:

(Alternatively, right-click anywhere in the System Management tab (at the left). A context menu appears:

Click the ‘Add Control System’ command in the context

menu.)

3) The ‘Add Control System’ dialog appears:

Enter a control system name. Enter the IP address of the

primary NV920 system controller. If there is a secondary

system controller, check the ‘Redundant’ box and enter

the secondary IP address:

Product Number: QG0014-03 Revision: A0; Date: 11/26/14 7

Page 8

NV920 Control System

If a red icon appears, the control

system you identified in step 2 is

not connected, malfunctioning, or

not properly specified.

(The IP addresses you enter should belong to the configuration and monitoring network to which your PC

belongs.)

Click ‘Save and Clear’ if you want to add another system

controller to NV9000-SE Utilities or click ‘Save and Dismiss’ if you are finished.

A green icon should have appeared in the title of the ‘System Management’ pane. An icon and the system name

should appear in the pane as well:

It can take from several seconds to a minute for NV9000-SE

Utilities to discover the system state completely.

4) Load the system controller(s) with a new or updated configuration and restart the system controllers.

Be sure you have opened the configuration you want to

become active in the controller. (The sample configuration available from the installation CD can be used.)

In the ‘System Management’ pane, click the icon of the

system controller you want to configure. The system management page opens:

The system controller icon must be green, otherwise the page

does not open. Yellow icons represent system with warninglevel errors. Red icons indicate severe errors or disconnected

systems.

There are two remaining steps:

• Click ‘Write configuration to ‹your system›’. Wait until

the write completes. Progress indicators appear and

then disappear.

• Click ‘Restart Controller 1’ to start the controller with

the new configuration. It takes about 30 seconds. Wait

until the restart completes.

If you have a redundant system, also click ‘Restart Controller 2’.

As an alternative, you can click ‘Dynamic Update Apply

Changes to Local System’.

From this point onward, you can define (and refine) your

NV920 configurations and test them.

Sample Configuration

You can either use Grass Valley’s sample configuration as a

starting point or begin with a new (empty) configuration.

When you begin to define a new configuration, we suggest

you follow the order of the pages in the ‘Configuration’ pane.

Refer to the User’s Guide or on-line help for detailed information.

Follow these steps to obtain the sample configuration.

1) Load the SB0033 CD in your CD-ROM drive. The main

screen appears:

8 Product Number: QG0014-03 Revision: A0; Date: 11/26/14

Page 9

NV920 Control System

Click ‘Router Control System’. The next window appears:

Click ‘Sample Database’. The folder containing the database opens. It contains a .zip file that you should copy to

your file system or a USB memory device.

2) Launch NV9000-SE Utilities. Choose ‘Import from ZIP

archive...’ from the ‘File’ menu. Browse to select the .zip

file. Click ‘Open’. Give the configuration a name. SE takes

a few seconds to save the configuration.

The sample database is at revision 4.x and you will see an alert

message regarding that. To complete the load, click ‘Yes’ to

proceed.

Follow these steps to load the configuration in a system controller:

3) In NV9000-SE Utilities, with the configuration open, go to

the ‘System Management’ pane and click the controller’s

icon. (It must be green.) Then click ‘Write configuration to

‹your system›’ in the system management page.

Click ‘Start’ or ‘Restart’.

4) After about 30 seconds, the controller should be running

with the sample configuration.

The sample configuration has very little to do with the

devices, routers, and panels in your system. You will not be

able to operate your system until you load a configuration

that represents your system.

However, you can perform takes. To see this, click the SDI

icon to open the SDI (router) page.

Choose an output and an input and click the ‘Take’ button. To lock an output, choose an output and click ‘Lock’.

The take and the lock appear in the list. The lock appears

as an ‘L’ next to the output.

Other Topics

Setting Your PC’s IP Address

Follow these steps to set the IP address of any PCs connected

to the system controller:

1) Launch ‘Settings > Network Connection’ from you PC’s

Start menu. The following window appears:

2) Double-click the appropriate ‘Local Area Connection’ for

the controller’s house network. Then, choose the ‘General’ tab and click ‘Properties’.

Product Number: QG0014-03 Revision: A0; Date: 11/26/14 9

Page 10

NV920 Control System

3) Select Internet Protocol (TCP/IP). Click ‘Properties’ again:

4) Select ‘Use the following IP address’ and enter an IP

address for the PC:

2) Login to the system controller (which you will see is running Windows XP embedded).

3) Go into Windows ‘Network Connection’ on the controller

and find one of the Ethernet ports.

4) Give it an IP address (and subnet mask) that is unique on

your facility’s network. It should remain a fixed address.

5) Close all network configuration windows.

6) Log out.

7) Repeat these steps for the other system controller, if there

is one.

Installing NV9000 Tools on Your PC

The system controller comes with several useful applications

that you can run if you are logged into the controller.

• EC9700 (Control GUI).

• Panel, GUI, and Salvo Editor (a.k.a. PGSE)

• EC9710 (Sta tus GUI)

• System Manager

• Tieline Status GUI

You will probably want to copy these to some or all of your

configuration and GUI PCs.

Follow these steps to distribute the tools:

1) From the system controller, copy

C:\nvision\envy\install\client\SV0269-04.msi

to the target PC.

The released tools installer is SV0269-04, version F. However, it

might be in that folder as Setup.exe.

2) Run the installer on the PC. (The installer takes you

through several steps, asks a few questions, and in particular, asks for the address(es) of you controller(s):

The IP address must be unique on the house network. (The

subnet mask must be 255.255.255.0.)

5) Click OK and it is done. Close all the Network Connections windows.

Matching Your House Network

To add your system controller to your facility’s “house network”, follow these steps:

1) Attach a keyboard, monitor, and mouse to your system

controller. Use the USB and VGA ports at the rear of the

Enter the house net address(es) of the controller(s).

Some of these applications require setup or configuration

in NV9000-SE Utilities. Read the associated manual

(downloadable from the Grass Valley web site) or call Grass

Valley tech support.

NV920 to do so.

10 Product Number: QG0014-03 Revision: A0; Date: 11/26/14

Page 11

NV920 Control System

54321

Rx

Rx+

Tx

Tx+

GND

In the Americas, call toll-free +1-800-547-8949 (9 am to 9 pm EST)

In Europe, the Middle East, Africa, or the UK, (9 am to 6 pm, GMT)

call +44 (0) 118 952 3444

For playout automation, (9 am to 5:30 pm, GMT)

call +44 (0) 870 500 4350

In France, call +33 1 55 86 87 88 (9 am to 6 pm, GMT + 1)

In Asia, call +852-2539-6987 (9:30 am to 5 pm, GMT + 8)

In Malaysia, call +60 3 2247 1808

In China, call +86-10-5873-1814(9:30 am to 5 pm, GMT + 8)

In emergencies, call +1 800-547-8949 or +1 514 333 1772

Find warranty, RMA notice, tech support, and other notices in the User’s Guide.

Specifications are subject to change without notice. © 2 014 Belden, Inc. All Rights

Reserved. NVISION is a registered trademark of Grass Valley, Inc. All other

trademarks are the property of their respective owners.

Serial Port

The serial port provides RS-485 communication on a male

DE9 connector. This is the pinout of the serial port:

Misc. Advice

When you login to the system controller, the default user ID

is envyadmin and the default password is software.

If you have only one power cord, you will hear a high-pitched

beep when you turn on your controller. Press the red alarm

mute button at the rear to stop the beeping.

When you turn off your controller, never just disconnect

power. Always press the ‘Power Down to Remove’ button of

each system controller before you power down.

The default pathname of NV9000-SE Utilities configuration

storage (on your PC) is

C:\Documents and Settings\‹user›\CtrlSysConfigs

and does not exist until you first launch NV9000-SE Utilities.

The NV920 frame has two power supplies for redundancy. If

power is interrupted, a power supply failure alarm sounds.

This audible alarm does not cease until the power supply

source is once again stable. To turn off the power supply

alarm, press the red power supply alarm mute button located

on the rear of the frame, as shown in Figure 2 (on page 2).

NV920 Specifications

Spec Data

Power Auto-ranging, 100 –240 VAC, 47–63 Hz.

150 Watts, 4–2

Weight 29.8 lb (13.5 kg)

Size 1RU × 21.1 inches deep (53.6 cm)

USB ports 2, high-speed

Monitor port VGA, HD15

Serial port DE9, RS-485

Ethernet ports 3, RJ-45, two 10/100/1000baseT;

one 10/100baseT

A, each module.

System Controller Specifications

Spec Data

Weight 2 9.8 lb (13.5 kg)

Processor Intel, Atom, N450, 1.6 GHz

OS Windows XP Embedded

RAM 2 GB

Disk Two, 500 GB

Contact Information

Contact Grass Valley if you need information about NVISION

router control systems or third-party automation systems.

Korean Compliance (KCC) Statement

KCC-REM-XEI-NV920D

A 급 기기

( 업무용 방송통신 기자재 )

Class A Equipment

(Commercial Broadcasting & Communication

Equipment)

이 기기는 업무용 (A 급 ) 전자파적합기기로서 판

매자 또는 사용자는 이 점을 주의하시기 바라

며 , 가정외의 지역에서 사용하는 것을 목적으로

합니다 .

Please note this is a Class A device. Sellers or users need to

take note of this and should not use this equipment in a

domestic environment.

Product Number: QG0014-03 Revision: A0; Date: 11/26/14 11

Loading...

Loading...