Page 1

NV5256

Machine Control Router

User’s Guide

Miranda Technologies Inc.

3499 Douglas B. Floreani

Montreal, Quebec

Canada H4S 2C6

Page 2

NV5256 Machine Control Router — User’s Guide

• Revision: 1.8

• Software Version: -na-

• Part Number: UG0018-08

• Copyright: © 2011 Miranda Technologies. All rights reserved.

• No part of this manual may be reproduced in any form by photocopy, microfilm, xerography or

any other means, or incorporated into any information retrieval system, electronic or mechanical, without the written permission of Miranda Technologies, Inc.

• The information contained in this manual is subject to change without notice or obligation.

• All title and copyrights as well as trade secret, patent and other proprietary rights in and to the

Software Product (including but not limited to any images, photographs, animations, video,

audio, music, test, and “applets” incorporated into the Software Product), the accompanying

printed materials, and any copies of the Software Product, are owned by Miranda Technologies,

Inc. The Software Product is protected by copyright laws and international treaty provisions.

Customer shall not copy the printed materials accompanying the software product.

Notice

The software contains proprietary information of Miranda Technologies, Inc. It is provided under a

license agreement containing restrictions on use and disclosure and is also protected by copyright

law. Reverse engineering of the software is prohibited.

Due to continued product development, the accuracy of the information in this document may

change without notice. The information and intellectual property contained herein is confidential

between Miranda and the client and remains the exclusive property of Miranda. If you find any

problems in the documentation, please report them to us in writing. Miranda does not warrant that

this document is error-free.

FCC Statement

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own expense.

Declaration of Conformance (CE)

All of the equipment described in this manual has been designed to conform with the required

safety and emissions standards of the European Community. Products tested and verified to meet

these standards are marked as required by law with the CE mark. (See Symbols and Their Mean-

ings on page v.)

ii Rev 1.8 • 08 Jul 11

Page 3

When shipped into member countries of the European Community, this equipment is accompanied

by authentic copies of original Declarations of Conformance on file in Miranda GVD offices in

Grass Valley, California USA.

Trademarks

Miranda is a registered trademark of Miranda Technologies, Inc.

Brand and product names mentioned in this manual may be trademarks, registered trademarks or

copyrights of their respective holders. All brand and product names mentioned in this manual serve

as comments or examples and are not to be understood as advertising for the products or their manufactures.

Software License Agreement and Warranty Information

Contact Miranda for details on the software license agreement and product warranty.

Technical Support Contact Information

Miranda has made every effort to ensure that the equipment you receive is in perfect working order

and that the equipment fits your needs. In the event that problems arise that you cannot resolve, or

if there are any questions regarding this equipment or information about other products manufactured by Miranda, please contact your local representative or contact Miranda directly through one

of the appropriate means listed here.

• Main telephone: 530-265-1000 (9 am to 9 pm PST)

Fax: 530-265-1021

In the Americas, call toll-free: +1-800-224-7882 (9 am to 9 pm EST)

In Europe, the Middle East, Africa, or the UK, call +44 (0) 1491 820222 (9 am to 6 pm, GMT)

In France, call +33 1 55 86 87 88 (9 am to 5 pm, GMT + 1)

In Asia, call +852-2539-6987 (9 am to 5 pm, GMT + 8)

In China, call +86-10-5873-1814

• Emergency after hours: toll-free: +1-800-224-7882

Tel: +1-514-333-1772

•E-Mail:

In the Americas, support@miranda.com

In Europe, the Middle East, African or the UK, eurotech@miranda.com

In France, eurotech@miranda.com

In Asia, asiatech@miranda.com

In China, asiatech@miranda.com

• Website: http://www.miranda.com

• Mail Shipping

Miranda GVD Miranda GVD

P.O. Box 1658 125 Crown Point Court

Nevada City, CA 95959, USA Grass Valley, CA 95945, USA

Note Return Material Authorization (RMA) required for all returns.

NV5256 Machine Control Router • User’s Guide iii

Page 4

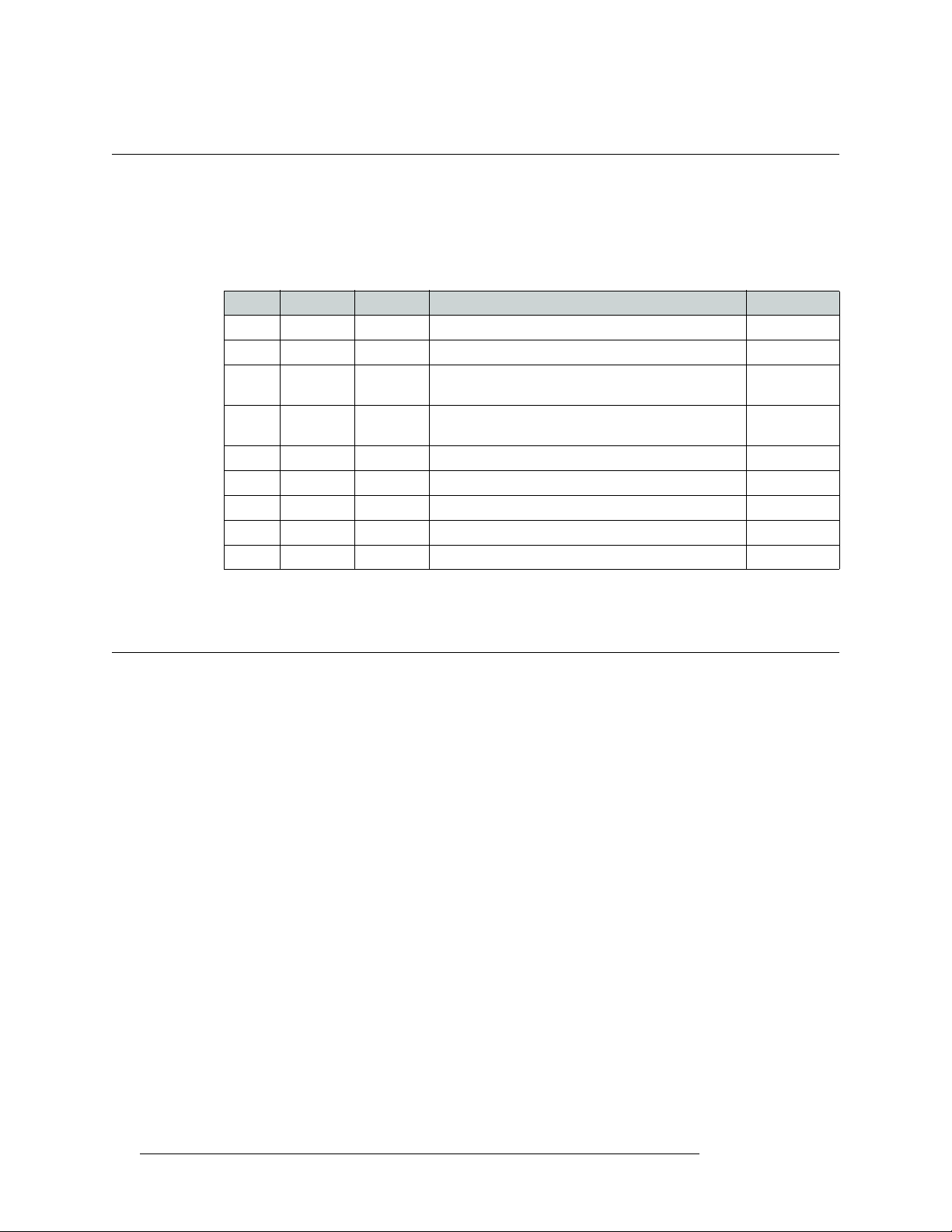

Change History

The table below lists the changes to the Machine Control Router User’s Guide.

• User’s Guide Part # UG0018-08

• Software version: -na-

Rev Date ECO Description Approved By

0.9 30 Mar 07 12960 New document. Preliminary Release D.Cox

1.1 12 Jul 07 13355 Corrections. D.Cox

1.2 07 Aug 07 13430 The wiring in the BP-PORT-64 breakout panel has

1.3 22 Jan 08 14014 Added a pinout diagram of the AES 3-pin reference

1.4 22 Oct 08 14426 Updated formats. DEM/D.Cox

1.5 31 Mar 09 15703 Format change. DEM/D.Cox

1.6 10 Oct 09 16114 Corrected contact information. DEM

1.7 18 Aug 10 17186 Added reference to PS6100. Minor corrections. D.Cox

1.8 08 Jul 11 17628 RJ-45 to RS-232 connection corrected. D.Cox

D.Cox

been corrected.

D.Cox

connectors.

Restriction on Hazardous Substances (RoHS)

Miranda is in compliance with EU Directive RoHS 2002/95/EC governing the restricted use of certain hazardous substances and materials in products and in our manufacturing processes.

Miranda has a substantial program in place for RoHS compliance that includes significant investment in our manufacturing process, and a migration of Miranda product electronic components and

structural materials to RoHS compliance.

It is our objective at NV to maintain compliance with all relevant environmental and product regulatory requirements. Detailed information on specific products or on the RoHS program at Miranda

is available from Miranda Customer Support at

1-800-719-1900 (toll-free) or

1-530-265-1000 (outside the U.S.).

iv Rev 1.8 • 08 Jul 11

Page 5

Important Safeguards and Notices

This section provides important safety guidelines for operators and service personnel. Specific

warnings and cautions appear throughout the manual where they apply. Please read and follow this

important information, especially those instructions related to the risk of electric shock or injury to

persons.

Warning

Any instructions in this manual that require opening the equipment cover or

enclosure are for use by qualified service personnel only. To reduce the risk of

electric shock, do not perform any service other than that contained in the operating instructions unless you are qualified to do so.

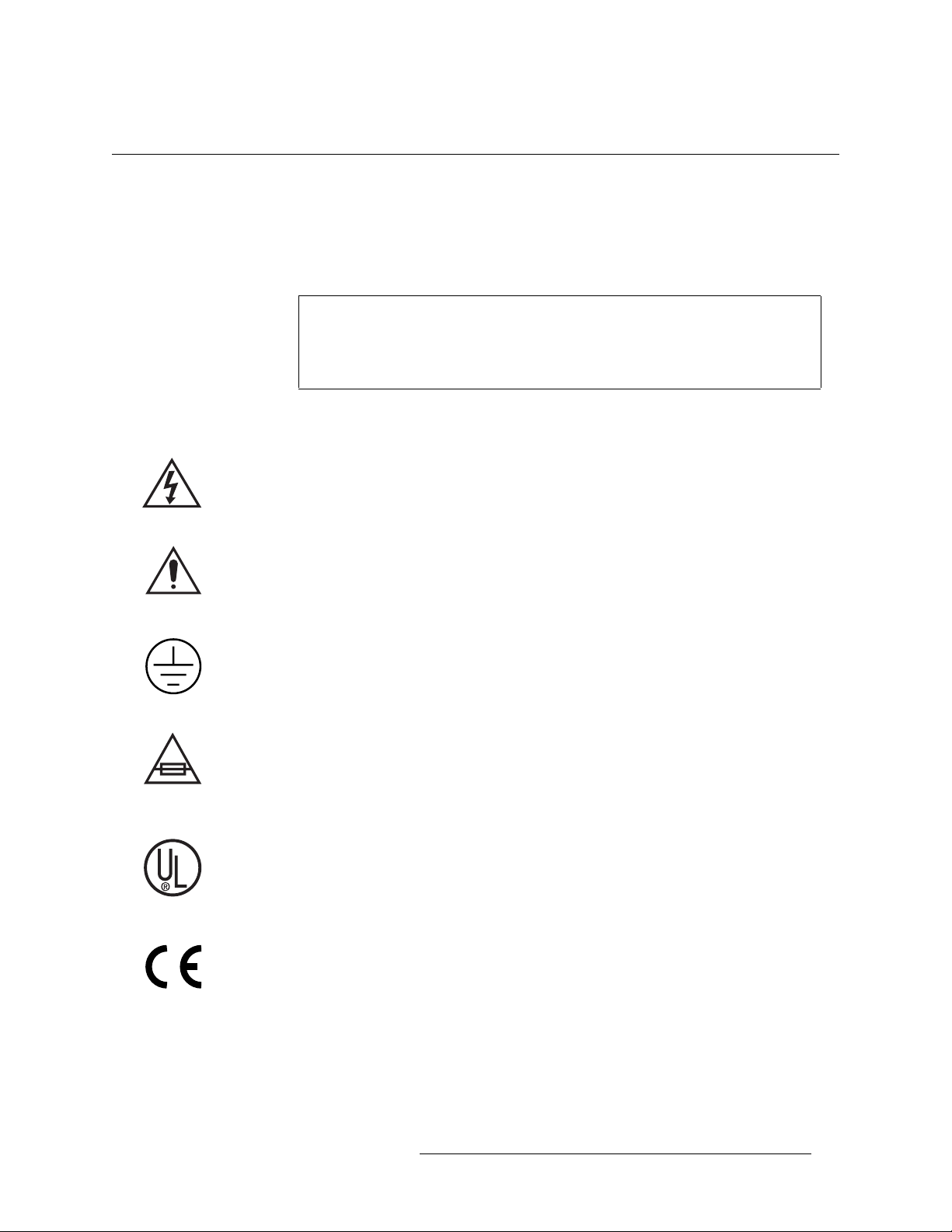

Symbols and Their Meanings

The lightning flash with arrowhead symbol within an equilateral triangle alerts the user to the presence of dangerous voltages within the product’s enclosure that may be of sufficient magnitude to

constitute a risk of electric shock to persons.

The exclamation point within an equilateral triangle alerts the user to the presence of important

operating and maintenance/service instructions.

The Ground symbol represents a protective grounding terminal. Such a terminal must be connected

to earth ground prior to making any other connections to the equipment.

The fuse symbol indicates that the fuse referenced in the text must be replaced with one having the

ratings indicated.

The presence of this symbol in or on Miranda equipment means that it has been designed, tested

and certified as complying with applicable Underwriter’s Laboratory (USA) regulations and recommendations.

The presence of this symbol in or on Miranda equipment means that it has been designed, tested

and certified as essentially complying with all applicable European Union (CE) regulations and

recommendations.

NV5256 Machine Control Router • User’s Guide v

Page 6

General Warnings

A warning indicates a possible hazard to personnel which may cause injury or death. Observe the

following general warnings when using or working on this equipment:

• Heed all warnings on the unit and in the operating instructions.

• Do not use this equipment in or near water.

• This equipment is grounded through the grounding conductor of the power cord. To avoid electrical shock, plug the power cord into a properly wired receptacle before connecting the equipment inputs or outputs.

• Route power cords and other cables so they are not likely to be damaged.

• Disconnect power before cleaning the equipment. Do not use liquid or aerosol cleaners; use

only a damp cloth.

• Dangerous voltages may exist at several points in this equipment. To avoid injury, do not touch

exposed connections and components while power is on.

• Do not wear rings or wristwatches when troubleshooting high current circuits such as the power

supplies.

• To avoid fire hazard, use only the specified fuse(s) with the correct type number, voltage and

current ratings as referenced in the appropriate locations in the service instructions or on the

equipment. Always refer fuse replacements to qualified service personnel.

• To avoid explosion, do not operate this equipment in an explosive atmosphere.

• Have qualified service personnel perform safety checks after any service.

General Cautions

A caution indicates a possible hazard to equipment that could result in equipment damage. Observe

the following cautions when operating or working on this equipment:

• When installing this equipment, do not attach the power cord to building surfaces.

• To prevent damage to equipment when replacing fuses, locate and correct the problem that

caused the fuse to blow before re-applying power.

• Use only the specified replacement parts.

• Follow static precautions at all times when handling this equipment.

• This product should only be powered as described in the manual. To prevent equipment damage, select the proper line voltage on the power supply(ies) as described in the installation documentation.

• To prevent damage to the equipment, read the instructions in the equipment manual for proper

input voltage range selection.

• Some products include a backup battery. There is a risk of explosion if the battery is replaced by

a battery of an incorrect type. Dispose of batteries according to instructions.

• Products that have (1) no on/off switch and (2) use an external power supply must be installed

in proximity to a main power output that is easily accessible.

vi Rev 1.8 • 08 Jul 11

Page 7

Table of Contents

Chapter 1 Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Chapter Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

The PDF Document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Terms, Conventions and Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Chapter 2 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

I/O Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Router Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Router Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Router Expansion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Router Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Breakout Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

SMS7000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Signal Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Machine Control Forward . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Machine Control Reverse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Machine Control Broadcast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

DataXY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Port Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Controlling and Controlled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

DTE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

DCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Dynamic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Master. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Slave. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 3 Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Control Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Serial Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Ethernet Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Diagnostic Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

AES Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Inter-Frame Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Aux Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Video Reference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Redundant Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Time Code Reference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

System Alarm Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Power Supply Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

NV5256 Machine Control Router • User’s Guide vii

Page 8

Table of Contents

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Ground Lug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Expansion Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

I/O Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Breakout Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

RS-232 Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

General Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Port Cards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Expansion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

The Expansion Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Release Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Clock Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Inter-Frame Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Terminators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

10Base2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Chapter 4 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

UniConfig—Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

UniConfig—Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Configure Port Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Perform Takes in UniConfig . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Other. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Chapter 5 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Periodic Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Intake Air Filter Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Battery Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Fuse Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

LED Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Chapter 6 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Mechanical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

I/O Card Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Expansion Card Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Communication Port Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Reference Port Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Chapter 7 Misc. Topics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Control Port Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

AES Reference Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

viii Rev 1.8 • 08 Jul 11

Page 9

1. Preface

Chapter 1 provides an introduction to the NV5256 User’s Guide. It presents the following topics:

• Chapter Structure

• The PDF Document

• Terms, Conventions and Abbreviations

Chapter Structure

The following chapters provide information regarding the NV5256 Machine Control Router:

• Chapter 1, Preface

terms and conventions.

• Chapter 2, Introduction

• Chapter 3, Detail

• Chapter 4, Configuration

• Chapter 5, Maintenance

• Chapter 6, Specifications

NV5256.

• Chapter 7, Misc. Topics

An Index

is also available for your reference.

, (this chapter) outlines easy ways to use this guide and provides a list of

, is a brief introduction to the NV5256.

, discusses the features and functions of the NV5256.

, discusses configuration of the NV5256.

, discusses the features and functions of the NV5256.

, presents the electrical, mechanical, and other specifications for the

, presents miscellaneous information.

The PDF Document

This guide is provided in PDF format, allowing you to use Acrobat’s “bookmarks” to navigate to

any desired location. You can also easily print a hardcopy. Please note:

• Use the Table of Contents or the bookmarks page to jump to any desired section.

• Many hyperlinks are provided within the chapters.

• Use the Index to jump to specific topics within a chapter. Each page number in the index is a

hyperlink.

• Use Acrobat’s ‘Go to Previous View’ and ‘Go to Next View’ buttons to retrace your complete

navigational path.

NV5256 Machine Control Router • User’s Guide 1

Page 10

1. Preface

Terms, Conventions and Abbreviations

• Use the ‘First Page’, ‘Previous Page’, and ‘Next Page’, and ‘Last Page’ buttons to go to the

first, previous, next, or last page within a PDF file.

Note To display the navigation buttons, right-click the Tool Bar area, and check

‘Navigation’.

• Use Acrobat’s extensive search capabilities, such as the ‘Find’ tool and ‘Search’ tool to perform

comprehensive searches as required.

Terms, Conventions and Abbreviations

The following conventions are used throughout this guide:

• The symbol

• Entries enclosed in single quotes denote the names of control panel buttons and knobs, or menu

items.

• Choose ‘Aux’ to ...

• Press ‘Keyer 2’ button ...

The following terms and abbreviations are used throughout this guide:

• The term “router” refers to the NV5256 machine control router, unless it used in a broader context such as “NV9000 Router Control System.”

• The terms “panel” and “control panel” refer to NV9000 control panels.

S denotes either an example or a special message.

2 Rev 1.8 • 08 Jul 11

Page 11

2. Introduction

Chapter 2 provides an introduction to the NV5256 User’s Guide. It presents the following topics:

Prerequisites

Please observe the following important prerequisites:

Overview

The NV5256 is a machine control router — a successor to the NV3256. A machine control router

transmits control messages and responses between devices such as VTRs and edit stations.

Physically, the NV5256 has an 8RU frame that holds the following items:

• Prerequisites

• Overview

• Installation

• Functions

• Equipment and software properly installed.

• NV9000 requirements met.

• All control panels properly configured.

• 16 I/O cards (RS-422/485 or RS-232)

• 16 RJ-45 backplanes.

• 2 expansion cards (for redundancy).

• 2 control cards (for redundancy).

• 2 power supplies (for redundancy).

A single NV5256 frame provides a 256×256 routing matrix. Two NV5256 frames can be connected

in tandem, using expansion cables, to provide a 512×512 matrix. A frame need not be fully populated. The NV5256 can be as minimal as a 16×16 router.

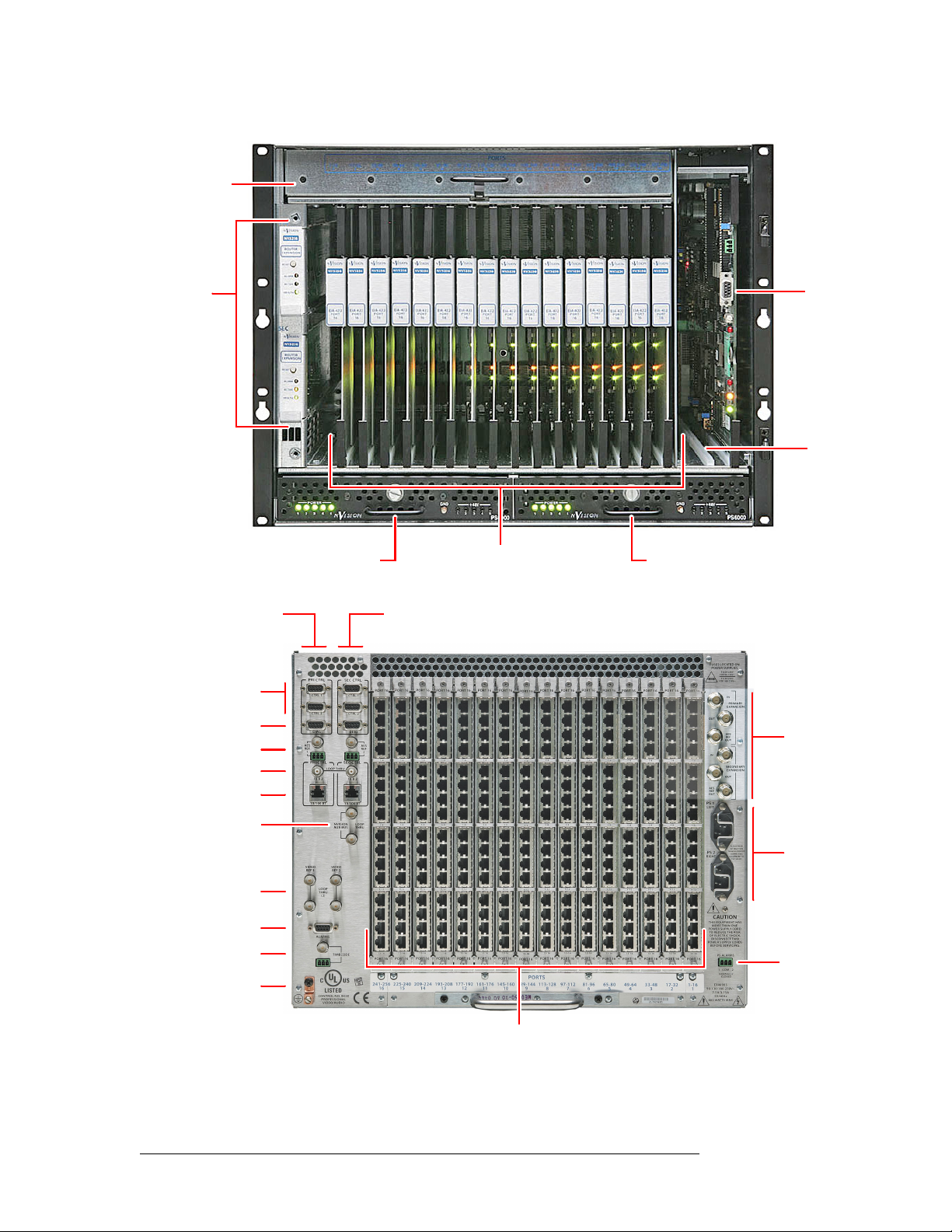

The following figures show the NV5256 features.

NV5256 Machine Control Router • User’s Guide 3

Page 12

2. Introduction

Overview

Fan Tray

Expansion

Cards (2)

Figure 2-1. NV5256, Front View

Primary Control

Card Ports

Serial Control

Diagnostic Ports

AES Ref.

Inter-Frame Conn.

Ethernet

Power Supply Module

Port s

Port I/O Cards (16)

Redundant Control

Card Ports

Router

Control

Card (diagn.

port)

Empty Control

Card Slot

Power Supply Module

Expansion

Ports

Aux Bus

Main Power

Video Ref.

System Alarms

(T.C. Ref.)

Ground Lug

Port I/O Backplanes (16)

Figure 2-2. NV5256, Rear View

Power Supply

Alarms

4 Rev 1.8 • 08 Jul 11

Page 13

2. Introduction

Overview

I/O Signals

I/O signals are serial (either RS-422 or RS-232) at up to 115.2 kBaud. Signals are bidirectional:

commands in one direction; responses in the other.

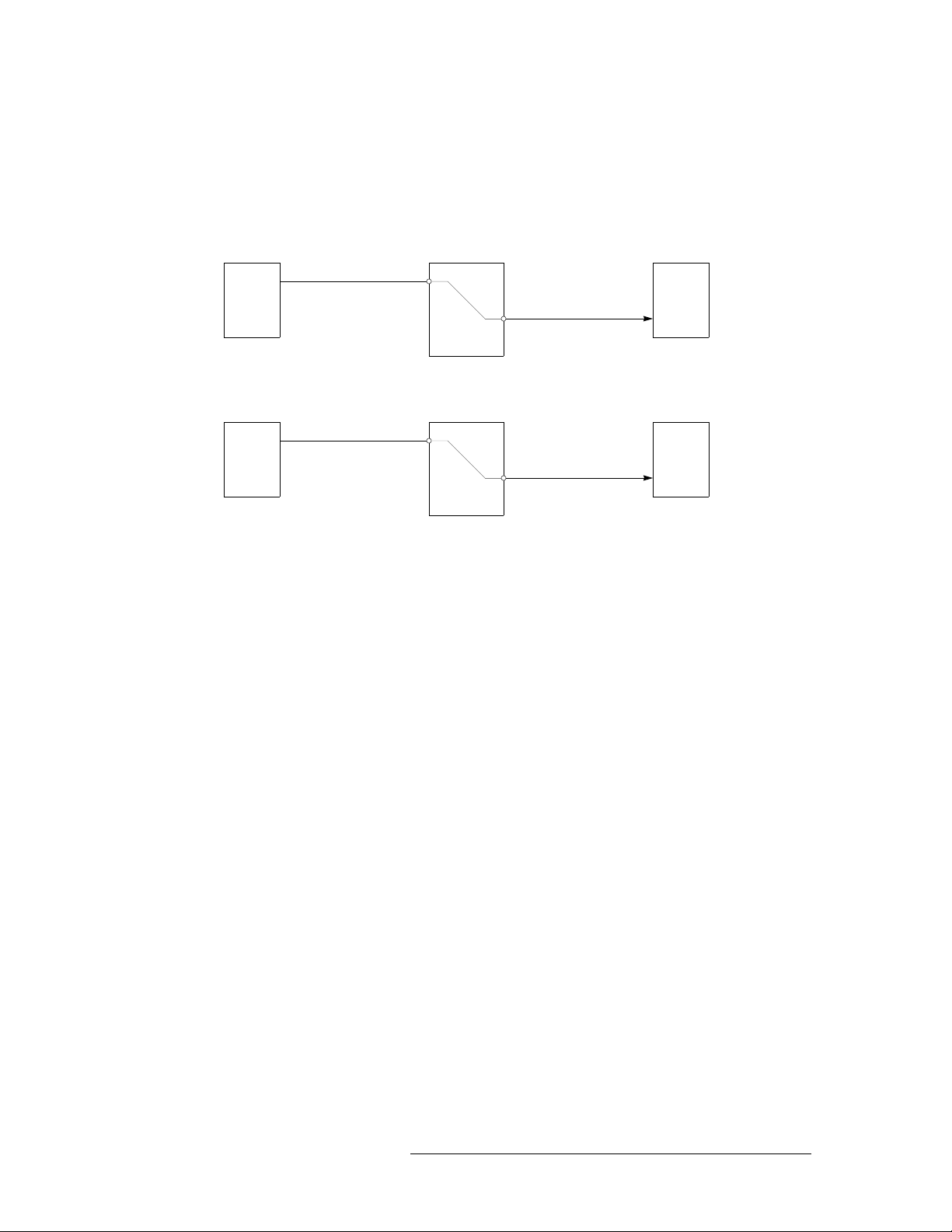

A port can be considered a “controlled” port or a “controlling” port.

Controlling device

NV5256

Controlled device

controlling

SRC DST

port

controlled

port

controlling

port

controlled

port

A destination can also be the controlling device:

port

NV5256

controlled

port

Controlling device

controlling

port

Controlled device

controlled

SRC DST

port

controlling

For example, a recording VTR sends signals from an edit list to various source machines in an edit

suite.

In most, if not all, cases a controlling device must communicate with a controlled device and not

another controlling device. (The reason is that a transmitter must connect to a receiver.)

S The Tx-to-Rx connection, of course, depends on the cable. Straight-through cables are consid-

ered preferable.

Router Configuration

The NV5256 router has several configurable options. It supports several signal options that can be

configured for each port.

The router can be (and must be) configured to operate according to your system constraints. You

will need to specify the size of the router matrix, the type of ports, communication parameters, and

so on.

Your router control system must also be configured. In an NV9000 router control system, you will

specify source and destination device names, router names, levels, level sets, and so on.

The NV5256 itself must be initialized through UniConfig.

Router Control

The NV5256 can be controlled by an NV9000 Router Control System. An NV9000 system controls

one or more routers of different types. Central to the system are the NV9000 servers. The NV9000

can include one or more control panels with which operators may perform routes through the

NV5256 and through other routers.

Alternatively, you can use a compatible third-party control system such as the SMS7000.

S Using an SMS7000 control system requires specially configured router control cards.

NV5256 Machine Control Router • User’s Guide 5

Page 14

2. Introduction

Overview

The NV5256 has these control connections:

Router Expansion

Two NV5256 frames can be connected to create an expanded router. Six expansion ports are at the

top right at the rear of the router. There are 6 BNC connections

Router Options

• Ethernet, from an NV9000 router/panel network (through a switch), to primary and redundant

control cards.

• Serial control from primary server and secondary server to primary and secondary control cards

(4 connections).

• Video reference (4 connections). Loop-through for main and redundant reference signal.

• AES reference. Two BNC and two STP connectors for each control card.

• “Node Bus” interface for SMS7000.

• System alarm outputs and power supply alarm outputs

— 3 coming in and 3 going out.

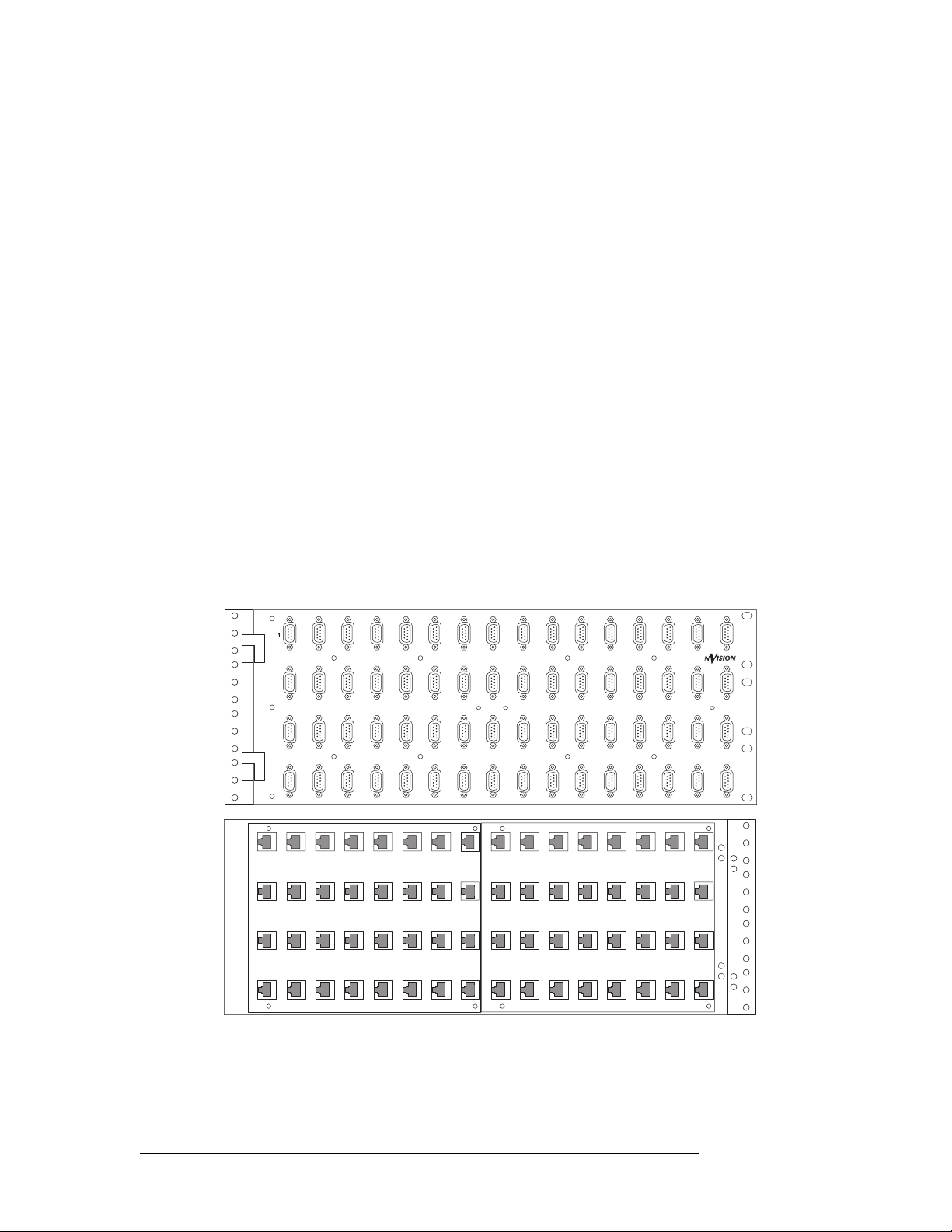

Breakout Panel

A 64-port breakout panel is available that has RJ-45 connectors on one side and DE9 (female) connectors on the other. This panel can make it easier to use DE9 connectors if you prefer them.

2 3 4 5 6 7 8 9 10 11 12 13

MACHINE CONTROL

BREAKOUT PANEL

17 18 19 20 21 22 23 24 25 26 27 28 29

33 34 35 36 37 38 39 40 41 42 43 44 45

49 50 51 52 53 54 55 56 57 58 59 60 61

BP-PORT-64

14 15 16

30 31 32

46 47 48

62 63 64

Front

Rear

The breakout panel is RS-422 only

S Older versions of the breakout panel might not function correctly.

6 Rev 1.8 • 08 Jul 11

Page 15

Functions

2. Introduction

Functions

SMS7000

If you are using an SMS7000 router control system, you will require an SMS7000 mezzanine card

installed on all router control cards.

The NV5256 router can be configured with partitions of 4 types. Each partition is considered a

physical level. The physical levels can be of 4 “signal types.” The signal types accommodate the

different characteristics of Miranda’s NVISION series routers and third-party routers.

Any of the router’s ports can be specified as one of 7 different types, generally configuring the port

as a controlling port, a controlled port, or a port whose type can be changed dynamically.

The port types accommodate (1) the different devices you might have in use and (2) the connection

requirements that differ between RS-422 and RS-232 ports.

The signal types and port types are specifiable as parameters in UniConfig. Those parameters, however, affect the behavior and operating characteristics of the router, which are discussed briefly

here.

See Chapter 4, Configuration

on page 27 for more information.

Signal Types

Four “signal types” are available:

Machine Control Forward Machine Control Broadcast

Machine Control Reverse DataXY

NV5256 physical levels in NV9000 router control systems always are “machine control forward.”

Third-party control systems are “machine control reverse.”

A controlling device sends commands to a controlled device. The controlled device passes

responses (such as status) back to the controlling device. A source device can be a controlling

device or a controlled device. A destination device can be a controlling device or a controlled

device.

When you are configuring some NV9000 control panels, you can create a “source is master” button

that toggles whether the source or the destination is the master (i.e., controlling device).

Some control panels have a broadcast button that allows one source to control multiple destination

devices. (“Source is master” is a requirement for machine control broadcast.)

Machine Control Forward

“Machine control forward” means that the source device is the controlling device.

Machine Control Reverse

“Machine control reverse” means that the destination device is the controlling device.

NV5256 Machine Control Router • User’s Guide 7

Page 16

2. Introduction

Functions

Machine Control Broadcast

This level type applies only to third-party router control systems. Use this level type if you have a

third-party control system and you want to be able to perform broadcast machine control takes.

DataXY

“DataXY” is a type of physical level on which data flow, much like video and audio signals in a

normal X/Y router. There is no concept of command and response on this type of level.

Port Types

Seven port types are available:

Controlling and Controlled

These port settings fix the direction of the router port to “controlling” or “controlled.” The port’s

connection for Tx and Rx is fixed. This allows the port to be routed as a source or destination while

maintaining, for example, Rx on pins 7 and 2 and Tx on pins 8 and 3.

Controlling DTE Master Dynamic

Controlled DCE Slave

S Pins for Tx on a controlling machine are 8 and 3. Tx pins for a controlled machine are 7 and 2.

S For more about machine control data, review the SMPTE 207M standard.

DTE

DTE has the same meaning for RS-232 as “controlling” does for RS-422.

DCE

DCE has the same meaning for RS-232 as “controlled” does for RS-422.

Dynamic

A dynamic port can be a controlling or controlled port depending on whether it is connected to a

master port or slave port. The port’s configuration is dynamic and can change during operation.

Dynamic ports are typically assigned to VTRs.

Master

Any dynamic port connected to a “master” port will be a controlled port.

The NV5256 applies logic to the port direction setting when a master port is connected to a

dynamic port. In this case, the machine at the dynamic port is always controlled and the machine at

the master port is always controlling.

A good example is an Avid editor controlling two VTRs.

Slave

“Slave” means the opposite of “master”: any dynamic port connected to a slave port will be a controlling port.

8 Rev 1.8 • 08 Jul 11

Page 17

2. Introduction

Installation

Summary

In general, a controlling machine must connect, through the router, to a controlled machine. That is

because Tx must connect to Rx and vice versa.

S In NV9000-SE Utilities, when you add the NV5256 router to your system, set ‘Signal Type’ to

‘Machine Control’. Also set both ‘Output Protect’ and ‘Output Lock’ to ‘In Server’.

S In NV9000-SE Utilities, when you configure a control panel, ‘semi-automatic’ is the preferred

setting for ‘XY data routing mode’. This is defined in the SE documentation:

“If the device to be acquired is already in use on the data level, alert the user

user to perform the route by pressing ‘Take’ a second time. If ‘Take’ is not pressed again,

the route is cancelled. If the device is not in use, the take occurs automatically. This is the

recommended mode.”

The alternatives are ‘fully automatic’ and ‘manual’.

S In NV9000-SE Utilities, you have the choice of making “source is master” the control panel

default or not.

— but allow the

Installation

The NV5256 is intended to mount in a standard 19-inch equipment rack. The frame is heavy

(approximately 100

lb, or 45 kg, fully loaded). Enlist the help of several persons during the mount-

ing process.

To help reduce weight, you can remove the power supplies and modules temporarily. Make note of

their location prior to removal. Do not drop or stack the modules.

To mount the equipment frame into a rack:

1 Swing the front door open all the way and then lift it up to remove it.

2 Lift the frame into the desired position within the rack. Have several helpers keep the frame in

position. Or use a jack.

3 Do not use the cards or other internal components as hand holds. Follow anti-static precautions

to protect the circuit boards. The handle on the bottom rear of the frame may be used for lifting

the frame.

4 Install rack screws into the 8 holes provided. It is important to use all 8 screw holes.

5 Replace any assemblies (power supplies, circuit cards) that you removed and replace the front

door.

The front rack-mounting brackets include keyway openings to accept an optional lifting bar. If you

wish, you can obtain a lifting bar by contacting your sales representative or Miranda Technical Support.

NV5256 Machine Control Router • User’s Guide 9

Page 18

2. Introduction

Installation

Mounting

Slot (8 places)

Keyway Slot

(4 places)

Power Supply 1 Power Supply 2

S Warni ng: Make certain that your work area is free of unnecessary objects that block personnel

Rear handle

movement or that might interfere with their footing. Careless handling of the NV5256 frame

could result in personal injury.

S Warni ng: Disconnect power, if it is connected, before mounting the frame in the rack.

S Warni ng: The NV5256 draws cooling air from the front through the door and exhausts it at the

top rear edge of the frame. Make certain that airflow is not blocked at these locations. If air flow

is restricted, overheating may occur. The frame must have its door installed and closed for

proper airflow through the chassis. Filters are located on the inside of the door assembly and

should be maintained regularly.

S Rear panel cover plates (placed in backplane slots that have no backplanes) are essential for

cooling. Although you can remove them temporarily, make sure that unused backplane slots

have cover plates during normal operation.

10 Rev 1.8 • 08 Jul 11

Page 19

3. Detail

Chapter 3 describes the structure and use of the NV5256 Machine Control Router. It presents the

following topics:

Connections

The rear of the router has a bay that holds up to 16 I/O backplanes. Unused backplane slots are generally covered with a plate that improves cooling air flow. Each backplane has 16 RJ-45 connectors. All the backplanes are identical, but the I/O cards are of two types: RS-422 and RS-232.

S Ports on a single card are either all RS-422 or all RS-232.

To the left of the backplanes are a variety of control connectors and reference connectors. To the

right of the backplanes are expansion connectors and power connectors.

• Connections

• Alarms

• Power

• I/O Cables

• Port Cards

• Expansion

• Terminators

• Jumpers

NV5256 Machine Control Router • User’s Guide 11

Page 20

3. Detail

R

1

5

Connections

Control Ports

At the top left portion of the rear of the NV5256 frame are 6 DE9 connectors, and further below

that are 2 Ethernet connectors:

for Primary

Control Card

for Secondary

Control Card

CTRL 1

CTRL 2

Diagnostic

Ethernet

PRI CTRL

AES

REF

1

PRI CTRL

10/100 BT

CTRL 1

CTRL 2

DIAG

LOOPTHRU

NVISION

SEC CTRL

CTRL 1

CTRL 2

DIAG

SEC CTRL

10 B 210 B 2

10/100 BT

LOOP

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

AES

REF

2

1-4

1-4

5-8

5-8

1-4

1-4

5-8

5-8

1-4

1-4

5-8

5-8

1-4

1-4

5-8

5-8

1-4

1-4

5-8

5-8

S A secondary (router) control card is for redundancy and is not required. If you have an

expanded system (two router frames), make connections only to one frame. The frame to which

you make connections is the “master” frame and it controls the second frame.

Serial Control

The CTRL1 and CTRL2 ports are DE9, female, RS-422. See Control Port Connectors, page 43, for

their pinout information.

PO

You can use these connectors for control using a serial protocol from (1) a primary or secondary

NV9000 router control system, (2) a primary or secondary third-party router control system, or (4)

a router automation system.

Cases:

1 If you are using an NV9000 control system with a serial protocol or if you are using a third-

party control system, connect the primary CTRL1 port to a COM port on the control system’s

server. Similarly connect the secondary CTRL1 port if your router has a secondary control card.

2 If you have a redundant server, connect the primary CTRL2 port to a COM port on the redun-

dant server. Similarly connect the secondary CTRL2 port if your router has a secondary control

card.

3 If you do not have a redundant server, but have an automation system, connect the primary

CTRL2 port to a COM port of the automation system. Similarly connect the secondary CTRL2

port if your router has a secondary control card.

12 Rev 1.8 • 08 Jul 11

Page 21

3. Detail

Connections

Ethernet Control

The Ethernet connectors are used when you have an NV9000 connected using an Ethernet protocol.

Cases:

1 If you are using an NV9000 control system with an Ethernet protocol, connect the primary

Ethernet port to the “Router/Panel” network switch connected to the NV9000 server. Similarly

connect the secondary Ethernet port if your router has a secondary control card.

2 If you have a redundant server, then no router connections are required, but the redundant

server should be connected to the “Router/Panel” network switch.

3 If you have an automation system, connect a COM port of the automation system to either pri-

mary serial port, CTRL1 or CTRL2. Similarly connect a COM port to either secondary serial

port if your router has a secondary control card.

The server’s COM ports must be set up to be compatible with the router’s serial ports— the same

Baud rate, parity settings and so on.

An automation system’s COM ports must also be compatible with the router’s serial ports.

Diagnostic Ports

The DIAG ports are DE9, female, RS-232 or RS-422. See Control Port Connectors, page 43, for

their pinout information.

AES Ref,

BNC

AES Ref,

Phoenix

These ports are for configuration, firmware uploads, and testing. The ports are typically used with

UniConfig to initialize either the primary control card or the secondary control card.

The DIAG ports are not used during normal operation.

See Chapter 4, Configuration

, on page 27, for information about UniConfig and its use.

AES Reference

AES reference is used to “clock-lock” the data traffic between two frames in an expanded router. If

you have a stand-alone router, you do not need AES reference.

If you do have an expanded router, choose one of the following 2 methods:

1 Supply an AES reference to the primary control card of both frames. You can use either connec-

tor. If you have a secondary control card, supply an AES reference to that also.

Use the connectors at the top left portion at the rear of the NV5256 frame:

for Primary

Control Card

AES

REF

1

CTRL 2

DIAG

PRI CTRL

LOOPTHRU

SEC CTRL

See AES Reference Connectors

CTRL 2

DIAG

for Secondary

Control Card

AES

REF

2

on page 43 for the Phoenix pinouts.

1-41-41-41-41-41-41-41-41-41-4

2 Connect the primary AES reference output on the master frame to the primary AES reference

input of the slave frame. If you have redundant expansion cards, connect the redundant AES

reference output of the master frame to the redundant AES reference input of the slave frame.

NV5256 Machine Control Router • User’s Guide 13

Page 22

3. Detail

R

Connections

PORT 16

PORT 16

Use the connectors at the top right portion at the rear of the NV5256 frame:

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

OUT

IN

PRIMARY

EXPANSION

AES

REF

OUT

IN

1-4

1-4

1-4

1-4

1-4

1-4

1-4

1-4

1-4

1-4

1-4

1-4

SECONDARY

EXPANSION

OUT

AES

REF

OUT

PS 1

See Expansion

on page 24 for additional information.

AES reference

(primary)

AES reference

(secondary)

(The video reference does not lock the cards.)

If the frames in an expanded router are not clock-locked, data errors will occur when the router uses

ports across frame boundaries.

Inter-Frame Communication

At the top left portion of the rear of the NV5256 frame are two 10Base2 (BNC) connectors:

for Primary

Control Card

PRI CTRL

CTRL 1

SEC CTRL

CTRL 1

for Secondary

Control Card

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

PO

10Base2

AES

REF

1

CTRL 2

DIAG

PRI CTRL

10/100 BT

LOOPTHRU

CTRL 2

DIAG

SEC CTRL

10 B 210 B 2

10/100 BT

AES

REF

2

1-4

1-4

1-4

1-4

1-4

1-4

1-4

1-4

1-4

1-4

The 10Base2 connectors are used to connect two frames in an expanded router. If you have a standalone router, you do not need the connectors.

If you have an expanded router, connect the primary 10Base2 connector on one frame to the primary 10Base2 connector on the other.

Do not connect the secondary 10Base2 connectors, even if you have a secondary control card.

14 Rev 1.8 • 08 Jul 11

1

Page 23

3. Detail

1

Connections

S In older routers, stand-alone termination is required. In newer routers, it is not. In an older sys-

tem, place 50Ω terminators on both connectors.

In any expanded router, place 50Ω terminators on unused 10Base2 connectors.

Aux Bus

At the middle left portion of the rear of the NV5256 frame are 2 ‘NVISION Aux Bus’ (BNC) connectors:

Aux Bus

Video

Reference

10/100 BT

NVISION

AUX BUS

10/100 BT

LOOP

THRU

If you are using an SMS7000 router control system with the NV5256, connect the SMS7000 to the

NVISION Aux Bus (a.k.a. Node Bus) connector.

The NV5256 has two aux bus connections. The connection is loop-through: you can pass the

SMS7000 “node bus” control signals on to another device if it is required. You can connect a

redundant control system on the “node bus.”

If you are using an SMS7000 control system, terminate the “node bus” with 75Ω terminators.

S Using an SMS7000 requires an SMS7000 mezzanine card installed on each router control card.

Jumpers J4 and J6 must be set. See Jumpers

, page 26, for detail.

Video Reference

At the lower left portion of the rear of the NV5256 frame are 4 Video Reference (BNC) connectors:

VIDEO

REF 1

LOOP

THRU

(2)

VIDEO

REF 2

9-129-129-129-129-129-129-129-129-129-12

5-5-85-85-85-85-85-85-85-85-85-8

9-

The NV5256 provides video reference connections ‘VIDEO REF 1’ and ‘VIDEO REF 2’. These

connections allow you to synchronize port switches with a video frame’s switch point. The video

reference can be NTSC, PAL, or tri-level sync.

S Tri-level sync is not supported on older EM0374 control cards.

At least one video reference connection must be connected. Otherwise, the control card’s front red

LED remains lit and takes will not occur at defined switch points.

Redundant Reference

There are two video reference connections. You can use the reference connectors in 2 ways:

• Single reference.

• Redundant reference.

NV5256 Machine Control Router • User’s Guide 15

Page 24

3. Detail

-

6

T

T

Alarms

Time-Code

Reference

A redundant reference uses identical, but distinct, reference signals. If one reference source

fails, the other acts as a fail-over.

S The NV5256 does not support “dual reference” mode.

If you have an expanded router, use the loop-through connector to connect the master and slave

frames. Terminate any reference chains with 75Ω terminators.

Time Code Reference

At the lower left portion of the rear of the NV5256 frame are 2 connectors for time-code reference:

ALARMS

13-16

13-16

13-16

13-16

13-16

13-16

13-16

13-16

13-16

TIMECODE

13-16

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

POR

13-

Alarms

Alarm

Connector

241-256

16

225-240

15

209-224

14

193-208

13

177-192

12

161-176

11

145-160

10

129-144

113-128897-112781

9

The NV5256 does not use time-code reference. You can ignore these connectors.

Two alarm connectors (system, and power-supply) allow you to construct alarm indicator circuits

of your own.

System Alarm Outputs

At the lower left portion of the rear of the frame is a female DE9 connector for system alarms:

ALARMS

13-16

13-16

13-16

13-16

13-16

13-16

13-16

13-16

13-16

PORTS

TIMECODE

This connector allows you to create alarm circuits of your own.

The internal alarm signalling is provided by solid-state relays that turn on in the event of an alarm

condition. Table 3-1 describes the individual alarm connections:

13-16

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

POR

13-

Table 3-1. Alarm Signals

Pin Signal Description Possible Alarm Condition(s)

1, 9 Alarm Com Common Common connection for all alarm signalling pins. This is a

“return” for an external circuit.

2 Alarm 1 Major alarm Missing reference inputs, possible failure of fans or over-

temperature conditions on one or more modules.

3 Alarm 2 Minor alarm Any of alarms conditions 3, 4, 5 or 6.

4 Alarm 3 Power supply Main power supply module is missing.

5 Alarm 4 Video reference Missing video reference signal 1 or 2 (if applicable).

16 Rev 1.8 • 08 Jul 11

Page 25

3. Detail

Alarms

Table 3-1. Alarm Signals

Pin Signal Description Possible Alarm Condition(s)

6 Alarm 5 AES or time code

reference

7 Alarm 6 Fans or internal

Temperature

8 Alarm 7 Controller health Control card(s) are not “healthy.”

S Pins 2 through 8 signal alarm conditions that are signalled on either the primary or secondary

control cards. The connector offers no way to distinguish which control card has an alarm.

Figures 3-1 and 3-2 show sample system-level alarm circuits. (You can use alarm signalling

devices other than LEDs, or in addition to LEDs.)

Missing AES reference signals or loss of system clock. (AES

is optional. Note: AES does not generate alarm in standalone

case.)

Failure of any one of three fans. Over-temperature conditions

on one or more modules.

External Power

1

Internal alarm signals normally

clear, controlled by software

COM

Figure 3-1. Simple Alarm Circuit

30VDC max, 150mA max

Normally off, the LEDs

turn on to indicate failure

Here, LEDs are all off unless a failure occurs. The LED for the failed circuit turns on.

This is an alarm circuit that can drive heavier loads, not just LEDs.

Customer-supplied relay

contacts NC, (but open during

alarm condition)

External Power,

30VDC max, 150mA max

Normally on, the LEDs turn

off to indicate failure

1

Internal alarm signals normally

clear, controlled by software

COM

Figure 3-2. Alarm Circuit to Drive Loads

In this case, the LEDs are normally on and turn off when a failure occurs.

CAUTION: If the alarm load is inductive, protect the internal alarm relay contacts with a reversedbiased diode. The external supply voltage should not exceed ±30VDC and the load resistors should

be sized to limit contact current to less than 150mA.

NV5256 Machine Control Router • User’s Guide 17

Page 26

3. Detail

TO REDUCE THE RISK

9

Power

13-16

PORT 16

PORT 166

2

161-176

11

145-160

Power Supply Alarms

At the lower right portion of the rear of the NV5256 frame is a Phoenix 3-pin connector for power

supply alarms:

OF ELECTRIC SHOCK,

DISCONNECTT WO

POWER SUPPLYCORDS

BEFORE SERVICING.

13-16

13-16

13-16

13-16

13-16

13-16

13-16

13-16

13-16

13-16

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

PORTS

113-128897-112781-96

129-144

10

9

6

65-80549-64

4

33-48317-32

1-16

1

2

The NV5256 has alarm outputs for each power supply installed in the frame. An internal solid-state

relay is provided for each supply. The relay turns on when there is an alarm condition.

Figure 3-3 shows suggested alarm circuit implementations. You can use signalling devices other

than LEDs or in addition to LEDs. For example, you can operate a buzzer or other audible alarm to

warn operators of a potential problem.

PS ALARMS

12COM

NORMALLY

CLOSED

E146905

90-130/180-250V~

7.5A/3.75A

50/60Hz

660 WATTS MAX

PS Alarm

Connector

Power

30VDC max, 150mA max

External Power

Normally off, the

LEDs turn on to

indicate failure

Internal alarm signals

normally clear, controlled

by software

12

COM

Extermal Power,

30VDC max, 150mA max

Customer-supplied relay

contacts NC (and closed

during normal operation)

Normally on, the

LEDs turn off to

indicate failure

Internal alarm signals

normally clear, controlled

12

by software

Figure 3-3. Power Supply Alarms

CAUTION: The voltage of the external power supply for alarm signalling should not exceed

±30VDC. Resistors should be sized to limit the current through each internal alarm contact to less

than 150mA.

If the load is inductive, the alarm contacts should be protected with a parallel, reverse-biased diode.

The NV5256 has two power supply bays (and two power connectors) to support redundancy. Only

one power supply is actually required.

18 Rev 1.8 • 08 Jul 11

Page 27

3. Detail

REF

9

Power

Connectors

At the middle right portion of the rear of the NV5256 frame are 2 AC connectors:

OUT

PS 1

LEFT

5-8

5-8

5-8

5-8

5-8

5-8

5-8

5-8

5-8

5-8

5-8

5-8

PLEASE READ

INSTRUCTION

MANUAL BEFORE

PS 2

CONNECTING

EQUIPMENTTO

RIGHT

9-12

9-12

9-12

9-12

9-12

9-12

9-12

9-12

9-12

9-12

9-12

-12

THE MAINS

The NV5256 frame has one (IEC) 3-conductor power connection for each of its 2 power supplies.

These should be connected to a 90–130VAC or 180–250VAC 15A grounded circuit wired in accordance with local electrical codes.

Fuses for both AC power inputs are located on their respective power supplies. Ensure that the fuse

ratings comply with specific requirements in your area. A 7.5A fuse is required for 110/120VAC

applications. For 220/240VAC operation, a 3.75A fuse is required.

AC connector

for PS 1

AC connector

for PS 2

For increased protection against loss of power, we suggest that each power supply be connected to

a separate branch circuit. A wire bail can be used to grip the power cable and hold it in place to

reduce the possibility of accidental loss of power.

The power cords represent the only means of disconnecting main power from the NV5256. Make

sure to clearly mark the line side power connection with its function so that in the event of an emergency, power can be disconnected quickly. Make sure to disconnect both power cords before servicing any internal frame components.

Power Supply

The PS61001 power supply accepts a wide range of AC input voltages and produces five +48 VDC

outputs. Each of the five circuits producing the +48 volt outputs is identical. The power supply

automatically senses the AC input voltage (90–130VAC or 180–250VAC) and adjusts itself to

maintain a relatively constant DC output. You do not have to select the voltage. The five regulated

outputs are directed to the various regulators that produce the DC voltages required by the local circuits.

Each +48VDC output powers one of the five green LEDs and output test points on the front of the

power supply. Under normal operation, all five LEDs should be on. If any is not, it is likely that the

corresponding branch circuit has failed. When the power supply output voltages are measured at

the test points, the voltage should be approximately +48 VDC under a full load. If modules have

been removed from the frame or options are not installed, some or all of the test point voltages

could be somewhat higher than +48 VDC.

1. Older master control frames in the field might still use PS6000 power supplies.

NV5256 Machine Control Router • User’s Guide 19

Page 28

3. Detail

-

6

13

T

13 16

13 16

13 16

13 16

13 16

13 16

13 16

13 16

13 16

13 16

Power

There are four low-speed fans located at the front edge of the power supply. They pull a small quantity of air across the internal heat sinks.

The top power connector on the rear panel corresponds to the power supply on the left and the bottom connector corresponds to the power supply on the right (as you face the front of the frame).

Ground Lug

Ground Lug

PORT 16

RT 16

1-4

At the lower left portion of the rear of the NV5256 frame is a ground lug:

TIMECODE

CONTROL NO. 9K50

PROFESSIONAL

VIDEO/AUDIO

PORT 16

241-256

16

PORT 16

225-240

15

PORT 16

209-224

14

PORT 16

193-208

13

PORT 16

177-192

12

PORT 16

161-176

11

PORT 16

145-160

10

PORT 16

PORTS

129-144

113-128897-112781

9

PORT 16

PORT 16

POR

Connect this “lug” to earth ground using 8–14 AWG wire.

Expansion Connectors

At the top right portion of the rear of the NV5256 frame are 6 Expansion (BNC) connectors:

FUSES LOCATED ON

POWER SUPPLIES

T 8.0A 250V

FOR 90-130V~

T 6.3A 250V

FOR 180-250V~

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

PORT 16

1-4

1-4

1-4

1-4

1-4

1-4

1-4

1-4

1-4

1-4

1-4

PS 1

LEFT

IN

PRIMARY

EXPANSION

OUT

AES

REF

OUT

IN

SECONDARY

EXPANSION

OUT

AES

REF

OUT

Expansion

Connector

See Expansion

on page 24.

20 Rev 1.8 • 08 Jul 11

Page 29

I/O Cables

3. Detail

I/O Cables

All ports are serial, either RS-422 or RS-232, operating at up to 115.2kBaud. The backplane interface is RJ-45. Each RJ-45 port on each port backplane has the following pinout:

1 Gnd

Controlling

Port

1

8

2 n.c.

3

4

5

6

7 Gnd

8 Gnd

Tx +

Rx

Rx +

Tx

It use 4 wires whose usage is controlled by the following circuit. The port can be configured as

“controlling” or “controlled” when the port’s I/O card is RS-422/485 and DTE or DCE when the

port’s I/O card is RS-232. That is because the definition of the port can be reversed during configuration or during operation. This is the circuit:

Controlled

Port

Rx +

Tx

Tx +

Rx

input data

output data

Select Input = A Ena

A Ena

A

B

A Ena

+

Rx

Tx

+

Rx

Tx

RJ-45

3

A

6

5

B

4

When Tx A is enabled (A Ena), Rx B

is selected and the port passes Rx B

data;

Tx B is enabled when Tx A is disabled

(A Ena

passes Rx A data.

These are the functions of the pins:

RS-422 RS-232

Pin

Controlling Controlled DTE DCE

3 Tx+ Rx+ Tx Rx

4 Rx– Tx– n.c. n.c.

5 Rx+ Tx+ Rx Tx

6 Tx– Rx– n.c. n.c.

(The other pins are grounded except for pin 2 which is not connected.)

Breakout Panel

). Rx A is selected, and the port

If you are using the BP-PORT-64 breakout panel, you might need to know the mapping of the signals from the RJ-45 side to the 9-pin (female) side. The breakout panel is RS-422/485 only. See

Breakout Panel

NV5256 Machine Control Router • User’s Guide 21

on page 6 for an illustration.

Page 30

3. Detail

I/O Cables

This is the RJ-45 to DE9 mapping for RS-422:

RJ-45 DE9

1

2

to NV5256 backplane to your device

1

8

3

4

5

6

7

8

1

2

3

4

5

6

7

8

9

1 Gnd

2 n.c.

3

4

5

6

7 Gnd

8 Gnd

This cable wiring is applicable whether the port is a controlling port or controlled port.

S Older breakout panels might have incorrect wiring. Contact Miranda if your breakout panel

does not function correctly.

1

6

9

5

RS-232 Cables

If you make your own RS-232 cables, follow this pattern:

RJ-45 DE9

1

2

to NV5256 backplane to your device

1

8

3

4

5

6

7

8

1

2

3

4

5

6

7

8

9

1 Gnd

2 n.c.

3

4 n.c.

5

6 n.c.

7 Gnd

8 Gnd

This cable wiring is applicable whether the port is DTE or DCE.

(Note: Use either pin 7 or pin 8 of the RJ-45 for ground. It is not necessary to use both.)

General Notes

1

6

9

5

Any DE9-to-DE9 cables you might use will be straight-through.

22 Rev 1.8 • 08 Jul 11

Page 31

Port Cards

3. Detail

Port Cards

The NV5256 has slots for 16 port I/O cards. Each card supports 16 inputs from its corresponding

backplane. There are two types of port cards:

• The EM0503-01 module, supporting RS-422/485.

• The EM0503-50 module, supporting RS-232.

Other than this distinction, the cards are functionally identical. You can install any port card in any

slot that is useful to your system design.

S The NV5128 frame and its I/O cards are nearly identical in appearance to the NV5256 frame

and its I/O cards. Therefore, the NV5256 cards and slots are keyed so that you cannot successfully insert an NV5128 card into the NV5256 frame.

LEDs

Five LEDs are on the front of the card. (Note that there is metal card extender in front of the card.

The LEDs are nevertheless visible.) There names and functionality are as follows:

Name Color Function

Alarm Red A power rail is under voltage by 10% or more.

Power Green The power rails are good.

FGPA Loaded Yellow The FPGA has loaded properly.

COM Good Green Communication with the router control card is good.

COM Bad Red Communication with the router control card is bad.

The LEDs are listed in the order they appear at the front of the card.

Under normal operation, the ‘Power’ light is green, the ‘FPGA loaded’ light is yellow, and the

‘COM good’ light is green. The other lights are off.

Another LED

frame’s expansion link is invalid. This LED is red. It lights when the frame’s expansion cards are

absent or when the frame receives errors from the expansion card. In a stand-alone router, this LED

will be on.

— serial link error — exists in the center of the board. This LED indicates whether the

NV5256 Machine Control Router • User’s Guide 23

Page 32

3. Detail

PS 1

PRIMARY

EXPANSION

SECONDARY

EXPANSION

IN

OUT

AES

REF

OUT

IN

AES

REF

OUT

OUT

Expansion

Expansion

The NV5256 can be expanded to a maximum of 512 ports. To accomplish this, interconnect two

NV5256 frames. The frames share each other’s input space. The first frame receives commands

from the router control system and acts as the master to the second frame.

The interconnect is simple and uses the frame expansion connectors at the back of the frame.

NV5256, SlaveNV5256,Master

Ports 1256 Ports 257512

Exp. In

Exp. Out

Primary

AES Ref

Exp. In

Secondary

Pri. AES Ref In

Sec. AES Ref In

10/100BaseT

Exp. Out

AES Ref

10Base2NV9000

Belden

8281

50W coax

Exp. In

Exp. Out

AES Ref

Exp. In

Exp. Out

AES Ref

Pri. AES Ref

Sec. AES Ref

10Base2

Primary

Secondary

Figure 3-4. Expansion Connectors and Expansion Connections

The frame expansion connectors are driven by the frame expansion cards (EM0502-00) in the

frame. A frame really requires only one expansion card; the second is recommended for redundancy. If both cards and links are installed, the frame will switch from one expansion link to the

other if the current link goes bad.

A frame expansion card multiplexes (TDM) the local frames inputs and sends them out the frame

expansion “Out” port to the other frame. It receives the other frame’s inputs from the “In” port.

Connect the primary input on the master frame to the slave frame’s primary output. Connect the

primary output on the master frame to the primary input on the slave frame. If you have a redundant

expansion card, connect the secondary expansion connections the same as the primary connections.

The expansion cards have built-in redundancy control. Each card reports its own health to the other

card and to the router control card. The first healthy card to start up during initial boot takes over

the expansion link and is the main transmitter and receiver. If, at any time, the link becomes

“unhealthy,” the other expansion card takes over the expansion link if it is healthy.

You can use 75Ω Belden 8281 cable, up to 250 meters, to make these connections.

The Expansion Card

The NV5256 has 2 slots for expansion cards. A stand-alone router requires no expansion card. One

card is required for expansion. The second expansion card provides redundancy.

Release Switch

An expansion card has a front panel reset switch. It forces the active card to release, so that the

24 Rev 1.8 • 08 Jul 11

other expansion card can take over.

Page 33

3. Detail

Terminators

LEDs

Three leds are on the front of the card. Their name and functionality are as follows:

Name Function

Alarm Indicates when the serial link is not error-free or the P.S. is bad.

Active Indicates the card is healthy and supplying the Frame TDM stream to the frame.

Health Indicates Good power, Good Serial link, FPGA loaded

A red ‘serial link error’ LED is in the center of the card. This LED indicates whether the frame

TDM link is invalid (has data bit errors).

Clock Lock

For the expanded router to operate correctly, the frames must be “clock-locked” to each other. The

following is a list of ways to accomplish the clock locked frames.

1 Supply an AES reference to both frames.

2 Connect the primary AES reference output on the master frame to the primary AES reference

input of the slave frame. If you have a redundant expansion card, connect the secondary AES

reference output of the master frame to the second AES reference input of the slave frame.

The video reference does not lock the cards.

If the frames are not clock-locked, data errors will occur when the router uses ports across video

frame boundaries.

Inter-Frame Communication

The expansion connections transport machine control data.

Additionally, the two frames must communicate with each other. Connect one 10Base2 connector

on the master frame, with 50Ω coaxial cable, to a 10Base2 connector on the slave frame. Place a

50Ω terminator on each unused 10Base2 connector.

Terminators

10Base2

The NV5256 ships with two 50Ω terminators for each frame. The terminators are required for an

expanded router.

S In older routers, termination for a stand-alone router is required. In newer routers, it is not.

If you have an expanded router, use terminators as described under Inter-Frame Communication

.

Ethernet

The NV5256 ships with 1 Ethernet terminator for each router control card. These terminators are

required if you do not use Ethernet (for example, if you are using a third-party router control sys-

NV5256 Machine Control Router • User’s Guide 25

Page 34

3. Detail

Jumpers

Jumpers

tem). The router control cards will not come out of reset without either an Ethernet connection or

an Ethernet terminator.

(The terminator looks like an RJ-45 plug without the cable.)

Plug a terminator into the Ethernet port of every router control card that does not use Ethernet.

The control card has several jumper sets:

ON

J29

GND

CONSOLE

DIAG

JUMPER

OFF

J28

Rx

Tx

SICK

LED7

ACTIVE

LED8

HEALTH

LED9

SMS7000

U190

SBUS

J1

TXDRXD

10B2

SBUS

J2

10B2

SBUS

J1

TXDRXD

10B2

SBUS

J2

10B2

SMS7

SBUS

J4

SMS7

SBUS

J6

TIME CODE

110

75

J12

HI Z

SMS7

SBUS

J4

SMS7

SBUS

J6

J13

AESREF2

J16

AESREF1

Mezzanine Card

(Optional)

PC043602

J13

AESREF2

J16

AESREF1

Set impedance jumpers (J12, J13, J16) as follows:

For Phoenix 110W, place both jumpers on the upper 4 pins.

For BNC 75W place both jumpers on the middle 4 pins.

For Phoenix Hi-Z, place both jumpers on the bottom 4 pins.

For BNC Hi-Z, set the left jumper on the bottom 2 pins and

set the right jumper on the middle 2 pins

Figure 3-5. EM0374 Router Control Card Jumpers

Table 3-2 describes the jumpers appropriate to the NV5256. Jumpers not listed should be left in the

factory position:

Table 3-2. EM0374 Jumpers

Jumper Settings

J1, J2 Frame-to-frame communication. Leave these jumpers in the 10B2 position. The control card

(and therefore the NV5256) does not support SBus yet.

J4, J6 SMS7000 option. Place the jumpers in the SMS7 position to use a SMS7000 control system

and the Node Bus connectors. Otherwise, leave the jumpers in the SBus position. (SBus is not

supported.)

Note: Using an SMS7000 requires an SMS7000 mezzanine card to be installed.

J13, J16 AES reference termination options. See Figure 3-5 for jumper settings.

26 Rev 1.8 • 08 Jul 11

Page 35

4. Configuration

Chapter 4 describes the structure and use of the NV5256 Machine Control Router. It presents the

following topics:

Summary

• Summary

• UniConfig—Stage 1

• UniConfig—Stage 2

There are several phases to configuring an NV5256 router.

1 Use UniConfig (first) to define its network address and (second) to define its basic partitions

and specify its port types.

2 Then, use the NV9000 “browser” application or NV9000-SE Utilities to define its device con-

nections and “add” the router to the router control system.

We discuss UniConfig briefly. Refer to the NV9000 User’s Guide and the NV9000-SE Utilities

documentation for additional information.

UniConfig runs on a PC that you will connect to your router control card. In all cases, to launch

UniConfig, do either of the following:

1 Double-click UniConfig.exe in the software folder. The default pathname is:

C:\nvision\utils\UniConfig.exe

2 Double-click a UniConfig icon on your desktop:

UniConfig— Stage 1

You must assign IP addresses to the NV5256’s router control card(s) before you proceed with other