Page 1

KAM-XM-SERIES

KAM-XM-UDC/UPC/UNC/DNC MODULES

Instruction Manual

SOFTWARE VERSION 1.4.1

071833002

AUGUST 2005

Page 2

Contacting Grass Valley

Region Voice Fax Address Web Site

North America (800) 547-8949

Support: 530-478-4148

Pacific Operations +852-2585-6688

Support: 852-2585-6579

U.K., Asia, Middle East +44 1753 218 777 +44 1753 218 757

France +33 1 45 29 73 00

Germany, Europe +49 6150 104 782 +49 6150 104 223

Copyright © Thomson Broadcast and Media Solutions All rights reserved.

Grass Valley Web Site

Sales: (530) 478-3347

Support: (530) 478-3181

+852-2802-2996

Grass Valley

P.O. Box 599000

Nevada City, CA 959597900 USA

www.thomsongrassvalley.com

The www

Online User Documentation

.thomsongrassvalley.com web site offers the following:

— Current versions of product catalogs, brochures,

data sheets, ordering guides, planning guides, manuals, and release notes

in .pdf format can be downloaded.

FAQ Database

— Solutions to problems and troubleshooting efforts can be

found by searching our Frequently Asked Questions (FAQ) database.

Software Downloads

— Software updates, drivers, and patches can be down-

loaded.

2 KAM-XM-SERIES Instruction Manual

Page 3

Contents

Preface

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

KAM-XM Series

Up/Down Conversion Modules

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Module Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Supported Up/Down Conversion Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Quick Start Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Module Placement in the 2000 Frame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

KAM-XM-R Rear Module Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

GPI0 Connections for GPI Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Power Up and Module Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Configuration and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Configuration Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Up and Down Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Format Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Aspect Ratio Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Proc Amp Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Detail Enhance Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Noise Reduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Spike Filtering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Brickwall Filtering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Temporal Recursive Filtering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Color Legalizer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

GPI and E-MEM Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Configuration Summary Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Newton Control Panel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Web Browser Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Web Page Operations and Functional Elements. . . . . . . . . . . . . . . . . . . . . . . . . . 36

Links and Web Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Status Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

License Web Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Setup Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Format Web Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Aspect Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Proc Amp Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Detail Enhance Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Spike Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Brickwall Web Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

KAM-XM-SERIES Instruction Manual 3

Page 4

Contents

Temporal Recursive Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Mosquito Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Advanced Aperture Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Color Legalizer Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Grain Insertion Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

GPI Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

E-MEM Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Slot Config Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Software Update Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Power-up Diagnostics Failure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Module Repair. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Index

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

4 KAM-XM-SERIES Instruction Manual

Page 5

Preface

About This Manual

This manual describes the features of a specific 2000 Series module in the

Kameleon Media Processing System. As part of this module family, it is

subject to Safety and Regulatory Compliance described in the 2000 Series

frame and power supply documentation (see the 2000 Series Frames Instruc-

tion Manual

).

KAM-XM-SERIES Instruction Manual 5

Page 6

Preface

6 KAM-XM-SERIES Instruction Manual

Page 7

KAM-XM Series Up/Down Conversion Modules

Introduction

This manual covers installation, configuration and operation of the following Kameleon KAM-XM Series modules:

• KAM-XM-UDC – HDTV Up/Down Converter

• KAM-XM-UPC – HDTV High Quality Up Converter

• KAM-XM-UNC – HDTV Up Converter with Advanced SDTV Noise

Reduction

• KAM-XM-DNC – HDTV Down Converter

Module functionality is summarized in Table 1.

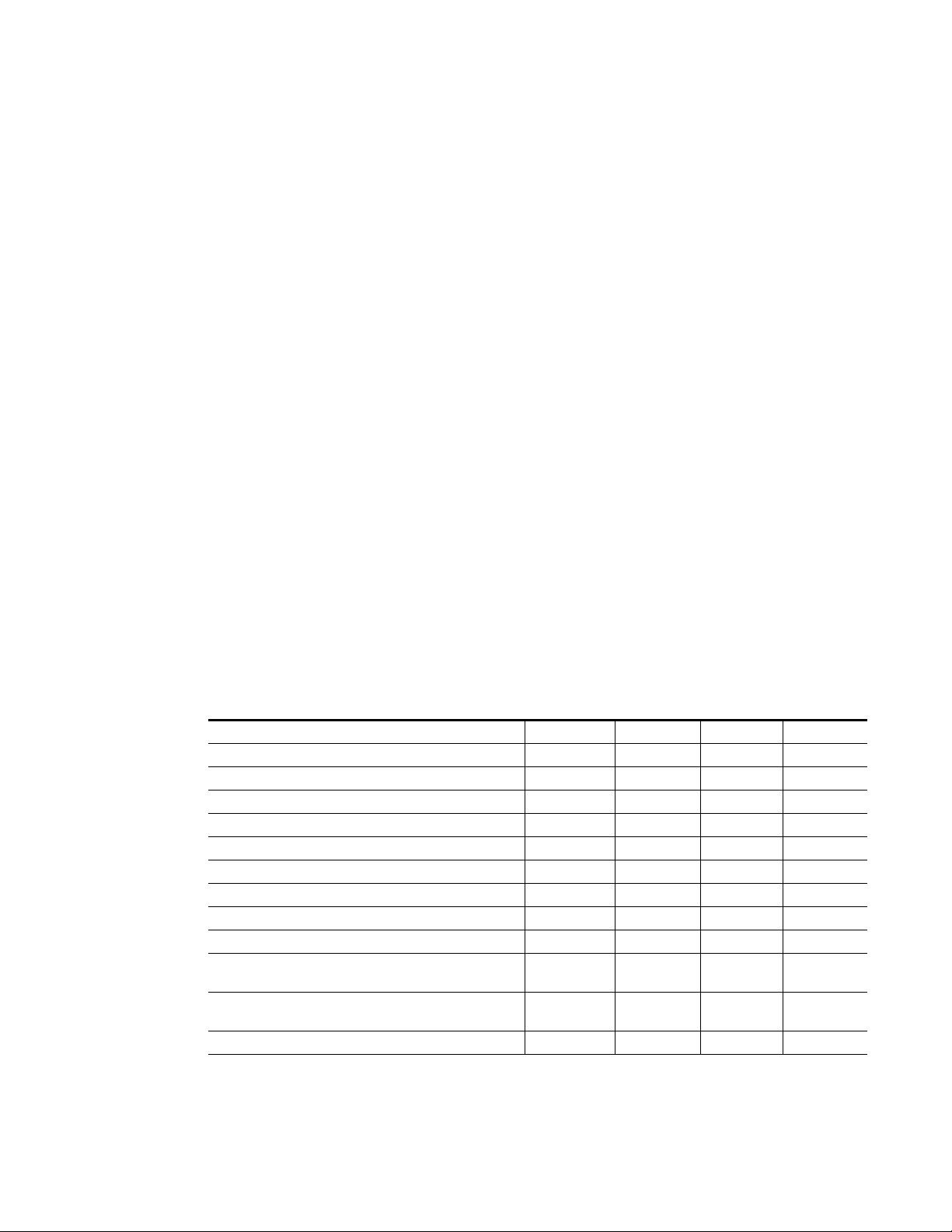

Table 1. KAM-XM Up and Down Converter Module Summary

Function KM-XM-UDC KM-XM-UPC KM-XM-UNC KM-XM-DNC

Aspect Ratio Control X X X X

Proc Amp Adjustments (for video processing) X X X X

Color Space Conversion X X X X

Detail Enhancement X X X X

Spike Filter (Adaptive Median filtering) X

Brickwall Filter X

Temporal Recursive Filter (Auto or Manual mode) X

GPI Control (3 external GPI inputs controlling E-MEMs) X X X X

Color Legalizer Control X X X X

First 2 audio groups of HD video are re-embedded into SDI

stream

First 2 audio groups of SDTV video re-embedded into HD output stream with compensating delay.

Re-insertion of Closed Caption data into HD output stream X X X

XX

XXX

KAM-XM-SERIES Instruction Manual 7

Page 8

Module Descriptions

The KAM-XM Up/Down conversion series modules also feature:

• Proprietary Teranex™ PixelMotion™ De-interlacing,

• Support of SD and HD video with embedded audio, including

Dolby-E,

• Hot-swap capability,

• Operates in the same frame with other 2000 and Kameleon modules,

• Three external GPI inputs to trigger selectable Preset 1-10 registers,

• Network control with the Newton Control Panel or Kameleon web control, and

• Support of NetConfig™ configuration tool and NetCentral™

SNMP-based monitoring system.

Module Descriptions

Each KAM-XM module uses the same circuit board with the application

software enabled for the particular module type. The module type is identified by a sticker on the circuit board and the Model name is identified in

the web page header. For up/down conversion rates supported, refer to

Table 2 on page 9.

The modules described in this manual include the following:

• KAM-XM-UDC – supports broadcast quality up and down conversion

of SD and HD video with embedded audio with the standard conversion controls. This application utilizes de-interlacing on a

pixel-by-pixel basis for preserving fine detail from the original image.

Down conversion offers an anti-aliasing filter.

• KAM-XM-UNC – supports broadcast quality HD up conversion for

SDI video with or without embedded audio with the standard conversion controls. In addition, this module also offers advanced noise

reduction with adaptive median spike, brickwall, and temporal recursive filter controls. This application utilizes de-interlacing on a

pixel-by-pixel basis for preserving fine detail from the original image.

• KAM-XM-UPC – supports broadcast quality HD up conversion for SDI

video with or without embedded audio with the standard conversion

controls. This application utilizes de-interlacing on a pixel-by-pixel

basis for preserving fine detail from the original image.

• KAM-XM-DNC – this broadcast quality down converter application

also utilizes de-interlacing on a pixel-by-pixel basis. Once the image

has been de-interlaced and down converted, detail enhancement can be

applied to the image to further shape the output. The first two groups

of audio from the HD video are re-embedded into the standard definition SDI video signal.

8 KAM-XM-SERIES Instruction Manual

Page 9

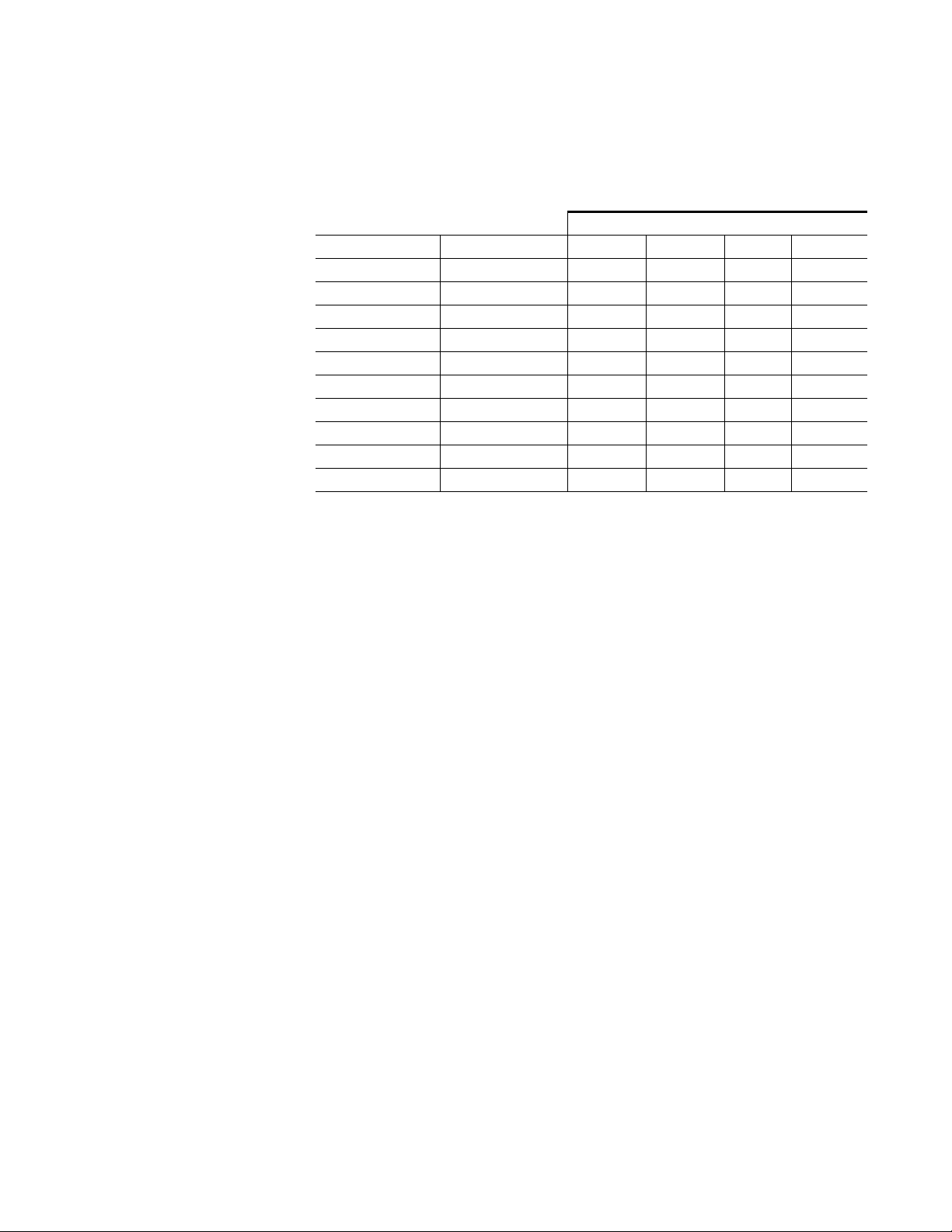

Supported Up/Down Conversion Rates

The modules support the conversion rates summarized in Table 2.

Table 2. Format Conversion Input/Output Combinations

Input Format Output Format UNC UPC DNC UDC

480i59.94 480i59.94 X X X

480i59.94 720p59.94 X X X

480i59.94 1080i59.94 X X X

576i50 576i50 X X X

576i50 720p50 X X X

576i50 1080i50 X X X

720p50 576i50 X X

720p59.94 480i59.94 X X

1080i50 576i50 X X

1080i59.94 480i59.94 X X

Module Descriptions

KAM-XM-

KAM-XM-SERIES Instruction Manual 9

Page 10

System Requirements

System Requirements

Operation of the KAM-XM modules in 2000 Series frames has the following

hardware and software requirements:

• Modules must be installed in a 2000T1DNG or 2000T3DNG Kameleon

2000 Series frame containing a a 2000GEN module.

• The frame must have a 2000NET module with assembly number

671-5231-01 or later running software version 3.2.2 or later.

Note

All KAM-XM module sets require two vertical module slots of frame space.

Frame density for the 1 RU frame is two module sets and six module sets

for a fully stuffed 3 RU frame. Both dual and single height Kameleon and

2000 modules can be mixed in the frames.

These requirements are necessary for proper cooling support and interface

to the Newton Control Panel configuration, NetConfig and GUI control, and

SNMP monitoring.

Existing Kameleon frames can be upgraded with the necessary

modules and software for proper operation. Contact your sales representative for more information.

10 KAM-XM-SERIES Instruction Manual

Page 11

Quick Start Guide

This Quick Start Guide is provided for an overview of installing the

KAM-XM modules. Each step gives you a link to a more detailed description of each process.

1.

3.

2.

4.

6.

7.

Install the KAM-XM modules in the 2000 Kameleon frame. Install the

XM-IO-1 Rear module first, then install the front module in the

corresponding front slot ( Module Placement in the 2000 Frame on

page 12).

Connect the 2000 frame to the network and navigate the web browser

to the frame. This process is described in detail in the 2000NET

Instruction Manual available on-line.

Navigate to the module you would like to configure and click on the

appropriate slot to access the module links ( Links and Web Pages on

page 38).

Quick Start Guide

Click on the Slot Config link on the left side of the page ( Slot Config Web

Page on page 65). This page allows you to assign a name to this module.

Assigning easily recognizable names will help later in the configuration

process.

5.

Cable the rear module signal connections ( Cabling on page 16).

Configure the input and output formats on the Format web page

( Format Web Page on page 44).

Configure the Reference source on the Setup web page ( Setup Web Page

on page 42). Select the type of reference from either the input signal or

an external reference (2000GEN module installed in the 2000 frame).

8.

Continue with module configuration depending on the module type.

KAM-XM-SERIES Instruction Manual 11

Page 12

Installation

Installation

Module Placement in the 2000 Frame

Installation of a KAM-XM module set is a process of:

• Placing the KAM-XM rear module in a frame slot,

• Placing the front media module in the corresponding front slot, and

• Cabling signal ports.

There are twelve slot locations in both the front and rear of a Kameleon

3 RU frame to accommodate KAM-XM modules. A KAM-XM module set

consists of a front media module and a dual height rear module that

requires two module slots.

Each KAM-XM front media module plugs into the front of the 2000 frame

mid-plane. The rear module plugs into the corresponding rear slot to

provide the input and output interface connectors.

A 3 RU 2000T3 frame fully stuffed with KAM-XM front and rear modules

will accommodate up to six module sets. A 1 RU 2000T1 frame will accommodate up to 2 module sets.

The KAM-XM front and rear module can be plugged in and removed from

a Kameleon 2000 Series frame with power on. When power is applied to the

module, LED indicators reflect the initialization process (see

Module Status

To install a KAM-XM module set in a frame:

For fully stuffing a 3 RU frame with KAM-XM modules, locate a vacant

1.

slot in slot 2, 4, 6, 8, 10, or 12 of the rear of the frame (Figure 1 on

page 13). The rear module uses two slots.

Note

on page 19).

This configuration (using slots 2, 4, 6, 8, and 10) is only suggested when fully

stuffing the frame with KAM-XM modules. There are no restrictions on which

slot to use as long as there is room in the frame. You may use any two slots

(odd or even numbered) for a KAM-XM module with any Kameleon or 2000

module combination.

Power Up and

12 KAM-XM-SERIES Instruction Manual

Page 13

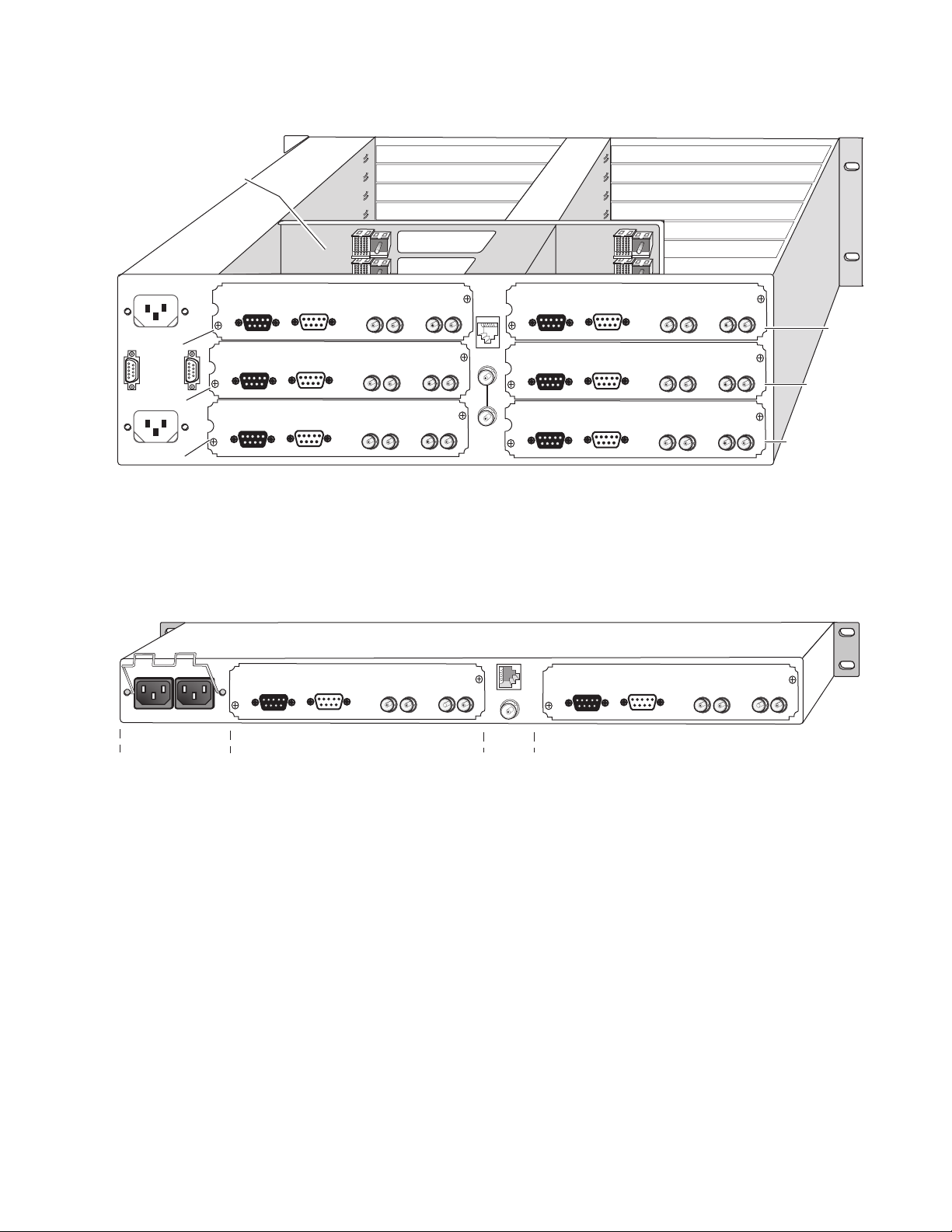

Mid-frame motherboard

with power and

communication buses

Slot 8

Slot 10

Figure 1. 2000T3NG Frame, Rear View

Installation

Slot 2

Slot 4

Slot 12

Power connections

Slot 6

Use rear media module slots 2, 4, and 6Use rear media module slots 8, 10, and 12

For a 1 RU frame, place the rear module in the lower slot as shown in

Figure 2.

Figure 2. 2000T1DNG Frame, Rear View

1

3

J101

J102

2

4

Media section

rear slots 3-4

Network

and reference

input connections

Media section

rear slots 1-2

8330_05r1

8330_17

KAM-XM-SERIES Instruction Manual 13

Page 14

Installation

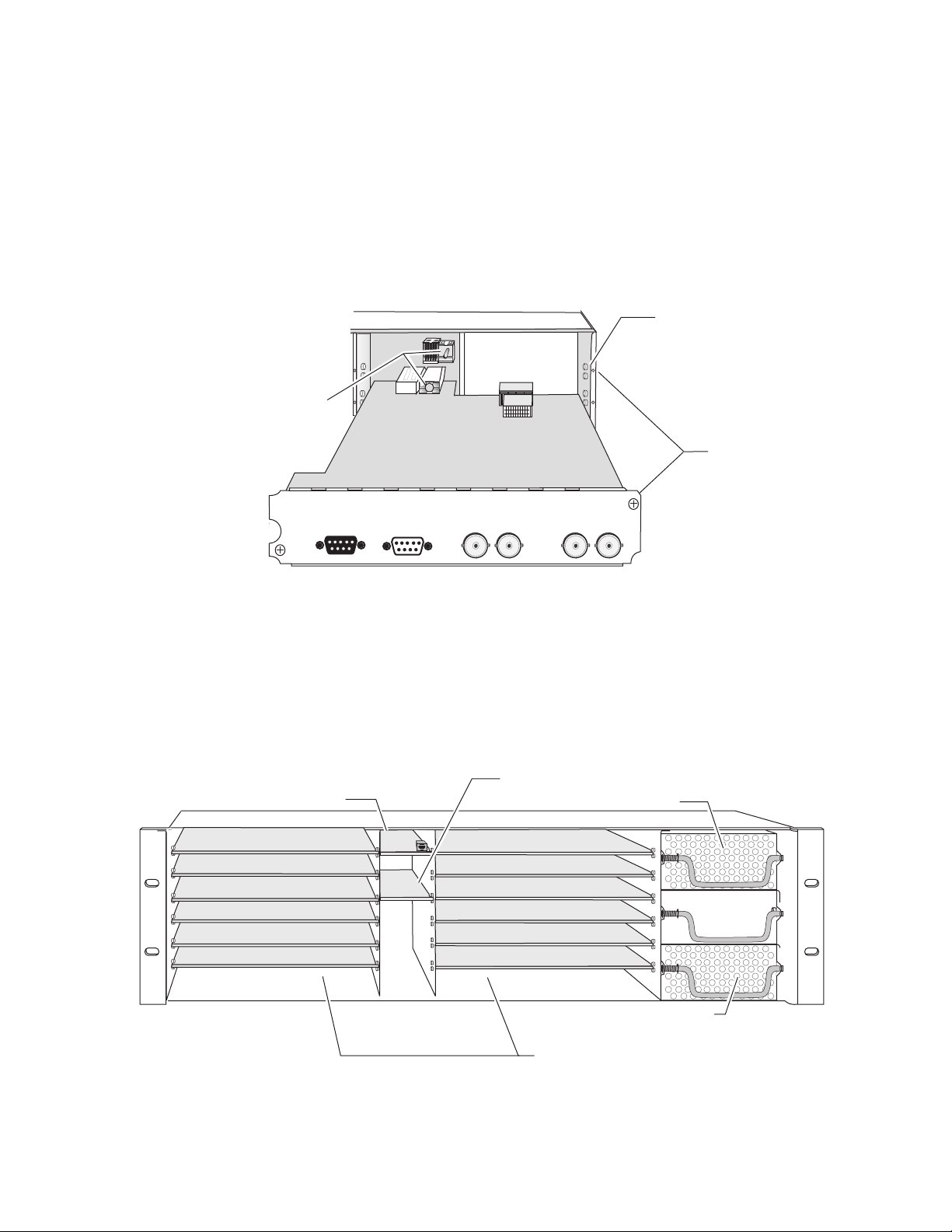

Insert the rear module into the vacant rear slot of the frame as

illustrated in Figure 3.

Verify that the module connector seats properly against the midplane.

Using a crossblade screwdriver, tighten the two screw locks to secure

the module in the frame.

Figure 3. Installing KAM-XM Rear Module

2000 frame (rear view)

Alignment post

and receptacle

Board edge guides

(both sides)

Screw locks

(both sides)

2.

3.

4.

5.

RS-232

J7

Locate the front slot 2, 4, 6, 8, 10, or 12 in the frame corresponding to the

rear module circuit board. The 3 RU frame front view is illustrated in

Figure 4 and the 1 RU frame is shown in Figure 5 on page 15.

Note

Figure 4. 2000T3 Frame, Front Slots

Network Slot (13)

(1)

(2)

(3)

(4)

(5)

(6)

Module slots where the KAM-XM should be installed are highlighted in gray

for a fully stuffed 2000T3 frame and for any 2000T1 frame.

(13)

(15)

GP10

LOOPINOUT2OUT1

J5

J4J5

J1

J2

8330_03r1

Reference Distribution Slot (15)

Main Power Supply Slot (18)

(7)

(8)

(9)

(10)

(11)

(12)

Fan Sled

Slot (19)

8173-04r1

Secondary Power

Supply Slot (20)

Front Media Slots (1-12)

14 KAM-XM-SERIES Instruction Manual

Page 15

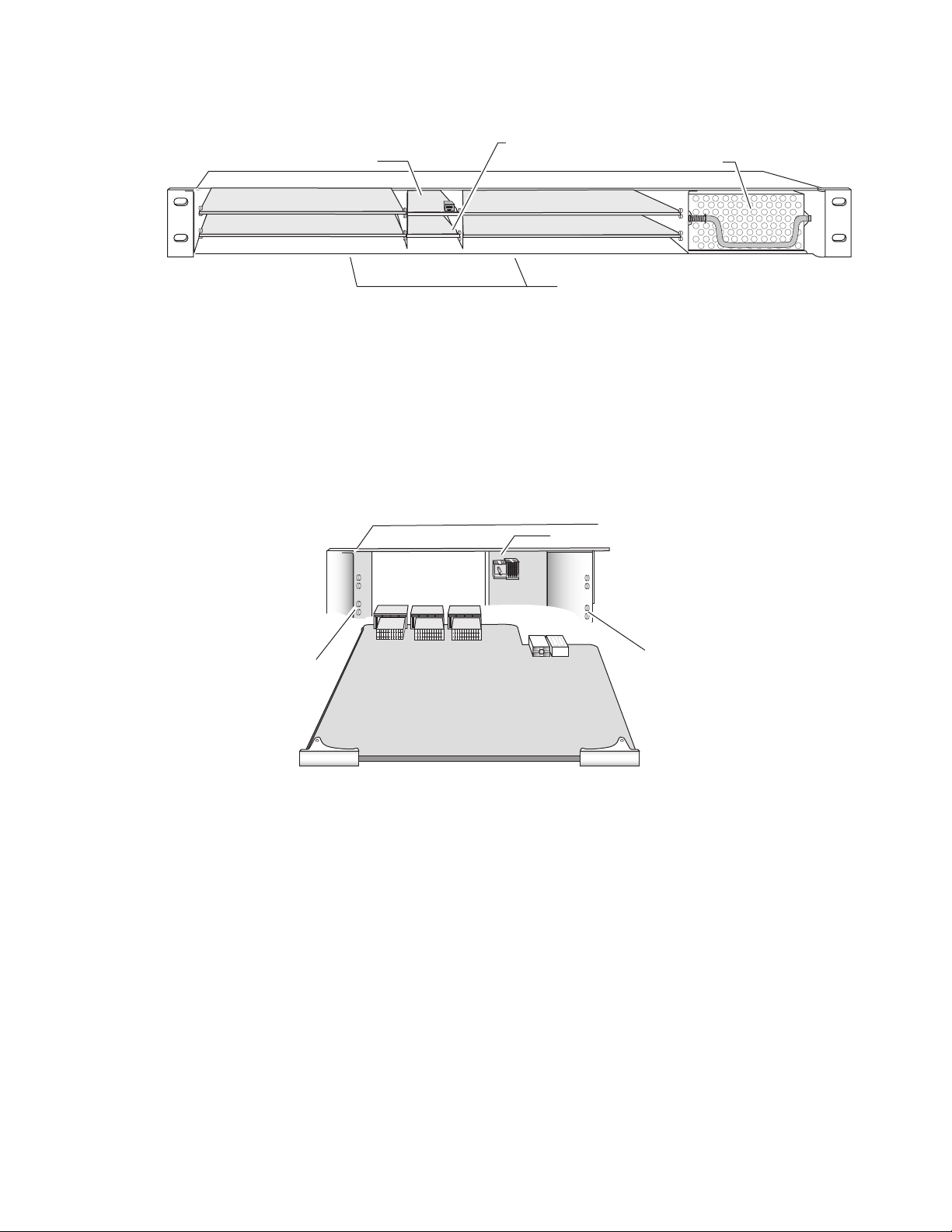

Figure 5. 2000T1 Frame, Front Slots

Network Slot (5)

Reference Distribution Slot (6)

Power Supply Slot (7)

Installation

6.

8.

(1)

(2)

(5)

(6)

(3)

(4)

Front Media Slots (1-4)

With the component side up, insert the front media module in the

corresponding front slot (see Figure 6).

7.

Verify that the module connector seats properly against the midplane

and rear module connector.

Press firmly on both ejector tabs to seat the module.

Figure 6. Installing Front Media Module

2000 Frame (front view)

Alignment post and receptacle

8039-21

Board edge

guides

Board edge

guides

8330-10

KAM-XM

KAM-XM-SERIES Instruction Manual 15

Page 16

Installation

Cabling

All cabling to the KAM-XM module set is done on the corresponding Dual

Height KAM-XM-R rear module (XM-IO-1) at the back of the 2000 frame.

KAM-XM-R Rear Module Connections

Refer to Figure 7 for an illustration of the KAM-XM rear module.

The KAM-XM rear module provides the following input and output and

control connections.

• IN (BNC)– a serial digital input that may be either standard definition

(SD) or high definition (HD) video depending on the front module

type.

• LOOP (BNC)– provides an output for the input signal to be looped to

another destination.

XM-IO-1

RS-232

• OUT1 (BNC)– this serial digital output connection can be either SD or

HD depending on the front module type and the output format

selected.

• OUT2 (BNC)– this serial digital output connection can be either SD or

HD depending on the front module type and the output format

selected.

• RS-232 Port (DB-9, Male) – this serial port allows a direct interface to the

module for testing and configuration purposes. This port is not normally used.

• GPI0 Port (DB-9, Female) – this port allows connection of external GPI

(General Purpose Interface) signals to the module as described in GPI0

Connections for GPI Control on page 18.

Figure 7. KAM-XM Rear Module Input/Output Connectors

GPI0

LOOPINOUT2OUT1

J7

16 KAM-XM-SERIES Instruction Manual

J6

J4J5

J2

J1

8330_02

Page 17

Installation

KAM-XM-UPC

For a KAM-XM-UPC HDTV Up Converter, connect the SD signal to be up

converted to the IN (J2) BNC. Loop the signal from the LOOP (J1) BNC to

another destination if required.

Connect the OUT1 (J5) and OUT2 (J4) BNCs to the HDTV device.

KAM-XM-UDC

For a KAM-XM-UDC HDTV Up/Down Converter, connect the SD signal

to be up converted or the HD signal to be down converted to the IN (J2)

BNC. Loop the signal from the LOOP (J1) BNC to another destination if

required.

Connect the OUT1 (J5) and OUT2 (J4) BNCs to the HDTV device if up converting or the SDTV device if down converting.

KAM-XM-UNC

For a KAM-XM-UNC HDTV Up Converter with advanced SDTV noise

reduction, connect the SD signal to be up converted to the IN (J2) BNC.

Loop the signal from the LOOP (J1) BNC to another destination if required.

Connect the OUT1 (J5) and OUT2 (J4) BNCs to the HDTV device.

KAM-XM-DNC

For a KAM-XM-DNC Down Converter, connect the HDTV signal to be

down converted to the IN (J2) BNC. Loop the signal from the LOOP (J1)

BNC to another destination if required.

Connect the OUT1 (J5) and OUT2 (J4) BNCs to the SDTV device.

KAM-XM-SERIES Instruction Manual 17

Page 18

Installation

GPI0 Connections for GPI Control

The KAM-XM modules can receive up to three General Purpose Interface

(GPI) external triggers to automatically activate specific user preset

E-MEM registers configured on the GPI (page 58) and E-MEM web pages

(page 59). Customer-supplied external GPI triggers are wired through connector J6 (GPIO) on the rear module.

Inputs to the GPI are held high and expect a contact closure to ground to

activate the programmed presets. There is a 100 mA maximum sink to

ground.

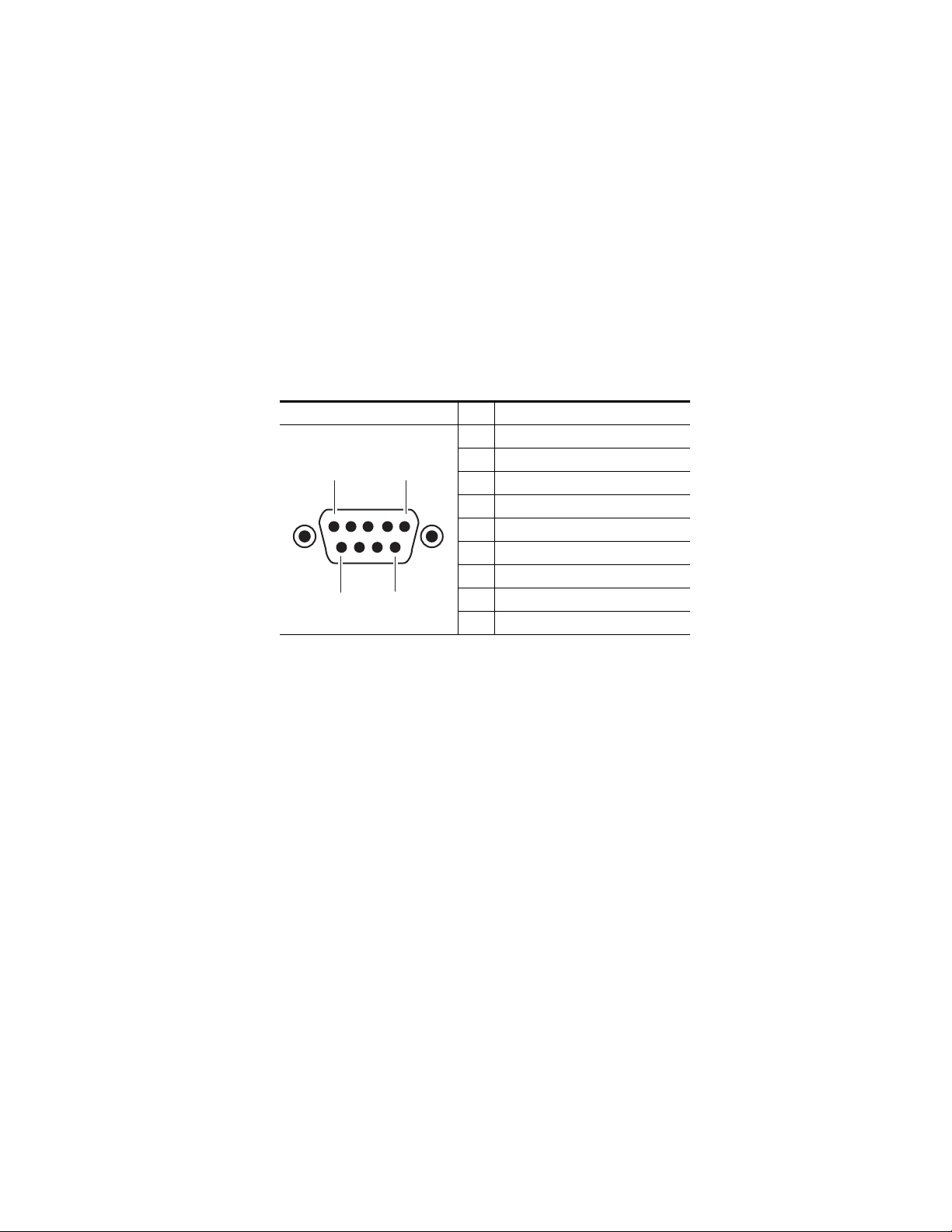

Table 3 provides pinouts for the GPI I/O control port, connector J6.

Table 3. Connector GP10 Wiring for GPI Control

GPIO Control Pin Connector J6

1 GPI Input 1

Pin 1

D-9 Female

Pin 6

Pin 5

Pin 9

2 GPI Input 2

3 GPI Input 3

4 Reserved

5 System Ground

6 System Ground

7 Not Connected

8 Reserved

8330_12

9 Reserved

18 KAM-XM-SERIES Instruction Manual

Page 19

Power Up and Module Status

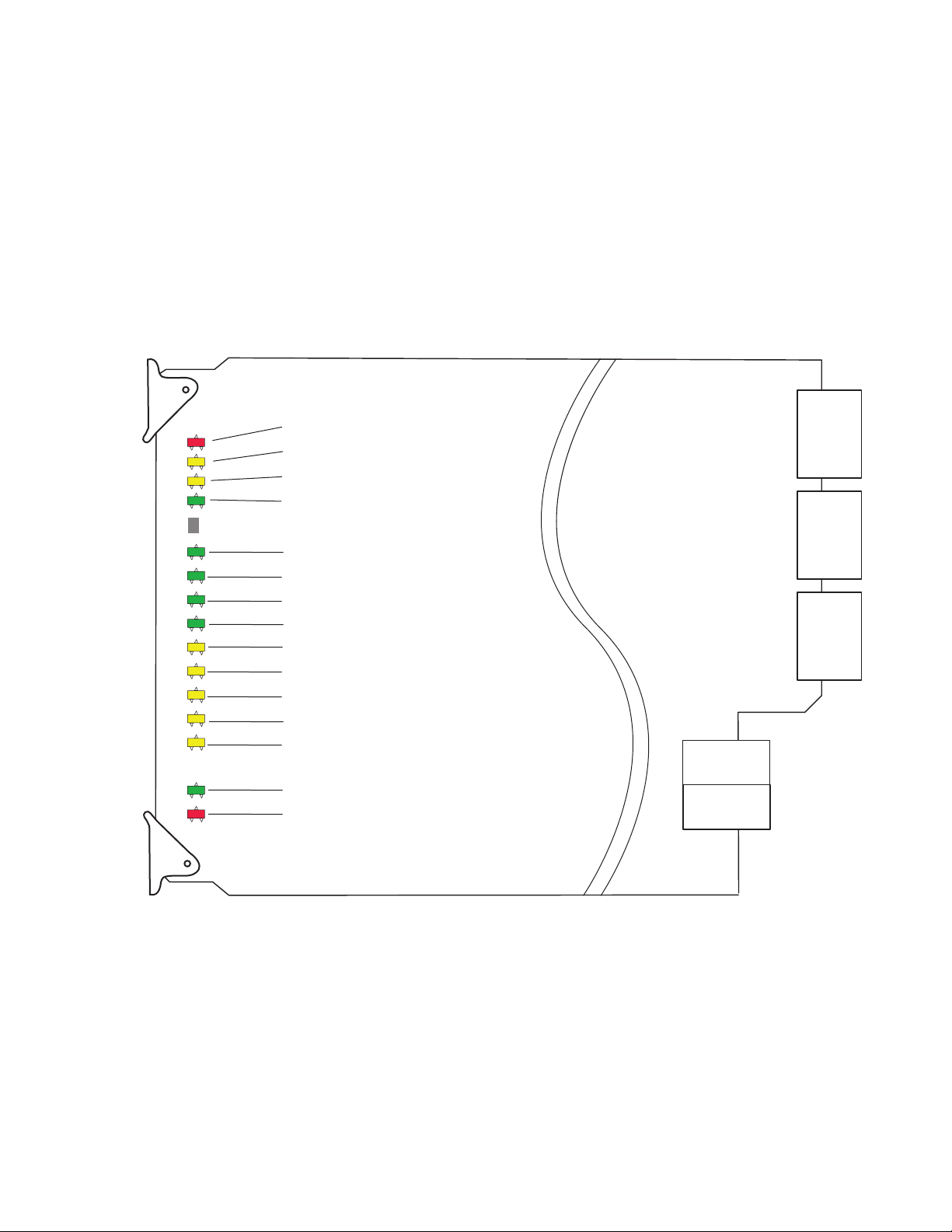

The front LED indicators are illustrated in Figure 8.

Upon power-up, the green PWR LED should light.

Note The KAM-XM module will take approximately 25 seconds to boot up.

Refer to Table 4 on page 20 to see a complete list of possible operating con-

ditions and the resulting indicator status.

Figure 8. Front Edge LEDs Indicators

Power Up and Module Status

FAULT

COMM

CONF

PWR

+3.3

SEQ

ACT

TC

PRSNT

AUD

PRSNT

FRM

LOCK

FBREF

ERR

UCREF

ERR

OFF

ERR

IFF

ERR

VOLT

TRIP

CH2

STAT

CH1

STAT

RESET

GND

FAULT (red)

COMM (yellow)

CONF (yellow)

PWR +3.3 (green)

SEQ ACT (green)

TC PRSNT (green)

AUD PRSNT (green)

FRM LOCK (green)

FBREF ERR (red)

UCREF ERR (red)

OFF ERR (red)

IFF ERR (red)

VOLT TRIP (red)

CH1 STAT (yellow)

RESET (green)

8269_07

KAM-XM-SERIES Instruction Manual 19

Page 20

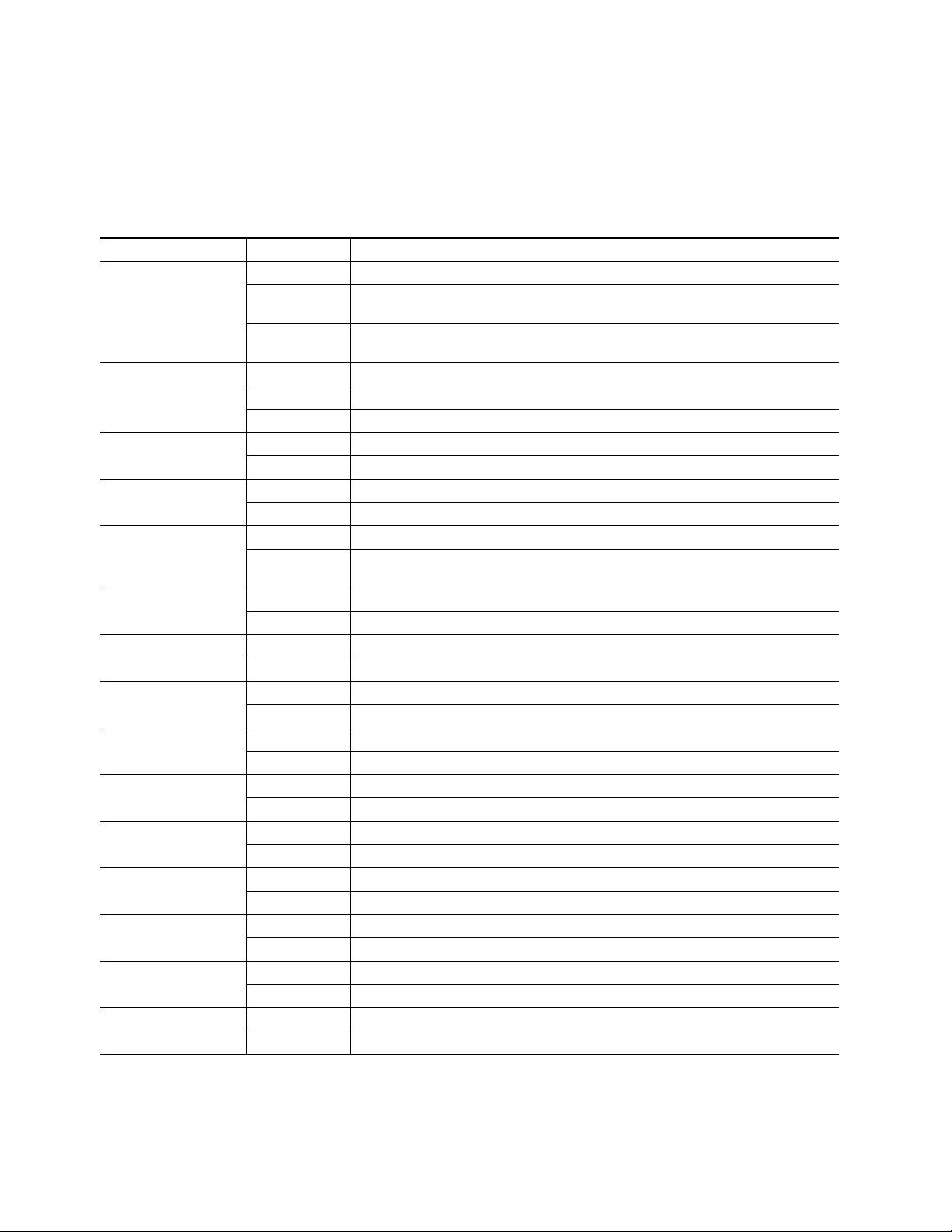

Power Up and Module Status

LED Indication Condition

FAULT

(red)

COMM

(yellow)

CONF

(yellow)

PWR +3.3

(green)

SEQ ACT

(green)

TC PRSNT

(green)

AUD PRSNT

(green)

FRM LOCK

(green)

FBREF ERR

(yellow)

UCREF ERR

(yellow)

OFF ERR

(yellow)

IFF ERR

(yellow)

VOLT TRIP

(yellow)

CH1 STAT

(green)

RESET

(red)

On continuously

Long flash

3 Short Flashes Location Command received by the module from a remote control system.

Short flash Activity present on the frame communication bus.

On continuously Normal operation, module is powered.

A red FAULT LED indicates an error situation and, when noted with the

other indicator LEDs, can indicate a specific problem area. Table 4 describes

signal output and LED indications for the various input combinations and

user settings.

Table 4. Indicator LEDs and Conditions Indicated

Off Normal operation.

Module has detected an Optic 1 or Optic 2 internal fault from the submodule or a write failure has

occurred on the front module.

No input is detected for the input or the input does not match the format selected manually, no rear

module is present, or the wrong rear module is present.

Off No activity on frame communication bus.

On Module is initializing, changing operating modes, or updating firmware.

Off Module is in normal operating mode.

Off No power to module, fuse blown, or module’s DC/DC converter failed.

Off Input video not detected or PLL unlocked.

Blinking

Off No timecode or bad timecode.

On Good timecode is detected.

Off No embedded audio detected.

On Embedded audio detected.

Off Input to output frame rates are not locked.

On Normal operation, input to output frame rates are locked.

Off No FrameBuilder refresh error detected.

On FrameBuffer refresh error detected, output could be corrupted such as bad output image.

Off No Microcode refresh error detected.

On Microcode refresh error detected, Microcode memory could be corrupted.

Off Normal operation, no Output FIFO underflow/overflow error detected.

On Output FIFO underflow/overflow error condition detected.

Off Normal operation, no input FIFO underflow/overflow error condition detected.

On Input FIFO is detecting underflow/overflow error condition.

Off Normal state, no under voltage trip detected.

On Under voltage trip detected, one or more supply voltages is below specification.

Off No input detected or bad input.

On Normal operation, good input detected.

Off Normal operation, board is not in Reset mode.

On Module is in reset mode, including FPGA configuration sequence.

Normal operation, Sequencer Active LED should be blinking to Indicate good video input and PLLs

locked.

20 KAM-XM-SERIES Instruction Manual

Page 21

Configuration and Adjustments

The KAM-XM modules are configured remotely using the 2000NET

network interface GUI and/or a networked Newton Control Panel.

Refer to the following sections for configuration instructions:

• Configuration Summary (page 21)

• Newton Control Panel Configuration (page 33)

• Web Browser Interface (page 34)

Operation of these control types is explained in detail in their respective

sections of this manual.

Note Before configuration, verify that system requirements have been met as

described in System Requirements on page 10.

Configuration Summary

Configuration and Adjustments

This section provides a summary of all available filters and controls that

can be adjusted on the KAM-XM module. Use this section for a summary

of what adjustments can be made. Table 5 on page 30 provides a summary

in table format of all controls and their ranges, default values, and remote

and control panel function names and locations for setting each value.

Up and Down Conversion

Up and down conversion in today’s facilities is required for interconnection between video formats that have different numbers of pixels/line,

lines/field, and in some cases, a different number of fields or

frames/second. This interconnection requires the use of up and down

format conversion devices.

Up conversion involves a three dimensional process for dealing with conversion of a moving image. Moving images exist in three dimensions. The

horizontal dimension is made up of individual pixels. The vertical dimension is made up of lines contained in the field or frame. These exist in what

is referred to as the spatial domain. The number of fields or frames per

second is known as the temporal domain.

Generally, the process of up conversion deals with changing the number of

pixels and lines in a format (spatial domain). This process is a form of

sample rate conversion. One main issue with this process is that of resolution. Resolution cannot be created so the resolution of the original input

signal must be carefully recovered and passed to the up converted output.

KAM-XM-SERIES Instruction Manual 21

Page 22

Configuration and Adjustments

This is done by a process of de-interlacing the input signal so that the full

vertical detail of the input is retained. On the KAM-XM modules this is

basically accomplished by using an enhanced version of motion compensated de-interlacing which generates a motion vector for every pixel in the

image.

In the process of up conversion, several factors must be addressed and the

following controls are provided on the modules for these considerations:

Format Conversion

The video input to the module and the video output from the module can

be selected as desired. On the Format web page (Figure 22 on page 45), the

currently detected input is reported, the desired format pulldown is available and the status of the desired conversion format is reported as available.

The available input/output format combinations are summarized in

Table 2 on page 9.

Two additional controls are included in format selection described below:

• Source Material – this control is provided to further distinguish the

type of input signal to the module. Two choices are available, Auto or

Video.

When set to Auto, the module will determine if the input material originated as video or film and adjust the filtering accordingly. In some situations, such as broadcast applications, where the input material

cannot be as easily interpreted by the module, the user can force the

mode to Video to prevent artifacts from occurring.

• Deinterlace Type – two types of de-interlacing are provided, PixelMotion and Vert Interpolation.

PixelMotion is a combination of motion-adaptive de-interlacing and

diagonal filtering. When using this technique, the image is analyzed to

determine if there is any motion. This information is used to determine

the filter characteristics used to de-interlace.

Vert Interpolation de-interlacing combines the two fields of video to

create a progressive frame regardless of the amount of motion content

in the image.

22 KAM-XM-SERIES Instruction Manual

Page 23

Aspect Ratio Modes

Most SD material is in a 4:3 aspect ratio while HD material is 16:9. Aspect

ratio in this case refers to the ratio of an image width to height, not related

to image size. The effect of aspect ratio in up conversion (4:3 to 16:9) is a

process of cropping, stretching, or squeezing the image. To address these

issues, the module provides a control for selecting one of three standard

aspect ratio conversion options:

• Anamorphic – this mode is designed to be used with material originally

captured with an anamorphic lens. It ensures that the top and bottom

edges of the input aspect ratio match the top and bottom edges of the

output aspect ratio. When used with standard 4:3 material, it will have

the effect of stretching the material horizontally as illustrated in

Figure 9. This results in a distortion of the geometry of the image, par-

ticularly causing circles to appear as ovals when present in the image.

Figure 9. 16:9 Anamorphic Mode

Configuration and Adjustments

16:9 conversion with horizontal stretch4:3 Original

• Common Top & Bottom – this mode ensures that the top and bottom

edges of the input image match the top and bottom edges of the output

aspect ratio. A 4:3 image set to this mode will appear centered in a 16:9

display with black bars, or pillars (pillarbox), on the left and right sides

as illustrated in Figure 10.

Figure 10. Common Top and Bottom Mode

KAM-XM-SERIES Instruction Manual 23

Page 24

Configuration and Adjustments

• Common Side (Common Left & Right) – this mode ensures that the left

Figure 11. Common Sides Mode

and right edges of the input image match the left and right edge of the

output aspect ratio. As illustrated in the Anamorphic example (Figure 9

on page 23), for a 4:3 image, the left and right edges are stretched to

match the left and right edges of the output.

In order to maintain correct geometry of the image, in Common Side

mode the input image is stretched vertically as well, creating a zoom

effect (Figure 11). This method results in correct geometry of the image

but also results in overall loss of approximately 33% of the input information in the vertical domain. This loss of information means less vertical information is available to the interpolation process resulting in

lowering the overall resolution of the output image.

Stretched

vertically

• FlexView – (currently only available in 480i/59.94 to 1080i/59.94 up

conversion) is a non-linear anamorphic aspect ratio designed for use

when converting 4:3 material to 16:9 without the traditional distortion

of a normal anamorphic stretch. FlexView leaves the center portion of

the image untouched and then applies increasing amounts of stretch

closer to the edges of the image, giving a more realistic conversion.

Other aspect ratio controls include the following:

• Zoom Crop – when turned on, will zoom the image by 3 pixels and then

crop the image by 3 pixels. This corrects issues that arise on the top or

bottom edge or on the left or right side of an image.

• Edge Trim – this control adjust the amount of border cropping in the X

and Y directions. It is adjustable from 0-50 or 0-20 pixels, depending on

the conversion currently in use.

• Fill Shade – this control is used when input the aspect ratio is smaller

than the output aspect ratio and there are areas in the output display

that are filled with black. The Fill Shade control adjusts the luminance

level (Y) and color (Cb and Cr) of these areas from 64 (digital black) to

940 (digital white).

24 KAM-XM-SERIES Instruction Manual

Page 25

Configuration and Adjustments

Proc Amp Controls

Proc Amp controls are provided for making adjustments to the output

video signal. Each Proc Amp function must be enabled before adjustments

can be made.

The following Proc Amp controls are available:

• Video Gain – sets the overall amplitude with a range of ± 6 dB.

• Black Level – adjusts the black level with a range of ± 30 IRE.

• Hue – adjusts the phase with a range of ± 9 degrees.

• Saturation – adjusts the chroma saturation with a range of ± 6 dB.

• RP 177 checkbox – check this box when using video converted from

film production as specified by SMPTE Recommended Practice RP 177.

Detail Enhance Controls

Once the image has been de-interlaced and up converted, detail enhancement can be applied to the image to further sharpen the output detail. This

process utilizes an industry standard film compositing technique called

unsharp masking. The filtering process adds an additional level of image

detail by detecting the edges of objects and adjusting the contrast ratio

around these objects to help separate them from the background. This edge

sharpening filter allows for both positive and negative aperture correction.

The following user adjustable controls are available in Detail Enhance:

• Horizontal – enabling the horizontal control allows the user to soften or

sharpen the horizontal detail in the image. The range of this control is

± 7.0 dB.

• Vertical – enabling the vertical control allows the user to soften or

sharpen the vertical detail in the image. The range of this control is

± 7.0 dB.

• Anti-Alias Filter – in down conversion modes only, an anti-alias filter

can be enabled in the down conversion process to smooth edges such

as graphics.

KAM-XM-SERIES Instruction Manual 25

Page 26

Configuration and Adjustments

Noise Reduction

Two of the modules covered in this manual (KAM-XM-UNC – Up Converter with Noise Reduction and KAM-XM-UDC– Up/Down Converter)

provide the additional noise filtering and reduction controls described

below.

Spike Filtering

This is an adaptive median filter that works well in removing random

impulse noise. This type of filtering performs spatial processing to determine which pixels in an image have been affected by impulse noise. The

adaptive median filter classifies pixels as noise by comparing each pixel in

the image to its surrounding neighbor pixels. The size of the neighborhood

is adjustable, as well as the threshold for the comparison.

A pixel that is different from a majority of its neighbors, as well as being not

structurally aligned with those pixels to which it is similar, is labeled as

impulse noise. These noise pixels are then replaced by the median pixel

value of the pixels in the neighborhood that have passed the noise labeling

test. This results in a prime benefit of not eroding edges or other small

structures in the image with repeated application of the adaptive median

filter.

This type of filtering provides controls for setting the adaptive threshold of

the luminance and the chroma channels. The filter must be enabled to allow

processing.

Brickwall Filtering

This is a low pass filter with a sharp cutoff. This type of high-order low pass

filter attenuates high frequencies (image detail) while leaving low frequency information unaffected. Impulse and Gaussian noise contain high

frequency components and will be diminished with this filter is on.

This filter is primarily intended for pre-compression processing, to attenuate high frequency information that will normally be quantized away in

the compression process. When used for pre-compression, it can improve

the efficiency and quality of the compression process. By controlling the

manner in which the detail is removed, compression artifacts can be minimized. A boost can be applied after the brickwall filter to accentuate the

remaining edges in the filtered image.

One of the benefits of removing high frequency noise before compression

is that there are more bits to spend when generating the compressed stream

since there is less information to compress. In addition, the potential for

loss of desirable information due to the compression of small details is

decreased, resulting in a more consistent output.

26 KAM-XM-SERIES Instruction Manual

Page 27

Controls for this filter type include the following:

• Enable – the filter must be enabled.

• Boost – sets the amount of amplitude prior to the cutoff frequency. This

boosting of the amplitudes gives the appearance of sharpening in the

image to help compensate for blurring that occurs when filtering out

high frequency information.

• Cutoff – sets the cutoff frequency so that information greater than this

value will be filtered. Information less than the cutoff value will be left

alone.

• Direction Control – allows setting the filter to affect both the horizontal

and vertical axes or just the horizontal or vertical axis.

Temporal Recursive Filtering

This noise reducer is a motion adaptive temporal recursive filter that works

well in removing random and Gaussian noise. Each pixel in the filter

process is labeled as motion, no motion, or noise.

Configuration and Adjustments

Each of these classes of pixels is treated differently in the noise reduction

process as follows:

• For pixels in which there is no motion, low Gaussian noise may be

reduced via temporal processing by a weighted averaging over successive frames.

• For pixels labeled as random noise, spatial processing replaces these

pixels.

• Pixels labeled as being in motion are left as is to avoid artifacts that may

be introduced through temporal processing.

Controls for temporal filtering include the following:

• Enable – the filter must be enabled.

• Red Overlay – when turned on, the filter superimposes a red overlay

onto areas in the input image where the temporal recursive filter identifies motion. This red overlay will display what area is not being filtered.

• Auto – when Auto mode is turned on, a feedback controller is engaged

that dynamically sets the distance, no motion, and motion slider controls based on noise and motion measurements. The pixels determined

to be in motion will be shown in red as shown in Figure 12 on page 28.

These pixels will not have any noise reduction applied to them.

The Bias control in Auto mode adjusts the noise set point in the temporal recursive controller. The higher the bias, the more aggressive the

controller is towards the noise in the scene. The lower the bias setting,

the more sensitive the controller is towards motion in the scene.

KAM-XM-SERIES Instruction Manual 27

Page 28

Configuration and Adjustments

• Manual mode – when Auto mode is turned off, the temporal recursive

filter is in Manual mode. This will activate a number of controls for

manual temporal filtering.

The Distance control is set to determine the sensitivity to motion

between the current frame and historical frames. This threshold represents a percentage of the current pixel value that the historical pixel

value must be within in order to be considered unchanged. Therefore,

a setting of zero would detect motion at every pixel, applying no filtering occurring. A setting of 40 would be less sensitive to motion, temporally filtering every pixel which could result in blurring or any

objects or areas that are in motion. If the Distance control is set too low,

too little filtering may occur, whereas, if set too high, too much filtering

will be applied.

The No Motion control sets the historical weighting factor for areas in

the frame where no motion has been detected. A setting of 100% forces

the filter to use only historical data in areas where no motion has been

detected. A setting of zero forces the filter to use only current data in

areas where no motion has been detected.

The Motion control sets the historical weighting factor for areas in the

frame where motion has been detected. A setting of 100% forces the

filter to use only historical data in areas where motion has been

detected. A setting of zero forces the filter to use only current data in

areas where motion has been detected.

Red Overlay showing

pixels in motion

Figure 12. Temporal Recursive Filter Red Overlay

28 KAM-XM-SERIES Instruction Manual

Page 29

Color Legalizer

Color legalizer controls are provided to set the upper and lower limits for

luma and chroma values to be within legal limits for broadcasting and

downstream equipment.

Each luma and chroma value is a 10-bit value making the minimum limit 0

and the maximum limit 1019. High and low luma and chroma limit controls are provided for setting the upper and lower limits that the module

will output. By default, these controls will cut off values outside of the legal

range.

GPI and E-MEM Controls

Configuration is provided for setting up GPI triggers from external

devices. Up to ten different module preset configurations can be defined

then assigned to the three external GPIs or recalled on the E-MEM web

page.

Configuration and Adjustments

KAM-XM-SERIES Instruction Manual 29

Page 30

Configuration and Adjustments

Configuration Summary Table

Table 5 provides a complete summary of the KAM-XM functions and a

comparison of the functionality available with each control type along with

the ranges and default values for each parameter.

Table 5. Summary of KAM-XM Configuration Functions

Function

Type

Reference input selection Input Input or External

Adjust Genlock Offset when

external reference selected

Closed Caption Line select Line 9 Line 9 to 19

Ignore bad video control Don’t Ignore

Blank VBI lines

(525 line rate only)

Format Conversion Input

selection

Current Input Format 480i59.94 See list above

Input Available – Yes or No

Format Conversion Output

Current Output Format 480i59.94 See list above

Output Available – Yes or No

Apply format control _ _

Source Material selection Video Video or Auto

Deinterlace Type selection PixelMotion

Default

0 µs ± 2000 µs

Not Blanked Blank or Not Blanked

Up Converter:

480i59.94

Down Converter:

720p50

Up Converter:

480i59.94

Down Converter:

576i50

Range/Choices

Resolution

Ignore or

Don’t Ignore

480i59.94

576i50

720p50

720p59.94

1080i50

1080i59.94

See list above

PixelMotion or

Vert Interpolation

Web Page/

Function Name

Setup/

Reference pulldown

Setup/

Genlock Offset (microseconds)

Setup/

Closed Caption Line

Setup/

Bad Video Ignore checkbox

Setup/

Blank Line checkboxes

(525: Line 20, 21, 22, 23, 283,

284, 285, 286)

Format/

Input pulldown

Format/

Current read-only column

Format Conversion/

Available read-only column

Format/

Output pulldown

Format/

Current read-only column

Format/

Available read-only column

Format/

Apply button

Format/

Source Material pulldown

Format/

Deinterlace Type pulldown

Newton

Panel

Ref All modules.

–

CCLine

– All modules

Blank20

Blank283

Blank21

Blank284

Blank22

Blank285

Blank23

Blank286

InDesired All modules.

InCurrent

InAvailable

OutDesired

OutCurrent

Available

ApplyFmt

–

–

Notes/

Conditions

Up conversion

modes.

Up conversion

modes.

All modules.

Changing formats

in some cases will

cause application to

reload. Wait for

module to reload.

Up conversion

modes.

30 KAM-XM-SERIES Instruction Manual

Page 31

Table 5. Summary of KAM-XM Configuration Functions

Configuration and Adjustments

Function

Type

Current Aspect selection Anamorphic

Zoom Crop enable Off On or Off

Edge Trim – X or Y Trim 0 pixels

Fill Shade – Y/Cb/Cr Channels

Video Gain Enable Off On or Off

Video Gain adjustment 0 dB ± 6.0 dB

Black Level Enable Off On or Off

Black Level adjustment 0 IRE ± 30 IRE

Hue Enable Off On or Off

Hue adjustment 0 degrees ± 9.0 degrees

Saturation Enable Off On or Off

Saturation adjustment 0 dB ± 6 dB

RP 177 enable Off On or Off

Horizontal Detail Enhance

Enable

Horizontal Detail Enhance 0 dB ± 7 dB

Vertical Detail Enhance

Enable

Vertical Detail Enhance 0 dB ± 7 dB

Anti-aliasing filter enable Off On or Off

Default

64 64-940

Off On or Off

Off On or Off

Range/Choices

Resolution

Anamorphic,

Common Top,

Common Side, or

FlexView

(480i/59.94 to

1080i/59.94 only)

0 to 50 pixels

0 to 20 pixels

Web Page/

Function Name

Aspect/

Current Aspect pulldown

Aspect/

Zoom Crop On checkbox

Aspect/

Edge Trim X or Y Trim control

Aspect/

Fill Shade Y, Cb or Cr control

ProcAmp/

Video Gain Enabled checkbox

ProcAmp/

Video Gain control

ProcAmp/

Black Level Enabled checkbox

ProcAmp/

Black Level control

ProcAmp/

Hue Enabled checkbox

ProcAmp/

Hue control

ProcAmp/

Saturation Enabled checkbox

ProcAmp/

Saturation control

ProcAmp/

RP 177 On checkbox

Detail Enhance/

Horizontal Enable checkbox

Detail Enhance/

Horizontal (dB) control

Detail Enhance/

Vertical Enable checkbox

Detail Enhance/

Vertical control

Detail Enhance/

Anti-Alias Filter checkbox

Newton

Panel

Aspect

Crop

XTrim

YTrim

FillY

FillCb

FillCr

GainEn

Gain

BlackEn

Black

HueEn

Hue

SaturEn

Satur

_

EnhHorEn

EnhHorDB

EnhVerEn

EnhVerDB

AntiAlias

Notes/

Conditions

All modules

All modules.

Each control must

be enabled,

All modules.

Each control must

be enabled

Down conversion

modes only

KAM-XM-SERIES Instruction Manual 31

Page 32

Configuration and Adjustments

Table 5. Summary of KAM-XM Configuration Functions

Function

Type

Luma Limit High 4 4 to 1019

Luma Limit Low 979 4 to 979

Chroma Limit High 4 4 to 1019

Chroma Limit Low 979 4 to 979

Available on KAM-XM-UNC only:

Spike filter enable Off On or Off

Spike Luma/Chroma control 90% 1 to 100%

Brickwall filter enable Off On or Off

Brickwall Boost control 0 dB 0, 1, 2, 3 or 4 dB

Brickwall Cutoff setting 3.5 MHz

Brickwall direction Horizontal & Vertical

Temporal Recusive filter

enable

Temporal Recursive Red

Overlay enable

Temporal Recursive Auto On On or Off

Temporal Recursive Bias 0 ± 6

Temporal Recursive Distance 15% 0 to 40%

Temporal Recursive No

Motion

Temporal Recursive Motion 0% 0 to 100%

Default

Off On or Off

Off On or Off

50% 0 to 100%

Range/Choices

Resolution

0.9, 1.0, 1.25, 1.50,

1.75, 2.0, 2.25, 2.5,

2.75, 3.0, 3.25, 3.5,

3.75, 4.0, 4.25, 4.5,

4.75, 5.0, 5.25, 5.5

MHz

Horizontal & Vertical

Horizontal

Vertical

Web Page/

Function Name

Color Legalizer/

Color Legalizer Levels/

Luma Limit High control

Color Legalizer/

Color Legalizer Levels/

Luma Limit Low control

Color Legalizer/

Color Legalizer Levels/

Chroma Limit High control

Color Legalizer/

Color Legalizer Levels/

Chroma Limit Low control

Spike/

Enable pulldown

Spike/

Luma & Chroma control

Brickwall/

Enable pulldown

Brickwall/

Boost control

Brickwall/

Cutoff control

Brickwall/

Direction pulldown

Temporal Recursive/

Enable pulldown

Temporal Recursive/

Red Overlay pulldown

Temporal Recursive/

Auto pulldown

Temporal Recursive/

Auto pulldown

Temporal Recursive/

Distance control

Temporal Recursive/

No Motion control

Temporal Recursive/

Motion control

Newton

Panel

LumaLmtH

LumaLmtL

ChromaLmtH

ChromaLmtL

SpikeEn

SpkLuma

SpkChroma

BrickEn

Boost

Cutoff

Dir

RcrsvEn

RedOvEn

Auto

Bias Auto mode only

Distance

Motion

(PID 1096)

NoMotion

Conditions

All modules.

Control must be

enabled.

Control must be

enabled

Manual mode only

(Auto off)

Notes/

32 KAM-XM-SERIES Instruction Manual

Page 33

Newton Control Panel Configuration

A Newton Control Panel (hard or soft version) can be interfaced to the

Kameleon 2000 Series frame over the local network. Control panel access

offers the following considerations for module configuration and monitoring:

• Ability to separate system level tasks from operation ones, minimizing

the potential for on-air mistakes.

• Ability to group modular products—regardless of their physical locations—into logical groups (channels) that you can easily manipulate

with user-configured knobs.

• Update software for applicable modules and assign frame and panel IP

addresses with the NetConfig Networking application.

• Recommended for real-time control of module configuration parameters, providing the fastest response time.

Note Not all module functions are available with the control panel, such as E-MEM

and factory default recalls. The available control panel controls for the

module are listed in Table 5 on page 30.

Configuration and Adjustments

An example of the Newton Configurator is shown in Figure 13.

Figure 13. Newton Configurator Example

Refer to the documentation that accompanies the Newton Modular Control

System for installation, configuration, and operation information.

KAM-XM-SERIES Instruction Manual 33

Page 34

Configuration and Adjustments

Web Browser Interface

The web browser interface provides a graphical representation of module

configuration and monitoring.

Use of the web interface offers the following considerations:

• Provides complete access to all module status and configuration func-

• Web access will require some normal network time delays for pro-

tions, including naming of inputs and outputs, factory parameter and

name default recalls, E-MEM functions, slot configuration, and SNMP

monitoring controls.

cessing of information.

• Configuration parameter changes may require pressing the

button or

become effective.

• Web interface recommended for setting up module signal and slot

names, E-MEMS, and reporting status for SNMP and monitoring.

Refer to the Frame Status page shown in Figure 14 on page 35. The Kameleon and 2000 modules can be addressed by clicking either on a specific

module icon in the frame status display or on a module name or slot

number in the link list on the left.

Note The physical appearance of the menu displays on the web pages shown in

Enter, upload processing time, and a manual screen refresh to

this manual represent the use of a particular platform, browser and version

of 2000NET module software. They are provided for reference only. Displays

will differ depending on the type of platform and browser you are using and

the version of the 2000NET software installed in your system. This manual

reflects 2000NET software version 4.0.0.

Apply

34 KAM-XM-SERIES Instruction Manual

Page 35

Configuration and Adjustments

Figure 14. 2000NET GUI

The Links section lists the frame and its current modules. The selected link's Status

page is first displayed and the sub-list of links for the selection is opened. The sub-list

allows you to select a particular information page for the selected device.

Content display section displays the information page

for the selected frame or module (frame slot icons are also

active links).

Refresh button for manual

update of page

8330_11r2

KAM-XM-SERIES Instruction Manual 35

Page 36

Configuration and Adjustments

Web Page Operations and Functional Elements

The following conventions and functional elements (shown at left) are used

in KAM-XM web page operations. (The examples shown throughout this

manual represent 2000NET software version 4.0.0 or later):

Pulldown Menus

Button

Radio button

Check box

Refresh button

Coarse Adjust

Fine Adjust

Enter

Low Limit

Status Indicator

Entry Field

Status LED

High Limit

• Pulldown menus allow you to choose selections from a list.

• Clicking on a button performs an immediate action such as recall of

defaults, clearing of states, learning configurations, and selecting all or

none of a selection.

• Radio buttons are used to make a choice of one parameter in a group.

• Check boxes are used when a selection can be enabled or included in a

group. Multiple checkbox selections or enables can be made.

•A

Refresh button (circular arrow) is provided at the top of each web page

for manual refresh to view recently changed parameters.

• Each numerical adjustment control has a

Coarse adjust button (left and

right top double arrows) which increases or decreases the step value by

a factor of 10. The

Fine adjust button (left and right inside single arrows)

increases or decreases the step value by 1.

To change a value, use the arrow button controls or enter a value into

the number field and select the

Enter button (*) or use the Enter key on

your keyboard. The Status Indicator bar will follow the value selected.

Use the

Low and High Limit buttons to go directly to the lowest and

highest limits for the parameter.

• An entry field allows naming of various module functions such as

input or output signals, asset tag, and slot identification.

8341_13

• The Status LED is explained below.

Status LED icon

The Status LED icon reports communication status for the frame slot and is

a link to the module Status page where Warnings and Faults are displayed.

LED colors indicate:

• Green = Pass – no problems detected

• Yellow = Configuration error warning

• Red = Fault condition detected

Variables:

• Model and Description are read-only generated by the module

• Frame Location is entered in 2000 Series Frame configuration

• Slot number reports the module’s location in the frame

• Last Recalled E-MEM reports the name of the last E-MEM recalled

36 KAM-XM-SERIES Instruction Manual

Page 37

Configuration and Adjustments

An example of the Status page for each of the modules covered in this

manual are shown in Figure 15 (UDC), Figure 16 (UPC), Figure 17 (UNC),

and Figure 18 (DNC).

Figure 15. KAM-XM-UDC Status Header

Figure 16. KAM-XM-UPC Status Header

Figure 17. KAM-XM-UNC Status Header

Figure 18. KAM-XM-DNC Status Header

KAM-XM-SERIES Instruction Manual 37

Page 38

Configuration and Adjustments

Links and Web Pages

The Kameleon 2000 GUI provides the following links (see graphic at left) to

configuration web pages for all of the modules covered in this manual

unless otherwise specified:

• Status – reports input signal status, warnings, and module information

• License – reports the module type (page 41)

• Setup – provides controls for selecting the video reference for the

• Format – provides controls for setting input and output format

• Aspect – provides aspect ratio conversion options (page 46)

• ProcAmp – provides processing amplifier controls (page 48)

• Detail Enhance – provides horizontal and vertical detail enhancement

including part number, serial number and software versions (page 39)

module, the genlock offset, closed captioning lines and blanking controls (page 42)

(page 44)

controls (page 49)

• The following web pages are available only with the KAM-XM-UNC

module:

• Spike – provides adaptive median filter for random noise removal

(page 50)

• Brickwall – provides a low pass filter with a sharp cutoff for

impulse and gaussian noise conditions (page 51)

• Temporal Recursive – provides a motion adaptive filter for

removing random and gaussian noise (page 52)

• Mosquito – is not available in this application (page 55)

• Advanced Aperture – is not available in this application (page 55)

• Color Legalizer – provides luma and chroma high and low limit controls for setting legal color limits (page 56)

• Grain Insertion – is not available in this application (page 57)

• GPI – enable and assign E-MEM registers to GPI Inputs 1-3 for external

recall (page 58)

• E-MEM – provides ten Preset registers for store and recall of module

configuration (page 59)

• Slot Config – provides Slot ID and Memory functions, Frame Health

reporting and SNMP reporting enable/disable controls (page 65)

• Software Update – gives software update information (page 68)

A summary of all configuration value ranges, defaults, and control types is

given in Table 5 on page 30.

38 KAM-XM-SERIES Instruction Manual

Page 39

Status Web Page

Configuration and Adjustments

Use

this

link

The Status web page (Figure 19 on page 40) provides an overall indication

of the health of the system in the following sections:

• Status Header – the same on all KAM-XM configuration pages (see Web

Page Operations and Functional Elements on page 36),

• Color-coded communication status for each component and path,

• Summary of all fault/warning conditions, and

• Identification, Version and Download Status reporting.

Color-coded Status Indicators and Links

Each box on the Status page represents a KAM-XM module. Arrows represent signal paths that may or may not be monitored. These elements act as

links when their function is active (indicated by underlined function

name).

Color code:

• Green = Pass – operating as expected.

• Yellow = Warning – signal is absent, has errors, or is misconfigured.

• Red = Fault – a component has failed.

• Grey = Not monitored.

Identification

The Identification section lists the following information about the module:

• Part Number

• Serial Number

• Hardware Version

• License Tag

Version

The Version section lists currently loaded Program, Software, and Video

and Audio firmware.

Download Status

The current software version is listed in the Download Status area for all

download components. The version for each of these components should

be the same.

KAM-XM-SERIES Instruction Manual 39

Page 40

Configuration and Adjustments

Figure 19. KAM-XM Status Web Page

Warning/Fault

reporting area

40 KAM-XM-SERIES Instruction Manual

Page 41

License Web Page

Configuration and Adjustments

Use

this

link

The License web page (Figure 20) displays read-only values for identifying

the License Tag and Key and the type of module in the Licensed Packages

area.

Note This information is set at the factory to determine module type and options.

Figure 20. KAM-XM License Web Page

Module version

KAM-XM-SERIES Instruction Manual 41

Page 42

Configuration and Adjustments

Setup Web Page

The Setup web page (Figure 21 on page 43) provides the following controls

Use

this

link

for the module:

•

Reference – set the module reference to either Input (from the currently

selected video input) or

frame).

External (from the 2000GEN module in the

When

the amount of offset in microseconds as needed to match the external

reference.

•

Closed Caption Line – select the line on which to place closed captioning.

•

Bad Video Input – when the Ignore checkbox is selected, the module will

not perform an application restart and will only lose the output for 2

frames. Under normal circumstances if a video switch/error occurs in

the input SDI signal, the module will perform an application restart to

recover, resulting in a 3 second loss of video output.

Note This mode requires that the source and frame be synchronized via an external

• Blank Line – Select the On checkbox to blank the corresponding line in the

vertical interval.

External is selected, the Genlock Offset control will be available. Set

reference.

42 KAM-XM-SERIES Instruction Manual

Page 43

Figure 21. KAM-XM Setup Web Page.

Configuration and Adjustments

KAM-XM-SERIES Instruction Manual 43

Page 44

Configuration and Adjustments

Format Web Page

The Format web page (Figure 22 on page 45) provides the following con-

Use

this

link

trols for the module:

•

Note Changing the input or output format will cause the module to reload the appli-

Note All possible input and output values will be listed and can be selected in the

Format Conversion – in the Format Conversion display, the Current input

and output format are displayed. To change the input, use the Input

Desired pulldown and select the format. If it is available a Yes will appear

in the

Available column. Possible input and output formats, as well as the

defaults for an up and down converter are summarized in Table 2 on

page 9.

cation. This will take approximately 60 seconds and a reloading message will

appear during this time. Select the Refresh button at the top of the page to

see the new settings after this time has elapsed.

Select the Apply button to set the values.

pulldowns. If the value does not apply to the application it will be reported as

not available.

• Source Material – select the type of source material being fed to the

module (

Video or Auto). When set to Auto, the module will determine if

the input material is video or film originated and adjust the filtering

accordingly. In some situations, such as broadcast applications, where

the input material cannot be as easily interpreted by the module, the

user can force the mode to

•

Deinterlace Type – select the type of deinterlacing for the module (PixelMotion or Vert Interpolation). Select PixelMotion for material that has motion or

Vert Interpolation for images where motion is not a concern. Refer to

Video to prevent artifacts from occurring.

Format Conversion on page 22 for more explanation on using a partic-

ular de-interlace type.

44 KAM-XM-SERIES Instruction Manual

Page 45

Figure 22. KAM-XM Format Web Page.

Configuration and Adjustments

KAM-XM-SERIES Instruction Manual 45

Page 46

Configuration and Adjustments

Aspect Web Page

The Aspect web page (Figure 23 on page 47) provides the following con-

Use

this

link

trols for selecting and adjusting the aspect ratio mode for the module:

•

Note Changing the aspect from Common Sides or to Common Sides will cause the

• Zoom Crop – when enabled by checking the On checkbox, zooms the

Current Aspect – Set the desired Aspect mode to one of the following:

• Anamorphic

• Common Side (Common Left & Right)

• Common Top & Bottom

Refer toAspect Ratio Modes on page 23 for an overview for setting the

aspect ratio mode.

module to reload the application. This will take approximately 60 seconds and

the module will display a message stating that the application is reloading.

Select the Refresh button to see the new settings after this time has elapsed.

image by 3 pixels and then crops the image by 3 pixels. This allows correction of issues that occur on the top and bottom or left and right edges

of an image.

•

Fill Shade – when the input aspect ratio is smaller than the output aspect

ratio there are areas in the output display filled with black. The Fill

Shade controls adjust the luminance (Y) and color (Cb and Cr) of the

black display areas.

•

Edge Trim – use the X Trim and Y Trim controls to adjust the amount of

border cropping in pixels in the X and Y directions performed on the

image.

46 KAM-XM-SERIES Instruction Manual

Page 47

Figure 23. KAM-XM Aspect Web Page

Configuration and Adjustments

KAM-XM-SERIES Instruction Manual 47

Page 48

Configuration and Adjustments

Proc Amp Web Page

The Proc Amp web page (Figure 24) provides the controls for adjusting the

Use

this

link

video processing parameters for the output of the module. Ranges and

default values are summarized in Table 5 on page 30.

Each control must be enabled by checking the

Use the Proc Amp controls to set the following parameters:

•

•

•

•

Enabled checkbox.

Video Gain – sets the overall amplitude of the output video signal from

± 6 dB.

Black Level – adjusts the black level of the video output signal ±30 IRE.

Hue – adjusts the phase of the output video signal ± 9 degrees.

Saturation – adjusts the chroma saturation of the output video signal

± 6 dB.

Check the

duction as required by SMPTE Recommended Practice RP 177.

Figure 24. KAM-XM ProcAmp Web Page

RP 177 On checkbox when using video converted from film pro-

48 KAM-XM-SERIES Instruction Manual

Page 49

Use

this

link

Detail Enhance Web Page

The Detail Enhance web page (Figure 25) provides the controls for determining the amount of detail enhancement applied to the signal.

Each control must be enabled by checking the corresponding

checkbox.

Use the following controls to perform detail enhancement:

•

Horizontal – this control is used to soften or sharpen the horizontal detail

in the image (± 6 dB).

•

Vertical – this control is used to soften or sharpen the vertical detail in

the image (± 6 dB).

•

Anti-Alias Filter – (active in modules with down conversion capability

only) turn anti-aliasing

Figure 25. KAM-XM Detail Enhance Web Page

Configuration and Adjustments

Enable

On or Off with the pulldown.

KAM-XM-SERIES Instruction Manual 49

Page 50

Configuration and Adjustments

Spike Web Page

The Spike web page (Figure 26) is active only on the KAM-XM-UNC

Use

this

link

module.

This web page provides noise reduction with an adaptive median filter that

works well in reducing random impulse noise. Refer to Spike Filtering on

page 26 for a discussion of the Spike filter.

•

•

Figure 26. KAM-XM Spike Web Page

Enable – enable or disable the Spike control with the Enable pulldown.

Luma & Chroma – sets the adaptive threshold of the filter in the luminance

and chrominance channels. This threshold represents a percentage of

the central pixel value that surrounding neighbors must be within in

order to be considered similar.

Setting the filter to 100 (maximum) forces the filter on for every pixel,

resulting in a standard median filter being applied to the entire luminance and chrominance channels.

50 KAM-XM-SERIES Instruction Manual

Page 51

Use

this

link

Configuration and Adjustments

Brickwall Web Page

The Brickwall web page (Figure 27) is active only on the KAM-XM-UNC

module.

This web page provides noise reduction by using a low pass filter with a

sharp cutoff to attenuate high frequencies. This type of filter is best for

diminishing Gaussian and impulse noise. Refer to Brickwall Filtering on

page 26 for a discussion on using the Brickwall filter.

Enable the control by selecting

lowing controls for the Brickwall filter:

•

Boost – sets the amount of boosting in dB of amplitudes prior to the

cutoff frequency. This gives the appearance of sharpening the image to

help compensate for blurring that occurs when filtering out high frequency information.

•

Cutoff – sets the cutoff frequency in MHz above which information will

be filtered while information below the cutoff will be left untouched.

•

Direction – this control allows the user to set the direction in which the

filters above will affect the picture.

•

Vertical applies the filters to the vertical axis only.

•

Horizontal applies the filters to the horizontal axis only.

•

Horizontal & Vertical applies the filters to the both axes.

Figure 27. KAM-XM Brickwall Web Page

On in the Enable pulldown then use the fol-

KAM-XM-SERIES Instruction Manual 51

Page 52

Configuration and Adjustments

Temporal Recursive Web Page

The Temporal Recursive web page is active only on the KAM-XM-UNC

Use

this

link

module.

This is a motion adaptive temporal recursive filter that works well in

removing random and Gaussian noise. Refer to Temporal Recursive Filtering

on page 27 for a discussion on using this filter.

Enable the Temporal Recursive control by selecting

down.This filter can operate in either

Auto or Manual mode.

On in the Enable pull-

Auto Mode

Use the following controls for removing noise:

•

Red Overlay – when enabled (On), a red overlay is superimposed onto

areas in the input image where the temporal recursive filter identifies

motion.

•

Auto – enabling this mode (Figure 28) engages a feedback controller that

dynamically sets the

able in

from the scene.

•

Bias – is active only in Auto mode. This control adjusts the noise set point

in the temporal recursive controller. The higher the bias the more

aggressive the controller is towards noise in the scene. The lower the

bias setting the more sensitive the controller is towards motion.

Figure 28. KAM-XM Temporal Recursive – Auto Mode

Manual mode based on noise and motion measurement extracted

Distance, No Motion and Motion control setting avail-

52 KAM-XM-SERIES Instruction Manual

Page 53

Configuration and Adjustments

Manual Mode

Enable Manual control by turning Auto off. The web page will appear as

shown in Figure 29.

Use the controls below in Manual Mode:

•

Red Overlay – when enabled (On), a red overlay is superimposed onto

areas in the input image where the temporal recursive filter identifies

motion.

•

Auto – disabling Auto (Off) puts the Temporal Recursive filter in Manual

mode.

Figure 29. KAM-XM Temporal Recursive – Manual Mode

KAM-XM-SERIES Instruction Manual 53

Page 54

Configuration and Adjustments

• Distance – sets the distance threshold to determine the sensitivity to

•

•

motion between the current frame and historical frames. The range of

this control is from 0 – 40, with the nominal value for the distance

threshold at 15. A setting of 0 will detect motion at every pixel, causing

no filtering to occur. A setting of 40 will be less sensitive to motion, temporally filtering every pixel, which may result in blurring of any