Page 1

Instructions for Use

Washing machine

Page 2

Thank you for your confi dence in purchasing our washing machine, and congratulations on the

excellent choice.

Your new washing machine meets the requirements of modern treatment of laundry. It is rational in

the consumption of energy, water and washing agents.

Our appliances are friendly to the environment. Some of the materials may be recycled, others

deposited or decomposed. To avoid pollution of environment, once your appliance is no longer

useful, take it to your local authorized waste appliance dealer.

The appliance is intended exclusively for use in households. If the appliance is used for

professional purposes, for profi t, or for purposes beyond regular use in a household, or if appliance

is used by a person who is not a consumer, the warranty period equals the shortest warranty period

possible as stipulated by the relevant legislation.

390909

Description of washing machine ..................................3

Cautions .......................................................................... 4

Installation and connection ........................................... 5

Operation .........................................................................9

Tips for washing and energy saving ..........................16

Cleaning and maintenance .......................................... 17

Troubleshooting ...........................................................19

Tables ............................................................................ 23

2

Page 3

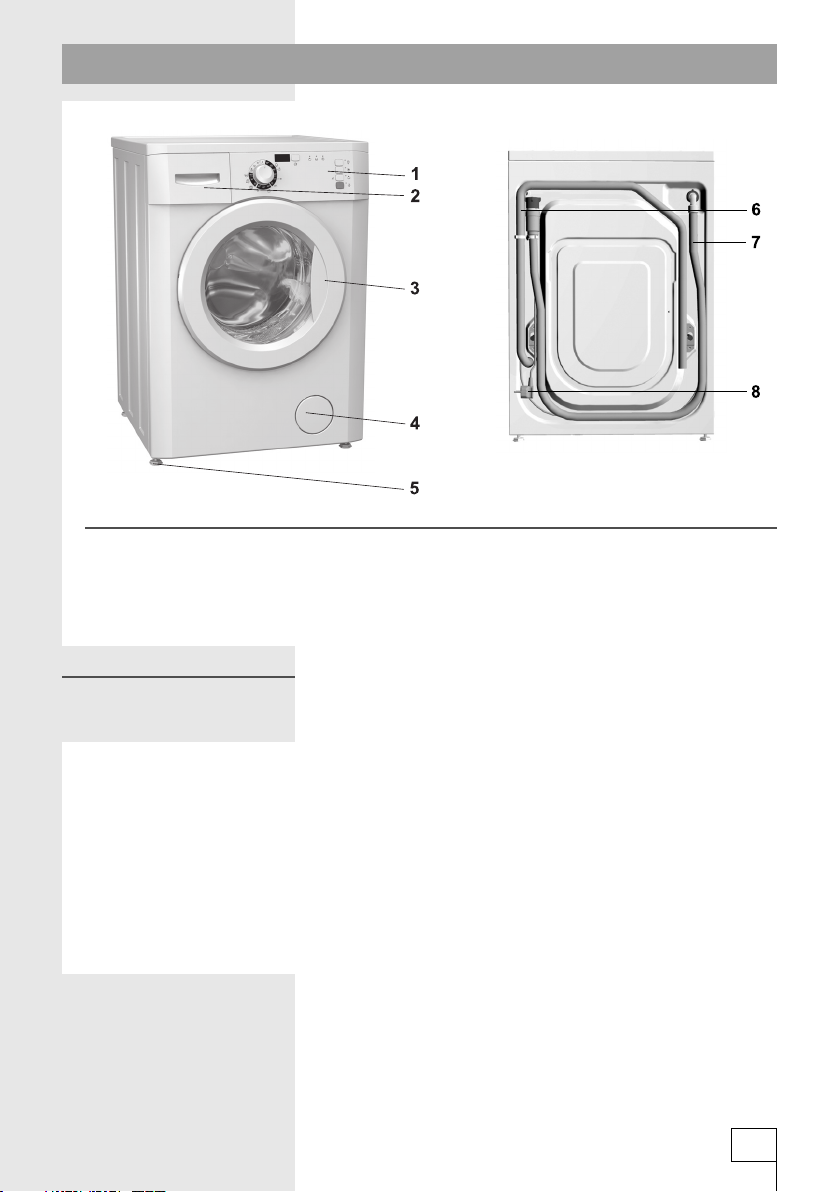

Description of washing machine

1. Front panel

2. Detergent dispenser

3. Door

4. Filter lid

Technical information

(depending on model)

• Max. load: 7 kg /6 kg / 5,5 kg

Dimensions (w x d x h):

600 mm x 600 mm x 850 mm

Depth with door open: 105 cm

Weight (net): 72 kg

Nominal voltage: 230 V, 50 Hz

Rated power: 2000 W

Power socket: (230 V, 50 Hz, 10 A)

Water pressure: min. 0,05 MPa, max. 0,8 MPa

Fuse: 10 A

Rating plate with basic information is located above the opening of

the machine.

5. Adjustable legs

6. Water outlet hose

7. Water inlet hose

8. Mains power cable

• Max. load: 5 kg

Dimensions (w x d x h):

600 mm x 440 mm x 850 mm

Depth with door open: 88 cm

Weight (net): 61 kg

Nominal voltage: 230 V, 50 Hz

Rated power: 2000 W

Power socket: (230 V, 50 Hz, 10 A)

Water pressure: min. 0,05 MPa, max. 0,8 MPa

Fuse: 10 A

390909

3

Page 4

Cautions

• Be sure to remove transport brackets prior fi rst use of the appliance. Attempted operation of the

blocked machine may result in irreparable damage which is not covered by the manufacturer’s

warranty!

• When connecting your washing machine to water supply, be sure to use brand new water inlet

hose and appropriate sealing gaskets (attached).

• Do not locate the machine in a room with temperature below 0°C. Parts of the machine may be

damaged if frozen.

• Install the washing machine in a perfectly horizontal position, on solid fl at concrete fl oor.

• Follow the instructions for correct installation and water and mains connections.

• Never immerse the end of the drain hose into the draining water.

• Prior starting the washing cycle lock the door by pressing them at the designed spot.

• Door may not be open during the washing cycle.

• We recommend running the self-cleaning program before the fi rst wash in order to remove any

impurities from the washing machine drum (see chapter on” Selecting additional functions”).

• Use only detergents and softeners for machine wash. Manufacturer may not assume

responsibility for any damage and eventual discoloring of gaskets and plastic components as a

consequence of incorrect use of bleach and/or coloring agents.

• For removal of lime residues use such agents with added anti-corrosion agents. Follow the

manufacturer’s instructions. Finish the lime removal by multiple rinsing to remove completely

eventual acid residues.

• Never use detergents containing solvents, since there is a danger of creating toxic gasses which

may damage the machine and result in ignition or explosion.

• This product does not release silver ions during the washing cycle.

• Upon completion of washing operation close the water faucet.

• Before any transport block the machine by inserting at least one transport blocking rod. Prior this

operation disconnect the appliance from the mains power!

• Rating plate with basic information is located above the opening of the machine.

• The warranty shall not apply to consumables (bulbs), minor discoloration or deviations of color,

increased noise level as a consequence of appliance age, which does not affect appliance

functionality, and aesthetical defi ciencies which do not affect appliance functionality or safety.

• The appliance is manufactured in compliance with all relevant safety standards; however, it is

recommended that persons with impaired physical, motional, or mental abilities, or persons with

inadequate experience and knowledge, do not use the appliance without due supervision. The

same recommendation applies to minors using the appliance.

Before connecting the appliance read these instructions carefully. Repairing the failure

arising from inappropriate connections or use of the appliance is not covered by the

guarantee.

The symbol on the product or on its packaging indicates that this product may not

be treated as household waste. Instead it shall be handed over to the applicable

collection point for the recycling of electrical and electronic equipment. By

ensuring this product is disposed of correctly, you will help prevent potential

negative consequences for the environment and human health, which could

otherwise be caused by inappropriate waste handling of this product. For more

detailed information about recycling of this product, please contact your local city

390909

offi ce, your household waste disposal service or the shop where you purchased the

product.

4

Page 5

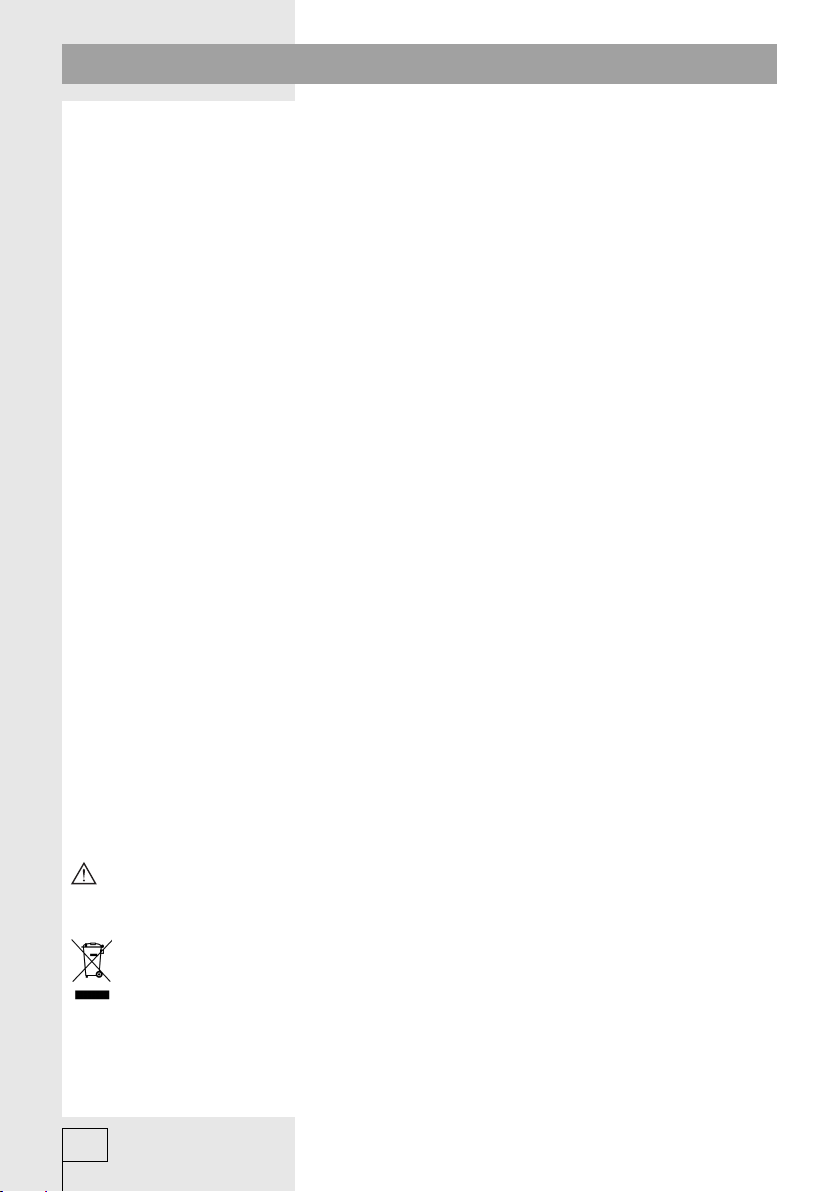

Installation and connection

Package removal

Removal of transport

brackets

In removing the wrapping be careful not to damage the

appliance with a sharp object.

Before connecting the appliance, let it warm up to room

temperature (wait for two hours).

• Our appliances are packed in environmentally friendly

materials which may be recycled, deposited or decomposed

without any threat to the environment.

• To this end all wrappings are marked accordingly.

• Move the pipes.

• Loosen screws (A) at the rear of the machine (Fig. 1).

• Remove the brackets (B) (Fig. 1) and slide them into the

groove on the blocking rod (Fig. 2) - the right one should be

turned around.

• Use the brackets to rotate blocking rods for 90° and pull them

out.

• Close the openings with attached plastic pegs.

Save transport brackets for eventual later use.

Fig. 1 Fig. 2

Leveling the appliance

Be sure to remove the transport brackets prior fi rst use,

otherwise the appliance may be permanently damaged.

In such cases the warranty conditions are void.

• Put the appliance in horizontal position by turning the

adjustable legs. The legs are adjustable up to +/- 1 cm.

After the adjustment tighten the nuts fi rmly (A) - towards

the bottom of the machine!

Vibrations, moving of the appliance and loud operation

due to incorrect setting of the adjustable feet shall not

be covered by this warranty.

The appliance should be placed on a surface with

concrete base; the surface should be dry and clean in

order to prevent slipping. The adjustable feet should

also be cleaned before installation.

390909

5

Page 6

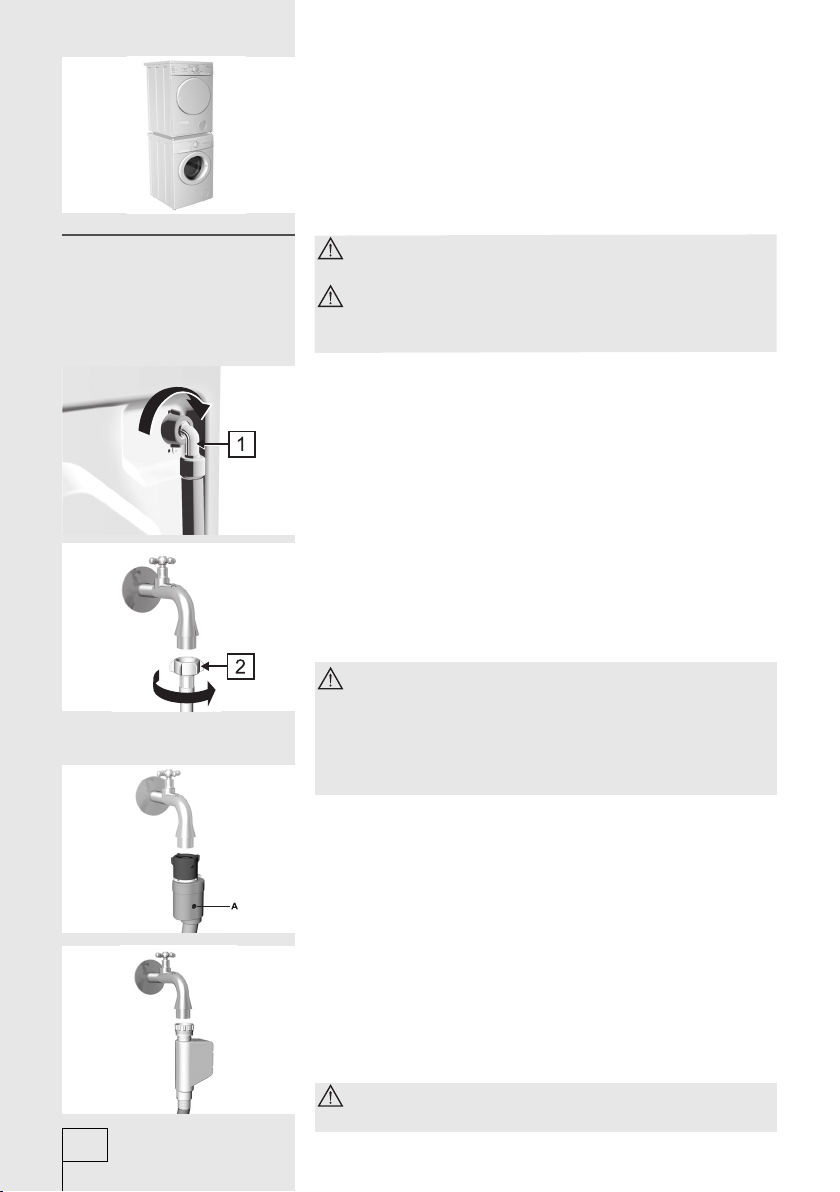

• If you have a tumble dryer of the same dimensions, you can

place it on top of the washing machine.

Water inlet connection

To ensure correct operation of the appliance, water

pressure inlet must be between 0,05 and 0,8 MPa.

Minimum water pressure can be established by measuring

the quantity of poured out water. 3 litres of water must be

poured out from completely opened tap in 15 seconds.

• Take the water inlet hose from the drum and attach the inlet hose

angle extension (1) to the washing machine by screwing it onto

the provided thread (certain models only).

• Insert the gasket with a fi lter net into the straight inlet hose

attachment nut (2) and screw the nut onto the water tap. (With

some models, the gasket with fi lter net is already fi tted and any

additional fi tting into the nut on the straight attachment is not

required).

• If your model has connections for both hot and cold water, then

connect one hose to the cold water supply (blue wing nut or blue

mark on the hose) and the other one to the hot water supply (red

wing nut or red mark on the hose), as indicated on the back wall

of the appliance (letters C and H) (C - cold; H – hot).

The inlet hose should be tightened manually, fi rmly

enough to prevent any leaks. After tightening the hose,

check for any leaks.

Use of pliers, wrenches, or other similar tools is not

allowed when installing the hose, as these tools can

damage the nut thread.

Partial Aqua-stop (water stop system)

In case of damage on the interior pipe, leaking is prevented by

automatic closing system which stops water inlet to the machine. In

such cases display A turns red.

Inlet pipe must be replaced.

390909

Complete Aqua-stop (certain models only)

In case of damage on the interior pipe, leaking is prevented by

automatic closing system which stops water inlet to the machine.

Security system also detects whether there is any water leakage

within the interior of the machine. In such cases washing is

suspended, machine switches on the pump and signals error.

Do not immerse the Aqua-stop system inlet pipe into the

water, because it contains the electric valve!

6

Page 7

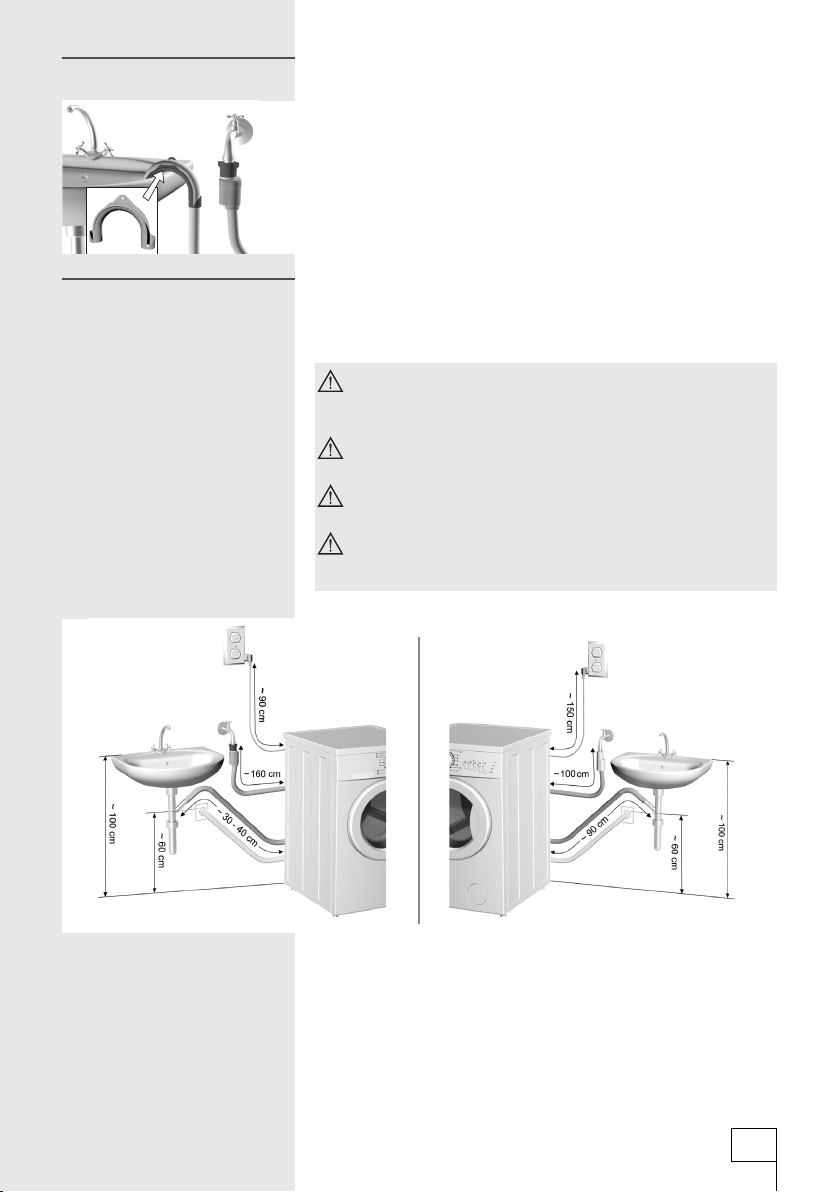

Water outlet connection

• Fix the outlet hose to run into the sink or the bathtub, or

connect it directly to the wall drain outlet (diameter min. 4 cm).

• Wall drain must be installed properly and must enable

occasional cleaning.

• Fasten the outlet hose support with a piece of rope led through

the hose elbow, to prevent the hose from slipping to the fl oor.

The end of outlet hose should be placed between minimum 60

cm and maximum 100 cm above the fl oor level.

Connect the appliance to

the mains supply

• Plug the mains power cable to the wall mains socket.

• Required voltage and other information are written on the

rating plate above the door opening of the machine.

The wall socket must be accessible at all times and

must be equipped with an earth lead (in accordance

with the local safety regulations).

The permanent connection must be fi tted by an

authorized personnel only.

Damaged mains power cable may be replaced only by

the producer or his authorized personnel.

Never plug the appliance into the electric shaver socket

or hair dryer socket.

390909

7

Page 8

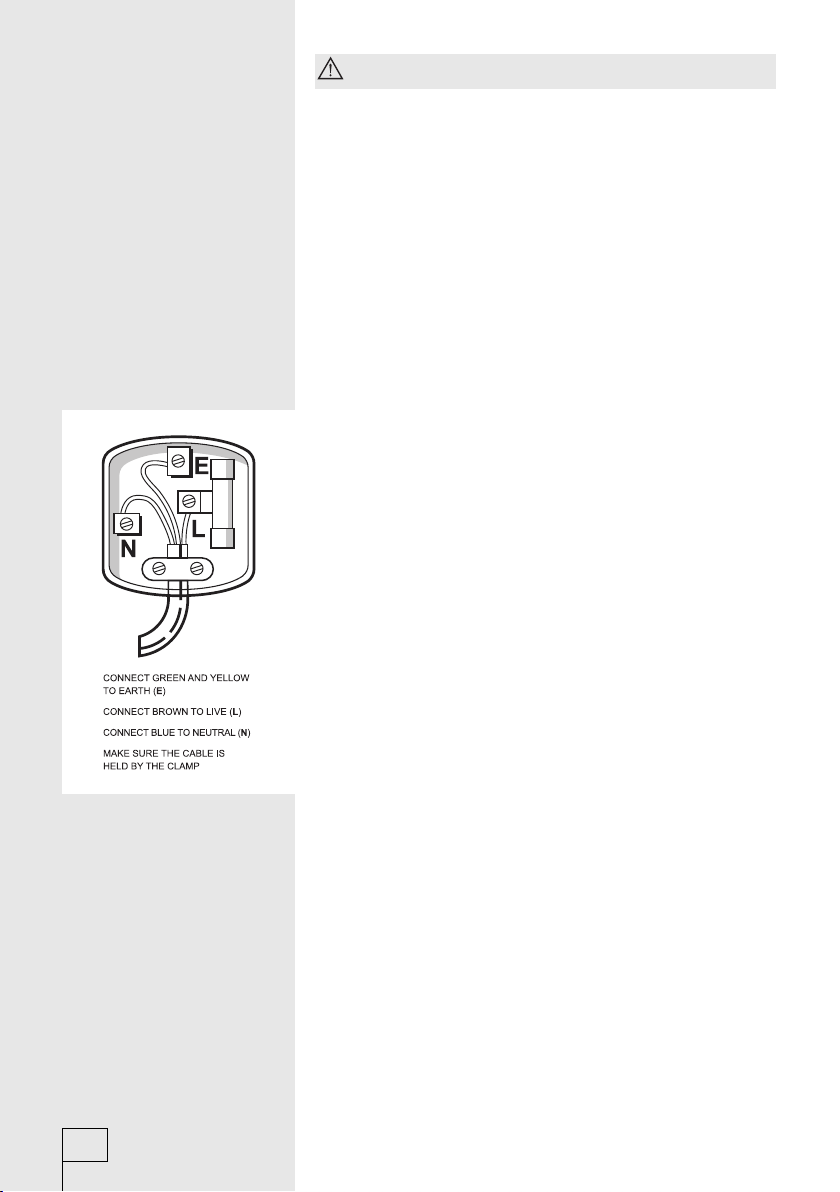

This appliance must be earthed!

Connect the appliance with the cable and plug to a suitable 13

amp socket which is properly earthed.

Required nominal voltage and frequency are indicated on the

rating plate.

The connection to the mains supply and earthing have to be

made according to current standards and regulations. The

appliance resists temporary voltage tolerance up to -15 to +10 %.

If the fi tted plug is not suitable for your socket outlet, then it

should be cut off and disposed of safely in order to avoid a

possible shock hazard.

A suitable plug of 13 amp or 15 amp rating should then be fi tted

to the cable.

The wires in the mains lead are coloured in accordance with the

following code (see fi g.).

1. The GREEN AND YELLOW wire must be connected to the

terminal in the plug, which is marked with the letter E or by the

earth, symbol or coloured green or green and yellow.

2. The BLUE wire must be connected to the terminal which is

marked with the letter N or coloured black.

3. The BROWN wire must be connected to the terminal which is

marked with the letter L or coloured red.

390909

8

Page 9

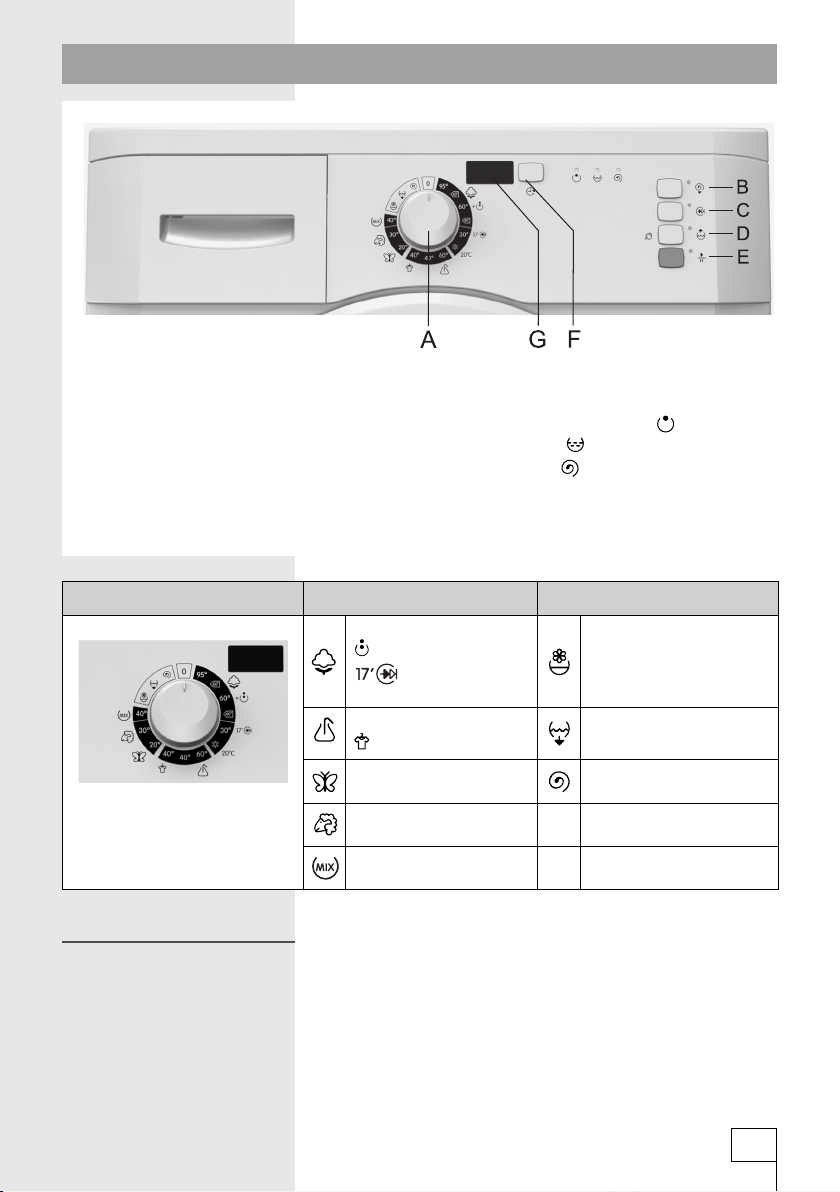

Operation

A - program selector knob

B - key - selection of spinning speed (rpm)

/ stop pump

C - short program (Quick wash)

D - higher water level (Water plus)

E - START / PAUSE button

F - delayed start

G - display

Program selector Basic programs Partial programs

Cotton

Pre-wash

20°-Tap water + (ECO)

Synthetics

Easy iron

Delicate Spinning

Wool

Mix

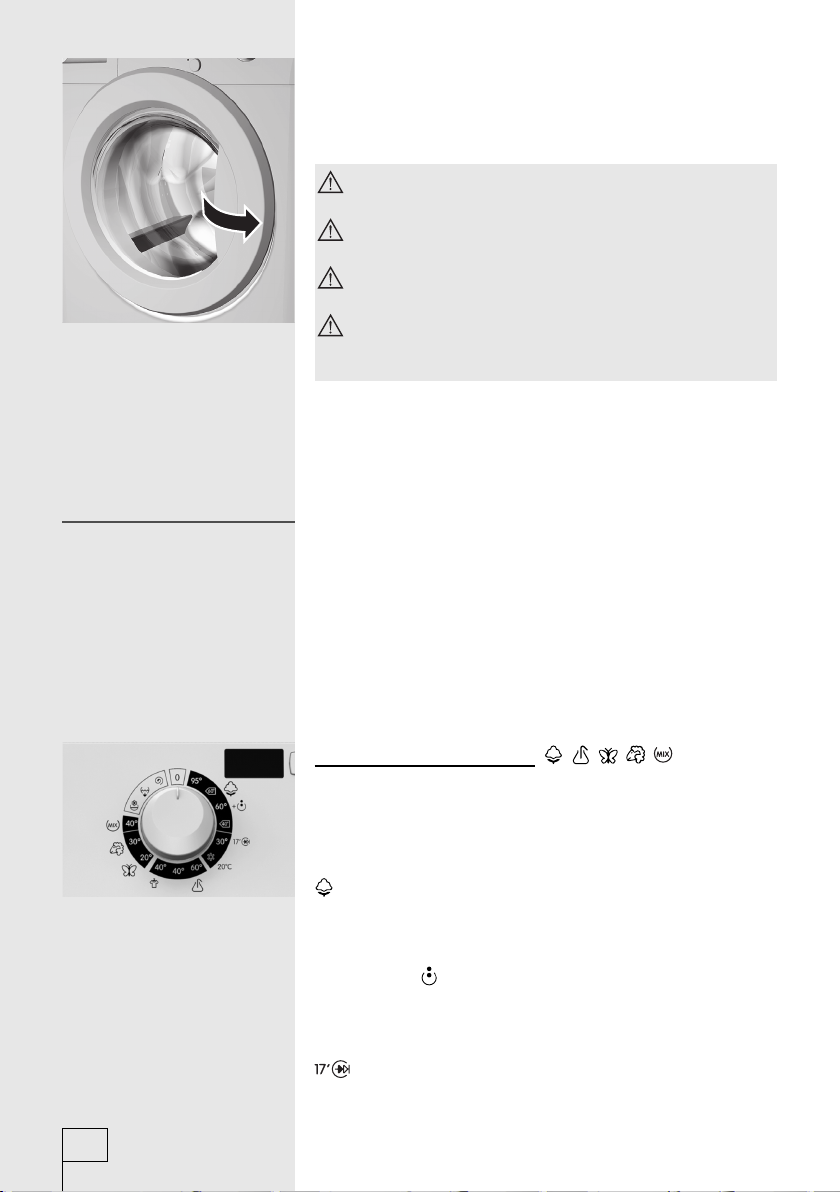

Washing procedure

• Open the door of the machine.

• Load the laundry into the drum.

• Close the door.

• Open the water inlet faucet.

• Select the desired program.

• Add washing and treatment agents (detergent and softener).

• Start the operation by pushing the START knob (E).

Signal LED’s:

- washing program stages

• wash + pre-wash

• rinse

• spin

Softening

Quick program

(Conditioner)

Pumping water (Drain)

390909

9

Page 10

- Open the door of the machine.

Door is opened by pulling the handle (lever) on the right hand

side of the door towards you.

- Sort the laundry by the type of fabrics.

Do the buttons and zippers, tie the strings and pull out

the pockets.

Very delicate laundry should be put in a special protective

sack.

It is suggested to load the drum with items of different

sizes.

Pay attention to the labels on the clothes, indicating

the recommending washing mode (see table of textile

treatment symbols on the last page of these instructions).

- Load the laundry into the drum.

Check that the drum is empty.

- Close the door of the appliance.

- Open the water inlet faucet.

- Push the ON/OFF button and select washing program.

Washing machine

operation

390909

Program is selected by turning the program selector (A) from

the “0” position to the desired washing program. LED next to

the START key starts fl ashing. Duration of the selected program

is indicated on the display. The program selector (A) may be

turned in both directions, and the appropriate program selected

according to the type of laundry washed and the required

washing temperature (see Program Chart for help). You may

select basic or partial programs.

Select additional functions by pressing their relevant knobs (E).

- Selection of basic programs (

Basic programs represent integral programs containing all washing

stages, including softening and spinning (see Program Chart). They

are selected by turning the program selector (A) to the appropriate

position.

, , , , )

Cotton: whites/colored

Normally stained cotton and fl ax bed linen and underwear, table

cloth, bathroom towels, top garments, etc.

To wash heavily soiled laundry that will not discolor, use the program

with a prewash

For smaller loads (non-delicate cotton, linen, synthetic, and mixed

fabric) and smaller quantities of soiled laundry (laundry refreshment,

laundry wet with perspiration, etc.), we recommend the use of the

quick program. To activate the program, turn the (A) button

to the setting “Cotton 30°C” and then press the “Short Program (C)”

key. You will save both energy and time.

.

10

Page 11

The Cotton 15° program is intended for washing less soiled laundry,

using detergents (washing gels) specially designed for washing at

such temperatures.

Using this program will save you both time and power as water

heater will only be engaged if the water inlet temperature is lower

than 15°C.

Synthetics

Normally stained shirts, blouses and other polyester and polyamide

garments, or a mixture of these fabrics with cotton.

If you wish the laundry not to be excessively creased at the end of

washing, use easy ironing program

.

Delicate

This is a program for delicate fabrics (dresses, skirts, blouses) and

curtains.

Wool

Special, delicate program for washing woolen products indicated

as appropriate for machine washing, as well as for very delicate

products on which hand washing is indicated as appropriate.

Mix

Special program for washing normally stained colored laundry made

from various resistant fabrics at 40°C.

- Selection of additional function ( , , , , )

Additional functions alter the basic washing cycle procedure.

Particular function is switched on by pressing the relevant knob.

The selection is confi rmed when the LED next to the key lights up. If

certain function is not available for the selected program, signal LED

will not illuminate.

The function is switched off by pressing the same button again signal LED goes off.

Select the particular function after the selection of the

basic program, but prior pressing the START button (E).

Display (G)

After setting the basic and partial programs and pressing the START

(E) button, washing time is indicated on the display. After the end of

washing, the display reads END.

During washing, the remaining washing time is indicated in hours

and minutes.

If no program is selected and started and no other action is taken

within fi ve minutes after turning on the machine, the display will be

automatically turned off to save energy.

11

390909

Page 12

The display will turn on again when you rotate the program selector

dial or press any button.

If no action is taken after the end of the program, the display will also

turn off after fi ve minutes.

Washing stage signal lamps and the START/PAUSE key fl ash

intermittently.

Low water temperature, low network voltage, and

smaller loads of laundry may extend the washing time;

the time indicated on the display is constantly adjusted

to account for such conditions.

LOW POWER MODE

P o = weighted power in ‘off mode’ [W] 0,10

P l = weighted power in the ‘left on mode’ [W] 0,65

T l = time in ‘left on mode’ [min] 10,0

Delayed start (F)

Press the (F) button; the time “00:00” will be indicated on the

display (G). Each time the button is pressed again, the time on

the display will be increased by one hour (maximum delay is 23

hours). After the time has been selected, the LED over the button

lights up (and remains lit). If no other button is pressed in the

following 5 seconds, program duration is indicated on the display.

The function is activated when the START (E) button is pressed.

Time is decreased by minutes. When the count-down is over, the

washing program starts automatically.

• To interrupt or change the delayed start setting, press the

START / PAUSE button (E).

• To change the delay time, select a new time by pressing the

(F) button. Press START to resume the count-down. To quickly

interrupt the delayed start, press the (F) button and hold it for

three seconds. Press the START button to resume the program.

390909

12

Spinning speed (rpm) / Pump stop

By pressing the (B) button, you can decrease the spinning speed

(in rounds per minute) to “0”. After pressing the button for the

fi rst time, the optimum rpm setting for the selected program is

indicated. By each subsequent press on the button, the spinning

speed is decreased. The last selection is “pump stop”, which

means that laundry remains soaked in the last rinsing water. Use

this function to prevent creasing when you are not able to take

the laundry out of the washing machine immediately after the

washing cycle is over. This function is particularly appropriate for

synthetics

recommended with wool

and delicate laundry . Use of this function is not

.

Page 13

Short program (Quick wash) (selection with a button (C))

• energy-saving program

• appropriate for washing lightly soiled laundry or smaller

quantities of clothes

• reduces washing and rinsing time

• reduces water consumption (with some programs)

• by pressing the key quick program on the program Cotton

.

30°C, activate the program Cotton 30°C-quick

Higher water level (Water plus) (selection with a button (D))

• Improves rinsing, which is particularly important if your skin is

oversensitive to detergents.

• For washing heavily soiled laundry.

Auto-clean program (SterilTub)

Run this program to eliminate any impurities, bacteria, and odor

from the washing machine.

Before running the auto-clean program, empty the washing

machine drum; there shouldn’t be any clothes in the washing

machine during the auto-clean (SterilTub) program.

Adding a small amount of powder detergent will additionally

improve the effect of the auto-clean program.

To run the auto-clean program, rotate the program selector knob

(A) to the position “Cotton 95°C”, then pressing the (D) (higher

water level) key and hold it for three seconds.

“Cln” and the time remaining until the end of the program will

alternate on the display.

If you do not regularly use washing program with temperatures

over 60 °C, it is recommended to run the auto-clean program at

least once per month.

- Selection of partial programs ( , , )

These are independent programs and may be used when you do

not need the entire washing program. In case you would like to

use more additional programs in a sequence, you must turn off

the appliance prior any new program selection (turn the program

selector (A) to “0” for at least one second).

Softening (Conditioning)

The program is intended for softening, starching, or impregnating

clean clothes.

Softening program can also be used as an independent or

additional rinse program; in this case, however, do not add any

fabric softener or conditioner.

The program is completed by a spinning cycle at 1,000 rpm.

Spinning speed can be decreased.

13

390909

Page 14

Pumping the water out (Draining)

Use it when the washing program was interrupted or if pump stop

function was engaged, and you only wish to pump the water out of

the drum, without spinning.

Spinning

Aggressive spinning for non-delicate laundry at high spin RMP.

Spinning rpm can be decreased by pressing the (

of spinning speed (rpm).

- Adding washing and softening agents

(see Tips for washing and energy saving)

• pre-wash compartment

• main wash compartment

• softener compartment

If you do not apply the program which includes the pre-wash

feature, you may add washing detergent directly into the drum,

using the measuring vessel.

When adding softener, be careful to fi ll the dispenser only

up to the marked level.

Be sure to close the detergent dispenser when opening/

closing the appliance door.

) key - selection

Start the operation

390909

14

• Push the START button (E). The machine starts operating after

a few seconds. LED indicating the current washing stage lights

up. If the door is not closed after the machine is switched on, the

START LED starts fl ashing again after a few seconds.

When you close the door, the machine initiates the selected

program. Time remaining until the end of the washing program is

indicated on the display (for LED).

• As each washing stage is completed the relevant washing stage

indicator LED goes off and the subsequent one goes on.

• In case you would like to alter the washing program after the

initiated washing operation, turn the program selector for one

second to the position “0”, followed by the selection of a new

program. Switching the machine off deletes any previously

selected additional functions(i.e. Pump stop), so they have to be

reactivated.

Upon switching OFF, all additional pre-selected functions

are deleted; therefore they must be switched-ON again.

- End of washing program

The end of washing program is signalized by fl ashing washing

progress LEDs. The message “End” is indicated on the display.

• Washing machine door can be opened.

Page 15

• Take the laundry out of the drum and remove any remaining

particles or foreign bodies from the door seal.

• Leave the door ajar to let the machine dry.

• Close the water inlet tap.

• Turn off the washing machine by rotating the program selector

knob (A) to position “0”.

• After the end of washing program, power supply should be turned

off by pulling the mains cord plug out of the outlet.

Interruptions

• By the user

Selecting PUMP STOP function

If the setting pump stop was selected, the program stops at the

last rinsing cycle and the symbol for pump stop

the display. LED next to the START key is fl ashing. The program

can be completed by pressing the START (E) button; in this case,

the program will fi nish with a spinning cycle, as defi ned by the

program. Spinning rpm can be decreased by pressing the (

selection of spinning speed (rpm).

The program can also be changed by rotating the program selector

knob (A) to “0” and choosing either spinning or only pumping out the

water between additional programs or cycles.

Manual cancellation

The program is cancelled if the program selector knob (A) is rotated

to position “0”. If there is water in the machine, select one of the

additional programs (pumping

and complete the program.

PAUSE knob

By pressing the PAUSE knob (E) program may be suspended

at any time. After certain time you may open the door if there is

no water in the drum, otherwise this is not possible. Program is

continued by pressing the START knob (E).

• Failures

Program is suspended in case a failure occurs. These are

indicated by the fl ashing LED-s and sound signal is heard (see cf.

Failures).

, spinning ) to empty the drum

is indicated on

) key -

• Power failure

At electric cutout the program is interrupted, however, after the

power supply has been re-established, the program operation

automatically proceeds.

If a power failure occurs when the drum is still full of

water, be careful not to open the door before you pump

the water out.

390909

15

Page 16

Tips for washing and energy saving

• Before washing sort out the laundry according to the type, degree of dirtiness and color resistance.

• Prior selecting the washing program consult the sewn tab with information on a particular piece of

laundry (see Maintenance Chart on the last page).

• Wash separately the new colored textile products for the fi rst time.

• Wash heavily soiled laundry in small quantities and add more detergent.

• Treat stubborn stains with special stain remover, it will save energy.

• With lightly stained laundry select washing program without pre-wash, use short program and

select lower washing temperature. This way you may save up to 50% of energy.

• Avoid washing too little quantities of laundry because of energy saving and for better performances

of the appliance.

• The largest allowed quantity of dry laundry is indicated in the Program chart.

• Before washing empty the pockets, close zip fasteners, and remove any metal fasteners or badges

that might clog the drain or damage the laundry or drum interior.

• Loosen the stacked laundry prior inserting it into the drum.

• Use only detergents for machine wash.

• Add powder or liquid detergents according to the manufacturer’s instructions.

• For different washing temperatures and selected washing programs, please note the

recommendations provided by detergent manufacturers.

• If water hardness in your pipeline exceeds 14°dH, we recommend using water softeners. Any

damage to the heater due to failure to use a water conditioning agent shall not be covered by this

warranty.

• Chlorine-based whitening agents are not recommended, as it can damage the heater.

• To improve your washing results we recommend 2/3 load on Cotton programs.

390909

16

Hardness

scale

1 - Soft < 8,4 < 1,5 < 15 < 150

2 - Medium 8,4 - 14 1,5 - 2,5 15 - 25 150 - 250

3 - Hard > 14 > 2,5 > 25 > 250

In case of hard water add detergent according to the Chart for

degree and add appropriate quantity of water softener (see

manufacturer’s instructions).

• If you do not apply the program which includes the pre-wash

feature, you may add washing detergent directly into the drum.

• If you use thick liquid softener it is recommended to dilute

it with water, to prevent clogging of dispenser compartment

ducts.

• Washing machine is equipped with the dispenser partition

gate, so you may pour liquid detergent also into the central

compartment. If you use powder detergent the gate is lifted up,

and in case of liquid detergent it is slid down.

• Liquid detergents are intended for main wash only, without

pre-wash.

• Insert particularly delicate linen (stockings, delicate female

underwear, etc.) into the special bag.

Degree of hardness

°dH(°N) m mol/l °fH(°F) p.p.m.

Page 17

• High spin RPM leave less moisture in laundry which dries out

much quicker in the tumble dryer, thereby saving energy.

Do not put clods of detergent into the soap dispenser

as the tube in the washing machine may clog.

Cleaning and maintenance

Disconnect the washing machine from the mains

before cleaning!

• The casing should be cleaned with soft cloth and mild

detergent.

• The interior of the drum and the door gasket is cleaned by

washing at 60°C without laundry and adding half quantity of

detergent.

• Frequent, or predominant, washing at low temperatures, using

liquid detergents, may result in development of bacteria which

causes odor in the washing machine.

To prevent this, we recommend running the auto-clean

program occasionally (see chapter “OPERATION / selecting

additional functions”).

• If necessary, clean the detergent dispenser. Pull it out from its

casing completely by pressing the fl ap (see Fig.).

• If necessary, clean the cover of the bung under the running

water.

390909

17

Page 18

• Wash it under running water using a brush, and dry it. Remove

any leftover dried detergent from the bottom of the casing.

• Clean the entire rinsing area of the washing machine with a

brush, especially the nozzles on the upper side of the rinsing

chamber.

• Clean frequently the water inlet hose screen under running

water.

• After each wash wipe the door rubber gasket. This will prolong

its useful life.

• Open the fi lter lid using fl at screwdriver or similar tool.

390909

• Filter needs occasional cleaning, especially following heavily

shaggy or old laundry.

18

Page 19

• Carefully turn the fi lter insert in anticlockwise direction and let

the water slowly drain; then remove the fi lter and clean it under

running water.

• Insert the fi lter back as shown on the picture, and tighten by

turning it in clockwise direction. To ensure good sealing the

gasket surface (A) must be dirt free.

Troubleshooting

Washing machine controls the operation of particular functions during washing. If irregularities

are detected, the fault is signaled by displaying a message (Fx) on the display, and by rhythmical

fl ashing of the LEDs. The machine signals the fault as soon as it is detected, and the program

progress is paused. If the fault is in the heating system, the machine completes the washing

program, but without the heating function.

If the fault is signaled during washing machine operation, the error code and remaining washing

time are indicated alternately on the display.

The fault is indicated until the washing machine is turned off.

Failures:

2 - Two fl ashes: door is not correctly closed

3 - Three fl ashes: inappropriate water intake

7 - Seven fl ashes: inappropriate water outlet.

In these cases, you will be able to remedy the failure by yourself (See Troubleshooting table).

1 - One fl ash: temperature sensor failure

4 - Four fl ashes: spinning sensor failure

5 - Five fl ashes: motor failure

6 - Six fl ashes: Heater failure

In these cases, turn off the machine, then turn it back on and repeat the program. If the failure

reoccurs, contact your nearest authorized service center. The LEDs will continue to fl ash until the

machine is turned off.

390909

19

Page 20

Various interferences from the environment (e.g. electric devices) may also cause the machine to

signal faults. In such case:

- turn off the appliance and wait a few seconds;

- turn on the appliance and repeat the washing program.

If the fault reoccurs, call the service center.

The warranty does not cover faults caused by interference from the environment (lightning strike,

electric circuit, natural disasters, etc.).

Failure Possible cause Remedy

The machine does not

work (indicator LED’s are

not illuminated).

Machine is not powered. Check if:

• power in the socket,

• the fuse is OK,

• plug is in the socket.

FAILURE 2

Washing program does

Door is not properly closed. Push it towards the machine.

not start

• At the beginning of the

washing program: on/off

LED is fl ashing

• During washing: LEDs

periodically fl ash twice

FAILURE 3

Water does not enter the

machine (after approx. 4

min the machine reports

failure - LEDs periodically

Disturbed water inlet.

Check if:

• the water tap is open,

• inlet pipe net fi lter is clean.

Push the START button.

fl ash three times).

Water is leaking from the

machine.

Filter is not tightly screwed in.

Inlet pipe is not tightly screwed

Tighten the fi lter properly.

Tighten the inlet pipe.

to the machine or to the water

faucet.

The machine moves

during operation.

Outlet pipe fell to the fl oor.

The machine is not properly

leveled.

Transport brackets are not

Affi x the outlet pipe to the drain.

Level the machine with the

adjustable legs.

Remove transport brackets.

removed.

The machine vibrates

during the spin.

Excessive foaming during

washing.

Unevenly distributed laundry,

especially with very small

quantities (for ex. only the

bathrobe).

This is normal, the machine will

reduce the RPM if vibrations are

too strong.

Wash larger quantity of laundry.

Excessive measure of detergent. Use washing powder according to

the instructions by the producer

and according to the water

hardness and soiled laundry.

Use only detergents for machine

washing.

390909

20

Page 21

Failure Possible cause Remedy

FAILURE 7

Water is poorly pumped

out or not at all (machine

reports failure - the LEDs

periodically fl ash seven

times).

Water outlet is clogged Check if:

• the fi lter is clean,

• outlet pipe is not jammed,

• the drain is clogged,

• outlet pipe is positioned higher

than 1m.

Push START again

Laundry is not properly

spun.

No failure is reported.

The machine switched on the

UKS* function. Because of bad

laundry balance, the machine has

The machine operates normally.

Wash large and small pieces of

laundry together.

automatically reduced spin RPM.

Greasy wads appear on

the laundry.

Too little detergent (laundry was

very greasy).

Wash the laundry again.

Add more detergent for such soiled

laundry, or use liquid detergent.

Laundry is stained after

washing.

You used liquid detergent or

detergent for colored laundry

Use the detergent containing

whitener.

which does not contain whitener.

White powdery residues

on the laundry.

It is not the consequence of bad

rinsing, but because of neophosphate detergents containing

non soluble components

(zeolites) for water softening.

Such substances may be

Immediately rinse the laundry once

again.

• Use liquid detergents which do

not contain zeolites.

• Try removing the residues with

the brush.

deposited upon the laundry.

Detergent residues in the

dispenser.

Low water fl ow pressure.

Some detergents may stick to the

dispenser rather hard if it is wet.

• Clean the inlet pipe fi lter net.

• In case of low water pressure

increase water level.

• Wipe the dispenser prior loading

detergent.

Softener is not completely

rinsed, or water is left in

Sucking cover is not correctly

positioned or is clogged.

Clean the dispenser and fi rmly fi x

the cover to its place.

the dispenser dish.

Unpleasant smell in the

washing machine drum.

• Remains of fabrics, washing

agent and softener in the fi lter.

• Development of germs

• Check whether the fi lter is clean.

• Run the auto-clean program

(see chapter: selecting additional

functions)

Washing time is longer

than usual.

Time indicated on the

display is corrected during

the washing cycle.

• Low temperature of inlet water.

• Due to unevenly distributed

load, the machine has activated

the UKS*.

• Low mains voltage.

• There has been a failure in the

power supply.

• Washing program time may be up

to 60% longer; however, this does

not imply a fault in the machine.

• Washing time is extended by the

power supply down-time.

21

390909

Page 22

Failure Possible cause Remedy

FAILURE 1

Program temperature not

reached (the machine

reports a failure - the

LEDs periodically fl ash

once)

Temperature sensor disconnected

from the electronic circuit.

• Turn off the appliance and wait for

a few seconds;

• turn the appliance back on and

repeat the washing program.

If the failure is reported again, call a

service technician.

FAILURE 4

Spinning rpm not reached

in the selected program

(the machine reports

a failure - the LEDs

periodically fl ash four

times)

• rpm sensor disconnected

• Motor overload due to too high

water level (manual addition of

water) or too big laundry load

• Motor failure

• Turn off the appliance and wait for

a few seconds;

• turn the appliance back on and

repeat the washing program.

If the failure is reported again, call a

service technician.

(in some models,

FAILURE 2 is displayed)

FAILURE 5

Motor operation

interrupted; or motor does

not operate (the machine

reports a failure - the

LEDs periodically fl ash

fi ve times)

Motor overload or motor failure. • Turn off the appliance and wait for

a few seconds;

• turn the appliance back on and

repeat the washing program.

If the failure is reported again, call a

service technician.

FAILURE 6

Program temperature not

reached (the machine

reports a failure - the

LEDs periodically fl ash six

times)

• Heater failure

• Inlet water too cold

• Manual addition of water

• Turn off the appliance and wait for

a few seconds;

• turn the appliance back on and

repeat the washing program.

If the failure is reported again, call a

service technician.

* UKS: universal stability control - this function prevents excessive vibrations during spinning.

In case you were not successful in repairing the malfunctions in

spite of the above suggestion chart, call the nearest authorized

service shop.

Repairing the failure arising from inappropriate connections or

use of the appliance is not covered by the guarantee, and the

repair expenses are paid by the customer.

390909

22

Page 23

Tables

Program chart

- 7 kg (A-30%)n

Water

Basic programs

Max. load

[kg]

Temp. [°C]

Spin

[max. RPM]

Remaining moisture

content [%]

Duration

Cotton 7 95

Cotton* 7/3,5** 60 59-53 153/153** 49/40** 0,89/0,71**

Cotton + prewash 7 60 59-53 158 68 1,40

Cotton*

Cotton 7 30 59-53 82 60 0,35

Cotton - quick 17’ 2 30 1000 59 17 40 0,17

Cotton - Tap water +

(ECO)

Synthetics 3,5 60

Synthetics 3,5 40 30 93 52 0,56

Synthetics - easy ironing 3 40

Delicate 3 20 37 53 55 0,36

Wool 2 30 600 52 46 42 0,20

Mix 3,5 40 1000 59 80 45 0,42

Partial programs

Softening (Conditioner)

Pumping water (Drain)

Spinning

7/3,5** 40 59-53 140/140** 49/40** 0,68/0,59**

3,5 20

7 1000 59 14 16 0,03

7 - / 3 - 0,001

7

59-53 166 66 2,10

1000-

1400

1000-

59-53 98 69 0,18

1400

1000

1000-

1400

30 109 55 0,90

37 95 52 0,45

700

59-53 14 - 0,05

cons.

RPM RPM

[min.]

[L]

1000 - 1400

Energy

cons.

[kWh]

1000 - 1400

* Testing program by EN 60456 with the selection of max. spin RPM.

** Half load

Standard 60 °C cotton programme ’ and the ‘standard 40 °C cotton programme ’ are

the standard washing programmes to which the information in the label relates. that These

programmes are suitable for cleaning normally soiled cotton laundry and that they are the most

effi cient programmes in terms of combined energy and water consumption.

390909

23

Page 24

Program chart

- 6 kg (A-20%)n

Water

Basic programs

Max. load

[kg]

Temp. [°C]

Spin

[max. RPM]

Remaining moisture

content [%]

Duration

Cotton 6 95

Cotton* 6/3** 60 62-53 153/153** 50/35** 0,89/0,71**

Cotton + prewash 6 60 62-53 158 53 1,34

Cotton* 6/3** 40 62-53 140/140** 50/36** 0,66/0,59**

Cotton 6 30 62-53 82 50 0,27

Cotton - quick 17’ 2 30 1000 59 17 40 0,17

Cotton - Tap water +

(ECO)

Synthetics 3 60

Synthetics 3 40 30 93 52 0,56

Synthetics - easy ironing 2,5 40

Delicate 2,5 20 37 53 55 0,36

Wool 2 30 600 52 46 42 0,20

Mix 3 40 1000 59 80 45 0,42

Partial programs

Softening (Conditioner)

Pumping water (Drain)

Spinning

320

6 1000 59 14 16 0,03

6 - / 3 - 0,001

6

62-53 166 58 2,05

8001400

800-

62-53 98 50 0,18

1400

1000

8001400

30 109 55 0,90

37 95 52 0,45

700

62-53 14 - 0,05

cons.

RPM RPM

[min.]

[L]

800 - 1400

Energy

cons.

[kWh]

800 - 1400

* Testing program by EN 60456 with the selection of max. spin RPM.

** Half load

Standard 60 °C cotton programme ’ and the ‘standard 40 °C cotton programme ’ are

the standard washing programmes to which the information in the label relates. that These

programmes are suitable for cleaning normally soiled cotton laundry and that they are the most

effi cient programmes in terms of combined energy and water consumption.

390909

24

Page 25

Program chart

- 6 kg (A-10%)n

Water

Basic programs

Max. load

[kg]

Temp. [°C]

Spin

[max. RPM]

Remaining moisture

content [%]

Duration

Cotton 6 95

Cotton* 6/3** 60 62-44 153/153** 45 0,98/0,95**

Cotton + prewash 6 60 62-44 158 53 1,34

Cotton* 6/3** 40 62-44 140/140** 45 0,66/0,59**

Cotton 6 30 62-44 82 45 0,27

Cotton - quick 17’ 2 30 1000 59 17 40 0,17

Cotton - Tap water +

(ECO)

Synthetics 3 60

Synthetics 3 40 30 93 52 0,56

Synthetics - easy ironing 2,5 40

Delicate 2,5 20 37 53 55 0,36

Wool 2 30 600 52 46 42 0,20

Mix 3 40 1000 59 80 45 0,42

Partial programs

Softening (Conditioner)

Pumping water (Drain)

Spinning

320

6 1000 59 14 16 0,03

6 - / 3 - 0,001

6

62-44 166 51 2,05

8001400

800-

62-44 98 45 0,18

1400

1000

8001400

30 109 55 0,90

37 95 52 0,56

700

62-44 14 - 0,05

cons.

RPM RPM

[min.]

[L]

800 - 1400

Energy

cons.

[kWh]

800 - 1400

* Testing program by EN 60456 with the selection of max. spin RPM.

** Half load

Standard 60 °C cotton programme ’ and the ‘standard 40 °C cotton programme ’ are

the standard washing programmes to which the information in the label relates. that These

programmes are suitable for cleaning normally soiled cotton laundry and that they are the most

effi cient programmes in terms of combined energy and water consumption.

390909

25

Page 26

Program chart

- 5,5 kg (A-10%)n

Water

Basic programs

Max. load

[kg]

Temp. [°C]

Spin

[max. RPM]

Remaining moisture

content [%]

Duration

Cotton 5,5 95

Cotton* 5,5/2,75** 60 62-53 153/153** 45 0,93/0,90**

Cotton + prewash 5,5 60 62-53 158 53 1,34

Cotton*

Cotton 5,5 30 62-53 82 45 0,27

Cotton - quick 17’ 2 30 1000 59 17 40 0,17

Cotton - Tap water +

(ECO)

Synthetics 2,5 60

Synthetics 2,5 40 30 93 40 0,52

Synthetics - easy ironing 2,5 40

Delicate 2 20 37 53 55 0,31

Wool 1,5 30 600 52 46 42 0,18

Mix 2,5 40 1000 59 80 45 0,39

Partial programs

Softening (Conditioner)

Pumping water (Drain)

Spinning

5,5/2,75** 40 62-53 140/140** 45 0,56/0,49**

2,75 20

5,5 1000 59 14 16 0,03

5,5 - / 3 - 0,001

5,5

62-53 166 51 2,00

800-

1400

800-

62-53 98 45 0,18

1400

1000

800-

1400

30 109 43 0,93

37 95 40 0,52

700

62-53 14 - 0,05

cons.

RPM RPM

[min.]

[L]

800 - 1400

Energy

cons.

[kWh]

800 - 1400

* Testing program by EN 60456 with the selection of max. spin RPM.

** Half load

Standard 60 °C cotton programme ’ and the ‘standard 40 °C cotton programme ’ are

the standard washing programmes to which the information in the label relates. that These

programmes are suitable for cleaning normally soiled cotton laundry and that they are the most

effi cient programmes in terms of combined energy and water consumption.

390909

26

Page 27

Program chart

- 5 kg (A-20%)n (slim)

Water

Basic programs

Max. load

[kg]

Temp. [°C]

Spin

[max. RPM]

Remaining moisture

content [%]

Duration

Cotton 5 95

Cotton* 5/2,5** 60 62-53 146/146** 42/36** 0,68/0,62**

Cotton + prewash 5 60 62-53 155 49 0,99

Cotton*

Cotton 5 30 62-53 75 42 0,15

Cotton - quick 17’ 2 30 1000 59 17 30 0,13

Cotton - Tap water +

(ECO)

Synthetics 2,5 60

Synthetics 2,5 40 33 96 33 0,34

Synthetics - easy ironing 2 40

Delicate 2 20 40 50 50 0,26

Wool 1,5 30 600 55 44 42 0,18

Mix 2,5 40 1000 59 78 39 0,31

Partial programs

Softening (Conditioner)

Pumping water (Drain)

Spinning

5/2,5** 40 62-53 137/137** 42/38** 0,55/0,52**

2,5 20

5 1000 59 14 9 0,02

5 - / 3 - 0,001

5

62-53 155 45 1,95

800-

1400

800-

62-53 98 42 0,17

1400

1000

800-

1400

33 104 35 0,61

40 95 33 0,34

700

62-53 14 - 0,04

cons.

RPM RPM

[min.]

[L]

800 - 1400

Energy

cons.

[kWh]

800 - 1400

* Testing program by EN 60456 with the selection of max. spin RPM.

** Half load

Standard 60 °C cotton programme ’ and the ‘standard 40 °C cotton programme ’ are

the standard washing programmes to which the information in the label relates. that These

programmes are suitable for cleaning normally soiled cotton laundry and that they are the most

effi cient programmes in terms of combined energy and water consumption.

390909

27

Page 28

Program chart /

Additional functions

Program

Basic programs

Cotton

Cotton with prewash

Synthetics

Delicate

Wool

Mix

Partial programs

Softening (Conditioner)

Pumping water (Drain)

Spinning

possibility

Spinning speed (rpm) /

Pump stop

/

/

/

/

/

/

Short program

Higher water level

Due to variations in the type and quantity of laundry,

spin speed, variations in power voltage, and the

temperature and moisture of ambient, the measured

values of the duration of the program and power

consumption with the end user may vary somewhat

from the displayed values.

390909

28

Page 29

Maintenance chart

Normal wash

Max.

washing

temp. 95°C

Delicate wash

Whitening

Whitening in cold water

Ironing Hot iron max.

200°C

Dry cleaning Dry cleaning in all

solvents

Drying Place on

Hang wet Hang

fl at surface

Max.

washing

temp.

60°C

Max.

washing

temp.

40°C

Hot iron max.

150°C

Perchlorin-

etyhlene

R11, R113,

Kerosene

Max.

washing

temp.

30°C

Manual

washing

Whitening not allowed

Hot iron max.

110°C

Dry cleaning in

kerosene, in pure

alcohol and in

R 113

High

temperature

Low

temperature

Washing

not

allowed

Ironing not

allowed

Dry cleaning not

allowed

Tumble drying

not allowed

We reserve the rights to make any changes or mistakes in these operation

instructions.

29

390909

Page 30

390909

30

Page 31

Page 32

PS PG0A LED en (04-14)

Loading...

Loading...