Giles FSH-5 User Manual

Operations & Service Manual

FSH-5 & FSH-6

Models: FSH-5 & FSH-6

Giles Foodservice Equipment

ISO 9001 Registered • Committed to Quality

2750 Gunter Park Drive West • Montgomery, AL 36109 USA

Phone: 334.272.1457 • Fax: 334. 239.4117 • Website: www.gfse.com

Toll Free: 800.554.4537

Form No. 64898 (Rel. Date: 07/1999; Rev. Date: 04/2017; Rev. G)

(USA & Canada Only)

LIMITED WARRANTY

• Subject to the terms and conditions of this Limited Warranty as herein stated, all Giles Enterprises, Inc.,

Foodservice Equipment and parts purchased new from an authorized Giles Enterprises, Inc., representative

are warranted as to defects in material or workmanship for a period of 24 months from the date of installation, provided, however, that with regard to labor costs in connection with this warranty, see below. All installations must be made by a qualified installing agency in accordance with all applicable codes and/or regulations in the jurisdiction in which installed. Limited warranty coverage is extended to the original owner only

and is void if the unit is resold.

• During the Limited Warranty period, Giles Enterprises, Inc. will replace or recondition, at its factory, any part

or parts of this unit which Giles Enterprises, Inc. inspectors judge defective, provided the unit has been subjected to normal usage, properly installed, operated and serviced. This Limited Warranty does not cover cosmetic damage, and damage due to acts of God, accident, misuse, alteration, negligence, abuse of the Giles

Foodservice Equipment or the use of unorthodox repair methods. All parts replaced under this Limited

Warranty carry only the unexpired term of this Limited Warranty. Limited Warranty service may be furnished

only by an authorized Giles Enterprises, Inc., representative.

• If Limited Warranty service is requested, Giles Enterprises, Inc., will send factory-authorized service representatives to repair, recondition, replace or inspect units of its manufacture with such labor being rendered

without cost to owner for twenty-four (24) months from the date of installation. Otherwise, service, including labor and transportation charges or other expenses, in connection with the removal or installation of any

part or parts supplied under this Limited Warranty, are specified on the original sales contract between the

purchaser and the authorized Giles Enterprises, Inc., representative.

• Failure to use Giles OEM repalcement parts and OEM replacement filters may void this Limited Warranty.

• Giles Enterprises, Inc. reserves the right to change or improve its equipment and parts in any way without

obligation to alter such equipment or parts previously manufactured.

• Giles Enterprises, Inc. makes no further warranties, express or implied including implied warranties of merchantability or fitness for a particular purpose, and has no other obligation or liability not specifically stated

herein.

• Repair or replacement as provided under this limited warranty is the exclusive remedy. Giles Enterprises, Inc.,

shall not be liable for any incidental or consequential damages for breach of any express or implied warranty on this product, except to the extent prohibited by applicable law. Any implied warranty of merchantability or fitness for a particular purpose on this product is limited in duration to the duration of this limited warranty.

• Used Giles Enterprises, Inc., Foodservice Equipment or parts or Giles Enterprises, Inc., Foodservice Equipment

or parts not purchased from an authorized Giles Enterprises, Inc., representative, carry no warranties, express

or implied.

Table Of Contents

Model: FSH-5 & FSH-6

Safety v

Safety Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Specific Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1. Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-2. Standard Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-3. Optional Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-4. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

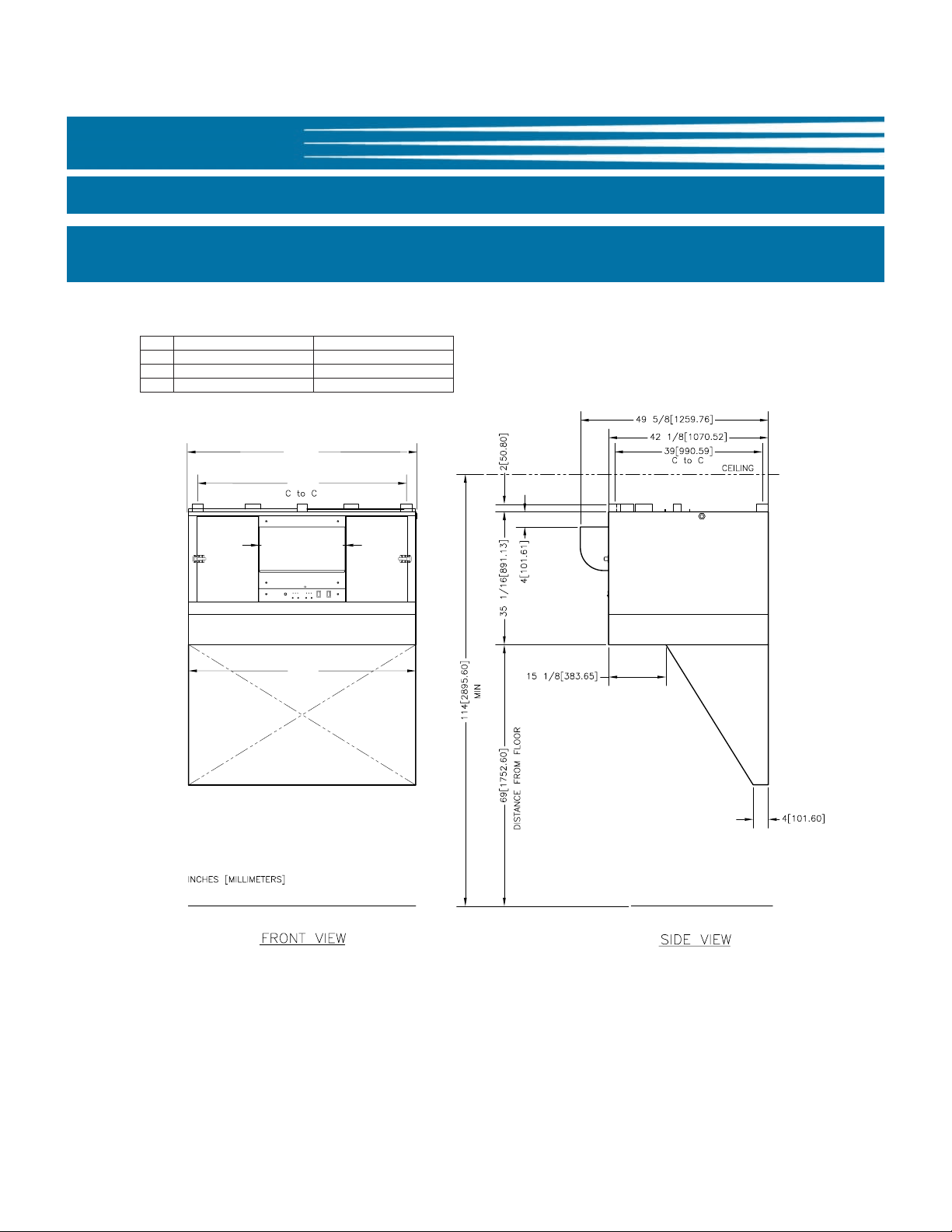

1-4.1. Overall Dimensions for FSH-5 & 6 (Ceiling Mount) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

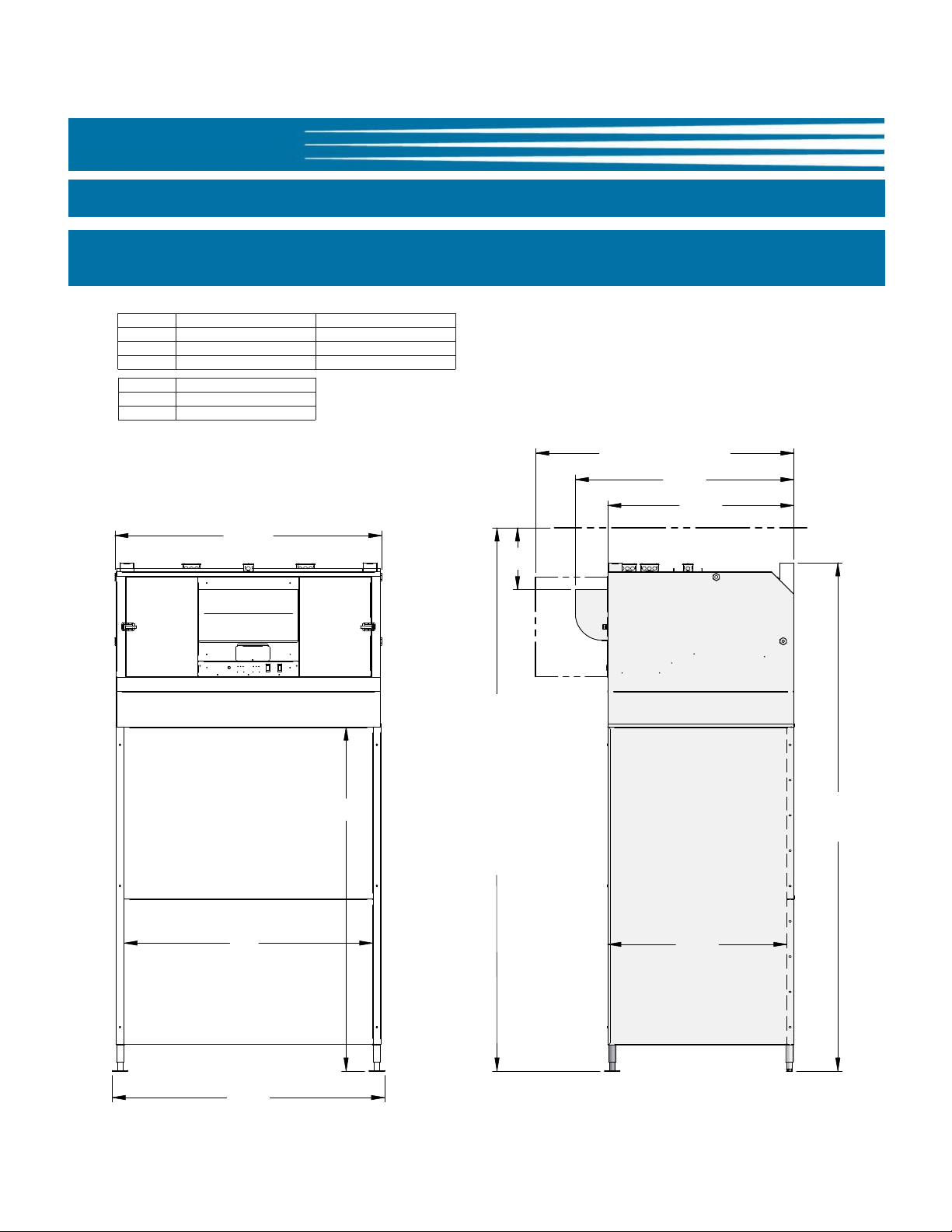

1-4.2. Overall Dimensions for FSH-5 & 6 (Stand Mount) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-4.3. Listings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-4.4. Hood Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2-01. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2-02. Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2-03. Hood Mounting Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2-03. Hood Skirt Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2-04. Hood Stand Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2-05. Cooking Appliance limitations and clearances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

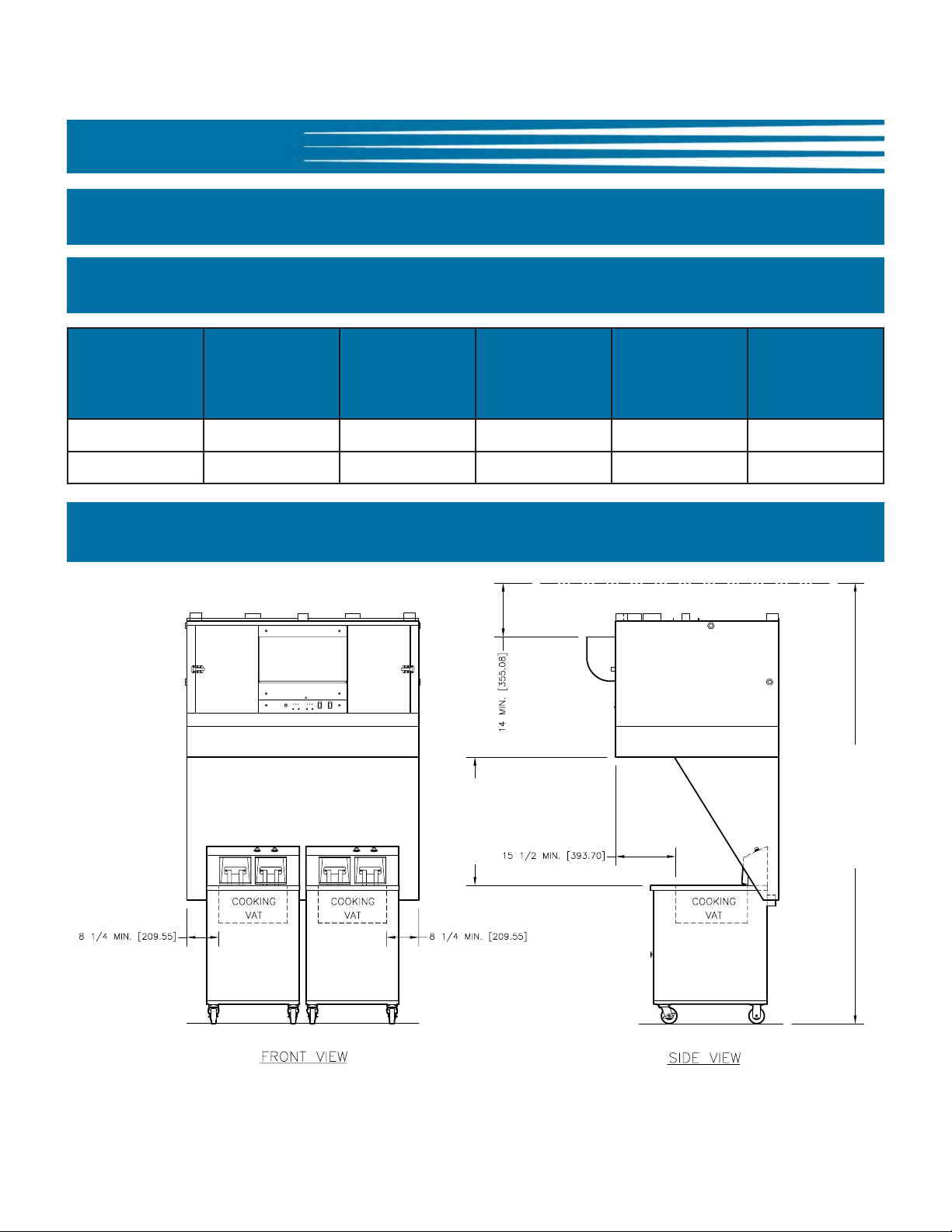

2-05.1. Fryer limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2-05.2. Fryer clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

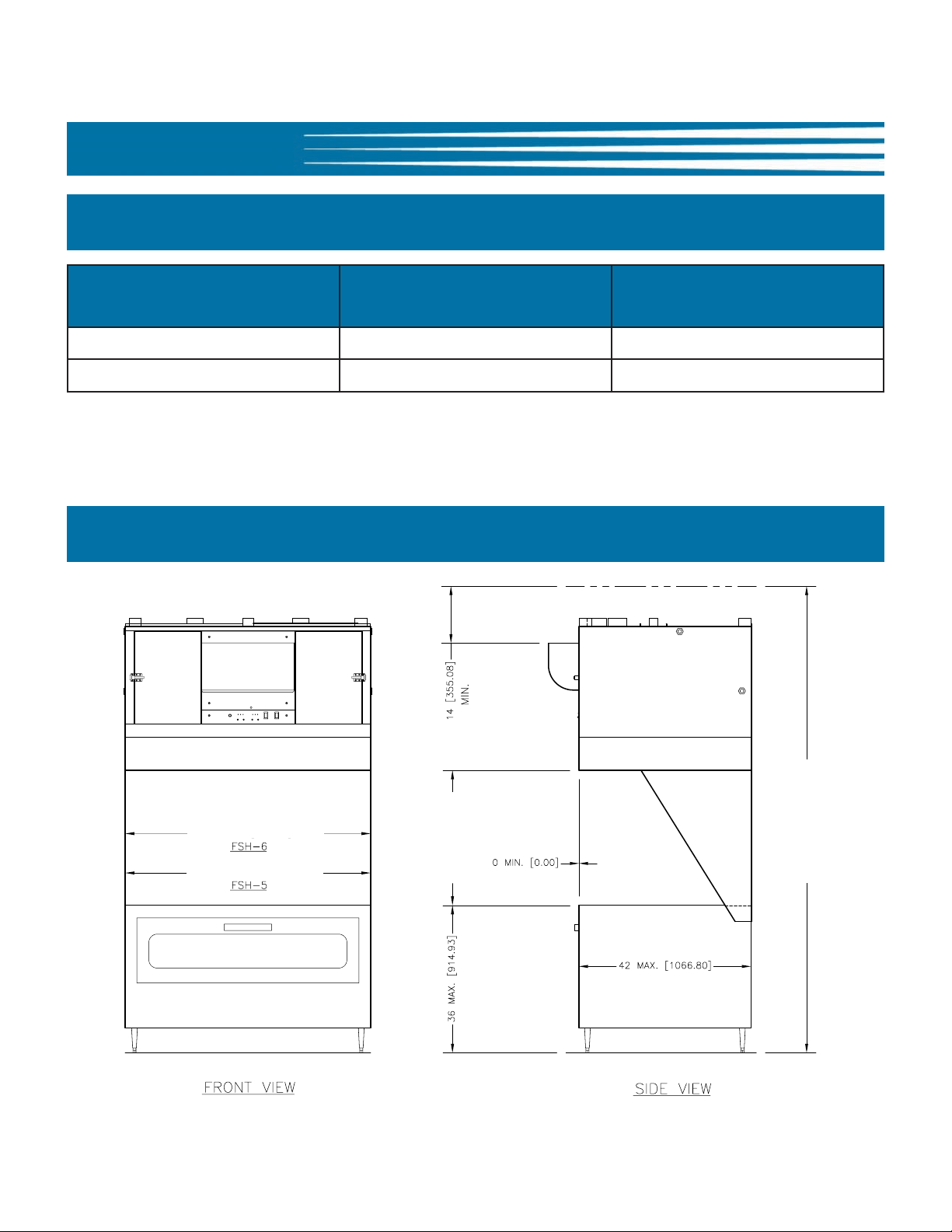

2-05.3. Oven limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2-05.4. Oven clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

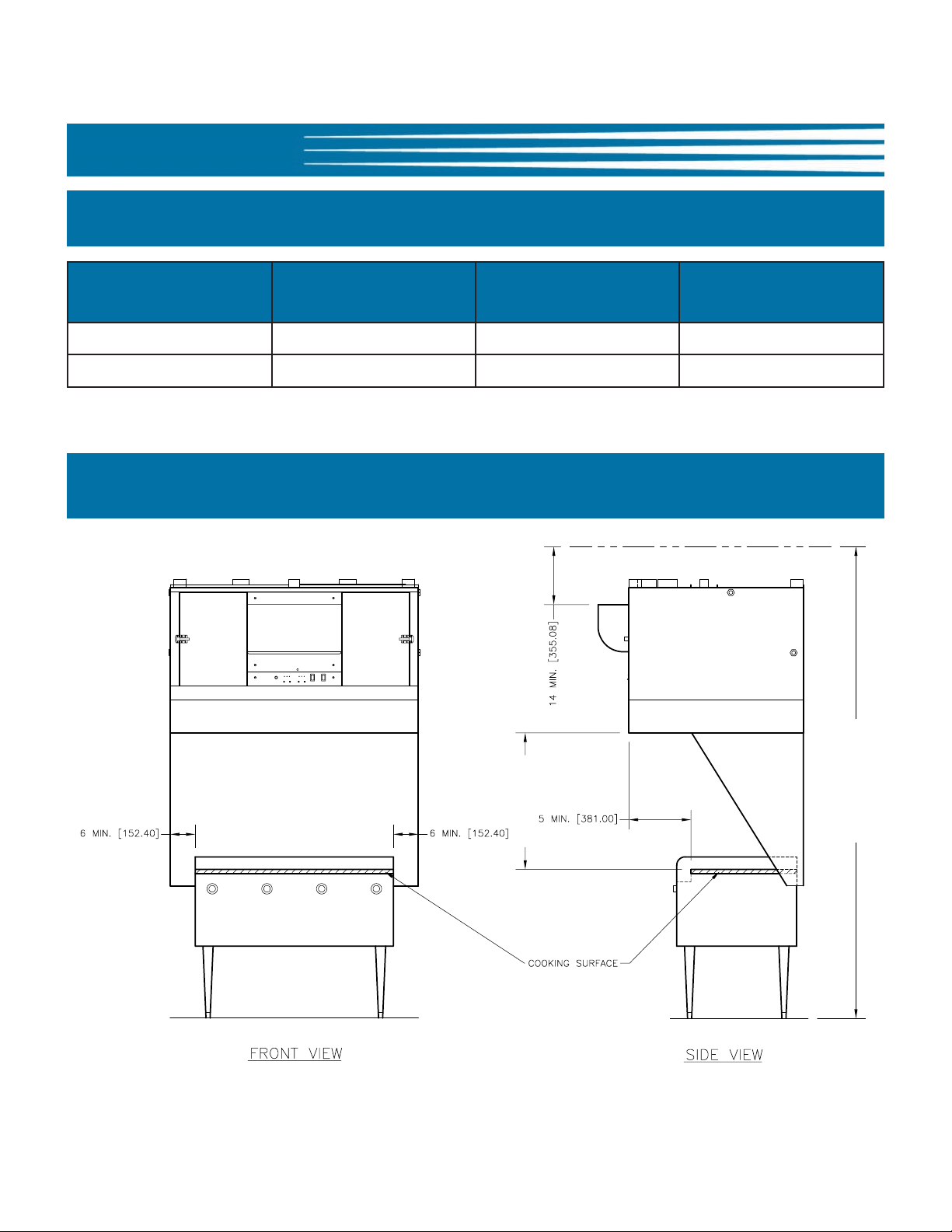

2-05.5. Griddle limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2-05.6. Griddle clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2-05.7. Range limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2-05.8. Range clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2-06. Hood Electrical Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2-06.1. Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2-06.2 Routing Power Wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2-06.3 Hood and Appliance Interlock Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2-07. Fire Suppression System Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2-07.1. Fire Suppression System Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2-07.2. Fire Suppression Fusible Links. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-07.3. Appliance Nozzles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-07.4. Fire Extinguisher Nozzle Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2-07.5. General Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3. Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3-01. Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3-02. Filter Chamber and Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3-03. Accessories (Included) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

iii

Model: FSH-5 & FSH-6 Table Of Contents

4. Operation & Filter Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4-01. Hood Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4-02. Filters and Filter Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4-02.01. Ventless Hood Filter Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4-02.02. Baffle Filter Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4-02.03. Baffle Filter Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4-02.04. Baffle Filter Missing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4-02.05. Baffle Filter Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4-02.06. Pre-Filter Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4-02.07. Pre-Filter Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4-02.08. Pre-Filter Filter Missing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4-02.09. Pre-Filter Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4-02.10. EAC Filter Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4-02.11. EAC Filter Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4-02.12. EAC Filter Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4-02.13. EAC Filter Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4-02.14. Charcoal Filter Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4-02.15. Charcoal Filter Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4-02.16. Charcoal Filter Missing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4-02.17. Charcoal Filter Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4-03. Filter Alarm Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5. Hood Cleaning and Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5-1. Monthly Interlock Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5-2. Quarterly Hood Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5-3. Semi-Annual Fire Suppression System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5-4. Annual Fire Suppression System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5-5. 12 Year Fire Suppression System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5-6. Maintenance and Service Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6-1. Troubleshooting Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7. Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7–1. Parts Ordering and Service Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7-2. Component Drawer & Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7-3. Front View -Doors and Panel removed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7-4. Baffle Filters and Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7-5. Doors and Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7-6. Stand Mount Skirts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

iv

Model: FSH-5 & FSH-6Safety

Safety

Safety Overview

The instructions contained in this manual have been prepared as an aid to learning the proper procedures for

installing and servicing this new unit.

Throughout this manual, safety precautions are identified through the use of safety alert symbols and three key

words: DANGER

which they apply. Suggested, recommended, and other noteworthy information will be identified by use of NOTES.

Additionally, certain words are used to convey a specific meaning or to add emphasis, as follows:

Shall: understood to be mandatory.

Should: understood to be advisory.

May: understood to be permissive.

Will: indicates a future event/condition to occur.

!!

or Safety Alert symbols used in conjunction with the key words (DANGER, WARNING, or CAUTION),

immediately preceding precautionary measures pertaining to subsequent instructions, alert to the potential of

personal injury hazards. Obey all safety messages that follow this symbol to avoid possible injury or death. Failure

to adhere to safety precautions identified by the safety alert symbol may also void the warranty.

, WARNING, and CAUTION. All safety alert information will precede the instructions or sections to

DANGER

!

• Indicates an imminently hazardous situation, which will result in serious injury, even death, if not avoided.

WARNING

!

• Indicates a potentially hazardous situation, which could result in serious injury, even death, if not avoided.

CAUTION

!

• Indicates a potentially hazardous situation or unsafe practice, which may result in minor or moderate injury, if not

avoided.

CAUTION

• When used without the safety alert symbol, CAUTION indicates a potentially hazardous situation, which may

result in equipment or property damage and void the warranty, if not avoided.

NOTE:

• Identifies suggested, recommended, or other noteworthy information.

v

Model: FSH-5 & FSH-6 Safety

Specific Safety Precautions

For your safety, please read and observe the following important safety precautions when operating or servicing

your Giles equipment to avoid personal injury and/or damage to the equipment.

DANGER

!

• Turn off the unit and disconnect main power supply before cleaning or performing maintenance.

• DO NOT hose down the unit’s interior or exterior with water.

• Failure to comply with DANGER notices will result in serious injury, even death; equipment and/or property

damage; and will void the warranty.

WARNING

!

• Consult a qualified electrician to ensure that:

a. Installation is in compliance with all electrical specifications and local building codes.

b. Circuit breakers and wiring are of sufficient rating and gauge for supplying power to this equipment.

c. Unit is properly grounded during installation. Improper grounding may result in electrical shock to the user.

• Improper installation, adjustments, alterations, service, or maintenance could result in serious injury, even death;

equipment and/or property damage; will void the warranty.

• DO NOT use or store flammable liquids, or materials producing flammable vapors, in the vicinity of this or any

other appliance!

• Failure to comply with WARNING notices could result in serious injury, even death; equipment and/or property

damage; and will void the warranty.

CAUTION

!

• Ensure the unit is positioned in a safe location, and that the leveling legs have been properly adjusted so that the

unit is level and stable.

• The unit must remain in the upright (vertical) position.

• Exercise care when removing the wood crating and moving the unit from the shipping skid. The unit is very

heavy (stand mounted units will be extremely top-heavy). Use appropriate handling equipment and/or sufficient

manpower to lift and move the unit.

• DO NOT operate the unit unless you fully understand the components and their intended function (see Section

3).

• Failure to comply with CAUTION notices may result in minor to moderate injury, equipment and/or property

damage, and void the warranty.

vi

Model: FSH-5 & FSH-6Safety

CAUTION

• The electronic components on the Control Panel are impact-sensitive. Exercise care around the Control Panel to

avoid damage and maintain proper operation.

• When cleaning the unit DO NOT

a. Steam clean.

b. Use products containing chlorine or other caustic chemicals.

c. Use abrasive products, steel wool or scouring pads.

• DO NOT alter, add attachments or otherwise modify this equipment!

• DO NOT attempt to dry the EAC cell after cleaning by installing it and running the Hood to force air dry, or by

running an appliance below the Hood in attempt to heat dry the cell. This can potentially damage the EAC

system leading to failure and voiding the warranty. The EAC cell must air dry at ambient room temperature,

preferably overnight.

• Take care not to bend the collection fins or break the ionizer wires on the Electrostatic Air Cleaner (EAC) cell.

Doing so will prevent the system from properly capturing grease particulate, and cause power to the appliance

underneath the Hood to be shutdown.

• Failure to comply with CAUTION notices may result in equipment and/or property damage, and void the

warranty.

NOTE:

:

• If the crate is damaged upon receipt, immediately inspect the unit and notify the freight company of any damage to the

unit.

• To aid the electrician, or technician during installation or service, an electrical wiring diagram is provided with the unit. It

should be attached to the unit’s rear panel.

• Comply with all appropriate state and/or local heath regulations regarding the cleaning and sanitation of equipment.

• Consultation with a professional HVAC company may be required for some installations for purpose

of confirming proper room air exchange rate, and to determine the heat load capabilities of the

existing air conditioning system.

• Exhaust ventilation is recommended for areas in which recirculating hoods are used. Giles recommends 50 CFM per linear

foot of hood space. This amount could vary based on local codes and the site-specific installation requirements.

• The sound level of the Hood when operating is approximately 73 dB.

vii

viii

Introduction Model: FSH-5 & FSH-6

1. Introduction

Thank you for the purchase of a new Giles Ventless Recirculating Hood System, Model FSH-5 or FSH-6; manufactured

by Giles Foodservice Equipment, Montgomery, Alabama (USA), hereafter referred to as "Giles". These two models

are available as either a ceiling hung, or a stand mounted model. The stand mounted version measures 72” from

the floor to the bottom edge on the hood skirt.

Proper care and maintenance of this unit will ensure years of trouble-free service and to help protect your

investment in this equipment, we recommend taking a few moments to familiarize yourself with the installation,

operation, cleaning, and maintenance procedures described in this manual. We urge you to read these instructions

before installing or using this hood. Adherence to these recommended procedures will minimize potential for costly

downtime and future equipment repairs. Please retain this manual for future reference.

1-1. Construction

The Ventless Hood System is constructed primarily of Series 430 stainless steel.

1-2. Standard Features

Control Panel

• Two LED light clusters indicate the status of the EAC filters, right and left side.

• FILTER MISSING light indicates that one (or more) of the filters (Baffle, Pre-filter, Charcoal) is either missing or

installed improperly.

Filters

• Baffle Filters - capture and remove large grease particles from the air stream.

• Pre-Filters - capture and remove smaller grease particulate and moisture.

• Electronic Air Cleaners (EAC) - capture smoke & fine particle air contaminates.

• Charcoal Filters - help eliminate undesirable cooking aromas.

Fire Suppression System Plumbing

Hood is pre-plumbed at the factory and ready for connection to a listed fire suppression system. Includes piping,

plenum nozzles, fusible link brackets and conduit. Procurment, installation and final commissioning of the actual

fire extinguishing system is the responsibility of the purchaser.

1-3. Optional Features

Inter-Locked Start System (ILS)

• Push To Start feature requires the user to press a start button in order to restart the Hood, and consequently

provide power to the served appliance, after a power interruption. Some jurisdictions require this feature to

guard against unattended start-up of Hood and appliance(s).

Floor Stand Mount

• 72” high stand mount is available instead of the standard ceiling hung mount (measured from floor to bottom

edge of the hood skirt).

1

Model: FSH-5 & FSH-6 Introduction

(A)

(B)

(C)

1-4. Specifications

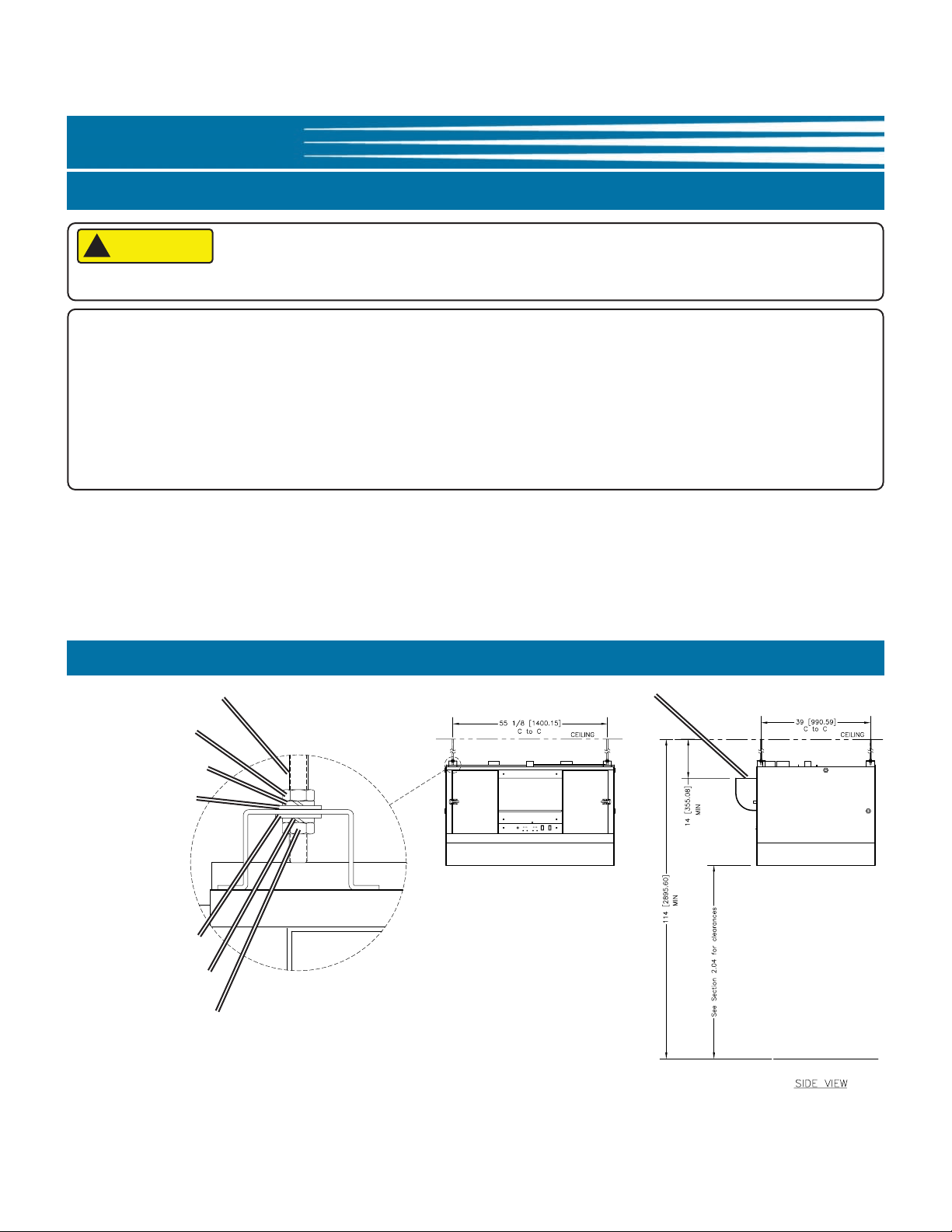

1-4.1. Overall Dimensions for FSH-5/6 (Ceiling Mount model)

DIM FSH-5 FSH-6

(A) 60-9/16 [1538.3] 72-9/16 [1843.1]

(B) 55-1/8 [1400.2] C to C 67-1/8 [1705.0] C to C

(C) 59-15/16 [1521.9] 71-15/16 [1705.0]

2

Model: FSH-5 & FSH-6Introduction

(D)

(A)

115 1/4

49 5/8

58 9/16 DOOR OPEN

(B)

14

(E)

MIN. CEILING HEIGHT

42 1/4

40 5/8

(C)

[1487.5 DOOR OPEN

[1260.5]

[1073.2]

[355.6]

[2927.4]

[1031.9]

[FRONT] [SIDE]

1-4. Specifications

1-4.2. Overall Dimensions for FSH-5/6 (Stand Mount model)

DIM FSH-5 FSH-6

(A) 60-9/16 [1538.3] 72-9/16 [1843.1]

(B) 56-7/16 [1433.5] 68-7/16 [1738.3]

(C) 61-3/4 [1568.5] 73-3/4 [1873.3]

(D) 72 [1828.8]

(E) 117-3/16 [2976.6]

(with 72” Stand Mt)

INCHES [MILLIMETERS]

3

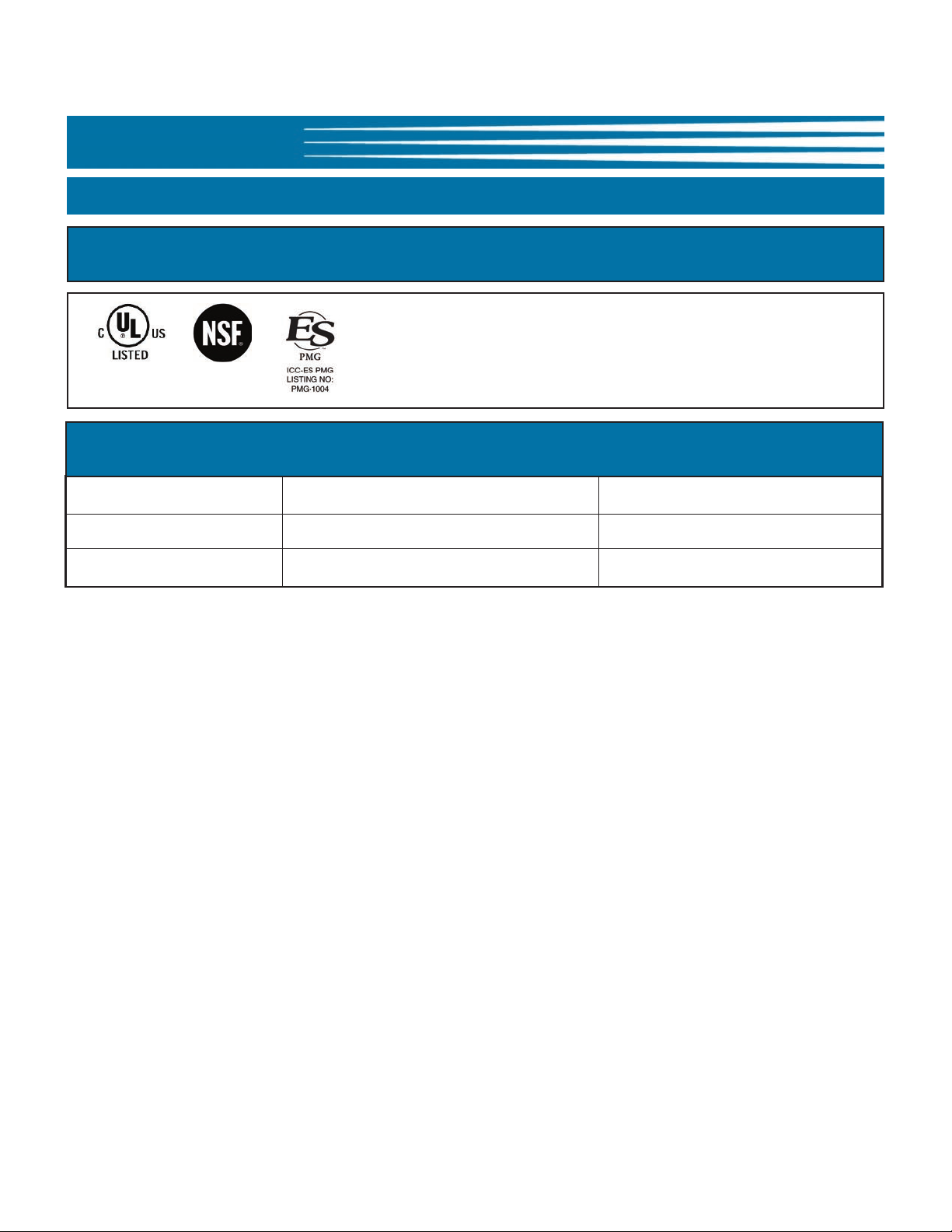

1-4. Specifications

1-4.3. Regulatory Listings

1-4.4. Hood Weights

Hood Crated Weight Uncrated Weight

FSH-5 664 lbs [302 kg] 464 lbs [211 kg]

IntroductionModel: FSH-5 & FSH-6

FSH-6 733 lbs [333 kg] 553 lbs [251 kg]

4

Model: FSH-5 & FSH-6Installation

2. Installation

This section summarizes procedures necessary to install the new FSH-5 or FSH-6 Hood. Before installing or servicing

this equipment, please read the contents of this manual thoroughly. Following these procedures will help to ensure

a safe and proper installation.

NOTE:

• A HVAC specialist may be required for some installations to confirm proper air

exchange and the heat load capabilities of existing air conditioning systems.

Exhaust ventilation is recommended for areas in which recirculating hoods are used. Giles recommends 50 CFM

•

per linear foot of hood space. This amount could vary based on local codes and site-specific installation requirements.

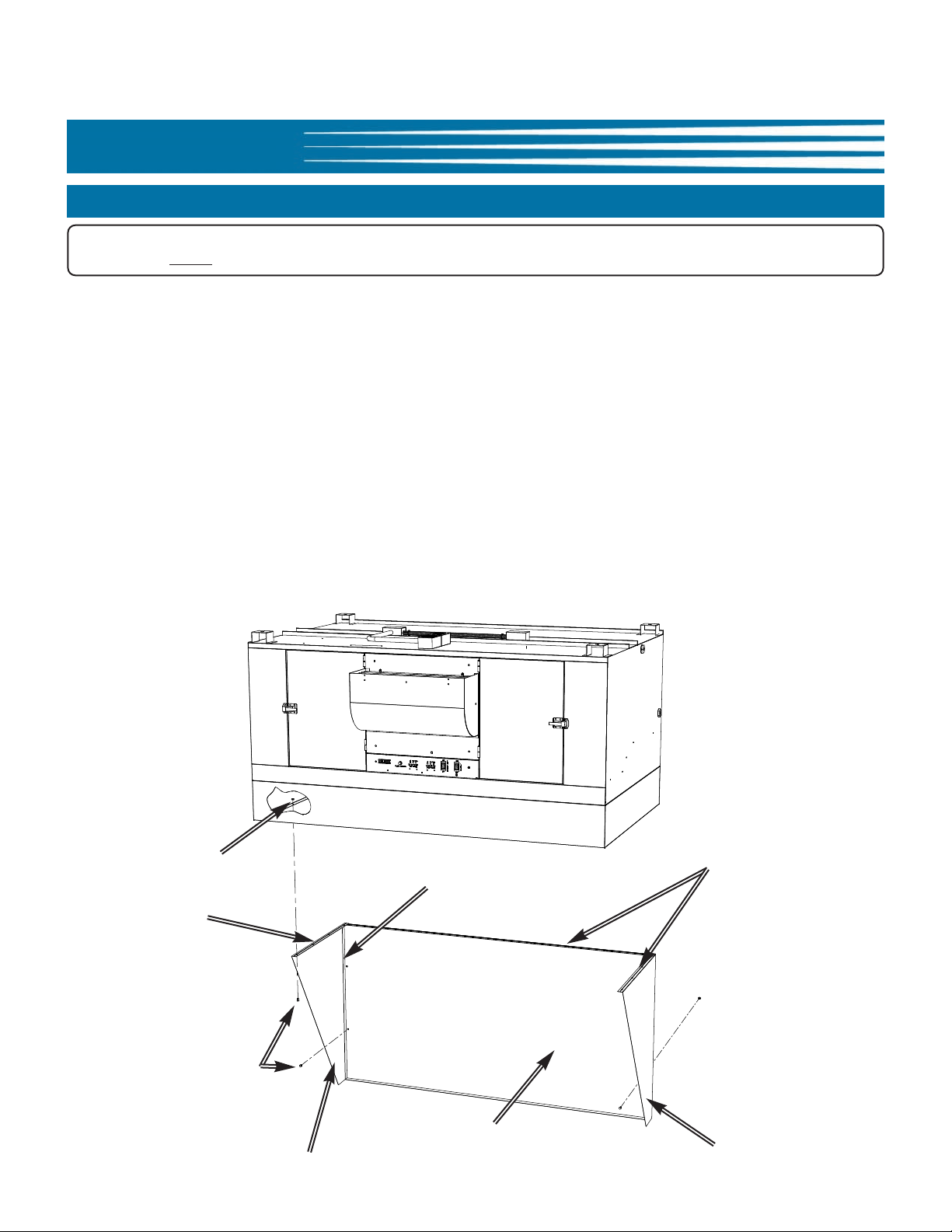

2-01. Unpacking

!! IMPORTANT NOTE:

If the palletized unit shows signs of damage, immediately inspect the equipment and other packaged components, and notify the freight company of any damages.

The unit is palletized on a wooden shipping skid and protected with a wooden framework; secured with high-tensile

plastic strapping and wrapped in machine applied stretch-wrap. Following these steps to unpack.

1. Position the palletized unit in an area that has sufficient space for unpacking.

2. Cut and remove stretch-wrap and all strapping. Remove all auxiliary items which are packed with the unit and

set aside in a safe place.

3. Use appropriate tools to remove the protective wooden framework from around the unit.

CAUTION

!

The unit is very heavy and bulky! Use suitable equipment and/or sufficient manpower to lift and move the hood

from the shipping skid ... see Section 1-4.4,

4. In many cases, to facilitate ease of movement, it is preferable to leave the unit on the base skid until time to

install it in the desired permanent location. Carefully remove the Hood from the shipping skid using suitable

equipment and/or sufficient manpower, and safe work practices.

Hood Weights.

!! IMPORTANT NOTE:

When removing the unit from the skid, take precautions not to damage to the bottom edge of hood skirt. If possible, it is

advisable to rig and lift the hood from the topside, utilizing the hood’s hanging brackets.

5

Model: FSH-5 & FSH-6 Installation

2-02. Location

CAUTION

!

DO NOT ALTER, ADD ATTACHMENTS, OR OTHERWISE MODIFY THE EQUIPMENT.

NOTE:

• A HVAC specialist may be required for some installations to confirm proper air

exchange and the heat load capabilities of existing air conditioning systems.

Exhaust ventilation is recommended for areas in which recirculating hoods are used. Giles recommends 50 CFM

•

per linear foot of hood space. This amount could vary based on local codes and site-specific installation requirements.

• The sound level of the hood when operating is approximately 73 dB.

1. Do not obstruct the exhaust air outlet. Maintain a minimum clearance of 14 inches (355.6mm)

between the air outlet and ceiling, or any overhead obstructions.

2. Ensure that the intended mounting site is structurally sound and capable of supporting the hood’s weight.

See Section 1-4.4, Hood Weights.

2-03. Hood Ceiling Mounting Detail

1/2” All-Thread

1/2” Hex Nut

1/2” Lock Washer

1/2” Flat Washer

1/2” Flat Washer

1/2” Lock Washer

1/2” Hex Nut

Exhaust Air Outlet

1. Ensure the hood is level, left to right and front to back. Use 1/2” All-thread to

hang Hood and install fasteners as shown above.

2. Ensure all mounting fasteners are tight and secure. To perform properly, the

ceiling mounted Hood must have Backsplash and Side Skirts installed, see

Section 2-3.2. Hood Skirt Installation.

6

Model: FSH-5 & FSH-6Installation

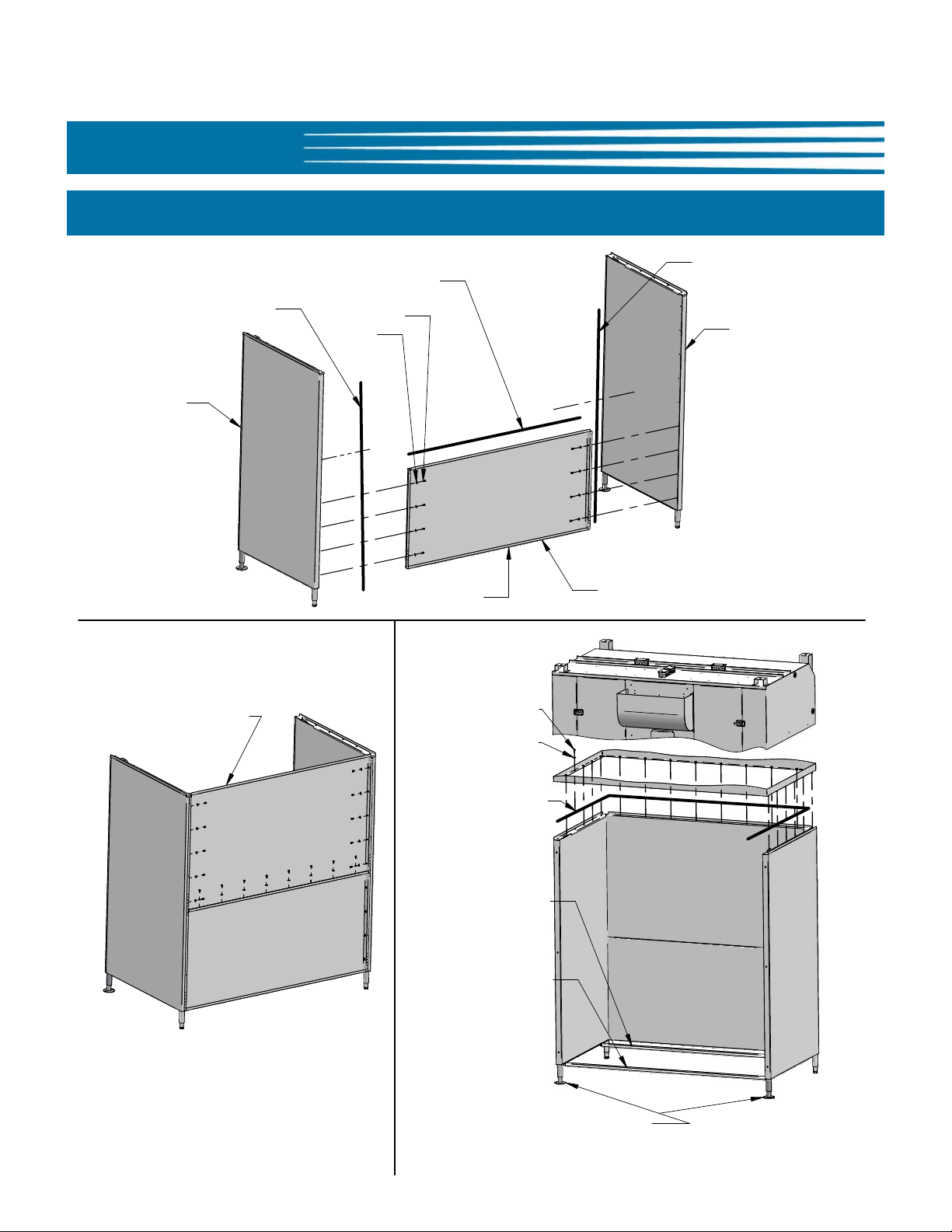

2-03. Hood Skirt Installation

NOTE:

Hood Skirts MUST

1. Peel all protective film from parts before assembling.

2. Apply a bead of Hi-Temp Silicone (included) to the top flanges of both Side Skirts.

3. Attach Left and Right Side Skirts to hood with enclosed fasteners (do not tighten completely).

4. Apply a bead of the Hi-Temp Silicone to the top flange of the Rear Backsplash Skirt.

5. Attach Rear Skirt to hood with enclosed fasteners (do not tighten completely) .

6. Fasten Left and Right Skirts to Rear Skirt.

be installed on ceiling mount Hoods to ensure proper capture performance.

7. Completely tighten all fasteners and wipe any excess silicone from the assembled Skirt.

(21) 1/4-20 Nut

Bead of Hi-Temp

Silicone

Fit Rear Skirt inside flanges of

Side Skirts

*Tube of Hi-Temp

Silicone is enclosed

Bead of Hi-Temp

Silicone

(21) 1/4-20 X 3/8 Screw

Left Skirt

Rear Skirt

Right Skirt

7

Model: FSH-5 & FSH-6 Installation

STEP 1

STEP 2

RIGHT SIDE

LEFT SIDE

REAR BOTTOM PANEL

WASHER

SCREW

BEAD OF HIGH TEMP

SILICONE (INCLUDED)

BEAD OF HIGH TEMP

SILICONE (INCLUDED)

SCREWS

WASHER

BEAD OF HIGH TEMP

SILICONE (INCLUDED)

FASTEN FRONT LEGS

TO FLOOR, AS REQUIRED

BY LOCAL CODE OR GENERAL

CONTRACTOR

P

MONTGOMERY, ALABAMA

ENTERPRISES, INC.

STEP 3

NOTE NO HOLES ON BOTTOM FLANGE

BEAD OF HIGH TEMP

SILICONE (INCLUDED)

REAR TOP PANEL

APPLIANCE POSITIONING

CHANNEL (INSTALL

BEFORE APPLIANCE IS

PLACED UNDER HOOD)

APPLIANCE POSITIONING

CHANNEL (INSTALL

AFTER APPLIANCE IS

PLACED UNDER HOOD)

2-04. Hood Stand Installation (Stand Mount model)

8

2-05. Cooking Appliance Limitations and clearances

2-05.1. Fryer Limitations (Electric Appliances Only)

Model: FSH-5 & FSH-6Installation

Hood Max. Temp. Max. kW Input

Max.

Shortening

Capacity

Max Cooking

Surface (per

Fryer)

FSH-5 400° 20 80.0 380 Sq. In. 760 Sq. In.

FSH-6 400° 20 80.0 380 Sq. In. 760 Sq. In.

2-05.2. Fryer Clearances (side-to-side overhang clearance does not apply

with Stand Mount model)

Max Cooking

Surface (Total

all Fryers)

0” when using stand option

Inches [mm]

33” [844.0]min -

42” [1066.8]max

0” when using stand option

114”[2895.60] (Ceiling)

117-3/16” [2976.56](72” Stand)

MIN. CEILING HEIGHT

123-1/8” [3127.38](78” Stand)

9

Model: FSH-5 & FSH-6 Installation

2-05.3. Oven Limitations (Electric Appliances Only)

Hood Max. Temp.

FSH-5 500° 55

FSH-6 500° 55

2-05.4. Oven Clearances

Max. kW Input

(Total all Ovens)

Inches [mm]

10

72 max [1828.8] ceiling mount

68 max [1727.2] stand mount

60 max [1522.0] ceiling mount

56 max [1422.4] stand mount

42” [1066.8]max

114”[2895.60] (Ceiling)

117-3/16” [2976.56](72” Stand)

MIN. CEILING HEIGHT

123-1/8” [3127.38](78” Stand)

Model: FSH-5 & FSH-6Installation

2-05.5. Griddle Limitations (Electric Appliances Only)

Hood Max. Temp. Max. kW Input Max Cooking Surface

FSH-5 400° 25 48 X 26

FSH-6 400° 25 60 X 26

2-05.6. Griddle Clearances (side-to-side overhang requirement does not

apply with Stand Mount model)

0” when using

stand option

Inches [mm]

0” when using

stand option

33”[838.2] MIN.

42” [1066.8] MAX

114”[2895.60] (Ceiling)

117-3/16” [2976.56](72” Stand)

MIN. CEILING HEIGHT

123-1/8” [3127.38](78” Stand)

11

Loading...

Loading...