Giles GGF-720 User Manual

Operations & Service Manual GGF SERIES

GGF-400, GGF-720

Models: GGF-400

GGF-720

Giles Enterprises, Inc.

An ISO-9001 Registered Company

2750 Gunter Park Drive West Montgomery, AL 36109 USA

Phone: 334.272.1457Fax: 334.239.4117 Internet: www.gfse.com

(Toll Free): 800.554.4537 (USA & Canada Only)

Form No. 65474 (Rel. Jan.2009, Rev. Sep.2016, Rev. E)

POST IN A PROMINENT LOCATION, Instructions to be followed in the event the user smells gas. This information shall be obtained by consulting the local gas supplier.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors or liquids in the vicinity of this or any other appliance.

! WARNING

•Improper installation, adjustment, alteration, service, or maintenance can cause property damage, injury, or death.

•Read the installation , operating, and maintenance instructions thoroughly before installing or servicing this equipment.

LIMITED WARRANTY

• Subject to the terms and conditions of this Limited Warranty as herein stated, all Giles Enterprises, Inc., Foodservice Equipment and parts purchased new from an authorized Giles Enterprises, Inc., representative are warranted as to defects in material or workmanship for a period of 24 months from the date of installation, provided, however, that with regard to labor costs in

connection with this warranty, see below. All installations must be made by a qualified installing agency in accordance with all applicable codes and/or regulations in the jurisdiction in which installed. Limited warranty coverage is extended to the original owner only and is void if the unit is resold.

• During the Limited Warranty period, Giles Enterprises, Inc. will replace or recondition, at its

factory, any part or parts of this unit which Giles Enterprises, Inc. inspectors judge defective, provided the unit has been subjected to normal usage, properly installed, operated and serviced. This Limited Warranty does not cover cosmetic damage, and damage due to acts of God, accident, misuse,

alteration, negligence, abuse of the Giles Foodservice Equipment or the use of unorthodox repair methods. All parts replaced under this Limited Warranty carry only the unexpired term of this Limited Warranty. Limited Warranty service may be furnished only by an authorized Giles Enterprises, Inc., representative.

• If Limited Warranty service is requested, Giles Enterprises, Inc., will send factory-authorized

service representatives to repair, recondition, replace or inspect units of its manufacture with such labor being rendered without cost to owner for twenty-four (24) months from the date of installation. Otherwise, service, including labor and transportation charges or other expenses, in connection with the removal or installation of any part or parts supplied under this Limited Warranty, are specified on the original sales contract between the purchaser and the authorized Giles Enterprises, Inc.,

representative.

•Giles Enterprises, Inc. reserves the right to change or improve its equipment and parts in any way without obligation to alter such equipment or parts previously manufactured.

•Giles Enterprises, Inc. makes no further warranties, express or implied including implied warranties of merchantability or fitness for a particular purpose, and has no other obligation or liability not specifically stated herein.

•Repair or replacement as provided under this limited warranty is the exclusive remedy. Giles Enterprises, Inc., shall not be liable for any incidental or consequential damages for breach of any express or implied warranty on this product, except to the extent prohibited by applicable law. Any implied warranty of merchantability or fitness for a particular purpose on this product is limited in duration to the duration of this limited warranty.

•Used Giles Enterprises, Inc., Foodservice Equipment or parts or Giles Enterprises, Inc., Foodservice Equipment or parts not purchased from an authorized Giles Enterprises, Inc.,

representative, carry no warranties, express or implied.

Table Of Contents |

Model: GGF-400, GGF-720 |

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Safety Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v Specific Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

1. |

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 |

1-1. |

Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 |

1-2. |

Standard Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 |

1-3 |

Optional Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 |

1-4. |

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

1-4.1. |

Overall Dimensions for GGF-400, GGF-720 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

1-4.2. |

Regulatory Listings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3 |

1-4.3. |

Basket Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3 |

1-4.4. |

Cooking Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3 |

2. |

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 5 |

2-01. |

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 6 |

2-02. |

Clearances, Gas Supply, and Electrical Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 7 |

2-03. |

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8 |

2-04 |

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8 |

2-05 |

Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8 |

2-05.01 |

Utility Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8 |

2-06. |

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9 |

2-07. |

Power Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10 |

2-08. |

Gas Line Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10 |

2-08.01 |

Typical Gas Line Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

11 |

2-09 |

Gas Orifice Configuration and Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

12 |

2-10. |

Gas Pressure Setting and Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

13 |

2-11 |

Blower Vacuum Switch Setting and Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

14 |

2-12 |

Filter Pump Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

15 |

2-13. |

Restraint Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

16 |

2-14. |

Perform Boil Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

16 |

2-15 |

Clean Fry Basket and Filter Pan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

16 |

3. |

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

17 |

3-1. |

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 18 |

3-2. |

Lower Cabinet Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

20 |

3-3. |

Filter Pan Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

22 |

3-4. |

Basket and Elevator Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

24 |

3-5. |

Accessories (Included) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

26 |

3-6. |

Accessories (Not Included). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

28 |

4. |

Unit Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

31 |

4-1. |

Settings before testing unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 31 |

4-2. |

Power test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

32 |

4-3. |

Operational Check of Burner System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

32 |

4-4. |

Filter Pump Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

33 |

iii

Model: GGF-400, GGF-720 |

Table Of Contents |

4-5. Perform Boil Out Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4-6. Clean Filter Pan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5. Fryer Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5-1. Cooking Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36 5-1.1. Button and Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37 5-1.2. Programming a Cooking Temperature and Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38 5-1.3. Enter a cooking cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40 5-1.4. Exit the current cooking cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40 5-1.5. Enter Cool Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41 5-1.6 Exit Cool Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41 5-1.7. Lower and raise cooking basket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41 5-1.8. Enter Boil out cycle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42 5-1.9 Exit Boil out cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42 5-2. Cooking Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43 5-3. Filtering Liquid Shortening . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47 5-4. Removal of Liquid Shortening . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49 5-5. Normal Shut-Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52 5-6. Emergency Shut-Down. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6. Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6-1. Boil-Out Procedure (Cleaning the Fry Pot) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53 6-2. Cleaning the Filter Pan and Renewing Filter Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7-1. Temperature Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7-2. Oil Filtration System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

7-3. Basket Elevator System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

8. Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

8–1. Parts Ordering and Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

8-2. Control Panel & Front Header. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

8-3. Front Lower Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

8-4. Rear Lower Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

8-5. Basket Cover and Basket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

8-6. Filter Pan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

8-7. Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

iv

Safety

Safety

Model: GGF-400, GGF-720

Safety Overview

The instructions contained in this manual have been prepared to aid you in learning the proper procedures for installing and servicing your new unit.

Throughout this manual, safety precautions are identified through the use of the safety alert symbol and three signal words: DANGER, WARNING and CAUTION. All safety alert information precedes the step(s) to which they apply. Suggested, recommended or other noteworthy information is identified through the use of NOTES. Additionally, certain words are used to indicate a specific meaning or to add emphasis.

The following words are used as indicated throughout the manual:

Shall: understood to be mandatory.

Should: understood to be advisory.

May: understood to be permissive.

Will: indicates a future event/condition to occur.

! or !

Used in conjunction with signal words (DANGER, WARNING or CAUTION) to alert you of potential personal injury hazards, immediately preceding precautionary measures that pertain to subsequent step(s). Obey all safety messages that follow this symbol to avoid possible injury or death. Failure to adhere to safety precautions identified by the safety alert symbol may also void the warranty.

!DANGER

•Indicates an imminently hazardous situation which, if not avoided, will result in death or serious personal injury.

!WARNING

•Indicates a potentially hazardous situation which, if not avoided, could result in death or serious personal injury.

!CAUTION

•Indicates a potentially hazardous situation which, if not avoided, may result in minor to moderate personal injury. Also used to alert against unsafe practices.

CAUTION

•When used without the safety alert symbol, CAUTION indicates a potentially hazardous situation which, if not avoided, may result in equipment or property damage, and void the warranty.

NOTE:

• Identifies suggested, recommended, or other noteworthy information.

v

Model: GGF-400, GGF-720 |

Safety |

Specific Safety Precautions

For your safety, please observe the following precautions when operating or servicing your Giles, Model GGF Gas Fryer. Read the following important safety information to avoid personal injury and/or damage to

the equipment.

! DANGER

• Place unit’s power switch in the OFF position and turn supply power at the facility’s circuit breaker panel before cleaning or performing maintenance.

• DO NOT wash down the GGF Fryer’s interior or exterior with water from a spray hose.

• Failure to comply with these DANGER notices will result in death, serious personal injury or equipment and property damage.

! WARNING

• Consult a certified electrician to ensure that:

•• all electrical specifications and codes are met.

•• circuit breakers and wiring are of sufficient rating and gauge.

• The GGF Fryer must be properly grounded and all electrical specifications must be met during installation.

• Improper installation, adjustment, alteration, service or maintenance could result in death or serious injury, equipment/property damage, and void the warranty.

• DO NOT use or store gasoline, other flammable liquids or materials that generate flammable vapors in the vicinity of this or any other appliance!

• Failure to comply with WARNING notices could result in death or serious injury, and equipment/property damage and void the warranty.

! CAUTION

• The GGF Fryer, must remain in the upright (vertical) position.

• Exercise care when removing the unit from from shipping packaging.

• DO NOT operate the GGF Fryer, unless you fully understand the components and their intended function (see Section 3).

• The GGF Fryer, and its parts become very HOT during operations! Temperatures inside the unit’s cabinet may exceed 150°F (65.5°C).

Exercise caution when operating, loading/unloading food items, cleaning or servicing. Wearing of thermal oven mitts is recommended.

• Failure to comply with CAUTION notices may result in minor to moderate personal injury, equipment/property damage, and void the warranty.

vi

Safety |

Model: GGF-400, GGF-720 |

!CAUTION

•Fryers must be adequately and properly grounded. Improper grounding may result in electrical shock. Always refer to local electrical code to ensure proper grounding of this or any other electrical equipment. Always consult with a certified electrician or other qualified service technician to ensure breakers and wiring are of sufficient rating and gauge for the equipment being operated.

•Giles Fryers are available from the factory wired for various voltages, phase and Hz. Check the rating plate inside the front door of the fryer to determine correct supply power required.

•Ensure the fry kettle is positioned in a secure, safe location with casters in the locked position.

•Consult an electrician to ensure all electrical specifications have been met and the unit is properly grounded. The wiring diagram included with this manual should aid electrician in the installation of the fryer.

•Due to the high temperature of shortening during cooking operations, it is extremely important that the user exercise caution when operating this equipment to avoid personal injury.

•Before attempting to operate the unit, refer to Section 3 to familiarize yourself with the various control functions. Once you have read and fully understand Section 3, please follow the steps below precisely in order to prevent equipment damage or malfunction.

•Be careful not to puncture the filter paper when using brushes to unclog the Drain Valve.

•Allow the unit to cool down a minimum of 15 minutes before cleaning or servicing.

CAUTION

•The electronic components of the Control Panel are impact-sensitive. Exercise care around the Control Panel to maintain proper operation.

•DO NOT install the unit next to combustible walls and materials. Failure to maintain safe distances may result in fire.

•During cleaning of the GGF Fryer:

••DO NOT steam clean or use water sprayed from a hose.

••DO NOT use products containing chlorine.

••DO NOT use abrasive products, steel wool or scouring pads.

••DO NOT use oven cleaner.

•Failure to comply may violate local health codes.

•DO NOT modify, alter or add attachments to this equipment!

vii

Model: GGF-400, GGF-720 |

Safety |

NOTE:

•If upon receipt, palletized unit shows any signs of damage, immediately inspect the GGF Fryer and its associated components, and notify the freight carrier of any and all damages.

•To aid the electrician, an electrical wiring diagram is contained in this manual. Refer to the wiring diagram during installation or servicing. A diagram is also attached to the Back Panel of the Fryer.

•Comply with all appropriate state and/or local heath regulations regarding cleaning and sanitation of this equipment.

viii

Introduction

1.Introduction

Model: GGF-400, GGF-720

THANK YOU for purchasing a new Giles Model GGF-400 or GGF-720 Gas Fryer, manufactured by Giles Enterprises, Inc., Montgomery, Alabama (USA), hereafter referred to as "Giles". Every unit is thoroughly inspected and tested prior to shipment. Proper care and maintenance will ensure years of trouble-free service.

To help protect your investment in this state-of-the-art cooking equipment, we recommend you take a few moments to familiarize yourself with the installation, cleaning and maintenance procedures contained in this manual. Adherence to these recommended procedures minimizes the potential for costly “Down-Time” and equipment repairs. Please retain this manual for future reference.

1-1. Construction

The GGF-400 & GGF-720 Fryer is constructed of durable stainless steel.

1-2. Standard Features

Programmable Controller - Controls cooking oil temperature and cook time, and features 8 separate programmable menu keys. Monitors fryer status and displays warning messages, such as “Low Oil“ or “Drain Open”, if needed. Pre-programmed Boil-Out program & Cool Mode function.

Dual Burner system - Unique dual burner system on Model GGF-720 delivers maximum BTU’s when needed, while saving gas during light load cooking and idle periods.

Automatic Basket Lift - Automatically lowers product when menu program is started and lifts basket from hot oil at the conclusion of the cook cycle.

Oil Filtration System - Completely self-contained; helps to extend the life of cooking oil. Designed to perform a filter cycle within approximately five (5) minutes.

1-3. Optional Features

1

Model: GGF-400, GGF-720 |

Introduction |

1-4. Specifications

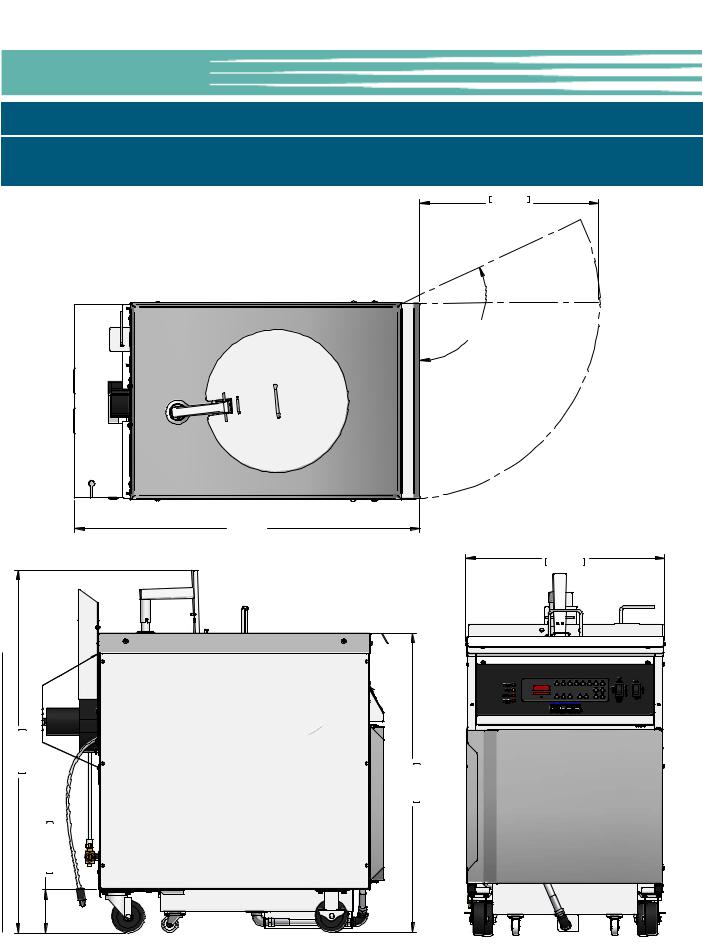

1-4.1. Overall Cabinet Dimensions for GGF-400, GGF-560, GGF-720

|

|

|

556mm |

|

|

|

217/8 |

1 |

1 |

5 |

° |

|

REVERSIBLE

DOOR SWING

4211/32

44 7/16 1129mm |

5 1/4 133.99mm |

2 |

619mm24 3/8

36 5/8 931mm

Introduction |

Model: GGF-400, GGF-720 |

1-4.2.Regulatory Listings

1-4.3.Basket Sizes

|

Model |

Basket Size (useable inside dim.) |

Volume |

||||

|

|

|

|

|

|

|

|

|

|

Diameter |

Height |

cu. inch |

cu. meter |

||

|

|

|

|

|

|

||

|

|

in |

mm |

in |

mm |

||

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

GGF-400 |

12.37 |

314.19 |

10.25 |

260.35 |

1231.83 |

0.0201 |

|

|

|

|

|

|

|

|

|

GGF-720 |

14.50 |

368.30 |

13.03 |

331.35 |

2151.65 |

0.0353 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1-4.4.Cooking Capacity

Model |

Liquid Shortening Capacity ** |

Chicken Capacity |

|

lb |

kg |

gallon |

liter |

lb |

kg |

Piece |

|

Count* |

||||||

|

|

|

|

|

|

|

|

GGF-400 |

45 |

21 |

5.8 |

21.9 |

14 |

6.3 |

40 |

GGF-720 |

75 |

34 |

9.7 |

36.7 |

24 |

10.8 |

72 |

** Never exceed max. fill line on fryer. |

* Avg. 2-3/4 lb. 8-way cut chicken |

!CAUTION

•Exceeding product (chicken) capacity or over-filling vat with shortening may cause personal injury and/or equipment or property damage.

3

Model: GGF-400, GGF-720 |

Introduction |

4

Installation |

Model: GGF-400, GGF-720 |

2. Installation

This section provides a summary of the procedures necessary for proper installation of your new Giles Model GGF Gas Fryer. To prevent personal injury or equipment damage, please ensure the following steps are taken and the following check sheet is initialed and dated.

CAUTION

•Various installation steps MUST be performed only by a Licensed Electrician or Qualified Gas Technician.

NOTE:

•When installed, appliance must be electrically grounded in accordance with the local codes, or in the absence of local codes, with the National Electrical Code, ANSI/NFPA 70, or Canadian Electrical code, CSA C22.2, as applicable.

|

|

|

|

INSTALLATION CHECK SHEET |

Check |

Date |

Initial |

Section |

Description |

X |

8/18/05 |

CSY |

0.0 |

Completely read Manual (EXAMPLE) |

|

|

|

2-01. |

Inspect crate for damage |

|

|

|

|

|

|

|

|

2-01. |

Uncrate |

|

|

|

|

|

|

|

|

2-02. |

Proper clearances |

|

|

|

|

|

|

|

|

2-04. |

Proper ventilation |

|

|

|

|

|

|

|

|

2-05. |

Proper circuit breaker installed (Licensed Electrician Only) |

|

|

|

|

|

|

|

|

2-06. |

Proper electrical connections (Licensed Electrician Only) |

|

|

|

|

|

|

|

|

2-07. |

Unit has power (Licensed Electrician Only) |

|

|

|

|

|

|

|

|

2-08. |

Gas line connected (Qualified Gas Technician Only) |

|

|

|

|

|

|

|

|

2-09. |

Correct gas orifice installed (Qualified Gas Technician Only) |

|

|

|

|

|

|

|

|

2-10. |

Correct gas pressure setting (Qualified Gas Technician Only) |

|

|

|

|

|

|

|

|

2-11. |

Correct blower vacuum switch setting (Qualified Gas Technician Only) |

|

|

|

|

|

|

|

|

2-12. |

Filter Pump operating |

|

|

|

|

|

|

|

|

2-13. |

Restraint device installed |

|

|

|

|

|

|

|

|

2-14. |

Performed Boil-Out procedure |

|

|

|

|

|

|

|

|

2-15. |

Cleaned Filter Pan |

|

|

|

|

|

5

Model: GGF-400, GGF-720 |

Installation |

2-01. Unpacking

The Fryer should arrive palletized on a wooden skid, secured with high-tensile plastic strapping and wrapped by machine applied stretch wrap.

CAUTION

•The Fryer must remain in an upright (vertical) position.

•Exercise care when lifting or moving the unit.

•Exercise care when removing the wooden crate and shipping materials from around the unit.

•Failure to comply with these CAUTION notices may result in minor to moderate injury, equipment or property damage, and void the warranty.

NOTE:

•If when received, the palletized unit exhibits any signs of damaged, immediately inspect the Fryer and associated items, and notify the freight carrier of damages.

1.Carefully cut and remove the plastic shipping wrap and strapping.

2.Remove and properly dispose of shipping materials.

3.Carefully remove the Fryer from the shipping pallet. The GGF Fryer is very heavy, weighing approximately 280 lbs (127 kg) uncrated. Extreme care should be taken when lifting or moving the unit to prevent personal injury and/or equipment damage.

6

Installation |

Model: GGF-400, GGF-720 |

2-02. Clearances, Gas Supply and Electrical Locations

COMBUSTIBLES

18”[457.2]

NON-COMBUSTIBLES

4”[101.6]

4”[101.6] 18”[457.2]

4”[101.6]

NON-COMBUSTIBLES

18”[457.2]

COMBUSTIBLES

24619mm3/8

24619mm3/8

44 7/16 1129mm |

36 931mm |

WITH 72” [1829] |

|

120V ONLY SUPPLIED |

5/8 |

|

|

CORD |

|

1/2” NPT GAS LINE |

5 1/4 133.99mm |

|

|

CONNECTION |

|

INCHES [mm]

7

Model: GGF-400, GGF-720 |

Installation |

2-03. Location

CAUTION

• DO NOT MODIFY, ALTER OR ADD ATTACHMENTS TO THIS EQUIPMENT

1.Keep the appliance and surrounding area free and clear of combustible materials. See illustration 2-02; Clearance, Gas Supply and Electrical Locations.

2.Make sure this unit is secured in position and will not move. See 2-13; Restraining Device.

2-04. Ventilation

NOTE:

•Guidelines for proper ventilation system requirements may differ by locale. Always consult with local authorities to ensure compliance.

This appliance is to be installed, used and maintained in accordance with the Standard for Ventilation Control & Fire Protection of Commercial Cooking Operations, NFPA 96-1994.

Consult a professional, certified, HVAC company for assistance in designing a ventilation hood system for this unit.

2-05. Electrical Requirements

!CAUTION

•Fryers must be adequately and properly grounded. Improper grounding may result in electrical shock. Always refer to your local electrical code to ensure proper grounding of this or any other electrical equipment. Always consult with an electrician or other qualified service person to ensure breakers and wiring are of sufficient rating and gauge for the equipment being operated.

•Giles Gas Fryers are available from the factory in the voltage and phase listed below. Check the rating plate on the inside of the fryer’s front door to determine the correct power supply.

Table 2-05.01. Utility Specifications

Model |

Voltage |

Hz |

Phase |

AMPS |

Breaker |

Gas Specifications |

||

Required |

||||||||

|

|

|

|

|

|

|

||

GGF-400 |

120 |

60 |

1 |

7.0 |

15 |

This equipment requires a 1/2” |

||

GGF-400 |

208-230 |

60 |

1 |

4.0 |

10 |

gas line w/in-line regulator (not |

||

GGF-720 |

120 |

60 |

1 |

7.0 |

15 |

supplied). Input line gas |

||

GGF-720 |

208-230 |

60 |

1 |

4.0 |

10 |

pressure must be regulated at: |

||

|

|

|

|

|

|

5”- 9” w.c. |

Natural |

|

|

|

|

|

|

|

13”- 16” w.c. |

LP |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

8

Installation |

Model: GGF-400, GGF-720 |

2-06. Electrical Connections

All Fryers

1.Connect Fryer power plug to an appropriate receptacle which is protected by a properly sized circuit breaker, See Table 2-05.01.

NOTE:

•When installed, appliance must be electrically grounded in accordance with the local code, or in the absence of local code, with the National Electrical Code, ANSI/NFPA 70, or Canadian Electrical code, CSA C22.2, as applicable.

9

Model: GGF-400, GGF-720

2-07. Power test

The following test will ensure the unit has power.

1.Verify that the main circuit breaker supplying power to the unit is ON.

3

2. Ensure the Selector Switch is in the center

OFF 1 position.

3. Place the Power Switch in the ON |

|

2 |

|

position. The green POWER light |

|

|

|

3 |

|

||

should turn on and the Controller display should illuminate; after a few seconds the display should read “Hold”.

If one, or both, of these conditions is not present, refer to the Trouble-shooting Procedures in Section 6-01.

4. Place the Power Switch in the OFF 4

position.

5. Proceed to 2-08; Gas Line Connection.

Installation

1 2

4

2-08. Gas Line Connection

!CAUTION

•The flue gases of this appliance must be vented to the outside in accordance with National Fuel Gas Code, ANSI Z223.1-1988 and terminate in a UL listed outside vent terminal; for Canadian installations reference CANI-B149.1 or .2, “Installation Codes for Gas Burning Appliances and Equipment”. The quick disconnect device must comply with the Standard for Quick-Disconnect Devices for Use with Gas Fuel, ANSI Z21.411989, (in Canada CANI 6.9 M79).

•Ensure the Gas Connector and Line complies with Standard for Movable Gas Appliance, ANSI, 69-1987 and Addenda Z21.69-1989 (in Canada CANI-6-10-88).

•This unit MUST be installed with an In-line Regulator (Supplied by Customer).

• This unit MUST only be installed by a Qualified Gas Technician.

•Ensure both the Facility Shut-Off Valve and the Fryer’s Shut-Off Valve are in the OFF position.

1.After the facility Shut-Off Valve and Quick Disconnect have been installed, connect a 1/2” flexible gas line to the 1/2” Fryer shut-off valve located in the rear of the unit. See 2-08.01; Typical Gas Line Configuration. Note: The flexible gas line should be long enough to allow the Fryer to be moved away from wall for servicing and cleaning.

10

Installation |

Model: GGF-400, GGF-720 |

2-08.01 Typical Gas Line Configuration

NOTE:

•Installation must comply with local code, or in the absence of local code, with the National Fuel Gas Code, ANSI Z223.1/NFPA 54 or, in Canada, Natural Gas and Propane Installation Code, CSA B149.1 including:

1The appliance must be disconnected from the incoming gas supply line, at the shut-off valve, during any testing of the piping at test pressures in excess of 1/2 psi (3.5kPa)

2The appliance must be isolated from the incoming gas supply line, by closing the fryer’s manual shutoff valve, during any testing of the piping at test pressures equal to or less than 1/2 psi (3.5kPa)

*1/2” Flexible Gas Line

*Quick Disconnect

*In-Line Regulator

* Shut-Off Valve

To 1/2” Fryer

Shut-Off Valve

* Supplied by customer.

11

Model: GGF-400, GGF-720 |

Installation |

2-09. Gas Orifice Configuration and Replacement

NOTE:

•This unit is shipped with factory installed gas Orifice(s) suited for 0 > 3,000 feet above MSL (Natural Gas) or 0 > 4,000 feet above MSL (LP Gas).

Gas flow varies at different elevations. Verify the elevation of the installation location. If the elevation is greater than noted above,the gas orifice(s) must be changed. To confirm that proper orifices are installed or to exchange orifice(s), follow the steps below.

!CAUTION

•If changing Gas Types always consult factory for proper Conversion Kit.

1.Ensure power to the unit is disconnected.

2.Confirm that gas valves are in the OFF position.

3.Remove the Fan Guard & Back Panel.

4.It should be possible to examine the stampings on orifice(s) without removing parts. Check information stamped into Orifice.

5.If the Orifice(s) are incorrect for the installation altitude, disconnect Gas Line(s) at the Manifold fitting(s).

6.Remove Manifold(s) from Bracket. Remove & replace Orifice(s) with the correct part. See charts below.

7.Re-install Gas Manifold(s) with orifice(s), reconnect gas line(s), and replace Panel & Guard. Proceed to 2-10; Gas Pressure Setting and Adjustment..

Gas Orifice |

Burners |

|

*Covered |

Gas Type |

Altitude |

|

Range |

|

Gas Manifold |

|

Gas Line |

|

connects at |

|

this fitting |

Orifice chart for GGF-400 fryers. |

Orifice chart for GGF-720 fryers. |

12

Installation |

Model: GGF-400, GGF-720 |

2-10. Gas Pressure Setting and Adjustment

Use the following procedure to set the Fryer manifold pressure to correct setting. This ensures that the BTU input of burner(s) is at the proper level.

1.Fill the Fry Pot with water to the FULL line.

!CAUTION

•NEVER check or adjust the gas pressure without the Fry Pot filled with water.

2.Remove the Gas Valve Access Panel (lower left corner, back of Fryer).

3.Remove the Pressure Tap Plug from the Gas Valve.

4.Remove the Pressure Adjustment Cover Plug on the Gas Valve.

5. Connect a digital manometer to the Gas Valve PressureTap.

6. Place the Gas Shut-Off Valve in the OPEN

position.

7. Place the Power Switch in the ON position |

|

and the Selector Switch in the COOK |

|

position. |

Pressure Tap Plug |

|

8.The burner(s) should ignite and the unit will begin heating.

9.With burner(s) ON, use a screwdriver to adjust the Gas Valve Pressure as follows:

Pressure

Adjustment

Cover Plug

GAS TYPE |

GGF400 (in w.c.) |

GGF720 (in w.c.) |

|

|

|

NATURAL |

3.5 |

4.0 |

|

|

|

LP |

10.5 |

11.0 |

|

|

|

10.Place the Power Switch in the OFF position and the Selector Switch in the OFF position.

11.Remove the manometer and replace the Pressure Tap Plug.

12.Replace the adjustment screw cover plug.

13.Replace the Gas Valve Access Panel.

14.Proceed to 2-11; Blower Vacuum Switch Setting, or drain water from the fry pot into a suitable container.

*Not supplied with unit

* Manometer with pressure tube

* Screw Driver for adjusting pressure

* Screw Driver for adjusting pressure

13

Model: GGF-400, GGF-720 |

Installation |

2-11. Blower Vacuum Switch Setting and Adjustment

The Blower Vacuum Switch ensures that the unit has proper draft air-flow before allowing the gas valve to open for ignition. Use the following steps to ensure that the Blower Vacuum Switch is adjusted to the proper setting.

1.Fill the Fry Pot with water to the FULL line.

!CAUTION

•NEVER check or adjust the Blower Vacuum Switch without having fry pot filled with water, or oil.

2.Place the Power Switch in the ON position, the Power Light will illuminate.

3.Place the Selector Switch in the COOK position; Heat Light will illuminate and burner(s) will light.

!CAUTION

•During the next step use great caution and wear oven mitts. The air exhausted from the flue stack is EXTREMELY HOT!!

4.Using a non-combustible material, such as a piece of metal, cover about half of the flue stack opening, diagonally from corner to corner.

5.The Heat Light should turn off & the burner(s) should shutdown. When the opening is unblocked, the burner(s) should re-light. Proceed to step 10.

If the burner(s) fails to shutdown, the Blower Vacuum Switch must be adjusted as follows.

6.Turn off power & close the gas valve.

7.Remove front Control Panel screw and lower the Panel.

8.Locate pressure switch on left side of the control box.

9.Slowly rotate the pressure switch adjustment dial - clockwise increases sensitivity, counterclockwise decreases. Repeat steps 2 - 5.

Continue adjustments until the burner(s) shutdown when approx. half the flue stack opening is blocked.

10.Drain water from the Fry Pot into a suitable container (NOT Filter Pan). Proceed to Section 2- 12.

Non-Combustible

Material

Flue Stack

Vacuum Switch

14

Installation |

Model: GGF-400, GGF-720 |

2-12. Filter Pump Test

The following test will ensure the Filter Pump is operating correctly.

!CAUTION

•Before proceeding with this test, ensure the unit has adequately cooled. Contact with HOT parts is possible if not thoroughly cooled.

1.Open the Cabinet Door and, if required, disconnect the Filter Pan quick-disconnect from the unit and remove the Filter Pan.

2. Place the Power Switch in the ON 1

position.

3.Place the palm of your hand over the Filter Pan quick-disconnect opening.

4.Briefly place the Selector Switch to the

PUMP 2 position, briefly run pump, and then return switch to the OFF 3

position. If suction is felt against the palm, the pump is operating correctly. Proceed to Section 2-13; Restraint Device.

If no suction is felt, refer to the Troubleshooting procedures in Section 6-02.

3 1

2

Filter Pan Quick

Disconnect

Filter Pan

With Filter Pan removed, place hand over quick-disconnect opening.

15

Model: GGF-400, GGF-720 |

Installation |

2-13. Restraint Device

This unit requires use of a Restraint Device of some type (not included with the unit) to prevent Fryer from being unintentionally moved and to prevent strain on electrical and gas line connections. The Restraint Cable length must be shorter than both electrical cord, or conduit, and the flexible gas line. A restraint anchor must be fastened to a non-movable wall. Use a quick disconnect latch on one end of the Restraint Cable so the cable can be removed during servicing. After installation of the Restraint Device proceed to 2-1; Perform BoilOut Procedure.

* Restraint Anchor attached to non-movable wall

*Restraint Cable

*Quick Disconnect Latch

Eye Bolt on Unit

* Supplied by customer.

2-14. Perform Boil-Out Procedure

Perform a Boil-out Procedure to remove any dust, dirt or debris that may have accumulated in the pot during shipping. Follow Section 5-01; Boil-Out Procedure. After performing the Boil Out Procedure proceed to Section 2-15; Clean Fry Basket and Filter Pan.

2-15. Clean Fry Basket and Filter Pan

Thoroughly clean the Fry Basket and the Filter Pan to remove any dust, dirt, oils or debris that may have accumulated during shipping or manufacturing. Follow Section 5-02; Cleaning the Filter Pan and replacing Filter Paper after Boil-Out.

Fryer installation is now complete. Please proceed to the Overview Section.

16

Overview |

Model: GGF-400, GGF-720 |

3. Overview

The following section provides a brief overview of the components, functions and accessories associated with the Giles Model GGF-400 & GGF-720 Gas Fryer. Please review this section carefully before proceeding any further.

Basket & Elevator

Assembly

Figure 3-4

Control Panel

Figure 3-1.

Lower Cabinet

Area

Figure 3-2.

Filter Pan Assembly

Figure 3-3.

17

Loading...

Loading...