Page 1

WORKSHOP MANUAL

COGUAR

Page 2

Reproduced by

OWNERS CLUB

OF BRITAIN

from information obtained from original or copied

manuals originally issued by

Piaggio/Gilera

Whilst every care has been taken to ensure

accuracy of the contents, I Gotta Gilera does not

accept any liability of any type due to any errors or

omissions, and use of this manual will denote

acceptance of this condition.

NOTES:

We have found one obvious error within the original manual, but have copied it

exactly as it originally appeared together with a note advising that it is an error.

If you find any other errors, please email pppdrive@talktalk.net so that this manual

can be updated to be as accurate as is possible.

Page 3

COGUAR WORKSHOP MANUAL

This manual was written by Piaggio-Gilera for use in Piaggio-Gilera

dealers and authorised servicing workshops. It is assumed that the

person using this manual for maintenance and repairs on Piaggio-Gilera

Coguar models has a basic knowledge of mechanical principles and

procedures concerning vehicle repair techniques.

Information concerning important variations in vehicle characteristics or in

certain repair operations will be communicated as an update to this

manual.

However, it is not possible to carry out a completely satisfactory job

without the necessary systems and tools. Therefore, please consult the

pages in this manual dealing with special tools and the special equipment

catalogue.

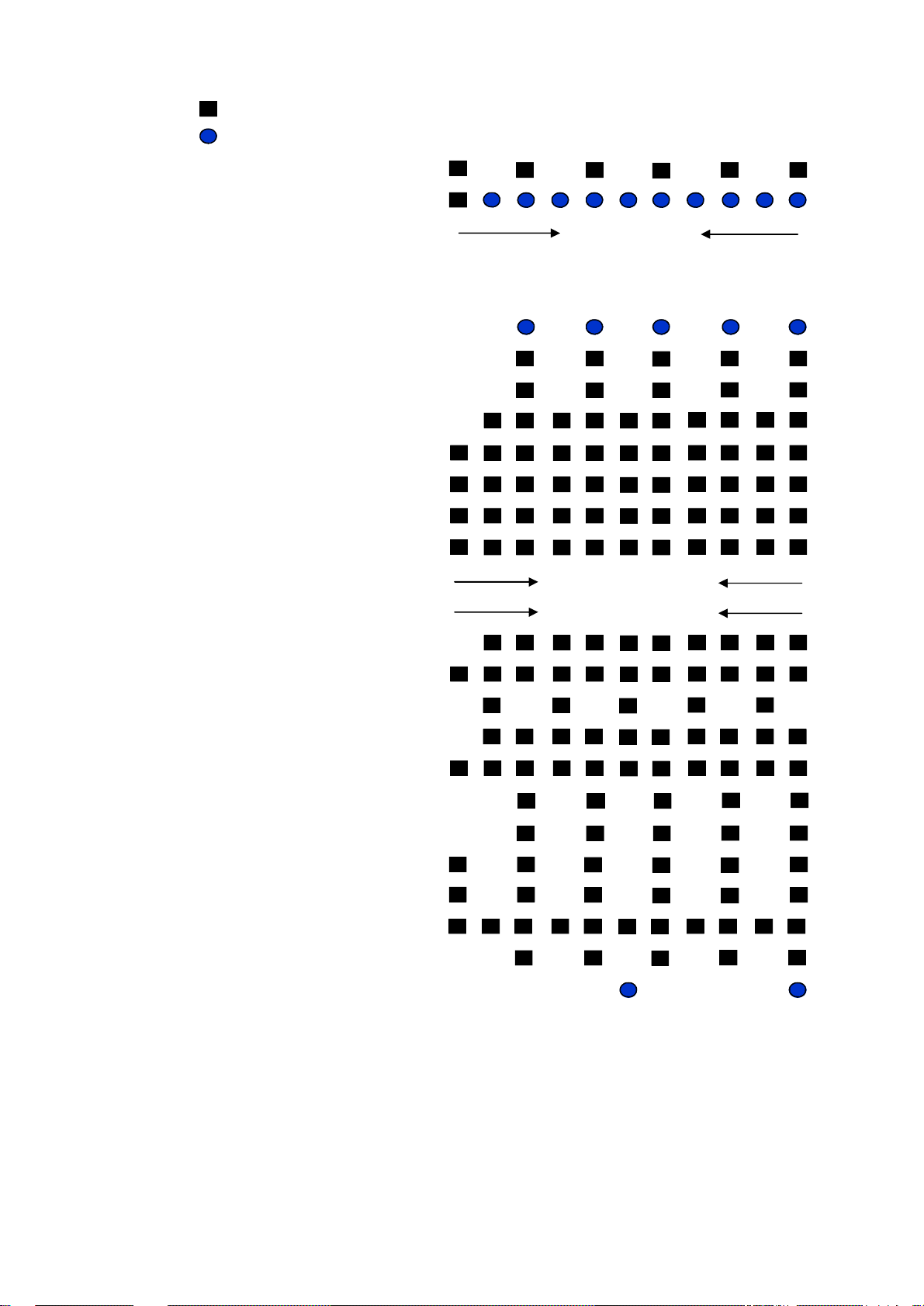

NOTE This indicates a note that gives important information to make the

………..procedure clearer and easier to carry out.

Important note

Warning

This indicates certain precautions that are to be taken to avoid

injuries to the person repairing the vehicle.

NOTE - For all that concerns the specific operations on the Coguar

………….engine, see the “SERVICE STATION MANUAL 4T SPEED

………….125cc ENGINE.”

This indicates special procedures that are to be followed

to avoid damaging the vehicle.

Page 4

GENERAL INFORMATION

Safety regulations

If it is necessary to work on the vehicle with the engine running, make sure that the

environment is well ventilated, if necessary using a suitable exhaust system. Never

run the engine in closed places since the exhaust gasses are toxic.

The battery electrolyte contains sulphuric acid. Protect your eyes, clothes and skin.

Sulphuric acid is highly corrosive; if it comes into contact with the eyes or skin, wash

with plenty of water and go immediately to a Doctor.

The battery produces hydrogen which can be highly explosive. Do not smoke and

avoid naked flames and sparks near the battery, especially when recharging it.

Petrol is very inflammable and under some conditions can explode. Do not smoke

in the work area and keep clear of naked flames and sparks.

Clean the brake shoes, drums and pads in well ventilated areas directing the

compressed air jet to avoid taking in the dust caused by the wear on the shoes.

Although the brake lining does not contain asbestos, inhalation of the dust is still

harmful.

Maintenance rules

Use original PIAGGIO-GILERA spare parts and lubricants recommended by the

manufacturer. Spare parts other than originals or that do not conform can damage

the vehicle.

Only use the special tools designed for this vehicle.

Always use new seals, seal rings and split pins when assembling.

After disassembly, clean the components with non flammable solvent. Lubricate all

working surfaces before reassembling, except for the bevel pairs.

After reassembly, check that all the components have been installed correctly and

operate perfectly.

For disassembly, overhaul and reassembly operations, only use tools with metric

measurements. The metric screws, nuts and bolts are not interchangeable with

English measurement couplings. The use of unsuitable tools or couplings could

damage the vehicle.

When working on the vehicle electrical system, check the correct assembly of the

electrical connections, especially those connecting the to earth and the battery.

Vehicle identification

Vehicle

COGUAR 125 cc

Frame prefix

ZAPM1700000001001

Engine prefix

JD09E

Page 5

INDEX

Specifications

Vehicle overhaul data

Special equipment

Maintenance and troubleshooting

Electrical system

Front suspension

Rear suspension

Braking system

Pre-delivery operations

Section

1

1

1

2

3

4

5

6

7

Page 6

GENERAL INFORMATION 1

SUB INDEX

Specifications

Torque settings

Section - Page

1 - 1

1 - 2

1

Page 7

SPECIFICATIONS

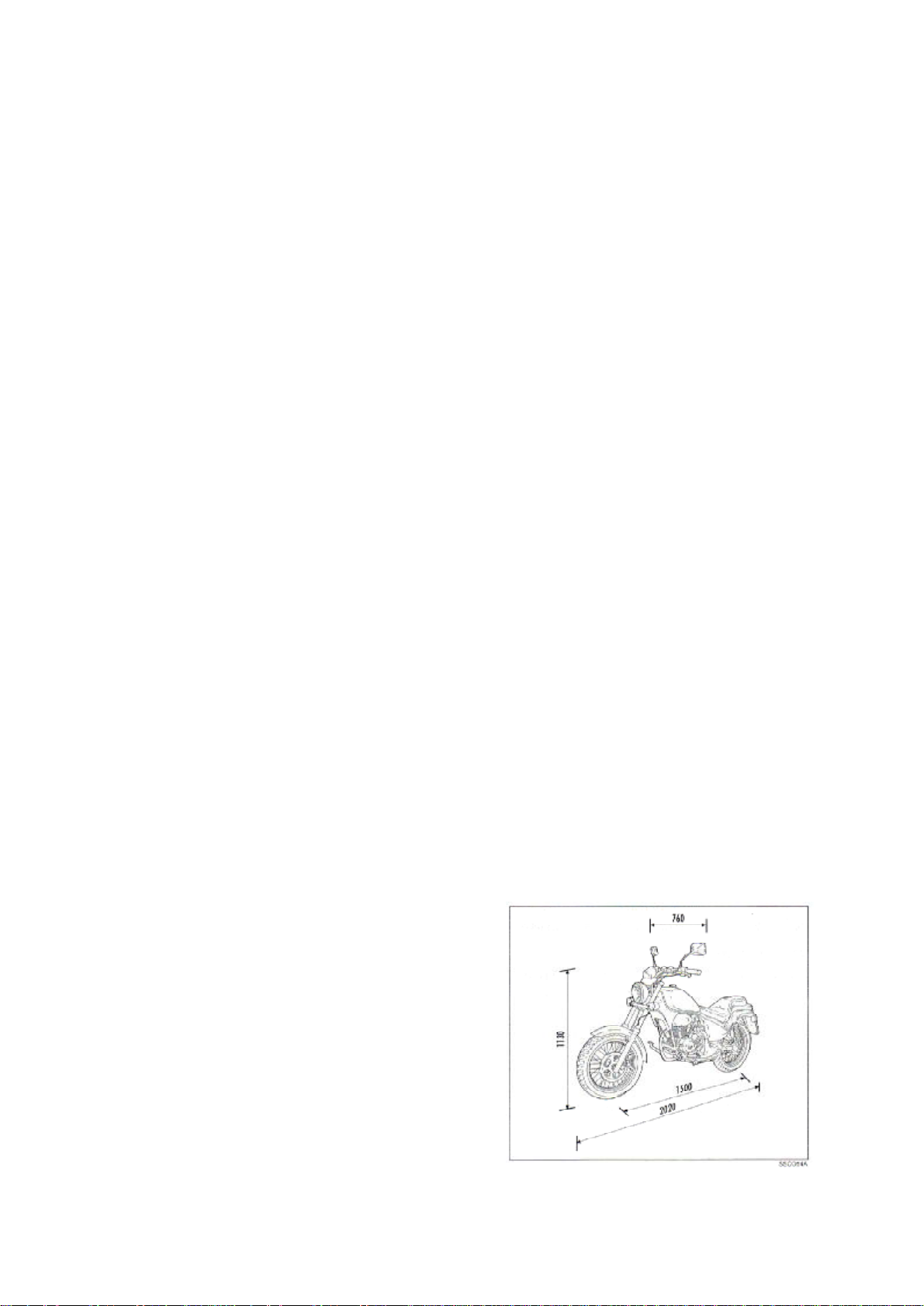

Dimensions and weight

Width

Length

Wheelbase

Height

Dry weight

760mm

2020mm

1500mm

1130mm

141kg

Engine

Type

4 stroke

Cylinders

Bore

Stroke

Capacity

Comp. Ratio

56.5mm

49.5mm

124cc

9.2±0.5:1

Timing: single shaft with cams

in head, two valves, chain

driven on right-hand side.

Carburettor

Air Cleaner

Start up

Lubrication

Fuel supply

Cooling

KEIHIN PDC3F

Paper

Electric starter

Forced, wet sump

Unleaded petrol,

carburettor,

gravity system

Air

Performance

Engine idling

Max power at

shaft

Max torque at

shaft

Max speed

1400±100rpm

7.9kW/8250rpm

10Nm/7000rpm

102kph

Transmission

Geared primary, chain secondary.

Capacities

Petrol (inc reserve) 12 lt

Reserve 2.2 lt

Engine oil

Sump 1.0 lt

Total system capacity 1.2 lt

Fork oil 280cc

Frame

1

Single tube with double closed cradle.

Suspension

Front: Hydraulic fork with 35mm rod

………..and 130mm stroke.

Rear: Dual shock-absorbing element

………...with 84mm stroke.

Brakes

Front: 260mm diameter disc, with

…………hydraulic control dual floating

…………shoe, lever on r-h handlebar.

Rear: 160mm diameter drum, with

…………mechanically controlled

…………expansion calliper.

Wheels

Stainless steel spokes aluminium rims

Front: 2.50 X 17”

Rear: .3.00 X 17”

Tyres

Front: .100/80 - 17”

Rear: 130/70 - 17”

Pressures (cold):

Front: 1.8 bar (1.9 with passenger)

Rear: 2.0 bar (2.2 with passenger)

Electrical components

Generator

Ignition

3 phase, ac

Electronic with

variable spark

Spark advance

(before TDC)

Spark plug

Battery

15° at 1400rpm

32° at 3450rpm

NGK DPR8EA-9

ND X204EPR-U9

12V - 9Ah

advance

1-1

Page 8

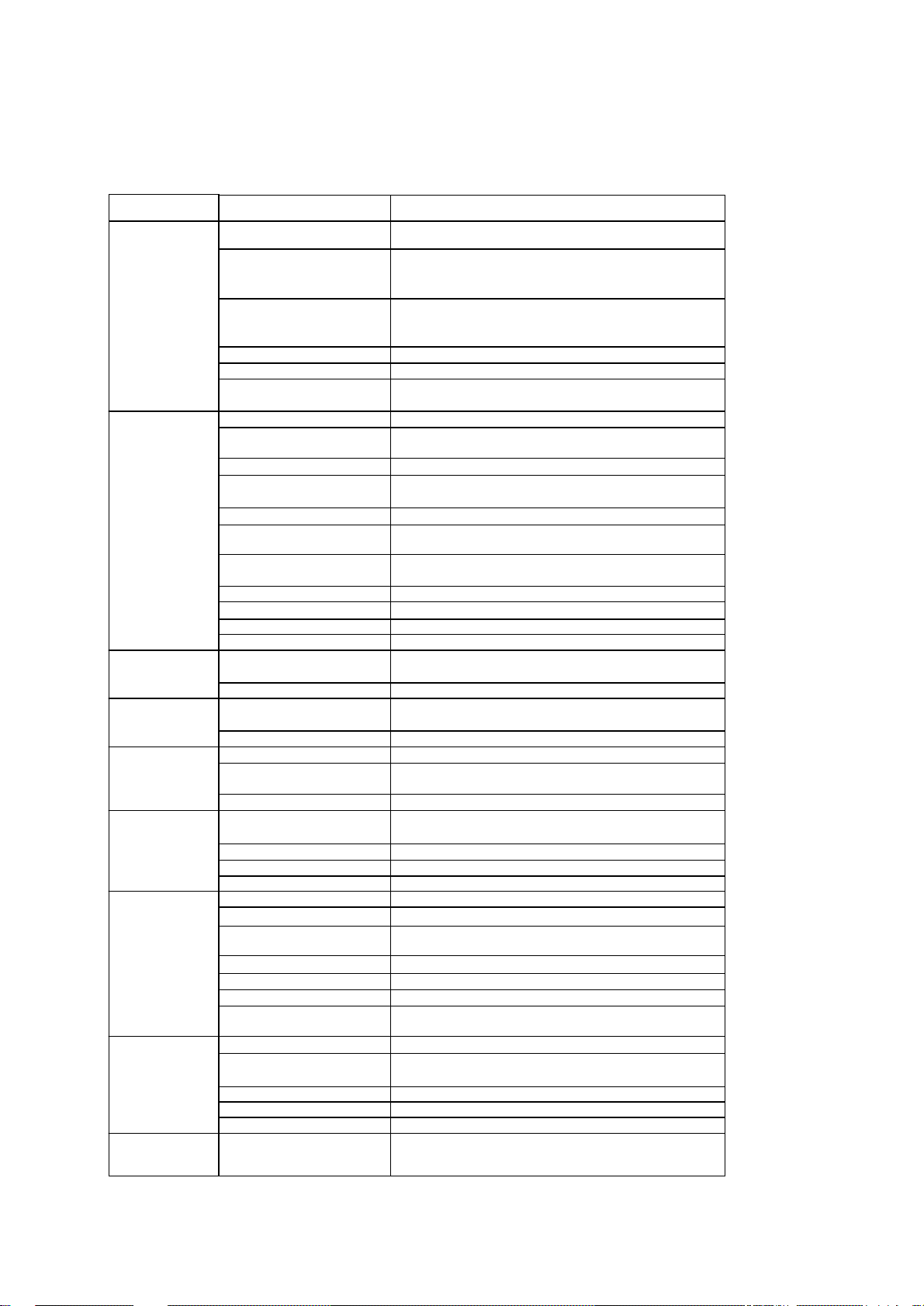

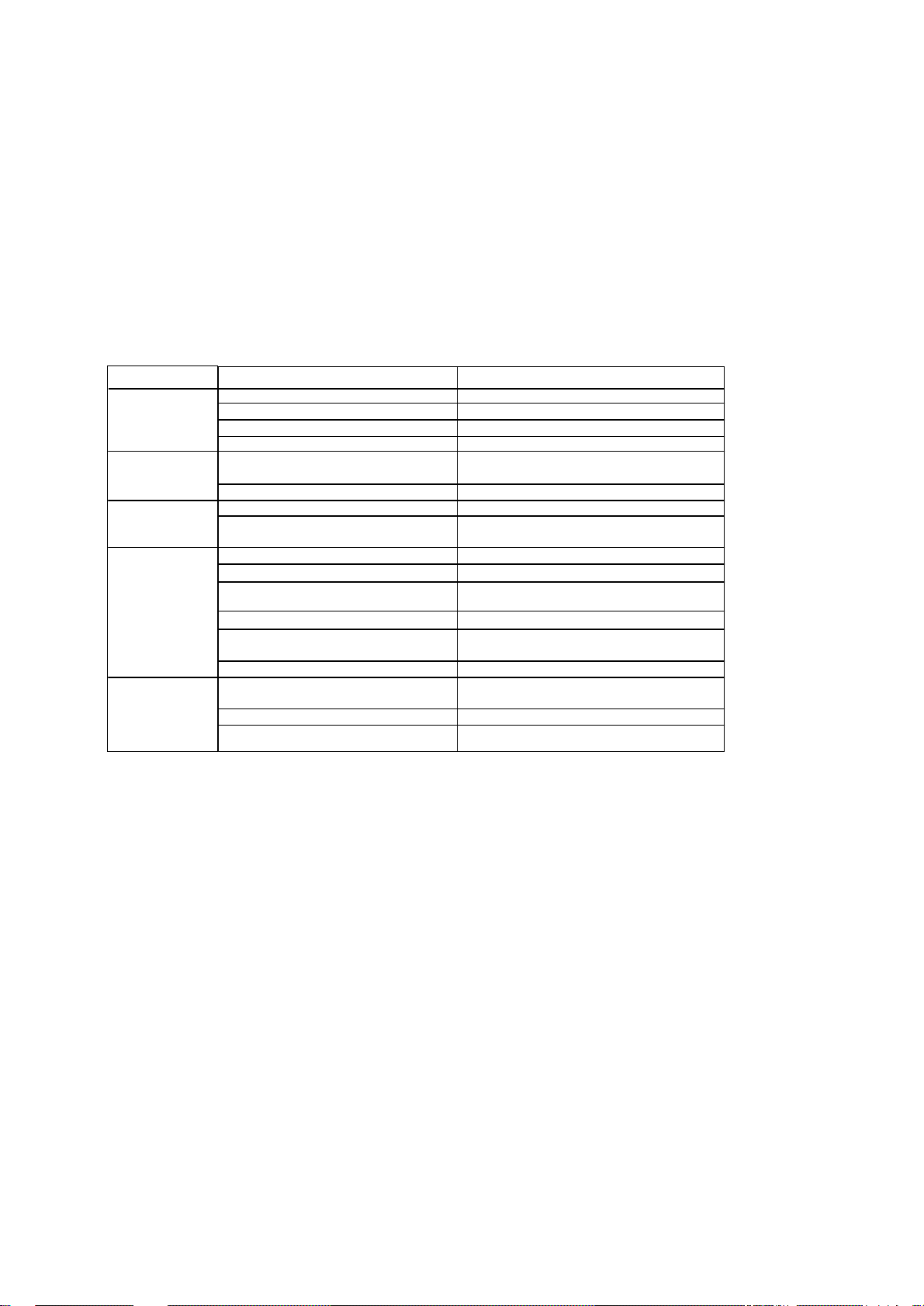

TORQUE SETTINGS

FASTENING

Engine to frame (rear)

Engine (front & upper)

Side stand to frame

Stand fastening nut

Pedal plate to frame

Chain guard

Handlebar to upper plate

Fork upper plate to rods

Fork lower plate to rods

Fork lower ring

Fork upper ring

Front brake shoe to fork

Shoe/pump fitting

Front wheel axle

Front wheel fastening bolt

Rear shock absorber to frame

Fork to frame

Rear wheel axle

Block retainer

Front brake pump fastening U-bolt

L-H lever holder fastening U-bolt

Throttle grip

Light/indicators device

Saddle to frame

Tank to frame

Filter casing to frame front

Filter casing to frame rear

Tool box to frame

R-H & L-H tube cover

Headlight bracket to upper plate

Km cntr bracket to headlight plate

Headlight to bracket

Front mudguard to fork

Rear light to mudguard

Breather

Handles to frame front

Handles to frame rear

Spray guard to frame

Pinion guard

Exhaust pipe to frame

Exhaust pipe to engine

Gear lever

THREAD

Screw M10x1.25

Screw M8

Screw M10x1.25

Nut M10x1.25

Screw M10

Screw M6

Nut M10

Screw M8

Screw M10x1.25

M25x1

M24x1

Screw M8

Screw M10

M 12x1.25

Screw M8

Screw M12

Screw M12x1.25

Screw M14x1.5

Screw M10x1.25

Screw M6

Screw M6

Screw M5

Screw M5

Screw M6

Screw M6

Screw M6

Screw M6

Screw M6

Screw M5

Screw M5

Screw M5

Screw M5

Screw M6

Nut M6

Screw M6

Screw M6

Screw M8

Screw M6

Screw M6

Screw M10x1.25

Nut M6

Screw M6

TORQUE in

Nm (kgm)

32÷40 (3.2÷4.0)

20÷25 (2.0÷2.5)

40÷45 (4.0÷4.5)

40÷45 (4.0÷4.5)

20÷22 (2.0÷2.2)

4÷7 (0.4÷0.7)

45÷50 (4.0÷5.0)

20÷22 (2.0÷2.2)

35÷40 (3.5÷4.0)

27÷33 (2.7÷3.3)

37÷43 (3.7÷4.3)

20÷22 (2.0÷2.2)

13÷17 (1.3÷1.7)

65÷70 (6.5÷7.0)

20÷22 (2.0÷2.2)

70÷80 (7.0÷8.0)

65÷70 (6.5÷7.0)

60÷70 (6.0÷7.0)

40÷45 (4.0÷4.5)

6÷7 (0.6÷0.7)

6÷7 (0.6÷0.7)

3÷4 (0.3÷0.4)

3÷4 (0.3÷0.4)

4÷7 (0.4÷0.7)

4÷7 (0.4÷0.7)

4÷7 (0.4÷0.7)

4÷7 (0.4÷0.7)

4÷7 (0.4÷0.7)

4÷7 (0.4÷0.7)

5÷8 (0.5÷0.8)

5÷8 (0.5÷0.8)

5÷8 (0.5÷0.8)

8÷10 (0.8÷1.0)

4÷7 (0.4÷0.7)

4÷7 (0.4÷0.7)

7÷10 (0.7÷1.0)

20÷22 (2.0÷2.2)

8÷10 (0.8÷1.0)

4÷7 (0.4÷0.7)

40÷45 (4.0÷4.5)

10÷12 (1.0÷1.2)

4÷7 (0.4÷0.7)

1-2,1

Page 9

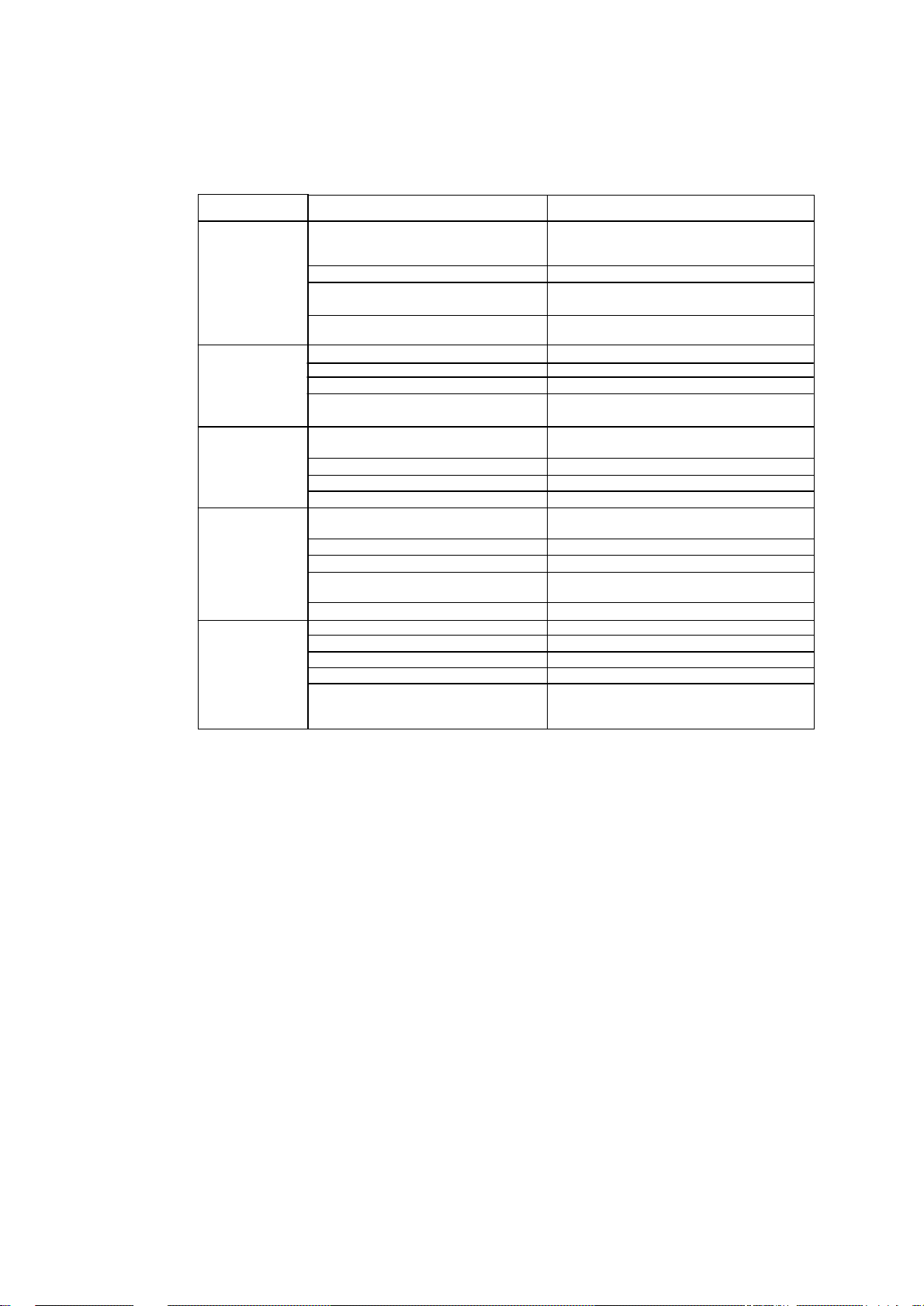

Tightening torque Nm (kgm) according to type of material tightened

Steel screw

8.8 diam.

M4

M5

M6

M7

M8

M10

M12

M14

Plastic with

metal spacer

2 (0.2)

4 (0.4)

6.5 (0.65)

Brass, Copper,

aluminium and

alloys

2 (0.2)

4 (0.4)

6.5 (0.65)

10.5 (1.05)

16 (1.6)

Iron, steel

3 (0.3)

6 (0.6)

10.5 (1.05)

17 (1.7)

26 (2.6)

52 (5.2)

100 (10.0)

145 (14.5)

1-2,2

Page 10

MAINTENANCE AND TROUBLESHOOTING 2

SUB INDEX

Schedule Servicing times

Troubleshooting

Section - Page

2 - 1

2 - 2

2

Page 11

SCHEDULED SERVICE

CHECK

REPLACE

Km X 1,000

Months

Nuts, bolts & fastenings

Spark Plug

Drive Chain (clean & lubricate)

Engine oil vapour recovery circuit

Engine idling speed

Air Cleaner

Engine oil mesh filter (clean)

Centrifuge engine oil filter (clean)

Brake Shoes (adjust)

Valve clearance (adjust)

Electrical system & battery

Brake & Clutch Levers (grease)

Front Brake fluid level

1 6 12 18 24 30 36 42 48 54 60

4 12 24 36

Drain at each of scheduled times in header above

Check/adjust at each of sched times in header above

Every 500 kms

Brake Fluid

Engine Oil

Front Brake Pads

Tyre pressure & wear

Headlight (check & adjust)

Drive chain guard, check for wear

Vehicle & brake test (road test)

Km counter transmission (lube)

Suspension (check operation)

Steering (adjust)

Throttle transmission (adjust)

Clutch transmission (adjust)

Transmission (lubricate)

Front Brake Pipe

Coupon labour time

65 75

Replace Every 2 Years

Replace Every 3,000 kms

130

75

130

90

130

75

130

75

155

Engine oil

Cable lube oil

Km counter

Trans. Grease

Joint/pin grease

Brake fluid

Specifications

SAE 20W/50 synthetic oil exceeding API SG

Four-stroke engine oil

Lithium-based soap grease, NLG13

Complex calcium-based soap grease NLG12

SAE J1703, NHTSA 116 DOT4, ISO 4925

Recommended

Selenia HI Scooter 4T

Selenia HI Scooter 4T

JOTA 3 FS

Arexons system TW249

TUTELA TOP 4

2-1

Page 12

SYMPTOM

Engine turns

but does not

start.

Irregular idling

ratio, poor

performance,

the engine

stops.

The engine

misfires when

accelerating.

Fuel delay on

accelerating.

Poor

performance

or high fuel

consumption

Backfire.

Lean mixture.

Rich mixture.

Idling speed

too high.

TROUBLESHOOTING

FUEL FEED

POSSIBLE CAUSE

No fuel in tank.

Engine flooded.

No spark (faulty ignition

system).

Air cleaner clogged up.

Intake air leakage.

Faulty throttle control.

Faulty starter.

Faulty ignition system.

Dirt in fuel

Irregular air intake.

Incorrect idling ratio.

Incorrect idling mixture

screw calibration.

Poor compression in

cylinder.

Starter jammed.

Rich mixture.

Lean mixture.

Carburettor clogged up

Faulty ignition system.

Lean mixture.

Faulty ignition system.

Lean mixture.

Fuel feed clogged up.

Faulty ignition system.

Air cleaner clogged up.

Faulty ignition system.

Faulty carburettor.

Lean mixture.

Rich mixture.

Fuel nozzles clogged up.

Faulty float valve.

Fuel tank breather

clogged up.

Fuel filter clogged up.

Fuel feed tube squeezed.

Breather clogged up.

Incorrect air intake.

Air cleaner clogged up.

Taper pin or taper nozzle

worn.

Faulty float valve.

Float level too high.

Starter jammed.

Irregular air intake.

REMEDY

Refuel.

Turn the starter to position 3 (off). Open the throttle

fully and turn engine for a few seconds. Do not

persist in turning starter motor.

Check the connections and the battery charge.

Possible problems may concern the coil, the control

unit or the impulse generator.

Replace the air cleaner.

Check the air cleaner and the carburettor.

Check the throttle control free travel. If required

adjust the cable tension.

Check the starter (and lubricate if required).

Check the battery, the ignition coil, the control unit,

the spark plug and all connections.

Drain and wash out the tank & the carburettor.

Check the air cleaner, the carburettor & the intake

manifold.

Adjust.

Adjust.

Check the head and spark plug fastening. Replace

the gas rings or the head gasket if, required.

Release and lubricate the starter.

Check the air cleaner condition.

Check the air cleaner condition.

Overhaul the carburettor.

Check the battery, the ignition coil, the control unit,

the spark plug and the respective connections.

Check the air cleaner condition.

Check the battery, the ignition coil, the control unit,

the spark plug and the respective connections.

Check the air cleaner condition.

Clean the tube.

Check the battery, the ignition coil, the control unit,

the spark plug and the respective connections.

Replace the air cleaner.

Check the battery, the ignition coil, the control unit,

the spark plug and the respective connections.

Check and replace if required.

Check the air cleaner condition.

Check the air cleaner condition.

Overhaul the carburettor.

Replace the complete float.

Clean the hole.

Replace the filter.

Clean the tube.

Clean the tube.

Check the cleaner, the carburettor and the intake

manifold.

Replace the air cleaner.

Replace.

Replace the complete float.

Adjust.

Release and lubricate the starter.

Check the air cleaner, the carburettor & the intake

manifold.

2-2,1

Page 13

CLUTCH AND GEARBOX LINKAGES

SYMPTOM

Clutch lever

is too stiff.

Clutch does not

disengage or bike

moves slowly with

clutch disengaged.

Clutch slips.

The gears

are difficult

to engage.

The gears

slip

POSSIBLE CAUSE

The clutch cable is damaged, twisted

or dirty.

Incorrect clutch cable route.

Faulty clutch disengagement plate

bearing.

Damaged clutch disengagement

mechanism.

Excessive clutch lever play.

Deformed clutch metal plates.

Loose clutch hub fastening nut.

Seized or worn clutch

disengagement mechanism.

Engine oil level too high or incorrect

viscosity.

Worn clutch friction plates.

Worn clutch springs.

No clutch lever play.

Incorrect clutch operation or

adjustment.

Bent or damaged gearbox fork.

Bent gearbox fork shaft.

Bent or damaged gearbox control

shaft.

Damaged gearbox drum grooves.

Worn gears or engagement cavities.

Bent gearbox fork shaft.

Broken gearbox drum retainer.

Worn or bent gearbox forks.

Broken gearbox linkage return

spring.

REMEDY

Check cable and replace it if required.

Re-route.

Replace damaged components.

Check cable route.

Adjust.

Replace.

Fasten.

Release, check wear and replace the

component, if required.

Check engine oil level and viscosity.

Replace complete plate assembly.

Replace clutch springs.

Adjust lever play.

Check if fault is adjustment or worn

component.

Replace damaged/worn parts.

Replace damaged/worn parts.

Replace damaged/worn parts.

Replace damaged/worn parts.

Replace damaged/worn parts.

Replace damaged/worn parts.

Replace damaged/worn parts.

Replace damaged/worn parts.

Replace damaged/worn parts.

2-2,2

Page 14

CYLINDER HEAD AND VALVES

Head related problems generally have a considerable influence of engine

performance. Such problems can be diagnosed by checking

compression either with a sound sensor or a stethoscope to identify any

incorrect noise.

If the low ratio performance is poor, check whether there is white smoke

in the crankcase breather tube. The white smoke is the symptom of a

seized segment.

SYMPTOM

Poor

compression:

Valves

Poor

Compression:

Head

Excessive

smoke

Excessive

noise

Irregular idling

POSSIBLE CAUSE

Incorrect valve clearance.

Burnt or bent valve.

Incorrect timing.

Worn valve spring.

Imperfect head gasket tightness or

damaged gasket.

Deformed or cracked head.

Damaged valve stem oil seal.

Cracked head.

Damaged head gasket.

Incorrect valve clearance.

Seized valve or broken valve spring.

Worn or damaged rocker arm or

camshaft.

Loose or worn timing chain.

Worn or damaged timing chain

take-up device.

Worn camshaft gears.

Poor compression.

Air intake leakage.

Incorrectly adjusted decompressor.

REMEDY

Adjust.

Replace.

Adjust.

Replace.

Replace the gasket.

Replace the head and respective gasket.

Replace the part.

Replace.

Replace.

Adjust.

Replace.

Replace worn or damaged parts.

Replace worn or damaged parts.

Replace worn or damaged parts.

Replace the camshaft.

Check the head and spark plug fastening

Replace the piston rings and head gasket

Check air cleaner and carburettor.

Adjust.

2-2,3

Page 15

CYLINDER AND PISTON

This section contains a description of the service operations related to the

cylinder and the piston. When removing the parts, mark them so to

ensure they are refitted in the correct position. Before inspecting the

parts, clean them with a solvent and dry with compressed air. When

removing the cylinder from the crankcase, make sure not to damage the

coupling surfaces.

SYMPTOM

Poor

compression

Excessive

smoke

Irregular idling

Overheating

Knock or

incorrect noise

Poor

compression

POSSIBLE CAUSE

Worn cylinder or gas rings

Excessive accumulation of carbon

deposits on the piston top or in the

firing chamber.

Worn cylinder, piston or gas rings.

Incorrectly fitted gas rings.

Scratched or damaged piston or

cylinder.

Deformed or cracked upper cylinder

level.

Insufficient compression.

Excessive accumulation of carbon

deposits on the piston top or in the

firing chamber.

Worn cylinder, piston or gas rings.

Excessive accumulation or carbon

deposits.

Worn or seized cylinder-piston

assembly.

REMEDY

Replace the worn components.

Eliminate the scaling from the chamber

or the piston.

Check and replace worn parts.

Check & replace gas rings if required.

Check and replace worn parts.

Replace the head and the respective

gasket.

Check correct fastening of spark plug.

Check condition of the piston gas rings.

Check the head gasket.

Eliminate the scaling from the chamber

or the piston.

Check and replace worn parts.

Eliminate the scaling.

Replace cylinder-piston assembly.

2-2,4

Page 16

CRANKCASE-GEARBOX-CRANKSHAFT

SYMPTOM

Noisy engine

Gears slip

Gears difficult

to engage

ALTERNATOR AND ON-WAY STARTER CLUTCH

SYMPTOM

Starter motor

turns but the

engine will not

start

POSSIBLE CAUSE

Worn main bearing.

Worn connecting rod big end roller

bearing.

Worn gearbox bearing.

Worn gears or engagement cavities.

Bent gearbox fork shaft.

Worn or bent gearbox forks.

Damaged drum retainer arm.

Incorrect clutch adjustment.

Bent or damaged gearbox fork.

Bent gearbox fork shaft.

Bent or damaged gearbox control

shaft.

Damaged gearbox drum grooves.

POSSIBLE CAUSE

Faulty one-way starter clutch.

Faulty gear coupling.

Damaged starter motor transmission

gear.

REMEDY

Replace the worn components.

Replace the worn components.

Replace the worn components.

Replace the worn components.

Replace the worn/damaged parts.

Replace the worn/damaged parts.

Replace the worn/damaged parts.

Overhaul the clutch.

Replace the worn/damaged parts.

Replace the worn/damaged parts.

Replace the worn/damaged parts.

Replace the drum.

REMEDY

Overhaul.

Replace worn/damaged parts.

Replace the worn part.

2-2,5

Page 17

RECHARGING SYSTEM AND BATTERY

Insufficient battery charge (voltage lower than the set value)

Measure the recharge voltage with

the battery fully charged and in

good condition

Wrong

The standard voltage value is not

reached as the engine revolution

speed increases

Correct

Check current dispersion on the

previously disconnected battery

terminals (dispersion check)

Dispersion

No dispersion

Faulty battery

Disconnect the 2-pole connector from

the regulator/rectifier and check the

battery dispersion current again

Disconnect the 3-pole connector

from the regulator/rectifier and

check for continuity between each

of the yellow wires and the other

two (stator check)

Correct

With the engine running and the

electrical circuit connected check

for alternating voltage at the

regulator/rectifier 3-pole connector

yellow wire terminals

Wrong

Dispersion

Faulty

Regulator/

Rectifier

Short-circuited wiring

Faulty stator

Wrong

No dispersion

Short-circuited

wiring

Faulty ignition

switch

Correct

Faulty Regulator/Rectifier

2-2,6

Page 18

Excessive battery charge (set voltage too high)

Measure the recharge voltage with

the battery fully charged and in

good condition

The set voltage is very much higher

than the standard value

Correct

Faulty battery

Check continuity in the earth wire to

frame on the regulator/rectifier

2-pole connector

Correct

Wrong

Open circuit in wiring

Faulty contacts in connectors

Faulty Regulator/Rectifier

2-2,7

Page 19

IGNITION SYSTEM

PART STANDARD VALUE

Spark Plug

Ignition coil

Impulse generator

Ignition timing

Advance

Maximum advance

NGK

DENSO

Spark gap

peak voltage

peak voltage

(“F” mark)

Opens

Closes

15° BTDC at 1400 rpm

TROUBLESHOOTING

Ignition faults are often caused by oxidised or faulty contacts. Check all

connections before proceeding. Check whether the battery is sufficiently

charged. If the battery charge is inadequate, the starter motor may turn

too slowly and the plug will not spark. Furthermore, only spark plugs with

correct thermal degree specifications should be used. Disrespect of these

precautions may severely damage the engine.

Check the following before troubleshooting;

- faulty spark plug

- badly connected spark plug cap or loose ignition wire connections

- water in the spark plug cap (dispersion of ignition coil secondary voltage)

If the plug does not spark, temporarily replace the ignition coil with a spare

in perfect condition and test the spark. If the plug sparks, replace the

faulty ignition coil.

DPR8EA9

X24EPR-U9

0.8 - 0.9 mm

100V minimum

0.7V minimum

1800 ± 150 rpm

3450 ± 150 rpm

32° BTDC

2-2,8

Page 20

STARTER SYSTEM

Check for the following before troubleshooting;

- blown main fuse (20A) or secondary fuse (15A).

- disconnected battery or starter motor wire.

- flat battery.

The starter motor should turn when the gearbox is in neutral.

The starter motor will turn when a gear is selected only in certain

conditions as shown in the following table.

Gearbox position

Any gear

Side Stand

Up

Clutch Lever

Down

THE STARTER MOTOR DOES NOT TURN

Check whether the battery terminals

are either loose or disconnected

and whether a battery wire is

broken on short-circuited

Wrong

Check whether the terminals and

the starter relay 4-pole connector

are either loose or disconnected

Check whether the starter motor

wire is broken, disconnected or

Normal

Not normal

Normal

Not normal

loose

Normal

Starter Motor

Pulled

Released

Pulled

Released

Battery terminals are not connected

Battery wire open or

short-circuited

Terminals or 4-pole connector not

connected

Starter motor wire not connected

Starter motor wire open circuit

Turns

Does not turn

Does not turn

Does not turn

With the emergency switch and the

ignition at O, press the starter

button and check whether starter

relay clicks

It does not click The starter

SEE PAGE 2-2,10

Connect the starter motor terminal

It clicks

terminal (do not use small wires

given the vast amount of current)

motor turns

Starter motor wire loose

or disconnected

Faulty starter relay

directly to the positive battery

The starter motor

does not turn

Faulty starter

motor

2-2,9

Page 21

From page 2-2,9

Check the starter relay coil

earth wire

Check the voltage between the

white/purple wire and the earth on

the starter relay 4-pole connector

Loose contact in the starter relay

Continuity

Voltage

Faulty starter relay

connector

No

continuity

No voltage

Faulty neutral switch

Faulty diode unit

Faulty side stand switch

Faulty contact in a connector

Open circuit in the wiring

Faulty emergency switch

Faulty ignition switch

Faulty starter button

Faulty contact in a connector

Open circuit in the wiring

2-2,10

Page 22

ELECTRICAL SYSTEM 3

SUB INDEX

Recharging system and battery

Battery

Section - Page

3 - 1

3 - 2

3

Page 23

RECHARGING SYSTEM AND BATTERY

General

Always turn the ignition switch to C before disconnecting an electrical

component.

Important note

Some electrical components can be damaged if they are

disconnected - or if their connectors or terminals are disconnected with the ignition switch at C and the component is powered.

Remove the battery for long storage periods. Recharge it completely and

store it in a cool, dry place. Recharge the battery every two weeks to

ensure maximum life.

The battery can be damaged if the charge is too low or too high and also

if it is not recharged for a long period of time. These conditions will

reduce the battery life. Also in normal conditions of use, the battery

performance will deteriorate after two or three years.

After charging, the battery will re-acquire it’s original voltage. The original

voltage however will be rapidly reduced and the battery will be completely

drained under a considerable load. For this reason, problems of

excessive charging may be related to the battery and not to the

recharging system as may appear. For example, if a battery cell is shortcircuited and the battery voltage does not increase, the regulator/rectifier

will provide the battery with excessive voltage leading to an excessive

recharging symptom. In these conditions, the electrolyte level will drop

rapidly.

Before seeking the fault in the recharging system, you should check the

battery conditions of use and maintenance. Check whether the battery

has been subjected to frequent, large loads, e.g. if the headlight and

taillight were kept on for a long time with the vehicle not running.

The battery will discharge autonomously when the vehicle is not in use.

For this reason, recharge the battery every two weeks to prevent

sulphating.

When checking the recharging system, follow the instructions indicated in

the troubleshooting flow chart (section 2 of this manual).

The alternator can be serviced also with the engine fitted in the frame.

PART

Battery

Alternator

Voltage regulated by the regulator/rectifier 14.0 - 14.8 V at 5000 rpm

Capacity

Current dispersion

Voltage (20°C) completely charged

to be charged

Recharge current slow recharge

quick recharge

Power

Recharging coil resistance (20°C)

SPECIFICATIONS

200W at 5000 rpm

12V - 9Ah

0 mA maxi

Over 12.8 V

Under 12.3 V

0.7A / 5-10 h

5.0A / 1.0 h

0.1 - 1.0 Ω

3-1

Page 24

BATTERY

Warning

The battery electrolyte contains sulphuric acid, it is poisonous and can cause

serious burns. Avoid contact with the eyes, skin and clothes. If it comes into

contact with the eyes, wash with plenty of water for 15 minutes and go to a Doctor

as quickly as possible. If the liquid is swallowed, drink a large quantity of water

or milk immediately, swallow milk of magnesia, beaten egg or vegetable oil. Call a

Doctor immediately. The gas coming from the battery during recharging could

explode under certain conditions. Keep well clear of sparks, naked flames or

cigarettes. Ventilate the environment when recharging the battery. Always shield

the eyes when working near batteries. Keep out of the reach of children.

BATTERY MAINTENANCE

The battery is the electrical component that

requires the greatest care and the most

diligent maintenance. The most important

maintenance prescriptions are;

1) Checking the electrolyte level.

The electrolyte level should be checked

frequently. It should reach the upper level.

Use distilled water only for topping up.

Check the vehicle electrical system if

frequent topping up is required because the

battery is being over-charged and will

deteriorate rapidly.

2) Checking the charge.

Check the electrolyte density after topping

up the level with a specific tool (see fig

opposite). The density should be 30-32° Bé

when the battery is fully charged which

corresponds to a specific weight of 1.26 -

1.28 at a temperature higher than 15°C. If

the density is lower than 20° Bé, the battery

is completely flat. Recharge it. When the

battery is being charged, the voltage in

each element should be 2.6 - 2.8V. The

discharge limit in each element is 1.8V. At

the end of the recharge, check electrolyte

level and density as well as the voltage in

each element. Recharge the battery

regularly if the vehicle is not used for a

certain period of time (over one month).

The battery will be completely drained after

three months of storage. Be careful not to

invert the connections when refitting the

battery in the vehicle. The earth wire

(black) with the (-) reference mark should

be connected to the negative terminal (-)

while the other two red wires with the (+)

reference mark should be connected to the

positive (+) pole.

3-2,1

Page 25

PREPARING CHARGED-DRY CELL BATTERIES FOR USE

1) Remove the short closed tube and the caps. Pour sulphuric acid into

the elements to reach the upper level (amount for battery with a specific

weight of 1-26 corresponds to 30° Bé at a temperature higher than 15°C).

2) Leave to rest for two hours.

3) Charge at an initial intensity equal to approximately one tenth of the

battery capacity until the voltage reaches a value of approximately 2.7V

in each element. The electrolyte density should be approximately 1.27,

which corresponds to 31° Bé. The values should be stabilised and the

recharging operation should take from 15 to 20 hours.

4) After recharging, top up the electrolyte (with distilled water - remove

any acid in excess). Cap and clean accurately.

5) Finally, fit the battery in the vehicle respecting the connections.

REMOVING THE BATTERY

NOTE: Always turn the ignition

switch to C before removing or installing the battery.

- Remove the side fairing.

- Remove the two screws and the

battery bracket.

NOTE: Always disconnect the

negative battery first and then the

positive terminal from the battery.

- Remove the bolt and the negative

battery wire then the positive wire

cap, with the respective bolt and

the wire.

- Remove the battery

REFITTING THE BATTERY

- Reverse the removal sequence to

refit the battery. Apply grease to

the terminals.

CHECKING THE BATTERY CHARGE

- Measure the battery voltage with

a digital multimeter.

VOLTAGE:

Fully charged: over 12.8V

Insufficient charge: under 12.3V

3-2,2

Page 26

RECHARGING

- Remove the battery:

- Connect the positive wire (+) on the

battery charger to the positive terminal

(+) on the battery;

- Connect the negative wire (-) on the

battery charger to the negative

terminal (-) on the battery.

CURRENT/RECHARGING TIME

Slow recharging: 0.7 A / 5 - 10 hours

Quick recharging: 5.0 A / 1.0 hour maximum

Warning

The gas released by the battery during the recharging process can

explode in certain conditions. Keep sparks and sources of heat

away from a recharging battery. Remove the battery from the

vehicle by disconnecting the negative (-) terminal first.

- After refitting the battery in the vehicle and connecting the terminals to

the electrical circuit, protect the terminals with electrical contact grease.

TOOLS

• Battery charger (single) 445492

• Battery charger (multiple) 445493

Important note

Use a quick battery recharge only in an emergency. The slow

recharge cycle is preferable. Do not exceed the specified current

and the recharging time shown on the battery. Excessive current or

longer recharging times can damage the battery.

INSPECTING THE RECHARGING CIRCUIT

NOTE: The multimeter can be damaged if used to measure circuits with

…………a higher capacitance than that of the device. Before starting, set

………….the multimeter to the maximum load and reduce it progressively

………….to obtain the correct setting without damaging the tool.

CHECKING THE REGULATED

VOLTAGE

- Remove the battery and fit a fully

charged battery in its place;

- Start the engine and take it to running

temperature. Stop the engine.

- Connect the multimeter between the

positive and negative terminals.

Important note

Do not confuse the positive and negative battery terminals to

prevent short-circuits. Do not disconnect the battery or a

recharging system wire before switching off the ignition switch.

Disrespect of this precaution can damage the multimeter and the

electrical systems.

3-2,3

Page 27

- Switch the headlight on and start the

engine.

- Read the voltage on the multimeter

with the engine idling at 5000 rpm.

REGULATED VOLTAGE 14.0 - 14.8 V

at 5000 rpm

- The battery is in good condition if the

value read on the multimeter

corresponds to the regulated voltage.

NOTE: The speed at which the voltage

starts increasing cannot be measured as

it varies according to the temperature

and the alternator load.

- A battery which drains often is to be

considered deteriorated, after excluding

other problems to the recharging system,

even if the outcome of the regulated

voltage test is OK. The presence of one

of the following symptoms may indicate

a possible fault in the recharging system.

1. Voltage lower than the registered

value

Recharging system wiring broken or

short-circuited or faulty contacts in a

connector.

Alternator broken or short-circuited.

Faulty regulator/rectifier.

2. Excessive regulated voltage

Faulty regulator/rectifier connection to

earth.

Faulty battery.

Faulty regulator/rectifier.

SEARCHING FOR DISPERSION

Disconnect the battery earth wire (-).

Connect the positive ammeter probe (+)

to the battery earth wire and the negative

ammeter probe (-) to the negative (-)

battery terminal.

- Turn the ignition switch to C so to

power the circuit.

- Turn the emergency switch to C to

prevent reading the control unit power

current.

- Engage a gear and keep the side stand

up so to prevent powering the respective

warning lights.

NOTE: Before starting , set the

multimeter to a high load and reduce it progressively so to obtain

the correct setting. A flow of current exceeding the selected load

can blow the multimeter fuse.

When measuring the current,

switch the direction indicators

and the lights off.

PRESCRIBED CURRENT

DISPERSION 0 mA max.

- If the current dispersion

exceeds the set value, there is

probably a short-circuit. Locate

the short-circuit by disconnecting

the connections one by one and

measuring the current.

Check that there is no dispersion in the

system.

3-2,4

Page 28

REGULATOR/RECTIFIER

Checking the wiring

- Remove the tank.

- Disconnect the regulator/rectifier

2-pole connector. Then check that

the terminals are not loose or

corroded.

BATTERY CIRCUIT

Make sure that there is voltage

between the red wire (+) and the

black wire (-).

If there is no voltage, check the

following;

Item

Battery

charging

wire

Earth

wire

Connector

(+) red & (-)

earth

Black and

(-) earth

Standard values

Battery voltage

Continuity

If the outcome is different, the

problem is in the wiring.

RECHARGING CIRCUIT

NOTE: You do not need to remove

the stator winding to carry out this

test.

- Disconnect the 2-pole connector

connecting the regulator/rectifier

and the alternator.

- Measure the resistance between

each of the connector terminals and

the other two.

CONNECTION: Yellow and yellow

VALUE: - 0.8 Ω (20°)

- If the recharging coil resistance is

out of specifications, check the

continuity between the connector

terminals and earth.

There should be no continuity.

If there is continuity between the

connector yellow wire and earth,

replace the stator.

If there is no continuity, proceed

with the voltmeter checks on the

stator, described in chapter 11,

engine manual.

3-2,5

Page 29

INTENTIONALLY BLANK

Page 30

3-2,6

Page 31

ELECTRICAL SYSTEM COMPONENTS

1/. Front light cluster with double full/dipped beam headlight bulb

……...(12V-55/60W-H4) and side light (12V-5W)

2/. Left-hand switch (light switch, direction indicator switch, horn

……....button)

3/. Right-hand switch (engine stop/start switch, light switch, starter

……….button)

4/. Left-hand warning lights (side/tail warning light, full beam warning

……….light, left-hand direction indicator warning light)

5/. Right-hand warning lights (right-hand direction indicator warning

……….light, stand down warning light, neutral warning light)

6/. Front direction indicators (12V-10W, two)

7/. Clutch lever button

8/. Kilometre counter bulb (12V-3W)

9/. Ignition switch

10/. Front brake switch

11/. Horn

12/. Diodes

13/. Direction indicator repeater

14/. Double fuse holder (one 15A, one 20A)

15/. Voltage regulator

16/. Battery (12V-9Ah)

17/. Starter motor relay

18/. Starter motor

19/. Stand switch

20/. Rear brake button switch

21/. Three-phase magnet flywheel

22/. HV coil

23/. Spark plug

24/. Electronic ignition device

25/. Rear direction indicators (12V-10W, two)

26/. Rear light cluster with double taillight/brake light bulb (12V-5/21W)

27/. Number plate light (12V-5W)

28/. Neutral switch

WIRING

COLOUR

CODE

B

Blue

Bk

Bn

G

Gr

O

P

R

V

W

Y

Black

Brown

Green

Grey

Orange

Pink

Red

Purple

White

Yellow

3-2,7

Page 32

GENERAL WIRING DIAGRAM

3-2,8

Page 33

ELECTRICAL SYSTEM

1/. Light switch

2/. Light selector

3/. Kilometre counter light (12V-3W)

4/. Number plate light (12V-5W)

5/. Warning light(12V-1,2W)

6/. Taillight (12V-5W)

7/. Front side light (12V-5W)

8/. Flash button

9/. Full beam headlight warning light

10/. Double light (12V-55/60W)

11/. Direction indicator repeater

12/. Horn

13/. Horn button

14/. Neutral switch

15/. Brake switches

16/. Four direction indicators (12V-10W)

17/. Two direction indicator warning lights

18/. Direction indicator switch

19/. Stand switch

20/. Diode

21/. Diode

22/. Neutral warning light (12V-1.2W)

23/. Stand switch

24/. Diode

25/. Brake light (12V-21W)

26/. Side stand warning light

27/. 15A fuse

28/. Voltage regulator (12V DC)

29/. Engine stop switch

30/. Starter button

31/. Starter relay

32/. Ignition switch

33/. CSI electronic control unit

34/. Starter motor

35/. Battery (12V-9Ah)

36/. 20A Fuse

37/. HV coil

38/. Spark plug

39/. Three-phase magnet flywheel

3-2,9

Page 34

FRONT SUSPENSION 4

SUB INDEX

Removing the handlebar

Removing the shock absorbers

Removing the fork lower plate

Section - Page

4 - 1

4 - 2

4 - 2

4

Page 35

FRONT SUSPENSION

REMOVING THE HANDLEBAR

Remove the side rearview mirrors.

Loosen the two Allen screws and

remove the clutch control lever.

Loosen the two cross-slotted screws

on the left-hand control cluster.

Loosen the two Allen screws and

remove the front brake cylinder.

Loosen the two cross-slotted screws

on the right-hand control cluster and

remove the cluster.

Loosen the four Allen screws on the

two central elliptical supports.

Remove the two control clusters and

replace the handlebar.

Refitting notes:

Position the handlebar in the two

central elliptical supports with the two

control cluster notches upwards.

Fit the clutch lever by positioning the

fastening U-bolt pointing upwards.

TIGHTENING TORQUE

Left-hand lever holder U-bolt screws .6 - 7 Nm (0.6 - 0.7 kgm)

Front brake cylinder U-bolt screws 6 - 7 Nm (0.6 - 0.7 kgm)

4-1

Page 36

REMOVING FRONT SHOCK ABSORBERS

If you need to replace the two central

elliptical supports, loosen the two

lower nuts and pull the supports up.

Take the washers. Refit and torque

the nuts as prescribed.

TICHTENING TORQUE

Handlebar support lower nuts;

45 - 50 Nm (4.5 - 5.0 kgm)

REMOVING THE FRONT TELESCOPIC

SHOCK ABSORBERS

Position the vehicle so to remove the

front wheel.

Loosen the Allen screw on the rear

part of the right hand fork cover.

Use an 8 mm Allen wrench to loosen

the wheel axle.

Remove it from the right-hand side

and take the shim from the left-hand

side. Release the kilometre counter

transmission.

Fully deflate the front tyre.

Loosen the screws on the fork cover.

Move the carcass aside and remove

the front mudguard. Take the

support plate and the respective

washers.

4-2,1

Page 37

Remove the left-hand rod, loosen

the two Allen screws and

disconnect the shoe assembly,

leaving the brake pipe in place.

Loosen the four screws (two on

each rod, i.e. two on the upper plate

and two on the lower fork).

Loosen the side direction indicator

support screws.

Remove the front telescopic shock

absorbers downwards.

DISASSEMBLING THE FRONT

SHOCK ABSORBERS

Loosen the upper cap and drain the

oil (approx. 280cc). Collect the oil

in a specific container (oil

specifications FORK BY MOTO

RIDER).

Take the shim and the cup and

remove the spring.

Use two ½” extensions and a 12

mm Allen wrench to hold the pump

assembly in position from inside the

rod. At the same time, from the

outside, loosen the Allen screw on

the end of the cover.

4-2,2

Page 38

Remove the following components from inside the cover;

the pump, the spring and the bushing.

Reassemble by reversing the disassembly sequence.

TIGHTENING TORQUE

Telescopic shock absorber upper cap 37 ÷ 43 Nm (3.7 ÷ 4.3 kgm)

Telescopic shock absorber lower screw 37 ÷ 43 Nm (3.7 ÷ 4.3 kgm)

REMOVING THE FORK LOWER

PLATE

Remove the telescopic shock

absorbers as described above.

Loosen the steering tube fastening

nut and remove the complete

handlebar from the top. Remove or

loosen the right and left-hand

electrical blocks and the brake and

clutch lever supports as required.

Make sure not to damage the

electrical wiring.

Loosen the ring and remove it with

the respective dust guard. Take the

shim.

Use a rubber hammer and punch to

extract the upper ball bearing from

the sleeve from below.

Check the operation of the two

bearings. Replace if necessary.

After replacing the bearings, grease

them (with complex calcium soapbased grease, NLG12, Arexons

System TW 249).

Refit by reversing the removal

sequence.

4-2,3

Page 39

REAR SUSPENSION 5

SUB INDEX

Removing rear shock absorbers

Removing rear rocking fork

Refitting rear rocking fork

Section - Page

5 - 1

5 - 1

5 - 2

5

Page 40

REAR SUSPENSION

REMOVING THE REAR SHOCK

ABSORBERS

Support the vehicle.

Remove the covering caps.

Loosen the three Allen screws and

remove the handle.

Loosen the upper and lower

screws and take the respective

shims. Then remove the complete

shock absorber. If it is damaged,

replace it.

REFITTING THE REAR SHOCK

ABSORBER

Refit the rear shock absorbers by

reversing the removal sequence.

TIGHTENING TORQUE

Rear shock absorber to frame

70 ÷ 80 Nm (7.0 ÷ 8.0 kgm)

REMOVING THE REAR

ROCKING FORK

Support the vehicle so to remove

the rear wheel.

Remove the side fairings.

Loosen the screws and take the

respective shims, then release the

rear shock absorbers.

Loosen the screws and remove the

chain guard.

Remove the rear wheel hub

retainer bar and take the

respective fasteners and washers.

Disconnect the rear brake control

transmission.

5-1

Page 41

Loosen the rear wheel fastening bolt,

remove the chain from the crown gear

and remove the rear wheel.

Remove the covering caps and loosen

the through bolt. Take the respective

shims.

Remove the rear rocking fork with

respective rubber bushing.

REFITTING THE REAR ROCKING

FORK

Check the rubber bushing conditions

before refitting. Replace the entire fork

if the rubber bushing is worn or

damaged.

TIGHTENING TORQUE

Rear fork to frame

65 ÷ 70 Nm (6.5 ÷ 7.0 kgm)

Rear wheel axle

60 ÷ 70 Nm (6.5 ÷ 7.0 kgm)

This is copied exactly from the original

manual but is obviously incorrect;

either the 60 Nm should read 65 or the

6.5 kgm should read 6.0

Rubber bushing retainer rod

40 ÷ 45 Nm (4.0 ÷ 4.5 kgm)

After refitting, adjust the rear brake

control transmission and the chain

tension as specified below.

Hold the vehicle in vertical position.

Loosen the nuts on wheel pin, on both

sides of the fork.

Turn the chain take-up eccentric

downwards to reach the required

tension (25 - 35 mm chain play).

Torque the wheel pin nuts on both

sides.

Top excursion 25 ÷ 35 mm

5-2

Page 42

BRAKING SYSTEM 6

SUB INDEX

General rules, brake hydraulic system

Replacing the rear brake callipers

Disassembling front brake shoe

Replacing front brake pads

Replacing the front brake cylinder

Filling and bleeding the system

Checking and replacing the front brake disc

Section - Page

6 - 1

6 - 1

6 - 2

6 - 2

6 - 3

6 - 3

6 - 3

6

Page 43

GENERAL RULES FOR OPERATION ON THE BRAKE

HYDRAULIC SYSTEM

Warning

If the liquid accidentally contacts the eyes, wash with plenty of

water and seek medical advice immediately.

Used hydraulic oil is harmful for the environment and must be collected

and disposed of in accordance with the law.

NOTE: When topping up or replacing, use only DOT4 - NHTSA 116.

Ensure perfect cleanliness.

Hydraulic oil is very corrosive on painted surfaces.

The braking system fluid is hygroscopic, which means it absorbs the

moisture from the air. If the moisture in the brake fluid exceeds a certain

value, braking becomes inefficient since the boiling point of the liquid is

reduced.

NOTE: Always take the fluid from sealed containers.

Under normal driving and climatic conditions, the fluid should be replaced

every two years.

If the brakes undergo serious strain, replace the fluid more frequently.

When refitting, the parts that are used again must be perfectly clean and

free from oil, diesel or grease, therefore they are to be carefully washed

with denatured alcohol.

NOTE: Do not leave rubber parts in the alcohol for more than 20

seconds. After washing, dry the parts with compressed air and a clean

cloth.

Warning

braking efficiency. In such cases, replace the pads and clean the

disc with a good quality solvent.

Hydraulic oil is corrosive. Always wear protective gloves.

Brake fluid on the disc or the brake pads decreases

REPLACING THE REAR BRAKE CALLIPERS

Remove the rear wheel by loosening the wheel axle nut and removing the

wheel axle. Remove rear brake retaining bar from the calliper holder

plate. Remove the brake control wire and move the chain aside.

Remove the rear wheel.

Remove the callipers with a lever, if required.

Replace the brake callipers and refit by reversing the removal sequence.

6-1

Page 44

DISASSEMBLING THE FRONT

BRAKE SHOE

Loosen the fitting screw and

disconnect the hydraulic pipe.

Collect the brake fluid in a suitable

container.

Loosen the two Allen screws and

disconnect the brake shoe assembly

from the fork.

Replace the brake fork assembly, top

up the oil level and bleed the system.

TIGHTENING TORQUE

Brake shoe fitting

13 ÷ 17 Nm (1.3 ÷ 1.7 kgm)

Brake shoe to fork

20 ÷ 22 Nm (2.0 ÷ 2.2 kgm)

REPLACING THE FRONT BRAKE

PADS

Loosen the pad plate central screw to

allow it to move. Remove the two

pins and release the pads.

NOTE: When refitting the new pads

you will need to insert the pistons in

their housings. Be careful not to

damage the pistons or the shoe body

when doing this.

Insert the pads, the pins and the plate

And torque the screw.

6-2

Page 45

REPLACING THE FRONT BRAKE CYLINDER

Disconnect the brake oil pipe from the

shoe and drain the oil by pumping the

brake lever.

Disconnect the pipe on brake cylinder

side. Release the complete brake

cylinder after loosening the two Allen

screws.

Refit, top up and bleed the system.

TIGHTENING TORQUE

Front brake cylinder U-bolts

6 ÷ 7 Nm (0.6 ÷ 0.7 kgm)

Front brake pipe fittings to cylinder

and to shoe

13 ÷ 17 Nm (1.3 ÷ 1.7 kgm)

FILLING & BLEEDING THE BRAKE

SYSTEM

Arrange the vehicle in vertical position

with the pipe correctly connected both

to the cylinder and to the brake shoe.

Fill the system with the prescribed fluid.

Apply the specific tool (manual Mityvac pump) to the bleeder fitting on the

brake shoe.

Operate the specific tool and pump the Brake lever at the same time.

Top up the oil reservoir constantly to prevent taking in air. The operation

ends when only oil is let out of the bleeder.

Fasten the bleeder screw at the correct torque.

NOTE: If air continues to be expelled during the bleeding operation,

check all the fittings. If no fault are found there, check the brake cylinder

and the shoe. During the bleeding operation, the brake lever may need

to be adjusted. This is because if the brake cylinder is too far forwards or

backwards, either the cylinder may not be recharged correctly or the fluid

pressure may drop in the circuit.

Important note

During this operation oil may seep out from the

breather screw onto the shoe and the disc. In this case carefully dry

the shoe and degrease the disk.

TIGHTENING TORQUE

Bleeder screw 8 ÷ 12 Nm (0.8 ÷ 1.2 kgm)

SPECIFIC TOOL

Manual pump 19.1.20329

CHECKING AND REPLACING THE

FRONT BRAKE DISC

Remove the front wheel.

Check that the brake disc is not

deformed or scratched. If faults are

found on the brake disk, replace by

means of the screws shown in the figure.

6-3

Page 46

PRE-DELIVERY OPERATIONS

Appearance check

Paint

Plastic mating

Scratches

Dirt

Tightness check

Safety locks

Securing screws

Electrical system

Emergency stop switch

Lights; full beam, dipped beam,

side/taillights, brake, parking and

respective warning lights

Brake light front and rear switches

Headlight adjustment according to

current laws

Direction indicators and respective

warning lights

Panel lights

Instrument panel warning lights

Horn

Starter

Levels check

Hydraulic braking system liquid

level

Engine oil level

Road test

Cold start

Instrument operation

Response to throttle control

Stability when accelerating and

braking

Front and rear brake efficiency

Front & rear suspension efficiency

Irregular noises

Static test after road test

Warm re-start

Starter operation

Holding idle (turning throttle)

Even steering rotation

Any leaks

Functional check

Hydraulic braking system

Lever stroke

Mechanical braking system

Pedal stroke

Clutch Correct operation

Engine Throttle grip stroke check

Check chain drive

Other

Check documents

Chassis and engine numbers check

Tool kit

Registration plate fitted

Locks check

Tyre pressure check

Rearview mirrors and any other

accessories fitted

Important note

The battery is to be charged before

use to ensure maximum performance.

If the battery is not fully charged before

the first use at low electrolyte level this

will cause premature battery failure.

Warning

Before charging the battery remove the

caps from all elements. Keep clear of

naked flames and sparks during battery

charging

Important note

When removing the battery from the

vehicle disconnect the negative cable

first. When installing the battery, fix the

positive cable first, then the negative.

Warning

The battery electrolyte is poisonous

and causes serious burns. It contains

sulphuric acid.

Do not allow it to contact the eyes, skin

or clothes. If it contacts the eyes,

wash with plenty of water for about 15

minutes and go to a Doctor as soon

as possible.

If the liquid is swallowed, immediately

drink lots of water or vegetable oil. Call

a Doctor immediately.

Always shield the eyes when working

near batteries.

Important note

Never use fuses with a higher

amperage than that recommended. The

use of a fuse with an unsuitable

amperage can cause damage to the

vehicle or become a fire hazard.

Important note

The tyre inflation pressure is to be

checked and adjusted with the tyres at

ambient temperature. Do not exceed

the specified inflation pressure as this

could cause the tyre to burst.

7

Loading...

Loading...