Page 1

GE

Oil & Gas Flow

PanaFlow™ XMT1000

User’s Manual

910-313 Rev. A

June 2017

Page 2

Page 3

GE

Oil & Gas

PanaFlow™ XMT1000

Panametrics Liquid Flow Ultrasonic Transmitter

User’s Manual

910-313 Rev. A

June 2017

www.gemeasurement.com

©2017 General Electric Company. All rights reserved.

Technical content subject to change without notice.

Page 4

[no content intended for this page]

ii

Page 5

Contents

Product Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Terms and Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Typographical Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Safety Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Auxiliary Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Environmental Compliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Chapter 1. Installation

1.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 CE Marking Compliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 Unpacking the XMT1000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4 Site and Clearance Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.4.1 Access to the Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4.2 Vibration Exposure Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.4.3 Sunlight Exposure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4.4 Local Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.4.5 Remote Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.4.6 Cable Lengths. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.4.7 Transducer Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.5 Making the Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.5.1 Wiring the Analog Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

1.5.2 Wiring the Digital Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

1.5.3 Wiring the Modbus/Service Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

1.5.4 Wiring the Line Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Chapter 2. Programming

2.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2.2 Using the Magnetic Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2.3 Passcodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

2.4 Glossary of Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

2.5 Menu Maps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Chapter 3. Error Codes and Troubleshooting

3.1 Error Display in the User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

3.1.1 Error Header . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

3.1.2 Communication Error String . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

3.1.3 Flow Error String . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

3.2 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

3.2.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

3.2.2 Flowcell Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

3.2.3 Transducer/Buffer Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

PanaFlow™ XMT1000 User’s Manual iii

Page 6

Contents

Appendix A. Specifications

A.1 Operation and Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

A.2 Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Appendix B. Modbus Communication

B.1 Modbus Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

B.2 Modbus Register Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Appendix C. HART Communication

C.1 Wiring the XMT1000 to the HART Communicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

C.2 HART Write Mode Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

C.3 HART Menu Maps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

C.3.1 HART Output Menu Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

C.3.2 HART Review Menu Map. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Appendix D. Foundation Fieldbus Communication

D.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

D.2 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

D.2.1 Network Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

D.2.2 Polarity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

D.2.3 Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

D.2.4 FISCO (Fieldbus Intrinsically Safe Concept). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

D.2.5 DD File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

D.2.6 Default Node Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

D.3 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

D.3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

D.3.2 Physical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

D.3.3 Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

D.3.4 User Layer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

D.3.5 Function Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

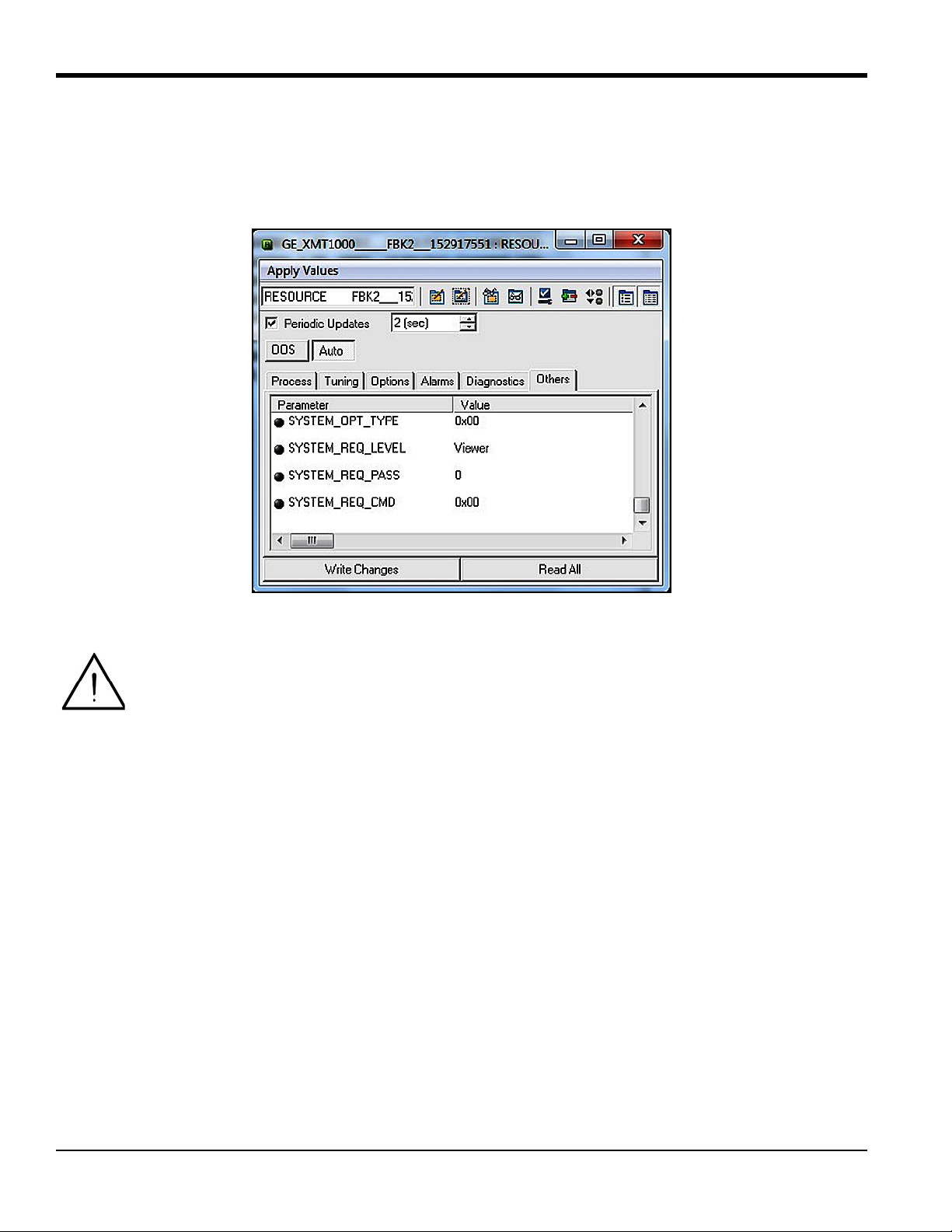

D.4 Resource Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

D.4.1 FF Revision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

D.4.2 Password. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

D.4.3 NAMUR NE107. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

D.5 XMIT Transducer Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

D.5.1 Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

D.6 Composite Transducer Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

D.6.1 Clearing the Totalizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

D.7 Channel Transducer Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

D.8 Analog Input Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

D.9 PID Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

iv PanaFlow™ XMT1000 User’s Manual

Page 7

Contents

D.10 Error Handling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

D.11 Simulation Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

D.12 Fieldbus Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

D.13 DPI620 FF Modular Communicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

PanaFlow™ XMT1000 User’s Manual v

Page 8

Contents

[no content intended for this page]

vi PanaFlow™ XMT1000 User’s Manual

Page 9

Preface

Product Registration

Thank you for purchasing a model PanaFlow™ XMT1000 from GE. Please register your product at

www.gemeasurement.com/productregistration

product information and special promotions.

for product support such as the latest software/firmware upgrades,

Services

GE provides customers with an experienced staff of customer support personnel ready to respond to technical inquiries,

as well as other remote and on-site support needs. To complement our broad portfolio of industry-leading solutions, we

offer several types of flexible and scalable support services including: Training, Product Repairs, Service Agreements

and more. Please visit www.gemeasurement.com/services

for more details.

Terms and Conditions

GE’s sales Terms and Conditions for your recent purchase of a GE product, including the applicable product Warranty,

can be found on our website at the following link: www.gemeasurement.com/sales-terms-and-conditions

Typographical Conventions

Note: These paragraphs provide information that provides a deeper understanding of the situation, but is not

essential to the proper completion of the instructions.

IMPORTANT: These paragraphs provide information that emphasizes instructions that are essential to proper setup of

the equipment. Failure to follow these instructions carefully may cause unreliable performance.

CAUTION! This symbol indicates a risk of potential minor personal injury and/or severe damage to

the equipment, unless these instructions are followed carefully.

WARNING! This symbol indicates a risk of potential serious personal injury, unless these instructions

are followed carefully.

Safety Issues

WARNING! It is the responsibility of the user to make sure all local, county, state and national codes,

regulations, rules and laws related to safety and safe operating conditions are met for each

installation.

Attention European Customers! To meet CE Marking requirements for all units intended for use in

the EU, all electrical cables must be installed as described in this manual.

PanaFlow™ XMT1000 User’s Manual vii

Page 10

Preface

Auxiliary Equipment

Local Safety Standards

The user must make sure that he operates all auxiliary equipment in accordance with local codes, standards,

regulations, or laws applicable to safety.

Working Area

WARNING! Auxiliary equipment may have both manual and automatic modes of operation. As

equipment can move suddenly and without warning, do not enter the work cell of this equipment

during automatic operation, and do not enter the work envelope of this equipment during manual

operation. If you do, serious injury can result.

WARNING! Make sure that power to the auxiliary equipment is turned OFF and locked out before

you perform maintenance procedures on this equipment.

Qualification of Personnel

Make sure that all personnel have manufacturer-approved training applicable to the auxiliary equipment.

Personal Safety Equipment

Make sure that operators and maintenance personnel have all safety equipment applicable to the auxiliary equipment.

Examples include safety glasses, protective headgear, safety shoes, etc.

Unauthorized Operation

Make sure that unauthorized personnel cannot gain access to the operation of the equipment.

viii PanaFlow™ XMT1000 User’s Manual

Page 11

Environmental Compliance

RoHS

The PanaFlow™ XMT1000 fully complies with RoHS regulations (Directive 2011/65/EU).

Waste Electrical and Electronic Equipment (WEEE) Directive

GE is an active participant in Europe’s Waste Electrical and Electronic Equipment (WEEE) take-back initiative

(Directive 2012/19/EU).

The equipment that you bought has required the extraction and use of natural resources for its production. It may

contain hazardous substances that could impact health and the environment.

Preface

In order to avoid the dissemination of those substances in our environment and to diminish the pressure on the natural

resources, we encourage you to use the appropriate take-back systems. Those systems will reuse or recycle most of the

materials of your end life equipment in a sound way.

The crossed-out wheeled bin symbol invites you to use those systems.

If you need more information on the collection, reuse and recycling systems, please contact your local or regional

waste administration.

Please visit http://www.gemeasurement.com/environmental-health-safety-ehs

information about this initiative.

for take-back instructions and more

PanaFlow™ XMT1000 User’s Manual ix

Page 12

Preface

[no content intended for this page]

x PanaFlow™ XMT1000 User’s Manual

Page 13

Chapter 1. Installation

Chapter 1. Installation

1.1 Introduction

To ensure safe and reliable operation of the XMT1000, it must be installed in accordance with the established

guidelines. Those guidelines, explained in detail in this chapter, include the following topics:

• Unpacking the XMT1000

• Selecting the location for the XMT1000 (local or remote)

• Installing the XMT1000 at the selected location

• Wiring the XMT1000

WARNING! The XMT1000 flow transmitter can measure the flow rate of many fluids, some of which

are potentially hazardous. The importance of proper safety practices cannot be overemphasized.

Be sure to follow all applicable local safety codes and regulations for installing electrical equipment

and working with hazardous fluids or flow conditions. Consult company safety personnel or local

safety authorities to verify the safety of any procedure or practice.

Attention European Customers! To meet CE Marking requirements, all cables must be installed as

described in “CE Marking Compliance” on page 1.

1.2 CE Marking Compliance

For CE Marking compliance or installation in high noise areas, the XMT1000 flow transmitter must be wired in

accordance with the instructions in this section.

IMPORTANT: CE Marking compliance is required for all units intended for use in EU countries.

The XMT1000 must be wired with the recommended cable, and all connections must be properly shielded and

grounded. Grounding of the chassis must be within 10 ft (3 m) of the transmitter. Refer to Tab le 1 below for the specific

requirements.

Table 1: Wiring Requirements

Connection Cable Type Ground Termination

Transducer Armored RG-62 a/U or equivalent Grounded using a cable gland.

Input/Output Armored 22 AWG shielded with armored material added to

outside of jacket

Power Armored 14 AWG 2 conductor Grounded using a cable gland.

Note: If the XMT1000 is wired as described above, the unit will comply with the EMC and LVD Directives.

Grounded using a cable gland.

PanaFlow™ XMT1000 User’s Manual 1

Page 14

Chapter 1. Installation

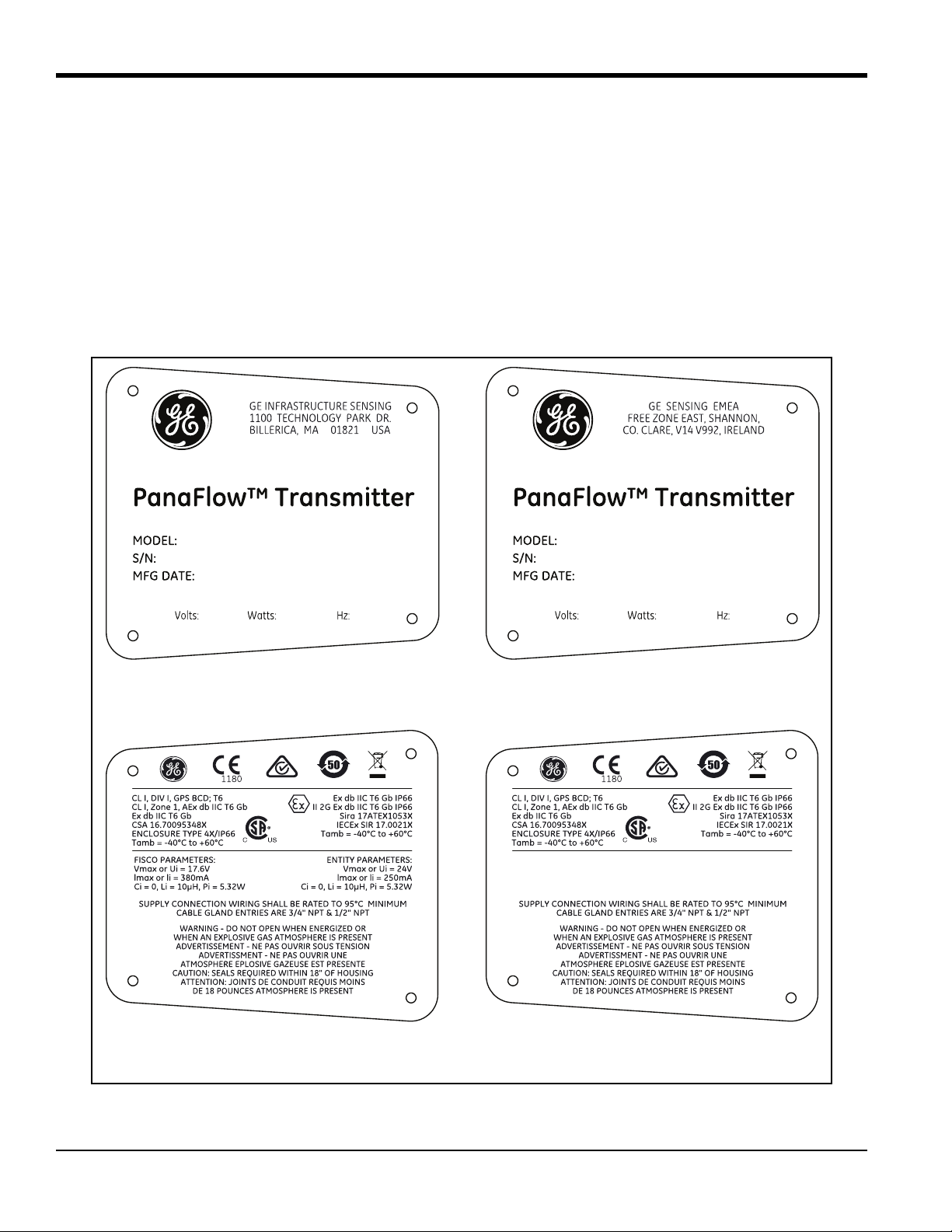

Model & Serial Number (Boston) Model & Serial Number (Shannon)

Certification (US/CAN, IECEx/ATEX)

[FISCO]

Certification (US/CAN, IECEx/ATEX)

[Standard]

1.3 Unpacking the XMT1000

Before removing the XMT1000 from its box, please inspect both the box and the instrument carefully. Each instrument

manufactured by GE is warranted to be free from defects in material and workmanship. Before discarding any of the

packing materials, account for all components and documentation listed on the packing slip. The discarding of an

important item along with the packing materials is all too common. If anything is missing or damaged, contact GE

Customer Care immediately for assistance.

The XMT1000 is supplied with both a serial number label and a certification label for identification of the instrument

(see Figure 1 below and Figure 2 on page 3). The system can be mounted either on an existing meter body (local

mounting) or at another location via a connecting cable (remote mounting).

Figure 1: Typical XMT1000 Labels (Aluminum Enclosure)

2 PanaFlow™ XMT1000 User’s Manual

Page 15

1.3 Unpacking the XMT1000 (cont.)

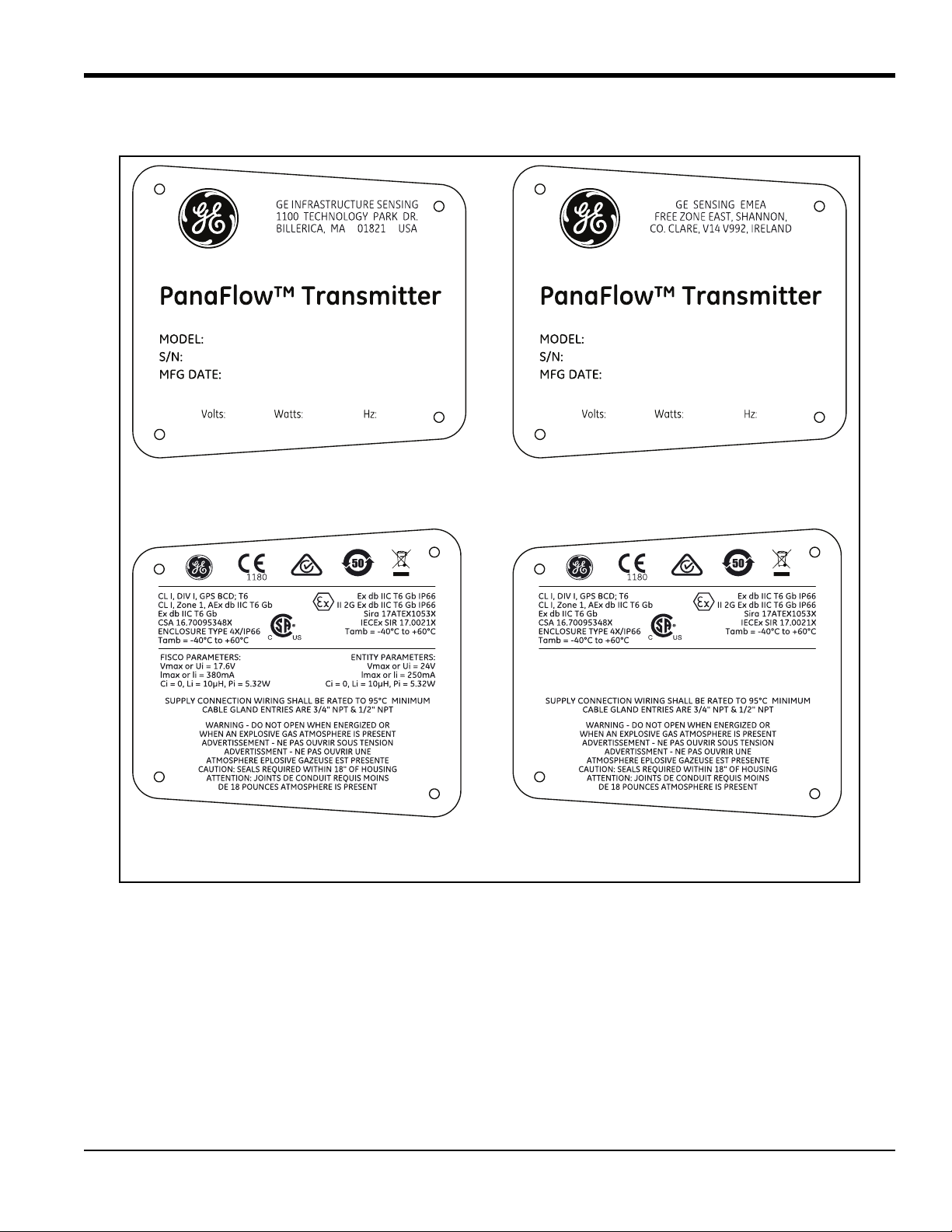

Model & Serial Number (Boston) Model & Serial Number (Shannon)

Certification (US/CAN, IECEx/ATEX)

[FISCO]

Certification (US/CAN, IECEx/ATEX)

[Standard]

Chapter 1. Installation

Figure 2: Typical XMT1000 Labels (Stainless Steel Enclosure)

1.4 Site and Clearance Considerations

1.4.1 Access to the Meter

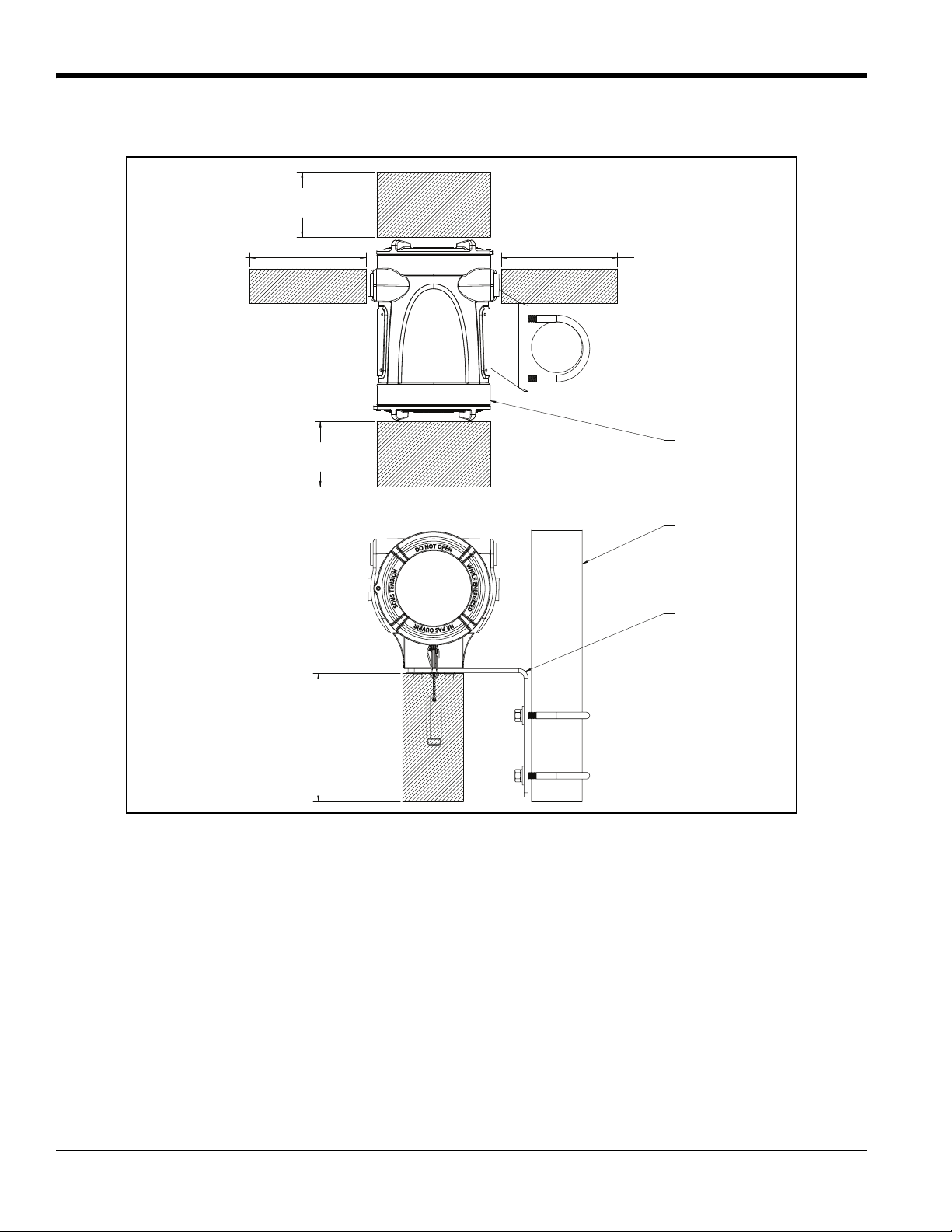

Because the relative location of the flowcell and the XMT1000 transmitter is important, use the guidelines in this

section to plan the XMT1000 installation.

For flowcell clearance recommendations, consult the manual for your specific flow meter system or contact GE for

assistance. Access to the XMT1000 flow transmitter should be uninhibited, as defined by the minimum clearance

distances around the enclosure specified in Figure 3 on page 4.

PanaFlow™ XMT1000 User’s Manual 3

Page 16

Chapter 1. Installation

1000 SERIES ELECTRONICS

12 in. (300 mm) CLEARANCE

MINIMUM RECOMMENDED

FOR CABLE ENTRY

12 in. (300 mm) CLEARANCE

MINIMUM RECOMMENDED

FOR CABLE ENTRY

12 in. (300 mm) CLEARANCE

MINIMUM RECOMMENDED

FOR SERVICE ACCESS

12 in. (300 mm) CLEARANCE

MINIMUM RECOMMENDED

FOR SERVICE ACCESS

12 in. (300 mm) CLEARANCE

MINIMUM RECOMMENDED

FOR CABLE ENTRY

CUSTOMER SUPPLIED 2” PIPE

1000 SERIES

REMOTE MOUNT KIT

1.4.1 Access to the Meter (cont.)

Figure 3: XMT1000 Enclosure Clearances (ref. dwg. 712-2164)

1.4.2 Vibration Exposure Considerations

Whenever possible, install the XMT1000 flow transmitter in a location isolated from vibrations. Avoid installing it near

equipment that generates low-frequency, high-energy random vibrations.

1.4.3 Sunlight Exposure

The installer should consider and limit exposure of the XMT1000 flow transmitter to direct sunlight. Sunshades should

be utilized in extreme environments.

4 PanaFlow™ XMT1000 User’s Manual

Page 17

Chapter 1. Installation

Flow Direction

10D 5D

BAD

Vertical

GOOD

Flow Direction

Flow Direction

Flowcell

Flow Direction

GOOD

BAD

Horizontal

Flowcell

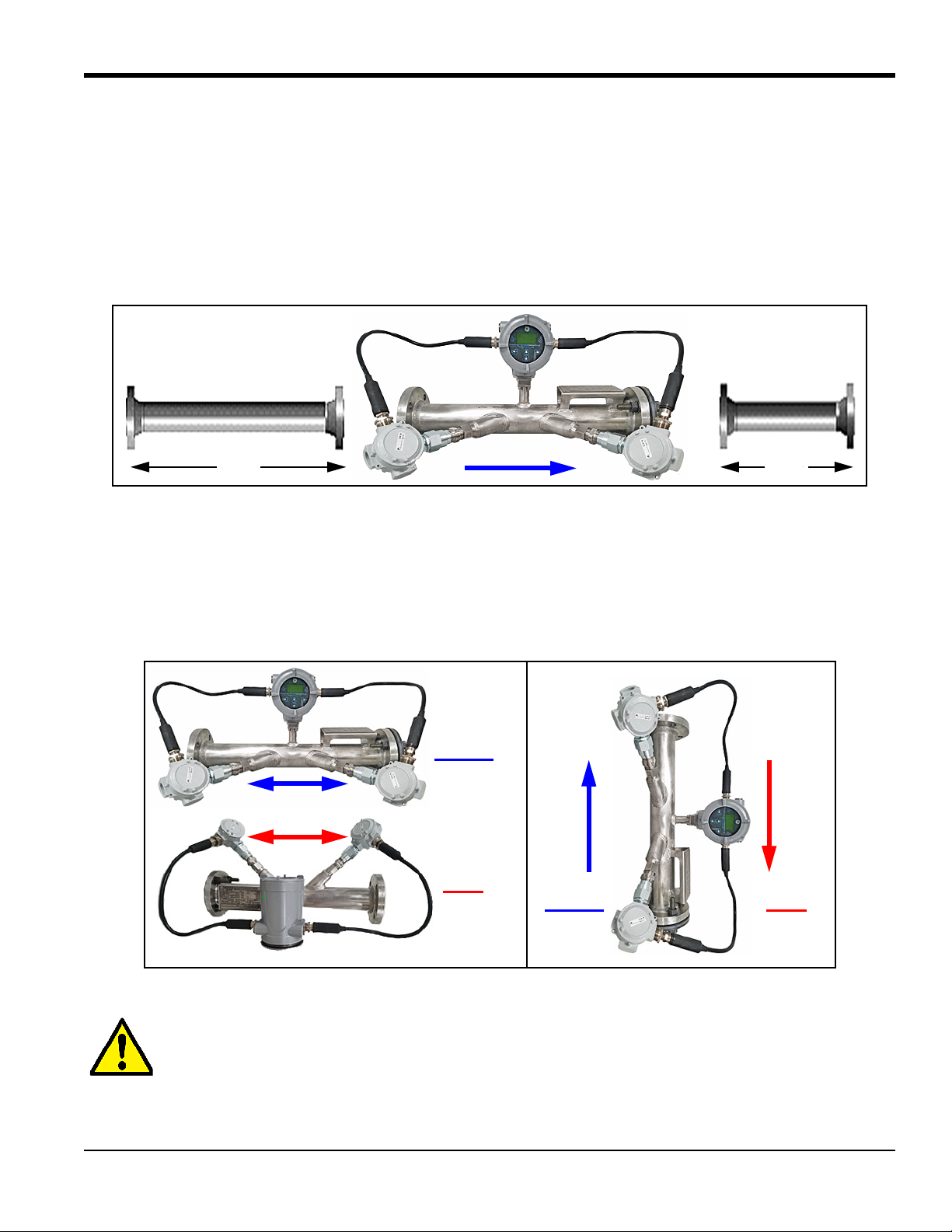

1.4.4 Local Mounting

The XMT1000 accuracy is affected by the flowcell location in the process piping and on the orientation of the

transducers. Thus, in addition to accessibility for maintenance, adhere to the following installation guidelines:

• Locate the flowcell so that there are at least 10 pipe diameters of straight, undisturbed flow upstream and

5 pipe diameters of straight, undisturbed flow downstream from the measurement point (see Figure 4 below).

Undisturbed flow means avoiding sources of turbulence in the fluid (e.g., valves, flanges, expansions, elbows,

etc.), avoiding swirl, and avoiding cavitation.

Figure 4: Minimum Straight Run Pipe Requirements

• Locate the transducers on a common axial plane along the pipe. Also, locate them on the side of the pipe

instead of on the top or the bottom, because the top of the pipe tends to accumulate gas and the bottom tends to

accumulate sediment. Either condition will cause unwanted attenuation of the ultrasonic signals. There is no

similar restriction with vertical pipes, as long as the fluid flow is upward to prevent free falling of the fluid or a

less than full pipe (see Figure 5 below).

Figure 5: Good and Bad Flowcell/Transducer Orientations

CAUTION! Do not place thermal insulation on or around the transducers, the junction boxes, or the

meter electronics. The transducer and junction box act as a heat sink that protects the transducer

PanaFlow™ XMT1000 User’s Manual 5

from high and low temperatures.

Page 18

Chapter 1. Installation

1.4.5 Remote Mounting

The standard XMT1000 enclosure is a powder-coated, aluminum, IP67 explosion-proof enclosure. Typically, the

enclosure is mounted as close as possible to the transducers. When choosing a site for a remote-mount installation,

which is recommended for process temperatures exceeding 150°C, make sure the location permits easy access to the

enclosure for programming, maintenance and service.

Attention European Customers! For compliance with the European Union’s Low Voltage Directive,

this unit requires an external power disconnect device such as a switch or circuit breaker. The

disconnect device must be marked as such, clearly visible, directly accessible, and located within

1.8 m (6 ft) of the unit.

1.4.6 Cable Lengths

Locate the XMT1000 as close as possible to the transducers. The maximum distance from the transducers for remote

mounting of the XMT1000 is 1000 ft (300 m) using RG-62 coaxial cable or equivalent. If longer distances are required,

consult the factory for assistance.

1.4.7 Transducer Cables

When installing the transducer cables, always observe established standard practices for the installation of electrical

cables. Do not route transducer cables alongside high amperage AC power lines or any other cables that could cause

electrical interference. Also, protect the transducer cables and connections from the weather and corrosive

atmospheres, and be sure to follow the manufacturer's installation guidelines if cable glands are provided.

6 PanaFlow™ XMT1000 User’s Manual

Page 19

Chapter 1. Installation

1.5 Making the Electrical Connections

This section contains instructions for making all the necessary electrical connections for the XMT1000 flow

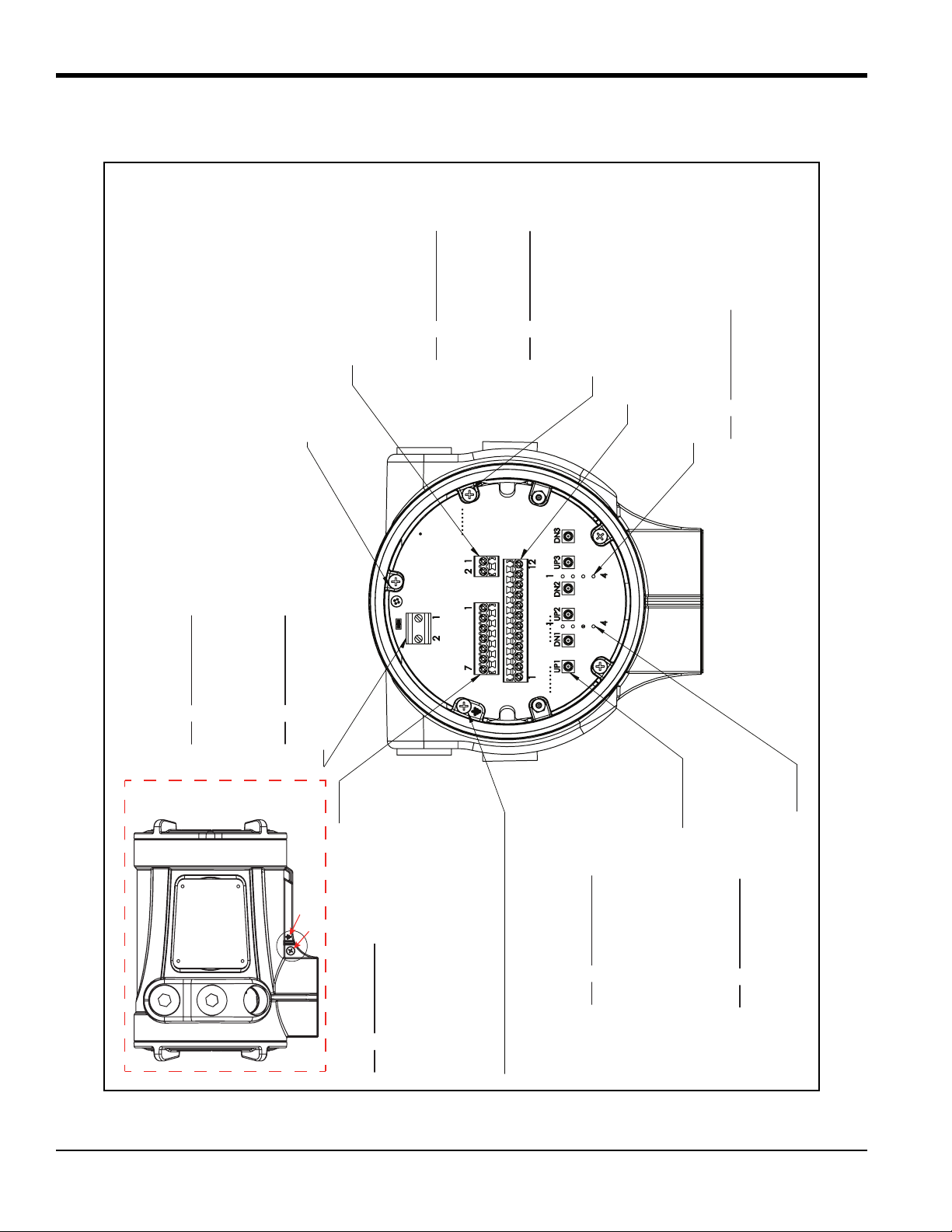

transmitter. Refer to Figure 6 on page 8 for a complete wiring diagram.

Note: Both flying lead and MCX transducer connectors are shown in the figure for completeness. Only the type of

connector appropriate for each meter ordered will be installed on the PCB.

WARNING! Always disconnect the line power from the XMT1000 before removing either the front

cover or the rear cover. This is especially important in a hazardous environment.

Attention European Customers! To meet CE Marking requirements, all cables must be installed as

described in “CE Marking Compliance” on page 1.

Prepare the XMT1000 for wiring by completing the following steps:

• To access the wiring terminals, complete the following steps:

1. Disconnect any previously wired power line from the unit.

2. Loosen the set screw on the wiring cover.

3. Place a rod or long screwdriver across the cover in the slots provided, and rotate the cover counterclockwise

until it comes free from the enclosure.

4. Install any required cable glands in the appropriate conduit holes on the opposite side of the enclosure.

5. Note the labels inside the rear cover to assist in wiring the power and option connections.

• Wiring any option set requires completion of the following general steps:

1. Disconnect the main power from the unit and remove the wiring cover.

2. Install a cable gland in the chosen conduit hole on the side of the electronics enclosure and feed a standard

26-12 AWG twisted-pair cable through this conduit hole.

3. Locate the Standard I/O or Analog I/O options terminal block and wire the option as indicated on the label

inside the wiring cover. Secure the cable gland.

4. If wiring of the unit has been completed, reinstall the wiring cover on the enclosure and tighten the set screw.

WARNING! Proper grounding of the XMT1000 enclosure via the external grounding screw on the

enclosure (see Figure 6 on page 8) is required to prevent the possibility of electric shock. All ground

screws should be hand tightened only, to a maximum allowable torque of 2.5 N-m (22 in-lb).

For specific instructions on wiring a particular output configuration, proceed to the appropriate sub-section.

PanaFlow™ XMT1000 User’s Manual 7

Page 20

Chapter 1. Installation

CH2 FLYING LEAD TERMINAL BLOCK (TB6)

ACCEPTS 26-12 AWG WIRE

PIN DESCRIPTION

1 CH 2 DOWNSTREAM SIG (+)

2 CH 2 DOWNSTREAM RTN (-)

3 CH 2 UPSTREAM RTN (-)

4 CH 2 UPSTREAM SIG (+)

CH1 FLYING LEAD TERMINAL BLOCK (TB5)

ACCEPTS 26-12 AWG WIRE

PIN DESCRIPTION

1 CH 1 DOWNSTREAM SIG (+)

2 CH 1 DOWNSTREAM RTN (-)

3 CH 1 UPSTREAM RTN (-)

4 CH 1 UPSTREAM SIG (+)

MCX TERMINAL CONNECTORS

ACCEPTS 50 RIGHT ANGLE MCX PLUG

PIN DESCRIPTION

UP1 CH 1 UPSTREAM

DN1 CH 1 DOWNSTREAM

UP2 CH 2 UPSTREAM

DN2 CH 2 DOWNSTREAM

UP3 CH 3 UPSTREAM

DN3 CH 3 DOWNSTREAM

*ENCLOSURE MAIN CUSTOMER GROUND

STANDARD I/O TERMINAL BLOCK (TB3)

ACCEPTS 26-12 AWG WIRE

PIN DESCRIPTION

1 RS485 MODBUS (+)

2 RS485 MODBUS (-)

3 RS485 COMMON

4 FREQUENCY/TOTALIZER/CAL (+)

5 FREQUENCY/TOTALIZER/CAL (-)

6 ANALOG 4-20MA OUT (+)

7 ANALOG 4-20MA RTN (-)

ADDITIONAL CUSTOMER GROUND, 3X

PCB GROUND

DIGITAL COMMUNICATION

TERMINAL BLOCK (TB1)

NONE, [OR]

+$577(50,1$/%/2&.

ACCEPTS 26-12 AWG WIRE

PIN DESCRIPTION

1 HART (+)

2 HART (-)

[OR]

)281'$7,21),(/'%86

ACCEPTS 26-12 AWG WIRE

PIN DESCRIPTION

1 FIELDBUS NET (+)

2 FIELDBUS NET (-)

ANALOG I/O TERMINAL BLOCK (TB2)

ACCEPTS 26-12 AWG WIRE

FOR FUTURE USE

LINE POWER TERMINAL BLOCK (TB4)

ACCEPTS 20-10 AWG WIRE

$&

PIN DESCRIPTION

1 (L1) LINE

2 (L2/N) NEUTRAL

* CONNECT GROUND TO CHASSIS

[OR]

'&

PIN DESCRIPTION

1 +

2 -

* CONNECT GROUND TO CHASSIS

CASTED GROUND SYMBOL

EXTERIOR GROUND SCREW

[TB1]

[TB2]

[TB3]

[TB4]

[TB5]

[TB6]

1.5 Making the Electrical Connections (cont.)

Figure 6: XMT1000 Terminal Board Wiring Diagram (ref. dwg. 702-2040)

8 PanaFlow™ XMT1000 User’s Manual

Page 21

Chapter 1. Installation

1.5.1 Wiring the Analog Outputs

The standard configuration of the XMT1000 flow transmitter includes one isolated 4-20 mA analog output.

Connections to this output may be made with standard twisted-pair wiring, but the current loop impedance for this

circuit must not exceed 600 ohms. Two additional analog outputs are available as an option.

To wire the analog outputs, complete the following steps:

1. Disconnect the main power to the unit and remove the wiring cover.

2. Install the required cable gland in the chosen conduit hole on the side of the electronics enclosure.

3. Refer to Figure 6 on page 8 for the location of the terminal block and wire the analog output as shown. Secure

the cable gland.

Attention European Customers! To meet CE Marking requirements, all cables must be installed as

described in “CE Marking Compliance” on page 1.

IMPORTANT: Analog output A is an active signal. Do not supply power to this circuit, as the circuit is powered by the

flow meter.

4. If wiring of the unit has been completed, reinstall the wiring cover on the enclosure and tighten the set screw.

WARNING! Make sure all covers, with their o-ring seals, are installed and the set screws tightened

before applying power in a hazardous environment.

Note: Prior to use, the analog output must be set up and calibrated. Proceed to the next section to continue the initial

wiring of the unit.

Note: See Appendix A, Specifications, for the load and voltage requirements.

PanaFlow™ XMT1000 User’s Manual 9

Page 22

Chapter 1. Installation

1.5.2 Wiring the Digital Output

The standard XMT1000 flow transmitter configuration includes one isolated digital output, which can be used as a

totalizer (pulse) output, a frequency output, or a calibration port. Wiring this output requires completion of the

following general steps:

1. Disconnect the main power to the unit and remove the wiring cover.

2. Install the required cable gland in the chosen conduit hole on the side of the electronics enclosure.

3. Refer to Figure 6 on page 8 for the location of the terminal block and wire the digital output as shown. Secure

the cable gland.

Attention European Customers! To meet CE Marking requirements, all cables must be installed as

described in “CE Marking Compliance” on page 1

4. If wiring of the unit has been completed, reinstall the wiring cover on the enclosure and tighten the set screw.

1.5.2a Wiring as a Totalizer (Pulse) Output

Wire this option in accordance with the connections shown on the label in the rear cover (see Figure 6 on page 8).

Refer to Appendix A, Specifications for the load and voltage requirements.

1.5.2b Wiring as a Frequency Output

Wire this option in accordance with the connections shown on the label in the rear cover (see Figure 6 on page 8).

Refer to Appendix A, Specifications for the load and voltage requirements.

1.5.2c Wiring as a Calibration Port

The XMT1000 flow transmitter is equipped with a calibration port specifically designed for calibrating the XMT1000.

It is wired for a frequency output. To wire to this port, refer to Figure 6 on page 8 and complete the following steps:

Note: Performing a calibration of the meter requires entering an Admin-level password.

1. Disconnect the main power to the unit and remove the rear cover.

2. Install the required cable gland in the chosen conduit hole on the side of the electronics enclosure.

3. Feed one end of the cable through the conduit hole, wire it to the terminal block.

4. If wiring of the unit has been completed, reinstall the wiring cover on the enclosure and tighten the set screw.

WARNING! Make sure all covers, with their o-ring seals, are installed and the set screws tightened

before applying power in a hazardous environment.

10 PanaFlow™ XMT1000 User’s Manual

Page 23

Chapter 1. Installation

1.5.3 Wiring the Modbus/Service Port

The XMT1000 flow transmitter is equipped with a Modbus communication port for either a connection to Vitality (PC

software) or to a separate control system. The port is an RS485 interface.

IMPORTANT: The maximum cable length for an RS485 connection is 4000 ft (1200 m).

To wire to this RS485 serial port, refer to Figure 6 on page 8 and complete the following steps:

1. Disconnect the main power to the unit and remove the rear cover.

2. Install the required cable gland in the chosen conduit hole on the side of the electronics enclosure.

3. Feed one end of the cable through the conduit hole, and wire it to the terminal block.

4. If wiring of the unit has been completed, reinstall the wiring cover on the enclosure and tighten the set screw.

Note: Prior to use, the serial port must be programmed.

WARNING! Make sure all covers, with their o-ring seals, are installed and the set screws tightened

before applying power in a hazardous environment.

PanaFlow™ XMT1000 User’s Manual 11

Page 24

Chapter 1. Installation

1.5.4 Wiring the Line Power

The XMT1000 may be ordered for operation with power inputs of either 100-240 VAC or 12-28 VDC. The label on the

side of the enclosure lists the meter’s required line voltage and power rating. Be sure to connect the meter to the

specified line voltage only.

Attention European Customers! For compliance with the European Union’s Low Voltage Directive,

this unit requires an external power disconnect device such as a switch or circuit breaker. The

disconnect device must be marked as such, clearly visible, directly accessible, and located within

1.8 m (6 ft) of the unit.

WARNING! Improper connection of the line power leads or connecting the meter to the incorrect

line voltage may damage the unit. It may also result in hazardous voltages at the flowcell and

associated piping as well as within the electronics enclosure.

Refer to Figure 6 on page 8 to locate the terminal blocks and connect the line power as follows:

1. Prepare the line power leads by trimming the line and neutral AC power leads (or the positive and negative DC

power leads) to a length 0.5 in. (1 cm) shorter than the ground lead. This ensures that the ground lead is the last

to detach if the power cable is forcibly disconnected from the meter.

2. Install a suitable cable gland in the conduit hole. If possible, avoid using the other conduit holes for this

purpose, to minimize any interference in the circuitry from the AC power line.

Attention European Customers! To meet CE Marking requirements, all cables must be installed as

described in “CE Marking Compliance” on page 1.

3. Route the cable through the conduit hole and connect the line power leads to the power terminal, using the pin

number assignments shown in Figure 6 on page 8.

IMPORTANT: The ground wire must be connected to the system chassis.

4. Leaving a bit of slack, secure the power line with the cable clamp.

5. If wiring of the unit has been completed, reinstall the wiring cover on the enclosure and tighten the set screw.

WARNING! Make sure all covers, with their o-ring seals, are installed and the set screws tightened

before applying power in a hazardous environment.

CAUTION! The transducers must be properly wired before applying power to the meter.

12 PanaFlow™ XMT1000 User’s Manual

Page 25

Chapter 2. Programming

Chapter 2. Programming

2.1 Introduction

This chapter provides instructions for programming the various features of the XMT1000 flow transmitter. Before the

XMT1000 can begin taking measurements, settings for the User Preferences and Inputs/Outputs must be entered and

tested. To program your XMT1000, see the next section for programming instructions and refer to “Menu Maps” on

page 16 to configure the desired features.

Note: For help with the programming of any system parameters which may be unclear, refer to “Glossary of Terms”

on page 15 for a brief description of the standard flow meter terminology used in this manual.

2.2 Using the Magnetic Keypad

The display window on the XMT1000 includes the components shown in Figure 7 below.

Figure 7: The Display and Keypad

IMPORTANT: The XMT1000 magnetic keypad enables programming of the instrument through the glass faceplate

without removing the cover. Thus, all programming procedures may be performed while the unit is

installed in a hazardous area.

PanaFlow™ XMT1000 User’s Manual 13

Page 26

Chapter 2. Programming

INITIALIZE . . .

XMT 1000

Velocity

m/s

9.3

2.2 Using the Magnetic Keypad (cont.)

Above the display, the blue light is for power indication and the red light is for system health indication. Once system

power is applied, the blue light stays on until power is lost. The red light blinks when the system is in error. When the

red light is off - the system is operating without error.

The six keys on the magnetic keypad are used to program the XMT1000:

• [√] - confirms the choice of a specific option and data entry within that option

• [] - enables users to exit from a specific option without entering unconfirmed data

• [] and [] - enable users to highlight a specific window in the display option or to scroll through a list of

options (parameters, letters, and numbers, 0-9 as well as the negative sign and decimal point) in a menu

• [] and [] - enable users to scroll to a specific option, among choices in an option, or to a character in a text

entry.

When the XMT1000 is powered up, the initial screen display appears, followed by meter boot up, then by a display of

measurement parameters.

As a guide to help follow the programming instructions in this chapter, the XMT1000 menu maps have been

reproduced in Figure 8 on page 17 through Figure 15 on page 24.

IMPORTANT: If the keypad has not been pressed for 10 minutes, the XMT1000 exits the Keypad Program and returns

to displaying measurements. Because changes can only be retained after the user confirms them, the

meter discards any unconfirmed configuration changes.

2.3 Passcodes

The default passcodes for the XMT1000 flow transmitter are:

• Default Operator Password = 111111

• Default Admin Password = 111111

IMPORTANT: The default Admin password must be changed before the meter is placed into service, and the new

Admin password must be properly secured. Unauthorized access to the Admin menus may result in

programming changes that have a negative impact on the performance and operation of the meter.

14 PanaFlow™ XMT1000 User’s Manual

Page 27

Chapter 2. Programming

2.4 Glossary of Terms

Backlight: The LCD display backlight has three user-adjustable parameters. The brightness, the contrast, and the

•

length of inactivity which triggers automatic shutdown can be individually set within available limits.

• Error Handling: The manner in which various XMT1000 outputs respond to automatically generated system errors

can be set by the user by selecting the options from a drop-down list.

• Frequency Output: In frequency mode, the digital output generates a pulse with a frequency that is proportional to

the magnitude of the measured flow parameter (e.g., 10 Hz = 1ft

3

/hr).

• HART: HART is a serial communication protocol used for industrial automation. Its main advantage is that it can

communicate over 4-20 mA analog instrumentation current loops over the pair of wires used by the analog only

host system.

• K-Factor: To calibrate the XMT1000 against a reference value, the raw flow velocity readings may need to have a

correction factor applied. This K-Factor can be a single constant or a table of K-Factor vs. Velocity values.

• Loop Powered: Loop powered analog devices use the power provided by the meter itself rather than by an external

power supply. This results in a simple 2-wire connection between the meter and the external device.

• Mass Flow: Mass flow is the mass of fluid passing the measurement point in a given period of time. This value is

calculated by the meter from the measured flow velocity and the programmed pipe and fluid parameters.

• Modbus: Modbus is a serial communication protocol developed by Modicon

controllers. It is a method used for transmitting information over serial lines between electronic devices.

®

for use with its programmable logic

• Pulse Output: In pulse/totalizer mode, the digital output generates a pulse with a width corresponding to one unit

of the measured flow parameter (e.g., 1 pulse = 1 ft

3

).

• Reynolds Correction: When turned on, a factor based on the kinematic viscosity and the flow rate of the fluid is

applied to all measurements. Reynolds correction should be On for most applications.

• Serial Port Settings: When the XMT1000 serial port is connected to an external serial device, communication

between the two devices only occur if the serial port settings of the two devices match. These settings include:

baud rate, data bits, stop bits, and parity.

• Special Transducer: If your transducer has no number engraved on the body, select SPECIAL in the Transducer

Number menu.

• Tw: The TW parameter is the time the transducer signal spends traveling through the transducer body and the

transducer cable. This value must be subtracted from the total signal transit time to calculate the actual signal

transit time only through the fluid.

• Totalizer: The totalizer accumulates a running total of the amount of fluid which passes the measurement point

between specified start and stop times.

• Tracking Window: The tracking window is used to detect the receive signal when you are unsure of the fluid

sound speed. For the XMT1000 flow transmitter, the Tracking Window is always ON.

• Zero Cutoff: When the measured flow rate is below the zero cutoff value, the display is forced to 0.00. This is to

avoid rapid fluctuations in the reading whenever the flow rate is close to zero.

PanaFlow™ XMT1000 User’s Manual 15

Page 28

Chapter 2. Programming

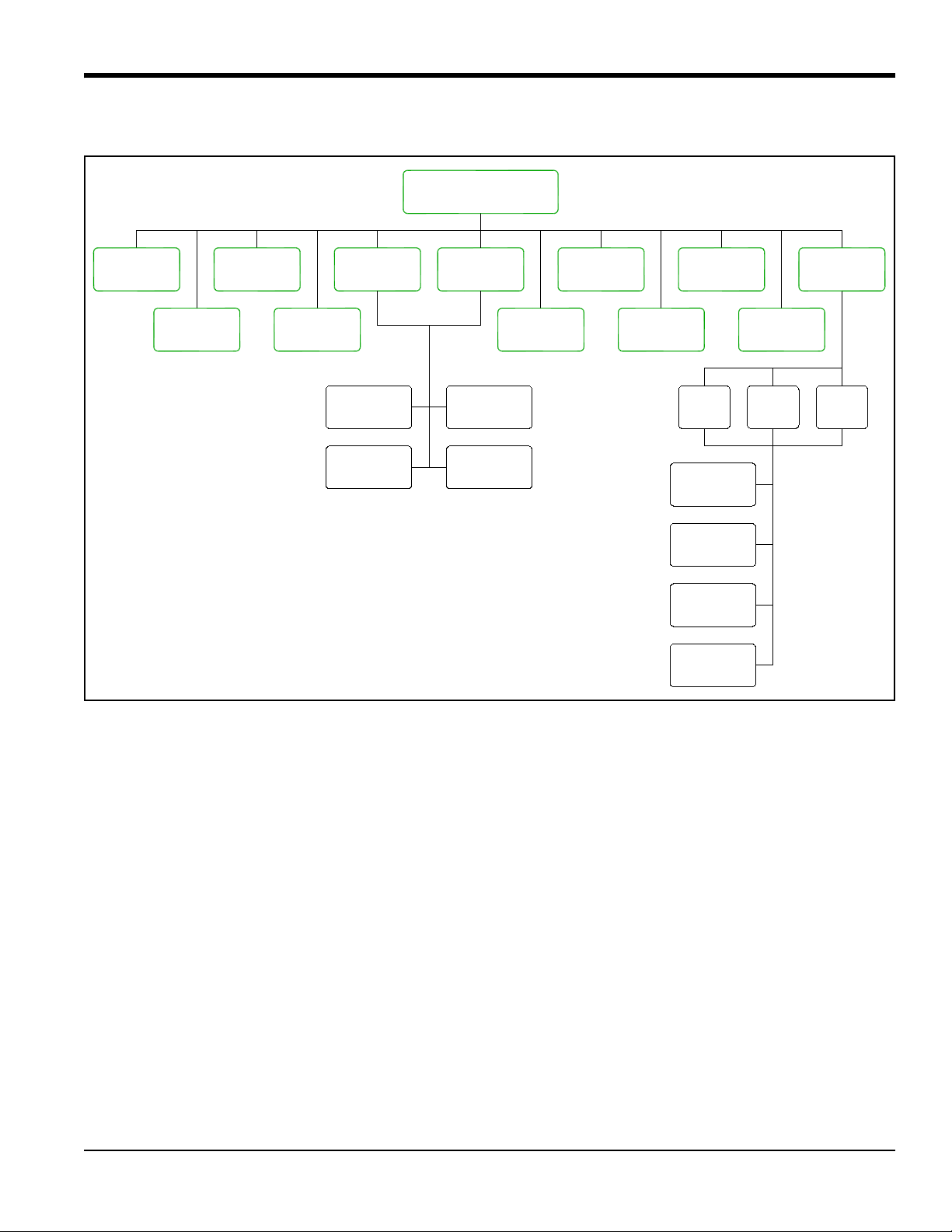

2.5 Menu Maps

Use the menu maps in this section to program the desired XMT1000 features.

• "Measurement Display Menu Map (Rev. 10)" on page 17

• "Main Menu Map (Rev. 10)" on page 18

• "SYSTEM Menu Map (Rev. 10)" on page 19

• "MAIN Board I/O Menu Map (Rev. 10)" on page 20

• "OPTION Boards Menu Map (Rev. 10)" on page 21

• "SENSOR SETUP Menu Map (Rev. 10)" on page 22

• "CALIBRATION Menu Map (Rev. 10)" on page 23

• "ADVANCED Menu Map (Rev. 10)" on page 24

In addition, the following menu maps are available in Appendix C:

• “HART Output Menu Map” on page 54

• “HART Review Menu Map” on page 55

IMPORTANT: Not all users will have access to all of the above menus. Some menus are restricted to only those users

with the proper passcodes.

16 PanaFlow™ XMT1000 User’s Manual

Page 29

2.5 Menu Maps (cont.)

Velocity

Volumetric

Actual

Volumetric

Standard

Mass

Soundspeed

Diagnostics

Total

Batch

Total

Inventory

Forward

Net

Time

Reverse

Ch 1 Ch 2 Ch 3

Values

Flow

Quality

Signal

Process

Signal

Status

System

Measurement Menu

Press to Enter the Display

9

K-Factor

Reynolds

Number

Reylnolds

K-Factor

Temperature

On Board

Chapter 2. Programming

Figure 8: Measurement Display Menu Map (Rev. 10)

PanaFlow™ XMT1000 User’s Manual 17

Page 30

Chapter 2. Programming

PASSWORDS

When the keypad is locked, press

[ ], [ ], [ ] to open the password

screen. Enter an Admin password

to unlock the keypad.

(Operator Password)

9

88

Operator Password (default password = 111111)

Admin Password (default password = 111111)

Contact the factory for instructions.

If Admin password is lost, meter must be reset.

Main Menu

Diagnostics

Program

Lockout

Keypad

1 Variable 2 Variables Totalizer

Forward Total

Reverse Total

Net Total

Totalizer Time

Display Format

Admin

Operator

Factory

XXXXXX

Password

SYSTEM

MAIN Board I/O

OPTION Boards

HART SENSOR SETUP CALIBRATION

Save Change?

Display

ADVANCED

No

Active Settings

Save to

Commissioned

Save to

2.5 Menu Maps (cont.)

Figure 9: Main Menu Map (Rev. 10)

18 PanaFlow™ XMT1000 User’s Manual

Page 31

2.5 Menu Maps (cont.)

(see Units list)

Not visible in Operator menu.

Admin password is required.

SYSTEM

MAIN Board I/O

OPTION Boards

SENSOR SETUP CALIBRATION ADVANCED

Password

Operator/Admin

Password

Change

Operator

Admin

Velocity

Mass

Totalizer

Density

Volumetric

Actual

Volumetric

Standard

Flow Units

m/s

ft/s

Flow Limits

SoS Low Limit

SoS High Limit

Density

Settings

Measure

Zero Cutoff

Averaging

Volumetric

Actual

Backlight

Always On

Timeout

Timeout Time

Display

Language

Label

About

System Date

Meter Tag

Meter Setup

System S/N

Product Type

MAIN Board

FLOW Board

COM Board

IO Board

Sensor S/N

KV Inputs

Path Error

HART

Chapter 2. Programming

Figure 10: SYSTEM Menu Map (Rev. 10)

PanaFlow™ XMT1000 User’s Manual 19

Page 32

Chapter 2. Programming

SYSTEM

MAIN Board I/O

OPTION Boards

HART SENSOR SETUP CALIBRATION ADVANCED

Password

Operator/Admin

Baud Rate

Bit/Parity

Port

Modbus/Service

8 no

8 odd

8 even

Address

Stop Bit

12

38400 57600

115200

9600 19200

2400 4800

Calibrate

Measurement

Velocity

HIGH OTHER

HOLD LOW

4mA 20mA

Mass

Sound Speed

Batch Total

Diagnostic

Volumetric

Actual

Volumetric

Standard

Total

Inventory

Analog Output

Error Handling

Full Value

Base Value

of Scale

Percentage

Digital Output

Pulse

Frequency

Off

Pulse Value

Error Handling

Measurement

Reverse Batch

Test Pulses

On Time

Forward Batch Net Batch

Measurement

Velocity

Mass

Sound Speed

Batch Total

Diagnostic

Volumetric

Actual

Volumetric

Standard

Total

Inventory

Full Frequency

Full Value

Base Value

Error Handling

Test Frequency

HOLD LOW HIGH OTHER HIGH OTHER

HOLD LOW

2.5 Menu Maps (cont.)

Figure 11: MAIN Board I/O Menu Map (Rev. 10)

20 PanaFlow™ XMT1000 User’s Manual

Page 33

2.5 Menu Maps (cont.)

(Admin access only)

SYSTEM

MAIN Board I/O

OPTION Boards

SENSOR SETUP CALIBRATION ADVANCED

Password

Operator/Admin

FF HART

HART Info

Revision

Hardware

Revision

Software

Output

Analog

Measurement

Analog

Volumetric

Actual

Volumetric

Standard

Velocity

Mass

of Scale

Percentage

Calibrate

4mA 20mA

Base Value

Handling

Error

HOLD LOW

HIGH OTHER

Full Value

Revision

Hardware

Revision

Software

HART

Chapter 2. Programming

Figure 12: OPTION Boards Menu Map (Rev. 10)

PanaFlow™ XMT1000 User’s Manual 21

Page 34

Chapter 2. Programming

(No Off for Ch1)

SYSTEM

MAIN Board I/O

OPTION Boards

HART SENSOR SETUP CALIBRATION ADVANCED

Password

Operator/Admin

0.2 0.5

1M 2M

4M

Pipe OD

Pipe ID/WT

Configure

Channel

Ch 1 Ch 2 Ch 3

In

mm

Pipe OD

ID-In ID-mm WT-In WT-mm

Pipe ID

Thickness

Wall

Path

Length

Axial

Standard

Special

Frequency

Static Tw

Transducer

Configure

Off

Midradius

Other

Chord Input

TD

2.5 Menu Maps (cont.)

Figure 13: SENSOR SETUP Menu Map (Rev. 10)

22 PanaFlow™ XMT1000 User’s Manual

Page 35

2.5 Menu Maps (cont.)

SYSTEM

MAIN Board I/O

OPTION Boards

HART SENSOR SETUP CALIBRATION ADVANCED

Password

Operator/Admin

Type

Calibration

Points

Calibration

Config

Calibration

Run

Calibration

Table

Calibration

Factor

Calibration

Velocity

Composite

Off

Gate

Frequency

Number

Reynolds

Chapter 2. Programming

Figure 14: CALIBRATION Menu Map (Rev. 10)

PanaFlow™ XMT1000 User’s Manual 23

Page 36

Chapter 2. Programming

SYSTEM

MAIN Board I/O

OPTION Boards

SENSOR SETUP CALIBRATION ADVANCED

Password

Operator/Admin

Limits

Signal Setup

Active Tw

Transmit Volt

Error Log

Reset Settings

Flash Update

On

Off

Hi

Low

View Log

Reset Log

Commission

Reset to

Factory

Reset to

Update

Main Board

Limit

Corr Peak %

Velocity Low

Velocity High

Acceleration

Amp Disc Min

Amp Disc Max

Limit

Limit

Limit

Limit

Limit

HART

Ch 2 Ch 3Ch 1

Delta T Offset

% of Peak

Min Peak %

Max Peak %

Errors Allowed

2.5 Menu Maps (cont.)

Figure 15: ADVANCED Menu Map (Rev. 10)

24 PanaFlow™ XMT1000 User’s Manual

Page 37

Chapter 3. Error Codes and Troubleshooting

Chapter 3. Error Codes and Troubleshooting

3.1 Error Display in the User Interface

The bottom line of the LCD displays a single, top priority error message during Measurement Mode. This line, called

the Error Line, includes two parts: Error header and Error String. The Error header indicates the error pattern and error

number, while the Error string gives a detailed description of the error information

3.1.1 Error Header

Table 2: Error Header

Error Pattern Error Header

Communication error Cn (n is error number)

Flow error En (n is error number)

System error Sn (n is error number)

XMIT error Xn (n is error number)

OPT error On (n is error number)

3.1.2 Communication Error String

The XMT1000 flow transmitter electronics includes two independent sub-systems. The purpose of the Communication

error string is to convey to the operator an issue with communication between these two sub-systems.

Table 3: Communication Error String

Error Header Error Message

C1 Flow PCB Comm error

PanaFlow™ XMT1000 User’s Manual 25

Page 38

Chapter 3. Error Codes and Troubleshooting

3.1.3 Flow Error String

Flow errors are errors detected by the Flow PCB in the course of making a flow measurement. These errors can be

caused by disturbances in the fluid, such as excessive particles in the flow stream or extreme temperature gradients.

The errors could also be caused by an empty pipe or other such issue with the fluid itself. Flow errors are typically not

caused by a malfunction of the flow measurement device, but by an issue with the fluid itself.

Note: For troubleshooting tips, see “Diagnostics” on page 27.

Table 4: Flow Error String

Error Code Error Message Description

E1: SNR The Signal to Noise ratio is

low.

E2: Soundspeed The measured soundspeed

exceeds programmed limits.

The acoustic signal from the process is very low. This could

be due to bubbles, other fluid conditions, an empty pipe,

broken cables, transducers, couplant or buffers.

The error may be caused by incorrect programming, poor

flow conditions or poor transducer orientation. It may also

occur if signal quality is poor.

E3: Velocity Range The measured velocity exceeds

programmed limits.

E4: Signal Quality The signal quality is lower than

the programmed limits.

This error may be caused by incorrect programming, poor

flow conditions and/or excessive turbulence.

This means the signal shape, upstream to downstream

reciprocity, or signal correlation value has fallen below the

correlation peak limit. The cause is usually the same as E6 or

E5.

E5: Amplitude The signal amplitude exceeds

the programmed limits.

This error may occur due to high signal attenuation or

amplification due to changes in fluid properties, or

transducer/buffer/couplant issues.

E6: Cycle Skip A cycle skip is detected while

processing the signal for

measurement.

E15: Active Tw The Active Tw measurement is

invalid.

This is usually due to poor signal integrity, possibly because

of bubbles in the pipeline, sound absorption by very viscous

fluids, or cavitation.

A transducer or cable is damaged, or a transducer needs to

be re-coupled. This may also be due to incorrect

programming, or extreme process temperatures.

E22: Single Channel

Accuracy

One of the measurement

channels is in error.

One measurement channel is in error; accuracy of the

measurement may be compromised because the meter might

be using a sister chord substitution.

E23: Multi Channel

Accuracy

Two or more measurement

channels are in error.

Two or more measurement channels are in error; accuracy of

the measurement may be compromised because the meter is

using a sister chord substitution.

E28: Software Fault There is a software malfunction This is a software malfunction. Try power cycling the meter.

If the error persists after power cycle, contact GE factory.

E29: Velocity Warning The measured velocity exceeds

programmed warning limits.

E31: Not Calibrated The flow meter has not been

calibrated.

26 PanaFlow™ XMT1000 User’s Manual

This error may be caused by incorrect programming, poor

flow conditions and/or excessive turbulence.

The flow meter has not been calibrated and hence is not

making measurements.

Page 39

Chapter 3. Error Codes and Troubleshooting

3.2 Diagnostics

3.2.1 Introduction

This section explains how to troubleshoot the XMT1000 if problems arise with the electronics enclosure, the flowcell,

or the transducers. Indications of a possible problem include:

• Display of an error message on the LCD display screen, Vitality PC software, or HART.

• Erratic flow readings

• Readings of doubtful accuracy (i.e., readings which are not consistent with readings from another flow

measuring device connected to the same process).

If any of the above conditions occurs, proceed with the instructions presented in this section.

3.2.2 Flowcell Problems

If preliminary troubleshooting with the Error Code Messages and/or the Diagnostic Parameters indicates a possible

flowcell problem, proceed with this section. Usually, flowcell problems are either fluid problems or pipe problems.

Read the following sections carefully to determine if the problem is indeed related to the flowcell. If the instructions in

this section fail to resolve the problem, contact GE for assistance.

3.2.2a Fluid Problems

Most fluid-related problems result from a failure to observe the flow meter system installation instructions. Refer to

Chapter 1, Installation, to correct any installation problems.

If the physical installation of the system meets the recommended specifications, it is possible that the fluid itself may

be preventing accurate flow rate measurements. The fluid being measured must meet the following requirements:

• The fluid must be homogeneous, single-phase, relatively clean and flowing steadily. Although a low

level of entrained particles may have little effect on the operation of the XMT1000, excessive amounts of solid

or gas particles will absorb or disperse the ultrasound signals. This interference with the ultrasound

transmissions through the fluid will cause inaccurate flow rate measurements. In addition, temperature

gradients in the fluid flow may result in erratic or inaccurate flow rate readings.

• The fluid must not cavitate near the flowcell. Fluids with a high vapor pressure may cavitate near or in the

flowcell. This causes problems resulting from gas bubbles in the fluid. Cavitation can usually be controlled

through proper installation design.

• The fluid must not excessively attenuate ultrasound signals. Some fluids, particularly those that are very

viscous, readily absorb ultrasound energy. In such a case, an error code message will appear on the display

screen to indicate that the ultrasonic signal strength is insufficient for reliable measurements.

• The fluid sound speed must not vary excessively. The XMT1000 will tolerate relatively large changes in

the fluid sound speed, as may be caused by variations in fluid composition and/or temperature. However, such

changes must occur slowly. Rapid fluctuations in the fluid sound speed, to a value that is considerably above

the limit programmed into the XMT1000, will result in erratic or inaccurate flow rate readings. Refer to

Chapter 2, Programming, and make sure that the appropriate sound speed limit is programmed into the meter.

PanaFlow™ XMT1000 User’s Manual 27

Page 40

Chapter 3. Error Codes and Troubleshooting

3.2.2b Pipe Problems

Pipe-related problems may result either from a failure to observe the installation instructions, as described in

Chapter 1, Installation, or from improper programming of the meter (see Chapter 2, Programming, for details). By far,

the most common pipe problems are the following:

• The collection of material at the transducer location(s). Accumulated debris at the transducer location(s)

will interfere with transmission of the ultrasound signals. As a result, accurate flow rate measurements are not

possible. Realignment of the flowcell or transducers often cures such problems, and in some cases, transducers

that protrude into the flow stream may be used. Refer to Chapter 1, Installation, for more details on proper

installation practices.

• Inaccurate pipe measurements. The accuracy of the flow rate measurements is no better than the accuracy

of the programmed pipe dimensions. For a flowcell supplied by GE, the correct data will be included in the

documentation. For other flowcells, measure the pipe wall thickness and diameter with the same accuracy

desired in the flow rate readings. Also, check the pipe for dents, eccentricity, weld deformity, straightness and

other factors that may cause inaccurate readings. Refer to Chapter 2, Programming, for instructions on

programming the pipe data.

In addition to the actual pipe dimensions, the path length (P) and the axial dimension (L), based on the actual

transducer mounting locations, must be accurately programmed into the flow meter. For a GE flowcell, this

data will be included with the documentation for the system. If the transducers are mounted onto an existing

pipe, these dimensions must be precisely measured.

• The inside of the pipe or flowcell must be relatively clean. Excessive build up of scale, rust or debris will

interfere with flow measurement. Generally, a thin coating or a solid well-adhered build up on the pipe wall

will not cause problems. Loose scale and thick coatings (such as tar or oil) will interfere with ultrasound

transmission and may result in incorrect or unreliable measurements.

28 PanaFlow™ XMT1000 User’s Manual

Page 41

Chapter 3. Error Codes and Troubleshooting

3.2.3 Transducer/Buffer Problems

Ultrasonic transducers are rugged, reliable devices. However, they are subject to physical damage from mishandling

and chemical attack. The following list of potential problems is grouped according to transducer type. Contact GE if

you cannot solve a transducer-related problem.

• Leaks: Leaks may occur around the transducer buffers and/or the flowcell fittings. Repair such leaks

immediately. If the leaking fluid is corrosive, carefully check the transducer and cables for damage, after the

leak has been repaired.

• Corrosion Damage: If the transducer buffer material was not properly chosen for the intended application,

they may suffer corrosion damage. The damage usually occurs either at the electrical connector or on the face.

If corrosion is suspected, remove the transducer from the flowcell and carefully inspect the buffer electrical

connector and the transducer face for roughness and/or pitting. Any transducer damaged in this manner must

be replaced. Contact GE for information on transducers in materials suitable for the application.

• Internal Damage: An ultrasonic transducer consists of a ceramic crystal bonded to the transducer case. The

bond between the crystal and the case or the crystal itself may be damaged by extreme mechanical shock

and/or temperature extremes. Also, the internal wiring can be corroded or shorted if contaminants enter the

transducer housing.

• Physical Damage: Transducers may be physically damaged by dropping them onto a hard surface or striking

them against another object. The transducer connector is the most fragile part and is most subject to damage.

Minor damage may be repaired by carefully bending the connector back into shape. If the connector can not be

repaired, the transducer must be replaced.

IMPORTANT:Transducers must be replaced in pairs. Refer to Chapter 2, Programming, to enter the new transducer

data into the meter.

If the instructions in this section fail to resolve the problem, contact GE for assistance.

PanaFlow™ XMT1000 User’s Manual 29

Page 42

Chapter 3. Error Codes and Troubleshooting

[no content intended for this page]

30 PanaFlow™ XMT1000 User’s Manual

Page 43

Appendix A. Specifications

Appendix A. Specifications

A.1 Operation and Performance

Fluid Types

Acoustically conductive fluids, including most clean liquids, and many liquids with entrained solids or gas bubbles.

Maximum void fraction depends on transducer, interrogation carrier frequency, path length and pipe configuration.

Transducer Types

All liquid wetted transducers

Pipe Sizes

Standard: 1 in. to 76 in. (25 mm to 1930 mm)

Optional: >76 in. (1930 mm) consult factory

Data Logging

Storage standard on meter, up to 10,000 flow data points with up to 26 parameters per data point

(requires Vitality™ software)

Measurement Parameters

Volumetric Flow, Mass Flow, Flow Velocity and Totalized Flow

Flow Accuracy (Velocity)

Up to ±0.3% of reading (achievable when supplied with a complete flow meter system and process calibration).

Accuracy depends on pipe size, installation and number of measurement paths.

Note: The accuracy statement assumes measurement of a single phase homogeneous liquid with a fully developed

symmetrical flow profile passing through the meter. Applications with piping arrangements that create an

asymmetrical flow profile may require extended piping straight runs and/or flow conditioning for the meter to

perform to this specification.

Repeatability

±0.1% to 0.3% of reading

Range (Bidirectional)

–40 to 40 ft/s (–12.2 to 12.2 m/s)

Meter Turndown

400:1

Optional PC Software

Vitality™ PC software for added functionality

PanaFlow™ XMT1000 User’s Manual 31

Page 44

Appendix A. Specifications

A.2 Electronics

Enclosure

Standard: Epoxy-coated aluminum weatherproof 4X/IP66

Class I, Div 1, Groups B, C & D, Flameproof II 2 G Ex d IIC T5/T6

Optional: Stainless steel

Dimensions (Standard)

We ig ht : 10 lb (4.5 kg)

Size (h x d): 8.2 in. x 6.6 in. (208 mm x 168 mm)

Paths

1, 2 or 3 paths

Display

128 x 64 mono-color LCD display, configurable for single or dual measurement parameters

Display Languages

English

Keypad

Built-in magnetic, six-button keypad, for full functionality operation

Inputs/Outputs

Standard: one analog output**, one digital output*, service/Modbus (RS485)

Optional: one analog output** with HART

*Digital outputs are programmable as either pulse or frequency outputs

**Analog outputs are NAMUR NE43 compliant

Power Supplies

Standard: 100-240 VAC (50/60 Hz)

Optional: 12 to 28 VDC

Power Consumption

15 Watts maximum

Wiring Connection

Conduit entries include 6 x 3/4” NPT and 1 x 1/2” NPT on bottom, consult GE for available adapters

32 PanaFlow™ XMT1000 User’s Manual

Page 45

Appendix A. Specifications

A.2 Electronics (cont.)

Electronics Classifications (Pending)

USA/Canada- Explosion-proof Class I, Division 1, Groups B, C, & D

ATEX - Flameproof II 2 G Ex d IIC T6 Gb

IECEx - Flameproof Ex d IIC T6 Gb

RoHS compliance (Directive 2011/65/EU)

CE Marking (EMC directive 2014/30/EU, LVD 2014/35/EU)

WEEE compliance (Directive 2012/19/EU)

Electronics Mounting

Standard: Local Mounting (on meter body)

Optional: Remote Mounting (recommended for process temperatures exceeding 150°C). The maximum distance is

1000 ft (300 m) using RG-62 coaxial cable or equivalent. If longer distances are required, consult the factory for

assistance.

Terminal Blocks

Table 5: Standard Terminal Block (Output A)

I/O Type Connection Specifications

Analog Output Active Output Output current: 0-22 mA

Max load: 600 Ω

Pulse, Frequency Active Output Output voltage: 5 VDC

Max. voltage with light load: 7 VDC

RS485 Modbus RS485

Communications

Standard RS485 Communications

Operating Temperature

–40° to 140°F (–40° to +60°C)

Note: The LCD display is only visible down to -13°F (-25°C).

Storage Temperature

–40° to 158°F (–40° to 70°C)

Humidity (Operating and Storage)

10-90% RH

PanaFlow™ XMT1000 User’s Manual 33

Page 46

[no content intended for this page]

34 PanaFlow™ XMT1000 User’s Manual

Page 47

Appendix B. Modbus Communication

Appendix B. Modbus Communication

B.1 Modbus Protocol

In general, the PanaFlow XMT1000 flow meter follows the standard Modbus communications protocol defined by the

reference MODBUS APPLICATION PROTOCOL SPECIFICATION V1.1b. This specification is available at

www.modbus.org

communicate with the flow meter.

Listed below are two limits of this implementation:

• The PanaFlow XMT1000 supports only four of the standard function codes. These are Read Holding Registers

(0x03), Read Input Registers (0x04), Write Multiple Registers (0x10), and Read File Record (0x14).

and

• The flow meter needs a 15 msec gap between Modbus requests. The prime objective of the flow meter is to

measure flow, so the Modbus server has a low priority.

B.2 Modbus Register Map

on the Internet. With this reference as a guide, an operator could use any Modbus master to

Table 6: XMT1000 Modbus Register Map - Revision 4.19

Reg #

in Hex

Health Check + Identification (Input Registers)

210 210 NONE Product Type unitless RO 4 INT32

System Real RW

400

System Int RW

500 500 Operator eUnit_ActVol Global Unit group 1 for

502 Operator eUnit_Day Global Unit group 2 for

504 Operator eUnit_Db Global Unit group 3 for

506 Operator eUnit_Dens Global Unit group 4 for

508 Operator eUnit_Diam Global Unit group 5 for

50A Operator eUnit_Hz Global Unit group 6 for

50C Operator eUnit_Kv Global Unit group 7 for

50E Operator eUnit_mA Global Unit group 8 for

510 Operator eUnit_Mass Global Unit group 9 for

512 Operator eUnit_MS Global Unit group 10 for

Access

Level

Register ID Description Units RO/RW

unitless RW 4 INT32

Actual Volumetric

unitless RW 4 INT32

Day

unitless RW 4 INT32

dB

unitless RW 4 INT32

Density

unitless RW 4 INT32

Dimension

unitless RW 4 INT32

Hz

unitless RW 4 INT32

Viscosity

unitless RW 4 INT32

mA

unitless RW 4 INT32

Mass

unitless RW 4 INT32

Milli Second

Size in

Bytes

Format

PanaFlow™ XMT1000 User’s Manual 35

Page 48

Appendix B. Modbus Communication

Table 6: XMT1000 Modbus Register Map - Revision 4.19 (cont.)

Reg #

in Hex

514 Operator eUnit_NS Global Unit group 11 for

Access

Level

Register ID Description Units RO/RW

unitless RW 4 INT32

Size in

Bytes

Format

Nano Second

516 Operator eUnit_Percent Global Unit group 12 for

unitless RW 4 INT32

Percent

518 Operator eUnit_Second Global Unit group 13 for

unitless RW 4 INT32

Second

51A Operator eUnit_StdVol Global Unit group 14 for

unitless RW 4 INT32

Standard Volumetric

51C Operator eUnit_Therm Global Unit group 15 for

unitless RW 4 INT32

Therm

51E Viewer eUnit_TotTime Global Unit group 16 for

unitless RW 4 INT32

Totalizer time

520 Operator eUnit_Totalizer Global Unit group 17 for

unitless RW 4 INT32

Totalizer

522 Operator eUnit_Unitless Global Unit group 18 for

unitless RW 4 INT32

Unitless

524 Operator eUnit_US Global Unit group 19 for

unitless RW 4 INT32

Micro Second

526 Operator eUnit_Vel Global Unit group 20 for

unitless RW 4 INT32

Velocity

528 Operator eUnit_Rey Global Unit group 21 for

unitless RW 4 INT32

Reynolds

52A Gen User eUnit_Temp Global Unit group 22 for

unitless RW 4 INT32

Temperature

52C Gen User eUnit_Pressure Global Unit group 23 for

unitless RW 4 INT32

Pressure

540 540 Viewer eSysReq_Level system request level unitless RW 4 INT32

542 Viewer eSysReq_

system request password unitless RW 4 INT32

Password

544 Viewer eSysReq_

system request command unitless RW 4 INT32

Command

546 Factory eInventory_

Command

580 580 Operator ePCModbus_

inventory request

unitless RW 4 INT32

command

PC MODBUS baud rate unitless RW 4 INT32

Baudrate

582 Operator ePCModbus_

PC MODBUS parity unitless RW 4 INT32

Parity

584 Operator ePCModbus_

PC MODBUS stop bits unitless RW 4 INT32

Stop

586 Operator ePCModbus_

PC MODBUS meter addr unitless RW 4 INT32

Address

588 Operator ePCModbus_

Bits

58A Operator ePCModbus_

PC MODBUS bits per

unitless RW 4 INT32

character

PC MODBUS termination unitless RW 4 INT32

Termination

36 PanaFlow™ XMT1000 User’s Manual

Page 49

Table 6: XMT1000 Modbus Register Map - Revision 4.19 (cont.)

Reg #

in Hex

Access

Level

Register ID Description Units RO/RW

5C0 5C0 Operator eSystem_

TagShort