Page 1

PanaFlow™ XMT1000

Panametrics Liquid Flow

Ultrasonic Transmitter

The XMT1000 is a new, cost-eective ultrasonic ow

transmitter that builds on Panametrics ow expertise

and on years of reliable performance from its XMT868i

predecessor. It oers state-of-the-art ow measurement

capability in a rugged, locally-mounted or remote-

mounted transmitter certied for use in hazardous

areas. It brings a new level of performance with improved

accuracy, congurable inputs and outputs, and multiple

ultrasonic transducer path options.

Liquid Flow Measurements for a

Wide Range of Applications

• Hydrocarbon liquids • Water & wastewater

• Crude oil • Distilled water

• Lubricating oil • Hot/chilled water

• Diesel fuel oil • Chemicals

• Solvents • Beverages

• Liquied natural gas (LNG)

Non-Intrusive, Reliable, and Accurate

Flow Measurement

The PanaFlow XMT1000 comes from a long line of

proven ultrasonic ow meters from Panametrics.

It shares all the advantages of ultrasonic ow

measurment: no moving parts to wear, no lters

or strainers, no maintenance requirement, no

pressure drop, and no drifting or required periodic

calibration.

Its on-board digital signal processor (DSP) provides

proprietary digital signal coding and correlation

detection routines, automatic adjustment to

changing uid properties, and dynamicallycongured operating software to simplify

programming.

The XMT1000 oers:

• Improved accuracy of 0.3% of reading

• One, two or three-channel operation

• Four congurable inputs/outputs for analog or

digital communication

• Suitability for a wide range of pipe sizes and

materials

Panameterics.com

Page 2

Improved Programming Capability

PanaFlow XMT1000 Flow

The XMT1000 introduces a magnetic six-button keypad

to allow safe programming and diagnostics verication

in your hazardous (classied) location. There is no need

to open the case to use a PC to program, eliminating

the cost and time associated with obtaining hot work

permits, and there is no need for an additional handheld

programmer. Just touch the glass of the XMT1000 with

the magnetic wand to change any parameter setting.

If you prefer your PC interface, the PanaFlow XMT1000

comes standard with MODBUS RS485 connectivity,

providing full access to the meter’s diagnostics and

programming using Vitality™ software. Vitality also

provides continuous logging capability of up to 10,000

points with 26 parameters logged per point.

Multi-Channel, Multi-Path Options

Reduce Costs and Improve

Performance

The XMT1000 may be congured as a one-channel,

two-channel or three-channel meter for measurement

exibility. It also oers one, two or three ultrasonic

transducer paths. A single path can provide cost

eective ow measurement while multiple paths

improve ow measurement accuracy and repeatability

and add redundancy.

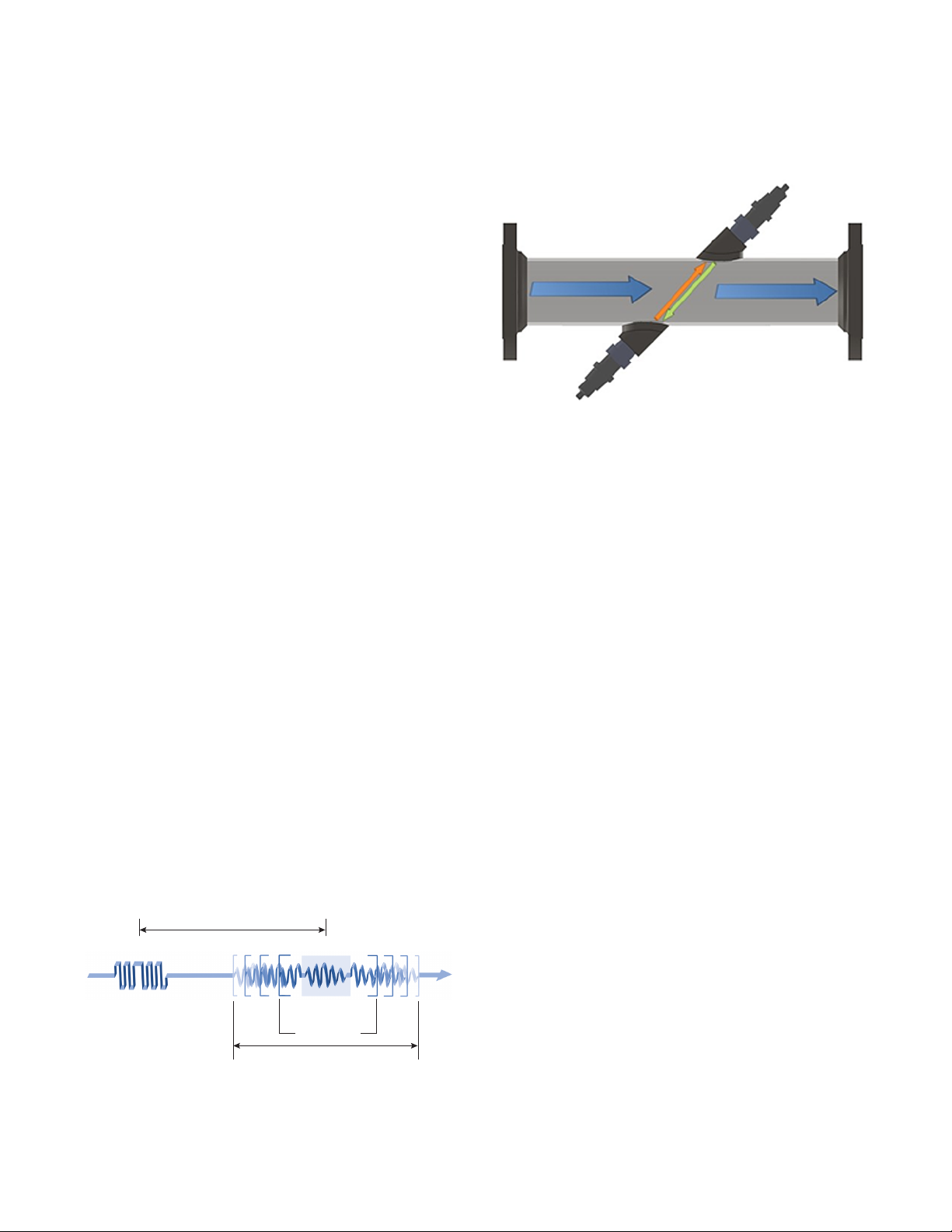

Automatically Adjusts to Changing

Fluid Properties

Standard in all PanaFlow XMT1000 transmitters, our

unique Automatic Tracking Window™ (ATW™) feature

ensures accurate ow measurements even when uid

properties are unknown or changing. ATW dynamically

sweeps the receiver window whenever the sound speed

of the uid changes. This powerful feature lets you

measure ow when the uid sound speed is unknown, or

is changing.

Variable Time Interval

Transmit Signal Receive Signal

ATW ensures accuracy when

fluid conditions change.

Tracking Window

Locked onto

Receive Signal

Range of Tracking Window

Time

Transmitter Uses Transit-Time Flow

Measurement Technique

Downstream Wetted

Transducer

Upstream Wetted

Transducer

The transit time ow measurement method utilizes two

transducers to serve as both ultrasonic signal generators

and receivers. When mounted on a pipe, they are in

acoustic communication with each other. In operation,

each transducer functions as a transmitter, generating a

certain number of acoustic pulses, and then as a receiver

for an identical number of pulses. The time interval

between transmission and reception of the ultrasonic

signals is measured in both directions. When the liquid

in the pipe is not owing, the transit-time downstream

equals the transit-time upstream. When the liquid is

owing, the transit-time downstream is less than the

transit-time upstream.

The dierence between the downstream and upstream

transit times is proportional to the velocity of the owing

liquid, and its sign indicates the direction of ow.

Wetted Transducers

The XMT1000 can be used with a variety of wetted

systems including the PanaFlow system. The PanaFlow

system oers a fully integrated ow meter solution

that includes the XMT1000 electronics, ow cell, and

transducers, which simplies installation.

The PanaFlow XMT1000 can be used with other

PanaFlow systems or may be congured as a custom

meter solution with wetted transducers to meet specic

application needs.

Page 3

XMT1000 Specications

Operation and Performance

Fluid Types

Acoustically conductive uids, including most clean

liquids, and many liquids with entrained solids or gas

bubbles. Maximum void fraction depends on transducer,

interrogation carrier frequency, path length and pipe

conguration.

Transducer Types

All liquid wetted transducers

Pipe Sizes

Standard: 1 in. to 76 in. (25 mm to 1930 mm)

Optional: >76 in. (1930 mm), consult factory

Data Logging

Storage standard on meter, up to 10,000 ow data

points with up to 26 parameters per data point

Measurement Parameters

Volumetric Flow, Mass Flow, Flow Velocity and

Totalized Flow

Flow Accuracy (Velocity)

Up to ±0.3% of reading (achievable when supplied with

a complete ow meter system and process calibration).

Accuracy depends on pipe size, installation and number

of measurement paths.

The accuracy statement assumes measurement of a

single phase homogeneous liquid with a fully developed

symmetrical ow prole passing through the meter.

Applications with piping arrangements that create an

asymmetrical ow prole may require extended piping

straight runs and/or ow conditioning for the meter to

perform to this specication.

Repeatability

±0.1% to 0.3% of reading

Range (Bidirectional)

–40 to 40 ft/s (–12.2 to 12.2 m/s)

Electronics

Enclosure

Epoxy-coated aluminum or stainless steel

Dimensions (Standard)

• Weight: 10 lb (4.5 kg)

• Size (D x H x W): 8.40 in. x 6.42 in. x 5.87 in.

(213.4 mm x 163.1 mm x 149.1 mm)

Channels

One, two or three-channel options

Display

128 x 64 mono-color LCD display, congurable for

single or dual measurement parameters

Keypad

Built-in magnetic, six-button, lockable keypad

Standard Inputs/Outputs

• One 4 to 20 mA isolated output, 600 Ω maximum load

• One additional output, may be congured as either a

pulse or frequency output.

Digital Interfaces

Standard: RS485/Modbus®

Optional: HART® 7.0 protocol, with 4 dynamic variables,

includes one additional 4 to 20 mA analog output

Optional: Foundation Fieldbus® FISCO, LAS capable with

5 AI blocks and a PID block

Power Supplies

Universal 100-240 VAC 50/60 Hz ±10% or 12 to 28 VDC

Power Consumption

15W maximum, Typically <7W

Inrush current: 25 A maximum @ 100 µs

15 A maximum @ 1 ms

Temperature Range

Operating: -40°F to 140°F (-40°C to +60°C)

Storage: –67°F to 167°F (–55°C to 75°C)

Meter Turndown

400:1

Optional PC Software

Vitality™ PC Software for added functionality

Certications

• US/CAN: Class I, Division 1, Groups B, C, D;

Class I, Zone 1, Ex d IIC T6;

Class I, Division 2, Groups A, B, C, D;

Class I, Zone 2, Ex nA IIC

• ATEX/IECEx: Ex d IIC T6 FISCO outputs (pending)

Ta = -40°C to +60°C, Type 4X

Page 4

PanaFlow XMT1000 Part Number

XMT1000 - B - C - D - E - F - G - H - I - Z (Description)

Model:

1

2

3

4

AC

DC

0

1

AL

SS

00

1

2

0

1

2

0

XMT1000 Liquid Ultrasonic Flow Meter

Paths:

Single path with MCX connectors

Two or three path with MCX connectors

Single path with ying leads

Dual path with ying leads

Power:

100-20 VAC power supply

12-28 VDC power supply

Conformal Coating:

No conformal coating

Conformal coating

Enclosure:

Powder coated aluminum enclosure

316/316L stainless steel enclosure

Input/Output:

4 to 20 mA isolated output, one additional output (pulse or frequency output)

Certications:

US/Canada Class I, Division 1, Group B, C, D T6 Ta = -40°C to +60°C

Type 4X/IP66 hazardous locations installations

IECEx/ATEX Exd IIc T6 Gb IP66 Ta = -40°C to +60°C

hazardous locations installations

Digital Communications:

Standard: RS485/Modbus

HART communication with four dynamic variables

Foundation Fieldbus

Frequency:

Standard frequency

Specials:

0

No special

S

Special

XMT1000 - 2 - AC - 0 - SS - 00 - 1 - 2 - 0 - 0 (example part number string)

Copyright 2019 Baker Hughes, a GE company, LLC (“BHGE”).

Panametrics and logo are registered trademarks of BHGE in the

United States and other countries. All product and company

names are trademarks of their respective holders.

920-668B

Loading...

Loading...