Page 1

GE

Sensing & Inspection Technologies

VeriDri

TM

Moisture Transmitter

User’s Manual

Page 2

GE

Sensing & Inspection Technologies

VeriDri

TM

Moisture Transmitter

User’s Manual

916-095B

January 2009

Page 3

January 2009

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Sample System Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Inserting the Transmitter in the Sample System/Process. . . . . 4

Making Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Operating the Transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Powering Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Error Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cleaning the Transmitter Probe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Removing the Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Soaking the Sensor and Shield. . . . . . . . . . . . . . . . . . . . . . . . 11

Evaluating the Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Moisture Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Operating Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Storage Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Warm-up Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Calibrated Accuracy @ 77°F (25°C) . . . . . . . . . . . . . . . . . . . . 14

Repeatability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Response Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Electronics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Moisture Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

iii

Page 4

January 2009

Introduction

The GE Sensing & Inspection Technologies VeriDriTM is a lowcost, loop-powered transmitter that provides accurate dew/frost

point measurements covering an overall range of –110

o

(-166

to 104oF). It can also be provided to cover a number of

moisture ranges from 0 to 10,000 PPMv.

The VeriDri is supplied with one 4 to 20 mA analog output that is

factory-configured for a specified range.

The VeriDri is easy to install, operate and maintain. This manual

contains the following sections:

o

to 40°C

• Sample System Guidelines

• Inserting the Transmitter in the Sample System/Process

• Making Wiring Connections

• Operating the Transmitter

• Cleaning the Transmitter Probe

• Specifications

VeriDri Moisture Transmitter 1

Page 5

January 2009

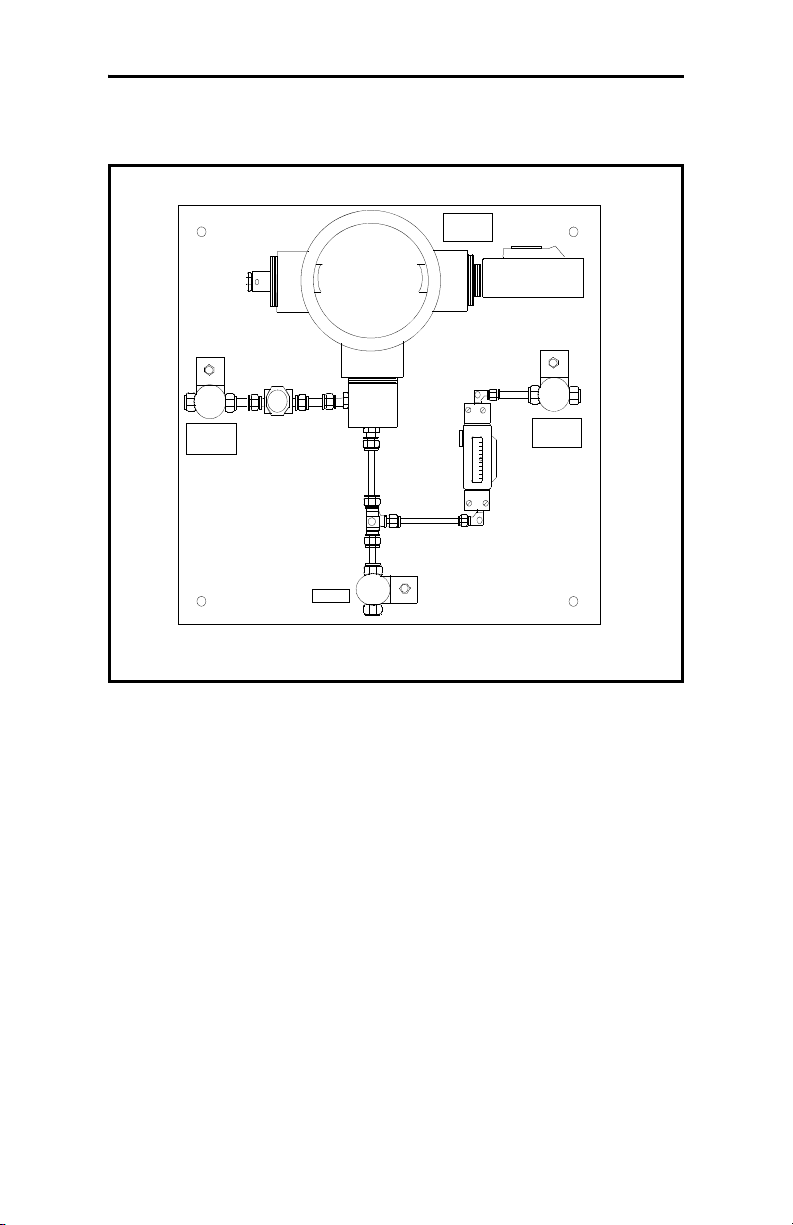

Sample System Guidelines

You can install the VeriDri transmitter into a sample system or

directly into the process. GE recommends that the unit be

installed in a sample system to protect the probe from coming

into contact with damaging elements in the process.

Before constructing a sample system, you should consult a GE

Applications Engineer and adhere to the guidelines below. See

Figure 1 on the next page for an example of a sample system.

• Consult Specifications on page 13 for dimensions and other

requirements.

• Sample systems should be kept very simple.

• The transmitter should be installed so it is perpendicular to

the sample inlet.

• The sample system should contain as few components as

possible and all or most of those components should be

located downstream of the measurement location.

• If possible, you should use stainless steel material for all

wetted parts.

• Sample system components should not be made of any

material that will affect measurement. Most common filters

and pressure regulators are not suitable for sample systems

because they have wetted parts that may absorb or release

components (such as moisture) into the sample system.

They may also allow ambient contamination to enter the

sample system.

2 VeriDri Moisture Transmitter

Page 6

Sample System Guidelines (cont.)

Sample

Cell

January 2009

Sample

Inlet

Vent

Figure 1: Example of a Sample System

Sample

Outlet

VeriDri Moisture Transmitter 3

Page 7

January 2009

Inserting the Transmitter in the Sample System/Process

!CAUTION!

If you are mounting the VeriDri directly into

the process line, you must consult the factory

for proper installation instructions and precautions

before beginning the following procedure.

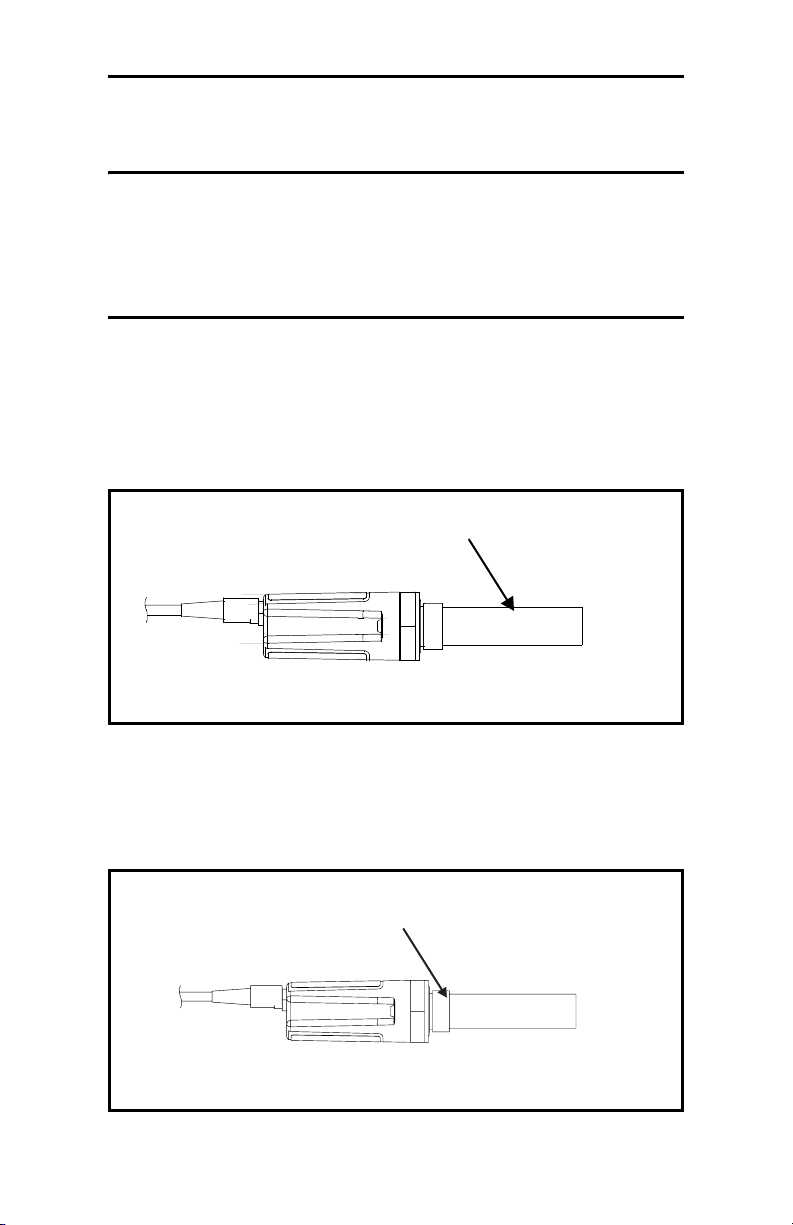

Use the steps below to install the VeriDri:

1. Make sure the sintered or sheet stainless-steel shield is in

place. The shield protects the aluminum oxide sensor from

damaging elements in the process.

Shield

2. The probe is mounted into the process via the 3/4-16 straight

male thread located on the probe. Thread the probe end of the

transmitter into the process/sample system fitting. Make sure

not to cross thread it.

3/4-16 UNF-2A

4 VeriDri Moisture Transmitter

Page 8

January 2009

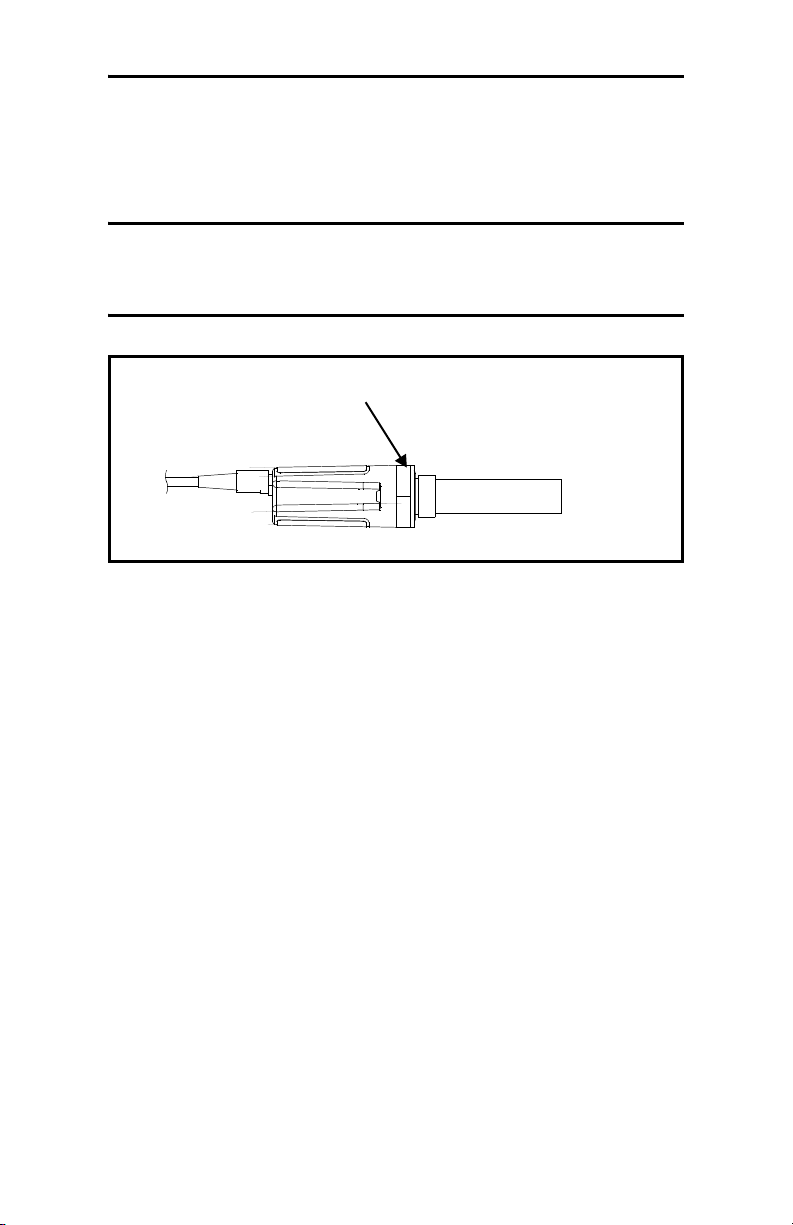

Inserting the Transmitter in the Sample

System/Process (cont.)

3. Using a 1-1/8 in. wrench, tighten the probe securely into the

process using the probe hex nut.

!CAUTION!

Do not apply force to the transmitter

module to tighten the unit into its fitting.

Probe Hex Nut

VeriDri Moisture Transmitter 5

Page 9

January 2009

Making Wiring Connections

You must wire the transmitter using the factory-supplied cable

which is available in a variety of lengths.

Note: If you need to lengthen cables, refer to Table 1 below to

splice an extension onto the existing cable. Connect

positive to positive and negative to negative.

Use the following steps to wire the transmitter to your system.

1. Push the female connector end on the transmitter cable into

the mating male connector on the transmitter module. Make

sure the pins are properly aligned. Once inserted, secure the

connectors together by sliding the metal sleeve on the cable

over the connectors and turning it clockwise until it is tight.

2. Using the flying leads at the other end of the transmitt er cable,

connect the transmitter to your power supply and data

acquisition system (DAS) as shown in Figure 2 on the next

page. Refer to Table 1 below for a description of the leads in

the factory-supplied cable.

Table 1: Cable Lead Descriptions

Lead Color* Connection Description

Blue (+) 7 to 28 VDC

Brown (−) 7 to 28 VDC

Connect the shield to ground if desired.

*The blue and brown leads also produce a current output

equivalent to 4 to 20 mA.

3. Trim any unused leads back to the outer cable jacket in order

to remove the bare tinned wire and prevent accidental short

circuits.

The VeriDri is now ready for operation.

6 VeriDri Moisture Transmitter

Page 10

Making Wiring Connections (cont.)

January 2009

Note: The blue and brown leads also generate a

current output equivalent to 4 to 20 mA.

+

7-28 VDC

Power and

Blue

Brown

7-28 VDC

−

Circuits

Measurement

Figure 2: Wiring Connections

VeriDri Moisture Transmitter 7

Page 11

January 2009

Operating the Transmitter

After proper installation, the VeriDri Transmit ter is very easy to

use; simply power the unit up and you are ready to begin taking

measurements. Since the VeriDri stores moisture calibration data

in non-volatile FLASH memory, you do not have to enter data

manually or worry about losing data during a power loss.

Probes may need to be cleaned occasionally depending on the

application. Consult a GE Applications Engineer for required

cleaning intervals.

If a problem should arise with the probe, see Error Handling

below for how the transmitter reacts to error conditions.

!CAUTION!

Any attempt to open the module or remove

the sensor probe will void the warranty.

Powering Up

After the VeriDri is wired as described in the previous section,

you may apply power to the unit. The transmitter takes

approximately 20 seconds to initialize and begin normal

operation. The unit will meet specified accuracy in 3 minutes.

Error Handling

In the event of an error condition, the analog output reading is

forced to the following values:

• ≥ 22 mA to indicate a shorted probe

• ≤ 3.5 mA to indicate an open probe

8 VeriDri Moisture Transmitter

Page 12

January 2009

Cleaning the Transmitter Probe

!CAUTION!

Be sure to perform the probe cleaning procedure in a

well ventilated area. Observe all necessary safety

precautions when handling cleaning solvents

To clean the moisture probe, you will need the following:

• Three glass (NOT metal) containers containing the

following solvents:

• 2 containers of approximately 300 ml of reagent-grade

hexane or toluene each.

• 1 container of approximately 300 ml of distilled (NOT

deionized) water.

IMPORTANT: Make sure the containers are deep enough to

submerge the pr obe. Do not place the transmitter

module into the solvents. You should only insert

the sensor portion of the transmitter into the

solvents.

• Rubber or latex gloves.

• Oven set at 50°C ± 2°C (122°F ± 3.6°F) for drying probe.

• 1-1/8 in. wrench

Use the sections that follow to properly clean the probe.

VeriDri Moisture Transmitter 9

Page 13

January 2009

Removing the Transmitter

Use the following steps to remove the transmitter from the

installation site:

Note: Once the probe is cleaned, it must dry in the oven for 24

hours.

1. Using a 1-1/8 in. wrench, unthread the transmitter from the

fitting on the sample system/process using the probe hex nut

as shown below.

Probe Hex Nut

2. Record the dew point of the ambient air.

3. Disconnect the cable from the module.

4. Unscrew the stainless-steel shield from the probe mount and

carefully remove it without touching the sensor.

!CAUTION!

Any attempt to open the module or remove

the probe from the module will void the warranty.

Shield

10 VeriDri Moisture Transmitter

Page 14

January 2009

Soaking the Sensor and Shield

!CAUTION!

Do not place the transmitter module into the solvents.

You should only insert the sensor portion of the

transmitter into the solvents. Also, do not allow the

sensor to come into contact with the surfaces of the

cleaning containers or any other hard surface.

1. Wearing gloves, place the sensor in the first container of

hexane or toluene and allow it to soak for 10 minutes.

2. Remove the sensor from the hexane or toluene and soak it in

the container of distilled water for 10 minutes.

3. Remove the sensor from the distilled water and soak it in the

second (clean) container of hexane or toluene for 10 minutes.

4. Remove the sensor from the hexane or toluene and set it aside

until the shield has completed the cleaning cycle.

5. Repeat steps 1 to 3, above, to clean the shield. To ensure the

removal of any contaminants that may have become

embedded in the porous walls of the shield, swirl the shield in

the solvents during the soaking procedure.

6. Remove the shield from the hexane or toluene.

7. Carefully replace the shield over the exposed sensor without

touching it.

8. Place the sensor with the shield in an oven set at 50°C ± 2°C

(122°F ± 3.6°F) for 24 hours.

VeriDri Moisture Transmitter 11

Page 15

January 2009

Evaluating the Probe

1. Re-connect the cable to the transmitter module and measure

the dew point. Make sure you measure the same ambient air as

measured in step 2 on page 10.

2. Compare the two ambient air readings. If the new ambient air

reading is within ±2°C (±3.6°F) of the first reading, the

cleaned probe is properly calibrated and may be reinstalled. If

it is not, proceed to step 3 below.

3. If the probe is still not reading the ambient air accurately,

repeat the cleaning procedure using soaking times that are 5

times the previous cleaning sequence, until two consecutive

ambient air readings are identical.

If the above cleaning procedure does not result in accurate

readings, contact the factory for assistance.

12 VeriDri Moisture Transmitter

Page 16

Specifications

Moisture Ranges

January 2009

• –110

• –110

o

to 20°C

o

to –50°C

• –90°C to 10°C

• –80°C to –30°C

• –80° to 20°C

o

• –30

• –130

• –130

• –40

• –50

to 20°C

o

to 70°F

o

to –40°F

o

to 70°F

o

to 50°F

• -100° to 0°F

• 0 to 10 PPMv

• 0 to 100 PPMv

• 0 to 1000 PPMv

• 0 to 10,000 PPMv

Note: PPMv ranges based on constant pressure, provided at

time of order placement.

Operating Temperature

–40° to 60°C (–40° to 140°F)

Storage Temperature

70°C (158oF) maximum. The probe should be stored with the

plastic cover and desiccant packet threaded onto the probe. Store

in a cool, dry environment.

VeriDri Moisture Transmitter 13

Page 17

January 2009

Warm-up Time

Meets specified accuracy in 3 minutes

Calibrated Accuracy @ 77°F (25°C)

• ±3.6°F (±2°C) from -85°F to 50°F (-65°C to 10°C) dew/frost

point

• ±5.4°F (±3°C) from -112°F to -86°F (-80°C to -66°C) dew/

frost point

Repeatability

• ±0.9°F (±0.5°C) from -85°F to 50°F (-65°C to 10°C) dew/frost

point

• ±1.8°F (±1.0°C) from -112°F to -86°F (-80°C to -66°C) dew/

frost point

Response Time

Less than 5 seconds for 63% of a step change in moisture content

in either wet-up or dry-down cycle

Electronics

Power

• Supply voltage: 7 to 28 VDC (loop-powered, customer

supplied)

• Output: 4 to 20 mA

• Output Resolution: 0.01 mA

• Max. Loop R = 50 Ω × (PSV–7),

where PSV = Power Supply Voltage

Example: Given a 24 VDC Power Supply,

Max. Loop R = 50 Ω × (24–7)

= 850 Ω

• Cable: 2 m (6 ft.) standard (consult factory for custom lengths)

14 VeriDri Moisture Transmitter

Page 18

Mechanical

Sample Connection

• 3/4 in. (16 mm) 16 straight male thread with O-ring

• G 1/2 in with optional adapter

Operating Pressure

µHg to 5,000 psig (345 bar)

5

Enclosure

Type 4X/IP67

European Compliance

Complies with the following:

• EMC Directive 2004/108/EC and PED 97/23/EC for

DN<25

• EN 61326:1998

Class A, Annex A, Continuous Unmonitored Operation

(For EN 61000-4-3 transmitter meets performance criteria

A and in a number of frequencies, criteria B per EN 61326)

Dimensions

January 2009

• Overall: 6.76 × 1.13 in. (17.17 × 2.87 cm)

• Electronics with cable: 4.08 × 1.13 in. diameter

(10.36 × 2.87 cm)

• Weight: 5 oz (140 grams)

VeriDri Moisture Transmitter 15

Page 19

January 2009

Moisture Sensor

Sensor Type

Thin-film aluminum oxide moisture sensor probe

Calibration

Each sensor is individually computer-calibrated against known

moisture concentrations, traceable to NIST

Calibration Interval

Sensor recalibration at GE Sensing is recommended every six to

12 months depending on application

Calibration Data

Factory-calibrated, stored in FLASH

Flow Rate

• Gases: Static to 10,000-cm/s linear velocity at a pressure of 1

atm.

• Liquids: Static to 10-cm/s linear velocity at density of

1 g/cc

16 VeriDri Moisture Transmitter

Page 20

January 2009

Warranty

Each instrument manufactured by GE Sensing, Inc. is

warranted to be free from defects in material and

workmanship. Liability under this warranty is limited to

restoring the instrument to normal operation or replacing the

instrument, at the sole discretion of GE Sensing, Inc. Fuses and

batteries are specifically excluded from any liability. This

warranty is effective from the date of delivery to the original

purchaser. If GE Sensing, Inc. determines that the equipment

was defective, the warranty period is:

• one year from delivery for electronic or mechanical failures

• one year from delivery for sensor shelf life

If GE Sensing, Inc. determines that the equipment was

damaged by misuse, improper installation, the use of

unauthorized replacement parts, or operating conditions

outside the guidelines specified by GE Sensing, Inc., the repairs

are not covered under this warranty.

The warranties set forth herein are exclusive and are in lieu

of all other warranties whether statutory, express or

implied (including warranties or merchantability and fitness

for a particular purpose, and warranties arising from course

of dealing or usage or trade).

Page 21

January 2009

Return Policy

If a GE Sensing, Inc. instrument malfunctions within the

warranty period, the following procedure must be completed:

1. Notify GE Sensing, Inc., giving full details of the problem,

and provide the model number and serial number of the

instrument. If the nature of the problem indicates the need

for factory service, GE Sensing, Inc. will issue a RETURN

AUTHORIZATION NUMBER (RAN), and shipping instructions

for the return of the instrument to a service center will be

provided.

2. If GE Sensing, Inc. instructs you to send your instrument to a

service center, it must be shipped prepaid to the authorized

repair station indicated in the shipping instructions.

3. Upon receipt, GE Sensing, Inc. will evaluate the instrument

to determine the cause of the malfunction.

Then, one of the following courses of action will then be taken:

• If the damage is covered under the terms of the warranty,

the instrument will be repaired at no cost to the owner and

returned.

• If GE Sensing, Inc. determines that the damage is not

covered under the terms of the warranty, or if the warranty

has expired, an estimate for the cost of the repairs at

standard rates will be provided. Upon receipt of the owner’s

approval to proceed, the instrument will be repaired and

returned.

Page 22

GE

Sensing

DECLARATION

OF

CONFORMITY

We, GE Sensing

declare under our sole responsibility that the

to which this declaration relates, is in conformity with the following standards:

• EN 61326:1998, Class A, Annex A, Continuous Unmonitored Operation

(For EN 61000-4-3, the above units meet performance Criteria A, and in a limited

number of frequencies, performance Criteria B per EN 61326.)

• EN 60529:1991+A1:2000

IP67

following the provisions of the 2004/108/EC EMC Directive.

The units listed above and any ancillary sample handling systems supplied with them do

not bear CE marking for the Pressure Equipment Directive, as they are supplied in

accordance with Article 3, Section 3 (sound engineering practices and codes of good

workmanship) of the Pressure Equipment Directive 97/23/EC for DN<25.

January 8, 2009

Date of Issue

1100 Technology Park Drive

Billerica, MA 01821

USA

VeriDri™ Moisture Transmitter

Mr. Gary Kozinski

Certification & Standards, Lead Engineer

CERT-DOC-H1 (August 2004)

Page 23

GE

Sensing

DECLARATION

DE

CONFORMITE

Nous, GE Sensing

déclarons comme étant de notre seule responsabilité que le

sur lequel porte ce document, est conforme aux spécifications suivantes :

• EN 61326:1998, Classe A, Annexe A, Fonctionnement continu sans surveillance

(Pour EN 61000-4-3, les appareils ci-dessus sont conformes au critère A de performance

et, dans un nombre limité de fréquences, au critère B de performance, selon EN 61326.)

• EN 60529:1991+A1:2000

IP67

conformément aux dispositions de la directive 2004/108/EC (compatibilité

électromagnétique).

Les appareils indiqués plus haut et tous les accessoires d’échantillonnage fournis avec ne

portent pas la marque CE pour la directive concernant les équipements de pression, dans la

mesure où ils sont fournis conformément à l’article 3, section 3 (pratiques d’ingénierie sûres

et codes de bienfacture) de la directive concernant les équipements de pression 97/23/EC

pour DN<25.

1100 Technology Park Drive

Billerica, MA 01821

USA

Transmetteur d’humidité VeriDri™

8 janvier 2009

Date d’émission

Certification et normes, ingénieur de fil

Mr. Gary Kozinski

CERT-DOC-H1 (August 2004)

Page 24

GE

Sensing

KONFORMITÄTS-

ERKLÄRUNG

Wir, GE Sensing

erklären unter alleiniger Eigenverantwortlichkeit, dass die Produkte

auf das sich diese Deklaration bezieht, die folgenden Normen erfüllen:

• EN 61326:1998, Class A, Annex A, kontinuierlicher, überwachungsfreier Betrieb

(Für EN 61000-4-3 erfüllen die obigen Geräte die Leistungskriterien A und in bei einer

begrenzten Anzahl von Frequenzen die Leistungskriterien B gemäß EN 61326.)

• EN 60529:1991+A1:2000

IP67

und dass sie die Anforderungen der EMC-Direktive 2004/108/EC einhalten.

Die oben aufgeführten Geräte und zugehörige, mitgelieferte Schallwandler (Messrohre

werden in einer separaten Konformitätserklärung behandelt) tragen keine

CE-Kennzeichnung gemäß der Druckgeräte-Richtlinie, da sie in Übereinstimmung mit

Artikel 3, Absatz 3 (gute Ingenieurpraxis) der Druckgeräte-Richtlinie 97/23/EG für DN<25

geliefert werden.

1100 Technology Park Drive

Billerica, MA 01821

USA

VeriDri™ Feuchtigkeitsmesswandler

8. Januar 2009

Außtellungsdatum

Bescheinigung und Normen, Leitungsingenieur

Hr. Gary Kozinski

CERT-DOC-H1 (August 2004)

Page 25

USA

1100 Technology Park Drive

Billerica, MA 01821-4111

Web: www.gesensinginspection.com

Ireland

Shannon Industrial Estate

Shannon, County Clare

Ireland

Loading...

Loading...