Page 1

GE Industrial

Sensing

Model UTX878

Ultrasonic Flowmeter

Abridged Manual

Page 2

GE Industrial

Sensing

Model UTX878

Ultrasonic Flowmeter

Abridged Manual

914-253A

June 2004

Model UTX878 is a GE Panametrics product. GE Panametrics has joined other GE high-technology sensing

businesses under a new name—GE Industrial Sensing.

Page 3

June 2004

Table of Contents

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Return Policy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Site Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Electronics Enclosure Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Transducer Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Cable Lengths. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Transducer Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Mounting the UTX878 Electronics Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Making the Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Preparing the Unit Before Making Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Wiring the Line Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Unlocking and Locking the UTX878 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Unlocking the UTX878 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Locking the UTX878 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Programming the UTX878 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Activating a Channel/Path (Status) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Entering Transducer Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Entering Pipe Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Entering the Pipe Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Entering Pipe Lining Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

iii

Page 4

June 2004

Table of Contents (cont.)

Entering Fluid Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Entering Fluid Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Entering Reynolds Correction Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Entering Path Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Installing the Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Setting Transducer Spacing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Installing the Transducers on the Pipe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Wiring the Transducers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Adjusting the 4-20 mA Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Entering Global Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Entering Base (Zero) and Span Output Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Entering Output Type and Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Entering Base and Span Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Trimming 4-20 mA Values via the Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

iv

Page 5

June 2004

Warranty Each instrument manufactured by GE Infrastructure Sensing, Inc. is

warranted to be free from defects in material and workmanship.

Liability under this warranty is limited to restoring the instrument to

normal operation or replacing the instrument, at the sole discretion of

GE Infrastructure Sensing, Inc.. Fuses and batteries are specifically

excluded from any liability. This warranty is effective from the date of

delivery to the original purchaser. If GE Infrastructure Sensing, Inc.

determines that the equipment was defective, the warranty period is:

• one year for general electronic failures of the instrument

• one year for mechanical failures of the sensor

If GE Infrastructure Sensing, Inc. determines that the equipment was

damaged by misuse, improper installation, the use of unauthorized

replacement parts, or operating conditions outside the guidelines

specified by GE Infrastructure Sensing, Inc., the repairs are not

covered under this warranty.

The warranties set forth herein are exclusive and are in lieu of

all other warranties whether statutory, express or implied

(including warranties or merchantability and fitness for a

particular purpose, and warranties arising from course of

dealing or usage or trade).

Return Policy If a GE Infrastructure Sensing, Inc. instrument malfunctions within the

warranty period, the following procedure must be completed:

1. Notify GE Infrastructure Sensing, Inc., giving full details of the

problem, and provide the model number and serial number of the

instrument. If the nature of the problem indicates the need for

factory service, GE Infrastructure Sensing, Inc. will issue a RETURN

AUTHORIZATION number (RA), and shipping instructions for the

return of the instrument to a service center will be provided.

2. If GE Infrastructure Sensing, Inc. instructs you to send your

instrument to a service center, it must be shipped prepaid to the

authorized repair station indicated in the shipping instructions.

3. Upon receipt, GE Infrastructure Sensing, Inc. will evaluate the

instrument to determine the cause of the malfunction.

Then, one of the following courses of action will then be taken:

• If the damage is covered under the terms of the warranty, the

instrument will be repaired at no cost to the owner and returned.

• If GE Infrastructure Sensing, Inc. determines that the damage is not

covered under the terms of the warranty, or if the warranty has

expired, an estimate for the cost of the repairs at standard rates

will be provided. Upon receipt of the owner’s approval to proceed,

the instrument will be repaired and returned.

v

Page 6

Introduction To ensure safe and reliable operation of the Model UTX878

Ultrasonic Flowmeter, the system must be installed and programmed

in accordance with the guidelines established by GE Infrastructure

Sensing, Inc. engineers. Those guidelines, explained in detail in this

guide, include the following topics:

• Unpacking the Model UTX878 system

• Selecting suitable sites for the electronics enclosure and the

transducers

• Installing the transducers

• Installing the electronics enclosure

• Wiring the electronics enclosure

• Programming the UTX878

!WARNING!

Be sure to follow all applicable local safety codes and

regulations for installing electrical equipment. Consult

company safety personnel or local safety authorities to

verify the safety of any procedure or practice.

June 2004

!ATTENTION EUROPEAN CUSTOMERS!

To meet CE Mark requirements, all cables must be installed

as described in Appendix B, CE Mark Compliance, of the

User’s Manual.

UTX878 Abridged Manual 1

Page 7

June 2004

Unpacking Carefully remove the electronics enclosure and the transducer/cable

assembly from the shipping containers. Before discarding any of the

packing materials, account for all components and documentation

listed on the packing slip. The discarding of an important item along

with the packing materials is all too common. If anything is missing

or damaged, contact the factory immediately for assistance.

Site Considerations Because the relative location of the transducers and the electronics

enclosure is important, use the guidelines in this section to plan the

UTX878 installation.

Electronics Enclosure Location

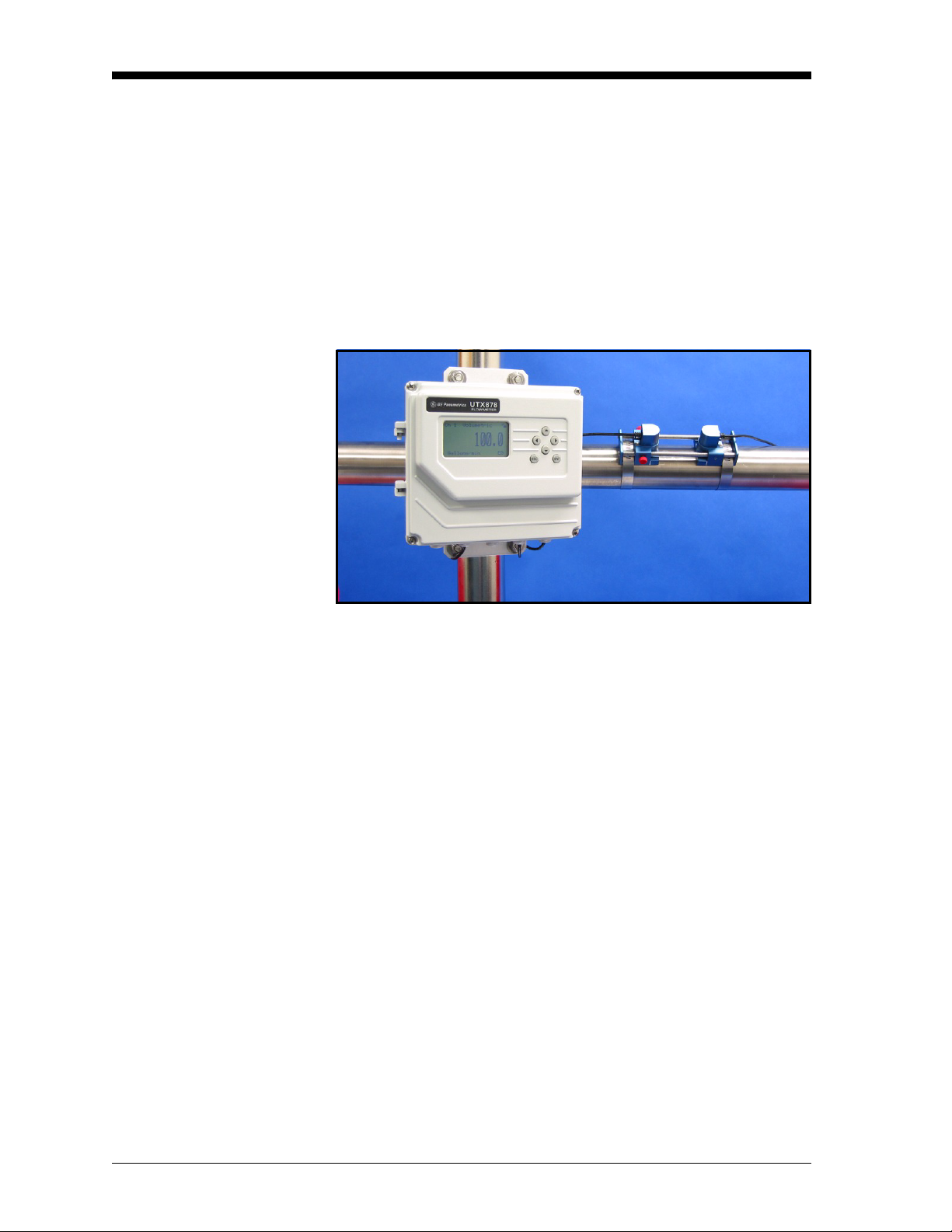

Figure 1: UTX878 Enclosure in Typical Installation

The standard UTX878 electronics enclosure (shown in Figure 1

above) is epoxy-coated aluminum rated for weatherproof NEMA 4X,

IP67 applications. Typically, the enclosure is mounted as close as

possible to the transducers. When choosing a site, make sure the

location permits easy access to the electronics enclosure for

programming, maintenance and service.

2 UTX878 Abridged Manual

Page 8

June 2004

Transducer Location For a given fluid and pipe, the Model UTX878’s accuracy depends

primarily on the location and spacing of the transducers. In addition

to accessibility, when planning for transducer location, adhere to the

following guidelines:

• Locate the transducers so that there are at least 10 pipe diameters

of straight, undisturbed flow upstream and 5 pipe diameters of

straight, undisturbed flow downstream from the measurement

point. Undisturbed flow means avoiding sources of turbulence in

the fluid such as valves, flanges, expansions, and elbows; avoiding

swirl; and avoiding cavitation.

• Locate the transducers on a common axial plane along the pipe.

Locate the transducers on the side of the pipe, rather than the top or

bottom, since the top of the pipe tends to accumulate gas and the

bottom tends to accumulate sediment. Either condition will cause

increased attenuation of the ultrasonic signal. There is no similar

restriction with vertical pipes. However, vertical pipes with

downward flow should be avoided in order to insure a full pipe at

the measurement point.

Cable Lengths Locate the electronics enclosure as close as possible to the

transducers. GE Infrastructure Sensing, Inc. can supply UTX878

transducer cables in fixed lengths from 10 ft (3 m) up to 100 ft (30 m)

in length for remote location of the electronics enclosure.

Transducer Cables When installing the transducer cables, always observe established

standard practices for the installation of electrical cables. Do not route

transducer cables alongside high amperage AC power lines or any

other cables that could cause electrical interference. Also, protect the

transducer cables and connections from the weather and corrosive

atmospheres. Do not run the transducer cables along a pipe with a

surface temperature over 75°C (167°F).

IMPORTANT: Use only the cables and transducers that have been

supplied with the UTX878.

Mounting the UTX878 Electronics Enclosure

The standard Model UTX878 electronics package is housed in a

epoxy-coated aluminum weatherproof NEMA 4X, IP67 enclosure

suitable for indoor or outdoor use. Refer to Chapter 7, Specifications,

of the User’s Manual for the mounting dimensions and the weight of

this enclosure.

UTX878 Abridged Manual 3

Page 9

June 2004

Making the Electrical Connections

Preparing the Unit Before Making Electrical Connections

This section contains instructions for making all the necessary

electrical connections to the Model UTX878 flow transmitter. Refer

to Figure 2 on the next page for a complete wiring diagram.

!ATTENTION EUROPEAN CUSTOMERS!

To meet CE Mark requirements, all cables must be installed

as described in Appendix B, CE Mark Compliance, of the

User’s Manual.

!WARNING!

Always disconnect the line power from the Model UTX878

before removing the front cover.

Prepare the unit as described below before making any electrical

connections.

1. Disconnect any previously wired power line from the unit.

2. Remove the screws on the front cover.

3. Install any required cable clamps on the appropriate conduit holes

on the bottom of the enclosure.

Proceed to the next section to make the desired wiring connections.

4 UTX878 Abridged Manual

Page 10

June 2004

Figure 2: UTX878 Wiring Diagram (Dwg. #702-528_2)

UTX878 Abridged Manual 5

Page 11

June 2004

Wiring the Line Power The Model UTX878 operates on 15-30 VDC loop power. The label

on the side of the electronics enclosure lists the meter’s required line

voltage and power rating. Be sure to connect the meter only to the

specified line voltage and with a shielded cable.

Refer to Figure 2 on the previous page to locate the power terminal

block and connect the line power as follows:

1. Follow the instructions on page 6 to prepare the unit before you

connect power.

2. Connect the UTX878 case to the earth ground with a grounding

cable.

3. Strip 1/4-in. of insulation from the end of each of the two line

power leads.

4. Route the shielded cable through the conduit hole and connect the

power leads to the power terminal block as shown in Figure 2. Tie

the shield drain wire to the ground bus bar inside the UTX878, but

leave the shield wire open on the power supply end

ground loops and for CE certification).

(to avoid AC

5. Leaving a small amount of slack, secure the power line with the

cable clamp.

Note: If you are using a 4-20 mA loop current measuring resistor,

add the resistor in series with the power supply Loop_Rtn end

(TB3-2). You must configure the loop current measuring

equipment as follows:

• The negative side (-) of the probe goes to the power supply

side of the resistor.

• The positive side (+) of the probe goes to the UTX878 side

of the resistor.

6. If you are installing the UTX878 for the first time, replace the

front cover, tighten the screws, and see the next page to unlock

and program the meter and determine the transducer spacing.

6 UTX878 Abridged Manual

Page 12

June 2004

Unlocking and Locking the UTX878

T o prevent unauthorized tampering with either the display or the user

program, the UTX878 offers a pair of security codes. Once you have

set the security level, an operator requires one of these codes to

change either the display (Prog Lock) or the display and the user

program (Full Lock).

Unlocking the UTX878 To unlock the display and/or the user program:

1. Press

[ESC], [ENT], [ESC]. A Security Check window, similar to

Figure 3 below, opens.

Security Check

ENTER VALUE

9999

[ENT] = save changes

[ESC] = undo changes

[W] [X] = move cursor

[S] [T] = change value

Figure 3: Security Check Window

2. Using the arrow keys, change the code number to the value

desired for your security level.

• For Prog Lock (granting access only to the display), the number

2719.

is

• For Full Lock (granting access to the display and user

program), the number is

3. Press [ENT]. The display screen reappears, with the lock removed

or partially unlocked. Security will remain at this level until you

change the level in the user program, as described on the next

page.

7378.

UTX878 Abridged Manual 7

Page 13

June 2004

Locking the UTX878 You can access the security level in two ways.

From the display screen:

1. Press the [X] key three times, until the lock in the upper right

corner is highlighted.

2. Press

From the User Program:

1. Press

2. Press the [X] key until USER is bracketed.

3. The menu highlights Set Security. Press

4. The screen shows three options:

[ENT], and proceed to step 4 below.

[ESC]. The UTX878 stops displaying data and enters the User

Program.

[ENT].

• Full Lock, which prevents a user from changing any part of the

display or user program without the appropriate code:

• Prog Lock, which allows a user to change the display but not to

enter the user program:

• Unlocked, which allows access to both the display and the user

program.

Scroll to the desired option and press

5. Press

[ESC] to return to the User Program, or continue pressing

[ESC] to return to the display screen. If you have chosen to fully

lock the UTX878, the screen appears similar to Figure 4 below,

with a solid lock in the upper right corner. (For a meter with only

the user program locked, the lock shows a keyhole in the center.)

[ENT] twice.

Ch 1 Velocity

0.0

Meters/sec E1

Figure 4: UTX878 Screen with Locked Program

8 UTX878 Abridged Manual

Page 14

June 2004

Programming the UTX878

Activating a Channel/Path (Status)

Before you install the transducers, you must program the UTX878 to

determine appropriate transducer spacing. The meter requires data in

five submenus: Status, Transducer, Pipe, Fluid and Path. (For

information on the other submenus, refer to the UTX878 User’s

Manual.)

In the Status submenu of the PROG menu, you can activate or

deactivate a channel/path. While the channel/path should be activated

when you receive your unit, you should verify that the channel/path is

active before you begin programming.

To access the Status submenu:

1. Press

2. Press the [X] key until

[ESC]. The UTX878 enters the User Program.

PROG is bracketed in the top left corner and

[ENT].

press

3. Use the [S] and [T] keys to scroll to the desired channel or to

2-path Averaging and press

[ENT]. The screen appears similar to

Figure 5 below.

Note: For information on the 2-Path Avg option, see the User’s

Manual.

PROG PROG/PROG

Status . . .

Transducer . . .

Pipe . . .

Fluid . . .

Path . . .

Signal . . .

T

K Factor . . .

Figure 5: The PROG Menu

4. Press

5. The screen offers two options,

[ENT] to open the Status submenu.

ON and OFF. Use the [S] and [T]

keys to scroll to the desired selection and press

[ENT].

IMPORTANT: On any menu, if you scroll to a differ ent option, press

[ENT] twice to select that option (once to enter and

again to confirm the selection).

6. Press

[ESC] (or [ENT] twice if you have selected the other option) to

return to the channel menu.

UTX878 Abridged Manual 9

Page 15

June 2004

Entering Transducer Parameters

The Transducer submenu enables you to enter parameters for

preprogrammed or special clamp-on transducers. Remember to

record all programmed data in Appendix C, Data Records, of the

User’s Manual.

Note: If you have programmed the Status submenu, proceed directly

to Step 4.

To access the Transducer submenu:

1. Press

2. Press the [X] key until

[ESC]. The UTX878 enters the User Program.

PROG is bracketed in the top left corner and

[ENT].

press

3. Use the [S] and [T] keys to scroll to the desired Channel and

[ENT].

press

4. Scroll to the Transducer submenu and press

5. Scroll to Clamp-on and press

[ENT].

[ENT].

6. Scroll to either Preprogrammed (for the standard transducers) or

Other (for special transducers), and press

[ENT].

7. The program also asks for the Wedge Temperature. Scroll to the

Wedge TMP option and press

keys to enter the temperature, and press

[ENT]. Then use the [S] and [T]

[ENT].

Note: The wedge temperature of the transducer can be

approximated by inputting an average value for the surface

temperature of the outside pipe wall.

8. Do one of the following:

• For preprogrammed transducers, scroll to the desired

Transducer Number (either UTXDR-407 (2 MHz) or UTXDR408 (4 MHz) ) and press

return to the

PROG menu.

[ENT]. Then press [ESC] three times to

• For other transducers, refer to the User’s Manual.

IMPORTANT: Other (special) transducers have no engraved

number on the housing and are rarely used. Examine

the transducer housing carefully for a number.

10 UTX878 Abridged Manual

Page 16

June 2004

Entering Pipe Parameters

In the Pipe submenu, you can specify preprogrammed or special pipe

parameters. Remember to record all programmed data in Appendix C,

Data Records, of the User’s Manual. In the

Pipe submenu and press

[ENT].

PROG menu, scroll to the

Entering the Pipe Material 1. The menu offers two options, Material and Lining. Be sure the

Material option is highlighted, and press

2. Two other options now appear, Preprogrammed and Other. Scroll

to the desired option, and press

[ENT].

3. The menu now varies with your choice in Step 2.

[ENT].

• For preprogrammed materials, a list of materials opens. Table 1

below covers the available preprogrammed materials on the list.

Press the [

Press

T] or [S] keys to scroll to the appropriate material.

[ENT] to confirm the choice.

• For other materials, the meter asks for the material Soundspeed.

[ENT] to open the window. Then use the arrow keys to enter

Press

the known soundspeed, and press

.

Table 1: Preprogrammed Pipe Materials

Pipe Material Category Specific Material

Al - Aluminum Rolled or None

Brass None

[ENT].

Cu - Copper Annealed, Rolled or None

CuNi - Copper/Nickel 70% Cu 30% Ni or 90% Cu 10% Ni

Glass Pyrex, Flint, or Crown

Gold Hard-drawn

Inconel None

Iron Armco, Ductile, Cast, Electrolytic

Monel None

Nickel None

Plastic Nylon, Polyethylene, Polyproplene,

PVC (CPVC), or Acrylic

Steel Carbon Steel, Mild or Stainless Steel

Tin Rolled

Titanium None

Tungsten Annealed, Carbide, Drawn

Zinc Rolled

UTX878 Abridged Manual 11

Page 17

June 2004

Entering the Pipe Material

(cont.)

4. The next required parameter is either the outside diameter (OD) or

the circumference (OD x

[ENT]. For either measurement, enter the desired value and

press

[ENT].

press

π). Scroll to the measured parameter and

Note: Obtain the required information by measuring either the pipe

outside diameter (OD) or circumference at the transducer

installation site. The data may also be obtained fr om standard

pipe size tables found in Sound Speeds and Pipe Size Data

(914-004).

5. The meter also requires the Wall Thickness (WT). Scroll to the WT

option, and press

thickness, and press

[ENT]. Use the arrow keys to enter the known

[ENT].

Note: To obtain an accurate pipe wall thickness measurement, use

an ultrasonic thickness gauge.

6. If you have selected certain materials (such as carbon or stainless

steel, cast iron, PVC and CPVC), the UTX878 offers the option of

entering the pipe dimensions by a standardized schedule. (This

option does not appear unless you have selected one of these

materials; if you have, proceed to step a below.) Once you enter

the nominal pipe size and schedule number, the UTX878

determines the OD and wall thickness from an internal table.

a. Scroll to the Schedule option, and press

[ENT].

b. A list of pipe sizes opens, from 15 to 200 mm (0.5 to 8 in.).

Scroll to the desired pipe size, and press

[ENT].

c. A list of schedules opens. Scroll to the desired schedule, and

[ENT].

press

You ha ve finished entering the pipe parameters. Press

[ESC] until you

return to the Pipe Material/Lining window.

12 UTX878 Abridged Manual

Page 18

Entering Pipe Lining Data To access the Lining option:

1. From the Pipe submenu, scroll to the Lining option, and press

[ENT].

2. Two options appear, Material and Thickness. Be sure Material is

highlighted, and press

[ENT].

3. Two other options now appear, Preprogrammed and Other. Scroll

to the desired option, and press

4. The menu now varies with your choice in Step 3.

• For preprogrammed linings, the screen shows a list of Lining

Materials, listed in Table 2 below. Scroll to the appropriate

material. If the pipe has no lining, select None. Press

confirm the choice.

• For other materials, the next screen asks for the lining

Soundspeed. Press

the arrow keys to enter the known soundspeed, and press

[ENT] to open the soundspeed window. Use

June 2004

[ENT].

[ENT] to

[ENT].

Table 2: Preprogrammed Lining Materials

Lining Material Options

None

Tar/Epoxy

Glass (Pyrex)

Asbestos Cement

Mortar

Rubber

Teflon

Note: If your pipe lining is not on the drop-down list, consult GE

Infrastructure Sensing, Inc. for further information.

5. The meter also requires the Lining Thickness. Return to the Lining

screen, scroll to the Thickness option, and press

arrow keys to enter the known thickness, and press

[ENT]. Use the

[ENT].

UTX878 Abridged Manual 13

Page 19

June 2004

Entering Fluid Data The Fluid submenu allows you to specify the fluid you are measuring,

as well as the Reynolds Correction factor and tracking windows.

Remember to record all programmed data in Appendix C, Data

Records, of the User’s Manual. From the

Fluid submenu and press

[ENT] twice.

PROG menu, scroll to the

Entering Fluid Type 1. Two options appear, Fluid Type and Reynolds. Scroll to Fluid

Type and press

2. Two other options appear, Normal and Tracking. Tracking refers

to Tracking Windows, which are used to detect the receive signal

when you are unsure of the fluid sound speed, or when the fluid

sound speed changes drastically under process conditions. Scroll

to the desired option and press

3. You can now select between Preprogrammed and Other fluids.

Scroll to the desired option, and press

[ENT].

[ENT].

[ENT].

• For Normal fluids, you can program the expected fluid

Temperature. Scroll to the Temperature option and press

Then use the arrow keys to enter the process temperature, and

[ENT].

press

[ENT].

• For fluids monitored with a T r acking Window, the meter offers

the selections of Water (up to either 100 or 260°C) or Oil.

Scroll to the desired listing and press

[ENT].

4. The menu now varies, depending on your selections in steps

2 and 3.

• If you have selected Preprogrammed fluids, the UTX878

supplies a list of preprogrammed fluids. As shown in Table 3

on the next page, the list varies, depending on whether you have

selected normal or tracking window fluid types. In either case,

scroll to the desired fluid and press

[ENT].

• If you selected Other, the UTX878 asks for the fluid

soundspeed (for Normal fluids) or minimum and maximum

soundspeed (for Tracking Window fluids). In either case, scroll

to the soundspeed option and press

enter the appropriate soundspeed, and press

5. Press the

[ESC] key until you return to the Fluid Type window.

[ENT]. Use the arrow keys to

[ENT].

14 UTX878 Abridged Manual

Page 20

June 2004

Entering Fluid Data

(cont.)

Entering Reynolds Correction Data

Table 3: Preprogrammed Fluid Types

Tracking Windows Off Tracking Windows On

Water (0-260°C) Water (0-100°C)

Sea Water Water (0-260°C)

Oil (22°C) Oil

Crude Oil

Lube Oil (X200)

Methanol (20°C)

Ethanol

LN2 (-199°C)

Freon (R-12)

Diesel

Gasoline

Reynolds Correction is a correction factor based on the Kinematic

Viscosity and flow rate of the fluid. It is necessary, as the velocity of

the fluid measured along a diametrical path must be related to the

total area average velocity over the entire pipe cross-section. This

factor should be

clamp-on transducers. To access Reynolds Correction data:

ON in most applications, including all those that use

1. From the Fluid Type window, scroll to Reynolds and press

2. The screen shows three options: Off, Single and Table. Scroll to

the desired option, and press

3. The menu varies, depending on your selection in Step 2.

[ENT].

[ENT].

• If you select Off, no further choices are available.

• If you select Single, the UTX878 will select and automatically

display the Kinematic Viscosity. To change the value, press

[ENT]. Use the arrow keys to change the value (available in

document #914-004, Sound Speeds and Pipe Size Data), and

[ENT].

press

UTX878 Abridged Manual 15

Page 21

June 2004

Entering Reynolds

Correction Data (cont.)

• If you select Table, the screen displays three options: Units, Rows

Used and Edit Table.

a. If you scroll to Units and press

more options: Velocity, Soundspeed and Diagnostic. If you

select either Velocity or Soundspeed and press

displays the measurement units (either metric or English).

[ESC] or [ENT] to return to the previous screen. But if you

Press

scroll to Diagnostic and press

of signal to be used, Signal Strength Up or Signal Strength Dn.

Scroll to the appropriate signal, and press

b. If you select Rows Used, the program asks for the number of

rows you wish to use. Enter the desired number (from 2 to 20)

and press

[ENT].

c. If you select Edit Table, the table opens with a series of rows.

Scroll to the desired row, and press

d. For each row, the screen displays the Reynolds Correction

number (X) and the Kinematic Viscosity (KV). If you wish to

change either value, scroll to the value and press

arrow keys to change the value (available in document #914004, Sound Speeds and Pipe Size Data), and press

[ENT], the screen displays three

[ENT], the screen

[ENT], the meter asks for the type

[ENT].

[ENT].

[ENT]. Use the

[ENT].

e. Repeat steps c and d until you have programmed all of your

available data (from 2 to 20 rows).

[ESC] until you return to the PROG menu, or continue pressing

Press

[ESC] until the display screen reappears.

16 UTX878 Abridged Manual

Page 22

June 2004

Entering Path Data In the Path submenu, you can specify and check the path taken by the

transducer signal. Remember to record all programmed data in

Appendix C, Data Records, of the User’s Manual. From the

menu, scroll to the Path submenu and press

[ENT].

1. The meter first asks for the number of Traverses, or times the

signal crosses the pipe. Press

traverses for your installation, and press

[ENT], scroll to the number of

[ENT] to confirm the entry.

Note: The great majority of UTX878 applications call for two

traverses. Figure 6 below illustrates signal paths for a typical

two-traverse installation.

PROG

Figure 6: Signal Paths for a Two-Traverse Installation

2. The remaining prompt displays the Transducer Spacing, as

calculated from the information entered. Use this number to set

the spacing of the transducers (the minimum spacing is 0.9 in.). If

necessary, you can overwrite the spacing to match the actual

physical spacing of the transducers. Press

[ENT] to open the

Spacing window, and use the arrow keys to change the value.

Then press

[ENT] to confirm the value.

IMPORTANT: It is recommended that you do not use a spacing

other than the one calculated by the UTX878.

However, if you do us e a different spacing, do not

change the spacing by more than ±10% from that

calculated by the UTX878.

[ESC] until you return to the PROG menu, or continue pressing

Press

[ESC] until the display screen reappears.

UTX878 Abridged Manual 17

Page 23

June 2004

Installing the Transducers

Setting Transducer Spacing

The transducers that have been specially designed for use with the

UTX878 are available in two models: 4 MHz for 1/2 to 2 in. pipes and

2 MHz for 2 to 8 in., and typically support 2-traverse applications.

The preattached cables come in lengths from 6 to 100 ft. (figure 7

below shows a typical UTX878 transducer).

Adjustment

Screws

Figure 7: UTX878 Transducer/Cable Assembly

To set the desired transducer spacing:

1. Loosen the red screws on the adjustable transducer (shown in

Figure 7 above).

2. Slide the adjustable transducer on the rails until you have

positioned it at the desired spacing. The physical spacing of the

transducers must match the Transducer Spacing parameter

calculated in the Path submenu (as discussed on the previous

page). Use the ruler on the rails and the white tick mark on the

transducer housing to assist in setting the correct spacing.

3. Tighten the red screws to secure the transducer to the rails.

Note: If your application requires one or three traverses, you can

remove the adjustable transducer fr om the rails and use it as a

separate transducer at a 180° angle from the stationary

transducer, as shown in Figure 8 below.

Figure 8: Positioning for 1- or 3-Traverse Applications

18 UTX878 Abridged Manual

Page 24

June 2004

Installing the Transducers on the Pipe

Note: Some pipe pre paration may be required before securing the

transducers to the pipe. Remove any paint or coating from the

surface in contact with the transducers. A flat, smooth surface

is ideal.

1. Apply the supplied couplant to the transducer faces, as shown in

Figure 9 below.

Figure 9: The Transducer Faces

2. Put the transducer fixture at the desired location on the pipe.

Secure it with the supplied stainless steel clamps. Figure 10 below

illustrates a typical installation.

Note: Installation on the sides (at 3 and 9 o’clock) of the pipe is

ideal. The top of the pipe might contain bubbles, while the

bottom might contain sediment.

Figure 10: A Typical Transducer Installation

Once on the pipe, an internal spring mechanism ensures proper

mechanical pressure by “pressing” the transducer face against the

pipe surface. Refer to the next page to wire the transducer cables to

the UTX878.

UTX878 Abridged Manual 19

Page 25

June 2004

Wiring the Transducers !WARNING!

Always disconnect the line power from the Model UTX878

before removing the front cover. Before connecting the

transducers, discharge any static buildup by shorting the

twisted pairs of the transducer cables to the metal shield

on the cable connector.

1. Disconnect the line power and remove the screws from the front

cover. Refer to the wiring diagram in Figure 2 on page 5 and

connect the transducer cables to the terminal block (TB-1) for

Channel 1. Then, secure the cable clamp.

Note: The RED cable leads are the SIG (+) leads and the BLACK

cable leads are the RTN (-) leads. The shield cable leads are

connected to the ground bus.

!ATTENTION EUROPEAN CUSTOMERS!

To meet CE Mark requirements, all cables must be installed

as described in Appendix B, CE Mark Compliance, of the

User’s Manual.

2. For a 2-path averaging UTX878, repeat step 1 to connect the CH2

transducers to the terminal block for Channel 2. It is not

that both channels/paths of a 2-Channel unit be connected.

Note: The UTX878 uses two channels or paths to make more

accurate flow measurement by averaging, subtracting or

adding the channels/paths together. Disabling a channel will

increase the meter response time.

3. Connect the transducer shield wires to the UTX878 ground bus.

4. Do one of the following:

required

• To wire the UTX878 RS232 serial port, refer to the User’s

Manual.

• If you have completed installation, replace the front cover on

the enclosure, tighten the screws and reconnect line power.

The UTX878 is now ready for operation.

20 UTX878 Abridged Manual

Page 26

June 2004

Adjusting the 4-20 mA Loop

To ensure proper operation of the UTX878, you must enter the

CONFIG menu and set the global parameters for your individual

requirements. The available parameters include:

• Metric or English units

• 4-20 Loop Settings (low and high values)

To enter the

enter the User Program) and press the [X] key once.

Entering Global Units In the Units submenu, you can choose to display all measurements in

either metric or English formats.

Note: You cannot choose to display some measurements in English

To access the Units submenu:

1. Press

2. Press the [X] key until

3. Press

CONFIG menu from the display screen, press [ESC] (to

formats and others in metric.

[ESC]. The UTX878 enters the User Program.

CONFIG is bracketed and press [ENT].

[ENT] to enter the Units submenu.

4. Use the [S] and [T] keys to scroll to the desired selection (metric

or English) and press

[ENT]. The UTX878 returns to the CONFIG

menu.

IMPORTANT: In any menu, if you scroll to a different option, press

[ENT] twice to select that option (once to enter and

again to confirm the selection).

UTX878 Abridged Manual 21

Page 27

June 2004

Entering Base (Zero) and Span Output Values

Entering Output Type and Units

The 4-20 Loop submenu enables you to enter the information needed

to set up output parameters: unit type, base (zero) and span values,

and error handling. To enter data in the 4-20 Loop submenu:

1. Press

2. Press the [X] key until

3. Press [T] to reach the 4-20 Loop submenu, and press

[ESC]. The UTX878 enters the User Program.

CONFIG is bracketed and press [ENT].

[ENT].

1. In the Loop submenu, press [ENT] to enter the Units option.

2. The menu displays five options:

DIFF. Use the [S] and [T] keys to scroll to the desired option,

and

and press

Note:

[ENT].

Channel 2, AVG, SUM and DIFF are only available for a

Channel 1, Channel 2, AVG, SUM

2-Channel UTX878.

3. The screen now displays three measurement parameters: velocity,

volumetric, and soundspeed. Scroll to the desired selection and

[ENT].

press

4. The menu now asks for the unit type.

• For velocity or soundspeed measurements, the menu offers a

single selection (either feet/sec or meters/sec, depending on

your choice of units). Press

return to the previous menu.

[ENT] to confirm the entry and

• For volumetric measurements, the menu offers a list of output

units (either metric or English). Scroll to the desired units and

press

[ENT].

[ESC] until you return to the CONFIG menu.

Press

22 UTX878 Abridged Manual

Page 28

June 2004

Entering Base and Span Values

Trimming 4-20 mA Values via the Keypad

1. In the Loop option, press [T] and [ENT] to enter the Base option.

2. The Base window opens. Use the arrow keys to enter the desired

base (4 mA) value for the analog output, and press

3. The UTX878 returns to the Loop menu. Press [T] and

[ENT].

[ENT] to

enter the Span option.

4. The Span window opens. Use the arrow keys to enter the desired

span (20 mA) value for the analog output, and press

[ENT].

1. In the User Program, press the [X] key until CAL is bracketed,

with 4-20 Loop highlighted. Press

2. Scroll to Mode and press

Test[Trim] and press

[ENT]. In the Mode window, scroll to

[ENT].

[ENT].

3. Return to the Loop window, and scroll to Percent.

4. In the Percent window , use the arrow keys to set the percentage to

100%. Press

5. Now use the arrow keys to set the percentage to 0%. Press

[ENT]. Record the value shown on the ammeter.

[ENT].

Record the value shown on the ammeter.

6. Return to the Loop window, and scroll to Base Trim. Press

[ENT].

7. Use the arrow keys to enter the base trim value, the value recorded

in step 5. (The loop current should now be the same as the

ammeter reading). It should read 4.0 +/-0.01 mA.) Press

[ENT].

8. Repeat steps 3 and 4.

9. Return to the Loop window, and scroll to Span Trim. Press

[ENT].

10.Use the arrow keys to enter the span trim value, the value recorded

in step 4. (The loop current should now be the same as the

ammeter reading. It should read 20.0 +/-0.01 mA.) Press

11.Return to the Loop window , and scroll to Mode. Press

to Normal, and press

[ENT].

[ENT].

[ENT]. Scroll

UTX878 Abridged Manual 23

Page 29

GE Industrial

Sensing

We, Panametrics Limited

Shannon Industrial Estate

Shannon, County Clare

Ireland

declare under our sole responsibility that the

UTX878 Ultrasonic Flowmeter

including UTXDR-407 & UTXDR-408 Flow Transducers

to which this declaration relates, are in conformity with the following standards:

• EN 61326:1998, Class A, Annex A, Continuous Unmonitored Operation

following the provisions of the 89/336/EEC EMC Directive.

DECLARATION

OF

CONFORMITY

Shannon - April 9, 2004

Mr. James Gibson

GENERAL MANAGER

TÜV

TÜV ESSEN

ISO 9001

U.S.

CERT-DOC-H0 August 2004

Page 30

USA

1100 Technology Park Drive

Billerica, MA 01821-4111

Web: www.geSensing, Inc..com

Ireland

Shannon Industrial Estate

Shannon, County Clare

Ireland

Loading...

Loading...