Page 1

GE

Sensing & Inspection Technologies

™

AquaTrans

Panametrics Liquid Flow

Ultrasonic Transmitter

UTX878

Applications

The AquaTrans UTX878 is a loop-powered, fullfeatured clamp-on ow ultrasonic transmitter

system for ow measurement of:

• Potable water

• Wastewater

• Discharge water

• Treated water

• Cooling and heating water

• Other liquids

Features

• 4-wire HART output

• 2-wire standard output option

• Low power consumption

• Suitable for pipe sizes from 1/2 in to 20 in (13 mm

to 500 mm) diameter

• Full external keypad

• Large integral display

• Simple meter and transducer installation and

setup

• Velocity, volumetric and totalized ow

• Economical non-intrusive ow measurement

Page 2

The AquaTrans UTX878 ow ultrasonic transmitter

combines the simplicity of a loop-powered meter

installation with proven, advanced clamp-on ultrasonic

ow transmitter technology. It provides customers with

an economical solution for ow measurement in pipes

up to 20 in (500 mm).

HART Output or 2-wire Standard

The AquaTrans UTX878 comes with HART protocol as an

available output. This protocol requires the meter to be

installed as a 4-wire device. The UTX878 is also available

as a 2-wire device without HART; the 2-wire UTX878 may

be preferable when replacing existing 2-wire devices.

Two-Channel Model

An optional second channel provides the capability

to measure ow at a single point to obtain two-path

averaging of the ow measurement for increased

accuracy.

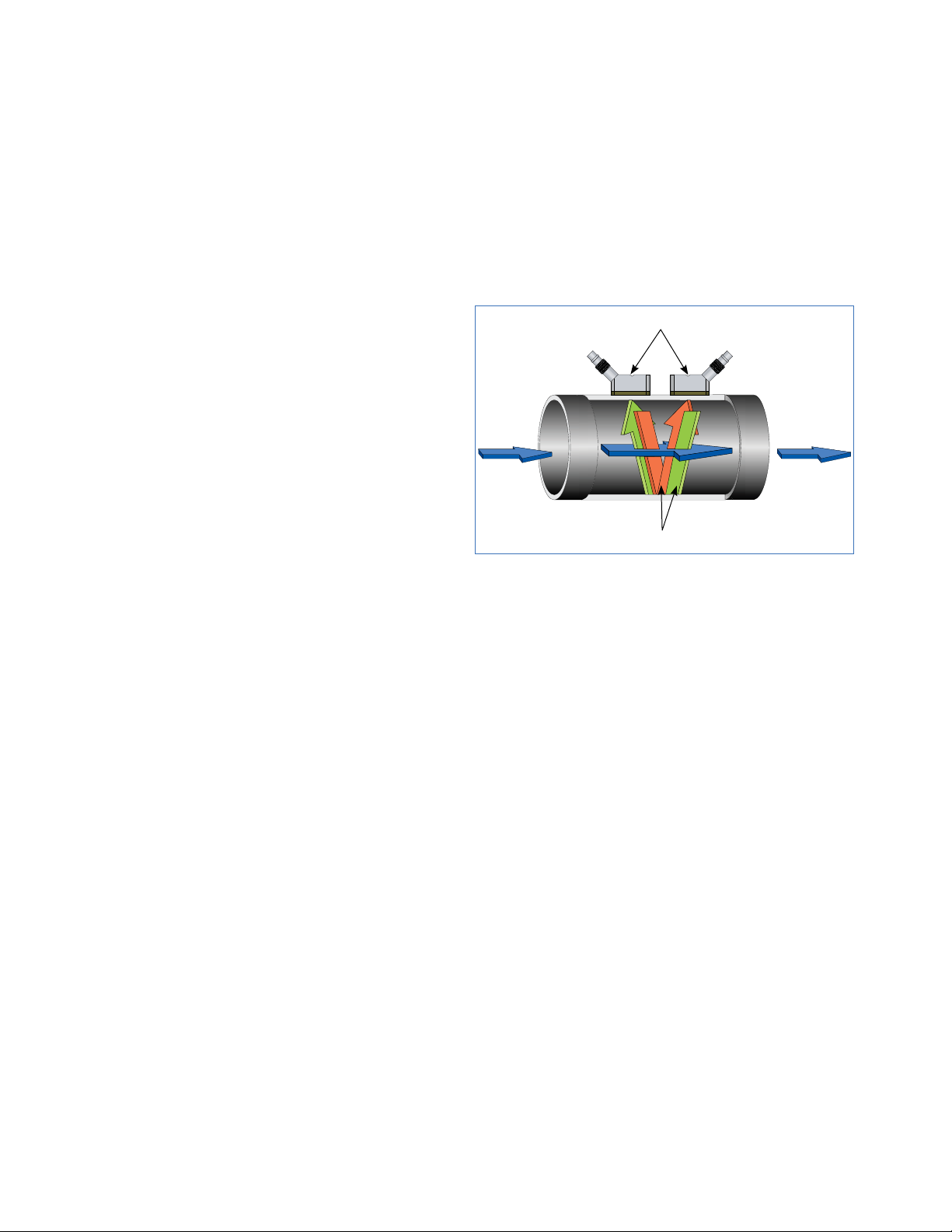

Uses the Transit-Time Flow

Measurement Technique

The Correlation Transit-Time™ technique uses a pair of

transducers with each transducer sending and receiving

coded ultrasonic signals through the uid. When the

uid is owing, signal transit-time in the downstream

direction is shorter than in the upstream direction; the

dierence between these transit-times is proportional to

the ow velocity. The AquaTrans UTX878 measures the

time dierence and uses programmed pipe parameters

to determine ow rate and direction.

Flowmeter Transducers

Fluid

Flow

Ultrasonic Signal Path

Transit-time ow measurement technique

Page 3

UTX878 Specications

Operation and Performance

Fluid Types

Acoustically conductive uids, including most clean

liquids, and many liquids with entrained solids or gas

bubbles. Maximum void fraction depends on transducer,

interrogation carrier frequency, path length and pipe

conguration.

Upstream

transducer

Downstream

transducer

Pipe Sizes

• 1/2 in to 1.5 in (13 mm to 40 mm): UTXDR-408

• 1 in to 4 in (25 mm to 100 mm): UTXDR-407

• 2 in to 12 in (50.8 mm to 300 mm): UTXDR-410

• 8 in to 20 in (200 mm to 500 mm): UTXDR-409

Pipe Materials

All metals and most plastics. Consult GE for concrete,

composite materials, and highly corroded or lined pipes.

Flow Accuracy (Velocity)

0.5% of reading (achievable with process calibration)

Pipe ID>6 in (150 mm): ±1% to 2% of reading typical

Pipe ID<6 in (150 mm): ±2% to 5% of reading typical

Accuracy depends on pipe size and installation and

whether measurement is one-path or two path.

Repeatability

±0.1% to 0.3% of reading

Range (Bidirectional)

–40 ft/s to 40 ft/s (–12.2 m/s to 12.2 m/s)

Rangeability (Overall)

400:1

Specif ications assume a fully developed ow prole

(typically 10 diameters upstream and 5 diameters

downstream of straight pipe run) and ow velocity greater

than 1 ft/s (0.3 m/s).

Schematic of loop-power

Electronics

Flow Measurement

Patented Correlation Transit-Time mode

Enclosure

Epoxy-coated aluminum weatherproof Type 4X/IP67

Dimensions (h x w x d)

Size 8.8 in x 8.2 in x 3.6 in (220 mm x 210 mm x 90 mm,

weight 3.9 lb (1.77 kg)

Display

128 x 64 pixel LCD graphic display

Keypad

6 button external keypad

Power Supply

15 to 30 VDC loop power

Power Consumption

700 mW maximum

Memory

FLASH memory; eld upgradable

Operating Temperature

–4°F to 140°F (–20°C to 60°C)

Measurement Parameters

Volumetric ow, totalized ow and ow velocity

Storage Temperature

–4°F to 158°F (–20°C to 70°C)

Standard Inputs/Output

• One 2-wire 4 to 20 mA output

• Optional 4-wire HART 4-20 mA output

Digital Interface

RS232

European Compliance

System complies with EMC Directive 89/336/EEC

Page 4

Clamp-On Flow Ultrasonic Transducers

Area Classication

General purpose

Operating Temperature

UTXDR-407 and 408: -4°F to 250°F (-20°C to 120°C)

UTXDR-407 and 408 IP67

UTXDR-409 and 410 IP66

UTXDR-409 and 410: -4°F to 300°F (-20°C to 150°C)

Transducer Cable

Mounting

Stainless steel strap

25 ft. (7.5 m) standard cable with transducers

Optional 50 ft. (15 m) or 100 ft. (30 m) lengths with

transducers

Ordering Information

Model

UTX Output

A Single looped powered 4-20 mA output; 2-wire device

H Hart, Single 4-20 mA loop; 4-wire device)

Cable Connection

CG Plastic cable glands

NPT 1/2” NPTF

M20 M20

BCG Nickel-plated Brass cable glands

Option Card

00 No option card

TT Two totalizers

Transducer

407 2 MHz transducer for 0.5 - 6 inch (13-150 mm) pipe

408 4 MHz transducer for 0.5 - 1.5 inch (13-50 mm) pipe

409 500 kHz transducer/clamping xture for 4 - 20 inch (80-500 mm) pipe

410 1 MHz transducer/clamping xture for 2 - 12 inch (50-300 mm) pipe

Cable Length

25 25 ft (7.5 meters) of cable

50 50 ft (15 meters) of cable

100 100 ft (30 meters) of cable

Pipe OD

A Straps for pipe OD from 0.5 in. (13 mm) to 2 in. (50 mm)

B Straps for pipe OD from 2 in. (50 mm) to 6 in. (125 mm)

C Straps for pipe OD from 6 in. (125 mm) to 12 in. (300 mm)

D Straps for pipe OD from 12 in. (300 mm) to 20 in. (500 mm)

UTX - - - - -

www.gesensinginspection.com

920-004E

© 2010 General Electric Company. All Rights Reserved. Specications are subject to change without notice. GE is a registered trademark of General Electric Company. Other company or product

names mentioned in this document may be trademarks or registered trademarks of their respective companies, which are not aliated with GE.

Loading...

Loading...