Page 1

g

Spectra RMS™ Circuit Breakers

Motor-Operated Mechanisms for Spectra RMS™

Breaker Types SE150, SF250

Description

A motor-operated mechanism is designed to open, close,

and reset a circuit breaker by remote control.

In an operating installation, the customer must supply

normally open ON and OFF push-buttons, external wiring,

a control power source, and any control circuitry.

Electrical Operation

With the breaker and operating mechanism in their OFF

positions, press the ON button to energize the motor,

closing the breaker. When the breaker handle reaches the

ON position, the control circuitry is disconnected by an

internal limit switch.

When the OFF button is pressed, the motor is energized,

opening the breaker. After the breaker handle reaches the

OFF position, a limit switch de-energizes the control

circuit.

When the circuit breaker trips automatically, there is no

external trip indication, unless a separate bell alarm

accessory is provided to actuate a warning device. It is

necessary to press OFF to reset the breaker.

GEH-5613 Installation Instructions

Type

SE150

Push to

Open

Automatic Reset

For automatic reset, an auxiliary switch, available as an

accessory, returns the breaker to the OFF/RESET position

after it has tripped. The switch is mounted inside the

breaker and wired in parallel with the OFF button. When

the breaker trips, the switch closes, moving the breaker

handle to the OFF/RESET position. After the motoroperated mechanism has reset the breaker, the limit switch

again opens the circuit. To use automatic reset, the ON

push-button must be SPDT type and wired as in Figure 5.

(The Auto/Reset scheme applies to ac devices only and is

not applicable for dc applications.

Manual Operation

Lift the cover to disengage the handle and operate the

breaker handle. To return to electrical operation, align the

breaker handle with the operating mechanism and close

the cover.

Type

SF250

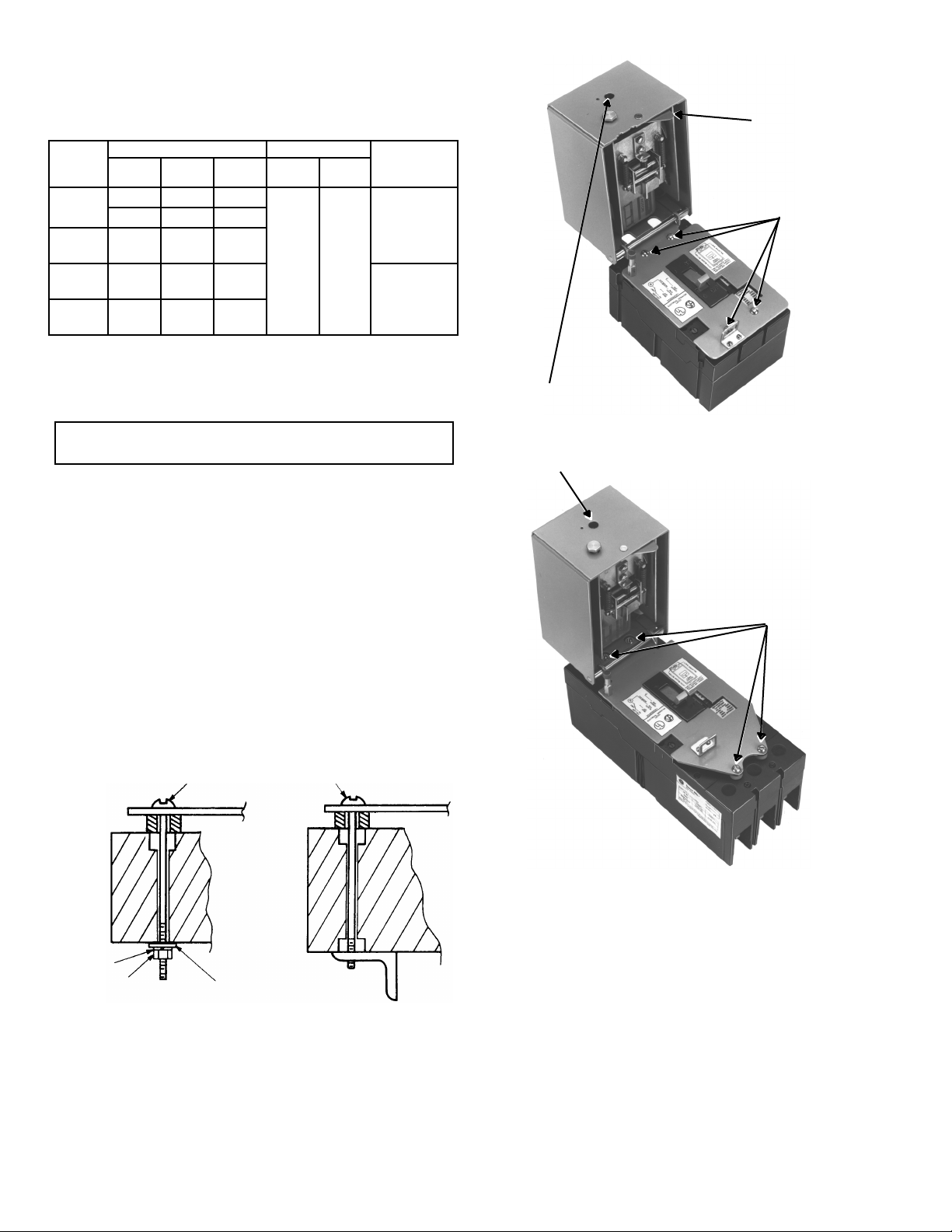

Figure 1. Spectra RMS circuit breakers.

Page 2

Electrical Data

Table 1 contains the electrical specifications for the motoroperated mechanism.

Control Timing (Sec)

Catalog

No. Volts

SEMOM1 120 Vac 10.5 5.0

SFMOM1 125 Vdc 13.5 4.0

SEMOM2

SFMOM2

SEMOM8

SFMOM8

SEMOM9

SFMOM9

240 Vac 6.5 3.0

24 Vdc 31 15.5

48 Vdc 20 7.0

In-Rush

Amps

Running

Amps Closing

Opening

Reset

.15 .13

Table 1. Electrical specifications.

Recommended

Fuse

1 Amp

Time Delay

2 Amp

Time Delay

Move Shutter

if Necessary

Mounting

Screws

Installation

WARNING: The circuit breaker must be de-energized

before the motor operator is installed.

1. Mount the circuit breaker using the diagonal

mounting screw locations.

2. Connect the line and load circuit breaker terminals.

3. Install the motor operating mechanism using the

remaining diagonal mounting screw locations,

shown in Figure 2. See Figure 3 for alternate

mounting methods.

4. Align the racking mechanism and the circuit

breaker handle by rotating the lead screw or by

moving the breaker handle. Close the cover.

5. Electrically test the mechanism according to the

specifications in Table 1. Refer to Figure 5 for a

schematic and auto reset diagram.

10-32 x 4.25 Screw (E Frame)

10-32 x 6 Screw (F Frame)

Rotate Lead

Screw Assembly

to Align Racking

Mechanism with

Circuit Breaker

Handle

Type

SF250

Type

SE150

Mounting

Screws

Lock

Washer

Nut

Breaker Supported

by Bus Structure

Figure 2. Mounting the motor-operated mechanism on the breaker.

Flat Washer

Breaker Supported

Figure 3. Breaker mounting methods.

Page 3

Figure 4. Outline drawings.

Page 4

oto

Mechanism

Switch

Yellow–ON

Interlock

Switch

Push-Button

Control Station

NOTE: When

using automatic

reset, the ON

push-button must

be SPDT type

and wired as

shown.

Limit

This Line

Automatic

Reset Only

M

rMotor-Operated

Black–Common

Red–OFF

Auto/Reset not

Intended for Use

on dc Applications

Green

Grd

L1

L2

Fuses

For Trip Indication

Use Circuit Breaker

with Internal Bell

Alarm Switch

For Automatic Reset and ON

& OFF Lights Use Circuit

Breaker with Internal

Auxiliary Switch

Indication Lights

(Supplied by Customer)

Customer-

Supplied

Equipment

Figure 5. Wiring diagram for SE/SF Motor-Operated Mechanism.

(All switch contacts are shown with the circuit breaker in the ON position.)

These instructions do not cover all details or variations in equipment nor do they provide for every possible contingency that

may be met in connection with installation, operation, or maintenance. Should further information be desired or should

particular problems arise that are not covered sufficiently for the purchaser’s purposes, the matter should be referred to the

GE Company.

g

GE Industrial Systems

General Electric Company

41 Woodford Ave., Plainville, CT 06062

GEH5613 R01 0989 © 1989 General Electric Company

Loading...

Loading...