Page 1

06/06/2005

Addendum #1 to GEK-39672G

Instructions for making bus connections across shipping split sections

Introduction

PowerVac switchgear is shipped in splits of one, two, three or four stacks. When

connecting shipping splits together it may be required to make the connections across the

main bus or the tie bus. The main bus can be accessed from the front of the gear through

the breaker compartment and the tie bus can be accessed from the rear. Breakers and

rollouts should be removed from the switchgear before the bus connections can be made

across the shipping split.

This addendum supplements the instructions provided in the main body of the instruction

book in pages 28 to 32. Ground bus connections across shipping splits shall be made as

specified in page 35 of the instruction book.

WARNING : All primary and secondary circuit devices must be de-energized and the

primary circuit grounded before undertaking any work on the switchgear.

Main bus connections across the shipping split

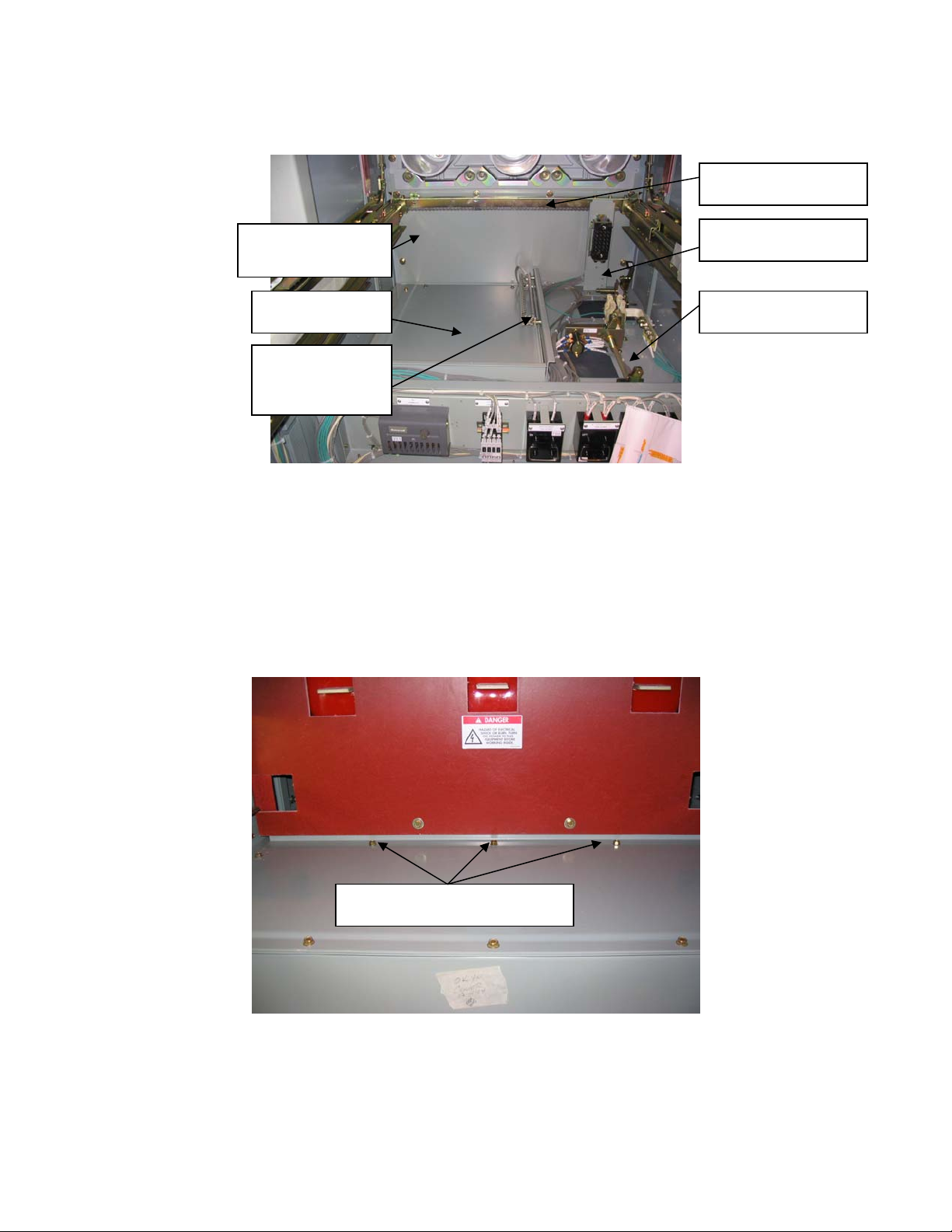

Step – 1, Remove horizontal barrier

A horizontal barrier located between the front upper and lower compartments has to be

removed. This barrier is shown in Fig – A(1)-1.

If heaters are provided, the heater shown in Fig – A(1)-1 will have to be removed in order

to remove the horizontal barrier.

Do not remove the pan on which the breaker ground shoe is located. Item # 4 in Fig –

A(1)-1. In most cases the pan shown as item #4 will have a cover over it ( cover not

shown in Fig A(1)-1). It is not required to remove the cover.

Page 2

(

(6) Do not remove

(3) Remove

later)

(2) Remove

(1) Remove

heater

Fig – A(1)-1

Front upper compartment

For stacks that have a 2 High PT/CPT tray in the front upper compartment, the procedure

for removing the horizontal barrier is different from that shown above. For such stacks,

remove the three taptites ( self threading bolts ) shown in Fig A(1)-2 in the front upper

compartment. When these taptites are removed, the barrier underneath shown in Fig –3

can be removed.

(5) Do not remove

(4) Do not remove

Remove these three taptites

Fig A(1) - 2

Front upper compartment intended for 2-High rollouts

51

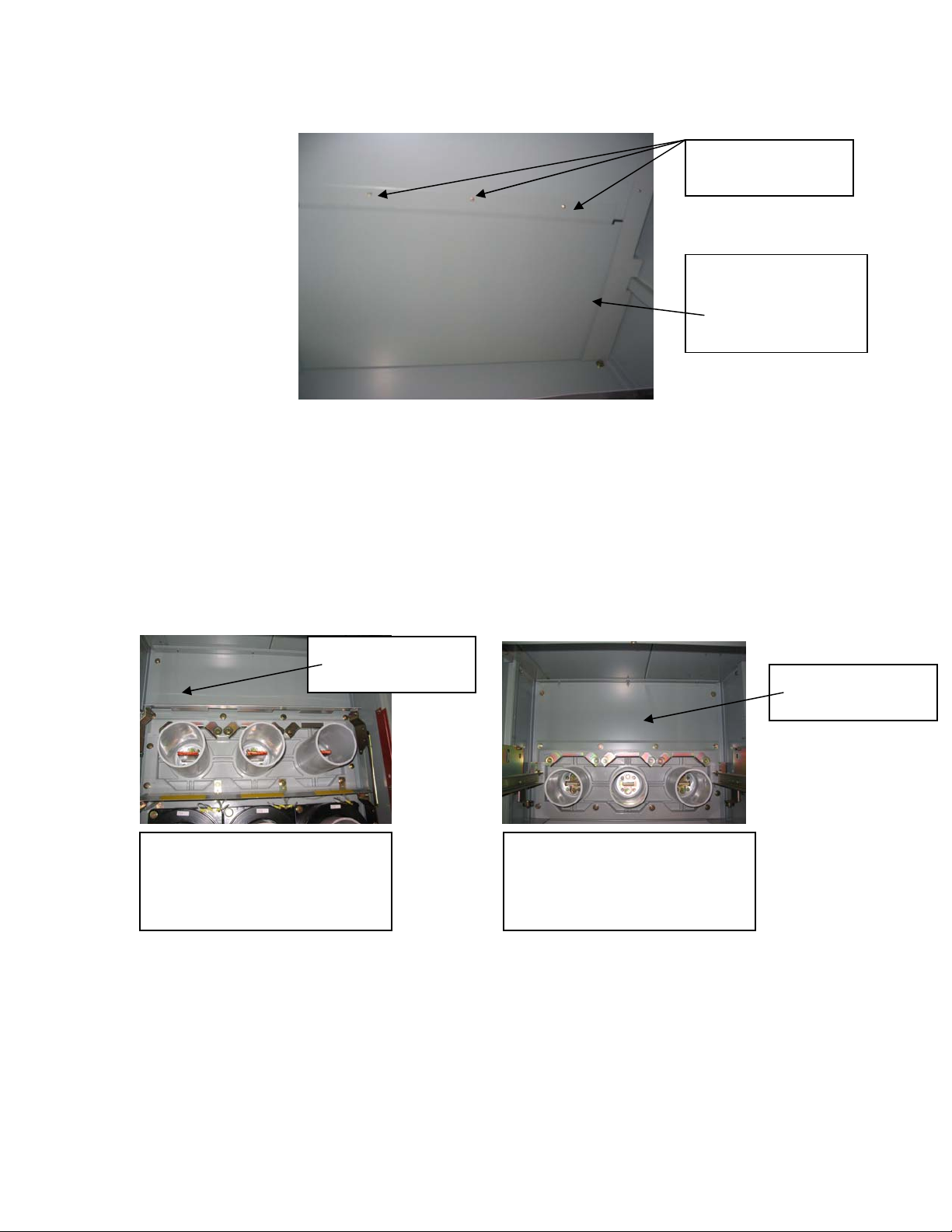

Page 3

p

p

The underside of

the taptites

This barrier can be

removed when the 3

taptites are removed.

Fig – A(1)-3

View looking up into the front bottom compartment of a 2 High-A rollout stack

Step – 2, Remove vertical mid barrier in front lower compartment

Remove the vertical mid barrier located in the upper part of the lower front compartment.

This barrier is located approximately 49 inch from the front of the stack. See Fig – A(1)4a for identification of barrier in the breaker compartment and A(1)-4b for identification

of barrier in a PT/CPT rollout compartment

Remove this

barrier

Fig A(1)-4a

View looking into typical

front lower breaker

artment

com

Step – 3, Remove vertical mid barrier in front upper compartment

Remove the vertical mid barrier located in the lower part of the upper front compartment.

This barrier is located approximately 49 inch from the front of the stack. See item # 3 of

View looking into typical

front lower PT/CPT rollout

Fig A(1)-4b

artment

com

Remove this

barrier

52

Page 4

Fig – A(1)-1. Do not remove the secondary disconnect block ( item # 5 ) or the chain (

item # 6 ). This barrier can be removed by sliding it down. This will expose the main bus

compartment as shown in Fig – A(1)-5

Tape

Boots

Tape

Tape

Fig – A(1)-5

View looking into main bus compartment from the front

( Porcelain inter-unit bus supports )

Step – 4, Remove glastic shipping supports

Unbolt and remove the glastic shipping supports taking care to ensure that splice plates

and spacers provided in the bus joint do not fall off. Loosely refasten bus hardware to

hold the splice plates and spacers in place. Discard the shipping supports. The red

insulating boots will have to be removed to access the bolts for the shipping supports.

The boots are held together using plastic re-useable pull-apart fasteners.

Step –5a, Remove inter-unit bus supports ( Go directly to step 5b if polyester glass bus

supports are provided)

a) Apply strong adhesive tape so as to keep the two glastic supports together

temporarily. The tape may be applied in 4 places – above, below and between the

porcelain bus supports. See Fig A(1)-5 and Fig A(1)-6. In Fig A(1)-6, the bus

support is shown outside the switchgear to get good picture clarity. It is not

required to remove the bus supports out of the switchgear.

b) Remove the ¼ - 20 fasteners used to mount the bus support to the side sheet.

There should be 4 ( 2 for poly glass) on the top and 4 ( 2 for poly glass ) at the

bottom. The hex nut should be towards the outside on the left hand side of the

side sheet.

c) Gently remove the bus support assembly away from the side sheet and into the

bus compartment. Let it rest temporarily in a vertical position inside the bus

compartment.

Copper Main bus or

Glastic shipping supt.

53

Page 5

Fig – A(1)-6

Location of tape

Fig A(1)-7

Typical Bus compartment with polyester glass inter-unit bus support

Step – 6 Align switchgear stacks

a) Gently align the next stack on the left with this stack taking care not to damage

the porcelain bus supports.

b) When the eight bus support holes ( four holes for polyester glass bus supports )

are aligned, replace the bus support assembly against the side sheet and use the ¼

- 20 hardware to fasten the bus supports and the two side-sheets together as shown

in Fig A(1)-8

c) A black rubber gasket is provided to cover the edge of the side sheets around the

perimeter of the bus pass-through cutout for 15kV gear. It should be ensured that

this gasket is in place.

54

Page 6

Fig – A(1)-8

View showing stacks bolted together

Step – 7, Make bus connections ( for polyester glass bus supports go directly to step 7c )

a) Position the rubber cushion so that it is approximately in the center of the

porcelain support. Apply RTV sealant ( 0282A3566P005 ) around the rubber

cushion to hold it in place.

b) Gently insert the main bus through the bus support taking care not to break or

chip the porcelain. The main bus should pass through a rubber bus cushion

located inside the porcelain bus support. If the rubber bus cushion falls off, reinsert the cushion on the busbar as shown in Fig – A(1)-9 and pass the busbar

through the porcelain support.

c) For polyester glass inter-unit bus supports insert the bus through the

corresponding slots in the orange polyester glass material.

d) Make main bus connections at the bus joint. The main bus should be inserted into

its vacant slot between the splice plates. The bus should line up with the main bus

coming into the joint from the other side.

e) Tighten bus connections to between 30 and 35 ft-lb.

55

Page 7

Fig – A(1)-9

Shows rubber cushion inserted over bus

Step 8, Finishing up

a) Re-assemble the boots that were removed in step 4.

b) Remove tape applied in step 5a ( for porcelain only )

c) Ensure that no tools or other material is left behind in the bus compartment

d) Re-assemble the vertical mid-barriers and the horizontal pan that were removed

in steps 1 to 3

e) Before energizing the switchgear conduct Insulation resistance (Megger) and HV

Hipot tests ( optional ) as described in the instruction books.

56

Page 8

Tie bus connections across the shipping split

Steps 4 through 8 are the same for making the tie bus connections. The tie bus

compartment can be accessed from the rear of the switchgear by removing the rear bus

barrier of the tie bus compartment. Fig – A(1)-10 shows a typical bottom tie bus

compartment with the rear bus barrier removed.

Fig – A(1)-10

Typical Rear tie bus compartment with the rear bus barrier removed.

If the tie bus compartment has 2 inch x ¼ inch aux bus running between stacks, inter-unit

bus supports are not required and will not be provided.

57

Page 9

06/06/2005

Addendum #2 to GEK-39672G

Instructions for bolting stacks together across shipping split sections

Introduction

PowerVac switchgear is shipped in splits of one, two, three or four stacks. This

instruction provides details on bolting the stacks together across the shipping splits. This

instruction is applicable to indoor, indoor drip proof and outdoor switchgear. However,

for indoor drip proof and outdoor construction additional assembly instructions for

connecting the roof and aisle sections are provided in the INSTALLATION section of

this instruction book.

WARNING : All primary and secondary circuit devices must be de-energized and the

primary circuit grounded before undertaking any work on the switchgear.

All breakers have to be racked out and PT/CPT rollouts have to be drawn out of the

shipping split stacks before proceeding with the inter-unit bolting.

Step – 1, Inter-unit bus connections.

Make inter-unit bus connections as specified in addendum #1 of GEK-39672G.

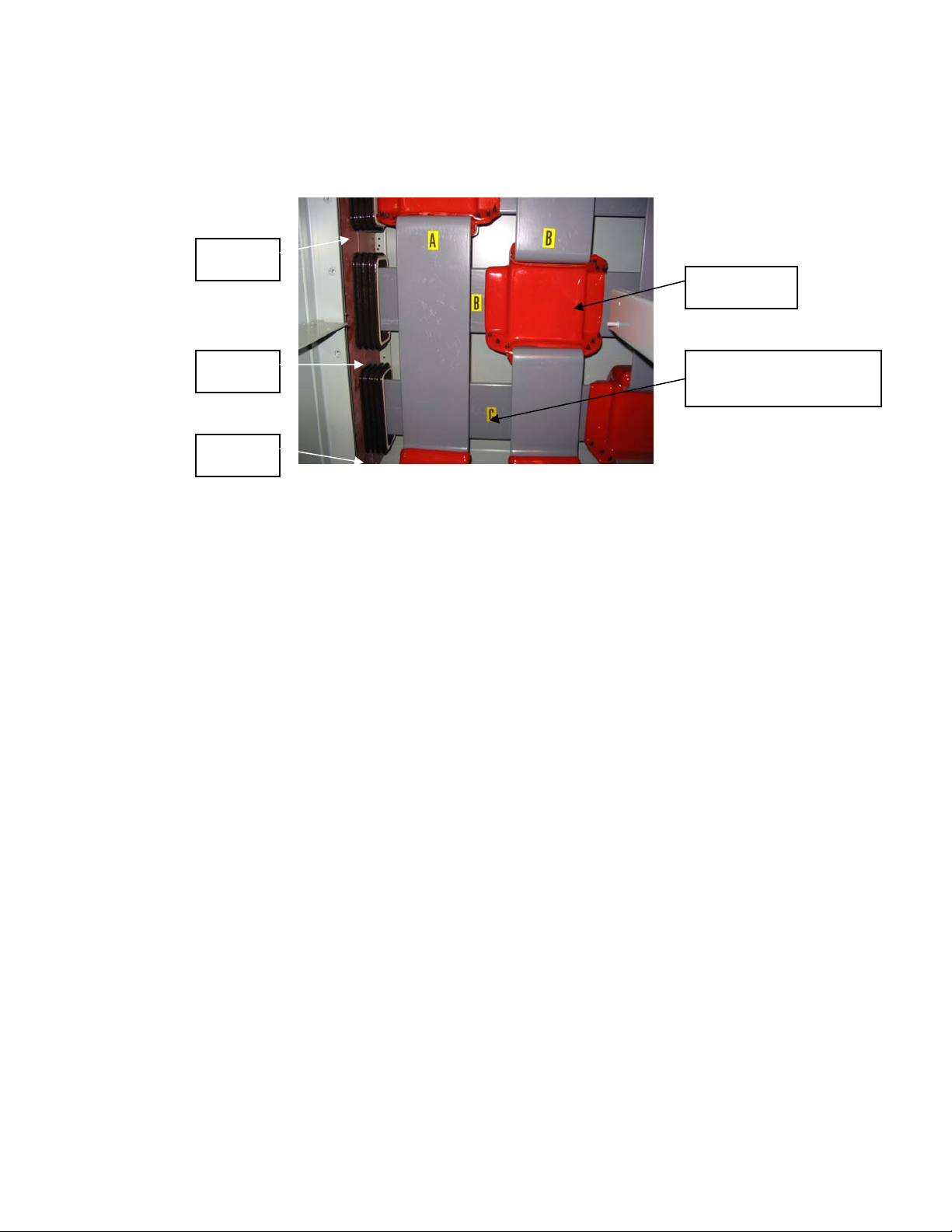

Step –2, Center-post bolting

Two sets of 0.38 x 3.00 inch hardware and two sets of 0.38 x 3.25 inch hardware are

provided for this purpose. Refer Fig A(2)-1 and Fig A(2)-2.

58

Page 10

Factory connections

Perimeter

bolting

Perimeter

bolting

Center-post ( 4 places)

Fig A(2)-1

Sectional view of inter-unit bolting

Center-post bolting

Fig A(2)-2

Typical Center-post bolting

The center-post bolting has to be done at 2 places in the front upper compartment and at

two places in the front bottom compartment. The 3.25 inch long bolts may be used where

it is required to bolt through the red glastic sheet shown in the upper portion of Fig A(2)–

2.

59

Page 11

Step – 2 Perimeter bolting

Sixteen sets of 0.38 x 1.00 inch hardware is provided for perimeter bolting. The

following guidelines shall be followed :

a) Minimum of 3 bolts on each vertical post

b) For 82 inch deep and 94 inch deep stacks, a minimum of two bolts on each depth

post with at least one bolt in the front compartment and one bolt in the rear

compartment.

c) For 106 inch deep stacks, a minimum of three bolts on each depth post with at

least one bolt in the front compartment and one location in the rear compartment.

Where there are no accessibility issues it is generally recommended that perimeter bolting

be done at all 16 locations.

NOTE : If the units have to be moved or lifted after installation, they should be lifted

only at the shipping splits.

60

Page 12

Page 13

Intentionally Left Blank.

62

Page 14

Intentionally Left Blank.

63

Page 15

Loading...

Loading...