Page 1

DEH–027

32:(5/($'(5706\VWHP

0RGEXV

8VHU¶V*XLGH

0RQLWRU

Page 2

WARNINGS

CAUTIONS

NOTES

DEH–027

WARNINGS, CAUTIONS, AND NOTES

AS USED IN THIS PUBLICATION

Warning notices are used in this publication to emphasize that hazardous voltages, currents, or

other conditions that could cause personal injury exist in this equipment or may be associated

with its use.

Warning notices are also used for situations in which inattention or lack of equipment

knowledge could cause either personal injury or damage to equipment.

Caution notices are used for situations in which equipment might be damaged if care is not

taken.

Notes call attention to information that is especially significant to understanding and operating

the equipment.

This document is based on information available at the time of its publication. While efforts

have been made to ensure accuracy, the information contained herein does not cover all details

or variations in hardware and software, nor does it provide for every possible contingency in

connection with installation, operation, and maintenance. Features may be described herein that

are not present in all hardware and software systems. GE Industrial Systems assumes no

obligation of notice to holders of this document with respect to changes subsequently made.

REFERENCES

GE Industrial Systems makes no representation or warranty, expressed, implied, or statutory,

with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of the information contained herein. No warrantees of merchantability or fitness for

purpose shall apply.

For details of the Modbus RTU protocol, refer to PI-MBUS-300 Rev. E from Modicon/AEG

Schneider Automation. For details of RS-485 communications, refer to the EIA-485 standard.

POWER LEADER™ is a trademark of General Electric Company.

Modbus RTU® is a registered trademark of AEG Schneider Automation.

Modbus® is a registered trademark of Modicon Inc.

Windows and Windows NT are registered trademarks of Microsoft Corporation.

© Copyright 1999 GE Company

All Rights Reserved

Page 3

POWER LEADER Modbus Monitor

................................

................................

................................

................................

..........

................................

................................

................................

................................

...........

................................

................................

................................

................................

.....

Table of Contents

CHAPTER 1 INTRODUCTION

Overview.....................................................................................................................................................................................1

Theory of Operation..................................................................................................................................................................2

PMCS operation ...................................................................................................................................................................2

Monitor operation with PMCS .............................................................................................................................................3

Monitor stand-alone operation..............................................................................................................................................3

Multiple Modbus Monitors...................................................................................................................................................3

Supported Devices......................................................................................................................................................................4

Typical Network Configurations..............................................................................................................................................6

Physical Description ..................................................................................................................................................................7

Specifications..............................................................................................................................................................................8

Environmental............................................................................................................................................................................8

Catalog Numbers .......................................................................................................................................................................8

CHAPTER 2 INSTALLATION

Valid Network Architectures....................................................................................................................................................9

Mounting ....................................................................................................................................................................................9

Control Power Connections....................................................................................................................................................10

Grounding...........................................................................................................................................................................10

RS-485 Connection(s)..............................................................................................................................................................10

RS-485 Termination Considerations...................................................................................................................................11

Software Installation ...............................................................................................................................................................12

Modbus Monitor Configuration Tool .................................................................................................................................12

Modbus Monitor Proxy.......................................................................................................................................................13

Maintenance.............................................................................................................................................................................13

1

9

CHAPTER 3 CONFIGURATION

Modbus Monitor Configuration Tool....................................................................................................................................15

Notes on Modbus Monitor Configuration Tool Keyboard Interface ..................................................................................17

Device Table.......................................................................................................................................................................18

Groups ................................................................................................................................................................................21

Communication Timeout Setting........................................................................................................................................22

Port Configuration Settings.................................................................................................................................................22

Advanced Configuration.........................................................................................................................................................22

Read Files from a Monitor..................................................................................................................................................22

Write Files to a Monitor .....................................................................................................................................................24

Print Files............................................................................................................................................................................24

PC to Monitor Connection......................................................................................................................................................25

PC-Monitor Communications.................................................................................................................................................25

Monitor Setup Menu ...............................................................................................................................................................26

Program Upgrade................................................................................................................................................................26

Screen Saver Configuration................................................................................................................................................26

Set Password.......................................................................................................................................................................27

RS-485 Port Configuration.................................................................................................................................................27

Auto-Detection for SLT......................................................................................................................................................27

Set Date & Time.................................................................................................................................................................27

15

i

Page 4

POWER LEADER Modbus Monitor

................................

................................

................................

................................

..............

................................

................................

................................

.................

................................

................................

................................

..................

................................

................................

................................

................

................................

................................

................................

...........................

................................

................................

................................

..

................................

........

................................

................................

..............

................................

................................

................................

................................

................................

....

Table of Contents

CHAPTER 4 OPERATION

Introduction..............................................................................................................................................................................29

Keypad/Menu Navigation .......................................................................................................................................................29

Main Menu...............................................................................................................................................................................29

Look at a Device.................................................................................................................................................................30

Look at the Local Event Log...............................................................................................................................................32

PMCS Event Log................................................................................................................................................................33

Notes on Password Protection.................................................................................................................................................30

Using the Modbus Monitor with PMCS ................................................................................................................................33

CHAPTER 5 ERRORS AND DIAGNOSTICS

CHAPTER 6 TROUBLESHOOTING GUIDE

CHAPTER 7 ADVANCED CONFIGURATION

Step 1: Define a New Device Type..........................................................................................................................................41

Step 2: Define the Device Type as Hybrid or Generic .........................................................................................................42

Step 3: Create the Device Type’s Register Map...................................................................................................................42

Add Register.......................................................................................................................................................................43

Modify Register..................................................................................................................................................................43

Delete Register....................................................................................................................................................................43

Utilized Register Block List (URBL)......................................................................................................................................43

Step 4. Customize the Display.................................................................................................................................................44

Notes on Hybrid/Generic Device Types .................................................................................................................................45

Special Handling Registers.................................................................................................................................................45

Hybrid Device Types..........................................................................................................................................................45

Generic Device Types.........................................................................................................................................................46

Defining Hybrid and Generic Device Types.......................................................................................................................46

Defining the Register Set....................................................................................................................................................46

29

35

37

41

APPENDIX A: MODBUS PROTOCOL

Implementation Basics.............................................................................................................................................................49

Modbus RTU Message Format...............................................................................................................................................49

CRC-16 Algorithm..............................................................................................................................................................50

Message Framing and Timing.................................................................................................................................................50

Register Groupings..................................................................................................................................................................50

Data Conventions.....................................................................................................................................................................51

Format for Floating Point and Long Integer Data Types ....................................................................................................51

APPENDIX B: MODBUS MONITOR REGISTER MAP

APPENDIX C: REGISTER DATA FORMATS SUPPORTED BY THE MODBUS MONITOR

APPENDIX D: SUPPORTED FIRMWARE REVISIONS FOR TID’S

GLOSSARY

ii

49

53

55

51

60

Page 5

POWER LEADER Modbus Monitor

List of Figures and Tables

List of Figures

Figure 1. POWER LEADER Modbus Monitor. ...............................................................................................................1

Figure 2. PMCS DDE communications cycle...................................................................................................................2

Figure 3. Monitor Proxy and PMCS DDE communications.............................................................................................3

Figure 4. Monitor acting as master to a network of POWER LEADER devices. ............................................................6

Figure 5. Typical PMCS network incorporating Monitor. ...............................................................................................6

Figure 6. Front view of Monitor, showing dimensions.....................................................................................................7

Figure 7. Side view of the Monitor, showing dimensions and connections.....................................................................7

Figure 8. Valid Modbus Monitor network architectures. .................................................................................................9

Figure 9. Cutout pattern for mounting the Monitor........................................................................................................10

Figure 10. RS-485 port and RS-485 connector pinouts..................................................................................................11

Figure 11. RS-485 Terminations.....................................................................................................................................11

Figure 12. RS-485 network wiring..................................................................................................................................12

Figure 13. Removing the cooling fan filter.....................................................................................................................13

Figure 14. Configuration Tool main screen....................................................................................................................16

Figure 15. Configuration Tool View dialog. ..................................................................................................................16

Figure 16. New Configuration screen.............................................................................................................................17

Figure 17. Port Configuration screen..............................................................................................................................17

Figure 18. Modify Configuration screen. .......................................................................................................................18

Figure 19. Configuration Tool Device Table screen. .....................................................................................................18

Figure 20. Add a Network Device dialog. ......................................................................................................................19

Figure 21. Select PMCS Topic File dialog.....................................................................................................................20

Figure 22. PMCS Configuration information screen......................................................................................................20

Figure 23. AutoDetect dialog box...................................................................................................................................20

Figure 24. Configuration Tool Group Configuration screen..........................................................................................21

Figure 25. Add New Group screen. ................................................................................................................................21

Figure 26. Modify Groups screen...................................................................................................................................22

Figure 27. Configuration Tool Operational Parameters screen......................................................................................22

Figure 28. Monitor Configuration Tool: Read Configuration dialog.............................................................................22

Figure 29. Device Types Result Log. .............................................................................................................................24

Figure 30. Monitor Configuration Tool Write Configuration dialog. ............................................................................24

Figure 31. Monitor Configuration Tool’s Print dialog...................................................................................................25

Figure 32. PC to Monitor RS-232 connection. ...............................................................................................................25

Figure 33. Monitor Main menu.......................................................................................................................................25

Figure 34. Monitor Setup menu......................................................................................................................................26

Figure 35. Monitor Keypad.............................................................................................................................................29

Figure 36. Monitor Main menu (details).........................................................................................................................29

Figure 37. Monitor View menu.......................................................................................................................................30

Figure 38. Device Groups screen....................................................................................................................................30

Figure 39. Monitor Devices list......................................................................................................................................31

Figure 40. Device Data screen........................................................................................................................................31

Figure 41. Monitor View Devices menu structure..........................................................................................................32

Figure 42. Sample Event Log screen. .............................................................................................................................32

Figure 43. Monitor Diagnostics Menu............................................................................................................................35

Figure 44. Monitor Configuration Tool: New Device Type dialog................................................................................41

iii

Page 6

POWER LEADER Modbus Monitor

Figures and Tables

Figure 45. Save As.... dialog box....................................................................................................................................42

Figure 46. Monitor Configuration Tool: Modify Device Types dialog. ........................................................................42

Figure 47. Monitor Configuration Tool: Register Map dialog.......................................................................................42

Figure 48. Monitor Configuration Tool: Add Register dialog box................................................................................43

Figure 49. Customize Display dialog box. .....................................................................................................................44

Figure 50. Assign/Unassign Registers dialog.................................................................................................................44

Figure 51. Insert Screen dialog.......................................................................................................................................45

List of Tables

Table 1. Devices supported by the Monitor. ....................................................................................................................5

Table 2. Monitor specifications........................................................................................................................................8

Table 3. Monitor environmental requirements.................................................................................................................8

Table 4. Monitor catalog numbers....................................................................................................................................8

Table 5. Device firmware revisions supported by the Modbus Monitor........................................................................59

iv

Page 7

POWER LEADER Modbus Monitor

Chapter 1

Introduction

Chapter 1 – Introduction

Overview

The GE POWER LEADER Modbus Monitor, shown in

Figure 1, is a microprocessor-based device that connects

to an industry-standard Modbus RTU network,

implemented on RS-485 wiring. The Monitor tracks

metering and status information collected by GE

POWER LEADER power management devices and a

variety of third-party power management devices. The

Monitor provides a convenient station for viewing of

data from remote devices.

Figure 1. POWER LEADER Modbus Monitor.

Modbus RTU networks are designed on a master-slave

architecture. Only one master per network is permitted.

The master queries the slaves when it needs their data,

and slave devices may only communicate on the network

in response to a request from the master.

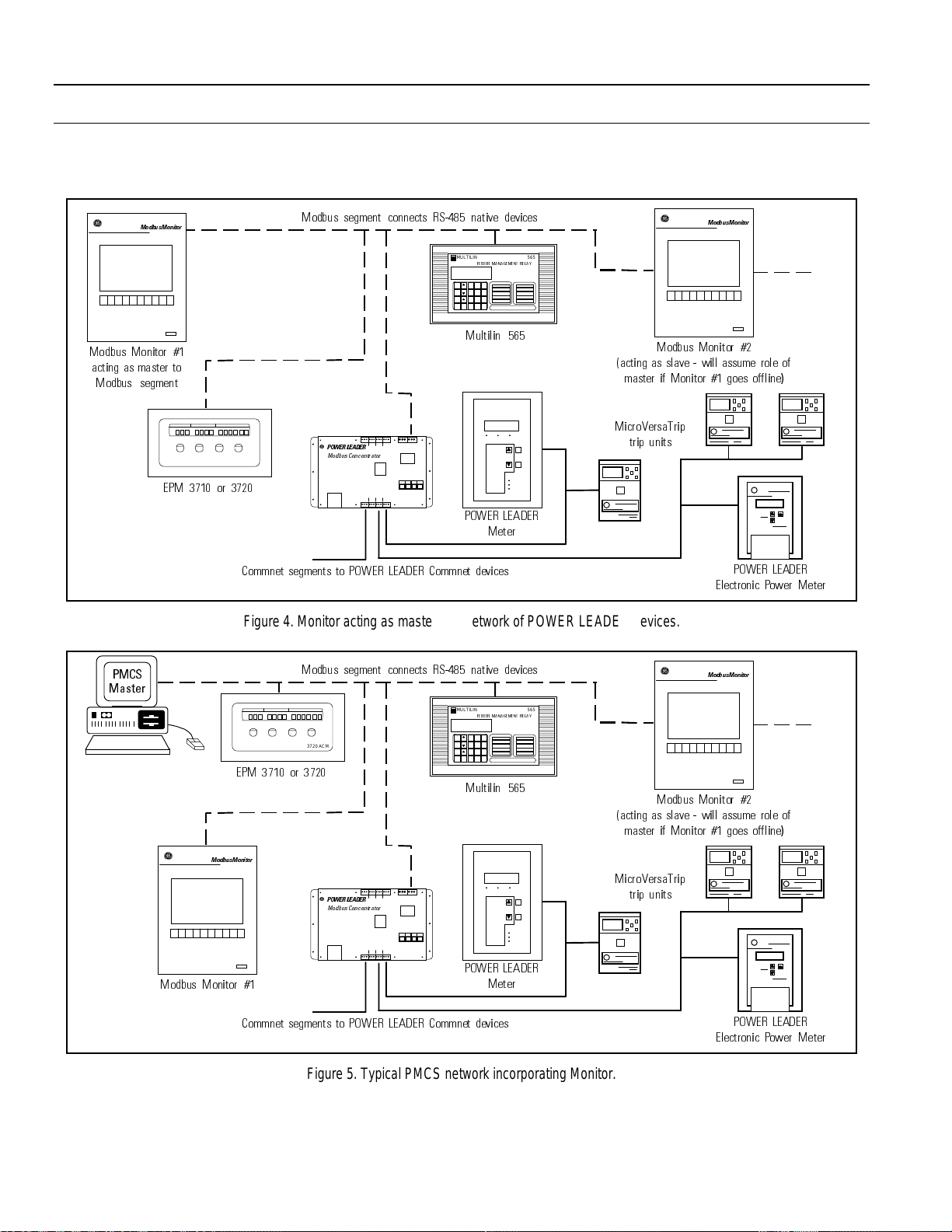

The Monitor can operate in either of two roles. First, it is

capable of acting as a master on one or two Modbus

segments of power management devices, collecting data

from the devices for local display, as shown in Figure 4.

Second, it is capable of behaving as a “second-incommand” to GE’s Power Management Control System

(PMCS), as shown in Figure 5. In this role, the Monitor

resides on the RS-485 network with other POWER

LEADER devices, performing its monitoring duties but

behaving as a slave device to the PMCS master.

However, if the master is disabled for some reason,

perhaps a computer problem or a power failure at the

host PC, the Monitor will immediately and transparently

assume the role of master to the other devices.

NOTE: The POWER LEADER Modbus Monitor is

compatible only with GE Power Management Control

System software, version 5.1, version 6.0 or greater. It is

not certified to be compatible with any other host

software.

Once installed and wired to control power and network

connections, the Monitor must be configured for

communications (Modbus address, baud rate, etc.) on the

RS-485 network. It must also be configured with the

identity and type of the other network devices. This

configuration is performed using a software application,

the Modbus Monitor Configuration Tool, running on a

PC. When you are ready to download the configuration

to a Monitor, you’ll connect the PC to the

communications port on the Monitor’s front panel using

an RS-232 straight-through cable (provided with

Monitor).

NOTE: In this manual, the term SEGMENT or

MODBUS SEGMENT will refer to a single RS-485

communications network operating under the Modbus

protocol. A Monitor may be connected to one or two

Modbus segments, depending on whether it is a single or

dual port version.

1

Page 8

POWER LEADER Modbus Monitor

Chapter 1 – Introduction

Theory of Operation

As mentioned previously, the POWER LEADER

Modbus Monitor has two modes of operation. It can

operate as a stand-alone master to one or two Modbus

segments of compatible devices or it may operate in

conjunction with the GE Power Management Control

System (PMCS) software. In this second mode, the

Monitor collects the data it needs to display and also

watches for the PMCS to go off-line. If for some reason

the Monitor does not sense the PMCS being online as

Modbus master, the Monitor will immediately and

transparently assume the role of master on the Modbus

segment(s).

We’ll explain briefly how PMCS operates, and then the

relationship of the Monitor to the PMCS, and finally the

operation of the Monitor independent of PMCS.

PMCS operation

The GE Power Management Control System consists of

four basic parts: (1) power management devices, (2) an

RS-485 network (“Modbus segment”) connecting these

devices to (3) a host computer running GE’s Power

Management Control System software and a Dynamic

Data Exchange (DDE) server, which monitors the

devices for data requested by (4) client software

programs, and feeds this data back to the clients

requesting it.

The power management devices vary in complexity and

intended use, but in general their function is similar: they

collect data on specific electrical metered, status and

event parameters (volts, amps, power consumption,

peaks, trips, etc.). The various information they monitor

is recorded in specific memory locations called registers.

Registers are organized by address. The complete list of

a devices’ registers, their addresses and their contents is

referred to as a register map.

PMCS has been preprogrammed with the register maps

of a variety of GE and third party devices. When the user

configures PMCS with the details of what devices are

connected to his network, the software automatically

associates the appropriate register map with the given

device type. This enables the software to locate

information in a device based on its type.

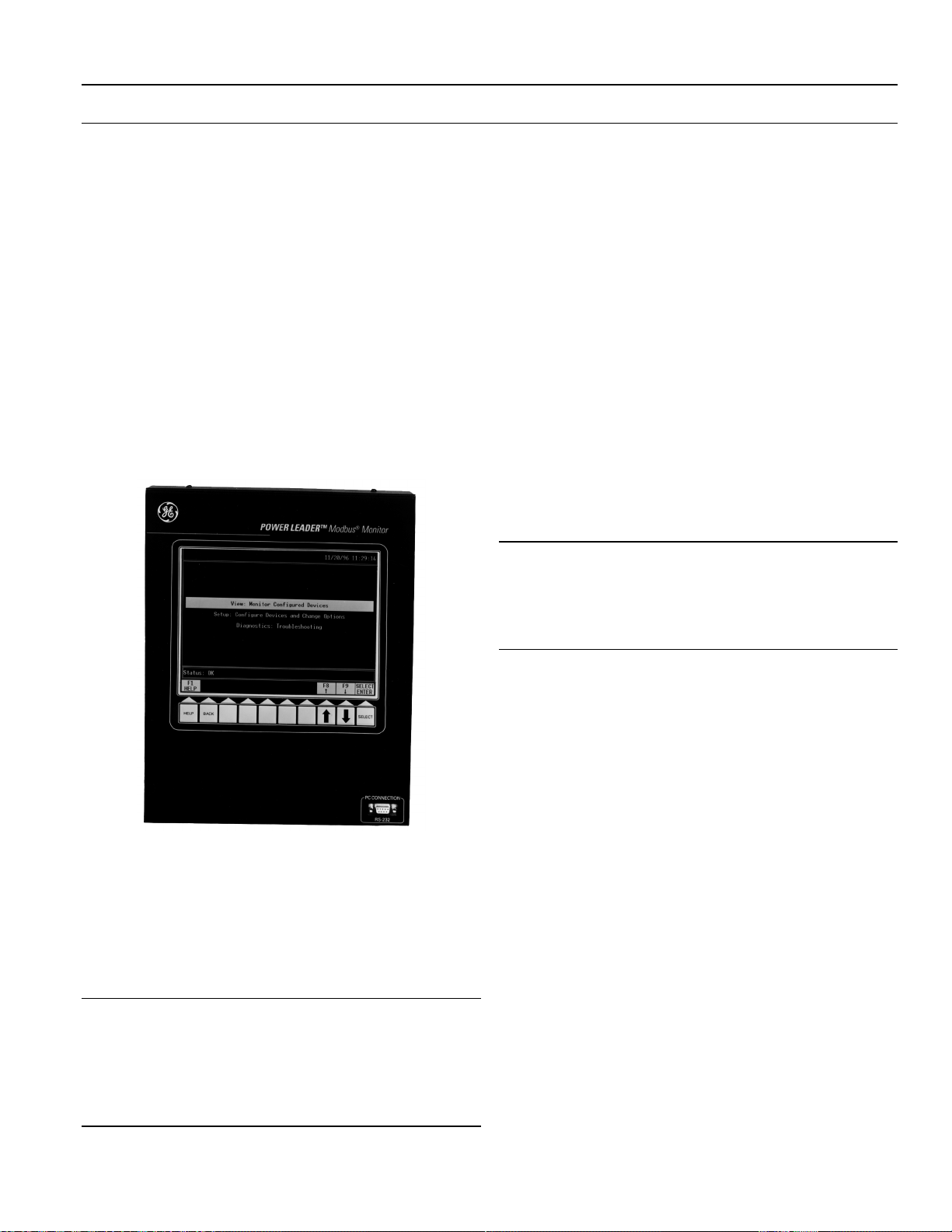

PMCS operates using a client-server architecture called

DDE - Dynamic Data Exchange. DDE is a means of

exchanging information between software programs

operating on a PC. Client programs request information

from a Server program; the Server program fills these

requests. In the case of the PMCS DDE Server, these

requests are for power management information being

gathered by physical power management devices on

Modbus segments connected to the PC. An example of

PMCS DDE communications is shown in Figure 2.

30&6 IXOILOOV &OLHQWV

UHTXHVW F RP SOH WL QJ

WKH ''( WUDQVD FW L RQ

30&6

6HUYHU

'HYLFH UHS OL HV

WR 6HUYHU V

UHTXHVW IRU GD WD

Figure 2. PMCS DDE communications cycle.

&OLHQW

''(

'HYLFH

&OLHQW LQLWLDWHV ''(

WUDQVDFWLRQ E\

UHTXHVWLQJ GDWD IURP

WKH ''( 6HUYHU

30&6

''(

6HUYHU

6HUYHU UHTXHVW V GDWD

IURPGHYLFH RYHU

56 QHWZRUN

Client software such as the PMCS Event Logger or

Waveform Capture is used to analyze particular data

from devices. Each client program needs particular

pieces of data from particular devices. The client sends a

DDE request to the Server, the Server queries the

devices for the requested information, and when it has

received the information from the devices, it replies to

the client’s request with the desired information.

An important aspect of DDE is its ‘dynamic’ nature;

once a client has requested information from the Server,

a ‘DDE link’ to that data is established. The Server will

continue to monitor that information and, if any changes

occur, will forward the new data to the client.

2

Page 9

Monitor operation with PMCS

POWER LEADER Modbus Monitor

Chapter 1 – Introduction

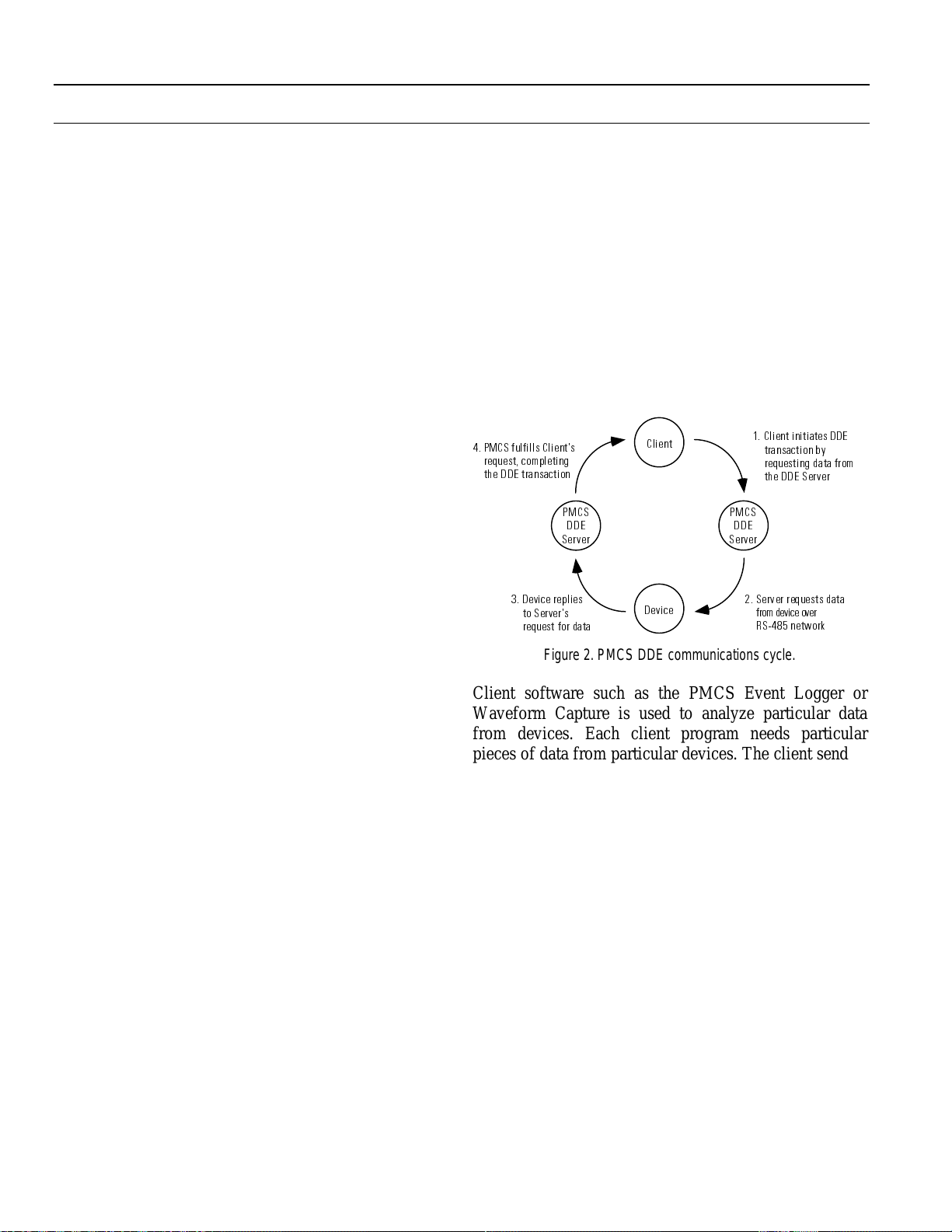

The Proxy’s role in assisting the Monitor in DDE

communications is shown in Figure 3.

The Monitor’s place in this scenario is as a backup

device to the PMCS software on the host computer, and

also as a remote monitor, enabling viewing of PMCS

device data at locations other than the host PC.

When the PMCS DDE Server is present on a network,

Monitors on the network operate as slaves to the PMCS

system acting as master. Because Modbus networks

operate on a master-slave architecture, which allows

only the master device to initiate communications, a

Monitor cannot directly request information from the

devices it needs to track. A special client application

called the Monitor Proxy provides the means for a

Modbus Monitor to obtain the data it requires from

network devices. The Proxy runs on the host PC

alongside the PMCS DDE Server.

When the Monitor Proxy application is launched, its first

task is to query the PMCS DDE Server, checking for any

Monitor devices on the segment. If Monitor devices are

found, the Proxy records their device names and then

asks the DDE Server for each Monitor’s request list

information. The Monitor’s request list is a listing of all

devices and specific data the Monitor needs to display.

The Monitors send their request lists back to the Server,

which passes this information on to the Monitor Proxy,

completing the DDE transaction.

The Proxy now knows which devices each Monitor

needs to track for data and events. The Proxy uses the

information in the Monitor’s request lists to establish

DDE links with the Server for the devices and

corresponding registers. The Server begins polling these

devices for data and sending the data back to the Proxy.

As a slave device, the Monitor cannot initiate

communications or requests for data. However, there is

nothing to prevent the Monitor from ‘eavesdropping’ on

network traffic. The Monitor watches the segment for

requests to and responses from the devices it is supposed

to track and uses this information to update its displays.

The Proxy itself has no need for the data from the

devices, since its purpose is merely to create the

conversation so that the Monitor can eavesdrop on the

reply. The Proxy discards all device data received from

the DDE Server.

D 3UR[\ GLVFDUGV GDWD

KDYLQJ QR XVH IRU WKH

30&6 IXO ILOO V 3UR [ \ V

UHTXHVW FRPSOHWLQJ

WKH ''( WUDQVDFWLRQ

0RQLWRU

D 0RQLWRU HDYHVGURSV

RQ GHYLFHV UHSO\

UHFRUGLQJ WKH GDWD

IRU LWV RZQ OR JV

GDWD LWVHOI

30&6

''(

6HUYHU

'HYLFH UHSOLHV

WR 6HUYHUV

UHTXHV W IRU GDW D

3UR[\

FOLHQW

'HYLFH

3UR[\ LQLWLDWHV ''(

WUDQVDFWLRQ E\

UHTXHVWLQJ GDWD

QHHGHG E\ 0RQLWRU IURP

WKH ''( 6HUYHU

30&6

''(

6HUYHU

6HUYHU UHTXHVWV GDWD

IURP GHYLFH RYHU

56 QHWZRUN

Figure 3. Monitor Proxy and PMCS DDE communications.

The Proxy can also send the PMCS event log to a

Monitor when requested. The Monitor can store the

latest 50 PMCS events if the PMCS Event Logger client

is running on the host PC with the DDE Server.

Monitor stand-alone operation

To a limited degree, the Monitor functions in a manner

very similar to the PMCS DDE Server, acting as master

to a network of power management devices.

The Monitor has been preconfigured with the register

maps of a variety of GE and third-party power

management devices. The user programs the Monitor

with the Modbus addresses and device types of the

devices on the segment(s), and tells the Monitor what

information he wishes to monitor from each device. The

Monitor will query the devices for the desired data and

display it on-screen.

Multiple Modbus Monitors

Up to two Modbus Monitors are permitted on a single

segment. In compliance with the Modbus master-slave

architecture, only one device may act as master at a

given time. However, while one Monitor is acting as

master, the second Monitor is constantly checking for

the master’s presence. Should the master go off-line, the

second Monitor will immediately assume the role of

master device.

3

Page 10

POWER LEADER Modbus Monitor

Chapter 1 – Introduction

Supported Devices

The Modbus Monitor supports three classes of power

management devices: tightly integrated devices, generic

devices, and hybrid devices.

Tightly integrated devices are those device types which

are predefined in the Monitor. The Monitor has a copy of

these devices’ register maps in its memory, and knows

precisely where to find any data it needs from such a

device. The register maps of tightly integrated devices

may not be changed in any way. The display screens of

tightly integrated device types are also pre-defined and

may not be changed (see hybrid devices, below, for more

information on customizing displays).

Generic devices are user-defined. The Modbus Monitor

supports any power management device with registerbased Modbus RTU communications via RS-485. To set

up a generic device, the user must manually enter the

register map (or those parts of interest) into the Modbus

Monitor via the Monitor Configuration Tool (see

Chapter 7, Advanced Configuration). In contrast to the

tightly integrated devices, whose register maps have

already been programmed into the Monitor, the Monitor

knows nothing about a generic device until the user

enters this data. Event recording and special handling

registers are not supported for generic device types.

The third type of device supported by the Monitor is the

hybrid device. This device type is derived from a tightly

integrated device, but is not as loosely defined as a

generic device. A hybrid device type’s register map and

display screens are copied from the register map of a

tightly integrated device, but they may be modified like a

generic device. This allows some flexibility to be

supported by the Monitor without giving up the

convenience of pre-defined tightly integrated devices.

The display screens of tightly integrated devices may be

customized by creating a new hybrid device type based

on the tightly integrated device type in question, and

then modifying the display portion of the device type.

Chapter 7, Advanced Configuration, discusses the

creation and configuration of generic and hybrid device

types.

The Monitor supports up to 31 device types, including

the 21 tightly-integrated devices shown in Table 1. All

tightly integrated devices are fully supported by PMCS

6.0; a sub-set (devices indicated by an asterisk) is

supported by PMCS 5.1.

4

Page 11

POWER LEADER Modbus Monitor

Chapter 1 – Introduction

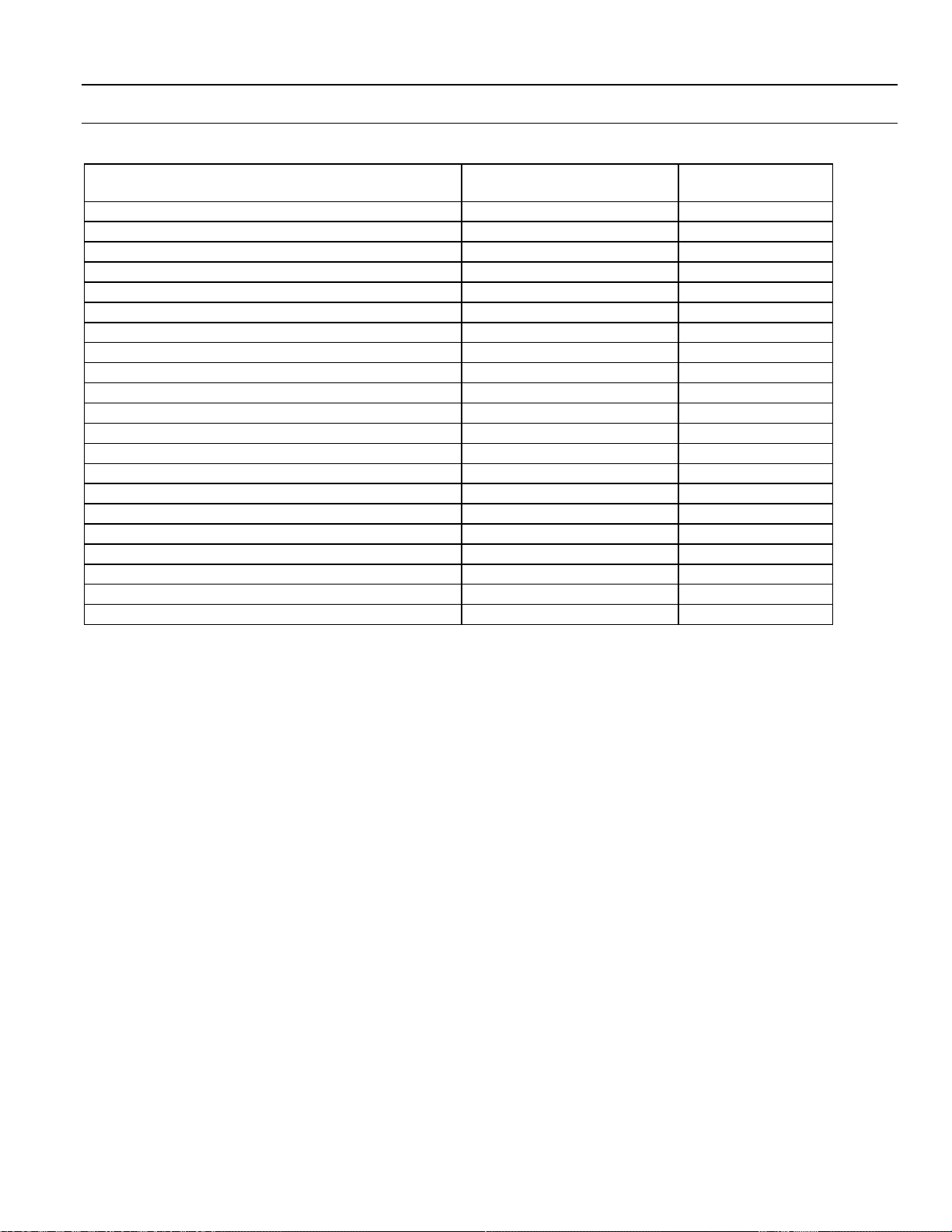

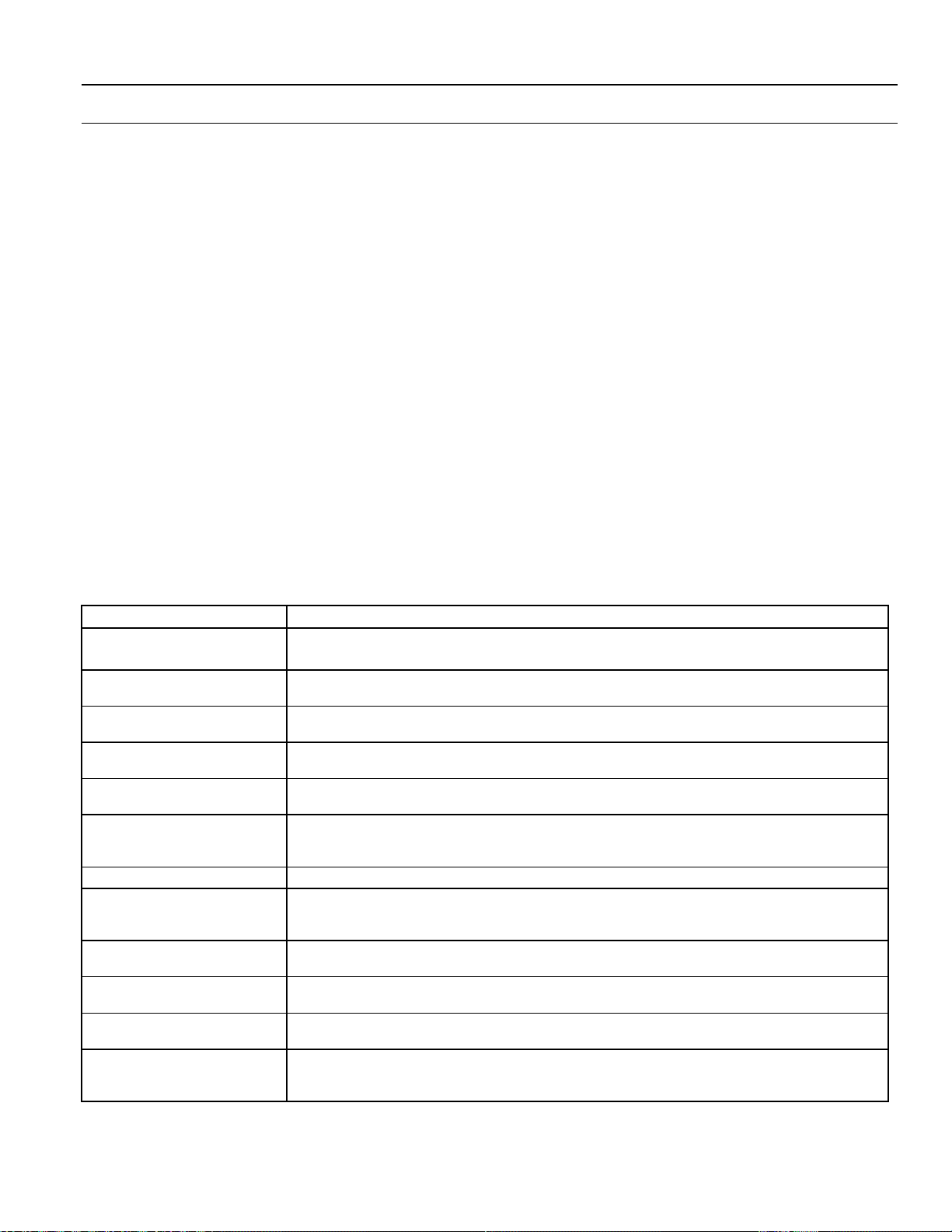

Device Name as displayed on Monitor

screen

POWER LEADER EPM* PL EPM Metering

POWER LEADER Meter* PL Meter Metering

EPM 3710* EPM 3710 Metering

EPM 3720* EPM 3720 Metering

MULTILIN Power Quality Meter (PQM)* Multilin PQM Metering

POWER LEADER MDP Overcurrent Relay* MDP Relay Protection

Spectra MicroVersaTrip™ * Spectra MVT PM Protection

Enhanced MicroVersaTrip™ C* Enhanced MVT PM (RMS9C) Protection

Enhanced MicroVersaTrip™ D* Enhanced MVT PM (RMS9D) Protection

Spectra ECM™ Electronic Control Module* Spectra ECM Protection/Control

MULTILIN 239 Motor Protection Relay* Multilin 239 Protection/Control

MULTILIN 269 Plus Motor Management Relay* Multilin 269 Protection/Control

MULTILIN SR469 Motor Management Relay* Multilin 469 Protection/Control

MULTILIN SR489 Generator Management Relay* Multilin 489 Protection/Control

MULTILIN 565 Feeder Management Relay* Multilin 565 Protection/Control

MULTILIN 735 Feeder Relay* Multilin 735 Protection/Control

MULTILIN SR745 Transformer Management Relay* Multilin 745 Protection/Control

MULTILIN SR750 Feeder Management Relay* Multilin 750 Protection/Control

MULTILIN SR760 Feeder Management Relay Multilin 760 Protection/Control

System Monitor SM-3 Voltage Regulator SM3 Protection/Control

EPM 7300 PML7300 Protection/Control

Function

Table 1. Devices supported by the Monitor.

5

Page 12

POWER LEADER Modbus Monitor

Chapter 1 – Introduction

Typical Network Configurations

0RGEXV0RQLWRU

0RGEXV 0RQLWRU

DFWLQJ DV PDVWHU WR

0RGEXV VHJPHQW

(30 RU

0RGEXV VHJPHQW FRQQHFWV 56 QDWLYH GHYLFHV

MULT ILIN

)(('(5 0$1$*(0(17 5(/$ <

565

0XOWLOLQ

DFWLQJ DV VODYH ZLOO DVVXPH UROH RI

PDVWHU LI 0RQLWRU JRHV RIIOLQH

0LFUR9HUVD7ULS

WULS XQLWV

3720 ACM

32:(5/($'(5

0RGEXV&RQFHQWUDWRU

32:(5 /($'(5

0HWHU

&RPPQHW VHJPHQWV WR 32:(5 /($'(5 &RPPQHW GHYLFHV

Figure 4. Monitor acting as master to a network of POWER LEADER devices.

0RGEXV0RQLWRU

0RGEXV 0RQLWRU

32:(5 /($'(5

(OHFWURQLF 3RZHU 0HWHU

30&6

0DVWHU

(30 RU

0RGEXV0RQLWRU

0RGEXV 0RQLWRU

&RPPQHW VHJPHQWV WR 32:(5 /($'(5 &RPPQHW GHYLFHV

0RGEXV VHJPHQW FRQQHFWV 56 QDWLYH GHYLFHV

3720 ACM

MULT ILIN

)(('(5 0$1$*(0(17 5(/$ <

565

0XOWLOLQ

32:(5/($'(5

0RGEXV&RQFHQWUDWRU

32:(5 /($'(5

0HWHU

Figure 5. Typical PMCS network incorporating Monitor.

0RGEXV0RQLWRU

0RGEXV 0RQLWRU

DFWLQJ DV VODYH ZLOO DVVXPH UROH RI

PDVWHU LI 0RQLWRU JRHV RIIOLQH

0LFUR9HUVD7ULS

WULS XQLWV

32:(5 /($'(5

(OHFWURQLF 3RZHU 0HWHU

6

Page 13

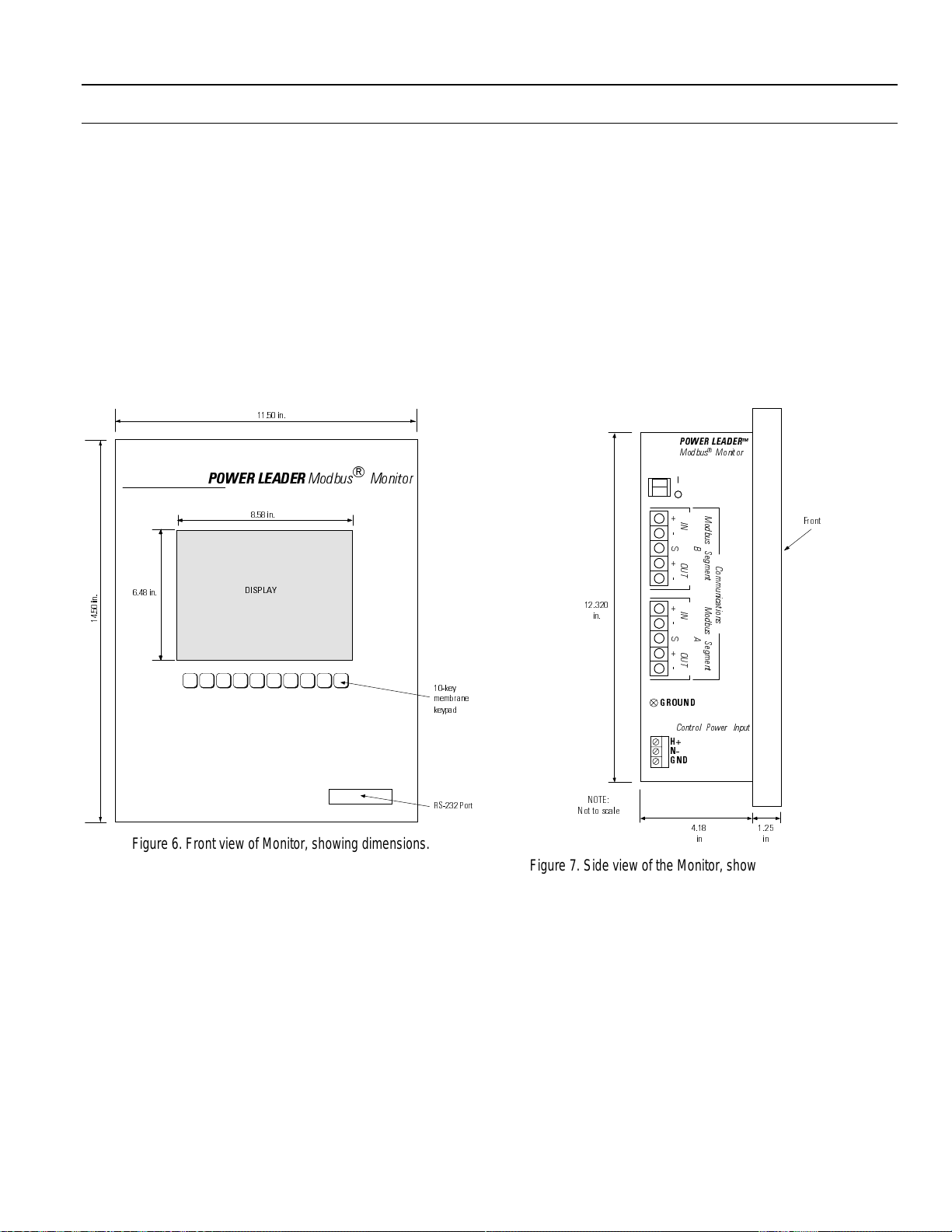

Physical Description

Figure 6 and Figure 7 show the dimensions of the

Monitor. The important features of the Monitor are listed

below:

• The Monitor’s front panel display is used for viewing

device data and event messages during operation, for

diagnostics purposes, and for some very limited

configuration capabilities.

• The keypad is located directly beneath the display. Ten

keys are used for navigating the menus of the Monitor.

LQ

32:(5 /($'(5

0RGEXV0RQLWRU

POWER LEADER Modbus Monitor

Chapter 1 – Introduction

• A set of three terminals for AC or DC control power

input are provided on the side of the case.

• A grounding screw is provided above the control power

connection.

• Two five-terminal connectors on the side of the case

provide daisychained RS-485 input and output

connections to one or two Modbus segments.

• The on/off switch for the Monitor is located on the side of

the case above the RS-485 connectors.

32:(5 /($'(5

0RGEXV0RQLWRU

70

LQ

LQ

LQ

',63/$<

Figure 6. Front view of Monitor, showing dimensions.

NH\

PHPEUDQH

NH\SDG

56 3RUW

0RGEXV 6HJPHQW

LQ

127(

1RW WR VFDOH

,1 287 ,1 287

%

0RGEXV 6HJPHQW

$

66

*5281'

&RQWURO 3RZHU ,QSXW

+

1

*1'

LQ

&RPPXQLFDWLRQV

)URQW

LQ

Figure 7. Side view of the Monitor, showing dimensions and

connections.

7

Page 14

POWER LEADER Modbus Monitor

Chapter 1 – Introduction

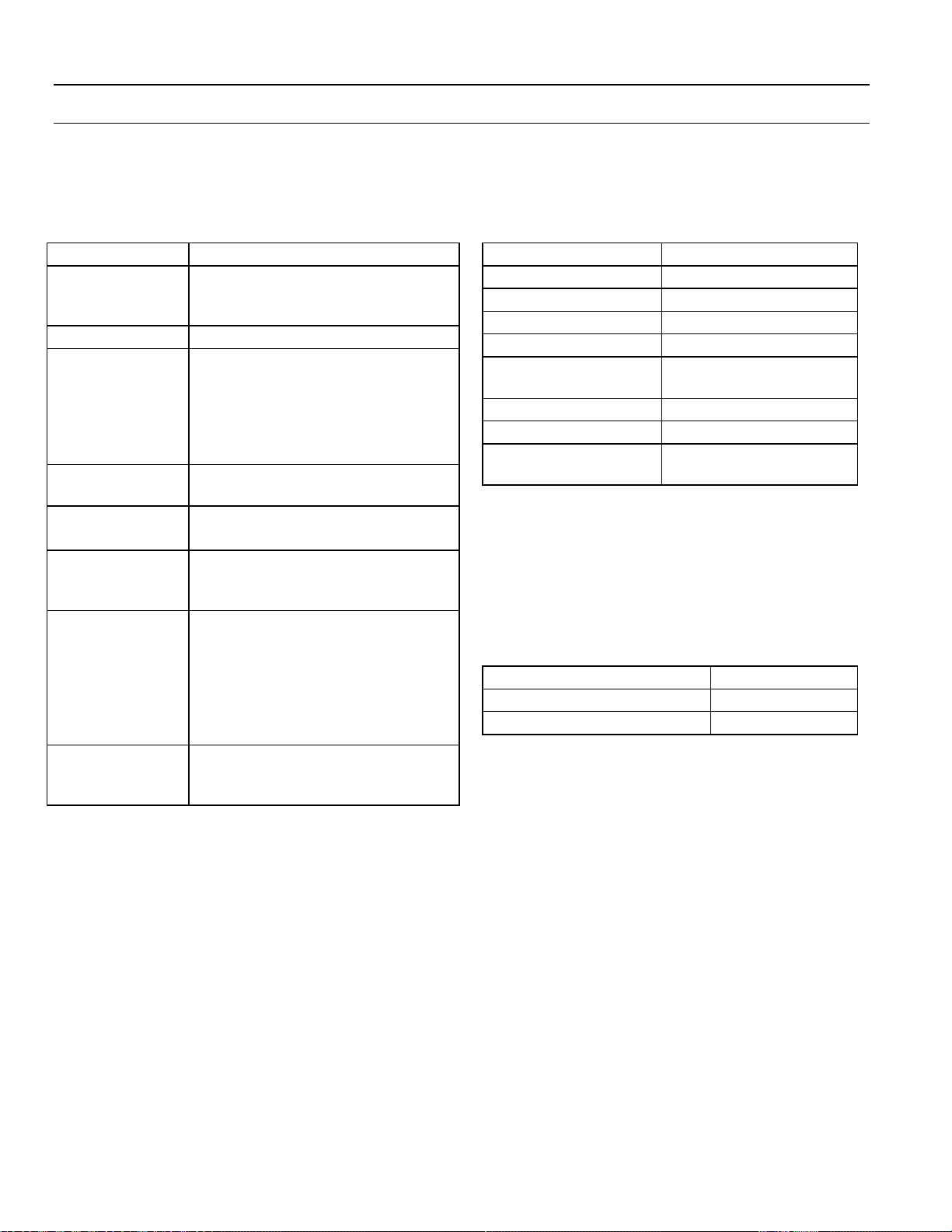

Specifications

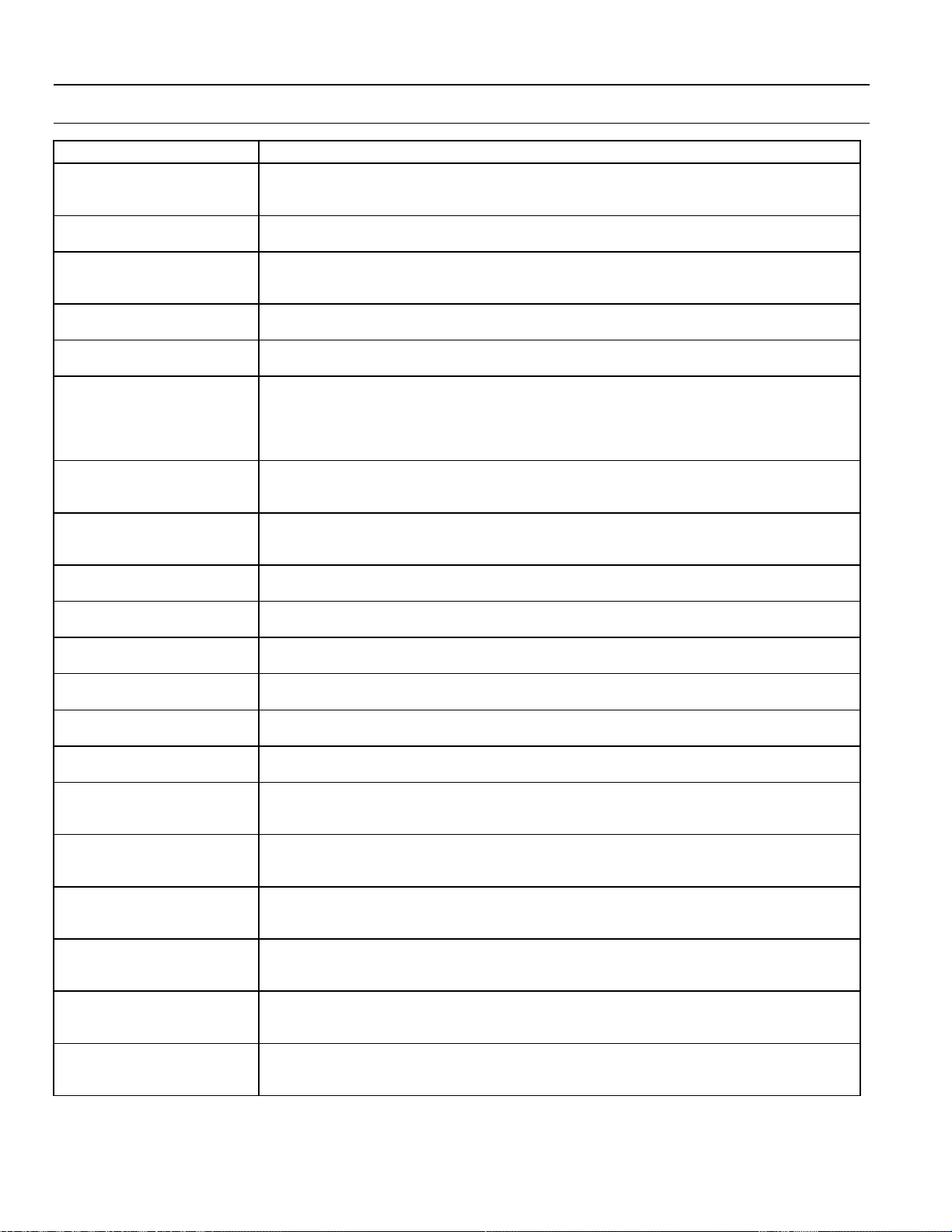

The specifications of the Modbus Monitor are listed in

Table 2.

Parameter Value

Control power 100–240 Vac, 50, 60 Hz;

125–250 Vdc;

30 W min

Current draw for fusing Use 1.5A – 3.0A slow-blow fuse

Modbus communications Two RS-485 ports, 1200 baud, 2400 baud, 4800

baud, 9600 baud, and 19.2 Kbaud supported; no

parity, eight data bits, one stop bit.

Mating connector: Precision Connector Designs

(PCD) ELFT03260 or equivalent (supplied with

unit)

RS-485 Modbus

interconnections

Standards: UL 508, File No. E146421

Device types supported The Monitor supports up to 32 device types,

Devices per Modbus

segment

Compatible Modbus RTU

Host Software

Bare wire, AWG #12–24

CSA: C22.2 No. 14, File No. LR-77871-25

including the 21 Tightly Integrated Device types

and the Modbus Monitor device type itself.

Per the Modbus standard, up to 32 total ‘drops’

(devices) per segment,

applicable) PMCS host.

Up to 215 commnet devices may be supported via

Modbus Concentrators.

See GEH-6502,

Guide

, for details.

GE Industrial Systems

Power Management Control System, version 5.1 or

greater

including

Monitors and (if

PMCS Network Architecture

Environmental

The environmental requirements of the Monitor are

listed in Table 3.

Parameter Value

Operating temperature 0° C to +65° C

Storage temperature –20° C to +80° C

Relative humidity 5% to 95% noncondensing

Environmental exposure NEMA 12

Vibration response and

endurance

Fast transient surge ANSI C37.90.1

Radiated EMI withstand ANSI C37.90.2

Electrostatic discharge IEC 801–2

Table 3. Monitor environmental requirements.

IEC 255–21–1

Severity Class 1

Severity Class 4

Catalog Numbers

Two versions of the Monitor are available: a single RS485 port version and a dual RS-485 port version. Catalog

numbers for each version are shown in Table 4.

Description Catalog Number

Monitor, single RS-485 port PLMNTR1

Monitor, dual RS-485 port PLMNTR2

Table 4. Monitor catalog numbers.

Table 2. Monitor specifications.

8

Page 15

Chapter 2

Installation

The installation of a Monitor is straightforward and

relatively simple. The device is mounted in an

appropriate cutout in switchgear or a panelboard, control

power and grounding connections are made, and the RS485 connections to one or two Modbus segments are

made. Software necessary to configure the Monitor must

be installed on a PC. Finally, if the Monitor is to be used

as part of a PMCS system, a special client software

package called the Modbus Monitor Proxy must be

installed on the host PC where PMCS runs. This chapter

presents the instructions for each of these procedures.

Valid Network Architectures

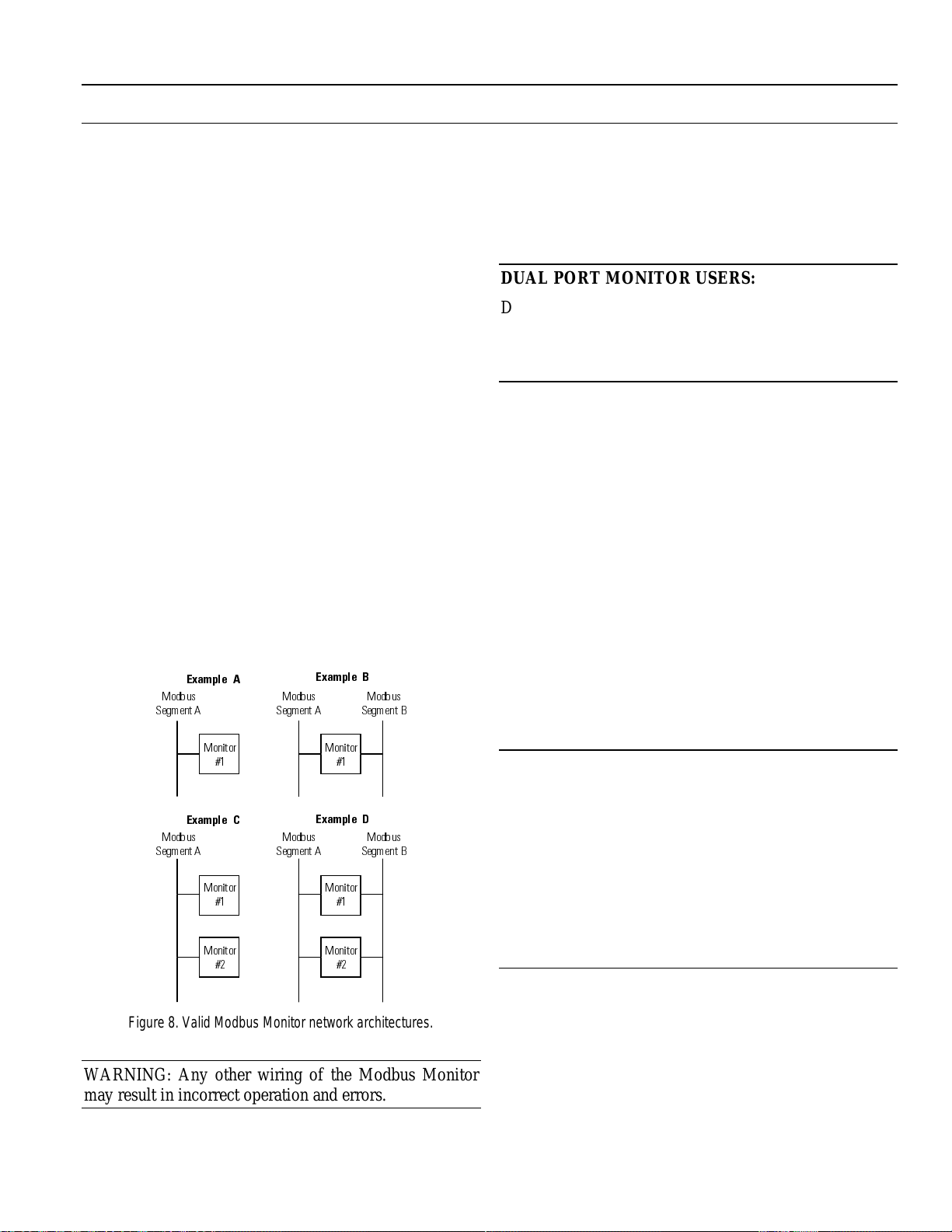

There are only four permissible network architectures

with which the Modbus Monitor may be used. Select the

architecture appropriate for the network you have

designed. Refer to GEH-6502, the POWER LEADER

PMCS Network Architecture Guide for information on

designing RS-485 networks. These are shown in Figure

8, below.

0RGE XV

6HJPHQW $

0RGE XV

6HJPHQW $

([DPSOH %

0RGE XV

6HJPHQW %

0RQLWRU

([DPSOH '

0RGE XV

6HJPHQW %

0RQLWRU

0RQLWRU

([DPSOH $

0RGEXV

6HJPHQW $

0RQLWRU

([DPSOH &

0RGEXV

6HJPHQW $

0RQLWRU

0RQLWRU

POWER LEADER Modbus Monitor

Chapter 2 – Installation

DUAL PORT MONITOR USERS:

DO NOT CONNECT THE MONITOR’S TWO RS-485

PORTS TO THE SAME MODBUS SEGMENT. This

will cause communications errors and misoperation of

the Monitor.

Example A shows a single Modbus Monitor wired to a

single Modbus segment. Example B shows the same

monitor in a dual-port version, wired to two different

Modbus segments.

Examples C and D illustrate fully loaded Modbus

segments - no more than 2 Monitors are permitted on a

given Modbus segment.

Example C illustrates a pair of Monitors connected to a

single Modbus segment. In this example, the Monitors

may be either single port or dual-port versions, provided

both are the same. You may not mix single-port and

dual-port Monitors on a Modbus segment (see note

below.)

Example D shows the same pair of Monitors wired to a

second Modbus segment.

IMPORTANT: With regard to Example C (two Monitors

on a single RS-485 segment) it is NOT permissible to

mix different models of Monitors on a segment.

Monitors #1 and #2 MUST be of the same model, either

both single-port or both dual-port.

The nature of the other network architectures makes this

concern irrelevant for examples A, B and D, since in

Example A you could have either a single or a dual port

Monitor, and in Examples B and D, you may only use a

dual-port monitor(s).

Figure 8. Valid Modbus Monitor network architectures.

WARNING: Any other wiring of the Modbus Monitor

may result in incorrect operation and errors.

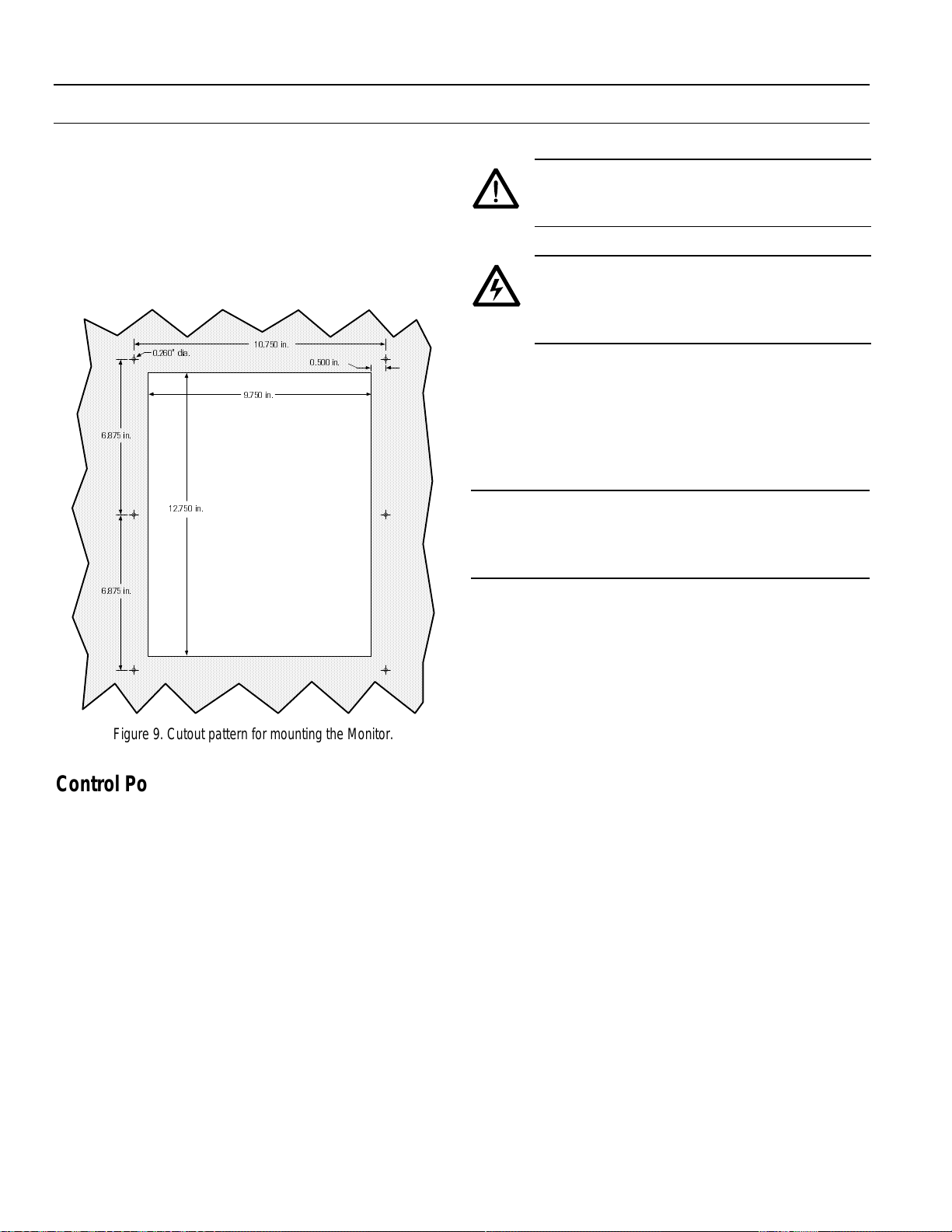

Mounting

The hole pattern for mounting the Monitor in switchgear

is shown in Figure 9. Insert the Monitor through the

mounting hole, being careful to line up the six faceplate

studs with the six holes drilled in the panel. From the

9

Page 16

POWER LEADER Modbus Monitor

Chapter 2 – Installation

back of the panel, apply the lock washers and mounting

nuts (included with the Monitor) to the studs. Hand

tighten them with a small wrench.

Be sure to allow clearance behind the unit so that the fan

can operate effectively and along the bottom of the unit

where the ventilation vents are located. A minimum of

0.25 inch must be allowed.

GLD

LQ

LQ

LQ

NOTE: Failure to properly connect earth ground to

the Monitor may result in inconsistent or noisy

network communications.

WARNING: Failure to properly connect earth

ground may result in voltages hazardous to

personnel and equipment being present at the

Monitor enclosure.

RS-485 Connection(s)

LQ

LQ

LQ

Figure 9. Cutout pattern for mounting the Monitor.

Control Power Connections

Control power connections are made on the side of the

case. The connectors are labeled H+, N-, and GND. The

appropriate power cable terminations are spade lugs on

AWG #12–18 wire. See Table 2 for control power

voltage ranges. Hand-tighten connection screws with a

Phillips head screwdriver.

On the side of the Monitor case are two five-pin

connectors labeled Modbus Segment A and Modbus

Segment B.

NOTE:

Both connectors are present and labeled

regardless of whether the individual Monitor is a single

or dual port version. In the single port version, the

Segment B connector is disabled.

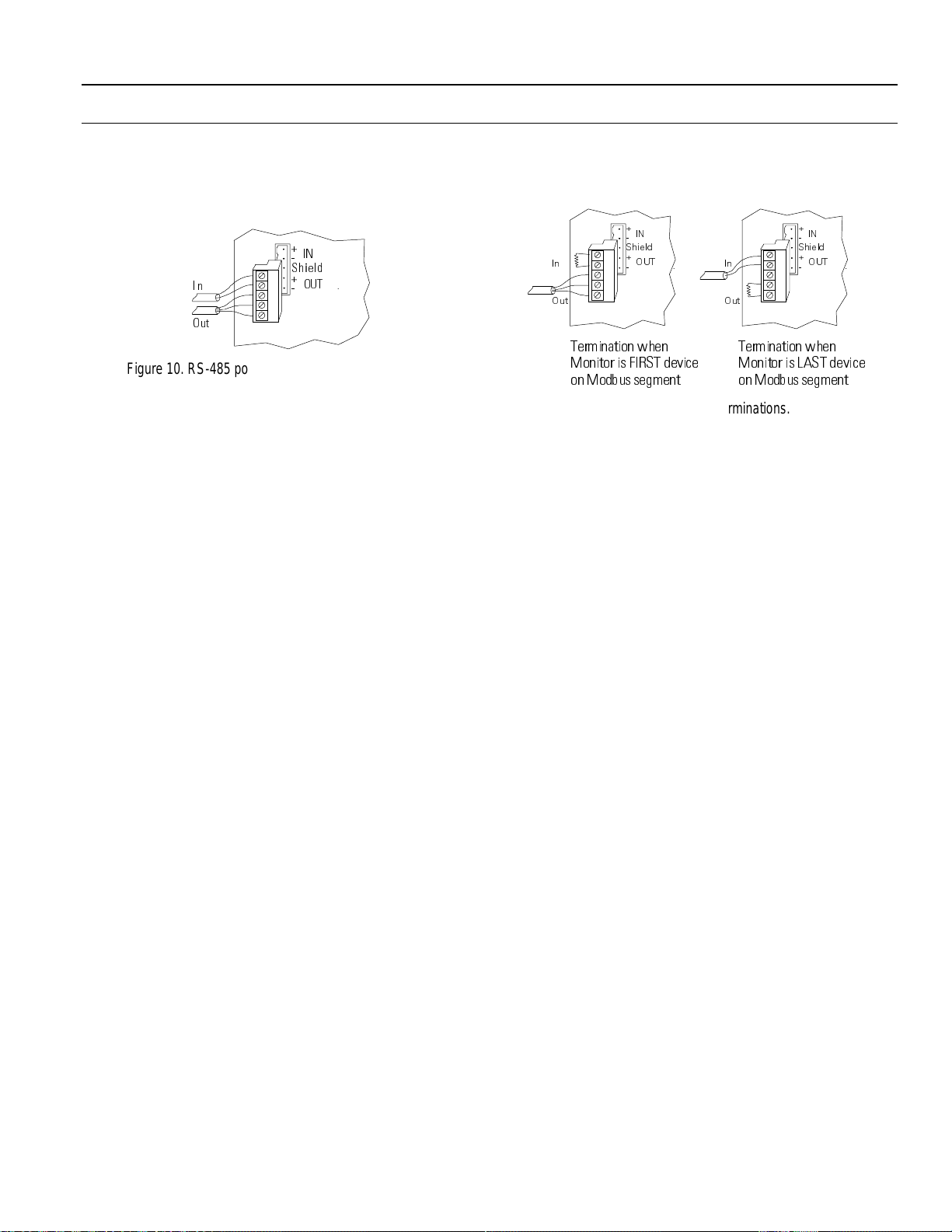

Mating connectors (one for each segment) are included

with the Monitor for customer connection. The pinout

for assembling the mating connector is shown in Figure

10. If the Monitor is to be the first or last device on the

RS-485 network, it must be terminated using the

enclosed terminating resistor. Place the resistor between

the appropriate + and - connections on the mating

connector. (See below for details on RS-485

termination).

Grounding

The Monitor chassis should be connected to earth

ground for personnel safety reasons. Connect earth

ground to the green-colored grounding screw on the side

of the Monitor enclosure. Earth ground connection

requires #14 AWG or thicker wire and a ring or spade

lug.

10

Page 17

POWER LEADER Modbus Monitor

Chapter 2 – Installation

When the assembly is complete, plug the connector into

port labeled Segment A on the side of the Monitor, as

shown in Figure 10.

,1

6KLHOG

,Q

2XW

287

Figure 10. RS-485 port and RS-485 connector pinouts.

The connectors labeled

should be wired to the cable

IN

coming from the host (or previous device), or should be

terminated if the Monitor is the first device on the

Modbus segment. The

RS-485 IN

connector of the next Modbus device, or

connectors are wired to the

OUT

terminated if the Monitor is the final device on the

Modbus segment. Please study and follow the RS-485

grounding considerations and termination rules below to

ensure the correct operation of your Modbus segments.

If the Monitor is to be connected to a second Modbus

segment, follow the procedures outline above to wire the

connector, and plug it into the port labeled

Segment B

on the side of the Monitor. Note that

Modbus

termination considerations are independent for each

segment; i.e., the Monitor may need to be terminated for

one or both RS-485 segments, or for neither, if it is

positioned in the middle of the segment(s).

Figure 11 illustrates appropriate termination of an RS485 segment at the Modbus Monitor

,1

6KLHOG

,Q

2XW

287

7HUPLQDWLRQ ZKHQ

0RQLWRULV ),567 GHYLFH

RQ 0RGEXV VHJPHQW

Figure 11. RS-485 Terminations.

,Q

2XW

7HUPLQDWLRQ ZKHQ

0RQLWRULV /$67 GHYLFH

RQ 0RGEXV VHJPHQW

,1

6KLHOG

287

RS-485 Termination Considerations

Per the EIA485 standard, every RS-485 network must be

terminated at both ends. If the Modbus Monitor is the

first device, place the supplied 120-ohm, 1/2-watt

resistor between the + and - connectors of the

port. If the Modbus Monitor is the last device, place the

supplied 120-ohm, 1/2-watt resistor between the + and connectors of the

RS-485 OUT

port.

RS-485 IN

11

Page 18

POWER LEADER Modbus Monitor

Chapter 2 – Installation

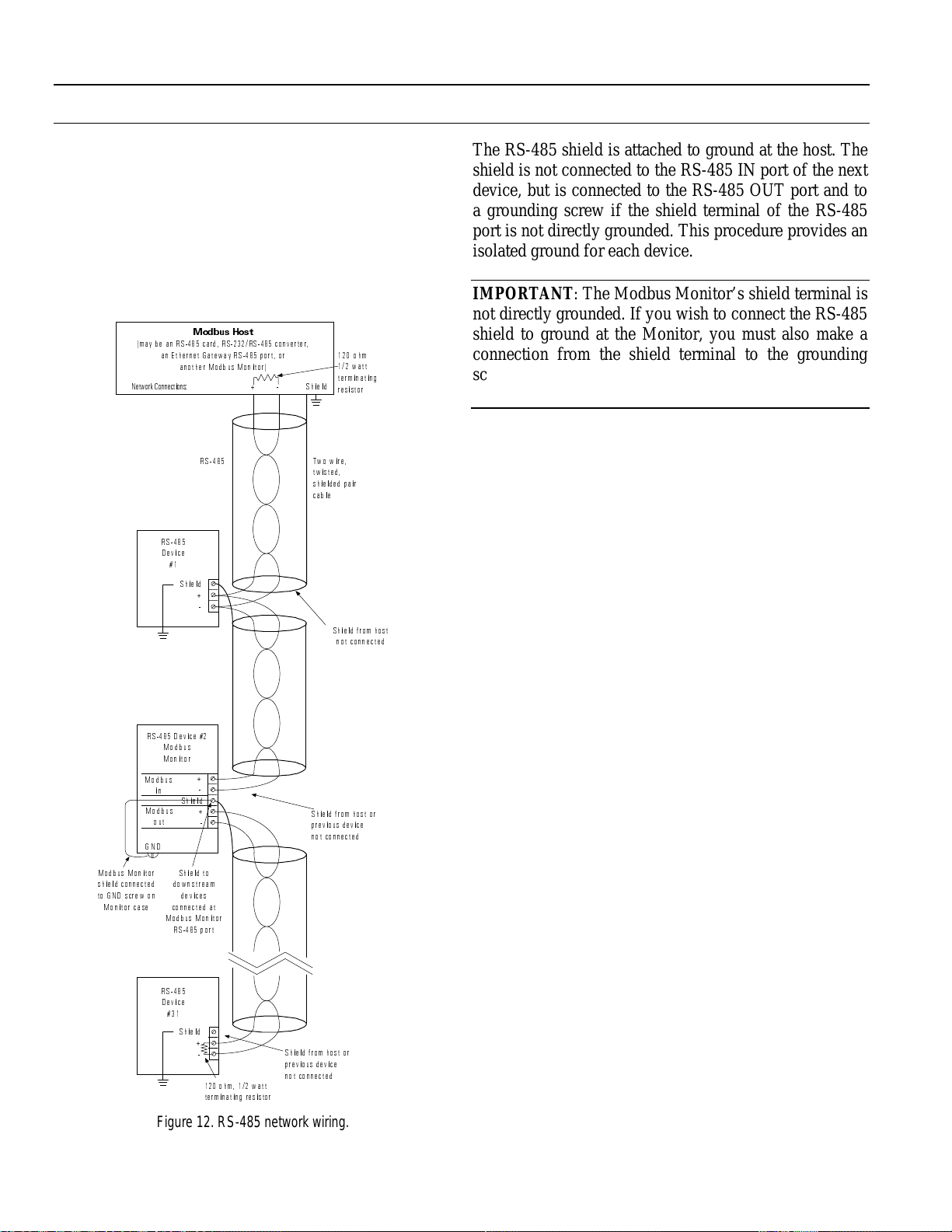

RS-485 Grounding Considerations

Figure 12 illustrates correct wiring for communications

and shield grounding. By following this example, a

secure grounding point will be provided for each device

on the network. Any surge will dissipate locally without

being carried up or down the network to other devices,

thus minimizing the chance for damage to devices due to

surge or EMI.

PD\ EH DQ 56 FDUG 56 56 FRQYHUWH U

1HWZRUN &RQQHFWLRQV 6K L H O G

0RGEXV

0RGEXV

*1'

0RGEXV 0RQLWRU

VKLHOG FRQQHFWH G

WR *1' VFUHZ RQ

0RQLWRU F DVH

0RGEXV +RVW

DQ (WKHUQHW *DWHZD \ 56 SRUW RU

DQRWKHU 0R GEXV 0 RQLWRU

56

56

'HYLFH

6KLHOG

56 ' HYLFH

0RGEXV

0RQLWRU

LQ

6KLHOG

RXW

6KLHOG WR

GRZQVWUHDP

GHYLFHV

FRQQHFWH G DW

0RGEXV 0RQLWRU

56 SRU W

RKP

ZDWW

WHUP LQDW LQJ

UHVLVWRU

7ZR ZL UH

WZLV WHG

VKLHOGHG SDLU

FDEOH

6KLHOG IURP KRVW

QRW FRQQHFWHG

6KLHOG I URP KRVW RU

SUHYLR XV G HYLFH

QRW FRQQHFWHG

The RS-485 shield is attached to ground at the host. The

shield is not connected to the RS-485 IN port of the next

device, but is connected to the RS-485 OUT port and to

a grounding screw if the shield terminal of the RS-485

port is not directly grounded. This procedure provides an

isolated ground for each device.

IMPORTANT: The Modbus Monitor’s shield terminal is

not directly grounded. If you wish to connect the RS-485

shield to ground at the Monitor, you must also make a

connection from the shield terminal to the grounding

screw on the Monitor’s case. Use AWG #12-14 wire for

this connection.

Software Installation

Modbus Monitor Configuration Tool

Configuration of the Monitor requires a Windows-based

software program, the Modbus Monitor Configuration

Tool. This program is included with the Modbus

Monitor, on several 3.5” high density floppy disks. This

section describes installation of this software onto a PC.

A laptop PC’s portability lends itself well to this use if

configurations are to be downloaded to Monitors already

installed in the likely facility-floor setting. However, it is

acceptable to create configuration files on a desktop PC

and then copy the files to a laptop for transportation to

the Monitor’s location.

The Configuration Tool requires a 486 or better PC

running Windows 3.1x, at least 8 megabytes of RAM,

and a floppy drive for installing the Configuration Tool

from the floppy disk. A minimum of 15 megabytes of

hard disk space is required to install the Configuration

Tool. A mouse is recommended for ease of use, but not

required.

To install the Monitor Configuration Tool on the

selected PC:

56

'HYLFH

6KLHOG

RKP Z DWW

WHUPLQDWLQJ UHVLVWRU

6KLHOG I URP KRVW RU

SUHYLRXV GHYLFH

QRW FRQQHFWHG

Figure 12. RS-485 network wiring.

1. Power up the PC and launch Windows. Start the

Windows Program Manager.

2. Insert the Monitor Configuration Tool disk

labeled “DISK 1”.

3. Select Run from the Program Manager’s File

Menu.

4. Enter A:\setup.exe and press return.

12

Page 19

POWER LEADER Modbus Monitor

Chapter 2 – Installation

A new program group with the name Modbus Monitor

Configuration Tool will be created. In it will be a

README file and the Configuration Tool application.

Double-click on the application’s icon to launch the

Configuration Tool.

Modbus Monitor Proxy

For the Modbus Monitor to function in slave mode in a

PMCS system, the Modbus Monitor Proxy client

program must be installed on the host PC where the

PMCS DDE Server is running. Complete the PMCS

installation, then perform the Proxy installation as

described below. The Modbus Monitor Proxy program is

included with the Modbus Monitor on 3.5” high density

floppy disk(s).

NOTE: PMCS requires the Windows NT 4.0 operating

system, therefore the Modbus Monitor Proxy also

requires NT 4.0.

To install the Modbus Monitor Proxy:

Maintenance

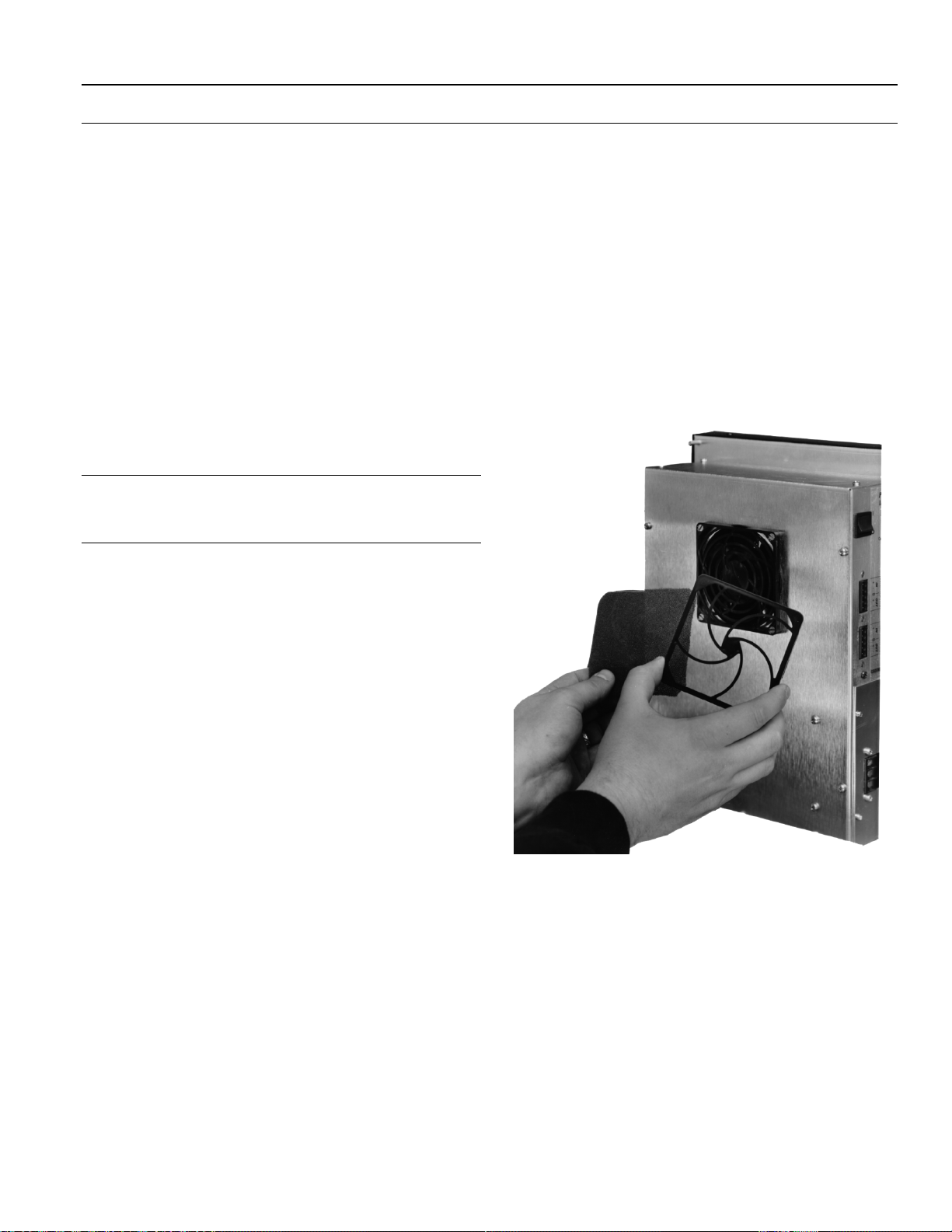

The Modbus Monitor requires very little operational

maintenance due to its heavy-duty industrial

construction. However, it is recommended that the

cooling fan filter be cleaned periodically to prevent

unnecessary heat buildup inside the Monitor case.

To clean the fan filter, remove the plastic gasket from

the rear of the Monitor case, then remove the fan filter

itself, as shown in Figure 13. Gently vacuum or shake

the filter to remove any accumulated dust or debris, or

blow the debris off using a can of compressed air.

Replace the filter and gasket when cleaning is complete.

1. Log in to Windows NT on the host PC.

2. Insert the Modbus Monitor Proxy disk labeled

Disk 1.

3. Select Run from the Windows NT Start menu.

4. Enter A:\SETUP and hit return.

Follow the on-screen instructions. The installer will

prompt you to select a directory to install the Proxy in.

The default is C:\Monitor.

You will be prompted to locate the PMCS DDE Server’s

.ini file. This file is usually located in the WINNT\

directory and will have the name GE32MODB.ini or

GE32ENET.ini.

If you’re using the PMCS Event Logger client program,

you’ll also be asked to locate the directory where the

Event Logger database file is located. The file name is

EventLog.mdb and is usually located in the directory

GE_PMCS\EventLog\ .

To use the Proxy, launch the application from the Start

menu. You’ll find an icon for the program named GE

Modbus Monitor Proxy. Launching the Proxy

application automatically starts the PMCS DDE Server.

Figure 13. Removing the cooling fan filter.

13

Page 20

POWER LEADER Modbus Monitor

Chapter 2 – Installation

(This page left blank intentionally.)

14

Page 21

POWER LEADER Modbus Monitor

Chapter 3

Configuration

Chapter 3 – Configuration

After installing the Modbus Monitor, some initial

configuration is required to set up the Monitor for

communications. Communications settings such as baud

rate, parity, and Modbus address must be set to

correspond with the network’s settings.

Once the Monitor has been successfully configured for

network communications, it must also be configured for

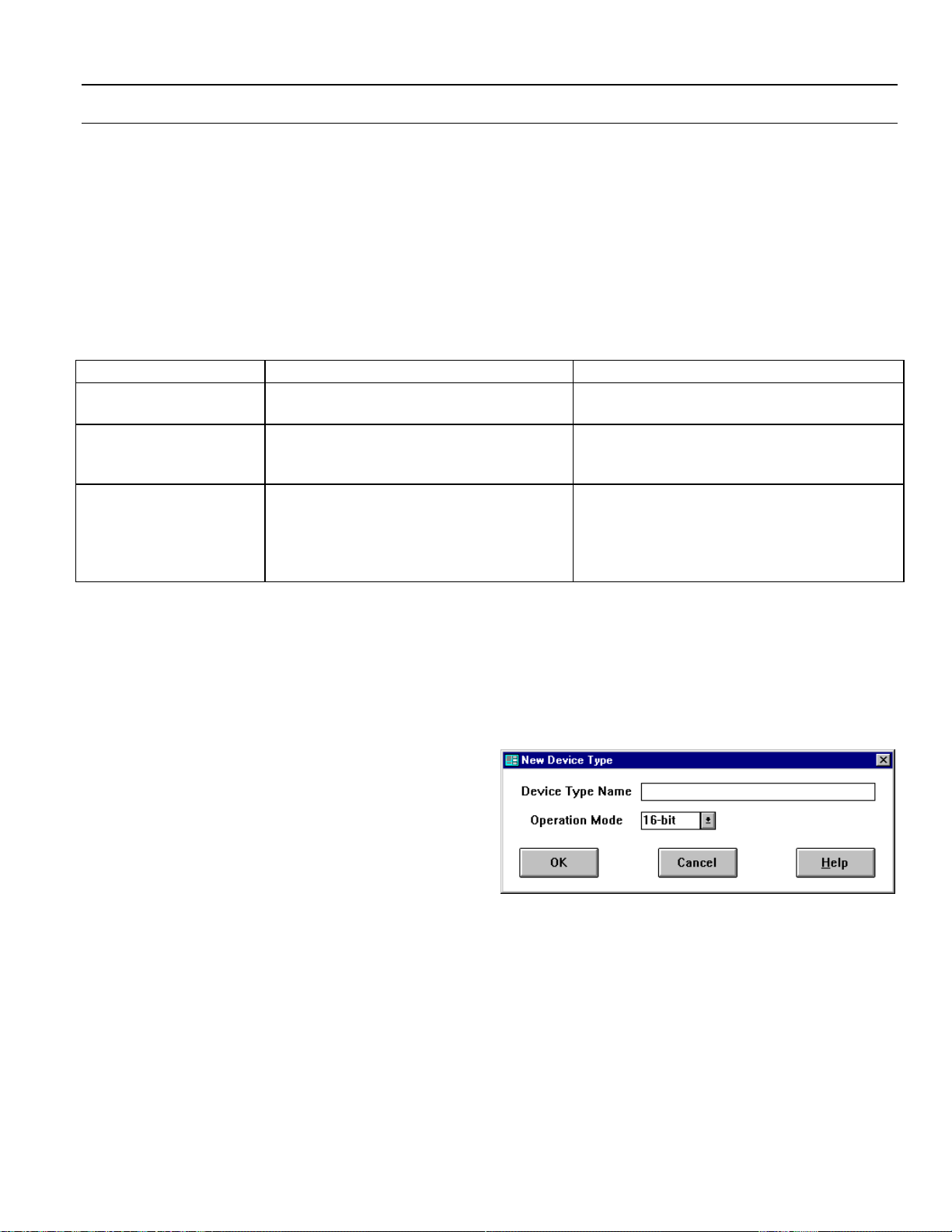

its task: monitoring the other devices on the network. To

successfully monitor other devices on the Modbus

segment(s), a Monitor must know the Modbus addresses

and device types of all the devices on the segment(s).

These configuration tasks require the use of the Modbus

Monitor Configuration Tool, a Windows-based software

program included with the Modbus Monitor.

The Modbus Monitor Configuration Tool is used to

create a “profile” of the Monitor, consisting of all the

different configurable attributes, such as

communications settings, information on devices

connected to the Modbus segment(s), the register maps

for these devices, etc.

Once the desired profile has been established, it can be

downloaded to the Monitor via the RS-232 port on the

Monitor’s front panel. When a new profile has been

downloaded to the Monitor, the old profile will be

replaced and the new profile will take effect.

This chapter will cover using the Configuration Tool to

create a profile for the Monitor and how to download the

profile to the Monitor. Later in the chapter, we’ll discuss

what other configuration options are available from the

Monitor’s display/keypad, not requiring the

Configuration Tool.

Modbus Monitor Configuration Tool

First, launch the Monitor Configuration Tool from the

Windows Program Manager. The Modbus Monitor

Configuration Tool main window will appear (Figure

14).

There are three pulldown menus available from the main

screen of the Configuration Tool. The first, File, offers

standard options to create a new database of Monitor

configurations, open an existing database, or create a

new database by Saving the current database As… under

a new file name. Within one database, you may have

many Monitor configurations. This allows you to group

configurations by project or customer; for instance, you

might have a file called Customer_A and within that file,

there might be configurations named Plant 1 Monitor 1,

Plant 1 Monitor 2, Paint Shop Monitor, etc.

The Configuration pulldown menu offers access to the

Print dialog box (discussed later in this chapter) and the

View dialog box, which permits you to create, modify or

delete configurations within a database. The View dialog

box is shown in Figure 15.

The third pulldown menu, Help, offers the standard

Contents item, which accesses the Configuration Tool’s

HELP table of contents, and the About dialog, which

gives information about the version of the Configuration

Tool you are using.

15

Page 22

POWER LEADER Modbus Monitor

Chapter 3 – Configuration

Figure 14. Configuration Tool main screen.

Figure 15. Configuration Tool View dialog.

16

Page 23

We’ll begin by creating a New Monitor Configuration.

Select the Define a New Monitor Configuration radio

button and then click OK. (If you wish to make changes

to an existing monitor configuration, select Modify an

Existing Monitor Configuration.)

The New Configuration dialog box appears:

Figure 16. New Configuration screen.

Enter the name to be assigned to the new monitor. The

name must be between 4 and 20 alphanumeric

characters. Next, from the pull-down list labeled

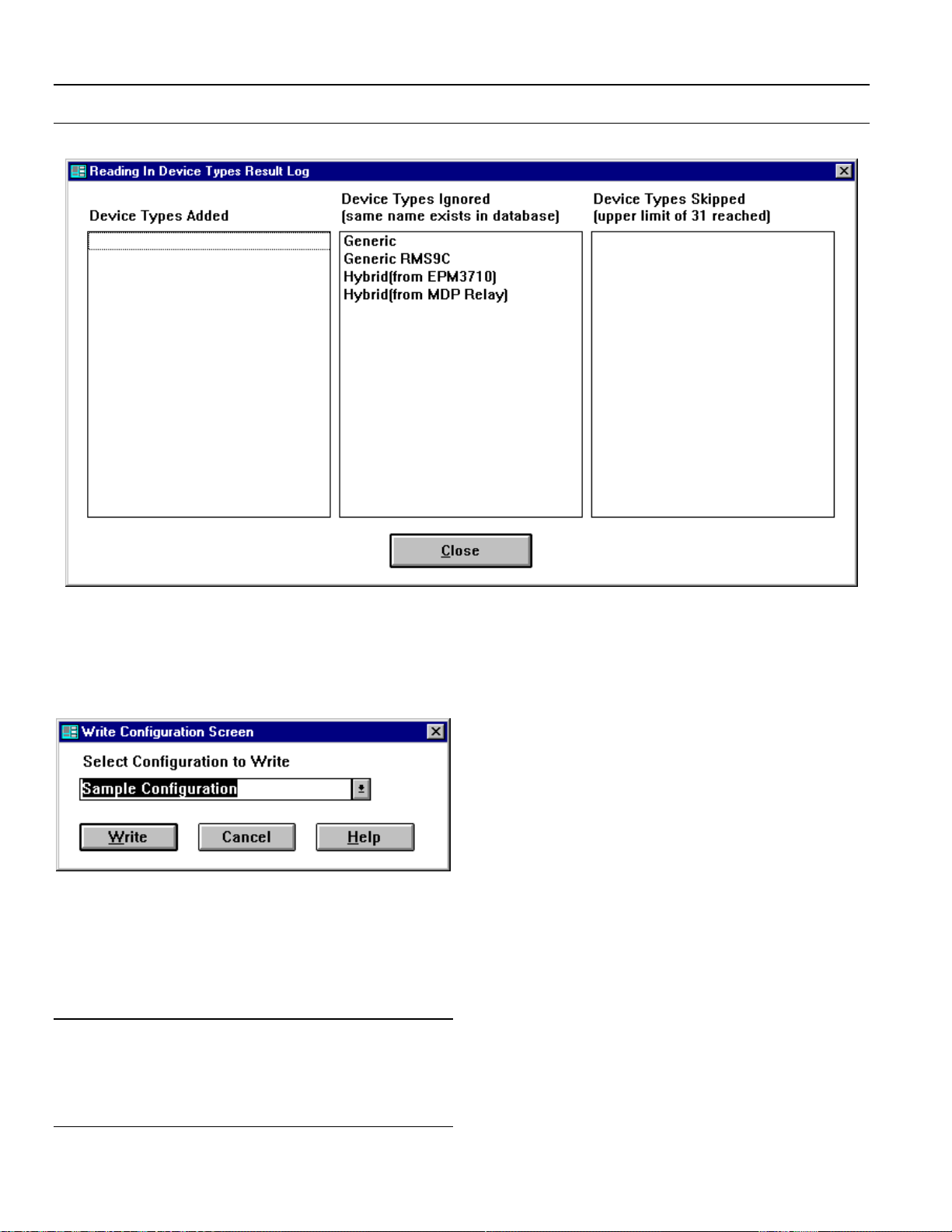

“Number of Ports”, select the number of Modbus ports

(1 or 2) appropriate for the particular Monitor you’ll be

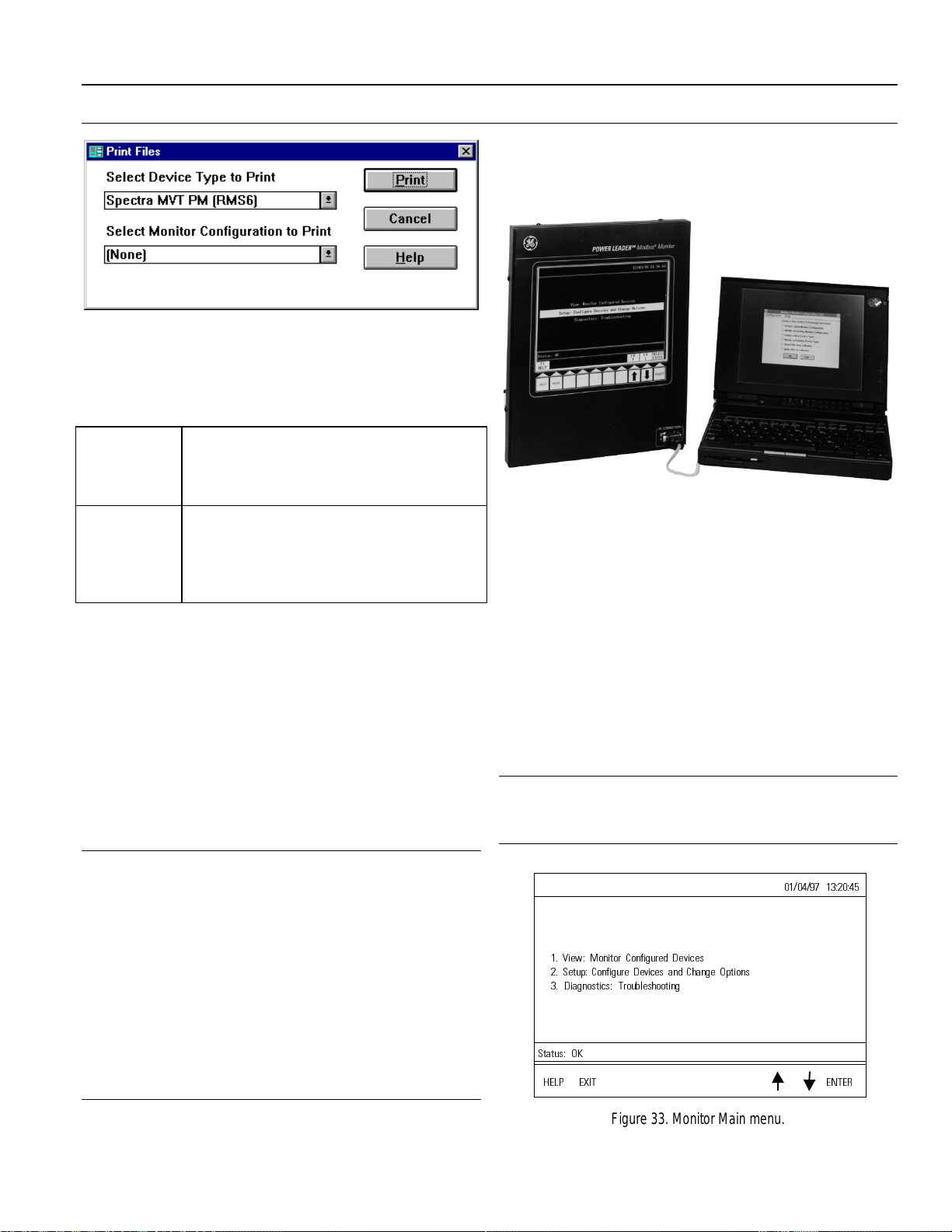

configuring, then click OK to display the Port

Configuration dialog box (Figure 17).

POWER LEADER Modbus Monitor

Chapter 3 – Configuration

Figure 17. Port Configuration screen.

Complete the configuration for the RS-485

communications segments, setting the Baud Rate, Parity,

Flow Control and Stop Bits to match the

communications specifications for the rest of each

segment. The default values are pre-selected and are

typically not changed for Modbus RTU systems: Baud

Rate: 19200, Parity: None, Flow Control: None, Stop

Bits: 1. These fields are described in the following table.

Notes on Modbus Monitor Configuration Tool Keyboard Interface

While using a mouse makes navigating the dialog boxes of the Configuration Tool much easier, not all laptop computers are

equipped with a mouse or trackpad. Therefore there are keyboard shortcuts available to complete all dialog boxes of the

Configuration Tool.

To select an option button gro uping, press the TAB key until the desired selection is highlighted. Then use the up/down arrow

keys to select the desired option.

To select items from a pull-down list, press the Tab key until the pull-down list box is active, p ress alt-down arrow to d isplay th e

full pull-down list. Use the up/down arrow keys to scroll to your desired selection, then press TAB to move the desired command

button, or press ENTER to accept the default command of that dialog box.

To select items from a standard list box, TAB to the list box, then press the do wn arrow key to highlight the first item in the list.

Then use the up/down arrow keys to make your selection. Press TAB to move to the desired command button or ENTER to accept

the default command of that dialog box.

Selecting the Default System Menu (the upper left hand corner of the window) is done by pressing the Alt key, then the down

arrow key (NOT as a combination, but as a sequence). Use the up/down arrow keys to select the desired item or press the short-cut

key (example: “m” for Move or “c” for Close).

Short cut keys are available for most command buttons in a window. Use the Tab key to move the desired button, then press

ENTER or the SPACE BAR. Additionally, some command buttons include a short-cut key combination, indicated by the

underlined letter of the button’s caption. Pressing Alt and that letter simultaneously invokes that command. For example, on the

Device Table screen, you can add a new device by pressing ALT+A.

17

Page 24

POWER LEADER Modbus Monitor

Chapter 3 – Configuration

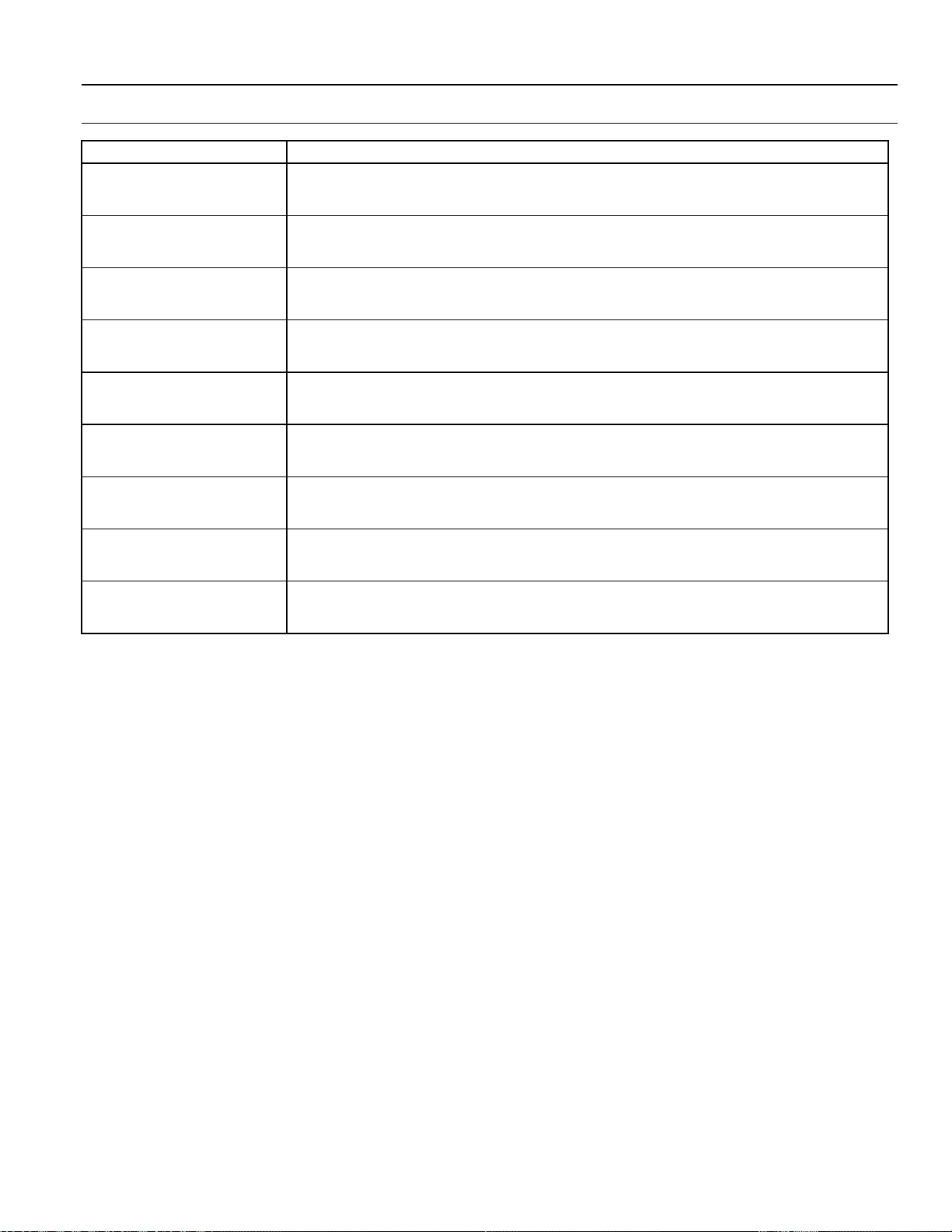

Segment For two port Monitors, select the segment to configure;

the rest of the values in this dialog box will apply to the

segment selected here. A one-port Monitor will have

this box frozen to “A” as port B will be unavailable.

Monitor Address Select the Modbus Address for the segment selected

above. Addresses assigned to other devices will not be

available.

Baud Rate Select the communications speed for the segment. The

Monitor supports baud rates of 1200, 2400, 4800, 9600

and 19.2kbaud.

Parity If the segment being configured uses parity in its

communications, select that here. Default is none.

Flow Control If the segment being configured uses flow control in its

communications, select that here. Default is none.

Stop Bits Select the number of stop bits used by this segment.

Default is one stop bit.

If you make a mistake, press Reset to Defaults to restore

the default values.

which contains the parameters for the functioning of the

Monitor. Select the Modify an Existing Monitor

Configuration radio button and click OK. The Modify

Configuration screen is displayed:

NOTE: If you have a single-port version of the Monitor,

the segment pull down list is disabled, and you will only

need to configure the settings for Segment A. However,

for a dual port Monitor you MUST configure these

settings for BOTH ports, even if you intend to use only

one port.

Select the Monitor’s Modbus RTU address for the

segment from the Network Address pull-down list. The

valid range of Modbus addresses for a Modbus Monitor

is 1–247. Address zero is reserved for broadcast

messages, per the Modbus standard. The Modbus

address assigned to each Monitor must be unique to

avoid communication conflicts with other Modbus

devices on the RS-485 network.

NOTE: Addresses which have already been utilized will

not appear in the pull-down address list; this helps to

avoid addressing conflicts. However, you should still

check the list of device addresses for each segment to be

sure that every device has a unique Modbus address.

Figure 18. Modify Configuration screen.

From this screen, we can select any existing monitor

configuration file and adjust any of the configuration

parameters of that file.

Select the desired configuration name from the pulldown list at the top of the dialog box, then select the

parameter you wish to modify from the list box beneath,

and click OK. The following sections describe the

various aspects of a Monitor configuration file.

Device Table

The Monitor keeps track of the devices attached to its

Modbus segment(s) by keeping a table of devices for

each port. The Device Table lists the name, type,

location and Modbus address of each device connected

to an RS-485 port.

Click OK to accept changes and return to the main

screen.

Now that we’ve defined the monitor’s identity, we need

to set the monitor’s attributes. Modify Configuration

provides access to the Monitor’s configuration file,

Figure 19. Configuration Tool Device Table screen.

18

Page 25

NOTE: IF YOU ARE USING PMCS AND WISH TO

COPY THE CONFIGURATION INFORMATION

FROM YOUR PMCS SETUP, SKIP AHEAD TO

CREATE FROM PMCS. You do not need to manually

add devices if you copy the configuration from the

PMCS topic file.

Add Device

To add a device to the current configuration, press Add

Device. The Add a Network Device dialog box appears:

POWER LEADER Modbus Monitor

Chapter 3 – Configuration

Device Name Enter the device name as 4 to 20 alphanumeric

characters.

Device Location Optionally, enter the device location or a note about the

device in this field. 4 to 20 alphanumeric characters.

Device Type Select the correct device type (MUST match the

physical device) from this pulldown list.

Scan Rate Select the rate at which you wish the device to be

polled for display data. Default is 1000 ms; other

options are available, but lowering this value may result

in degraded network performance, while increasing this

value may result in stale data being gathered.

Network Address Select the Modbus address for the device here. This

must match the address that has been set at the

device. Address which have already been assigned are

not available from this list.

When you have completed these fields, press OK to

accept the new device. Cancel returns to the Device

Table dialog without adding a new device.

Figure 20. Add a Network Device dialog.

The Current Configuration field shows the current

configuration name and segment. Enter the device name

and (optionally) the location. These fields may be from 4

to 20 alpha-numeric characters long. Next select the

appropriate device type, the scan rate for the device, and

the Modbus address of the device from the pull-down

lists. These explanations of the fields are as follows:

Modify Device

To modify an existing device, select the device from the

device table list, then press Modify Device. Make any

necessary changes and press OK.

Delete Device

To delete a device, select it from the device table list and

press Delete. You will be prompted for confirmation.

The remaining two options, Create from PMCS and

AutoDetect, allow you to create the entire device list for

a particular segment automatically.

Create from PMCS

This item applies only to systems where the Modbus

Monitor will be a slave on a PMCS network.

The PMCS DDE Server keeps track of all its

configuration data in a .cfg file. This file is created

during the setup process of the PMCS DDE Server; for

its location, refer to the PMCS documentation, especially

the Read-This-Book-First guide. The Modbus Monitor’s

Configuration Tool can reference this file (or a copy of

it) to extract the information relevant to a particular

Modbus segment which a Monitor will be connected to.

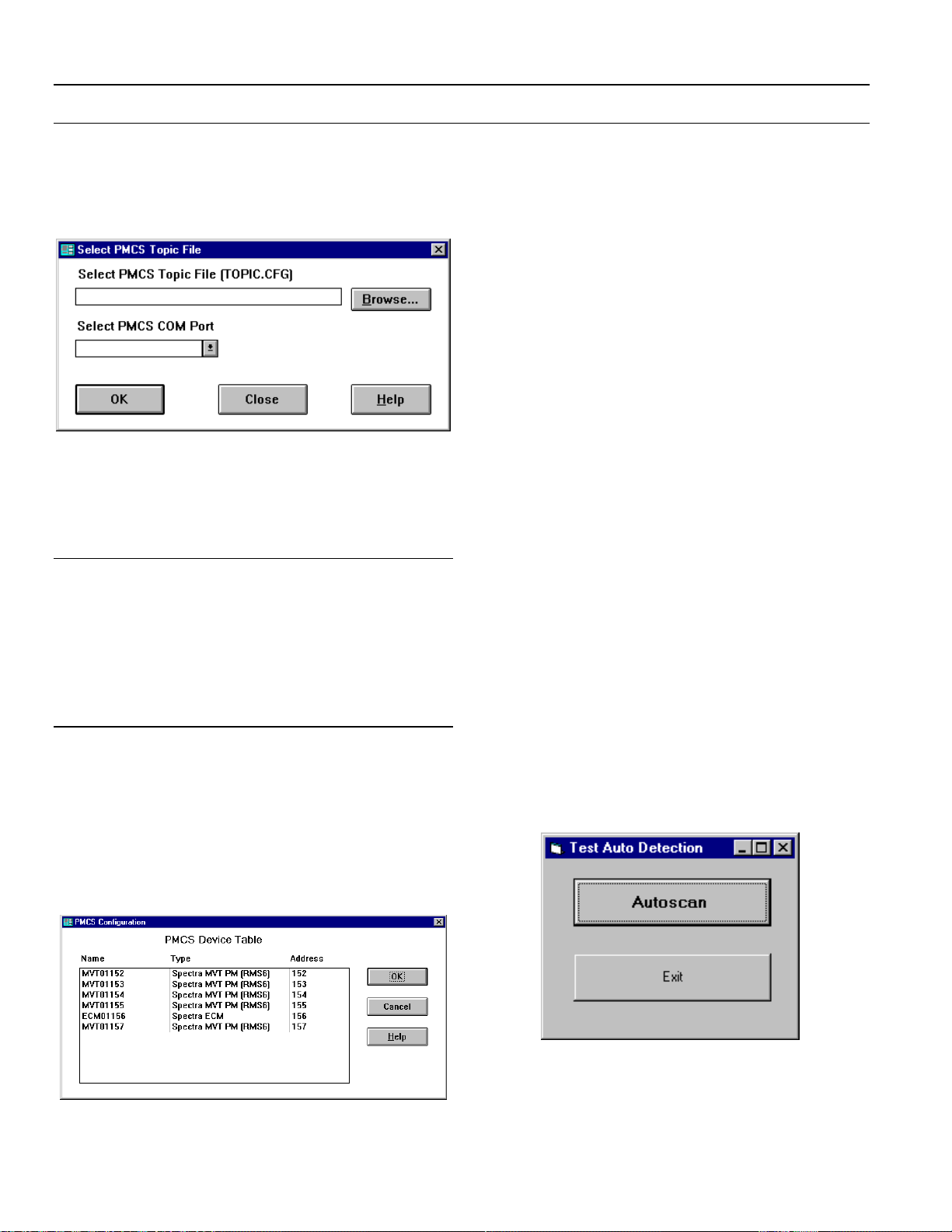

Select Create from PMCS from the Device Table dialog

box. The Select PMCS Topic File dialog appears, as

19

Page 26

POWER LEADER Modbus Monitor

Chapter 3 – Configuration

shown below in Figure 21. The topic file’s default name

is TOPIC.CFG, but check with the PMCS administrator

to make sure that this is the correct name for your PMCS

topic file.

Figure 21. Select PMCS Topic File dialog.

You will be prompted to locate the DDE Server’s .cfg

file. Click Browse and locate the file. Highlight it and

click OK.

NOTE: If you are using the Monitor Configuration Tool

on a different PC than the PMCS DDE Server runs on,

you will not have access to the PMCS topic file directly.

Copy the topic file from the PMCS DDE Server PC to

the PC where the Configuration Tool is located. The

Configuration Tool is just reading the data out of the

topic file and does not need to access the original topic

file.

Now select the PMCS COM port of the Modbus segment

to which your Monitor will be attached. The PMCS DDE

Server can support up to 256 com ports and Modbus

segments; obviously, we want the configuration data for

the segment our Monitor will be connected to.

If you are satisfied with the data collected from the

PMCS .cfg file, click OK; otherwise, click Cancel.

The Configuration Tool will check the data imported

from the .cfg file for address conflicts. If address

conflicts are found the conflicting devices are not added

to the configuration.

AutoDetect

Another option to obtain segment configuration

information is to perform an AutoDetect. This function

allows the Monitor Configuration Tool to check the

Monitor’s RS-485 ports for attached devices, and create

the Device Table from the responses received from this

poll.

For this option to work, the PC running the

Configuration Tool must be connected to the Monitor via

the RS-232 port, as we’ll be asking the Monitor to

provide us with information about the network to which

it is attached. RS-485 port configuration must already

have been completed as well, so that the Monitor will be

able to properly use the RS-485 port in question.

Selecting this option causes the Monitor to begin

querying the selected Modbus segment for any devices

which may be present on the network, similar to an

electronic roll call. The Monitor sends out a message to

each Modbus address on the Modbus segment asking “Is

there anyone out there?” If there is a device present at

the address, it replies, identifying itself by Modbus

address, device type, etc.

Select AutoDetect from the Device Table dialog box to

display the AutoDetect dialog:

The PMCS Configuration data collected from the .cfg

file is displayed as shown in Figure 22.

Figure 22. PMCS Configuration information screen.

Figure 23. AutoDetect dialog box.

This process may take several minutes, as the Monitor

polls every Modbus address, waits for a reply, and

20

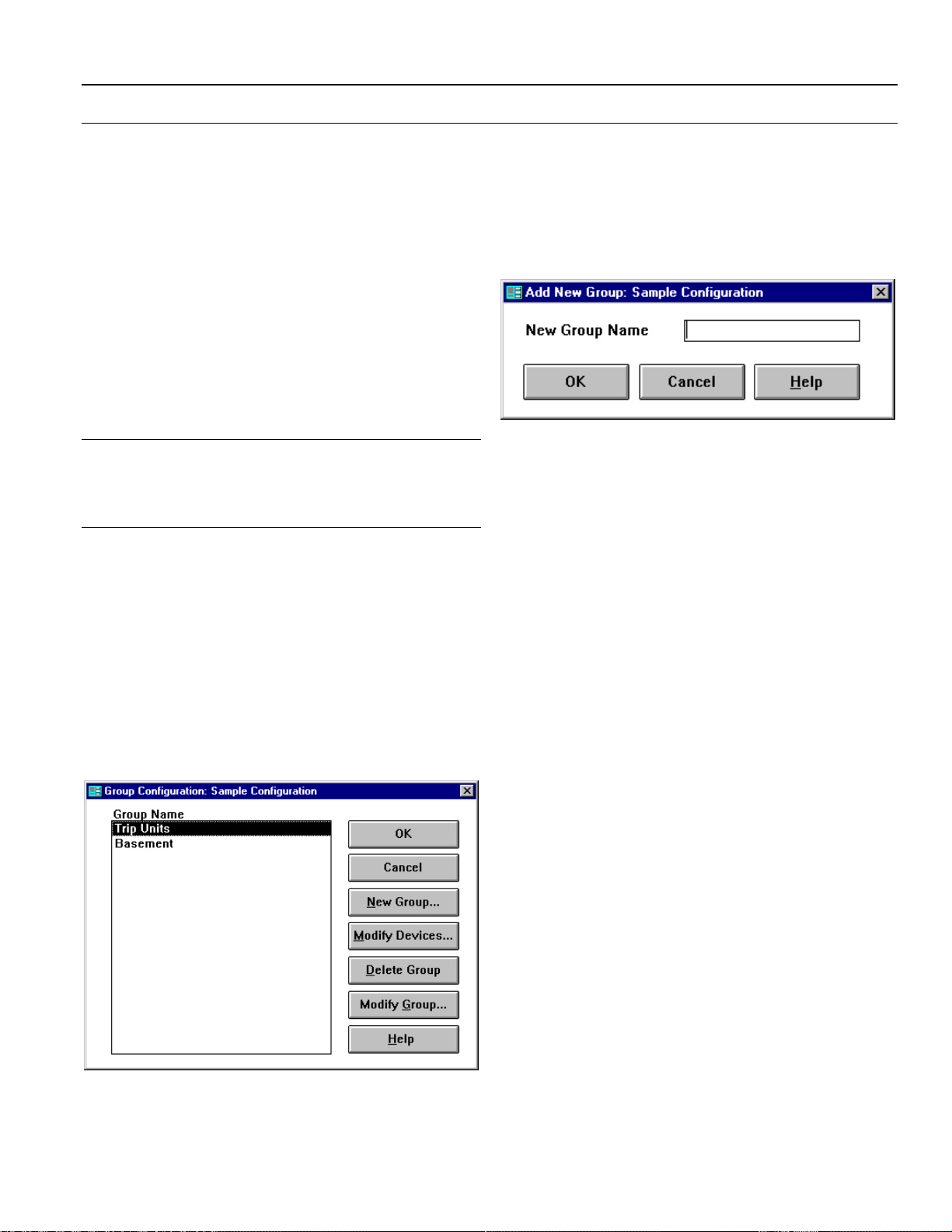

Page 27

POWER LEADER Modbus Monitor

Chapter 3 – Configuration

records the replies from all devices present. While the

Auto Detect routine is in process, the Configuration Tool

is suspended. A progress indicator is displayed showing