Page 1

DEH 41502 PBI - PBII Stationary Conversion Kit Instruction R01

Overview

The Power Break Stationary Conversion Kit provides all

the necessary parts and information to assist in the

replacement of a Power Break I stationary circuit breaker

with an equivalently rated Power Break II stationary

circuit breaker (refer to Table 1). This instruction manual

describes the modifications that need to be performed on

the equipment and breaker for installation. For complete

Power Break II installation and operation instructions,

refer to the GEH6279 instruction manual.

Frame

Rating

800A

1600A

2000A

2500A

Front Connect

2500A

Back Connect

3000A

Back Connect

3000A

Front Connect

4000A

Table 1: List of various breaker frame sizes with their respective

conversion kits.

800A Stationary Breaker

Operation

Type

Manual

Electrical

Manual

Electrical

Manual

Electrical

Manual

Electrical

Manual

Electrical

Manual

Electrical

Manual

Electrical

Manual

Electrical

Conversion

Kit

SSF08TPCCR 1

SSF16TPCCR 1-2

SSF20TPCCR 1-2

SSF40TPCCMR

SSF40TPCCER

SSF40TPCCMR

SSF40TPCCER

SSF40TPCCMR

SSF40TPCCER

SSF40TPCCMR

SSF40TPCCER

SSF40TPCCMR

SSF40TPCCER

Page

3

3

3

3

3

Power Break® Stationary Conversion Kit

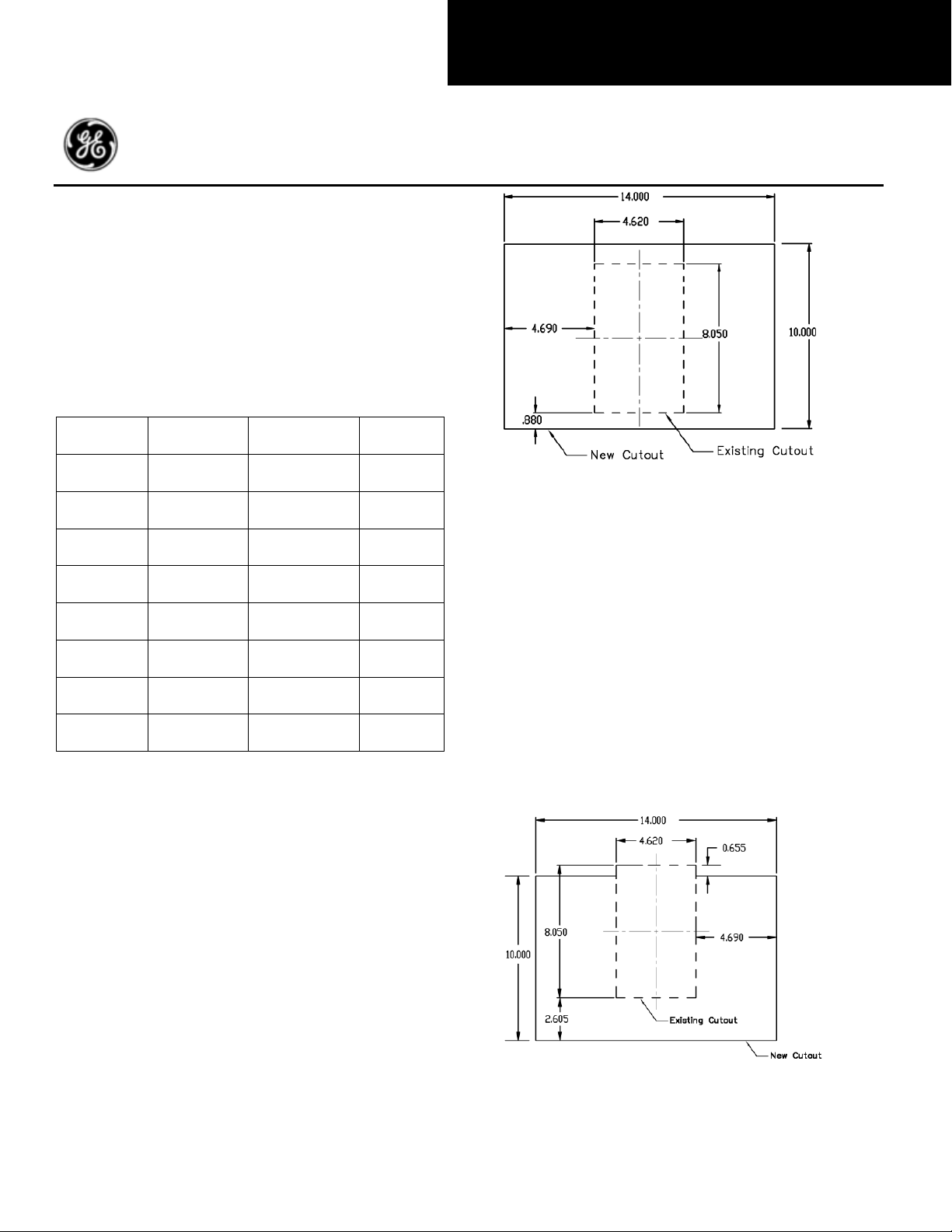

Figure 1: 800A Panel Cutout

Breaker Installation

Ensure that all accessory connections are secure. Line up

mounting holes with enclosure. Place the bolts and tighten

to 300 in-lbs.

1600–2000A Stationary Breaker

In order to make the conversion to a 1600A or 2000A

Power Break II breaker, four modifications are required.

Begin process by removing existing breaker from

equipment.

Panel Cutout

Figure 2 shows the 14” x 10” cutout required using the

existing cutout as reference (dashed). Once cutout is

complete, mount the standard trim plate using #8-32

screws and torque to 5 in-lbs.

The 800A Power Break II design is similar in dimension to

the 800A Power Break I breaker. The only modification

required is the panel cutout. Begin process by removing

existing breaker from equipment.

Panel Cutout

A 14” x 10” cutout is required for the Power Break II

breaker to fit. Figure 1 shows the new front panel cutout

using the existing cutout as reference (dashed line in

Figure 1). Once cutout is complete, mount the standard

trim plate using #8-32 screws and torque to 5 in-lbs.

Figure 2: 1600 - 2000A Panel Cutout

1

Page 2

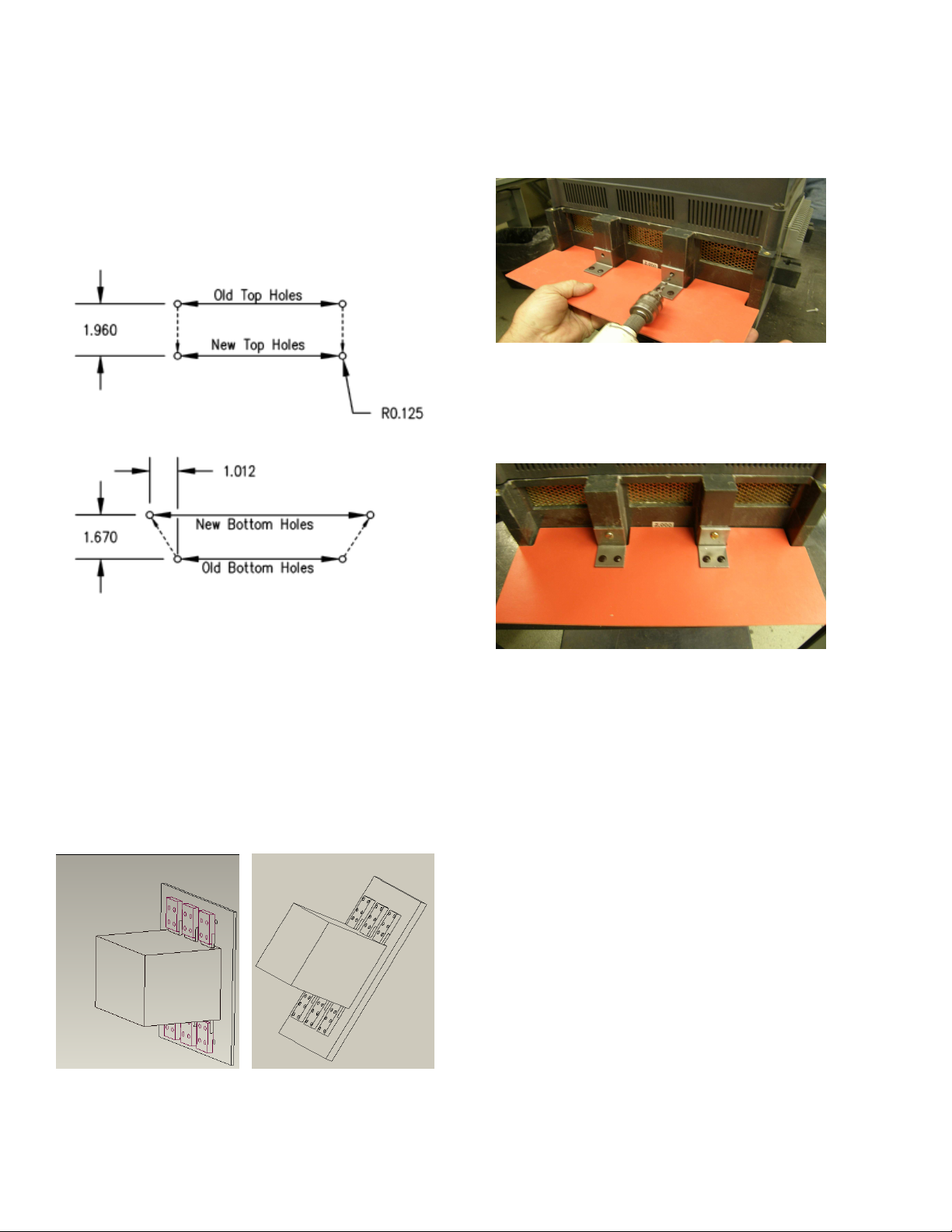

Mounting Hole Relocation

Line Shield

Since the mounting holes for the Power Break II breaker

do not align with the holes in panel, new mounting holes

need to be drilled on the panel breaker mounting space.

Figure 3 shows the new locations for the 1600A-2000A

breakers. A 1:1 scale template is provided with the kit to

guide in the drilling of the holes, which should be made for

a ¼-20 tap. It is important to note that new non

magnetic mounting boards or channels may need to be

installed in the existing housing to accommodate for the

relocation of the mounting holes.

Due to the addition of the strap extensions, a shield is

required in the line side of the breaker. To install, place line

shield so that the top of mounting bracket aligns with

where breaker base and mid cover meet. Mark the area to

drill using a drill or white pencil (Figure 5).

Figure 5: Mark the Area for Drilling Holes

After marking the area, drill the holes to a depth of

approximately 0.75” using a 0.156” bit. Finally install the

line shield using #10-16 thread cutting screws provided

(Figure 6).

Figure 3: 1600-2000A Mounting Hole Relocation

Line /Load Strap Extensions

The Power Break I 1600A and 2000A breakers are longer

than their Power Break II counterparts. To compensate

for the difference in length, 6 line strap extensions are

provided with the conversion kit. Please note that the

length for the straps is different, 1600A is 4” long and

2000A is 5.25”. Bolt the extensions using 1/2” screws to the

line and load straps to a torque of 300 in-lbs. The

extensions should be bolted as shown on Figure 4.

Figure 6: Line Shield Installation

Breaker Installation

Ensure that all accessory connections are secure. Line up

mounting holes with enclosure. Place the bolts and tighten

to 300 in-lbs.

Neutral Sensor

For Power Break I connected in a three-phase four-wire

system please note the following regarding neutral sensor:

- If the Power Break I has an Enhanced MVT Plus/PM

trip unit, the neutral sensor can be reused

- If the Power Break I has an Original MVT, RMS-9, or

EPIC trip unit, the neutral sensor can be reused.

However, a 1:1 isolation CT might be required to

properly isolate from multiple grounds.

- For Power Break I with any other trip unit, the

neutral sensor must be replaced. See Page 31, GET8052C for Neutral Sensor Options.

Figure 4: Installed 1600A (left) and 2000A (right) Strap Extenders

2

Page 3

2500-4000A Stationary Breaker

Breakers with a frame size from 2500A to 4000A are

considered large frame. They include the 2500A front

connected (FC), 2500A back connected (BC), 3000A FC,

3000A BC, and 4000A FC. As in the case of the 800A

breakers, the Power Break II designs are similar in

dimensions to the Power Break I breakers. Only the panel

cutout needs to be modified to be ready for breaker

installation. Begin process by removing existing breaker

from equipment.

Panel Cutout

The 2500A FC, 2500A BC, 3000A FC, and 3000A BC require

a 14” x 16.07” cutout for the Power Break II breaker to fit.

Figure 8 shows the new front panel cutout using the

existing cutout as reference (red line in Figure 7).

Trim Plate

Once cutout is complete, mount the provided trim plate

using #8-32 screws and torque to 5 in-lbs. Please note the

trim plate is determined by the Power Break I that is to

be replaced. Figure 9 shows the 2 types of trim plates used

in large frame breakers. If the equipment had an

electrically operated Power Break I, SSF40TPCCE kit

should be used (left). If the breaker was Manually operated,

use SSF40TPCCM kit (right).

Figure 9: Trim Plates: Electrical (left), Manual (right)

Figure 7: 2500A FC, BC, 3000A FC, and BC Panel Cutout

The cutout for the 4000A breaker should be 14” by 13.54”

and it is shown in Figure 8.

Figure 8: 4000A Panel Cutout

Figure 10: Trim Plates: Electrical (left), Manual (right)

Breaker Installation

Ensure that all accessory connections are secure. Line up

mounting holes with enclosure. Place the bolts and tighten

to 225 in-lbs for 2500-3000A breaker, or 300 in-lbs for a

4000A.

Neutral Sensor

For Power Break I connected in a three-phase four-wire

system please note the following regarding neutral sensor:

- If the Power Break I has an Enhanced MVT Plus/PM

trip unit, the neutral sensor can be reused

- If the Power Break I has an Original MVT, RMS-9, or

EPIC trip unit, the neutral sensor can be reused.

However, a 1:1 isolation CT might be required to

properly isolate from multiple grounds.

- For Power Break I with any other trip unit, the

neutral sensor must be replaced. See Page 31, GET8052C for Neutral Sensor Options.

3

Page 4

These instructions do not cover all details or variations in equipment nor do they provide for every possible contingency that may be met in

operation, or maintenance. Should further information be desired or should particular problems arise that are not

Appendix: Additional Information

Table 1: Weights of Various PBII Breaker Frame Sizes

Frame

Rating

800A

1600A

2000A

2500A

Front Connect

2500A

Back Connect

3000A

Back Connect

3000A

Front Connect

4000A

Table 2: Bolt Sizes and Recommended Mounting Torques for Bus Connections.

Frame Rating Bolt Torque (in-lbs)

800A (1) ½ in 300

1600A-2000A (2) ½ in 300

2500A

3000A

4000A (6) ½ in 300

Operation

Type

Manual

Electrical

Manual

Electrical

Manual

Electrical

Manual

Electrical

Manual

Electrical

Manual

Electrical

Manual

Electrical

(4) 3/8 in 225

(4) 3/8 in 225

Weight (lbs)

71

80

79

88

178

187

167

176

179

188

216

225

320

329

Table 3: Minimum Ventilation Cutout Areas

PBI PBII

Stationary Total Top Bottom Total Top Bottom

800A

1600A

2000A

2500A

3000A

4000A

N/A N/A N/A N/A N/A N/A

60 30 30 60 30 30

160 80 80 86.4 43.2 43.2

160 80 80 160 80 80

270 135 135 270 135 135

280 140 140 270 135 135

connection with installation,

covered sufficiently for the purchaser’s purposes, the matter should be referred to the GE Company.

GE Industrial Solutions

General Electric Company

41 Woodford Ave., Plainville, CT 06062

DEH41502 R01 © 2010 General Electric Company

4

Loading...

Loading...