Page 1

Title page

IISO9001:2000

G

E

M

U

L

T

I

L

I

N

R

E

G

I

S

T

E

R

E

D

GE Digital Energy

Multilin

MX350

Automatic Transfer Control

System

Low voltage power transfer control

MX350 revision: 1.2x

Manual P/N: 1601-9071-A2

GE publication code: GEK-113497A

Copyright © 2010 GE Multilin

GE Digital Energy

Power Quality / Zenith

830 W. 40th Street

Chicago IL, 60609

USA

Tel: 800-637-1738

email: GEPQSales@ge.com

Internet: http://www.gedigitalenergy.com/ats

*1601-9071-A2*

Instruction manual

GE Multilin's Quality

Management System is

registered to ISO9001:2000

QMI # 005094

Page 2

© 2010 GE Multilin Incorporated. All rights reserved.

GE Multilin MX350 Automatic Transfer Control System instruction manual for revision 1.2x.

MX350 Automatic Transfer Control System, EnerVista, EnerVista Launchpad, EnerVista

MX350 Setup, and FlexLogic are registered trademarks of GE Multilin Inc.

The contents of this manual are the property of GE Multilin Inc. This documentation is

furnished on license and may not be reproduced in whole or in part without the permission

of GE Multilin. The content of this manual is for informational use only and is subject to

change without notice.

Part number: 1601-9071-A2 (April 2010)

Page 3

Table of Contents

1. INTRODUCTION Overview ............................................................................................................1 - 1

Cautions and warnings............................................................................................................... 1 - 1

Description of the Automatic Transfer Controller system.......................................... 1 - 2

ATS types ........................................................................................................................................... 1 - 5

Specifications ....................................................................................................1 - 6

Timing specifications ................................................................................................................... 1 - 6

Protection specifications............................................................................................................ 1 - 6

User interface specifications.................................................................................................... 1 - 7

Metering and monitoring specifications............................................................................. 1 - 7

Inputs specifications .................................................................................................................... 1 - 7

Outputs specifications ................................................................................................................ 1 - 8

Power supply specifications.....................................................................................................1 - 8

Communications specifications ............................................................................................. 1 - 9

Testing and certification............................................................................................................. 1 - 9

Physical specifications ..............................................................................................................1 - 10

Environmental specifications.................................................................................................1 - 10

Order codes for MX350................................................................................. 1 - 11

Example of an MX350 order code .......................................................................................1 - 11

2. INSTALLATION Mechanical installation ...................................................................................2 - 1

Dimensions....................................................................................................................................... 2 - 1

Product identification .................................................................................................................. 2 - 2

Mounting ........................................................................................................................................... 2 - 2

Module withdrawal and insertion .......................................................................................... 2 - 4

Module and terminal identification....................................................................................... 2 - 6

Electrical installation .......................................................................................2 - 7

Power supply module.................................................................................................................. 2 - 8

CPU module...................................................................................................................................... 2 - 9

Input/Output modules...............................................................................................................2 - 10

Dielectric strength testing .......................................................................................................2 - 14

3. INTERFACING WITH

THE MX350 AT

CONTROLLER

Graphical control panel...................................................................................3 - 1

Introduction to the graphical control panel...................................................................... 3 - 1

MX350 graphical display pages.............................................................................................. 3 - 6

MX350 programming techniques........................................................................................3 - 13

EnerVista™ MX350 Setup Software............................................................ 3 - 17

Software requirements.............................................................................................................3 - 17

Troubleshooting the USB driver............................................................................................3 - 17

Installing the EnerVista™ MX350 Setup software........................................................3 - 20

Connecting EnerVista MX350 Setup to the relay .........................................................3 - 20

Working with setpoints and setpoint files........................................................................3 - 23

Upgrading relay firmware .......................................................................................................3 - 29

Power analysis ............................................................................................... 3 - 30

Waveform capture......................................................................................................................3 - 30

Data logger.....................................................................................................................................3 - 34

4. ACTUAL VALUES Actual values overview....................................................................................4 - 1

MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL toc–i

Page 4

Metering ............................................................................................................ 4 - 2

Current metering............................................................................................................................4 - 2

Voltage metering............................................................................................................................4 - 2

Power metering ..............................................................................................................................4 - 3

PQ metering......................................................................................................................................4 - 3

Status................................................................................................................. 4 - 4

Status messages ............................................................................................................................4 - 4

Input and output status ..............................................................................................................4 - 4

System Page.....................................................................................................................................4 - 5

Flex Page............................................................................................................................................4 - 5

5. SETPOINTS Understanding setpoints................................................................................ 5 - 1

Setpoint text abbreviations .......................................................................................................5 - 2

Configuration setpoints ................................................................................. 5 - 3

ATS setpoints....................................................................................................................................5 - 3

ATS types............................................................................................................................................5 - 4

Chicago Transfer Alarm Panel (CTAP) option ....................................................................5 - 7

Common ATS setpoints ...............................................................................................................5 - 8

Current and voltage transformers .........................................................................................5 - 9

Inputs................................................................................................................................................ 5 - 10

Outputs ............................................................................................................................................ 5 - 10

Communications setpoints.....................................................................................................5 - 10

System..............................................................................................................................................5 - 12

Events ...............................................................................................................................................5 - 13

Zenith................................................................................................................................................5 - 13

Operation setpoints ...................................................................................... 5 - 14

Timers ............................................................................................................................................... 5 - 15

Control............................................................................................................. 5 - 16

General............................................................................................................................................. 5 - 16

Interlock...........................................................................................................................................5 - 18

Alarms ..............................................................................................................................................5 - 19

Security............................................................................................................ 5 - 20

6. EXERCISER Information....................................................................................................... 6 - 1

Setup....................................................................................................................................................6 - 2

Test........................................................................................................................................................6 - 2

7. DIAGNOSTICS Events ................................................................................................................ 7 - 1

Statistical information.................................................................................... 7 - 3

Phasors.............................................................................................................. 7 - 4

Product information........................................................................................ 7 - 5

Reports .............................................................................................................. 7 - 6

Waveform ......................................................................................................... 7 - 7

Datalog.............................................................................................................. 7 - 8

8. FLEXLOGIC™ FlexLogic™ overview....................................................................................... 8 - 1

Introduction to FlexLogic™........................................................................................................8 - 1

9. COMMUNICATIONS Communications interfaces .......................................................................... 9 - 1

toc–ii MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL

Page 5

Digital Energy

NOTE

CAUTION

DANGER

Multilin

MX350 Automatic Transfer Control

System

Chapter 1: Introduction

Introduction

Overview

The MX350 is a modular control and monitoring system designed specifically for lowvoltage transfer switch application. The MX350 provides the following key benefits.

• Flexible control and communication options to suit any low-voltage transfer switch

application.

• Small footprint.

• Modular design reduces the number of spare components for maintenance and

testing.

• Integrated pushbuttons and LED indicators reduce external components and wiring.

• DIN rail and Panel Mounting.

• Multiple communication protocols allows simple integration into monitoring and

control systems.

• Graphical control panel interface provides local control and access to system

information.

• Automation FlexLogic™ with interlocking and programmable logic control.

Cautions and warnings

Before attempting to install or use this device, it is imperative that all caution and danger

indicators in this manual are reviewed to help prevent personal injury, equipment damage,

or downtime. The following icons are used to indicate notes, cautions, and dangers.

Figure 1: Note icons used in the documentation

MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL 1–1

Page 6

OVERVIEW CHAPTER 1: INTRODUCTION

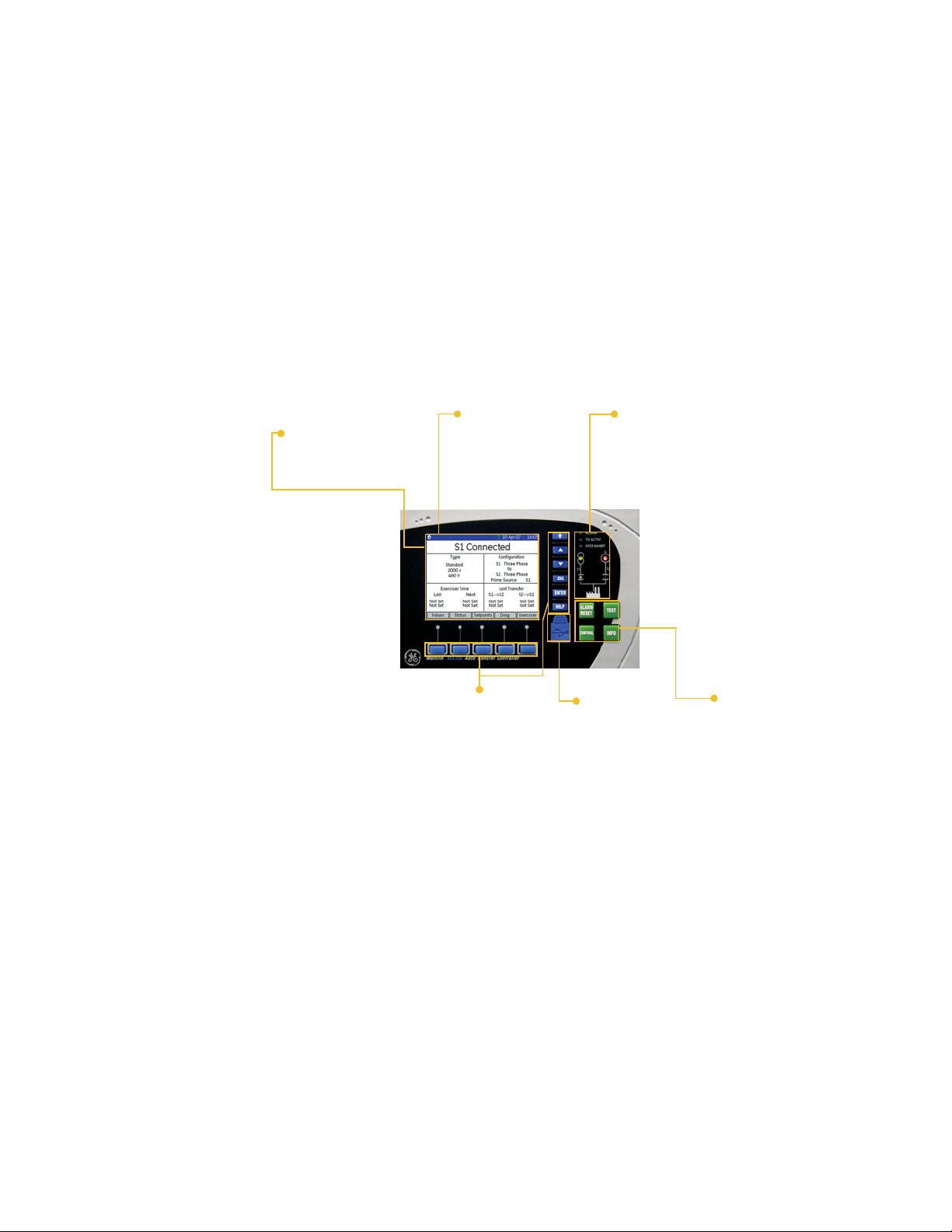

Graphical display

• Large metering values

• Wide viewing angle

Soft key navigation

• Graphical module control

Front port access

• USB for laptop connection

Integrated functionality

• Metering, control

• Event recorder

LED indication

• Time delay indication

• Alarm indication

• Transfer inhibit indication

• Source available & connected

indication

Ease of use

• Graphical interface

• Self-description

Mounting options

•DIN Rail

• Through door

889723A1.CDR

Front panel control

• Integrated device control

• Dedicated control keys

The standard note icon emphasizes a specific point or indicates minor problems that may

occur if instructions are not properly followed.

The caution icon indicates that possible damage to equipment or data may occur if

instructions are not properly followed.

The danger icon provides users with a warning about the possibility of serious or fatal

injury to themselves or others.

Description of the Automatic Transfer Controller system

The MX350 is equipped with a graphical control panel:

• Includes a 89 mm (3.5-inch) 320 by 240 pixel backlit colour LCD screen, 15

pushbuttons, and 7 LED indicators, which provide access to actual values, fault and

alarm lists, event records, and setting configuration. A USB port is provided for laptop

computer connection.

Figure 2: MX350 feature overview

1–2 MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL

The MX350 includes the following input/output capabilities:

• 5 to 25 contact outputs

• 5 to 32 contact inputs

The following option packages are available:

Option A:

• Full function ATS control with full sensing and control capabilities, depending on order

option.

• Expanded diagnostics, high-speed 256-event capture, 365-day exerciser, EnerVista

launchpad, USB interface for uploading and downloading setup parameters

• 4 programmable inputs and 4 outputs assignable to additional ATS features

• Full complement of programmable ATS control switches (AUTO/MAN, Preferred Source

selector, Commit/No Commit Xfer, Transition Mode Select (for Closed Transition switch

models).

Option B:

Option Package A plus:

• 10 customer programmable digital and 10 analog alarms

Page 7

CHAPTER 1: INTRODUCTION OVERVIEW

• 20 channel data logger, customer configurable sample period from 1 cycle to 60

minutes

• Waveform capture, 10 channels, up to 256 cycles each 16 samples/sec

• Auto Load Shed with voltage, frequency and kW triggers

Option C:

Option Package B plus:

• 4 additional inputs and outputs (total 8 in, 8 out

Option D:

Option Package C plus:

• 4 additional inputs and outputs (total - 12 in, 12 out)

• FlexLogic for user-customized control logic

Option M:

• Configuration for Manual operation only (non-Automatic)

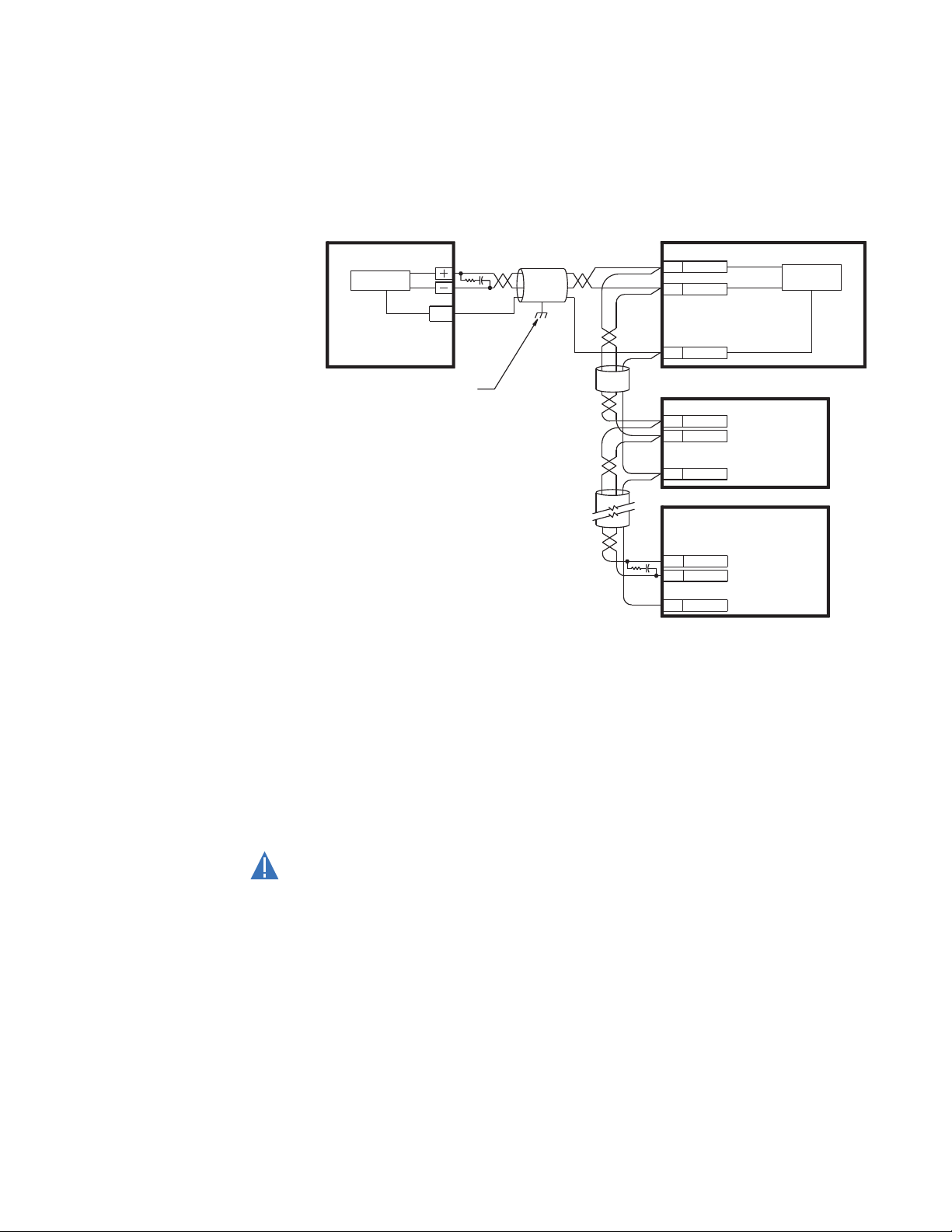

A single-line diagram for the MX350 is shown below.

MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL 1–3

Page 8

OVERVIEW CHAPTER 1: INTRODUCTION

GEN

X1

H1

H1

X1

METERING

V, A, W, VAR, VA, PF, HZ

TO LOAD

UTA

UTILITY

(SOURCE-1)

VOLTAGE

CARD

SOURCE

2

POWER

SUPPLY

1

SOURCE

CARD

VOLTAGE

METERING

NEUTRAL

CT CARD

ATS

CONTROLLER

170VDC

RS485 - MODBUS RTU

ETHERNET - MODBUS TCP/IP

NOTE:1

K

CARD

P

ENGINE START CONTACT

I/O

CARD

24VDC

TO K CARD

AND

I/O CARD

SUPPLIED BY OTHERS

(3)

CT'S

(1)

CT

NOTE:1

TO

SOURCE-2

NOTE:1- FOURTH POLE/NEUTRAL POLE IS AN OPTIONAL FEATURE.

NOTE:1

NOTE:1

27 59 47

25

475927

46

51R

50G 51G

889739A1.CDR

Figure 3: Single line diagram

Table 1: MX350 protection functions

ANSI device Description

25 Synch check

27 Undervoltage

46 Current balance

47 Voltage phase reversal

50G (option) Ground instantaneous overcurrent

51G (option) Ground time overcurrent

51 (option) Overcurrent

59 Overvoltage

1–4 MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL

Page 9

CHAPTER 1: INTRODUCTION OVERVIEW

ATS types

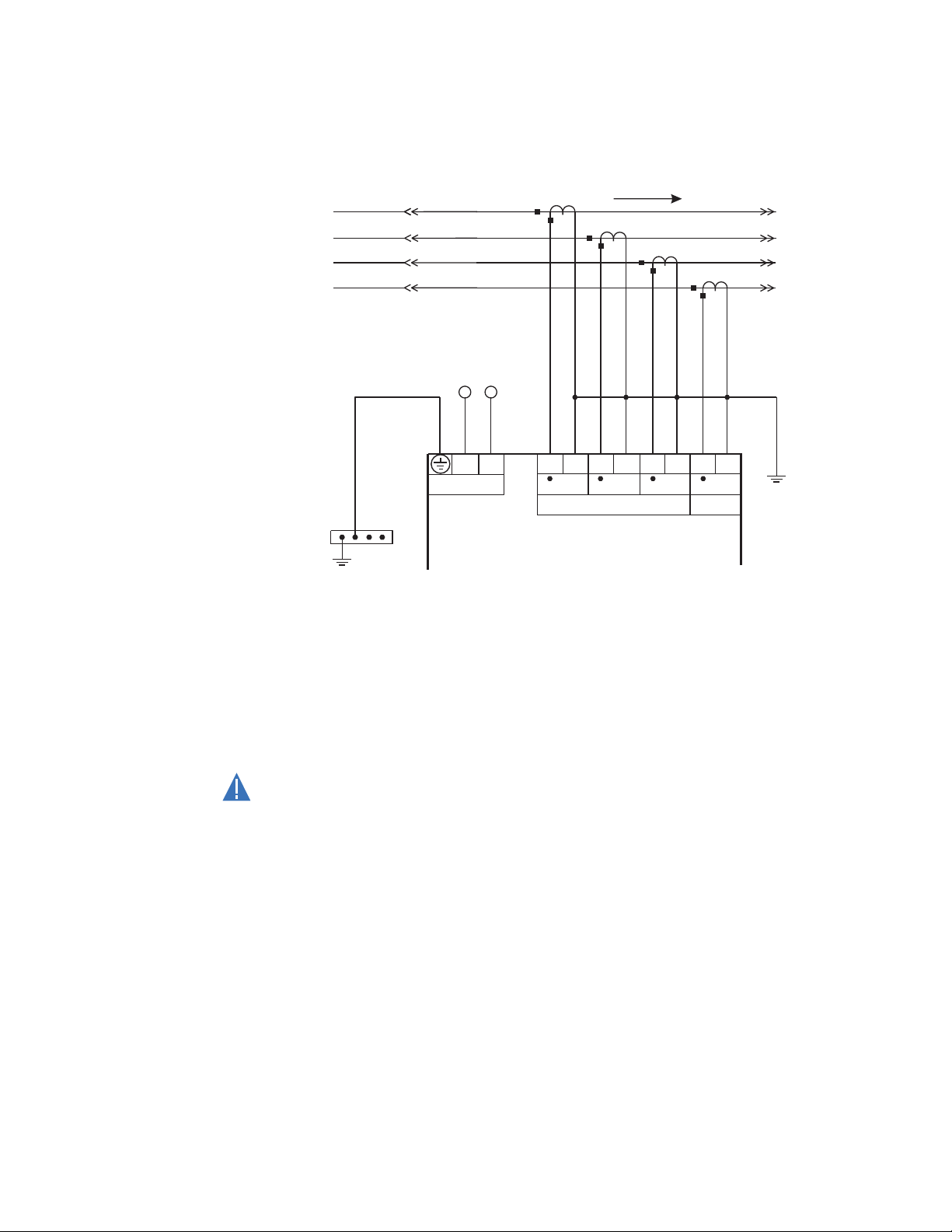

Automatic Transfer switch types to be controlled by the Controller are Standard (Open)

Transition, Delayed Transition, and Closed Transition. The figure below shows the one-line

diagram for all three types.

Figure 4: Automatic transfer switch types

In addtion, the MX350 can control the Bypass/Isolation type version of the three basic ATS

types.

MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL 1–5

Page 10

SPECIFICATIONS CHAPTER 1: INTRODUCTION

NOTE

Specifications

NOTE:

Specifications are subject to change without notice.

Timing specifications

GENERAL TIMING ACCURACY

Accuracy:................................................................±500 ms

Protection specifications

OVERVOLTAGE

Pickup level:........................................................... 1.05 to 1.10 × VT in steps of 0.01 (programmable)

Dropout:.................................................................. 1.03 to 1.08 × VT in steps of 0.01 (programmable)

Time delay:............................................................ No programmable time delay

UNDERVOLTAGE

Pickup level:........................................................... 0.75 to 0.99 × VT in steps of 0.01 (programmable)

Dropout:.................................................................. 0.85 to 1.00 × VT in steps of 0.01 (programmable)

Time delay:............................................................ No programmable time delay

OVERFREQUENCY

Pickup level:........................................................... 50.1 to 63.0 Hz in steps of 0.1 (programmable)

Dropout:.................................................................. 50.0 to 62.9 Hz in steps of 0.1 (programmable)

Time delay:............................................................ No programmable time delay

Accuracy:................................................................±0.05 Hz

UNDERFREQUENCY

Pickup level:........................................................... 45.0 to 59.9 Hz in steps of 0.1 (programmable)

Dropout:.................................................................. 45.1 to 60.0 Hz in steps of 0.1 (programmable)

Time delay:............................................................ No programmable time delay

Accuracy:................................................................±0.05 Hz

POWER FACTOR

Pickup level:........................................................... 0.99 lag to 0.99 lead in steps of 0.01 (programmable)

Dropout:.................................................................. pickup + hysteresis

Time delay:............................................................ 0 to 65535 seconds in steps of 1

Accuracy:................................................................±0.05

VOLTAGE IMBALANCE

Pickup level:........................................................... 0.05 to 0.20 in steps of 0.01 (programmable)

Dropout:.................................................................. 0.03 to 0.18 in steps of 0.01 (programmable)

Time delay:............................................................ 1 to 60 seconds in steps of 1

CURRENT IMBALANCE

Range:......................................................................4 to 40% in steps of 1

Pickup level:........................................................... 0.04 to 0.40 in steps of 0.01 (programmable)

Time delay:............................................................ 1 to 60 seconds in steps of 1 s

Timing accuracy:................................................±500 ms

Elements:................................................................alarm

Accuracy:................................................................±2%

1–6 MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL

Page 11

CHAPTER 1: INTRODUCTION SPECIFICATIONS

CALCULATION METHOD

( [I

- IAV] / IAV ) x 100%

M

Where:

I

= average phase current

AV

I

= current in a phase with maximum deviation from I

M

AV

THD ALARM (CURRENT/VOLTAGE)

Pickup level:...........................................................0.1% to 100.0% in steps of 0.1% (programmable)

Time delay:.............................................................0 to 65535 seconds in steps of 1

OVERCURRENT (PER PHASE/NEUTRAL)

Pickup level:...........................................................0.01 to 2.00 × Nominal Current in steps of 0.01%

(programmable)

Time delay:.............................................................0 to 65535 seconds in steps of 1

User interface specifications

GRAPHICAL CONTROL PANEL

Size: ...........................................................................height 102mm, width 153mm, depth 35mm

LCD: ...........................................................................89 mm (3.5-inch) colour, 320 by 240 pixels

LED indicators: .....................................................7 LEDs

Pushbuttons:.........................................................Alarm Reset, Test, Ctrl, Info, plus 11 LCD screen display

control keys

Ports:.........................................................................USB 2.0 type Mini-B for laptop computer connection

Metering and monitoring specifications

EVENT RECORDER

Capacity: .................................................................256 events

Data storage:........................................................non-volatile memory

FREQUENCY METERING

Range: ......................................................................40.00 to 70.00 Hz in steps of 0.01

Accuracy:................................................................±0.05 Hz

POWER METERING

Real power range: ..............................................–2000.0 to 2000.0 kW in steps of 0.1

Apparent power range:....................................0.0 to 2500.0 kVA in steps of 0.1

Accuracy:................................................................±2.0% of full scale with 5 A CT

POWER FACTOR METERING

Range: ......................................................................–0.99 to +0.99 in steps of 0.01

Accuracy:................................................................±0.05

Inputs specifications

CONTROL VOLTAGE INPUT

Input range:...........................................................60 V to 300 V AC

Nominal frequency: ...........................................50 or 60 Hz

DIGITAL INPUTS

Nominal input voltage:.....................................24 V DC

Recognition time:................................................2 cycles

Continuous current draw:...............................4 mA

Type:..........................................................................opto-isolated inputs

External switch: ...................................................wet contact

MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL 1–7

Page 12

SPECIFICATIONS CHAPTER 1: INTRODUCTION

NOTE

PHASE CURRENT INPUTS

Range:......................................................................2.5 to 7.5 A (1.5 × CT)

Input type:.............................................................. 5 A

Frequency: ............................................................. 50 or 60 Hz

Accuracy:................................................................ ±2.0% of Full Scale, where Full Scale = 1.5 × CT Primary

Withstand (at 5A nominal):............................. 0.2 s at 100×

1.0 s at 50×

2.0 s at 40×

continuous at 3× rated current

PHASE VOLTAGE INPUTS (THREE-PHASE VOLTAGE)

Input range:........................................................... 120 to 600 V (nominal)

Nominal frequency:...........................................50 or 60 Hz

Accuracy:................................................................ ±2% of reading, or ±1 V, whichever is greater

NOTE:

Phase current Input Type of 1 A is not supported.

Outputs specifications

FORM-C RELAY

Contact material:................................................silver-alloy

Operate time:........................................................ 10 ms

Maximum contact load: ..................................10 mA at 5 V DC

Maximum switching rate:...............................300 operations per minute (no load), 30 operations per

minute (load)

Mechanical life:.................................................... 10 000 000 operations

Continuous current:........................................... 10 A

Make and carry for 0.2s:.................................. 30 A per ANSI C37.90

FORM-C OUTPUT RELAY BREAK CAPACITY

AC resistive, 120 V AC:......................................10 A normally-open, 5 A normally-closed

AC resistive, 240 V AC:......................................10 A normally-open, 8 A normally-closed

AC inductive, PF = 0.4 pilot duty:..................2.5 A

DC resistive, 30 V DC:........................................10 A

SOLID STATE OUTPUT RELAY

Operate time:........................................................ < 1 ms

Nominal voltage:................................................. 24 V DC

Maximum current:.............................................. 0.5 A

Power supply specifications

POWER SUPPLY

Nominal:.................................................................. 120 to 240 V AC

125 to 250 V DC

Range:......................................................................60 to 300 V AC (50 and 60 Hz)

84 to 250 V DC

Ride-Through:....................................................... 35 ms

ALL RANGES

Voltage withstand:.............................................2 × highest nominal voltage for 10 ms

Power consumption: ......................................... 16 W typical, 25 W maximum

1–8 MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL

Page 13

CHAPTER 1: INTRODUCTION SPECIFICATIONS

Communications specifications

ETHERNET (COPPER)

Modes:......................................................................10/100 MB (auto-detect)

Connector:..............................................................RJ-45

SNTP clock synchronization error: ..............<200 ms (typical)

Protocol: ..................................................................Modbus TCP

RS485 PORT

Port: ...........................................................................opto-isolated

Baud rates:.............................................................up to 115 kbps

Protocol: ..................................................................Modbus RTU, half-duplex

Maximum distance: ...........................................1200 m

Isolation:..................................................................2 kV

USB PORT

Standard specification: ....................................Compliant with both USB 2.0 and USB 1.1

Data transfer rate:..............................................USB device emulating serial communications port at

115 kbps

Connector:..............................................................USB2.0 Mini-B

Testing and certification

TESTING AND CERTIFICATION

Test Reference Standard Test Level

Dielectric Voltage Withstand: EN60255-5 2.0 KV

Impulse Voltage Withstand: EN60255-5 5 KV

Insulation Resistance: EN60255-5 500 V DC > 100 Mohm

Damped Oscillatory: IEC61000-4-18/IEC60255-22-1 2.5 KV CM, 1 KV DM

Electrostatic Discharge: EN61000-4-2/IEC60255-22-2 Level 4

RF Immunity: EN61000-4-3/IEC60255-22-3 Level 3

Fast Transient Disturbance: EN61000-4-4/IEC60255-22-4 Level 4

Surge Immunity: EN61000-4-5/IEC60255-22-5 Level 3 & 4

Conducted RF Immunity: EN61000-4-6/IEC60255-22-6 Level 3

Power magnetic Immunity: IEC61000-4-8 Level 4

Voltage Dip & Interruption: IEC61000-4-11 0,40,70% dips 250/300cycle

Radiated & Conducted Emissions: CISPR11 /CISPR22/ IEC60255-25 Class A

Ingress Protection: IEC60529 IP20 (base unit) IP54 (Control

Environmental (Cold): IEC60068-2-1 -20

Environmental (Dry heat): IEC60068-2-2 85

Relative Humidity Cyclic: IEC60068-2-30 6-day variant 2

Fast Transient Disturbance: IEEE C37.90.1 4 KV CM & DM

SWC Damped Oscillatory: IEEE C37.90.1 2.5 KV CM

Electrostatic Discharge: IEEE C37.90.3 8 KV CD, 15 KV AD

interrupts

Panel)

o

C 16 hrs

o

C 16hrs

MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL 1–9

Page 14

SPECIFICATIONS CHAPTER 1: INTRODUCTION

APPROVALS

Applicable Council Directive According to

CE compliance: Low voltage directive EN60255-5, EN60947-1, EN60947-6-1

EMC Directive EN61000-6-2/ EN61000-6-4

ISO: Manufactured under a registered

quality program

Physical specifications

DIMENSIONS

Size: ........................................................................... Base: 62 mm [2.44"] (W) × 90 mm [3.54"] (H) × 113 mm [4.45"]

Weight (Base):....................................................... 0.75 kg [1.65 lb]

Environmental specifications

ENVIRONMENTAL SPECIFICATIONS

Ambient temperatures:

Storage/shipping: - 40

Operating: -20

* 1" around Base Unit

ISO9001

(D) (+ terminals 10mm [0.39"])

Expansion: 62 mm [2.44"] (W) × 90 mm [3.54"] (H) × 113 mm

[4.45"] (D)

GCP: 153 mm [6.02"] (W) × 102 mm [4.02"] (H) × 35 mm [1.38"]

(D)

o

C to 90oC *

o

C to 60oC * (Base Unit and Basic Control Panel)

o

-20

C to 50oC * (Graphical Control Panel)

o

Humidity: Operating up to 95% (non condensing) @ 55

per IEC60068-2-30 Variant 2, 6days)

Altitude: 2000 m (max)

Overvoltage Category: II

Ingress Protection: IP20 (Base Unit), IP54 (Control Panel)

1–10 MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL

C (As

Page 15

CHAPTER 1: INTRODUCTION ORDER CODES FOR MX350

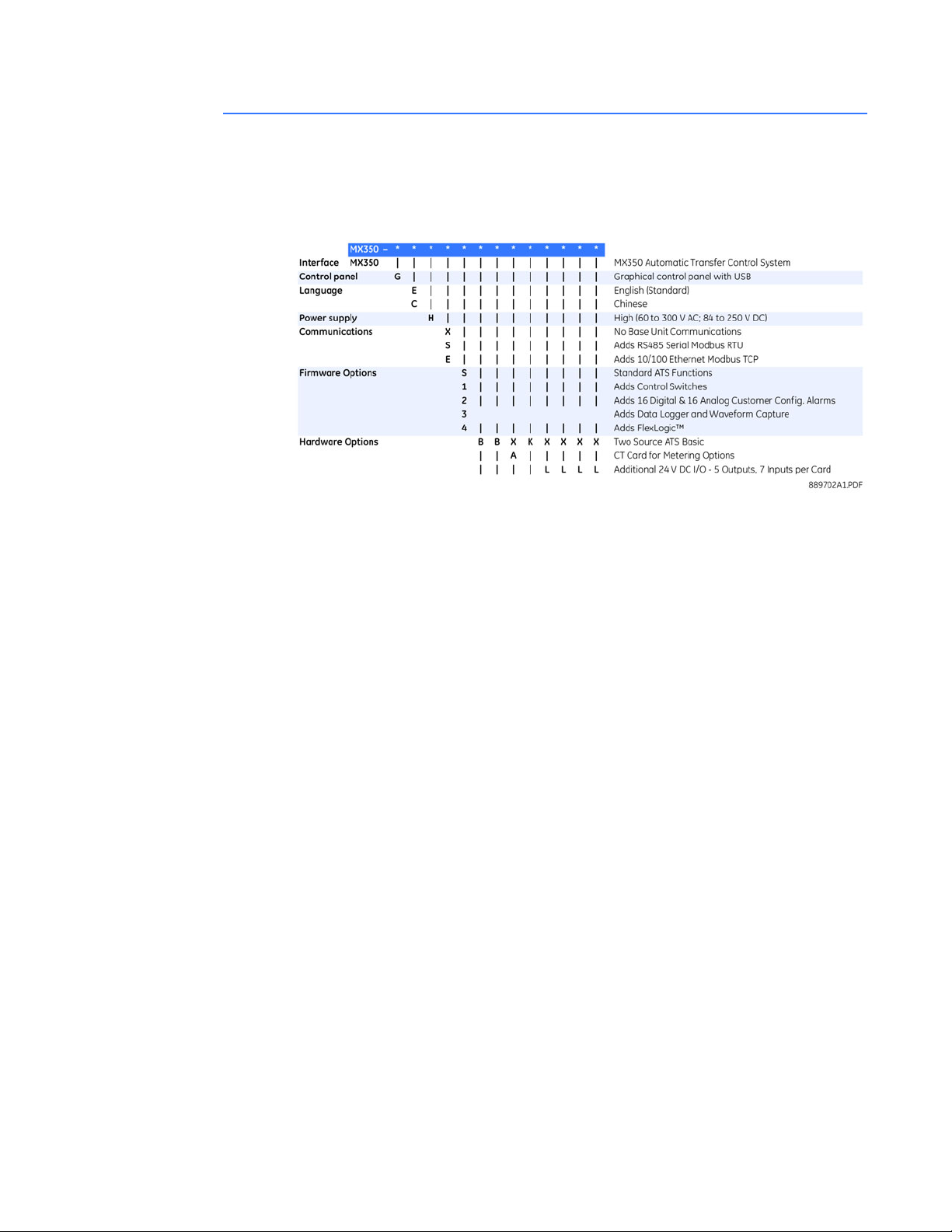

Order codes for MX350

The information to specify an MX350 relay is provided in the following order code figure.

Figure 5: MX350 order codes

Example of an MX350 order code

MX350-GEHE3BBAKLL: MX350 with graphical control panel incl. USB port, English

language display, high voltage control power supply (84 to 250 VDC or 60 to 300VAC), RS485 Modbus RTU port and 10/100 Modbus TCP/IP Ethernet port), data logger and

waveform capture, source 1 voltage sensing, source 2 voltage sensing, load current

sensing, P relay function, and two input/output cards.

MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL 1–11

Page 16

ORDER CODES FOR MX350 CHAPTER 1: INTRODUCTION

1–12 MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL

Page 17

Digital Energy

Multilin

MX350 Automatic Transfer Control

System

Chapter 2: Installation

Installation

Mechanical installation

This section describes the mechanical installation of the MX350 system, including

dimensions for mounting and information on module withdrawal and insertion.

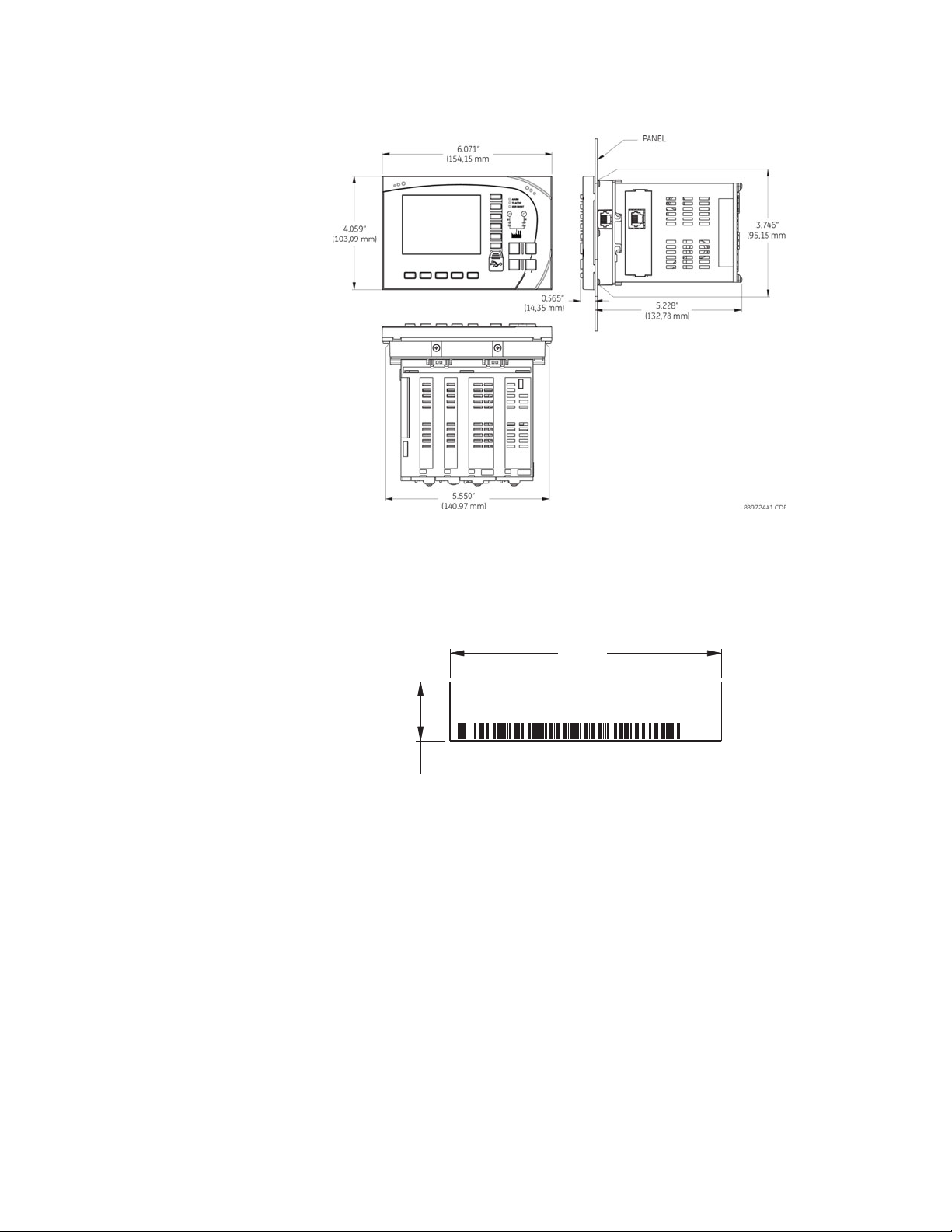

Dimensions

The MX350 is packaged in a modular arrangement.

The dimensions of the MX350 are shown below. Additional dimensions for mounting and

panel cutouts are shown in the following sections.

MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL 2–1

Page 18

MECHANICAL INSTALLATION CHAPTER 2: INSTALLATION

2.425”

(61.6 mm)

0.525”

(13.3 mm)

889748A1.CDR

Model:

Serial Number:

Firmware:

Mfg. Date:

Figure 1: MX350 dimensions

Product identification

The product identification label is located on the side panel of the MX350. This label

indicates the product model, serial number, firmware revision, and date of manufacture.

Figure 2: MX350 label

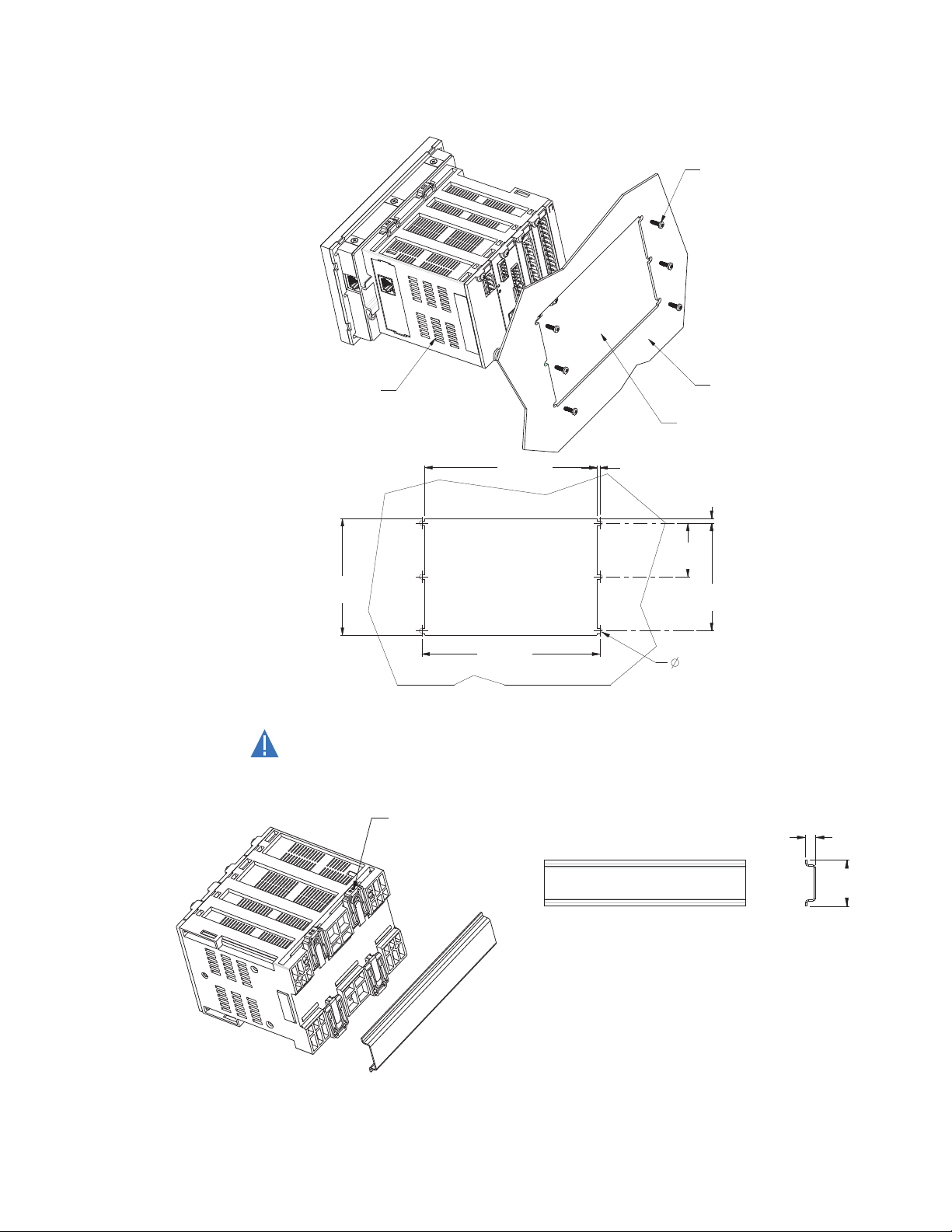

Mounting

The MX350 can be mounted three ways: standard panel mount, DIN rail mount, and screw

mount for high vibration environments.

The standard panel mount and cutout dimensions are illustrated below.

2–2 MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL

Page 19

CHAPTER 2: INSTALLATION MECHANICAL INSTALLATION

CAUTION

#4 - 40x3/8in SELF-TAP PAN HD PHILIPS

QTY: 6 (SUPPLIED); GE PART NO. 1402-0017

TIGHTENING TORQUE: 8 lb-in

REAR OF PANEL

CUTOUT AND

MOUNTING HOLES

INSTALL RELAY

FROM FRONT

OF THE PANEL

3.775”

(95,89 mm)

5.580”

(141,73 mm)

0.105”

(2,67 mm)

0.138”

(3,49 mm)

3.500”

(88,90 mm)

0.130”

(3,30 mm)

(QTY: 6)

5.790”

(147,07 mm)

1.750”

(44,45 mm)

889725A1.CDR

SNAP-IN THE DIN CLIPS (QTY: 4)

FOR DIN RAIL MOUNTING

0.30”

(7,6 mm)

1.38”

(35,1 mm)

DIN 3 RAIL

889726A1.CDR

Figure 3: Panel mounting and cutout dimensions

CAUTION:

The DIN rail mounting is illustrated below. The DIN rail conforms to EN 50022.

To avoid the potential for personal injury due to f ire hazards, ensure the unit is

mounted in a safe location and/or within an appropriate enclosure.

Figure 4: DIN rail mounting

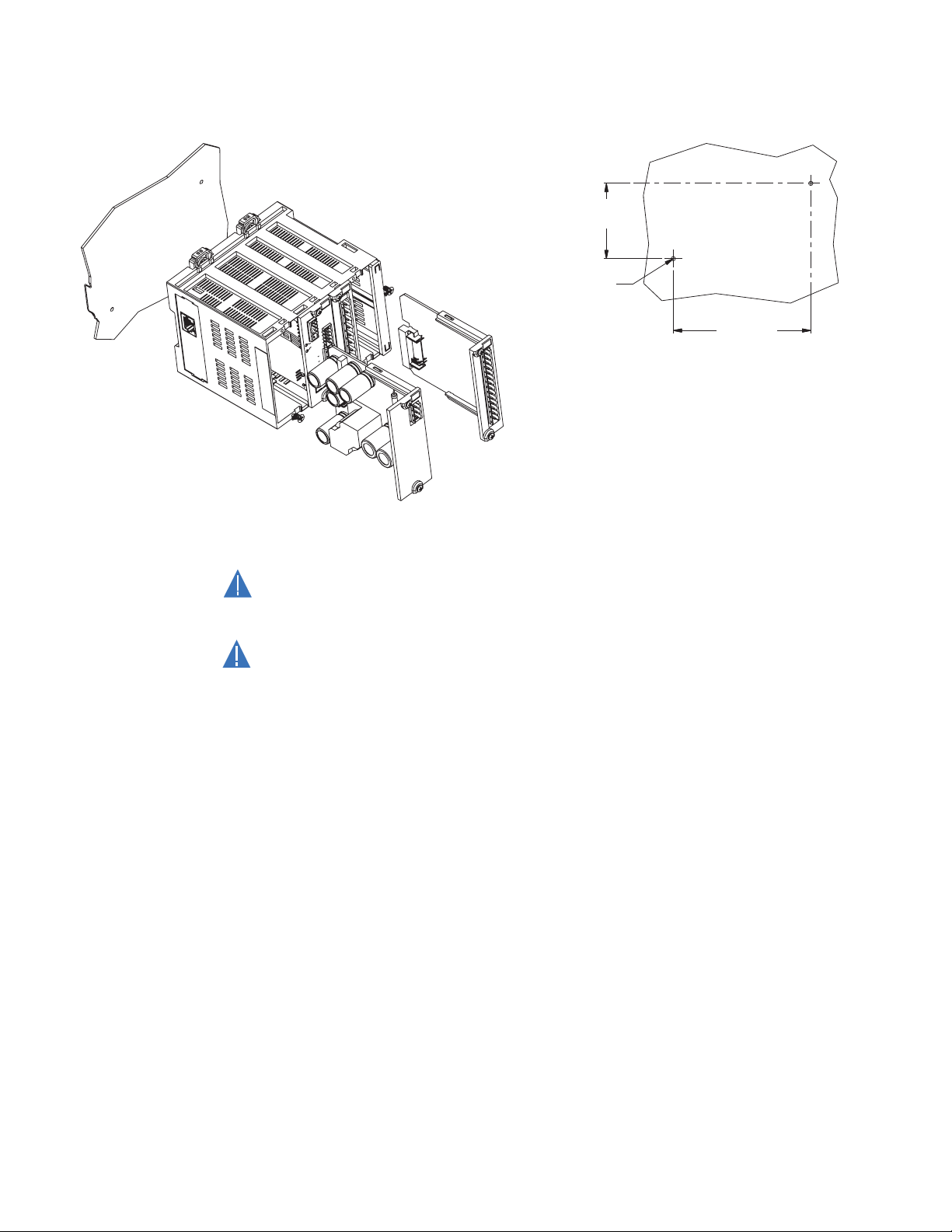

The screw mount for high vibration environments is illustrated below.

MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL 2–3

Page 20

MECHANICAL INSTALLATION CHAPTER 2: INSTALLATION

DANGER

CAUTION

MEETS VIBRATION REQUIREMENT OF

IEC 60255 SEC 21.1, 21.2, & 21.3

2.250”

(57,15 mm)

#6 -32 THREADED HOLE

QTY: 2

4.100”

(104,14 mm)

889727A1.CDR

Figure 5: Screw mounting

DANGER:

CAUTION:

Module withdrawal and insertion

Module withdrawal and insertion may only be performed when control power has been

removed from the unit. Inserting an incorrect module type into a slot may result in

personal injury, damage to the unit or connected equipment, or undesired operation!

Proper electrostatic discharge protection (for example, a static strap) must be used

when coming into contact with modules while they are removed from the MX350.

The MX350 is a modular protection system. This allows for easy withdrawal and insertion

of modules for fast replacement. Modules must only be replaced in their original factory

configured slots.

Use the following procedure to withdraw a module.

1. Ensure that control power has been removed from the MX350.

2. Record the slot location of the module to ensure that the same or replacement

module is inserted into the correct slot.

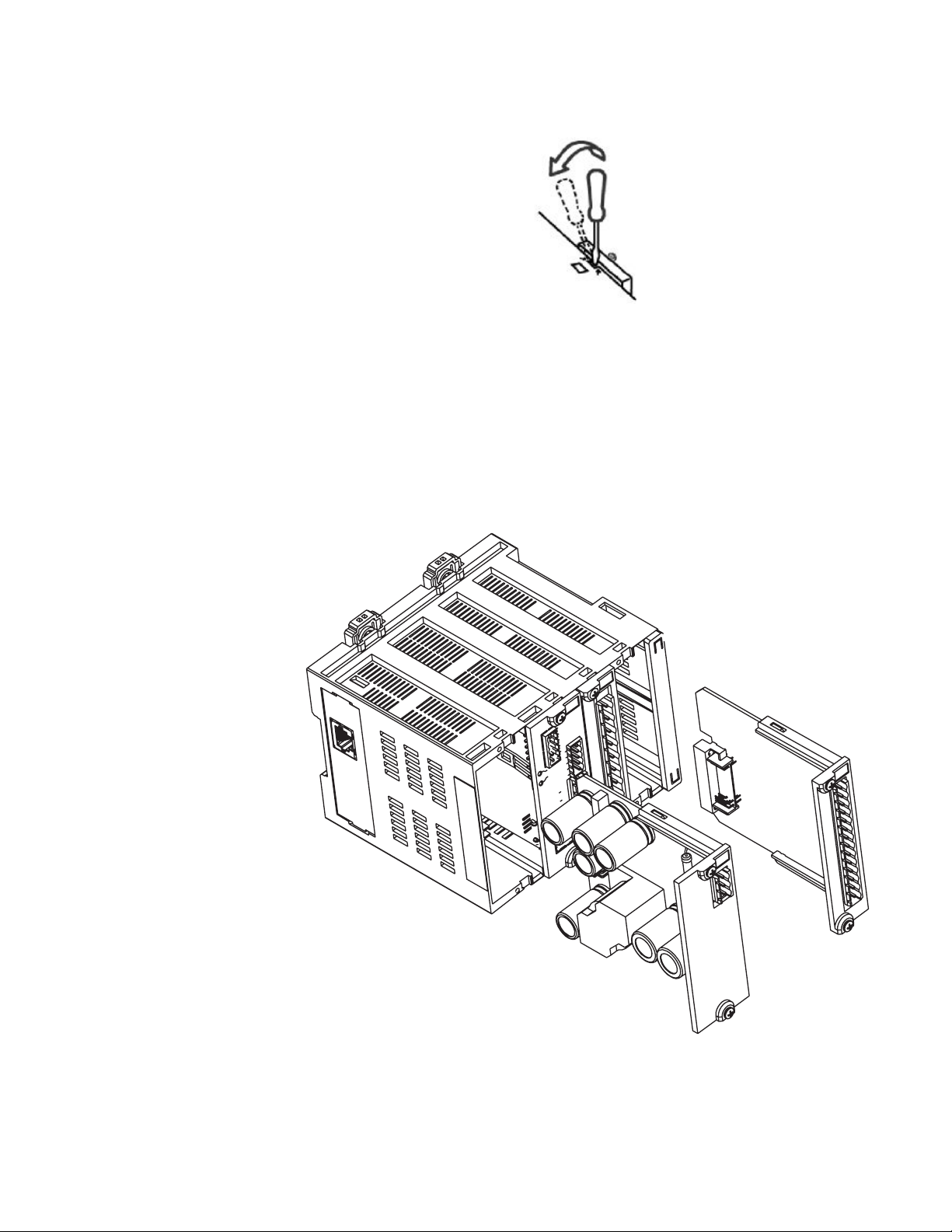

3. Remove the two captive screws at the top and bottom of the module.

4. Slide a flat-blade screwdriver into the opening above the module marked by the two

arrows on top of the MX350 case.

5. Press down on the screwdriver and pivot towards the unit to unlatch the module from

the MX350 case.

2–4 MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL

Page 21

CHAPTER 2: INSTALLATION MECHANICAL INSTALLATION

889733A1.CDR

889734A1.CDR

Figure 6: Removing a module from the MX350

Use the following procedure to insert a module.

1. Ensure that control power has been removed from the MX350.

2. Ensure that the module is being inserted into the correct slot.

3. Align the module card edges with the slot track as shown in the diagram below.

4. Gently slide the modules into the slot until the modules latch into the opening marked

by the two arrows on top of the MX350 case.

5. Attach the two captive screws to anchor the module to the case (use a tightening

torque of 3.5 lb.-in.).

Figure 7: Inserting modules into the MX350

MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL 2–5

Page 22

MECHANICAL INSTALLATION CHAPTER 2: INSTALLATION

NOTE

Module and terminal identification

The MX350 input/output and metering modules are labeled with the “IO_” prefix followed

by a one-character identifier as follows.

Table 1: Input/output and metering module nomenclature

Module Description

IO_A CT module

IO_B VT module

IO_K 4 inputs, 4 outputs, plus relay for engine control

IO_L 7 inputs, 5 outputs

The MX350 terminals are labeled with a two-character identifier. The first character

identifies the module slot position and the second character identifies the terminals within

the module. For example, the first terminal in a module in slot F is identified as “F1”.

NOTE:

Do not confuse the slot designation with the module ordering designation. That is, terminal

“F1” does not imply an IO_F module. Rather, it indicates the first terminal of whatever

module is in slot F, which can only be an IO_K module.

2–6 MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL

Page 23

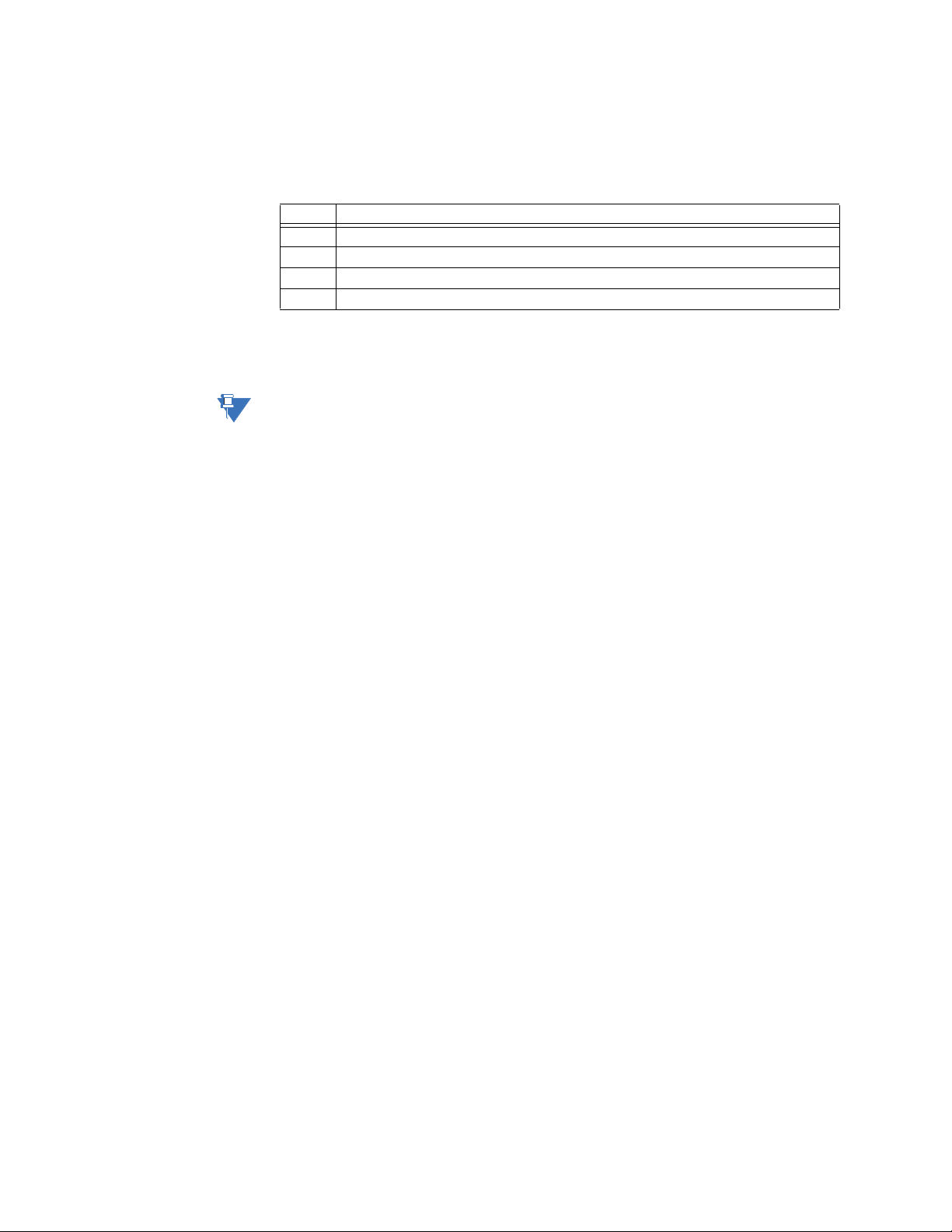

CHAPTER 2: INSTALLATION ELECTRICAL INSTALLATION

CAUTION

Expansion module

Expansion module

to base unit with a

single connector

CT Input

Three-phase plus

ground/neutral

VT inputs

Optional TCP/IP

Ethernet

RS485 communications

Switched power supply

allows AC or DC control

voltage

889740A2.CDR

K Card

Expansion module

to base/expansion unit

with a single connector

LCard LCard

Expansion module

Reserved

Reserved

Electrical installation

This section describes the electrical installation of the MX350 system. An overview of the

MX350 terminal connections is shown below.

Figure 8: MX350 terminal connection overview

CAUTION:

The MX350 can contain up to ten modules. The first four modules (slots A through D) reside

in the base unit while all subsequent modules (slots E and J) reside in expansion units.

Each expansion unit can contain up to two modules. Slots A through G make up the basic

MX350. The next three modules (slots H through J) are optional I/O modules.

Table 2: Module slot position

Slot Module types

A Power supply module

B CPU module with communications

CIO_B module

DIO_B module

E IO_A module (optional)

FIO_K module

GIO_L module

H IO_L module (optional)

I IO_L module (optional)

The following figure shows a typical module arrangement for an expanded unit .

Use gauge size appropriate for the voltage and current draw of the device.

The MX350 is not to be used in any way other than described in this manual.

MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL 2–7

Page 24

ELECTRICAL INSTALLATION CHAPTER 2: INSTALLATION

CAUTION

PSU

60-300 VAC

84-250 VDC

L

LISTED

IND.CONT.EQ.

52TL

E200434

N

8

7

6

5

4

3

2

1

MS

NS

THERM RS485

V-

10/100

ETHERNET

GROUND

CT I/P

I

L

C

H

V+

+

–

C

+

–

FIELD BUS

8

7

6

5

4

3

2

1

ABCDEFGH

Slot position

Base unit Expansion modules

889749A1.CDR

14

13

12

11

10

9

8

7

6

5

4

3

2

1

14

13

12

11

10

9

8

7

6

5

4

3

2

1

14

13

12

11

10

9

8

7

6

5

4

3

2

1

8

7

6

5

4

3

2

1

R

SG

14

13

12

11

10

9

8

7

6

5

4

3

2

1

I

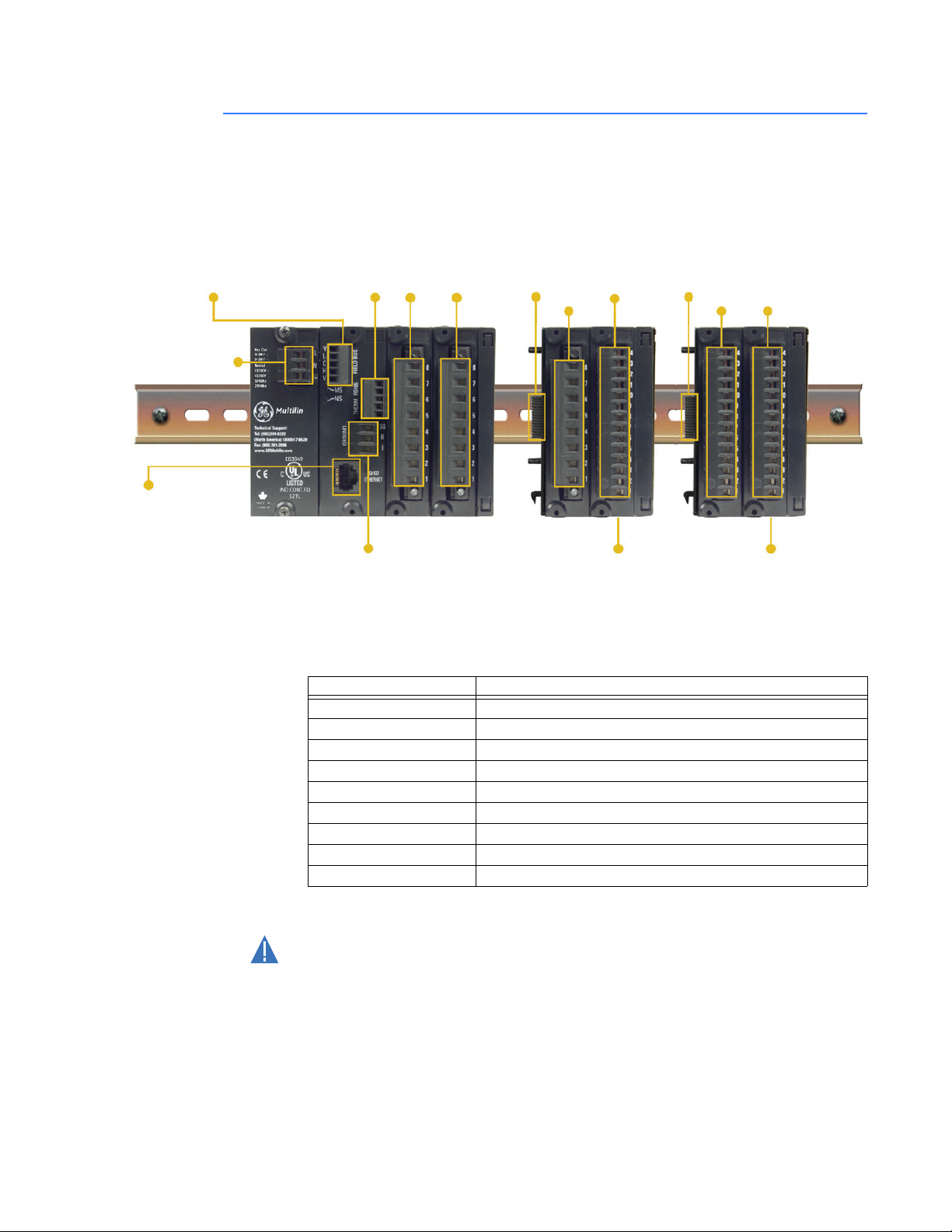

Figure 9: Typical module arrangement

Power supply module

The power supply module in slot A supplies control power to the MX350 system. A supply

voltage between 60 to 300 V AC or 84 to 250 V DC is required to power the MX350

CAUTION:

Check the voltage rating of the unit before applying control power! Control power

outside of the operating range of the power supply will damage the MX350.

2–8 MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL

Page 25

CHAPTER 2: INSTALLATION ELECTRICAL INSTALLATION

CAUTION

SCADA, PLC, OR

PERSONAL COMPUTER

COM

OPTOCOUPLER

DATA

IED

SHIELD

889745A1.CDR

UP TO 32 IEDs,

MAXIMUM CABLE

LENGTH OF

1200 m (4000 ft .)

LAST

DEVICE

(*) TERMINATING IMPEDANCE AT E ACH END

(typically 120 ohms and 1 nF)

TWISTED PAIR

ZT(*)

RS485 +

RS485 -

COMMON

RS485 +

RS485 -

COMMON

IED

RS485 +

IED

RS485 -

COMMON

GROUND THE SHIELD AT THE

SCADA/PLC/COMPUTER ONLY

OR THE UNIT ONLY

DATA

OPTOCOUPLER

B1

B2

B3

ZT(*)

CPU module

The main CPU module and optional communications board is contained in slot B. The main

CPU module provides a Modbus RTU RS485 port. The optional communications board

provides an Ethernet port.

RS485 connections Figure 10: Typical RS485 connection

CAUTION:

MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL 2–9

One two-wire RS485 port is provided. Up to 32 MX350 IEDs can be daisy-chained together

on a communication channel without exceeding the driver capability. For larger systems,

additional serial channels must be added. Commercially available repeaters can also be

used to add more than 32 relays on a single channel. Suitable cable should have a

characteristic impedance of 120 ohms (for example, Belden #9841) and total wire length

should not exceed 1200 meters (4000 ft.). Commercially available repeaters will allow for

transmission distances greater than 1200 meters.

Voltage differences between remote ends of the communication link are not uncommon.

For this reason, surge protection devices are internally installed across all RS485 terminals.

Internally, an isolated power supply with an optocoupled data interface is used to prevent

noise coupling.

To ensure that all devices in a daisy-chain are at the same potential, it is imperative

that the common terminals of each RS485 port are tied together and grounded only

once, at the master or at the MX350. Failure to do so may result in intermittent or failed

communications.

The source computer/PLC/SCADA system should have similar transient protection devices

installed, either internally or externally. Ground the shield at one point only, as shown in the

figure above, to avoid ground loops.

Correct polarity is also essential. The MX350 IEDs must be wired with all the positive (+)

terminals connected together and all the negative (–) terminals connected together. Each

relay must be daisy-chained to the next one. Avoid star or stub connected configurations.

The last device at each end of the daisy-chain should be terminated with a 120 ohm

¼ watt resistor in series with a 1 nF capacitor across the positive and negative terminals.

Observing these guidelines will ensure a reliable communication system immune to

system transients.

Page 26

ELECTRICAL INSTALLATION CHAPTER 2: INSTALLATION

CAUTION

A

C

B

Power flow

–

+

E1

E2

E4E3

Phase current inputs

Automatic Transfer Control System

To switchgear

ground bus

889744A1.CDR

E5

E6 E7

CT1 CT2 CT3

Control power

LN

E8

G/F

N

Input/Output modules

Phase current inputs

(IO_A module)

CAUTION:

Figure 11: Typical phase current input connections

The MX350 has three channels for phase current inputs, plus an additional channel input

for ground/neutral current, each with an isolating transformer. The phase CTs should be

chosen so the nominal current is not less than 50% of the rated phase CT primary. Ideally,

the phase CT primary should be chosen such that the nominal current is 100% of the

phase CT primary or slightly less, never more. This will ensure maximum accuracy for the

current measurements. The maximum phase CT primary current is 4000 A.

The MX350 measures up to 1.5 times the phase current nominal rating. CTs with 1 A or 5 A

secondaries must be used if the FLA is greater than 5 A. The chosen CTs must be capable

of driving the MX350 phase CT burden.

Polarity of the phase CTs is critical for negative-sequence unbalance calculation,

power measurement, and residual ground current detection (if used).

2–10 MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL

Page 27

CHAPTER 2: INSTALLATION ELECTRICAL INSTALLATION

A

C

B

–

+

D1

D2 D4D3

Phase voltage inputs

Auto Transfer Control

D5

D6 D7

VT1 VT2 VT3

Control power

LN

D8

N/C

–

+

C1

C2 C4C3

Phase voltage inputs

Auto Transfer Control

889735A1.CDR

C5

C6 C7

VT1 VT2 VT3

Control power

LN

C8

N/C

N

Typically

generator

Typically

utility

LOAD

A

C

B

–

+

D1

D2 D4D3

Phase voltage inputs

Auto Transfer Control

D5

D6

VT1 VT2 VT3

Control power

LN

D7 D8

N/C

–

+

C1

C2 C4C3

Phase voltage inputs

Auto Transfer Control

889736A1.CDR

C5

C6

VT1 VT2 VT3

Control power

LN

C7 C8

N/C

From

Source 2

(generator)

From

Source 1

(utility)

LOAD

Phase voltage inputs

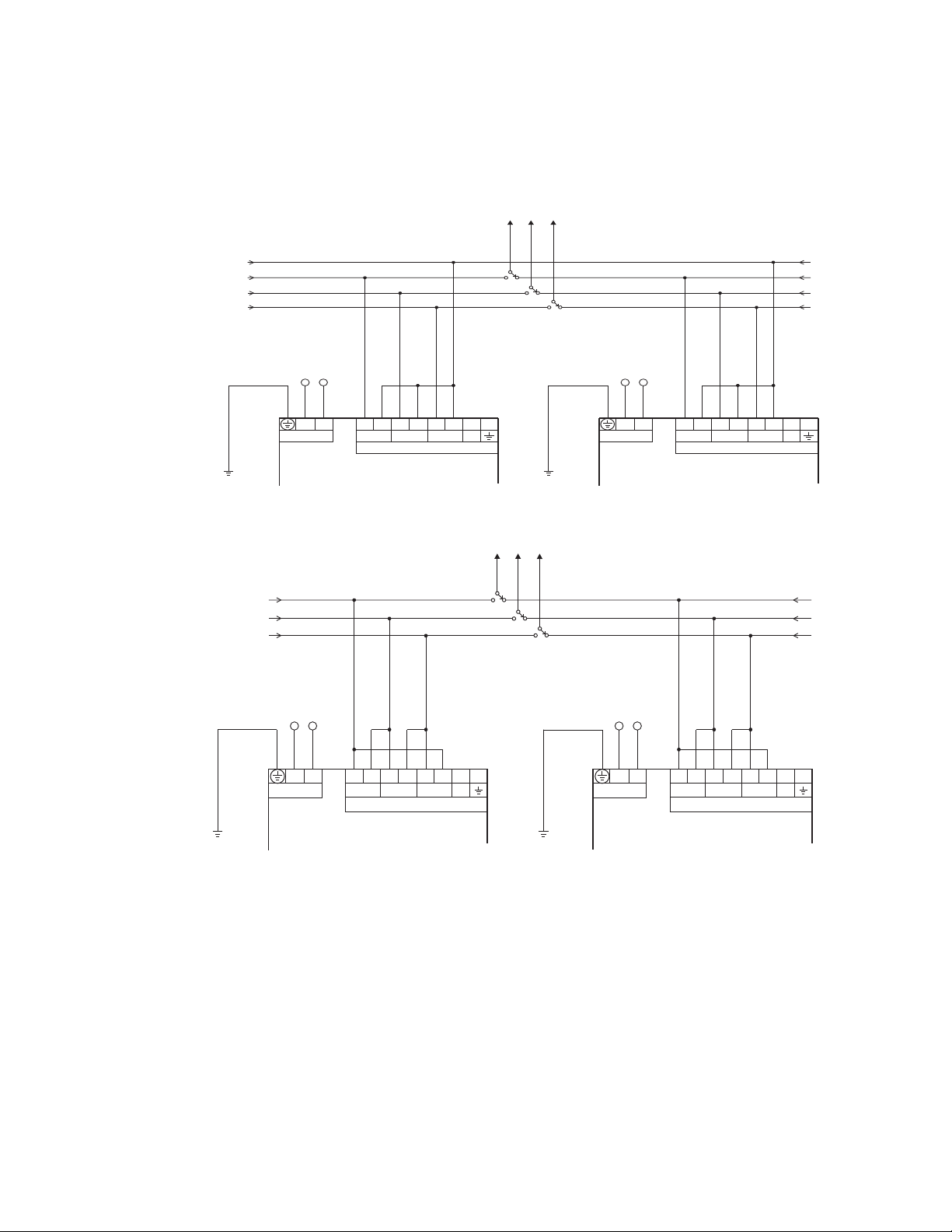

(IO_B module)

The MX350 has three channels for AC voltage inputs. There are no internal fuses or ground

connections on the voltage inputs. Polarity is critical for correct power measurement and

voltage phase reversal operation.

Figure 12: Wye voltage connection

Figure 13: Delta voltage connection

MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL 2–11

Page 28

ELECTRICAL INSTALLATION CHAPTER 2: INSTALLATION

~1

~2

~4

~3

~5

~6

Auto Transfer Control

~8

~9

~11

~10

~12

~13

~7

~14

INPUT COMMON

Inp

com

SOURCE 2 LIMIT SW

DELAYED INPUT

Inp 4

Inp 3

Inp 2

Inp 1

SOURCE 1 LIMIT SW

DELAYED INPUT

SOURCE 2 LIMIT SW

INPUT

SOURCE 1 LIMIT SW

INPUT

P. RELAY - ENGINE

START - N.C.

P. RELAY - COMMON

P. RELAY - ENGINE

START - N.O.

COIL CONTROL REL AYS

3&4COMMON

COIL CONTROL REL AY

DEL (OPEN SRC 2)

COIL CONTROL REL AY

DEL (OPEN SRC 1)

COIL CONTROL REL AYS

1&2COMMON

COIL CONTROL REL AY

SOURCE 2

COIL CONTROL REL AY

SOURCE 1

SSR 3&4

COM

SSR 1&2

COM

SSR

SSR

SSR

SSR

SOURCE 2 LIMIT SWITCH (+24 V DC ACTIVE)

SOURCE 1 LIMIT SWITCH (+24 V DC ACTIVE)

NC

NC

NC

24VDC

24VDC

TO SOLENOID

TO SOLENOID

~1

~2

~4

~3

889741A1.CDR

~5

~6

Auto Transfer Control

~8

~9

~11

~10

~12

~13

~7

~14

INPUT COMMON

Inp

com

SOURCE 2 LIMIT SW

DELAYED INPUT

Inp 4

Inp 3

Inp 2

Inp 1

SOURCE 1 LIMIT SW

DELAYED INPUT

SOURCE 2 LIMIT SW

INPUT

SOURCE 1 LIMIT SW

INPUT

P. RELAY - ENGINE

START - N.C.

P. RELAY - COMMON

P. RELAY - ENGINE

START - N.O.

COIL CONTROL REL AYS

3&4COMMON

COIL CONTROL REL AY

DEL (OPEN SRC 2)

COIL CONTROL REL AY

DEL (OPEN SRC 1)

COIL CONTROL REL AYS

1&2COMMON

COIL CONTROL REL AY

SOURCE 2

COIL CONTROL REL AY

SOURCE 1

SSR 3&4

SSR 1&2

SOURCE 2 LIMIT SWITCH (+24 V DC ACTIVE)

SOURCE 1 LIMIT SWITCH (+24 V DC ACTIVE)

NC

NC

NC

0 VDC

0 VDC

24VDC

24VDC

TO SOLENOID

TO SOLENOID

STARTER

CCTRY

GEN

A

B

C

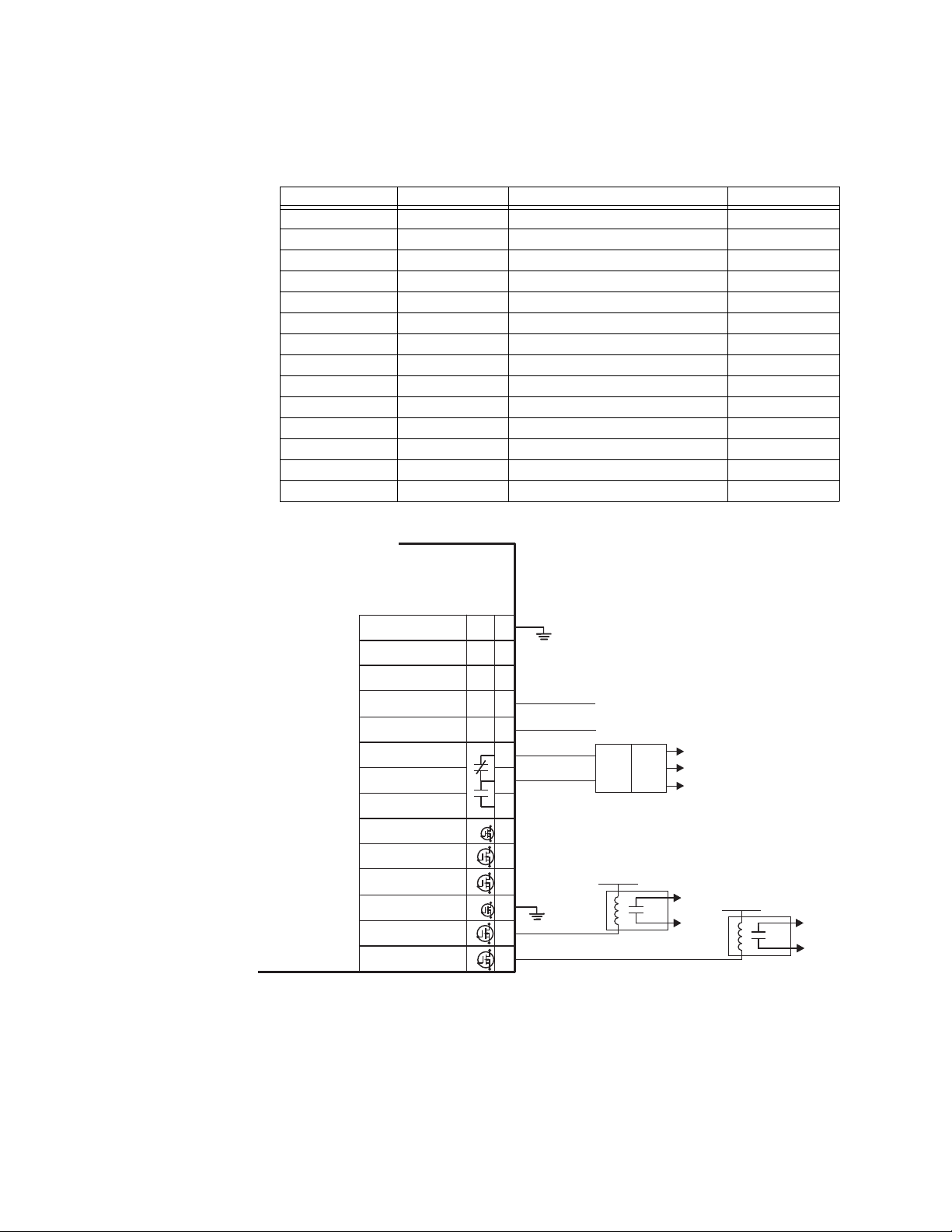

Type IO_K module

connections

The IO_K module handles the automatic delayed start of the engine in case there is a total

power outage, i.e. Source 1 power fails and the MX350 is not powered by an auxiliary

power source. The terminal assignments are as follows:

Terminal Type Function Type

F1 Output S1 Sol Relay N.O.

F2 Output S2 Sol Relay N.O.

F3 N/A Common F1, F2 N/A

F4 Output S1 Del Sol Relay N.O.

F5 Output S2 Del Sol Relay N.O.

F6 N/A Common F4, F5 N/A

F7 Output Engine Start Signal (P Relay) N.O.

F8 N/A Engine Start Signal, Common N/A

F9 Output Engine Start Signal (P Relay) N.C.

F10 Input SN Limit Switch pos.

F11 Input SE Limit Switch pos.

F12 Input SNO Limit Switch pos.

F13 Input SEO Limit Switch pos.

F14 N/A Input Common N/A

Figure 14: IO_K module connections - standard ATS

2–12 MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL

Page 29

CHAPTER 2: INSTALLATION ELECTRICAL INSTALLATION

NOTE

~1

~2

~4

~3

~5

~6

Auto Transfer Control

~8

~9

~11

~10

~12

~13

~7

~14

Inp

com

Inp 7

Inp 6

Inp 5

Inp 4

LOAD SHED FROM S2

TEST WITH LOAD

DISCONNECT SW

LOAD SHED FROM S2

SSR

COM

SSR3

SSR5

SSR4

SSR2

SSR1

NO

~1

~2

~4

~3

889742A1.CDR

~5

~6

Auto Transfer Control

~8

~9

~11

~10

~12

~13

~7

~14

Inp

com

In

SSR

SSR

NC

Inp 3

Inp 2

Inp 1

LOAD SHED

HARDWARE

FOR LOCAL

OPTION

TO BREAKER

24VDC

0 VDC

0 VDC

USER DEFINED

USER DEFINED

USER DEFINED

USER DEFINED

USER DEFINED

USER DEFINED

USER DEFINED

USER DEFINED

USER DEFINED

USER DEFINED

Type IO_L module

connections

NOTE:

IO_L modules provide all user configurable I/O. Additionally, some of the I/O points on the

first L module in slot G are used for some factory configured I/O. The terminal

configuration is as follows:

Terminal Terminal Terminal Type Function

G1 H1 J1 Output Output 1

G2 H2 J2 Output Output 2

G3 H3 J3 Output Output 3

G4 H4 J4 Output Output 4

G5 H5 J5 Output Output 5

G6 H6 J6 Common Common, Ouputs 1 to 5

G7 H7 J7 Input Input 1

G8 H8 J8 Input Input 2

G9 H9 J9 Input Input 3

G10 H10 J10 Input Input 4

G11 H11 J11 Input Input 5

G12 H12 J12 Input Input 6

G13 H13 J13 Input Input 7

G14 H14 J14 Common Common, Inputs 1 to 7

Terminals G7 and G8 are always used as DS and Q2, respectively. Depending on the type

of switch and the features ordered, Terminals G1 through G5 as well as G9 through G13

may not be available for customer configuration.

Figure 15: IO_L module - standard ATS

MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL 2–13

Page 30

ELECTRICAL INSTALLATION CHAPTER 2: INSTALLATION

Do not HI-POT test

HI-POT test at 1.9 kV AC for 1 second, or

1.6 kV AC for 1 minute (per UL 508)

LINE FAULT

ON

POWER

FAULT

RESET

kV

VOLTAGEADJUST

HV ON

DIELECTRIC STRENGTHTESTER

BLACK RED

Remove surge ground during test

*

CPU module

C8

C7

C6

C5

C4

C3

C2

C1

Surge Ground

D1

D2

D3

D4

D5

D6

D7

D8

CT Module

CT1

CT2

CT3

CT4

Power

supply

L

N

G

Automatic Transfer Control System

VT1 module

VT1

VT3

RS485

Thermistor

VT2

Core

balance

Surge Ground

889738A1.CDR

+

–

C

+

–

R

ISG

*

*

*

*

*

D8

D7

D6

D4

D3

D2

D1

Surge Ground

D5

VT1

VT3

VT2

VT2 module

*

*

*

*

*

Dielectric strength testing

Figure 16: Testing for dielectric strength

2–14 MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL

It may be required to test for dielectric strength (“flash” or “HI-POT”) with the MX350

installed. The MX350 is rated for 1.9 kV AC for 1 second, or 1.6 kV AC for 1 minute (per UL

508) isolation between relay contacts, CT inputs, VT inputs and the surge ground terminal

SG. Some precautions are required to prevent damage to the MX350during these tests.

Filter networks and transient protection clamps are used between VT input and the surge

ground terminal. This is intended to filter out high voltage transients, radio frequency

interference (RFI), and electromagnetic interference (EMI). The filter capacitors and

transient suppressors may be damaged by continuous high voltage. Disconnect the surge

ground terminals (C8 and D8) during testing of VT inputs. The CT inputs, control power, and

output relays do not require any special precautions. Low voltage inputs (less than

30 volts), and RS485 communication ports are not to be tested for dielectric strength under

any circumstance (see above).

Page 31

Digital Energy

Multilin

MX350 Automatic Transfer Control

System

Chapter 3: Interfacing with the

MX350 AT Controller

Interfacing with the MX350 AT Controller

There are four methods of interfacing with the MX350 ATS Controller.

• Interfacing via the graphical control panel.

• Interfacing via remote inputs.

• Interfacing via communicated inputs.

• Interfacing via the EnerVista™ MX350 Setup software.

This section provides an overview of the interfacing methods available with the MX350. For

additional details on interface parameters (for example, settings, actual values, etc.), refer

to the individual chapters.

Graphical control panel

The MX350 graphical control panel provides the operator with rapid access to relevant

information and controls using intuitive sequences. It also provides all available

information and setting control, again with intuitive sequences.

Introduction to the graphical control panel

The central feature of the graphical control panel is a 89 mm (3.5-inch) 320 by 240 pixel

backlit color LCD screen. The panel also contains keys (pushbuttons) that control the

display and perform commands. In addition, the interface contains ALARM RESET, TEST,

CONTROL, and INFO direct acting control pushbuttons.

The display also contains several LED indicators that provide a summary of the machine

status. Details are displayed on the screen when the user navigates to the appropriate

page.

MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL 3–1

Page 32

GRAPHICAL CONTROL PANEL CHAPTER 3: INTERFACING WITH THE MX350 AT CONTROLLER

889700A1.CDR

LED indicators

Soft-keys

Graphical

display

Control keys

Function keys

USB port

Header bar

Selected page

Soft-key labels

Path indication Date and timeAccess level

Color convention

for soft-key labels

(blue)

(grey)

(red)

(grey / grey text)

(orange)

Commands

Active Tab

Inactive Tab

Status

Unavailable Feature

Figure 1: MX350 front panel with example default display

Graphical display Each display page consists of the three components shown below.

Figure 2: Graphical display overview

The header bar (white text on a blue background) displays the hierarchical path name, the

date and time in 24-hour format, and the current password access level. The hierarchical

path is always displayed on the left top side of the graphical display. The present time is

displayed on the right top side.

The soft-key labels are indicated on the bottom line. The soft-keys are used for navigation,

performing functions, and for acknowledgement.

• Navigation: soft-keys can be used to traverse across and down the hierarchy of

pages.

• Functional: soft-keys can be used to perform page-specific functions.

• Acknowledgement: soft keys can be used to acknowledge popup windows.

Soft-keys labels change to show relevant selections for the displayed screen. The color of

each soft-key label indicates its functionality. Soft-keys are highlighted for the displayed

page, unauthorized keys are “greyed-out”, and unused keys are not displayed.

3–2 MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL

Page 33

CHAPTER 3: INTERFACING WITH THE MX350 AT CONTROLLER GRAPHICAL CONTROL PANEL

Header bar

Selected page

Soft-key labels

Path indication Date and timeAccess level

Color convention

for soft-key labels

(blue)

(grey)

(red)

(grey / grey text)

(orange)

Commands

Active Tab

Inactive Tab

Status

Unavailable Feature

The remainder of the screen shows the selected page. Pages are organized in a

hierarchical or tree-based menu structure. To improve readability, some pages are labeled

with rectangular outlines or colored backgrounds. Some pages contain too many fields to

display at once. These pages display arrows bars at the right edge to indicate that the

page continues below the screen. When recalled, scrolled pages are re-positioned at the

top of the page.

Fields display actual value or setting information, and have behaviours that allow help

display, editing, and control.

Each Actual Value analog field displayed on the home page has an associated alarm limit

and changes color to orange when that limit is exceeded. Fields with an associated trip

limit change their color to red when that limit has tripped. Fields that are disabled or

unavailable are greyed-out.

Keypad The function keys perform the labeled functionality. The summary of function key

operation is shown below.

Table 1: Summary of function key operations

Key Operation

HOME Single press recalls the home page; double press recalls the default display

UP Scroll up page, select field, tab to next field, increment value

DOWN Scroll down page, select field, tab to previous field, decrement value

ESC Single press closes pop-up, cancels editing, deselects field, moves to previous page;

ENTER Single press freezes scrolling and selects field, edits selected field, saves edited value;

HELP Displays context sensitive help and Modbus address

sustained press logs out (cancels security passcode entry)

double press sets the selected field/page as default; sustained press logs in (enter

security passcode)

The HOME key always recalls the root or home page. The home page allows access to all

sub-pages and also contains a status and process values summary. Double pressing the

HOME key recalls the default display. Like a screen-saver, the default display appears after

a period of inactivity and displays user-selected information. A typical display is shown

below, indicating that the system load is connected to the utility.

Figure 3: Typical default display (actual size)

The UP and DOWN keys function in different ways depending on their context.

• Where a scroll bar is displayed, the UP and DOWN keys scroll the page up and down.

MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL 3–3

Page 34

GRAPHICAL CONTROL PANEL CHAPTER 3: INTERFACING WITH THE MX350 AT CONTROLLER

• Where there is no scroll bar or it is greyed-out, the first press of the UP and DOWN

keys selects the first field. Subsequent presses tab up and down through the fields,

scrolling as required.

• When a field is open for editing, the UP and DOWN keys increment/decrement the

value of that field.

The ENTER key functions in different ways depending on its context.

• If there are no selected fields, the ENTER key will freeze any scroll bars and select the

first field on the display.

• If a field is selected, pressing ENTER will attempt to open it for editing.

• If a field is opened for editing, pressing enter will exit the edit sequence.

• Double pressing the ENTER key at any time selects the displayed page as the default

display.

• A sustained press on ENTER prompts the security passcode and displays a dialog box

that allows passcode entry.

For example, pressing and holding the ENTER key, or attempting a control where a

password is required, displays the following page.

Figure 4: Passcode entry dialog box

The ESC key functions in different ways depending on its context.

• If a pop-up dialog box is displayed, the ESC key closes it.

• If an edit sequence is in progress, the ESC key cancels the edit.

• If a field is selected, the ESC key de-selects it.

• In all other instances, the ESC key moves back one page in the menu structure.

• A sustained press on the ESC key clears the security passcode and prompts for

confirmation.

The HELP key functions in different ways depending on its context.

• If a field is selected, the HELP key displays a help window for the field.

• If a help window is displayed, the HELP key closes it.

Help windows are also closed when any other key is pressed. A typical help window is

shown below.

Figure 5: Typical MX350 help window

3–4 MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL

Page 35

CHAPTER 3: INTERFACING WITH THE MX350 AT CONTROLLER GRAPHICAL CONTROL PANEL

Pressing an invalid key displays a message explaining the problem and recommending a

solution. Where the keypress is invalid because a security passcode is required, the dialog

window will be a passcode entry window.

Control keys The MX350 has four large direct control keys: ALARM RESET, TEST, CONTROL, and INFO.

• ALARM RESET: allows the user to silence any audible alarm.

• TEST: takes the user directly to the System Test Screen.

• CONTROL: takes the user directly to the Control Screen that allows the user to select

certain modes of operation.

• INFO: takes the user directly to the Event Report screen.

LED indicators The control panel LEDs summarize the status of the transfer switch:.

• ALARM: indicates that there is a problem with the ATS, or that a user configurable

alarm condition is active, or that the ATS is not in AUTO mode.

• TD ACTIVE: indicates that the controller is timing before taking the next control action.

• XFER INHIBIT: indicates that the controller will not automatically transfer to the other

source and that operator intervention is required.

• S1 (Source-1, typically utility power) Available LED: indicates that S1 is present and

within user defined limits.

• S2 (Source-2, typically generator power) Available LED: indicates that S2 is present and

within user defined limits.

• S1 (Utility) Status LED: indicates that the load is connected to S1 power.

• S2 (Generator) Status LED: indicates that the load is connected to S2 power.

MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL 3–5

Page 36

GRAPHICAL CONTROL PANEL CHAPTER 3: INTERFACING WITH THE MX350 AT CONTROLLER

Amps

Power

Volts

PQ

Values

Inputs

Outputs

System

Message

Flex

Summary

Status

Reset

Operation

Control

Security

Config

Setpoints

Phase B

Phase C

Phase A

Phase A

Phase B

Phase C

Phase A

Phase B

Outputs

Comms

System

Events

Zenith

Waveform

Faults

Alarms

Control

Stats

Phasors

About

Events

Report

Diag

ATS

CT-VT

Inputs

Virtual

Waveform

Datalog

Phase C

V1 Harm

V2 Harm

I Harm

Summary

V1 Harm

V2 Harm

I Harm

Summary

V Inputs

V Outputs

S1 Setting

S2 Setting

Timers

General

Interlock

Alarms

Reset

Setup

889701A1.CDR

Main menu

Level 1 Level 2 Level 3 Level 4

ExerCancel

Info

Exerciser

Datalog

Test

MX350 graphical display pages

A summary of the MX350 page hierarchy is shown below.

Figure 6: MX350 display page hierarchy

3–6 MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL

Page 37

CHAPTER 3: INTERFACING WITH THE MX350 AT CONTROLLER GRAPHICAL CONTROL PANEL

Header bar

Selected page

Soft-key labels

Path indication Date and timeAccess level

Color convention

for soft-key labels

(blue)

(grey)

(red)

(grey / grey text)

(orange)

Commands

Active Tab

Inactive Tab

Status

Unavailable Feature

Home display page The home page represents the root of the entire menu structure. An overview of the

system status is displayed which indicates the following items:

• Load connected to Source 1 or Source 2

• Type of ATS being controlled

• Amperage rating of ATS

• Voltage rating of ATS

•Source 1 type

•Source 2 type

• Preferred source selection

• Information on the System Exerciser

• Information regarding the last load transfer.

Figure 7: Typical MX350 home display

The Values, Status, Setpoints, Diag, and Exerciser soft-keys are displayed on the home

page. The Status soft-key will be highlighted if any alarm condition is present.

Pressing any of the soft-keys displays the first sub-page in the hierarchy. Pressing the ESC

key within any of these sub-pages returns directly to the home page.

Default display The default display is automatically shown when no control key has been pressed for five

minutes. It can also be recalled at any time by double-clicking the HOME key.

The default display can be set to the home page, any actual values page, or any status

page. A page can be set to be the default display by navigating to that page and doublepressing the ENTER key. The default display setting is saved in non-volatile memory.

If a page is set as the default display, the soft-keys will be those of the selected page.

Actual values pages The actual values pages are divided into five sections.

MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL 3–7

• Summary (overview of primary actual values)

• Amps (metered current values)

• Volts (metered voltage values)

• Power (metered power values)

• PQ (metered power quality values)

The actual values summary page displays a summary of the analog actual values. The

current, voltage, power, and PQ actual values pages are accessible from the summary

page through the corresponding soft-keys at the bottom of the screen.

Page 38

GRAPHICAL CONTROL PANEL CHAPTER 3: INTERFACING WITH THE MX350 AT CONTROLLER

Some typical actual values screens are shown below.

Figure 8: Typical actual values summary page

Figure 9: Typical actual values current page

Figure 10: Typical actual values voltage page

Status pages The status pages provide the user with up-to-date information on the current status of the

ATS that the MX350 is controlling.

Status pages are divided into five sections.

• Message (displays all locked out conditions plus conditions such as alarms, internal

faults, control status, etc.).

• Inputs (displays the present state of assigned contact inputs).

• Outputs (displays the present state of assigned contact outputs).

• System (displays the present state of the communications interface).

3–8 MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL

Page 39

CHAPTER 3: INTERFACING WITH THE MX350 AT CONTROLLER GRAPHICAL CONTROL PANEL

• Flex (displays the present state of the FlexLogic™ engine and number of lines used.)

A typical display is shown below:

Figure 11: Typical status message page

Message types are classified by color and associated icon type, as follows::

• Red Triangle = Alarm

• Orange Square = Status

• Black Text = Information Message

Message can have an associated countdown timer, if applicable.

When the controller is first powered up, the status page will display any parameters that

must be entered for proper operation of the associated ATS.

Inhibits

These include Transfer Inhibits like Q3 or Q7.

Faults / Alarms

These trigger depending on the respective protection setpoints. A typical example would

be “S1 Failure.”

Information Messages

Information can be one of two types:

– information only

– information with navigation (marked on the Status page with an Enter symbol on

the right)

By pressing the Enter key when an information message with navigation is highlighted, the

Grapical Control Panel will take the user directly to the respective page.

Setpoints pages The Setpoints pages are divided into five sections.

• Config (contains basic configuration setpoints)

• Operation (contains range limits for both power sources and timer values for transfer

operations)

• Control (contains basic control function setup, also accessible via the green CONTROL

key)

• Security (contains the password security setpoints)

• Factory (for access by GE only)

The Home > Setpoints page displays a warning message concerning unexpected

performance if setpoints are improperly changed. It is recommended that all relay outputs

capable of causing damage or harm be blocked before a setpoints change is made and it

is clear the relay is performing as intended with the new setpoints.

MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL 3–9

Page 40

GRAPHICAL CONTROL PANEL CHAPTER 3: INTERFACING WITH THE MX350 AT CONTROLLER

Figure 12: setpoints home page

To streamline the setpoint entry process, the graphical control panel will not display

setpoints that are not relevant at the specific instance. For instance, if a process interlock

function is disabled, the six setpoints associated with that interlock function will not be

displayed. If all ten process interlock functions are disabled, the MX350 will display only 10

successive “Disabled” list items. If one of the interlock functions were then enabled, then

room is made on the display for the six setpoints which are now functional.

The setpoint pages are in a common format of up to twelve lines. Each line has a column

that displays the setpoint name and unit, and another column displaying the value

entered.

The Home > Setpoints > Config > CT-VT page is shown below.

Figure 13: Typical setpoints page

Diagnostics pages The diagnostic pages are divided into five sections.

• Events (event recorder data for up to 256 events)

• Stats (statistical data on the last transfer event)

• Phasors (metered phasor data)

• About (product information)

Typical diagnostic pages for Events, Stats, Phasors, and Product Information are shown

below.

3–10 MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL

Page 41

CHAPTER 3: INTERFACING WITH THE MX350 AT CONTROLLER GRAPHICAL CONTROL PANEL

NOTE

Figure 14: Typical Events page

Figure 15: Typical Stats page

Figure 16: Typical Phasors page

NOTE:

Voltage metering displayed on this page is L-N for a 3-phase system. L-L values are shown

on the Voltage Metering page. See the Voltage Metering section in the Actual Values

chapter of this manual.

MX350 AUTOMATIC TRANSFER CONTROL SYSTEM – INSTRUCTION MANUAL 3–11

Page 42

GRAPHICAL CONTROL PANEL CHAPTER 3: INTERFACING WITH THE MX350 AT CONTROLLER

Control page This page is used to view the active control modes. For example, selection of primary

source, automatic vs manual initialization of transfer, etc.

Figure 17: Typical control page display

Refer to the Control chapter for details on control page functionality.

Popup windows There are three types of popup windows:

• Setpoint editor popup windows.