Page 1

Basic Installation and User’s Guide

for the Millennium II Controller

J85501P-1

Product Manual

Select Code 167-792-181

Comcode 108994645

Issue 3

January 2008

Page 2

Notice:

The information, specifications, and procedures in this manual are subject to change

without notice. Lineage Power assumes no responsibility for any errors that may appear

in this document.

© 2008 Lineage Power

All International Rights Reserved

Printed in U.S.A.

Page 3

Basic Installation and User’s Guide for the Millennium II Controller

Table of Contents

1 Introduction.................................................................................................................... 4

Millennium II.................................................................................................................. 4

Customer Service Contacts............................................................................................. 5

2 Product Description....................................................................................................... 6

Overview......................................................................................................................... 6

Feature Summary............................................................................................................ 6

General Specifications .................................................................................................. 11

Hardware....................................................................................................................... 12

3 Safety............................................................................................................................. 15

Safety Statements.......................................................................................................... 15

Warning Statements and Safety Symbols..................................................................... 17

Precautions.................................................................................................................... 18

Special Installation Notes ............................................................................................. 19

4 New Installations.......................................................................................................... 21

Controller Connections ................................................................................................. 23

Installing Circuit Packs................................................................................................. 24

Thermal Probes ............................................................................................................. 28

USB Interface................................................................................................................ 29

Wiring Alarm Outputs .................................................................................................. 29

Wiring Alarm and Control Inputs................................................................................. 32

Fuses ............................................................................................................................. 35

Front Panel Display....................................................................................................... 35

Controller Defaults........................................................................................................ 39

Controller Display Menu Maps .................................................................................... 46

5 Acceptance Testing ...................................................................................................... 58

Introduction................................................................................................................... 58

Tools and Test Equipment ............................................................................................ 58

Test Precautions............................................................................................................ 58

Test Sequences.............................................................................................................. 59

6 Controller Retrofits ..................................................................................................... 67

Millennium Basic Controller Retrofit........................................................................... 67

Millennium Intelligent Controller Retrofit ................................................................... 85

7 Troubleshooting ......................................................................................................... 104

Controller Circuit Pack ............................................................................................... 104

Option Cards ............................................................................................................... 104

Controller Alarm Descriptions.................................................................................... 104

Clear Events................................................................................................................ 110

Uninstall Devices........................................................................................................ 111

8 Spare Parts ................................................................................................................. 112

9 Product Warranty...................................................................................................... 113

Revision History............................................................................................................ 115

Issue 3 January 2008

3

Page 4

Basic Installation and User’s Guide for the Millennium II Controller

1 Introduction

Millennium II

The J85501P-1 Galaxy Millennium II controller is the next generation full-featured

power system controller from Lineage Power. It provides control, monitoring, and alarm

monitoring functions over a multi-drop serial interface that interconnects system

rectifiers, converters, Bay Interface Cards (BICs), and other serial devices. It utilizes

robust RS-485 serial busses that support the Galaxy Protocol (GP) to communicate to

these devices. The Millennium II has a plethora of I/O and monitoring options. It can

monitor and control battery plants containing up to 64 Galaxy serial rectifiers, up to 16

serial converters, and up to 32 BICs. A maximum combination of 85 GP nodes can be

directly managed on the rectifier serial bus. The Millennium II performs many functions

described more thoroughly in following sections. Following is a high level view.

• Alarm Detection, Identification, and Reporting

• System and Component Status

• System and Feature Configuration

• System Alarm Thresholds

• Battery Management (Slope Thermal Compensation/Recharge Current Limit)

• Battery discharge testing

• Reserve Time Prediction

• Selective high/low voltage shutdown

• Float/Boost Mode Control

• Low Voltage Disconnect Management

• Remote Access Control And Multiple Level Password Security

• Control and Operations

• History

• Statistics

This controller replaces the existing +24V and -48V versions of the Millennium

controller with a single unit. While becoming easier to use, the Millennium II adds

additional functionality to the comprehensive feature set now provided by the existing

Millennium. The Millennium II is

separate Independent (Basic), Intelligent, and network interface circuit packs of the

existing Millennium controller have been integrated into a single standard board offering

with the Millennium II. This eliminates the need to manage multiple boards for features

as well as plant voltage. Intelligent functionality with remote 10/100 Base-T network

access capability to display power system operating status and available information via

the world wide web (internet) or your enterprise network (intranet) using standard

browsers such as Microsoft Internet Explorer® or Netscape® Navigator is now the

standard offering.

Issue 3 January 2008

Lineage Power’s new flagship controller product. The

4

Page 5

Basic Installation and User’s Guide for the Millennium II Controller

Not only are the software features of the Millennium all contained in the Millennium II,

the new controller is physically backwards compatible for field upgrades and

replacements. The Millennium II can also be used as an upgrade to the door mounted

Galaxy Vector controller When performed, this installation adds newer and more

available technologies to the power system. The old Millennium chassis is replaced with

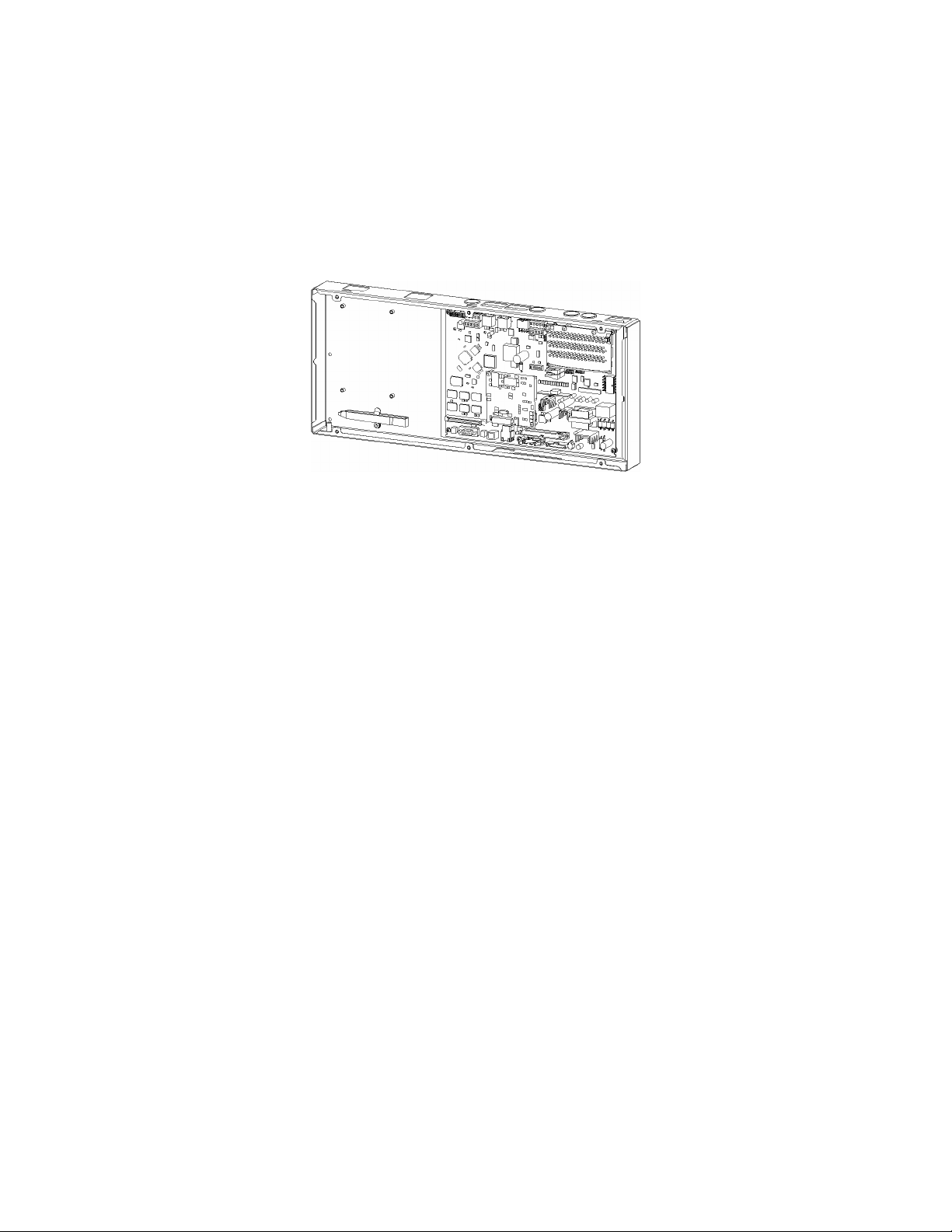

the new Millennium II chassis shown in the figure following. All existing and future GPS

cabinet systems remain supported by the Millennium II.

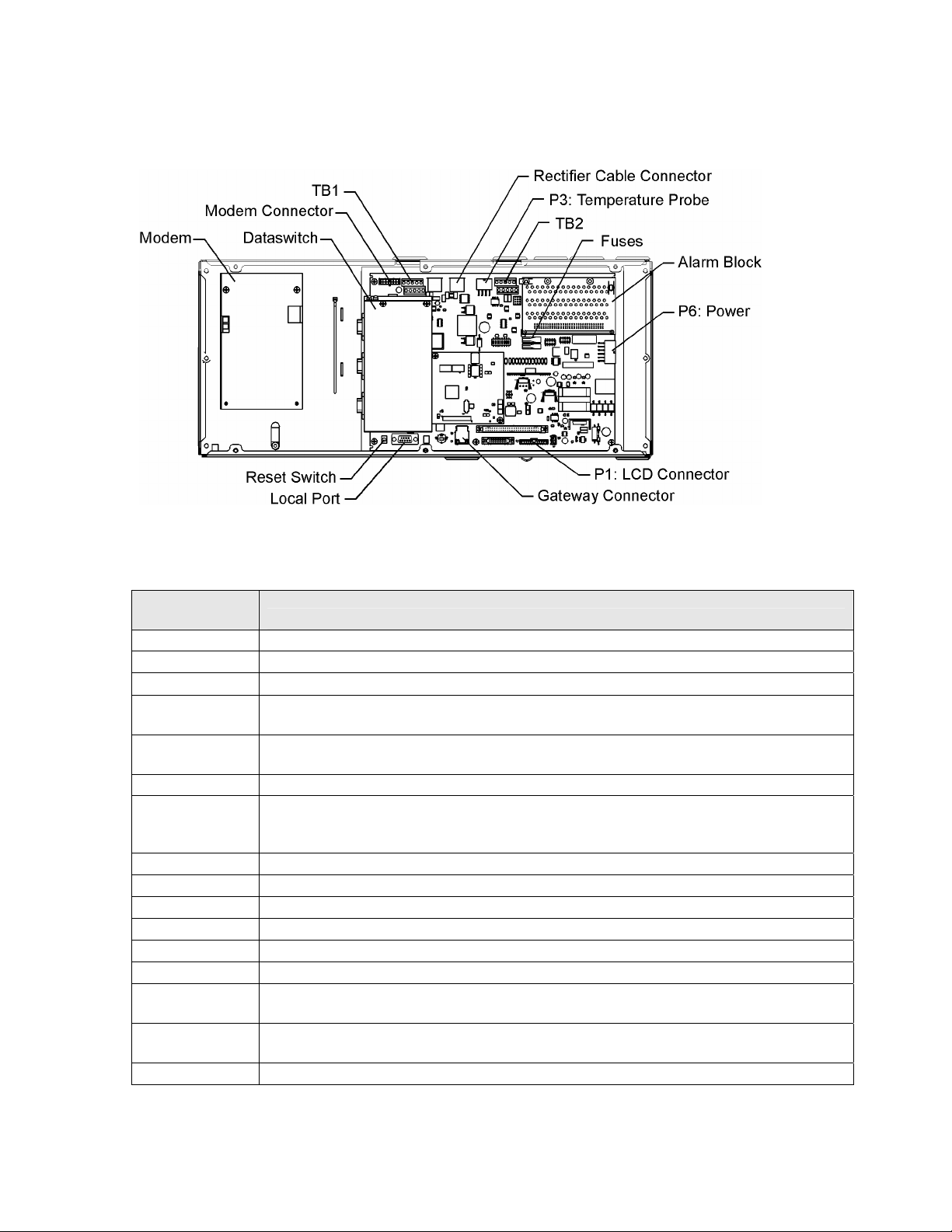

Figure 1-1:Galaxy Millennium II Controller

Customer Service Contacts

Customer Service, Technical Support, and Warranty Service

For customers in the United States, Canada, Puerto Rico, and the US Virgin Islands, call

1-800-THE-1PWR (1-800-843-1797). This number is staffed from 7:00 am to 5:00 pm

Central Time (zone 6), Monday through Friday, on normal business days. At other times

this number is still available, but for emergencies only. Services provided through this

contact include initiating the spare parts procurement process, ordering documents,

product warranty administration, and providing other product and service information.

For other customers worldwide the 800 number may be accessed after first dialing the

AT&T Direct country code for the country where the call is originating, or you may

contact your local field support center or your sales representative to discuss your

specific needs.

Customer Training

Lineage Power offers customer training on many Power Systems products. For

information call 1-972-284-2163. This number is answered from 8:00 a.m. until 4:30

p.m., Central Time Zone (Zone 6), Monday through Friday.

On-Line Power Systems Product Manuals and Software

Power Systems on-line product manuals and software are available on-line. Software

includes Easy View and SNMP MIB.

Issue 3 January 2008

5

Page 6

Basic Installation and User’s Guide for the Millennium II Controller

2 Product Description

Overview

The Millennium II has been designed to be a complete power system monitor and

controller with a variety of alarming and remote access capabilities that complies with all

relevant regulatory requirements, respectively. It is the nerve center of the battery plant

that utilizes serial monitored and controlled rectifiers, converters, and system peripherals.

It monitors and controls the plant rectifiers, distribution, and batteries. It can also monitor

and control peripheral power equipment, including standby generators, converter plants,

and inverters.

The Millennium II monitors and control battery plants containing up to 64 Galaxy serial

rectifiers, up to 16 serial converters, and up to 32 Bay Interface Cards (BICs). A

maximum combination of 85 GP nodes can be directly managed on the rectifier RS485

serial bus. The following table contains the Lineage Power rectifiers that can interface with

the Galaxy Millennium II:

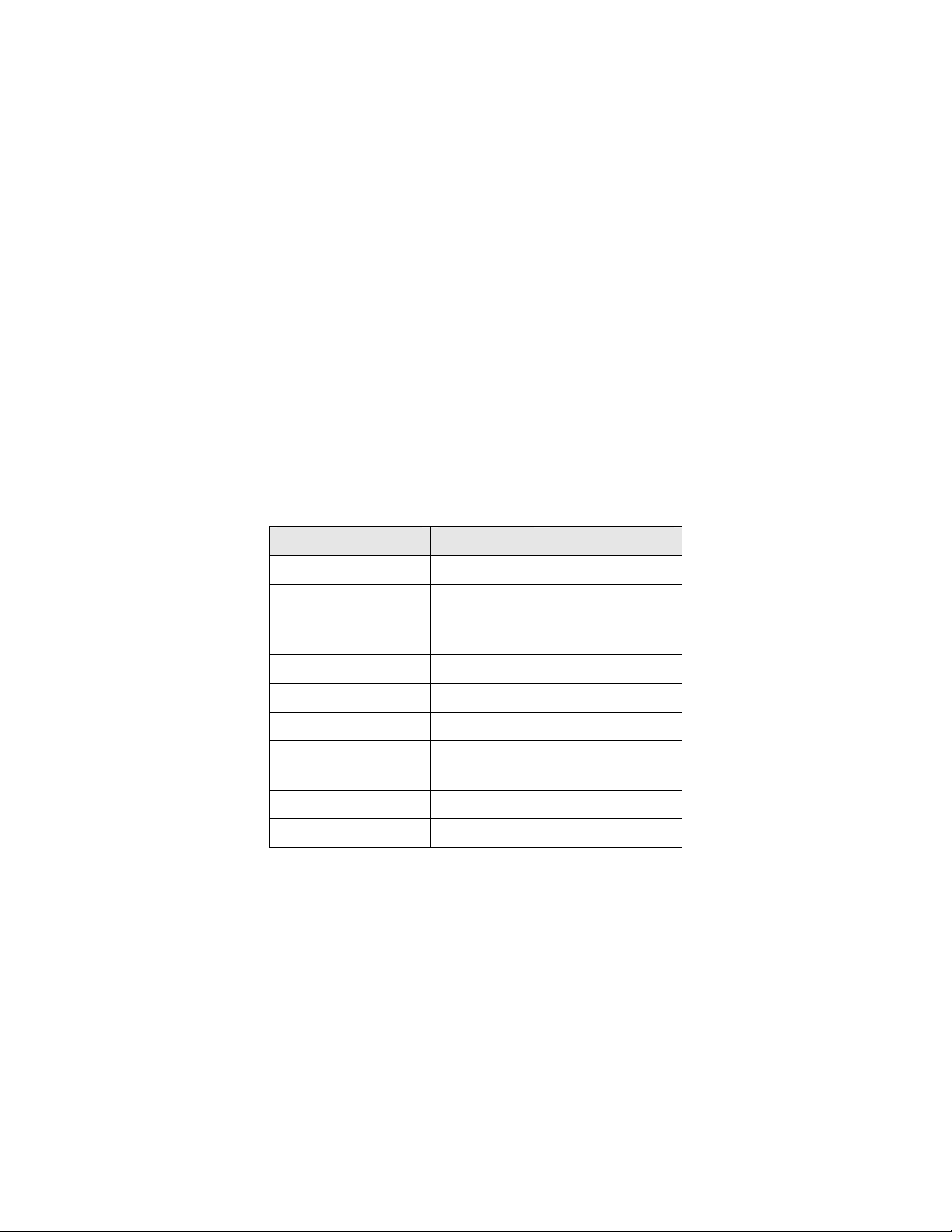

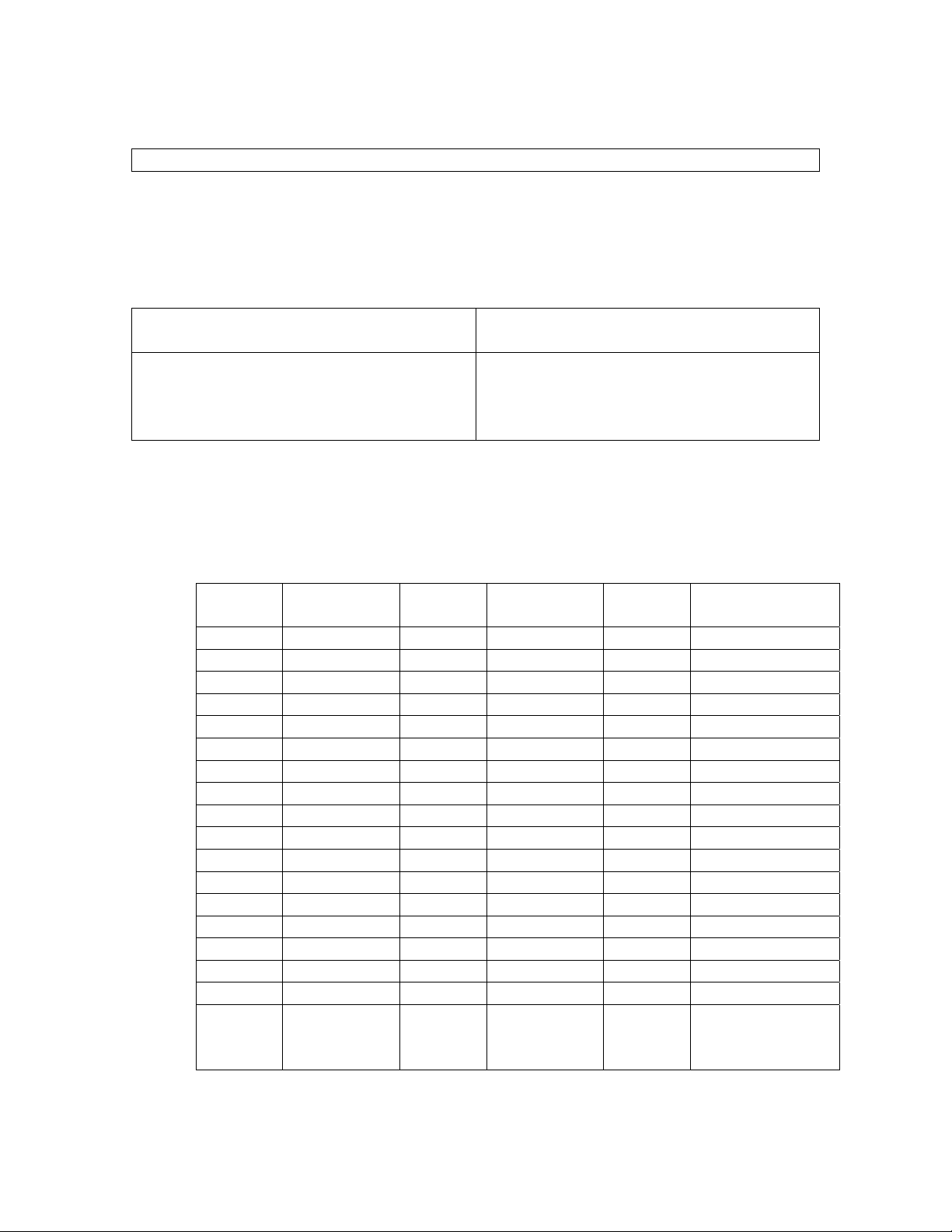

Table 2-A: Rectifiers That May Be Used With Millennium II

Model Vdc Current

570A -48V 100A

595A, 595B,

595C, 595LTA,

595LTB

596A / 596D -48V 50A / 100A

596B +24V 100A / 125A

596F +24V 100A

NP +24V / -

CPS6000 QS86X -48V 7.5A – 50A

AC3000 -48V 60A

-48V 200A/220A

24A – 50A

48V

Feature Summary

The Millennium II has combined and enhanced its Millennium predecessor’s Basic,

Intelligent, and Network functionality into its standard offering. This controller unit

supports

the features available in the Millennium II.

Lineage Power‘s most extensive controller feature set. Following is a summary of

Issue 3 January 2008

6

Page 7

Basic Installation and User’s Guide for the Millennium II Controller

Standard System Features

Monitoring and control of up to

85 RS485 serial connected

devices

Alarms

• Maximum of 64 serial switchmode rectifiers

• Maximum of 32 Bay Interface Cards (BICs)

• Maximum of 16 serial converters

• Standard and custom User Defined system

alarms

• Alarm test

• Alarm cut-off

• Multiple-level alarm severity: Critical, Major,

Minor, Warning, and Record-Only

Rectifiers

• Automatic rectifier restart

• Reserve engine transfer

• High Voltage Shutdown

• Energy management

• Remote rectifier (on/off) control

• Automatic rectifier sequence control

• N + X redundancy check

• Digital voltage regulation and rectifier load

share

Contactor/Disconnect Control

• Low Voltage Load

• Low Voltage Battery

Interfaces

• Enhanced Front Panel Display

• Local PC Port

• Modem

• LAN (Gateway Card)

• X.25/TL1

Peripheral Monitoring and

Control

• Up to 512 monitoring channels

• On board generic voltage channel

• On board 4-20mA transducer interface

Maintenance Tools

• User Programmable Alarms

• History

• Statistics

• Diagnostics

• Derived Channels

• Inventory Management

• Configuration Backup/Restore

Memory

• Non-Volatile

• Battery Backed

• Remote and Local Software Upgrade

Issue 3 January 2008

7

Page 8

Basic Installation and User’s Guide for the Millennium II Controller

Enhanced Front Panel User Interface

Cabinet door mounted

LCD

• Front access without opening the cabinet door

• 8-line by 40-character (240 x 64) backlit

display with digital contrast adjust

Menu Driven User Interface

• Re-designed user friendly menu driven LCD

with similar push-button membrane switch

interface

• Menu structure similar to other Lineage Power

controllers

Audible Alarm Buzzer

• Integrated on display assembly

• May be Enabled/Disabled

LEDs

• 12 individual user configurable status LEDs:

Critical, Major, Minor, Normal, AC System,

Battery, Controller, Distribution, Rectifier,

Remote Modules, Modem, and Battery On

Discharge

Test Jacks

Local Port

• Used to verify displayed system bus voltage

• DB-9 RS232 system port for local terminal

access or event log printing

• ANSI T1.317 serial access

• EasyView Windows-based software for

configuration and reporting

• Ground referenced

Compatibility

• Backwards compatible to existing Millennium

Remote Access And Features

Integrated 10/100Base-T

Ethernet Network capability

Optional Modem access

Issue 3 January 2008

• Supports TCP/IP Version 5, SNMP Version

2c, SMTP, TL1, DHCP, Telnet, FTP

• Standard and custom web pages for standard

browsers (HTTP)

• Compatible to Galaxy Manager

• Standard shielded RJ-45 interface referenced

to chassis

• Remote access via internal BSM5 Modem

option (56k bps Modem)

• Remote access capability via external Modem

• Callback security

8

Page 9

Basic Installation and User’s Guide for the Millennium II Controller

Optional BSW Dataswitch

TL1

Easy View PC User Interface

Security

Battery Management

Slope Thermal Compensation

(STC)

Recharge Current Limit

Reserve Time Prediction

Battery Discharge Testing

Float/Boost Mode Control

Temperature Disconnect

Emergency Power Off

• Connections to 3 standard RS232 devices for

pass-through and alarm management

• BSN extension to provide 3 additional RS232

serial connections

• Configurable RS-232/485 port for remote via

TL1/X.25

• Windows-based software, for configuration

and reporting through local terminal or

• Modem connections

• Multiple password-protected security levels

• Dip Switches

• Enhanced Security Features enable or disable

many controller features

• High temperature compensation

• Low temperature compensation

• Step temperature

• STC Enable/Disable

• Low temperature Enable/Disable

• mV/°C adjustments

• Control rechargerate for batteries

• Supports a variety of batteries

• Use configurable Low Reserve Time Alarm

• Integrated “At Rate Calculator” for estimation

purposes

• Manual

• Periodic

• Plant Battery Test (PBT) input driven

• Battery Discharge trace data

• Manual Timed Boost- Locally T1.317 and

remotely initiated

• External Timed Boost

• Battery Thermal Protect module Boost (BTP)

• Auto Boost terminated by time or current

• Manual front panel Boost

• Programmable high temperature

• User programmable

Issue 3 January 2008

9

Page 10

Basic Installation and User’s Guide for the Millennium II Controller

Integrated Monitoring Inputs/Outputs

System Voltage and Current monitoring

System Shunts

• Maximum of 2 (more with BICs and RPMs)

• Battery or Load

• Battery or Return Side

4-20 mA

• Single channel

• Input

0-5 Vdc

• Single Channel

• Input

• Selectable resistors for: 5, 30 and 60 Vdc

ranges

Temperature Probe

• 4 Channels

• 1 – 10/30k Thermal Probe Inputs

• 3 – 10k Thermal Probe Inputs

Binary Inputs

• 22 Inputs

• Engine signal inputs

• Battery test inputs

• External Float/Boost control

• 2 User programmable

Remote Peripheral Monitoring

• Integrated serial bus

• Maximum 300 M serial bus

• 512 channels

• Transducer interface

• Battery, Shunt monitoring

• Channels can be programmed for custom

alarms

Integrated Outputs

Traditional Office Alarms 19 Form C alarm outputs

2 User programmable relay outputs

Alarm Battery Supply

Issue 3 January 2008

• 1.3A Fused

10

Page 11

Basic Installation and User’s Guide for the Millennium II Controller

General Specifications

Basic Millennium II specifications are summarized in table 2-B. Consult service center

for other details.

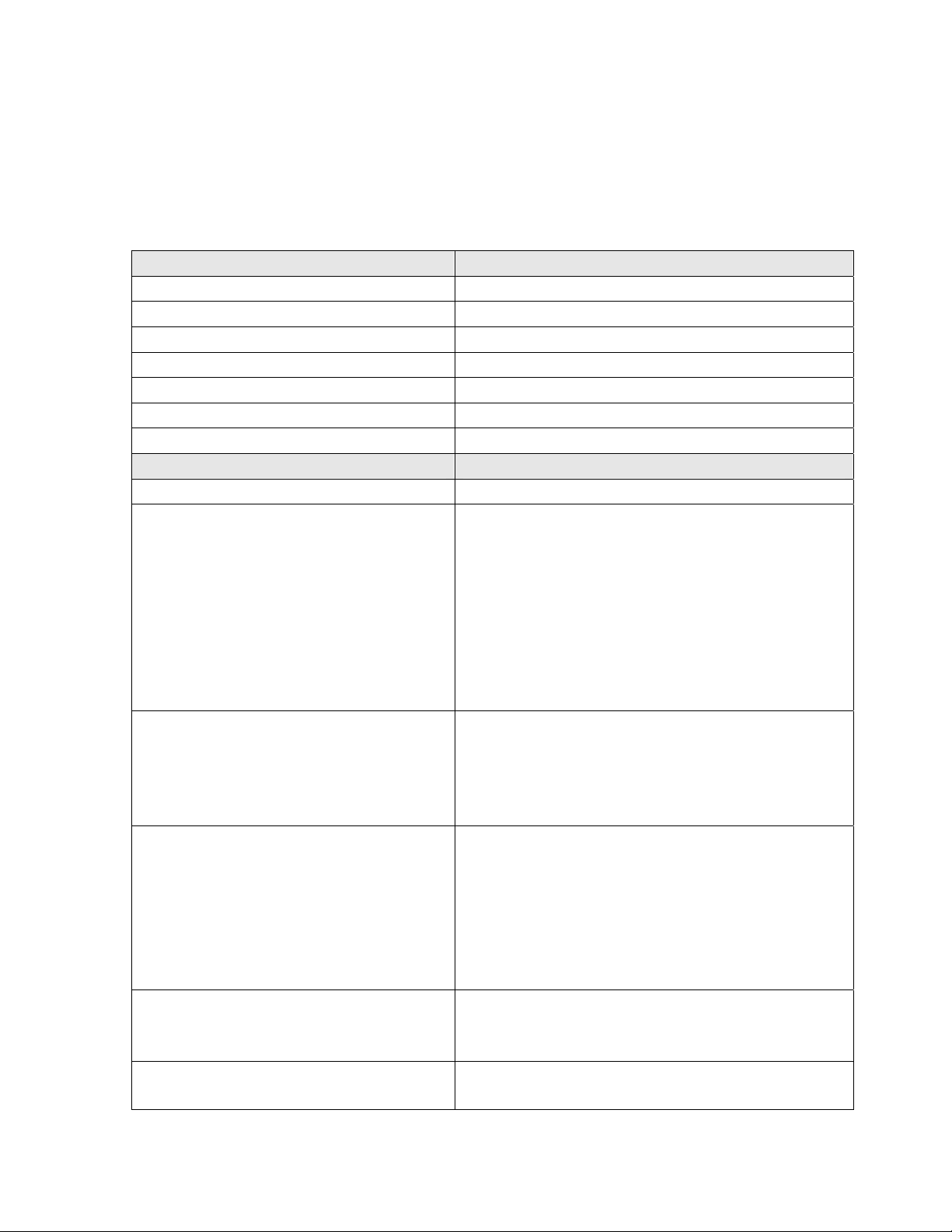

Table 2-B: General Millennium II Controller Specifications

General Specifications

Input Voltage Range ±24 Vdc, -48 Vdc (Range: 18-60V)

Maximum Input Power 36W depending upon options

Operating Temperature Range -40 to 75 °C (-40 to 167 °F)

Storage Temperature Range -40 to 85 °C (-40 to 185 °F)

Physical Specifications 9.24 in. H, 20.76 in. W, 2.14 in. D

Display 8-line by 40-character backlit LCD

Cabinet Mounting Requirements Door mounted

Input/Outputs Specifications

Form C Alarm Output Contact Ratings 60VDC at 0.5A

Plant Voltage Measurement

Accuracy

0 to 50 °C (±.05% of full scale + 1

count)

-40 to 85 °C (±0.1% of full scale + 1

count)

Resolution

Plant Current Measurement (Up to 2

shunts)

Accuracy

Resolution

Temperature Measurement

Accuracy

Thermistor temperature

One-Wire Serial probes

Resolution

4-20mA Input Monitor

Accuracy

Resolution

General (0-5V) Input

Accuracy

48V Systems: ±40 mV

24V Systems: ±25 mV

48V Systems: ±70 mV

24V Systems: ±40 mV

0.01V

0 to +50 °C : ±0.5% of full scale

-40 to +85 °C: ±1.25% of full scale

1A

-5 to +55 °C: ±2°C

-40 to +85 °C: ±3°C

-5 to +55 °C: ±1°C (next release)

-40 to +85 °C: ±3°C

0.1°C

±100µA

±10.0µA

0 to +50 °C: ±0.5% of full scale

Issue 3 January 2008

11

Page 12

Basic Installation and User’s Guide for the Millennium II Controller

Resolution

Safety And Standards Specifications

Electrostatic Discharge IEC 801-2 level 2, 4, 5

Radiated Emissions FCC Class B, CISPR 22 level B

Safety UL Unlisted Component as Part of GPS Power

NEBs Level 3 Tested and Complaint with Galaxy Power

It should also be noted that the Millennium II is suitable for use in power plants with or

without batteries. In batteryless plants, the loss of ac power causes an immediate loss of

dc power to the controller and the activation of all office alarm relays. When ac power is

restored, plant rectifiers will return to their last specified voltage set point, and the

controller will automatically return to its last configuration.

-40 to +85 °C: ±1.0% of full scale

0.01VDC

System

Systems

Hardware

Chassis

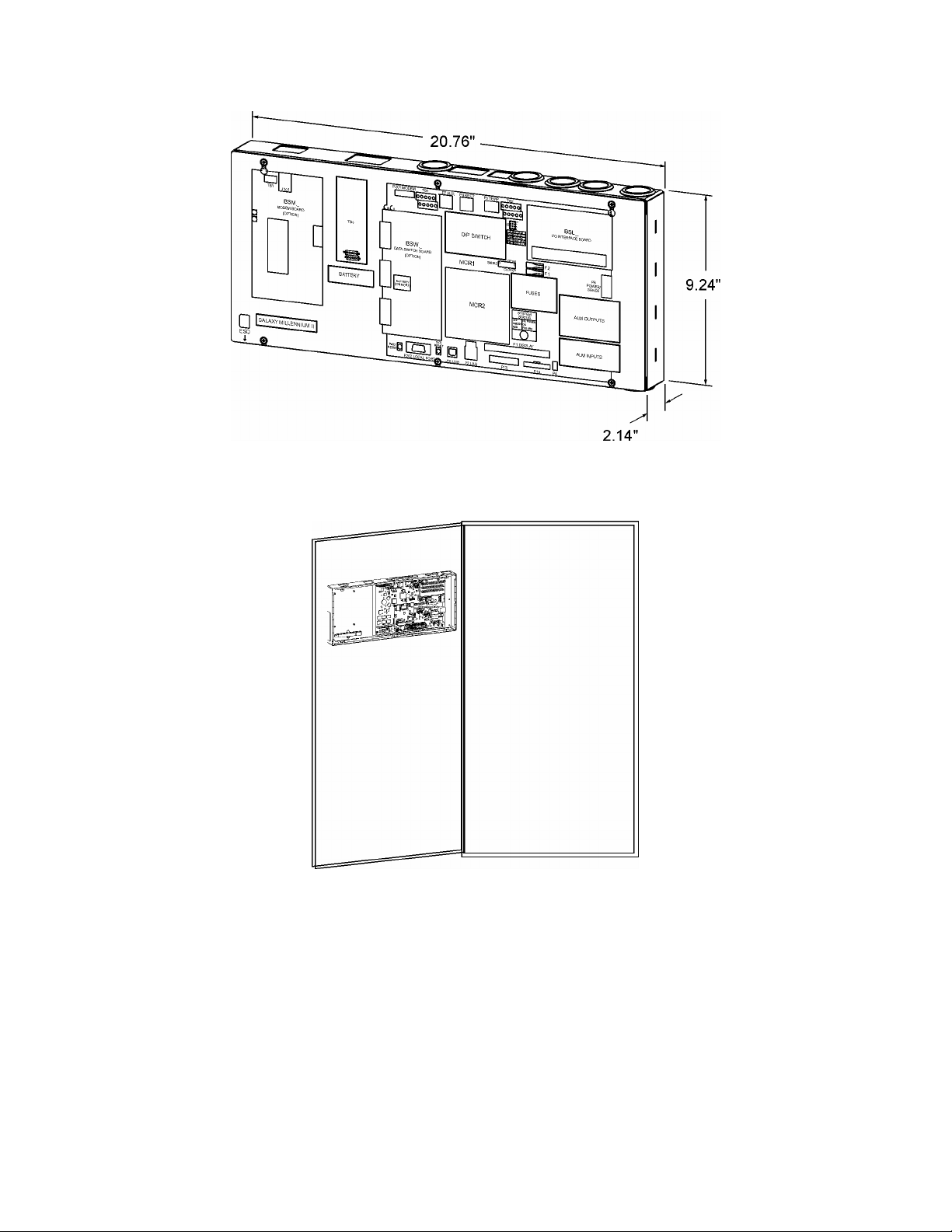

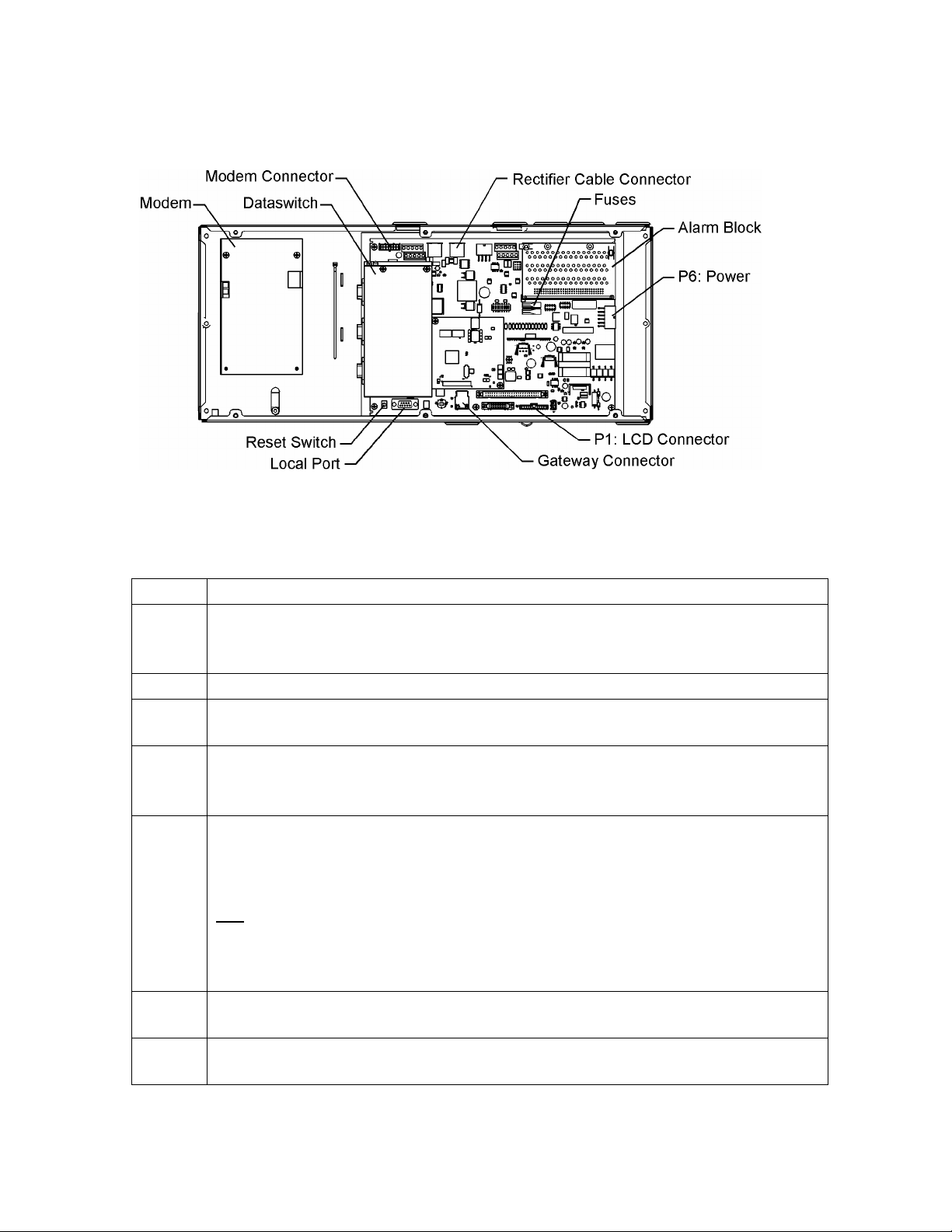

The Galaxy Millennium II, like its Millennium predecessor, is low-profile enclosure

mounted on the inside front cabinet door of a Galaxy Power System (GPS) plant. See

Figure 2-1, and 2-2. This arrangement occupies no space within the frame mounting

racks, thus allowing additional room for other plant equipment. The unit is pre-installed

in the factory for all applicable GPS configurations. However, it has been designed to be

backwards compatible to existing Millennium to allow field replacements or upgrades. It

is composed of two main components: a rust resistant metal enclosure and a clear plastic

cover. The metal enclosure interfaces with the cabinet door and provides appropriate

cable routing entrances to the circuit pack it secures. A maintenance friendly clear plastic

cover is used to protect the enclosed circuit packs. This cover also provides clear and

quick visibility to individual circuit pack alarm status indicators and all wiring

connections without removing a cover allowing quick board integrity and connectivity

checks without removing cover.

Issue 3 January 2008

12

Page 13

Basic Installation and User’s Guide for the Millennium II Controller

Figure 2-1: Controller Dimensions

Figure 2-2: Millennium Mounted on Cabinet Door

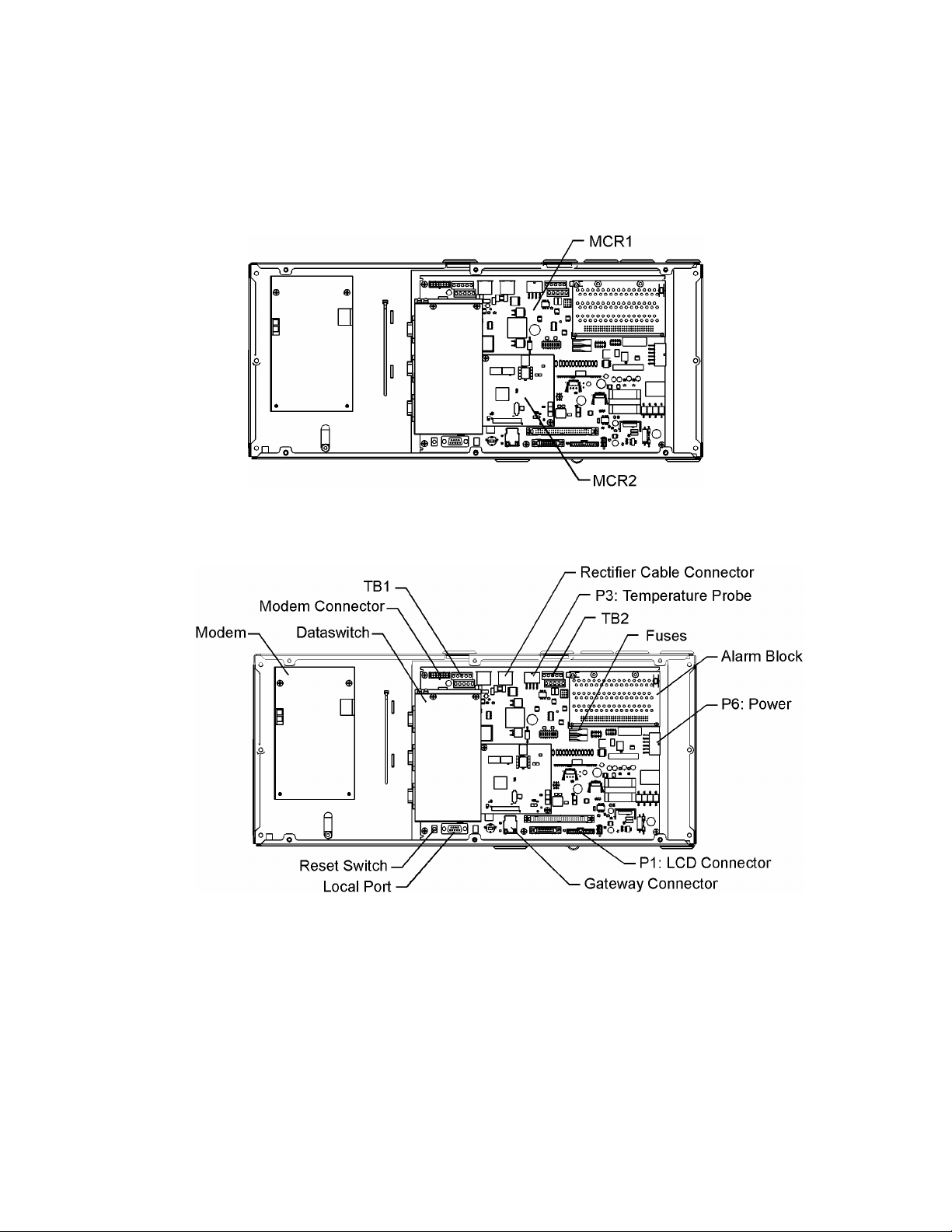

Controller Circuit Packs

MCR1 and MCR2

The core of the Galaxy Millennium II controller consists of a matched pair of surface

mount technology circuit packs, MCR1 and MCR2. These circuit cards are attached and

secured together at the factory. See Figure 2-3. The MCR1 is the larger of the two boards

and contains all the external input/output interfaces, local and remote user interface

circuitry, measurement circuits, real time clock, wide input range power converter, and

connections for the MCR2. The MCR2 contains the main 32-Bit 66MHz microprocessor

Issue 3 January 2008

13

Page 14

Basic Installation and User’s Guide for the Millennium II Controller

with 16Mbytes of Flash memory and 8Mbytes of RAM. It also contains the hardware for

the Ethernet control. Factory calibration values for the analog circuits located on the

MCR1 are stored in memory on the MCR2.

Figure 2-3: MCR1 and MCR2 Boards

Figure 2-4: Millennium II Primary Interfaces

Figure 2-4 illustrates all of the primary interfaces located on the MCR1 for the

Millennium II controller.

Issue 3 January 2008

14

Page 15

Basic Installation and User’s Guide for the Millennium II Controller

3 Safety

Safety Statements

Please read and follow all safety instructions and warnings before installing, maintaining,

or repairing the Millennium II controller:

• The CE Mark demonstrates compliance with the European Union Council

Directives for Low Voltage and EMC.

• The Millennium II platform is Underwriters Laboratories (UL) recognized per

Subject Letter 1801, DC Power Distribution Centers for Telecommunications

Equipment.

• Install only in restricted access areas (dedicated equipment rooms, equipment

closets, or the like) in accordance with articles 110-16, 110-17, and 110-18 of the

U.S. National Electric Code (NEC), ANSI/NFPA No. 70, and pursuant to

applicable local codes.

• This equipment is to be used in controlled environments (an area where the

humidity is maintained at levels that cannot cause condensation on the equipment,

the contaminating dust is controlled, and the steady-state ambient temperature is

within the range specified).

• This equipment has been evaluated for continuous use in ambient temperature from

-40°C to 75°C.

• This equipment must not be installed over combustible surfaces.

• For installations in the United States, Listed compression connectors are to be used

to terminate Listed field-wired conductors where required. For all installations,

the appropriate connector is to be applied only to the correct size conductor as

specified by the connector manufacturer, using only the connector manufacturer’s

recommended tooling or tooling approved for that connector.

• If the proper connector for the country of installation is not provided, obtain

appropriate connectors and follow manufacturer’s and all local requirements for

proper connections. All national and local rules and regulations should be followed

when making field connections.

• All input and output connections comply with SELV requirements.

• Insulation on field-wired conductors should be rated no less than 90° Celsius. Wire

conductor size should be sized per electrical codes for 90° Celsius wire, and based

on the ampacity of the associated protection device. Wiring internal to enclosed

equipment cabinets should be rated at 105° Celsius (minimum).

Issue 3 January 2008

15

Page 16

Basic Installation and User’s Guide for the Millennium II Controller

• Torque or secure electrical connections to the values specified on labels or in the

product documentation.

• Alarm contacts on the office alarm connector are not fused within the controller;

therefore, current limiting protection for these contacts must be provided by

external circuits. Maximum ratings for alarm connections are 60Vdc and 0.5

amperes. Exceeding these maximum ratings could result in fire or damage to the

unit.

• In enclosed equipment cabinets, the Millennium II mounting framework must be

connected directly to the cabinet ac service ground bus. For applications in huts,

vaults, and central offices, the Millennium II mounting framework must be

connected to the system integrated ground grid.

• Installing fuses not specified for use in controller may result in equipment damage.

Use only replacement parts listed in this manual and on the equipment drawings.

• The telecom-type (e.g., GMT type) fuses can produce sparks during interruption or

clearing of a fault on a high energy circuit. Use only fuses provided with safety

caps for this type of circuit. Installing telecom-type fuses not equipped with safety

caps may result in injury to service personnel.

Issue 3 January 2008

16

Page 17

Basic Installation and User’s Guide for the Millennium II Controller

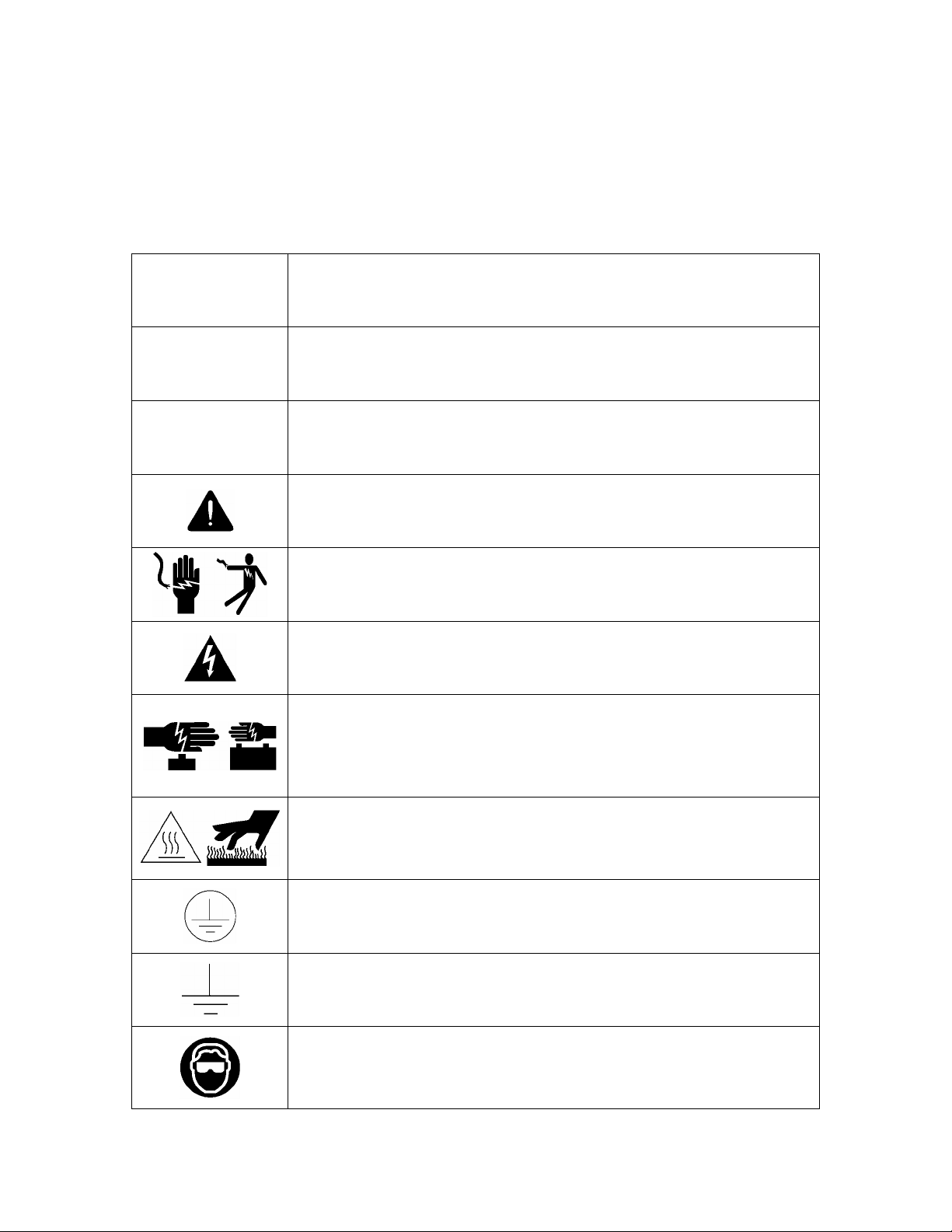

Warning Statements and Safety Symbols

The symbols may sometimes be accompanied by some type of statement; e.g.,

“Hazardous voltage/energy inside, or Risk of injury. This unit must be accessed only by

qualified personnel.” Signal words as described below may also be used to indicate the

level of hazard.

Indicates the presence of a hazard that will cause death or severe personal

DANGER

WARNING

CAUTION

injury if the hazard is not avoided.

Indicates the presence of a hazard that can cause death or severe personal

injury if the hazard is not avoided.

Indicates the presence of a hazard that will or can cause minor personal

injury or property damage if the hazard is not avoided.

This symbol identifies the need to refer to the equipment instructions for

important information.

These symbols (or equivalent) are used to identify the presence of

hazardous ac mains voltage.

This symbol is used to identify the presence of hazardous ac or dc

voltages. It may also be used to warn of hazardous energy levels.

One of these two symbols (or equivalent) may be used to identify the

presence of rectifier and battery voltages. The symbol may sometimes be

accompanied by some type of statement, for example: “Battery voltage

present. Risk of injury due to high current. Avoid contacting conductors

with uninsulated metal objects. Follow safety precautions.”

One of these two symbols may be used to identify the presence of a hot

surface. It may also be accompanied by a statement explaining the hazard.

A symbol like this with a lightning bolt through the hand also means that

the part is or could be at hazardous voltage levels.

This symbol is used to identify the protective safety earth ground for the

equipment.

This symbol is used to identify other bonding points within the equipment.

Issue 3 January 2008

This symbol is used to identify the need for safety glasses and may

sometimes be accompanied by some type of statement, for example:

“Fuses can cause arcing and sparks. Risk of eye injury. Always wear

safety glasses.”

17

Page 18

Basic Installation and User’s Guide for the Millennium II Controller

Precautions

When working on or using this type of equipment, the following precautions should be

noted:

• This unit must be installed, serviced, and operated only by skilled and qualified

personnel who have the necessary knowledge and practical experience with

electrical equipment and who understand the hazards that can arise when working

on this type of equipment.

• The equipment could be powered by multiple ac inputs. Ensure that the appropriate

circuit protection device for each ac input being serviced is disconnected before

servicing the equipment. Do not disconnect permanent bonding provisions unless

all ac inputs are disconnected.

• Batteries may be connected in parallel with the output of the rectifiers. Turning off

the rectifiers will not necessarily remove power from the bus. Make sure the battery

power is also disconnected and/or follow safety procedures while working on any

equipment that contains hazardous energy/voltage.

• Hazardous energy and voltages are present in the unit and on the interface cables

that can shock or cause serious injury. Follow all safety warnings and practices

when servicing this equipment. When equipped with ringer modules, hazardous

voltages will be present on the ringer output connectors.

In addition to proper job training and safety procedures, the following are some basic

precautions that should always be used:

• Use only properly insulated tools.

• Remove all metallic objects (key chains, glasses, rings, watches, or other jewelry).

• Wear safety glasses. Fuses can produce sparks. High energy levels on buses and

distribution components can produce severe arcing.

• Test circuits before touching.

• Lock out and tag circuit breakers/fuses when possible to prevent accidental turn on.

• Be aware of potential hazards before servicing equipment.

• Identify exposed hazardous electrical potentials on connectors, wiring, etc. (note the

condition of these circuits, especially wiring).

• Use care when removing or replacing covers; avoid contacting circuits.

Issue 3 January 2008

18

Page 19

Basic Installation and User’s Guide for the Millennium II Controller

Special Installation Notes

Deutsch

Installationsanleitung

Eingangsspannung ( Voltage ) : 2x AC 120/200-240V V

Eingangsstrom ( Current ) : QS801A, max 45A, QS800A, max 30A

Eingangsleistung ( Watts ) :

Nennfrequenz ( Frequency ) : 50 / 60 Hz

Seriennummer ( Assembly No. ):--

Modellnummer (Modell No. ) : QS801A, QS 800A

Abmessungen sind nur zur Referenz : 150mm x 22.5mm x 77.5mm

( Dimensions are for reference only )

Max. Umgebungstemperatur : max. 75 deg. C

( Max. Operation temperatur )

Achtung: Für kontinuierlichen Feuerschutz sollte die Sicherung nur mit einer des

gleichen Types ersetzt werden.

Sicherungswert :

( Warning : For continued protection against fire replace with same type and

rating of fuse )

Das System ist ein Gerät der Schutzklasse I / Überspannungs Kategorie II

( Power Supply is a Class I equipment / overvlotage category II )

Ausgangsspannungen und –stöme: DC 58 V / SELV

( Output Voltage and Current )

--Das Gerät darf nur in Räumen mit beschränktem Zutritt aufgestellt werden.

( Nur ausgebildetes Personal )

--Nur für Aufstellung auf Boden oder einer anderen brennbaren Oberfläche

geeignet.

--Das Gerät hat keinen eigenen Ausschalter, es muß daher mit einem Ein- und

Ausschalter im Versorgungskreis versehen sein.

--Das Gerät ist für den Einbau in IT- Geräte in einem Rahmen bestimmt (siehe

weitere Anleitung)

--Beim Einbau des Gerätes ist daraf zu achten das alle Anforderungen gemäß

EN60950 eingehalten werden.

ACHTUNG: HOHER ABLEITSTROM

VOR ANSCHLUSS AN DEN VERSORGUNGSSTROMKREIS

UNBEDINGT ERDUNGSVERBINDUNG HERSTELLEN

Issue 3 January 2008

19

Page 20

Basic Installation and User’s Guide for the Millennium II Controller

Espanol

Notas especiales para instalaciones en países de habla hispana

• Instrucciones de instalación

(Installation Instructions)

• Voltaje (Voltage):

Vea tabla 2-A

• Corriente (Current):

Vea tabla 2-A

• Frecuencia (Frequency):

50/60Hz

• Voltaje y corriente de salida (Output Voltage and Current):

Vea tabla 2-A

• Temperatura IREa de operación (Maximum Operation Temperature):

75°C (167°F)

• Sin cabina contra incendios, suelo no combustible

(No IRE enclosure, non-combustible floor)

• Evaluado en EN60950

(Evaluated to EN60950)

Issue 3 January 2008

20

Page 21

Basic Installation and User’s Guide for the Millennium II Controller

4 New Installations

The Millennium II is factory pre-installed and pre-configured with industry standard

defaults for thresholds and feature operability in GPS cabinet applications. In addition,

customer specific default controller settings may be available upon request. This section

provides:

Preparation and Precautions

Procedures for the proper addition of optional packs

Input and output wiring to the controller and the installation and

wiring of optional features

Controller default configuration information such as alarm severity

and description, system voltage, shunt information

Controller configuration information

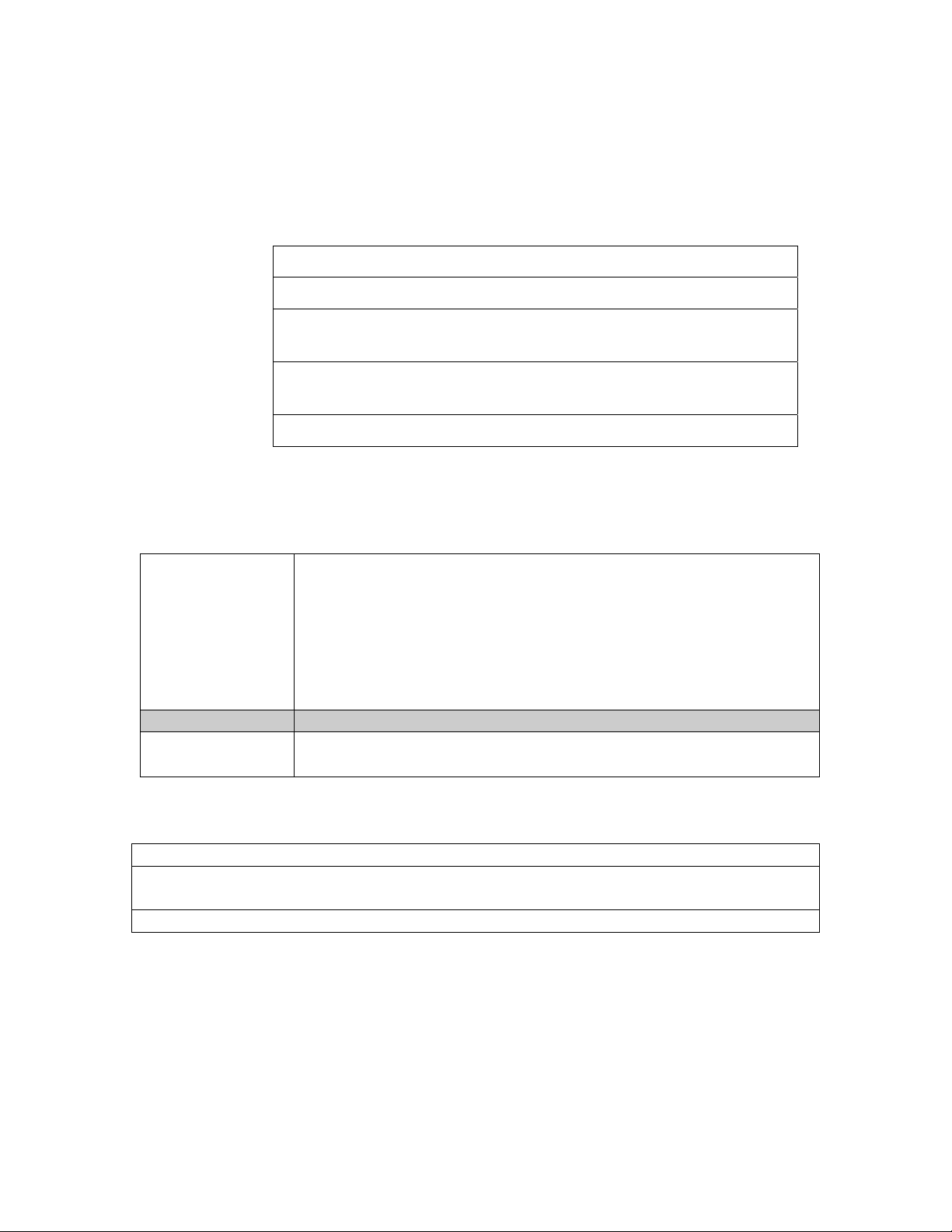

Preparation

The following

Installation

procedures should

be performed

AFTER:

But BEFORE:

Precautions

Observe ESD protection while installing circuit packs.

Wear grounded antistatic wrist straps when handling all circuit packs. The wrist strap

must contact the skin and is not to be worn over clothing.

Never hand a circuit pack from a grounded to a non-grounded person or vice-versa.

• All the equipment frames (initial and supplemental bays, free-

standing rectifiers, etc.) are anchored in place.

• The battery stands have been erected and the batteries installed.

• The overhead cable racks have been installed and the power

cables have been run and terminated.

• The plant’s charge and discharge bus bar assemblies have been

installed.

• Connecting the batteries to the plant charge and discharge bus

bars or turning up the plant rectifiers.

Issue 3 January 2008

21

Page 22

Basic Installation and User’s Guide for the Millennium II Controller

Safety

Action Verified

Always consider personal safety before beginning any procedure. Review

the Safety section.

Be aware of the presence of unfused battery potential in the vicinity of

the controller.

Use only insulated tools.

Make sure the system is properly grounded per the National Electrical

Code and local building codes.

Remove all metal jewelry before beginning the installation.

Installation Materials

Item Verified

Wire cutters and strippers

18 to 22 AWG wire

Jewelers screwdriver (Flat and Phillips)

Small needle nose pliers

Digital meter, +/- 0.02%

Screw Drivers (flat-blade and Phillips)

ESD wrist strap

Wire-wrap tool or Amp alarm punch-down tool

Issue 3 January 2008

Figure 4-1: Millennium II

22

Page 23

Basic Installation and User’s Guide for the Millennium II Controller

Controller Connections

Figure 4-2: Millennium II Controller Connections

Table 4-A: Millennium II Interface Reference

Interface

Reference Description

P1

P2

P3

P6

P7

P8

P9

P13

P14

P15

P201

P202

P205

TB1

TB2

J10

Connectorized interface for large parallel format 8x40 LCD assembly

10/100 Base-T LAN/Ethernet interface

Connectorized interface for 10K/30K thermistor probe options or 210E

Connectorized input for input power, monitoring of two shunts, plant sense voltage, and

Major Fuse alarm (Same connection as on the Millennium)

RJ45 receptacle for ground referenced Auxiliary RS485 circuit and One-Wire temperature

monitoring devices

BSL1-4 circuit pack Interface connector for Input/Output to controller

RJ45 receptacle for isolated RS485 system component monitoring and control of rectifiers,

converters, low voltage disconnect contactors, and bay level alarm inputs (Serial Rectifier

bus)

Factory test connector (not used in the field)

Connectorized interface for future smaller serial format LCD

Connectorized interface for future smaller serial format LCD

Connectorized interface for optional Modem

Ground referenced DB-9 for local RS232 serial port

Option board connector

Terminal block interface for RS232/RS485 Auxiliary port and Remote Peripheral Module

(RPM) connections

Terminal block interface for three additional 10K thermistor probe or 210E connection

options

USB interface (reserved for future use)

Issue 3 January 2008

23

Page 24

Basic Installation and User’s Guide for the Millennium II Controller

Installing Circuit Packs

Figure 4-3: Millennium II Controller Connections

Modem Card

The optional Modem card may require field installation. To do so, perform the following

steps:

Step Action

NOTE:

1. Remove the controller front cover.

2. Install the BSM on the 4 standoffs, to left of the controller MCR1 board using

3. Connect the 848091798 cable assembly between the BSM J100 plug and P201

4.

5. Operate the reset switch on the MCR1 board in the lower left corner of the

NOTE:

Installation or replacement of this pack can be done “hot”; power removal is not

necessary.

four 845143866 screws.

on the MCR1 board.

Note: This step may be performed at a later time

Install phone line wiring from Connect the existing telephone cable to the RJ11

connector at the top of the board

OR

Connect Tip/Ring conductors to TB1 at the top of the board.

NOTE: Tip is TB1 pin 1 (Pin closest to the RJ11 connector) and Ring is Pin 3.

Pin 2 is not used.

MCR1 board. (see Figure 4-3)

The Password Reset button is to the LEFT of the serial port connector, and the

Controller Reset is to the right of the serial connector.

Issue 3 January 2008

24

Page 25

Basic Installation and User’s Guide for the Millennium II Controller

Data Switch Card

Step Action

NOTE:

Installation or replacement of this pack can be done “hot”; power removal is

not necessary.

2. Install two 407882133 standoffs on the BSJ intelligent board. Screw threads

are protruding just below TB1, located at the upper left hand corner of the

MCR1 board.

3. Place BSW pack inside the 847950938 insulator.

4. Plug BSW pack into the P205 connector on the BSJ intelligent controller

board

5. Secure the BSW board to the standoffs with two 900562208 screws.

NOTE:

To install the Data Switch Extension board, please see the User’s Guide for

Millennium II Controller Advanced Features manual.

Alarm Termination Board

Alarm Termination board options provide for wire wrapped or insulation displacement

(punch down) terminations. The Alarm Termination Board for a specific application may

require field installation. To do so, perform the following steps:

Step Action

1. In the upper right hand corner of the MCR1 board, find the alarm board

already installed.

2. Remove the two screws holding the board at the top.

3. Holding the board on both sides, slowly, but firmly, remove the alarm board

from the P8 connector.

4. Unpack the new board from its box, carefully observing proper ESD

procedures.

5. Connect the alarm board to P8 and press down firmly, until the board is

seated.

6. Secure the alarm board at the top using the two screws removed earlier.

Issue 3 January 2008

25

Page 26

Basic Installation and User’s Guide for the Millennium II Controller

Gateway (LAN) Connections

Step Action

NOTE:

The Gateway card has been designed into the MCR1/MCR2 boards and

requires no additional circuit packs.

NOTE:

The Gateway has an IEEE 802.3 compliant 10Base-T network interface.

Since the cable length required to connect to the network is variable, this

cable must be supplied by the user.

1. At the controller, connect one end of the network interface cable to P2. This

connector is located at the bottom center of the MCR1 board, and

immediately below the MCR2 board.

2. Connect the other end to an IEEE 802.3 compatible network.

3. Configure the Gateway for the network by contacting the customer’s

network administrator. Detailed configuration information may be found in

the User’s Guide for Millennium II Controller Advanced Features manual.

Rectifier Cabling

Step Action

NOTE:

For new installations, the Millennium II rectifier cabling has been factory

wired and installed to the cabinet BIC/BLJ board for alarm and rectifier

communication.

NOTE:

For connector integrity, verify that the cable is installed and connected

properly.

1. Verify that the rectifier cable is connected to P9, and NOT P7(AUX) cable

connector.

2. Verify that the cable connector is properly seated into P9, and that it is not

loose.

3. Verify that the rectifier cable terminating on the BIC/BLJ board is connected

to P9 and also not loose.

Remote Peripheral Monitoring (RPM)

RPM provides data acquisition capability far beyond that normally available in a power

system controller. Monitoring modules available consist of:

• Shunt monitors (6 channels + 1 temperature channel)

• 0-100mV dc Voltage monitors (6 channels + 1 temperature channel)

• 0-3V dc Voltage monitors (6 channels + 1 temperature channel)

• 0-16V dc Voltage monitors (6 channels + 1 temperature channel)

• 0-200V dc Voltage monitors (6 channels + 1 temperature channel)

• Temperature monitor (7 Channels)

• Control Relay module (3 sets of programmable form C relay outputs)

Issue 3 January 2008

26

Page 27

Basic Installation and User’s Guide for the Millennium II Controller

The user may connect a maximum of 95 of any combination of these modules serially.

Step Action

NOTE:

The Remote Peripheral Monitoring feature has been designed into the MCR1

board and requires no additional circuit packs. Monitoring and control

modules ARE required, based on the application.

NOTE:

This section only describes a single module connection to the controller.

Modules MUST BE PROGRAMMED after they have been installed or they

may not function properly. Detailed connection and configuration

information may be found in the User’s Guide for Millennium II Controller

Advanced Features manual.

1. Using the RPM bus cable (comcode 407377704), wrap the cable through the

EMI inductor bead twice. Place the bead approximately 3 inches from the

end of the cable.

2. Connect the bus cable to:

TB-1 Pin

Assignments

TB-1 Pin

Descriptions

RPM

Conductor

RPM Conductor

Description

Color

6 *6 Blue or White Power/Communications

8 *8 Blue or White Power/Communications

9 or 10 FGND Bare wire Shield

*connections of the bus wire are NOT polarity sensitive.

3. Secure the module connection unit and route the wires through the openfaced bottom of the connection unit.

4. Make the connections to TB2 on the connection unit:

TB-2 Pin

Assignments

RPM

Conductor

RPM Conductor

Description

Color

IN Blue or White Power/Communications

OUT Blue or White Power/Communications

SHIELD Bare wire Shield

*connections of the bus wire are NOT polarity sensitive.

* there are 2 IN, and 2 OUT connections. Either one may be used.

5. Locate the control unit. This is the half with circuitry on it.

6. In the lower right hand side of the control unit (inside), are two rotary

switches. Set SW-1 (LO) to 1. The module will be recognized as 01 by the

controller. Other modules added cannot have the same address or 00 for the

address.

7. Carefully attach the control unit to the connection unit using the ribbon

connector.

Issue 3 January 2008

27

Page 28

Basic Installation and User’s Guide for the Millennium II Controller

NOTE:

8. After approximately 1 minute, the green LED on the front of the module will

This connector/cable is not keyed, so be careful to line up the pins properly.

blink once approximately every 5 seconds. Detailed troubleshooting

information may be found in the User’s Guide for Millennium II Controller

Advanced Features manual.

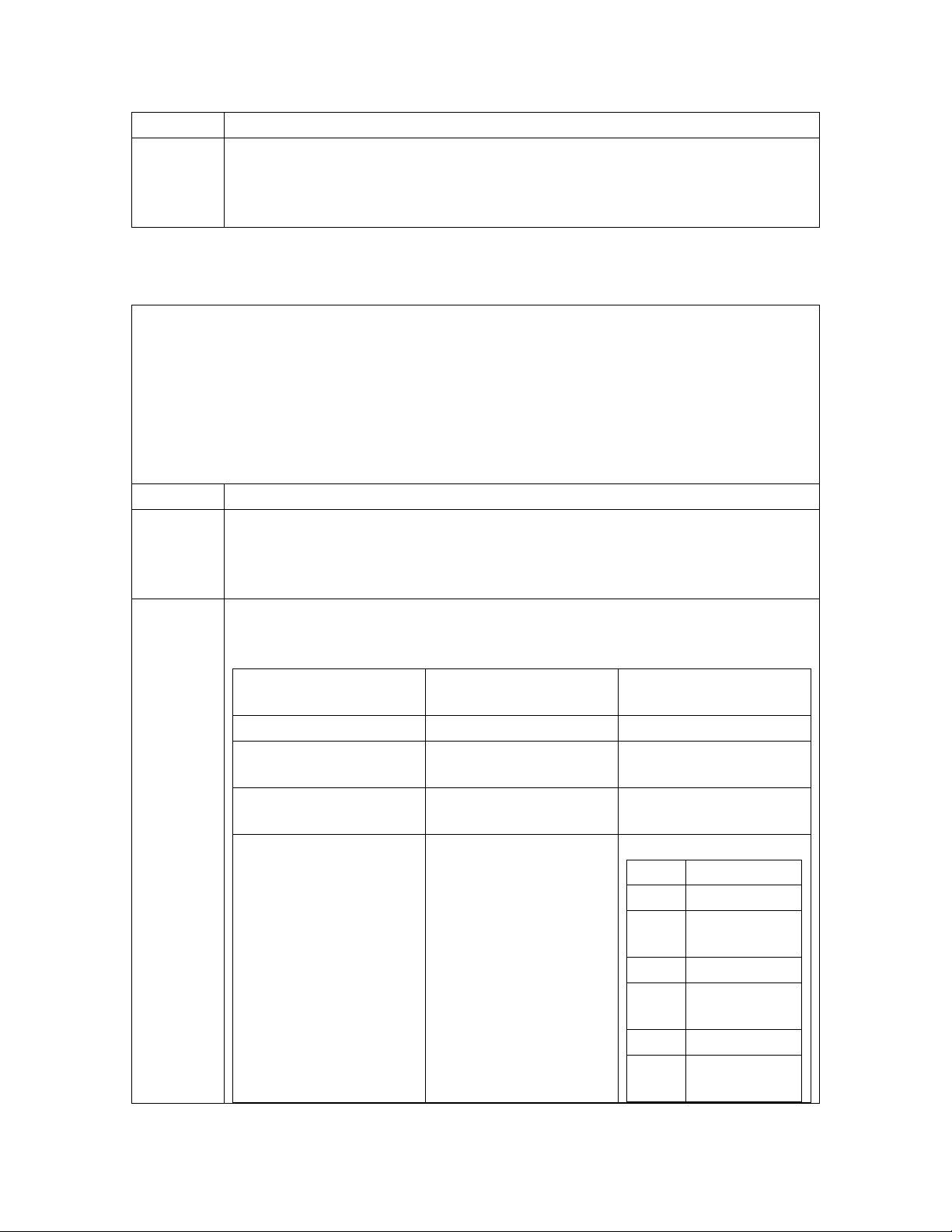

Thermal Probes

Without thermal probes, many of the controller’s battery management features will not

function, or produce erroneous results. Some features requiring thermal inputs are:

• Slope Thermal Compensation

• Reserve Time Prediction

• High Temperature Alarm

• Ambient High and Low Temperature Alarms

• High Temperature Disconnect

Step Action

NOTE:

1. The following table shows the type of probe and connector location on the

The controller supports a number of thermal probe inputs. The type of probe

used determines where it is connected on the controller. Detailed thermal

probe and battery management information may be found in the User’s

Guide for Millennium II Controller Advanced Features manual.

Millennium:

Type of Probe Comcode Controller Connection

Location

10/30K P3

210E Thermal Probe

Mux

1 Wire Temperature

Monitoring Devices

Terminal Block

Interface for 3

additional 10k probes

or 210E connection

P3

P7

TB2

Pin Description

1 Probe 2

2 Probe 2

RTN

3 Probe 3

4 Probe 3

RTN

5 Probe 4

6 Probe 4

RTN

Issue 3 January 2008

28

Page 29

Basic Installation and User’s Guide for the Millennium II Controller

USB Interface

This interface is reserved for future use.

Wiring Alarm Outputs

These external alarms may be wired to customer external office alarms at their

destination.

Form-C Alarm Contact Ratings 60Vdc, 0.3A

Conductor Size for terminating on Alarm

board

Refer to Table 4-B and 4-C for lead designations and their descriptions for leads

terminating on the BSL alarm interface board.

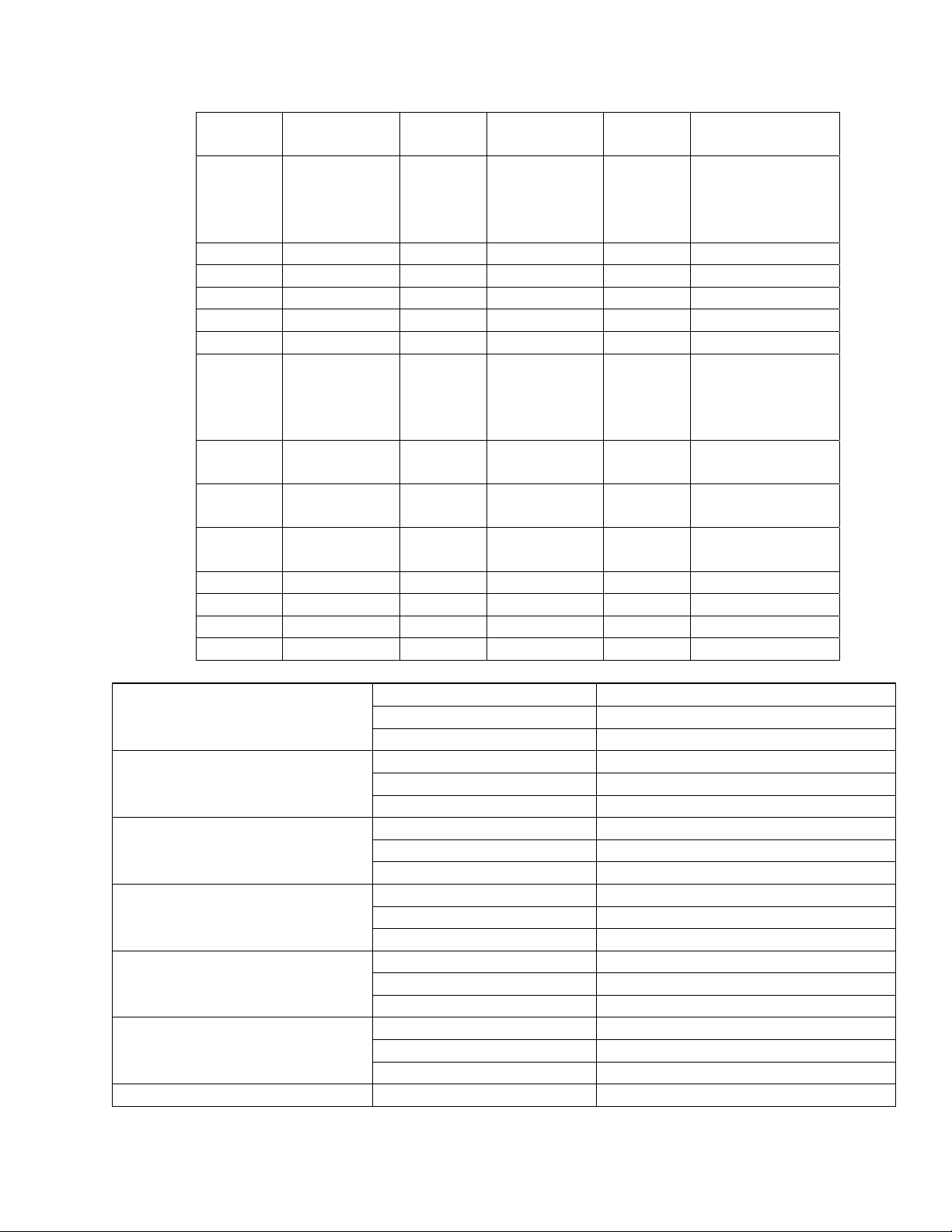

Table 4-B: Controller Alarm Descriptions and Pin Numbers

Pin

Number

1 PCRAO 33 MJFR 65 FAN

2 PCRAC 34 MNFR 66 AMN

3 PCRAR 35 MNFC 67 TFLT

4 PCRVR 36 MNFO 68 TBST

5 PCRVC 37 BDO 69 TRTN

6 PCRVO 38 BDC 70

7 PCREO 39 BDR 71

8 PCREC 40 ACFR 72 OS

9 PCRER 41 ACFC 73 TR1

10 PMJAR 42 ACFO 74 TEQ

11 PMJAC 43 RFAO 75 ETR

12 PMJAO 44 RFAC 76 ETRR

13 PMJEO 45 RFAR 77 RO

14 PMJEC 46 HVR 78 ROR

15 PMJER 47 HVC 79 TR2

16 PMJVR 48 HVO 80 TR4

17 PMJVC 49 UR1O 81

18 PMJVO 50 UR1C 82 TBD

Signal

Name

Pin

Number

18 – 22AWG (if less than 18AWG, use

multi-conductor cable for mechanical

integrity)

Signal

Name

Pin

Number

Signal Name

PBTR

PBT

RBRPO

now general

I/O-1

Issue 3 January 2008

29

Page 30

Basic Installation and User’s Guide for the Millennium II Controller

Pin

Number

19 PMNAO 51 UR1R 83 USR1PRESENT/

20 PMNAC 52 CTLRR 84 LVD1

21 PMNAR 53 CTLRC 85 TR3

22 PMNVR 54 CTLRO 86

23 PMNVC 55 UR2O 87

24 PMNVO 56 UR2C 88

25

26 - 58 UR3R

27 - 59 UR3C

28 PMNER 60 UR3O

29 PMNEC 61 LVD2 93 ABS

30 PMNEO 62 LVD2R 94 ABS

31 MJFO 63 FAJ 95 DG

32 MJFC 64 AMJ 96 DG

Critical-Audio

Critical-Visual

Critical-External

Power Major-Audio

Power Major –External

Power Major –Visual

Signal

Name

5V

Pin

Number

Signal

Name

Pin

Number

Signal Name

BTP

now general

I/O-2

-

4-20mA in

4-20mA Rtn

57 UR2R 89 USR3PRESETN/

BTPFLT

now general I/O-

3

90 USR3DETECT/

Now VLVR

91

BTMJ

0-5V in

Now VLVC

92

0-5V Rtn

Now VLVO

1 PCRAO

2 PCRAC

3 PCRAR

4 PCRVR

5 PCRVC

6 PCRVO

7 PCREO

8 PCREC

9 PCRER

10 PMJAR

11 PMJAC

12 PMJAO

13 PMJEO

14 PMJEC

15 PMJER

16 PMJVR

17 PMJVC

18 PMJVO

Issue 3 January 2008

30

Page 31

Basic Installation and User’s Guide for the Millennium II Controller

Power Minor-Audio

Power Minor –Visual

Power Minor –External

Major Fuse

Minor Fuse

Battery On Discharge

AC Fail

Rectifier Fail

High Voltage

User Relay 1

Controller Fail

User Relay 2

Very Low Voltage

19 PMNAO

20 PMNAC

21 PMNAR

22 PMNVR

23 PMNVC

24 PMNVO

28 PMNER

29 PMNEC

30 PMNEO

31 MJFO

32 MJFC

33 MJFR

34 MNFR

35 MNFC

36 MNFO

37 BDO

38 BDC

39 BDR

40 ACFR

41 ACFC

42 ACFO

43 RFAO

44 RFAC

45 RFAR

46 HVR

47 HVC

48 HVO

49 UR1O

50 UR1C

51 UR1R

52 CTLRR

53 CTLRC

54 CTLRO

55 UR2O

56 UR2C

57 UR2R

58 VLVR

59 VLVC

60 VLVO

Issue 3 January 2008

31

Page 32

Basic Installation and User’s Guide for the Millennium II Controller

Wiring Alarm and Control Inputs

In a standard Galaxy Power System configuration, plant level alarms are sent to the

controller via the Bay Interface Card through serial data communication. The following

alarm inputs are provided for discretionary use in non-standard applications.

Table 4-C: Controller Alarm and Control Inputs

Alarm Pin

Number

Low Voltage 2 Disconnect State Detect 61 LVD2

Fuse Alarm Major 63 FAJ

Fuse Alarm Minor 65 FAN

Auxiliary Alarm Major 64 AMJ

Auxiliary Alarm Minor 66 AMN

Timer Float Control 67 TFLT

Timer Boost Control 68 TBST

Plant Battery Test 71 PBT

Open String Detect 72 OS

Transfer Rectifier 1 73 TR1

General Purpose Input 4 74 IN-4 previously TEQ

General Purpose Input -5 (Previously

Engine Transfer)

Reserve Operation 77 RO

Transfer Rectifier 2 79 TR2

Transfer Rectifier 4 80 TR4

Reserve Battery-Emergency Power Off 81 RBRPO

General Purpose Input 1 82 IN-1

BTP or General Purpose Input 2 83 IN-2/BTP

Low Voltage 1 Disconnect State Detect 84 LVD1

Transfer Rectifier 3 85 TR3

General Purpose 4-20mA Measuring

Circuit

General Purpose 4-20mA Measuring

Circuit-RTN

BTPFLT or Generic Input 3 89 IN-3/ BTPFLT

Low Voltage 3 Disconnect State Detect

Also

Battery Thermal Protect Major

General Purpose 0-5Vdc Measuring

Circuit

General Purpose 0-5Vdc Measuring

Circuit-RTN

75 IN-5 Previously ETR

87 4-20mA

88 4-20mAR

90 LVD3/ BTMJ

91 0-5V

92 0-5VR

Signal Name

Issue 3 January 2008

32

Page 33

Basic Installation and User’s Guide for the Millennium II Controller

BSL-63 FAJ: Fuse Alarm Major

An optional battery potential input, must use an external 1K ohm 2W current limiting

resistor at the source. A Fuse Alarm Major is generated when battery potential is

received.

BSL-65 FAN: Fuse Alarm Minor

A battery potential input is required, which must use an external 1K ohm, 2W current

limiting resistor at the source. A Fuse Alarm Minor is generated when battery potential is

received.

BSL-72 OS: Open String Alarm

A battery potential input is required, which must use an external 1K ohm 2W current

limiting resistor at the source. This circuit is used to signal Galaxy that a battery string

protective device or switch is in the open position. An Open String Alarm is generated

when battery potential is received.

BSL-64 AMJ: Aux Major

A battery potential input is required, which must use an external 1K ohm, 2W current

limiting resistor at the source. This circuit is used to allow Galaxy to monitor another

power device and provide alarms for it. An Aux Major Alarm is generated when battery

potential is received.

BSL-66 AMN: Aux Minor

A battery potential input is required, which must use an external 1K ohm, 2W current

limiting resistor at the source. This circuit is used to allow Galaxy to monitor another

power device and provide alarms for it. An Aux Minor Alarm is generated when battery

potential is received.

LVD1: BSL-84 Low Voltage Disconnect Active

A battery potential input is required, which must use an external 1K ohm, 2W current

limiting resistor at the source if not using standard Lineage Power LVD circuit boards or

controller. This circuit is used to inform Galaxy that the monitoring circuit of a Low

Voltage Disconnect device has failed. In standard Galaxy Power Systems, the Bay

Interface board monitors these alarms and informs the Controller through the serial

interface connection.

LVD2/LVD2R: BSL-61/62 Low Voltage Disconnect Active

A closure between these points or a ground signal into LVD2/ BSL-61 is used to inform

Galaxy that the a Low Voltage Disconnect device has opened. In standard Galaxy Power

Systems, the Bay Interface board monitors these alarms and informs the Controller

through the serial interface connection.

External Boost Option

A variety of external devices may be used to initiate boost in Galaxy. Wiring is required

from positions 67/68/69 on the BSL board for operation of this feature. Providing a

contact closure between TBST and TRTN initiates the boost feature. A contact closure

between TFLT and TRTN returns the plant to float. Additional information on External

Boost can be found in the User’s Guide for Millennium II Controller Advanced Features

manual.

Issue 3 January 2008

33

Page 34

Basic Installation and User’s Guide for the Millennium II Controller

Rectifier Sequence Option

The controller is capable of sequencing rectifiers on line after detecting a AC is being

provided by emergency generator. Internal Rectifier Sequencing requires external wiring

to ETR/ETRR on BSL pin numbers 75/76, and optionally RO/ROR on BSL pin numbers

77/78, in order to function.

The controller can also accept ground signals onto TR1 to TR4 on BSL 73/79/ 85/80

from an external device to control the sequencing of plant rectifiers in groups as follows:

Table 4-D: TR leads and Associated Rectifiers

TR

Rectifiers Affected

Signal

TR1 G01, G02, G09, G10, G17, G18, G25, G26, G33, G34, G41, G42, G49, G50,

G57, G58

TR2 G03, G04, G11, G12, G19, G20, G27, G28, G35, G36, G43, G44, G51, G52,

G59, G60

TR3 G05, G06, G13, G14, G21, G22, G29, G30, G37, G38, G45, G46, G53, G54,

G61, G62

TR4 G07, G08, G15, G16, G23, G24, G31, G32, G39, G40, G47, G48, G55, G56,

G63, G64

Additional information on the Rectifier Sequence Options can be found in the User’s

Guide for Millennium II Controller Advanced Features manual.

Battery Temperature Option

Slope Thermal Compensation and Battery Reserve Time Prediction features of the

controller, require that battery temperature be monitored. If either of these features is to

be configured in Galaxy software, a battery temperature input must be connected to P3

temperature probe connector on the Controller board.

Three optional cables are used to connect to various battery arrangements:

Cable Assembly Connects to:

848152997 KS20472 round cell thermistor

848152989 ring or paddle type thermistors

848153003 210E Thermal Probe Multiplexer

Refer to User’s Guide for Millennium II Controller Advanced Features manual for

additional information on these features.

Alarm Battery Supply Signals

Table 4-E: ABS Pin Numbers

Signal

Pin No.

Name

ABS 93

ABS 94

DG 95

DG 96

Issue 3 January 2008

34

Page 35

Basic Installation and User’s Guide for the Millennium II Controller

Fused Battery Supply

BSL-93, 94 ABS: Alarm Battery Supply

This is an alternate plant voltage source for user alarm systems. This power is fused with

a 1-1/3 ampere ABS fuse.

BSL-95,96 DG: Discharge Ground

Plant ground/return source for user alarm systems.

Fuses

Two Fuses, located on the MCR1 board, provide protection for the controller input power

and Alarm Battery Supply, used to power alarm panels or other devices requiring the

power system voltage at no more than 1.3A.

Figure 4-4: Millennium Controller Fuses

FUSE Description Fuse Size

F1 Controller Input Power 3A

F2 Alarm Battery Supply

(ABS)

1.3A

Front Panel Display

LCD

The primary local interface for the Millennium II is an eight-line LCD assembly mounted

to the front of the primary GPS cabinet door. This user interface is a panel that includes a

backlit LCD module, two sections of status LEDs, system voltage test jacks, and an array

of simple push-button controls. This controller supports multiple LCD display

assemblies. It is backwards compatible to both existing Millennium LCD assemblies L51

and L50 shown in Figure 4-5. It is also compatible with the enhanced L52 LCD display

assembly (see figure 4-6) specifically developed for the Millennium II. This new display

Issue 3 January 2008

35

Page 36

Basic Installation and User’s Guide for the Millennium II Controller

assembly is compatible to existing GPS cabinet doors and is functionally backwards

compatible to the Millennium. It looks very similar to the L51 option. LCD assembly, but

the L52 also provides a built-in audible alarm and digital contrast adjust that are only

available when used with the Millennium II controller.

Figure 4-5: Controller Front Panel Displays

Figure 4-6: Detailed Controller Front Panel Display – L51/52

Issue 3 January 2008

36

Page 37

Basic Installation and User’s Guide for the Millennium II Controller

LEDs

Depending on the LCD option utilized, the LCD assemblies contain two rows of LEDs at

the right side of the interface board or two columns of LEDs at the left side of the

interface board as seen in figure 4-5. The segregated sections of LEDs provide an

indication of the alarm source (rectifier, battery, distribution, communication, controller,

remote modules) and the severity (Critical, Major, Minor, Nominal) of the various

alarms. Operation of the status LEDs can be reconfigured via the local or remote

controller interfaces.

Push Buttons

A group of push-button keys identified in table 4-F, provides the primary method of

locally interacting with the Galaxy Millennium II controller. These keys are used singly

or in combination to navigate through the menus and follow industry standard

functionality. Following is the general description of all the keys.

Table 4-F: Push-Button Key Functionality

Key Function

Up arrow Use to navigate the menu; press the key to move the

cursor up one line.

Down arrow Use to navigate the menu; press the key to move the

cursor down one line.

Left arrow Use to navigate the menu; press the key to move the

cursor left one field.

Right arrow Use to navigate the menu; press the key to move the

cursor right one field.

ADJUST Plus

Use to adjust (increase) the value of a field.

(+)

ADJUST Minus

Use to adjust (decrease) the value of a field.

(-)

MENU Press this key any time to bring the MAIN menu on

line.

HELP Press this key to display limited on-line help

information.

ENTER Use this key to save a value that has been changed, or

to select a menu item.

ESCAPE Use this key to abort a change, or to go back to the

immediate higher level menu.

Lamp Test

Use this key to test the display and LEDs

(L50 Only)

Issue 3 January 2008

37

Page 38

Basic Installation and User’s Guide for the Millennium II Controller

Test Jacks

The Millennium II LCD panel assemblies also provide test jacks to provide the ability of

using an external meter to monitor the Plant Voltage as seen in figure 4-7. Voltages to the

front panel test jacks are current limited and ESD protected. The controller measures this

voltage to regulate the system bus voltage as well as display it as the battery plant bus

voltage. The value of this voltage is used for many other controller related features.

Serial (PC) Port

A ground referenced RS-232 local port is provided at the front of the display to allow

easy connection to a personal computer or terminal using ANSI T1.317 object oriented

command language. Lineage Power’s EasyView is also available to provide a user friendly

system interface locally or remotely. See figure 4-6.

Alarm Buzzer

The audible alarm buzzer is located on the front panel display assembly. It can be

programmed from the front panel display to operate as follows:

Contrast Adjust

• For L50, L52 Displays:

Press the + or – keys and hold until the display changes it’s contrast

setting. Once the desired setting is reached, release the button.

• For L51 Displays:

Using a small flat head jeweler’s screwdriver, insert it into the small

opening at the top of the display assembly (above the UP arrow). Turn

clockwise or counter clockwise until the display contrast is set.

Issue 3 January 2008

• Disabled for ALL Alarms

• Audible on PCR

• Audible on PMJ

• Audible on PMN

38

Page 39

Basic Installation and User’s Guide for the Millennium II Controller

Controller Defaults

Dip Switch Settings

The Millennium has 8 dip switch positions (SW202) that may be changed. SW202 is

located on the MCR1 board, above the MCR2 board. (See figure 4-7)

Figure 4-7: Millennium II Controller Dip Switches

Table 4-G: Millennium II Controller Dip Switch Settings

Switch

Position

SW202-8 1 Front Panel Configuration ENABLED DISABLED

SW202-7 0 Modem/Aux/Local/Gateway/USB/

SW202-6 0 Enhanced Security Mode (See

SW202-5 1 Auxiliary Port Configuration RS-232 RS-485

SW202-4 1 Remote Rectifier in Standby ENABLED DISABLED

SW202-3 0 Boost Mode ENABLED DISABLED

SW202-2 1 Reserved for Future Use ENABLED DISABLED

SW202-1 1 Reserved for Future Use ENABLED DISABLED

Default Description Closed

(1)

ENABLED DISABLED

IRDA Port Setting Configuration

(Remote Access)

ENABLED DISABLED

table 4-H, for features affected

Open

(0)

Issue 3 January 2008

39

Page 40

Basic Installation and User’s Guide for the Millennium II Controller

Table 4-H: Enhanced Remote Security Features

The modem and auxiliary ports can be configured for full access and read-only using DIP

switch 202-7. Restricted access is also available. This prevents changes ia the modem and

auxiliary ports that will affect the state of the plant, even when logged in as a Super-User

or Administrator. This enhanced remote security is enabled and disabled with DIP switch

SW202-6. The functions and parameters restricted with the enhanced remote security

feature are listed in this table.

Enable or disable Rectifier Restart feature

Change All Rectifier On Threshold

Change Timed Manual Boost Duration

Change Boost Current Threshold

Change Rectifier Status to “Standby”/ “Vacant” status is prohibited. The change to

“On”status is allowed.

Change Rectifier Shunt Voltage configuration

Change Rectifier Float High Voltage Shutdown Threshold

Change Rectifier Boost High Voltage Shutdown Threshold

Change Rectifier Float Set Point

Change Rectifier Boost Set Point

Change Rectifier Boost Current Limit

Change Converter Voltage Set-Point

Change Converter Low Voltage Disconnect Threshold

Change Converter Low Voltage Reconnect Threshold

Enable or disable Converter Low Voltage Disconnect feature

Change Converter Status to “Standby”/ “Vacant” status is prohibited. The change to

“On”status is allowed.

Change Battery High Temperature Threshold

Enable or disable Battery Current Limit

Change Battery Limit Threshold

Change Battery Contactor Status to “Open” status is prohibited. The change to “Close”

status is allowed.

Change Battery Disconnect Threshold

Change Battery Reconnect Threshold

Change Very Low Voltage Alarm Threshold and Severity

Change Multiple Rectifier Fail Alarm Threshold and Severity

Change Limited Recharge Current Alarm Threshold and Severity

Change Excess Rectifier Drain Alarm Threshold and Severity

Change Engine Transfer Timeout Alarm Threshold and Severity

Change Reserve Time Low Alarm Threshold and Severity

Change Multiple Converter Fail Alarm Threshold and Severity

Change Battery On Discharge Alarm Threshold and Severity

Issue 3 January 2008

40

Page 41

Basic Installation and User’s Guide for the Millennium II Controller

Voltage Threshold Ranges and Default Values

Table 4-I: Voltage Threshold Ranges and Default Values

Low High Default

Very Low Voltage (VLV)

24V 20.00 25.50 23.00

48V 40.00 51.00 46.00

Battery on Discharge (BD)

24V Float 23.00 28.00 25.00

24V Boost 23.00 28.00 25.00

48V Float 46.00 55.00 51.00

48V Boost 46.00 55.00 51.00

High Float Voltage (HFV)

24V Float 24.75 29.75 26.50

24V Boost 25.75 31.75 26.50

48V Float 50.00 60.00 53.00

48V Boost 52.00 60.00 53.00

High Voltage Shutdown Alarm (HV)

24V Float 24.75 29.75 26.8

24V Boost 25.75 31.75 26.8

48V Float 50.00 60.00 53.6

48V Boost 52.00 60.00 53.6

Rectifier On Threshold (ROT)

24V 20.00 25.00 22.00

48V 40.00 51.00 44.00

Controller Alarm Severity, LED and Relay Default Values

Table 4-J:Controller Alarm Severity, LED and Relay Default Values

Symbol Default Designation Default

Severity

Default LED Default

Relay

AAC ACO Active RO None None

ABS Alarm Battery Supply Fuse Major CTLR CTLR

AMJ Auxiliary Major Major None None

AMN Auxiliary Minor Minor None None

ATA Alarm Test Active RO None None

Issue 3 January 2008

41

Page 42

Basic Installation and User’s Guide for the Millennium II Controller

Symbol Default Designation Default

Severity

Default LED Default

Relay

ATB Alarm Test Aborted RO None None

ATF Alarm Test Failed Warning None None

BBL Memory Backup Battery Low Warning None None

BCA Battery Type Conflict Warning None None

BDA Battery on Discharge Major BD BD

BFA Battery Test Failed Minor BAT None

BID Bay Interface ID Conflict Major CTLR CTLR

BTA Battery Test Active RO BD BD

BTJ Battery Thermal Major Major BAT None

BTN Battery Thermal Minor Minor BAT None

CCH Configuration Changed RO None None

CDFA Converter Distribution Fuse Major RECT MJF

CDID Converter ID Conflict Major RECT None

CFA Converter Fail Minor RECT None

CLC Clock Changed RO None None

CMA Minor Communications Failure Minor CTLR None

CMFA Multiple Converter Fail Major RECT None

CNF1 Contactor 1 Failed Major BAT None

CNF2 Contactor 2 Failed Major BAT None

CNF3 Contactor 3 Failed Major BAT None

CNO1 Contactor 1 Open Major BAT None

CNO2 Contactor 2 Open Major BAT None

CNO3 Contactor 3 Open Major BAT None

COF Queue Overflow Warning None None

COR Number Did Not Respond Warning None None

CPA Circuit Pack Fail Major CTLR CTLR

CRA Controller Fail Major CTLR CTLR

DID Rectifier ID Conflict Major RECT None

EMD Energy Management Disabled Warning None None

EPD Excess Plant Drain Minor RECT None

EPO Emergency Power Off Critical BATT None

EPR External Password Reset Warning None None

ETO Engine Transfer Timeout Minor AC None

EXL Excessive Login Attempts Warning None None

FAJ External Fuse Major Major DIST MJF

FAN External Fuse Minor Minor DIST MNF

HCL History Cleared RO None None

Issue 3 January 2008

42

Page 43

Basic Installation and User’s Guide for the Millennium II Controller

Symbol Default Designation Default

Severity

Default LED Default

Relay

HFV High Float Voltage Minor RECT None

HVA High Voltage Major RECT HV

LMR Limited Recharge Minor RECT None

LVD Low Voltage Disconnect Minor BAT None

LVDA Low Voltage Disconnect Fail Minor BAT None

MCM Major Communication Fail Minor CTLR None

MDF Module Failure Minor RM None

MOR Measurement Out Of Range Minor RM None

MTC Module Type Conflict Warning None None

NNC Number Not Configured Warning None None

OSA Open String Minor BAT None

PFD Password At Default Warning None None

PGI Program Line Invalid Major None None

PHT Processor Halt RO None None

POR Number Did Not Respond Warning None None

RLS1 Redundancy Loss Ninor RECT None

RPI Rectifier/Plant Inconsistency Warning None None

RTL Reserve Time Low Minor BAT None

SNC Shunt Not Configured Warning None None

STF Self Test Failed Minor CTLR CTLR

TPA Thermal Probe Failure Minor CTLR CTLR

URC User Relay Conflict Warning None None

VLA Very Low Voltage Critical BAT UR3

VSF Sense/Control Fuse Major CTLR CTLR

ZID ID Not Configured Major RECT None

Issue 3 January 2008

43

Page 44

Basic Installation and User’s Guide for the Millennium II Controller

Table 4-K: Rectifier Alarm Defaults

Symbol Default Designation Default

Severity

Default LED Default

Relay

ACF AC Fail Minor AC ACF

CLM Rectifier Current Limit RO None None

ERD Excess Rectifier Drain Minor RECT None

ETS External Transfer Shutdown Minor RECT None

HPA Half Power Minor RECT None

LCA Low Current Alarm Minor RECT None

LSF Load Share Fuse Minor RECT None

MACF Multiple AC Fail Major AC ACF

MAN Manual Off Minor RECT None

MFA Multiple Rectifier Fail Major RECT RFA

MMAN Multiple MAN Alarm Major RECT None

PHA Phase Or Low Output Minor AC None

RIC Rectifier Incomplete Config Warning None None

RFA Rectifier Fail Minor RECT RFA

Default Display

The default display shown in figure 4-8 provides basic system status. The controller

returns to this display after approximately three minutes after the last time a key is

pressed.

Figure 4-8: Millennium II Controller Default Display

The first line shows:

# of Alarms # of Warnings Date Time

The larger text in the middle of the screen shows:

Plant Voltage Plant Load (Current)

Issue 3 January 2008

44

Page 45

Basic Installation and User’s Guide for the Millennium II Controller

The bottom line(s) show:

An Hourglass may appear in the lower left hand corner of the screen.

This indicates that a configuration change is being saved to non-volatile

memory.

Audible Alarm Cutoff State(Toggle)

(Only shown if an alarm is active)

Plant Mode (Default Float)

Screen information is updated approximately every two seconds. The front panel display

offers a series of menus that allow the user to:

• Configure

• Control

• View Status

• View History

• View Statistics

• Perform Diagnostics

These menu operations are accomplished by navigating through different screens.

Issue 3 January 2008

45

Page 46

Basic Installation and User’s Guide for the Millennium II Controller

Controller Display Menu Maps

Configuration Menu Map

Issue 3 January 2008

46

Page 47

Basic Installation and User’s Guide for the Millennium II Controller

Control and Operations Menu Map

Issue 3 January 2008

47

Page 48

Basic Installation and User’s Guide for the Millennium II Controller

Status Menu Map

Issue 3 January 2008

48

Page 49

Basic Installation and User’s Guide for the Millennium II Controller

History Menu Map

Issue 3 January 2008

49

Page 50

Basic Installation and User’s Guide for the Millennium II Controller

Statistics Menu Map

Issue 3 January 2008

50

Page 51

Basic Installation and User’s Guide for the Millennium II Controller

Minimum Configuration

Front Panel

The Millennium II controller’s primary user interface is the front panel, which includes a

backlit LCD, and an array of pushbutton controls. SW202-8 must be set to ENABLED

for changes to be made from the front panel. This section covers only the basic

operations that must be performed so that the controller is minimally configured. For

more advanced operations, please see the User’s Guide for Millennium II Controller –

Advanced Features.

Step Configuration

Attribute to

Menu Path/Action Customer

Value

Change

1.

DATE/TIME

Format

This field allows you to select one of the

following date formats: MM/DD/YY,

DD/MM/YY, YY/MM/DD, MM/DD/YYYY,

DD/MM/YYYY, YYYY/MM/DD. Use the

<+> or <-> key to select the desired format

and press <ENTER> to save the change.

Month Use this field to change the month; the

possible value is from 1 to 12.

Day Use this field to change the day of the month;

the possible value is from 1 to 31.

Year Use this field to change the year; the possible

value is from 1992 and up.

NOTE:

Please note that the system will validate the

entries before the system date is modified.

2.

TIME

Issue 3 January 2008

51

Page 52

Basic Installation and User’s Guide for the Millennium II Controller

Format

This field allows you to select one of the

following time display formats: 12 or 24 hour.

Use the <+> or <-> key to select the desired

format and press <ENTER> to save the

change.

Time