Page 1

User Manual for the

HE300GEN250,

HE300GEN251

Genius

Serial Bus

Interface Option Card for

GE AV-300i

Adjustable Speed Drive

First Edit ion

23 September 1999

MAN0308-01

Page 2

PREFACE 23 SEP 1999 PAGE 3

PREFACE

This manual explains how to use the Horner AP G’s Genius Serial Bus Interfac e Opti on Car d for GE

Drives AV-300i Adjustabl e S peed Dr ives.

Copyright (C) 1999 Horner A PG, LLC., 640 North Sherman Drive I ndianapolis, Indiana 46201. All right s

reserved. No part of this publi cation may be reproduced, transmitted, transcri bed, stored in a retrieval

system, or translated into any language or computer language, in any form by any means, el ectronic,

mechanical, magnetic, optical, chemical, manual or otherwise, without the prior agreement and written

permission of Horner A PG, LLC.

All software described i n this document or media is also copyrighted materi al subject to the terms and

conditions of the Hor ner S oft ware Li c ense Agreement.

Information in this document is subject to change without notic e and does not represent a com mitm ent on

the part of Horner APG, LLC.

Series 90-30 and VersaPro are t r ademarks of GE Fanuc Automation.

AV-300i Drive is a trademark of GE Motors & Industrial Systems.

IGE Control System Toolbox is a trademark of GE Motors & Industrial Sy stem s.

For user manual updates, contact Horner APG, Technical Support

Division, at (317) 916- 42 74 or visi t our web sit e at www. h ea pg.c om .

Page 3

PAGE 4 23 SEP 1999 PREFACE

LIMITED WARRANTY AND LIMITATION OF LIABILITY

Horner APG, LLC. ("HE-APG") warrants to the original purchaser that the Genius Serial Bus Interface

Option Card for GE Drives AV-300i Adjustable Speed Drives manufactured by HE-APG is free f rom

defects in material and workmanship under normal use and servic e. The obligation of HE-APG under this

warranty shall be limited to the repair or exchange of any part or parts which may prove def ective under

normal use and servi ce within two (2) years from the date of manufacture or eighteen (18) mont hs from

the date of install ation by the origi nal purc haser whichev er occur s first, such def ect t o be di scl osed to t he

satisfaction of HE-APG after examination by HE-APG of the allegedly defective part or parts. THIS

WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED

INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS FOR USE AND OF ALL

OTHER OBLIGATIONS OR LIABILITIES AND HE-APG NEITHER ASSUMES, NOR AUTHORIZES ANY

OTHER PERSON TO ASSUME FOR HE, ANY OTHER LIABILITY IN CONNECTION WITH THE SALE

OF THIS Genius Serial Bus Interface Option Card for GE Drives AV-300i Adjustable Speed. THIS

WARRANTY SHA LL NOT APPLY TO T HIS Genius Serial B us Interface Option Card for G E Drives AV300i Adjustable Speed Drives OR ANY PART THEREOF WHICH HAS BEEN SUBJECT TO

ACCIDENT, NEGLIGENCE, ALTERATION, ABUSE, OR MISUSE. HE-APG MAKES NO W ARRANTY

WHATSOEVER IN RESPECT TO ACCESSORIES OR PARTS NOT SUPPLIED BY HE. THE TERM

"ORIGINAL PURCHASER", AS USED IN THIS WARRANTY, SHALL BE DEEMED TO MEAN THAT

PERSON FOR WHOM THE Genius Serial Bus Interface Option Card for GE Drives AV-300i

Adjustable Speed Drives IS ORIGINALLY INSTALLED. THIS WARRANTY SHALL APPLY ONLY

WITHIN THE BOUNDARIES OF THE CONTINENTAL UNITED STATES.

In no event, whether as a result of br eac h of contract, warranty, tort (including negligence) or ot her wise,

shall HE-APG or its suppliers be liable of any special, consequenti al, incidental or penal damages

including, but not limi ted to, loss of profit or revenues, loss of use of the produc ts or any associated

equipment, dam age to associat ed equipment, cost of capit al, cost of substitute product s, facilities,

services or replacem ent power, down time costs, or claims of original purchaser's customers for such

damages.

To obtain warranty service, return the product to your distributor with a description of the

problem, proof of purchase, post paid, insured and in a suitable package.

ABOUT PROGRAMMING EXAMPLES

Any example programs and program segments in this manual or provided on accompanying diskettes are

included solely for illustrative purposes. Due to the m any variables and requirements associated wit h any

particular installation, Horner APG cannot assume r espon si bility or liability for actual use based on the

examples and diagrams. It is the sol e r esponsibility of the system designer utilizing Genius Serial Bus

Interface Option Card for GE Drives AV-300i Adjustable Speed to appropri ately design the end system,

to appropriat ely integrate the Genius Serial Bus Interf ac e Opti on Car d for GE Drives AV-300i

Adjustable Speed Drives and to make safety provisions for the end equipment as is usual and customary

in industrial applications as defined in any codes or standard s whi c h apply.

Note: The programming examples shown in this manual are for illustrative

purposes only. Proper machine operation is the sole responsibility of the

system integrator.

Page 4

PREFACE 23 SEP 1999 PAGE 5

TABLE OF CONTENTS

PREFACE............................................................................................................................................... 3

LIMITED WARRANTY AND LIMITATION OF LIABILITY......................................................................... 4

ABOUT PROGRAMMING EXAMPLES ................................................................................................... 4

CHAPTER 1: INTRODUCTION..............................................................................................................7

1.1 Product Description ................................................................................................................... 7

1.2 Functional Overview.................................................................................................................. 7

1.3 Before Getting Started - Order of Configuration and Set up ........................................................ 8

1.4 Required References and Resourc es........................................................................................ 9

CHAPTER 2: DRIVE OVERVIEW .........................................................................................................11

2.1 General....................................................................................................................................11

2.2 Two Versions of SBI Cards Available / Using an Additional Option (DGF Car d) ........................11

2.3 High and Low Priority Communication Channels ......................................................................11

2.4 DGF P a rameters......................................................................................................................12

CHAPTER 3: GEN250/251 COMMUNI CATIO NS (SBI CA RD) ..............................................................13

3.1 GEN250/251 Operation............................................................................................................13

3.2 Automatic Data Transfer ..........................................................................................................13

3.3 GEN250/251 to/fr om GBC Communication using Global Data..................................................13

3.4 SBI (GEN250/251) Configuration Procedures using GE Toolbox Software................................14

3.4.1 Initial Steps Before Starting Configuration .........................................................................14

3.4.2 SBI (GEN250/251) Configuration Procedures....................................................................15

CHAPTER 4: GENIUS COMMUNICATIONS.........................................................................................29

4.1 Introduction to G enius .............................................................................................................29

4.2 Network Architecture................................................................................................................29

4.3 Genius Communications Services............................................................................................30

4.4 I/O Service...............................................................................................................................30

4.5 Global Data..............................................................................................................................30

CHAPTER 5: PLC CONFIGURATION...................................................................................................31

5.1 General....................................................................................................................................31

5.2 Series 90-70 Confi gur ation.......................................................................................................31

5.3 Series 90-30 Confi gur ation.......................................................................................................33

a. Device Typ e.............................................................................................................................34

b. Input References (Input 1 Ref, Input 2 Ref) ..............................................................................34

c. Input Length (Input 1 Len, I nput 2 Len).......................................................................................34

d. Output References (Output 1 Ref, Output 2 Ref) ......................................................................35

e. Output Length (Output 1 Len, Output 2 Len).............................................................................35

CHAPTER 6: AV-300i DRIVE PARAM ETE RS........................................................................................37

6.1 Drive Parameter Descriptions...................................................................................................37

CHAPTER 7: WIRING DIAGRAMS.......................................................................................................39

7.1 Gen iu s Wiring:.........................................................................................................................39

7.2 RS232/RS485 Pinout:..............................................................................................................40

Page 5

PAGE 6 23 SEP 1999 PREFACE

CHAPTER 8: INSTALLATION OF GEN250/251 OPTION CARD...........................................................41

8.1 General....................................................................................................................................41

8.2 GEN 250 Installation................................................................................................................41

8.2.1 Installation Hardware.........................................................................................................41

8.2.2 Installation Procedures......................................................................................................41

8.2.3 Cover Removal.................................................................................................................41

8.2.4 Housing Remov al..............................................................................................................42

8.2.5 Regulation Car d Rem ov al .................................................................................................43

8.2.6 Mounting the GEN250 Car d ..............................................................................................43

8.2.7 Re-assembly.....................................................................................................................45

8.3 GEN 251 Installation................................................................................................................48

8.3.1 Installation Hardware.........................................................................................................48

8.3.2 Installation Procedures......................................................................................................48

CHAPTER 9: GEN250/251CARD LED INDI CATORS............................................................................51

Page 6

CH. 1: INTRODUCTION 23 SEP 1999 PAGE 7

CHAPTER 1: INTRODUCTION

1.1 Product Descrip tion

The Genius Serial Bus Interface Option Card for GE AV-300i Adjustabl e Speed Drive

(HE300GEN250/251) is a Genius Serial Bus Interf ac e (SBI) that resides

(GEN250) or is located

externally

to the drive (GEN251). The GEN250/251 allow communication over a

Genius Network by providing a communication port between an AV-300i drive and a master device (such

as a Genius Bus Controll er ), whic h is l oc ated in a PLC.

1.2 Functional Overview

Figure 1.1 depicts a func tional overview of the major devices used wit h the GEN250/251 in a Genius

Network.

1. To allow communications between t he Genius Bus Controller (GBC) in the PLC and the AV-300i drive,

specific parameters must be the same for the GEN250/251 as the GBC. Parameter information is

configured and loaded into the GEN250/251 via a PC. This is accomplished using the GE Control

System Toolbox Softw are Con figu rat io n Tool .

internally

within the drive

6. SBI

(GEN251) -

Provides a

comm port

between the

drive and

Genius

Network.

external

Is

the drive. Must

be used when

the DGF Card

is installed.

to

1

. A PC is use d to

download

the conf iguration into

each AV-300i drive on

the Genius Network.

The c onfigur ation is

downloaded into the

drives via the

connector on the

GEN250/251.

SBI

1

GEN25

AV-300i Drive

DGF Card

-

2. A Series 90-30 PLC

Series 90-70 PLC

or

is used.

SBI

0

GEN25

AV-300i Drive

5. SBI

(GEN250) -

Provides a

comm port

between the

drive and

Genius

Network.

internal

Is

the drive.

3. Genius Bus

Controller

as the

Genius Network.

4. Genius Network

Has up to 32 devices.

to

functions

Master

for the

7. DGF Card

Option

provides extra

functionality.

-

Figure 1.1 – Overview of GEN250/ 251 in a Genius Network

Page 7

PAGE 8 23 SEP 1999 CH.1: INTRODUCTION

2. – 4. A PLC is the main controlling elem ent of the G enius Network and contains the Genius Bus

Controller (GBC) module, which functions as the master for the Genius Network. Communications over

the Genius Network are coordi nated via the master device. The GBC serves as an int erface between the

PLC and the Genius Network. The Genius Network contains up to 32 devices.

5. – 6. The GEN250/251 allow communications over a Genius Network by providing a communication

port between an AV-300i drive and a master device such as a Genius Bus Controller (GBC), which is

located in a PLC.

The GEN250/251 serve as Serial Bus Interfaces (SBI) and are GENA based. Thus, the GEN250/251 are

slave only Genius comm unic ations devices and can not control other dev ices on the Genius bus. They

also can not look at other devic e data. Communication is accomplished using t he standar d Genius

format by sending Broad cast (Glo bal) Data to the GBC and listening to Directed Contro l Data

GBC. The GEN250/251all ow up to 32 words of B r oadc ast Data and up to 16 words of Directed Data to

be configured per drive.

The GEN250 and the GEN251 have identical functions but differ physically. The GEN250 is placed

internally

reason for the external m ounting capability is that some applications require the instal lation of an

additional option card (DGF Option Card) in the AV-300i drive where a GEN250 is typic ally insert ed.

Thus, the GEN251 can be used as an interface in such cases, because it is external to the AV-300i. (The

DGF Option Card is discussed in Ch apter Two.)

within the AV-300i drive. The GEN251 is

externally

mounted outside of the AV-300i drive. The

from

the

1.3 Before Getting Started - Order of Configuration and Setup

This manual covers several procedures involving various devices that must be configur ed and setup.

Although not requi r ed, the following order is suggested to setup and configure the GEN250/251 and other

related Genius devices in an orderly and efficient manner.

1. Analyze the specifi c ations and requirements of the applic ation.

Note: Refer to Section 1.2 for a functional overview of a Genius Network containing the

GEN250/251 modul es i n this user manual (Horne r Ge nius Serial Bus Interface Option Card

for GE AV-300i Adjustable Speed Drive user manual [MAN0308]). It is also recommended

to read Chapter 4 which cover s el em ents applicable to Genius Communicati ons.

2. Become familiar with the parameters listed in the GE Indust rial Con t rol Systems AV-300i

before

Adjusta ble S pe e d Dr ives Instruction Manual

a. Determine whic h par am eters must be used to meet the requirements and specif ic ations of the

applicati on.

Required parameters must be determined before starting conf igur ation procedures for the

starting any configuration procedures.

SBI (GEN250/251).

Note: There is a chapter in GE’s manual that provides Parameter Lists and includes tables that

list the paramet er s i n

informati on about t he par am eters, which is needed for configurat ion.

alphabetical order

and

numeric order

. Each table provides different

Page 8

CH. 1: INTRODUCTION 23 SEP 1999 PAGE 9

b. Determine which of t he r equir ed par am eters need to be high priority or low priority when

communicati ng with AV-300i Drive. High priority parameters can be accessed much more quickly than

low priority par am eters. There is a limit of six high priority paramet er s. (See Ch apter 2 for information

covering high and l ow pri ori ty parameters in this user manual (Horner Genius Serial Bus Interface

Option Card for GE AV-300i Adjustable Speed Drive [MAN0308]. Also recommended is Chapter 6,

which provides addit ional information about drive parameters.)

3. Install the SBI Car d (GE N250/251) into the AV-300i Drive. (See Chapter 8 for procedures.)

4. Wire the Genius Network and t he S BI Car d (GE N250/251). (See Chapter 7 for wiring

diagrams.)

5. Configure t he SBI (GEN250/ 251) usi ng GE Control System Toolbox Soft ware. Upon c om pleting

the configuration, information is provi ded that is usef ul to know for configuring the Geni us Bus Controller

(GBC) and for writing the Ladder pr ogr am . (See Chapter 3 for GEN250/251 configurat ion

procedures.)

Note: It is highly recommended that the user refer to t he GE Control Toolbox Help File at this time

to obtain highly useful information regardi ng the G enius Network Conf iguration. Select Help, click on

Contents, click Index tab, and type Genius Configuration.

6. Configure t he Genius Bus Controller (GBC) using Logicm aster 90. Using summary screen

information from the GEN250/251 configuration, determine the Global Data length and the Directed

Control Data lengt h as well as baud rat e and network id information. (See Chapter 5.)

7. Write the Ladder program and r efer to the summary information in the GE N250/251 configuration.

1.4 Required References and Resou rces

This manual is to be used in conj unction with the in GE Industrial Control Systems AV-300i Adjustable

Speed Drives Inst ructio n Manu al, the GE Control System Toolbox software con f ig uration help file,

and the GE Fanuc Genius I/O System and Communications User Manual.

NOTE: It is highly recommended t hat t he user refer to the GE Control Toolbox Help File at this tim e to

obtain highly useful information regardi ng the Geni us Network Conf iguration. Select Help, click on

Contents, click Index tab, and type Genius Configuration.

Page 9

PAGE 10 23 SEP 1999 CH.1: INTRODUCTION

NOTES

Page 10

CH. 2: DRIVE OVERVIEW 23 SEP 1999 PAGE 11

CHAPTER 2: DRIVE OVERVIEW

2.1 General

It is important to have a basic understanding of how the AV-300i Drive interacts with the Genius Serial

Bus Interface (SBI ) such as the GEN250/ 251.

2.2 Two Versions of SBI Cards Availab le / Using an Additional Option (DGF Card)

There are two versions of the SBI c ar d - the

GEN251.

Note that there instances when the user needs to use both an SBI card as well as a separate opti on

called a DGF card. Only one option c ar d (either the GEN250 internal SBI card or the DGF card) can be

installed within the drive. If the applic ation requires

must be mounted

the drive. If the applicati on does not r equire a DGF card, either the GEN250 SBI card or the GEN251

SBI card can be used.

The SBI provides a communi c ations path between itself and the drive. The SBI can ac c ess any

predefined parameter within t he AV-300i drive. Reference the AV-300i instruction manual f or a

description of each of the available drive paramet er s.

2.3 High and Low Priority Communication Channels

The SBI provides two communic ations channels to and from the drive, high priority and low priority. A

maximum of 16 directed control word parameters and 32 global data word parameters are allowed. Of

these, up to 6 can be assigned to the high pri or ity channel. The balance must be assigned to the to the

low priority channel . All parameters assigned to the high prior ity channel are exchanged with the drive

every 2 milliseconds. The drive can also pack/unpack up to 16 high priority bit parameters into/fr om a

single high priori ty word parameter. If this feature is used, 5 high priority word parameter s and 16 hi gh

priority bit param eters can be processed. Due to the relatively small number of parameters available in

the high priorit y channel, these parameters should be reserved for the most critical parameters.

To access each low priori ty par am eter, the SBI must poll the drive one paramet er at a time. Thi s process

is very time consuming. A minimum of 100 milli seconds is required to access each drive parameter. The

SBI can also pack/unpack up to 16 low prior ity bit parameters into/f r om a single low priority word

parameter.

internal

to the drive. In this case, the GEN251 SBI c ar d must be mount ed

internally

mounted GEN250 and the

both

an SBI card and a DGF card, the DGF card

externally

mounted

external

to

Page 11

PAGE 12 23 SEP 1999 CH.2: DRIVE OVERVIEW

2.4 DGF Parameters

The DGF provides an additional group of low priority parameters independent of the drive's parameters.

The only way to directly ac c ess the DGF param eters is via the low priority communic ations channel.

Page 12

CH. 3: GEN250/251 COMM. 23 SEP 1999 PAGE 13

CHAPTER 3: GEN250/251 COMMUNICATIONS (SBI CARD)

3.1 GEN250/251 Operati on

Automatic Data Transfer is a type of Genius communication that c an be used between the G enius Bus

Controll er (GBC) and the SBI.

The automatic data t r ansfer type of communication uses broadcast (global) data to transfer inf ormation

from the GEN250/251to the GBC, and directed control data to transfer information from the GBC to the

SBI. With this data type, the GBC is always communicating with the SBI.

3.2 Automatic Data Transfer

To communicate with G enius using Automatic Data Transfer, all of t he requi r ed par am eter information

previously discussed in the Drive Overview section (the global data to transfer information from the SBI,

and Directed Cont r ol Data t o transfer data from the GBC to the SBI) must be configured and l oaded into

the SBI.

The GEN250/251 configuration is accomplished using the GE ToolBox software configur ation tool. The

configurati on por tion consists of the Genius bus configur ation parameters and two memory maps, t he

global data memory map, and the directed control data memory map. The memory maps associat e

parameter names (or parameter numbers) and other paramet er information with corresponding G enius

data words. The GE ToolBox confi gur ation tool uses “pick lists” for choosing par ameters. The pick lists

change depending on which ac c ess method is chosen. This eliminates the need to manually determine

all of the information described in the Drive Overvi ew secti on.

The global data mem ory map contains a parameter name (or parameter number) and other parameter

informati on for eac h global data word from the drive to the GBC. The directed cont r ol data memory map

contains a param eter nam e ( or parameter number) and other parameter information for each directed

control word from the GBC to t he drive. Once the memory maps are created using GE ToolBox, they are

downloaded into the GEN250/251 non-volatil e memory .

The software configur ation tool is setup in such a manner so that when the user choose s a parameter

from the “pickli st” , t hat param eter is set at that global data word or directed data word. When the

GEN250/251scans a configuration, it separates the hi gh pr iority words and the low priority words and

stores them in two differ ent arrays.

3.3 GEN250/251 to/from GBC Communication using Global Data

After the configur ation is downloaded from the configuration tool to the SBI, the GEN250/251 t hen

configures the drive. The drive must be made aware of all of the high priority parameters (both Word and

Bit) that need to be passed between itself and the GEN250/251.

High priority par am eters are passed automatically between the drive and the GEN250/251 every 2

milliseconds.

Page 13

PAGE 14 23 SEP 1999 CH.3: GEN250/251 COMM.

Low priority par am eters are polled by the GEN250/251 as fast as the low pri ori ty c ommunications channel

allows. Each dir ected data parameter is individually polled, and then each global data par am eter is

individually polled; this sequence is repeated i ndefinitely. The greater the number of low priority

parameters that are c onfigured, the longer this polli ng pr oc ess takes. T he time required for the

GEN250/251 to poll one low priority drive parameter is greater than 102 milliseconds.

WARNING: If using the Toolbox on-line diagrams, t he low pri or ity parameters between the SBI and

the drive may cease to functi on. This is of concern, because the drive m ay stop updating low priority

parameters when on-line diagrams are displayed. This incl udes the r epor ting of the Bus Loss

Alarm.

3.4 SBI (GEN250/251) Conf ig uration Procedures using GE Toolbox Softw are

3.4.1 Initial Steps Befor e S tarting Configuration

Note: It is important to consult Section 1.3 prior to configuration. Section 1.3 provides a

suggested order for conf igurat ion and setup and contains a detailed li st of resource i nformation.

1. Prior to configuration, analyze the specifications and requirements of the applic ation. Become familiar

with the parameter s li sted in the GE Industrial Control Systems AV-300i Adjustable Speed Drives

before

Instruction Manual

starting any configuration procedures.

a. Determine which param eters must be used to meet the requirements and specif ic ations of the

applicati on.

Required parameters must be determined before starting conf igur ation procedures for the

SBI (GEN250/251).

b. Determine which of the required paramet er s need to be high priority or low priority when

communicati ng with AV-300i Drive. High priority parameters can be accessed much more quickly than

low priority par am eters. A maxim um of six hi gh pri ori ty Directed Control Data param eters and six high

priority Global Data parameters can be configured for each AV-300i.

3. Install the SBI Car d (GE N250/251) into the AV-300i Drive. (See Chapter 8 for procedures.)

4. Wire the Genius Network and t he S BI Car d (GE N250/251). (See Chapter 7 for wiring.)

5. When configuring the AV-300i/HE300GEN250, t her e is terminology that must be

understood. (See Chapter 6.)

Page 14

CH. 3: GEN250/251 COMM. 23 SEP 1999 PAGE 15

3.4.2 SBI (GEN250/251) Configuration Procedures

In this configuration example, the user followed the steps in Sectio n 3. 4.1 and has predetermined

which parameters and prio rities to choose for the two types of data in Genius – Directed Con t rol

Data and Global Data.

To configure for Direct ed Control Data, the parameter for Word0 is going to be “Discrete Bit Word,”

and the parameter f or Wo rd1 is going to be “Speed ref 1.” The user is going to select the words to

be high priority. The user must configure the bits as well. Bit0 is going to be “Enable Drive,” and

the parameter f or Bit 1 is goi ng to be “Star t/ S top.” To configure Global Data, the user employ s the

similar procedur es al though the desired parameter s and priorities can vary.

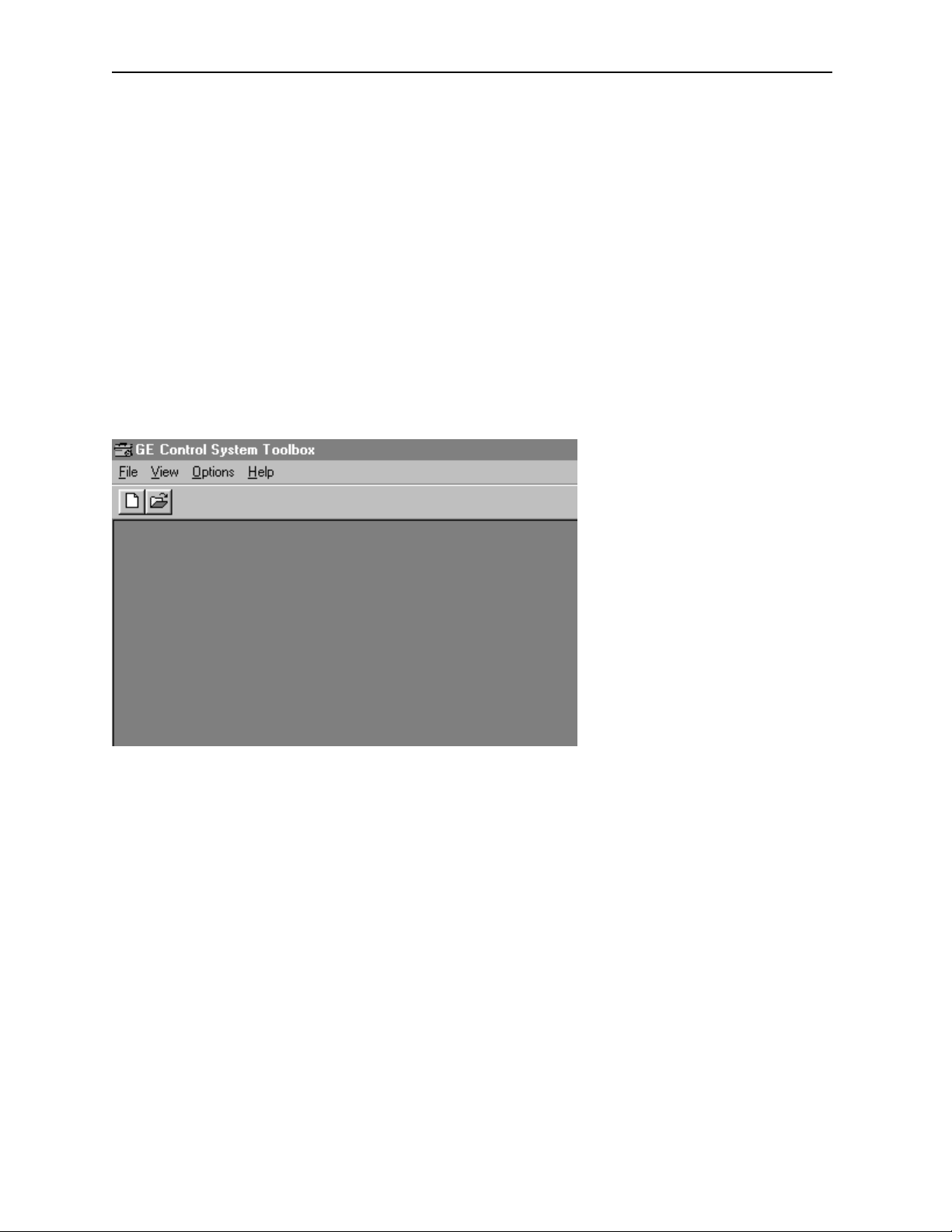

1. Install GE Control S yst em Toolbox Sof t ware by following the manufactur er ’s i nstr uc tions.After

openng the GE Toolbox Software, the following screen appears. S elec t File, New.

Figure 3.1

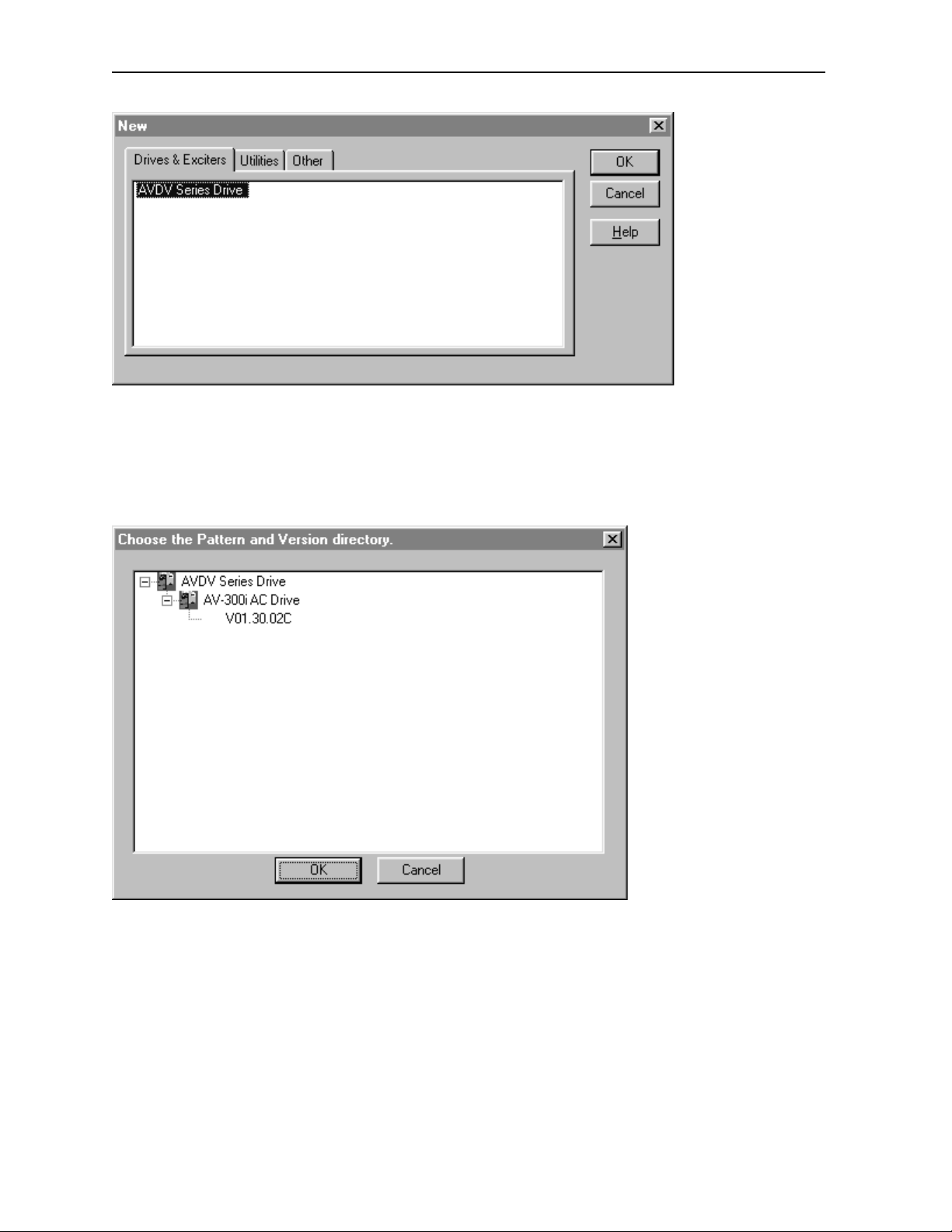

2. The following screen appear s. S elect AVDV Series Driv e and press OK.

Page 15

PAGE 16 23 SEP 1999 CH.3: GEN250/251 COMM.

Figure 3.2

3. The following screen appears. Select the AV-300I AC drive type and drive fi rmware version.

Note that there can be ot her drive information listed on thi s screen.

Figure 3.3

Page 16

CH. 3: GEN250/251 COMM. 23 SEP 1999 PAGE 17

4. Type in the User ID such as the user’s ini tials. Press OK.

Figure 3.4

5. Select the desir ed drive. In this configuration exam ple, the 6KAVI43F75 model is selected.

Press OK.

Figure 3.5

Page 17

PAGE 18 23 SEP 1999 CH.3: GEN250/251 COMM.

6. The following screen appear s. This step requires the user to name the configuration file for the

drive that is being configured. It also requires that the user selec t the Genius network.

In this example, the drive configuration name is AVDV1. If a diff er ent driv e nam e is desired ( such as

AVDV2), doubl e-click on the highlighted name (or right - cli c k on the nam e and sel ec t Modify).

Figure 3.6

7. The following screen appear s. Type in the drive name in the Name block, and from the Net work

block, select Genius from the pull-down menu. Press OK.

Figure 3.7

NOTE: It is highly recommended t hat t he user refer to the GE Control Toolbox Help File at this time to

obtain highly useful information regardi ng the Geni us Network Conf iguration. Select Help, click on

Contents, click Index tab, and type Genius Configuration.

Page 18

CH. 3: GEN250/251 COMM. 23 SEP 1999 PAGE 19

8. The following screen appear s. On the left side of the screen. a “tree” appear s. Note that the

Genius network is now listed as a part of the tree. The right side of the screen provides a status page

that correlat es to whatever item is highlighted on the “tree.”

Place the cursor on the Ex pand B ox locat ed in front of the word “Genius” on the left-side of the screen

and click the box to reveal t he items associated with Genius confi gur ation.

Figure 3.8

9. The following screen appears.

Figure 3.9

Page 19

PAGE 20 23 SEP 1999 CH.3: GEN250/251 COMM.

Figure 3.9 indic ates the types of data that must be configured in a Genius Network. The data types

include Directed Dat a and Global Data. To see the items that must be configured for each data type,

place the cursor in t he Expand box loc ated in front Directed Data and click. Then, do the same thing for

Global Data.

In this configuration example, the user followed the steps in Sectio n 1. 3 and predetermined that

he/she is going to configure th e Directed Data and select parameters for specific Words and Bits.

The parameter f or Word0 is “Discrete Bit Word,” and the parameter for Word1 is “Speed ref 1.” The

user is going to select the words to be high priority. The user must configure the bits of the

Discrete Bit Word as well. Bit0 is “Enable Drive,” and the parameter for Bit1 is goi ng to be

“Start/St op.” To configure Global Data, the user employs the sam e pr oc edur es to sel ec t desir ed

parameters and priorities.

NOTE: It is highly recommended t hat t he user refer to the GE Control Toolbox Help File at this time to

obtain highly useful information regardi ng the Geni us Network Conf iguration. Select Help, click on

Contents, click Index tab, and type Genius Configuration.

10. The following screen appears.

Figure 3.10

Directed Dat a and Global Dat a hav e three sub-items that can be configured.

Be sure to read the suggestions in Section 1.3. It is important to know in advanc e which drive

parameters and priorities are going to be selected in the next steps of the configuration pr oc edur es.

Place the cursor into the Expand box located in front of Directed Cont rol Dat a Configuration and click.

Note: The following procedures apply to Glob al Data Con f ig uration as well. The parameters used

differ howev er.

Page 20

CH. 3: GEN250/251 COMM. 23 SEP 1999 PAGE 21

11. Choose a Word to configure by double-clicking on the desired word (or ri ght-click on the word and

select Modify).

Figure 3.11

12. The following screen appears. Select a source and description usi ng pull- down m enus. P r ess OK.

Figure 3.12

I

For this example, t he user is going to assign “high priority” to the Discrete B it Word. Thus, the selected

source is Discrete Bit Word to Device. A description must be assigned as High Priority.

Note: Because the user made the selections shown on Figur e 3.12 screen, one of the high priority words

is used up. This means that there are 5 words rem aining that can be assigned as high priority.

(In Directed Dat a, t her e ar e 16 tot al words. Global Data has 32 possible words.)

Page 21

PAGE 22 23 SEP 1999 CH.3: GEN250/251 COMM.

13. The following screen appears.

Figure 3.13

The status of Word 0 is depicted. Follow the same procedure to configur e other Words. Figure 3.14

depicts selections made to Word 1.

Figure 3.14

Page 22

CH. 3: GEN250/251 COMM. 23 SEP 1999 PAGE 23

14. Figure 3.15 depicts the status of Word 1. To exit out of the Directed Control Data Configurati on ,

click on the Collapse Box in front of Directed Control Data Configurati on .

Figure 3.15

15. The following screen reappears. P lace cursor on the Expand box in front of Discrete Bi t s High

Priority and click.

Figure 3.16

Page 23

PAGE 24 23 SEP 1999 CH.3: GEN250/251 COMM.

16. The following screen appears.

Figure 3.17

The user must now configur e the bit s i n the high priority words that have been defined. Select the

appropriate bit by doubl e- c licking on it (or right-cli ck on t he bit and selec t Modify).

17. The following screen appears.

Figure 3.18

Using the pull-down menu, select a Description parameter and press OK. Continue the same process for

other applicable bits (such as Bit #1 in this example confi gur ation). In this configuration ex am ple, Bit #0

uses the parameter shown in Figur e 3.18.

Page 24

CH. 3: GEN250/251 COMM. 23 SEP 1999 PAGE 25

18. The following screen appears. F igure 3.19 screen depicts the status of Bit #1. In this example, the

parameter select for Bit #1 is Start/Stop.

Figure 3.19

If the user decides to remov e a par am eter from a bit, double-click on the bit (or right- cli c k and press

Modify) and select No Description as depict ed in Figure 3.20 and press OK.

Figure 3.20

19. Put the cursor in front of t he Expand/ Collapse box in front of Discret e Bits (High Priority) and

click. Figure 3.21 appears.

Page 25

PAGE 26 23 SEP 1999 CH.3: GEN250/251 COMM.

To configure the Genius Network to be compatible with the Genius Bus Controller (GBC), place the cursor

in the Expand/Coll apse box in front of Genius. Double-clic k (or ri ght-click and press Modify).

Figure 3.21

20. Select the maxim um levels (as shown in Figure 3.22) using pull- down menus. The Global Data

Length and Direct ed Data Length selection in this box is the siz e of the Genius data m ap r egar dless of

the number of words configur ed. Press OK. Then press Save As to save the configuration.

Figure 3.22

Page 26

CH. 3: GEN250/251 COMM. 23 SEP 1999 PAGE 27

21. The following screen appears. P r ess Save.

Figure 3.23

22. The following screen appears. S elect Device, Download Network Configuration or Upload

Network Configuration. A serial interface cable must be connected di r ectly to t he Genius SBI interface

card.

Figure 3.24

Page 27

PAGE 28 23 SEP 1999 CH.3: GEN250/251 COMM.

23. The screen appears. In thi s example, the user selected to download the program . Press Yes.

Figure 3.25

The configuration process for the GEN250/251 is compl eted. Section 1.3 provides a of steps to follow

after this configur ation is completed. It is appropriate to now configure the Genius Bus Controller (GBC)

using Logicmaster 90. Usi ng summar y screen information from the GEN250/ 251 c onfiguration,

determine the Global Data length and the Directed Control Data length as well as baud rate and network

id informati on. (See Chapter 5.) Afterwards, write the Ladder program , and again, refer to the summary

information in the GEN250/251 configuration.

Page 28

CH. 4: GENIUS 23 SEP 1999 PAGE 29

CHAPTER 4: GENIUS COMMUNICATIONS

This chapter is just a bri ef overview and introduction to the Geni us network. It does not c ov er detailed

informati on on the Seri al B us Option card or the AV-300i drives.

4.1 Introduction to Genius

Genius is a high speed token passing net work which has been used in industrial applications for many

years. The network supports up to 32 devices, with baud rates of up to 153.6kbaud. A wide variety of

Genius devices exist which can reside on the network, ranging from intelligent I/O blocks to mor e

sophisticated communications devic es such as personal c om puters. In recent years a number of third

party devices have em er ged, including Operator Interface Units, valve manifolds, RF tag reader s, etc.

In a typical industrial application, Genius devi c es are distributed throughout a fairly wide area, wired in a

daisy chained fashi on with a single shielded, twisted pai r . The Serial B us Interface Genius option card

allows the AV300/DV300 Dr ives to be distributed on the fact ory fl oor on the sam e twisted pair as the I/O

blocks and other Genius devices. This provides a new level of PLC integration for the drives. The

physical natur e of t he network can allow for great savings in wiring, as many discrete wires can be

replaced with a single c ommunications cable. This allows tasks such as starting, stopping, rev er si ng, and

changing speeds to be accomplished over the LAN. In addition, drive parameters and

previously not av ailable to the PLC are easily accessible.

diagnostic dat a

Figure 4.1.

4.2 Network Architecture

Normally, a GE Fanuc programm able controller runs the network, t hr ough a P LC m odule c alled a Genius

Bus Controller (GB C). Devices (up to 32 in num ber ) ar e wir ed in a daisy chained fashion. Network

devices support f our c ommunications terminals, Serial 1, Serial 2, Shield In and Shield Out. The network

is terminated at each end wit h an appr opr iate terminating resistor . The value of the resistor should be

chosen to match the char acter istic impedance of the cable. Refer to GE Fanuc Automation publication

GFK-90486 for hel p in select ing an appropriate cable type for your application. Note: If the charact eristic

impedance of the cable is unknown, 120 ohm terminating resistors should be used.

Typical Genius Devices and Architecture

Page 29

PAGE 30 23 SEP 1999 CH. 4: GENI US

Each of the (up to) 32 devices on the network is assigned a Genius Bus Address ranging f r om 0 to 31.

Bus Controller s are most typically assigned a Genius Bus Address of 31. In applications with redundant

bus controller s, the “backup” bus controller is address 30. Bus address 0 i s normally reserved for the

Genius Hand Held Monit or.

Among other tasks, the bus cont r oller allows Genius I/O (including the drives) on the network to be

mapped into PLC memory, monitoring inputs and controlling outputs. Intelligent, data intensive Genius

devices also share their data with the PLC through communications with the bus controller.

4.3 Genius Communicatio ns Services

As stated previ ousl y, the Serial Bus Interface Genius option c ar d allows the drive to reside directly on the

Genius LAN, providing dr ive control and data access capabilities to the PLC. There are three types of

communicati ons that can occur on the Genius LAN. These are I/O Services and Global Data. The Serial

Bus Interface opti on c ar d support s al l three of these communicati ons ty pes.

4.4 I/O Service

I/O Service is the manner in whic h data is transferred to and from Genius I/O Block s. Out puts are

selectively wri tt en to each I/O block from the CPU bus controller each scan. Many I/O block s al so

broadcast inputs to t he bus every bus scan.

4.5 Global Data

Global data is data broadc ast over the network at large, with no particular “destination” . Each Genius

device has the capacit y to broadc ast up to 128 bytes of global data. Intelligent devices which reside on

the LAN (bus controll er s, OI Us, etc.) can read this data off the network. These dev ic es are intelligent

enough to interpr et t his data, as the data content differ s from Geni us device to Genius device. Drive

feedback dat a consists of parameters such as speed referenc e, t or que, current, faults, function settings,

etc. The Serial Bus interface allows the system designer to sel ect whic h data is broadcast by the drive as

global data. This is im portant for two reasons. First of all, the data which is desired t o be m onitored on a

regular basis vari es fr om application to applicati on. Second, the amount of global data broadcast by t he

drive is directly pr opor tional to response time.

In general, the proc edur e for configuring the drive’s Gl obal output data is a process of mapping the global

output data words to driv e par am eters. There are three different means in whic h this “mapping” of global

data output words to driv e par am eters can be accomplished. These are; from t he keypad, from the

Genius Hand Held Monit or, and from the optional personal comput er configuration utility. Chapters are

dedicated to eac h of these configuration means.

Page 30

CH. 5: PLC CONFIG 23 SEP 1999 PAGE 31

CHAPTER 5: PLC CONFIGURATION

5.1 General

This chapter discusses the configuration of the PLC in Genius applications using the AV-300i drives with

the Serial Bus Interface option board. As mentioned in a previous chapter , Genius LANs performing

control requir e a Genius Bus Controller. Most GE Fanuc PLCs offer a module which acts as the bus

controller. T his document discusses configuration of the Series 90 PLCs -- Series 90-30 and Seri es 90-

70.

5.2 Series 90-70 Configu rat io n

For successful int egr ation of the Series 90-70 GBC, the document GFK - 0398,

Controller User's M anual

Configuration of Series 90-70 PLC system requires the use of Logicmaster 90-70, the personal com puter

software package used for ladder logic programming and system setup. Configuration of the Genius

devices residing on the LAN with Logicmaster 90-70 can not be acc om plished until the Genius Bus

Controll er (GBC) is confi gur ed. For instructions on that process, consult GFK-0398 from GE Fanuc.

After confi gur ation of the GBC has been completed, the Genius devic es residing on the LAN may be

configured by z oomi ng into the slot containing the GBC. A Logicmaster screen sim ilar to that below will

appear:

is required.

Series 90-70 Genius Bus

Figure 5.1 – Logicmaster 90-70 Configuration Screen

This is a representation of the Genius LAN, with each device shown as a "block ". Because only eight

devices can be shown on the screen at once, the screen "wraps around" from left t o right . The left and

right cursor keys are used to select the device to be configured. When the desired block is highlighted,

the type of Genius devic e c an be select ed usi ng the function keys. The GEN250/251is conf igured as a

"Generic Genius I/O Dev ic e". This device is selected by pressing the "Other " (F7) function key, and

selecting t he "Generic I/O" device from the devices listed.

Page 31

PAGE 32 23 SEP 1999 CH. 5: PLC CONFIG.

Figure 5.2. Generic I/O device Configuration Screen

Below, each configuration parameter is described. The proper setting for a drive with a default data

configurati on is al so li sted. Figure 5.3 lists the default drive dat a c onfiguration.

a. %I Length (Default = 16)

The number of %I's assigned to the drive should be equal to 16 times the number of bit- m apped global

data words broadcast by t he drive. Bit mapped parameters should be mapped first in the

GEN250/251and defined using %Is in the PLC configuration.

b. %Q Length (Default = 16)

The number of %Qs assigned to the drive should be 16 times the number of bit-mapped directed control

words (directed dat a) . Bit mapped par am eters should be mapped first in the drive and defined using

%Qs in the PLC configurati on.

c. %AI Length (Default = 6)

The number of %AIs assigned to the drive should be equal to the number of non-bitm apped global data

words broadcast by the drive.

d. %AQ Length (Default = 1)

The number of %AQs assigned to the drive should be equal to the number of non-bitm apped directed

control words.

Page 32

CH. 5: PLC CONFIG 23 SEP 1999 PAGE 33

e. Reference Addresses

In addition to the length of each of the four I/O references (%I, %Q, %AI, %AQ ), the starting reference

address for each I/O type must be set for each of the I/O references with a non-zero length. This

reference addr ess must not conflict with any other I/O module or Genius devi c e.

f. Redundancy

If the AV-300i is used in a redundant application, this parameter should be set to YES.

g. Input Default

The input defaults can be set t o OFF or HOLD, as desired.

h. Outputs Enabled

If outputs from the PLC are to be enabled (most cases), this paramet er should be set t o Y ES.

NOTE: The reference types available for m apping into Series 90-30 memory are more numerous than

those available for the Series 90-70. This is due to the fact that the Series 90-70 performs more data

type checking than the Series 90-30. This extra checking requir es that the number and type of memory

references mat c h exactl y in the Seri es 90-70. The S eries 90-30 requires only that the amount of

data match exactl y.

5.3 Series 90-30 Configu rat io n

For full inform ation on the configuration of Genius LANs with the Series 90-30 PLC, consult the GE

Fanuc’s

The Series 90-30 PLC is configur ed usi ng Logicmaster 90-30. In the configur ation package, the Genius

Bus Controller (GB C) confi gur ation screen appears as follows:

Series 90-30 Genius Bus Controller User's Manual

.

Page 33

PAGE 34 23 SEP 1999 CH. 5: PLC CONFIG.

Figure 5.3. Series 90-30 G BC Configuration Screen

The devices residing on the Genius LAN are configured in the lower "Device Data" section of the screen.

The cursor keys are used to navigate around the screen. When the cursor is on the "Dev ic e Data"

section of the screen, t he P ageUp and P ageDown keys are u sed to sel ec t the Device number. Once the

proper device number is di spl ay ed for the AV-300i, the following parameters can be set.

a. Device Type

The AV-300i is confi gur ed as a GENERI C dev ic e type, which is the default.

b. Input References (Input 1 Ref, Input 2 Ref)

These parameters specify where the SBI’s global data is mapped in Series 90-30 memory. Legal

reference types for these parameters are %I, %G, %AI, and %R. As you can see, the global data

broadcast by the GEN250/251can be divided into two different areas of PLC memory. For instance, part

of the global data could be mapped into %I, and the remainder into %AI. Two non-consecutive areas of

the same referenc e type c ould also be mapped. For instance, part of the global data c ould be mapped to

%R1, and the remainder t o %R500.

c. Input Length (Input 1 Len, Input 2 Len)

These parameters specify how much global data is broadcast by the S BI. If the I nput Ref er enc e specif ied

is bit-type (%I, %G), the length parameter is in bits. If the Input Reference specified is word type (%AI,

%R), the length param eter is in words. The total amount of data mapped into the Series 90-30 must

exactly matc h the total am ount of global data broadcast by the SBI.

Page 34

CH. 5: PLC CONFIG 23 SEP 1999 PAGE 35

d. Output References ( Output 1 Ref, Output 2 Ref)

These parameters specify where the AV-300i directed c ontrol data is mapped in Series 90-30 memory.

Legal reference types for these parameters are %Q, %G, %AQ, and %R. As you can see, the directed

data input by the GEN250/ 251c an be div ided into two different areas of PLC m emory. For instance, part

of the global data could be mapped into %Q, and the remainder into %AQ. Two non-consecutive areas

of the same reference type c ould also be mapped. For instance, part of the directed data could be

mapped to %R1, and the remai nder to %R500.

e. Output Length (O utput 1 Len, Output 2 Len)

These parameters specify how much directed data is received by the SBI. If the Output Reference

specified is bit-type (%Q, %G), the length parameter is i n bits. If the O utput Reference specified is word

type (%AQ, %R), the length param eter is in words. The total amount of data mapped from the S eri es 9030 must exactly match t he tot al am ount of global data received by the SBI.

Page 35

PAGE 36 23 SEP 1999 CH. 5: PLC CONFIG.

NOTES

Page 36

CH. 6: AV-300i 23 SEP 1999 PAGE 37

CHAPTER 6: AV-300i DRIVE PARAMET ERS

6.1 Drive Parameter Descript ions

The parameters and parameter numbers associated with t he AV-300 and DV - 300 adjustable speed

drives are listed as “Pick Lists” in the software confi gur ation tool, and can be accessed with the hand held

monitor attac hed to t he drive. For fur ther information on these parameter s, c onsul t the AV-300i

instruction manuals.

Due to revisions to the param eters, the parameter inform ation is not contained in this manual. The

information can be obtained from the AV-300i Instructions Manual.

The following sections explain how the AV-300 and DV-300 Manual Parameter T abl e relates to the

Software Configuration Tool Pick Lists.

a. Directed Control Data:

This is a Genius Bus term. Directed Control Data refers to data that i s autom atically transferred from the

PLC to the AV-300i. The AV-300I can receive up to 16 data words in this manner.

b. Global Data:

This is a Genius Bus term. Global Data refers to data that is automatically transferred from the AV-300i to

the PLC. The AV-300I can transmi t up to 32 data words this manner.

c. Word Parameters:

These are parameter s whose data values are represented by a 16 bit number s.

d. Bit Parameters:

These are parameter s whose data values are represented by 1 bit. The only v alues all owed for bit

parameters are zer o ( 0 or FALSE) or one (1 or TRUE ).

e. High Priority Data:

The AV-300i provides for up to 12 parameters to be declared as High Priori ty, 6 Directed Control Data

words and 6 High Priority Global Data words. Only AV-300i parameters designated as High Priority

parameters can be assigned to the high priority channel. For a complete list of the high priority

parameters, r efer to the AV-300i instruction parameter list. All 12 of these parameters are passed

between the HE300GEN250 and the AV-300I every 2 milliseconds. To com pute a typical update time the

Genius bus scan time and the ladder c ode scan time must be added to the 2 milliseconds.

f. Low Priority Data:

All parameter s that are not declared as High Priority must use the Low Pri ori ty Channel. Parameters

passed on the Low Priorit y Channel ar e updated very slowly compared the High Pr iori ty data. Each of

these parameters requires a minimum of 102 milliseconds to be passed between the HE300GEN250 and

the AV-300i. To compute the best case update time, the Genius bus scan time and the ladder code scan

time must be added to 102 milliseconds times the number of Low Priorit y parameters that are configured.

Page 37

PAGE 38 23 SEP 1999 CH. 6: AV-300i

g. High & Low Priority Bit Parameters:

Bit parameters are divided into the following 4 categories:

High Priority Directed Control Bit s, bit s sent from the PLC to the AV-300i

High Priority Global Bits, bits sent from the AV-300i to the PLC,

Low Priority Directed Control Bits, bits sent fr om the PLC to the AV-300I and

Low Priority Global Bi ts, bits sent from the AV-300i to the PLC.

Up to 16 individual bit par am eters can be assigned to each of these four categories. For each category

that any Bit Parameters are assi gned, there must be a place holder assigned in the corresponding word

configurati on ( Dir ec ted Control Data Configuration and/or Global Data Configurati on) . This place holder is

used to indicat e were in the Genius data stream the bit data is to be placed. The GE Tool box

configurati on tool calls these place holders “Di screte Bit Word” and can be assigned either High or Low

Priority. Note that a High Priority Discrete Bit Wor d requi r es one of the 6 available High Priority Word

positions leaving only 5 available for other Word Param eter assignments. Most applications will require

both High Priority Directed Control Bits and High Pri ori ty Global Bits to be used.

Page 38

CH. 7: WIRING 23 SEP 1999 PAGE 39

CHAPTER 7: WIRING DIAGRAMS

7.1 Genius Wiring:

Figure 7.1. - Typical Genius Wiring Diagram

RS-232/485 G ENIUS

Figure 7.2. Seri al Bu s Interface Genius Connector

For further instruction on wiring, consult t he GE Fanuc User Manual ( Genius I/O Systems and

Communications).

Page 39

PAGE 40 23 SEP 1999 CH.7: WIRING

7.2 RS232/RS485 Pinout:

6

789

12345

RECEPTACLE ASSEMBLY

CONTACT NUMBERS

RS-232 APPLICATION

CONTACT DESCRIPTION CONTACT DESCRIPTION

1

2

3

4

5

6

7

8

9

* CONTACTS 1, 6, AND 9 ARE

INTERNALLY CONNECTED I N

RS-232 MODE.

The following jumper s are associated with RS485 (J2).

a. JP1 - Jumper on places a 120 Ohm terminating resistor on the circuit.

b. JP2 - Places 5 volts at J2, Pin 9. JP2 consists of six individuals headers. All headers must be

placed on the right side of JP2 for RS-232 operation or plac ed on the lef t side for RS-485.

c. J P 3 – M ust be jum per ed for RS-232 operation and must be removed f or RS-485 oper ation.

CD OUT*

TXD OUT

RXD IN

NO CONNECTION

GND

DSR OUT*

CTS IN

RTS OUT

RI OUT*

RS-485 APPLICATION

1

SHIELD

2

DO NOT CONNECT

3

A

4

100 OHM PULL DOWN

5

GND

6

DO NOT CONNECT

7

B

8

CONNECTED TO PIN 4

9

+5 VOLTS

d. JP4 – Do NOT jumper.

For more information on the hardware setup, see the GE Control Tool box Help file.

Page 40

CH. 8: INSTALLATION 23 SEP 1999 PAGE 41

CHAPTER 8: INSTALLATION OF GEN250/251 OPTION CARD

8.1 General

The following chapter describes the installati on pr oc edur es for the GEN250 and the GEN251. The

procedures differ in that the GEN250 is installed

external

8.2 GEN 250 Installation

to the drive.

8.2.1 Installation Hardwar e

Included in the pac k aging with the GEN250 are the following items:

a. The option card.

b. One installati on kit ( c onsi sting of two metal standoffs, two plastic spacers, two Phillips head screws,

four lock-washers, and one 6” telephone type cable, and one 6” 2- wir e power cable.)

8.2.2 Installation Procedures

inside

the AV-300i drive while the GEN251 is installed

The GEN250 option car d is instal led inside the drive cover, so that t he NEMA rating of t he drive is

maintained after installation of the opti on card.

Note: It is highly recommended that the user consult the Installation chapter and the W iri ng c hapter in

GE AV-300i Drive Manual

the

1. Power down the drive.

Warning: Failure to power down the drive can result in injury or death due to electrical shock

and can cause damage to equipment.

for additional information.

8.2.3 Cover Removal

a. Press the area on both sides of the drive to remove the lower cover as shown in Fig. 8.1.

b. Remove the control panel f r om the drive by pulling up

force to pull up the contr ol panel. Then, disconnect the telephone cable connection located beneath the

control panel at the panel end. (See Figure 8.1.)

c. Remove cover from the drive.

gently

and tilting the control panel. Do not use

Page 41

PAGE 42 23 SEP 1999 CH.8: INSTALLATION

PULL KEYPAD

FROM CASE AND

DISCONNECT LEAD

PRESS THIS AREA ON

BOTH SIDES TO REMOVE

LOWER UNIT

Figure 8.1 – Installi ng GEN250

8.2.4 Housing Removal

Note: If there is existing wiring connected in any of the four terminal blocks, unpl ug the terminals and

leave the wiring int ac t. Note that three blocks are located on the regulation board (top), and one is

located on the power board (bott om).

a. Remove two screws located at the front of the lower board to remove the lower panel and free the

case. (See Figure 8.2.)

Note: If wired, the Protector Earth Ground c onnec tor is attached to one of the screws.

before

b..Refer to the following caution statement

separate the bottom of t he housi ng from the heat sink casting

mounting bosses and the power board.

securing the upper end of housi ng.

Caution: To avoid breaking off t abs, do not separate t he bottom more than one-half inch.

The housing is now free of the base.

Gently

performing this step. To remov e the case,

approximately ½ inch

pull outward and slide upward to disengage the tabs

to clear the two

carefully

Page 42

CH. 8: INSTALLATION 23 SEP 1999 PAGE 43

8.2.5 Regulation Card Removal

a. Disconnect the ribbon cable between the power card and regulation card.

b. Remove four screws securing the regulation card to standoffs and remov e c ar d. (Figure 8.2.)

c. Remove the regulation car d. Lay it f ac e down.

8.2.6 Mounting the GEN250 Car d

Note: Be sure to configure the jumpers on th e GEN250 card b efo re in st alling it in the drive. See

Figure 8.6 (for locati on of ju mpers) and Secti on 7.3.

a. Screw the two threaded met al standoffs into the board on the component si de. (S ee Figure 8.3.)

b. Then, snap the two plastic standoffs into the board on the component si de.

c. Snap the two plastic standoffs into the regulation card. (Figur e 8.4.)

d. Install two screws through the regulator card and into the standoffs.

e. Install the telephone jumper cable between the regulator c ar d and the GEN250.

f. Plug the two-wire power cable into the socket on the GEN250. The left-hand wir e is connected to

regulator car d connect or point #19. The other wire goes to point #18 during r e- assembly.

Page 43

PAGE 44 23 SEP 1999 CH.8: INSTALLATION

DISCONNECT RIBBON CABLE BETWEEN

POWER CARD AND REGULATION CARD

COVER TAB

DISCONNECT

THREE TERMINAL

BLOCKS

REMOVE FOUR SCREWS

SECURING THE REGULATION

CARD TO STANDOFFS

AND REMOVE CARD.

REMOVE TWO SCREWS TO

REMOVE LOWER PLATE

GENTLY SEPARATE BOTTOM OF COVER FROM HEAT SINK

CASTING APPROX. ½ INCH TO CLEAR 2 MOUNTING

BOSSES & POWER BOARD.

SLIDE UP TO DISENGAGE

TABS SECURING UPPER END OF CASE. THEN RAISE

THE COVER UPWARD TO FREE THE TOP END.

WARNING: TO AVOID BREAKING TABS, DO NOT

SEPARATE THE BOTTOM MORE THAN ½ INCH.

Figure 8.2 – Installi ng GEN250

Page 44

CH. 8: INSTALLATION 23 SEP 1999 PAGE 45

SCREW TWO STANDOFFS

INTO BOARD

J3

STEP 1

Figure 8.3 – Installi ng GEN250

INSTALL POWER CABLE

IN T O TERMINA L 18 & 1 9

INSTALL TWO

SCREWS

SNAP TWO PLASTIC

STANDOFFS INTO BOARD

INSTA LL JUMPER C ABLE

SNA P TWO S TAND O FFS

INTO REGULATION CARD

18

19

STEP 2

ATTACHM ENT OF PCB TO REGULATION CARD

Figure 8.4 – Installi ng GEN250

8.2.7 Re-assembly

a. Mount the regulator c ar d with t he GEN250 att ac hed on the four standoffs with four screws. (See

Figure 8.4.)

b. Reconnect the ribbon cable between the lower power card and the regulation card. (See Figure 8.2.)

c. Replace the housing by sli ding the housing tabs into the recess and slide downward until the points at

the lower end are engaged over pins.

d. Reconnect the four plugs that were removed during disassembl y. Connec t t he two wires fr om the

GEN250 to points #18 and #19 (Figur e 8.5).

Page 45

PAGE 46 23 SEP 1999 CH.8: INSTALLATION

e. Before replacing the lower panel, remove the two knockouts aligned with the connectors on the lower

side of the GEN250 card (Figure 8.5).

f. Install two screws to hold both the lower plate and the lower end of the housing.

g. Connect the telephone cable to the back of the keypad and snap the keypad into t he housi ng.

h. Replace cover.

Page 46

CH. 8: INSTALLATION 23 SEP 1999 PAGE 47

To Pin18

18

19

Remove knockouts for

GEN250’s connectors.

Figure 8.5 – Installi ng GEN250

18. Reinstall termi nal plugs that were previously disconnected in Step 5. (Figure 8.5.)

19. To reinstall the plat e, rem ov e the t wo knockouts covering the GEN250 connectors.

To Pin 19

20. Secure the plate with two screws.

21. Install the supplied telephone cable between the regulation card and the GEN250.

22. Plug the supplied 2-W ir e power cable into the connection J3 on the GEN250. (See Figur e 8.3 f or

J3’s location.)

Page 47

PAGE 48 23 SEP 1999 CH.8: INSTALLATION

8.3 GEN 251 Installation

8.3.1 Installation Hardwar e

The GEN251 is included as part of an assembly which includes the DIN rail mounti ng adapter and one (1)

2- ft. telephone ty pe c able and one ( 1) 2-ft. 2- wir e power cable.

8.3.2 Installation Procedures

The GEN251 option car d is instal led external to the drive.

Note: It is highly recommended that the user consult the Installation chapter and the W iri ng c hapter in

GE AV-300i Drive Manual

the

1. Power down the drive.

Warning: Failure to power down the drive can result in injury or death due to electrical shock

and can cause damage to equipment.

Note: Be sure to configure the jumpers on th e GEN251 card b efo re in st alling it. See Figure 8.6

(for location of jump ers) and Sectio n 7. 3.

for additional information.

2. Mount the GEN251 assembly onto the DIN rail. (Figure 8.6.)

3. Establish a ground at one of the four m ounting tabs to the DIN rail mounting bracket s.

4. Remove cover of the drive. (Ref er to Figure 8.1.)

5. Attach the supplied telephone type cable between the GEN251 and the regulation board.

(Figure 8.7.)

Note: Pop-out the center of one of the plastic plugs from the plate and run the cable into the appropri ate

connection on t he regul ator card.

6. Plug the two-wire cable int o the G E N251. Rout e the power cabl e through the knockouts that cov er the

GEN251 connectors and pl ug into Terminal pin 18 (black) and pin 19 (red). (Figure 8.7.)

7. Replace cover.

Page 48

CH. 8: INSTALLATION 23 SEP 1999 PAGE 49

Mounting Tab (One at each corner)

Din Rail

JP2

(Consists

JP1

J2

of 6 headers.)

Six LEDs

19

18

J4

J3

J1

JP4

Figure 8.6 – Installi ng GEN251

J2

J4

J3

J1

JP3

Figure 8.7 – Installi ng GEN251

The drive is now ready to be operated with the GEN250/251option card.

Page 49

PAGE 50 23 SEP 1999 CH.8: INSTALLATION

NOTES

Page 50

CH. 9: LED INDICATORS 23 SEP 1999 PAGE 51

CHAPTER 9: GEN250/251CARD LED INDICATORS

The GEN250/251car d has six LE D indic ators for general troubl eshooting. See Figure 9.1 for the location

of the LED’s.

1. The “Power” indicator informs the user that the GEN250/251card is getting power. If the Drive is

powered up, and this li ght is not illuminated, ensure the ribbon cable is properly connected.

2. The “Reset” indicat or i s ill umi nated as long as the power light is illuminated. If the GEN250/251card

appears to be having pr oblem s, and the reset LED is not illuminated, contact Horner APG’sTechnical

Support.

3. The “Transmit” indicator flashes when data is transmitted to a PC while reading the configuration from

the GEN250/251car d with the software configuration tool.

4. The “Receive” indic ator flashes when data is received while wri ting a configuration to the

GEN250/251using the software configuration tool.

5. The “GENA OK” indicator is ill umi nated unless there is a fault with the GENA board.

6. The “COMM OK” indicator illumi nates when the GENA board is communicati ng with t he GBC properly.

If the “COMM OK” LED is not illuminated af ter configuration, check the following:

a. Make sure the GEN250/251configuration Global Data and Direc ted data length matches the Summary

Global Data words, and the Directed Control Data words (In the soft ware conf iguration tool).

b. Make sure the Cable is wired correctly between the GBC and the GEN250/251card.

c. Check the GBC configuration (LM90 Configuration pack age) . The Global data length, and the

Directed control data length must match the input length and the output length respectively .

Serial Bus Interface LED description, and nomencl ature.

Table 9.1 – LED Indicators

D1 Receiv e Data (Serial Port) D4 Reset ( Is OFF if unit is reset.)

D2 Transmit Data (Serial Port) D8 GENA OK

D3 Power D9 COMM OK

Page 51

PAGE 52 23 SEP 1999 CH.9: LED INDICATORS

J2

D1

D2

D8

D9

D3

D4

J4

J3

J1

Figure 9.1 –Close-up View of LEDs

Loading...

Loading...