Page 1

User Manual for the

HE300GEN150

Option Card for

GE Adjustable Frequency Drives

(AF-300 G11 / P11 Series Drives)

First Edit ion

13 April 2000

MAN0373-01

Page 2

MAN0373-01 13 APR 2000 PAGE 3

PREFACE

This manual expl ains how to use the Horner AP G HE300GEN150 option card.

Copyright (C ) 2000 Horner APG, LLC., 640 Nort h Sherman Drive I ndianapoli s, Indiana 46201. All ri ghts

reserved. No part of this publ ication may be reproduced, transmitted, transcri bed, stored in a retrieval

system, or translated into any language or computer language, in any form by any means, electronic,

mechanical, magnetic, optical, chemical, manual or otherwise, without the prior agreement and written

permission of Horner A PG, LLC.

All software described i n this document or media is also copyrighted mat erial subjec t to the terms and

conditions of t he Hor ner S oft ware Li c ense Agreement.

Informati on in this document is subject to change without notice and does not repr esent a commitm ent on

the part of Horner APG, LLC.

Genius, Series 90-30, and Logicmaster are trademarks of GE Fanuc Automation North Ameri c a, I nc.

AF-300 G11 and AF-300 P 11 are tr adem ar k s of General Electric.

For user manual updates, contact Horner APG, Technical Support

Division, at (317) 916- 42 74 or visi t our web sit e at www. h ea pg. c om .

Page 3

PAGE 4 13 APR 2000 MAN0373-01

LIMITED WARRANTY AND LIMITATION OF LIABILITY

Horner APG, LLC.("HE-APG") warrants to the origi nal purchaser that HE300GEN150 manufactured by

HE-APG is free from defec ts in material and workmanship under normal use and servi ce. The obligation

of HE-APG under this warranty shall be limit ed to the repair or exc hange of any part or parts whic h may

prove defective under normal use and service within two (2) years from the date of manufacture or

eighteen (18) m onths from the date of install ation by the original pur chaser whichever occurs fir st, such

defect to be disclosed to the satisfaction of HE-APG after examination by HE-APG of the allegedly

defective part or parts. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES

EXPRESSED OR IMPLIED INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR USE AND OF ALL OTHER OBLIGATIONS OR LIABILITIES AND HE-APG NEITHER ASSUMES,

NOR AUTHORIZES ANY OTHER PERSON TO ASSUME FOR HE-APG, ANY OTHER LIABILITY IN

CONNECTION WIT H THE S ALE OF T HIS HE300GE N150. THIS W ARRANTY SHA LL NOT APPLY TO

THIS HE300GEN150 OR ANY PART THEREOF WHICH HAS BEEN SUBJECT TO ACCIDENT,

NEGLIGENCE, ALTERATION, ABUSE, OR MISUSE. HE-APG MAKES NO WARRANTY

WHATSOEVER IN RESPECT TO ACCESSORIES OR PARTS NOT SUPPLIED BY HE-APG. THE

TERM "ORIGINAL PURCHASER", AS USED IN THIS WARRANTY, SHALL BE DEEMED TO MEAN

THAT PERSON FOR WHOM THE HE300GEN150 IS ORIGINALLY INSTALLED. THIS WARRANTY

SHALL APPLY ONLY WITHIN THE BOUNDARIES OF THE CONTINENTAL UNITED STATES.

In no event, whether as a result of br eac h of contract, warranty, tort (including negligence) or otherwise,

shall HE-APG or its suppliers be liable of any special, consequential, incident al or penal dam ages

including, but not limited to, loss of profit or rev enues, loss of use of the products or any associated

equipment, dam age to associated equipment, cost of c apital, cost of substitute pr oduc ts, facilities,

services or replac em ent power, down time costs, or claims of original purchaser's custom er s for such

damages.

To obtain warranty service, return the product to your distributor with a description of the

problem, proof of purch ase, post paid, insured and in a suitable package.

ABOUT PROGRAMMING EXAMPLES

Any example programs and program segments in this manual or provided on accompanying diskett es are

included sol ely for illustrative purposes. Due to t he m any variables and requirements associated wi th any

particular installation, Horner APG cannot assume responsibility or li ability for actual use based on the

examples and diagram s. It is the sol e r esponsibility of the system desi gner utilizing HE300GEN150 to

appropriately design the end system, to appropriately integrate the HE300G E N150 and to make safety

provisions for the end equipment as is usual and custom ar y in industrial applications as defined in any

codes or standards which apply.

Note: The programming examples shown in this manual are for illustrative

purposes only. Proper machine operation is the sole responsibility of the

system integrator.

Page 4

MAN0373-01 13 APR 2000 PAGE 5

Table of Contents

PREFACE................................................................................................................................................3

LIMITED WARRANTY AND LIMITATION OF LIABILITY..........................................................................4

ABOUT PROGRAMMING EXAMPLES ....................................................................................................4

CHAPTER 1 : INTRODUCTION...................................................................................................... ........7

1.1 Product Descri ption ................................................................................................................... 7

1.2 Genius Network Overview......................................................................................................... 7

1.3 Genius Network Architecture..................................................................................................... 8

1.4 Genius Communications Services............................................................................................. 8

1.4.1 I/O Service......................................................................................................................... 8

1.4.2 Global Data ........................................................................................................................ 8

1.4.3 Datagrams......................................................................................................................... 9

1.5 Required Referenc es and Resourc es........................................................................................ 9

CHAPTER 2 : INSTALLATION..............................................................................................................11

2.1 Installation Procedures for the Option Card ( GEN150)..............................................................11

2.2 Gen iu s Wiring..........................................................................................................................12

CHAPTER 3 : OPTION CARD CONFIGURATION (USING AF-300 KEYPAD).......................................15

3.1 Keypad Functionality................................................................................................................15

3.2 Option Card Configuration Parameters.....................................................................................15

3.2.1 User Defined Parameters..................................................................................................16

3.3 Operation Configuration Parameters........................................................................................18

3.3.1 Description of Parameter H30 ...........................................................................................18

3.3.2 Descripti on of Par am eters o27 and o28.............................................................................18

3.3.3 Network Loss....................................................................................................................19

CHAPTER 4 : GENIUS BUS CONTROLLER CONFIGURATION ..........................................................21

4.1 PLC Configuration....................................................................................................................21

4.2 Series 90-70 Configuration.......................................................................................................21

CHAPTER 5 : AF-300 DRIVE PARAMETERS.......................................................................................25

5.1 Drive Parameter Descriptions...................................................................................................25

5.2 Data Format Specification........................................................................................................32

Data format [6]: Decimal data (Positive, negative): Min. unit 0.01........................................................32

CHAPTER 6 : DATAGRAM ACCESS....................................................................................................39

6.1 General....................................................................................................................................39

6.2 Write to Drive using Datagram..................................................................................................39

6.3 Read from Drive using Datagram .............................................................................................42

6.4 PLC Ladder Code ....................................................................................................................43

APPENDIX A: COMM_REQ COMMAND BLOCK DESCRIPTIONS.......................................................45

Page 5

PAGE 6 13 APR 2000 MAN0373-01

Page 6

MAN0373-01 13 APR 2000 PAGE 7

CH.1

CHAPTER 1: INTRODUCTION

1.1 Product Descrip ti on

The Horner APG option c ar d (HE300G E N150) enables GE Adjustable Frequency Drives (models AF-300

G11 or P11) to reside direc tly on a Genius network. The option card is installed within the AF-300 G11 or

P11 (AF-300) and pr ov ides drive control and data access capabilities to a PLC.

For clarification pur poses, the combination of the HE300GEN150 O ption Card and the GE Drive

Note:

(AF-300 G11 or P11) is ref er r ed to as “AF-300” throughout the manual.

1.2 Genius Network Overvi ew

Genius is a high-speed, tok en pas si ng network, which is used in many industr ial applications. T he

network supports up to 32 devices with baud rates of up to 153.6Kbaud. A wide variety of Genius

devices exist, which can reside on the network rangi ng from intelligent I/O block s to more sophisticated

communications devices such as personal com puters. In recent years a number of third party devic es

have emerged including operator interface units, valve manifolds, and RF tag reader s.

Figure 1.1 – Typical Genius Network

In a typical industrial application (Figur e 1.1), Genius devices are distri buted throughout a fairl y wide area,

wired in a daisy chained fashion with a single shiel ded, t wisted pair. The option card (GEN150) allows

the AF-300G11/P11 drives to be distributed on the factor y floor on the same twisted pair as the I/O bloc k s

and other Genius devic es. The option card provides a new level of PLC integr ation for the drives.

Page 7

PAGE 8 13 APR 2000 MAN0373-01

CH. 1

The physical natur e of t he Genius network can allow for great savi ngs i n wiring, as many discrete wires

can be replaced wit h a singl e c ommunications cable. This allows tasks such as start ing, stopping,

reversing, and changing speeds to be accomplished over the LAN. In addition, drive parameters and

diagnostic dat a previously not availabl e to the PLC are easil y accessible.

1.3 Genius Network Archi t ect ure

The Genius network archi tecture is depicted i n Figure 1.1. Normally, a GE Fanuc programmable

controller runs the network through a PLC module called a Geni us Bus Contr oller (GBC). Up to 32

devices are wired i n a daisy chained fashion. Network devi c es support f our communications termi nals,

Serial 1, Serial 2, S hield In and Shield Out. The network is terminat ed at each end with an appropriate

terminating resistor.

Each device on the net work (up to 32 devices) is assigned a Genius Bus Address ranging from 0 to 31.

Bus Controllers are typically assigned a Genius Bus Addres s of 31. In applications with redundant bus

controllers, the backup bus controller is address 30. Bus addre ss 0 is normally reserved for the Genius

Hand Held Monitor.

Among other tasks, t he bus cont r oller allows Genius I/O (including the drives) on the network to be

mapped into PLC memory, monitoring inputs and controlling outputs. Intelligent, data intensive Genius

devices also share thei r data with the PLC through communicati ons with the bus controller.

1.4 Genius Communicat io ns Services

The option card allows the drive to reside directly on the Genius LAN providing drive control and dat a

access capabil ities to the PLC. There are three types of communications that can occur on the Genius

LAN. These are I/O Servic es, Global Data, and Datagrams. The option card supports all three of these

communications types.

1.4.1 I/O Service

I/O Service is the m anner in whic h data is transferred to and from Genius I/O Bl oc k s. Out puts are

selectively written to each I/O block from the CPU bus controller during each scan. The outputs written by

the CPU bus controller to the AF-300 drives include start /stop, fwd/rev, frequency (speed), fault reset, and

other outputs. M any I/O bl oc k s al so broadcast inputs to the bus every bus scan. The AF-300 does not

support thi s means of c ommunication as it broadcasts it s inputs (f eedback) as Global Data.

1.4.2 Global Data

Global data is data br oadc ast over the network at large, with no particular destination. Eac h Genius

device has the capacity to broadcast up to 128 bytes of global dat a. Intelligent devices, which resi de on

the LAN (bus controllers, OIUs, etc.), can read this data off the network. These devices are intelligent

and are able to interpret the data, which differs from Genius device to Genius device. The option c ar d

utilizes global data to broadcast drive feedbac k data over Genius. Drive feedback data consi sts of

parameters such as speed reference, torque, current, faults, and function settings.

The option card allows the system designer to select whic h data is broadcast by the drive as global dat a.

This is import ant f or two reasons. First, the data, which is desired to be monitored on a regular basis

varies from applic ation to applicati on. Second, the amount of global data broadcast by the drive is

directly proportional to response time. The abili ty to control the amount and content of global data output

is a vital feat ur e of the option c ar d.

Page 8

MAN0373-01 13 APR 2000 PAGE 9

CH.1

In general, the pr oc edur e for configuring the drive’s Gl obal output data is a process of mapping the gl obal

output data words to drive parameters. There are two different means in which this mapping of global

data output words to drive parameters can be accomplished. These include mapping from the key pad

and from the driv e configur ation utility. The keypad conf iguration method is described i n Chapter 2.

1.4.3 Datagrams

Datagrams are messages sent over the Genius LAN from one device to another . Datagrams are typically

performed in PLC applications through a communications request or COMREQ. Typically, CO MREQs

are used for occasi onal data access. For instance, COMREQs are not typically used to monitor speed

reference on a conti nuous basis, but it might be used to change a drive par am eter once per shift or once

per week. Datagram s (t hr ough COMREQs) c ould also be used to upload or download all drive

parameters over the net work. In PLC applications, a bus controller is required to perform datagr am s or

COMREQs.

1.5 Required Referen ces and Resou rces

This manual is to be used in conjunction with the GE FUJI Electri c instruc tion manuals for the AF-300

G11 and P11 series driv es. The manual num ber s for the driv es are as follows:

AF-300G11: Manual # GEI-100363

AF-300P11: Manual # GEI-100364

Page 9

PAGE 10 13 APR 2000 MAN0373-01

CH. 1

NOTES

Page 10

MAN0373-01 13 APR 2000 PAGE 11

CH.2

CHAPTER 2: INSTALLATION

2.1 Installatio n Procedures for the Option Card (GEN150)

The option card is designed to be m ounted to the AF-300 drive in the same locati on as the k ey pad. The

same mounting instructions found in the GE FUJI AF-300 Drive Instr uc tion Manual(s) for mounting the

keypad to the drive are also used for mounting the option car d to t he drive. The keypad is, then, mounted

to the option card. ( Reference numbers for the drive instruc tion manuals are found in Section 1. 5 in this

manual.)

The following ar e the necessary steps for installi ng the opti on c ar d:

1. Power down the drive.

2. Remove the keypad f r om the top cov er.

3. Mount the option c ar d in the sam e loc ation where the keypad was removed. (Sec uri ng the two

screws, one in the upper left and the other in the lower right).

4. Mount the keypad to t he option card. (Securing the two screws, one in t he upper left and the

other in the lower right).

5. Connect the remov able terminal strip with the Genius field wiring to the option card.

6. Power up the drive as needed.

Figure 2.1 shows an example of how the option card is installed i n an under 40 Horsepo wer drive.

Figure 2.1 - Example Installatio n in an Under 40 Horsep ow er Drive

Page 11

PAGE 12 13 APR 2000 MAN0373-01

CH. 2

2.2 Genius Wiring

Up to 32 devices are wired in a daisy-c hained fashion in a Genius network. ( S ee Figure 1.1 for an

overview of Genius network. ) The network is terminated at eac h end with an appr opr iate terminating

resistor (Figure 2.2). The value of the resistor is chosen to match the characteristic im pedanc e of the

cable. Refer to GE G enius I/O and System Communications Us er Manual (GE-90486) for help in

selecting an appr opr iate cable type for the application.

If the characteristic impedance of the cable is unknown, 120-ohm terminating resistors need to be

Note:

used

Figure 2.2 – Typical Ge nius Wirin g Te c h niques

Network devi c es support f our c ommunications terminal s, S erial 1, Serial 2, Shield In and Shield Out.

(Figure 2.3. )

Figure 2.3 – Genius Connector

The LED designators and connector pin out are shown in Figur e 2.3. In additi on to the normal Genius

connections showing in Figure 2.2, Frame Ground must be at tached to the “FG” terminal, Terminal 5.

Page 12

MAN0373-01 13 APR 2000 PAGE 13

CH.2

Table 2.1 -– Genius LEDs

LED Description

GENA OK Illuminated unless there is a fault with the GENA

board.

COMM OK The “COMM OK” indicator illuminates when the GENA

board is communicating with the Genuis Bus

Controller (GBC) properly. If the “COMM OK” LED is

not illuminated after configuration, check the follow ing:

Make sure the cable is wired correctly between the

GBC and the option card.

Check the GBC configuration (LM90 Configuration

package). The Global data length, and the Directed

control data length must match the input length and

the output length respectively.

Page 13

PAGE 14 13 APR 2000 MAN0373-01

CH. 2

NOTES

Page 14

MAN0373-01 13 APR 2000 PAGE 15

CH.3

CHAPTER 3: OPTION CARD CONFIGURATION (USING AF-300 KEYPAD)

3.1 Keypad Function ali t y

The keypad functions and operations are covered i n the drive manufacturer document ation. This

document is concer ned only with describing the key pad functions that are used to configure the option

card and effect the option card operation.

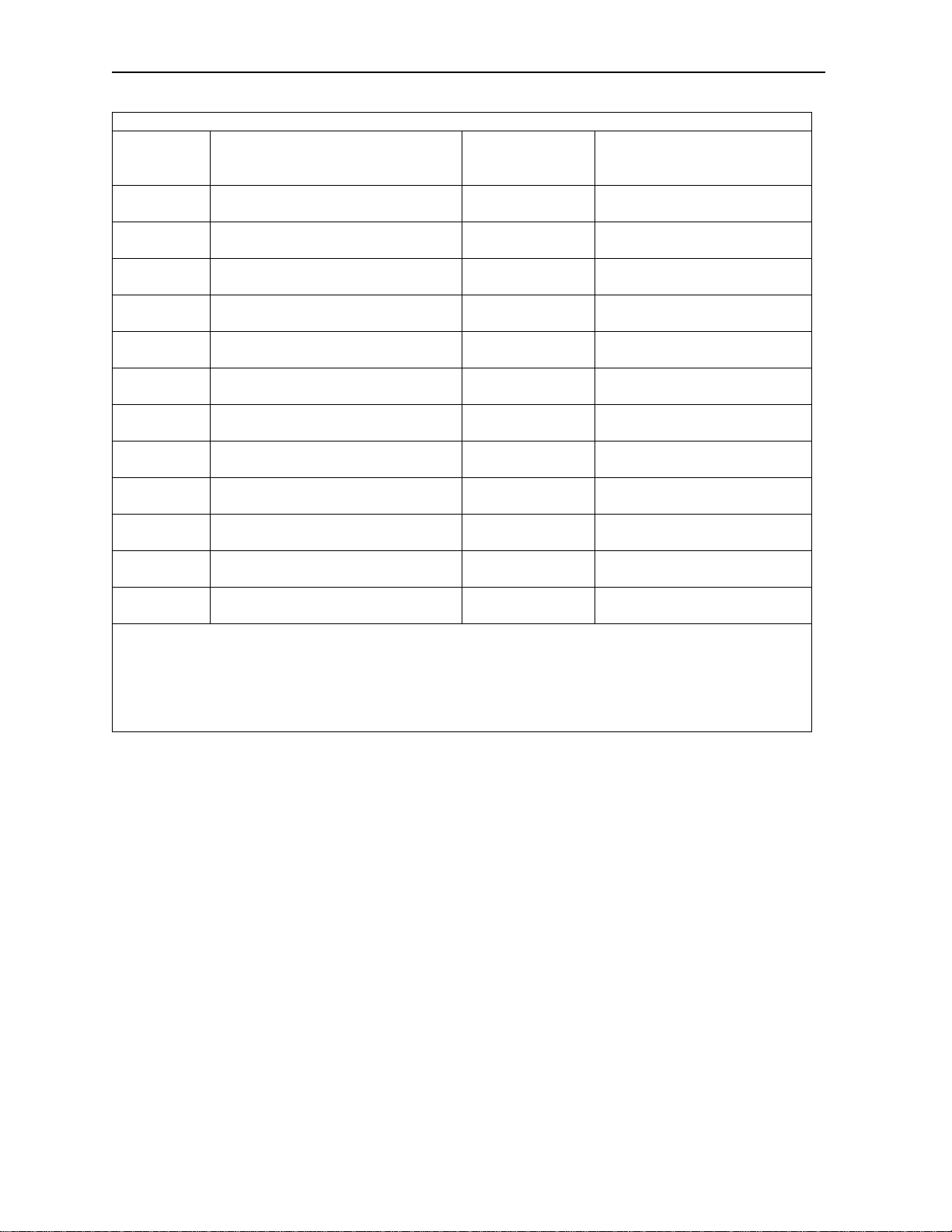

3.2 Option Card Configuration Parameters

The following table lists and describes the parameter settings used to confi gure the Option Card

parameters. As described prev iously, Genius devices have the capacity to broadcast 128 byt es (64

words) of global data and receive 128 bytes (64 words) of directed data. The Option Card is limited to 24

bytes (12 words) of global data and 20 bytes (10 words) of direct ed data. The parameter values can be

changed using the instr uc tions found in the drive manufac turer’s documentati on.

Table 3.1 – Parameter Settings

Option

Card

Parameter

o30 Bus Address 0- 31 ( 1- 30

o31 Baud Rate

•

0 = 153.6K EXT

•

1 = 153.6K STD

•

2 = 76.8K

•

3 = 38.4K

•

255 = Reset parameters to

default

o32 Global Data Lengt h 0 - 12 7

o33 Directed Dat a Length 0 - 10 4

o34 User Defined Broadcast Data 1 1-254

o35 User Defined Broadcast Data 2 1-254

o36 User Defined Broadcast Data 3 1-254

o37 User Defined Broadcast Data 4 1-254

o38 User Defined Broadcast Data 5 1-254

o39 User Defined Broadcast Data 6 1-254

o40 User Defined Broadcast Data 7 1-254

o41 User Defined Broadcast Data 8 1-254

o42 User Defined Broadcast Data 9 1-254

o43 User Defined Broadcast Data 10 1-254

Description Valid Input

Values

typical)

0-3

255

0;255*

0;255*

0;255*

0;255*

0;255*

0;255*

0;255*

0;255*

0;255*

0;255*

Default Value (o 31 = 255)

1

1 = 153.6K standard

M14 Operating State

M06 Actual Frequency

M11 Output Current

M10 Motor Output

M16 Fault Memory 0

M07 Actual Torque

M01 Frequency Comm and

255

255

255

Page 15

PAGE 16 13 APR 2000 MAN0373-01

CH. 3

Table 3.1 – Parameter Settings

Option

Card

Parameter

o44 User Defined Broadcast Data 11 1-254

o45 User Defined Broadcast Data 12 1-254

o46 User Defined Cont r ol Data 1 1-254

o47 User Defined Cont r ol Data 2 1-254

o48 User Defined Cont r ol Data 3 1-254

o49 User Defined Cont r ol Data 4 1-254

o50 User Defined Cont r ol Data 5 1-254

o51 User Defined Cont r ol Data 6 1-254

o52 User Defined Cont r ol Data 7 1-254

o53 User Defined Cont r ol Data 8 1-254

o54 User Defined Cont r ol Data 9 1-254

o55 User Defined Cont r ol Data 10 1-254

Note: If the Option Car d detects and invalid parameter value then the parameter number containing

the invalid value appear s at o31 ( B us address). It is recommended that parameter o31 be checked

after the configuration is completed to make sure that all parameter values are valid.

Description Valid Input

Values

0;255*

0;255*

0;255*

0;255*

0;255*

0;255*

0;255*

0;255*

0;255*

0;255*

0;255*

0;255*

Default Value (o 31 = 255)

255

255

S06 Operation Comm and

S01 Frequency Cmd

S07 Universal Do

S12 Universal Ao

255

255

255

255

255

255

* 0 and 255 are used to notate unused configuration parameter.

3.2.1 User Defined Parameters

The object of the user defined configuration param eters is to create a selectable data m ap for the G enius

data. There are 254 available parameters and only 12 broadcast and 10 control data words available on

the Genius network. The sel ec table map allows the user to confi gur e what parameters and how many

are to be used.

Page 16

MAN0373-01 13 APR 2000 PAGE 17

CH.3

The following table shows how the user defined map translat es to GB C global and control data words.

Table 3.2 – Translation of Global and Data Words

Global Data

(Option Card to GBC)

Broadcast Data

Parameter

Number

11AI111AQ1

22AI222AQ2

33AI333AQ3

44AI444AQ4

55AI555AQ5

66AI666AQ6

77AI777AQ7

8 8 AI8 8 8. AQ8

99AI999AQ9

10 10 AI10 10 10 AQ10

11 11 AI11

12 12 AI12

Parameter Value Appears in

GBC Word #

Word PLC Word PLC

Control Data

Parameter

Number

Control Data

(GBC to Option Card)

GBC Word written to

Parameter

Page 17

PAGE 18 13 APR 2000 MAN0373-01

CH. 3

3.3 Operation Configuration Parameters

The previous section described parameter s that are used to directly configure the Option Card. There are

other confi gurable parameters in the drive that eff ec t t he oper ation of the Option Card, (GEN150), such

as drive control and er r or handling. The following table lists and describes the parameter setti ngs that

affect the Option Car d oper ation.

Table 3.3 - Parameter Effect on Option Card Op erat io n

Operation

Parameter

H30

o27 Loss of Network Behavior

o28 ERR5 timer setting (used with o27) 0.0 – 60.0 S 0.0 Seconds

Link

Function

Value Freq. from

0 Disabled Disabled

1 Enabled Disabled

2 Disabled Enabled

3 Enabled Enabled

•

0 = Immediate trip – Code ERR5

•

1 = ERR5 trip after timer setting o28

•

2 = Re-check after the timer setting o28

•

3 = Ignore communication error

Description Valid Input

Values

0-3 0

Commands from

Option

Card

Option Card

0-3 0

Default Value

3.3.1 Description of P ar am eter H30

Parameter H30 is used to spli t the Frequency and Command control between the drive and the Option

Card. The frequency and/or the stop/start commands can be controlled completely by the driv e,

completely by t he option card or split so one of the commands is contr olled by the drive and the other is

controlled by the option card.

3.3.2 Description of P ar am eters o27 and o28

Parameters o27 configures how the drive reacts t o a loss of network. Out of the f our set tings, the first (0)

setting allows f or an immediate trip when a network problem occur s. The last setting (3) configures the

drive to ignore the er r or . The middle two settings (1 and 2) use a timer setting (o28) in c onjunc tion with

the error setting. Parameter o28 contains the timer setting that is used when o27 is configur ed for a value

of 1 or 2.

Page 18

MAN0373-01 13 APR 2000 PAGE 19

CH.3

3.3.3 Network Loss

Network loss (ERR5) occurs when the CO M M OK led is not on. There are a few reasons that cause this

condition. The f oll owing table lists the most common reasons for a network loss (ERR5) condition:

Table 3.4 – Network Loss Conditions

1 G enius cable broken or not connected

2 T he Global and Directed data lengt hs do NOT match

the settings in the GBC.

3 T he P LC is not in RUN m ode.

Page 19

PAGE 20 13 APR 2000 MAN0373-01

CH. 3

NOTES

Page 20

MAN0373-01 13 APR 2000 PAGE 21

CH.4

CHAPTER 4: GENIUS BUS CONTROLLER CONFIGURATION

4.1 PLC Configuration

This chapter discusse s the c onfiguration of the P LC in Genius applications using the AF-300 drive with

GEN100 Genius opti on boar d. As mentioned in a previous chapter, Genius LANs performing control

require a Genius Bus Controller. Most GE Fanuc PLCs offer a module whic h acts as the bus controller.

This document discusse s conf iguration of the Series 90 PLCs -- Ser ies 90-30 and Series 90-70.

4.2 Series 90-70 Confi gu rat io n

For successful integration of the Series 90-70 GBC, t he doc um ent GF K - 0398, Series 90-70 Genius Bus

Controller User's M anual is required.

Configuration of Series 90-70 PLC system requir es the use of Logicmaster 90-70, the personal c om puter

software package used f or ladder logic programming and system setup. Configuration of the Genius

devices residi ng on the LAN with Logicmaster 90-70 cannot be ac c om plished until the Genius Bus

Controll er (GBC) is confi gur ed. For instructions on that process, consult GFK-0398 from GE Fanuc.

After configuration of the GBC has been completed, the Genius devices residing on the LAN may be

configured by zooming into the slot containing the G B C. A Logicmaster screen si m ilar to that below will

appear:

Figure 4.1 - Logicmaster 90-70 Config uration Screen

Page 21

PAGE 22 13 APR 2000 MAN0373-01

CH.4

This is a representat ion of the Genius LAN, with each device shown as a "block". Because only eight

devices can be shown on the screen at once, the screen "wraps around" from left to right. The left and

right cursor keys are used to select the device to be configured. When the desired block is highlight ed,

the type of Genius devi c e c an be select ed usi ng the function keys. The AF-300 is confi gured as a

"Generic Genius I/O Dev ic e". This device is selected by pressing the "Ot her" (F7) function key, and

selecting t he "G eneri c I/O" dev i c e from the devic es li sted.

Figure 4.2 – Generic I/O Device Configuration S creen

Below, each configuration parameter is described. The proper setting for a driv e with a default data

configuration is also listed.

%AI Length (Default = 6)

The number of %AIs assigned to the A F-300 drive should be equal to the number of global data words

broadcast by the drive.

%AQ Length (Default = 1)

The number of %AQs assigned to the A F-300 dr ive should be equal to the number of directed control

words.

Figure 4.3

lists the default drive data configuration.

Page 22

MAN0373-01 13 APR 2000 PAGE 23

CH.4

Reference Addresses

In addition to the l ength of each of the four I/O references (%I, %Q, %AI, %AQ), the starting reference

address for each I/O type m ust be set for each of the I/O references with a non-zer o length. This

reference address should not conflict with any other I/O module or Genius device.

Redundancy

If the AF-300 is used in a redundant application, this parameter should be set to YES.

Input Default

The input defaults can be set to OFF or HOLD, as desired.

Outputs Enabl ed

If outputs from the PLC ar e to be enabled (most cases), this parameter should be set to YES.

Note that the reference t ypes available for mapping into Series 90- 30 memory are more numerous

than those avail abl e for the S eries 90-70. This is due to the fact that the Series 90-70 perf orms

more data type checkin g than the Series 90- 30. This extra checking requires that the nu mber and

type of memory referen ces to mat ch exactly in the Series 90-70. The Series 90-30 requires only

that the amount of data match exactl y.

4.3 Series 90-30 Confi gu rat io n

For full information on the configuration of Genius LANs with the Series 90-30 PLC, consult the GE Fanuc

document GFK-1034, Series 90- 30 Genius B us Controller Us er ' s Manual.

The Series 90-30 PLC is confi gur ed usi ng Logicmaster 90-30. In the confi gur ation package, the Geni us

Bus Controller (GBC) configuration screen appears as follows:

Figure 4.3 – Series 90-30 GBC Configuration Screen

Page 23

PAGE 24 13 APR 2000 MAN0373-01

CH.4

The devices residing on the Genius LAN are configured in t he lower "Device Data" section of the screen.

The cursor keys are used to navi gate around the screen. When the cursor is on the " Dev ic e Data"

section of the screen, the PageUp and PageDown keys are used to select t he Dev ic e number. Once the

proper device num ber is di spl ay ed for the AF-300, the following parameters can be set.

Device Type

The AF-300 is configur ed as a GE NE RIC devic e type, which is the default.

Input References (In pu t 1 Ref, Input 2 Ref)

These parameter s specify where the AF-300's global data is mapped in Series 90-30 memory. Legal

reference types for these parameters are %I, %G, %AI, and %R. The global data broadcast by the AF300 can be divided into t wo different areas of PLC memory. For instance, par t of the global data can be

mapped into %I and the r em ainder into %AI. Two non-consecutive areas of t he same reference type can

also be mapped. For instanc e, part of the global data can be mapped to %R1 and the rem ainder to

%R500.

Input Length (Input 1 Len, Input 2 Len)

These parameter s specify how much global data is broadcast by t he AF- 300. If the Input Reference

specified is bi t-type (%I, %G), the length parameter is i n bits. If the Input Reference specified is word type

(%AI, %R), the length par am eter is in words. The total amount of data mapped i nto t he Series 90-30

must exactl y match t he tot al am ount of global data broadcast by the AF-300.

If bit-type par am eters are used then they must be defined in the fir st global words of the drive. They must

also be configur ed as bi t-type data in the bus controller

Output References ( Ou tput 1 Ref, Output 2 Ref)

These parameter s specify where the AF-300's dir ected c ontrol data is mapped in Series 90-30 mem ory.

Legal referenc e types for these parameters are %Q, %G, %AQ, and %R. As you can see, the direc ted

data input by the AF-300 can be divided into two different areas of PLC m em ory. For instance, part of the

global data could be mapped into %Q, and the remainder into %AQ. Two non-consecutive areas of the

same reference type c ould also be mapped. For instance, part of the directed data could be mapped to

%R1, and the remainder to %R500.

Output Length (Output 1 Len, Output 2 Len) Output

These parameter s specify how much directed data is received by the AF-300. If the Output Reference

specified is bi t-type (%Q, %G), the length parameter is i n bits. If the O utput Reference specified is word

type (%AQ, %R), the length par am eter is in words. The total amount of data mapped fr om t he S eri es 9030 must exactly match the total amount of global data received by the AF-300.

If bit-type par am eters are used then they must be defined in the fir st global words of the drive. They must

also be configur ed as bi t-type data in the bus controller .

Page 24

MAN0373-01 13 APR 2000 PAGE 25

CH.5

CHAPTER 5: AF-300 DRIVE PARAMETERS

5.1 Drive Parameter Descript ions

The following table contains the communication index number used for mapping the drive parameters into

Genius I/O. Each communic ation index number is associated wit h a specif ic parameter. The details

about the specific parameters can be found in the manual suppli ed with the drive.

Table 5.1 – Communication P aramet er In dex

Comm

Index

G11

data

E11

Hex Description Keypad

data

0--0

1S01S011

2--2

3--3

4--4

5S05S055

6S06S066

7S07S077

8S08S088

9S09S099

10 S10 S10 A

11 S11 S11 B

12 S12 S12 C

13 - - D

14 - - E

15 M01 M01 F

16 - - 10

17 - - 11

18 - - 12

19 M05 M05 13

20 M06 M06 14

21 M07 M07 15

22 M08 M08 16

23 M09 M09 17

24 M10 M10 18

25 M11 M11 19

26 M12 M12 1A

27 M13 M13 1B

28 M14 M14 1C

Frequency comm and

Frequency comm and

Operation command

Universal Do

Accel Time

Deccel Time

Driving Torque Limi t

Braking Torque Limit

Universal Ao

Frequency (Motor speed) setting (final )

Torque command (final)

Torque current c ommand (final)

Magnetic flux command (final)

Frequency setting (final)

Actual frequency

Actual value of torque

Torque current

Output frequency

Motor output

Output current (rms)

Output voltage (rms)

RUN command, Di, RESET input (final)

Operation state

Data

Format

2

5

14

15

3

3

5

5

2

2

5

2

6

6

5

5

5

3

14

16

Page 25

PAGE 26 13 APR 2000 MAN0373-01

CH. 5

Table 5.1 – Communication P aramet er In dex

29 M15 M15 1D

30 M16 M16 1E

31 M17 M17 1F

32 M18 M18 20

33 M19 M19 21

34 M20 M20 22

35 M21 M21 23

36 - - 24

37 M23 M23 25

38 M24 M24 26

39 M25 M25 27

40 M26 M26 28

41 M27 M27 29

42 - - 2A

43 - - 2B

44 - - 2C

45 M31 M31 2D

46 M32 M32 2E

47 M33 M33 2F

48 M34 M34 30

49 M35 M35 31

50 M36 M36 32

51 M37 M37 33

52 M38 M38 34

53 M39 M39 35

54 M40 M40 36

55 M41 M41 37

56 M42 M42 38

57 M43 M43 39

58 M44 M44 3A

59 M45 M45 3B

60 M46 M46 3C

61 M47 M47 3D

62 M48 M48 3E

63 - 3F

64 - 40

65 - 41

66 - 42

67 - 43

General-pur pose output terminal

Alarm content latest

Alarm content 1st pr ev ious

Alarm content 2nd pr ev ious

Alarm content 3r d previous

Total operation time

DC link voltage

Motor temper ature

Model code

Capacity code

ROM version

Processing code in abnormal transmission

Frequency (Motor speed) setting at alarm

final

Torque command at al arm (final)

Torque current c ommand at alarm (final)

Magnetic flux command at alarm(final)

Frequency setting at alarm final

Actual frequency at alarm

Actual value of torque at alarm

Torque current at alarm

Output frequency at alarm

Motor output at alarm

Output current ( rms) at alarm

Output voltage (rms) at alarm

RUN command, Di, RESET input at alarm

Operation state at alarm

General-pur pose output terminal at alarm

Total operation time at alarm

DC link voltage at alarm

Internal tem per ature of inverter at alarm

Temperature of cooling fin at alarm

Lifetime of main circuit capacitor

Lifetime of capacitor on PCB

Lifetime of cooli ng fan

15

10

10

10

10

1

1

17

11

1

20

2

5

2

6

6

5

5

5

3

14

16

15

1

1

1

1

3

1

1

Page 26

MAN0373-01 13 APR 2000 PAGE 27

O

S

T

CH.5

Table 5.1 – Communication P aramet er In dex

68 - 44

69 - 45

70 F00 46

71 F01 47

72 F02 48

73 F03 49

74 F04 4A

75 F05 4B

76 F06 4C

77 F07 4D

78 F08 4E

79 F09 4F

80 F10 50

81 F11 51

82 F12 52

83 F13 53

84 F14 54

85 F15 55

86 F16 56

87 F17 57

88 F18 58

89 F20 59

90 F21 5A

91 F22 5B

92 F23 5C

93 F24 5D

94 F25 5E

95 F26 5F

96 F27 60

97 F30 61

98 F31 62

99 F33 63

100 F34 64

101 F35 65

102 F36 66

103 F40 67

104 F41 68

105 F42 69

106 E01 6A

Data protection DATA PRTC 1

Frequency command 1 FREQ CMD 1 1

Operation method

Maximum frequenc y 1 MAX Hz-1 1

Base frequency 1 BASE Hz-1 1

Rated voltage 1 RATED V-1 1

Maximum voltage 1 MAX V-1 1

Acceleration time 1 ACC TIME1 12

Deceleration time 1 DEC TIME1 12

Torque boost 1 TRQ BOOST1 12

Electronic Thermal 1 (Select) ELCTRN OL1 3

Electronic Thermal 1 (Level) OL LEVEL1 1

Electronic T hermal 1 (Time constant) TIME CNST1 19

Electronic t hermal overload relay (for DB

resistor ) DBR OL 3

Restart mode after momentary power failure RESTART 1

Frequency limiter (High) H LIMITER 1

Frequency limiter (Low) L LIMITER 1

Gain (for freq set signal) FREQ GAIN 1

Bias frequency FREQ BIAS 1

DC brake (Starting freq.) DC BRK Hz 3

DC brake (Braking level) DC BRK LVL 1

DC brake (Braking time) DC BRK t 3

Starting frequency (Freq.) START Hz 3

Starting fr equency (Holding time) HOLDING t 3

Stop frequency STOP Hz 1

Motor sound (Carrier freq. ) MTR SOUND 1

Motor sound (Sound tone)

FMA (Voltage adjust) FMA V-ADJ 1

FMA (Function) FMA FUNC 1

FMP (Pulse rate) FMP PULSES 1

FMP (Voltage adjust) FMP V-ADJ 1

FMP (Function) FMP FUNC 1

30RY operation mode 30RY MODE 1

Torque limit er 1 (Driving) DRV TRQ 1 1

Torque limit er 1 (braking) BRK TRQ 1 1

Torque vector control 1

X1 terminal function X1 FUNC 1

PR METHOD 1

OUND TONE 1

RQVECTOR1 1

Page 27

PAGE 28 13 APR 2000 MAN0373-01

O

CH. 5

Table 5.1 – Communication P aramet er In dex

107 E02 6B

108 E03 6C

109 E04 6D

110 E05 6E

111 E06 6F

112 E07 70

113 E08 71

114 E09 72

115 E10 73

116 E11 74

117 E12 75

118 E13 76

119 E14 77

120 E15 78

121 E16 79

122 E17 7A

123 E20 7B

124 E21 7C

125 E22 7D

126 E23 7E

127 E24 7F

128 E30 80

129 E31 81

130 E32 82

131 E33 83

132 E34 84

133 E35 85

134 E36 86

135 E37 87

136 E40 88

137 E41 89

138 E43 8A

139 E44 8B

140 E45 8C

141 C01 8D

142 C02 8E

143 C03 8F

144 C04 90

145 C05 91

X2 terminal function X2 FUNC 1

X3 terminal function X3 FUNC 1

X4 terminal function X4 FUNC 1

X5 terminal function X5 FUNC 1

X6 terminal function X6 FUNC 1

X7 terminal function X7 FUNC 1

X8 terminal function X8 FUNC 1

X9 terminal function X9 FUNC 1

Acceleration time 2 ACC TIME2 12

Deceleration time 2 DEC TIME2 12

Acceleration time 3 ACC TIME3 12

Deceleration time 3 DEC TIME3 12

Acceleration time 4 ACC TIME4 12

Deceleration time 4 DEC TIME4 12

Torque limit er 2 (Driving) DRV TRQ 2 1

Torque limit er 2 (braking) BRK TRQ 2 1

Y1 terminal function Y1 FUNC 1

Y2 terminal function Y2 FUNC 1

Y3 terminal function Y3 FUNC 1

Y4 terminal function Y4 FUNC 1

Y5A, Y5C terminal func. Y5 FUNC 1

FAR function (Hysteresis) FAR HYSTR 3

FDT function (Level) FDT1 LEVEL 1

FDT signal (Hysteresis) FDT1 HYSTR 3

OL function (Mode select)

OL function signal (Level) OL1 LEVEL 19

OL function signal (Timer) OL1 TIMER 3

FDT2 function (Level) FDT2 LEVEL 1

OL2 function (Level) OL2 LEVEL 19

Display coefficient A COEF A 12

Display coefficient B COEF B 12

LED Monitor (Function) LED MNT R 1

LED Monitor (Display @ STOP mode) LED MNTR2 1

LCD Monitor (Function) LCD MNTR 1

Jump frequency (Jump freq 1) JUM P Hz 1 1

Jump frequency (Jump freq 2) JUM P Hz 2 1

Jump frequency (Jump freq 3) JUM P Hz 3 1

Jump frequency (Hysteresis) JUMP HYSTR 1

Multistep f r equenc y setting (Freq. 1) MULTI Hz-1 5

L1 WARNING 1

Page 28

MAN0373-01 13 APR 2000 PAGE 29

E

CH.5

Table 5.1 – Communication P aramet er In dex

146 C06 92

147 C07 93

148 C08 94

149 C09 95

150 C10 96

151 C11 97

152 C20 98

153 C30 99

154 C31 9A

155 C32 9B

156 C33 9C

157 P01 9D

158 P02 9E

159 P03 9F

160 P04 A0

161 P05 A1

162 P06 A2

163 P07 A3

164 P08 A4

165 P09 A5

166 H03 A6

167 H04 A7

168 H05 A8

169 H06 A9

170 H07 AA

171 H08 AB

172 H09 AC

173 H10 AD

174 H11 AE

175 H12 AF

176 H13 B0

177 H14 B1

178 H15 B2

179 H16 B3

180 H18 B4

181 H19 B5

182 H20 B6

183 H21 B7

184 H22 B8

Multistep f r equenc y setting (Freq. 2) MULTI Hz-2 5

Multistep f r equenc y setting (Freq. 3) MULTI Hz-3 5

Multistep f r equenc y setting (Freq. 4) MULTI Hz-4 5

Multistep f r equenc y setting (Freq. 5) MULTI Hz-5 5

Multistep f r equenc y setting (Freq. 6) MULTI Hz-6 5

Multistep f r equenc y setting (Freq. 7) MULTI Hz-7 5

JOG frequency JOG Hz 5

Frequency command 2 FREQ CMD 2 1

Offset adjust (termi nal [12] ) BIA S 12 4

Offset adjust (termi nal [C1] ) GAIN 12 3

Analog setti ng signal filter REF FILTER 5

Number of motor 1 poles M 1 P OLES 1

Motor 1 (Capacity) M1 -CAP 5

Motor 1 (Rated current) M1-lr 19

Motor 1 (Tuning) M1 TUN1 21

Motor 1 (On-line Tuning) M1 TUN2 1

Motor 1 (No-load current) M1-lo 19

Motor 1 (%R1 setting) M1-%R1 5

Motor 1 (%X setting) M1-%X 5

Slip compensation control SLIP COMP1 5

Data initializing DATA INIT 1

Fan stop operati on FAN STOP 1

Rev. phase sequence lock REV LOCK 1

Start mode START MODE 1

Energy-saving operation

DEC mode DEC MODE 1

Instantaneous OC limiting INST CL 1

Torque control TRQ CTRL 1

PID control (Mode select) PID MODE 1

PID control (Feedback signal) FB SIGNAL 1

PID control (P-gain) P-GAIN 5

1

1

1

NERGY SAV 1

Page 29

PAGE 30 13 APR 2000 MAN0373-01

T

CH. 5

Table 5.1 – Communication P aramet er In dex

185 H23 B9

186 H24 BA

187 H25 BB

188 H26 BC

189 H27 BD

190 H28 BE

191 H30 BF

192 H31 C0

193 H32 C1

194 H33 C2

195 H34 C3

196 H35 C4

197 H36 C5

198 H37 C6

199 H38 C7

200 H39 C8

201 A01 C9

202 A02 CA

203 A03 CB

204 A04 CC

205 A05 CD

206 A06 CE

207 A07 CF

208 A08 D0

209 A09 D1

210 A10 D2

211 A11 D3

212 A12 D4

213 A13 D5

214 A14 D6

215 A15 D7

216 A16 D8

217 A17 D9

218 A18 DA

219 o01 DB

220 o02 DC

221 o03 DD

222 o04 DE

PID control (I-gain) I-GAIN 3

PID control (D-gain) D-GAIN 1

PID control (Feedback filter ) FB FILTER 5

PTC thermistor (Mode select) PTC MODE 1

PTC thermistor (Level) PTC LEVEL 5

Droop operation DROOP 4

Serial link (Function select) LINK F UNC 1

Modbus-RTU (Address) ADDRESS 1

Modbus-RTU (Mode select on no response

error) MODE ON ER 1

Modbus-RTU (Timer) TIMER 3

Modbus-RTU (Baud rate) BAUD RATE 1

Modbus-RTU (Data l ength) LENGTH 1

Modbus-RTU (Pari ty check) PA RITY 1

Modbus-RTU (Stop bit s) STOP BITS 1

Modbus-RTU (No resp. error detection time) NO RES t 1

Modbus-RTU (Response interval) INTERVAL 5

Maximum frequenc y 2 MAX Hz-2 1

Base frequency 2 BASE Hz-2 1

Rated voltage 2 (at Base frequency 2) RATED V-2 1

Maximum voltage 2 MAX V-2 1

Torque boost 2 TRQ BOOST2 1

Electronic thermal 2 (Select) ELCTRN OL2 1

Electronic thermal 2 (Level) O L LEVEL2 19

Electroni c thermal 2 (Thermal time

constant) TIME CNST2 3

Torque vector control 2

Number of motor 2 poles M 2 P OLES 1

Motor 2 (Capacity) M2-CAP 5

Motor 2 (Rated current) M2-Ir 19

Motor 2 (Tuning) M2 TUN1 21

Motor 2 (On-line Tuning) M2 TUN2 1

Motor 2 (No-load current) M2-Io 19

Motor 2 (%R1 setting) M2-%R1 5

Motor 2 (%X setting) M2-%X 5

Motor 2 (Slip compensation cont r ol 2) SLIP COMP2 5

Control method selection

Speed filter time constant

Number of feedback pulses

P-gain of feedback

RQVECTOR2 1

1

1

1

1

Page 30

MAN0373-01 13 APR 2000 PAGE 31

CH.5

Table 5.1 – Communication P aramet er In dex

223 o05 DF

224 o06 E0

225 o07 E1

226 o08 E2

227 o27 E3

228 o28 E4

229 o30 E5

230 o31 E6

231 o32 E7

232 o33 E8

233 o34 E9

234 o35 EA

235 o36 EB

236 o37 EC

237 o38 ED

238 o39 EE

239 o40 EF

240 o41 F0

241 o42 F1

242 o43 F2

243 o44 F3

244 o45 F4

245 o46 F5

246 o47 F6

247 o48 F7

248 o49 F8

249 o50 F9

250 o51 FA

251 o52 FB

252 o53 FC

253 o54 FD

254 o55 FE

255 - FF

I-gain of feedback

Feedback speed detection filter

Feedback pulse corr ec tion coeff 1

Feedback pulse corr ec tion coeff 2

Bus loss be havior

Bus loss time r

Bus address

Baud rate

Global Data Lengt h

Directed Dat a Length

User Defined Broadcast Data 1

User Defined Broadcast Data 2

User Defined Broadcast Data 3

User Defined Broadcast Data 4

User Defined Broadcast Data 5

User Defined Broadcast Data 6

User Defined Broadcast Data 7

User Defined Broadcast Data 8

User Defined Broadcast Data 9

User Defined Broadcast Data 10

User Defined Broadcast Data 11

User Defined Broadcast Data 12

User Defined Cont r ol Data 1

User Defined Cont r ol Data 2

User Defined Cont r ol Data 3

User Defined Cont r ol Data 4

User Defined Cont r ol Data 5

User Defined Cont r ol Data 6

User Defined Cont r ol Data 7

User Defined Cont r ol Data 8

User Defined Cont r ol Data 9

User Defined Cont r ol Data 10

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Page 31

PAGE 32 13 APR 2000 MAN0373-01

CH. 5

5.2 Data Format Speci ficat io n

Data format [1]: Integer data (Positive): Min. unit 1

Example) If F15 (Fr equenc y limi ter, upper limit)= 60Hz

Since 60 = 003C

H

Data format [2]: Integer data (Positive, negative): Min. unit 1

Example) -20

Since -20 = FFEC

H

Data format [3]: Decimal data (Positive): Min. unit 0.1

Example) If F17 (gain frequency setting signal) = 100.0%

Since 100.0

×

10 = 1000 = 03E8

H

Data format [4]: Decimal data (Positive, negative): Min. unit 0.1

Example) If C31 (Analog input offset adjust, terminal12) = - 5.0%

Since - 5.0

×

10= - 50 = FFCE

H

Data format [5]: Decimal data (Positive): Min. unit 0.01

Example) If C05 (multi-step frequency 1) = 50.25Hz

Since 50.25

×

100 = 5025 = 13A1

H

Data format [6]: Decimal data (Positive, negative): Min. unit 0.01

Example) If M07 (actual torque value)= - 85.38%

Since - 85.38×100= - 8538=DEA6

H

Data format [7]: Decimal data (Positive): Min. unit 0.001

Example) If o05 (f ollow - up side A S R 1 constant ) = 0.105s

Since 0.105

×

1000 = 105 = 0069

H

Data format [8]: Decimal data (Positive, negative): Min. unit 0.001

Example) If bei ng - 1.234

Since - 1.234

×

1000 = - 1234 = FB2E

H

Data format [9]: Integral data (Positive): Min. unit 2

Example) If P01 (M otor 1 num ber of poles) =2pole

Since 2 = 0002

H

Page 32

MAN0373-01 13 APR 2000 PAGE 33

CH.5

Data format [10]: Alarm code

Code Description Code Description

0 No al arm --- 28 PG wir e br eaki ng Pg

Overcurrent, during

1

acceleration (INV output )

Overcurrent, during

2

deceleration (INV output )

Overcurrent, during steady

3

state operation (INV output )

5 Ground fault EF 34 Option communication

OC1 31 Memory error Er1

OC2 32

Keypad panel

transmi ssion err or

Er2

OC3 33 CPU error Er3

Er4

error

Overvoltage, during

6

OU1 35 Option error Er5

acceleration

Over voltage, during

7

OU2 36 PL error Er6

deceleration

Overvoltage, during steady

8

OU3 37 Output wiring error Er7

state operation

10 DC undervoltage LU 38 RS485 comm unic ation

Er8

error

11 Power supply open phase Lin

14 Blown DC fuse FUS

16 Output wiring error Er7

17 Overheat, heat sink, inverter OH1

18 Overheat, outside thermal OH2

19 Overheat, unit inside temp. OH3

22 Overheat, DB resistor dbH

23 Overload, motor 1 OL1

24 Overload, motor 2 OL2

25 Overload, inverter OLU

27 Overspeed OS

Example) If over - volt age, during acceleration (OU1).

Since 6 = 0006

H

Data format [11]: Capacity code

Code Capacity (HP) Code Capacity (HP) Code Capacity (HP)

7 0.07 (spare) 1500 15 15000 150

15 0.15 ( spare) 2000 20 17500 175

25 0.25 2500 25 20000 200

50 0.5 3000 30 25000 250

100 1 4000 40 30000 300

200 2 5000 50 35000 350

300 3 6000 60 40000 400

500 5 7500 75 45000 450

750 7.5 10000 100 50000 500

1000 10 12500 125

Example) 30HP

Since 30

×

100 = 3000 = 0BB8

H

Page 33

PAGE 34 13 APR 2000 MAN0373-01

CH. 5

Data format [12]: Index data ( ACC/DEC t ime, display coefficien t )

Polarity

000

Index

portion

Not yet used

0: 0.01

1: 0.1

2: 1

3: 10

0: Positive (+), 1: Negat ive ( - )

Example) If F07 (acceleration time 1) = 20.0 s

Since 20.0 = 0.1

×

200 ⇒ 0400

+ 00C8H = 04C8

H

Data format [13]: Pattern operation

Direction

of rot a ti

on

0

Time

Index

portion

Not yet

used

0: 0.01

1: 0.1

2: 1

3: 10

Data portion

×

×

×

×

H

001–999 (0.00–9.99)

100–999 (10.0–99.9)

100–999 (100–999)

100–999 (1000–9990)

Data portion

×

×

×

×

001–999 (0.00–9.99 )

100–999 (10.0–99.9 )

100–999 (100–999 )

100–999 (1000–9990 )

st

ACC/DEC time

0: 1

nd

ACC/DEC time

1: 2

rd

ACC/DEC time

2: 3

th

ACC/DEC time

3: 4

0: Forward rotati on, 1: Reverse rotation

Example) If C22 (Stage1) = 10.0s R2 (10s, reverse rotation, acceleration tim e 2/deceler ation time 2)

Since 10.0 = 0.1

×

100 ⇒ 9000

+ 0400H + 0064H = 9464

H

H

Page 34

MAN0373-01 13 APR 2000 PAGE 35

CH.5

Data format [14]: Operation command

RST

Alarm

0000

Not yet used Multi-function command

X9 X8 X7 X6 X5 X4 X3 X2 X1 REV FWD

reset

(All bit are ON by 1)

Example) If S06 (oper ation command) = FWD, X1 and X5 = ON

Since 0000 0000 0100 0101

= 0045H

b

Data format [15]: Universal output terminal

1514131211109876543210

00000000000

Not yet used Universal output

(All bit are ON by 1)

Example) If M15 (Univ er sal output terminal)=Y1 and Y5 = ON

Since 0000 0000 0001 0001

= 0011

b

H

FWD: Forward rotation Command

REV: Reverse rotation Command

Y5 Y4 Y3 Y2 Y1

Data format [16]: Operating state

1514131211109876543210

BUSY WR RL ALM DEC ACC IL VL TL NUV BRK INT EXT REV FWD

(All bit are ON or active by 1)

FWD: Under forward operation IL: Under current limiting

REV: Under r everse operation ACC: Under ac c eleration

pre-excitation) ALM: Lump alarm

INT: Inverter trip RL: Transmission valid

BRK: Under br aking Function writi ng ri ght

(undervoltage at 0) 1: RS 485

TL: Under torque limiting

VL: Under v oltage limiting BUSY: Under data writing (processing)

DEC: Under decelerat ionEXT: Under DC br ak ing (or under

WR:

0: Keypad panelNUV: DC link voltage is established

2: Link (option)

Page 35

PAGE 36 13 APR 2000 MAN0373-01

CH. 5

Data format [17]: Type code

Type Generation Series Voltage series

Code Type Generation Series Voltage series

1 VG G11/P11 For domestic 100V single phase

2 G - For Asia 200V single phase

3 P - For China 200V three phase

4 E - For Europe 400V three phase

5 C - For USA 575V three phase

6S - - -

Data format [18]: Code setting

Data 4 Data 3 Dat a 2 Data 1

Example) If o22 (Ai function selection)=123

Since 123=0123

H

Data format [19]: Amperage value Decimal data (positive):

Min. unit 0.01 for in vert er capacity is not more than 30HP

Min. unit 0.01 for not less th an 40HP respectively

Example) If F11 (el ectr onics thermal overload relay 1 level)107.0A (40HP)

Since 107.0×10=1070=042E

H

If F11 (electroni c s thermal overload relay 1 level)= 3.60A ( 1HP )

Since 3.60×100=360=0168

H

Data format [20] Tran smission error code

Code Description Code Description

1 FC (f unction code) error 71 CRC error (no respon se)

2 Ill egal addr es s 72 Pari ty er ror (no response)

3 Ill egal data (Data range error)

7NAK

- Priority for link

- No right for writing error

- Forbidden writing error

73 Other er rors (no response)

- Framing error

- Overrun error

- Bufferfull error

Example) If illegal address

Since 2=0002

H

Page 36

MAN0373-01 13 APR 2000 PAGE 37

0

1

0

1

CH.5

Data format [21] Auto tuning

0 000 00

REV

FWD

Not yet used 0–2

Example: If P04 (mot or 1 auto - tuning) =1: Forward rotation

Since 0000 0001 0000 0001

=0101

b

H

Data portion

: Without forward rotation command.

: With forward rotation command.

: Without rever se rot ation command.

: With reverse rotation command.

Page 37

PAGE 38 13 APR 2000 MAN0373-01

CH. 5

NOTES

Page 38

MAN0373-01 13 APR 2000 PAGE 39

CH. 6

CHAPTER 6: DATAGRAM ACCESS

6.1 General

Global and direct ed data are the standard methods used to send and receiving drive parameter data.

Datagrams can also be used to send and receive drive parameter data. Sending and receiving data using

datagrams is done using a c ommunications request (COMM_RE Q) in the PLC logic. There two

communications requests that are support by the drive card, Write Device (20H) and Read Device ( 1E H ). The

specific s on using communications requests are found in the Series 90-30 Genius Bus Control ler User’s Manual

(GFK-1034) or refer to Appendix A for the Write and Read datagram COM M _REQ v alues. The f ollowing

sections descri be specific portions of the datagrams that are specific to communicating with the option card.

6.2 Write to Drive using Datagram

The Send Datagram COMM _REQ ( 14) i s used to send a Writ e Device datagram. The Write Device datagram is

used to write from the PLC to param eters in the drive. The COMM_REQ allows multipl e sequential parameters

to be written. A starting par am eter number is supplied, the number of param eters and the values of the

parameters. The following is an example of a Write Device dat agr am to set the drive speed to 30.00Hz

(Figure 6.1).

Page 39

PAGE 40 13 APR 2000 MAN0373-01

CH. 6

|%I0001 %M0001

+--] [---------------------------------------------------------------------(^)-|

|%M0001 +-----+ +-----+ +-----+

+--] [---+BLKMV+-----------------+BLKMV+-----------------+BLKMV+| | INT | | INT | | INT |

| | | | | | |

| CONST -+IN1 Q+-%R0100 CONST -+IN1 Q+-%R0107 CONST -+IN1 Q+-%R0114

+00010

|

1

| |

+00001

2

| |

+00512

5

| |

| | | | | | |

| CONST -+IN2 | CONST -+IN2 | CONST -+IN2 |

| +00000 | | +00032 | |

+10000

6

| |

| | | | | | |

| CONST -+IN3 | CONST -+IN3 | CONST -+IN3 |

| +00008 | | +00032 | | +00000 | |

| | | | | | |

| CONST -+IN4 | CONST -+IN4 | CONST -+IN4 |

| +00050 | | +00000 | | +00000 | |

| | | | | | |

| CONST -+IN5 | CONST -+IN5 | CONST -+IN5 |

| +00000 | |

+00008

3

| | +00000 | |

| | | | | | |

| CONST -+IN6 | CONST -+IN6 | CONST -+IN6 |

| +00000 | |

+00256

4

| | +00000 | |

| | | | | | |

| CONST -+IN7 | CONST -+IN7 | CONST -+IN7 |

| +00014 +-----+ +00000 +-----+ +00000 +-----+

|

|%M0001 +-----+ %M0002

+--] [-----------+COMM_|+--------------------------------------------------( )-| | REQ ||

| | ||

| %R0100 -+IN FT++

| | |

| CONST -+SYSID|

| 0005 | |

| | |

| CONST -+TASK |

| 00000001 +-----+

|

Figure 6.1 – Ladder Example #1 (Write to Drive)

Page 40

MAN0373-01 13 APR 2000 PAGE 41

CH. 6

The starting address for the COMM_REQ is the first word in the fir st bloc k m ov e at %R100. Table 6.1 pr ov ides

an explanati on of the values in the example (Figure 6.1) that ar e ei ther specific to the drive or change depending

on the COMM_REQ values. The values i n the exam ple are bold and are noted by superscript numbers that

correlat e to t he num ber s in Table 6.1

Table 6.1 – Superscript Not es (Ladd er #1 E xampl e)

Superscript

Number

1 Address Com mand Length Number of words from Address+6 to

2 Addr es s+ 7 Devi c e Num ber Device to receive COMM_REQ; 0-31,

3 Address+11 Datagram Length

4 Address+12 Starting Parameter

5 Address+14 Number of Parameter

6 Addres s+ 15 to

COMM_REQ

Location

Address+n

Name Description

Address+n

or 255 to broadcast

Length of datagram content beginning

(Bytes)

Number

(High byte)

Values to Write

(High byte)

Parameter Value Value(s) to be writt en sequentially to

at Address+12

High byte of word contains starting

drive paramet er.

High byte of word contains number of

parameter values, in bytes, to write to

the drive.

drive starti ng with the parameter

number at Address+12 and ending

with the paramet er number + number

of parameters.

Page 41

PAGE 42 13 APR 2000 MAN0373-01

CH. 6

6.3 Read from Drive using Datagram

The Request Datagram Repl y COMM _REQ (15) is used to send a Read Device datagram. The Read Device

datagram is used to read parameters from the drive to the PLC. The COMM_REQ allows m ultiple sequential

parameters t o be read. A starti ng par am eter number is supplied and the number of parameters to read. The

following is an exam ple of using a Read Device datagram to read the driv e speed setting (Parameter 1).

|%I0001 %M0001

+--] [---------------------------------------------------------------------(^)-|

|%M0001 +-----+ +-----+ +-----+

+--] [---+BLKMV+-----------------+BLKMV+-----------------+BLKMV+| | INT | | INT | | INT |

| | | | | | |

| CONST -+IN1 Q+-%R0100 CONST -+IN1 Q+-%R0107 CONST -+IN1 Q+-%R0114

+00014

|

1

| |

+00001

2

| | +00200 | |

| | | | | | |

| CONST -+IN2 | CONST -+IN2 | CONST -+IN2 |

| +00000 | | +00032 | |

+00064

4

| |

| | | | | | |

| CONST -+IN3 | CONST -+IN3 | CONST -+IN3 |

| +00008 | | +00030 | |

+00256

5

| |

| | | | | | |

| CONST -+IN4 | CONST -+IN4 | CONST -+IN4 |

| +00050 | | +00000 | | +00000 | |

| | | | | | |

| CONST -+IN5 | CONST -+IN5 | CONST -+IN5 |

| +00000 | |

+00006

3

| |

+00256

6

| |

| | | | | | |

| CONST -+IN6 | CONST -+IN6 | CONST -+IN6 |

| +00000 | | +00031 | | +00000 | |

| | | | | | |

| CONST -+IN7 | CONST -+IN7 | CONST -+IN7 |

| +00015 +-----+ +00008 +-----+ +00000 +-----+

|

|%M0001 +-----+ %M0002

+--] [-----------+COMM_|+--------------------------------------------------( )-| | REQ ||

| | ||

| %R0100 -+IN FT++

| | |

| CONST -+SYSID|

| 0005 | |

| | |

| CONST -+TASK |

| 00000001 +-----+

|

Figure 6.2 - Ladder Example #2 ( Read From Drive)

Page 42

MAN0373-01 13 APR 2000 PAGE 43

CH. 6

The starting address for the COMM_REQ is the first word in the fir st bloc k m ov e at %R100. Table 6.2 pr ov ides

an explanati on of the values in the example that are either specif ic to the drive or change depending on the

COMM_REQ values. The val ues i n the exam ple ar e bold and ar e noted by superscript numbers that cor r elate

to the numbers in Table 6.2.

Table 6.2 – Superscript Not es for Ladder E xampl e #2

Superscript

Number

COMM_REQ

Location

Name Description

1 Address Command Length Number of words from Address+6 to Address+n

2 A ddr es s+ 7 Device Number Device to receiv e COMM_REQ; 0- 31

3 Addr es s+ 11 Datagram Length

(Bytes)

Length of datagram content beginning at

Address+16

4 Addr es s+ 15 Maxim um Data Length This number must be large enough to

accommodate t he r eply message otherwis e

data will be lost

5 Addr es s+ 16 Starting Parameter

Number

High byte of word contains starting drive

parameter.

(High byte)

6 Addr es s+ 18 Number of Parameter

Values to Read

High byte of word contains number of parameter

values, in bytes, to read from the drive.

(High byte)

The description of the reply datagram from the drive is cont ained in Table 6.3. A general descripti on c an be

found in the Series 90-30 Genius Bus Controller User’s Manual (G FK-1034).

Table 6.3 – Reply Datagram Description

COMM_REQ

Name Description

Location

Address

Data Length in Bytes (High Byte)

Device Number (Low byt e)

Address+1

Subfuncti on Code (High Byte)

Function Code (Low Byte)

Address+2 Starting Parameter # (High Byt e)

Always 0 (Low Byte)

The high byte of the word contains the total number of

bytes in the reply and the low byte contains the device

number where the reply originated.

The high byte of the word contains the Subfunction

code and the low byte contains the Function code of

the reply datagram .

The high byte of the word contains the starting

parameter number and low byte is always 0.

Address+3 Always 0 The word is always 0.

Address+4 # of Data Bytes (High byte)

Always 0 (Low Byte)

Address+5 to

Address+n

Drive Parameter V alue( s)

The high byte of the word contains the number of data

bytes and the low byte is always 0.

The word contains the value for request drive

parameter number.

6.4 PLC Ladder Code

In Examples 1 and 2, the COMM_REQ requires four inputs; Power, IN, SY SID and TAS K. The Power i nput is

assigned to a contac t t hat is on for only one scan. Leaving this contact on causes the dat agr am to be sent

multiple times and slows down the response time on the Genius LAN. The I N input is set to a %R reference that

contains all of the registers determined in the ex am ples. The SYSI D input specifies which rack and slot has the

Genius Bus Controll er that receives this command. The upper byt e is the r ac k number and the lower byte is the

slot number. The value of 0005 in the examples represents rack 0 slot 5. The TASK input is al ways set t o a 1.

Page 43

PAGE 44 13 APR 2000 MAN0373-01

CH. 6

NOTES

Page 44

MAN0373-01 13 APR 2000 PAGE 45

APPENDIX A

APPENDIX A: COMM_REQ COMMAND BLOCK DESCRIPTIONS

COMMAND BLOCK FOR WRITE DEVICE DATAGRAM (14):

Address Command Length Number of words from Address+6 to Address+n

Address +1: No Wait 0

Address +2: Status Block Memory Type 70(%I ),72(%Q),8(%R), 10( %A I), or 12(%AQ)

Address +3: S tatus Block Off set Beginni ng addr ess f or COMR EQ status

Address +4: Idle Timeout Value 0

Address +5: M ax . Communication Time 0

Address +6: Com mand Number 14

Address +7: Dev ice Number for Receivi ng Devi c e 0-31, or 255 to broadcast message

Address +8: Function Code 20H (32)

Address +9: Subfunction Code (hex ) 20H (32)

Address +10: Priorit y 0 for Normal, or 1 for High

Address +11: Datagram Length (in bytes) Number of bytes from Address+12 to Address+n

Address +12:

To Address +n:

Datagram Content Datagram Content

READ DEVICE DATAGRAM (15):

Address Command Length Number of words from Address+6 to Address+ n

Address +1: No Wait 0

Address +2: Status Block Memory Type 70(%I ) , 72(%Q), 8(%R), 10(%AI), or 12(%AQ)

Address +3: S tatus Block Off set Beginni ng addr ess f or COMREQ st atus

Address +4: Idle Timeout Value 0

Address +5: M ax . Communication Time 0

Address +6: Com mand Number 15

Address +7:

Address +8: Function Code 20H (32)

Address +9: S ubfunction Code (hex) 1EH (30)

Address +10: Priorit y 0 for Normal, or 1 for High

Address +11: Datagram Length (in bytes) Number of bytes from Address+12 to Address+n

Address +12: Subfunction Code of Reply (hex) 1FH (31)

Address +13: Memory Type for Reply 8(%R), 10(%AI), or 12(%AQ)

Address +14: Memory Offset Starting address within this memory ty pe

Address +15: Maximum Data Memory Number of words required by reply

Address +16:

To Address +n:

Device Number for Receiv ing

Device

Datagram Content Dat agr am Content

0-31

Page 45

PAGE 46 13 APR 2000 MAN0373-01

APPENDIX A

NOTES

Page 46

MAN0373-01 13 APR 2000 PAGE 47

APPENDIX A

INDEX

Comm_Req Command Block..............................45

Communicati ons Serv ices

Datagrams.........................................................9

Global Data.......................................................8

I/O Service........................................................8

Datagrams

General ...........................................................39

PLC Ladder Code............................................43

Reading From Drive ........................................42

Writing to Drive................................................39

Drive Parameters (AF-300) .................................25

Genius

Architecture.......................................................8

Communications Services.................................8

Network Overview.............................................7

Wiring..............................................................12

Genius Bus Controller

PLC Configuration...........................................21

Global Data...........................................................8

Installation

Option Card.....................................................11

Manuals

Drives (AF-300) ................................................ 9

Operation Parameters

Network Loss...................................................19

Parameter H30 ................................................18

Parameters o27 and 028..................................18

Option Card

Configuration Parameters................................15

Keypad Functions ............................................15

Operations Parameters....................................18

User Defined Paramet ers.................................16

PLC Ladder Code................................................43

Product Descri ption.............................................. 7

Read Device Datagram .......................................45

Series 90-70 Configuration..................................21

Wiring

Genius .............................................................12

Write Device Datagram........................................45

Page 47

PAGE 48 13 APR 2000 MAN0373-01

Loading...

Loading...